Page 1

Installation and Maintenance Manual IM-802

Group: Unitary

Part Number: IM-802

Date: August 2005

Supersedes: March 2005

ACU Split System Air Conditioners

7-1/2 & 10 TON

© 2004 McQuay International

IM-802 Page 1

Page 2

Table of Contents

MODEL NOMENCLATURE . . . . . . . . . . . . . . . . . . . . 3

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

GENERAL WARNINGS . . . . . . . . . . . . . . . . . . . . . . . 5

PRODUCT DESCRIPTION . . . . . . . . . . . . . . . . . . . . 6

DUCTWORK CONSIDERATIONS . . . . . . . . . . . . . . . 6

SITE SELECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

TYPICAL INSTALLATION . . . . . . . . . . . . . . . . . . . . . 7

RIGGING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

UNIT CORNER WEIGHT . . . . . . . . . . . . . . . . . . . . . . 7

REFRIGERANT TUBING . . . . . . . . . . . . . . . . . . . . . . 7

ELECTRICAL WIRING . . . . . . . . . . . . . . . . . . . . . . . 9

SYSTEM EVACUATION AND CHARGING . . . . . . 10

SYSTEM EVACUATION . . . . . . . . . . . . . . . . . . . . . 11

PRELIMINARY CHARGE ADJUSTMENT . . . . . . . . 12

FINAL CHARGE ADJUSTMENT . . . . . . . . . . . . . . . 12

EXPANSION VALVE INDOOR COILS . . . . . . . . . . 12

TROUBLE SHOOTING . . . . . . . . . . . . . . . . . . . . . . 13

WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . 14

"McQuay" is a registered trademark of McQuay International.

© 2004 McQuay International

"Illustrations and information cover the McQuay International products at the time of publication and we reserve the right to make changes in

Page 2 IM-802

design and construction at any time without notice."

