Page 1

Catalog 1112-2

Enfinity™ Large Horizontal Water Source Heat Pumps

with R-410A Refrigerant

Horizontal Models CCH Standard Range & CCW Geothermal Range

Unit Sizes 072 – 120 (6 to 10 Tons) • R-410A Refrigerant

Engineered for exibility and performance™

Page 2

Table of Contents

Introduction

........................................................................3

Nomenclature.....................................................................3

Features & Options ............................................................4-5

Control Features

Control Features ............................................................6

.................................................................6-9

MicroTech III Controller ..................................................7

I/O Expansion Module ....................................................8

MicroTech III Controller with Communication Module ....9

Applications ....................................................................10-14

Unit Location ................................................................10

Ductwork & Attenuation ................................................11

Typical Cooling and Heating Refrigeration Cycles .......12

Systems ..................................................................13-14

I

SO Performance Data .....................................................15

Water Loop ...................................................................15

Ground Loop ................................................................15

Ground Source .............................................................15

Heating & Cooling Capacity Data

Large Horizontal Unit .................................................16-21

Cooling Size 072 @ 2400 SCFM .................................16

Heating Size 072 @ 2400 SCFM .................................17

Cooling Size 096 @ 3000 SCFM .................................18

Heating Size 096 @ 3000 SCFM .................................19

Cooling Size 120 @ 4000 SCFM .................................20

Heating Size 120 @ 4000 SCFM .................................21

Operating Limits

Correction Factors

..............................................................23

..........................................................24

Airow Correction Factors ............................................24

Anitfreeze Correction Factors ......................................24

Performance Data - Fan Curves .....................................25

Size 072, 096 & 120 .....................................................25

Dimensional Data .......................................................26-28

Size 072 .......................................................................26

Size 096 .......................................................................27

Size 120 .......................................................................28

Accessories ................................................................29-34

Hanger Brackets ..........................................................29

Supply and Return Hoses ............................................29

Condensate Hose Kit ...................................................29

Combination Balancing & Shutoff (Ball) Valves ...........30

Motorized Valve ............................................................30

Multiple Unit Control Panel (MUCP).............................30

Thermostats and Wall Sensors ...............................31-32

Control Connection Diagrams .................................33-34

Typical Wiring Diagrams

............................................35-37

MicroTech III Controller with I/O Expansion Module &

Communication Module – 208/230V, 460V, 575V-60-3

Unit Sizes 096-120 .......................................................35

MicroTech™ III Controller with I/O Expansion Module &

Communication Module 208/230V, 460V, 575V-60-3

1.5 HP Motor ................................................................36

Electrical & Physical Data...............................................22

“McQuay” is a registered trademark of McQuay International.

©McQuay International 2009. All rights reserved throughout the world.

The information in this manual supersedes and replaces previous catalogues with regards to McQuay Water Source Heat Pump products.

Illustrations cover the general appearance of McQuay International products at the time of publication and McQuay International reserves the

right to make changes in design and construction at anytime without notice.

™®The following are trademarks or registered trademarks of their respective companies: LonTalk from Echelon Corporation, BACnet from ASHRAE, Protocol

Selectability, and MicroTech II from McQuay International.

Engineering Guide Specications

............................37-39

Page 2 of 42 McQuay Large Horizontal Water Source Heat Pumps Catalog 1112-2

Page 3

Introduction

Large Horizontal Water Source Heat

Pumps - Models CCH & CCW

Sizes 072-120 (6 to 10 Tons)

Model CCH (Standard Range: 55°F to 110°F)

Model CCW (Geothermal Range: 30°F to 110°F)

McQuay 6- to 10-ton horizontal units have a common

cabinet size and common water, condensate, and duct con-

nection locations for easier and more efcient installation.

The cabinet is constructed of unpainted, G-60 galva-

nized steel. Large panels provide access to the fan/motor

compartment and the compressor/control compartment.

The interiors of the top and side panels and the bottom of

the unit are covered with 1/2" thick, 1½ lb. dual-density

berglass insulation. The lter is supported by a factorymounted combination lter rack and return air duct collar,

eliminating the need for eld-mounted brackets.

The water and condensate connections protrude through

the outside of the cabinet. The water connections are FPT

type for easy connection to exible stainless steel hoses.

The large condensate connection provides effective conden-

sate removal.

The electrical components are located in the compressor

section of the unit. Holes are provided on the cabinet to facilitate main power and low voltage control wiring through

separate holes. All wiring connections are made internal to

the cabinet for maximum safety. Each unit is rated to accept

time delay fuses for branch circuit and is protected by a

resettable circuit breaker.

The standard control for all large capacity units is the

MicroTech™ III unit controller. The unit controller receives

its power from the 75VA control transformer.

A LonWorks® or BACnet® communication module is

available as an option.

Nomenclature

W CCH 1 120 B L Y S Y Y F

Product Category

W = WSHP

Product Identier

CCH = Large Horizontal - Standard Range

CCW = Large Horizontal - Geothermal

Design Series

1 = A Design 4 = D Design

2 = B Design 5 = E Design

3 = C Design

Nominal Capacity

072 = 72,000 BTU/h

096 = 96,000 BTU/h

120 = 120,000 BTU/h

Controls

B = MicroTech III

A = DDC Less Board

Network Module Option

L = LonWorks® Module

B = BACnet® Module

Y = None

Note: For illustration purposes only. Not all options available with all models.

Please consult McQuay Sales Representative for specic availability.

Voltage

D = 208-60-3

F = 208/230-60-3

H = 230-60-3

K = 460-60-3

L = 575-60-3

N = 380-50-3

Reserved

Y = None

Reserved

Y = None

Condensate Overow

S = Standard Overow

Sensor

Current Sensing

Y = None

Catalog 1112-2 McQuay Large Horizontal Water Source Heat Pumps Page 3 of 42

Page 4

CCH & CCW Features and Options

MicroTech® III Controller

Schrader Connections

L

onWorks®

Communication

Module

I/O Expansion Module

BACnet®

Communication

Module

Enfinity Large Horizontal Water

Source Heat Pumps

Sizes 072 - 120 (6 to 10 Tons)

Model CCH (Standard Range: 55°F to 110°F)

Model CCW (Geothermal Range: 30°F to 110°F)

1. Cabinet - Heavy gauge G-60 galvanized steel.

2. Fan Section - A forward curved, DWDI fan, solid steel shaft

mounted in ball bearings. Motor to be three phase,

Open- Drip Proof (ODP) type with variable pitch sheave

and adjustable base.

3. Insulation - All interior framework and panels are lined with

1/2" thick, 1½ lb. dual-density berglass insulation. Optional

(IAQ) closed-cell foam insulation.

4. Drain Pan - Heavy-gauge, insulated, galvanized steel or op-

tional stainless steel.

5. Filters - Standard 2" factory-installed lter rack with 2" throw-

away lters. Filter rack outtted with duct collar.

6. Refrigerant Circuit - All units have a dual refrigerant circuit

with scroll compressors, thermal expansion valve, plate to

plate heat exchanger, nned tube airside coil, reversing valve

and service valves.

LED Annunciators

7. Electrical - The control enclosure includes components neces-

sary for proper unit operation. These components include,

but not limited to: fan relay, compressor contactors, 24 VAC

control transformer and control circuit boards.

8. Schrader Connections - Four Schrader valves are located in-

side the end access panel – one on the low side and one on the

high side of the refrigeration circuit – for charging and servic-

ing. All valves

are 7/16" SAE ttings.

9. MicroTech® III Controllers – Designed for exibility, the control

board is used in standalone applications in conjunction with

the I/O expansion module for control of the second refrigerant

circuit. A separate L

onWorks® or BACnet® communication

module can be easily snapped onto the Microtech III board to

allow communication with a building automation system. The

control system accomodates the use of a two-stage heat/two-

stage cool 7-day programmable or non-programmable wall-

mounted thermostat, offered as a eld-installed option.

10. LED Annunciators – External LED status lights display fault

conditions to provide easy troubleshooting and diagnosis, vis-

ible without removing the access panel.

11. External Pipe Connections – Supply and return pipe connec-

tions located outside the cabinet make pipe connections easy

without removing access panels.

Safety Controls (Not Shown) - Low and high refrigerant pres-

sure switches and low refrigerant suction temperature

(freezestat) sensor.

Page 4 of 42 McQuay Large Horizontal Water Source Heat Pumps Catalog 1112-2

Page 5

CCH & CCW Features and Options

Cabinet Construction

McQuay 6- to 10-ton horizontal units have a common

cabinet size and common water, condensate, and duct connec-

tion locations for easier and more efcient installation.

The cabinet is constructed of heavy-gauge G-60 galva-

nized steel. Large panels provide access to the fan/motor

compartment and the compressor/control compartment. The

interiors of the top and side panels and the bottom of the unit

are covered with 1/2" thick, 1½ lb. dual-density berglass

insulation. Closed-cell foam (IAQ) insulation is available as

a selectable option, suitable for berglass-free applications.

