Page 1

© 2006 McCulloch

12802 Leffingwell Rd.

Santa Fe Springs, CA • U.S.A.

Made in China/Fabriqué à China/Hecho en China

User Manual

LOG SPLITTER

SAFETY OPERATION MAINTENANCE

WARNING • PLEASE READ

Both model number and serial number may be found on the main label . You should record both of them in a safe

place for future use.

Model: FB4052

Page 2

SAFETY WARNINGS & INSTRUCTIONS

EN

EN

• UNDERSTAND YOUR LOG SPLITTER

Read and understand the owner's manual and labels affixed to the log splitter. Learn

its application and limitations as well as the specific potential hazards peculiar to it.

• DRUGS, ALCOHOL AND MEDICATION

Do not operate the log splitter while under the influence of drugs, alcohol, or any medication that

could affect your ability to use it properly.

• AVOID DANGEROUS CONDITIONS

Put the log splitter on a 60 - 75cm high, stable, flat, and level work bench where there is plenty of

room for handling, and help the operator stay altert. Bolt the log splitter to the work surface if it

tends to slip, walk, or slide.

Keep your work area clean and well lighted. Cluttered areas invites injuries.

Do not use the log splitter in wet or damp areas or expose it to rain.

Do not use it in areas where fumes from paint, solvents or flammable liquids pose a potential hazard.

• INSPECT YOUR LOG SPLITTER

Check your log splitter before turning it on. Keep guards in place and in working

order. Form a habit of checking to see that keys and adjusting wrenches are

removed from tool area before turning it on. Replace damaged, missing or failed

parts before using it.

• DRESS PROPERLY

Do not wear loose clothing, gloves, neckties or jewelry (rings, wrist watches). They

can be caught in moving parts.

Protective electrically non conductive gloves and non-skid footwear are recommended when working. Wear protective hair covering to contain long hair, preventing it from get caught in machinery.

• AVOID ELECTRICAL SHOCK

Check that the electric circuit is adequately protected and that it corresponds with the power, voltage and frequency of the motor. Check that there is a ground connection, and a regulation differential switch upstream.

Ground the log splitter. Prevent body contact with grounded surfaces: pipes, radiators, ranges, and

refrigerator enclosures.

Never open the pushbutton box on the motor. Should this be necessary, contact a qualified electrician.

Mark sure your fingers do not touch the plug's metal prongs when plugging or unplugging the log

splitter.

• KEEP VISITORS AND CHILDREN AWAY

The log splitter must be always operated by one person only. Other people

should keep a safe distance from the work area, especially when the log splitter

is under operations. Never use another people to help you with freeing jammed

log.

• INSPECT YOUR LOG

Make sure there are no nails or foreign objects in logs to be split. The ends of the logs must be cut

square. Branches must be cut of flush with the trunk.

• DON'T OVERREACH

Floor must not be slippery.

Keep proper footing and balance at all times.

Never stand on log splitter. Serious injury could occur if the tool is tipped or if the cutting tools is

unintentionally contacted. Do not store anything above or near the log splitter where anyone might

stand on the tool to reach them.

• AVOID INJURY FROM UNEXPECTED ACCIDENT

Always pay full attention to the movement of the log pusher.

Do not attempt to load the log on until the log pusher has stopped.

Keep hands out of the way of all moving parts.

• PROTECT YOUR HANDS

• PROTECT YOUR EYES AND FACE

Any log splitter may throw foreign objects into the eyes. This can cause permanent

eye damage. Always wear safety goggles. Everyday eyeglasses have only impact

resistant lenses. They are not safety glasses.

Do not put the log splitter on the ground for operations. This is awkward operating

position that the operator has to bring his face close to the machine, and thus risks

being struck by wood chips or debris.

• EXTENSION CORDS

Improper use of extension cords may cause inefficient operation of the log splitter which can result

in overheating. Be sure the extension cord is no longer than 10m and its section is no less than

2.5mm2 to allow sufficient current flow to the motor.

Avoid use of free and inadequately insulated connections. Connections must be made with protected material suitable for outdoor use.

Keep you hands away from splits and cracks which open in the log; They may close

suddenly and crush or amputate your hands.

Do not remove jammed logs with you hands.

• DON'T FORCE TOOL

It will do a better and safer job at its design rate. Never try to split logs larger than those indicated

in the specifications table. This could be dangerous and may damage the machine.

Don't use log splitter for a purpose for which it was not intended.

• NEVER LEAVE TOOL RUNNING UNATTENDED

Don't leave tool until it has come to a complete stop.

32

Page 3

• DISCONNECT POWER

Unplug when not in use, before making adjustments, changing parts, cleaning, or

working on the log splitter; Consult technical manual before servicing.

EN

APPLICATION CONDITIONS

This log splitter is a home use model. It is designed for operating under ambient temperatures

between +5oC and 40oC and for installation at altitudes no more than 1000m above M.S.L. The surrounding humidity should less than 50% at 40oC. It can be stored or transported under ambient

temperatures between -25˚C and 55˚C.

EN

• PROTECT THE ENVIRONMENT

Take used oil to an authorized collection point or follow the stipulations in the country where the log splitter is used.

Do not discharge into drains, soil or water.

• MAINTAIN YOUR LOG SPLITTER WITH CARE

Keep the log splitter clean for best and safest performance.

• MAKE THE WORKSHOP CHILDPROOF

Lock the shop. Disconnect master switches. Store the log splitter away from children and others

not qualified to use it.

TABLE OF CONTENTS

Safety Warnings & Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Application Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Set up and Preparation for Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Plumbing Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Log Splitter Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Freeing a Jammed Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Replacing Hydraulic Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Sharpening Wedge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Trouble Shooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Parts Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

SPECIFICATIONS

Powerful 2.0HP Motor

Model Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .FB4052

Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120V~60Hz

Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1500W,IP54

Log Capacity

Diameter * . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2”-12” (5 ~ 25cm)

Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20.5” (52cm)

Splitting Force . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 t

Hydraulic Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16Mpa

Hydraulic Oil Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.5L

Overall Size

Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .940mm

Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .270mm

Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .510mm

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94.61 Lbs (43 kg)

The diameter of the log is indicative - a small log can be difficult to split when it has knobs or a particularly tough fiber. On the other hand, it may not be difficult to split logs with regular fibers even

if its diameter exceeds the max. figure indicated above.