Page 3

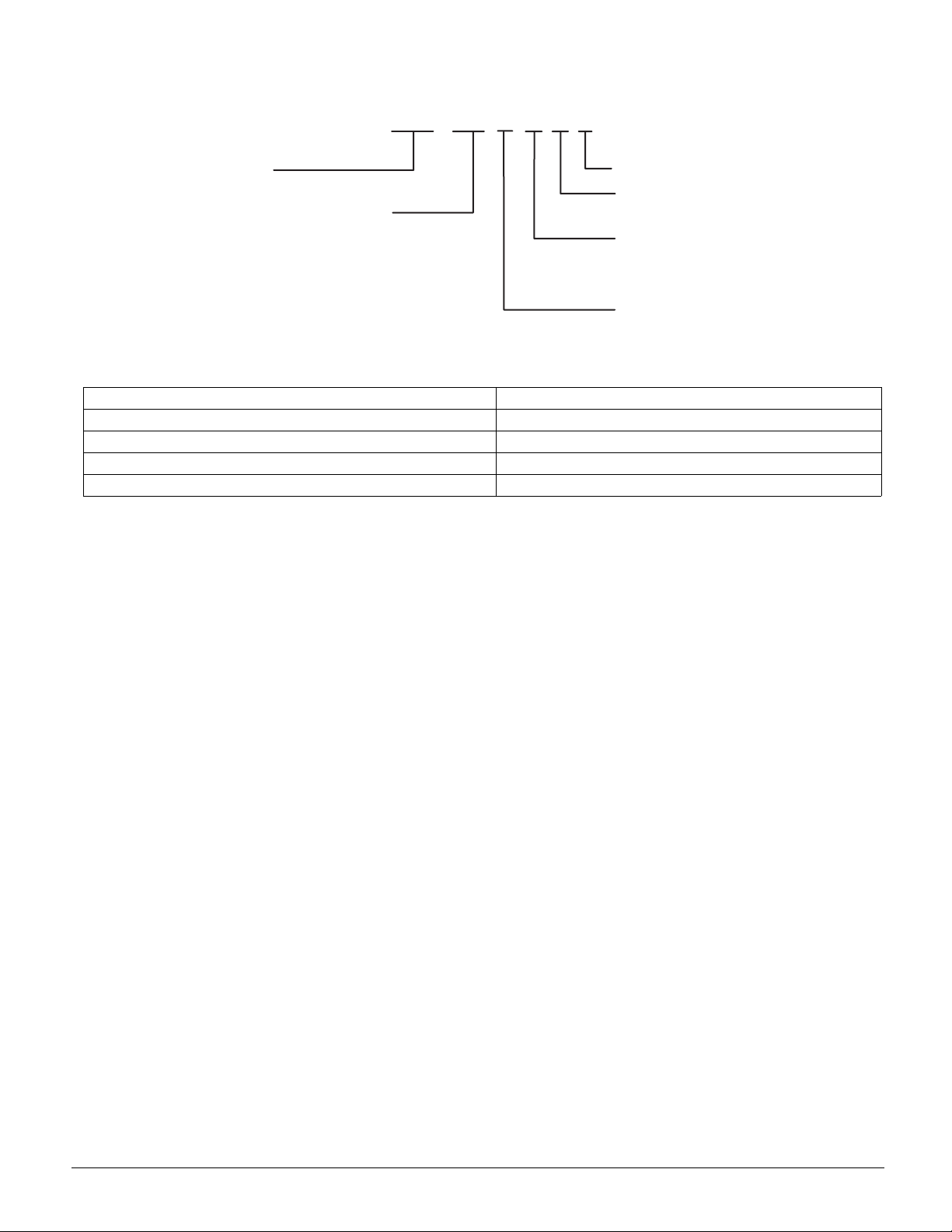

MODEL NOMENCLATURE

M

A

N

0

1

0

A

odel

CU = Air Cooled Cooling Unit

ominal Capacity (tons)

90 = 7-1/2

20 = 10

Table 1: Unit Nameplate Model Number Identifier

Unit Nameplate McQuay Model Number

CKL090-3L ACU090APEY

CKL090-4L ACU090AQEY

CKL120-3L ACU120APEY

CKL120-4L ACU120AQEY

ACU 090

PEY

Future Use

EER

E = 10.3

Voltage/Phase

P = 208-230/3/6

Q = 460/3/60

Vintage

IM-802 Page 3

Page 4

INTRODUCTION

General Description

These installation instructions cover the outdoor installation of

cooling only condensing units from 7½ to 10 tons. See the

product catalog applicable to your model for information

regarding specifications applicable to your model and accessories.

Receiving Inspection

McQuay products are carefully inspected prior to shipment

and the carrier has assumed responsibility for loss or damage

upon acceptance of the shipment.

Upon receiving your shipment, check all items carefully

against the Bill of Lading. Inspect the unit and/or accessories

for shipping damage as soon as they are received. Immediately file claims for loss or damage, either shipping or concealed, with the shipping company.

Check the unit nameplate to verify the model number and electrical characteristics are correct. In the event an incorrect unit

is shipped, it must be returned to the supplier and must NOT

be installed. The manufacturer disclaims all responsibility for

the installation of incorrectly shipped units.

Codes and Regulations

This product is designed and manufactured to permit installation in accordance with National Codes. System design

should, where applicable, follow information presented in

accepted industry guides such as the ASHRAE Handbooks. It

is the installer' s responsibility to install the product in accordance with National Codes and/or prevailing local codes and

regulations. The manufacturer disclaims all responsibility for

equipment installed in violation of any code or regulations.

IMPORTANT

The United States Environmental Protection Agency

(EPA) regulations cover introduction and disposal of

refrigerants in this unit. Failure to follow those

regulations can harm the environment and lead to

substantial fines. Because regulations can change, a

certified technician should perform any work done on

this unit. If you have any questions, please contact the

local office of the EPA.

Important Message to the Installer

This equipment is to be installed by an experienced installation

company and fully trained personnel. Carefully read all

instructions and take into account any special considerations

prior to installing the unit. Give this manual to the owner and

explain its provisions.

Important Message to the Owner

Read these instructions carefully and keep them near the product for future reference. Although these instructions are

addressed primarily to the installer, useful maintenance information is included. Have the installer acquaint you with the

operation of the product and periodic maintenance requirements.

Recognize Safety Symbols, Words, and Labels

The following symbols and labels are used throughout this

manual to indicate immediate or potential hazards. It is the

owner's and installer's responsibility to read and comply with

all safety information and instructions accompanying these

symbols. Failure to heed safety information increases the risk

of property damage and/or product damage, serious personal

injury or death. Improper installation, operation and mainte-

nance can void the warranty.

DANGER

Immediate hazards which WILL result in property

damage, product damage, severe personal injury and/

or death.

WARNING

Hazards or unsafe practice CAN result in property

damage, product damage, sever personal injury and/or

death.

CAUTION

Hazards or unsafe practices which CAN result in

property damage, product damage, and/or personal

injury.

Replacement Parts

Replacement parts can be obtained by contacting McQuay at

1

-800-37-PARTS. When contacting McQuay for service or

replacement parts, refer to the model number and serial number of the unit as stamped on the nameplate attached to the

unit.

Page 4 IM-802

Page 5

GENERAL WARNINGS

WARNING

Before servicing or installing the electrical power must

be in OFF. More than one disconnect may exist.

Failure to disconnect all power can cause electrical

shock, serious personal injury or death.

WARNING

The unit must have an uninterrupted, unbroken

electrical ground. Failure to properly ground can cause

severe personal injury or death.