The lter is supported by a factory-mounted combination lter

rack and return air duct collar, eliminating the need for eldmounted brackets.

The water and condensate connections protrude through

the outside of the cabinet. The water connections are FPT type

for easy connection to exible hoses. The large condensate

connection provides effective condensate removal.

The electrical components are located in the compres-

sor section of the unit. Holes are provided on the cabinet to

facilitate main power and low voltage control wiring through

separate holes. All wiring connections are made internal to the

cabinet for maximum safety. Each unit is rated to accept time

delay fuses for branch circuit and is protected by a resettable

circuit breaker.

Figure 1: Controls and Compressor Compartment

Extended range units include coil and piping insulation to

protect against condensation in low temperature geothermal

applications.

Safety controls include low suction temperature (freez-

stat) and high pressure switches to lock out compressor

operation at extreme conditions. The safety controls can

only be reset from the main disconnect switch - not from

the wall thermostat.

For additional safety, each unit has a 7 psi (48 kPa) low

pressure switch to protect the compressor from low refrig-

erant charge. The low setting prevents nuisance trips while

providing adequate protection.

Figure 2: Piping Compartment

Thermal Expansion Valve

Units include a Thermal Expansion Valve (TXV) for

refrigerant metering. The TXV allows the unit to operate at

optimum efciency with uid temperatures ranging from

25ºF to 110ºF (geothermal capable units only) and entering

air temperatures ranging from 40ºF to 90ºF. The TXV pre-

cisely meters the exact amount of refrigerant ow through

the system to meet the load and deliver rated heating and

cooling capacity.

Fan Section

The fan section includes the fan housing, fan wheel, fan

motor, adjustable sheave, high strength V-belt, and drain

pan. The standard drain pan is made of G-60 galvanized

Refrigeration System

Units have a dual circuit design and the two circuits

operate independently to enable load shedding when condi-

tions allow. Each circuit employs a random start feature to

prevent both compressors from energizing simultaneously

after an “unoccupied” cycle.

Units contain two of each refrigerant system compo-

nent, including high efciency compressors, plate-to-plate

heat exchangers, reversing valves, expansion valves,

high/low side refrigerant service valves, and required safety

controls. Large access panels are provided for easy service

access to any of these components.

The reversing valves are energized in the heating mode

and will “fail-safe” to the cooling mode, which is the pre-

dominant mode of operation.

The air-to-refrigerant coil is a dual circuit coil on one

slab. It is split equally along the horizontal axis for maxi-

mum efciency. The ns are lanced and the tubes have

nned edges on the inside to enhance heat transfer capabilities.

Catalog 1112-2 McQuay Large Horizontal Water Source Heat Pumps Page 5 of 42

steel and is insulated from the cabinet. A stainless steel

drain pan is available as an option. The pan has ample

height to allow self-priming of the condensate trap. The

fan motor is a single speed, high efciency PSC type with

an adjustable sheave for eld adjustment. The motor is iso-

lated from the fan housing to minimize vibration transmis-

sion to the cabinet. The fan housing protrudes through the

cabinet to provide adequate material to connect to a eldprovided exible duct collar. The fan discharge can exit

from the end or the side of the unit and must be congured

at the factory.

Optional Factory Installed Features

Geothermal range units are available for applications

requiring heating operation at reduced entering condi-

tions. The geothermal range unit will operate at 25ºF (5ºC)

minimum entering water temperature, 40ºF (5ºC) minimum

entering air temperature.

Page 6

Control Options – Control Choices And Added Functionality

The control enclosure houses the major operating electri-

cal controls including the MicroTech® III controller and I/O

expansion module, control transformer, compressor relays

and fan relay. Each component is easily accessed for service

or replacement.

Three unique control choices are offered with the Micro-

Tech III control system:

■ Standalone operation using a MicroTech III controller and

I/O expansion module

■ MicroTech III controller and I/O expansion module with a

LonWorks® communication module

■ MicroTech III controller and I/O expansion module with a

BACnet® communication module

Each option features direct quick-connect wiring to all

unit-controlled components for “clean” wiring inside the

control box. Each control circuit board receives power from

a 75 VA transformer.

Table 1: Control Options

Control Description Application Protocol

MicroTech III

(Standalone)

The MicroTech III controller is a standalone microprocessor-based control

board conveniently located in the unit

control enclosure for easy accessibility.

The board is designed to provide thermostat control of a Water Source Heat

Pump using a two-stage wall thermostat. The unit controller provides unitwide control of the WSHP and control

of the rst refrigerant circuit.

Each unit controller is factory programmed, wired,

and tested for complete control of single zone, standalone operation of your McQuay Water Source Heat

Pump.

Unit Controller

with

I/O Expansion

Module

The I/O Expansion Module is an extension of the Microtech III controller and

provides control of the second refriger-

ant circuit. External LED status lights

display fault conditions to provide easy

troubleshooting and diagnosis of the

second circuit.

Allows for:

• Control of second refrigeration circuit.

Uni t-mounted

or wall-mounted

thermostat

Wal l-mount ed

the rmostat or

sensor

LonWorks

Communication

Module

BACnet

Communication

Module

Page 6 of 42 McQuay Large Horizontal Water Source Heat Pumps Catalog 1112-2

The MicroTech III control system

accepts a plug-in LonWorks commu-

nication module to provide network

communications and added functional-

ity to easily integrate with an existing

BAS. The communication module can

be factory- or field-installed and is

tested with all logic required to monitor

and control the unit.

The MicroTech III controller accepts

a plug-in BACnet communication

module to provide network commu-

nications and added functionality to

easily integrate with an existing BAS.

The communication module can be

factory- or eld-installed and is tested

with all logic required to monitor and

control the unit.

Designed to be linked with a centralized building

automation system (BAS) through a L

munications network for centralized scheduling and

management of multiple heat pumps.

Designed to be linked with a centralized building

automation system (BAS) through a BACnet communications network for centralized scheduling and

management of multiple heat pumps.

onWorks com-

L o nMa rk 3 .4

certied

BACnet

MS/TP

Page 7

Control Features – MicroTech® III Unit Controller

The MicroTech III Controller is a microprocessor-based

control board conveniently located in the unit control box for

easy access through a removable access panel. The standalone

unit controller is a hard wired interface and provides all the

necessary eld connections. The board can be wired for 24volt AC output to the wall thermostat by using terminals R

& C. An LED annunciator is located on the front of the unit

chassis to allow quick check of the unit operating status.

MicroTech III Operating Features

Assumes cycle fan operation-not continuous fan operation:

■ Start-up – The unit will not operate until all the inputs

and safety controls are checked for normal conditions.

■ Cooling mode – On a call for cooling from the wall ther-

mostat, the controller will energize the fan relay and stage

compressors to satisfy the space temperature setpoint.

When the load is satised, the controller will disable the

compressor and fan.

■ Heating Mode – On a call for heating from the wall

thermostat, the controller will enable the fan, energize

circuit one reversing valve and circuit 1 compressor to

satisfy the space heating setpoint. If the space temperature

setpoint is not satiseld, circuit two reversing valve and

circuit 2 compressor will be energized and run until the

heating setpoint at the thermostat is satised.

■ Random Start Power-up Delay Timer – In the event of

a building power outage, this feature prevents multiple

units from starting simultaneously upon building power

restoration.

■ Unoccupied Mode – A simple “grounded” signal between

terminals U and C (no power source required), puts the

unit into the unoccupied mode for night setback operation.

■ Interstaging Timer – A default value of 5 minutes be-

tween staging of compressors, this feature minimizes short

cycling of compressors and improves comfort.

■ Override Mode – A switch on the deluxe automatic

changeover thermostat can be activated during the unoc-

cupied mode to put the unit back into the occupied mode

for two hours for after-hours heating or cooling.

■ Motorized Valve/Pump Restart – The IV/PR (H8) ter-

minals on the The MicroTech III unit controller are used

to energize (open) a motorized valve or start a water pump

to get water circulating prior to starting the compressor on

call for heating or cooling. The IV/PR (H8) terminal may

be “daisy chained” between a maximum of 200 units.

■ Brownout Protection – The MicroTech III unit controller

measures the input voltage and will suspend compres-

sor and fan operation if the voltage falls below 80% of

the unit nameplate rated value. A unique LED status is

generated.

■ Unit Shutdown – A simple grounded signal puts the unit

into the shutdown mode. Compressor and fan operations

are suspended. A unique LED status is generated.

■ Condensate Overow Protection – The MicroTech III

controller incorporates a liquid sensor at the top of the

drain pan. Upon sensing water ow, cooling operation is

suspended. A unique LED status is generated.

