Page 1

McQuaY”

Operation and

Maintenance Data

Bulletin No. OM 112

March, 1993

FormNo. 573440Y

Absorption Chiller

NC-U Model

/

Page 2

NOTESTO USERS

1 . Before operating this chiller, YOUd-mid first thoroughly read this

manual.

You may not understand all of the explanations for operation when

you firstly read this booklet, however, P1ease strictly follow the

directions as shown hereinafter.

2.Besure not toleak theair into thechiller atany cases.

(Take care when YOUhandle the manual purge values and service

valves. )

3 . Do not turn off the main supply power to the chiller.

If turn off the breaker, purge unit of the chiller does not work.

4 . Operate chilled water ‘ pump(s) and air handling unit(s) during

dilution cycle operation of the chiller.

Chiller has a few cooling capcity during diluted cycle operation.

5. Specifications and eqipment may be changed as required by the

manufacture without any notice and obligation to the users.

814-6-0502-452-01

Page 3

OfIRATIYM4UK

CONTENTS

SKTION 1

i:;

1.3

1.4

SKI’ION 2

2.1

;::

2.4

2.5

Slxm 3

3.1

::;

::;

3.6

Page No.

NmEs’m

~ ~~~ ................................... ~

m HUtCm OF AKORPI’IoN “----------------------------------------2

COOL14MR4TlhGCYUE DHRIPHON ------------------------------20

MU.HVHE4’IIR lLUSIRATRIN -----------------------------------------25

= ~~ .................. .

CMRATION---------------------------------------------------------------------39

&iRATION80ARD ------------------------------------------------------------40

TEMHRATURESE1-TINe---"-"------------------------------------------------43

!3U-DIAGNG!XICSFUNCHON --------------------------------------------51

FRMRATIONFUUSTARTUP-----------------------------------------------54

OPIRATION---------------------------------------------------------------------58

~~ -----------------------------------------------------------------72

DALY m~ ---"----"--"--------------"------------------------------73

=~WT~ _ on -----------------------------------------80

WATIR‘lRE4TbHfI’-----------------------------------------------------------82

MAMH’UNCEm ~----------------------------------------------- 86

PARTSINWIETION------------------------------------------------------------89

m----------------------------------------------------------------

------................. .------- ------.-- ..-,.------.---- .........”.-., -.

“--“--”-------------------------------”-37

lMTNAMx-"-----------"--"------------"------"---"--"--------"75

I

i

ii

SiCHON 4

4.1

4.2

:::

4.5

~ -M ................................................ 9 ~

INDICATIONLAMP---------------------------------------------------92

Fmm

FAILURE---------------------------------------------------------------94

IN ‘IHECIXHJhKOHRATION-------------------------------------95

JN ‘lHE HE4TIIWCHRATION------------------------------------98

TIME ~-----------------------------------------------------------lOl

Page 4

WTKNI ENwlESUWTKN

mm 1 G13WRALDB3UPTION ---"----"---""-"---------"----"""-----"---"----""`----"-1

1.1 ‘lHE FRINCIPLEw ABSORITloN“-””-----”---”-”----:”---------”:-----”----2

WHYDOIB A HEATING(l-HI-L?---------------------------------------2

(1)

‘IHEFRINcm OF ABSCRFTIoN"-"-----"""---------"------"-----"----- 4

(2)

smJI ETEcr TYPE (BASIC CYuE) “----”””---””----””-----””--- 7

(3)

w - ~ .................................................... 8

(4)

CUOLINGWA~--------------------------------------------------------------9

(5)

VAURJM --"" ----" -"-----" "---" ---" -"---- "-"-" ""---" -----" ---" -----" "-----" ----lo

(6)

LRHJM EROMJDE(LB- :

(7)

~~ ~ ...............................................................l6

(8)

CONTENTS

Page No.

AKOREHW)--’--”---””----””----------”-ll

1.2 (x)oLINGCYuE DEStxlFrIoN -----------`"----"------"----"----"-"----------"lo

(~) ~~ - ..............................................................l9

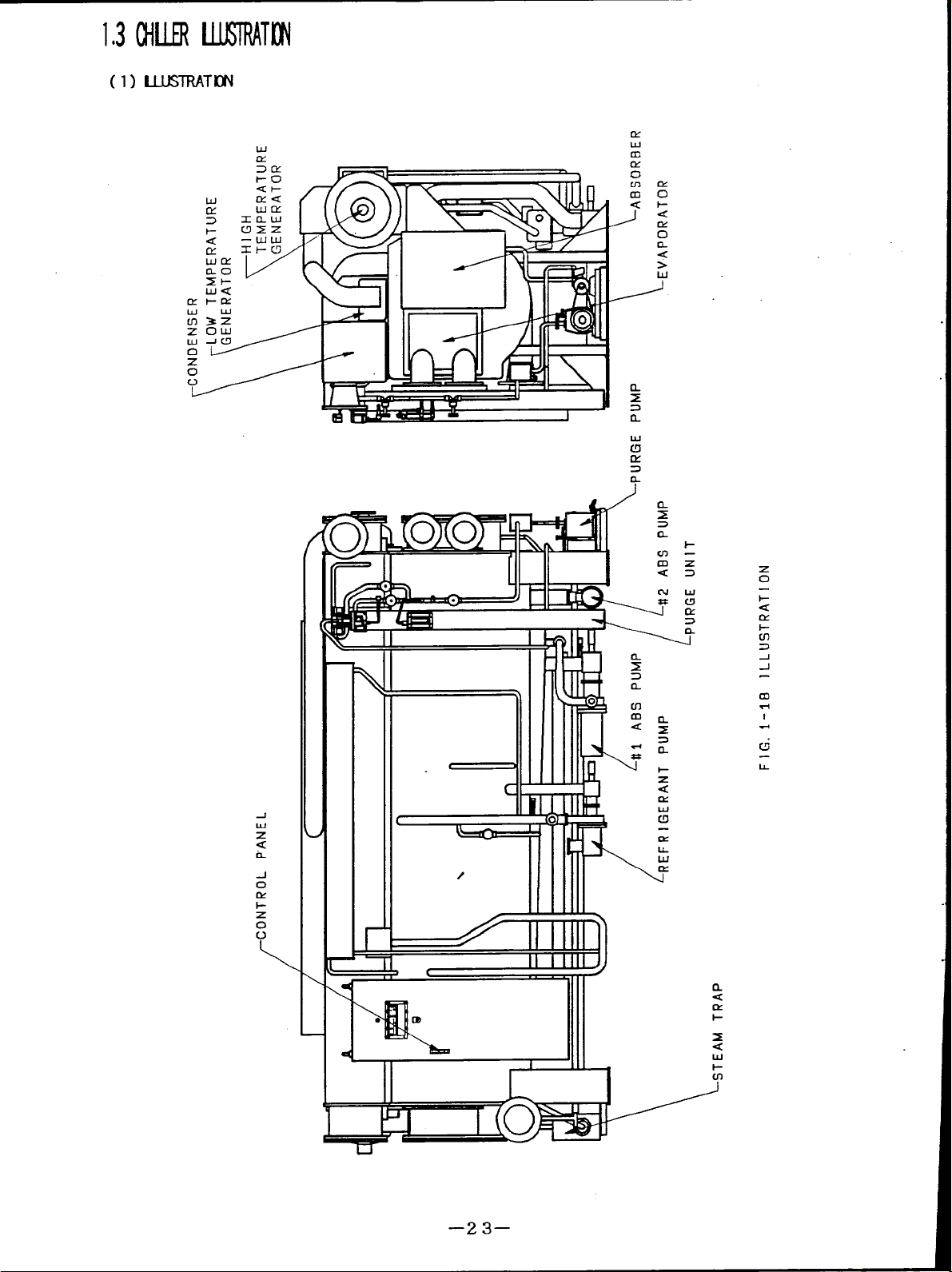

1.3 ~11.UR IUKIRATION --------------------------------------------------------23

(1) lUUSIRATION

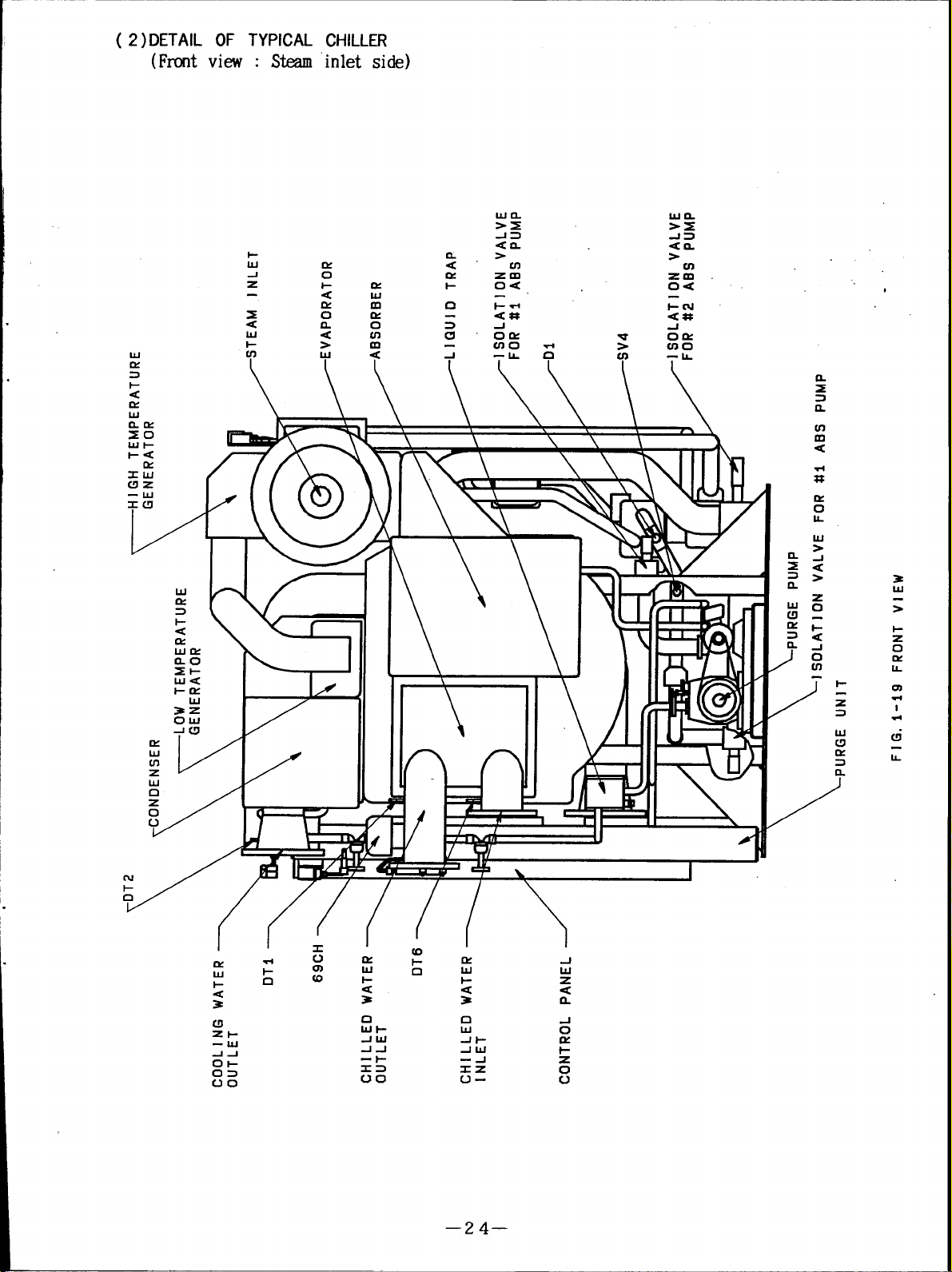

(2) ~A~ OF TYPIC4LU-IILLH?(m V~) ..........-....-.......24

(3) DETAROF TYPIC4LC1-HLUR(m VIEW)-----------------------25

(4) ~A~ ~ ~w ~~(R~ V~) ...........-...........26

(5) DETAITCF mm ~~(~ Vm) .......................27

(6) TYPBXL(DNIROLP~-------------------------------------------------28

(7) TYPEALm CONIROLVALVEANDm ~--.. ..... 30

(8) = ........................................................................3l

~.4 cJJqq’y ~~ .................................................................34

QIILI.EI WATIRANDU30UK WAIH------------------------------34

(1)

HIGHlXMPfRAllJREG134ERATOR---------------------------------------34

(2)

m-------" ""----"""--------"----"----------"-------""---------"-----"-"----""35

(3)

OITIIRS ----"----"-"----""-----""---"----"---""---------"""-"--""-"-"-"-----"-"-35

(4)

-----------------------------23

—l–

Page 5

1THE PRINCIPLEOFABSORPTION

(1)WHY

DOES A I-EATING CHILL ?

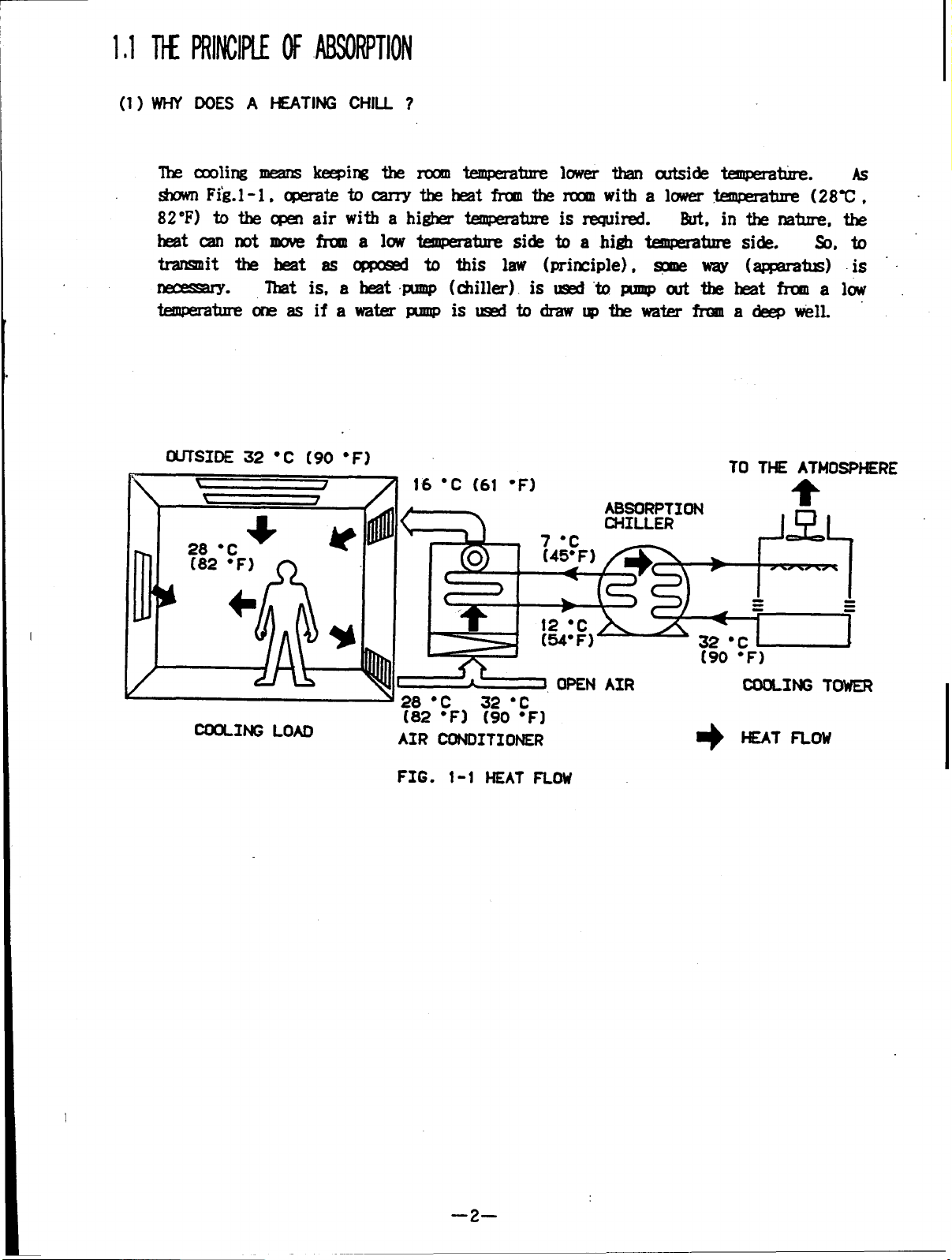

The cooling means keeping the room temperature lower than outside temperature. As

shown Fig.l-l, operate tocarry theheat from the room with alowert temperature (28C,

82 F) to the open air with a higher temperature isrequired.

heat can not move from low temperature side toahigh temperature side. So, to

transmit the heat as opposed to this law (principle), some way (apmratus) is

necessary.

temperature one asifawater pump isused todraw up the water from a deep well.

