Page 1

Wall Mounted Split Systems

Models:

MWM009J/JR

MWM015J/JR

M5WM010J/JR

M5WM015J/JR

Catalog

MWM - J - 2009

Page 2

Page 3

MWM-J-2009 Table of Contents

“McQuay” is a registered trademark of McQuay International. All rights reserved.

© 2009 McQuay International. All rights reserved throughout the world.

Bulletin illustrations cover the general appearance of McQuay International products at the time of publication.

We reserve the right to change design and construction specifi cations at any time without notice.

Table of Contents

Nomenclature......................................................................................................................1

Indoor Unit .....................................................................................................................1

Outdoor Unit ..................................................................................................................2

Product Line-Up .............................................................................................................3

Features...............................................................................................................................7

Application Information .....................................................................................................8

Operating Range ...........................................................................................................8

Refrigerant Circuit Diagram ...........................................................................................9

Controller ....................................................................................................................11

Installation Guideline ...................................................................................................12

Sound Data ........................................................................................................................24

Sound Pressure Level .................................................................................................24

NC Curve .....................................................................................................................25

Engineering & Physical Data ........................................................................................... 27

General Data ...............................................................................................................27

Component Data .........................................................................................................31

Performance Data ............................................................................................................. 35

Calculation Steps .........................................................................................................36

Performance Table ......................................................................................................39

Outline and Dimension ....................................................................................................45

Electrical Data ................................................................................................................... 46

Wiring Diagram ................................................................................................................. 48

Service and Maintenance.................................................................................................50

Troubleshooting ...............................................................................................................52

Exploded View and Part List ...........................................................................................60