■ Remote Reset of Automatic Lockouts – The Remote

Reset feature provides the means to remotely reset auto-

matic lockouts generated by high-pressure and/or lowtemperature faults. When the MicroTech III controller is

in automatic lockout due to one of these faults, and the

cause of the fault condition has been alleviated, energizing the O-terminal for 10 seconds or more will force the

control board to clear the lockout. A unit power cycle can

also be used to clear an automatic lockout if the conditions

causing the fault have been alleviated.

■ Intelligent Reset – The Fault Retry feature helps to

minimize nuisance trips of automatic lockouts caused by

high-pressure and/or low-temperature faults. This feature

clears faults the rst two times they occur within a 24-hour

period and triggers an automatic lockout on the 3rd fault.

The retry count is reset to zero every 24 hours.

■ Equipment Protection Control – The MicroTech III

controller receives separate input signals from the refrigerant high-pressure switch and the low suction line tem-

perature sensor. In a high-pressure situation, compressor

operation is suspended. In a low temperature situation,

the unit goes into a defrost cycle where the unit is put

into cooling operation for 60 seconds until the coaxial

heat exchanger is free of ice. Each switch generates its

own unique LED status.

Note: Most unit fault conditions are the result of operating

the equipment outside the unit specications.

Table 2: MicroTech III Controller LED & Fault Outputs

Mode / Fault

Occupied, Bypass,

Standby, or Tenant Off On Off Energized

Override

Unoccupied On On Off Energized

Condensate Overow On Off Off De-energized

High Pressure 1 Fault Off Off Flash De-energized

Low Pressure 1 Fault Off Off On De-energized

Low Temperature 1 Fault Flash Off Off De-energized

Brownout

Emergency Shutdown Off Flash Off De-energized

Room/Return Air or Low

Temp Sensor 1 Failure

Service Test Mode

Enabled

Serial EEPROM

Corrupted

Network “Ofine”

Received

1

Compressor relay/compressor terminal is labeled COMP, switched line of

the same electric input as any of the L1 terminals.

Status LED’s

1

Yellow Green Red Output-Terminal “A”

Off Flash Off De-energized

Flash Flash On De-energized

Flash Flash Flash De-energized

On On On De-energized

Off Off Off De-energized

Thermostat Alarm Light

Catalog 1112-2 McQuay Large Horizontal Water Source Heat Pumps Page 7 of 42

Page 8

Control Features – MicroTech III with I/O Expansion Module

I/O Expansion Module

The I/O Expansion Module is factory-installed for control

of the second refrigeration circuit.

The I/O Expansion Module has an independent LED an-

nunciator to identify operational fault conditions for the

second refrigeration circuit.

Table 3: I/O Expansion Module LED & Fault

Outputs

Terminal “A”

Invalid Conguration

Jumper Setting

Base Board

Communication Fail

High Pressure #2 Fault Off Off Flash De-energized

Low Pressure #2 Fault Off Off On De-energized

Unoccupied Mode On On Off Energized

Occupied, Bypass,

Standby, or Tenant

Override Modes

Note: Mode / Faults are listed in order of priority.

1

2

Mode / Fault

Low Suction Temp #2 Fault Flash Off Off De-energized

Sensor Failures Low Suction

Low Suction Temp #2, Flash Flash On De-energized

1

EWT (w/ Boilerless EH only)

2

Service Test Mode Enabled Flash Flash Flash De-energized

Normal Operation Off On Off De-energized

Boilerless electric heat only

Alarm/fault LED indications take precedence over service test mode LED

indication. The controller shall use service test mode if the service test

mode jumper is installed, even if the LED’s indicate an alarm/fault.

Yellow Green Red

Status LED's

Flash Flash Off De-energized

Off Flash Flash N/A

Off On Off Energized

Thermostat Alarm

Light Output

Figure 3: I/O Expansion Module Conguration

Jumper Terminals

Jumper Terminals

JP1 shorted in units with

2 compressors

JP1 through JP8 not

used with 2 circuit units.

Page 8 of 42 McQuay Large Horizontal Water Source Heat Pumps Catalog 1112-2

Page 9

Control Features – MicroTech III with Communication Module

MicroTech® III Controller with LonWorks® or

BACnet Communication Module

Each Ennity Large Vertical and Horizontal Water

Source Heat Pump can be equipped with a LonWorks or

BACnet communication module. The LonWorks module is

LonMark 3.4 certied and designed to communicate over a

LonWorks communications network to a Building Auto-

mation System (BAS). The BACnet module is designed to

communicate over a BACnet MS/TP communications net-

work to a building automation system. Both controllers are

microprocessor-based and can be factory or eld-installed.

The control modules are programmed and tested with all

the logic required to monitor and control the unit. Optional

wall sensors may be used with the communication modules

to provide limited local control of the Horizontal Water

Source Heat Pump. The MicroTech III controller monitors

water and air temperatures and passes information to the

communication module. The module communicates with

the BAS, to provide network control of the Water Source

Heat Pump.

MicroTech III LonWorks Communication Module

The LonWorks communication module is designed for

units that are integrated into a LonWorks communication

network for centralized scheduling and management of

multiple heat pumps.

MicroTech III Controller with Communication Modules

Features

The MicroTech III Controller with LonWorks or BACnet

Communication Module orchestrates the following unit

operations:

Enable heating and cooling to maintain space

temperature setpoint based on a room sensor setting

Enable fan and compressor operation

Monitors all equipment protection controls

Monitors room and discharge air temperatures

Monitors leaving water temperature

Relays status of all vital unit functions

An amber, on-board status LED indicates the status of the

MicroTech III LonWorks or BACnet module.

The MicroTech III Controller Includes:

A unit-mounted return air sensor

A unit-mounted discharge air sensor

A leaving water temperature sensor

The communication modules provide network access to

setpoints for operational control

Available Wall Sensors Include:

Room sensor

MicroTech III BACnet Communication Module

Designed to be linked with a centralized building auto-

mation system (BAS) through a BACnet communications

network for centralized scheduling and management of

multiple heat pumps.

Room sensor with LED status and tenant override

button

Temperature sensor with LED status, timed-override

button, and ±3°F setpoint adjustment

Room sensor with LED status, timed-override

button, 55° to 90°F setpoint adjustment

Catalog 1112-2 McQuay Large Horizontal Water Source Heat Pumps Page 9 of 42

Page 10

Applications

Typical Horizontal Unit Installation

Unit Location

It is important to leave enough space for service person-

nel to perform maintenance or repair. Locate the horizon-

tal unit to allow for easy removal of the lter and access

panels. Allow a minimum of 18" (46 cm) clearance on each

side of the unit for service and maintenance access and

do not install the unit above any piping. Always be sure

to leave at least one side of the lter rack unobstructed so

that the service personnel will be able to slide the lter out.

Each unit is suspended from the ceiling by four 3/8" thread-

ed rods fastened to the unit by a hanger bracket and rubber

isolator. The design should place the unit directly below the

structural members so that it is securely anchored.

Avoid installing units directly above spaces where

building occupants will reside (e.g. above ofce desks or

classrooms) to reduce the requirement for noise attenuation.

Do not place units above high trafc areas because service

access may be limited during occupied hours. For example,

units are typically installed above the hallway drop ceiling

in Schools and the supply and return air is routed directly

into classrooms. Local code may require re dampers to be

used with this application.

Piping

The WSHP unit is typically connected to the supply/return piping using a “reverse return” piping system which

includes a ow control device so that ow requirements are

met for each zone. A short, high pressure “exible hose” is

used to connect the unit to the building’s hard piping and

Figure 4: Typical Ceiling Installation

acts as a sound attenuator for both the unit operating noise

and hydraulic pumping noise. One end of the hose has a

swivel tting to facilitate removal of the unit for replace-

ment or service. Include supply and return shutoff valves

in the design to allow removal of a unit without the need to

shut down the entire heat pump system. The return valve

may be used for balancing and will typically have a “memory stop” so that it can be reopened to the proper position

for the ow required. Fixed ow devices are commercially

available and can be installed to eliminate the need for

memory stop shut off valves. Include Pressure / Temperature ports to allow the service technician to measure water

ow and unit operation.

Condensate Drain Piping

Condensate piping can be made of steel, copper or PVC

pipe. In most cases, PVC pipe eliminates the need to wrap

insulation around the pipe to prevent sweating. A threaded,

factory supplied condensate tting allows the connection of

PVC, exible vinyl hose or steel braided hose.

The condensate piping must be trapped at the unit and

pitched away from the unit not less than 1/4" per foot. A

vent is required after the trap so that the condensate will

drain away from the unit. The vent can also act as a clean

out if the trap becomes clogged. To avoid having waste

gases entering the building, the condensate drain should

not be directly piped to a drain/waste/vent stack. See local

codes for the correct application of condensate piping to

drains.