That is, aheat pump (chiller) isused topump out the heat from alow

But, in the nature, the

RE

COOLING LOAO

(82 “F) (90 ‘F]

AIR CONDITIONER

FIG. 1-1

HEAT FLOW

+

HEAT FLoW

–2–

Page 6

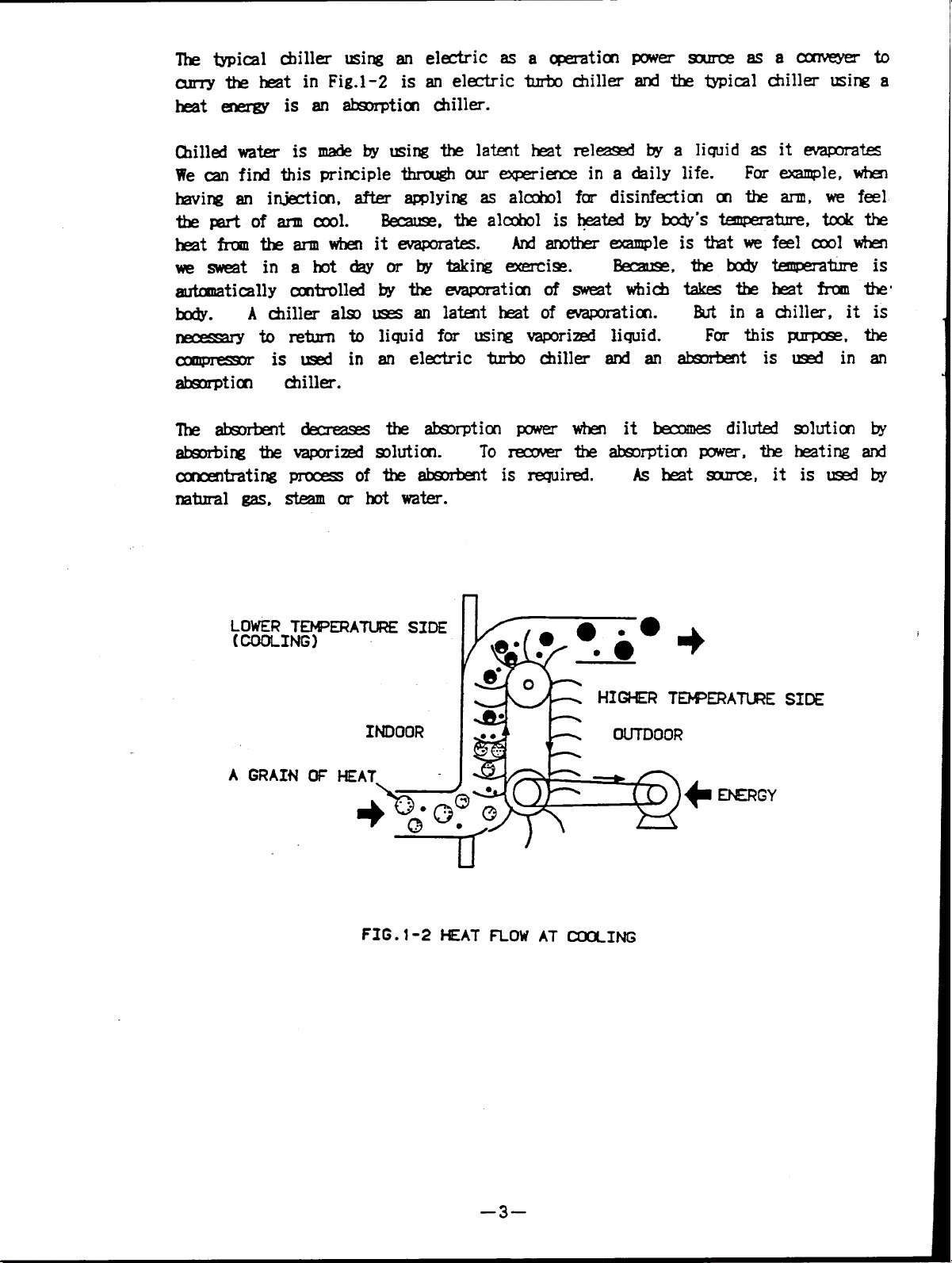

The typical chiller using an electric asa operation power source asaconveyerto

curry the heat inFig.1-2 is anelectric turbo chiller and the typical chiller using a

heat energy isanabsorption chiller.

chilled water is made by using the latent heat released by a liquid as it evaporates

We can find this principle through our experience in a daily life.

having an injection, after applying asalchol fordisinfection onthearm,wefeel

thepartofarm cool.

heat from thearm when itevaporates.

wesweat inahot day orbytaking exerxise.

automatically controlled by theevaporation ofsweat which takes theheat from the

body.

necessary toreturn to liquid for using vaporized liquid.

compressor isused in an electric turbo chiller and anabsorbent isused inan

absorption chiller.

The absorbent decreases the absorption power when itbecomes diluted solution by

absorbing thevaporized solution.

concentrating process ofthe absorbent isrequired.

natural gas, steam or hot water.

A chiller also uses anlatent heat ofevaporation.

Because, the alchol is heated by body’s temperature, took the

And another example is that we feelcool when

bercause, thebody temperature is

But in a chiller, it is

Toreceover theabsorption power, the heating and

Asheat source, itisused by

For example, when

For this purpose, the

INDOOR

A GRAIN OF HEAT=

FIG. 1-2

k!*%

-1=.

u

HEAT FLOW AT ~ING

HIGHER TEWERATU?E

smE

–3–

Page 7

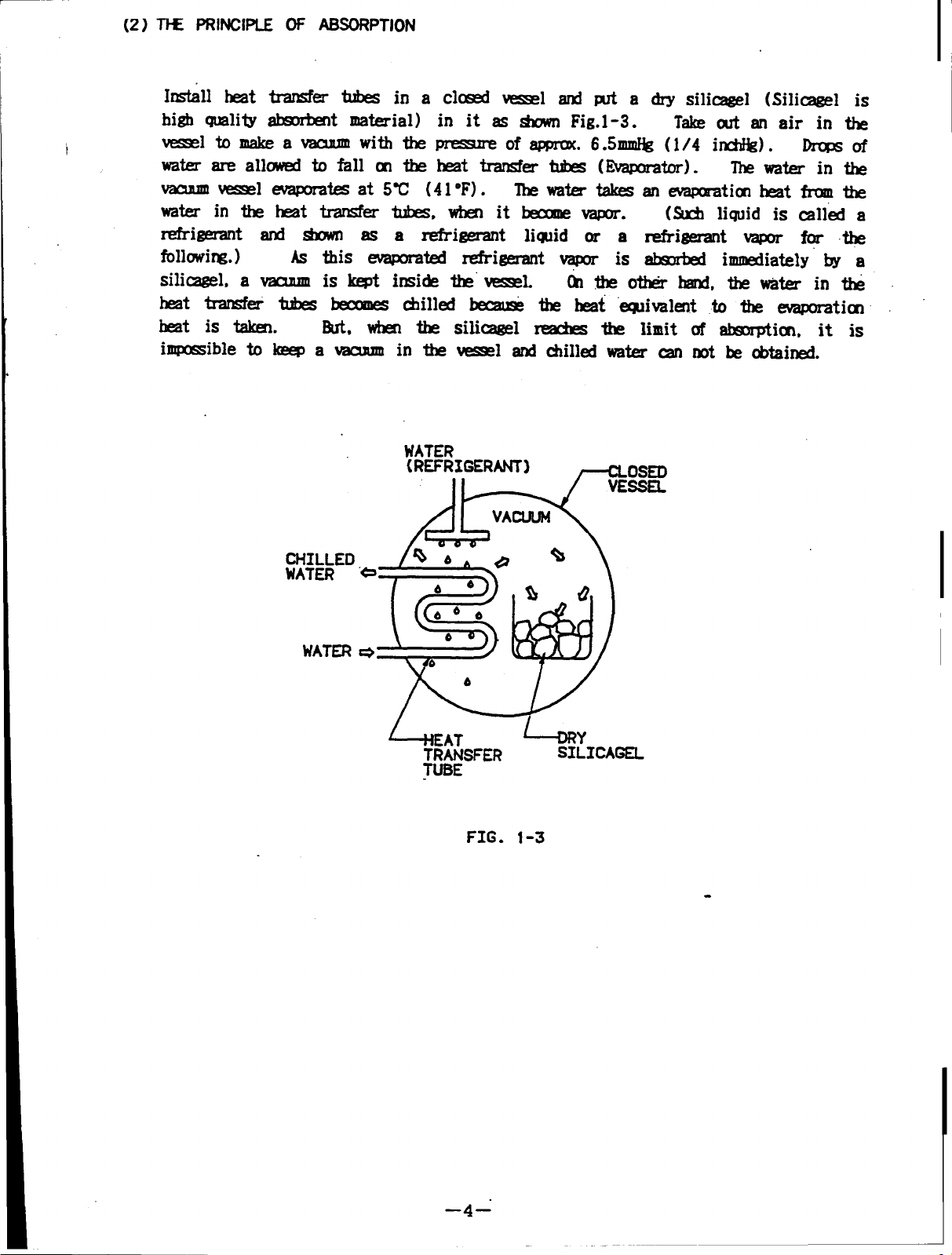

(2) J-w PRINCIPLE OF ABSORPTION

Install heat transfer tubes in a closed vessel and put a dry silicagel (Silicagel is

high quality absorbent material) in it as shown Fig.1 -3.

t

vesselto make avacuum with the pressure

of approx. 6.5mmHg (1/4 inchHg). Drops of

water are allowed to fall on the heat transfer tubes (Evaporator).

vacuum vessel evaporates at 5C (41F).

The water take anevaporation heat from the

water intheheat trasnfer tubes, when itbecome vapor.

Take out anairinthe

The water in the

(Such liquid is called a

refrigerant and shown as a refrigerant liquid or a refrigerant vapor for the

following.)

silicagel, a vacuum is kept inside the vessel.

As this evaporated refrigerant vapor is absorbed immediately by a

(Ontheother hand, thewater inthe

heat transfer tubes becomes chilled becasese the heat eqiovalent to the evaporation

heat is taken.

immpossibleto keep a vacuum

But, when the silicagel reaches the limit of absorption, it is

in the vessel and chilled water can not be obtained.

WATER

(REFRIGERANT)

CHILLED

WATER

MATER

e

*

6EA7

TRANSFER

TUBE

FIG. 1-3

+Y

SILICAGEL

—4–”

Page 8

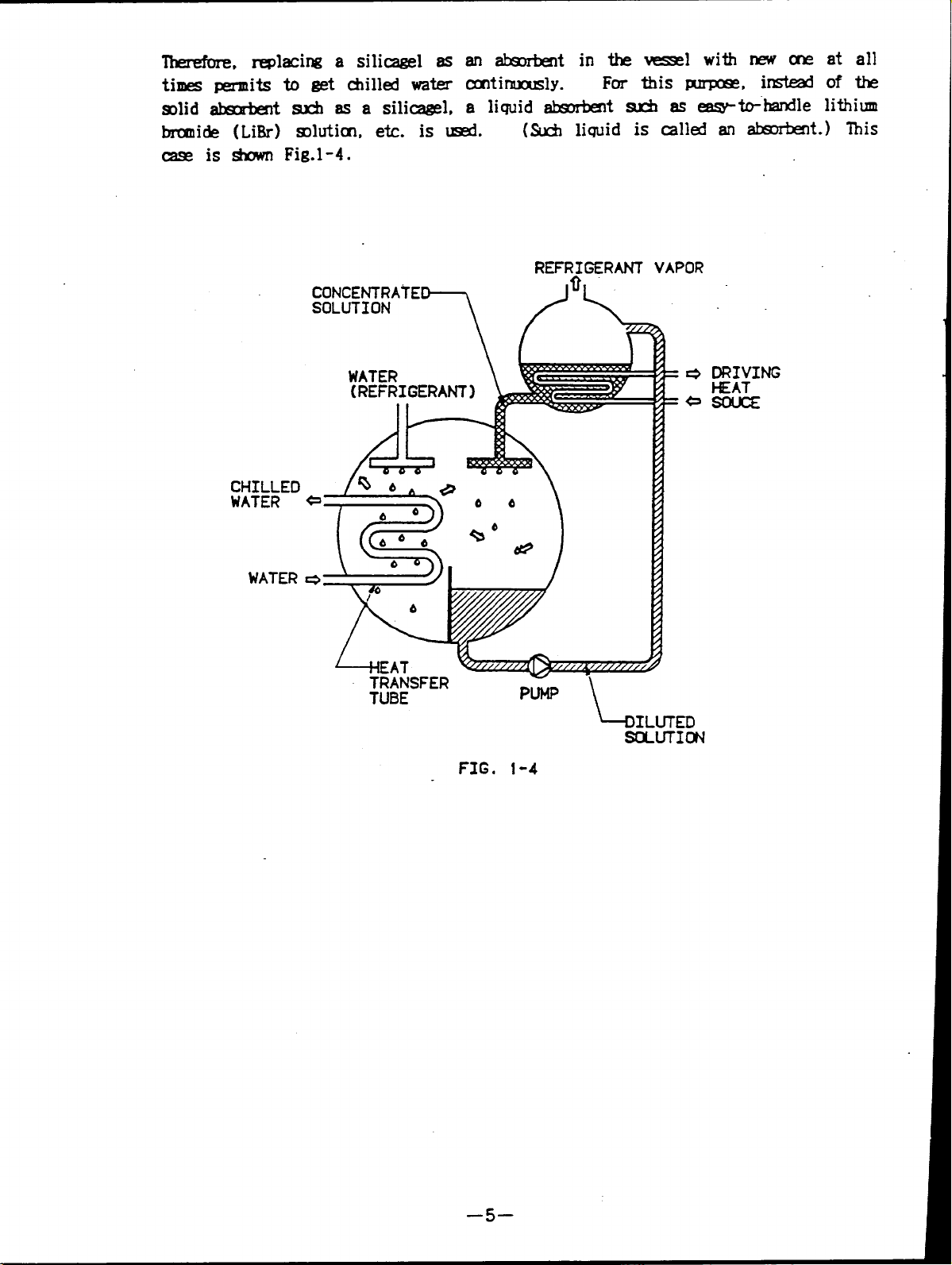

Therefore replacing a silicagel as an absorbent in the vessel with new one at all

times permits to get chilled water continuously.

For this purpose, instead of the

solid absorbent such as a silicagel, a liquid absorbent suchaseasy-to-handle lithium

bromide (LiBr) solution, etc. is used

(Such liquid is called an absorbent.) This

case is shown Fig.1-4.

CHILLED

WATER

WATER

CONCENTRATE

SOLUTION

L

EAT

TRANSFER

TUBE

REFRIGERANT

/

7

[

PUHP

bILUTED

VAPOR

S(MJTION

FIG. 1-4

–5–

Page 9

drops of LiBr solution areallowed tofall (Absorber) inside thevessel. The LiBr

solution absorbs refrigerant vapor.

But,when theabsorbent once absorbes the

refrigerant vapor, it is diluted and dereases ability to absorb. Resulting in the

chilled water can not be obtained.

I

in continuously. At this stage, thediluted solution is hinted by driving heat

This means that concentrated solution must befed

source (natural gas, steam or hot water:Generator). The heat causes the solution to

release the absorbed refrigerant and also

reconcentrates thesolution.

The refrigerant vapor which is released from the solution when heated,

separate vessel (Condenser) liquid refrigerant. Drops of

again introduced into the vacuum vessel andrecycled

This is shown

is cooled in a

this. water are.

Fig.1-5. ‘

FIG. 1-5

–6–

Page 10

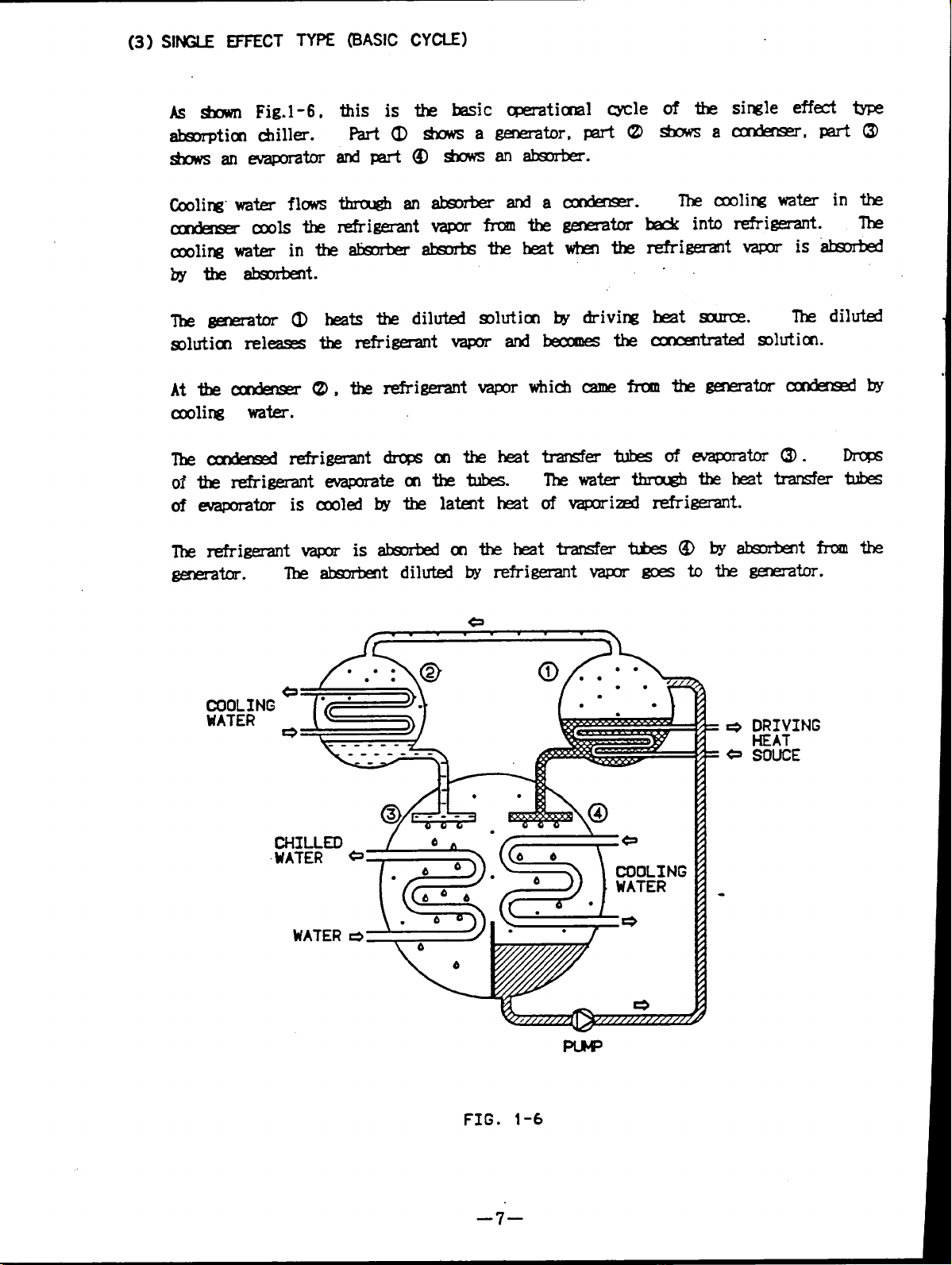

(3) SINGLE EFFECT TYPE (BASIC CYCLE)

Asshown Fig.1-6,

absorption chiller.

this is the basic operational cycle

Part (l)shows agenerator,

shows anevaporator

Cooling water flows

condensor cools the

cooling water intheabsorber absorbs the heat when the

bythe absorbent.

The generator (1)heats the diluted solution bydriving

solution releases the refrigerant vapor and becomes the

transfers tubes ofevaporator (3). Drops

The water through the heat transfer tubes

ofvaporized refrigerant.

of the single effect type

sbows acondenser, part (3)

The cooling water in the

back into refrigerant. The

regrigerant vapor is absorbed

heat source.

The diluted

concentrated solution.

