Page 1

//1MtrEULLOtrH,

t-

OPERATION

MAINTENANCE

SAFETY

Your new string trimmer is a complex tool.

For

your

own

safety,

please

read this

manual before attempting to operate

your

new unit.

Failure to follow instructions can

result in serious

personal

injury. Spend

a

few moments

to familiarize

vourself

with

tew moments

to lamrlranze

yoursell

wrtn

your

trimmer before each

use.

USER

MANUAL

MAC@ 291

6

EAGER BEAVER@ 28,282

GAs

STB'ruG

TRIMMERS

PN

98587-04

O U.S.A. . McCulloch Corooration.

1993 Printed in U.S.A

Page 2

Dear

Customer,

Thank

you

for

purchasing

a

McCullo-ch

product'

With

proper

operation

and

mainienance

it will

provide

you

with

years of

service,

ln

order

to

make

the

best

use

of

your investment'

be

CenfAtru

to

familiarize

yourself

with

the

contents

of

the

ENTIRE

User

Manual

before

attempting

to

operate

and

maintain

Your

unit.

Be

sure

to

carefully

follow

the

step-by-step

illustrations

in

this

manual

to start,

operate

and

maintain

your new

product.

ln the

manual

there

will

be

the

following

call-outs:

NOTE'

WARNING /

CAUTION

and

WARRANTY'

A

NOTE:

is

used

to

convey

additional

information'

to

highlight

a

particular

explanation,

or

expand

a step

description.

GENERALINFORMATION.

.

. .

.

3

1-..|

....

Introduction

1-2.

. ..

AboutYourManual

1-3....

AboutYourUnit

1-4.

...

AssemblY

Requirements

1-5.

...

Specifications

GENERALIDENTIFICATION.

...4

2-1

. .

..

General

ldentification

2-2.

. ..

Sd{etY

Features

SAFEWPRECAUTIONS.

.

..

..

5

3-1....

WhatToDo

3-2.

.

..

What

NOT

To

Do

ASSEMBLYINSTRUCTIONS

...7

4-1

. .

..

Handle

AssemblY

4-2.

.

..

SparkArrester

Installation

4-3.

.

. .

DebrisShield

Installation

FUELANDLUBRICATION

. ..

..8

5-1....

Fuel

5-2.

.

..

Mixing

Fuel

5-3.

...

FuelMixingTable

5-4.

.

..

Use

Of Blended

Fuels

OPERATINGINSTRUCTIONS

...9

6-1.

.. .

StartingACold

Engine

6-2.

.

..

To

StoP

The

Engine

6-3.

..

. WarmEngine

Start

A

WARNING

"..

CAUTION

ii"n1iti""

a

procedure

which,

if

not

undertaken

or

if

improperly

done,

can

result

in

serious

personal

iniury

or

damage

to

the

unit

and/or

both'

rn"

@

(wARRANW

sYMBoL)

serves

notice

that

unless

instructions

or

procedures

are

followed'

any

J.t"gt

l"rted

will

voidthe

warranty

and

repairs

will

be

at

owner's

expense'

Service

other

than

user

maintenance

should

be

o"rtormeO

bv

a

McCulloch

Authorized

Service

Center'

b.t"g"

or

conditions

which

render

this

product

inop"iiuru

caused

by

improper

maintenance

practices

will

void

the

manufacturer's

warranty'

McCulloch

CorPoratlon

Product

Servlce

DePartme

nt

TRIMMING

INSTRUCTIONS

.

11

7-1.

. .

.

Additional

Safety

Precautions

7-2.

. .

. Stringhead

Line

Release

7-3.

. .

.

Trimming

Procedures

MAINTENANCE

INSTRUCTIONS

13

8-1.

..

.

Preventive

Maintenance

8-2.

. .

. RePlacingCutterLine

8-3.

. .

.

Removing/

Replacing

Stringhead

8-4.

...AirFilter

8-5.

.

..

FuelCaP/Fuel

Filter

8-6.

. .

.

CarburetorAdiustment

8-7....SParkPlug

8-8.

. .

.

SParkArresterScreen

8-9.

.

. .

Debris

Shield

Knife

Sharpening

8-10.

..

StoringAUnlt

8-11.

. .

Removing

A

Unit

From

Storage

ACCESSORIES

&

LUBRICANTS

.

.'''''

18

TROUBLESHOOTINGTHESTRINGHEAD

. .

19

TROUBLESHOOTINGTHE

ENGINE

. .

.

. . 20

Page 3

1-1. INTRODUCTION

1.3.

ABOUT YOUR UNIT

Your

McCulloch

String

Trimmer

is a light,

portable,

hand-held

unit,

powered

by

a 2-cycle

engine, that

runs

cool and

quiet.

Your

unit features

a recoil

starter for

fast, consistent

starts and a precision

diaphragm

carburetor for

smooth

operation.

A

spark

arrester

screen

that meets

all

U.S. Forest

Service

Regulations

is

furnished

in

the user kit.

For

additional

information governing

use and

replacement

of

spark

arrester

screens

for

your

unit, see

Safety

Precautions

and Accessories

and

Replacement

Parts

in

this

manual.

1-2.

ABOUTYOUR

MANUAL

McCulloch

units are designed

to meet all

of

your

lawn

and

garden

trimming

needs. When

equipped with

a

debris shield

and stringhead,

your

unit can trim

unsightly

weeds

and tall

grass

in those hard

to reach areas

-

along

fences, walls, foundations

and around

trees.

1.4. ASSEMBLY

REQUIREMENTS

Your unit

will require assembly

of some

components

which

were

packed

separately

for shipping.

Please

follow

the

directions beginning

in Section

4-1,

Assembly

Instructions.

NEVER operate

your

unit

without a

properly

installed

debris shield.

Your

User

Manual

is both

a reference

and a service

handbook

that

provides

you

with

safety

precautions,

easy-to-follow

assembly,

fuel,

starting,

operating,

trimming

and

maintenance

instructions.

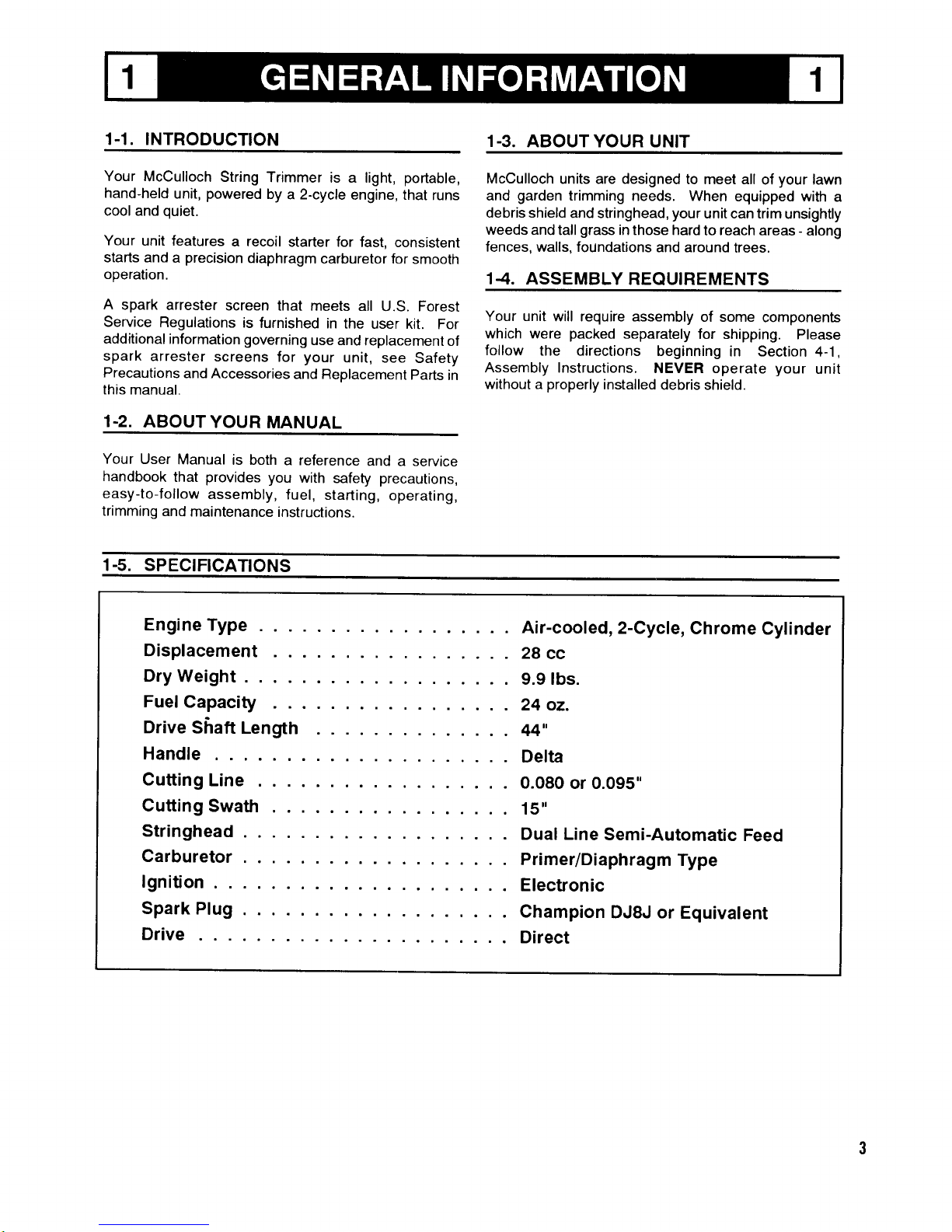

1.5. SPECIFICATIONS

Engine

Type

Air-cooled

,2-Cycle,

Chrome

Cylinder

Displacement

29

cc

DryWeight...