Figure 5: Typical Condensate Piping

Condensate

Drain (P Trap)

1 1/2"

(38mm)

Page 10 of 42 McQuay Large Horizontal Water Source Heat Pumps Catalog 1112-2

1 1/2"

(38mm)

Optional

Field Installed Vent

1/4" Per Foot

(21mm Per Meter)

Page 11

Ductwork and Sound Attenuation Considerations

Applications

Ductwork is normally applied to ceiling-mounted heat

pumps on the discharge side of the unit. A discharge collar

is provided on all horizontal unit models for fastening the

ductwork. Use a exible connector between the discharge

collar and the duct transformation to help reduce vibration

straight length of duct, 5 to 10 times the duct width, before

the next tting to smooth out airow. Diffusers that are lo-

cated in the bottom of a trunk duct can also produce noise.

For this same reason, volume control dampers should be

located several duct widths upstream from an air outlet.

transmission from the cabinet and to simplify disconnection

of the unit from the ceiling ductwork. If return ductwork

is to be used, attach a exible connector to the lter rack

collar to help reduce vibration transmission and removal of

the unit. Return plenum ducting should be at least 12 inches

away from the coil so that the coil is evenly loaded with

return air.

For Hotel, Motel, Dormitory or Nursing Home applica-

tions that use a single duct discharge, a velocity of 500 to

600 fpm is suggested. These applications typically have

static pressures as low as 0.05 inches of water and duct

lengths approximately six feet in length. The discharge

duct must be fully lined and have a square elbow without

turning vanes. Return air for these applications should

As a general recommendation, duct interiors should

have an acoustic / thermal lining at least 1/2 inch thick

over the entire duct run. For better sound attenuation, line

the last ve diameters of duct before each register with a

one-inch thick sound blanket. Elbows, tees and dampers

can create turbulence or distortion in the airow. Place a

enter through a “low” sidewall lter grille and route up the

stud space to a ceiling plenum. For horizontal heat pumps

mounted from the ceiling, an insulated return plenum is

sometimes placed at the return air opening to further

attenuate line-of-sight sound transmission through return

openings.

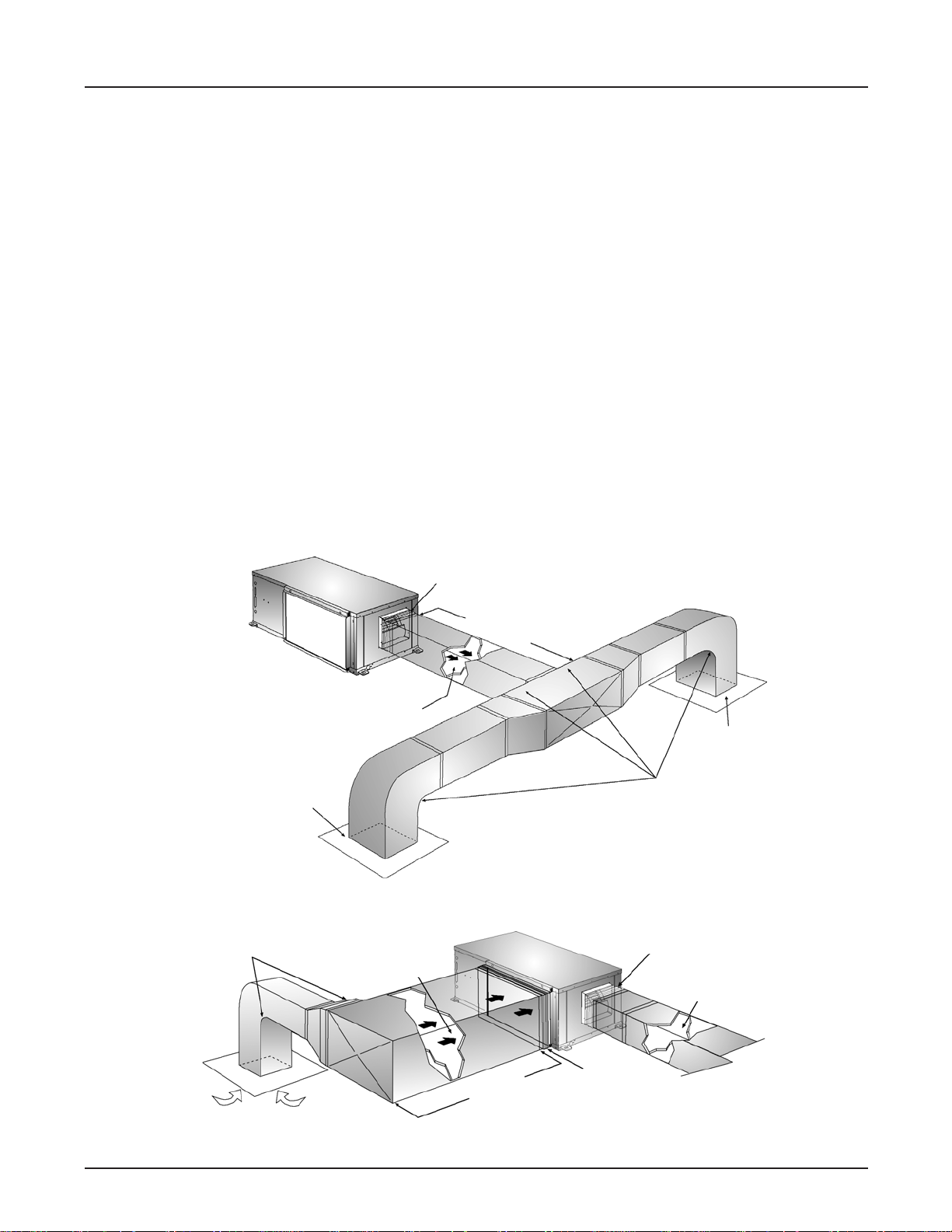

Figure 6: Suggested Supply Ducting per ASHRAE and SMACNA Publications

Flexible Connector

Acoustic/Thermal Lining

3ft. (.9m) to 5ft. (1.5m)

Acoustic/Thermal

Lining

Diffuser

(Ductwork Sized Based on Airow)

Figure 7: Suggested Return Ducting per ASHRAE and SMACNA Publications

Two 90° Turns Prior to the Intake

(Ductwork Sized Based on Airow)

Ductwork Supported

Independent of Unit

Acoustic/Thermal

Lining

Flexible Connector

Ductwork Supported

Independent of Unit

Diffuser

Two 90° Turns

Acoustic/Thermal

Lining

Return Air Intake

Located

Away from the

Unit Blower

Catalog 1112-2 McQuay Large Horizontal Water Source Heat Pumps Page 11 of 42

Acoustic/Thermal

Lining 10ft. (3 meters)

Flexible Connector

Page 12

Applications

Typical Cooling and Heating Refrigeration Cycles – Dual Compressors

Note: Typical temperature readings are at full load conditions at ISO-13256 for boiler-tower applications.

Figure 8: Cooling Refrigeration Cycle

When the wall thermostat calls for COOLING, the revers-

ing valve (de-energized) directs the ow of the refrigerant,

a hot gas, from the compressor to the water-to-refrigerant

heat exchanger (coaxial heat exchanger). There, the heat is

removed by the water, and the hot gas condenses to become

a liquid. The liquid then ows through a thermal expansion

valve to the air-to-refrigerant heat exchanger coil (evapora-

tor). The liquid then evaporates and becomes a gas, at the

same time absorbing heat and cooling the air passing over the

surfaces of the coil. The refrigerant then ows as a low pres-

sure gas through the reversing valve and back to the suction

side of the compressor to complete the cycle.

Figure 9: Heating Refrigeration Cycle

When the wall thermostat calls for HEATING, the

reversing valve (energized) directs the ow of the refriger-

ant, a hot gas, from the compressor to the air-to-refrigerant

heat exchanger coil (condenser). There, the heat is removed

by the air passing over the surfaces of the coil and the hot

gas condenses and becomes a liquid. The liquid then ows

through a thermal expansion valve to the water-to-refrigerant

heat exchanger (evaporator). The liquid then evaporates and

becomes a gas, at the same time absorbing heat and cooling

the water. The refrigerant then ows as a low pressure gas

through the reversing valve and back to the suction side of

the compressor to complete the cycle.

Page 12 of 42 McQuay Large Horizontal Water Source Heat Pumps Catalog 1112-2

Page 13

Applications – Systems

Water source heat pump systems are one of the most ef-

cient, environmentally friendly systems available for heating

and cooling buildings. High-efciency, self contained units

(sizes 7,000 btuh to 290,000 btuh) can be placed in virtually

any location within a building. Each unit responds only to

the heating or cooling load of the individual zone it serves.

This permits an excellent comfort level for occupants, better

control of energy use for building owners and lower seasonal

operating costs. The Air-Conditioning Refrigeration Institute

(ARI) and the International Standards Organization (ISO)

publish standards so that water source heat pumps are rated

for specic applications. The ARI/ISO loop options shown in

this catalog are typical water source heat pump loop choices

available in today’s market. These systems offer benets rang-

ing from low cost installation to the highest energy efciency

available in the market today.

