Page 1

GB

SE

DK

FI

NO

FR

NL

IT

DE

ES

PT

HU

PL

RU

EE

LV

LT

SK

HR

BA

RS

CZ

BG

UA

Operator’s manual 6-27

Bruksanvisning 28-49

Brugsanvisning 50-71

Käyttöohje 72-94

Bruksanvisning 95-116

Manuel d’utilisation 117-140

Gebruiksaanwijzing 141--164

Istruzioni per l’uso 165-187

Bedienungsanweisung 188-211

Manual de instrucciones 212-235

Instruções para o uso 236-259

Használati utasítás 260-281

Instrukcja obs∏ugi 282-305

эксплуатации 504-531

Käsitsemisõpetus 306-327

Lieto‰anas pamÇc¥ba 328-349

Naudojimosi instrukcijos 350-371

Návod na obsluhu 372-393

Priruãnik 394-415

Uputstvo o upotrebi 416-437

Priruãnik 438-459

SI Navodila za uporabo 460-481

Návod k pouÏití 482-502

експлоатациЯ 532-559

RO Instrucöiuni de utilizare 586-607

GR √‰ËÁ›Â˜ ¯Ú‹Ûˆ˜ 608-631

TR Kullanım kılavuzu 632-653

користувача 560-585

.

CS 35

CS 35S

Page 2

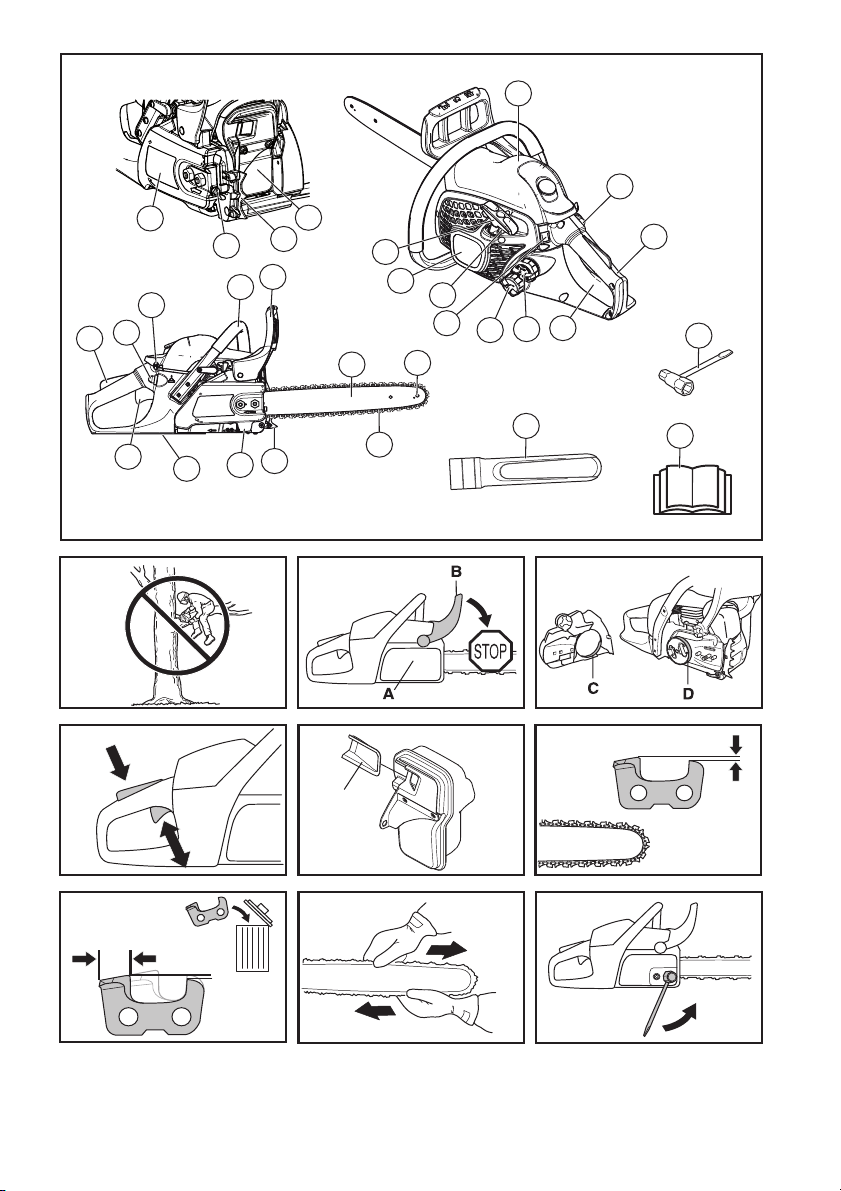

2

1

1

2

17

21

18

19

9

10

8

20

3

11

6

7

5

27

15

14

13

16

4

2

2

5

A

8

min 4mm

(0,16’’)