Page 4

Nomenclature MWM-J-2009

1

Nomenclature

Indoor Unit

M 5 WM 010 J R

Brand

M : Mcquay

Refrigerant

“ “

4

5

: Omitted if R22

: R407C

: R410A

Model Name

WM : Wall Mounted

Capacity Index

010

015

: 10,000 Btu/h

: 15,000 Btu/h

Series

G

J

: G Series

: J Series

Model Type

“ “

R

: Omitted if cooling only

: Heatpump

Page 5

MWM-J-2009 Nomenclature

2

Outdoor Unit

M 5 LC 010 C R

Brand

M : Mcquay

Refrigerant

“ “

4

5

: Omitted if R22

: R407C

: R410A

Model Name

LC : Single Split Condensing Unit

Capacity Index

010

015

: 10,000 Btu/h

: 15,000 Btu/h

Series

C : C Series

Model Type

“ “

R

: Omitted if cooling only

: Heatpump

Page 6

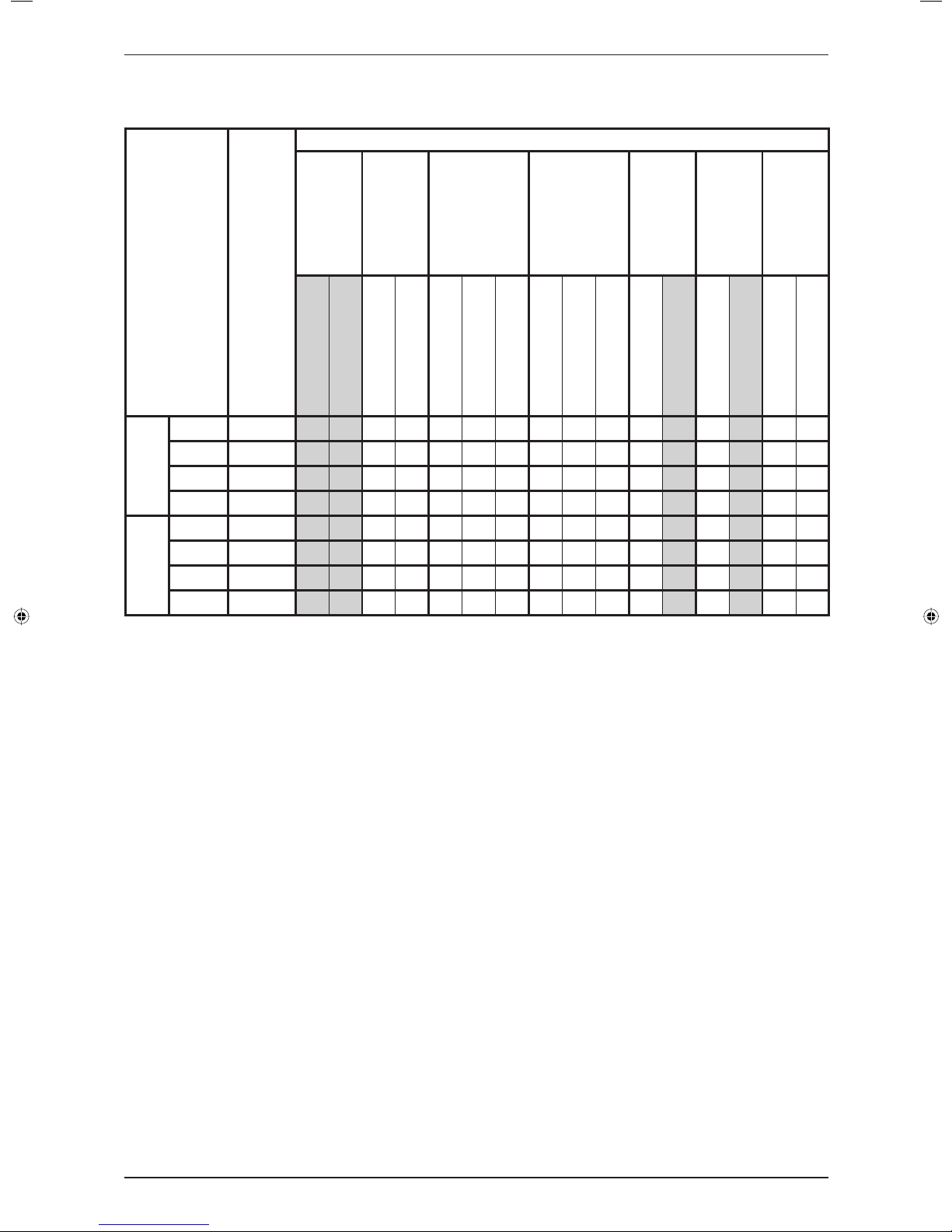

3

Product Line-Up MWM-J-2009

Product Line-Up

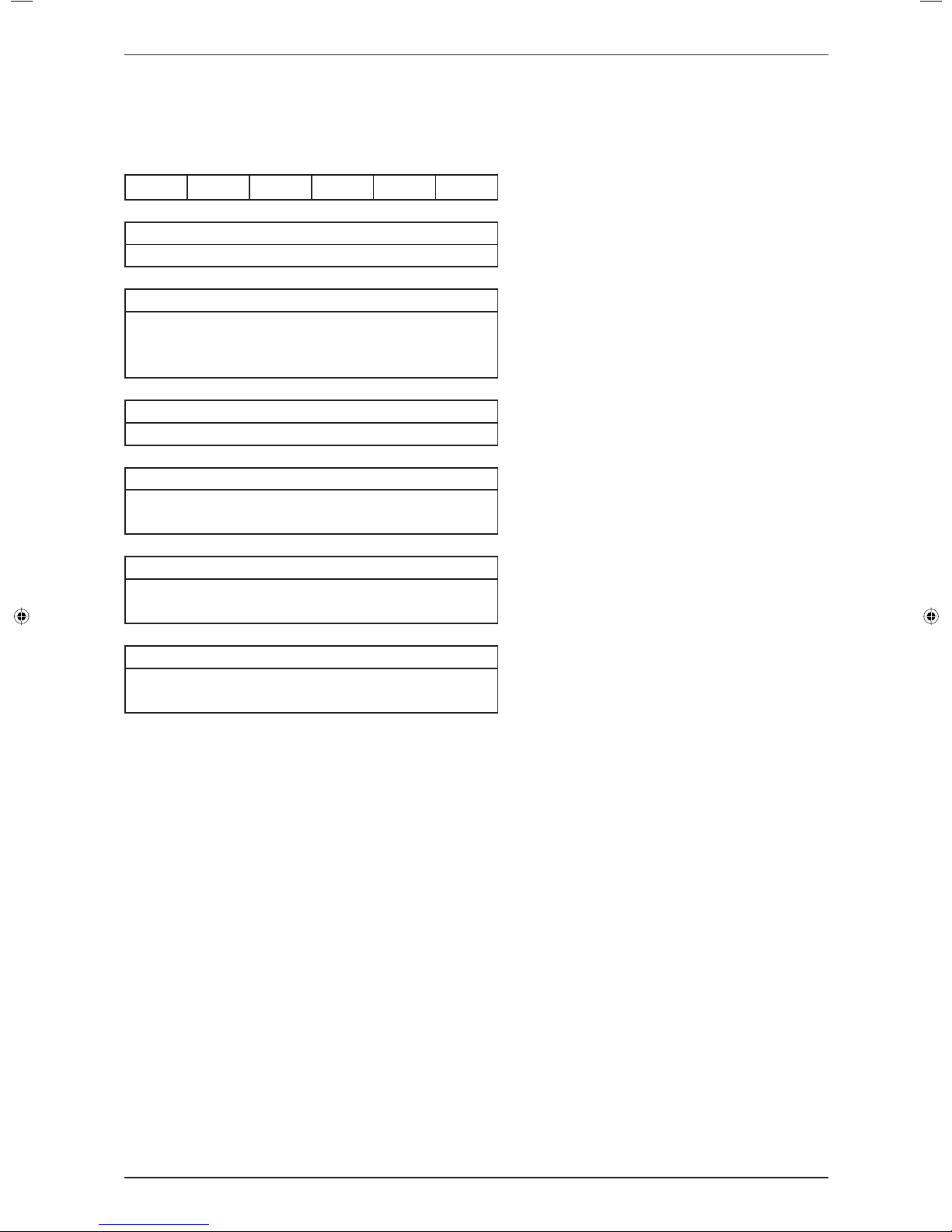

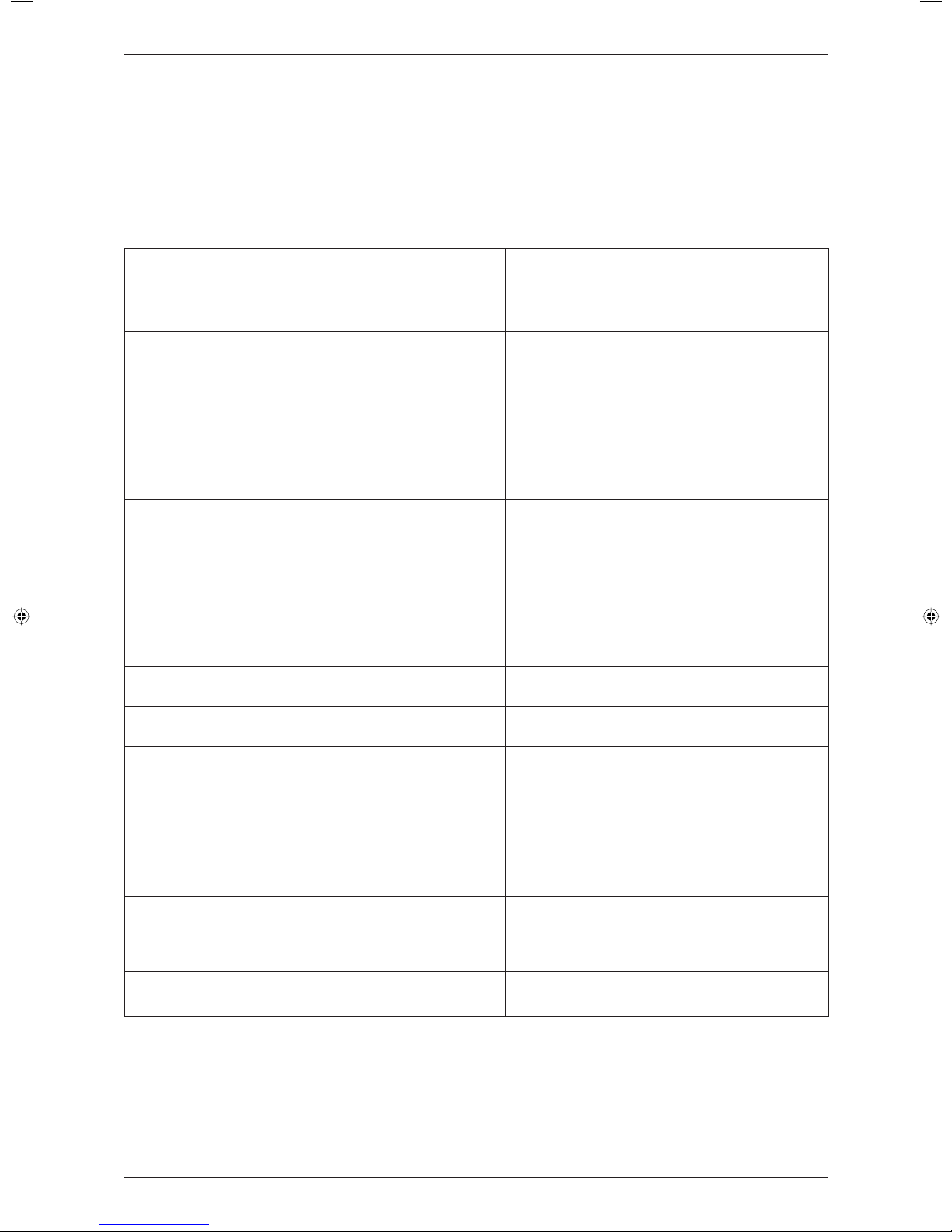

Indoor Unit

MWM-J

MWM

Nomenclature

Classifi cation

PCB

Handset

Air Purifi cation

Grille

Marking

Others

LGSN

G17

Saranet Filter

Bio Filter

A

CE

COOLING

ONLY

009J

ACBAA X X X X X X

009J

ACLAA X X X X X

015J

ACBAA X X X X X X

015J

ACLAA X X X X X

HEATPUMP

009JR

ACBAA X X X X X X

009JR

ACLAA X X X X X

015JR

ACBAA X X X X X X

015JR

ACLAA X X X X X

Page 7

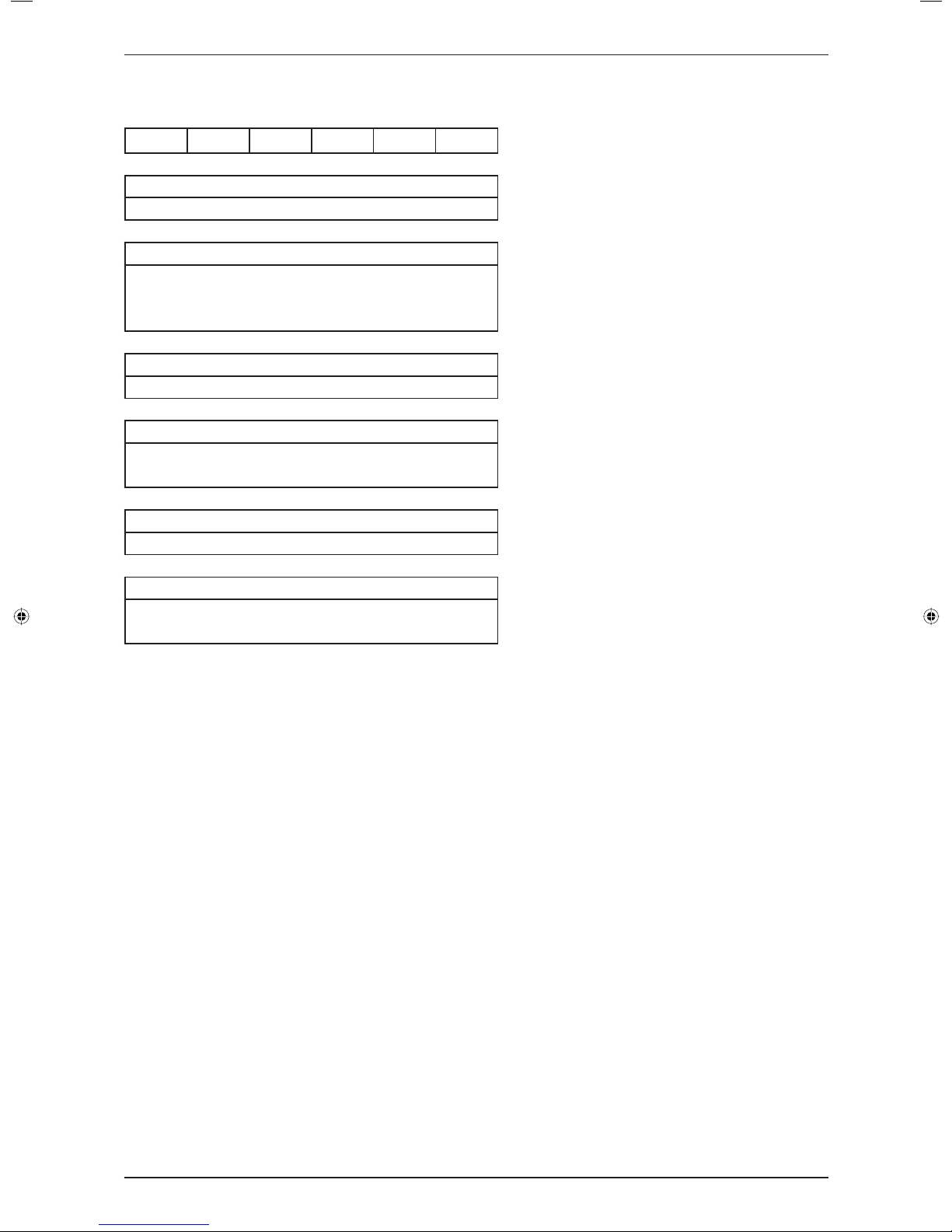

4

MWM-J-2009 Product Line-Up

Indoor Unit

M5WM-J

M5WM

Nomenclature

Classifi cation

PCB

Handset

Air Purifi cation

Grille

Marking

Others

LGSN

G17

Saranet Filter

Bio Filter

A

CE

COOLING

ONLY

010J ACBAA X X X X X X

010J ACLAA X X X X X

015J ACBAA X X X X X X

015J ACLAA X X X X X

HEATPUMP

010JR ACBAA X X X X X X

010JR ACLAA X X X X X

015JR ACBAA X X X X X X

015JR ACLAA X X X X X

Page 8

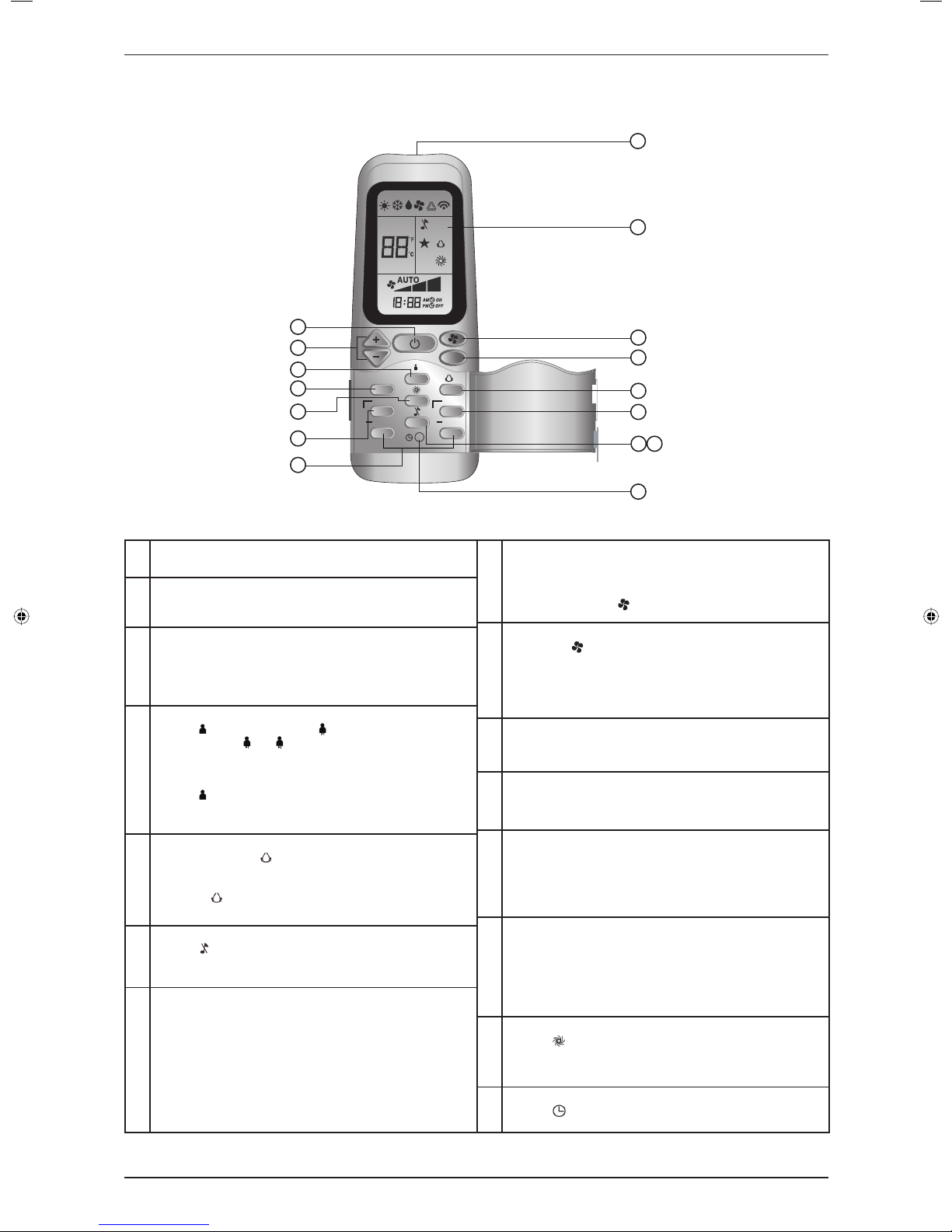

5

Product Line-Up MWM-J-2009

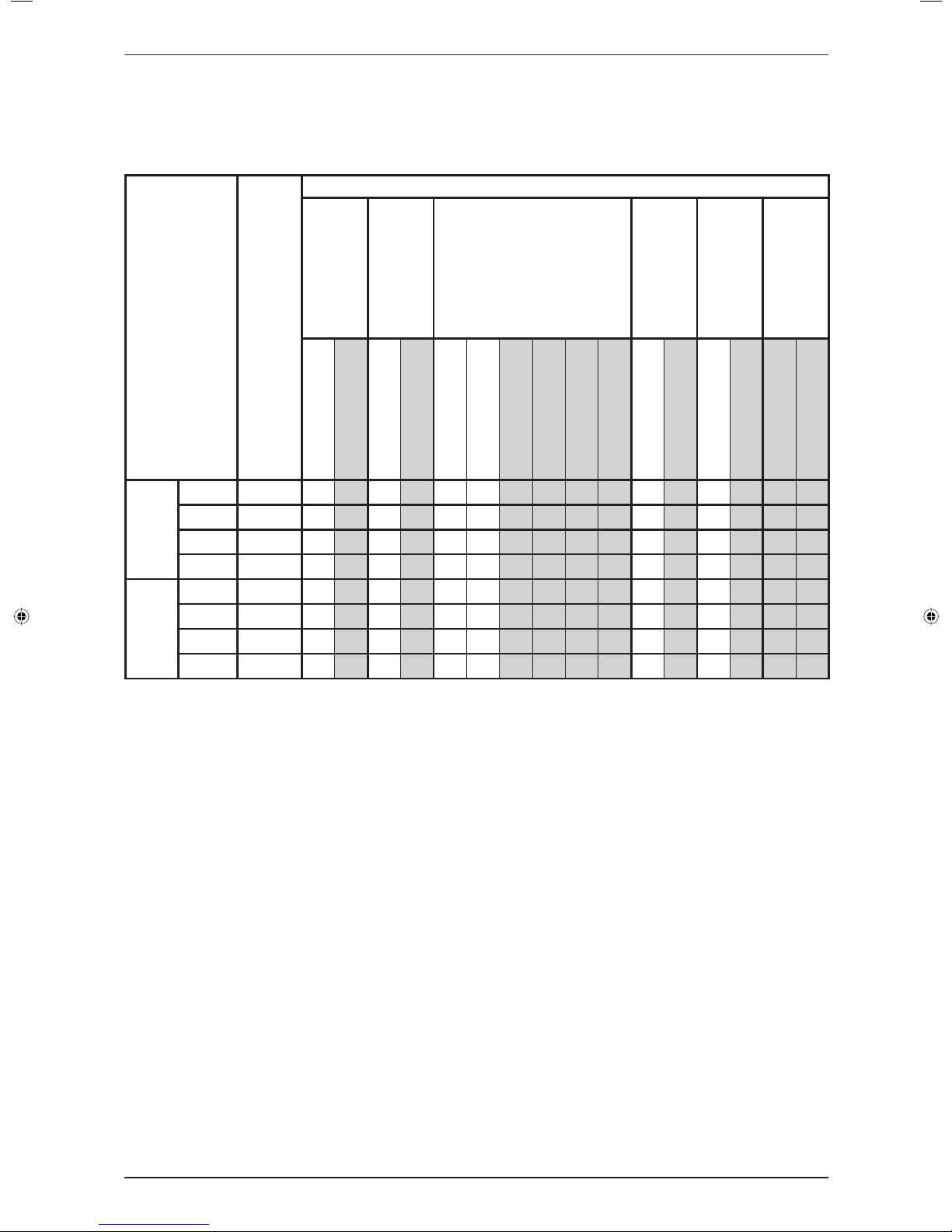

Outdoor Unit

MLC

MLC

Nomenclature

Classifi cation

PCB

Refrigerant

Control

FIN

Safety Devices

Compressor

Marking

Others

Cap Tube

EXV

Gold Coated

Blue Coated

Bare

Contactor HPLP

Rotary

CE

Drain Elbow

Low Ambient Kit

COOLING

ONLY

009C ACPOH X X X X

015C ACPOH X X X X

HEATPUMP

009CR ACPOH X X X X X

015CR ACPOJ X X X X X

Page 9

6

MWM-J-2009 Product Line-Up

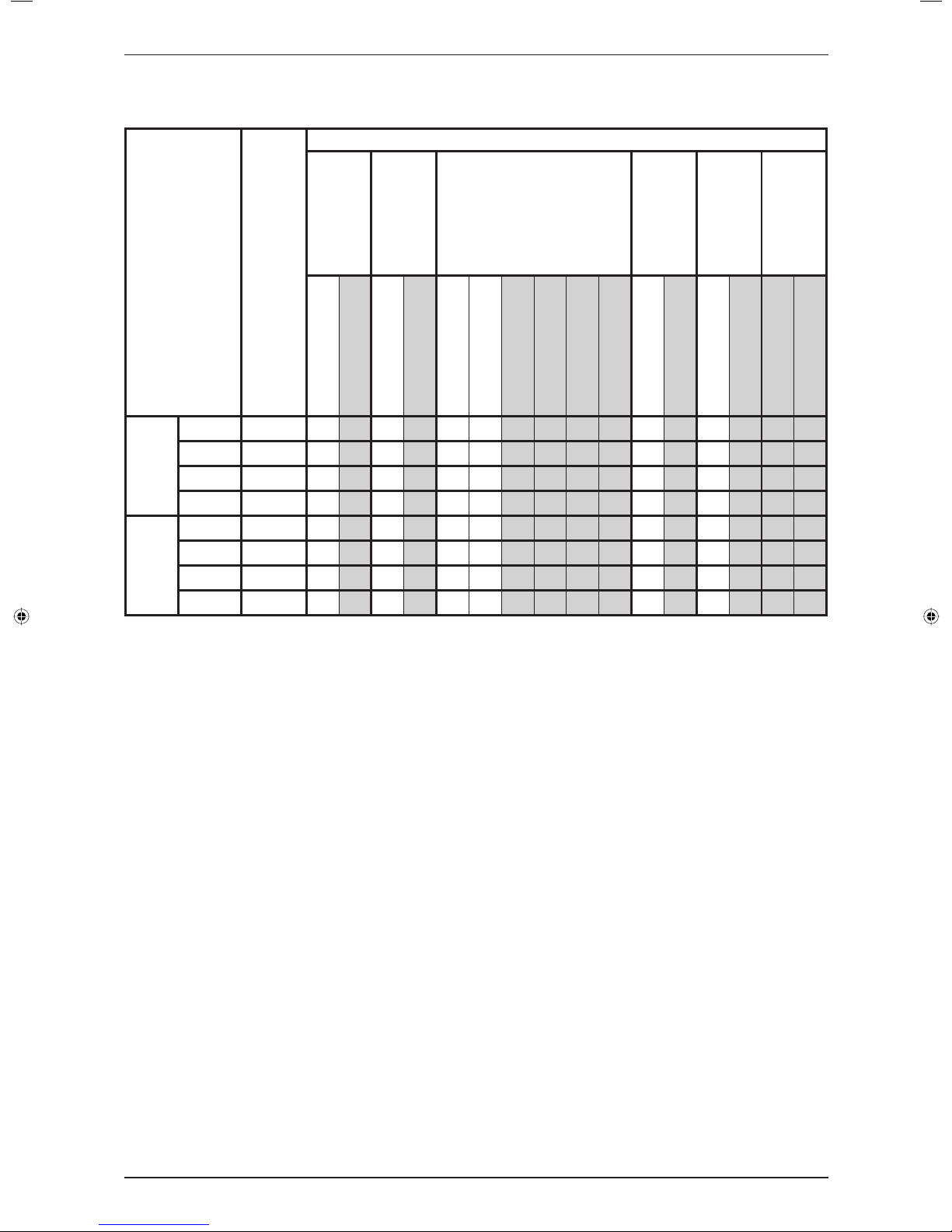

Outdoor Unit

M5LC

M5LC

Nomenclature

Classifi cation

PCB

Refrigerant

Control

FIN

Safety Devices

Compressor

Marking

Others

Cap Tube

EXV

Gold Coated

Blue Coated

Bare

Contactor HPLP

Rotary

CE

Drain Elbow

Low Ambient Kit

COOLING

ONLY

010C ACPGG X X X X X

010C ACPOG X X X X

015C ACPGG X X X X X

015C ACPOG X X X X

HEATPUMP

010CR ACPOG X X X X

015CR ACPOG X X X X

Page 10

7

Features MWM-J-2009

Features

Air Filtration with Bio Antibody Filter and Photo-catalytic Deodorizing Titanium Apatite

Filter

Bio Antibody Filter is effective against various airborne infectious viruses while Titanium Apatite Filter is able to

trap microscopic particles as well as break down and decompose odors. The fi lter can be used for approximately

3 years without replacement if wash about once every six months.

Self Diagnosis

The microprocessor provides the possibility to detect and diagnose any fault or malfunction that occurs in the

system. The error will be refl ected by the blinking of the LED lights.

On / Off Button on Indoor Unit

On/Off button is provided on the front panel of the unit. It can be used when the remote controller is missing or

if its battery has run out. (Note: This button can also be used for forced operation mode)

Auto Random Restart

Auto random restart function allows the unit to automatic restart as the last setting condition when the power

supply is resumed after power failure. However, the compressor will restart randomly if more than one unit is

installed and sharing the same phase of power.

Wireless Remote Controller

The compact LCD transmitter is able to operate the air conditioner unit within the distance of 8 meters.

Fan speed can be set at high / medium / low / super low or automatic.

Sleep mode auto control will gradually increase or decrease the setting temperature to provide a

comfortable surrounding for sleeping.

Air fl ow direction can be controlled automatically.

Room temperature is controlled by electronic thermostat.

The real time timer allows the air conditioner to be switched On and Off automatically based on user

settings.

Turbo mode function is available to enables the required set temperature to be achieved in a short time.

Personalized Setting allows user to preset and store 2 groups of personal settings (including timer setting)

in the handset.

Energy Effi ciency

Using a more effi cient compressor and superior R410A refrigerant, M5WM10JR series achieves the highest

European Energy Rating of A/A. This ensures higher energy savings is accomplished especially during daily

usage. M5WM-J series participates in the Eurovent Certifi cation Programme under category of Comfort Air

Conditioners rated below 12kW cooling capacity (AC1). The certifi ed data for the certifi ed models are listed in

the Eurovent Directory.

•

•

•

•

•

•

•

•

Page 11

8

MWM-J-2009 Application Information

Application Information

Operating Range

Ensure the operating temperature is in allowable range.

Cooling only

Note :

Standard operating range.

With Low ambient kit. (Optional item)

Please refer to local dealer for unit of this specification.

Indoor temp. (°CDB)

Cooling

Outdoor temp. (°CDB)

Indoor temp. (°CWB)

Outdoor temp. (°CDB)

Indoor temp. (°CWB)

Heating

Outdoor temp. (°CWB)

-9

16 21

6

30

-5

19

35

14

46

23

Standard

point

Low ambient kit

18

-5

19

35

14

46

23

Low ambient kit

Standard

point

Standard

point

! Caution :

The use of your air conditioner

outside the range of working

temperature and humidity can

result in serious failure.

Heatpump

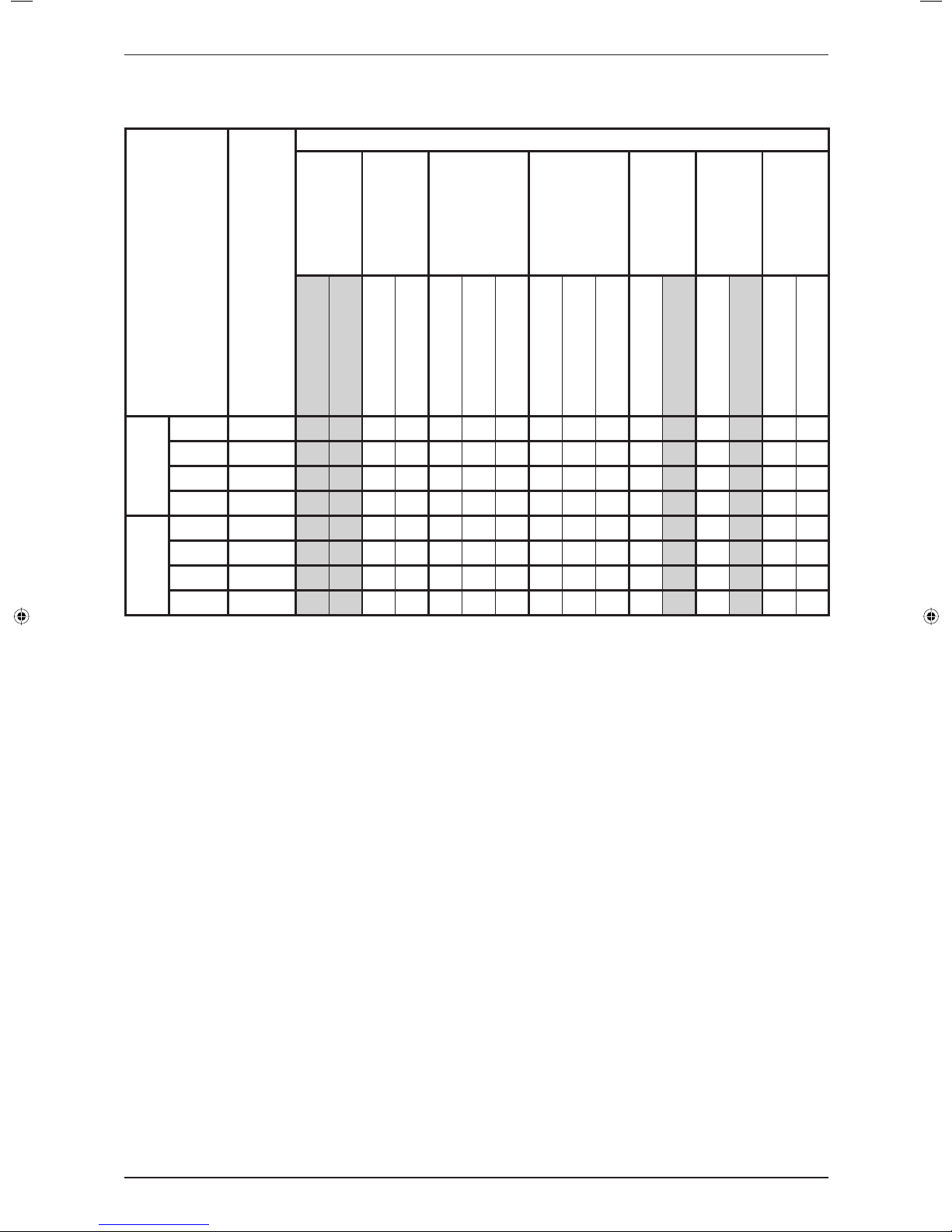

Page 12

9

Application Information MWM-J-2009

70034 049971

Refrigerant Circuit Diagram

Model: MWM009J - MLC009C M5WM010J - M5LC010C

MWM015J - MLC015C M5WM015J - M5LC015C

70034 023154

Model: MWM009JR - MLC009CR M5WM010JR - M5LC010CR

M5WM015JR - M5LC015CR

Page 13

10

MWM-J-2009 Application Information

70034 095236

Model: MWM015JR - MLC015CR

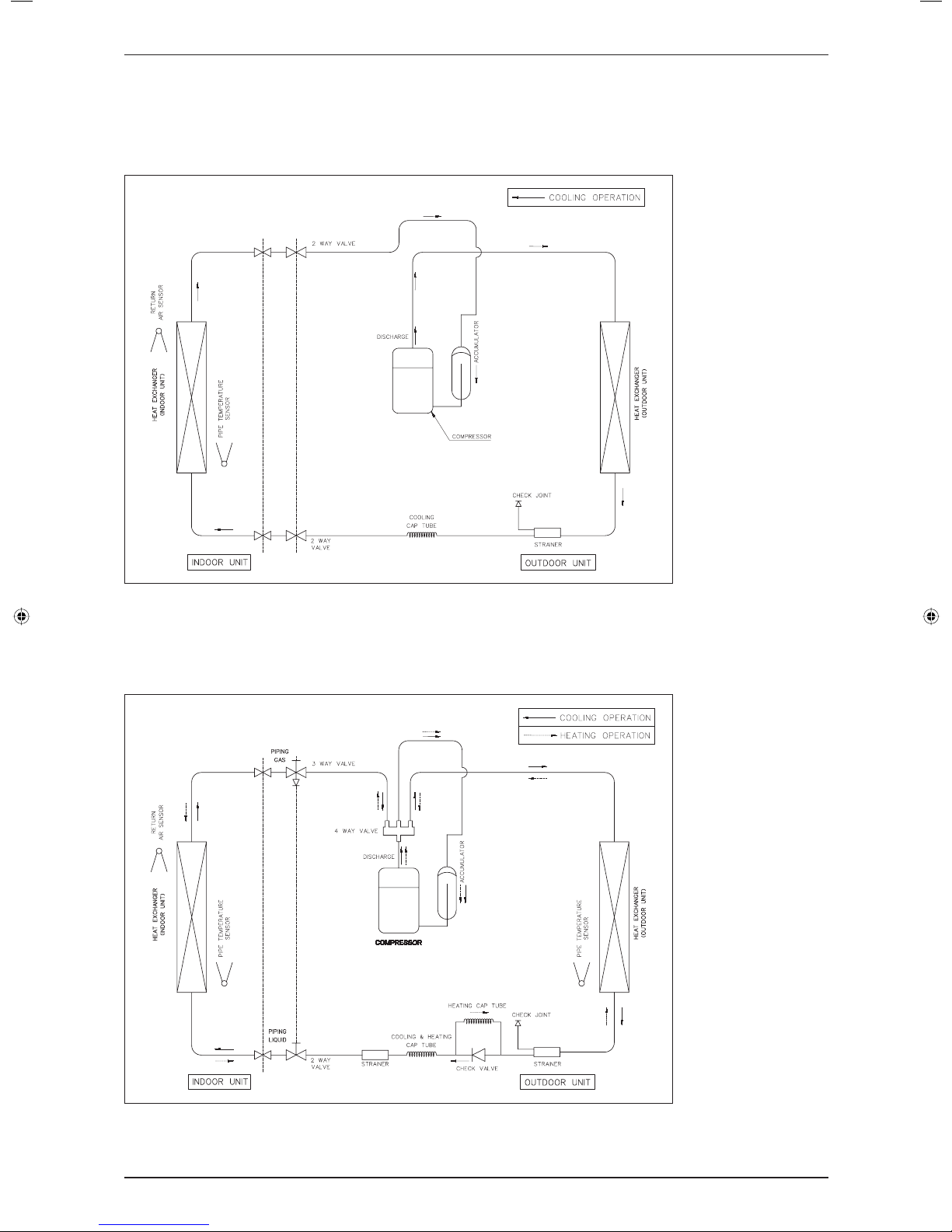

Page 14

11

Application Information MWM-J-2009

Controller

G17

Operation Guide

1 Transmission Source

The source where the signal will be transmitted.•

2 Signal Transmission Indication

Blink to confi rm that the last setting has been transmitted

to the unit.