WARNING

Installation and service by trained, qualified technicians

only. High pressure and electricity can cause severe

personal injury or death. Observe ALL warnings

contained in this manual and the labels/tags attached to

the equipment.

WARNING

When installing or servicing, wear protective gloves,

gear and eyeware. Also observe special safety

requirements (hard hats etc.).

CCAUTION

To protect the unit when welding close to the painted

surfaces, use a quenching cloth to prevent scorching or

marring of equipment finish.

CCAUTION

Read these instructions before performing this

installation or servicing this unit. All installations must

be in accordance with all national, state, or local

building codes.

IM-802 Page 5

Page 6

PRODUCT DESCRIPTION

When matched with the appropriate air handler(s) or evaporator coil(s) the ACU090/120 condenser complies with the rminimum efficiency equirements found in ASHRAE 90.1-1999.

See the product catalog for the indoor model selection recommendation.

Units are intended for use with a single stage room thermostat. This thermostat is not supplied with this equipment. Only

thermostats that use 24 VAC control circuitry are to be used.

Table 2: Physical Data

Net Weight (Lbs.) 345 395

Shipping Weight (Lbs.) 370 420

Refrigerant R-22

Compressor Type Scroll

Quantity 1

Oil Charge Initial/Recharge 85/81 110/106

Condenser Fan Type Propeller

Fan Diameter (in) 26

Fan Motor Type Direct Drive PCS

Fan Motor (HP) 1

Fan Motor (RPM) 1100

Nominal Cond. Airflow (CFM) 6600

Condenser Coil Material Riffled Copper Tubes / Al Fins

2

Face Area (Ft

Refrigerant Connections Sweat Type

Suction Line Connection (in) 1-3/8

Liquid Line Connection (in) 5/8

High Pressure Control (PSIG) 425 Cut-out / Manual Reset

Low Pressure Control (PSIG) 7 Cut-out / 25 Cut-in

)

ACU090 ACU120

30

DUCTWORK CONSIDERATIONS

For proper performance, size the indoor ductwork to accommodate 375-425 CFM per ton of cooling with a static pressure

not to exceed 0.5" WC. Inadequate ductwork that restricts airflow can result in improper cooling performance and compressor failure.

SITE SELECTION

This unit is designed for outdoor installations only.

Air Supply

Units are air-cooled condensers. For optimum unit performance, the installation site should provide unobstructed airflow. See the following figure for minimum clearances from

other air-cooled condensers and obstructions such as walls or

overhangs.

Note: Also consider adequate service clearances.

Figure 1. Recommended Clearances

60"

24"

12"

12"12"

Refrigerant System Requirements

The selected site should be no greater than 50’ below or 70’

above the evaporator section. For optimum performance, use

the minimum length of interconnecting tubing. Where possible, minimize bends and turns

Wiring and Tubing Protection

Protect electrical wiring and refrigerant tubing from damage

due to incidental contact, such as being walked upon.

Vibration and Sound Control

Units are engineered to produce the minimum sound and

vibration. To minimize sound or vibration issues, securely

mount the unit to a surface that is:

•Solid

• Greatest practical mass

• Ridged

• Minimum radiating surface

Where possible, the slab for a ground level unit should not be

connected to the wall or the building.

Prohibited Locations

Do not locate this unit in the following locations:

• Inside a building

• Directly under a vent termination from a gas appliance

• Within 3 feet of a clothes drier vent

• Where water may rise into the unit

Page 6 IM-802

Page 7

TYPICAL INSTALLATION

Typical locations for the unit are slab mounted and roof

mounted. For unit weight data, see the "Product Description"

section of this manual.

Slab Mounting

The slab must be capable of supporting the weight of the unit.

The slab should be a minimum of 6" wider than the unit in all

directions. If required, the slab should be elevated to help

avoid water damage due to flooding. Before installing the unit

onto a slab, the wooden shipping skid must be removed.

UNIT CORNER WEIGHT

The following figure and table is to be used for determining

the unit corner weight. The unit net weight and shipping

weight is provided in the “Product Description” section of this

manual.

Figure 3.

35.5"

D

C

Roof Mounting

Carefully consider the load carrying capability of the roof. If

possible, locate the unit where walls or partitions can offer

additional support. If doubt exists regarding the integrity of

the roof or its supporting structure, consult a structural engineer.

RIGGING

WARNING

All panels must be in position and secured before lifting

this equipment. Dislodged panels can cause equipment

damage, severe personal injury or death.

Figure 2. Rigging Unit for Lifting

41.5"

A

Table 3:

35.5"

B

Corner ACU090 ACU120

A 90 Lbs. 105 Lbs.

B 90 Lbs. 105 Lbs.

C 75 Lbs. 80 Lbs.

