McHale Fusion 3 Operator Instructor Manual

Fusion 3 Baler & Wrapper

Operator Instructor Manual

Issue 1

McHale

Ballinrobe

Co. Mayo, Ireland

Tel: +353 94 9520300

Fax: +353 94 9520356

Email: sales@mchale.net

Website: www.mchale.net

CLT00485_1

This page is intentionally blank

McHale Fusion 3 Baler & Wrapper

Thank you for buying this McHale machine, you have chosen wisely!

Given proper care and attention, you can expect it to provide you with

years of dependable service.

Warranty/Guarantee

Attention End User!

Please ensure your machine is fully registered with McHale,

by your dealer, at the time of delivery.

Failure of the dealer to register the machine will render your warranty void!

You can check the registration of your machine by visiting www.mchale.net.

It is important to quote the machine serial number when ordering spare parts or

requesting technical assistance. Space is provided below to record machine details.

See “Description of the serial number plate” on page 30.

Serial number:

Y ear of manufacturer:

Date of delivery:

If you require further copies of this instruction manual,

please quote part number: CLT00485

Due to a policy of continuous product development and improvement, McHale

Engineering reserves the right to alter machine specifications without prior notice and

any obligation to make changes or additions to the equipment previously sold.

Please note that all specifications marked with an in this manual only relate to

certain models or optional equipment. Also these specifications may not be available

in all countries.

It is vital to replace defective parts of the machine immediately and to use only genuine

McHale spare parts, as these are designed and manufactured to the same standard

as the original machine. Spare parts can be obtained from your McHale dealer.