•

3 Temperature Setting

To set the desired room temperature, press the v or V

button to increase orde crease the set temperature.

The temperature setting range is from 16°C to 30°C

(optional setting 20°C to 30°C).

•

•

4 Personalize Setting

Press

and hold for 3s, then will blink. Press again to

cycle between and

Set the desire setting, then leave the hand set for 4s

without pressing any key and it will save the setting into the

programme.

Press once to activate the P1 setting, press again to

cycle between P1 and P2.

Press any key to deactivate the personalize setting.

•

•

•

•

5 Automatic Air Swing (optional)

Press the SWING

button to activate the automatic air

swing function.

To distribute the air to a specifi c direction, press the

SWING button and wait until the louver move to the

desired direction and press the button once again.

•

•

6 Silent Function

Press

for quiet operation.

Fan speed turn to minimum speed.

Press again to deactivate the function.

•

•

•

7 Sleep Mode Setting

Press the SLEEP button will activate the sleep mode

function. This function is available under COOL, HEAT and

AUTO mode.

When the unit is operating under cooling mode, the set

temperature is increased by 0.5°C after 30 minutes, 1°C

after an hour, and 2°C after 2 hours.

When the unit is operating under heating mode, the set

temperature is decreased by 1°C after 30 minutes, 2°C

after an hour, and 3°C after 2 hours.

•

•

•

8 Operating Mode

Press the MODE button to select the type of operating

mode.

For cooling only unit, the available modes are: COOL (7),

DRY (6) and FAN (

).

•

•

9 Fan Speed Selection

Press the

button continuously will toggle the fan speed

in the following order:

Low p Med p High p Auto

Stop pressing when the desired fan speed appears on the

display screen.

•

•

10 “ON/OFF” Button

Press one to start the air conditioner unit.

Press again to stop the unit.

•

•

11 Timer Cancel

Press the TIMER CANCEL button to cancel the on timer

setting.

•

12 OFF Timer Setting

Press the OFF TIMER button will activate the off timer

function.

Set the desired off time by pressing the OFF TIMER button

continuously.

•

•

13 ON Timer Setting

Press the ON TIMER button will activate the on timer

function.

Set the desired on time by pressing the ON TIMER

button continuously. If the timer is set to 7.30am, the air

conditioner will turn on at 7.30am sharp.

•

•

14 Turbo Function

Press

for fast cooling.

Fan speed turn to maximum speed.

Press again to deactivate the function.

•

•

•

15 Clock Time Setting

Press

and hold to set the clock time.•

MODE

P1 P2

SLEEP

SET

CANCEL

ON TIMER

SET

CANCEL

OFF TIMER

6a 6b

12

15

11

13

14

7

4

3

10

9

2

1

8

5

Page 15

12

MWM-J-2009 Application Information

Installation Guideline

Safety Precautions

WARNING

CAUTION

Installation and maintenance should be performed by

qualifi ed persons who are familiar with local code and

regulation, and experienced with this type of appliance.

All fi eld wiring must be installed in accordance with the

national wiring regulation.

Ensure that the rated voltage of the unit corresponds

to that of the name plate before commencing wiring

work according to the wiring diagram.

The unit must be GROUNDED to prevent possible

hazard due to insulation failure.

All electrical wiring must not touch the refrigerant

piping or any moving parts of the fan motors.

Confi rm that the unit has been switched OFF before

installing or servicing the unit.

Disconnect from the main power supply before

servicing the air conditioner unit.

DO NOT pull out the power cord when the power is

ON. This may cause serious electrical shocks which

may result in fi re hazards.

Keep the indoor and outdoor units, power cable and

transmission wiring, at least 1m from TVs and radios,

to prevent distorted pictures and static. {Depending on

the type and source of the electrical waves, static may

be heard even when more than 1m away}.

•

•

•

•

•

•

•

•

•

Please take note of the following important points

when installing.

Do not install the unit where leakage of fl ammable

gas may occur.

If gas leaks and accumulates around the unit, it

may cause fi re ignition.

Ensure that drainage piping is connected properly.

If the drainage piping is not connected properly,

it may cause water leakage which will dampen

the furniture.

Do not overcharge the unit.

This unit is factory pre-charged. Overcharge will

cause over-current or damage to the compressor.

Ensure that the unit’s panel is closed after service

or installation.

Unsecured panels will cause the unit to operate

noisily.

Sharp edges and coil surfaces are potential

locations which may cause injury hazards. Avoid

from being in contact with these places.

Before turning off the power supply, set the remote

controller’s ON/OFF switch to the “OFF” position

to prevent the nuisance tripping of the unit. If this is

not done, the unit’s fans will start turning automatically

when power resumes, posing a hazard to service

personnel or the user.

Do not operate any heating apparatus too close to the

air conditioner unit. This may cause the plastic panel to

melt or deform as a result of the excessive heat.

Ensure the color of wires of the outdoor unit and

the terminal markings are same to the indoors

respectively.

IMPORTANT : DO NOT INSTALL OR USE THE

AIR CONDITIONER UNIT IN A LAUNDRY ROOM.

Do not use joined and twisted wires for incoming

power supply.

•

•

•

•

•

•

•

•

•

•

•

NOTICE

Disposal requirements

Your air conditioning product is marked with this symbol. This means that electrical and electronic products

shall not be mixed with unsorted household waste.

Do not try to dismantle the system yourself: the dismantling of the air conditioning system, treatment of

the refrigerant, of oil and of other parts must be done by a qualifi ed installer in accordance with relevant

local and national legislation. Air conditioners must be treated at a specialized treatment facility for re-use,

recycling and recovery. By ensuring this product is disposed of correctly, you will help to prevent potential

negative consequences for the environment and human health. Please contact the installer or local authority

for more information.

Batteries must be removed from the remote controller and disposed of separately in accordance with relevant

local and national legislation.

Page 16

13

Application Information MWM-J-2009

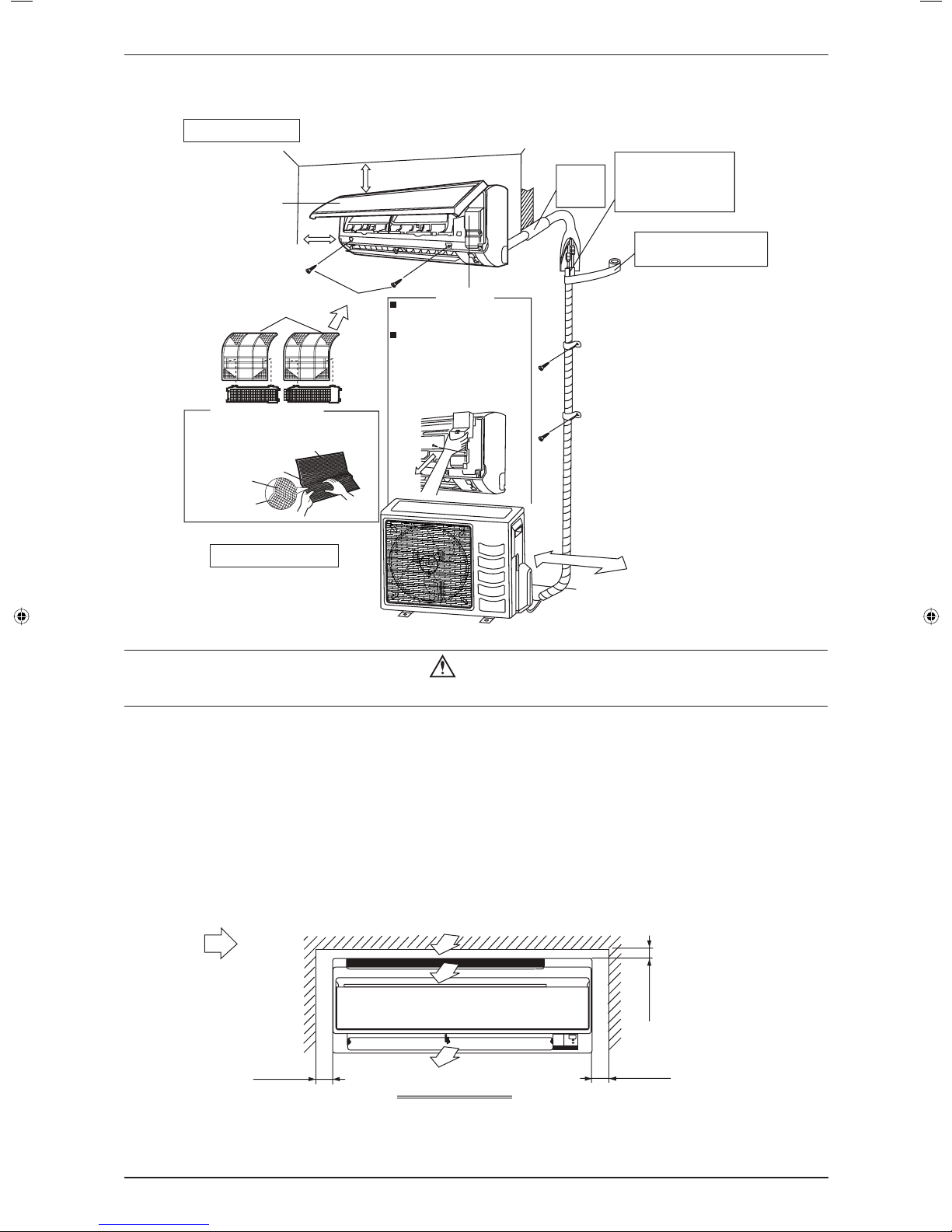

Installation Diagram

Indoor Unit

Air filter

M4 x 12L

Air-Purifying Filter with

bacteriostatic virustatic function (2)

Front panel

30mm or more from ceiling

Outdoor Unit

50mm or more from walls

(on both sides)

Air filter

Air-Purifying Filter with

bacteriostatic virustatic

function

Filter frame

Tab

Caulk pipe

hole gap

with putty.

Cut thermal insulation

pipe to an appropriate

length and wrap it with

tape, making sure that no

gap is left in the insulation

pipe's cut line.

Wrap the insulation pipe with

the finishing tape from bottom

to top.

Service lid

Opening service lid

Service lid is opening/closing

type.

Opening method

1) Remove the service lid

screws.

2) Pull out the service lid

diagonally down in

thedirection of the arrow.

1) Pull down.

250mm from wall

Caution

Before installing the unit, ensure that the power supply matches the power requirement of the air conditioner.•

Installation of Indoor Unit

Service Space

Install the indoor unit at a location with the following requirements

Location is suitable for wiring, piping and drainage.

No obstruction of air fl ow into and out of unit where cooler air can be evenly distributed.

Ensure that air discharge is not short circuited with air intake.

Ensure that wall is suffi ciently strong, rigid, fl at, perpendicular and vibration free.

Where air fi lter cassette can be slided in or out easily.

Where there is no danger of fl ammable gases.

Where there is no direct sunlight on unit.

min. 50

(Space for

maintenance)

Air flow

(Indoor)

min. 50

(Space for

maintenance)

03.n

im

rofecap

S(

)ecn

am

rof

rep

Required space

•

•

•

•

•

•

•

Page 17

14

MWM-J-2009 Application Information

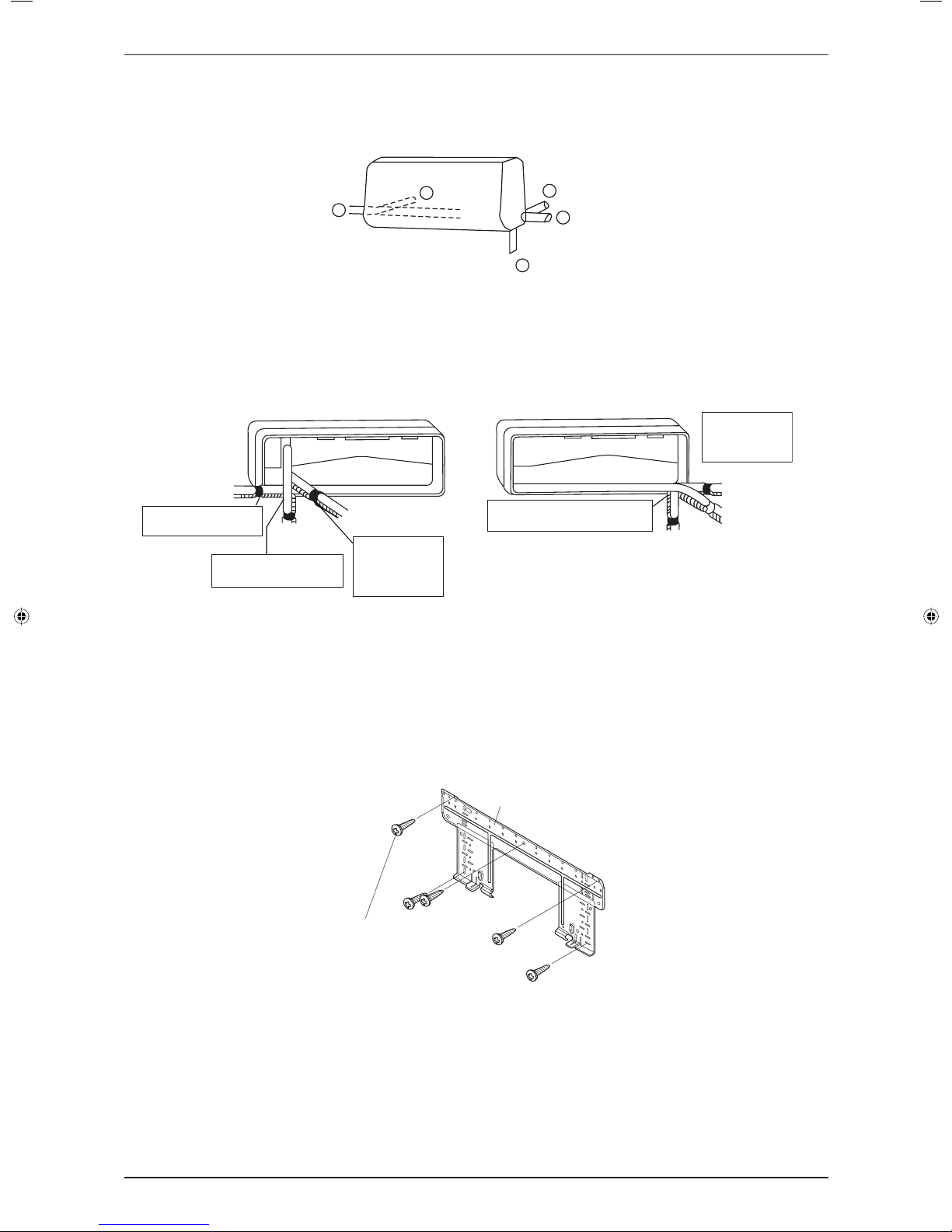

Routing of Piping

The refrigerant piping can be routed to the unit in one of 5 directions, by using the cut outs in the unit

casing (refer to Figure 1).

1

2

3

4

5

Figure 1

Carefully bend the pipes to the required position to align with the hole. For right hand and rear side draw

out, hold the bottom of the piping and fi x direction before shaping it to the desired position

(refer to Figure 2).

Right & Rear Side Routing

Right-back piping

Bind coolant pipe

and drain hose

together with

insulating tape.

Right-bottom

piping

Remove pipe port cover

here for right-bottom piping

Right-side

piping

Remove pipe port cover

here for right-side piping

Remove pipe port cover here for

left-bottom piping

Remove pipe port

cover here for

left-side piping

Left-back

piping

Left-side

piping

Left-bottom piping

Figure 2

Mounting Installation Plate

Paste the installation plan provided on the desired location on the wall and marks the holes location

accordingly.

Ensure the wall is strong enough to withstand the weight of the unit. Otherwise, it is necessary to reinforce

the wall with plates, beams or pillars.

Ensure the levelness of the installation plate, and fi x with 5 suitable screws.