54

Page 4

EN

EN

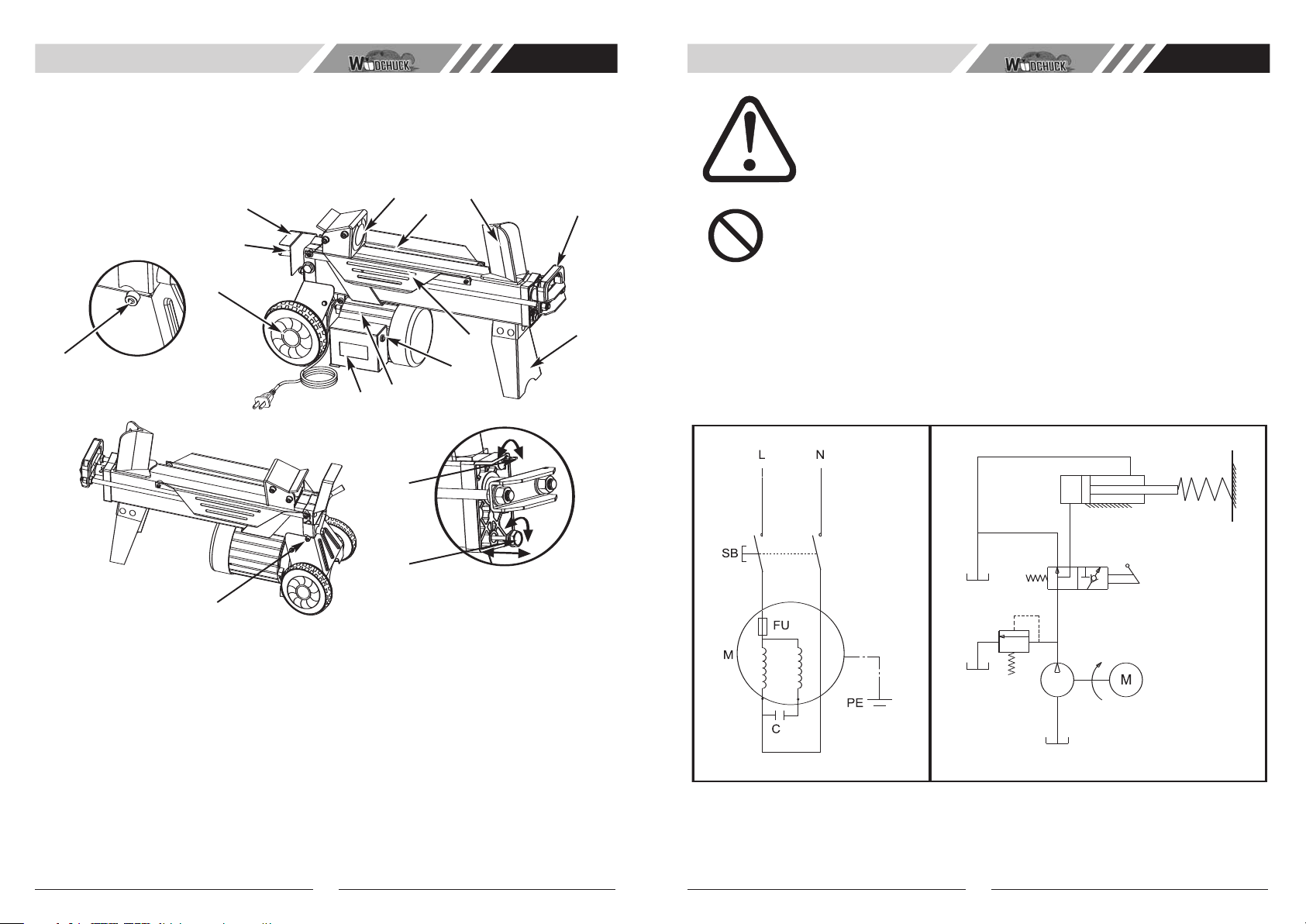

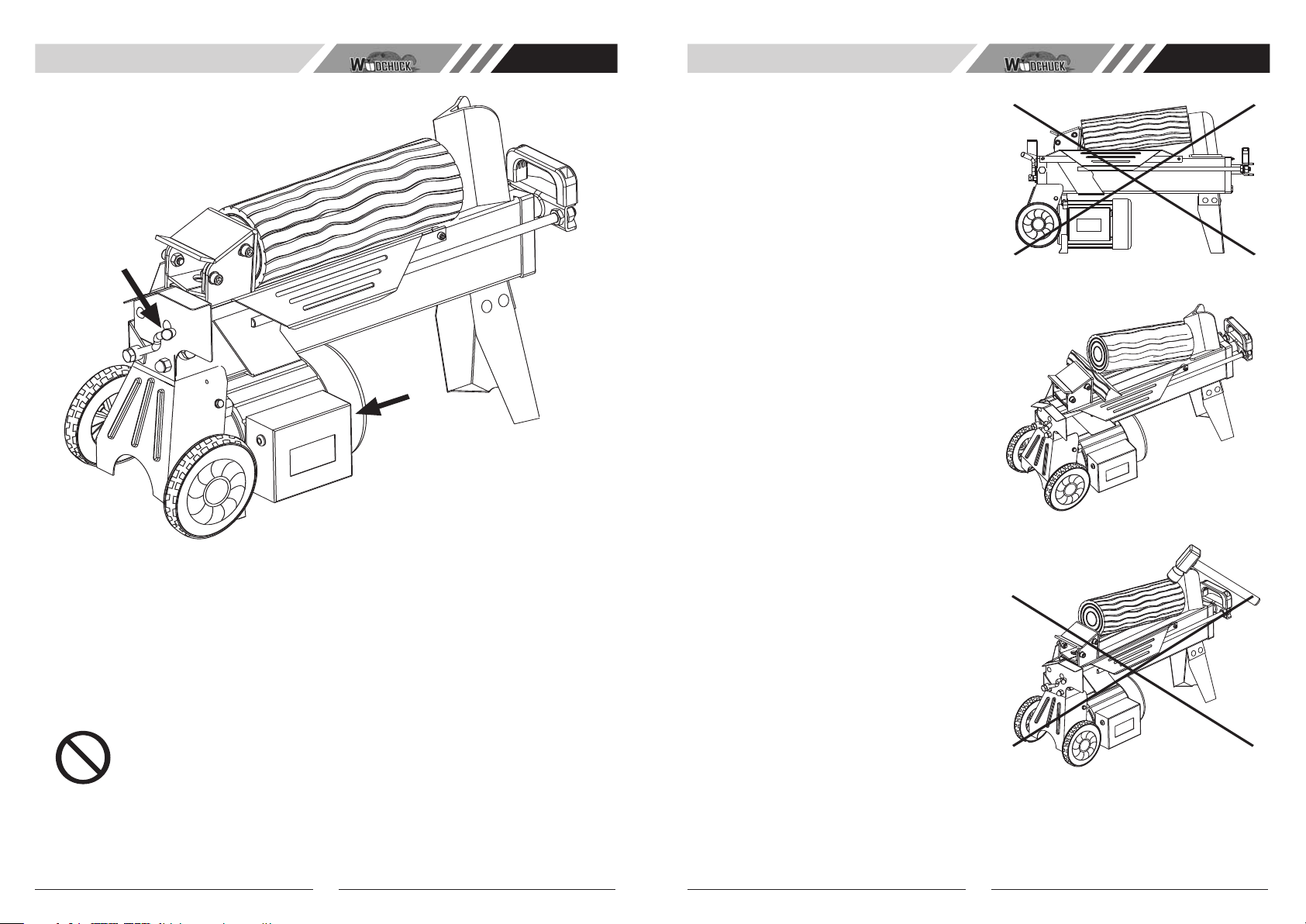

SET UP AND PREPARATION FOR OPERATION

1. Bolt the Support Leg to the Log Splitter, lift the log splitter by the handles at both ends and place it on

a 60 - 75cm high, stable, flat and level work surface.

2. Familiarize yourself with the controls and features of this log splitter in the illustrations.

1

12

11

10

15

8

9

13

3

2

6

7

4

5

FAILED TO LOOSEN THE BLEED SCREW WILL KEEP THE SEALED AIR IN

HYDRAULIC SYSTEM BEING COMPRESSED AFTER BEING DECOMPRESSED. SUCH CONTINUOUS AIR COMPRESSION AND DECOMPRESSION WILL BLOW OUT THE SEALS OF THE HYDRAULIC SYSTEM AND

CAUSE PERMANT DAMAGE TO THE LOG SPLITTER.

DO NOT ADJUST THE MAX PRESSURE LIMITING SCREW !.

Max pressure was set before the log splitter ex work and the max pressure limiting screw is sealed

with glue to ensure the log splitter works under pressure no more than 4 tons.The setting was done

by qualified mechanic with professional instruments.

Unauthorized resetting will cause the hydraulic pump fail to output enough splitting pressure or

RESULT IN SERIOUS INJURY AS WELL AS DAMAGE TO THE MACHINE .

WIRING DIAGRAM

PLUMBING DIAGRAM

14

15

1. Log Pusher

2. Work Table

3. Wedge

4. Lift Handle

5. Support Leg

Before operating the log splitter, the Bleed Screw should be loosened by some rotations until air

can go in and out of the oil tank smoothly.

Air flow thru the Bleed Screw hole should be detectable during the log splitter is under operations.

Before moving the log splitter, make sure the Bleed Screw is tightened to avoid oil leaking from this

point.

6. Log Retaining Plates

7. Switch

8. Motor

9. Pushbutton Box

10. Wheels for Minor Moving ONLY.

11. Hydraulic Control Lever

12. Control Lever Guard

13. Bleed Screw

14. Oil Drain Bolt w/ Dipstick

15. Max Pressure Limiting Screw

76

Page 5

LOG SPLITTER OPERATION

EN

EN

Always set logs firmly on the log retaining plates and

work table. Make sure logs will not twist, rock or slip

while being split. Do not force the blade by splitting the