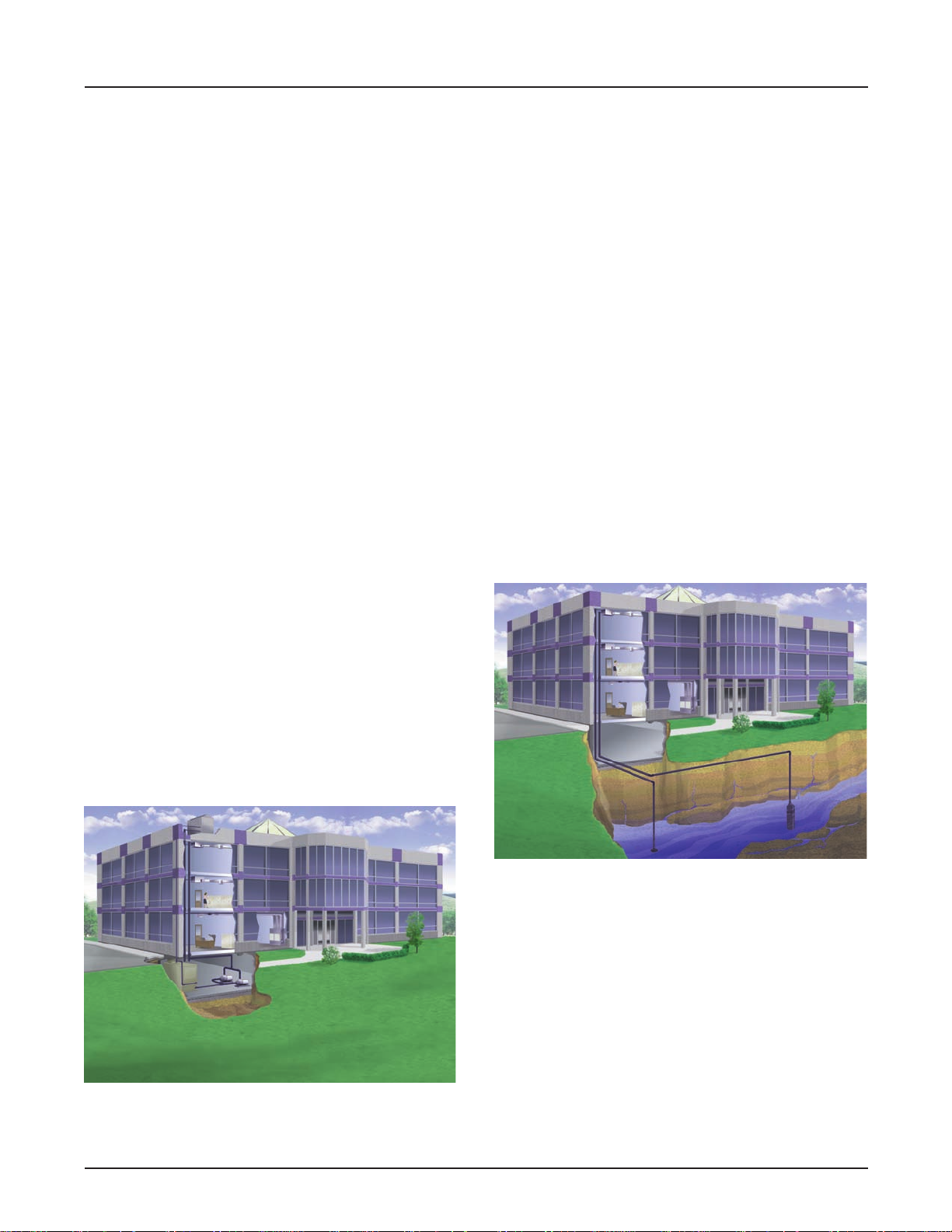

Boiler / Tower Applications: ARI 320 / ISO

13256-1

A “Boiler/Tower” application uses a simple two-pipe

water circulating system that adds heat, removes heat or

transfers rejected heat to other units throughout the build-

ing. The water temperature for heating is generally main-

tained between 65ºF – 70ºF and is usually provided by a

natural gas or electric boiler located in a mechanical room.

The condensing water temperature, during cooling months,

is maintained between 85ºF and 95ºF and requires the use

of a cooling tower to dissipate waste heat. Cooling tow-

ers can be located on the roof, or inside or adjacent to the

building. This application can be the lowest cost of the loop

options available.

Note: ASHRAE 90.1 standards require that circulating

pumps over 10 HP will require use of “variable frequency

drive” equipment and pipe insulation to be used whenever

water temperatures are below 60 degrees and above 105

degrees. See ASHRAE 90.1 Standards for details.

Open Loop Well Water Applications: ARI

325 / ISO 13256-1

“Open Loop” well water systems use ground water

to remove or add heat to the interior water loop. The

key benet of an open loop system is the constant water

temperature, usually 50ºF to 60ºF, which provides efcient

operation at a low rst cost. Most commercial designers

incorporate a heat exchanger to isolate the building loop

from the well water. Using heat exchangers can reduce

maintenance issues while still allowing the transfer of heat

from unit to unit as with the “Boiler/Tower System”. A successful design provides an ample amount of groundwater

(approximately 2 GPM per ton) and adequate provisions

for discharging water back to the aquifer or surface. Open

Loop applications are commonly used in coastal areas

where soil characteristics allow reinjection wells to return

the water back to the aquifer. Note that some states have requirements on the depths of return water reinjection wells,

and such wells must be approved by the United States En-

vironmental Protection Agency. Also, bad water quality can

increase problems with heat exchanger scaling. Suspended

solids can erode the heat exchanger. Strainers can be used

to contain suspended solids.

Figure 11: Open Loop Well Application

Figure 10: Boiler/Tower Application

Catalog 1112-2 McQuay Large Horizontal Water Source Heat Pumps Page 13 of 42

Page 14

Applications – Systems

Closed Loop Geothermal Applications ARI

330/ISO 13256-1

“Vertical Closed Loop” applications are installed by

drilling vertical bore holes into the earth and inserting

a plastic polyethylene supply/return pipe into the holes.

The vertical wells are connected in parallel reverse return

fashion to allow the water from the building to circulate

evenly throughout the boreeld. The circulating uid dissipates heat to the ground in a similar manner as a “tower”

and adds heat back to the loop like a boiler. If properly

designed, the loop eld can maintain the loop temperatures

necessary to condition the building without the use of a

boiler or a tower. Loop temperatures usually range from

37ºF to 95ºF in Northern climates. Southern applications

can see temperatures ranging from 40ºF to 100ºF. The

number of bore holes and their depth should be determined

by using commercial software that is specically designed

for vertical geothermal applications. Typical bore depths

of a vertical loop range from 150 to 400 feet and generally

require about 250 feet of surface area per ton of cooling.

Figure 12: Vertical Loop Application

Figure 13: Horizontal Loop Application

A “Surface Water” or “Lake” closed loop system is a

geothermal loop that is directly installed in a lake or body

of water that is near the building. In many cases, the body

of water is constructed on the building site to meet drainage

or aesthetic requirements. Surface loops use bundled

polyethylene coils that are connected in the same manner

as a vertical or horizontal loop using a parallel reverse

return design. The size and the depth of the lake is critical.

Commercial design services should be used to certify that a

given body of water is sufcient to withstand the building

loads. Loop temperatures usually range from 35ºF to 90ºF

and prove to be the best cooling performer and lowest

cost loop option of the three geothermal loops. Some

applications may not be good candidates due to public

access or debris problems from ooding.

Figure 14: Surface Water Loop Application

A closed loop “Horizontal” geothermal application

is similar to a vertical loop application with the exception

that the loops are installed in trenches approximately 5

feet below the ground surface. The piping may be installed

using a “four-pipe” or “six-pipe” design and could require

1,500 to 2,000 square feet of surface area per ton of

cooling. Loop temperatures for a commercial application

can range from 35ºF to 95ºF in Northern climates. Southern

climates can see temperatures ranging from 40ºF to

100ºF. Horizontal loops are generally not applied in urban

areas because land use and costs can be prohibitive. New

advances in installation procedures have improved the

assembly time of horizontal loops while keeping the rst

cost lower than a vertical loop.