COOLING

WATER

CHILLEO

WATER

WATER

----- .-

DRIVING

HEAT

SOUCE

FIG. 1-6

–7–

Page 11

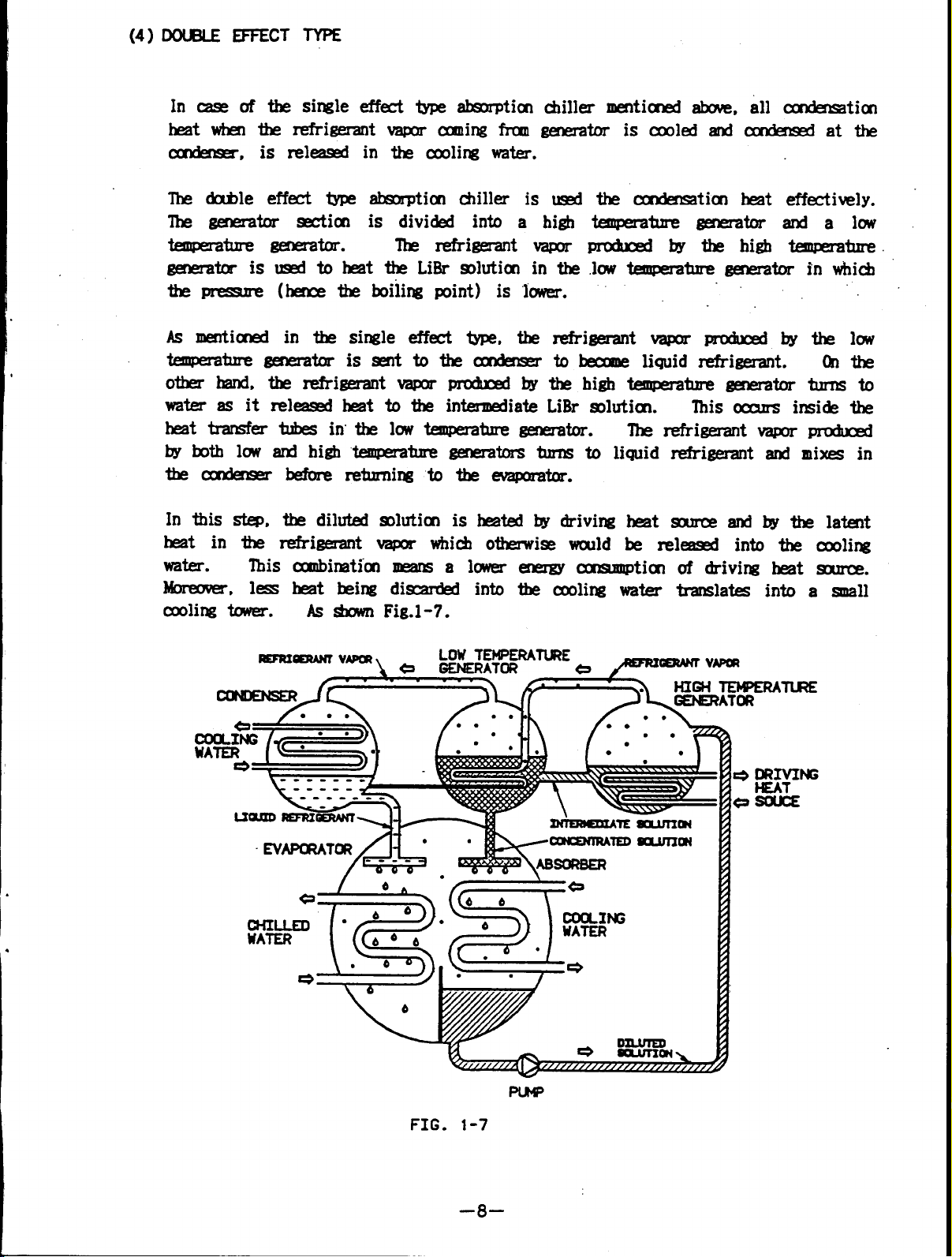

(4) DOUBLE EFFECT TYPE

In case of the single effect type absorption chiiller mentioned above, all condensation

heat whn the refrigerant vapors coming from generator iscooled and condensed atthe

condensor, is released in the cooling water.

The double effect type absorption chiller is used

The generator section is divided into a high

-- generator.

generator is used to heat the LiBr solution in the

the pressure (hence the boiling point) is lower.

As mentioned in the single effect type, the refrigerant vapor produced by the low

temperature generator issent tothecondensor

other hand, therefrigerant vapor produced bythehigh temperature generator turns to

water as it released heat to the intermediate LiBr solution.

heat transfer tubes in the low temperature generator.

byboth low and high temperature generators turns to liquid refrigerant and mixes in

thecondenser before returning totheevaporator.

In this step, the diluted solution is heated by driving heat source and by the latent

heat in the refrigerat vapor which otherwise would be released into the cooling

water.

Moreover, less heat being discarded into the cooling water translates into a snail

cooling tower.

This combination means a lower energy consumption of driving heat source.

As shown Fig.1-7.

The refrigerant vapor

the condensation heat effectively.

temperature generator and alow

produced by thehigh temperature

low temperature generator in which

to become liquid refrigerant. On the

This occurs inside the

The refiigerant vapor produced

.

I

FIG. 1-7

–8–

Page 12

(5) COOLING WATER

lo

The lower temperature of cooling water

a)

The absorption power ofLiBr solution isstrong atthe lower temperature ofthe

cooling water.

condensed temperature ofregrigerant downs.

low.

As the boiling temperature (generator temperature) oftheLiBr solution downs

when thecondensed pressure islow,

When thetemperature ofcooling water in thecondenser is

Therefore condensed pressure becomes

calolific value of driving heat source can

decrease. This means save energy.

It is not acceptable

b)

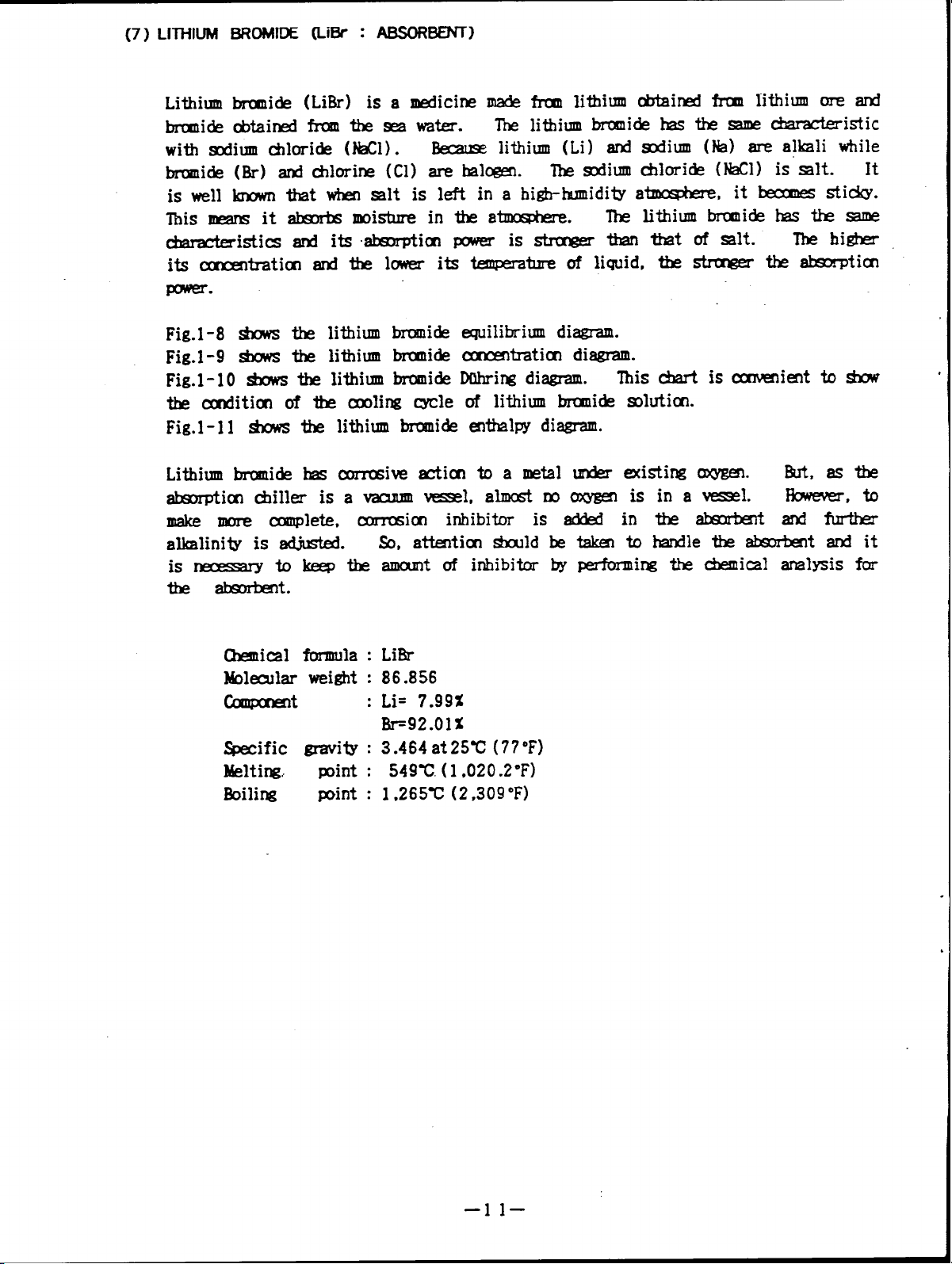

As shown Fig.1-8, a

LiBr solution of

temperature For

that the temperature of cooling water is too low.

few LiBr dissolves with water at low temperature.

That is, the

high concentration becomes crystallization under the lower

example, it is crystallized with concentration of 65% at the

temperature lower then 42C (108F), with concentration of 60% at the temperature

lower than 17C (63F).

Chiller has some problems when cooling water temperature becomes too high

c)

When thetemperature of thecooling water becomes tohigh, theabsorption power of the

LiBr solution decreases.

temperature and wastes much fuel.

The chiller can not get the normal chiller water

Therefore, to prevent this, the maintenance for

cooling water SYStem (epuipment and control) and water treatment are required.

d)

Water treatment of cooing water

The water treatment of the cooling water is an inportant factor for the chiller. If

thewater quality isno good, scale adheres totheinside ofthe heat transfer tubes,

resulting in the

decreases transfer heat effect and waste fuel. Astheheat transfer

tubes may become corroded, itisrequired to fully take care ofthe water treatment.

–9–

\

Page 13

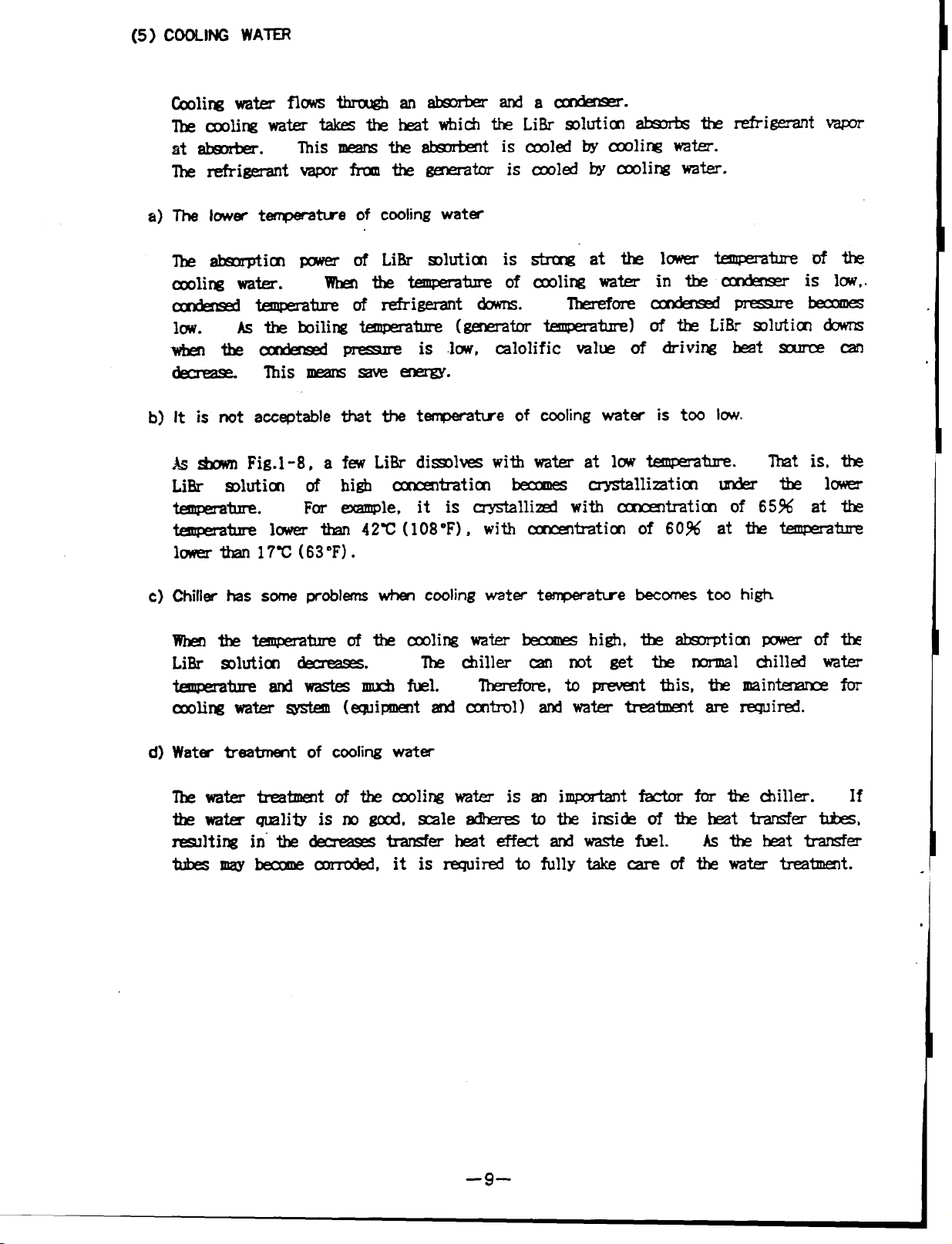

(6) VACUUM

Onthe earth, wearepressed bythe air.

pressure (1kg/cm, 14.2psi).

the vacuum.

When explaining the vacuum for the absorption chiller, it is required to

This pressure is called atmospheric

The pressure less than atmospheric pressure

is called

know the relation between the pressure and the evaporation pressure o the water.

lt is experienced in a daily life that the water is boiled (evaporated) at 100C

(212F) in the atmospheric pressure.

When the pressure

pressure (vacuum), the water boiled below 100C (21OF).

between the pressure and the evaporation temperature.

.

is lower than the atmosheric

Table 1-1 shows the relation

The water isevaporated atlower temperature, when thepressure is lower and lower.

Therefore, the inside the chiller should be always kept in high vacuum.

Since the

refrigerant is evaporated at 5C (41F) to get the chilled water of 7C (45F) by an

absorption chiller, it is required to keep a high-vacuum condition with pressure

of

6.54mmHg (1/4 inchHg) in the evaporator.

Table 1-1

Gauge Absolute

pressure

W“2G

m=me

*

(psig)

Atmospheric

pressure

t 0.5 ( 7.2)

1 ata.

{o (o) 760(29.9)

4

vacullB

(inch&)

10 (142)

8 (114)

Driving pressure for double effect type

5 ( 71)

1 (14.2) Driving pressure for single effect type

Atmospheric pressure

525.9 (20-3/4)

61.0 ( 2-3/8)

Pressure in the cmdenser

9.2 ( 3/8)

6.54( 1/4)

Pressure in the evajxmtor

–lo–

Page 14

(7) LITHIUM BROMIDE (LiBf : ABSORBENT)

Lithium bromide (LiBr) isamedicine made from lithium obtained fromlithium ore and

bromide obtained from theseawater.

with sodium chloride (NaCl).

Because lithium (Li) and sodium (Na) are alkali while

bromide (Br) and chloride (Cl) are halgen.

The lithium bromide has the same characteristic

The sodium chloride (NaCl) is salt. It

is well known that when salt is left in a high-humidity atmosphere, it becomes sticky.

This means itabsorbs moisture intheatmosphere.

The lithium bromide has the same

characteristics and its absorption power is stronger than that ofsalt.

its concentration and the lower its temperature of liquid. thestronger the absorption

power.