D 90 Lbs. 105 Lbs.

REFRIGERANT TUBING

CAUTION

Wrap service valves with a wet rag or similar approved

thermal heat trap around the valve to avoid damage

due to overheating.

WARNING

Wear protective clothing and eye protection when

making any welded connection.

Preparing the Tubing

Ends must be cut round and burr free and cleaned. Failure to

follow this practice can result in refrigerant leaks.

Post Brazing

Quench all welded joints with water or a wet rag.

Piping Size

Using a carefully estimated length of refrigerant tubing (distance between condenser and evaporator), apply the following

When lifting the unit, use spreader bars (field supplied) to help

avoid damage from lifting cables/straps. Also, to help avoid

damage to the cabinet louvers, use protective material (i.e. plywood) behind the cables/straps.

Arrange the straps to form a central suspension point (see Figure 2). When raising and setting the unit, observe all safety

rules. When the unit is in position, the wooden shipping skid

table to determine the tubing diameter:

Table 4: Tubing Diameter

Model

ACU090 5/8 1-1/8 5/8 1-3/8 5/8 1-3/8 5/8 1-3/8

ACU120 5/8 1-1/8 5/8 1-5/8 5/8 1-5/8 5/8 1-5/8

0"-24’ 25’-49’ 50’-74’ 75’-99’

LSLSLSLS

Outside Diameter Line Size (in)

and all lifting materials must be removed.

IM-802 Page 7

Page 8

Suction Line Insulation

Install all suction lines with a recognized tubing insulation that

is a minimum of 3/8" thick.

Hangers and Isolation

Insolate all refrigerant lines from the structure and support

with hangers. See Figure 4 for details.

Figure 4. Hangers and Isolation

Inverted Suction Line Loop

When the condenser is located at the same level or above the

evaporator section, employ an inverted loop on the suction

line. This practice will prevent liquid refrigerant from migrating into the compressor during shutdown. See Figure 5.

Figure 5. Inverted Loop

INVERTED LOOP

LIQUID LINE

CONDENSING UNIT

EVAPORATOR BLOWER

SUCTION LINE

8'

50' MAX

Oil Return

To facilitate oil return to the compressor, pitch a horizontal

suction line (1/2" per 10’) toward the condensing unit. See Figure 6.

Figure 6. Suction Line Pitch

CONDENSING UNIT

PITCH SUCTION LINE TOWARD OUTDOOR

UNIT 1/2" FOR EVERY 10' OF LINE

EVAPORATOR BLOWER

Condenser Above the Evaporator

When the condenser is located 4’ or greater above the evaporator section, install a suction line oil trap at the base of the riser.

Add an additional oil trap for each 20’ of vertical riser. See

Figure 7.

Figure 7. Suction Line Oil Trap

CONDENSING UNIT

ADDITIONAL SUCTION LINE OIL

70' MAX

LIQUID LINE

SUCTION LINE OIL TRAPS WHEN INDOOR UNIT

IS 4 FEET OR MORE BELOW OUTDOOR UNIT

TRAP FOR EACH 20' RISE OF PIPE

EVAPORATOR BLOWER

Filter Drier and Sight Glass

A liquid line filter drier is factory installed. A sight glass/

moisture indicator is provided with the unit. This is to be field

installed on the liquid line as close as practical to the service

valve.

Holding Charge

Units are factory shipped with a 2 lb. R-22 holding charge.

When welding, introduce an inert gas (i.e. nitrogen) through

the tubing to prevent the formation of copper oxide inside the

tubing.

TXV

For improved refrigerant management, equip the evaporator

coil with a thermal expansion valve (TXV).

Liquid Line Solenoid

A field supplied liquid line solenoid should be added to the liquid line as close as possible to the evaporator coil. Wire the

solenoid to close when the compressor stops to prevent refrigerant migration in the “OFF” cycle.

Evacuation and Charging

See the “Evacuation and Charging” section of this manual for

instructions.

LIQUID LINE

Page 8 IM-802

Page 9

ELECTRICAL WIRING

WARNING

Before servicing or installing this equipment, the

electrical power to this unit must be in the “OFF”

position. More than one disconnect may exist. Failure

to observe this warning may result in an electrical shock

that can cause personal injury.

WARNING

The unit must have an uninterrupted, unbroken electrical

ground. Failure to properly ground can cause severe

personal injury or death.

The unit must have an uninterrupted, unbroken electrical ground.

The electrical ground circuit may consist of an appropriately

sized electrical wire connecting the ground lug in the unit control box wire to the building electrical service panel. Other

methods of grounding are permitted if performed in accordance with the National Electric Code (NEC)/American

National Standards Institute (ANSI)/National Fire Protection

Association (NFPA) 70 and local/state codes. In Canada, electrical grounding is to be in accordance with the Canadian Electric Code CSA C22.1. Failure to observe this warning can

result in electrical shock that can cause serious personal injury

or death.