9.9tbs.

Fuef

Capacity

24 oz.

Drive

Shaft

Length

44"

Handle

Delta

Cutting

Line

O.O8O

or 0.095"

Cutting

Swath

15u

Stringhead

. . .

Duat Line

Semi-Automatic

Feed

Carburetor

.

primer/Diaphragm

Type

lgnition

Electronic

Spark

Plug

.

Champion

DJ8J or

Equivatent

Drive

Direct

Page 4

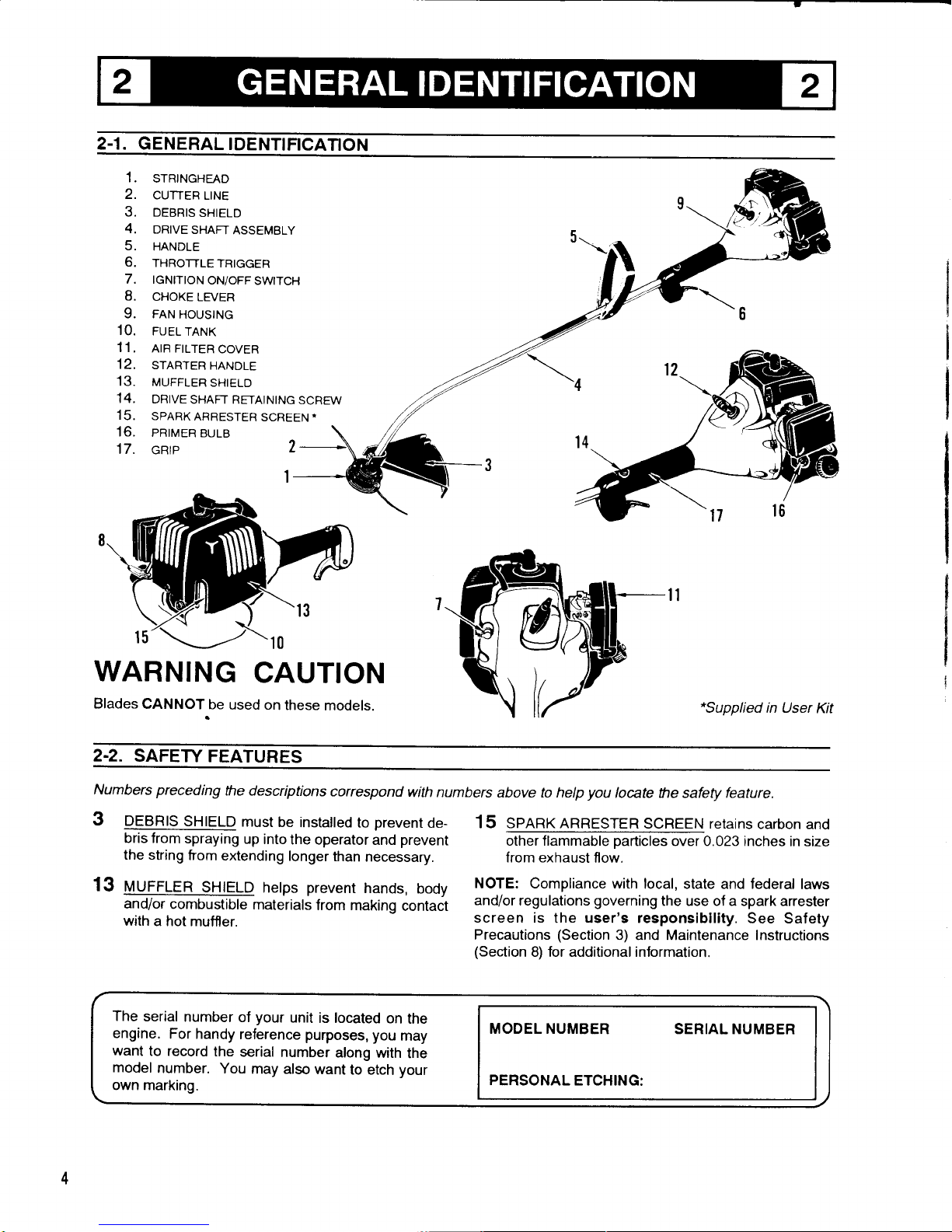

2.1. GENERAL

IDENTTFICATION

1.

STRINGHEAD

2.

CUTTER

LINE

3. DEBRIS

SHIELD

4.

DRIVE

SHAFT

ASSEMBLY

5.

HANDLE

6.

THRoTTLETRIGGER

7. IGNITIoN

oN/oFF

SWIToH

8.

cHoKE

LEVER

9. FAN

HoustNG

1

0. FUEL

TANK

11

, AIR FILTER

coVER

12,

STARTER

HANDLE

13.

MUFFLER

sHtELD

14.

DRtvE

sHAFT RETAINtNG

scREw

15.

SPARKARRESTER

SCREEN*

16.

PRIMER

BULB

17.

cRrP

\o

WARNING

CAUTION

Blades

CANNOT

be

used on

these

models.

"Supplied

in User

Kit

2-2.

SAFEW

FEATURES

Numbers preceding

the descriptions

correspond

with numbers

above to help

you

locate the safety feature.

3

DEBRIS

SHIELD

must

be

installed

to

prevent

de-

ffi|rort

spaytng

up

into

the operator

and

prevent

the string

from

extending

longer

than

necessary.

13

uurrlen

Sgtrlo

hetps

prevent

hands,

body

and/or

combustible

materials

from

making

contact

with

a hot

muffler.

15 Spnnx nnReSfER

SCneEru retains

carbon and

other flammable

particles

over 0.023 inches

in size

from exhaust

flow.

NOTE: Compliance with

local, state and federal

laws

and/or

regulations

governing

the use of a spark arrester

screen is

the user's responsibility.

See Safety

Precautions

(Section

3) and Maintenance Instructions

(Section

8) for additional information.

The

serial

number

of

your

unit

is located

on

the

engine.

For handy

reference

purposes,

you

may

want

to record

the

serial

number

along

with

the

model

number.

You

may also

want

to etch

your

own marking.

MODEL NUMBER

SERIAL

NUMBER

PERSONAL

ETCHING:

Page 5

3-1. WHAT

TO DO

READ

YOUR

USEB

MANUALAND

ALL

SUP-

PLEMENTS

(tF

ANY

ENCLOSED)

THOR_

OUGHLY

BEFORE

OPERATING

YOIJR

UNIT.

1.

WEAR

CLOSE

FITTING,

TOUGH

WORK

CLOTHING

that will

provide

protection,

such

as long

slacks

or trou_

sers,

safety

work

shoes,

heavy

duty

work

gloves,

a

safety

face

shield,

goggles

or safety

glasses

for

eye

protection

and

a

good

grade

of ear

plugs

or

other

sound

barriers

br hearing protection.

2.

REFUEL

lN

A SAFE

PLACE,

Open

fuet

cap

slowty

to

retease

any

pressure

which

may

have

formed

in fuel

tank.

To

prevent

a fire

hazard,

move

at least

10

Jeet

(3

meters)

lrom

fueling

area

before

starting.

3.

lF

FUEL

HAS

SPTLLED

ON

UNIT,

be sure

engine

has

been

dried

completely

before

starting

it.

4,

COMPLY

WITH

ALL

FIRE

PREVENTION

REGULATIONS.