24

21

12

23

22

3

6

A

B

9

25

4

7

10

26

A

C

B

– English

Page 3

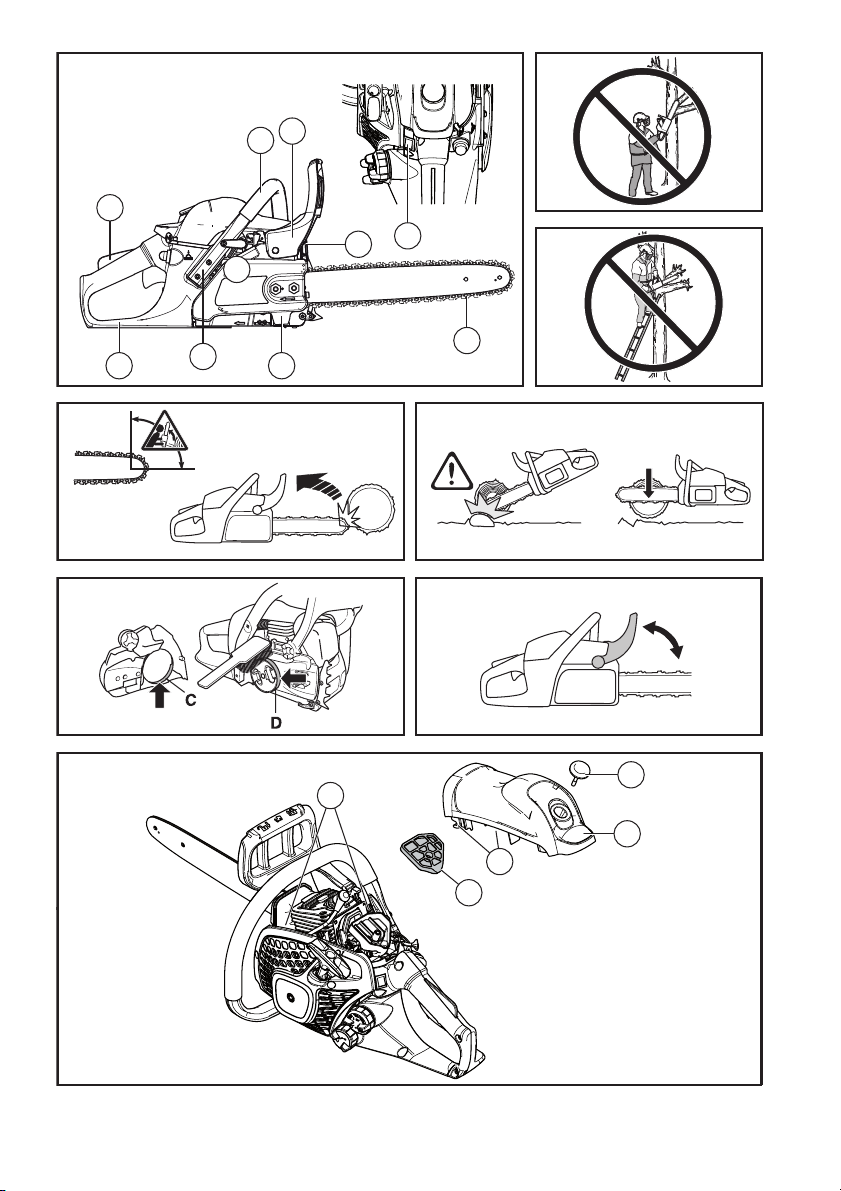

11

12

13

14 15 16

17

20

18 19

21

22

A

B

23

26

24 25

B

English – 3

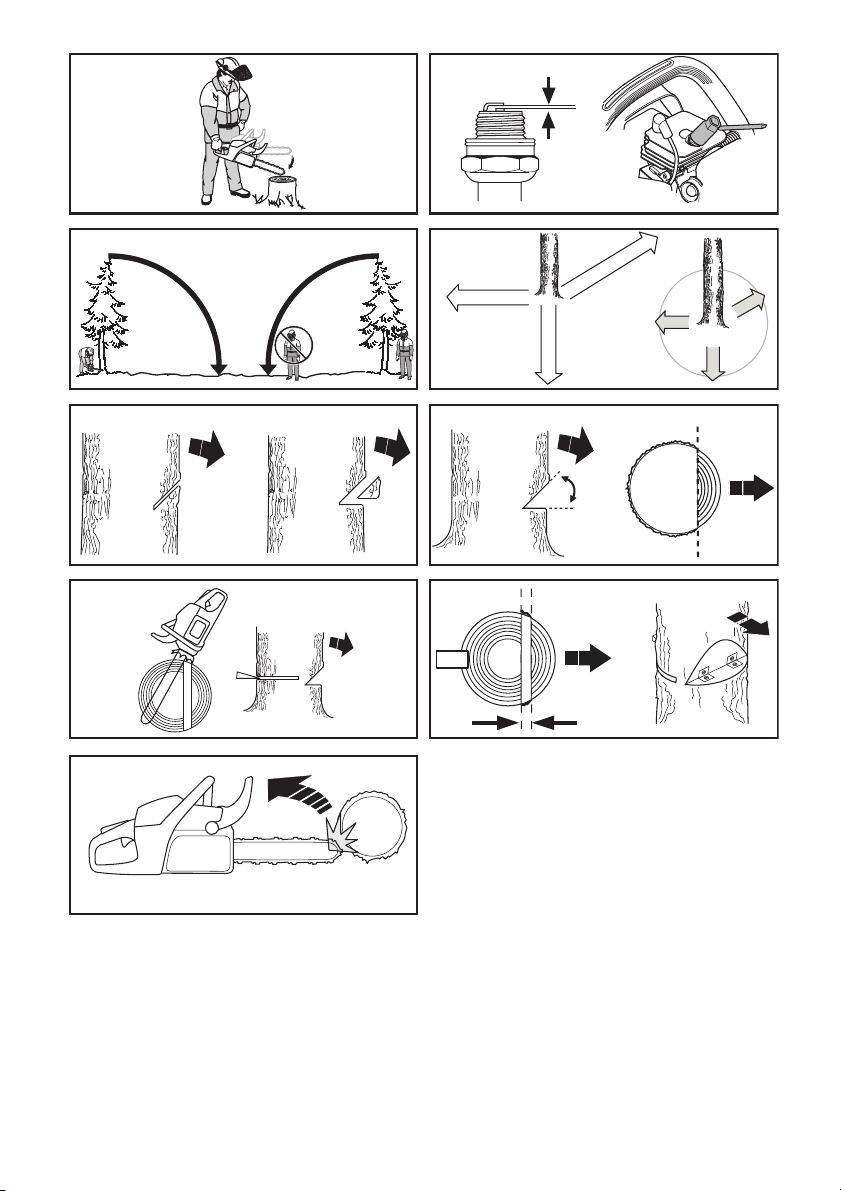

Page 4

27

30

32

28

A

E

C

D

G

H

B

F

I

J

29

31

33

34

4 – English

A

E

B

D

C

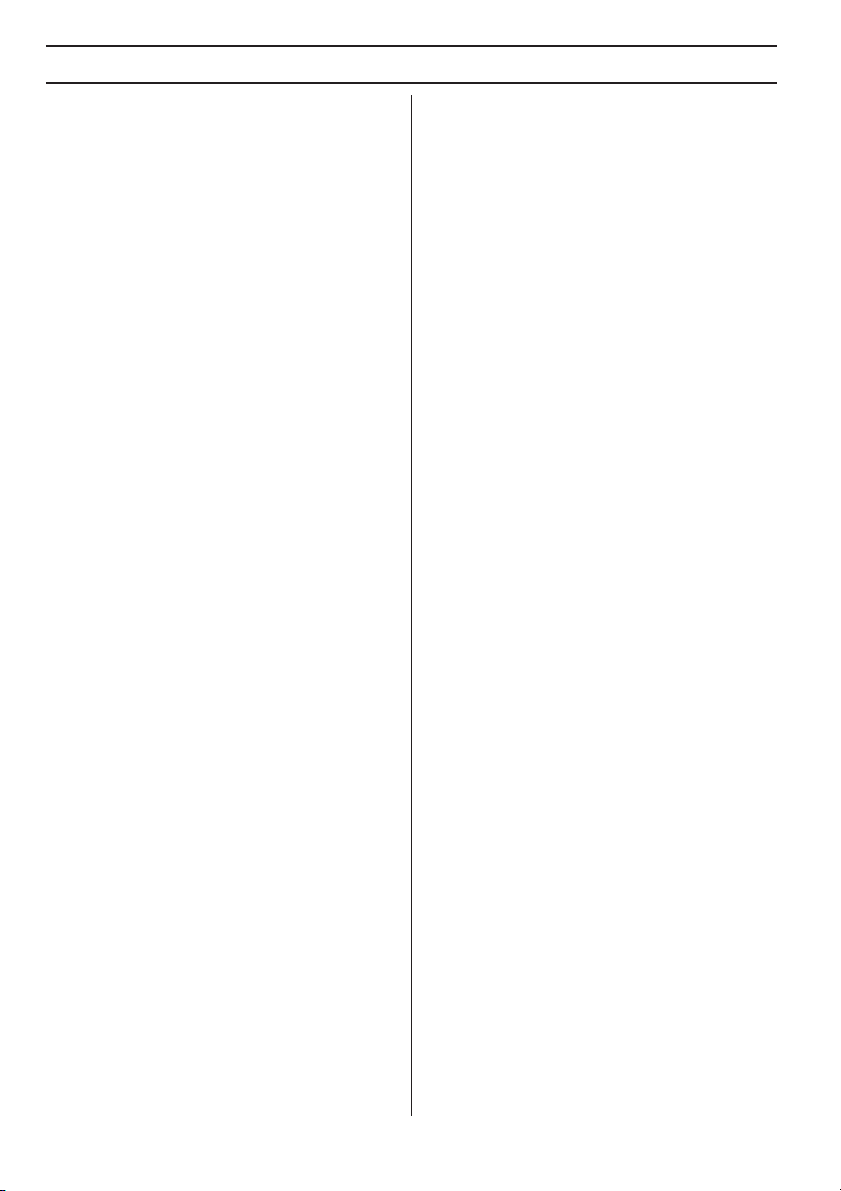

Page 5

35

37

39

41

36

38

Retreat path

40

42

0,6 mm

Dan

g

e

r zon

e

Danger zone

Felling direction

D

a

ng

er zo

Retreat path

1

2

ne

1

3

1

2

43

English – 5

Page 6

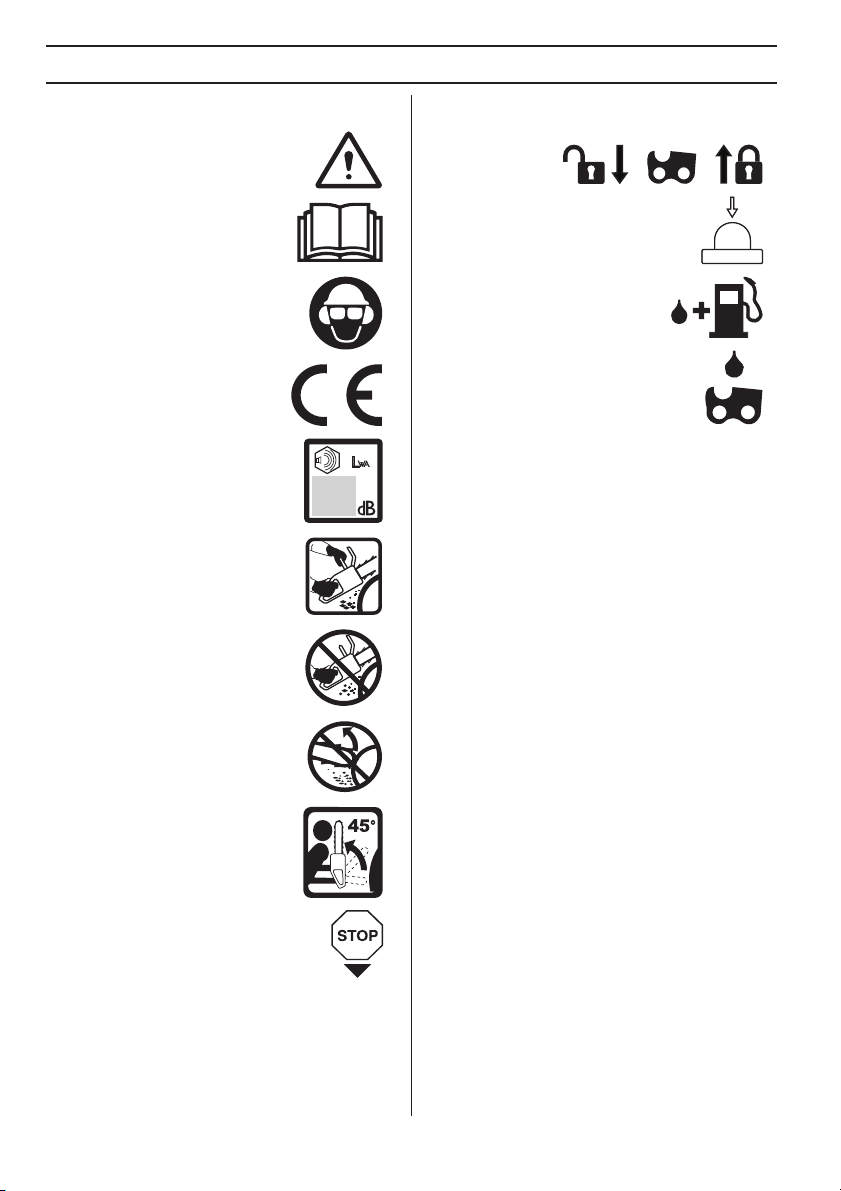

Symbols on the machine:

ARNING! Chain saws can be

dangerous! Careless or incorrect use can

result in serious or fatal injury to the

operator or others.