Mounting plate

Mounting plate

fixing screw

•

•

•

•

•

Page 18

15

Application Information MWM-J-2009

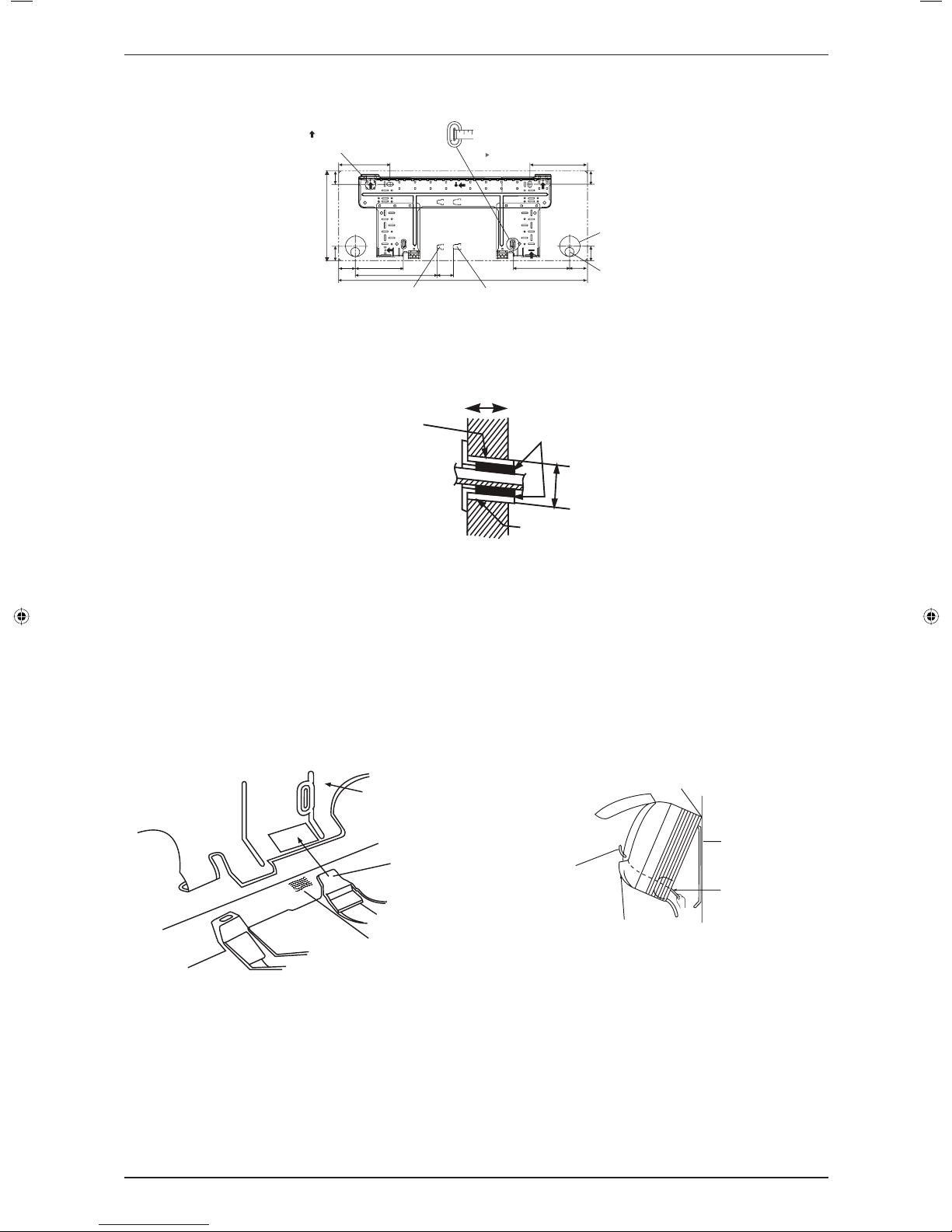

Fix the installation plate fi rmly to the wall, without tilting to left or right. Use a plumb line, if available.

Through

the wall

hole

Ø 65mm

Drain

hose

position

Recommended mounting plate

retention spots (5 spots in all)

Use tape measure as shown.

Position the end of a tape measure

at

Gas pipe end

Liquid pipe end

166

184

181.7

55554.5

153.8

263

51.9

800

45.9

42.2

288

42.2

45.9

42.2

All dimensions are in mm

In case of rear piping drawings out, drill a hole 65mm in diameter with a cone drill, slightly lower on the

outside wall.

Inside

Caulking

Outside

Wall embedded pipe

(Field supply)

Wall hole cover

(Field supply)

Wall embedded pipe

(Field supply)

Ø65

Hole with cone drill

Mounting Unit onto the Installation Plate

Hook the indoor unit onto the upper portion of the installation plate (engage the two hooks at the rear top of

the indoor unit with the upper edge of the installation plate). Ensure the hooks are properly seated onto the

installation plate by moving it to the left and right.

To attach the indoor unit, hook the claws of the bottom frame to the mounting plate. If the claws are diffi cult

to hook, remove the front grille.

To remove the indoor unit, push the marked area (at the lower part of the front grille) to release the claws.

If it is diffi cult to release, remove the front grille.

Mounting

plate

Clip

Mark (rear side)

Bottom frame

Front grille

Mounting plate

Interconnecting

wires

Hang indoor unit's hook here.

Wire guide

When stripping the

ends ofinterconnecting

wires in advance, bind

right endsof wires with

insulating tape.

•

•

•

•

•

Page 19

16

MWM-J-2009 Application Information

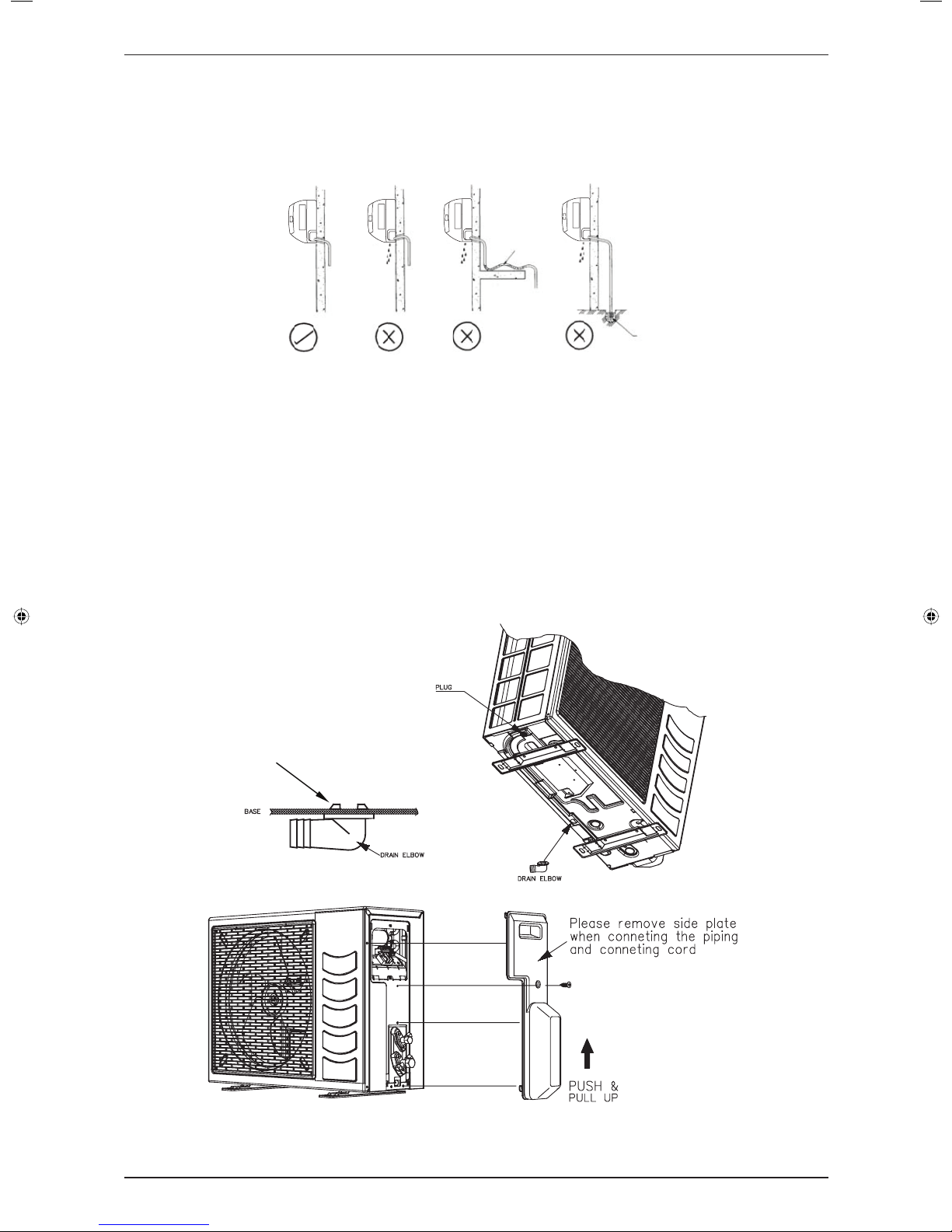

Water Drainage Piping

The indoor drain pipe must be downward gradient for smooth drainage. Avoid situation as shown in fi gure

below.

End

dipped

into

water

Water

leaking

Water

leaking

Water

leaking

Wrong

Wrong

Wrong

Drain

Water Drainage

Water

Retention

Correct

Installation of Outdoor Unit

Condensed Water Disposal of Outdoor Unit (Heat Pump Unit Only)

There are 2 holes on the base of outdoor unit for condensed water to fl ow out. Insert the drain elbow to

one of the holes.

To install the drain elbow, fi rst insert one portion of the hook to the base (portion A), the pull the drain elbow

in the direction shown by the arrow while inserting the other portion to the base. After installation, check to

ensure that the drain elbow clings to base fi rmly.

If the unit is installed in a snowy and chilly area, condensed water may freeze in the base. In such case,

please remove plug at the bottom of unit to smooth the drainage.

A

•

•

•

•

Page 20

17

Application Information MWM-J-2009

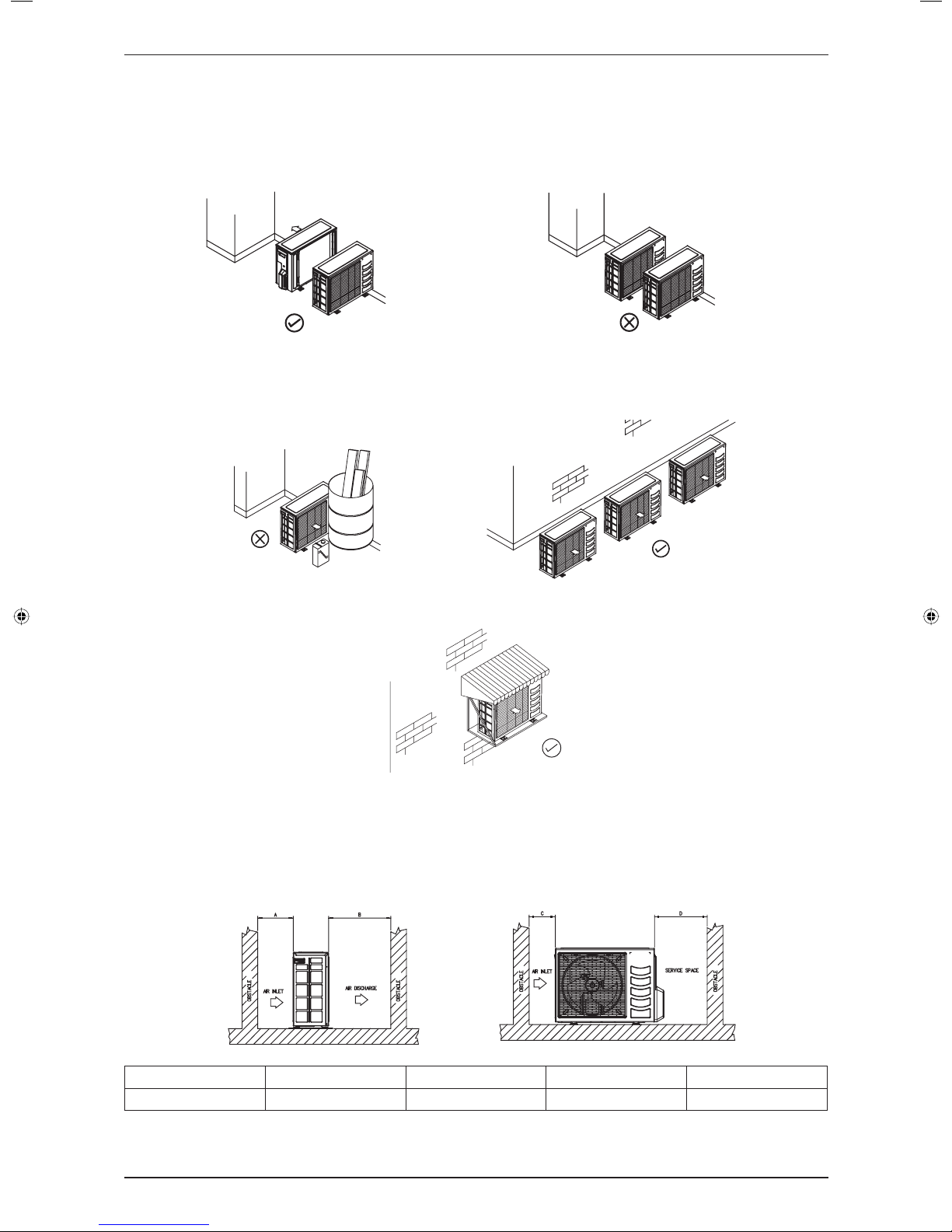

As condensing temperature rises, evaporating temperature rises and cooling capacity drops. In order to achieve

maximum cooling capacity, the location selected for outdoor unit should fulfi ll the following requirements:

Install the condensing (outdoor) unit in a way such that hot air distributed by the outdoor condensing unit

cannot be drawn in again (as in the case of short circuit of hot discharge air). Allow suffi cient space for

maintenance around the unit.

Ensure that there is no obstruction of air fl ow into or out of the unit. Remove obstacles which block air

intake or discharge.

The location must be well ventilated, so that the unit can draw in and distribute plenty of air thus lowering

the condensing temperature.

A place capable of bearing the weight of the outdoor unit and isolating noise and vibration.

A place protected from direct sunlight. Otherwise use an awning for protection, if necessary.

The location must not be susceptible to dust or oil mist.

Installation Clearance

Outdoor units must be installed such that there is no short circuit of the hot discharge air or obstruction to

smooth air fl ow. Select the coolest possible place where intake air should not be hotter than the outside

temperature (max. 45˚C).

ALL MODELS A B C D

Minimum Distance 300 mm 1000 mm 300 mm 500 mm

CAUTION : If the condensing unit is operated in an atmosphere containing oils (including machine oils), salt (coastal area),

sulphide gas (near hot spring, oil refi nery plant), such substances may lead to failure of the unit.

•

•

•

•

•

•

•

Page 21

18

MWM-J-2009 Application Information

Wiring

Electrical Connections

Wiring regulations on wire diameters differ from country to country. Please refer to your LOCAL

ELECTRICAL CODES for fi eld wiring rules. Be sure that installations comply with the rules and regulations.

General Precautions

Ensure that the rated voltage of the unit corresponds to the name plate before carrying out proper wiring

according to the wiring diagram.

Provide a power outlet to be used exclusively for each unit. A power supply disconnects and a circuit

breaker for over-current protection should be provided in the exclusive line.

The unit must be GROUNDED to prevent possible hazards due to insulation failures.

All wiring must be fi rmly connected.

All wiring must not touch the hot refrigerant piping, compressor or any moving parts of fan motors.

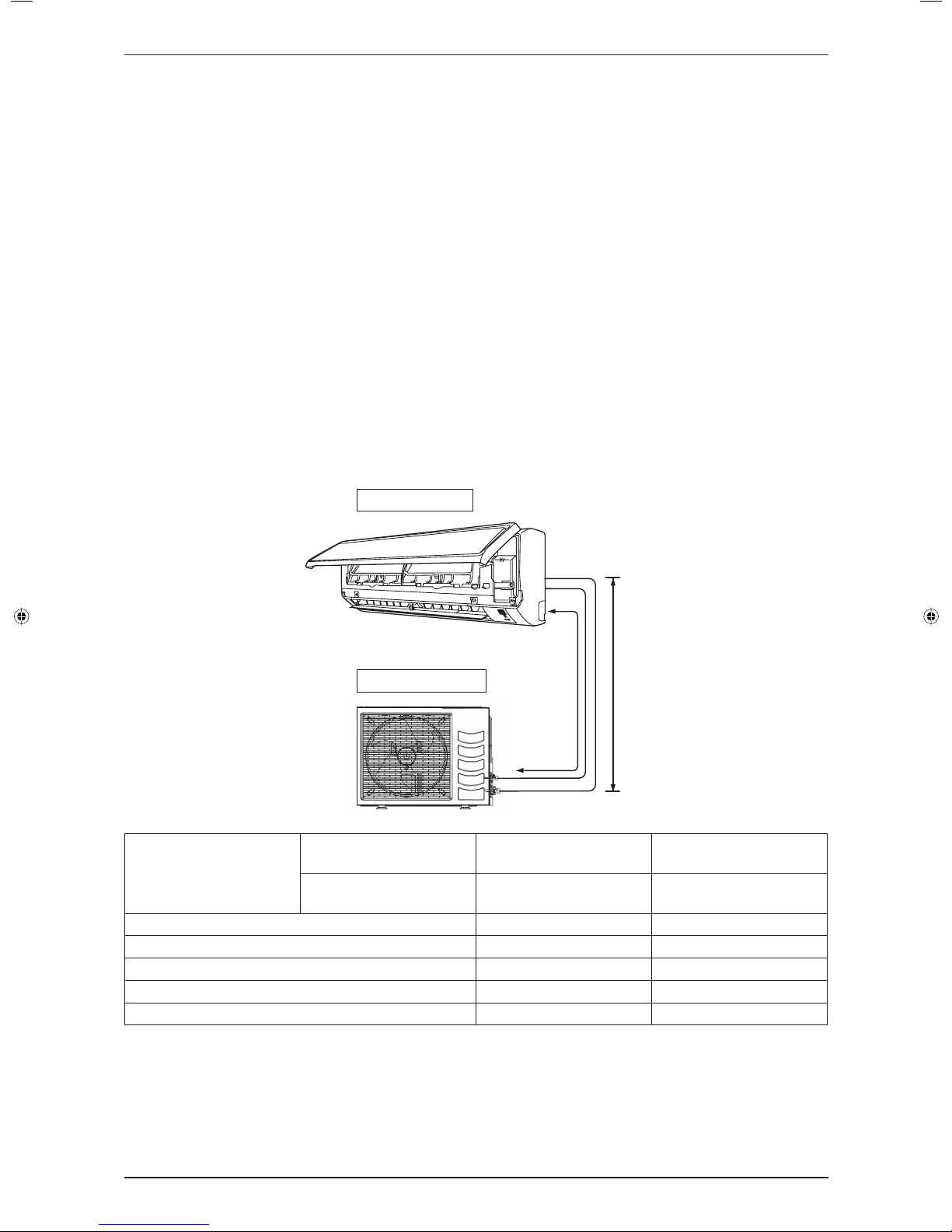

Refrigerant Piping

Piping Length and Elevation

When the pipe length becomes too long, both the capacity and reliability drop. As the number of bends increases,

system piping resistance to the refrigerant fl ow increases, thus lowering the cooling capacity, and as the result

the compressor may become defective. Always choose the shortest path and follow the recommendation as

tabulated below:

Outdoor Unit

Indoor Unit

LH

Model

Indoor

MWM009J/JR

M5WM010J/JR

MWM015J/JR

M5WM015J/JR

Outdoor

MLC009C/CR

M5LC010C/CR

MLC015C/CR

M5LC015C/CR

Min. Allowable Length, m (L) 3 3

Max. Allowable Length, m (L) 15 15

Max. Allowable Height, m (H) 10 10

Liquid, mm/in 6.35 / 1/4 6.35 / 1/4

Suction, mm/in 9.52 / 3/8 12.70 / 1/2

* Be sure to add the proper amount of additional refrigerant. Failure to do so may result in reduced performance

Remark: The refrigerant pre-charged in the outdoor unit is for piping length up to 7.6m/25ft.