log on the upper part. This will break the blade or dam-

age the machine.

Break log in the direction of its growing grain. Do not

place log across the log splitter for splitting. It may be

dangerous and may seriously damage the machine.

Do not attempt to split 2 pieces of logs at the same time.

One of them may fly up and hit you.

FREEING A JAMMED

LOG

• Release both controls.

• After the log pusher moves back and completely stops at its starting position, insert a

wedge wood under the jammed log.

• Start the log splitter to push the wedge wood to

go completely under the jammed one.

• Repeat above procedure with sharper slope

wedge woods until the log is completely

freed.

This log splitter is equipped with “ZHB” control system that requires to be operated by both hands of the

user - Left hand controls the hydraulic control lever while right hand controls the pushbutton switch. The log

splitter will freeze upon absence of either hand. Only after both hands release the controls, the log pusher

starts to return backward to the starting position.

Trigger type lock-out device is adopted to avoid accidental Hydraulic Control Lever pushdown. To operate

the Hydraulic Control Lever, draw the Trigger backward with the index finger before push the Hydraulic

Control Lever forward.

Never force the log splitter for more than 5 seconds by keeping pressure on it to split

excessively hard wood.

After this time interval, the oil under pressure will be overheated and the machine could be damaged. For

such extremely hard log, rotate it by 90o to see whether it can be split in a different direction. In any case,

if you are not able to split the log, this means that its hardness exceeds the capacity of the machine and

thus that log should be discarded to protect the log splitter.

Do not try to knock the jammed log off. Knocking about

will damage the machine or may launch the log and

cause accident.

98

Page 6

REPLACING HYDRAULIC OIL

Replace the Hydraulic oil in the log splitter after every 150

hours of use. Take following steps to replace it.