Page 14 of 42 McQuay Large Horizontal Water Source Heat Pumps Catalog 1112-2

Page 15

ISO Performance Data

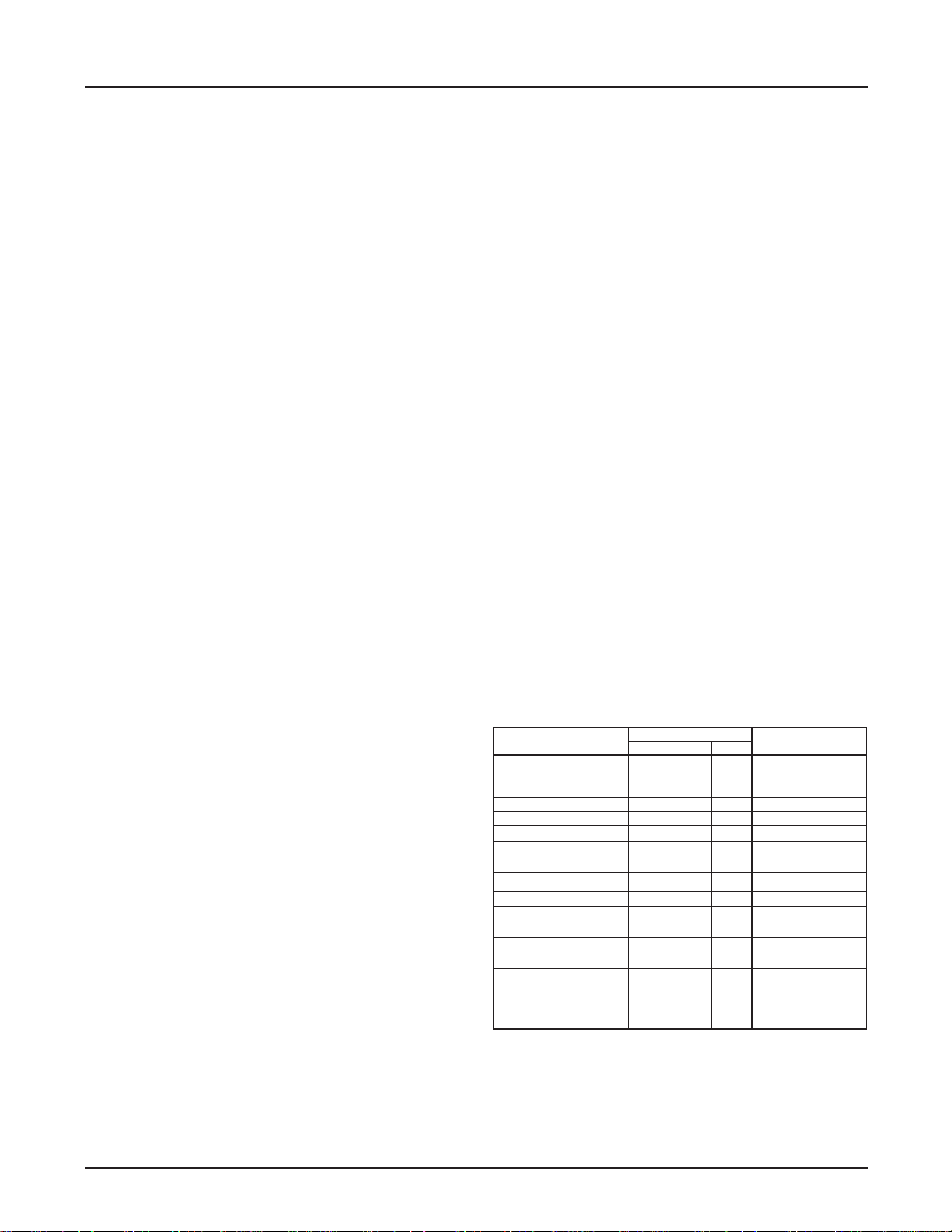

Table 4: Water Loop

Unit Size

CFM L/S GPM L/S Btuh

072

096

120

Note: Water Loop Performance Data – Rated in Accordance with ISO Standard 13256-1

Table 5: Ground Loop

Unit Size

CFM L/S GPM L/S Btuh

072

096

120

Note: Ground Loop Performance Data – Rated in Accordance with ISO Standard 13256-1

Airow Waterow

1133

2400

3000

4000

1416

1888

20.1

23.6

30.1

Airow Waterow

1133

2400

3000

4000

1416

1888

20.1

23.6

30.1

1.27

1.49

1.90

1.27

1.49

1.90

Voltage

208/230-60-3

460-60-3

575-60-3

208/230-60-3

460-60-3

575-60-3

208/230-60-3

460-60-3

575-60-3

Voltage

208/230-60-3

460-60-3

575-60-3

208/230-60-3

460-60-3

575-60-3

208/230-60-3

460-60-3

575-60-3

78100

94900

121800

77700

97300

124600

Cooling Heating

Watts EER COP Btuh Watts COP

22868

27788

35664

13.4

14.8

14.4

3.9

4.3

4.2

Cooling Heating

Watts EER COP Btuh Watts COP

22751

28490

36484

16.3

16.8

16.0

4.8

4.9

4.7

82700

94300

126200

58700

66100

92500

24215

27612

36953

17188

19355

27085

4.4

4.3

4.4

3.7

3.3

3.6

Table 6: Ground Source

Unit Size

CFM L/S GPM L/S Btuh

072

096

120

Note: Ground Source Performance Data – Rated in Accordance with ISO Standard 13256-1