•

•

•

•

•

•

Page 22

19

Application Information MWM-J-2009

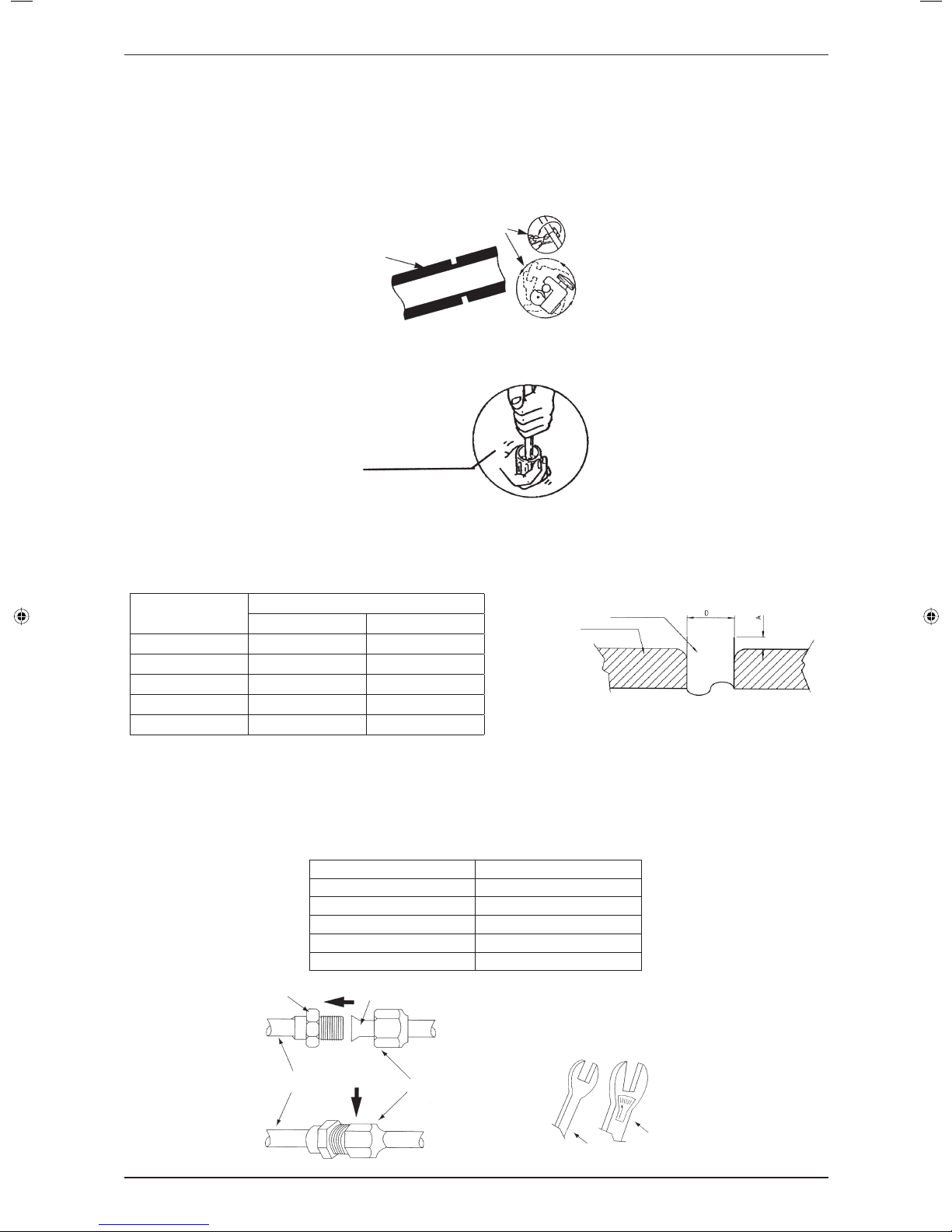

Piping Works

Do not use contaminated or damaged copper tubing. Do not remove plastic, rubber plugs and brass nuts

from the valves, fi ttings, tubings and coils until you are ready to connect suction or liquid line into valves or

fi ttings.

If any brazing work is required, ensure that the nitrogen gas is passed through coil and joints while the

brazing work is being done. This will eliminate soot formation on the inside walls of the copper tubings.

Cut the connection pipe with a pipe cutter.

Cutting copper tube

1/4t

Remove burrs from cut edges of the pipes with remover. Hold the end of the pipe downwards to prevent

metal chips from entering the pipe.

Remove burr

Insert the fl are nuts, mounted on the connection parts of both the indoor unit and outdoor unit onto the

copper pipes.

Flare the pipe with extra length above the fl aring tool as shown in the table.

The fl ared edge must be even and not cracked or scratched.

Ø Tube,

D (mm / in)

A (mm)

Imperial Die Rigid Die

6.35 / 1/4 1.3 0.7

9.52 / 3/8 1.6 1.0

12.70 / 1/2 1.9 1.3

15.88 / 5/8 2.2 1.7

19.05 / 3/4 2.5 2.0

Swaging block

Copper tube

Piping Connection to the Units

Align the center of the piping and tighten the fl are nut suffi ciently with fi ngers.

Finally tighten the fl are nut with torque wrench unit the wrench clicks.

When tightening the fl are nut with torque wrench, ensure the direction for tightening follows the arrow on

the wrench.

Pipe Size (mm/in) Torque (Nm)

6.35 (1/4) 18

9.52 (3/8) 42

12.70 (1/2) 55

15.88 (5/8) 65

19.05 (3/4) 78

Indoor piping

Flare nut

Flared tube

Flare joint

Spanar

Torque wrench

•

•

•

•

•

•

•

•

•

•

Page 23

20

MWM-J-2009 Application Information

Vacuuming and Charging

The pre-charged outdoor unit does not need any vacuuming or charging. However once it is connected, the

connecting pipe line and the indoor unit need to be vacuumed before releasing the R22/R407C/R410A from

the outdoor unit.

1. Open the service port core cap.

2. Connect pressure gauge to the service port.

3. Connect the line to vacuum pump. Open the charging manifold valve and turn the pump on. Vacuum to -0.1

MPa (-760mmHg) or lower. (Evacuation time varies by the pump but averagely in 1 hour).

Filter Dryer

(Mclecular-Sieve Type

Note : R22 - Nil

R410A - Nil

4. After evacuation, unscrew the spindle (diagram B) for the gas to run to indoor unit.

Additional Charge

The refrigerant gas is charged in the outdoor unit and, if the piping length is 7.6m, additional charge of the

refrigerant after vacuuming is not necessary.

When the piping length is more than 7.6m, additional refrigerant charge (g) per additional 1m length as

tabulated:

R22

Indoor MWM009J/JR MWM015J/JR

Outdoor MLC009C/CR MLC015C/CR

Additional Charge (g/m) 16 23

R410A

Indoor M5WM010J/JR M5WM015J/JR

Outdoor M5LC010C/CR M5LC015C/CR

Additional Charge (g/m) 9 6

•

•

Page 24

21

Application Information MWM-J-2009

Diagram shows typical charging method:

(Mclecular-Sieve Type)

Note : R22 - Nil

R410A - Nil

Caution

For R410A, avoid prolong exposure of an opened compressor, or the internal part of refrigerant piping to moist air.

The POE oil in the compressor and piping can absorb moisture from air.

•

Overall Checking

Ensure the following, in particular:

1. The unit is mounted solidly and rigid in position.

2. Piping and connections are leak proof after charging.

3. Proper wiring has been done.

Drainage check – pour some water into drain pan.

Test run

1. Conduct a test run after water drainage test and gas leakage test.

2. Watch out for the following:

(a) Is the electric plug fi rmly inserted into the socket?

(b) Is there any abnormal sound from the unit?

(c) Is there any abnormal vibration with regard to the unit itself or piping?

(d) Is there smooth drainage of water?

Check that:

1. Outdoor fan is running, with warm air blowing off the outdoor unit (cooling cycle).

2. Indoor blower is running and discharge cool air (cooling cycle).

3. Suction (low side) pressure is as per recommendations.

4. The remote controller has incorporated a 3 minutes delay in the circuit. Thus, it requires about 3 minutes

before the outdoor unit can start up.

Standard Operating Condition

Cooling only unit

Temperature Ts °C / °F Th °C / °F

Minimum indoor temperature 19.0 / 66.2 14.0 / 57.2

Maximum indoor temperature 32.0 / 89.6 23.0 / 73.4

Minimum outdoor temperature 19.4 / 66.9 -

Maximum outdoor temperature 46.0 / 114.8 -

Heat pump unit

Temperature Ts °C / °F Th °C / °F

Minimum indoor temperature 16.0 / 60.8 -

Maximum indoor temperature 30.0 / 86.0 -

Minimum outdoor temperature -8.0 / 17.6 -9.0 / 15.8

Maximum outdoor temperature 24.0 / 75.2 18.0 / 64.4

Ts : Dry bulb temperature Th : Wet bulb temperature

•

•

•

•

Page 25

22

MWM-J-2009 Application Information

Special Precautions When Dealing With Refrigerant R410A Unit

(1) What is new refrigerant R410A?

R410A is a new HFC refrigerant which does not damage the ozone layer. The working pressure of this

new refrigerant is 1.6 times higher than conventional refrigerant (R22), thus proper installation / servicing

is essential.

(2) Components

Mixture weight composition R32(50%) and R125(50%)

(3) Characteristic

R410A liquid and vapor components have different compositions when the fl uid evaporates or

condenses. Hence, when leak occurs and only vapor leaks out, the composition of the refrigerant

mixture left in the system will change and subsequently affect the system performance. DO NOT add

new refrigerant to leaked system. It is recommended that the system should be evacuated thoroughly

before recharging with R410A.

When refrigerant R410A is used, the composition will differ depending on whether it is in gaseous or

liquid phase. Hence when charging R410A, ensure that only liquid is being withdrawn from the cylinder

or can. This is to make certain that only original composition of R410A is being charged into the system.

POE oil is used as lubricant for R410A compressor, which is different from the mineral oil used for R22

compressor. Extra precaution must be taken not to expose the R410A system too long to moist air.

(4) Check list before installation / servicing

Tubing

Refrigerant R410A is more easily affected by dust of moisture compared with R22, make sure to

temporarily cover the ends of the tubing prior to installation.

Compressor oil

No additional charge of compressor oil is permitted.

Refrigerant

No other refrigerant other that R410A

Tools (size of service port is different from R22 system)

Tools specifi cally for R410A only (must not be used for R22 or other refrigerant)

i) Gauge manifold and charging hose

ii) Gas leak detector

iii) Refrigerant cylinder/charging cylinder

iv) Vacuum pump c/w adapter

v) Flare tools

vi) Refrigerant recovery machine

(5) Handling and installation guidelines

Like R22 system, the handling and installation of R410A system are closely similar. All precautionary

measures; such as ensuring no moisture, no dirt or chips in the system, clean brazing using nitrogen, and

thorough leak check and vacuuming are equally important requirements. However, due to its hydroscopic

POE oil, additional precautions must be taken to ensure optimum and trouble free system operation.

(a) During installation or servicing, avoid prolong exposure of the internal part of the refrigerant system to

moist air. Residual POE oil in the piping and components can absorb moisture from the air.

(b) Ensure that the compressor is not exposed to open air for more than the recommended time specifi ed

by its manufacturer (typically less than 10 minutes). Removed the seal plugs only when the compressor

is about to be brazed.

(c) The system should be thoroughly vacuumed to 1.0 Pa (700mmHg) or lower. This vacuuming level is

more stringent than R22 system so as to ensure no incompressible gas and moisture in the system.

•

•

•

•

•

•

•

Page 26

23

Application Information MWM-J-2009

(d) When charging R410A, ensure that only liquid is being withdrawn from the cylinder or can. This is

to ensure that only the original composition of R410A is being delivered into the system. The liquid

composition can be different from the vapor composition.

D

ip-pipe

Liquid

withdrawal

Invert cylinder

without dip-pipe

(e) Normally, the R410A cylinder or can is being equipped with a dip pipe for liquid withdrawal. However,

if the dip pipe is not available, invert the cylinder or can so as to withdraw liquid from the valve at the

bottom.

Page 27

24

MWM-J-2009 Sound Data

Sound Data

Sound Pressure Level

Model Speed

1/1 Octave Sound Pressure Level (dB, ref 20μPa) Overall

(dBA)

Noise

Criteria

125 Hz 250 Hz 500 Hz 1k Hz 2k Hz 4k Hz 8k Hz

MWM009J/JR

High 30 32 33 29 25 19 9 34 28

Medium 27 29 31 27 22 20 11 32 25

Low 24 26 28 23 19 19 11 29 22

S. Low 24 25 27 22 18 19 11 28 22

M5WM010J/JR

High 31 35 36 34 30 22 9 38 33

Medium 26 30 31 27 22 13 5 32 25

Low 24 26 27 22 15 7 7 27 21

S. Low 23 24 25 20 13 6 5 25 -

MWM015J/JR

M5WM015J/JR

High 32 35 36 34 31 22 11 38 33

Medium 30 32 33 29 25 16 10 34 28

Low 29 28 28 24 19 11 10 29 22

S. Low 28 26 27 22 17 9 9 27 21

Microphone position: 1m in front and 0.8m below the vertical centre line of the unit. (JIS C 9612)

Model Measuring location

MWM009J/JR

MWM015J/JR

M5WM010J/JR

M5WM015J/JR

Microphon

e

1.0m

0.8m

Standard : JIS C 9612

Page 28

25

Sound Data MWM-J-2009

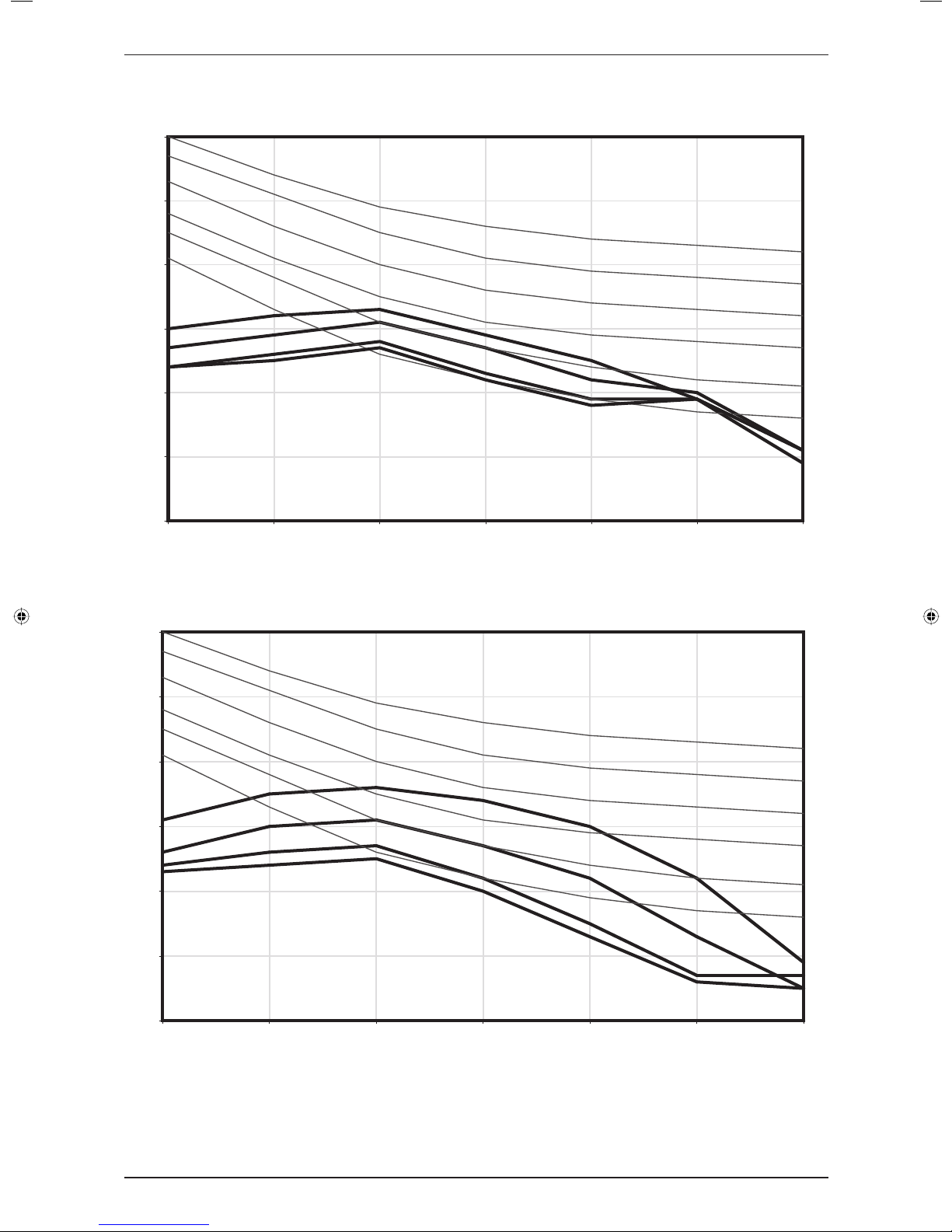

MWM009J/JR

NC CURVES

0

10

20

30

40

50

60

125 250 500 1000 2000 4000 8000

Octave-band frequency (Hz)

Sound pressure level (dB,ref20µPa)

High Fan

NC-30

NC-35

NC-40

NC-45

Low Fan

Medium Fan

NC-25

NC-20

S.Low Fan

M5WM010J/JR

NC CURVES

0

10

20

30

40

50

60

125 250 500 1000 2000 4000 8000

Octave-band frequency (Hz)

Sound pressure level (dB,ref20µPa)

High Fan

NC-30

NC-35

NC-40

NC-45

Low Fan

Medium Fan

NC-25

NC-20

S.Low Fan

Page 29

26

MWM-J-2009 Sound Data

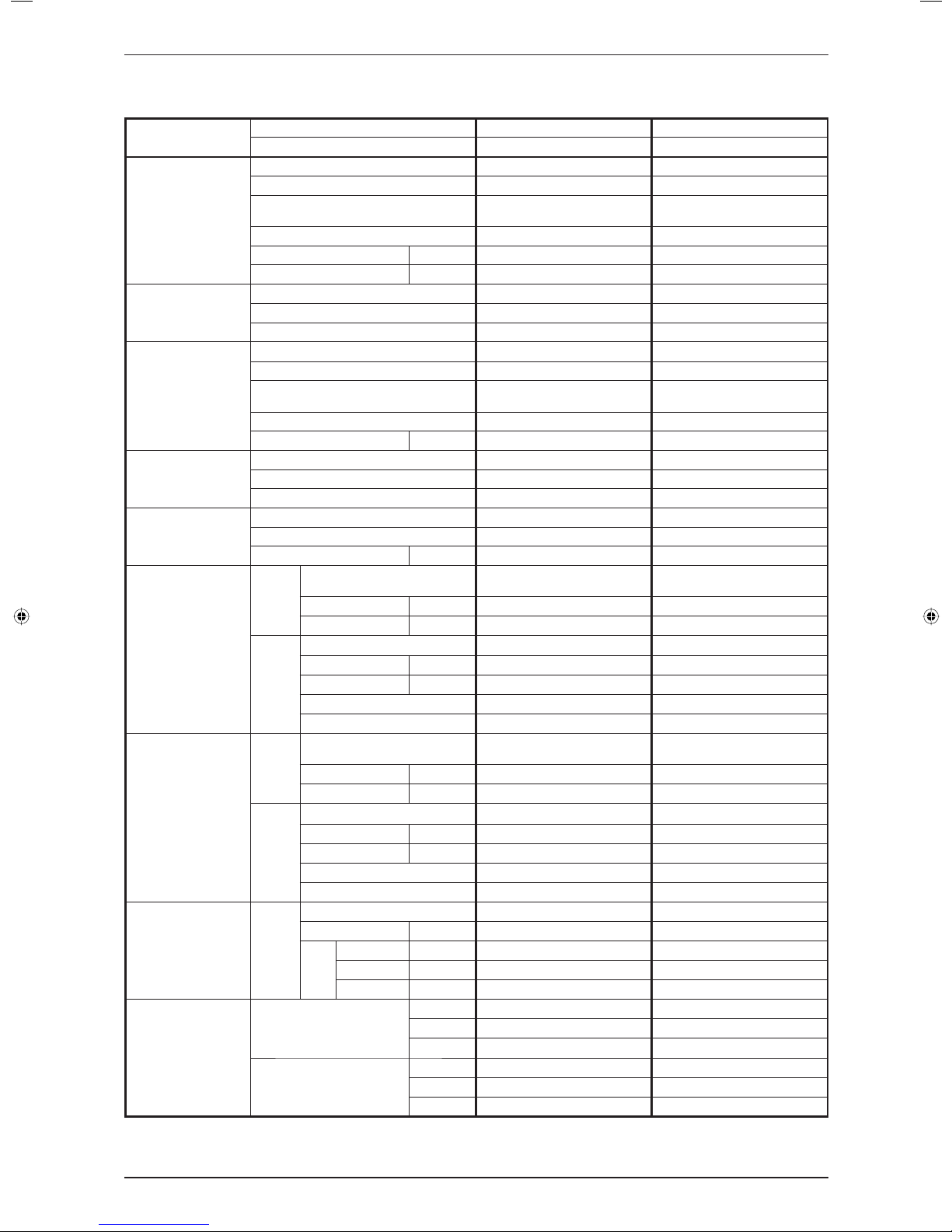

MWM015J/JR, M5WM015J/JR

NC CURVES

0

10

20

30

40

50

60

125 250 500 1000 2000 4000 8000

Octave-band frequency (Hz)