• Make sure all moving parts stops and the log splitter is

unplugged.

• Unscrew Oil Drain Bolt with Dipstick to remove it.

• Turn the log splitter on the Support Leg side over an 4

liters capacity container to drain the hydraulic oil off.

• Turn the log splitter on the the motor side.

• Refill fresh hydraulic oil at the volume as per the

hydraulic oil capacity of a particular model indicated in

above specifications table.

• Clean the surface of Dipstick on the Oil Drain Bolt and

put it back into the oil tank while keep the log splitter

vertically.

• Make sure the level of the refilled oil is just between 2

grooves around the Dipstick.

• Clean the Oil Drain Bolt before thread them back. Make

sure they are tightened to avoid leakage before place

the log splitter horizontally.

EN

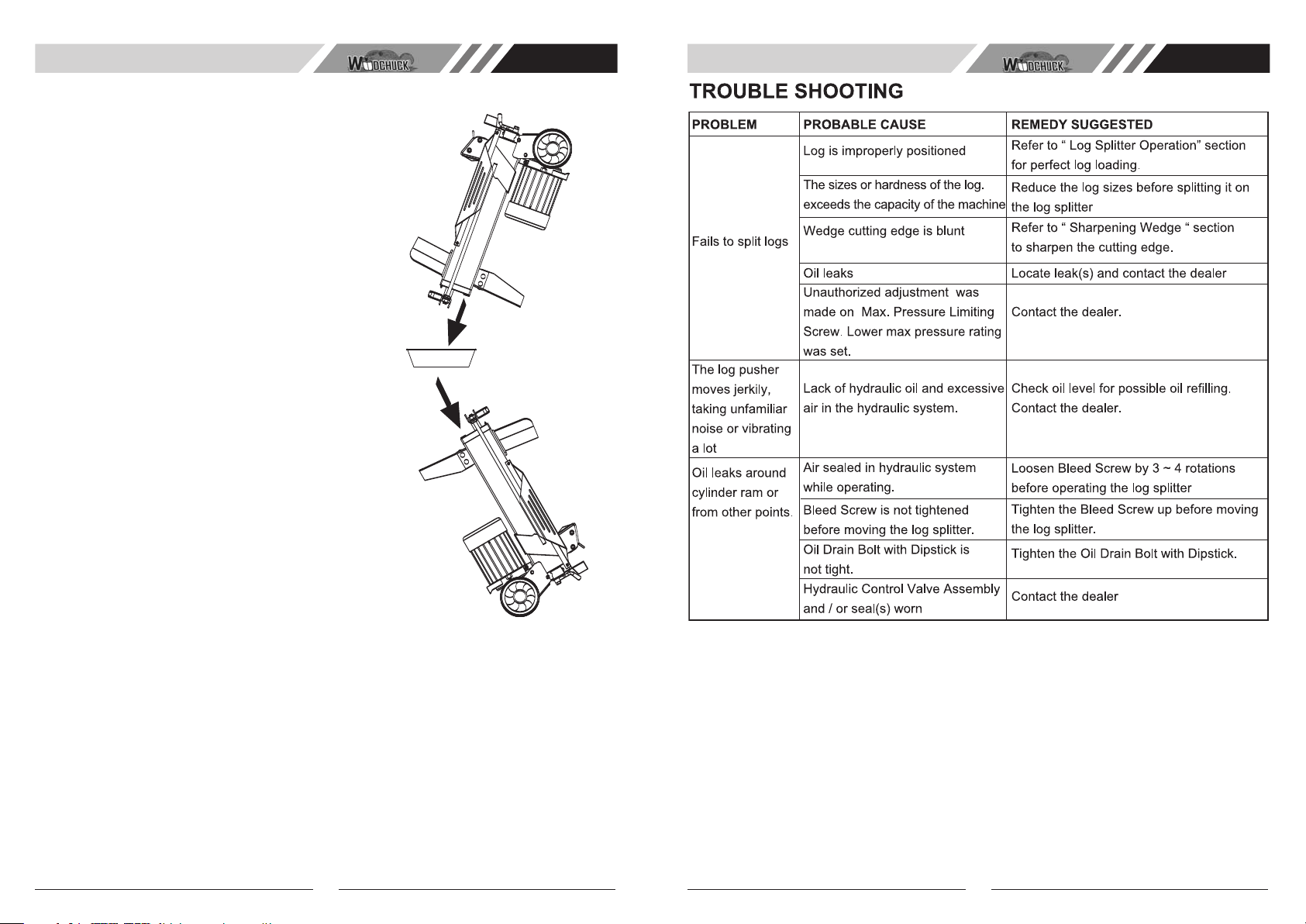

TROUBLE SHOOTING

EN

Periodically check oil level to ensure it is between 2

grooves around the Dipstick. Upon Lower oil level, oil

refilling is required.

Following hydraulic oils or equivalent are recommend for the log splitter's hydraulic transmission

system:

SHELL Tellus 22

MOBIL DTE 11

ARAL Vitam GF 22

BP Energol HLP-HM 22

SHARPENING WEDGE

After using the log splitters for some time, sharpen the wedge of the log splitter using a fine-toothed file and

smooth any burrs or crushed area along the cutting edge.

1110

Page 7

PARTS SCHEMATIC

EN

Manual del usuario

PARTIDOR DE TRONCOS

MANTENIMIENTO PARA USO SEGURO

ADVERTENCIA = LÉALO

Tanto el número de modelo como el número de serie se encuentran en la etiqueta principal. Debe anotar ambos

números en un lugar seguro por si tuviera que consultarlos en otro momento.

Modelo: FB4052

12

Page 8

ADVERTENCIAS E INSTRUCCIONES DE SEGURIDAD

ES

ES

• FAMILIARÍCESE CON EL PARTIDOR DE TRONCOS

Lea y comprenda el manual del propietario y las etiquetas fijadas en el partidor de

troncos. Aprenda su aplicación y limitaciones así como sus riesgos potenciales

específicos intrínsecos.