The higher

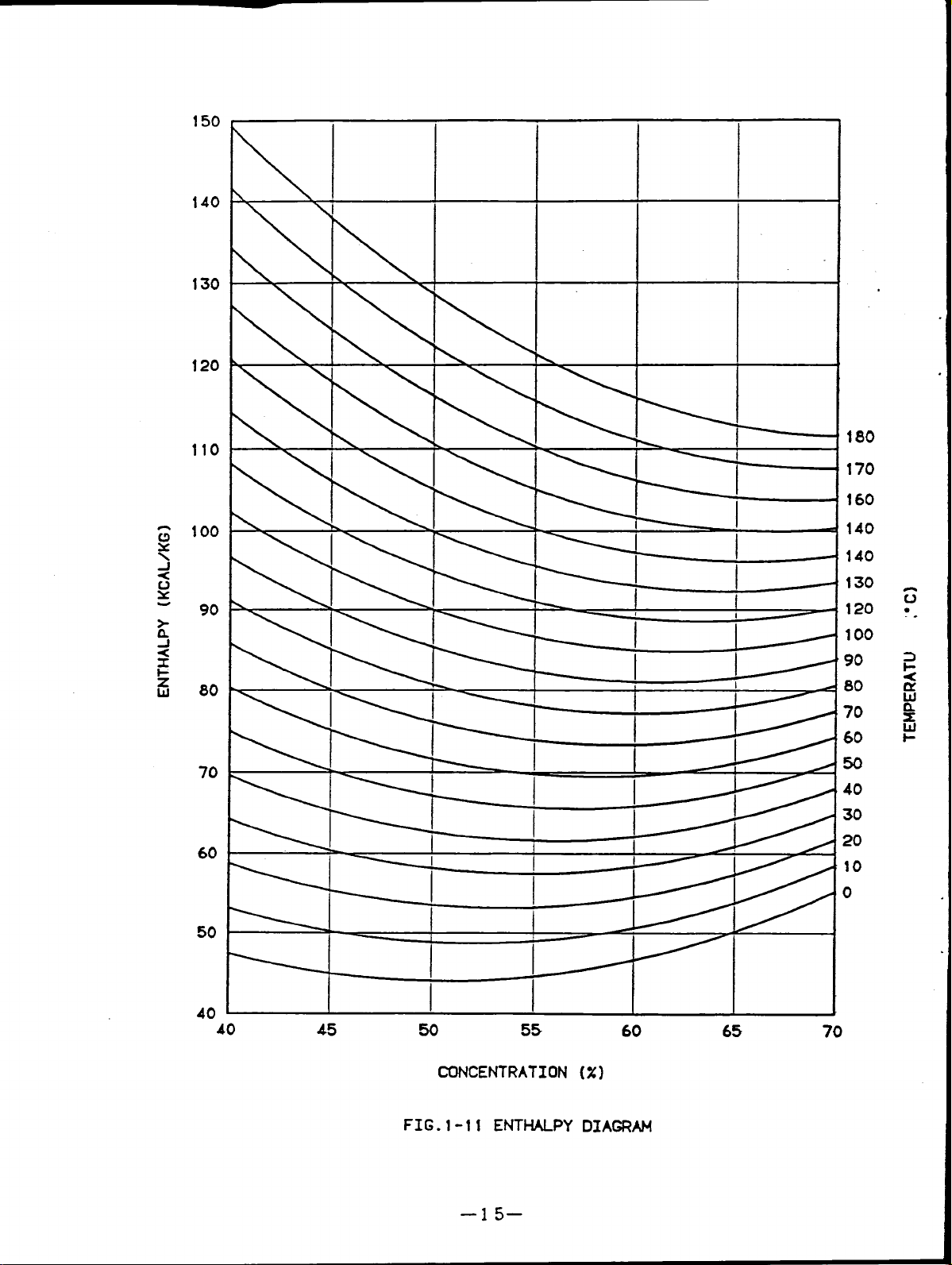

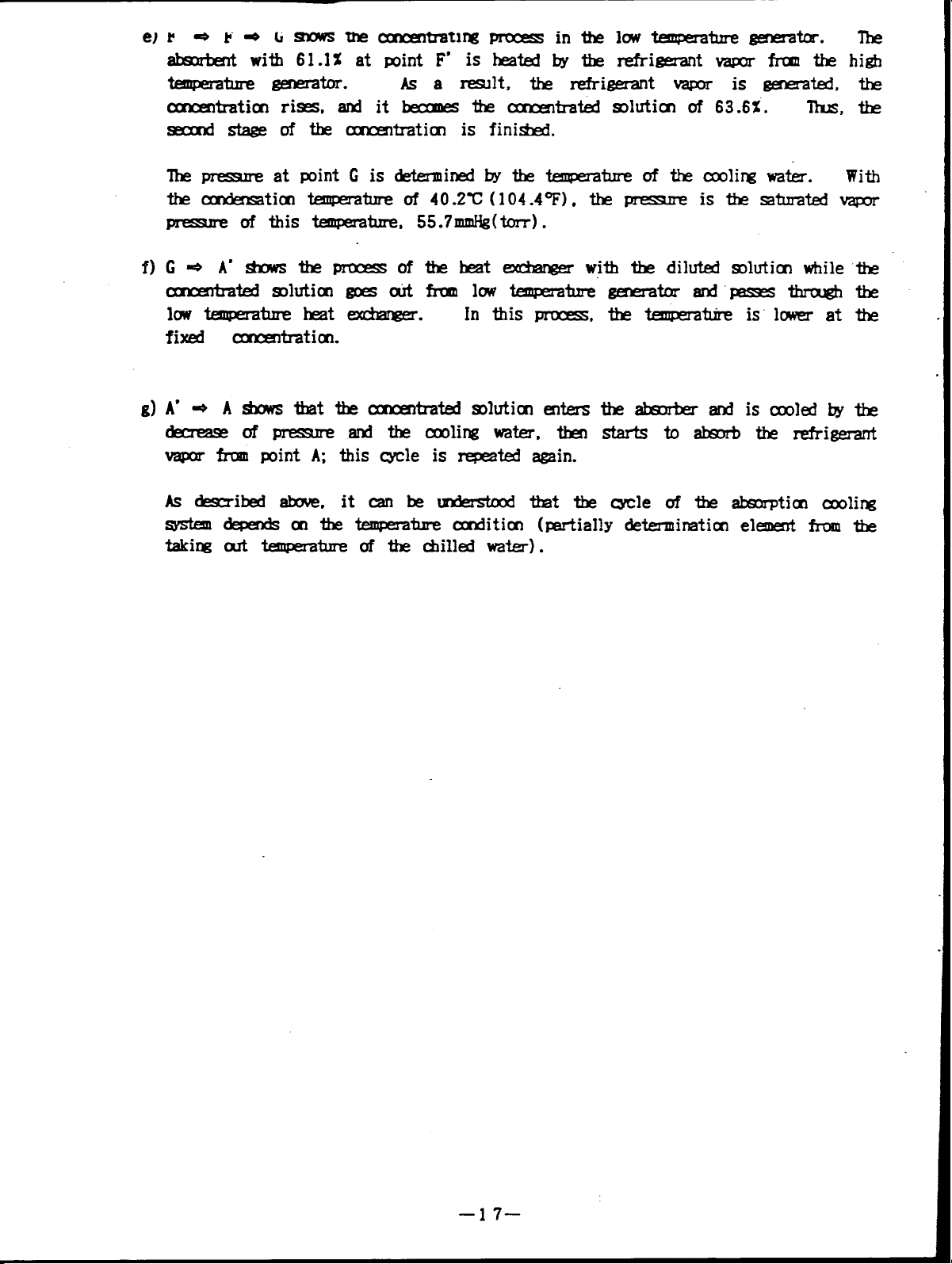

Fig.1-8 shows the lithium bromide

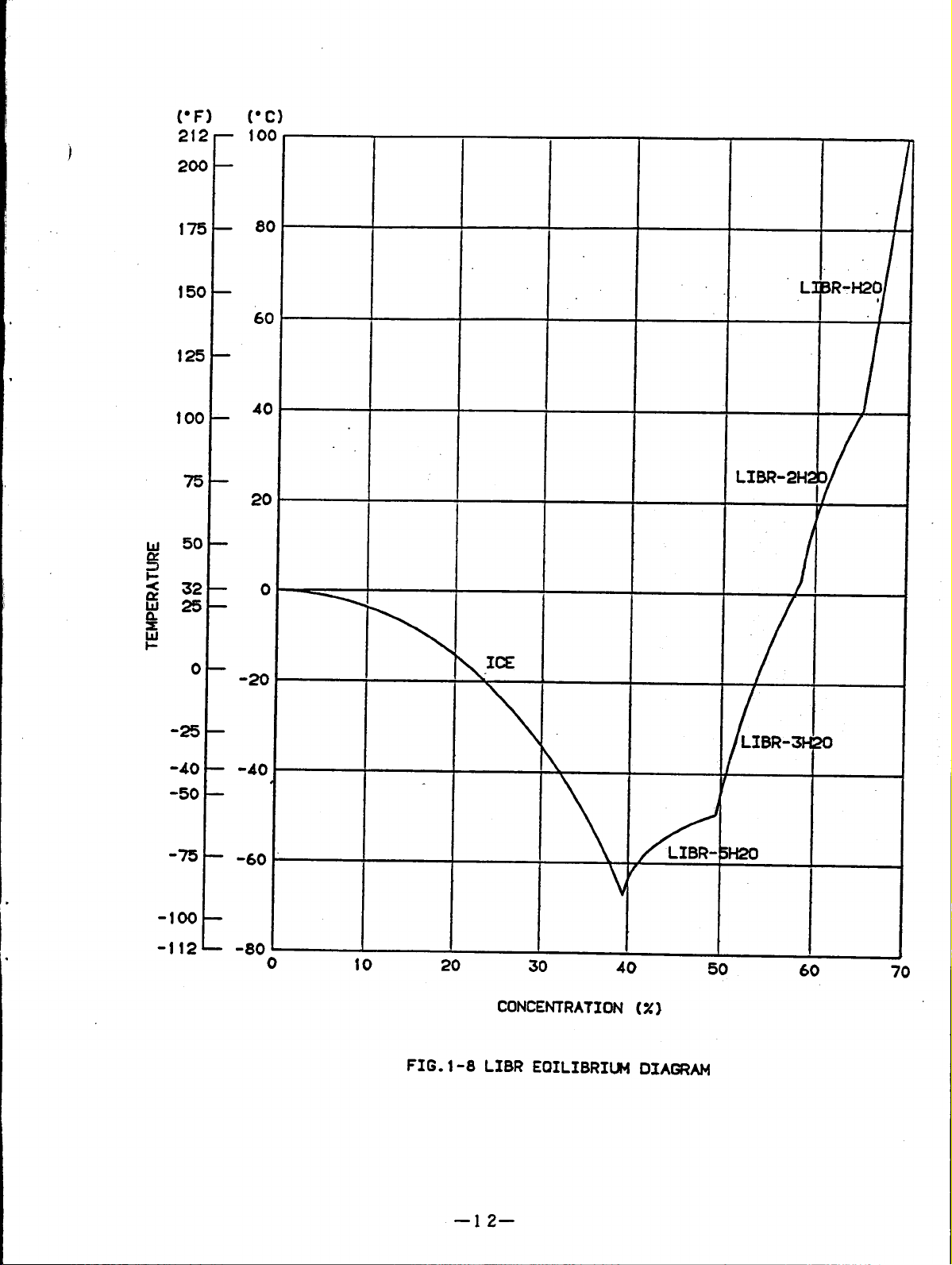

Fig.1-9 shows the lithium bromide

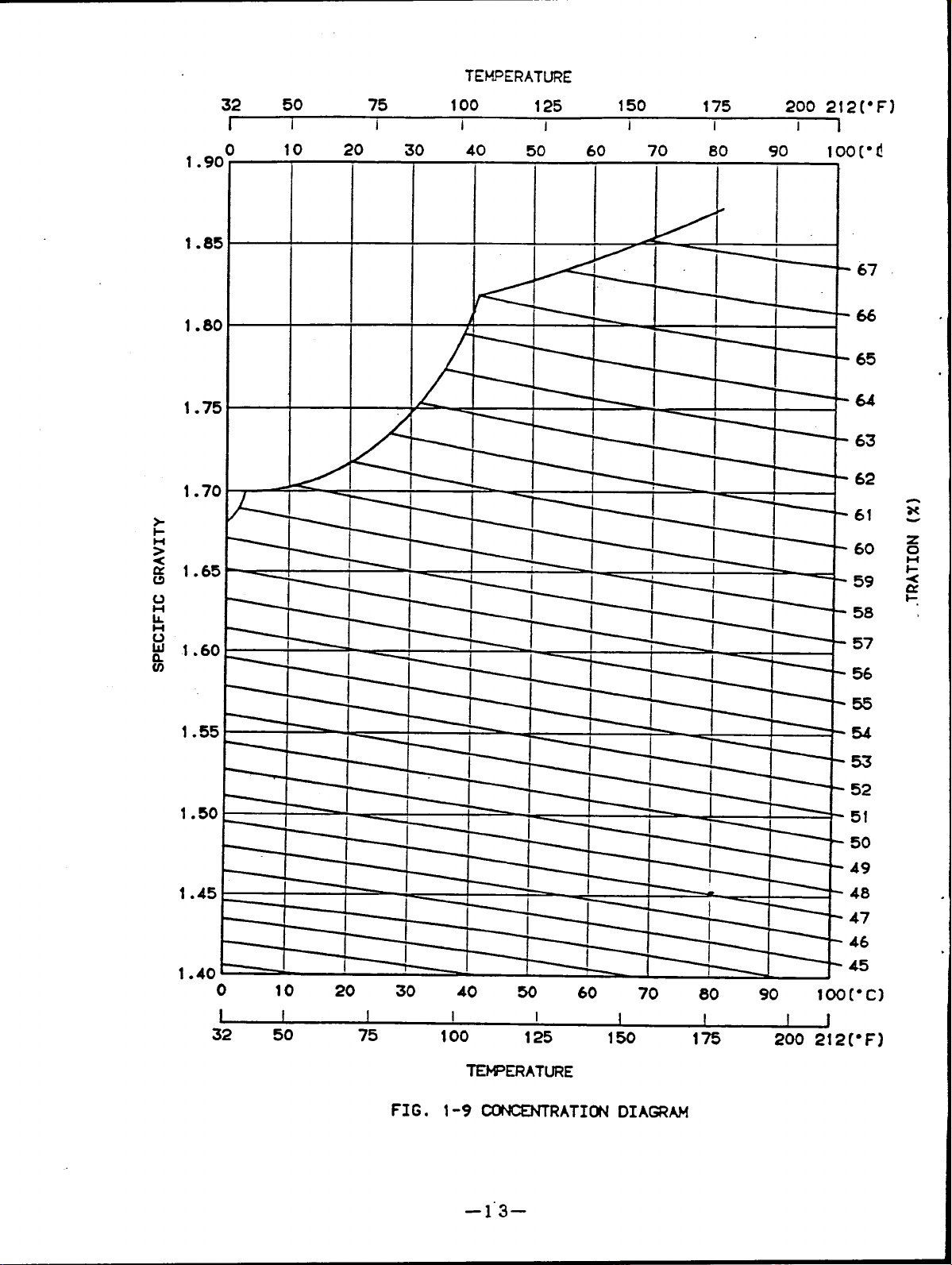

Fig.1-10 shows the lithium bromide

the condition of the cooling cycle

equilibrium diagram.

concentration diagram.

during diagram.

This chart is convenient to show “

of lithium bromide solution.

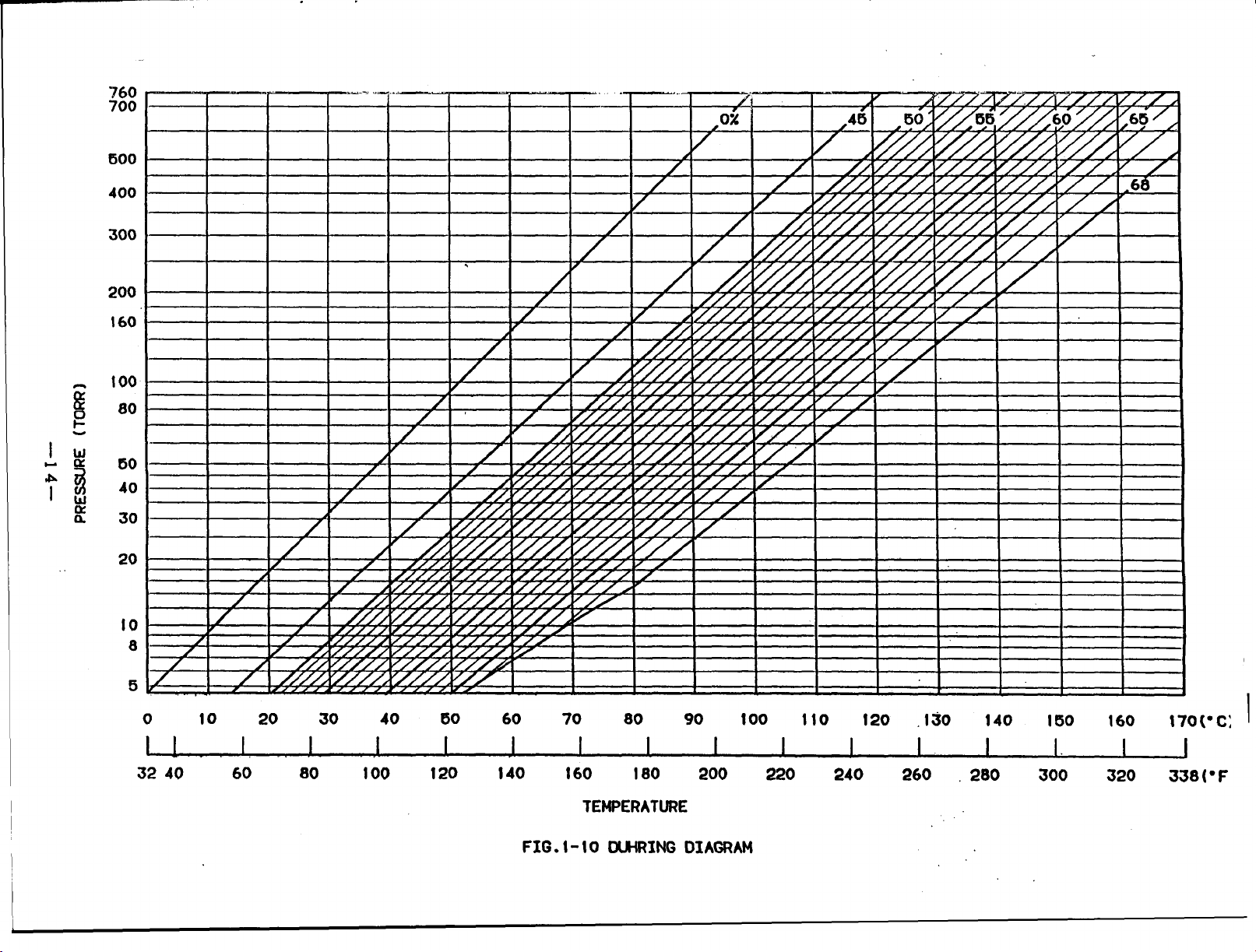

Fig.1-l1 shows the lithium bromide enthalpy diagram.

Lithium bromide has corrosive action to a metal under existing oxygen

But, asthe

absorption chiller is a vacuum vessel, almost no oxygen is in a vessel. However, to

make more complete, corrision inhibitor is added in the absorbent and further

alkalinity is adjusted.

So, attention should be taken to handle the absorbent and it

is neccessary to keep the amount of inhibitor bY performing thechemical analysis for

theabsorbent.

Chemical formula : LiBr

molecular weight : 86.856

Component

: Li= 7.99%

Br=92.OI%

specific gravity : 3.464 at25C (77°F)

Meltingr

point :

549C. (1 ,020 .2F)

Boiling point : 1.265C (2,309F)

–1 l–

Page 15

21

20

12!

100

80

L:

60

10(

-25

-40

-50

-75

40

LX5R-21+2

20

.

.

0

.

.

c

-40

-60

I

-1oo

-80

0

10

20

30

CONCENTRATI~ (%)

EOILIBRIUM DIAGRAM

40

50

60

70

I

Page 16

TEk!.!ERATURE

32 50 75

I

1.9C

1.85

1.8C

1.75

1.70

1.65

I

10 20 30 40 50 60 70 80 90

100

I

I

125

I

150

I

175 200

i

I

—

—.-.

t

100[”(!

63

62

61

60

59

67

.

x

.

1.60

1.55

1.50’

1.45

1.40

o

1

32 50

J

I

---r--t-”

I

—

I

I

3=1

10 20 30 40 w 60 70 80 go

I

75

1

I I

100

TEMPERATURE

125

I

150

I

175

100[’C)

I

J

200 212[”F)

58

57

56

55

54

52

51

50

49

48

FIG.