3

McHale Fusion 3 Baler & Wrapper

Table of Contents

1 Introduction 8

2 Product Information 9

2.1 Designated use of the machine 9

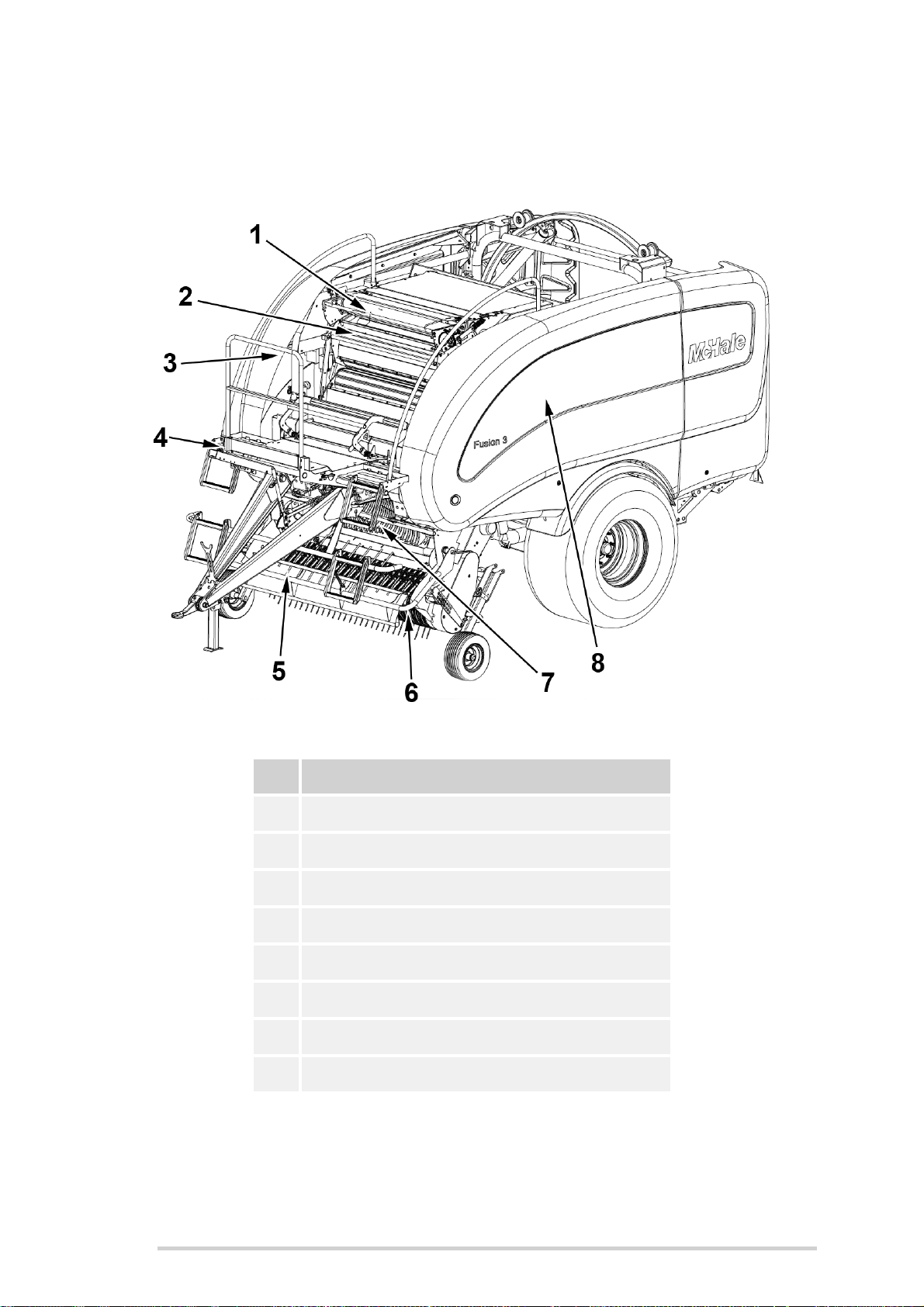

2.2 Front view 10

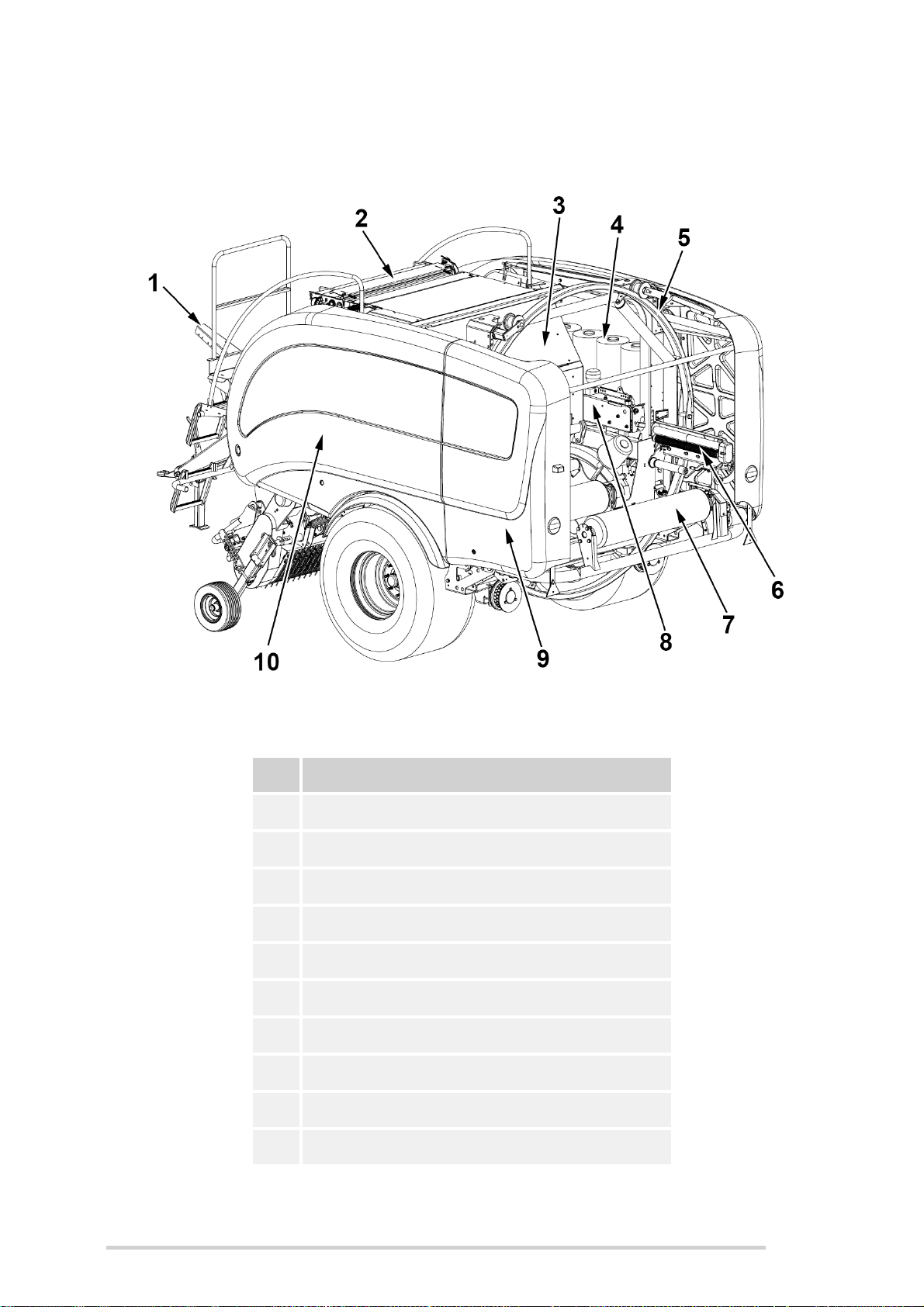

2.3 Rear view 11

2.4 General dimensions & specifications 12

2.5 Tractor attachment 12

2.6 Machine specifications 13

2.7 Tyre specifications 13

3 General Safety 14

3.1 Be aware of all safety information 14

3.2 Follow all safety instructions 14

3.3 Store all items carefully 15

3.4 Protective clothing 15

3.5 In case of emergencies 15

3.6 Stay clear of rotating elements 15

3.7 Operating the McHale Fusion 3 15

3.8 In the event of a fire 16

3.9 General safety warnings 16

4 Specific Safety Warnings 20

4.1 Electronic safety warnings 20

4.2 Hydraulic safety warnings 20

4.3 Noise level 21

4.4 Fire precautions 21

4.5 Special safety devices/instructions 21

4.6 Safety instruction decal locations 22

4.7 Safety warnings & instructions explained 23

4.8 Description of the serial number plate 30

4.9 Machine lifting guidelines 31

5 Tractor Requirements & Preparation 32

5.1 Tractor requirements 32

5.2 Control box installation 33

5.3 Attaching to drawbar 33

5.4 Attaching ‘break-away’ brake 33

5.5 Attaching the Fusion 3 to a 540 rpm PTO 34

5.6 Lighting system 34

5.7 Fusion 3 set-up & tractor hydraulic system 34

5.8 Which hydraulic system is used? 36

5.9 Hydraulic spool valve setup 36

5.10 Attaching hydraulic hosing to the tractor 37

5.11 Connecting the control box 38

4

McHale Fusion 3 Baler & Wrapper

6 Baler Requirements & Preparation 39

6.1 Net requirements 39

6.2 Care of the net roll 39

6.3 Care of the net wrapping system 40

6.4 Loading & operating the netter system 40

6.5 Net cutter setting 41

6.6 Net tension bar setting 43

6.7 Chopper unit knife removal & installation 43

6.8 Automatic lubrication system 48

6.9 Gear box oil 51

6.10 Tyre inflation pressures 51

6.11 Wheel chocks 52

6.12 Drawbar and PTO shaft stand usage 52

6.13 Drawbar adjustment 54

6.14 PTO Shaft adjustment & maintenance 55

7 Electronic Control System 58

7.1 Control box functions 59

7.2 Control box features 60

7.3 Menu Structure 65

7.4 Warning messages 70

7.5 Simulating a “bale to wrapping” cycle 74

8 Wrapper Operation 75

8.1 Loading plastic film 75

8.2 Plastic film requirements 77

8.3 Wrapping process 78

8.4 Dispenser adjustment 79

8.5 Cut and hold system 79

9 Road Traffic Safety & Operation 82

9.1 Before travelling on any public roadway 82

9.2 Road transportation 83

9.3 Road transportation with side tip attached 83

9.4 ‘Break-away’ brake 84

10 Field Operation & Baler Adjustments 85

10.1 Break-in period 85

10.2 Swath preparation 85

10.3 Pick-up reel height adjustment 86

10.4 Crop guard adjustment 87

10.5 Unblocking system 87

10.6 Chopping system 88

10.7 Selectable knives 88

10.8 Bale density gauge 89

10.9 Setting chamber pre-charge pressure 89

10.10 Chamber door lock 91

10.11 Spare film holders & door latch safety 91

10.12 Adjusting pick-up float springs 92

10.13 Chain adjustments 93

5

McHale Fusion 3 Baler & Wrapper

11 Accessories & Optional Equipment 98

11.1 Drawbar hitch options 98

11.2 Stand options 98

11.3 Brake options 99

11.4 Tyre options 99

11.5 Side tip option 99

11.6 Selectable Knives 100

11.7 Crop Roller 100

11.8 Dispenser gear options 101

12 Attachments 102

12.1 Side tip 102

13 Machine Maintenance 105

13.1 Maintenance intervals 105

13.2 Tightening torque values 108

14 Storage 109

14.1 End of season 109

14.2 Start of season 109

15 Trouble Shooting 111

15.1 Trouble shooting overview 111

16 Certification & Warranty 116

16.1 Declaration of Conformity 116

16.2 PDI Form 116

16.3 Change of ownership pre-checks 116

16.4 Limited Warranty 116

6

McHale Fusion 3 Baler & Wrapper

This page is intentionally left blank

7

McHale Fusion 3 Baler & Wrapper

1