• DROGAS, ALCOHOL Y MEDICAMENTOS

No utilice el partidor de troncos bajo la influencia de drogas, alcohol ni ningún medicamento que

pueda afectar a la capacidad de utilizar la máquina correctamente.

• EVITE CONDICIONES PELIGROSAS

Coloque el partidor de troncos en un banco de trabajo nivelado, estable, plano, a una altura de

entre 60 cm y 75 cm y en un lugar donde haya una gran cantidad de espacio para trabajar y ayude

al operador a permanecer en alerta. Atornille el partidor de troncos a la superficie de trabajo si

tiende a resbalarse, moverse o deslizarse.

Mantenga el área de trabajo limpio y bien iluminado. Las áreas abarrotadas de objetos son propicias para causar daños personales.

No utilice el partidor de troncos en áreas húmedas ni lo exponga a la lluvia.

No lo utilice el partidor de troncos en áreas donde los gases procedentes de pinturas, disolventes

o líquidos inflamables representen un peligro potencial.

• INSPECCIONE EL PARTIDOR DE TRONCOS

Compruebe el partidor de troncos antes de encenderlo. Mantenga los dispositivos

de seguridad en su lugar y listos para trabajar. Haga que las comprobaciones se

conviertan en un hábito asegurándose de que los utensilios y las llaves inglesas de

ajuste se han retirado del área de las herramientas antes de encender la máquina.

Reemplace los componentes dañados, que falten o que no funcionen antes de utilizar el dispositivo.

• USE INDUMENTARIA ADECUADA

No utilice ropa suelta, guantes, corbatas ni alhajas (anillos, relojes de pulsera, etc.).

Estos artículos se pueden enganchar en las piezas móviles.

Se recomienda utilizar guantes no conductores protegidos contra la electricidad

estática y calzado antideslizante cuando trabaje. Utilice un recubrimiento protector

para recogerse el pelo y evitar así que éste quede atrapado en la máquina.

• EVITE DESCARGAS ELÉCTRICAS

Compruebe que el circuito eléctrico está correctamente protegido y que se corresponde con la

potencia, voltaje y frecuencia del motor. Compruebe que hay una conexión a tierra y un conmutador diferencial de regulación.

Conecte a tierra el partidor de troncos. Evite que su cuerpo entre en contacto con superficies

conectadas a tierra: carcasas de tuberías, radiadores, cocinas y frigoríficos.

No abra nunca la caja de pulsadores del motor. Si tuviera que hacerlo, póngase en contacto con un

electricista profesional.

Asegúrese de que sus dedos no tocan las puntas metálicas del enchufe cuando enchufe o desenchufe el partidor de troncos.

• MANTENGA ALEJADAS A LAS PERSONAS AJENAS Y A LOS NIÑOS

El partidor de troncos siempre se debe utilizar por una sola persona. El resto de

personas deben mantenerse a una distancia segura del área de trabajo, especialmente cuando el partidor de troncos está funcionando. No utilice nunca a

otra persona para que le ayude a liberar un tronco atrapado.

• INSPECCIONE EL TRONCO

Asegúrese de que no hay clavos ni objetos extraños en los troncos que desea trocear. Las terminaciones de los troncos deben estar cortadas de forma cuadrada. Las ramas deben estar cortadas

de forma que queden alineadas con el tronco.

• NO ASUMA RIESGOS

El suelo no debe estar resbaladizo.

Mantenga la máquina en posición equilibrada en todo momento.

Nunca se ponga en el partidor de troncos. Podrían producirse daños personales graves si la herramienta se ladea o si se entra en contacto con las herramientas de corte involuntariamente. No

almacene nada sobre el partidor de troncos o junto a él donde nadie pudiera permanecer en la herramienta o alcanzarla.

• EVITE DAÑOS POR ACCIDENTES INESPERADOS

Preste siempre mucha atención al movimiento del impulsor de troncos.

No intente cargar el tronco hasta que el impulsor de troncos se haya

detenido. Mantenga las manos alejadas de la trayectoria de todas las

piezas móviles.

• PROTÉJASE LOS OJOS Y LA CARA

Cualquier partidor de troncos puede arrojar objetos extraños a los ojos. Este hecho

puede provocar daños irreparables en los ojos. Utilice siempre gafas de seguridad.

Las gafas de uso diario solamente tienen lentes resistentes a impactos. No son

gafas de seguridad.

No coloque el partidor de troncos en el suelo para trabajar. Es ésta una posición

incómoda en la que el operador tiene que colocar su cara junto a la máquina, por lo

que existe riesgo de que le golpeen virutas o restos de madera.

• ALARGADORES

El uso inadecuado de alargadores puede causar un uso ineficiente del partidor de troncos, lo que

puede provocar un sobrecalentamiento en la máquina. Asegúrese de que el alargador no mide más

de 10 m y que su sección no es inferior a 2,5 mm2 para que permita el suficiente flujo de corriente

al motor.

No utilice conexiones disponibles inadecuadamente aisladas. Las conexiones se deben realizar

con material protegido.

• PROTEJA SUS MANOS

Mantenga las manos alejadas de las grietas y rendijas abiertas en el tronco ya que

se pueden cerrar repentinamente y machar o amputar sus manos.

No quite los troncos atrapados con sus manos.

• NO FUERCE LA HERRAMIENTA

La máquina realizará un trabajo mejor y más seguro utilizando los parámetros para los que está

diseñada. No intente nunca partir troncos más grandes que los indicados en la tabla de especificaciones. Tal acción podría ser peligrosa y la máquina podría resultar dañada.

No utilice el partidor de troncos para un fin distinto para el que fue diseñado.

• NUNCA DEJE LA HERRAMIENTA DESATENDIDA Y EN FUNCIONAMIENTO

No abandone la herramienta hasta que se haya detenido completamente.

1514

Page 9

• DESCONECTE LA ALIMENTACIÓN

Desenchufe la máquina cuando no la utilice, antes de realizar ajustes, cuando cambie piezas, cuando la limpie o cuando trabaje con el partidor de troncos. Consulte

el manual técnico antes de solicitar ayuda al servicio técnico.