1-9 CONCENTRATI~

–1”3–

Page 17

760

700

600

400

300

200

160

100

80

u

60

40

30

20

10

8

5

o

I

3240 60 80 100 120 140

10 20 30 40 60 60 70 80 90

I 1, 1 1

I

I

FIG. t-10 DUHRING DIAGRAM

I

160

TEMPERATURE

180 200

1

100

I

220

110

I

120

I

240

260

.130

1.

140

I 1.

280 300 320

I 50

160

170(” C:

I

I

338(” F

I

Page 18

150

\

140

130

120

110

- 160

.

100

60

50

40

90

80

70

40

-l

45

~ 130

%!

—

I I

I I ---

(

—

120

70

60

50

40

30

20

10

0

50

55

60

65

70

CONCENTRATION (%)

FIG.1-11 ENTMU_PY DIAGRAM

–15–

Page 19

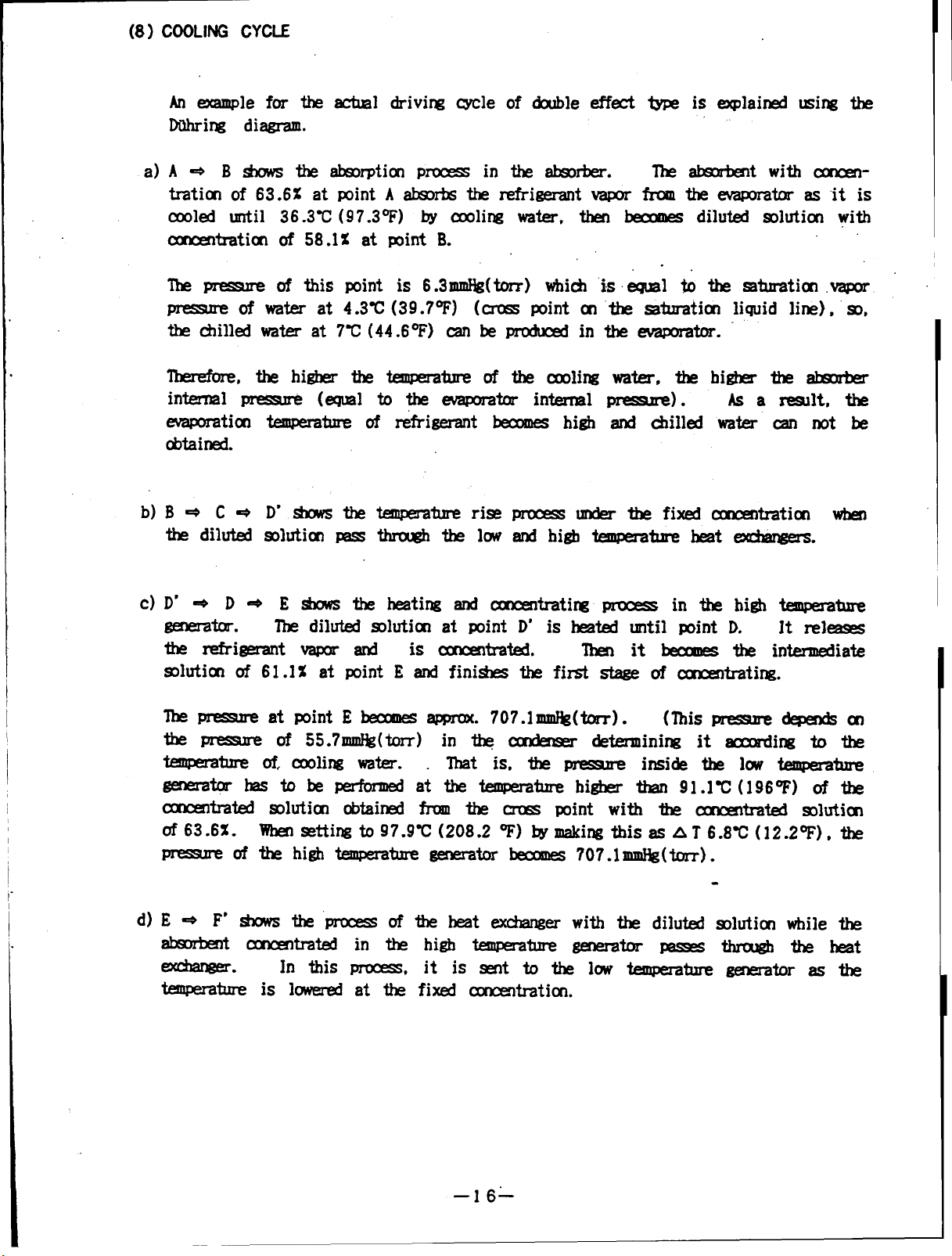

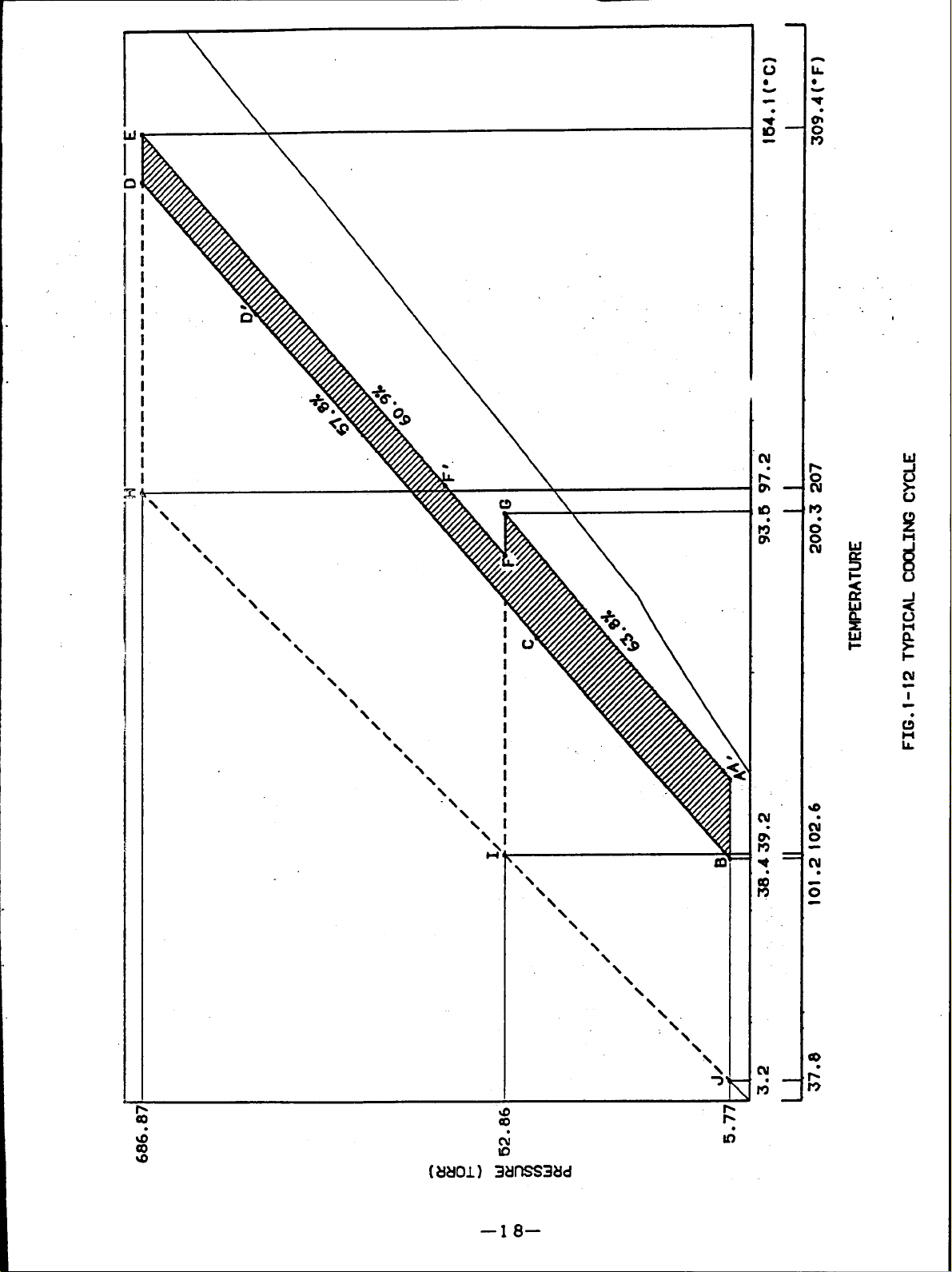

(8) COOLING CYCLE

An example for the actual driving cycle of double effect

Duhring diagram.

a) A-B shows theabsorption process in theabsorber.

tration of 63.62 at point A absorbs the refrigerant vapor

cooled until 36.3C (97.3F) by cooing water, then becomes diluted solution with

concentration of 58.1% at point B.

The pressure of this point is 6.3mnHg(torr) which is equal to the saturation vapor

pressure of water at 4.3C (39.7F) (cross point on the saturation liquid line), so,

the chilled water at 7C (44.6F) can be produced in the evaporator.

Therefore, the higher the temperature of thecooling water, thehigher the absorber

internal pressure

evaporation

obtained.

b) B- C-

the diluted

temperature ofrefrigerant becomes high and chilled water can not be

D' shows the temperature rise process under the fixed concentration when

solution pass through the low and high temperature heat exchangers.

(equal to the evaporator internal pressure .

type is explained using the

The absorbent with concen-

from the evaporator asitis

)

As a result, the

generator

the refrigerant vapor and is concentrated.

solution of 61.1% at point E and finishes the first stage of concentrating.

The pressure atpoint Ebecomes approx. 707.1mmHg(torr).

the pressure of 55.7mmHg(torr) in the condenser

temperature ofcooling water. That is,thepressure

generator has to be performed at the temperature higher than 91.1C (196F) of the

concentrated solution obtained from the cross point with the concentrated solution

of 63.6%.

pressure of the high temperature generator becomes 707.mmHg (torr).

I

The diluted solution at point D’ is healed until point D.

Then it becomes the intermediate

(This pressure depends on

determining it according to the

inside the low temperature

Whensetting to 97.9C (208.2F) bymaking this as^ 6.8C (12.2F), the

It releases

—16-

Page 20

F-F-G shows theconcentrating process in thelow

temper

e)

absorbent with 61.1% atpoint F'isheated bythe refrigerant vapor from the

temperature generator.

concentration rises, and it becomes theconcentrated solution of63.6%. Thus, the

second stage oftheconcentration isfinished.

The pressure atpoint Gisdetermined bythe temperature ofthe cooing water. With

thecondensation temperature of40.2C (104.4F) thepressure

pressure ofthis temperature, 55.7mmHg (torr).

G-A’shows theprocess ofthe heat exchanger with the diluted solution while the

f)

concentrated solution goes out from low temperature generator and passes through the

As a result, the refrigerant vapor isgenerated, the

isthesaturated vapor

g)

Asdescribed above, itcanbeunderstood that the cycle of the absorption cooling

system depends onthe

taking out temperature

temperature condition (partially determination element from the

of the chilled water).

theabsorber and iscooled bythe

starts toabsorb therefrigerant

–17–

Page 21

d

\

\

\

\

\

\

\

\

\

“\

\

\

\

\

\

\

-\

\

\

\

\

-\

\

\

\

\

\

\

\

\

\

\

\.

.\

\

u

a

.

\

i

:

\

\

;

\

.

I

m

.

&

H

h.

I

3tJf7SS3Ud

–18–

Page 22

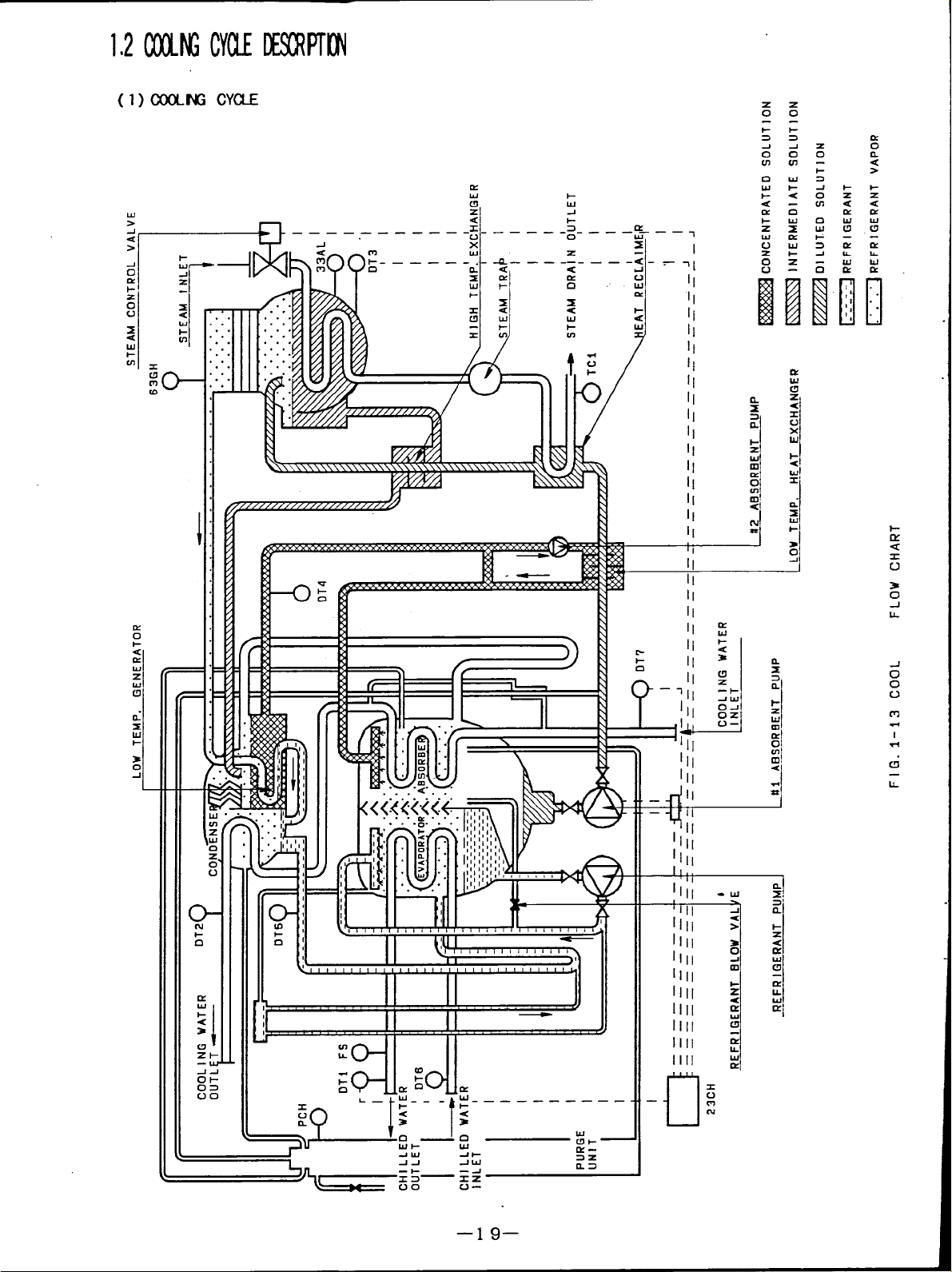

1$2(XIMGcm DEsowTnt”l

(l) COOLNG CYUE

K

IA.J

!&---+ i--------i------$----%--:

1-

w—

-1

z

.-1.

1-

-r

1LtY

t :

z

0

‘5

z

0

:

07

u

1-

Z

a

w

w

(5

El

II

[1

[

d

-d

1!1

i

o

0

Q-

1-

-w

-IA

ol03

00

11 [3!,, I,!!,,,,,!!< Ii II :

o-l

L

e

0

II II

—

——— ——— ———

c1

&

C!Y

L

II

II

II

lilt

111[

1111

1111

1111

—

I

—19—

Page 23

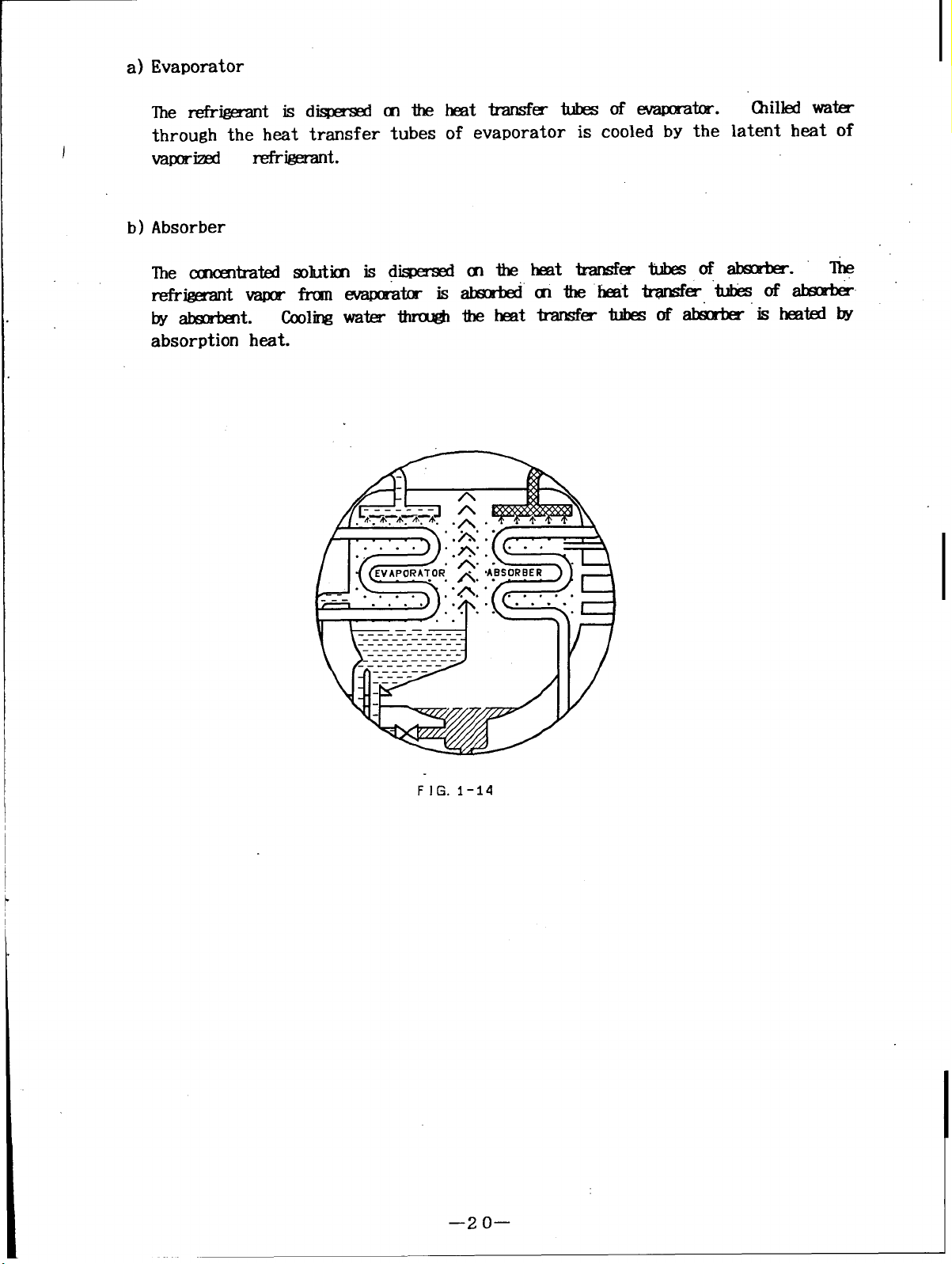

a) Evaporator

The refrigerant isdispersed onthe heat transfer tubes ofevaporator.