Sound pressure level (dB, ref20µPa)

High Fan

Medium Fan

Low Fan

NC-20

NC-30

NC-

NC-40

NC-25

NC-35

S.Low Fan

Page 30

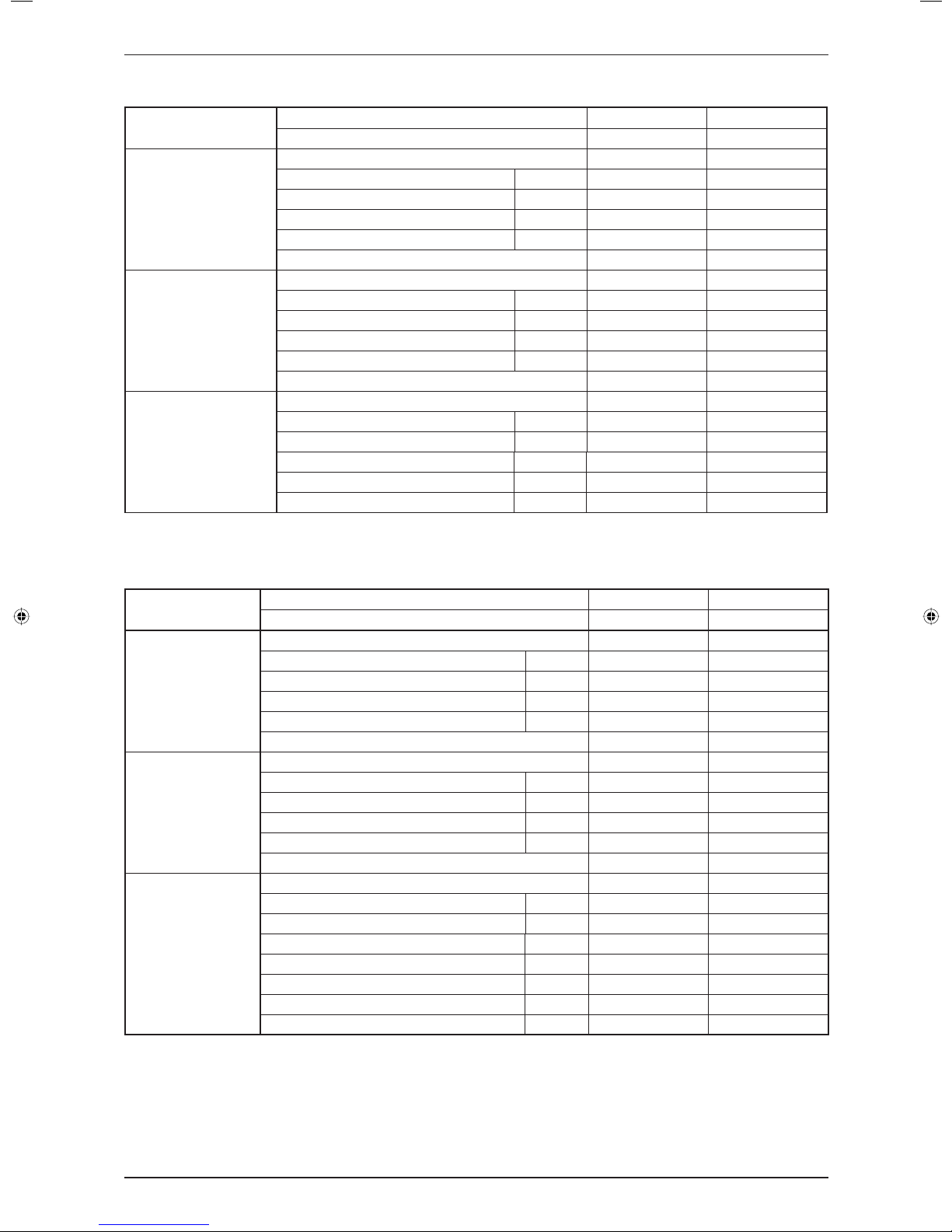

27

Engineering & Physical Data MWM-J-2009

Engineering & Physical Data

General Data - Cooling Only (R22)

MODEL

INDOOR UNIT MWM009J MWM015J

OUTDOOR UNIT MLC009C MLC015C

NOMINAL CAPACITY

Btu/h 8400 12000

W 2460 3520

NOMINAL TOTAL INPUT POWER W 925 1176

NOMINAL RUNNING CURRENT A 4.10 5.40

POWER SOURCE V/Ph/Hz 220 - 240 / 1 / 50 220 - 240 / 1 / 50

EER W/W 2.66 2.99

REFRIGERANT TYPE R22 R22

REFRIGERANT CONTROL (EXPANSION DEVICE) OUTDOOR CAP. TUBE OUTDOOR CAP. TUBE

INDOOR UNIT

CONTROL

AIR DISCHARGE

AUTO LOUVER (UP & DOWN) &

GRILLE (LEFT & RIGHT)

AUTO LOUVER (UP & DOWN) &

GRILLE (LEFT & RIGHT)

OPERATION LCD REMOTE CONTROL LCD REMOTE CONTROL

AIR FLOW

HIGH l/s / CFM 145 / 309 163 / 346

MEDIUM l/s / CFM 125 / 265 138 / 293

LOW l/s / CFM 105 / 223 113 / 240

SOUND PRESSURE LEVEL (H/M/L) dBA 34 / 32 / 29 38 / 34 / 29

UNIT DIMENSION

HEIGHT mm/in 288 / 11.3 288 / 11.3

WIDTH mm/in 800 / 31.5 800 / 31.5

DEPTH mm/in 204 / 8.0 204 / 8.0

PACKING DIMENSION

HEIGHT mm/in 350 / 13.8 350 / 13.8

WIDTH mm/in 874 / 34.4 874 / 34.4

DEPTH mm/in 280 / 11.0 280 / 11.0

UNIT WEIGHT kg/lb 12 / 26.5 12 / 26.5

CONDENSATE DRAIN SIZE mm/in 16 / 0.6 16 / 0.6

OUTDOOR UNIT

AIR FLOW l/s / CFM 349 / 740 457 / 969

SOUND PRESSURE LEVEL dBA 45 49

UNIT DIMENSION

HEIGHT mm/in 475 / 18.7 540 / 21.3

WIDTH mm/in 600 / 23.6 700 / 27.6

DEPTH mm/in 245 / 9.6 250 / 9.8

PACKING DIMENSION

HEIGHT

mm/in 535 / 21.1 620 / 24.4

WIDTH mm/in 712 / 28.0 810 / 31.9

DEPTH mm/in 320 / 12.6 330 / 13.0

UNIT WEIGHT kg/lb 33 / 72.6 34 / 75.0

PIPE CONNECTION

TYPE FLARE VALVE FLARE VALVE

SIZE

LIQUID mm/in 6.4 / 1/4 6.4 / 1/4

GAS mm/in 9.5 / 3/8 12.7 / 1/2

REFRIGERANT CHARGE kg/lb 0.65 / 1.43 0.75 / 1.65

1) ALL SPECIFICATIONS ARE SUBJECTED TO CHANGE BY THE MANUFACTURER WITHOUT PRIOR NOTICE.

2) ALL UNITS ARE BEING TESTED AND COMPLY TO ISO 5151.

3) NOMINAL COOLING AND HEATING CAPACITY ARE BASED ON THE CONDITIONS BELOW :

COOLING - 27°C DB / 19°C WB INDOOR AND 35°C DB / 24°C WB OUTDOOR

4) SOUND PRESSURE LEVEL ARE ACCORDING TO JIS B 8615 STANDARD. POSITION OF THE MEASUREMENT POINT IS 1m IN FRONT AND 1m

BELOW THE UNIT.

Page 31

28

MWM-J-2009 Engineering & Physical Data

General Data - Heat pump (R22)

MODEL

INDOOR UNIT MWM009JR MWM015JR

OUTDOOR UNIT MLC009CR MLC015CR

NOMINAL COOLING CAPACITY

Btu/h 8400 11800

W 2460 3460

NOMINAL HEATING CAPACITY

Btu/h 9000 13000

W 2640 3810

NOMINAL TOTAL INPUT POWER (COOLING)

W 925 1192

NOMINAL TOTAL INPUT POWER (HEATING) W 750 1064

NOMINAL RUNNING CURRENT (COOLING) A 4.10 5.50

NOMINAL RUNNING CURRENT (HEATING) A 3.40 4.90

POWER SOURCE V/Ph/Hz 220 - 240 / 1 / 50 220 - 240 / 1 / 50

EER W/W 2.66 2.90

COP W/W 3.52 3.58

REFRIGERANT TYPE R22 R22

REFRIGERANT CONTROL (EXPANSION DEVICE) OUTDOOR CAP. TUBE OUTDOOR CAP. TUBE

INDOOR UNIT

CONTROL

AIR DISCHARGE

AUTO LOUVER (UP & DOWN) &

GRILLE (LEFT & RIGHT)

AUTO LOUVER (UP & DOWN) &

GRILLE (LEFT & RIGHT)

OPERATION LCD REMOTE CONTROL LCD REMOTE CONTROL

AIR FLOW

HIGH l/s / CFM 145 / 309 163 / 346

MEDIUM l/s / CFM 125 / 265 138 / 293

LOW l/s / CFM 105 / 223 113 / 240

SOUND PRESSURE LEVEL (H/M/L) dBA 34 / 32 / 29 38 / 32 / 27

UNIT DIMENSION

HEIGHT mm/in 288 / 11.3 288 / 11.3

WIDTH mm/in 800 / 31.5 800 / 31.5

DEPTH mm/in 204 / 8.0 204 / 8.0

PACKING DIMENSION

HEIGHT mm/in 350 / 13.8 350 / 13.8

WIDTH mm/in 874 / 34.4 874 / 34.4

DEPTH mm/in 280 / 11.0 280 / 11.0

UNIT WEIGHT kg/lb 12 / 26.5 12 / 26.5

CONDENSATE DRAIN SIZE mm/in 16 / 0.6 16 / 0.6

OUTDOOR UNIT

AIR FLOW l/s / CFM 349 / 740 457 / 969

SOUND PRESSURE LEVEL dBA 45 49

UNIT DIMENSION

HEIGHT mm/in 475 / 18.7 540 / 21.3

WIDTH mm/in 600 / 23.6 700 / 27.6

DEPTH mm/in 245 / 9.6 250 / 9.8

PACKING DIMENSION

HEIGHT

mm/in 535 / 21.1 620 / 24.4

WIDTH mm/in 712 / 28.0 810 / 31.9

DEPTH mm/in 320 / 12.6 330 / 13.0

UNIT WEIGHT kg/lb 33 / 72.6 34 / 75.0

PIPE CONNECTION

TYPE FLARE VALVE FLARE VALVE

SIZE

LIQUID mm/in 6.4 / 1/4 6.4 / 1/4

GAS mm/in 9.5 / 3/8 12.7 / 1/2

REFRIGERANT CHARGE kg/lb 0.65 / 1.43 0.93/2.04

1) ALL SPECIFICATIONS ARE SUBJECTED TO CHANGE BY THE MANUFACTURER WITHOUT PRIOR NOTICE.

2) ALL UNITS ARE BEING TESTED AND COMPLY TO ISO 5151.

3) NOMINAL COOLING AND HEATING CAPACITY ARE BASED ON THE CONDITIONS BELOW :

a) COOLING - 27°C DB / 19°C WB INDOOR AND 35°C DB / 24°C WB OUTDOOR

b) HEATING - 20°C DB INDOOR AND 7°C DB / 6°C WB OUTDOOR

4) SOUND PRESSURE LEVEL ARE ACCORDING TO JIS B 8615 STANDARD. POSITION OF THE MEASUREMENT POINT IS 1m IN FRONT AND 1m

BELOW THE UNIT.

Page 32

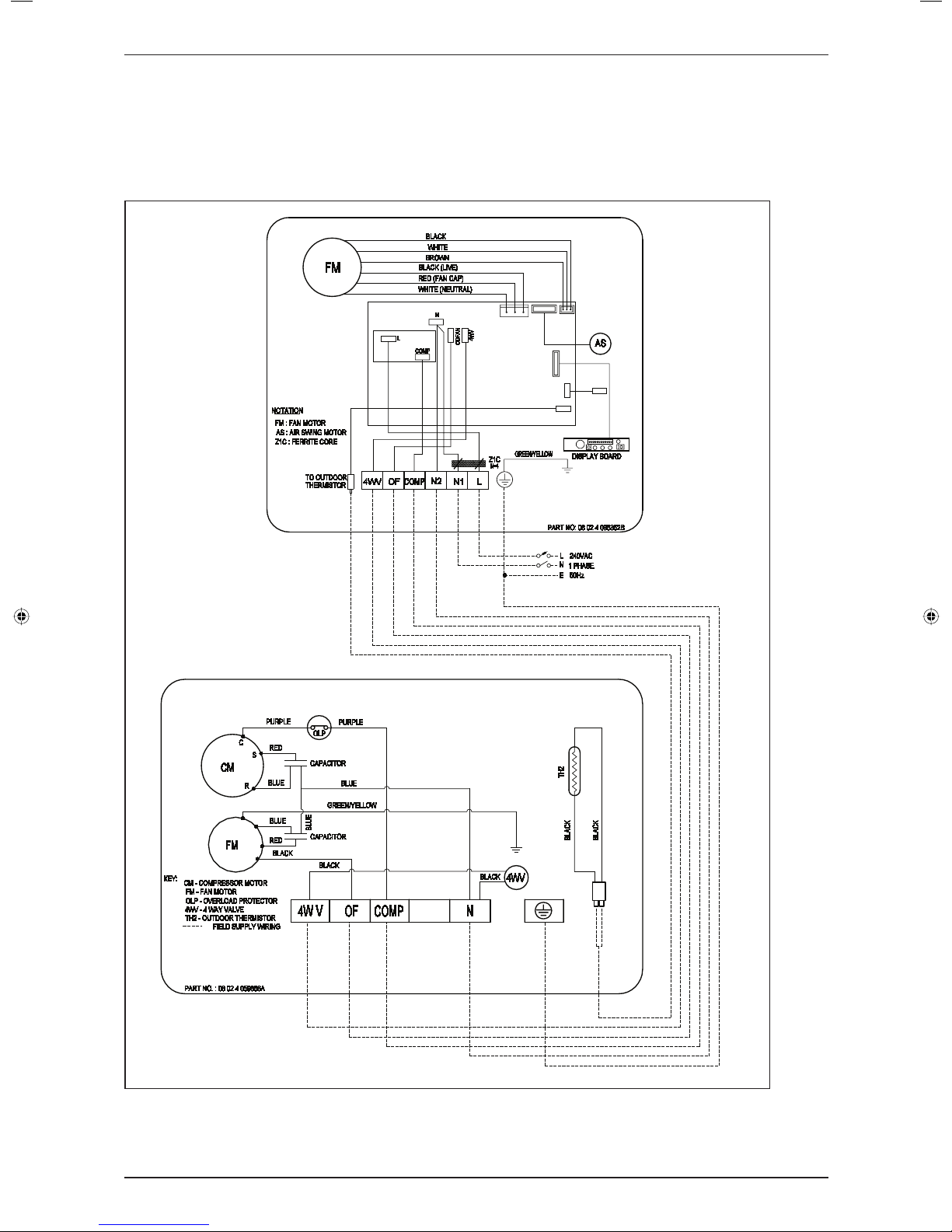

29

Engineering & Physical Data MWM-J-2009

General Data - Cooling Only (R410A)

MODEL

INDOOR UNIT M5WM010J M5WM015J

OUTDOOR UNIT M5LC010C M5LC015C

NOMINAL CAPACITY

Btu/h 9040 10750

W 2650 3150

NOMINAL TOTAL INPUT POWER

W 825 1094

NOMINAL RUNNING CURRENT A 3.70 5.10

POWER SOURCE V/Ph/Hz 220 - 240 / 1 / 50 220 - 240 / 1 / 50

EER W/W 3.21 2.88

REFRIGERANT TYPE R410A R410A

REFRIGERANT CONTROL (EXPANSION DEVICE) OUTDOOR CAP. TUBE OUTDOOR CAP. TUBE

INDOOR UNIT

CONTROL

AIR DISCHARGE

AUTO LOUVER (UP & DOWN) &

GRILLE (LEFT & RIGHT)

AUTO LOUVER (UP & DOWN) &

GRILLE (LEFT & RIGHT)

OPERATION LCD REMOTE CONTROL LCD REMOTE CONTROL

AIR FLOW

HIGH l/s / CFM 158 / 335 163 / 346

MEDIUM l/s / CFM 132 / 279 138 / 293

LOW l/s / CFM 105 / 222 113 / 240

SOUND PRESSURE LEVEL (H/M/L) dBA 38 / 32 / 27 38 / 34 / 29

UNIT DIMENSION

HEIGHT mm/in 288 / 11.3 288 / 11.3

WIDTH mm/in 800 / 31.5 800 / 31.5

DEPTH mm/in 204 / 8.0 204 / 8.0

PACKING DIMENSION

HEIGHT mm/in 350 / 13.8 350 / 13.8

WIDTH mm/in 874 / 34.4 874 / 34.4

DEPTH mm/in 280 / 11.0 280 / 11.0

UNIT WEIGHT kg/lb 12 / 26.5 12 / 26.5

CONDENSATE DRAIN SIZE mm/in 16 / 0.6 16 / 0.6

OUTDOOR UNIT

AIR FLOW l/s / CFM 396 / 840 457 / 969

SOUND PRESSURE LEVEL dBA 46 49

UNIT DIMENSION

HEIGHT mm/in 540 / 21.3 540 / 21.3

WIDTH mm/in 700 / 27.6 700 / 27.6

DEPTH mm/in 250 / 9.8 250 / 9.8

PACKING DIMENSION

HEIGHT

mm/in 620 / 24.4 620 / 24.4

WIDTH mm/in 810 / 31.9 810 / 31.9

DEPTH mm/in 330 / 13.0 330 / 13.0

UNIT WEIGHT kg/lb 34 / 75.0 34 / 75.0

PIPE CONNECTION

TYPE FLARE VALVE FLARE VALVE

SIZE

LIQUID mm/in 6.4 / 1/4 6.4 / 1/4

GAS mm/in 9.5 / 3/8 12.7 / 1/2

REFRIGERANT CHARGE kg/lb 0.80 / 1.76 0.89/1.96

1) ALL SPECIFICATIONS ARE SUBJECTED TO CHANGE BY THE MANUFACTURER WITHOUT PRIOR NOTICE.