CONDICIONES DE APLICACIÓN

Este partidor de troncos es un modelo de uso doméstico. Está diseñado para trabajar a una temperatura ambiente comprendida entre +5 ºC y 40 ºC y no se debe instalar en altitudes superiores a

los 1000 metros sobre el nivel medio del mar. La humedad ambiente debe ser inferior al 50% a 40

ºC. Se debe almacenar o transportar bajo temperaturas comprendidas entre -25 ºC y 55 ºC.

ESES

• PROTEJA EL MEDIOAMBIENTE

Lleve el aceite usado a un punto de recogida autorizado o siga la normativa correspondiente del país en el que utiliza el partidor de troncos.

No tire el aceite a ningún sumidero, a la tierra o al agua.

• MANTENGA EL PARTIDO DE TRONCOS EN BUENAS CONDICIONES

Mantenga el partidor de troncos limpio para conseguir siempre el rendimiento máximo y más

seguro.

• HAGA QUE EL LUGAR DE TRABAJO ESTÉ A PRUEBA DE LOS NIÑOS

Cierre el lugar de trabajo. Desconecte los interruptores principales. Almacene el partidor de troncos de forma que quede alejado de los niños y otras personas no cualificadas para su uso.

TABLA DE CONTENIDO

Advertencias e instrucciones de seguridad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Condiciones de aplicación . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Especificaciones técnicas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Configurar y preparar la máquina para su uso . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Diagrama de cableado . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Diagrama de conductos . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Funcionamiento del partidor de troncos . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Liberar un tronco atrapado . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Cambiar el aceite de hidráulico . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Afilar la cuña . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Solucionar problemas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Esquema de las piezas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

ESPECIFICACIONES TÉCNICAS

Motor 2.0HP potente

Número de modelo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .FB4052

Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120V~60Hz

Entrada . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1500W,IP54

Capacidad de troncos

Diámetro * . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2”-12” (5 cm~25 cm)

Longitud . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20.5” (52 cm)

Fuerza de corte . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 t

Presión hidráulica . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16Mpa

Capacidad de aceite hidráulico . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tamaño global

Longitud . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .940mm

Ancho . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .270mm

Alto . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .510mm

Peso . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94.61 Lbs (43 kg)

El diámetro de los troncos es indicativo: un tronco pequeño puede resultar difícil de partir si tiene

nudos o una fibra particularmente dura. Por el contrario, puede que no resulten tan difícil de partir

los troncos con fibras normales uniformes. Consulte la figura anterior.

. . . . 3.5L

1716

Page 10

ES

ES

CONFIGURAR Y PREPARAR LA MÁQUINA PARA

SU USO

1. Atornille la pata de apoyo al partidor de troncos, levántelo por sus asas situadas en ambas terminaciones y colóquelo en una superficie de trabajo nivelada, estable, plana y a una altura de entre 60 cm

y 75 cm.

2. Familiarícese con los controles y funciones de este partidor de troncos consultando las ilustraciones.

1

12

11

10

15

8

9

13

3

2

6

7

4

5

SI NO SE AFLOJA EL TORNILLO DE PURGA, EL AIRE ENCERRADO EN EL

SISTEMA HIDRÁULICO SE COMPRIMIRÍA Y DESCOMPRIMIRÁ UNA Y OTRA

VEZ. ESTE PROCESO DE COMPRESIÓN Y DESCOMPRESIÓN CONTINUO

REVENTARÁ LOS CIERRES HERMÉTICOS DEL SISTEMA HIDRÁULICO Y

PROVOCARÁ DAÑOS IRREVERSIBLES EN EL PARTIDOR DE TRONCOS.

¡NO AJUSTE EL TORNILLO LIMITADOR DE LA PRESIÓN MÁXIMA!

La presión máxima se fijó antes de que el partidor de troncos llegara a sus manos y el tornillo limitador de la presión máxima está precintado con pegamento para garantizar que la máquina funciona con una presión no superior a 4 toneladas. La configuración se realizó por mecánicos cualificados con instrumentos profesionales.

El reajuste no autorizado hará que la bomba hidráulica no pueda proporcionar la presión de corte

suficiente o PROVOCARÁ DAÑOS GRAVES PERSONALES Y A LA PROPIA MÁQUINA.

DIAGRAMA DE

CABLEADO

DIAGRAMA DE CONDUCTOS

14

15

1. Impulsor de troncos

2. Mesa de trabajo

3. Cuña

4. Asa elevador

5. Pata de apoyo

6. Placas de sujeción de troncos

7. Interruptor

Antes de utilizar el partidor de troncos, afloje el tornillo de purga girándolo hasta que el aire entre

y salga del tanque de aceite con facilidad.

El flujo de aire a través del tornillo de purga se debe detectar mientras se utiliza el partidor de troncos. Antes de mover el partidor de troncos, asegúrese de que el tornillo de purga está apretado

para evitar fugas de aceite.

8. Motor

9. Caja de pulsadores

10. Ruedas para pequeños

desplazamientos (SOLAMENTE).

11. Palanca de control del hidráulico

12. Cubierta de la palanca de control

13. Tornillo de purga

14. Tornillo de drenaje del aceite

con varilla de medición del nivel

15. Tornillo limitador de la presión

máxima

1918

Page 11

FUNCIONAMIENTO DEL PARTIDOR DE TRONCOS

Este partidor de troncos cuenta con un sistema de control “ZHB” que necesita ser utilizado con las dos

manos del operador: la mano izquierda maneja la palanca de control del hidráulico y la mano derecha con-

trola el interruptor de pulsador. El partidor de troncos se bloqueará en ausencia de cualquiera de las

manos. Solamente después de que ambas manos liberen los controles, el impulsor de troncos comenzará

a retroceder hasta recuperar la posición de inicio.

Se adopta el dispositivo de bloqueo de tipo gatillo para evitar el uso accidental de la palanca de control del

hidráulico. Para utilizar la palanca de control del hidráulico, eche el gatillo hacia atrás con el dedo índice

antes de empujar la palanca de control del hidráulico hacia delante.