Chilled water

through the heat transfer tubes of evaporator is cooled by the latent heat of

J

vaporized

b) Absorber

refrigerant.

FIG. I-14

—2 o—

Page 24

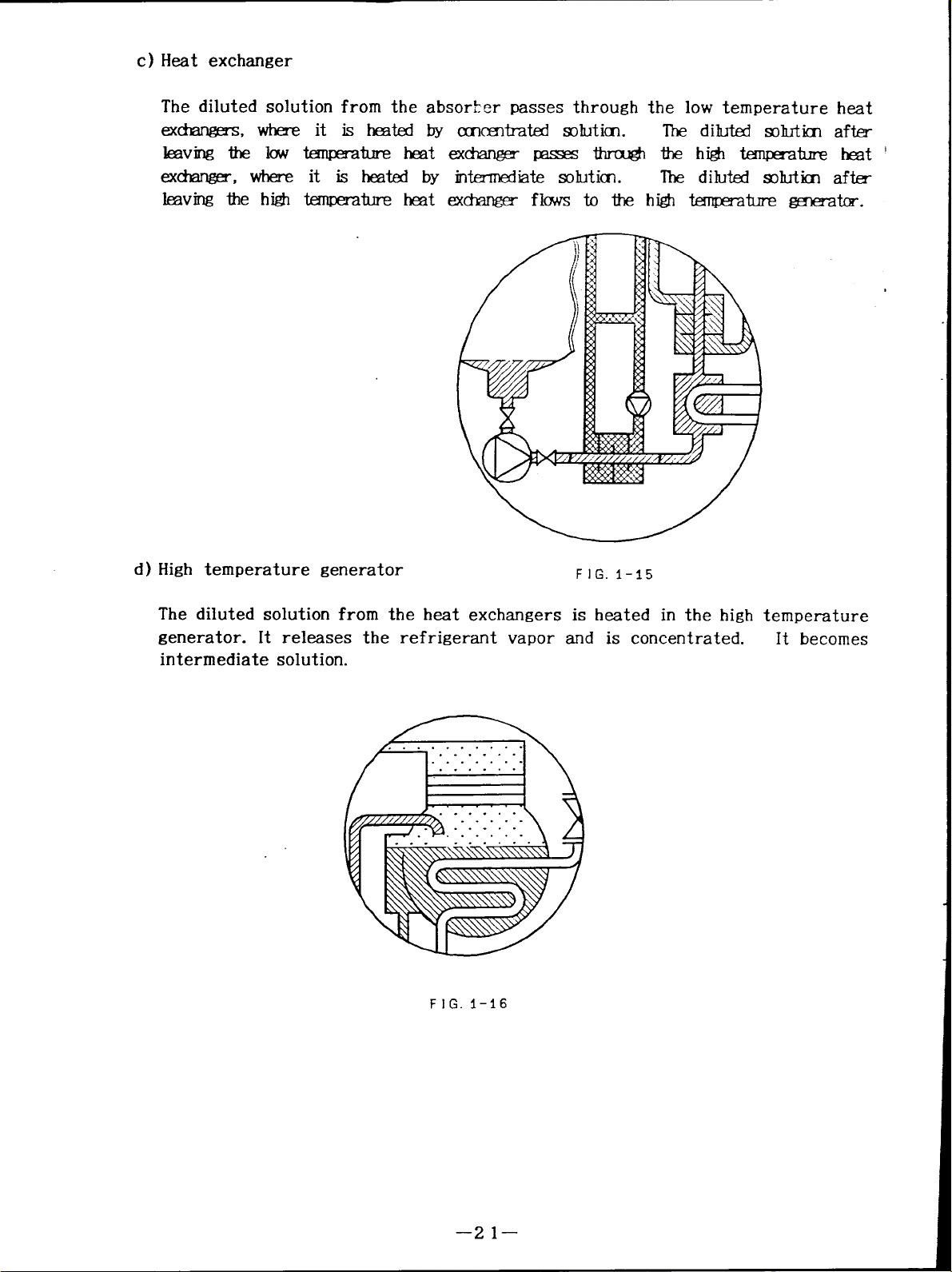

c) Heat exchanger

The diluted solution from the absor$er passes through the low temperature heat

exchangerss, where it is heated by concentrated solution.

The diluted solution after

leaving the low temperature heat exchanger passes through thehigh temperature heat

exchanger, where it is heated by intermdiate solution.

The diluted solution after

leaving the high temperature heat exchanger flows to the high temperature generator.

d ) High temperature generator

FIG. I-15

The diluted solution from the heat exchangers is heated in the high temperature

generator. It releases the refrigerant vapor

and is concentrated.

It becomes

intermediate solution.

FIG. 1-16

—21—

Page 25

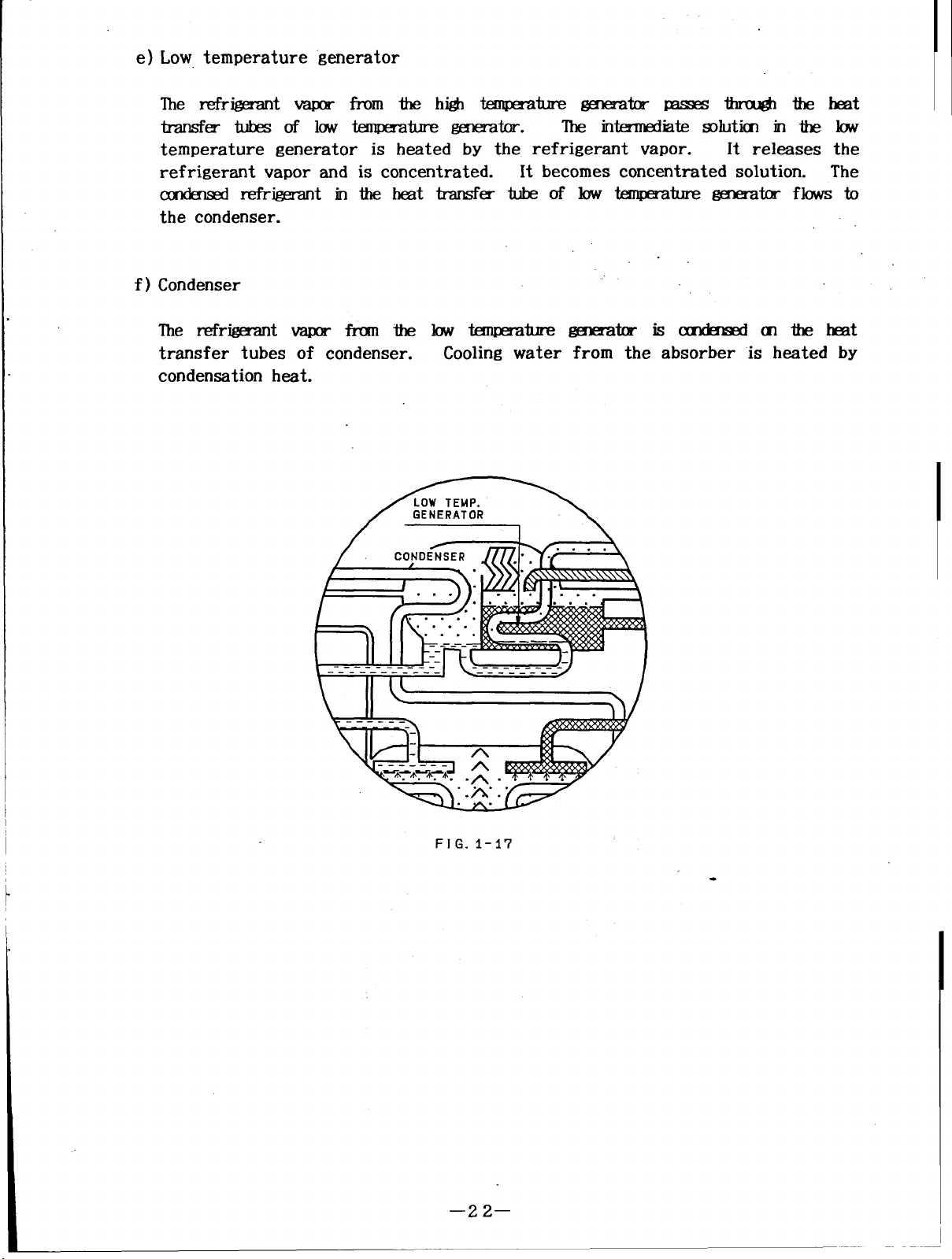

e) Low temperature generator

The refrigerant vapor from thehigh temperature generator passes through theheat

transfer tubes oflowtemperature generator.

The intermediate solution in the low

temperature generator is heated by the refrigerant vapor.

refrigerant vapor and is concentrated.

It becomes concentrated solution. The

condensed refrigerant intheheat transfer tube oflow temperature generator flows to

the condenser.

f)

Condenser

It releases the

The refrigerant vapor from thelowtemperature

transfer tubes of condenser.

Cooling water

condensation heat.

generator iscondensed ofthe heat

from the absorber is heated by

FIG. 1-17

—22–

Page 26

103MIERlMRATl$i

(l) UlJSTRATI14

w

CY

9’ 2.1

‘L=’

w

m

12

0

n

<

>

w

w

i-

-1

w

z

<

L

-1

0

CK

1-

Z

0

c-l

k

I

II I

II

w’

111

I

-1

-1

m

l-!

t

w

IL

u

I

D----r&”#--”

—23–

Page 27

( 2 )DETAIL OF TYPICAL

(Fret view :

Steam

1-

CHILLER

inlet side)

%%

-lx

an

>

:“

u

1-

Zm

oa

U-J

II \ \

1-

I

u

m

z

w

n

0/

UJ

IL

.

\

-1

:

<

n

a

Z*

—w

-I-I

ol-

03

00

0

wt-

-lW

-l_l

-t- --l

X3

00

0

W

-ii-

-lW

X2

cl-

–24–

Page 28

(3) IHAL OF TYPCALW-1%?

(Rmr Viw

: ham Wtlet Skk)

cl

w

Ix

0

-1

0

w-l

l-w

Zz

oa

c-la

3

C5

z

.-

w

w

m

1

w

1-

x

cl

x

\/’

// t---

>

1, 1 *

N

C!i

I.L

\

\

wl-

I-3

ma

–2 5–

I--J

<u

Ww

XCE

-I

Page 29

2

DT4

l-uul~

hlhl

i I-!w .

/

1111L\

Ill LDl / \\

\/

‘ISOLATION VALVE

FOR #2 ABS PUMP

[

PURGE PUMP

SV9

// \\

HEAT EXCHANGER

\

ISOLATION VALVE

FOR 81 ABS PUMP

II

\

‘ISOLATION ‘VALVE

FOR REF PUMP

\ ~,~~ ~,”~

IL

//

I Phil

\

\ \

\’

“kSV6 \

STEAM TRAP

1“

FIG. I-21 RIGHT VIEW

Page 30

.+

;U

mn

U.in

>X

-10

<n

>

Zm

0<

I-*

us

J

Oiz

ma

x

m

Wn

>Z

-la

<n

>

m

zm

oa

l-+

4#

-J

Otx

O-Jo

IL

cum

>>

(’U+

>>+

mm>

kii$kwmm+dll

/

\

\

1

7-

/

/

/

\

3

w

m

>

‘L--

-1

Ill

z

/

/

, , ,

/

>

Cr

u

1IL

w

A

l-u

ru

1

*

cl

IL

‘r

u

—2 7–

Page 31

(6) TYPCI CCNllW_ PKL

IndiCatiOn LAMP

OPERATION BOARD

EMERGENCY

STOP SWITCH

/’

,,

II

FIT. I-23 CONTROL PANEL

CONTROL PANEL

HIGH VOLTAGE

FIELD WIRING OPENING

/

CONTROL CIRCUIT

FIELD WIRING OPENING

—28—

Page 32

,,,CONTROL EOARD

,“

/’

/

/(’I

/

,1

,,

.

/

,coNTROL RELAY

.-

, FAN MOTOP

MODE SELECT SWITCH UNIT

I /’ 1,

I

/

II u“

POTENTIOMETER

/“””

/“’’FusEs

FUSE HOLDERS

TERMINAL BLOCK

~ CONTROL TRANSFORMER

POWER TRANSFORL’ER

INVERTER

/---’-’ ‘EACT”R

CIRCUIT BREAKER

/’”

WIRE CHANNELS

II -—H————H——+

lu-

FIG. 1-24 INSIDE OF CONTROL PANEL

1 ABSORBENT PUMP

NO.

MAGNETIC CONTACTOR

\

~ MAGNETIC CONTACTOR

)

i

~ REFRIGERANT PUMP

b

i

~ PURGE PUMP

)

)

i

~TERMINAL BLOCKS ,

NO.2 ABSORBENT PUMP

MAGNETIC CONTACTOR

MAGNETIC CONTACTOR

CONTROL CIRCUIT

MOTOR TERMINAL BLOCK

r

P

HIGH VOLTAGE

FIELD

INTERNAL WIRING

CONTROL CIRCUIT

FIELD WIRING TERMINAL BLOCK

WIRING TERMINAL BLOCK

—2 9–

Page 33

(7)nPmlS TEAMCwlRclv ALvE/ww EAM TRAP

REDUCI N

G

iPOSITION R

STEAM 1 LET

Y

FIG. 1-25 STEAM TRAP(PNEUMATIC TYPE)

‘-i=+’

STEAM OUTLET

/-

DRAIN INLET DRAIN OUTLET

F}G. I-26 STEAM TRAP

—3 o—

Page 34

(8) SYR430L

a)b)Chiller construction

symbol Name

EVA

ABS

COND

HT.GENE

HT.REC

LT.GENE

HT.EX High. ~tum kit exchanger

LT.EX w tanperatm? bet exchanger

#l AESKJMP No.1 Akrilmt llllnp

#2 AESKJMP

REF PUMP

Temperatum senmr

~tor

Hmt reclaim7-

Law tmlpe?atum genelatm

NO.2 Aknrbent Lump

——

Refr&ant pmlp

SY-mM

DT1

DT2

DT3

DT4

DT5

DT6

DT7

Name

Chilled water outlet

Ccoling water cutlet

High &mpe&mz generator

Low temrecatlm fmet-ator

.———

— —.

Chilled water inlet

Cooling water cutlet

Location

Chilled water outlet pipe

before flange.

cooling water

cutlet me

before flange.

%dc

Si& of high ~k

generator.

Intermediate fmlutim pipe of

LT.GENE outlet.

—.—

Refrke=mt pipe of ~

outlet.

Chilled water inlet pipe

kfm flange

Cooling water inlet pipe

before flange.

–31–

Page 35

symbol Name

Location

23CH

TC1 Strom dTain tmpemtum

El ,E2 ,E3 GmeAOr wlutim level

33AL Genmitor duticn level

63GH Gena’atm- DFslJR

69CH (Xilled wakr fkw Witch

PCH Palladium cell heater

I SYmM

V1

I

V2

Electronic controller

electrod

UXltrol” M swim

I

I No.2 m valve

Name

mvitrh Near b solutim Mel box

Inchxkd opemtim bc9rd

Skam dram outlet pipe

beklm flan@

Solution level box beside the

high temperature ~ti

In the control panel “

Chilled water outlet pipe

Topcnthe~ tank

I

Location

Besick themtank

p?si(ktheml%etadc

I

V3

V4

Refrigerant blow valve

I

IBesdethelxlrgetark

Evaporatm Sirk?

I

I

—32—

Page 36

e) Service valve

&mhol

Name

Svl Service mlve for maintmane

SV2

&nice wlve for manomk

SV3 *ice valve for refr~t

SV4 servi~ wdve for diluted

solution

SV5 &nice valve for rnternkxiiate

solution

SV6 Sewim mlve fw cmcmtrated

solution

SW

Service valve for gemator

~-

SV8

Setvice valve for ~tor

maintenance

SV9 !krvim valve for hczit

ex-

Imintmance

Location

E?eskk?themiank

Besi&t&lxJnge tank

(xl the refrigerant pip!?

I’karthe No.lalKr<lxmlp

(Outkt

PiPe of xl AK FuMP)

kskk the high tenzxzati

heat cX-

&si&thebw*ture

kat ex&arw-

On the solution level box

I?ottanofthehigh_k

-*

kick of high tmpczature

bt mknger’s I-Ezl&

f)

Sight glass

g)

F

Svl 1

Symbol

D1

D2

D3

ml

xl

Servi@ valve for @lladium

Tcx)the~tank

cell

Name

I.kunwr for dilukl mluticn

Location

outlet pipeof#l A5s FuMP

afk - valve

IMnPer for intermediate

solution

IkxnP=- fcr cxlncmt?akll

solution

Name

MeTIIEdiate dltim pipe

betwem HTE4 and LTGENE

Gncmtrated Solutial pti

betwem LTJ23W and LTEX

Location

sight glass fcr reil-igerant Ikskk eVam&or

level

—33–

Page 37

114SAFETYElm

(l) CHLLED WATER AN) COOLNG WATER

No Item

I

Setting point Alarm indication

1 Ink-lock of chilkd water pmnp

2 Interlock of Cmling water m

3 Fw flow rate of chilkxl wak

4 Gilled wak- fmzz IX-&Aim

(LAYw-cutof chilled wati cutlet knp.)

5 Low-cut of mling water inlet kmpemti

(2) HGli TEWERATLRE GEMRATOR

No

High-d of ~tor tempemtum(boling) 165°C (329”F)

6

Item

Indication lamp.

Indication lamp

50 %

2.5°C (36.5”F)

19”C (66.2”F)

after 30 min.