Please read the operator’s manual

carefully and make sure you

understand the instructions before

using the machine.

Always wear:

• Approved protective helmet

• Approved hearing protection

• Protective goggles or a visor

This product is in accordance with

applicable EC directives.

INTR ODUCTION

Chain brake, activated (front)

Chain brake, not activated (back)

Air purge

Refuelling.

Chain oil fill.

6

W

Noise emission to the environment

according to the European

Community’s Directive. The machine’s

emission is specified in the Technical

data chapter and on the label.

Both of the operator ′ s hands must be

used to operate the chain saw.

Never operate a chain saw holding it

with one hand only.

Contact of the guide bar tip with any

object must be avoided.

WARNING! Kickback may occur when

the nose or tip of the guide bar touches

an object, and cause a lightning fast

reverse reaction, kicking the guide bar

up and towards the operator. May

cause serious personal injury.

The engine is stopped by switching the

ignition off using the stop switch.

The rating plate

showing serial number.

yyyy is the production

year, ww is the

productionweek and

xxxxx is the sequential

number.

Other symbols/decals on the mac hine refer to special

certification requirements for certain markets.

yyyywwxxxxx

–

English

Page 7

INTR ODUCTION

1

Dear Customer ,

Thank y ou for choosing a McCulloch product. You are

thereby part of a story that started long ago, when the

McCulloch Corporation started its manufacturing of

engines during World War II. In 1949, when McCulloch

introduced its first light one-man chainsaw, woodworking

would never be the same again.

The line of innovative chainsaws would continue over the

decades, and business was expanded, first by airplane

and kart engines in the 1950s, then by mini chainsaws in

the 1960s. Later, in the 1970s and 80s, trimmers and

blower vacs were added to the range.

Today, as a part of the Husqvarna group, McCulloch

continues the tradition of powerful engines, technical

innovations, and strong designs that have been our

hallmarks for more than half a century. Lowering fuel

consumption, emissions and noise levels are of top

priority to us, as is improving safety and user-friendliness.

We certainly hope that you will be satisfied with your

McCulloch product, as it is designed to be your

companion for a long time. By following this operators

manual’s advice on usage, service, and maintenance, its

lifespan can be extended. If you should need professional

help with repair or service, please use the Service Locator

at www.mcculloch.com.

McCulloch has a policy of continuous product

development and therefore reserves the right to modify

the design and appearance of products without prior

notice.

This manual can also be downloaded at

www.mcculloch.com.

What is what on the c hain sa

w?

(1)

Cylinder cover

2 Air purge

3 Stop switch (Ignition on/off switch.)

4 Choke control/Start throttle lock

5 Rear handle with right hand guard

6 Information and warning decal

7 Fuel tank

8 Adjuster screws carburettor

9 Starter handle

10 Starter housing

11 Chain oil tank

12 Rating plate

13 Chain tensioning screw

14 Clutch cover

15 Throttle lockout (Prevents accidental operation of

throttle trigger.)

16 Front handle

17 Front hand guard

18 Muffler

19 Guide bar

20 Bar tip sprocket

21 Saw chain

22 Spiked bumper

23 Chain catcher

24 Throttle trigger

25 Guide-bar cover

26 Operator′s manual

27 Combi-tool

English

–

7

Page 8

CONTENTS

Contents

INTRODUCTION

Symbols on the machine: ...................................... 5

INTRODUCTION

Dear Customer, ..................................................... 7

What is what on the chain sa

CONTENTS

Contents ............................................................... 8

GENERAL SAFETY PRECAUTIONS

Before using a new chain saw .............................. 9

Important .............................................................. 9

Always use common sense .................................. 9

Personal protective equipment ............................. 10

Machine′s safety equipment ................................. 10

Cutting equipment ................................................. 12

ASSEMBLY

Fitting the bar and chain ....................................... 15

FUEL HANDLING

Fuel ....................................................................... 16

Fueling .................................................................. 17

Fuel safety ............................................................ 17

STARTING AND STOPPING

Starting and stopping ............................................ 18

WORKING TECHNIQUES

Before use: ............................................................ 19

General working instructions ................................ 19

How to avoid kickback ........................................... 22

MAINTENANCE

General ................................................................. 23

Carburettor adjustment ......................................... 23

Checking, maintaining and servicing chain saw

safety equipment .................................................. 23

Muffler ................................................................... 24

Air filter .................................................................. 24

Spark plug ............................................................. 24

Maintenance schedule .......................................... 25

TECHNICAL DATA

Technical data ....................................................... 26

Guide bar and saw chain combinations ................ 27

EC Declaration of Conformity ............................... 27

........................... 7

w?

8 – English

Page 9

GENERAL SAFETY PRECAUTIONS

w c

Before using a ne

• Please read this manual carefully

• (1) - (43) refer to figures on p. 2-5.

• Check that the cutting equipment is correctly fitted and

adjusted. See instructions under the heading

Assembly.

• Refuel and start the chain saw. See the instructions

under the headings Fuel Handling and Starting and

Stopping.

• Do not use the chain saw until sufficient chain oil has

reached the chain. See instructions under the heading

Lubricating cutting equipment.

• Long-term exposure to noise can result in permanent

hearing impairment. So always use approved hearing

protection.

WARNING! Under no circumstances ma

the design of the machine be modified

!

without the permission of the

manufacturer. Always use original

accessories. Non-authorized

modifications and/or accessories can

result in serious personal injury or the

death of the operator or others.

WARNING! A chain sa

tool if used carelessly or incorrectly and

!

can cause serious, even fatal injuries. It

is very important that you read and

understand the contents of this

operator’s manual.

hain saw

.

w is a dangerous

Important

IMPORTANT!

This chain sa

work such as felling, limbing and cutting.

You should only use the saw with the bar and chain

combinations we recommend in the chapter Technical

data.

Never use the machine if you are fatigued, while under

the influence of alcohol or drugs, medication or anything

that could affect your vision, alertness, coordination or

judgement.

Wear personal protective equipment. See instructions

under the ”Personal protective equipment” heading.

Do not modify this product or use it if it appears to have

been modified by others.

Never use a machine that is faulty. Carry out the safety

y

checks, maintenance and service instructions

described in this manual. Some maintenance and

service measures must be carried out by trained and

qualified specialists. See instructions under the

Maintenance heading.

Never use any accessories other than those

recommended in this manual. See instructions under

the headings Cutting equipment and Technical data.

CAUTION! Alw

visor to reduce the risk of injury from thrown objects. A

chain saw is capable of throwing objects, such as wood

chips, small pieces of wood, etc, at great force. This can

result in serious injury, especially to the eyes.

w for forest service is designed for forest

ays wear protective glasses or a face

WARNING! The inside of the m

contain chemicals that may be

!

carcinogenic. Avoid contact with these

elements in the event of a damaged

muffler.

WARNING! Long term inhalation of the

engine’s e

!

and dust from sawdust can represent a

health risk.

WARNING! This machine produces an

electromagnetic field during operation.

!

This field may under some

circumstances interfere with active or

passive medical implants. To reduce the

risk of serious or fatal injury, we

recommend persons with medical

implants to consult their physician and

the medical implant manufacturer before

operating this machine.

xhaust fumes, chain oil mist

uffler

WARNING! Running an engine in a

confined or badly ventilated area can

!

result in death due to asphyxiation or

carbon monoxide poisoning.

WARNING! Faulty cutting equipment or

ong combination of bar and saw

the wr

!

chain increases the risk of kickback!

Only use the bar/saw chain combinations

we recommend, and follow the filing

instructions. See instructions under the

heading Technical data.

Al

ys use common sense (2)

wa

It is not possible to cov

can face when using a chain saw. Always exercise care

and use your common sense. Avoid all situations which

you consider to be beyond your capability. If you still feel

uncertain about operating procedures after reading these

instructions, you should consult an expert before

continuing. Do not hesitate to contact your dealer or us if

you have any questions about the use of the chain saw.

We will willingly be of service and provide you with advice

as well as help you to use your chain saw both efficiently

er every conceivable situation you

English – 9

Page 10

GENERAL SAFETY PRECAUTIONS

and safely.

possible. Your dealer, forestry school or your library can

provide information about which training materials and

courses are available. Work is constantly in progress to

improve the design and technology - improvements that

increase your safety and efficiency. Visit your dealer

regularly to see whether you can benefit from new

features that have been introduced.

Per

• Approv

• Hearing protection

• Protective goggles or a visor

• Gloves with saw protection

• Trousers with saw protection

• Boots with saw protection, steel toe-cap and non-slip

• Always have a first aid kit nearby.

• Fire Extinguisher and Shovel

Generally clothes should be close-fitting without

restricting your freedom of movement.

Machine′′′′s safety equipment

In this section the machine’s safety f

function are explained. For inspection and maintenance

see instructions under the heading Checking, maintaining

and servicing chain saw safety equipment. See

instructions under the heading, What is what?, to find

where these parts are located on your machine.

The life span of the machine can be reduced and the risk

of accidents can increase if machine maintenance is not

carried out correctly and if service and/or repairs are not

Attend a training course in chain saw usage if

sonal pr

!

sole

TANT! Spar

IMPOR

and chain or other sources. Always have fire

extinguishing tools available if you should need them.