Nunca fuerce el partidor de troncos durante más de 5 segundos manteniendo presión

en él para partir madera excesivamente dura.

ES

ES

Coloque siempre los troncos firmemente en las placas

de sujeción de troncos y en la mesa de trabajo.

Asegúrese de que los troncos no se girarán, bal-

ancearán ni resbalarán mientras se parten. No fuerce la

hoja partiendo el tronco en la parte superior. Si lo hace,

la hoja se partirá o la máquina resultará dañada.

Parta los troncos en la dirección de su veta de crec-

imiento. No coloque los troncos atravesados en el par-

tidor de troncos para partirlos. Tal acción podría ser

peligrosa y la máquina podría resultar gravemente

dañada.

No intente partir 2 trozos de troncos al mismo tiempo.

Uno de ellos puede salir disparado y golpearle.

FREEING A JAMMED

LOG

• Libere ambos controles.

• Después de que el impulsor de troncos retroceda y se detenga completamente en su posición

inicial, inserte un trozo de madera con forma de

cuña bajo el tronco atascado.

• Inicie el partidor de troncos para empujar el

trozo de madera con forma de cuña hasta que

se haya introducido completamente debajo del

tronco atascado.

• Repita el procedimiento anterior con trozos de

madera con forma de cuña más pronunciada y

afilados hasta que el tronco quede completamente libre.

No golpee el tronco atrapado para extraerlo. Si lo gol-

pea, la máquina puede resultar dañada o puede salir

despedido y causar un accidente.

After this time interval, the oil under pressure will be overheated and the machine could be damaged. For

such extremely hard log, rotate it by 90o to see whether it can be split in a different direction. In any case,

if you are not able to split the log, this means that its hardness exceeds the capacity of the machine and

thus that log should be discarded to protect the log splitter.

2120

Page 12

ES

PÛngase en contacto con el

distribuidor.

El conjunto de la v·lvu la de control

del hidr·ul ico y/o los precintos

est·n ga stados.

Apriete el tornillo de drenaje del aceite

con varilla de mediciÛn del nivel de

aceite.

El tornillo de drenaje del aceite con

varilla de mediciÛn del nivel de

aceite no est· apretado.

Apriete el tornillo de purga antes de

desplazar el partidor de troncos.

El tornillo de purga no se ha

apretado antes de desplazar el

partidor de troncos.

Afloje el tornillo de purgado gir·ndolo

3 Û4 veces antes de utilizar el partidor

de troncos

Hay aire encerrado en el sistema

hidr·ul ico mientras se utiliza la

m· quina.

Hay fugas de aceite

alrededor del martillo del

cilindro o procedente de

otros puntos.

Compruebe el nivel de aceite por si

tuviera que rellenarlo.

PÛngase en contacto con el

distribuidor.

No hay aceite de hidr·u lico y hay

demasiado aire en el sistema

hidr·ul ico.

El impulsor de troncos

se mueve dando

sacudidas, haciendo un

ruido extraÒo o vibrando

en exceso.

PÛngase en contacto con el

distribuidor.

Se ha realizado un ajuste no

autorizado en el tornillo limitador

de la presiÛn m· xima. Se

estableciÛun valor de presiÛn

inferior.

Localice las fugas y pÛngase en

contacto con el proveedor

Hay fugas de aceite

Consulte la secciÛn ìAfilar la cuÒaî

para obtener informaciÛn sobre cÛmo

afilar la cuÒa de corte.

El filo de la cuÒa de corte est·

desafilado

Reduzca el tamaÒo de los troncos

antes de partirlos en el partidor de

troncos.

El tamaÒo o la dureza del tronco

supera la capacidad de la m· quina.

Cons

ulte la secciÛn ìFuncionamiento

del par

tidor de troncosî para obtener

inf

ormaciÛn sobre cÛmo colocar el

tronco perfectamente.

El tr

onco no se ha colocado

co

rrectamente.

No s

e pueden partir los

tr

oncos

SO

LUCI” N PROPUESTACAUSA PROBABLEPROBLEMA

CAMBIAR EL ACEITE DE

HIDRÁULICO

Cambie el aceite de hidráulico del partidor de troncos cada

150 horas de uso. Realice los pasos siguientes para cam-

biarlo:

• Asegúrese de que todas las partes móviles están

detenidas y que el partidor de troncos está desenchu-

fado.

• Desatornille el tornillo de drenaje del aceite con varilla

de medición del nivel para extraerlo.

• Levante el partidor de troncos sobre el lado de la pata

de apoyo y el recipiente de 4 litros de capacidad para

extraer el aceite de hidráulico.

• Levante el partidor de troncos sobre el lado del motor.

• Rellene el recipiente con aceite de hidráulico nuevo

hasta la capacidad del volumen del modelo concreto

que se indica en la tabla de especificaciones anterior.

• Limpie la superficie de la varilla del nivel de aceite y

vuelva a colocarla en el recipiente de aceite mientras

mantiene el partidor de troncos en posición vertical.

• Asegúrese de que el nivel del aceite rellenado se

encuentra justo entre las dos muescas marcadas en la

varilla del nivel de aceite.

• Limpie el tornillo de drenaje del aceite antes de

enroscarlo de nuevo. Asegúrese de que se ha apreta-

do perfectamente para evitar fugas antes colocar el

partidor de troncos en posición horizontal.

Compruebe periódicamente el nivel del aceite para asegurarse de que se encuentra entre las 2

muescas de la varilla del nivel de aceite. Cuando el aceite se encuentre en su nivel inferior será

necesario rellenarlo.

Se recomienda utilizar los siguientes aceites (o equivalentes) para el sistema de transmisión

hidráulico del partidor de troncos:

SHELL Tellus 22

MOBIL DTE 11

ARAL Vitam GF 22

BP Energol HLP-HM 22

AFILAR LA CUÑA

Después de utilizar el partidor de troncos durante mucho tiempo, afile su cuña utilizando una lima fina y

alise las rebabas y el área de colisión junto con el filo de corte.