We recommend

you

keep a

shoveland

fire

extinguisher

close

by

whenever

using

your

unrt

in

areas

where

dry

grass,

leaves

or

other

flammable

mate_

rials

are

present,

To

operate a gasoline-powered

prod-

uct

on

U.S.

National

Forest

Lands

or forest,

brush

or

grass-covered

lands

in

many

U.S.

states

-

including

California,

Maine,

New

Hampshire,

Oregon,

Washington

-

you

must

have

an

approved

spark

arrester

screen

properly

installed

and

maintained

on

the

engine

muffler.

The

spark

arrester

screen

must

remove

and

retain

carb_

on and

other

flammable

particles

over

0.023

inches

in

size

from

engine

exhaust

flow.

NOTE:

COMPLIANCE

WITH

ALL

LocAL,

STATE,

oR

FEDERAL

LAWS

IN THE

UNITED

STATES

IS THE

USER'S

BESPONSIBILITY.

Your

unit

comes

with

a sparK

arresrer

screen

furnishe?

in

the

user kit.

Replacement

sparK

arrester

screen

kits

are

available

at

your

nearest

McCulloch

Authorized

Service

Center

listed

under

.SAWS,

in

vour

Telephone

Directory

Yellow

pages.

lf

you

have

any

questions

concerning

spark

arrester

screens

or their

use,

wrrte

to:

McCulloch

Corporation,

product

Service

Depanment,

P.O.

Box

1 1990,

Tucson,

Arizona

85734.

Or,

vou

can

call our

toll-free

number,

USA: 1-800-423-6302.

Arizona

residents

call

1-800-221

-6507.

NOTES:

8.

9.

5. TURN

UNIT OFF

before setting

it down.

6.

ALWAYS

HOLD UNIT FIRMLY

WITH

BOTH HANDS.

the thumb and

f ngers encircling

the handles.

7. KEEPALLSCREWS

AND

FASTENERSTTGHT.

Never

operate your

equipment

when it

is improperly

adjusted

or not completely

and

securely

assembled.

KEEP HANDLES

DRY, clean

and free

of

fuel mixture.

KEEP STRINGHEAD

AS

CLOSE

TO GROUND

AS

PRACTICAL.

Avoid hitting

smail

objects

with

stringhead.

When

cutting

on a slope,

stand

below

stringhead.

NEVER

cut

or trim

on a hill

or slope,

etc.. if

there is

the slightest

chance

of slipping,

sliding

or

losing

firm footing.

10. CHECK

AREA

YOU

WILL BE

TRIMMING

FOR

DEBRIS

that

may

be struck

or thrown

during

operation.

Clear

area

before

operating

equipment.

11.

KEEP ALL

PARTS

OF YOUR

BODY

AND

CLOTHING

AWAY

FROM

STRINGHEAD

when

starting

or running

engine.

Before

starting

engine,

make

sure

stringhead

will

not come

in contact

with

any

obstacle.

12.

STOP

ENGINE before

examining

cutting

line.

13.

STORE

EOUIPMENT

AWAY

FROM

POSSIBLE

IGNITION

SOURCES,

such

as

gas-powered

water

heat-

ers,

clothes

dryers,

or oil-fired

furnaces,

portable

heat-

ers,

etc.

14. ALWAYS

KEEP

the

debris

shield,

stringhead,

ano

en-

gine

free of

debris

build-up.

15. TURN

IGNITION

SWITCH

TO

OFF

and remove

soarx

plug

boot

from

spark

plug

to

avord

any chance

of acci-

dental

starting

before

replacing

stringhead

or line.

16.

OPERATIONOFEOUTPMENT

should

atwavs

oe

re-

stricted

to

mature

and

properly

instructed

indviduals.

Page 6

3

SAFETY PRECAUTIONS

3

3.2.

WHAT

NOT TO DO

WARNING

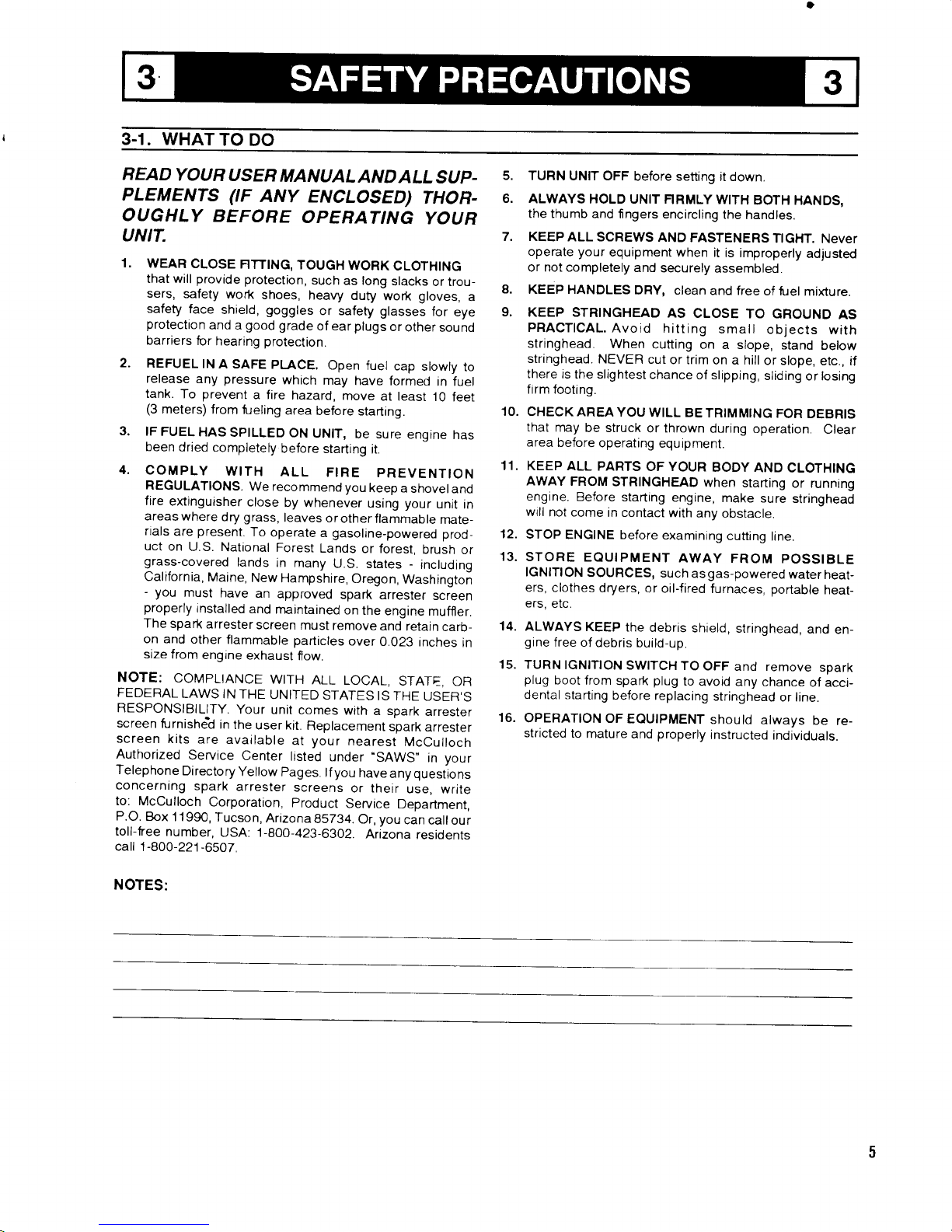

DO NOT

OPERATETHIS EOUIPMENT

with other

peo-

ple

or animals in

the imrnediate vicinity.

ALLOW a safe

distance

of at least 30 feet

(10

meters)

between operator

and other

people

or animals.

EDGINCJSCALPING

lS NOT RECOMMENDED

w h e n

other

people

or

animals are within 100 feet.

OO NOT SWEEP

WITH UNIT. Sweeping refers

to tilting

head

attachment

to sweep away debris from

sidewalks,

driveways,

etc.

tlfh

oo NoT usE ANy

orHER FUEL than

that rec-

\llommended in

your

nnnual.

Always follow instruc-

tions

in the Fuel

and Lubrication section

of this manual.

Never

use

gasoline

unless it is

properly

mixed with

2-cycle engine lubricant.

Permanent

damage to

engine

will result, voiding

manufacturer's

warranty.

5. DO NOT

OPERATE

EQUIPMENT wearing

loose

scarves, shorts,

dangling

jewelry,

key chains,

etc., or

while

barefoot.

OO NOT SMOKE

while refueling

or operating

equip-

ment.