Airow Waterow

1133

2400

3000

4000

1416

1888

20.1

23.6

30.1

1.27

1.49

1.90

Voltage

208/230-60-3

460-60-3

575-60-3

208/230-60-3

460-60-3

575-60-3

208/230-60-3

460-60-3

575-60-3

82500

103100

134400

Cooling Heating

Watts EER COP Btuh Watts COP

24157

30189

39354

21.3

21.5

20.7

6.2

6.3

6.1

71400

79800

115700

20907

23366

33878

4.2

3.8

4.2

Catalog 1112-2 McQuay Large Horizontal Water Source Heat Pumps Page 15 of 42

Page 16

Cooling Capacity Data – Large Horizontal, Size 072 @ 2400 SCFM

EWT GPM WPD

EA LWT TOT SEN kW EER TOT kW EER THR

30

40

50

60

70

80

85

90

100

110

12.0

18.0

24.0

12.0

18.0

24.0

12.0

18.0

24.0

12.0

18.0

24.0

12.0

18.0

24.0

12.0

18.0

24.0

12.0

18.0

24.0

12.0

18.0

24.0

12.0

18.0

24.0

12.0

18.0

24.0

System ISO

75

63

5.6

12.2

21.2

5.6

12.2

21.2

5.6

12.2

21.2

5.6

12.2

21.2

5.6

12.2

21.2

5.6

12.2

21.2

5.6

12.2

21.2

5.6

12.2

21.2

5.6

12.2

21.2

5.6

12.2

21.2

80

85

75

80

85

75

80

85

75

80

85

75

80

85

75

80

85

75

80

85

75

80

85

75

80

85

75

80

85

75

80

85

75

80

85

75

80

85

75

80

85

75

80

85

75

80

85

75

80

85

75

80

85

75

80

85

75

80

85

75

80

85

75

80

85

75

80

85

75

80

85

75

80

85

75

80

85

75

80

85

75

80

85

75

80

85

75

80

85

38.8

67

39.5

71

40.1

63

35.9

67

36.3

71

36.8

63

34.5

67

34.8

71

35.1

63

48.7

67

49.3

71

49.9

63

45.8

67

46.2

71

46.6

63

44.4

67

44.7

71

45.0

63

58.5

67

59.1

71

59.6

63

55.7

67

56.1

71

56.5

63

54.3

67

54.6

71

54.9

63

68.3

67

68.8

71

69.4

63

65.6

67

65.9

71

66.3

63

64.2

67

64.5

71

64.7

63

78.1

67

78.6

71

79.1

63

75.4

67

75.8

71

76.1

63

74.1

67

74.3

71

74.6

63

87.9

67

88.4

71

88.9

63

85.3

67

85.6

71

86.0

63

84.0

67

84.2

71

84.5

63

92.8

67

93.3

71

93.8

63

90.2

67

90.6

71

90.9

63

88.9

67

89.2

71

89.4

63

97.8

67

98.2

71

98.7

63

95.2

67

95.5

71

95.8

63

93.9

67

94.1

71

94.4

63

107.6

67

108.1

71

108.5

63

105.1

67

105.4

71

105.7

63

103.8

67

104.1

71

104.3

63

117.5

67

117.9

71

118.3

63

115.0

67

115.3

71

115.6

63

113.8

67

114.0

71

114.2

97582

104910

112560

98516

105990

113790

98985

106540

114380

93797

100780

108060

94783

101930

109380

95272

102510

110070

89651

96314

103270

90655

97499

104600

91193

98094

105290

85347

91655

98202

86337

92768

99518

86832

93359

100220

80798

86768

93022

81764

87920

94322

82277

88515

94949

76192

81873

87815

77151

82935

88959

77648

83457

89577

73946

79412

85167

74800

80434

86371

75284

81013

86953

71650

77026

82608

72594

77981

83703

72985

78483

84292

67216

72317

77597

68010

73171

78579

68387

73621

79111

63029

67952

73041

63704

68644

73798

64065

69031

74199

71437

74520

77607

71925

75053

78195

72171

75326

78477

69452

72471

75500

69969

73039

76118

70234

73326

76441

67264

70227

73211

67805

70828

73846

68088

71130

74174

64956

67873

70798

65486

68434

71422

65753

68733

71758

62531

65414

68337

63044

65996

68956

63317

66295

69254

60056

62932

65839

60579

63480

66390

60847

63746

66690

58837

61678

64563

59296

62198

65146

59560

62495

65427

57592

60459

63330

58128

60945

63858

58311

61202

64140

55193

58037

60912

55622

58473

61386

55822

58704

61642

52895

55774

58676

53267

56140

59050

53465

56336

59248

2.91

2.96

3.01

2.78

2.82

2.86

2.72

2.75

2.79

3.41

3.45

3.49

3.28

3.31

3.35

3.21

3.25

3.28

3.93

3.97

4.00

3.80

3.83

3.86

3.73

3.76

3.78

4.49

4.53

4.57

4.36

4.39

4.42

4.30

4.32

4.34

5.13

5.16

5.19

4.99

5.01

5.03

4.92

4.93

4.95

5.84

5.86

5.88

5.68

5.70

5.72

5.61

5.63

5.64

6.21

6.24

6.26

6.07

6.08

6.09

5.99

5.99

6.01

6.62

6.63

6.65

6.45

6.47

6.48

6.38

6.39

6.39

7.45

7.45

7.46

7.29

7.30

7.30

7.22

7.21

7.21

8.31

8.29

8.27

8.17

8.15

8.13

8.09

8.08

8.06

33.5

35.5

37.4

35.4

37.5

39.7

36.4

38.7

41.0

27.5

29.2

31.0

28.9

30.8

32.6

29.6

31.6

33.6

22.8

24.3

25.8

23.8

25.5

27.1

24.4

26.1

27.8

19.0

20.2

21.5

19.8

21.1

22.5

20.2

21.6

23.1

15.8

16.8

17.9

16.4

17.6

18.8

16.7

18.0

19.2

13.1

14.0

14.9

13.6

14.5

15.5

13.9

14.8

15.9

11.9

12.7

13.6

12.3

13.2

14.2

12.6

13.5

14.5

10.8

11.6

12.4

11.3

12.1

12.9

11.4

12.3

13.2

9.0

9.7

10.4

9.3

10.0

10.8

9.5

10.2

11.0

7.6

8.2

8.8

7.8

8.4

9.1

7.9

8.5

9.2

100920

108233

115883

101839

109313

117113

102308

109863

117703

97120

104103

111383

98106

105253

112703

98595

105833

113393

92974

99637

106593

93978

100822

107923

94516

101417

108613

88670

94978

101525

89660

96091

102841

90155

96682

103543

84121

90091

96345

85087

91243

97645

85600

91838

98272

79515

85196

91138

80474

86258

92282

80971

86780

92900

77269

82735

88490

78123

83757

89694

78607

84336

90276

74973

80349

85931

75917

81304

87026

76308

81806

87615

70539

75640

80920

71333

76494

81902

71710

76944

82434

66352

71275

76364

67027

71967

77121

67388

72354

77522

2.88

2.92

2.97

2.75

2.79

2.83

2.69

2.72

2.76

3.37

3.41

3.45

3.25

3.28

3.32

3.18

3.22

3.25

3.90

3.93

3.97

3.77

3.79

3.82

3.70

3.73

3.75

4.46

4.49

4.53

4.33

4.36

4.38

4.27

4.29

4.31

5.10

5.13

5.16

4.96

4.97

5.00

4.89

4.90

4.92

5.80

5.83

5.85

5.65

5.67

5.69

5.58

5.60

5.61

6.18

6.21

6.23

6.04

6.05

6.05

5.96

5.96

5.97

6.58

6.59

6.61

6.42

6.44

6.45

6.35

6.36

6.36

7.41

7.42

7.43

7.26

7.26

7.26

7.19

7.18

7.18

8.28

8.25

8.23

8.14

8.12

8.10

8.06

8.05

8.03

33.9

35.8

37.7

34.6

36.6

38.7

33.4

35.5

37.6

28.0

29.6

31.3

28.5

30.3

32.1

27.7

29.5

31.3

23.2

24.7

26.2

23.7

25.3

26.8

23.2

24.7

26.3

19.4

20.7

21.9

19.8

21.1

22.5

19.4

20.7

22.1

16.2

17.2

18.3

16.5

17.6

18.8

16.3

17.4

18.6

13.5

14.4

15.3

13.8

14.7

15.7

13.6

14.5

15.5

12.3

13.1

14.0

12.5

13.4

14.3

12.4

13.3

14.2

11.2

12.0

12.8

11.5

12.3

13.1

11.3

12.1

13.0

9.4

10.1

10.7

9.6

10.3

11.0

9.5

10.2

10.9

7.9

8.5

9.2

8.0

8.7

9.3

8.0

8.6

9.2

107140

114590

122380

107690

115270

123170

107950

115600

123530

104850

111940

119330

105450

112680

120230

105740

113060

120700

102290

109040

116090

102900

109800

116990

103230

110190

117450

99700

106100

112750

100290

106790

113600

100580

107160

114070

97100

103150

109480

97637

103830

110280

97928

104180

110670

94675

100410

106410

95161

100990

107060

95416

101270

107420

93595

99129

104940

93999

99656

105600

94231

99958

105930

92545

97946

103580

92983

98415

104160

93147

98662

104470

90702

95810

101110

91011

96174

101570

91160

96372

101830

89215

94056

99075

89442

94326

99399

89561

94474

99576

Page 16 of 42 McQuay Ennity Horizontal Water Source Heat Pumps Catalog 1112-2

Page 17

Heating Capacity Data – Large Horizontal, Size 072 @ 2400 SCFM

EWT GPM WPD

EA LWT TOT kW COP TOT kW COP THA

12.0

20

30

40

50

60

70

80

85

90

18.0

24.0

12.0

18.0

24.0

12.0

18.0

24.0

12.0

18.0

24.0

12.0

18.0

24.0

12.0

18.0

24.0

12.0

18.0

24.0

12.0

18.0

24.0

12.0

18.0

24.0

System ISO

60

15.9

5.6

12.2

21.2

5.6

12.2

21.2

5.6

12.2

21.2

5.6

12.2

21.2

5.6

12.2

21.2

5.6

12.2

21.2

5.6

12.2

21.2

5.6

12.2

21.2

5.6

12.2

21.2

16.1

16.4

17.3

17.4

17.6

17.9

18.1

18.2

24.8

25.1

25.4

26.5

26.7

27.0

27.4

27.6

27.7

33.6

34.0

34.3

35.7

36.0

36.2

36.8

37.0

37.2

42.2

42.7

43.1

44.8

45.1

45.4

46.1

46.3

46.6

50.7

51.2

51.8

53.8

54.2

54.5

55.3

55.6

55.9

59.1

59.7

60.3

62.7

63.1

63.5

64.5

64.8

65.2

67.3

68.0

68.8

71.5

72.0

72.5

73.7

74.0

74.4

71.4

72.2

72.9