Introduction

The McHale Fusion 3 Baler & Wrapper is a completely new product. This product

combines the baling process with the wrapping process, in one machine. The design

has been developed based on years of extensive research and development in the field

of round bale wrappers and balers. Given proper care and attention, the McHale

Fusion 3 will provide years of reliable and dependable performance.

Please do not assume that you know how to operate and maintain your machine before

reading this manual carefully. In order to prevent misuse, damage and accidents, it is

very important that everybody who will operate the McHale Fusion 3 be a fully trained

operator. They must read and fully understand all of the contents of this manual, before

operating the machine, paying particular attention to the following:

Safety instructions

Functions

Controls (hydraulic & electrical)

It is highly recommended to get acquainted with any new machinery slowly. Take time

to learn and understand all of the features of the machine. Proficiency will increase as

more experience is obtained.

If you have any questions in relation to the instructions in the manual, please contact

your McHale dealer. It is highly recommended that training be sought from your local

McHale dealer.

The operator is solely responsible for the safe use and maintenance of the machinery,

in accordance with this manual. Keep this manual safe and make sure it remains with

the machine, at all times.

8

McHale Fusion 3 Baler & Wrapper

2

Product Information

The McHale Fusion 3 is protected against many dangers to itself while being operated

from the control box in both manual and automatic cycles. However, it is of the utmost

importance for the safety of the operator and for others, that the operator pays attention

to all warnings and instructions given in this manual. In particular all safety devices,

decals, guards and controls must be in place and in fully functioning condition. Never

try to clear any malfunction when the tractor is switched on or while the machine is

running. Keep the “Danger Zone” (An area around the machine, detailed in “Danger

zone” on page 16) free of all persons and animals at all times, while the machine is in

operation. This manual must be read and fully understood by anyone who will operate

the machine.

2.1 Designated use of the machine

The McHale Fusion 3 is exclusively designed for normal use in agricultural

applications. The machine has been designed to pick up and compact stalks from the

ground, to produce cylindrical bales of forage, which are in turn wrapped with plastic

stretch film for the purpose of storing as fodder for feeding livestock. This designation

includes the movement of the machine, between fields by track or road, incidental to

the round baler/wrapper’s main use. The manufacturer will not be held responsible for

any loss or damage resulting from machine applications other than those specified

above. Any other use the machine may be put to, is entirely at the owners/operators

risk.

The designated use of the machine includes that:

the operating, maintenance and repair instructions given by the manufacturer

will be strictly fulfilled

exclusively persons who are familiar with it and instructed about the risks are

entitled to operate, maintain and/or repair the machine

the relevant health and safety requirements, that may be in force in the

country of use, will be strictly followed

no other equipment or accessories, other than released by McHale, are

installed in the machine. The use of any other equipment or accessory is

entirely at the owner/operators risk. In such cases, unauthorised

modifications/changes exclude any liability of the manufacturer.

WARNING: Loss of machine validity

By any alteration of safety equipment, the declaration of conformity and

the CE sign loses it’s validity for this machine.