DO

NOT START

EOUIPMENT WHEREYOU

FUEL IT,

Move

at least

10 feet

(3

meters)

from fueling

areas

before

starting.

DO NOT

OPERATE

UNIT WITHOUT A

MUFFLER

and

properly

installed muffler

shield.

OONOTTOUCH

or let

your

hands or

body come in

contact with

a hot mlffler

or spark

plug

wire.

10.

11.

1.

DO

NOT ALLOW DIRT.

FUEL OR DEBRIS to build uo

on engrne.

DO

NOT OPERATE UNIT

lN AWK\TVARO POS|IIONS,

otf balance, outstretched

arms, or one-handed. Always

use two hands

when

operating unit

with thumbs and

fingers encircling the

handles.

DO

NOT USE STEEL LINE OR PLASTIC-COATED

STEEL

LINE. The use of steel

line

or

plastic-coated

steel

line is

extremely

dangerous. Your stringhead is

designed

to

be

used with .080 or .095" diameter nylon

line.

DO NOT RAISE STRINGHEAD

above knee level while

unit is operating.

lnjury to operator could result.

DO NOT USE

ANY TYPE BLADE OR SAW CHAIN

CUTTER

HEAD unless soecified or included.

DO NOT

USE UNIT FOR ANY PURPOSES OTHER

than trimming

or mowing weeds or

grass.

DO NOTOPERATEUNIT

FOR PROLONGED PERIOOS,

Rest

periodically.

DO NOT

OPERATE UNIT WHILE UNDER THE

INFLUENCE OF ALCOHOL

OR

DRUGS.

DO NOT OPERATE UN]T UNLESS DEBRIS SHIELD

AND/OR GUARD IS INSTALLED AND IN GOOO

CONDITION.

1fhoo

Nor ADD, REMovE oR ALTER ANY

\l/coupoNENTs

oFTHts

pRooUCT.

Doing so

could cause

personal

injury and/or damage the

unit

void ing the rnanufacturer's warranty.

12.

2.

3.

4.

13.

14.

15.

16.

17.

18.

19.

6.

7.

L

9.

CAUTION

Extremely long

hair may be

drawn into the engine by the cooling

fan.

Ensure long

hair is

protected

and kept clear of the cooling

fan intake

area.

Page 7

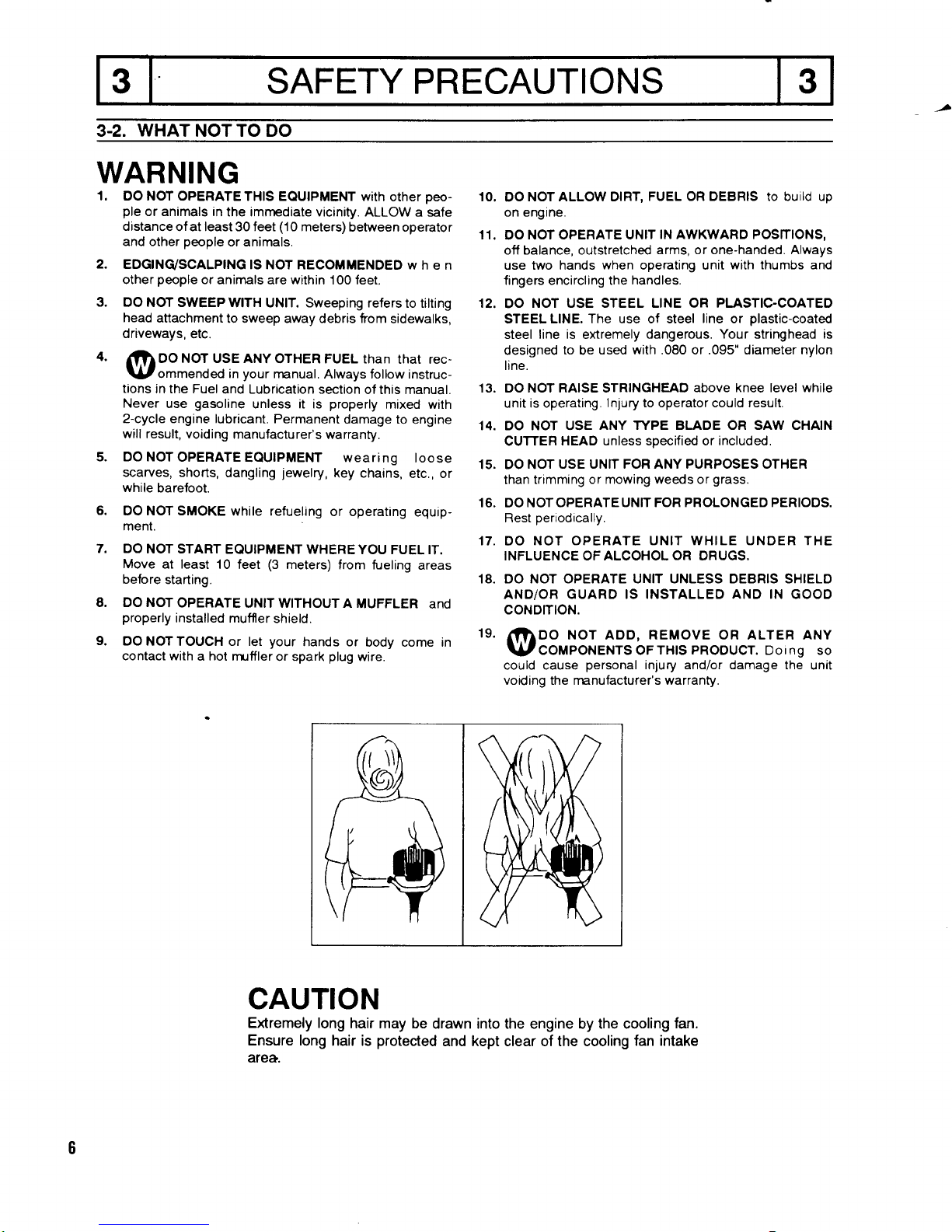

4.1. HANDLE

ASSEMBLY

NOTE:

The

Delta handle

is attached

to the shaft

but has

been turned

under

for ease

of

packing.

Figure

z1-1A

1 .

Loosen adjustment

knob

and rotate

handle

to top

of

shaft.

(Figure

4-1A)

2. Retighten

adjustment

knob

securely.

4.2.

SPARK

ARRESTER

INSTALLATION

NOTE:

Spark

Arrester

is required

when

using your

trimmeron

U.S. National

Forest

Lands. Checkvourlocal

state

requirements.

1 .

Place

your

unit on

a work bench

or level

surface

with

the muffler

facing you

as shown

in Figure

4-2A.

2.

Access

to the

screen

area can

be made

through

the

opening

on

the back

of

the muffler

shield.

lt is

not

necessafo

to

remove

the

muffler

shield to

install

the

screen.

REMOVE

SCREW

Figure

4'2A

3.

Using

a screwdriver,

remove

the

screen

cover

taining

screw.

(Figure

4-2A)

INSTALL

IN ORDER

SHOWN

>

:-@SCREEN

\K-

\

-COVER

\

Figure

rl-2B

-

scREw

4. Install

the spark arrester

screen,

the screen

cover

and scure in

place

with the retaining

screw.

(Figure

4-28)

NOTE:

A dirty spark

arrester screen

can dramatically

reduce

performance.