2) ALL UNITS ARE BEING TESTED AND COMPLY TO ISO 5151.

3) NOMINAL COOLING AND HEATING CAPACITY ARE BASED ON THE CONDITIONS BELOW :

COOLING - 27°C DB / 19°C WB INDOOR AND 35°C DB / 24°C WB OUTDOOR

4) SOUND PRESSURE LEVEL ARE ACCORDING TO JIS B 8615 STANDARD. POSITION OF THE MEASUREMENT POINT IS 1m IN FRONT AND 1m

BELOW THE UNIT.

Page 33

30

MWM-J-2009 Engineering & Physical Data

General Data - Heat pump (R410A)

MODEL

INDOOR UNIT M5WM010JR M5WM015JR

OUTDOOR UNIT M5LC010CR M5LC015CR

NOMINAL COOLING CAPACITY

Btu/h 9040 10750

W 2650 3150

NOMINAL HEATING CAPACITY

Btu/h 9550 11530

W 2800 3380

NOMINAL TOTAL INPUT POWER (COOLING)

W 825 1094

NOMINAL TOTAL INPUT POWER (HEATING)

W 775 988

NOMINAL RUNNING CURRENT (COOLING)

A 3.70 5.10

NOMINAL RUNNING CURRENT (HEATING)

A 3.20 4.70

POWER SOURCE

V/Ph/Hz 220 - 240 / 1 / 50 220 - 240 / 1 / 50

EER

W/W 3.21 2.88

COP

W/W 3.61 3.42

REFRIGERANT TYPE

R410A R410A

REFRIGERANT CONTROL (EXPANSION DEVICE)

OUTDOOR CAP. TUBE OUTDOOR CAP. TUBE

INDOOR UNIT

CONTROL

AIR DISCHARGE

AUTO LOUVER (UP & DOWN) &

GRILLE (LEFT & RIGHT)

AUTO LOUVER (UP & DOWN) &

GRILLE (LEFT & RIGHT)

OPERATION LCD REMOTE CONTROL LCD REMOTE CONTROL

AIR FLOW

HIGH

l/s / CFM 158 / 335 163 / 346

MEDIUM

l/s / CFM 132 / 279 138 / 293

LOW

l/s / CFM 105 / 222 113 / 240

SOUND PRESSURE LEVEL (H/M/L)

dBA 38 / 32 / 27 38 / 34 / 29

UNIT DIMENSION

HEIGHT

mm/in 288 / 11.3 288 / 11.3

WIDTH

mm/in 800 / 31.5 800 / 31.5

DEPTH

mm/in 204 / 8.0 204 / 8.0

PACKING DIMENSION

HEIGHT

mm/in 350 / 13.8 350 / 13.8

WIDTH

mm/in 874 / 34.4 874 / 34.4

DEPTH

mm/in 280 / 11.0 280 / 11.0

UNIT WEIGHT

kg/lb 12 / 26.5 12 / 26.5

CONDENSATE DRAIN SIZE

mm/in 16 / 0.6 16 / 0.6

OUTDOOR UNIT

AIR FLOW

l/s / CFM 396 / 840 457 / 969

SOUND PRESSURE LEVEL

dBA 46 49

UNIT DIMENSION

HEIGHT

mm/in 540 / 21.3 540 / 21.3

WIDTH

mm/in 700 / 27.6 700 / 27.6

DEPTH

mm/in 250 / 9.8 250 / 9.8

PACKING DIMENSION

HEIGHT

mm/in 620 / 24.4 620 / 24.4

WIDTH

mm/in 810 / 31.9 810 / 31.9

DEPTH

mm/in 330 / 13.0 330 / 13.0

UNIT WEIGHT kg/lb 34 / 75.0 34 / 75.0

PIPE CONNECTION

TYPE

FLARE VALVE FLARE VALVE

SIZE

LIQUID

mm/in 6.4 / 1/4 6.4 / 1/4

GAS

mm/in 9.5 / 3/8 12.7 / 1/2

REFRIGERANT CHARGE

kg/lb 0.80 / 1.76 0.89 / 1.96

1) ALL SPECIFICATIONS ARE SUBJECTED TO CHANGE BY THE MANUFACTURER WITHOUT PRIOR NOTICE.

2) ALL UNITS ARE BEING TESTED AND COMPLY TO ISO 5151.

3) NOMINAL COOLING AND HEATING CAPACITY ARE BASED ON THE CONDITIONS BELOW :

a) COOLING - 27°C DB / 19°C WB INDOOR AND 35°C DB / 24°C WB OUTDOOR

b) HEATING - 20°C DB INDOOR AND 7°C DB / 6°C WB OUTDOOR

4) SOUND PRESSURE LEVEL ARE ACCORDING TO JIS B 8615 STANDARD. POSITION OF THE MEASUREMENT POINT IS 1m IN FRONT AND 1m

BELOW THE UNIT.

Page 34

31

Engineering & Physical Data MWM-J-2009

Component Data - Cooling Only (R22)

MODEL

INDOOR UNIT MWM009J MWM015J

OUTDOOR UNIT MLC009C MLC015C

INDOOR FAN

TYPE

CROSS FLOW FAN CROSS FLOW FAN

QUANTITY

11

MATERIAL

GLASS REINFORCED ACRYL

STYRENE RESIN

GLASS REINFORCED ACRYL

STYRENE RESIN

DRIVE

DIRECT DIRECT

DIAMETER

mm/in 92 / 3.6 92 / 3.6

LENGTH

mm/in 607 / 23.9 607 / 23.9

INDOOR FAN MOTOR

TYPE

INDUCTION INDUCTION

QUANTITY

11

INDEX OF PROTECTION (IP)

IP44 IP44

OUTDOOR FAN

TYPE

PROPELLER PROPELLER

QUANTITY

11

MATERIAL

GLASS REINFORCED ACRYL

STYRENE RESIN

GLASS REINFORCED ACRYL

STYRENE RESIN

DRIVE

DIRECT DIRECT

DIAMETER

mm/in 356 / 14 406 / 16

OUTDOOR FAN

MOTOR

TYPE

INDUCTION INDUCTION

QUANTITY

11

INDEX OF PROTECTION (IP)

IP24 IP24

COMPRESSOR

TYPE

ROTARY ROTARY

OIL TYPE

RB68A or FREOL ALPHA68M RB68A or FREOL ALPHA68M

OIL AMOUNT

cm

3

/ fl .oz. 350 / 12.3 430 / 15.1

INDOOR COIL

TUBE

MATERIAL

SEAMLESS INNER GROOVE

COPPER

SEAMLESS INNER GROOVE

COPPER

DIAMETER mm/in 7.00 / 0.276 7.00 / 0.276

THICKNESS mm/in 0.28 / 0.011 0.28 / 0.011

FIN

MATERIAL

ALUMINIUM (HYDROPHILIC FIN) ALUMINIUM (HYDROPHILIC FIN)

THICKNESS

mm/in 0.11 / 0.004 0.11 / 0.004

FACE AREA

m

2

/ft

2

0.18 / 1.930 0.18 / 1.930

ROW

22

FIN PER INCH

18 18

OUTDOOR COIL

TUBE

MATERIAL

SEAMLESS INNER GROOVE

COPPER

SEAMLESS INNER GROOVE

COPPER

DIAMETER

mm/in 7.00 / 0.276 7.00 / 0.276

THICKNESS

mm/in 0.24 / 0.009 0.24 / 0.009

FIN

MATERIAL

ALUMINIUM (RAISE LANCE) ALUMINIUM (RAISE LANCE)

THICKNESS

mm/in 0.10 / 0.004 0.10 / 0.004

FACE AREA

m

2

/ft

2

0.31 / 3.400 0.36 / 3.940

ROW

11

FIN PER INCH

18 20

AIR QUALITY FILTER

TYPE

MILDEW PROOF PP FILTER MILDEW PROOF PP FILTER

QUANTITY

pc 22

SIZE

LENGTH

mm/in 302 / 11.9 302 / 11.9

WIDTH

mm/in 280 / 11.0 280 / 11.0

THICKNESS

mm/in 2.0 / 0.1 2.0 / 0.1

CASING

INDOOR UNIT

MATERIAL HIGH IMPACT POLYSTYRENE HIGH IMPACT POLYSTYRENE

FINISHING MAT MAT

COLOUR WHITE WHITE

OUTDOOR UNIT

MATERIAL GALVANISED MILD STEEL GALVANISED MILD STEEL

FINISHING POLYESTER POWDER POLYESTER POWDER

COLOUR LIGHT GREY LIGHT GREY

1) ALL SPECIFICATIONS ARE SUBJECTED TO CHANGE BY THE MANUFACTURER WITHOUT PRIOR NOTICE.

Page 35

32

MWM-J-2009 Engineering & Physical Data

Component Data - Heat Pump (R22)

MODEL

INDOOR UNIT MWM009JR MWM015JR

OUTDOOR UNIT MLC009CR MLC015CR

INDOOR FAN

TYPE

CROSS FLOW FAN CROSS FLOW FAN

QUANTITY

11

MATERIAL GLASS REINFORCED ACRYL

STYRENE RESIN

GLASS REINFORCED ACRYL

STYRENE RESIN

DRIVE

DIRECT DIRECT

DIAMETER

mm/in 92 / 3.6 92 / 3.6

LENGTH

mm/in 607 / 23.9 607 / 23.9

INDOOR FAN MOTOR

TYPE

INDUCTION INDUCTION

QUANTITY

11

INDEX OF PROTECTION (IP)

IP44 IP44

OUTDOOR FAN

TYPE

PROPELLER PROPELLER

QUANTITY

11

MATERIAL GLASS REINFORCED ACRYL

STYRENE RESIN

GLASS REINFORCED ACRYL

STYRENE RESIN

DRIVE

DIRECT DIRECT

DIAMETER

mm/in 356 / 14 406 / 16

OUTDOOR FAN

MOTOR

TYPE

INDUCTION INDUCTION

QUANTITY

11

INDEX OF PROTECTION (IP)

IP24 IP24

COMPRESSOR

TYPE

ROTARY ROTARY

OIL TYPE

RB68A or FREOL ALPHA68M RB68A or FREOL ALPHA68M

OIL AMOUNT

cm

3

/ fl .oz. 350 / 12.3 430 / 15.1

INDOOR COIL

TUBE

MATERIAL SEAMLESS INNER GROOVE

COPPER

SEAMLESS INNER GROOVE

COPPER

DIAMETER

mm/in 7.00 / 0.276 7.00 / 0.276

THICKNESS

mm/in 0.28 / 0.011 0.28 / 0.011

FIN

MATERIAL

ALUMINIUM (HYDROPHILIC FIN) ALUMINIUM (HYDROPHILIC FIN)

THICKNESS

mm/in 0.11 / 0.004 0.11 / 0.004

FACE AREA

m

2

/ft

2

0.18 / 1.930 0.18 / 1.930

ROW

22

FIN PER INCH

18 18

OUTDOOR COIL

TUBE

MATERIAL

SEAMLESS INNER GROOVE

COPPER

SEAMLESS INNER GROOVE

COPPER

DIAMETER

mm/in 7.00 / 0.276 9.52 / 3/8

THICKNESS

mm/in 0.24 / 0.009 0.28 / 0.011

FIN

MATERIAL

ALUMINIUM (RAISE LANCE) ALUMINIUM (HYDROPHILIC FIN)

THICKNESS

mm/in 0.10 / 0.004 0.11 / 0.004

FACE AREA

m

2

/ft

2

0.31 / 3.400 0.36 / 3.940

ROW

11

FIN PER INCH

18 18

AIR QUALITY FILTER

TYPE

MILDEW PROOF PP FILTER MILDEW PROOF PP FILTER

QUANTITY

pc 22

SIZE

LENGTH

mm/in 302 / 11.9 302 / 11.9

WIDTH

mm/in 280 / 11.0 280 / 11.0

THICKNESS

mm/in 2.0 / 0.1 2.0 / 0.1

CASING

INDOOR UNIT

MATERIAL HIGH IMPACT POLYSTYRENE HIGH IMPACT POLYSTYRENE

FINISHING MAT MAT

COLOUR WHITE WHITE

OUTDOOR UNIT

MATERIAL GALVANISED MILD STEEL GALVANISED MILD STEEL

FINISHING POLYESTER POWDER POLYESTER POWDER

COLOUR LIGHT GREY LIGHT GREY

1) ALL SPECIFICATIONS ARE SUBJECTED TO CHANGE BY THE MANUFACTURER WITHOUT PRIOR NOTICE.

Page 36

33

Engineering & Physical Data MWM-J-2009

Component Data - Cooling Only (R410A)

MODEL

INDOOR UNIT M5WM010J M5WM015J

OUTDOOR UNIT M5LC010C M5LC015C

INDOOR FAN

TYPE

CROSS FLOW FAN CROSS FLOW FAN

QUANTITY

11

MATERIAL GLASS REINFORCED ACRYL

STYRENE RESIN

GLASS REINFORCED ACRYL

STYRENE RESIN

DRIVE

DIRECT DIRECT

DIAMETER

mm/in 92 / 3.6 92 / 3.6

LENGTH

mm/in 607 / 23.9 607 / 23.9

INDOOR FAN MOTOR

TYPE

INDUCTION INDUCTION

QUANTITY

11

INDEX OF PROTECTION (IP)

IP44 IP44

OUTDOOR FAN

TYPE

PROPELLER PROPELLER

QUANTITY

11

MATERIAL GLASS REINFORCED ACRYL

STYRENE RESIN

GLASS REINFORCED ACRYL

STYRENE RESIN

DRIVE

DIRECT DIRECT

DIAMETER

mm/in 406 / 16 406 / 16

OUTDOOR FAN

MOTOR

TYPE

INDUCTION INDUCTION

QUANTITY

11

INDEX OF PROTECTION (IP)

IP24 IP24

COMPRESSOR

TYPE

ROTARY ROTARY

OIL TYPE

RB68A or FREOL ALPHA68M RB68A or FREOL ALPHA68M

OIL AMOUNT

cm

3

/ fl .oz. 350 / 12.3 430 / 15.1

INDOOR COIL

TUBE

MATERIAL SEAMLESS INNER GROOVE

COPPER

SEAMLESS INNER GROOVE

COPPER

DIAMETER

mm/in 7.00 / 0.276 7.00 / 0.276

THICKNESS

mm/in 0.28 / 0.011 0.28 / 0.011

FIN

MATERIAL

ALUMINIUM (HYDROPHILIC FIN) ALUMINIUM (HYDROPHILIC FIN)

THICKNESS

mm/in 0.11 / 0.004 0.11 / 0.004

FACE AREA

m

2

/ft

2

0.18 / 1.930 0.18 / 1.930

ROW

22

FIN PER INCH

18 18

OUTDOOR COIL

TUBE

MATERIAL SEAMLESS INNER GROOVE

COPPER

SEAMLESS INNER GROOVE

COPPER

DIAMETER

mm/in 7.00 / 0.276 9.52 / 3/8

THICKNESS

mm/in 0.28 / 0.011 0.33 / 0.013

FIN

MATERIAL

ALUMINIUM (RAISE LANCE) ALUMINIUM (SLIT FIN)

THICKNESS

mm/in 0.10 / 0.004 0.11 / 0.004

FACE AREA

m

2

/ft

2

0.36 / 3.940 0.36 / 3.940

ROW

11

FIN PER INCH

20 18

AIR QUALITY FILTER

TYPE

MILDEW PROOF PP FILTER MILDEW PROOF PP FILTER

QUANTITY

pc 22

SIZE

LENGTH

mm/in 302 / 11.9 302 / 11.9

WIDTH

mm/in 280 / 11.0 280 / 11.0

THICKNESS

mm/in 2.0 / 0.1 2.0 / 0.1

CASING

INDOOR UNIT

MATERIAL HIGH IMPACT POLYSTYRENE HIGH IMPACT POLYSTYRENE

FINISHING MAT MAT

COLOUR WHITE WHITE

OUTDOOR UNIT

MATERIAL GALVANISED MILD STEEL GALVANISED MILD STEEL

FINISHING POLYESTER POWDER POLYESTER POWDER

COLOUR LIGHT GREY LIGHT GREY

1) ALL SPECIFICATIONS ARE SUBJECTED TO CHANGE BY THE MANUFACTURER WITHOUT PRIOR NOTICE.

Page 37

34

MWM-J-2009 Engineering & Physical Data

Component Data - Heat Pump (R410A)

MODEL

INDOOR UNIT M5WM010JR M5WM015JR

OUTDOOR UNIT M5LC010CR M5LC015CR

INDOOR FAN

TYPE

CROSS FLOW FAN CROSS FLOW FAN

QUANTITY

11

MATERIAL GLASS REINFORCED ACRYL

STYRENE RESIN

GLASS REINFORCED ACRYL

STYRENE RESIN

DRIVE

DIRECT DIRECT

DIAMETER

mm/in 92 / 3.6 92 / 3.6

LENGTH

mm/in 607 / 23.9 607 / 23.9

INDOOR FAN MOTOR

TYPE

INDUCTION INDUCTION

QUANTITY

11

INDEX OF PROTECTION (IP)

IP44 IP44

OUTDOOR FAN

TYPE

PROPELLER PROPELLER

QUANTITY

11

MATERIAL GLASS REINFORCED ACRYL

STYRENE RESIN

GLASS REINFORCED ACRYL

STYRENE RESIN

DRIVE

DIRECT DIRECT

DIAMETER

mm/in 406 / 16 406 / 16

OUTDOOR FAN

MOTOR

TYPE

INDUCTION INDUCTION

QUANTITY

11

INDEX OF PROTECTION (IP)

IP24 IP24

COMPRESSOR

TYPE

ROTARY ROTARY

OIL TYPE

RB68A or FREOL ALPHA68M RB68A or FREOL ALPHA68M

OIL AMOUNT

cm

3

/ fl .oz. 350 / 12.3 430 / 15.1

INDOOR COIL

TUBE

MATERIAL SEAMLESS INNER GROOVE

COPPER

SEAMLESS INNER GROOVE

COPPER

DIAMETER

mm/in 7.00 / 0.276 7.00 / 0.276

THICKNESS

mm/in 0.28 / 0.011 0.28 / 0.011

FIN

MATERIAL

ALUMINIUM (HYDROPHILIC FIN) ALUMINIUM (HYDROPHILIC FIN)

THICKNESS

mm/in 0.11 / 0.004 0.11 / 0.004

FACE AREA

m

2

/ft

2

0.18 / 1.930 0.18 / 1.930

ROW

22

FIN PER INCH

18 18

OUTDOOR COIL

TUBE

MATERIAL SEAMLESS INNER GROOVE

COPPER

SEAMLESS INNER GROOVE

COPPER

DIAMETER

mm/in 7.00 / 0.276 9.52 / 3/8

THICKNESS

mm/in 0.28 / 0.011 0.33 / 0.013

FIN

MATERIAL

ALUMINIUM (RAISE LANCE) ALUMINIUM (HYDROPHILIC FIN)

THICKNESS

mm/in 0.10 / 0.004 0.11 / 0.004

FACE AREA

m

2

/ft

2

0.36 / 3.940 0.36 / 3.940

ROW

11

FIN PER INCH

20 18

AIR QUALITY FILTER

TYPE

MILDEW PROOF PP FILTER MILDEW PROOF PP FILTER

QUANTITY

pc 22

SIZE

LENGTH

mm/in 302 / 11.9 302 / 11.9

WIDTH

mm/in 280 / 11.0 280 / 11.0

THICKNESS

mm/in 2.0 / 0.1 2.0 / 0.1

CASING

INDOOR UNIT

MATERIAL HIGH IMPACT POLYSTYRENE HIGH IMPACT POLYSTYRENE

FINISHING MAT MAT

COLOUR WHITE WHITE

OUTDOOR UNIT

MATERIAL GALVANISED MILD STEEL GALVANISED MILD STEEL

FINISHING POLYESTER POWDER POLYESTER POWDER

COLOUR LIGHT GREY LIGHT GREY

1) ALL SPECIFICATIONS ARE SUBJECTED TO CHANGE BY THE MANUFACTURER WITHOUT PRIOR NOTICE.