Help prevent forest fires.

otective equipment

WARNING! Most chain sa

happen when the chain touches the

operator. You must use approved

personal protective equipment whenever

you use the machine. Personal protective

equipment cannot eliminate the risk of

injury but it will reduce the degree of

injury if an accident does happen. Ask

your dealer for help in choosing the right

equipment.

ed protective helmet

ks can come from the muffler, the bar

w accidents

eatures and their

carried out professionally. If you need further information

please contact your nearest service workshop.

WARNING! Never use a mac

defective safety components. Safety

!

equipment must be inspected and

maintained. See instructions under the

heading Checking, maintaining and

servicing chain saw safety equipment. If

your machine does not pass all the

checks, take the saw to a servicing

dealer for repair.

hine with

Chain brake and front hand guard

Your chain saw is equipped with a chain brake that is

designed to stop the chain if you get a kickback. The chain

brake reduces the risk of accidents, but only you can

prevent them.

Take care when using your saw and make sure the

kickback zone of the bar never touches any object.

• The chain brake (A) can either be activated manually

(by your left hand) or automatically by the inertia

release mechanism. (3)

• The brake is applied when the front hand guard (B) is

pushed forwards. (3)

• This movement activates a spring-loaded mechanism

that tightens the brake band (C) around the engine

drive system (D) (clutch drum). (4)

• The front hand guard is not designed solely to activate

the chain brake. Another important feature is that it

reduces the risk of your left hand hitting the chain if

you lose grip of the front handle.

• The chain brake must be engaged when the chain

saw is started to prevent the saw chain from rotating.

• Use the chain brake as a ”parking brake” when

starting and when moving over short distances, to

reduce the risk of moving chain accidentally hitting

your leg or anyone or anything close by.

• To release the chain brake pull the front hand guard

backwards, towards the front handle.

• Kickback can be very sudden and violent. Most

kickbacks are minor and do not always activate the

chain brake. If this happens you should hold the chain

saw firmly and not let go.

• The way the chain brake is activated, either manually

or automatically by the inertia release mechanism,

depends on the force of the kickback and the position

of the chain saw in relation to the object that the

kickback zone of the bar strikes.

If you get a violent kickback while the kickback zone of

the bar is farthest away from you the chain brake is

designed to be activated by the inertia in the kickback

direction.

If the kickbac

the bar is closer to you the chain brake will be

activated manually by the movement of your left hand.

k is less violent or the kickback zone of

10 – English

Page 11

GENERAL SAFETY PRECAUTIONS

• In the felling position the left hand is in a position that

mak

es manual activation of the chain brake

impossible. With this type of grip, that is when the left

hand is placed so that it cannot affect the movement

of the front hand guard, the chain brake can only be

activated by the inertia action.

Will my hand alwa

brake during a kickback?

No. It tak

es a certain force to move the hand guard

forward. If your hand only lightly touches the front guard

or slips over it, the force may not be enough to trigger the

chain brake. You should also maintain a firm grip of the

chain saw handles while working. If you do and

experience a kickback, your hand may never leave the

front handle and will not activate the chain brake, or the

chain brake will only activate after the saw has swung

around a considerable distance. In such instances, the

chain brake might not have enough time to stop the saw

chain before it touches you.

There are also certain positions in which your hand

cannot reach the front hand guard to activate the chain

brake; for example, when the saw chain is held in felling

position.

Will my inertia activ

always activate during kickback in the

event of a kickback?

No. First your brake must be in working order. Testing the

brake is simple, see instructions under the heading

Checking, maintaining and servicing chain saw safety

equipment. We recommend you do before you begin each

work session. Second the kickback must be strong

enough to activate the chain brake. If the chain brake is

too sensitive it would activate all the time which would be

a nuisance.

Will my chain brake al

from injury in the event of a kickback?

No. First, the chain br

provide the intended protection. Second, it must be

activated during the kickback as described above to stop

the saw chain. Third, the chain brake may be activated but

if the bar is too close to you the brake might not have

enough time to slow down and stop the chain before the

chain saw hits you.

Only you and proper working technique can eliminate

kickback and its danger.

Throttle trigg

The throttle lockout is designed to pre

operation of the throttle control. When you press the lock

(A) (i.e. when you grasp the handle) it releases the throttle

control (B). When you release the handle the throttle

control and the throttle lockout both move back to their

original positions. This arrangement means that the

throttle control is automatically locked at the idle setting.

(5)

ys activate the chain

ated chain brake

ways protect me

ake must be in working order to

er lockout

vent accidental

Chain catcher

The chain catcher is designed to catch the chain if it snaps

or jumps off. This should not happen if the chain is

properly tensioned (see instructions under the heading

Assembly) and if the bar and chain are properly serviced

and maintained (see instructions under the heading

General working instructions).

Right hand guard

Apart from protecting your hand if the chain jumps or

snaps

, the right hand guard stops branches and twigs

from interfering with your grip on the rear handle.

Vibration damping system

Your machine is equipped with a vibration damping

system that is designed to minimiz

operation easier.

The machine′s vibration damping system reduces the

transfer of vibration between the engine unit/cutting

equipment and the machine′s handle unit. The body of the

chain saw, including the cutting equipment, is insulated

from the handles by vibration damping units.

Cutting hardwoods (most broadleaf trees) creates more

vibration than cutting softwoods (most conifers). Cutting

with cutting equipment that is blunt or faulty (wrong type

or badly sharpened) will increase the vibration level.

WARNING! Overexposure to vibration

can lead to cir

!

damage in people who have impaired

circulation. Contact your doctor if you

experience symptoms of overexposure

to vibration. Such symptoms include

numbness, loss of feeling, tingling,

pricking, pain, loss of strength, changes

in skin colour or condition. These

symptoms normally appear in the

fingers, hands or wrists. These

symptoms may be increased in cold

temperatures.

e vibration and make

culatory damage or nerve

Stop switch

Use the stop switch to switch off the engine

. (26)

Muffler

The muffler is designed to reduce noise lev

direct exhaust fumes away from the user.

WARNING! The e

engine are hot and may contain sparks

!

which can start a fire. Never start the

machine indoors or near combustible

material!

In areas with a hot, dry climate there is a high risk of fires.

These areas are sometimes subject to government rules

requiring among other things the muffler must be

equipped with an approved type of spark arrestor mesh

(A). (6)

xhaust fumes from the

els and to

English – 11

Page 12

GENERAL SAFETY PRECAUTIONS

CAUTION!

use. This also applies during idling. Be aware of the fire

hazard, especially when working near flammable

substances and/or vapours.

Cutting equipment

This section describes how to choose and maintain y

cutting equipment in order to:

• Reduce the risk of kickback.

• Reduce the risk of the saw chain breaking or jumping

• Obtain optimal cutting performance.

• Extend the life of cutting equipment.

• Avoid increasing vibration levels.

General rules

• Only use cutting equipment recommended b

• Keep the chain’s cutting teeth properly

• Maintain the correct depth gauge setting! Follow

• Keep the chain properly tensioned! If the chain is

• Keep cutting equipment well lubricated and

The muffler gets very hot during and after

WARNING! Never use a sa

muffler, or with a damaged muffler. A

!

damaged muffler may substantially

increase the noise level and the fire

hazard. Keep fire fighting equipment

handy. If a spark arrestor screen is

required in your area, never use the saw

without or with a broken spark arrestor

screen.

off the bar.

See instructions under the heading Technical data.

sharpened! Follow our instructions and use the

recommended file gauge. A damaged or badly

sharpened chain increases the risk of accidents.

our instructions and use the recommended depth

gauge clearance. Too large a clearance increases

the risk of kickback.

slack it is more likely to jump off and lead to increased

wear on the bar, chain and drive sprocket.

properly maintained! A poorly lubricated chain is

more likely to break and lead to increased wear on the

bar, chain and drive sprocket.

w without a

our

y us!

Cutting equipment designed to reduce kickback

WARNING! Faulty cutting equipment or

ong combination of bar and saw

the wr

!

chain increases the risk of kickback!

Only use the bar/saw chain combinations

we recommend, and follow the filing

instructions. See instructions under the

heading Technical data.

The only way to a

kickback zone of the bar never touches anything.

By using cutting equipment with ”built-in” kickback

reduction and keeping the chain sharp and wellmaintained you can reduce the effects of kickback.

Guide bar

The smaller the tip radius the lower the chance of

kickback.

Saw chain

A chain is made up of a number of links, which are

available in standard and low-kickback versions.

IMPOR

danger of kickback.

!

Some terms that describe the bar and chain

To maintain the safety features of the cutting equipment,

you should replace a worn or damaged bar or chain with

a bar and chain combinations recommended by

Husqvarna. See instructions under the heading Technical

Data for a list of replacement bar and chain combinations

we recommend.

Guide bar

• Length (inches/cm)

• Number of teeth on bar tip sprocket (T).

• Chain pitch (inches). The spacing between the drive

links of the chain must match the spacing of the teeth

on the bar tip sprocket and drive sprocket.

• Number of drive links. The number of drive links is

determined by the length of the bar, the chain pitch

and the number of teeth on the bar tip sprocket.

• Bar groove width (inches/mm). The groove in the bar

must match the width of the chain drive links.

• Chain oil hole and hole for chain tensioner. The bar

must be matched to the chain saw design.