SOLUCIONAR PROBLEMAS

ES

2322

Page 13

ESQUEMA DE LAS PIEZAS

ES

24

Page 14

SERVICE SPARE PARTS LIST

REVISED DATE

4 TON LOG SPLITTER

SERVICE SPARE PARTS LISTSERVICE SPARE PARTS LISTSERVICE SPARE PARTS LISTSERVICE SPARE PARTS LISTSERVICE SPARE PARTS LIST

MODEL NO.

SPECIFY MODEL NO. WHEN ORDERING PARTS

FB4052 (65556)

REVISED DATE

8/7/2008

N/A

Page 15

TIYA model #65556

Q

TIYA No.

Parts No.

Description

Q

11

7200 405211

NUT, M14

2

210

22

7200-405222

WASHER

4

210

PARTS LIST

PARTS LIST

PARTS LIST

PARTS LIST

PARTS LIST

PARTS LIST

JF model # FB4052

TIYA No. JF Parts No. Description

JF

1 7200-405201 CYLINDER 1 210

2 7200-405202 PISTON O-RING 1 210

3 7200-405203 PISTON 1 210

4 7200-405204 O-RING 1 210

5 7200-405205 SPRING 1 210

6 7200-405206 POSITON ROD WELDMENT 1 210

7 7200-405207 NUT 2 210

8 7200-405208 WASHER 2 210

9 7200-405209 MOVING HANDLE 1 210

10 7200-405210 HEX. BOLT 2 210

11 7200-405211 NUT, M14 2 210

12 7200-405212 PLASTIC SEAL 1 210

13 7200-405213 WING SCREW/ BLEED SCREW 1 210

14 7200-405214 O-RING 1 210

15 7200-405215 LONG STUB 4 210

16 7200-405216 HEX. BOLT 6 210

17 7200-405217 SPRING WASHER 4 210

18 7200-405218 NUT 5 210

19 7200-405219 SUPPORT PLATE 2 210

20 7200-405220 TUBE FRAME/ OIL TANK 1 210

21 7200-405221 HEX. BOLT 4 210

-

23 7200-405223 UPPER PLASTIC INSERT 1 210

24 7200-405224 LOG PUSHER WELDMENT 1 210

25 7200-405225 NUT 4 210

26 7200-405226 O-RING 1 210

27 7200-405227 CYLINDER COVER-LEFT 1 210

28 7200-405228 COPPER GASKET 4 210

29 7200-405229 SAFETY VALVE SPRING 1 210

PARTS LIST

6/1/2009

P Code

Page 16

30 7200-405230 SCREW 1 210

3

700 05 3

VV O

0

54

7200 405254

LOOSE NUT

1

210

31 7200-405231 SAFETY VALVE BOLT 1 210

32 7200-405232 O-RING 1 210

33 7200-405233 ROUND HEAD NUT 3 210

34 7200-405234 LEVER GUARD 1 210

35 7200-405235 NUT 2 210

36 7200-405236 LEVER WELDMENT 1 210

37 7200-405237 LEVER HEAD 1 210

38 7200-405238 LEVER NUT 1 210

39 7200-405239 WHEEL FRAME PLATE WELDMENT 1 210

40 7200-405240 STEEL BALL 1 210

41 7200-405241 CIRCLIP 1 210

42 7200-405242 RESTORE VALVE SPRING 1 210

43 7200-405243 VALVE ROD 1 210

44 7200-405244 O-RING 1 210

45 7200-405245 VALVE SLEEVE 1 210

46 7200-405246 O-RING 5 210

47 7200-405247 O-RING 2 210

48 7200-405248 SLIDING SLEEVE SPRING 1 210

49 7200-405249 SLIDING SLEEVE 1 210

50 7200-405250 WASHER 1 210

51 7200-405251 VALVE PLUG 1 210

52 7200-405252 LOWER PLASTIC INSERT 1 210

53 7200-405253 DRAWING WELDMENT 1 210

54 7200-405254 LOOSE NUT 1 210

55 7200-405255 HEX. BOLT 1 210

56 7200-405256 WASHER 2 210

57 7200-405257 MOTOR SHAFT SEAL 1 210

58 7200-405258 SETEEL BALL, 2.5 1 210

59 7200-405259 SUPPORT LEG 1 210

60 7200-405260 CARRIAGE 5 210

61 7200-405261 CYLINDER COVER-RIGHT 1 210

62 7200-405262 DIPSTICK GASKET 1 210

63 7200-405263 DIPSTICK 1 210

Page 17

64 7200-405264 MOTOR WITH SWITCH 1 210

77

700 0577

G

0

88

7200 405288

WHEEL COVER

2

210

65 7200-405265 MOTOR 1 210

66 7200-405266 SWITCH BOX 1 210

67 7200-405267 BOLT 1 210

68 7200-405268 NUT 1 210

69 7200-405269 SPRING WASHER 3 210

70 7200-405270 BOLT 3 210

71 7200-405271 MOTOR COVER 1 210

72 7200-405272 MOTOR SUPPORT SHOE - LEFT 1 210

73 7200-405273 MOTOR SUPPORT SHOE - RIGHT 1 210

74 7200-405274 WASHER 9 210

75 7200-405275 PIN 2 210

76 7200-405276 GEAR HOUSING PLATE 1 210

77 7200-405277 GEAR 2 210

78 7200-405278 GEAR GEAR SHAFT SNAP WASHER 2 210

79 7200-405279 PIN 1 210

80 7200-405280 GEAR SHAFT 1 210

81 7200-405281 SLIDING BEARING 4 210

82 7200-405282 O-RING 2 210

83 7200-405283 PUMP COVER 1 210

84 7200-405284 BOLT 3 210

85 7200-405285 SPRING WASHER 9 210

86 7200-405286 WAHSER 9 210

87 7200-405287 BOLT 6 210

88 7200-405288 WHEEL COVER 2 210

89 7200-405289 WHEEL SHAFT SNAP RING 2 210

90 7200-405290 WHEEL 2 210

Loading...

Loading...