9

2.2 Front view

McHale Fusion 3 Baler & Wrapper

No. Machine Function

1 Netter unit

2 Net tension bars

3 Hydraulic section (Inside cover)

4 Chamber door pressure clock

5 Crop guard

6 Pick-up reel

7 Chopper unit

8 Wheel chocks & knife blanks (Inside cover)

10

2.3 Rear view

McHale Fusion 3 Baler & Wrapper

No. Machine Function

1 Hose carrier

2 Netter unit

3 Top chamber door

4 Spare film section (Inside cover)

5 Dispenser ring

6 Dispenser

7 Table roller

8 Cut & hold unit

9 Dispenser access door

10 Drive side

11

McHale Fusion 3 Baler & Wrapper

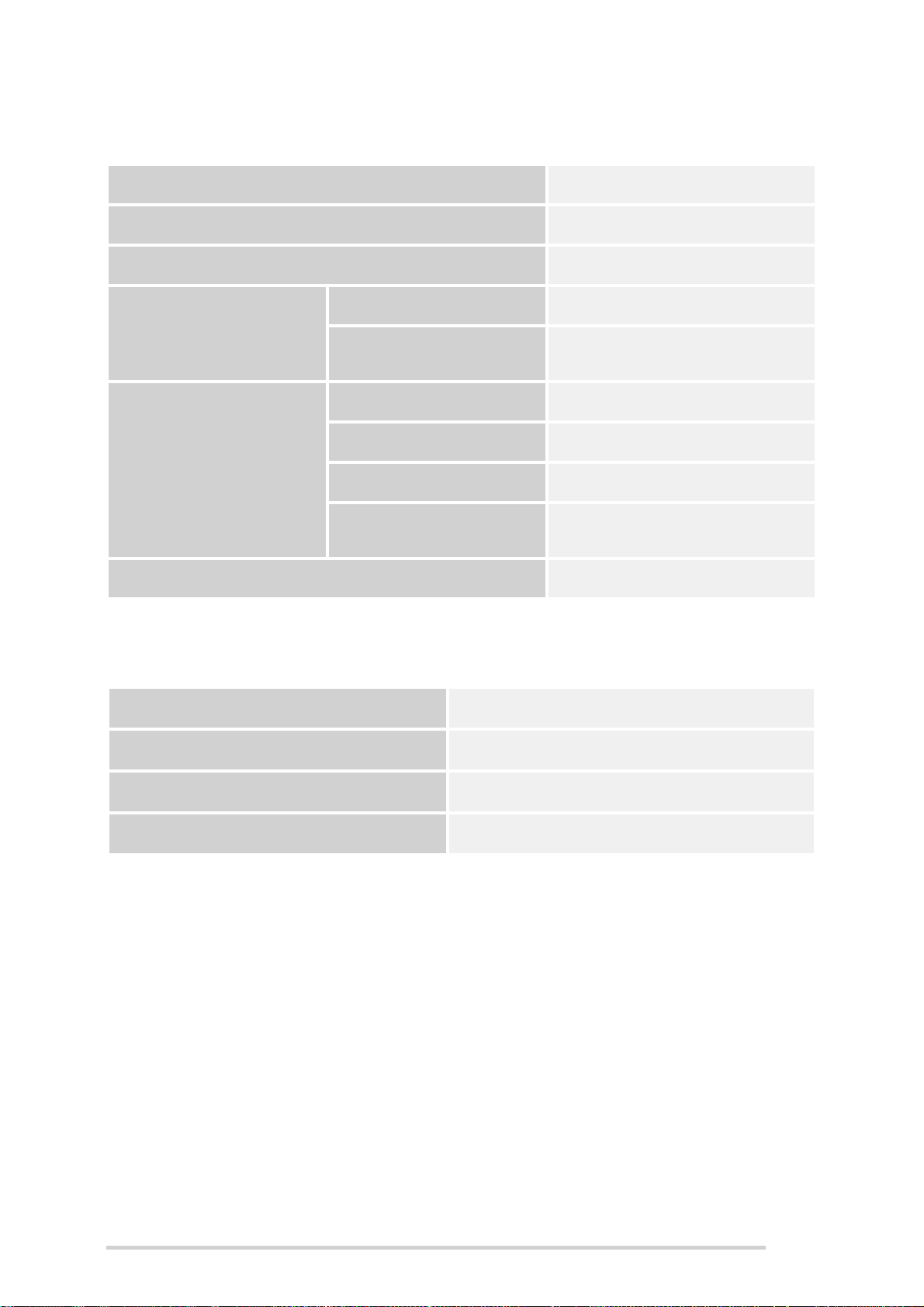

2.4 General dimensions & specifications

T ransport length 5.8 m (19’ 1”)

T ranspor t width 2.76 m (9’ 1”)

Transport height 3.02 m (9’ 11”)

T ransport weight 5700 kg (12,566 lbs)

Tyre dimensions 560/60 R22.5

Tyre pressure 1.65 bar/24 P.S.I.

Tyre dimensions (Pick-up reel) 170/60 - 8

Tyre pressure (Pick-up reel) 2.07 bar (30 P.S.I.)

Maximum road speed 40 km/h (25 mph)

Brake system

Check with national road traffic regulations in the individual country!

Hydraulic brakes (Cemagref approved)

Air brakes* (TUV approved)

2.5 Tractor attachment

Drawbar

PTO speed 540 rpm

Lighting 12 V / 7 pin socket

Electrics 12 V / 20 Amp euro socket

Hydraulic systems Load sensing, open centre, closed centre

Minimum pressure 180 bar (2610 P.S.I.)

Minimum flow rate

Low drawbar

High drawbar *

45 l/min (9.9 gal/min) @ 180 bar

(2610 P.S.I.)

(*) May not be available in all countries, check with your McHale dealer for availability

in your country.

Units are given in both metric and UK imperial values, with the latter shown in brackets.

12

McHale Fusion 3 Baler & Wrapper

2.6 Machine specifications

Bale chamber diameter 1.25 m (49”)

Bale chamber width 1.23 m (48”)

Pick-up width 2.00 m (78”)

Net width Max. 1.26 m (49.5”)

Net tying

Net length

Film width 750 mm (29½”)

Film stretch 70% (55% optional)

Plastic film

Dispenser rotary speed Max. 30 rpm

Film layers 2+2; 2+2+2; etc.

Film storage

2000 m / Max 4000 m

(2187 yd / Max 4374 yd)

8 Rolls (+ 2 Rolls on

dispenser)

2.7 Tyre specifications

Tyre type Pressure

560/60 R22.5 1.65 bar (24 P.S.I.)

650/50 R22.5 (Optional Specification) 1.65 bar (24 P.S.I.)

170/60 - 8 (Pick-up tyre) 2.07 bar (30 P.S.I.)

13

McHale Fusion 3 Baler & Wrapper

3

General Safety

3.1 Be aware of all safety information

Follow all safety precautions and practice safe operation of machinery, at all times.

Warning, caution, information & environmental messages:

When reading this manual, pay particular attention when you see the symbols below

i.e. Warning, Caution, Information & Environmental. They will be used at various points

in this manual and may also appear on safety decals on the machine. The purpose of

these messages is to ensure that the most important information stands out from the

rest of the text.

WARNING: This symbol indicates a potentially hazardous situation,

that if not avoided could result in machinery damage, personal injury

or even death.

CAUTION: This symbol indicates a potentially hazardous situation,

that if not avoided could result in machinery damage or personal

injury.

INFORMATION: This symbol is used to identify special instructions

or procedures which, if not followed strictly, could result in

machinery damage.