Saw chain

• Chain pitch (inches)

• Drive link width (mm/inches)

• Number of drive links.

void kickback is to make sure that the

TANT! No sa

w chain design eliminates the

WARNING! Any contact with a r

saw chain can cause extremely serious

injuries.

otating

12 – English

Page 13

GENERAL SAFETY PRECAUTIONS

Sharpening your chain and adjusting depth gauge setting

General information on sharpening cutting teeth

• Never use a blunt chain. When the chain is blunt you

have to exert more pressure to force the bar through

the wood and the chips will be very small. If the chain

is very blunt it will produce wood powder and no chips

or shavings.

• A sharp chain eats its way through the wood and

produces long, thick chips or shavings.

• The cutting part of the chain is called the cutter and

consists of a cutting tooth (A) and the depth gauge

(B). The cutters cutting depth is determined by the

difference in height between the two (depth gauge

setting).

When you sharpen a cutting tooth there are four important

factors to remember.

1 Filing angle

2 Cutting angle

3 File position

4 Round file diameter

It is very difficult to sharpen a chain correctly without the

right equipment. We recommend that you use our file

gauge. This will help you obtain the maximum kickback

reduction and cutting performance from your chain.

See instructions under the heading Technical data for

information about sharpening your chain.

WARNING! The risk of kic

increased if the depth gauge setting is

!

too large!

Adjustment of depth gauge setting

• The cutting teeth should be newly sharpened before

adjusting the depth gauge setting. We recommend

that you adjust the depth gauge setting every third

time you sharpen the cutting teeth. NOTE! This

recommendation assumes that the length of the

cutting teeth is not reduced excessively.

• You will need a flat file and a depth gauge tool. We

recommend that you use our depth gauge tool to

acheive the correct depth gauge setting and bevel for

the depth gauge.

• Place the depth gauge tool over the chain. Detailed

information regarding the use of the depth gauge tool,

will be found on the package for the depth gauge tool.

Use the flat file to file off the tip of the depth gauge that

protrudes through the depth gauge tool. The depth

gauge setting is correct when you no longer feel

resistance as you draw the file along the depth gauge

tool.

kback is

Tensioning the chain

WARNING! A slack c

and cause serious or even fatal injury.

!

hain may jump off

WARNING! Departure fr

sharpening instructions considerably

!

increases the risk of kickback.

Sharpening cutting teeth

To sharpen cutting teeth you will need a round file and a

file gauge. See instructions under the heading Technical

data for information on the size of file and gauge that are

recommended for the chain fitted to your chain saw.

• Check that the chain is correctly tensioned. A slack

chain will move sideways, making it more difficult to

sharpen correctly.

• Always file cutting teeth from the inside face. Reduce

the pressure on the return stroke. File all the teeth on

one side first, then turn the chain saw over and file the

teeth on the other side.

• File all the teeth to the same length. When the length

of the cutting teeth is reduced to 4 mm (5/32") the

chain is worn out and should be replaced. (8)

General advice on adjusting depth gauge setting

• When you sharpen the cutting tooth (A) the depth

gauge setting (C) will decrease. To maintain optimal

cutting performance the depth gauge (B) has to be

filed down to achieve the recommended depth gauge

setting. See instructions under the heading Technical

data to find the correct depth gauge setting for your

particular chain. (7)

om the

The more you use a chain the longer it becomes. It is

therefore important to adjust the chain regularly to take up

the slack.

Check the chain tension every time you refuel. NOTE! A

new chain has a running-in period during which you

should check the tension more frequently.

Tension the chain as tightly as possible, but not so tight

that you cannot pull it round freely by hand. (9)

• Loosen the bar nut that holds the clutch cover and

chain brake. Use the combination spanner. Then

retighten the bar nut as tightly as you can by hand.

(10)

• Raise the tip of the bar and stretch the chain by

tightening the chain tensioning screw using the

combination spanner. Tighten the chain until it does

not sag from the underside of the bar. (11)

• Use the combination spanner to tighten the bar nut

while holding up the tip of the bar. Check that you can

pull the saw chain round freely by hand, and that there

is no slack on the underside of the bar. (12)

The position of the chain tensioning scre

ws v

aries from model to model. See instructions under

sa

the heading What is what? to find out where it is on your

model.

w on our chain

English – 13

Page 14

GENERAL SAFETY PRECAUTIONS

Lubricating cutting equipment

WARNING! Poor lubrication of cutting

equipment ma

!

which could lead to serious, even fatal

injuries.

Chain oil

Chain oil must demonstrate good adhesion to the chain

and also maintain its flo

whether it is warm summer or cold winter weather.

TANT!

IMPOR

oil, dismantle and clean the groove in the bar and saw

chain before long-term storage. Otherwise there is a risk

of the saw chain oil oxidizing, which will result in the saw

chain becoming stiff and the bar tip sprocket jamming.

Filling with chain oil

• All our chain saws have an automatic chain lubrication

system. On some models the oil flow is also

adjustable.

• The saw chain oil tank and the fuel tank are designed

so that the fuel runs out before the saw chain oil.

However, this safety feature requires that you use the

right sort of chain oil (if the oil is too thin it will run out

before the fuel), and that you adjust the carburetor as

recommended (a lean mixture may mean that the fuel

lasts longer than the oil) and that you also use the

recommended cutting equipment (a bar that is too

long will use more chain oil).

Checking chain lubrication

• Check the chain lubrication each time you refuel.

Aim the tip of the bar at a light coloured surface about

20 cm (8 inches) away. After 1 minute running at 3/4

throttle you should see a distinct line of oil on the light

surface.

If the chain lubrication is not working:

• Check that the groove in the edge of the bar is clean.

Clean if necessary.

• Check that the bar tip sprocket turns freely and that

the lubricating hole in the tip sprocket is not blocked.

Clean and lubricate if necessary.

If the chain lubrication system is still not working after

carrying out the above checks and associated measures

you should contact your service agent.

Chain drive sprocket

The clutch drum is fitted with a spur sprocket (the chain

sprocket is welded on the drum).

Regularly check the degree of wear on the drive sprocket.

Replace if wear is excessive. Replace the drive sprocket

whenever you replace the chain.

When using vegetable based saw chain

y cause the chain to snap,

w characteristics regardless of

Checking wear on cutting equipment

Check the chain daily for:

• Visible cracks in rivets and links.

• Whether the chain is stiff.

• Whether rivets and links are badly worn.

Replace the saw chain if it exhibits any of the points

above.

We recommend you compare the existing chain with a

new chain to decide how badly the existing chain is worn.

When the length of the cutting teeth has worn down to

only 4 mm the chain must be replaced.

Guide bar

Check regularly:

• Whether there are burrs on the edges of the bar (A).

Remove these with a file if necessary. (13)

• Whether the groove in the bar has become badly worn

(B). Replace the bar if necessary. (13)

• Whether the tip of the bar is uneven or badly worn. If

a hollow forms on the underside of the bar tip this is

due to running with a slack chain.

• To prolong the life of the bar you should turn it over

regularly.

WARNING! Most chain sa

happen when the chain touches the

!

operator.

Wear per

sonal protective equipment. See

instructions under the ”Personal

protective equipment” heading.

Do not tackle an

are not adequately trained for. See

instructions under the headings

Personal protective equipment, How to

avoid kickback, Cutting equipment and

General working instructions.

Av

oid situations where there is a risk of

kickback. See instructions under the

heading Machine′′

Use the recommended protective

equipment and c

instructions under the heading General

working instructions.

Check that all the c

features are working. See instructions

under the headings General working

instructions and General safety

precautions.

w accidents

y job that you feel you

′′

s safety equipment.

heck its condition. See

hain saw safety

14 – English

Page 15

Fitting the bar and chain

ASSEMBLY

WARNING! Switch off the engine bef

carrying out any checks or maintenance.

!

ys wear gloves, when working with

Alwa

the chain, in order to protect your hands

from injury.

Check that the chain brak

moving the front hand guard towards the front handle.

Unscrew the bar nuts and remove the clutch cover. (14)

Fit the bar over the bar bolts. Place the bar in its rearmost

position. Place the chain over the drive sprocket locate it

in the groove on the bar. Begin on the top edge of the bar.

(15)

Make sure that the edges of the cutting links are facing

forward on the top edge of the bar.

Mount the clutch cover and remember to fit the chain

adjuster pin in the hole in the bar. Check that the drive

links of the chain fit correctly over the drive sprocket and

that the chain is correctly located in the groove in the bar.

Tighten the bar nut with your fingers.

Tension the chain by turning the chain tensioning screw

clockwise using the combination spanner. The chain

should be tensioned until it does not sag from the

underside of the bar. (11)

The chain is correctly tensioned when there is no slack on

the underside of the bar, and it can still be turned easily

by hand. Tighten the bar nut with the combination spanner

while holding up the tip of the bar. (12)

When fitting a new chain, the chain tension has to be

checked frequently until the chain is run-in. Check the

chain tension regularly. A correctly tensioned chain

ensures good cutting performance and long life. (9)

e is in disengaged position by

ore

Fitting a spiked bumper

To fit a spiked b

umper – contact your service agent.

English – 15

Page 16

FUEL HANDLING

Fuel

Note! The machine is equipped with a two-strok

and must always be run using a mixture of petrol and twostroke oil. It is important to accurately measure the

amount of oil to be mixed to ensure that the correct

mixture is obtained. When mixing small amounts of fuel,

even small inaccuracies can drastically affect the ratio of

the mixture.