Page 38

35

Performance Data MWM-J-2009

Performance Data

Interpolation and Extrapolation method can be used to get the total capacity, TC and sensible capacity, SC at

those temperatures which are not stated out in the table.

Example:

Model: MWM009J - MLC009C

Indoor Condition: 23°C DB, 15°C WB

Outdoor Condition: 37°C DB

Solution:

Overall

Based on the Performance Table

1. Refer to the Indoor DB column,

23°C is located between 20°C and 24°C (Thus, Interpolation need to be applied)

2. Refer to the Indoor WB column,

15°C only available in the case of Indoor DB = 20°C. (Thus, Extrapolation between 16°C WB and 17°C

WB during 24°C indoor DB is required)

3. Refer to the Outdoor DB column,

37°C is located between 35°C and 40°C. (Thus, Interpolation need to be applied)

Please follow the steps below in order to get the required capacity.

1st Step

Extrapolation of Indoor WB

Find TC, SC for

(a)

Indoor: 24°C DB, 15°C WB

Outdoor: 35°C DB

(b) Indoor: 24°C DB, 15°C WB

Outdoor: 40°C DB

2nd Step

Interpolation of Indoor DB

Find TC, SC for

(a)

Indoor: 23°C DB, 15°C WB

Outdoor:

35°C DB

(b) Indoor: 23°C DB, 15°C WB

Outdoor: 40°C DB

3

rd

Step

Interpolation of Outdoor DB

Find TC, SC for

(a) Indoor: 23°C DB, 15°C WB

Outdoor: 37°C DB

-

-

-

Page 39

36

MWM-J-2009 Performance Data

Calculation Steps

Details:

1

st

Step:

To obtain the Total capacity and Sensible capacity for

(a) Indoor Condition: 24°C DB, 15°C WB

Outdoor Condition: 35°C DB

Indoor DB˚C Indoor WB˚C

Outdoor DB, ˚C

35

TC (kW) SC (kW)

........

........

24

15

...........................................

x

1

y

1

16 2.401 1.727

17 2.434 1.640

Total capacity, TC

⇒ x

1

= 2.368kW (Same as Total capacity at 20°C Indoor DB / 15°C Indoor WB & 35°C Outdoor WB)*

Sensible capacity, SC

Extrapolation Method:

⇒

17º C – 15º C

=

1.640kW – y

1

17º C – 16º C 1.640kW – 1.727kW

⇒ y

1

= 1.814kW

(b) Indoor Condition: 24°C DB, 15°C WB

Outdoor Condition: 40°C DB

Indoor DB˚C Indoor WB˚C

Outdoor DB, ˚C

40

TC (kW) SC (kW)

........

........

24

15

...........................................

x

2

y

2

16 2.174 1.538

17 2.218 1.479

Total capacity, TC

⇒ x2 = 2.131kW (Same as Total capacity at 20°C Indoor DB / 15°C Indoor WB & 40°C Outdoor WB)*

Sensible capacity, SC

Extrapolation Method:

⇒

17º C – 15º C

=

1.479kW – y

2

17º C – 16º C 1.479kW – 1.538kW

⇒ y2 = 1.597kW

* This is due to 2 different conditions with same WB temperature, will have the same level of enthalpy. For more

details, please refer to psychrometrics chart

Page 40

37

Performance Data MWM-J-2009

2nd Step:

To obtain the Total capacity and Sensible capacity for

(a) Indoor Condition: 23°C DB, 15°C WB

Outdoor Condition: 35°C DB

Indoor DB˚C Indoor WB˚C

Outdoor DB, ˚C

35

TC (kW) SC (kW)

........

........

20 15

...........................................

2.368 1.181

23 15

x

3

y

3

24 15 2.368 1.814

Total capacity, TC

⇒ x

3

= 2.368kW (Same as Total capacity at 20°C Indoor DB / 15°C Indoor WB & 35°C Outdoor WB)*

Sensible capacity, SC

Interpolation Method:

⇒

24º C – 20º C

=

1.814kW – 1.181kW

24º C – 23º C 1.814kW – y

3

⇒ y

1

= 1.656kW

(b) Indoor Condition: 23°C DB, 15°C WB

Outdoor Condition: 40°C DB

Indoor DB˚C Indoor WB˚C

Outdoor DB, ˚C

40

TC (kW) SC (kW)

........

........

20 15

...........................................

2.131 0.963

23 15

x

4

y

4

24 15 2.131 1.579

Total capacity, TC

⇒ x

4

= 2.131kW (Same as Total capacity at 20°C Indoor DB / 15°C Indoor WB & 40°C Outdoor WB)*

Sensible capacity, SC

Interpolation Method:

⇒

24º C – 20º C

=

1.597kW – 0.963kW

24º C – 23º C 1.597kW – y

4

⇒ y2 = 1.597kW

* This is due to 2 different conditions with same WB temperature, will have the same level of enthalpy. For more

details, please refer to psychrometrics chart

Page 41

38

MWM-J-2009 Performance Data

3rd Step:

To obtain the Total capacity and Sensible capacity for

(a) Indoor Condition: 23°C DB, 15°C WB

Outdoor Condition: 37°C DB

Indoor DB˚C Indoor WB˚C

Outdoor DB, ˚C

35 37 40

TC (kW) SC (kW) TC (kW) SC (kW) TC (kW) SC (kW)

........

........

........

........

........

........

23 15

......................

2.368 1.656 x y 2.131 1.439

Total capacity, TC

Interpolation Method:

⇒

40º C – 35º C

=

2.131kW – 2.368kW

40º C – 37º C 2.131kW –

χ

⇒ x = 2.273kW

Sensible capacity, SC

Interpolation Method:

⇒

40º C – 35º C

=

1.439kW – 1.656kW

40º C – 37º C 1.439kW – y

⇒ y = 1.569kW

Page 42

39

Performance Data MWM-J-2009

Cooling Only (R22)

Model: MWM009J - MLC009C

Cooling Mode

ID

DB°C

ID

WB°C

Outdoor DB°C

20 25 30 35 40 46

TC(kW) SC(kW) TC(kW) SC(kW) TC(kW) SC(kW) TC(kW) SC(kW) TC(kW) SC(kW) TC(kW) SC(kW)

20

15 3.078 1.834 2.841 1.616 2.604 1.398 2.368 1.181 2.131 0.963 1.846 0.702

16 3.080 1.661 2.853 1.472 2.627 1.283 2.401 1.094 2.174 0.905 1.903 0.678

24

16 3.080 2.294 2.853 2.105 2.627 1.916 2.401 1.727 2.174 1.538 1.903 1.311

17 3.081 2.121 2.865 1.961 2.649 1.800 2.434 1.640 2.218 1.479 1.959 1.287

18 3.082 1.949 2.877 1.817 2.672 1.685 2.467 1.553 2.261 1.421 2.015 1.263

19 3.084 1.776 2.889 1.673 2.694 1.569 2.500 1.466 2.305 1.363 2.072 1.239

20 3.085 1.602 2.904 1.521 2.722 1.439 2.541 1.357 2.359 1.275 2.141 1.177

28

18 3.082 2.582 2.877 2.450 2.672 2.318 2.467 2.186 2.261 2.054 2.015 1.896

19 3.084 2.409 2.889 2.306 2.694 2.202 2.500 2.099 2.305 1.996 2.072 1.871

20 3.085 2.235 2.904 2.154 2.722 2.072 2.541 1.990 2.359 1.908 2.141 1.810

21 3.087 2.061 2.920 1.996 2.753 1.931 2.587 1.866 2.420 1.801 2.220 1.723

22 3.089 1.887 2.937 1.839 2.785 1.791 2.633 1.742 2.481 1.694 2.298 1.636

23 3.091 1.713 2.953 1.681 2.816 1.650 2.679 1.618 2.541 1.587 2.377 1.549

24 3.092 1.539 2.970 1.524 2.847 1.509 2.725 1.495 2.602 1.480 2.455 1.462

30

20 3.085 2.552 2.904 2.470 2.722 2.388 2.541 2.306 2.359 2.224 2.141 2.126

21 3.087 2.378 2.920 2.313 2.753 2.248 2.587 2.182 2.420 2.117 2.220 2.039

22 3.089 2.204 2.937 2.155 2.785 2.107 2.633 2.059 2.481 2.010 2.298 1.952

23 3.091 2.030 2.953 1.998 2.816 1.966 2.679 1.935 2.541 1.903 2.377 1.865

24 3.092 1.855 2.970 1.841 2.847 1.826 2.725 1.811 2.602 1.796 2.455 1.778

Model: MWM015J - MLC015C

Cooling Mode

ID

DB°C

ID

WB°C

Outdoor DB°C

20 25 30 35 40 46

TC(kW) SC(kW) TC(kW) SC(kW) TC(kW) SC(kW) TC(kW) SC(kW) TC(kW) SC(kW) TC(kW) SC(kW)

20

15 3.903 2.394 3.660 2.187 3.417 1.980 3.173 1.773 2.930 1.566 2.638 1.317

16 4.018 2.181 3.768 2.001 3.518 1.820 3.268 1.640 3.018 1.459 2.719 1.243

24

16 4.018 2.868 3.768 2.688 3.518 2.507 3.268 2.327 3.018 2.146 2.719 1.930

17 4.132 2.656 3.876 2.502 3.620 2.348 3.363 2.194 3.107 2.040 2.799 1.855

18 4.247 2.444 3.984 2.316 3.721 2.189 3.458 2.061 3.195 1.933 2.880 1.780

19 4.361 2.231 4.092 2.130 3.822 2.029 3.553 1.928 3.284 1.827 2.960 1.706

20 4.476 2.019 4.204 1.939 3.932 1.859 3.659 1.779 3.387 1.699 3.060 1.603

28

18 4.247 3.130 3.984 3.003 3.721 2.875 3.458 2.748 3.195 2.620 2.880 2.467

19 4.361 2.918 4.092 2.817 3.822 2.716 3.553 2.615 3.284 2.514 2.960 2.392

20 4.476 2.705 4.204 2.625 3.932 2.545 3.659 2.466 3.387 2.386 3.060 2.290

21 4.592 2.492 4.319 2.430 4.046 2.367 3.773 2.305 3.500 2.243 3.172 2.168

22 4.707 2.279 4.433 2.234 4.160 2.190 3.886 2.145 3.612 2.100 3.284 2.047

23 4.822 2.065 4.548 2.038 4.274 2.012 4.000 1.985 3.725 1.958 3.396 1.925

24 4.937 1.852 4.663 1.843 4.388 1.834 4.113 1.824 3.838 1.815 3.508 1.804

30

20 4.476 3.049 4.204 2.969 3.932 2.889 3.659 2.809 3.387 2.729 3.060 2.633

21 4.592 2.835 4.319 2.773 4.046 2.711 3.773 2.649 3.500 2.586 3.172 2.512

22 4.707 2.622 4.433 2.577 4.160 2.533 3.886 2.488 3.612 2.444 3.284 2.390

23 4.822 2.409 4.548 2.382 4.274 2.355 4.000 2.328 3.725 2.301 3.396 2.269

24 4.937 2.195 4.663 2.186 4.388 2.177 4.113 2.168 3.838 2.158 3.508 2.147

Page 43

40

MWM-J-2009 Performance Data

Heat Pump (R22)

Model: MWM009JR - MLC009CR

Cooling Mode

ID

DB°C

ID

WB°C

Outdoor DB°C

20 25 30 35 40 46

TC(kW) SC(kW) TC(kW) SC(kW) TC(kW) SC(kW) TC(kW) SC(kW) TC(kW) SC(kW) TC(kW) SC(kW)

20

15 3.078 1.834 2.841 1.616 2.604 1.398 2.368 1.181 2.131 0.963 1.846 0.702

16 3.080 1.661 2.853 1.472 2.627 1.283 2.401 1.094 2.174 0.905 1.903 0.678

24

16 3.080 2.294 2.853 2.105 2.627 1.916 2.401 1.727 2.174 1.538 1.903 1.311

17 3.081 2.121 2.865 1.961 2.649 1.800 2.434 1.640 2.218 1.479 1.959 1.287

18 3.082 1.949 2.877 1.817 2.672 1.685 2.467 1.553 2.261 1.421 2.015 1.263

19 3.084 1.776 2.889 1.673 2.694 1.569 2.500 1.466 2.305 1.363 2.072 1.239

20 3.085 1.602 2.904 1.521 2.722 1.439 2.541 1.357 2.359 1.275 2.141 1.177

28

18 3.082 2.582 2.877 2.450 2.672 2.318 2.467 2.186 2.261 2.054 2.015 1.896

19 3.084 2.409 2.889 2.306 2.694 2.202 2.500 2.099 2.305 1.996 2.072 1.871

20 3.085 2.235 2.904 2.154 2.722 2.072 2.541 1.990 2.359 1.908 2.141 1.810

21 3.087 2.061 2.920 1.996 2.753 1.931 2.587 1.866 2.420 1.801 2.220 1.723

22 3.089 1.887 2.937 1.839 2.785 1.791 2.633 1.742 2.481 1.694 2.298 1.636

23 3.091 1.713 2.953 1.681 2.816 1.650 2.679 1.618 2.541 1.587 2.377 1.549

24 3.092 1.539 2.970 1.524 2.847 1.509 2.725 1.495 2.602 1.480 2.455 1.462

30

20 3.085 2.552 2.904 2.470 2.722 2.388 2.541 2.306 2.359 2.224 2.141 2.126

21 3.087 2.378 2.920 2.313 2.753 2.248 2.587 2.182 2.420 2.117 2.220 2.039

22 3.089 2.204 2.937 2.155 2.785 2.107 2.633 2.059 2.481 2.010 2.298 1.952

23 3.091 2.030 2.953 1.998 2.816 1.966 2.679 1.935 2.541 1.903 2.377 1.865

24 3.092 1.855 2.970 1.841 2.847 1.826 2.725 1.811 2.602 1.796 2.455 1.778

Model: MWM009JR - MLC009CR

Heating Mode

ID

WB°C

Outdoor WB°C

-9 -6 -5 6 12 15 18

TC(kW) SC(kW) TC(kW) SC(kW) TC(kW) SC(kW) TC(kW) SC(kW) TC(kW) SC(kW) TC(kW) SC(kW) TC(kW) SC(kW)

15 1.169 1.169 1.441 1.441 1.532 1.532 2.528 2.528 3.071 3.071 3.343 3.343 3.615 3.615

17 1.145 1.145 1.414 1.414 1.503 1.503 2.523 2.523 2.988 2.988 3.250 3.250 3.512 3.512

19 1.122 1.122 1.386 1.386 1.474 1.474 2.517 2.517 2.904 2.904 3.157 3.157 3.409 3.409

21 1.098 1.098 1.359 1.359 1.445 1.445 2.512 2.512 2.821 2.821 3.064 3.064 3.306 3.306

23 1.090 1.090 1.335 1.335 1.417 1.417 2.386 2.386 2.737 2.737 2.971 2.971 3.204 3.204

25 1.083 1.083 1.312 1.312 1.388 1.388 2.260 2.260 2.654 2.654 2.877 2.877 3.101 3.101

27 1.076 1.076 1.288 1.288 1.359 1.359 2.134 2.134 2.571 2.571 2.784 2.784 2.998 2.998

FROST REGION

Page 44

41

Performance Data MWM-J-2009

Heat Pump (R22)

Model: MWM015JR - MLC015CR

Cooling Mode

ID

DB°C

ID

WB°C

Outdoor DB°C

20 25 30 35 40 46

TC(kW) SC(kW) TC(kW) SC(kW) TC(kW) SC(kW) TC(kW) SC(kW) TC(kW) SC(kW) TC(kW) SC(kW)

20

15 3.942 2.453 3.679 2.228 3.416 2.002 3.153 1.777 2.890 1.552 2.574 1.282

16 4.062 2.263 3.787 2.061 3.513 1.859 3.239 1.657 2.965 1.454 2.635 1.212

24

16 4.062 2.949 3.787 2.747 3.513 2.545 3.239 2.342 2.965 2.140 2.635 1.898

17 4.182 2.759 3.896 2.580 3.610 2.401 3.325 2.222 3.039 2.043 2.696 1.828

18 4.302 2.570 4.005 2.413 3.708 2.257 3.411 2.101 3.114 1.945 2.757 1.758

19 4.422 2.380 4.113 2.247 3.805 2.114 3.497 1.981 3.188 1.847 2.818 1.688

20 4.543 2.190 4.231 2.075 3.919 1.961 3.608 1.846 3.296 1.732 2.922 1.594

28

18 4.302 3.255 4.005 3.099 3.708 2.943 3.411 2.787 3.114 2.631 2.757 2.444

19 4.422 3.066 4.113 2.933 3.805 2.800 3.497 2.666 3.188 2.533 2.818 2.374

20 4.543 2.876 4.231 2.761 3.919 2.647 3.608 2.532 3.296 2.417 2.922 2.280

21 4.664 2.685 4.355 2.586 4.045 2.487 3.735 2.388 3.426 2.289 3.054 2.170

22 4.786 2.495 4.478 2.411 4.171 2.328 3.863 2.244 3.555 2.161 3.186 2.061

23 4.908 2.304 4.602 2.236 4.296 2.168 3.990 2.101 3.685 2.033 3.318 1.952

24 5.029 2.114 4.725 2.061 4.422 2.009 4.118 1.957 3.814 1.905 3.450 1.842

30

20 4.543 3.219 4.231 3.104 3.919 2.989 3.608 2.875 3.296 2.760 2.922 2.623

21 4.664 3.028 4.355 2.929 4.045 2.830 3.735 2.731 3.426 2.632 3.054 2.513

22 4.786 2.838 4.478 2.754 4.171 2.671 3.863 2.587 3.555 2.504 3.186 2.404

23 4.908 2.647 4.602 2.579 4.296 2.511 3.990 2.444 3.685 2.376 3.318 2.295

24 5.029 2.456 4.725 2.404 4.422 2.352 4.118 2.300 3.814 2.248 3.450 2.185

Model: MWM015JR - MLC015CR

Heating Mode

ID

WB°C

Outdoor WB°C

-9 -6 -5 6 12 15 18

TC(kW) SC(kW) TC(kW) SC(kW) TC(kW) SC(kW) TC(kW) SC(kW) TC(kW) SC(kW) TC(kW) SC(kW) TC(kW) SC(kW)

15 1.684 1.684 2.074 2.074 2.204 2.204 3.634 3.634 4.414 4.414 4.804 4.804 5.194 5.194

17 1.650 1.650 2.034 2.034 2.162 2.162 3.632 3.632 4.294 4.294 4.670 4.670 5.046 5.046