Setting point Alarm indication

Indication lamp

Indication lamp

Indication lamp

Indication lamp

7

High-art of gmmtcr ~

8

High-art of gmmitcr sohrticxI level

Ixnv-art of f3mm#or soluticn level

9

Crystallization protection

10

(High-cut of mhrticn an(mtmticn)

kg/an2G

o

I

.—

65% Indication lamp

after 10 mm. -

Indication lamp

I

Autmmtic red

Indication lamp

—34–

Page 38

(3) M3TOR

No

11

12 Ov

13

(4) OMRS

No

14

15

16

Item Setting point

~t day of !40.1 aklrklt plum

Ov

ellJrrmt mlayof No.2aklrbentpm-lp Rated ampemge

I

ermn-ent relay of mfrigemnt m

Ov

Item

rnvder Protection

Fuwer interruptim protectial

Wttering p@.ecticn of flow witch

RaM ~

MM ~

Setting point

100 m sec.

3 sec. Indication lamp

Alarm indication

Indication lamp

Indication lamp

Indication lamp

Alarm indication

Indication lamp

Rupture disk

17

–35–

Page 39

SECTION2 OPERATION

CONTENTS

&e No.

~I(jN 2

-TION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...~~

2.1 -TION Bf)~ .. . . . . .. .. . . . . . .. .. . . . . . . . . . . . . . .. .. .. .. . . . .. . . . . . .. .. .... . . ..~7

( 1) DETAILOF OPERATIONBOm ------.-.-------.....-... -...............37

(2) INSITWCTIONw mzYs ------.--------------------.......-... -.-..-........3g

2.2 TEMpERA~ ~1~ .......................................................4o

(1)

DETAIL OF MONITOR .. . . .. .. .. . . . . . .. . . . . . . . .. .. .. . . . . . . .. . . . .. .. . . . . . . . . . ..4o

(2) ~ OF ~ DIGITALDIspLAy --..............................41

(3) SETTI~ - ........................

------””----”----------------”----”43

2.3 SEIJ?-DIAG~I~ mION -------...-...................................46

(1) SEWDIAGW3TICSFUNCTION-----------------.--.-------.............46

(2) ERRORMESAGE

BY f31F-DIAGNOSTIC ..............................47

2.4 PREPARATIONFORSTARTw .................................................49

(1) CONFIRMATIONOF OPERATION

WI- ...................... 49

(2) CONFIRMATIONOF SETTINGnI~ --------.-...---.................49

(3) aFFIRMATIONw ~IPMENT .......”

....................................~()

2.5 ~ERATION -----------------------................................................5l

~1~ -TION ....................................................... 51

(1)

- (2)