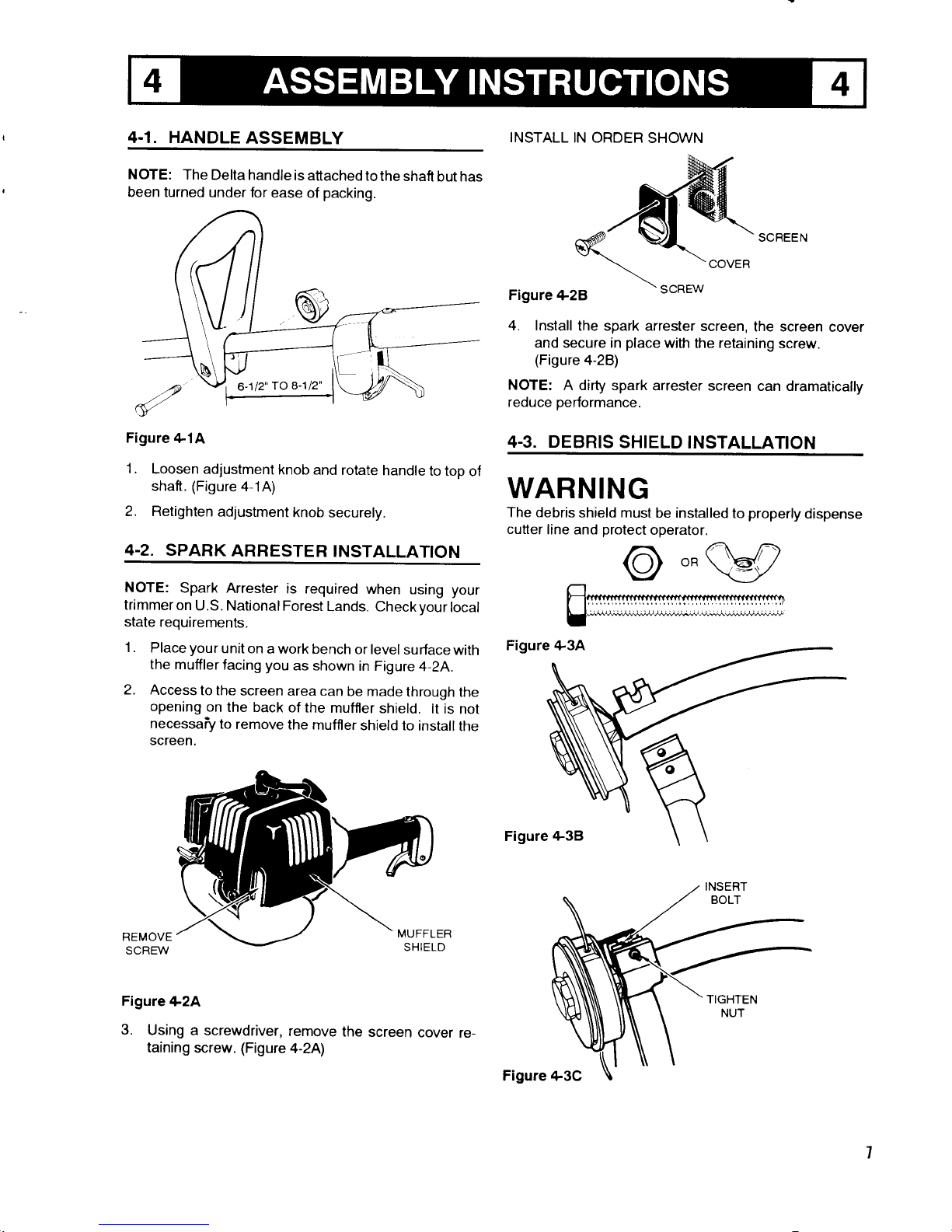

4.3. DEBRIS

SHIELD

INSTALLATION

WARNING

The debris

shield must

be installed

to

properly

dispense

cutter

line and

protect

operator.

@ ""Qg

Figure

zL3A

Figure

4-38

6-112"

To

8-112'

Figure

4-3C

Page 8

5.1. FUEL

Engine fuel is a mixture of

gasoline

and 2-cycle oil. The

correct ratio

of

gasoline

to oil is very important.

Follow

the ratios in the Fuel Mixing Table.

Use regular

grade

unleaded

gasoline

mixed with

McCulloch 40:1

custom 2-cycle engine oil for best

results. Use mixino

ratios in Section 5-3.

CAUTION

@

Never use

straight

gasoline

in

your

unit. Never use a fuel

mixture that has been stored for over

90 days.

This will

cause

permanent

engine damage

and

void the

manufacturer's warranty for

that

product.

CAUTION

@

lf 2-cycle

lubricant other than McCulloch Custom

Lubricant

is to be used, it must be

a

premium

grade

2-cycle oil mixed

at a

40:1 ratio. lf

insufficient lubrication

is

the cause of engine

damage, it voids the

manufacturer's

warranty for that

product.

5-2.

MIXING FUEL

Mix fuel in

a container equipped with

a flexible spout and

strainer.

See the Fuel Mixing Table for the

correct ratio

of

gasoline

to oil. Pour half of

the

gasoline

and all of the

oil

into the container.

Cover the container and shake

vigorously.

Add the rest

of

the

gasoline

and again shake

container to

thoroughly mix fuel and

oil.

GAUTTON

@

Never attempt

to mix

the

gasoline

and lubricating

oil in

the

fuel

tank

of the

unit.

Special starting

fluids

SHOULD NOT

be used because

seals

and other

rubber composition

parts

may be

damaged.

5.3. FUEL

MIXING

TABLE

GASOLINE

McCulloch

40:1 Ratio Custom Lubricant

1/2 U.S.

Gal.

1 U.S. Gal.

2.5 US

Gal.

5 U.>.

(:at.

1.6 oz.

3,2 oz.

8.0

oz.

16.0 oz.

48 ml

(cc)

95 ml

(cc)

237 ml

(cc)

475

ml

(cc)

1 Liter

5 Liters

20 Liters

0.9 oz,

4.3 oz.

17.O oz.

25 ml

(cc)

125 ml

(cc)

500 ml

(cc)

1 lmp. Gal.

2lmp.

Gal,

5lmp. Gal.

4.3 oz.

8.6

oz.

21 .4 oz.

125 ml

(cc)

250

ml

(cc)

52s ml

(cc)

Mixing

Procedute:

40 Part3 Gasoline to 1

Part Lubricant

1ml

=lcc

Ihe use of a fuel additive

such as STA-BILo Gas Stabilizer

or

an equivalent will

mrnimize the fornntion of

fuel

gum

deposits.

Such an additive

should only be used

when the

fuel/oil

mix rs

prepared.

Add 1 1 ml I 0.4 oz.

per gallon

of

gasoline

or mix

per

instructrons on container.

NEVER add

fuel

additives directly to

the unit fuel tank.

5.4. USE

OF BLENDED

FUELS

Today's fuels

are often a blend

of

gasoline

and one or more oxygenates such

as ethanol, methanol,

MTBE

(ether)

and axonal. These

blends are often referred to as

gasohol, premium

or super unleaded.

We recommend

regular unleaded

gasoline

for

use in

your

McCulloch

product.

However, if

you

choose to use a

blended

fuel or its use is unavoidable,

the following

precautions

are recommended.

1.

Always use fresh fuel mixed

peryou

r

User Manual.

Use the special additive ALCOHOL

PROTECiOR'o

1by

cold Eagle) or

equivalent

to inhibit conosion and

reduce

oiltfuel separation

(mix

as

directed).

Always agitate

the fuel mix before

fueling unit.

Defuel

tank and run engine dry be-

fore

stonng the unit.

PROBLEMS COMMON TO

BLENDED FUELS

Some

oroblems

associated with use of

blended

fuels

include:

.

Vaoor lock

.

Poor warm restart

.

Poor

performance

at high altitudes

.

Corrosron of fuel svstem

corDonentS

GASOHOL USE MAY REQUIRE

CARBURETOR ADJUSTMENTS

Your McOulloch engine

is lubricated by

oil mixed

with

the

fuel. Using

oxygenated fuels

may alter the airlfuel

ratio causing a lean

mix

(lessfuel,

more

atr).

lf this

condition is not corrected by

adjusting the

carburetor, engine

darnage due to

poor

lubrication rnay

result.

Your McCulloch Authorized

Service

Center can make these

adjustments.

a.

Page 9

NOTE:

lgnition

is always

"ON"

6-1.

STARTING

A COLD

ENGINE

NOTE:

To minimize

load

on engine

during

starting

and

warm-up,

trim

excess

cutter

line

to 5

inches.

(Figure

6-1A)

Your

unit

is designed

with a

3

position

choke;

"CHOKE"

,

'START'.

and

"RUN".

Figure

6-18

TO

START

ENGINE

1

. Move

choke

lever

to "CHOKE" position.

(Figure

6-18)

Figure

6-1C

2. Prime

the

carburetor.

times.

(Figure

6-1C)

Figure

6-1D

3.

Squeeze

the trigger

to the

FULL THROTTLE

position.

(Figure

6-1

D)

Figure

6-1E

4. Pull

starter rope

out a

short

way until

resistance

is

lelt

(approx.

4 inches).

Pull

starter

rope

briskly

4

times.

A smooth rapid

pull

is required

for

a strong

spark.

(Figure

6-1E)

NOTE:

Throttle

must

remain

in

fullthrottle position

until

engine

starts

and

warms

up

(approx.

1

0 seconds).

5.

Move

choke

lever

to "START"

position.

pull

starter

rope

again

4 tirnes

while

holding

trigger

at

the full

throttle position.

(Figure

6-1F)

6.

lf engine

fails

to start,

repeat

steps

1

through

5.