ENVIRONMENTAL: This symbol reminds you to respect the

environment in relation to the correct disposal of waste material.

3.2 Follow all safety instructions

Using this manual, read all safety instructions and messages, and

be aware of the meanings of all safety decals. If safety decals are

damaged or missing due to wear and tear or component

replacement, ensure that they are replaced. Refer to section 4.7 in

this manual (or spare parts book provided) to see the spare part

codes for the relevant decals, which are available from your McHale

dealer.

14

McHale Fusion 3 Baler & Wrapper

As with all machinery, learn all operations and use controls by reading this manual

thoroughly. Do not attempt to let anyone operate this machine without being fully

instructed.

3.3 Store all items carefully

Store all attachments such as spare net rolls, films rolls and any

other stored items in a secure and safe manner so as to prevent

items from falling. Keep storage areas clear of bystanders and

children.

3.4 Protective clothing

Always wear clothing and safety equipment that is fit for the job at

hand, never wear loose clothing. In the event of loud noises, wear

suitable protective hearing devices. Use of mobile phones or radio/

music headphones are not recommended while operating

machinery as these impair the operators attention.

3.5 In case of emergencies

In the event of any accident, emergency equipment should be kept

close at hand. A first aid kit and fire extinguisher along with

emergency phone numbers should always be available to machine

operators.

3.6 Stay clear of rotating elements

Serious injury or death can result from entanglement of clothing or body parts with PTO

shafts, drivelines and other rotating and moving components.

Keep all guards in place at all times, only wear close fitting clothing, and ensure that

tractor engine has stopped, key removed and that PTO has stopped turning before

carrying out any adjustments, connections or cleaning of PTO driven equipment.

3.7 Operating the McHale Fusion 3

In order to avoid serious injury or even death by being pulled into the machine:

Never attempt to feed net or crop into the baling chamber or attempt to unplug

pick-up area while the baler is running.

Disengage the PTO, apply handbrake, shut the tractor engine off and remove

the key from the ignition.

Stand well clear of the baler and tractor when the machine is operating.

15

McHale Fusion 3 Baler & Wrapper

3.8 In the event of a fire

In the event of a fire, the following is given only as a guideline

procedure as it is the operator’s decision to ascertain the

seriousness and hence the solution to the situation.

1. Switch control box to manual mode (See “Electronic Control System” on

page 58). Immediately tip bale off rear roller and leave roller in tipped position.

2. Eject the bale from the baling chamber by opening the chamber doors.

3. Move the tractor and baler away from the flammable material.

4. Disengage the PTO, turn off the tractor and remove the key from the ignition.

5. Remove all hosing and electrical looms from the machine.

6. With all connections removed, disengage the drawbar from the tractor.

7. Drive the tractor away from the baler.

8. Using a suitable fire extinguisher, put out all the fires.

WARNING: Fire prevention

It is recommended that the baler be kept reasonably clean and free of

build-ups of grass, lubricants, etc. This will help to reduce the risk of fires.

3.9 General safety warnings

Read and understand this operator manual before using the machine. If any of the

instructions appear unclear do not hesitate to contact your McHale dealer.

Only competent persons who have read and fully understood this manual are qualified

to operate this machine. The owner of this machine is obliged, by law, to ensure that

every operator understands all of the functions, controls, working processes and safety

warnings, before operating the machine.

Safety devices

All safety devices such as guards, protection parts and safety controls must

be in place and in fully functioning condition. It is forbidden to operate this

machine with defective or incomplete safety devices.

Danger zone

The ‘Danger Zone’ is the area around the rotating dispensers (approx. 2

metres radius from the rotating centre axis) & (a minimum of 5 metres) at the

back of the machine to allow for safe bale discharge.

NOTE: “Danger Zone” can vary in size

The operator must be aware of the ‘Danger Zone’ which can vary in size,

depending on operating conditions, i.e. hilly terrain.

16

McHale Fusion 3 Baler & Wrapper

It is the operator’s responsibility to ensure that there is no person in the

‘Danger Zone’ while operating the machine, especially during start up.

Before repair or reassembly

Safe lifting gear of sufficient capacity must be used for machine assembly. All

chains and slings used must be in good condition.

Before operation

The operator must ensure that the manufacturer’s instructions for attaching

and detaching the machine are followed. This includes the drawbar

attachment, the electric and hydraulic lines, in particular the lighting and brake

system.

The operator must ensure that all covers are closed and all safety devices are

in operating mode.

The operator must ensure that there is no person in the ‘Danger Zone’.

Always be familiar with the health and safety requirements that may be in

force in the country of use.

During Operation

While operating this machine on hilly or sloping ground the operator must take

extra precautions, in particular the ‘Danger Zone’ is increased in such

conditions as bales are more likely to roll away, causing a potential risk.

The operator must ensure that there is a minimum of 4 m clearance between

the machine and any obstacle above, in particular electrical high voltage lines.

Never operate the machine with dispenser safety arms damaged or missing.

Be careful when working with the cut and hold. Remember that the

accumulators are under pressure.

Avoid contact with the knife.

Do not attempt to clamp plastic film in the cut and hold mechanism.

Particular care must be taken, if the machine is left idle for any extended

period, to ensure that all sensors and safety features are working correctly.

WARNING: Do not carry people or animals on the machine

The operator must ensure that no persons or animals are carried on the

machine at any time or are hidden under the machine (on the tractor

persons are only allowed to sit on the relevant seats).

17

McHale Fusion 3 Baler & Wrapper

Before travelling on public roads

The owner of this machine is obliged by law to ensure that every operator has

a valid driving licence and is familiar with the road traffic regulations relating to

the country of use.

Always ensure that the electronic control box and oil supply are switched off.

Always attach the dispenser safety chain.

When parking, both wheels of this machine have to be blocked using the

wheel chocks and hand brake (if fitted) should be applied according to the

road traffic regulations, relating to the country of use.

Performing maintenance

Maintenance and repair work on the Fusion 3 should always be carried out in

accordance with this manual.

Maintenance and repair work exceeding the content of this manual should

only be carried out by qualified persons or your McHale dealer.