WARNING! Alwa

adequate ventilation when handling fuel.

!

ys ensure there is

Petrol

• Use good quality unleaded or leaded petrol.

•

• When working with continuous high revs (e.g. limbing)

Running-in

Avoid running at a too high speed for extended periods

during the first 10 hours.

Two-str

• For best results and perf

• Never use two-stroke oil intended for water-cooled

• Never use oil intended for four-stroke engines.

• A poor oil quality and/or too high oil/fuel ratio may

Mixing ratio

1:40 (2,5%) with Universal, Universal powered by

McCULLOCH two-stroke oil.

west recommended octane grade is 90 (RON).

The lo

If you run the engine on a lower octane grade than 90

so-called knocking can occur. This gives rise to a high

engine temperature and increased bearing load,

which can result in serious engine damage.

a higher octane is recommended.

oke oil

Universal powered by McCULLOCH two-stroke

engine oil, which is specially formulated for our aircooled two-stroke engines.

engines, sometimes referred to as outboard oil (rated

TCW).

jeopardise function and decrease the life time of

catalytic converters.

Petrol, litre Two-stroke oil, litre

5 0,125

10 0,25

15 0,375

20

ormance use Universal,

2,5% (1:40)

0,5

e engine

Mixing

• Alwa

ys mix the petrol and oil in a clean container

intended for fuel.

• Always start by filling half the amount of the petrol to

be used. Then add the entire amount of oil. Mix

(shake) the fuel mixture. Add the remaining amount of

petrol.

• Mix (shake) the fuel mixture thoroughly before filling

the machine’s fuel tank.

• Do not mix more than one month’s supply of fuel at a

time.

• If the machine is not used for some time the fuel tank

should be emptied and cleaned.

Chain oil

• We recommend the use of special oil (chain oil) with

good adhesion char

• Never use waste oil. This results in damage to the oil

pump, the bar and the chain.

• It is important to use oil of the right grade (suitable

viscosity range) to suit the air temperature.

• In temperatures below 0°C (32°F) some oils become

too viscous. This can overload the oil pump and result

in damage to the oil pump components.

• Contact y

our service agent when choosing chain oil.

acteristics.

16 – English

Page 17

FUEL HANDLING

Fueling

WARNING! T

precautions, will lessen the risk of fire:

!

Do not smoke and do not place any hot

objects in the vicinity of fuel.

Always stop the engine and let it cool for

a few minutes before refuelling.

When refuelling, open the fuel cap slo

so that any excess pressure is released

gently.

Tighten the fuel cap carefully after

refuelling.

Always move the machine away from the

refuelling area and source before

starting.

Clean the area around the fuel cap. Clean the fuel and

chain oil tanks regularly. The fuel filter must be replaced

at least once a year. Contamination in the tanks causes

malfunction. Make sure the fuel is well mixed by shaking

the container before refuelling. The capacities of the chain

oil tank and fuel tank are carefully matched. You should

therefore always fill the chain oil tank and fuel tank at the

same time.

WARNING! Fuel and fuel vapour are

highl

!

handling fuel and chain oil. Be aware of

the risks of fire, explosion and those

associated with inhalation.

aking the following

wly

y flammable. Take care when

Transport and storage

• Alwa

ys store the chain saw and fuel so that there is no

risk of leakages or fumes coming into contact with

sparks or naked flames from electrical equipment,

electric motors, relays/switches, boilers and the like.

• Always store fuel in an approved container designed

for that purpose.

• For longer periods of storage or for transport of the

chain saw, the fuel and chain oil tanks should be

emptied. Ask where you can dispose of waste fuel and

chain oil at your local petrol station.

• Ensure the machine is cleaned and that a complete

service is carried out before long-term storage.

• The guide bar cover must always be fitted to the

cutting attachment when the machine is being

transported or in storage, in order to prevent accident

contact with the sharp chain. Even a non-moving

chain can cause serious cuts to yourself or persons

you bump into with an exposed chain.

• Secure the machine during transport.

Long-term storage

Empty the fuel/oil tanks in a well ventilated area.

fuel in approved cans in a safe place. Fit the guide bar

cover. Clean the machine. See instructions under the

heading Maintenance schedule.

Store the

Fuel safety

• Nev

er refuel the machine while the engine is running.

• Make sure there is plenty of ventilation when refuelling

or mixing fuel (petrol and 2-stroke oil).

• Move the machine at least 3 m from the refuelling

point before starting it.

• Never start the machine:

1 If you have spilt fuel or chain oil on the machine. Wipe

off the spillage and allow remaining fuel to evaporate.

2 If you have spilled fuel on yourself or your clothes,

change your clothes. Wash any part of your body that

has come in contact with fuel. Use soap and water.

3 If the machine is leaking fuel. Check regularly for leaks

from the fuel cap and fuel lines.

WARNING! Never use a mac

visible damage to the spark plug guard

!

and ignition cable. A risk of sparking

arises, which can cause a fire.

hine with

English – 17

Page 18

STARTING AND STOPPING

Starting and stopping

WARNING! Note the follo

starting:

!

wing before

Note! Reactivate the chain brake by pushing the front

hand guard back towards the front handle. The chain saw

is now ready for use. There is a simplified start reminder

with illustrations to describe each step on the rear edge of

the saw (A). (22)

The chain brake m

the chain saw is started to reduce the

chance of contact with the moving chain

during starting.

Never star

chain and all covers are fitted correctly.

Otherwise the clutch can come loose and

cause personal injuries.

Place the machine on firm gr

sure you have a secure footing and that

the chain cannot touch anything.

Keep people and animals well a

the working area.

ust be engaged when

t a chain saw unless the bar,

ound. Make

way from

Starting

The chain brake m

started. Activate the brake by moving the front hand guard

forwards. (16)

Cold engine

Start position, 1: Move the ON/OFF switch to ON ”I”

position. (17)

Choke, 2: Set the choke control in the choke position.

When the choke/fast idle lever is pulled out to the full

extent, the correct throttle setting is set automatically. (17)

Air purge, 3: Press the air purge diaphragm repeatedly

until fuel begins to fill the diaphragm (about 10 times). The

diaphragm need not be completely filled. (18)

Pull the starter handle, 4: Grip the front handle with your

left hand. Hold the chain saw on the ground by placing

your right foot through the rear handle. Pull the starter

handle with your right hand and pull out the starter cord

slowly until you feel a resistance (as the starter pawls

engage) then pull firmly and rapidly until the engine fires.

(20)

Choke, 5: Push in the choke control as soon as the

engine fires which can be heard through a "puff" sound.

Pull the starter handle, 6: Keep on pulling the cord

powerfully until the engine starts.

Never twist the starter cord around your hand.

CAUTION! Do not pull the star ter cord all the way out and

do not let go of the starter handle when the cord is fully

extended. This can damage the machine.

As the chain brake is still engaged the speed of the engine

must be set to idling as soon as possible, this is achieved

by quickly disengaging the throttle lock. This prevents

unnecessary wear to the clutch, clutch drum and brake

band. Then let the machine idle for a few seconds before

you apply full throttle. (21)

ust be engaged when the chain saw is

Warm engine

Use the same starting procedure as for a cold engine but

without setting the choke control in the choke position.

(19)

WARNING! Long term inhalation of the

engine’s e

!

and dust from sawdust can represent a

health risk.

• Never start a chain saw unless the bar, chain and

clutch cover are fitted correctly. See instructions under

the heading Assembly. Without a bar and chain

attached to the chain saw the clutch can come loose

and cause serious injury. (23)

• The chain brake should be activated when starting.

See instructions under the heading Start and stop. Do

not drop start. This method is very dangerous

because you may lose control of the saw. (24)

• Never start the machine indoors. Exhaust fumes can

be dangerous if inhaled.

• Observe your surroundings and make sure that there

is no risk of people or animals coming into contact with

the cutting equipment.

• Always hold the saw with both hands. The right hand

should be on the rear handle, and the left hand on the

front handle. All people, whether right or left handed,

should use this grip. Use a firm grip with thumbs and

fingers encircling the chain saw handles. (25)

xhaust fumes, chain oil mist

Stopping

The engine is stopped by moving the stop s

stop position.

(26)

witch to the

18 – English

Page 19

WORKING TECHNIQUES

Before use:

A - Check that the chain brak

damaged.

B - Check that the rear right hand guard is not damaged.

C - Check that the throttle lockout works correctly and is

not damaged.

D - Check that the stop switch works correctly and is not

damaged.

E - Check that all handles are free from oil.

F - Check that the anti vibration system works and is not

damaged.

G - Check that the muffler is securely attached and not

damaged.

H - Check that all parts of the chain saw are tightened

correctly and that they are not damaged or missing.

I - Check that the chain catcher is in place and not

damaged.

J - Check the chain tension.

General working instructions

IMPORTANT!

This section describes basic safety rules for using a

chain saw. This information is never a substitute for

professional skills and experience. If you get into a

situation where you feel unsafe, stop and seek expert

advice. Contact your chain saw dealer, service agent or

an experienced chain saw user. Do not attempt any task

that you feel unsure of!

Before using a chain saw you must understand the

effects of kickback and how to avoid them. See

instructions under the heading How to avoid kickback.