CAUTION

To avoid risk of fire or equipment damage, use only

copper conductors.

Inspection of the Building Electrical Service

This unit is designed for 3-phase operation. DO NOT OPERATE ON A SINGLE PHASE POWER SUPPLY. Measure the

power supply to the unit. The supply voltage must be in agreement with the unit nameplate power requirements and within

the range shown below:

Table 5: Supply Voltage Range

Model Voltage

ACU090 208/230 187 253

ACU090 460 414 506

ACU120 208/230 187 253

ACU120 460 414 506

Minimum Supply

Voltage

Maximum Supply

Voltage

Voltage Balance

The supply voltage shall be unbalance (phase to phase) within

2%. To calculate the percentage of voltage unbalance use the

following formula:

Percentage

Voltage = 100 x

Unbalance

Max. Voltage Devation From Avg.Voltage

Avg. Voltage

Example

L1 - L2 = 220V

L2 - L3 = 216V

L1 - L3 = 213V

Avg. Voltage =(220 + 216 + 213) / 3

=649 / 3

=216

Max. Deviation from Avg. =220 - 216 = 4

% Voltage Unbalance = 100 x (4 / 216)

= 400 / 216

= 1.8%

Determine Wire Size

The selection of the appropriate supply wire size is important

to the operation of the equipment. When selecting the wire

size, the following are important elements of the decision:

• The wire size is sufficient to carry the Minimum Circuit Ampacity (MCA). The unit MCA can be found on the equipment nameplate and the following table.

Table 6: Minimum Circuit Ampacity

• The wire is appropriately sized to allow for no more than a 2%

• Refer to the latest edition of the National Electric Code or, in

Table 7: Maximum Allowable length in Feet to Limit Voltage

drop to 2%*

Model Voltage MCA

ACU090 208/230 37.8

ACU090 460 18.8

ACU120 208/230 43.3

ACU120 460 22.2

voltage drop from the building breaker/fuse panel to the unit.

Canada, the Canadian Electric Code when determining the correct wire size. The following table shows the current carrying

o

capabilities for copper conductors rated at 75

C with a 2% volt-

age drop.

Wire Size

(AWG)

14 75 50 37 NR NR NR NR NR

12 118 79 59 47 NR NR NR NR

10 188 125 95 75 63 54 NR NR

8 301 201 150 120 100 86 75 68

6 471 314 235 188 157 134 118 110

10 15 20 25 30 35 40 45

Min. Circuit Ampacity (MCA)

*Based on NEC 1996

IM-802 Page 9

Page 10

Example

A 208/230 volt ACU120 is to be installed. The distance

from the building breaker box to the unit is 75’. Calculate

the minimum wire size assuming no more than 2% voltage

drop.

MCA = 43.3 (from nameplate and table).

Applying previous table wire sizes less than #8 AWG cannot be used for circuits which have a rating of 45A. The #8

wire is not suitable because the maximum length for a 45A

circuit is 68’. Solution: a #6 AWG wire is suitable up to 110’.

Note: It is the contractor’s responsibility to follow the NEC

(USA) or CEC (Canada) when sizing the service wire for

this unit.

Service Disconnect Box

A service disconnect box is required as per NEC.

Fuse – HACR Breakers

Protection provided by either fuses or HACR type breakers.

Refer to the unit nameplate and the following table for the

maximum overcurrent protection permitted.

Table 8: Maximum Overcurrent Protection

Model Voltage *Max. Fuse

ACU090 208/230 60

ACU090 460 30

ACU120 208/230 60

ACU120 460 35

* Fuse or HACR Breaker of same value.

Line Voltage Wiring

Run all line voltage wiring through conduit from the service

disconnect box to the unit. Refer to the NEC (in Canada,

CEC) for the correct size conduit based on the wire size. The

conduit must enter the control box through the hole provided

in the bottom. Note: hole is sized for ¾” conduit. If permitted

by code, flexible conduit is preferred to minimize vibration

transmission from the unit to the building.

Connect the line voltage wires to the L1, L2, and L3 terminals

of the definite purpose contactor (located in the unit control

box). Refer to the wiring diagram attached to the unit when

making these connections. The unit wiring diagram is also

included at the end of this manual.

The unit must be grounded. The electrical ground circuit must

consist of an appropriately sized electrical wire connecting to

the ground lug in the unit control box and wired to the building

electrical service panel. Other methods of grounding are permitted if performed in accordance with the National Electric

Code (NEC)/American National Standards Institute (ANSI)/

National Fire Protection Association (NFPA) 70 and local/state

codes. In Canada, electrical grounding must be in accordance

with the Canadian Electric Code CSA C22.1.