When conducting maintenance work tie long hair behind your head. Do not

wear a necktie, necklace, scarf or loose clothing when you work near the

machine or moving parts. If these items were to get caught, severe injury

could result.

Before working on this machine, such as replacing net/film rolls, clearing

forage away from any part of the machine, or altering any setting, the operator

must ensure the following:

(a) The tractor has definitely stopped moving

(b) The hand brake is applied

(c) The engine is shut down

(d) The ignition key is removed

(e) PTO shaft is removed from PTO stub

(f) Electronic power supply and control box is disconnected

(g) Hydraulic oil supply is switched off

* It is forbidden to open any safety guards or to carry out any work on the machine, unless

the above specified precautions have been carried out.

When conducting maintenance work always support the machine properly.

Where possible, lower the attachment or implement to the ground before you

work on the machine. If it is not possible to lower the machine or attachment

to the ground, always securely support the machine or attachment. Do not

work under a machine that is solely supported by a jack. Never support the

machine with props that may break or crumble under continuous load.

Never disable any electrical safety circuits, tamper with safety devices or carry

out any unauthorised modification to the machine.

Avoid heating near pressurised fluid lines, as pressurised lines can be

accidentally damaged when heat goes beyond the immediate flame area.

18

McHale Fusion 3 Baler & Wrapper

During inspection

If carrying out an inspection during machine operation within the ‘Danger

Zone’ (highly dangerous and NOT recommended!), then there should be a

fully trained and competent second person operating both the tractor and

baler controls. If at any time the second operator loses sight of the inspector,

turn off all tractor power immediately! Such inspection should only be carried

out if all guards are fully in place, the machine is on level ground and a safe

distance is kept from any hazards on the machine i.e. pick-up region.

19

McHale Fusion 3 Baler & Wrapper

4

Specific Safety Warnings

4.1 Electronic safety warnings

This machine is equipped with electronic parts and components which comply

to the EMC directive 2004/108/CE but still may be influenced by

electromagnetic transmissions of other apparatus, such as welding machines,

etc.

Check electric cables regularly for signs of breakage or wear. If in doubt

always replace (faulty safety circuits will cause risks).

Do not modify any safety circuits.

4.2 Hydraulic safety warnings

The maximum pressure in the hydraulic system of this machine should not

exceed 210 bar.

Always ensure the system is not under pressure before working on the

machine. Oil under pressure can penetrate the skin and cause injury. Beware

of pipes under accumulator pressure, depressurise lines by unthreading

connections extremely slowly.

Hydraulically actuated devices, such as pick-up, cutting device and wrapping

ring, must be blocked mechanically against movement, before working on the

machine.

If any hoses are removed or replaced ensure they are marked and re-installed

to the correct position during re-assembly.

Check hoses regularly for signs of leakage or wear. If in doubt always replace.

The recommended maximum working time of hoses should not exceed 5

years. Only use exact specification McHale genuine replacement parts.

Do not work on hydraulic systems unless you are qualified to do so. This work

should only be carried out by qualified persons or your McHale dealer.

20

McHale Fusion 3 Baler & Wrapper

4.3 Noise level

The European Regulation 86/188/EEC directs employers and employees to

control the noise level at work. The noise level at field work may differ

according to the tractor, ground, crops and other environmental conditions.

In normal conditions, whilst driving the McHale Fusion 3, the noise level to

the driver’s ear does not exceed 70 dB (A) with the rear screen of the tractor

cabin open. The common noise level of the machine and the tractor is

primarily influenced by the tractor noise (radio is an additional noise source). It

is recommended to operate this machine with closed cabin windows.

4.4 Fire precautions

Be aware that crops are easily inflammable.

Do not smoke or make use of any open fire next to the machine.

A functioning fire extinguisher should always be available on the tractor.

The machine is to be kept clear of oil, grease, crops, string, plastic or any

other flammable material at all times.

Do not continue to work with overheated parts, cables or pipes, unless you

have identified and eliminated the reason for overheating.

4.5 Special safety devices/instructions

According to European safety regulation, the covers of this machine are

designed to be opened only by the aid of a special tool and to be closed

without a tool. To unlock the covers, the locks should be turned slightly anticlockwise with a 13 mm spanner or flat blade screwdriver. To lock the covers

push the cover towards the chassis until the fasteners lock into place. It is

forbidden to operate the machine without the covers or with them open. The

owner of the machine is obliged, by law, to ensure that all covers are inst alled

on the machine and are in good functioning condition.

When maintenance or repair work has to be carried out at the open bale

chamber, the additional upper chamber lever valve must be in the locked

position. Before the upper chamber can be closed it has to be unlocked again.

Before replacing the knives of the chopping system, make sure that all knives

are in the ‘UP’ position. Always use protective gloves when working at the

chopping system.

Avoid contact with the plastic film cutting knives.

21

McHale Fusion 3 Baler & Wrapper

4.6 Safety instruction decal locations

Figure 4.a - Decals on the front of the Fusion 3

22

Figure 4.b - Decals on the rear of the Fusion 3

McHale Fusion 3 Baler & Wrapper

4.7 Safety warnings & instructions explained

Danger areas which cannot be protected by any devices are marked by yellow safety

decals. Therefore it has to be ensured that all safety warnings and instructions are

understood and followed. If any of the decals are damaged or missing, they are

available from your McHale dealer. The relevant part numbers are shown in brackets.