Before using a chain saw you must understand the

difference between cutting with the top and bottom

edges of the bar. See instructions under the headings

How to avoid kickback and Machine’s safety equipment.

Wear personal protectiv

under the ”Personal protective equipment” heading.

Basic safety rules

1 Look around you:

•

To ensure that people, animals or other things cannot

affect your control of the machine.

• To make sure that none of the above might come

within reach of your saw or be injured by falling trees.

CAUTION! Follow the instructions above, but do not use a

chain saw in a situation where you cannot call for help in

case of an accident.

2 Do not use the machine in bad weather, such as

dense fog, heavy rain, strong wind, intense cold, etc.

Working in bad weather is tiring and often brings

added risks, such as icy ground, unpredictable felling

direction, etc.

(27)

e works correctly and is not

e equipment. See instructions

3 Take great care when removing small branches and

avoid cutting bushes (i.e. cutting many small branches

at the same time). Small branches can be grabbed by

the chain and thrown back at you, causing serious

injury.

4 Make sure you can move and stand safely. Check the

area around you for possible obstacles (roots, rocks,

branches, ditches, etc.) in case you have to move

suddenly. Take great care when working on sloping

ground.

5 Take great care when cutting a tree that is in tension.

A tree that is in tension may spring back to its normal

position before or after being cut. If you position

yourself incorrectly or make the cut in the wrong place

the tree may hit you or the machine and cause you to

lose control. Both situations can cause serious

personal injury.

6 Before moving your chain saw switch off the engine

and lock the chain using the chain brake. Carry the

chain saw with the bar and chain pointing backwards.

Fit a guard to the bar before transporting the chain

saw or carrying it for any distance.

7 When you put the chain saw on the ground, lock the

saw chain using the chain brake and ensure you have

a constant view of the machine. Switch the engine off

before leaving your chain saw for any length of time.

WARNING! Sometimes chips g

the clutch cover causing the chain to

!

jam. Always stop the engine before

cleaning.

et stuck in

General rules

1 If you understand what kickback is and how it happens

then you can reduce or eliminate the element of

surprise. By being prepared you reduce the risk.

Kickback is usually quite mild, but it can sometimes be

very sudden and violent.

2 Always hold the chain saw firmly with your right hand

on the rear handle and your left hand on the front

handle. Wrap your fingers and thumbs around the

handles. You should use this grip whether you are

right-handed or left-handed. This grip minimises the

effect of kickback and lets you keep the chain saw

under control. Do not let go of the handles!

3 Most kickback accidents happen during limbing. Make

sure you are standing firmly and that there is nothing

in the way that might make you trip or lose your

balance.

Lack of concentration can lead to kickback if the

kickback zone of the bar accidentally touches a

branch, nearby tree or some other object.

Have control over the workpiece. If the pieces you

intend to cut are small and light, they can jam in the

saw chain and be thrown towards you. This is not

necessarily dangerous in itself, but you may be

surprised and lose control of the saw. Never saw

English – 19

Page 20

WORKING TECHNIQUES

stacked logs or br

them. Only saw one log or one piece at a time.

Remove the cut pieces to keep your working area

safe.

4 Never use the chain saw above shoulder height

and try not to cut with the tip of the bar. Never use

the chain saw one-handed! (28)

5 You must have a steady stance in order to have full

control over the chain saw. Never work standing on a

ladder, in a tree or where you do not have firm ground

to stand on. (29)

6 Always use a fast cutting speed, i.e. full throttle.

7 Take great care when you cut with the top edge of the

bar, i.e. when cutting from the underside of the object.

This is known as cutting on the push stroke. The chain

tries to push the chain saw back towards the user. If

the saw chain is jamming, the saw may be pushed

back at you.

8 Unless the user resists this pushing force there is a

risk that the chain saw will move so far backwards that

only the kickback zone of the bar is in contact with the

tree, which will lead to a kickback. (30)

Cutting with the bottom edge of the bar, i.e. from the

top of the object downwards, is known as cutting on

the pull stroke. In this case the chain saw pulls itself

towards the tree and the front edge of the chain saw

body rests naturally on the trunk when cutting. Cutting

on the pull stroke gives the operator better control over

the chain saw and the position of the kickback zone.

9 Follow the instructions on sharpening and maintaining

your bar and chain. When you replace the bar and

chain use only combinations that are recommended

by us. See instructions under the headings Cutting

equipment and Technical data.

Basic cutting technique

!

anches without first separating

WARNING! Never use a c

holding it with one hand. A chain saw is

not safely controlled with one hand.

Always have a secure, firm grip around

the handles with both hands.

hain saw by

Terms

Cutting = General term for cutting through wood.

Limbing = Cutting branches off a felled tree.

Splitting = When the object you are cutting breaks off

before the cut is complete.

There are five important factors you should consider

before making a cut:

1 Make sure the cutting equipment will not jam in the

cut.

2 Make sure the object you are cutting will not split.

3 Make sure the chain will not strike the ground or any

other object during or after cutting.

4 Is there a risk of kickback?

5 Do the conditions and surrounding terrain affect how

safely you can stand and move about?

Two factors decide whether the chain will jam or the object

that you are cutting will split: the first is how the object is

supported before and after cutting, and the second is

whether it is in tension.

In most cases you can avoid these problems by cutting in

two stages; from the top and from the bottom. You need to

support the object so that it will not trap the chain or split

during cutting.

IMPORTANT! If the chain jams in the cut:

engine! Don’t try to pull the chain saw free. If you do you

may be injured by the chain when the chain saw

suddenly breaks free. Use a lever to open up the cut and

free the chain saw.

The following instructions describe how to handle the

commonest situations you are likely to encounter when

using a chain saw.

Limbing

When limbing thick branches you should use the same

approach as for cutting.

Cut difficult branches piece by piece.

Cutting

stop the

General

• Always use full throttle when cutting!

• Reduce the speed to idle after every cut (running the

engine for too long at full throttle without any load, i.e.

without any resistance from the chain during cutting,

can lead to serious engine damage).

• Cutting from above = Cutting on the pull stroke.

• Cutting from below = Cutting on the push stroke.

Cutting on the push stroke increases the risk of kickback.

See instructions under the heading How to avoid

kickback.

20 – English

WARNING! Never attempt to cut logs

y are in a pile or when a couple

while the

!

of logs are lying together. Such

procedures drastically increase the risk

of kickback which can result in a serious

or fatal injury.

If you have a pile of logs, each log you attempt to cut

should be removed from the pile, placed on a saw horse

or runners and cut individually.

Remov

e the cut pieces from the cutting area. By leaving

them in the cutting area, you increase the risk for

inadvertently getting a kickback, as well as increasing the

risk of losing your balance while working.

Page 21

WORKING TECHNIQUES

The log is lying on the ground.

chain jamming or the object splitting. However there is a

risk that the chain will touch the ground when you finish

the cut.

Cut all the way through the log from above. Avoid letting

the chain touch the ground as you finish the cut. Maintain

full throttle but be prepared for what might happen. (31)

If it is possible (can you turn the log?) stop cutting about

2/3 of the way through the log.

Turn the log and finish the cut from the opposite side.

The log is supported at one end. There is a high risk

that it will split.

Start by cutting from below (about 1/3 of the way through).

Finish by cutting from above so that the two cuts meet.

The log is supported at both ends. There is a high risk

that the chain will jam.

Start by cutting from above (about 1/3 of the way through).

Finish by cutting from below so that the two cuts meet.

Tree felling tec

IMPORTANT! It takes a lot of experience to fell a tree.

Inexperienced users of chain saws should not fell trees.

Do not attempt any task that you feel unsure of!

Safe distance

The safe distance between a tree that is to be f

anyone else working nearby is at least 2 1/2 tree lengths.

Make sure that no-one else is in this ”risk zone” before or

during felling. (37)

Felling direction

The aim is to fell the tree in a position where you can limb

and cross-cut the log as easily as possible. You want it to

fall in a location where you can stand and move about

safely.

Once you have decided which way you want the tree to fall

you must judge which way the tree would fall naturally.

Several factors affect this:

• Lean of the tree

• Bend

• Wind direction

• Arrangement of branches

• Weight of snow

• Obstacles within the reach of the tree: for example,

other trees, power lines, roads and buildings.

• Look for signs of damage and rot in the stem, this

makes it more probably that the tree will break and

start to fall before you expect it to.

You may find you are forced to let the tree fall in its natural

direction because it is impossible or dangerous to try to

make it fall in the direction you first intended.

hnique

There is little risk of the

elled and

Another very important factor, which does not affect the

felling direction but does affect your safety, is to make sure

the tree has no damaged or dead branches that might

break off and hit you during felling.

The main point to avoid is letting the tree fall onto another

tree. It is very dangerous to remove a trapped tree and

there is high accident risk. See instructions under the

heading Freeing a tree that has fallen badly.

IMPORT

ANT! During critical felling operations, hearing

protectors should be lifted immediately when sawing is

completed so that sounds and warning signals can be

heard.

Clearing the trunk and preparing your retreat

Delimb the stem up to shoulder height. It is safer to work

from the top down and to have the tree between you and

the saw.