PRIMER

t

-{

Pump

the

primer

bulb

10

Page 10

a

6 OPERATI

NG I NSTRUCTIONS

6

6-2. TO STOP

THE

ENGINE

NormalStopping:

Flgure

61G

7. Onceengineslarts,leavethechokeinthe"START"

position

for 10 seconds, then move

choke to "RUN"

position.

(Figure-6-1

G)

NOTE:

Your unit is equipped

with a throttle advance

which also can be

used during starting.

(Figure

6-1H)

NOTE: lf engine fails

to start, after repeated

attempts,

refer to Troubleshooting

section.

NOTE:

Always

pull

starter

rope straight up. Pulling

starter at

an angle will cause rope

to

rub

against the

eyelet.

This friction will cause rope to

fray and wear

quickly.

Always

hold starter handle when

rope retracts.

Never let

rope snap back from

extended

position.

This

could

cause rope to snag or fray

and also damage

the

starter assembly.

Figure 6-2A

1.

Release throttle

trigger. Let engine

return to idle.

Extend

stader rope 4"-6"

to absorb strain on starter

components

when engine stops.

Push

and

hold

ignition stop

switch until engine stops.

Allow starter

rope to

retract slowly.

(Figure

6-2A)

6.3,

WARM ENGINE

START

Flgure 6-3A

1. Place choke

in

"START"

position.

(Figure

6-3A)

2. Grasp throttle

handle firmly, squeeze throttle trigger

to FULL

throttle

position.

3.

Pull

starter

rope briskly until engine

starts, but

no

more

than 6 times. Keep throttle

at FULL

position

until

engine runs smoothly.

4.

lf engine

doesn't start,

place

choke

in

"RUN" posi-

tion and

pull

starter

rope 5 more times. lf engine

still

does not start

it is

probably

flooded.

Wait

5 minutes

and repeat

procedure

with choke in

"RUN"

position

and throttle fullopen.

t0

Page 11

7-1.

ADDITIONAL

SAFEW

PRECAUTIONS

Before

operating

your

unit, review

ALL SAFETY

PRE)AUT\oNS

in this manual.

WARNING

CAUTION

lF

UNFAMILIAR

WITHTRIMMING/CUTTING

tech-

niques,

practice

the

procedures

with ENGINE

in

'OFF'position.

ALWAYS

CLEAR

WORK

area

of debris

such as

cans,

bottles,

rocks,

etc. Striking

objects

can cause

serious

injury

to operator

or bystanders

and

also damage

equipment.

lf an

object is accidentally

hit, immediately

TURN

ENGINE

OFF

and examine

equipment.

lf

stringhead

is

cracked or

broken,

or

plastic

debris

shield

is

damaged,

replace

those

parts

immediately.

Never operate

unit with damaged

or defective

equip-

ment.

ALWAYS

HOLD

UNIT FIRMLY

with

both

hands.

thumbs

and

fingers

encircling

handles.

ALWAYS

WEAR

PROPER

CLOTHING,

work

shoes,

work

gloves,

safety

goggles

and ear

protection

to

guard

against

hearing

impairment,

ALWAYS

TRIM

OR CUT AT

HIGH

ENGINE

SPEEDS.

Do

not run

engine

slowly at

start

or during

trimming

operations.

DO NOT use equipment for

purposes

other than

trimming

or

mowing weeds.

NEVER

raise stringhead above knee height

during

operation.

DO NOT operate unit with other

people

or animals in

the immediate vicinity. Allow

a minimum of 30 feet

between operator and other

people

and animalswhen

trimming or mowing. Allow a distance

of 100 feet

between

operator and other

people

and

animalswhen

EDGING or SCALPING with

stringhead.

NEVER

OPERATE EQUIPMENT

if taking medication

that

produces

drowsiness or reduces reflexes.

NEVER OPERATE EQUIPMENT

while

drinking alco-

holic beverages

or while under the influence

of alcohol

or drugs.

lF OPERATING

UNIT ON A SLOPE,

stand below

the

cutting attachment.

DO NOT OPERATE

on a

siope

or hilly incline

if there is the slightest

chance of slipping

or losing

your

footing.

7-2.

STRINGHEAD

LINE

RELEASE

CAUTION

Periodically

remove weed

wrap to

prevent

overheating

the

drive

shaft. Weed wrap

occurs when

strands

of weeds

become entangled

around

the shaft beneath

the debris

shield

(Figure

7-28). Remove

weed wrap

with a screwdriver

or

similar device,

or refer to Section

8-3, Removing

/

Replac-

ing Stringhead.

Figure

7-2A

NOTE:

The

bump-and-feed

stringhead

allows for

quick

and

easy

line feeding

without the

need to stop

engine to

advance

line.

(Figure

7-2A)

WARNING

CAUTION

DO NOT

use steel

wire or

plastic-coated

steelwire.

To

release

fresh

line, run

engine at full

throttle and

"bump"

stringhead

against

lawn.

Line will automatically

Fiqure

7-28

release.

The

knife in

debris shield

will trim excess line.

' 'Y-'-

11

Page 12

7

TRIMMING

INSTRUCTIONS

7

7.3.

TRIMMING PROCEDURES

When

properly

equipped with a debris shield and

stringhead,

your

unit will

trim

unsightly weeds and tall

grass

in those hard-to-reach

areas

-

along fences, walls,

foundations and

around trees. lt can also be used

for

edging

along walkways

and driveways.

And it can be

used for

scalping to remove vegetation down to the

ground

for easier

preparation

of a

garden

or to clean out

a

particular

area.

WARNING

Do not use steel wire or

plastic-coated

steel wire of any

kind with

your

stringhead. Serious operator injury can

result.

NOTE:

Even with care, trimming around foundations,

brick or stone walls,

curves, etc., will result in above

normal string wear. To release

fresh line, see

instructions in Section 7-2,

Stringhead Line Release.

TRIMMING/MOWING

Swing trimmer

with a

sickle-like motion from

side to side. Do not tilt

the stringhead during

the

procedure.

Test

area to be trimmed for

proper

cutting height

Keep stringhead at

same level for even

depth of cut.

CLOSEB TBIMMING

Position trimmer straight ahead with a slight tilt so bottom

of stringhead

is above

ground

and string contact occurs

at

proper

cutting

point.

Always cut away from operator.

Do not

pull

trimmer in toward operator.

FE N C E,tr OU N DATI ON TR IM MI N G

Approach

trimming around chain link fences,

picket

fences, rock walls and foundations slowly to cut close

without whipping string against

the

barrier. lf the string

comes in contact with rock,

brick walls, or foundations, it

will break or fray.

lf

string

snags fencing, it will snap off .

TRIMMING AROUND

TREES

Trim around

tree trunks with a slow approach so string

does not contact

the tree bark. Walk around the tree

trimming

from left to right. Approach

grass

orweedswith

tip of string and tilt stringhead slightly forward.

WARNING

Use extreme

caution

when EDGING

or

SCALPING.

Keep

a distance

of

100 feet

between

operator,

other

people

and animals

during these

operations.

EDGING

Tilt unit to

the left

so that

stringhead

is

in a vertical

position.

This will allow

the nylon line

to sklm

along

the edge

of the

concrete.

Before

edging,

you

may

want to

adjust

the handle

so as

to make

this operation

as

effortless

as

possible.

Always

keep a distance

of

100 feet

from other

people

and

animals

when edging. Do

not attempt this

procedure

if there

is any chance

flying debris

could injure

operator,

other

people

or cause

damage to

property.

SCALPING

Scalping

refers lo

removal

of all

vegetation down

to the

ground.

To do

this, tilt

the stringhead

to about

a

30 degree

angle to

the

left. By adjusting

the

handle

you

will

have better

control

during

this operation.

Always keep

a

distance of

100 feet

from other

people

and

animals

when

scalping.

Do not attempt

this

procedure

if there is any

chance

flying debris

could injure

operator, other

people

or cause

damage

to

property.

WARNING

DO NOT

SWEEP

WITH TRIMMER

Sweeping

refers to tilting

stringhead to sweep

away

debris

from walkways,

etc. Your

trimmer is a

powerful

tool and

small stones

or other such

debris may

be

hurled

50 feet

or more,

causing injury

or damage to nearby

property

such

as automobiles,

homes and

windows.

12

Page 13

8.1.

PREVENTIVE

MAINTENANCE

Service

other

than routine

user

maintenance

items

should

be

performed

by

your

McCulloch

Authorized

Service

Center listed

in under

"SAWS"

in the Yellow

Pages

of

your

telephone

directory.

Keep

your

unit

clean.

Do not allow

filters, mufffer

and

cylinder

fins to become

plugged

or

covered with

dirt or

debris.

fi[

Never use

dirty fuel

or dirty

oil. Engine

damage

\lf

could result.