The decals featured on the McHale Fusion 3 are displayed with their meanings below:

Free flow return to tank

(CST00006)

Danger of rotating parts, foreign objects

Keep clear of machine while working

(CST00014)

Keep hands clear of rotation roller

(CTS00017)

Keep hands out of crush area

(CST00019)

Check wheel nuts daily

(CST00020)

23

McHale Fusion 3 Baler & Wrapper

Diagram of plastic film path through dispenser

(CST00022)

Lifting hook location

(CST00032)

Do not dismantle

High pressure always

(CST00056)

Grease daily

(CST00060)

Do not stand on the platform or elsewhere on the

machine when the machine is moving or working

(CST00107)

Keep clear of pickup area as long as the engine is

running and the PTO shaft is connected to the tractor

(CST00108)

24

Read instruction manual before use

(CST00110)

McHale Fusion 3 Baler & Wrapper

Beware of high-pressure hoses, even when the

machine is switched off

Also, read and understand manual before working on

any part of the hydraulic system

(CST00111)

Knives of the cutting device should only be removed

with an appropriate tool and protective gloves

(CST00112)

Turn off and remove key from tractor

Read and understand the manual before working on or

performing maintenance on the machine

(CST00113)

Close protective covers before operating the machine

(CST00114)

Hydraulic accumulator is under high pressure

Slowly release hydraulic pressure before carrying out

any maintenance

(CST00115)

Beware of rotating dispensers, ring and moving

wrapping table rollers

(CST000116)

Knife release lever:

horizontal position-locked

vertical position-unlocked

(CST00118)

25

McHale Fusion 3 Baler & Wrapper

Keep hands out of the crush area between the roller

and chassis rail

(CST00120)

Maximum hydraulic pressure and maximum PTO

speed. This machine must not be connected to

hydraulic systems with pressure higher than 210 bar

(CST00121)

Stay clear of rotating PTO shaft. Never use the

machine if the PTO guard is missing or damaged.

Entanglement in the rotating drive line can cause

serious injury or death. It is important to ensure that

the rotating guard on the drive line rotates freely.

Always stop the engine and ensure the driveline has

stopped before making connections, adjustments or

cleaning out PTO driven equipment.

(CST00132)

General warnings

(CST00134)

Disconnect the Fusion 3 feed line and turn off the

control box during road use. Read the operation

instruction manual before proceeding.

(CST00135)

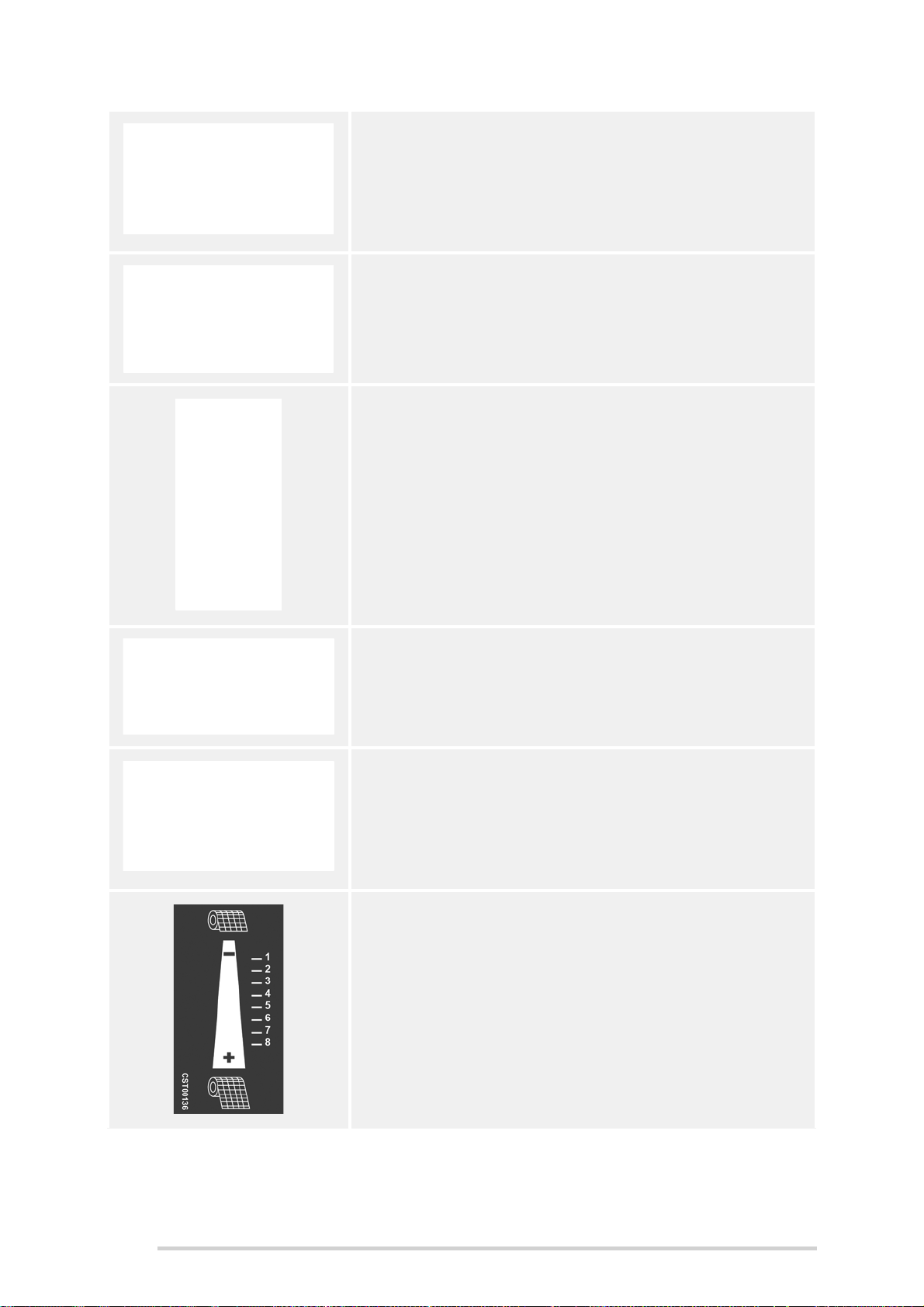

Net amount setting decal

(CST00136)

26

McHale Fusion 3 Baler & Wrapper

Dispenser park rotation decal

(CST00137)

Side Tip: Not for road use

(Placed on side tip only)

(CST00138)

Do not stand in the articulation area while the tractor

engine is running.

(CST00141)

Never perform any adjustments or reach into the netter

unless the PTO has been disengaged and the tractor

has been shut down and the key has been removed. It

is also recommended that the tension be released

from the netter knife to avoid it being tripped

accidentally.

(CST00142)

Stay clear of the rotating PTO shaft. Never use the

machine if the PTO guarding is missing or damaged.