Low Voltage Connections

Units require a 2-conductor low voltage circuit from the room

thermostat. The wires must be no smaller than 18 AWG. The

field connection for this circuit is to be made in the unit control

box using solderless connectors such as wire nuts. See Figure

8 for a typical low voltage hook-up.

Figure 8. Single State Low Voltage Hook-up

THERMOSTAT CHT18-60

Y1 RW1G

AIR

HANDLER

SAH090/120

CONDENSING

UNIT

ACU090/120

YELLOW

BROWN

RED

WHITE

BLUEBLUE

Control Box Components

See Figure 9 for the location of the electrical components.

Figure 9. Elecrical Component Locations

CONTACTOR

HIGH VOLTAGE

CONNECTIONS

HIGH VOLTAGE

ENTRANCE

CAPACITOR

GROUND LUG

LOW VOLTAGE

CONNECTIONS

LOW VOLTAGE

ENTRANCE

SYSTEM EVACUATION AND

CHARGING

WARNING

To avoid possible explosion, death, or injury, practice

safe handling of refrigerants.

WARNING

Refrigerants are heavier than air. They can “push out”

the oxygen in your lungs or in any enclosed space. To

avoid difficulty in breathing or death.

• Never sniff refrigerant.

• Never purge refrigerant.

Page 10 IM-802

Page 11

WARNING

If an indoor refrigerant leak is suspected, thoroughly

ventilate the area before beginning work.

WARNING

Liquid refrigerant can be very cold. To avoid possible

frostbite or blindness, avoid contact and wear protective

gloves and eyeware. If liquid refrigerant does contact

your skin or eyes, seek medical help immediately.

Always follow EPA regulations. Never burn refrigerant

as poisonous gas will be produced.

WARNING

To avoid possible explosion, use refrigerant cylinders

properly:

If you must heat a cylinder for faster charging, partly

immerse it in warm water. Never apply flame or steam

to the cylinder.

Store cylinders in a cool, dry place. Never use a

cylinder as a platform or a roller.

Never add anything other than R-22 to an R-22

cylinder.

Never fill a cylinder more than 80% full of liquid

refrigerant.

When removing refrigerant from a system, use only

returnable (not disposable) service cylinders. Check the

cylinder for its pressure rating and hydrostatic test date.

Check the cylinder for any damage, that may lead to a

leak or explosion. If in doubt, do not use the cylinder.

Leak Test

WARNING

To avoid the risk of fire or explosion, never use oxygen,

high pressure or flammable gas for leak testing of a

refrigeration system.

1. Verify that both hand valves on the gauge manifold are

closed relative to the center port (i.e., turned in all the

way). Attach this gauge manifold to the service valves on

the unit.

WARNING

To avoid possible explosion, the line from the nitrogen

cylinder must include a pressure regulator and a

pressure relief valve. The pressure relief valve must be

set to open at no more than 150 psig.

2. Connect a cylinder of dry nitrogen to the center port on

the gauge manifold.

3. Open the hand valve a minimal amount on the line coming from the nitrogen cylinder.

4. Open the high pressure valve on the gauge manifold.

Pressurize the refrigerant lines and the indoor coil to 150

psig (1034 kPA).

WARNING

To avoid possible explosion or equipment damage, do

not exceed 150 psig when pressure testing.

After you reach 150 psig, close the valve on the nitrogen cylinder. Disconnect it from the gauge manifold. If you plan to use

an electronic leak detector, add a trace of R-22 to the system (if

permitted by current EPA regulations).

5. Apply a soap solution on all connections and joints. If you

see bubbles, you have a leak. Mark these locations.

6. Use the gauge manifold to carefully release the nitrogen

from the system. If leaks were found, repair them. After

repair, repeat the above pressure test. If no leaks exist,

proceed to system evacuation.

SYSTEM EVACUATION

1. Connect the vacuum pump, high vacuum manifold set

with high vacuum hoses, thermocouple vacuum gauge

and charging cylinder as shown in Figure 10. Begin with

all valves fully closed.

2. If service fill valves are used for evacuation, use a core

remover to lift the valve core. It provides greater efficiency.

3. Confirm proper pump and gauge operation. Open the

shutoff valve that leads to the high vacuum gauge manifold. Start the pump. When the compound gauge (low

side) reading drops approximately 29 inches of vacuum,

open the valve to the thermocouple vacuum gauge and

evacuate until the gauge reads 250 microns or less.

4. Close the valve to the thermocouple vacuum gauge. This

avoids potential gauge damage from “pegging the meter”.

5. Open the high and low side valves on the gauge manifold.

Keeping the valve on the charging cylinder closed, open the

valve on the gauge manifold that leads to the cylinder.