Always

follow

instructions

in the

Fuel

and

Lubrication

section

of this manual.

A

good preventive

maintenance

program

will

prolong

the

life and maintain the

performance

of

your

McOulloch unit.

After

the first 7 days or 15 hours of operation,

whichever

comes

eadiest, take

your

unit to

your

McOulloch

Author-

ized Service Center for

an inspection and

check-up.

Your

dealer will be

pleased

to

help

you

set up a

preven-

tive maintenance

program

to suit

your

needs.

The rec-

ommended first 7-day or 1S-hour

check-ups

and a

follow-up

of regular

periodic

check-ups

and tune-ups

will

assure long, satisfactory

service from

your

McCulloch

product.

This service will

be

performed

at

your

McCul-

loch Authorized

Service Center at existing

service rates.

MAINTENANCE

CHECKLIST

NOTE:

The

maintenance

checklist

below

is a

guide

for

preventive

maintenance.

Cleaning, adjustment,

and

parts

replacement

may,

under

certain

conditions,

be required

at more

frequent intervals than

those indicated.

MAINTENANCE

CHECK

LIST

5

H

o

U

R

S

20

H

o

U

R

S

lil

r

I

ITEM

ACTION

SCREWS

/

NUTS

/BOLTS

INSPECT

/

TIGHTEN

CONTROLS

INSPECT

TFEPLACE

AS FEQUIFED

AIR FILTER

CLEAN

OR REPLACE

FUEL FILTEB

REPLACE

DEBRIS

SHIELD

INSPECT

REPLACEAS

REQUIRED

STRINGHEAD

INSPECT

REPLACEAS

REQUIRED

SPARK PLUG

CLEAN/ADJUST/FEPLACE

MUFFLER

TCLEAN

LAMINATION

GAP

*CLEANTADJUST

EXHAUST

PORTS

*CLEAN

a

SPARKARFESTER

SCBEEN

INSPECT

REPLACE

CYLINDEB

FINS

TCLEAN

CARBUFETOR

.CLEAN

STARTER

ROPE

INSPECT

a

*REPLACE

AS REOUIRED

DRIVE

SHAFT

TLUBRICATE

(Every

50

Hours)

a

FUEL

HOSES

INSPECT

a

*REPLACEAS

REOUIRED

tFlecommended

for Maintenance

by a McCulloch

Authorized

Service Center Technician

13

Page 14

8 MAI

NTENANCE

I NSTRUCTIONS

I

8.2. REPI.ACING CUTTER LINE

Figure 8-2A

1. Turn the knob COUNTERCLOCKWISE

and remove

it. lf required use string head wrench.

2. Remove the spooland spring.

3. Remove

any remaining cutter line.

(Figure

8-2A)

Figure

8-2D

6.

Lock each

end

into a slot on opposite

sides

of the

spool.

Install

the spring

over the

spindle. Insert

each end

of the

line through an

eyelet in the housing

and lower

the spool

into the

housing while feeding

the

line through

the eyelets. Ensure

the spring seats

itself into

the spool.

(Figure

8-2D)

HAND

TIGHT

ONLY

DO

NOT

USE

WRENCH

Figure

8-2E

7. Once the

spool

is in

place,

apply

pressure

on the

spool compressing

the spring. Pull

each end of the

line sharply to

unlock them

from the slots. Continue

to apply

pressure

to the spool

until the knob can be

threaded

CLOCIQVISE

onto the

spindle. Tighten

the

knob securely

by hand

only. DO NOT USE THE

STRINGHEAD

WRENCH

TO T]GHTEN.

(Figure

8-2E)

NOTE:

Apply

an anti-seize

compound

(Permatex@

'133A

Anti-seize

or equivalent) to

the threads to make the

knob

easier lo

remove next time

service

is

required.

Flgure

8-2F

8.

Trim the

excess

line to approximately

5

inches.

This

will minimize

load on engine

during starling and

warm-up.

(Figure 8-2F)

4. Double a 18ft. length of .095

(or

.OB0) cufter line.

Thread each end through

one of the two sets of holes

on the top of the spool. Pull both ends

evenly

through the holes.

(Figure

B-28)

Figure 8-2C

5. Wind both ends around

the

spool

together

in

a

CLOCKWISE

direction to within 6" of the ends. DO

NOT

TWIST UNE ON SPOOL. Twisting line

could

cause stringhead to feed improperly.

(Figure

8-2C)

14

Page 15

8-3.

REMOVING / REPI-ACING

STRINGHEAD

I MAI NTENANCE

I NSTRUCTIONS

8

Figure &3A

1. Turn the knob

COUNTERCLOCKWISE

to remove.

Use the stringhead

wrench if required.

2. Remove the spool

and spring from

the housing.

3. Remove the

housing. Gently

tap back of housing

to

loosen. (Figure

8-3A)

_?

o*

Figure

8-48

2.

Lift filter from Air

Box.

(Figure

8-4B)

3. Wash filter in soap

and water. DO NOT USE

GASOLINEI

4.

Air dry filter.

5. Reinstall filter

in

reverse

order of removal.

NOTE: Replace f lter if frayed,

torn,

damaged or

unable to clean.

8.5. FUEL CAP/FUEL FILTER

CAUTION

Remove fuel from unit and store in approved container

before starting this

procedure.

FUEL.AP

\ t--<

htu

Figure 8-5A

NOTE: Keep vent on fuel cap clean of debris.

(Figure

B-5A)

1. Liftfuel line outoftank. Steelwirewith hookorpaper

clip works well.

(Figure

8-5B)

HAND

TlGHT

ONLY

OO NOT

USE

STRINGHEAO

WRENCH

Figure 8-3B

4. Remove

the replacement

stringhead

from the

pack-

age

intact. Place

it on the spindle.

Ensure the

hex

on

the spindle is

well seated

into the housing.

5. Compress

the'spool into

the housing

and thread

the

knob

into the assembly.

Tighten

the knob

CLOCK-

WISE,

BY HAND

ONLY.

(Figure

8-38)

84. AIR FILTER

To Clean Air Filter:

AIR

FILTER

AIR FILTER

COVER

COVER SCREWS

Figure 8-4A

1 . Remove

2 screws holding

airfilter cover

remove

cover.

(Figure

8-4A)

15

FUEt

FILTER

in

place

and

Page 16

8

MAI

NTENANCE

I NSTRUCTIONS

I

Figure &5C

2.

Pull

off with a twisting motion.

(Figure

8-5C)

3. Replace fuelfilter.

NOTE:

Neveroperate the trimmerwithoutthe

filter. Internal engine damage could result !

CARBURETOR ADJUSTMENT

The carburetor was

pre-set

at the factory for optimum

performance.

lf further adjustments are necessary,

please

take

your

unit to the nearest McOulloch Author-

ized Service Center listed in the Yellow Pages.

8-7. SPARK PLUG

CENTER

ELECTRODE

SIDE

ELECTRODE

Figure

8-7B

4. Adjust

gap

to

.025 in. Bend

side electrode

only using

a

gapping

tool.

(Figure

8-78)

5.

Reinstall

spark

plug

and torque

to 105 to

130 inch

pounds.

Reconnect

spark

plug

boot.

8€.

SPARK

ARRESTER

SCREEN

NOTE:

lt is

not necessary

to take muffler

shield off to

replace

or install

a new spark

arrester

screen.

@

8-6.

fuel

SPARK PLUG

BOOT

Figure 8-7A

1 . Remove spark

plug

boot with a twist and

pull

motion.

(Figure

8-7A)

2. Remove the spark

plug.

3. Clean spark

plug

electrodes with

emery

cloth.

REMOVE

SCREW

Figure

8-8A

SCREEN

Flgure &88

1 ,

To replace spark

arrester

screen, remove

the retain-

ing screw

and screen

cover. Discard

old

screen.

Install

new screen.

(Figure

8-8A

& 8-88)

16

Page 17

8

MAI

NTENANCE

I NSTRUCTIONS

I

8.9.

DEBRIS

SHIELD

KNIFE

SHARPENING

1 . Remove

cutter

knife from

debris

shield.

2. Place

knife

in a bench

vise.

Sharpen

knife using

a

flat file,

being

careful

to maintain

the angle

of cutting

edge.

File in one

direction

only.

Figure 8-10A

B. Pour

1 teaspoon of

clean 2-cycle

oil into

the com-

bustion

chamber. Pull

starter

rope slowly

several

times

to coat internal

components.

Replace

spark

plug.

(Figure

8-10A)

9.

Store unit in a

cool, dry

place

away

from any

source

of ignition

such as an oil

burner, water

heater,

etc.