75.9

76.4

77.0

78.2

78.6

79.0

75.5

76.3

77.1

80.3

80.9

81.4

82.7

83.1

83.6

40774

40592

40394

40774

40592

40394

40774

40592

40394

48594

48016

47444

48594

48016

47444

48595

48016

47444

57617

56571

55563

57618

56573

55564

57619

56573

55565

67729

66161

64671

67733

66164

64674

67735

66166

64675

78829

76696

74675

78839

76704

74681

78842

76706

74684

90797

88066

85477

90822

88086

85491

90829

88091

85496

103490

100140

96938

103550

100180

96970

103560

100190

96979

110050

106400

102870

110140

106460

102910

110160

106470

102930

116740

112750

108910

116870

112840

108980

116900

112870

109000

70

80

60

70

80

60

70

80

60

70

80

60

70

80

60

70

80

60

70

80

60

70

80

60

70

80

60

70

80

60

70

80

60

70

80

60

70

80

60

70

80

60

70

80

60

70

80

60

70

80

60

70

80

60

70

80

60

70

80

60

70

80

60

70

80

60

70

80

60

70

80

60

70

80

60

70

80

60

70

80

3.59

4.04

4.53

3.59

4.04

4.53

3.59

4.04

4.53

3.70

4.16

4.66

3.70

4.16

4.66

3.70

4.16

4.66

3.83

4.31

4.82

3.83

4.31

4.82

3.83

4.31

4.82

3.99

4.48

5.01

3.99

4.48

5.01

3.99

4.48

5.01

4.18

4.68

5.22

4.18

4.68

5.22

4.18

4.68

5.22

4.39

4.89

5.44

4.39

4.89

5.44

4.39

4.89

5.44

4.62

5.13

5.69

4.62

5.13

5.69

4.62

5.13

5.69

4.74

5.26

5.81

4.74

5.26

5.82

4.74

5.26

5.82

4.87

5.39

5.95

4.88

5.39

5.95

4.88

5.39

5.95

2.4

2.0

1.7

2.4

2.0

1.7

2.4

2.0

1.7

2.9

2.4

2.0

2.9

2.4

2.0

2.9

2.4

2.0

3.5

2.9

2.4

3.5

2.9

2.4

3.5

2.9

2.4

4.0

3.4

2.8

4.0

3.4

2.8

4.0

3.4

2.8

4.6

3.9

3.2

4.6

3.9

3.2

4.6

3.9

3.2

5.1

4.3

3.6

5.1

4.3

3.6

5.1

4.3

3.6

5.6

4.8

4.0

5.6

4.8

4.0

5.6

4.8

4.0

5.8

5.0

4.2

5.8

5.0

4.2

5.8

5.0

4.2

6.1

5.2

4.4

6.1

5.2

4.4

6.1

5.2

4.4

39187

39005

38807

39187

39005

38807

39187

39005

38807

47007

46429

45857

47007

46429

45857

47008

46429

45857

56030

54984

53976

56031

54986

53977

56032

54986

53978

66142

64574

63084

66146

64577

63087

66148

64579

63088

77242

75109

73088

77252

75117

73094

77255

75119

73097

89210

86479

83890

89235

86499

83904

89242

86504

83909

101903

98553

95351

101963

98593

95383

101973

98603

95392

108463

104813

101283

108553

104873

101323

108573

104883

101343

115153

111163

107323

115283

111253

107393

115313

111283

107413

3.13

3.58

4.07

3.13

3.58

4.07

3.13

3.58

4.07

3.23

3.69

4.20

3.23

3.69

4.20

3.23

3.70

4.20

3.37

3.84

4.36

3.37

3.84

4.36

3.37

3.84

4.36

3.53

4.01

4.54

3.53

4.02

4.54

3.53

4.02

4.54

3.72

4.21

4.75

3.72

4.21

4.75

3.72

4.21

4.75

3.93

4.43

4.98

3.93

4.43

4.98

3.93

4.43

4.98

4.16

4.67

5.22

4.16

4.67

5.22

4.16

4.67

5.22

4.28

4.79

5.35

4.28

4.80

5.35

4.28

4.80

5.35

4.41

4.92

5.48

4.41

4.93

5.49

4.41

4.93

5.48

2.7

2.5

2.2

2.8

2.5

2.2

2.8

2.5

2.2

3.3

2.9

2.6

3.3

2.9

2.6

3.3

2.9

2.6

3.8

3.3

3.0

3.8

3.3

3.0

3.8

3.3

3.0

4.3

3.8

3.3

4.3

3.8

3.3

4.3

3.8

3.3

4.8

4.2

3.7

4.8

4.2

3.7

4.8

4.2

3.7

5.3

4.7

4.1

5.3

4.7

4.1

5.3

4.7

4.1

5.8

5.1

4.5

5.8

5.1

4.5

5.8

5.1

4.5

6.0

5.3

4.7

6.0

5.3

4.7

6.0

5.3

4.7

6.2

5.5

4.8

6.2

5.5

4.9

6.2

5.5

4.9

29122

27472

25685

29122

27472

25685

29122

27472

25685

36606

34523

32318

36606

34523

32319

36606

34523

32319

45191

42603

39921

45193

42604

39922

45193

42604

39923

54769

51628

48425

54773

51631

48428

54774

51633

48429

65264

61527

57753

65273

61535

57759

65276

61537

57762

76556

72195

67820

76580

72212

67832

76586

72218

67837

88503

83492

78488

88555

83533

78517

88568

83543

78526

94665

89337

84002

94745

89394

84046

94762

89409

84058

100940

95272

89616

101060

95356

89677

101080

95375

89694

Catalog 1112-2 McQuay Enity Horizontal Water Source Heat Pumps Page 17 of 42

Page 18

Cooling Capacity Data – Large Horizontal, Size 096 @ 3000 SCFM

EWT GPM WPD

EA LWT TOT SEN kW EER TOT kW EER THR

30

40

50

60

70

80

85

90

100

110

16.0

24.0

32.0

16.0

24.0

32.0

16.0

24.0

32.0

16.0

24.0

32.0

16.0

24.0

32.0

16.0

24.0

32.0

16.0

24.0

32.0

16.0

24.0

32.0

16.0

24.0

32.0

16.0

24.0

32.0

System ISO

63

12.0

26.1

45.4

12.0

26.1

45.4

12.0

26.1

45.4

12.0

26.1

45.4

12.0

26.1

45.4

12.0

26.1

45.4

12.0

26.1

45.4

12.0

26.1

45.4

12.0

26.1

45.4

12.0

26.1

45.4

75

80

85

75

80

85

75

80

85

75

80

85

75

80

85

75

80

85

75

80

85

75

80

85

75

80

85

75

80

85

75

80

85

75

80

85

75

80

85

75

80

85

75

80

85

75

80

85

75

80

85

75

80

85

75

80

85

75

80

85

75

80

85

75

80

85

75

80

85

75

80

85

75

80

85

75

80

85

75

80

85

75

80

85

75

80

85

75

80

85

42.4

67

42.9

71

43.4

63

40.8

67

41.2

71

41.5

63

39.9

67

40.2

71

40.4

63

52.4

67

52.8

71

53.3

63

50.8

67

51.1

71

51.5

63

49.8

67

50.1

71

50.4

63

62.3

67

62.7

71

63.2

63

60.7

67

61.1

71

61.4

63

59.8

67

60.1

71

60.3

63

72.2

67

72.6

71

73.1

63

70.6

67

71.0

71

71.3

63

69.7

67

70.0

71

70.3

63

82.1

67

82.5

71

82.9

63

80.6

67

80.9

71

81.2

63

79.6

67

79.9

71

80.2

63

91.9

67

92.3

71

92.8

63

90.5

67

90.8

71

91.1

63

89.6

67

89.8

71

90.1

63

96.9

67

97.3

71

97.7

63

95.4

67

95.7

71

96.0

63

94.5

67

94.8

71

95.0

63

101.8

67

102.2

71

102.6

63

100.4

67

100.7

71

101.0

63

99.5

67

99.7

71

100.0

63

111.7

67

112.1

71

112.5

63

110.3

67

110.6

71

110.9

63

109.4

67

109.7

71

109.9

63

121.6

67

122.0

71

122.3

63

120.2

67

120.5

71

120.8

63

119.4

67

119.6

71

119.8

108620

117220

126090

109060

117560

126660

109290

117750

127040

105330

113730

122660

105820

114320

123350

106130

114670

123770

101730

109840

118350

102220

110410

119070

102530

110760

119500

97953

105680

113850

98457

106270

114530

98762

106620

114950

93916

101300

109130

94423

101890

109820

94733

102260

110240

89641

96678

104150

90142

97272

104820

90456

97628

105240

87400

94287

101570

87911

94871

102250

88220

95230

102660

85116

91840

98957

85620

92427

99620

85933

92780

100030

80462

86832

93598

80945

87387

94235

81245

87735

94629

75544

81629

88028

76008

82161

88671

76300

82493

89051

73435

75836

78008

73658

76028

78311

73778

76151

78489

71786

74192

76420

72032

74468

76720

72183

74634

76900

70009

72436

74624

70258

72680

74922

70412

72836

75098

68125

70495

72671

68380

70769

72968

68535

70938

73150

66103

68455

70646

66354

68727

70938

66509

68897

71116

63999

66339

68539

64242

66610

68822

64395

66772

68997

62891

65254

67461

63147

65520

67744

63301

65683

67915

61741

64117

66347

61998

64391

66630

62157

64555

66804

59397

61790

64049

59638

62047

64320

59788

62207

64489

56925

59360

61673

57160

59615

61948

57310

59775

62110

2.58

2.62

2.58

2.50

2.54

2.18

2.45

2.48

1.93

3.08

3.12

3.16

3.01

3.04

3.08

2.97

3.00

3.03

3.57

3.61

3.64

3.51

3.54

3.56

3.47

3.49

3.52

4.09

4.12

4.15

4.02

4.05

4.07

3.98

4.00

4.02

4.65

4.67

4.69

4.57

4.59

4.61

4.53

4.55

4.57

5.27

5.29

5.31

5.19

5.20

5.22

5.14

5.16

5.17

5.61

5.63

5.65

5.53

5.54

5.56

5.48

5.49

5.50

5.98

5.99

6.01

5.89

5.90

5.91

5.84

5.85

5.86

6.80

6.80

6.81

6.71

6.71

6.71

6.65

6.65

6.65

7.74

7.73

7.73

7.65

7.64

7.62

7.59

7.57

7.56

30.4

32.4

35.3

31.2

33.3

39.8

31.7

33.8

43.4

25.8

27.6

29.5

26.4

28.3

30.3

26.8

28.7

30.7

22.2

23.8

25.5

22.7

24.3

26.1

22.9

24.7

26.5

19.2

20.7

22.1

19.6

21.1

22.6

19.8

21.3

22.9

16.6

17.9

19.2

16.9

18.2

19.6

17.1

18.4

19.8

14.3

15.4

16.5