Entanglement in rotating drive line can cause serious

injury or death. It is important to ensure that the

rotating guard on the driveline rotates freely. Always

stop the engine and ensure that driveline has stopped

before making connections, adjustments or cleaning

out PTO driven equipment.

(CST00143)

27

McHale Fusion 3 Baler & Wrapper

Crush hazard. Keep hands clear of rotating elements.

Do not remove the guard while the engine is running.

(CST00144)

Disconnect the power supply to the control box and

turn off the tractor before commencing work on the

electrical system or welding on the machine.

(CST00145)

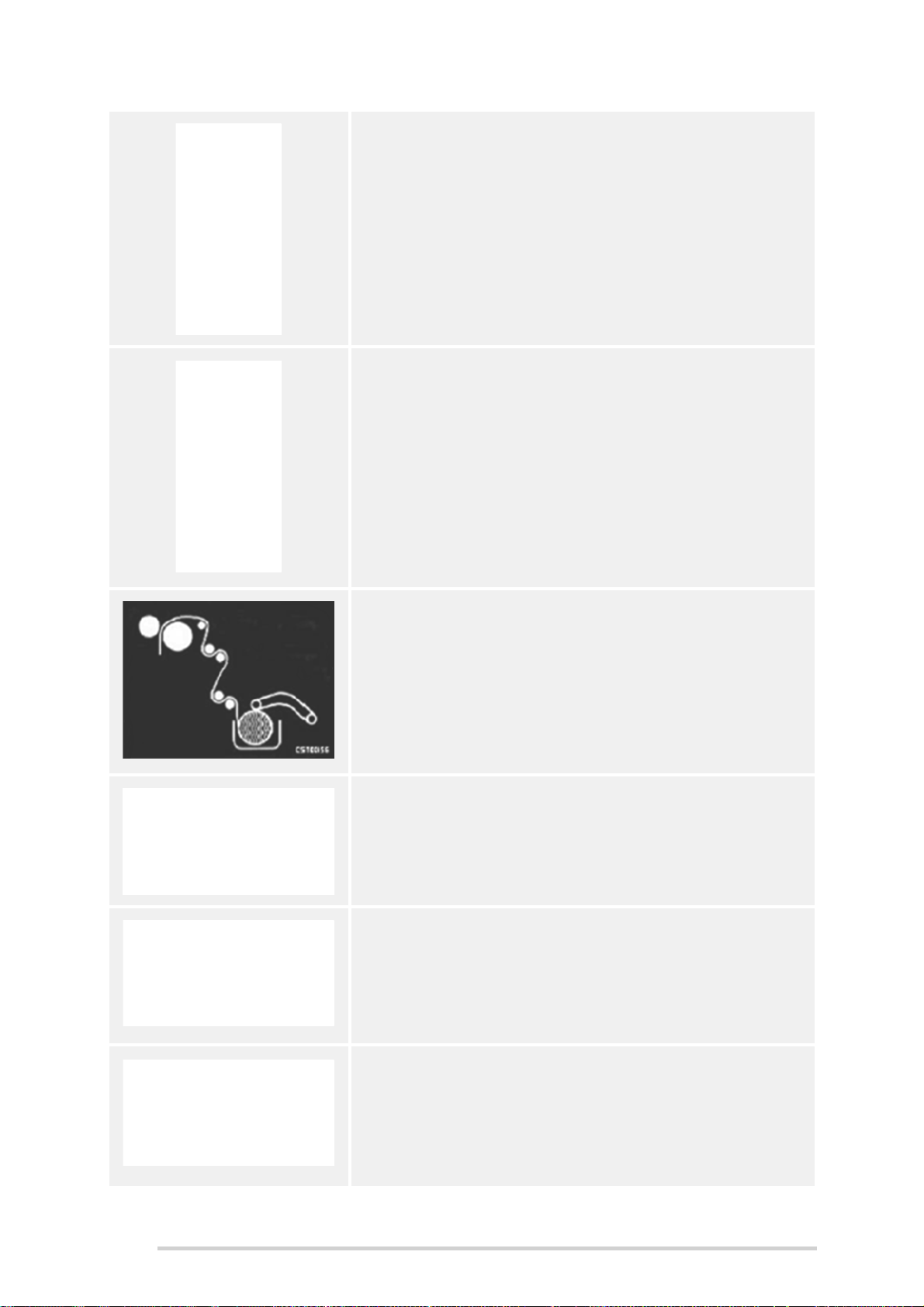

Diagram of net path through feeding rollers

(CST00156)

Ensure tyre pressure is at 1.65 BAR (24 P.S.I.)

pressure and torque nuts to 220Nm.

(CST00157)

Free rotating transfer roller

Do not step on this roller!

(CST00161)

Free rotating transfer roller

Do not step on this roller!

(CST00162)

28

McHale Fusion 3 Baler & Wrapper

Ensure area around brakes is clear of dry material

(CST00163)

Float decal. Indicating that during operation of the

baler, the control lever of the spool operating the pickup reel should be in the float position.

(CST00609)

The PTO wide angle joint must never exceed 80

degrees, both when stationary or during operation.

Permanent damage may result otherwise.

(CST00658)

Wheel direction

(CST00711)

Keep hands out of crush area

(CST00753)

Keep hands out of crush area

(CST00754)

Lock the chamber door before working on the open

bale-forming chamber

(CST00756)

29

McHale Fusion 3 Baler & Wrapper

4.8 Description of the serial number plate

The following is a description of the serial plate meanings:

a. Serial number of the machine

b. Year of manufacture of the machine

c. Model name/Number of the machine

d. Maximum vertical drawbar load (Newton’s)

e. Maximum horizontal drawbar load (Newton’s)

f. Maximum road speed (kilometres per hour)

g. Maximum gross weight at 10 kilometres per hour

h. Net weight of the machine

i. Maximum axle load at maximum road speed of 40 kilometres per hour

j. Vehicle width: with standard size tyres / optional specification tyres

k. Vehicle height (metres)

l. Vehicle length (metres) with no rear attachments / with side tip attachment

30

Loading...

Loading...