6. Evacuate the system to about 29 inches Hg as measured by

the compound (low side) gauge.

7. Open the valve to the thermocouple vacuum gauge. Evacu-

ate until the gauge reads 250 microns or less.

8. Close the valve to the vacuum pump. Wait five minutes,

then check the pressure on the thermocouple vacuum

gauge:

• If the pressure is not more than 1500 microns, the system is

leak-free and properly evacuated. Proceed to Step 9.

• If the pressure rises, but holds at about 5000 microns, moisture and non-condensibles are still present. Open the valve

to the vacuum pump, and go back to Step 7.

• If the pressure rises above 5000 microns, a leak is present.

Go back to “Leak Testing” section above

9. Close the valve to the thermocouple vacuum gauge. Close

the valve to the vacuum pump. Shut off the pump.

IM-802 Page 11

Page 12

Figure 10. System Evacuation Components

THERMOCOUPLE

VACUUM

GAUGE

DIAL-A-CHARGE

TO

RELATED

GAUGE

PORTS OF

COND. UNIT

LARGE DIAMETER

BRAIDED VACUUM

A. LOW S IDE VALV E

B. HIGH SIDE VA LVE

C. VACUUM PUMP

D. THERMOCOUPLE GAUGE

E. MANIFOLD GAUGE

F. CHAR GING CYLI NDER

HIGH VACUUM

MANIFOLD

HOSES

CHARGING CYLINDER

LOW SIDE

GAUGE

HIGH VACUUM PUMP

A

HIGH SIDE

GAUGE

D

B

C

E

F

PRELIMINARY CHARGE

ADJUSTMENT

CAUTION

See the wiring diagram or outdoor unit specification

sheet to determine if this unit has a crankcase heater. If

it does, you must connect electrical power to the unit for

four hours before operating the compressor. Failure to

do so can result in compressor damage.

CAUTION

During all installation and service work, follow all

regulations of the Environmental Protection Agency.

(This system uses R-22 - an HCFC [Hydrogenated

Chlorofluorocarbon].) Violation of EPA regulations can

cause environmental damage and result in fines or

other penalties.

Use a male hex head wrench (5/16" for liquid) to carefully

open the liquid valve stem on the unit. Use a service wrench

or crescent wrench to open the suction ball valve. The valve is

fully open with a 90-degree turn (i.e. the stem is inline with the

valve flow direction).

The outdoor unit is factory charged with 2 lb. R-22.

CAUTION

Use only refrigerant that is certified to meet ARI

Standard 700. Used refrigerant can cause compressor

damage and will void the warranty. Most portable

machines cannot clean used refrigerant well enough to

meet this ARI Standard.

CAUTION

When adding additional refrigerant to a system, add

only refrigerant vapor (not liquid) through the suction

valve (low side) on the outdoor unit. Any other practice

can cause compressor damage.

FINAL CHARGE ADJUSTMENT

CAUTION

Never operate the compressor with the suction valve

closed to “test the compressor pumping efficiency”. In

some cases, this can cause serious compressor

damage.

For 25’ of line set, the 7-1/2 ton charge is approximately 17 lb.

For 25’ of line set, the 10 ton is approximately 20 lb. of R-22.

Do not start with these amounts.

For installation greater than 25’ of line set, indoor unit airflow,

condensing unit location and number of tubing fittings will

have an impact on final unit charge amount. Start with half of

the 25’ line set charge and proceed.

Turn the electrical power on, and let the system run. Wait for

the refrigerant pressures to stabilize.

EXPANSION VALVE INDOOR COILS

NOTE: EXPANSION VALVE BULB; Must be in place on

suction line and insulated.

NOTE: EXPANSION VALVE INDOORS; At stabilized

cooling conditions and with an outdoor temperature

of 60°F or higher, the system should have from 9°F

to 13°F subcooling. For a proper subcooling reading, measure the refrigerant pressure and temperature at the outdoor unit’s liquid line service valve. If

you have less than 9°F subcooling, add charge. If

you have more than 13°F subcooling, remove

charge.

While reaching the proper subcooling level, it is important to

know the discharge line temperature. This temperature should

be at least 80°F over ambient or the unit is flooding back to the

compressor. If flooding (i.e. low discharge line temperature)

occurs, adjust the valve stem on the expansion valve inward

(clockwise viewing the end of the expansion valve). This will

increase the super heat.

After achieving the proper subcooling and a sufficient discharge temperature, make small adjustments to the expansion

valve stem to reach 8°F to 10°F of superheat. Adjusting the

valve stem in (clockwise) increases superheat. Adjusting the

valve stem out (counter clockwise) decreases superheat. If the

system is performing properly, re-install the service port caps

and the valve bonnets. With the valve opened, the valve bonnet is the primary seal against refrigerant leaks. Apply two

drops of clean oil to the cap threads, allowing the oil to run

down to the inner cap seal surface. Close the caps finger-tight.