8.1 1.

REMOVING

A UNIT FROM

STORAGE

Figure

8-9A

3.

Reinstall

knife.

Tighten

fasteners

securely.

(Figure

B-9A)

8.10.

STORING

A UNIT

Clean

and

gap

spark

plug

or install

a new spark

plug

with

proper

gap.

Prepare

unit for operation.

Fillfueltank

with

proper

fuel/ oil

mixture.

See Fuel

and

Lubrication

Section.

1.

Remove spark

plug.

2. Pull starter

rope briskly

to

clear excess

oil

from

combustion

chamber.

3.

fi[Failure

to

follow

these

steps

may cause

varnish

to

\l/form

in

the carburetor,

difficult

starting

or

perma-

nent

damage

after

storage.

1. Perform

all thd

general

maintenance

recommended

in

the Maintenance

Section

of

your

User

Manual.

2. Clean

exterior

of engine,

drive

shaft

assembly,

de-

bris

shield

and stringhead.

3.

Drain

fuelfrom

the

fueltank.

4.

After fuel

is drained,

start

engine.

5.

Run engine

at idle

until unit

stops.

This

will

purge

the

carburetor

of fuel.

6. Allow

engine

to

cool

(approximately

5 minutes),

7.

Using

a spark

plug

wrench,

remove

the spark

plug.

4.

5.

l7

Page 18

FOR PERFOBMANCE AND SAFETY REASOA'S

USE ONLY

GENUINE

McCULLOCH ACCESSORIES AND

BEPIACEMENT

PABTS.

DESCRIPTION

ACCESSORIES and REPLACEMENT PARTS

PART

NUMBER

Dual

Une Stringhead Assembly . .

Dual Line-on-Spool

Bump Knob

300160

3001s9

300339

3003s6

21904341

300323

22397541

224040

21698s

Bump Spring

Spark

Plug DJSJ

Air Filter

Debris

Shield

Spark Arrester

Screen

Fuel Filter

LUBRICANTS

3.2 oz. ONE

SHOT 22325141

224477

98463

8 oz.

(for

2.5

gal.

mix)

16 oz.

(with

easy

mix chamber)

18

Page 19

PROBLEM

PROBABLE

CAUSE

Line won't

feed.

Line

is

tangled

inside

stringhead.

Remove

spool

from

unit;

disassemble.

Untangle

line

and

wind correctly

in

direction

indicated

on spool

(see

Section

8).

Upon

removing

spool,

line

appears

to be melted

together.

Trim off

damaged

line

and rewind

line (see

Section

B).

Line

wound

in

wrong

direction

inside

stringhead.

Remove

spool.

Check

to be

certain

line is

wound

in

direction

indicated

on

line

element.

(see

Section

8)

Insufficient

line

inside

stringhead.

Remove

spool

and

install

new

line

(see

Section

B).

Internal

damage

to

stringhead

caused

by

bumping

head

too

hard

on

ground

while

advancing

line.

Disassemble

stringhead

and

examine

parts

for

damage.

Replace

parts

or entire

head

(See

Section

8).

Line

snaps

off

or frays.

lmproper

trimming procedures,

or

poor

quality

line.

See General

Trimming

Instructions

or replace

line (see

S6ction

B).

Unable

to

remove

stringhead

knob.

Stringhead

and

shaft

are

hot

to the

touch.

Stringhead

knob

over

tightened

-

use

stringhead

wrench

supplied in

user

kit.

U

s e

anf,i- se

ize

com

pou

nd

(Permatexw

133A

Anti-sdize

or

equivalent)

and

reinstall

knob

HAND

TIGHT

ONLY.

Weed

wrap.

Remove

weed

wrap

(see

Section

7).

l9

Page 20

PROBLEM

PROBABLE

CAUSE

CORRECTIVE

ACTION

Unit

won't

start

or starts

but

will

not

run.

I

ncorrect

starti

ng

Procedures

Follow

instructions

in

the User

Manual

(See

Section

6).

lncorrect

carburetor

mixture

adjustment

setting

Have

carburetor

adiusted

bY

an

Authorized

Service

Center.

Fouled

spark

plug

Remove,

clean

and

gaP (or rePlace)

spark

plug.

lf

plug is

wet, reinstall

plug

and

hold at

full

throttle

until

unit

starts.

lf

plug

is dry,

try

starting

with

choke

on

(See

Section

8).

Fuelfilter

plugged

Replace

fuelfilter

(See Section

B)'

Unit

starts,

but engine

has

low

power.

Incorrect

lever

position

on

choke

Move

to

RUN

position.

Dirty

spark

arrestor

screen

Replace

spark

arrester

screen.

Dirty

air

filter

Remove,

clean

and

reinstall

filter.

lncorrect

carburetor

mixture

adjustment

setting

Have

carburetor

adiusted

bY

Authorized

Service

Center.

an

Engine

hesitates

lncorrect

carburetor

mixture

adjustment

setting

Have

carburetor

adjusted

bY an

Authorized

Service

Center.

No

power

under

load

Runs erratically

Incorrectly

gapped

spark

Plug

Clean

/

gap

or replace

Plug.

Smokes

excessivelY

lncorrect

carburetor

mixture

adjustment

setting

Have

carburetor

adiusted

bY

Authorized

Service

Center.

an

lncorrect

fuel

mixture

Use

properly

mixed

fuel

(40:1

mixture)

.

FOR

WARRANW

OR

SERVICE

CONTACT

THE

NEAREST

MCCULLOCH

AUTHORIZED

SERVICE

CENTER

LISTED

UNDER

''SAWS'

IN

YOUR

TELEPHONE

DIRECTORY

YELLOW

PAGES.

IF

FURTHER

ASSISTANCE

IS

REQUIRED

CALL

THIS

TOLL-FREE

HOT

LINE'

PLEASE

REFERENCE

YOUR

MODEL

AND

SERIAL

NUMBER'

1€00423-6302

ln

Arizona:

1-800-221-6s07

M-F

6:00

AM

-

4:45

PM

(MST)

Page 21

/u

REFER

TO YOUR USER MANI.JAL

FOR MORE

DETAILED

INSTRUCTIONS

A. DEBRIS SHIELD

Loosen

xnoo

"no

:;" handte to the top

grip

and tighten knob.

J

.

HA.I.IDLE

Adfust

to a comfortable

distance

from

the rear

Loosen

the

screws slightly and rotate

the handle to the top a comfortable distance

from

the

rear

grip.

Tighten the screws.

BEFORE STARTING ENGINE:

Fuel

used

in this machine must

be

mixed with

McCulloch Custom Lubricant at 40:1 mix ratio

(3.2

oz.

oil to 1

gallon gasoline).

ASSEMBLY

QUICK

REFERENCE

FOLLOW THESE SIMPLE STEPS

TO ASSEMBLE

YOUR

TRIMMER

INSERT

EOLT

ACTUAL

SIZE

Locate

bolt

and

nut.

DELTA

HANDLE

Set

debris shield in

place.

Install

bolt and nut,

then

tighten

B.

c.

O U S A - McCulloch Concoration

Pnnted

rn USA

21

1373

Page 22

ltt.

CONSULTE

EN EL

MANUAL

DEL

USUARIO

SI

DESEA

INSTRUCCIONES

EN MAS

DETALLE

PROTECTORA

CONTRA ESCOMBROS

l1

1l

@"k2

Localice el

perno

y

la tuerca.

Coloque la

protectora

contra

escombros

en su lugar

Instale

el

perno

y

la tuerca, y apriete

MANIJA DELTA

Afloje la

perilla

y gire

la manila hasta arriba

Ajuste a una

distancia

comoda

del agarre

trasero y apriete

la

perilla

MANIJA EN J

Afloje los tornillos ligeramente

y gire

la manija hacia

su

posicion

superior,

a una distancia

comoda del

agarre

trasero. Apriete los

tornillos.

ANTES

DE ARRANCAR EL MOTOR: el combustible

usado

en

esta mAquina

debe

estar mezclado

con el

lubricante

Custom Lubricant

de

McCulloch

a una raz6n

de mezcla

de 40:1

(236

ml de aceite

por

10 litros

de

gasolina

-

3.2 onzas

de aceite

por

1

galon

de

gasolina).

CONSULTA

RAPIDA

PARA

EL

ENSAMBLAJE

SIGA

ESTOS SIMPLES

PASOS

PARA

ENSAMBI.AR

SU RECORTADORA

INTRODUZCA

EL

PERNO

APRIETE

O

U.S A - McCulloch Corooratron Printed in

USA

21

1373

Loading...

Loading...