OPERATIONBOARDWRINGOPERATION

~~~ TIM C~T .................................... ........... ......55

(3)

MAxI~ 1~ ~~OL ------------------.............................56

(4)

Imm co~m w #1 ~ PUMP-.................................57

(5)

(6)

_ OF CHILUZDWA~ ~~ ..........................58

------”---------”””-------””-53

–3 6–

Page 40

21 OPERATIONBOARD

( 1 )DETAIL OF OPERATION BOARD

CD... Q.:

.. ............

; TWPI?.RATORE

0 GENERAToR

!

\ o STEAM ORAIN

;OCNIWTLET

:OCO IINLET

! 0 CONTRCLVALVE

I==sii? ‘::’!

'------------------------------------------------------- T . . . .. . . . . . .. . . ...1

EATEXALARM

!

;ocHwmP.

~OCHI FLOW RATE 0#1 ARS. FfJIIP

:OCOUUY.

;O@W FLOW RATE

. . . . . . . .

OPERATION RIKORD

0 CHI~ OF’ZRATION

o c!ilLLm ottPFF

OREF. FIJIIP OPERATION ,. . . . . . . . . . . . . . . . ..~~

MOTORALARM

0

RW. PUMP

O #2 AK,. PIMP

SET POINT

orHmnP:: /STOF RON

. . . . . . . . . . . . . . . . . . . . . . . . .

GENERATORALARM

0 PRF-SSORE

o TIWPKIM(XNTRAT ION

a.:

::

::

,,

;0 OCNILLER ;

::

:0 OREF. PUM? \ :

;0

onl ARs. Pur :

!!..!.:E...I

AURM ( IKI?WJXK)

SYSTEM

OCHEPUIIP

OCOWFUMP

G9 -,

:.

, :

:

:

B~ .SlT3f

~. .. . . . . . . . . . .. r––q

[.E E:’

... .. .. . . .. .. . . .. . . .. .. .. . . . .

. . . . . .. .. .. . . . . . . . .

;-0 ALAM

.,

, :

: ;

: :

:,

I

.,

~-cs

FIG. 2-1 Typical Operation Board

i?5.!

–3 7–

Page 41

.

(1)Monitor

This area has some indication lamps

points, operating hours, number of

temperature, and digital display (Red ) which indicates

(2) Select key

There is “SELECT”key for selection ofdisplay data item.

in sequence by push the key.

automatically after approx. 1 minute.

chilled and hot water parameter.

(3) Equipment RUN-STOP indicator

This area has some “RUN” indication lamps (Green) and some “STOP” indication lamps

(Red) which indicate conditions oftheequipment.

(4) Alarm indicator

The indication lamp flickers when the chiller has abnormal condition.

(Red) which indicate temperature of several

burner ON-OFF times and setting point of

data of lighted item.

The item is displayed

The item returns to generator temperature

There are ^and * keys forsetting of

(6)Operation mode select key

There are keys for chiller operation.

(7)Alarm buzzer stop key

There is buzzer stop key when the buzzer sounds by abnormal condition of the

chiller.

—38—

Page 42

(2) INSTRUCTION OFKEYS

m

“SELECT” For theuseof item selection for display.

The item is displayed insequence

Change the item automatically when you push thekey continuously

than 1 second.

“^”

“*”

bypush the key

“OPERATION"

“STOP”

“LOCAL"

Operate the chiller by local mode.

The chiller does not operate when the mode is setto"remote"

The indication lamp on "OPERATION"key flickers when themode isset

“Local” .

Forthechiller operation, You must push the key over 1second

continuously.

This is protection of the chiller.

Please push the key continuously until flicker the indication lamp on

the key.

Stop the chiller by local mode.

“STOP” key is accepted on either mode of “Local” and “Remote”.

The indication lamp on “STOP” key flickers when the stop signal is

accepted bypush the key.

For the chiller stop, You must push the key over 1 second

continuously.

This is protection of the chiller.

Please push thekey continuously until flicker the indication lamp on

the key.

For the use of operation of the chiller by

“OPERATION”key on the

operation board.

When themode isset “Remote”, the chiller

does not operate.

“REMOTE"

“ BUZZERSTOP” For the use of stop of alarm buzzer when the buzzer sounds by

Fortheuse of

"OPERATION"

operation ofthechiller by remote panel

key is notaccepted on "Remote" mode

abnormal condition of the chiller.

—39–

Page 43

-“..

2,2TEMPERATURESETTING

( l) DETAIL OF “MONITOR

TEMPERATURE

“0 GENERATOR

o STEAMDRAIN

0 CHW OUTLET

o COWINLET

0 CONTROLVALVE

:

I

The data is displayed on the digital

indicated by indication lamp of item.

The data on the digital display is

1 minute automatically.

I

Fig. 2-2 is drown generator temperature.

z 3.

FIG. 2-2

OPERATIONRECORD

0 CHILLEROPERATION

() CHILLERON-OFF

0 REF. PUMPOPERATION “

I“o’%fi

W

O HOURS

OSTARTS

a

Monitor

display by “SELECT”key.

The item is selected by push on “SELECT”’key.

returned to generator temperature after approx.

SET POINT

0 CHWTEMP.

E

v

The selected item is

The indication lamp after digital display

Unit of temperature is “F ( Fahrenheit ).

lights according to unit of item.

–4 o–

Page 44

(2) SEQUENCE ON THE DIGITAL DISPLAY

iteiu is displwed in sxqueme

Sequence Lighted indication lamP

(symbol )

—.

Generator temperature

1

(GENERATOR)

Steam drain temperature I

2

(STEAMDRAIN)

Chi1led water

3

out let tenIperature

(CHw OUT~)

Cool ing water

4

inlet temperature

(CoW INLET)

Steam control valve

5

position

(CONTROLVALVE)

bypush the key.

Sample on the digital display

4--

.—

T

&qumce items am as follows;

3

G

G.

G

( 300.0)

z D 3- i2

( 203.0)

- 4- E

( 44.0)

H 5. G

( 85.0)

—

zfZ 9-7

( 209.7)

Chiller

6

Operating hours

7

;.:=; : ‘:”:”’;:”)-

l“’”

times

(CHILLERON-OFP)

Refrigerant pump

8

operating hours

(REF.PUMPOPERATION)

:

z=

( 120)

9 G D

( 900)

–41–

Page 45

Sequence Lighted indication lamp

— —

9 Chilled water

temperature setting

for temperature

(CHWTEMP.)

10

—— .—

11

Chilled water

temperature setting I

for proportional

(CHWTEMP.)

Chilled water

temperature setting

for integral

——

— —

Sarnpleon the digital display

.— -

I d

\

F

‘

- w D

z. G

—

(t 44. o)

(P 2.0)

(I 800)

12 ;;;*

for differential

(CHWTEMP.)

Display

Note) 1 It will happen to display below number between No.1O and No.11.

sequence repeats No.1 thru No. 17.

During chiller operation,

when cooling water inlet temperature is below setting point.

set automatically during below setting point of cooling water

temperature.

below setting point of cooling water inlet temperature.

Chilled water temperature is control by this number during

below number is displayed on the digital display

EImIml(c464,

;, ,

(d 10)

.

This number is

inlet

–4 2–

Page 46

( 3) SETTING METHOD

Chilled water outlet temperature is controlled by digital PID (Proportional, Integral

and differential).

a)

Chilled water setting point range

It is able to get chilled water of stable temperature.

Setting item Range

step

Chilled water outlet 41.0- 53.6 ‘F 0.1 -0.2

temperature

Proportional

Integral

Differential

(t)

(P) 2.0-

(I) o

(D)

o -’ 100 SEX

10.0 0.1- 0.2

- 2500 SEC 10 m Por PDactimat OS

19X P or PI acticm at O w

Note) Temperature data sampling is 10 second interval.

Notice 1.

Please confirm the indication lamp of setting item before setting.

“^”and” V

2.

If you change the setting during chiller operation, chiller is controlled by

3.

keys donot accept tocross the range number.

new setting point soon.

Original setting point is set at factory.

4.

5.

Setting point is stored by non-volatile memory of semiconductor.

Therefore, setting point is kept continuously when power cut off.

–4 3–

.

Page 47

c) To take

an example(Chilled water setting)

Setting item

Chilled water outlet

temperatlnw

Proportional

(t)

(F’)

:~tial+-t=: +++=+

Setting procedure is as follows;

10.

1 “SELECT”

2

Key

“A”

Digital display Explanation

, ImmIIl

Original

44.0 ‘F

2.0 2.5

Select the chi 1led water temperature

setting(CH MTEMP.) by push the key.

The indication lamp of “CHV TEMP.”

(t 44.0)

1ights. .

Target

46.0 ‘F

4

5

—

6

~

(t 44.2)

“A”

3

ErIIml

(t 46. O) data decreases 0.1. ”

“smT”

“A”

“A”

m

(P 2.0)

~

(P 2.1)

~

(P 2.5)

‘;git:i;$&es 0-1-

~:+j!y~;:;;:

Display data mdlcates proportional

‘Shthe “Win: ‘w”

of chi 1led water outlet temperature.

-—

‘lE;t:i;:zesO1*

—.

~gJ$FJ:::;::*

data decreases 0.1. ”

–44–

Page 48

I

No.

7

8 “A”

10 “SEIJXT”

11 “A”

Key

I

“SELECT”

Digital display

I

Enm!Ill

(I 800)

EInml

(d 10)

I

Push the “S3JXT” key.

Display data indicates integral of

chilled water outlet t~ture.

l%sh the “~ key.

Display data indicates different ial

of chilled witer outlet temperature.

J@lanat ion

12 “A”

—4 5—

Page 49

203SELF-DIAGNOSTICSFUNCTION

( 1 )SELF- DIAGNOSTICS FUNCTION

Self-diagnostics function starts, when the lnwaker of the chiller tum on.

a) %me indication lauws light as shown Fig.2-3.

Symix)l

Symbolo: Indication lamP lights.

o :Indication lamP does not litit.

.“.

symbol B : Indication lamP of the key lights. “ .,

TEMPERATURE

O -ATOR

c)SIEAHDRAIN

oawm

ocQwlNLEr

O CCNTROLVALVE

HZHZ13ii52 “

WATDlALARH

● 0IWTENP.

● OIWFLOI RATE ● ttlAES.PunP

● COWTENP.

● COWPWR ATE

OPERATIONRWORD

0 CXIW OFI?RATION

o cNILLmON-m

0

REP. FWP OPERATION

KITORALARM

● RW. PUMP

● #2ABs.mP

SRTPOINT

ooiw TulP.

v

GENERATORALARM SYSTRUAL4Rn(INTERJxm

● ms.$m

● TaP/~ TION

STCP RUN

● ● OIILLER

● ● REP.PUIIP

tHABs. PtnlP

● ●

● ● WAW. W

● ● PURCE PUMP

● CNFPWP

● cormP

FIG. 2-3

b)

Buzzer sounds 4

Some indication

c)

Self-diagnosis is worked.

times after 1 second of turn on the breaker.

lamp turn off after buzmr.

Version number is displayed on the digital display, if power circuit. has no error by

self- diagnosis.

Version number is as shown;

mzIml(v7.,

.

Note) Version number subjects to change chiller’s specification.

d)

Generator temperature is displayed on the digital display, if control circuit has no

error by self-diagnosis.

Generator temperature is as shown;

(Blew number is for reference.)

–46–

Page 50

.-

( 2) ERROR MESSAGE BY SELF- DIAGNOSTICS

Error message is displayed on the digital display, when the error is found in the

circuit.

In case of the error, it is necessary to call Sanyo’s service representative.

If necessary, please call to Sanyo’s service representative after memorized the error

message.

Power supply error

a)

This error massage is indicated the error of power supply to electronic controller.

The key access is not accept on this message.

It is necessary to call to Sanyo’s service representative.

~ (,,,)

Electronic controller error and setting point error

b)

(The message on the digital display flickers)

This error message is indicated the error of electronic controller or setting point.

Please call to Sanyo’s service representative with below error number.

It is not accepted the chiller operation during indication of this message.

=( Err*,

Indicate the kind of error message

Kind of error message

-------- @ Error number ERR-6

:-----i

; ;“”1

:: -

::

::

:-

-------------------- @ Error number ERR-5

,.

‘ --------------------------- @ Error number ERR-4

}.. . . . .... ~ Error number ERR-7

— ------ @ Error number ERR-1

. ..........

---- 0 Error number ERR-2

●-------- @ Error number ERR-8

‘--------------- @ Error number ERR-3

CDError number ERR-1 (Electronic controller error) : Call to senice.

CDWor number EIU-2 (Setting point error)

@ Error

@ Error number ERR-4 (Number of times data error) : Call to sewice.

@ Error number

@ Error number ~-6 (Electronic

number ERR-3 (Electronic controller error) : Call to semice.

~-5 (@eratiw buns data error) : Call to service.

controller error) : Call to service.

: W the

Semite.

to

S?tting

point and call

@ Error number ~-7 (Electronic controller error) : Call to =~ice.

@ Error number ~-8

(Electronic controller error) : Call to mvice.

–4 7–

Page 51

c) Power failure error

(The message on the digital display flickers)

This error message is indicated to return the power after power failure during

Operation( include dilution cycle operation).

The power failure means not only power failure( include over 100 millisecond power

interruption) but also artifical power turn off the breaker.

If will happen to indicate this message when the breaker is turned on at first after

field wiring.

~(~.~rr)

‘1

This error

d)

Sensor error

(Ihe message on the digital display flickers)

This error massage is indicated the temperature sensor

Chiller stops safety when high temperature generator

chilled water outlet temperature sensor(DTl ) are broken

The chiller operates continuously, when other sensors(DT2, DT4, DT5, DT6 and DT7) are

broken.

Please call to Sanyo’s service representative.

Kind of error message

message is cleared when “OPERATION”keyis pushed.

trouble.

temperature sensor( DT3)

during operation.

But it is possible to control bad condition.

............

.........

--- Indicate the kind of error ~

:------------------------------------------@ Error number SER-2 (DT2:

: :----------------------------------

:------------------------------@ Error number SER-3 (DT3:

@ Error number SER-5 (DT5:

Cooling water outlet)

Condenser)

High temp. generator)

and

- ,....! ‘ , — ,

I

— ,......i :..,

I

—0/

Note) It is posible to change the display data and ~tting point on the digital display

using the”SLWT”, ”A” and “v “ keys during error massage indication of

Electronic controller error, setting point error, pcwer failure error and -r

error.

— ------------0 Error number SER-4 (DT4:

1..........-----@ Error number SER-1 (DT1:

—

‘----;----------------------@ Error number SER-6 (DT6:

● ---------0 Error number SER-7 (DT7:

–48–

Lowtemp.” generator)

Chilld w.outlet)

Cooling water inlet)

Chilled w.inlet)

Page 52

2}4PREPARATIONFORSTARTUP

Please confirm below items again before operation.

(

l) CONFIRMATION OF OPERATION SWITCHES

a) Operation switches in the control panel

~;CI~;~DL

AUTO F CLOSE

MANUAL

\ \ \ \

> pu~p

(D Steam control valve mode select switcl-------------

REFRIGERANT PURGE

AUTO

STOP

MANUAL.

FIG. 2-4 TYPICAL OPERAT

PUMP

STOP

START

ON SWITCHES

“AUTO”position

@ Steam control valve open-close Witch ----------------“STOP”’position

@

~frigerant pump mode !x?lect switch ~~---------------“’AUTO”pxition

@ We pump operation switch -------------------------------“STOP” position

( 2 )CONFIRMATION OF SETTING POINTS

a) Chilled water “temperature Wtting

point

(Setting sample)

@ Chilled water outlet temperature ------------------------- 44°F

Q Proportional

..... ......

@ ]n~] ................................ .......... ............... .....800”

@ Differential

–4 9–

2

10

Page 53

CONFIRMATION OF EQUIPMENT

( 3)

a) Steam line

(1) Open the main valve of steam line.

(2) Never leak the steam around steam line.

b) Water system

(1)Some valves for chilled water line. .

(2) Some valves for cooling water line.

(3) Other system line.

c) Cooling water inlet temperature

(1) Cooling water inlet temperature

(2)Take care that the cooling water

d) Electric wiring connection

(l) Interlock of chilled water pump

(2) Interlock of cooling water pump

Note) Interlock signal is detected by energizd DC 24V from the chiller.

Please select the contact resistance within 100Q .

(Please seperate other power line.)

e) Remote signal connection

No

1 Answer back signal output Operation : ON

2 Stop indication lamP

-1

3 operation

Signal name

—

for operation stop :OFF

indication output ON signal when C/H

.— —— _

lamp

—

4 Alarm indicatim lamp output Abnormal : ON

——

5 Cooling mcde indication Output [Cooling mode

lamp

I

6 Remote ON-WE signal Input

..—

inlet temperature is kept above 66F

Signal Introduction

output ON signal when

chiller/heater stop

OPemt.es.

i--

Operation : OFF

:(IN

ON-OFFsignal of C/H

Pleas? select the

resistance

AC250V O.lA.

within

I

–5 o–

Page 54

(l) COOLING OPERATION

a)Local mode operation

<Operation)

confirm theoperaticn mode selectkey ontheoperation board.

“LOCAL” indication lamp of the key is lighting.

Ifyou operate the system bymanual, please operate chilled water pump and cooling

water pump sequentially.

Please continue topush the "OPERATION" keyonthe operation board atleast 1sec.

Confirm tolight “OPERATION”indication lamp ofthekey.

Chilled water pump and cooling water pump areoperated by automatically, ifthe

system

Chiller isoperated automatically bysequentially.

isconnected tothechiller.

<STOP)

Please continue topush "STOP" key onthe operation board atleast 1second.

Confirm to light “STOP" indication lamp ofthe key.

When thesystem is

Cooling water pump stops approx. 1thru 5 minutes later.

Chilled water pump stops approx. 2thru 6 minutes later.

chiller stops afterdilution cycle operation forapprox. 6 thur 15minutes.

connected tothechiller, pumps arestop asfollows;

—51–

1

Page 55

b) Remote mode operation

w

(Operation>

(1)Confirm the operation mode select key on theoperation board

"REMOTE”indication lamp

(2)Ifyou

water

(4)Chilled

Please cut offthechiller operation switch (orstopswitch) on the remote control

(1)

panel.

When thesystem isconnected

(2)

Cooling water pump stops approx. 1thru 5minutes later.

Chilled water pump stops approx. 2thru 6minutes later.

chiller stops afterdilution cycle operation forapprox. 6 thru 15minutes.

operate thesystem

pump sequentially.

make contact with

water pump and Cooling Water

is connected

is operated automatically by

to the chiller.

to the chiller, pumps arestopas follows;

squentially.

Please stop the secondary airconditioning units after stopped chiller

(3)

Page 56

( 2 ) OPERATION BOARD DURING OPERATION

a) The

operation beard during normal operation

Generator temperature is indicated on the digital display during operation.

Indication lamps light during operation as follows;

Symbolo : Indication lamp does not light.

symbol● : Indication lamp lights.

symbolH : Indication lamp of the key lights.

TENFSRATURR

● GENERATOR o fXIM OFERATION

o SIEAN DRAIN o CHH-LJR

ooi~m

o CO W INLET

o CWTRCL VALVE

OPERATION RECORD

OROFF

REF. FUMP OPF.RATION

0

A

v

SET POINT

Ooirm

STOF’ RUN

o

● oilLLFx

o

● REF. PIMP

o

● I!l ABS. PUMP

0

● #2 AM. PU!iP

● O PURGE PWP

o ALMY

Oizzm STOP

r—-j

k——

WATER LINE ALARM

ocslnT?lLP. 0 RIF. PUMP

OOi WFLW RATE O#IAM. PUHF’

00JWTEW. o #2 AK. PUMP 0 TEIIP/CONCENTRAT ION

OOIWFLCIW RATE

MOTOR ALARM

GENERATOR ALARM

0 PRJ?SSURE

FIG. 2-5 Typical operation bar-d

SYSTEM ALARM ( INTEIWXX)

OCNW PUMP

OCOSPUJIP

–53–

Page 57

c) Power failure error masage during operation

This message is indicated when it is happen to power failure above 100 millisecond.

Ihe message on the digital display flickers.

-(~.~rr) ~

Chiller

Chiller

after return the power supply.

d) Sensor error message

The message on the digital display flickers.

This error message is indicated

Chiller stops safety when high

chilled water outlet temperature

The chiller operates continuously,

broken.

Please call to Sanyo’s service

stops immediately, when it is happen to power, failure.

has no dilution cycle operation.

the temperature sensor trouble.

temperature generator temperature sensor( DT3) and

sensor(DTl ) are broken during operation.

when Other sensors(DT2, DT4, DT5, DT6 and DT7) are

But it is possible to

control bad condition.

representative.

.............

‘-----------Indicate the kind of error message

Please” operatee dilution” cycle operation ‘

Kind of error message

~--------------------------------------:--@ Error number SER-2 (DT2:

-: :

I t--~ ~ I I

I l-----~;“”-1 }--------------@ Errornumber SER-1 (DT1:

—0/

Note)

It is posible to change the display

using lhe”SELIET”, ”A” and “

Electronic controller error, setting

error.

,--------------------------------@ Error number SER-5 (DT5:

....

:! --------------------------@ Error number SER-3 (DT3:

.:

— ------------@ Error number SER-4 (DT4:

——

‘--------------------------- @ Error nuuber

●----------@j Error number SER-7 (DT7 : Cool ing water inlet)

SER-6 (DT6: Chilled/hot w.inlet)

data and setting point cn h digital display

v

“ keys during error masage indicaticm of

point error, puwer failure error and sensor

Cooling water outlet)

Condenser)

High temp. generator)

Lowtemp. generator)

Chi1led/hot w.outlet)

—b4—

Page 58

(3) CUWIW Tt& CHART

a) Dilution cycle

Operatim tim of

STEAM

CONTROL

VALVE

81 ABS

PUMP

ti2 ABS

PUMP

REF

PUMP

CHILLED

WATER

PUMP

COOLING ‘N

WATER

PUMP

100%

o

ON

OFF- –

ON

OFF- —

ON

OFF- –

ON

OFF- –

OFF

diluticm cycle is &cidd by gerEY+x tmpemturw.

I

I

I

I

I

I

I

I

[

I

I

I

I I I

1

I

I

I

[

I

I

I

I

I

I

I I

1

I

I

I

I

I I \

I

I

i

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

d

MIN. ~

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

! T2

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

-1

L,To*

CLOSE TIME OF CONTROL VALVE

FIG. 2-6 TIME CHART OF DILUTION CYCLE

—5 5–

Page 59

(4)MAXIMUM INPUT CONTROL

Steam control valve is controlled for chiller protection by cooling water inlet

temperature without specification.

Maximum input is decreased,

whencooling water inlet temperature is below 28C (82.4F)

or above 33C (91.4F).

a)

Control data

cooling water

controlled by

b)

Control diagram

.

inlet temperature

the data.

..— ————— .

10

z

~7.5

m

i-

.

5

100’ c

212°F

is detected 1 minute interval.

-—— .—— ——— ___ __

125.C

257”F

GENERATOR TEMPERATURE

FIG. 2-7

P

150.C 155’C

302.F 311”F

Maximum input is

CRYSTAL IZATION

EVASION AREA

FOR SOLUTION

HIGH TEMPERATURE

EVASION AREA

FOR HT.GENE

1

100

x

80

60

40

20

.——— —l– _______

I

J

.—— ——

I

I

I

I

I

1

I

I

I

I

o~

19.C2(I”C

66”F6B”F

22” c

?2” F

COOLING WATER INLET TEMPERATURE

1

——. ——— ———

I

I

24. C 26°C

‘?5’ F

79.F

FIG.

I

+––––_L_

I

I

I

I

I

I

I

I

I

2fl’c

82°F 86.

2-8

30* c

I

I

I

I

I

I

I

i

I

I

32°C

F

90” F 93.F

34°C

I

I

I

I

I

I

I

I

I

—56—

Page 60

(5) N’v?3?TER(xYWRuoF#l PJ3s FW?

Rotatkr-1 d N&l aklrtxlt ~ is Cr=?+alkd b’ invel-kr.

60

N

x

>

c1

z

I.1.l

28

a

a

w

w

IL

0

o

100

COOLING LOAD (%)

FIG. 2-9 TYPICAL CHAR ACT RI STIC

—5 7—

Page 61

( 6) PRESET OF CHILLED WATER TEMPERATURE

Setting point of chilled water outlet is imreased automatically, when cooling water

inlet temperature is lower.

digital display board.

In this case, setting point is able to indicate on the

Please push the “SELECT”key.

Temporary setting point is

indicated after chilled water setting point.

mIzIml(c464, ““”

.

,“.

Please check the cooling water inlet temperature, when you change the setting point of

chilled water outlet temperature.

to cooling water inlet temperature.

12”

C” ._–––––––_–––––

54’F

r /

11”

+ 52”

Because there is the limit for setting according

Setting range is as follows;

1

I

I

I

I

I

I

I

I

I

1

i

I

I

I

I

I

1

I

I 1

20” C 22” c 24* C 26*C 26° C

6B” F 72’ F 75” F 79” F B2° F

COOLING WATER INLET

TEMPERATURE

I

I I

–58–

FIG. 2-10

Page 62

SECTION

3 MAINTENANCE

SECTION3 MAINTENANCE----------------------- ----------------------------------------59

CONTENTS

Page No.

3.1 DAILYwIm~ "----------------------------------------------------------6o

(1) INSF12CTION0!? CHI~/HEA’IER ---------------------------:------60

(2) OPERATIONDATARECORD------------------------------------------------6O

3.2 9MSCNALMAINTENAKE-------------------------------------------------------62

(1) PURGING---------------------------------------------------------------------62

(2) MAINIENAMXOF PURGEPUMP-----------------------------------------64

(3) REFRIGERANTBLOWDOWN-----------------------------------------------65

(4) SOLUTIONMANAGEMENT---------------------------------------------------65

3.3 WATERTREATMENT--------------------------------------------------------------66

( 1) wA~ TREATMENT----------------------------------------------------------66

(2) WATERTREATMENTFOR LONGTERM SHUT DOWN------------------ 69

3.4 MAINTENANCEFOR INVER’IER------------------------------------------------70

( 1) INSULATIONTESTFOR INVERTFR““”-”-”---”---”-”””-------”-”””””-”-70

(2) INWECIIONBEFOREOFRRATION--------------------------------------70

(3) MAINTENAKE----------------- --------------------------------------------71

M&WWENT LOCATION-------------------------------------------------72

(4)

3.5 PARTSINSPECTION-------------------------------------------------------------73

–5 9–

Page 63

3.1DAILYMAINTENANCE

(1) INSPECTION OFTHE CHILLER

If you find the abnormal condition, please call to service representative.

(1) Steam leak.

(2)Abnormal noise ofabsorbent pumps

(3)Abnormal noise ofrefrigerant pump.

Please ask below items toyour system

(7)cleaning ofthe cooling tower and strainer ofthe

(8)Check thecondition of cooling tower.

(9) Check the air vent of the pipe line.

(2) OPERATIONDATARECORD

Please record the operation dataregularly.

It is useful to protection of trouble shooting.

The sample of operation data sheet is shown

contructor.

cooling water line.

Fig.3- 1 (see to next page).

—6 O—

Page 64

Operating record sheet

Iterns

1 Time

2 Ambient temp.

3 Chilled water flow rate

4 Chilled water inlet temp.

5 Chilled water outlet temp. “C / OF

6 Cooling water flow rate

7 Cooling water inlet temp.

8 Cooling water outlet temp. “C / OF

9 Generator pressure

10 Generator temp.

11 Steam drain temperature

12 Steam supply pressure

Uriit

“C / “F

m3/h “ gpm

“C / OF

mglh “ gpm

“C / “F

cmHg

“C / OF

‘C / OF

psig

Date :

. .

//

.

.

.

13 Steam control valve

position

Remark:

%

FIG. 3-1

—61—

Page 65

3.2 SEASONAL MAINTENANCE

It is

solution, etc.

( 1 )PURGING

a) Purging procedure

(During cooling operation and Stop)

necessay for the chiller to maintain the purging, refrigerant blow down and

Operate the purge pump.

Open the No.1 purge valve (VI).

Check the attained vacuum

by the manometer.

(Vacuum is below 4 mmHg.)

Open the No.2 purge valve (V2)

for 1 minute.

Close the No. 2 purge valve (V2).

Open the No.3 purge valve (V3)

for 30 minutes. “

Close the No.3 purge valve (V3).

Keep to operate the purge pump

for 30 minutes.

Close the No.1 purge valve (Vl ).

Stop the purge PumP.

PURGE PUMP

/

/

/’

/

/s”l

\vl

h

MANOMETER

PALLADIUM

CELL

V2

V3

SV2

Note) 1. Please open gas ballast valve

until sounding exhaust gas.

It is easy for purge pump oil

to become dirt, when gas ballast

valve

close.

T

3-2 PURGE UNIT

FIG.

\

\

PURGE

TANK

LIQUID

TRAP

–6 2–

Page 66

Mm9m!mmtofthevam

b)

Valve position

No Mmsammwn

1 Attaind vaammoflhe~rumP

2 Pressure in the shell

3 Pllrs2tank~

Reading method of

Please read the differential ofmercury surface

Usually, the right side surface of

If it reverse, please call to service representative.

manometer

t item

mercury ishigher

43

wnll-4-

1

V1

Open Close Close

Close Close

Close

V2 V3

open Close

than left side.

open

DIFFERENTIAL

‘PRESS”-’

t

0

I

FIG. 3-3 MANOMETER

3

0

—6 3–

Page 67

(2) MANTENPNEW- FUWEFUW

Please change the purge pump oil, when theattained vacuum ofpurge pump does not

attained to below 4 mmHg.

Open the drain cock.

Discharge the oil.

Close the drain cock.

Change the oil from oil surely port until the center of sight glass.

Note) l. When you change the purge pump oil, please stop the purge pump.

2. Recommend the turbine oil for purge pump. (IS0 viscosity grade : 56,58)

3. If purge pump does not operate, please call to Sanyo’s service

representative. 4. If attained vacuum above 4 mmHg when you change the oil,

please call toservice representative.

LIQUID TRAP

T

BALLAST

VALVE

“K

\

L

PURGE PUMP

FIG. 3-4 PURGE PUMP

/—EXHAU5T GAS PORT

DRAIN PLUG

SUPPLY PORT

OTOR

.

—64–

Page 68

few absorbent mixes in the refrigerant during cooling operation.

Chilled water outlet temperature rises up during refrigerant blow down.

But temperature drops after blown down.

b) Blow down procedure

(1) Confirm tooperate the refrigerant pump.

(2)Open theV4valve(for refrigerant blow valve) for 1 or 2 minutes

(3) Close the V4 valve.

(4)repeat (1) (2)and (3)about 3times

Note) Take care that the refrigerant pump does not have cavitation.

(4) SOLUTIUNMANAGEMENT

Itisnecessary

for the solution (Absorbent) to manage the inhibitor.

The inhibitor adjustment is required technical knowledge.

Please consult with

service representative.

\v 4

FIG.

—6 5—

3-5

Page 69

3.3WATER TREATMENT

It is important for chiller to manage the water treatment.

As the water treatment is required technical knowledge, please consult with service

representative.

(l)WATER TREATMENT

The cooling water ofthe open type recycling cooling tower lowers thetemperature of

the cooling water using the heat of vaporized latent heat and is reused. As this

time, the water isevaporated anddissolved salt(hardness

sulfate ion, etc. ) m the water will increase Namely, thecondensation phenomena

of water occur, and water quality will be gradually degraded.

are always in contact with each other m the cooling tower, the sulfurous acid gas,

dust, earth and sand, etc. in the atmosphere will intrude into the cooling tower,

further degrading the water quality.

Inthecooling water system, the trouble arising from water aremostly caused by

these causes and typical causes include corrosion. adhesion of scales and generation

of slimes.

Standard values of the water quality

a)

First of all, water quality control method is determined due to the results of

analyzing the water quality.

componet, chloride ion,

Asthe water and air

The standard values ofwater quality areshown intable 3-1asanexample.

quality should becontrolled within the standard values.

the blow control method in which all water is replaced periodically or water is

continuously and forcibly replaced as suppress the concentration of water asmuch as

possible and a method in which water processing chemicals are put into the water

because ofthe poor quality ofthemake-up water orsaving thewater..

The control method includes

And water

—66—

Page 70

‘fable 3-1 Standard wilws of the water quality

*1 Cooling water

Items

(he-pass or

Circulating water

m

Electrical

conduct ivi ty

(25°CKs/~)

M alkalinity 100 or less 50 or less

Total hardness 200 or less 50 or less

Chlorine ion

Sulfuric acid 200 or less

ion

Total iron l.Oor less

(2SC )

(m)

(m)

(m)

(m)

(m)

*2 6.5-8.0

800 or less

200 or less 50 or less

!lkike-lxl

%2 6.5-8.0

200 or less

50 or less

0.3

Chilled inter Tendency

Circulating Make-up COr-

inter

%2 6.5-8.0

500 or less

100 or less 50 or less

100 or less 50 or less

100 or less 50 or less

100 or less 50 or less

1.0 or less 0.3

*2 6.5-8.0 0

200 or less o

ros ion

o

o

0

Scale

0

o

o

0

Sulfur ion

(m)

Au.fmoniuuion

(m)

Silica (mm) 50 or less

—

Free carbonic

acid (m)

(Note 1)

Not detected

1.0 or less

*3 *3

Not detected

0.2 or less

30 or less

Not detected

0.5 or less

50 or less

10 10

Not detected

0.2 or less

30 or less

o

o

o

0

*l: TheStandadvaluesOfcmlingwatf?randmke-uPwakrarethe StarKkdValuesoftk

Jam Refrigemtim/Air Ccnditimcr In&s@ knciatim(JRA 9001-1980).

*2: Themsm* ttle Mvalue0f lilenlake-uP watfris6.oto8.ois thatnopmblein

wculd be ~ted as the #l value will

t.cmverevmifthe rilvaluetemmcmrily

the~watiti.

* 3 :Jam Refr&ratim/Air Cmditicner Ir&stry Associatim clarifies that thwzh they

arenotinchxklt in the standmk beta= the tolemncm at which failures may result

are not definite, free carbonic acid. manganese, residual chlorine, etc. do serve as

corrosive factors.

(Note 2)

FXhitmof thestandad values has astrmgkmring mthefaihmb tocornxim

or scale and if

assumed that corrosion or scale tends to be caused, therefore, these should be