Then tighten an additional two to three hex flats.

NOTE: Subsequent opening and replacing of the cap will

require only 1/2 to 1 hex flat. See the table below for

the torque required for an effective seal on the valve

bonnet (1/6 turn past finger tight).

Table 9: Valve Bonnet Torqure

Tubing Size Torque (Foot-Pounds)

5/8 14

1 3/8 16

After closing the valve bonnet, perform a final refrigerant leak

test on the valves and sweat connections. Return the room

thermostat to the desired settings.

Page 12 IM-802

Page 13

TROUBLE SHOOTING

IMPORTANT

Qualified installer/servicer only

When troubleshooting, the first step should always be

to check for clean coils, clean filter(s) and proper

airflow. Indoor airflow should be 375 to 425 CFM per

ton of cooling based on the size of the outdoor unit. The

most common way of establishing indoor airflow is

heating temperature rise. Indoor airflow will then be

(Heating output of equipment) / (1.1 x temp. rise). In

The ACU90/120 condenser is equipped with a 3-phase

scroll compressor. Improper phase rotation can

damage equipment.

If the unit sounds noisy and/or the suction and liquid pressures

are almost equal, the compressor is operating in the reverse

rotation. Reverse the two (2) incoming power supply leads.

other cases, measurement of external static pressure is

helpful. For details, see the Installation Instructions for

your indoor equipment.

Table 10: Trouble Shooting Analysis

COMPLANT PROBABLE CAUSE REMEDY

1. Purge or pump-down excessive charge.

2. Make certain that coil is not fouled in any way, or that air is not re-circulating.

3. Purge these gases from the system. Recharge system, if necessary.

1. Charge system until sight glass is clear of bubbles.

2. Replace compressor.

1. Open the liquid line valve.

2. Replace filter-dryer.

3. Detach the bulb from the suction line and hold in one hand. If no liquid refrigerant goes through the valve, replace the valve.

4. Test the unit for leaks. Add refrigerant until sight glass is free from bubbles,

after repairing leak.

5. Clean or replace filter.

6. Defrost and clean coil. Clean or replace filters.

7. Excessive liquid line drop. Check liquid line size.

8. Increase the blower speed.

1. Correct valve action or replace the valve.

2. Fasten bulb securely to suction line.

3. Replace compressor.

1. Close the disconnect switch.

2. Check the cause of failure and replace the fuse.

3. Adjust to lower temperature.

4. Turn selector switch knob to "Cool" position.

5. Replace contactor and/or relay.

6. Inspect and secure all electrical connections.

1. High Head Pressure

2. Low Head Pressure

3. Low Suction Pressure

4. High Suction Pressure

5. Compressor will not

start.

1. Excessive charge of refrigerant in system.

2. Inadequate supply of air across the condenser coil.

3. Non-condensate gases in the system.

1. System low on refrigerant.

2. Compressor valves broken.

1. Liquid line valve closed.

2. Restricted liquid line.

3. The bulb of the thermal expansion valve has lost its

charge.

4. System low on refrigerant.

5. Dirty filters.

6. Coil frosted up.

7. Flash gas in the liquid line.

8. Quantity of air through evaporator not adequate.

1. Expansion valve stuck open.

2. Expansion valve bulb not in contact with suction line.

3. Suction and/or discharge valve leaking or broken.

1. Disconnect switch open.

2. Blow fuse or fuse at disconnect switch.

3. Thermostat set too high.

4. Selector switch in "Off" position.

5. Contactor and/or relay coils burned out.

6. Loose or open electrical connection in either the control or power circuit.

3-Phase Scroll Compressor

CAUTION

IM-802 Page 13

Page 14

WIRING DIAGRAM

OUTDOOR POWER SUPPLY

L3

CC

T3

L2

T2

R

SC

COMP

ON

FAN

AUTO

COIL

INDOOR POWER SUPPLY

COOL

OFF

HEAT

24V

G

Y

THERMOSTAT

SYSTEM

SWITCH

W

LOW VOLTAGE

TRANSFORMER

CONTACTOR

COIL

COIL

FAN RELAY

COIL

C

CH

L1

C

T1

FC

MOTOR

P

H

P

L

R

THERMOSTAT

BULB

R

THERMOSTAT

SWITCH

THERMOSTAT

ANTICIPATOR

THERMOSTAT

ADJ. HEAT

ANTICIPATOR

Page 14 IM-802

Page 15

IM-802 Page 15

Page 16

This document contains the most current product information as of this printing. For the most up-to-date

product information, please go to www.mcquay.com.

www.mcquay.com • 800-432-1342

Loading...

Loading...