Remove any undergrowth from the base of the tree and

check the area for obstacles (stones, branches, holes,

etc.) so that you have a clear path of retreat when the tree

starts to fall. Your path of retreat should be roughly 135

degrees away from the intended felling direction. (38)

1 Danger zone

2 Retreat path

3 Felling direction

Felling

WARNING! Unless you ha

training we advise you not to fell trees

!

with a diameter larger than the bar length

of your saw!

Felling is done using three cuts. First you make the

directional cuts, which consist of the top cut and the

bottom cut, then you finish with the felling cut. By placing

these cuts correctly you can control the felling direction

very accurately.

Directional cuts

To make the directional cuts you begin with the top cut.

Stand to the right of the tree and cut on the pull stroke.

Next make the bottom cut so that it finishes exactly at the

end of the top cut. (39)

The directional cuts should run 1/4 of the diameter

through the trunk and the angle between the top cut and

bottom cut should be 45°.

The line where the two cuts meet is called the directional

cut line. This line should be perfectly horizontal and at

right angles (90°) to the chosen felling direction. (40)

Felling cut

The felling cut is made from the opposite side of the tree

and it must be perfectly horizontal. Stand on the left side

of the tree and cut on the pull stroke.

Make the felling cut about 3-5 cm (1.5-2 inches) above the

bottom directional cut.

ve special

English – 21

Page 22

WORKING TECHNIQUES

Set the spiked bumper (if one is fitted) just behind the

f

elling hinge. Use full throttle and advance the chain/bar

slowly into the tree. Make sure the tree does not start to

move in the opposite direction to your intended felling

direction. Drive a wedge or breaking bar into the cut as

soon as it is deep enough. (41)

Finish the felling cut parallel with the directional cut line so

that the distance between them is at least 1/10 of the

trunk diameter. The uncut section of the trunk is called the

felling hinge.

The felling hinge controls the direction that the tree falls in.

(42)

All control over the felling direction is lost if the felling

hinge is too narrow or non-existent, or if the directional

cuts and felling cut are badly placed.

When the felling cut and directional cut are complete the

tree should start to fall by itself or with the aid of a felling

wedge or breaking bar.

We recommend that you use a bar that is longer than the

diameter of the tree, so that you can make the felling cut

and directional cuts with single cutting strokes. See

instructions under the heading Technical data section to

find out which lengths of bar are recommended for your

saw.

There are methods for felling trees with a diameter larger

than the bar length. However these methods involve a

much greater risk that the kickback zone of the bar will

come into contact with the tree.

Freeing a tree that has fallen badly

Freeing a ”trapped tree”

It is very dangerous to remo

high accident risk.

Never try to fell the tree that is trapped.

Never work in the risk zone of the hanging trapped tree.

The safest method is to use a winch.

• Tractor-mounted

• Portable

Cutting trees and branches that are in tension

Preparations: Work out which side is in tension and where

the point of maximum tension is (i.e. where it would break

if it was bent even more).

Decide which is the safest way to release the tension and

whether you are able to do it safely. In complicated

situations the only safe method is to put aside your chain

saw and use a winch.

General advice:

Position yourself so that you will be clear of the tree or

branch when the tension is released.

Make one or more cuts at or near the point of maximum

tension. Make as many cuts of sufficient depth as

necessary to reduce the tension and make the tree or

branch break at the point of maximum tension.

ve a trapped tree and there is

Never cut straight through a tree or branch that is in

tension!

If you must cut across tree/limb, make two to three cuts,

one inch apart, one to two inches deep.

Continue to cut deeper until tree/limb bends and tension

is released.

Cut tree/limb from outside the bend, after tension has

been released.

How to av

!

oid kickback

WARNING! Kickbac

suddenly and violently; kicking the chain

saw, bar and chain back at the user. If

this happens when the chain is moving it

can cause very serious, even fatal

injuries. It is vital you understand what

causes kickback and that you can avoid

it by taking care and using the right

working technique.

k can happen very

What is kickback?

The word kickbac

reaction that causes the chain saw and bar to jump off an

object when the upper quadrant of the tip of the bar,

known as the kickback zone, touches an object. (30)

Kickback always occurs in the cutting plane of the bar.

Normally the chain saw and bar are thrown backwards

and upwards towards the user. However, the chain saw

may move in a different direction depending on the way it

was being used when the kickback zone of the bar

touched the object.

Kickback only occurs if the kickback zone of the bar

touches an object. (43)

Limbing

!

Make sure that you can stand and move about safely.

Work on the left side of the trunk. Work as close as

possible to the chain saw for maximum control. If possible,

let the weight of the chain saw rest on the trunk.

Keep the trunk between you and the chain saw as you

move along the trunk.

Cutting the trunk into logs

See instr

technique.

k is used to describe the sudden

WARNING! A majority of kickbac

accidents occur during limbing. Do not

use the kickback zone of the guide bar.

Be extremely cautious and avoid

contacting the log, other limbs or objects

with the nose of the guide bar. Be

extremely cautious of limbs under

tension. They can spring back toward

you and cause loss of control resulting

in injury.

uctions under the heading Basic cutting

k

22 – English

Page 23

MAINTENANCE

General

The user must only carry out the maintenance and

vice work described in this Operator's Manual. More

ser

extensive work must be carried out by an authorized

service workshop.

Carburettor adjustment

Your McCulloch product has been designed and

actured to specifications that reduce harmful

manuf

emissions.

Function

• The carburettor go

throttle control. Air and fuel are mixed in the

carburettor. The air/fuel mixture is adjustable. Correct

adjustment is essential to get the best performance

from the machine.

• The T-screw regulates the throttle setting at idle

speed. If the T-screw is turned clockwise this gives a

higher idle speed; turning it anti-clockwise gives a

lower idle speed.

Basic settings and running in

The basic carburettor settings are adjusted during testing

at the f

actory. Fine adjustment should be carried out by a

skilled technician.

Rec. idle speed: See the Technical data section.

Fine adjustment of the idle speed T

Adjust the idle speed with the T-screw. If it is necessary to

re-adjust, turn the T-screw clockwise while the engine is

running, until the chain starts to rotate. Then turn anticlockwise until the chain stops. When the idle speed is

correctly adjusted the engine should run smoothly in

every position and the engine speed should be safely

below the speed at which the chain starts to rotate.

WARNING! Contact your ser

dealer, if the idle speed setting cannot be

!

adjusted so that the chain stops. Do not

use the chain saw until it has been

properly adjusted or repaired.

verns the engine’s speed via the

vicing

Checking,

ser

vicing chain saw safety

maintaining and

equipment

Note! All service and repair wor

demands special training. This is especially true of the

machine’s safety equipment. If your machine fails any of

the checks described below we recommend that you

take it to your service workshop. Any maintenance

other than that described in this manual must be carried

out by your servicing dealer (retailer).

Switch off the engine and take off the ignition cab

before repairs or maintenance

Chain brake and front hand guard

Checking brake band wear

Brush off any w

brake and clutch drum. Dirt and wear can impair operation

of the brake. (32)

Regularly check that the brake band is at least 0,6 mm

thick at its thinnest point.

Checking the front hand guard

Make sure the front hand guard is not damaged and that

there are no visible defects such as cracks.

Move the front hand guard forwards and back to make

sure it moves freely and that it is securely anchored to the

clutch cover. (33)

Checking the inertia brake release

Place the chain saw, with the engine switched off, on a

stump or other stable surface. Release the front handle

and let the saw fall by its own weight, rotating around the

rear handle towards the stump.

When the bar hits the stump the brake should be

activated. (35)

Checking the brake trigger

Place the chain saw on firm ground and start it. Make sure

the chain does not touch the ground or any other object.

See instructions under the heading Starting and stopping.

Grasp the chain saw firmly, wrapping your fingers and

thumbs around the handles.

Apply full throttle and activate the chain brake by tilting

your left wrist forward onto the front hand guard. Do not let

go of the front handle.

immediatel

ood dust, resin and dirt from the chain

The chain should stop

y.

k on the machine

le

English – 23

Page 24

MAINTENANCE

Throttle trigger lockout

• Make sure the throttle control is loc

setting when the throttle lockout is released.

• Press the throttle lockout and make sure it returns to

its original position when you release it.

• Check that the throttle trigger and throttle lockout

move freely and that the return springs work properly.

• Star t the chain saw and apply full throttle. Release the

throttle control and check that the chain stops and

remains stationary. If the chain rotates when the

throttle control is in the idle position you should check

the carburettor idle adjustment.

Chain catcher

Check that the chain catcher is in place and not damaged.

Right hand guard

Check that the right hand guard is not damaged and that

there are no visib

le defects, such as cracks.

Vibration damping system

Regularly check the vibr

deformation.

Make sure the vibration damping units are securely

attached to the engine unit and handle unit.

ation damping units for cracks or

Stop switch

Start the engine and make sure the engine stops when

y

ou move the stop switch to the stop setting.

Muffler

Never use a machine that has a f

check that the muffler is securely attached to the machine.

Note: The spark arrestor screen (A) on this machine is

serviceable. The mesh must be replaced if it is damaged.

If the mesh is blocked the machine will overheat and this

will cause damage to the cylinder and piston. Never use a

machine with a muffler that is in poor condition. Never

use a muffler if the spark arrestor mesh is missing or

defective. (6)

After 75 hours of use, we recommend that your muffler be

replaced by your servicing dealer (retailer).

Air filter

The air filter must be regular

dirt in order to avoid:

• Carburettor malfunctions.

• Starting problems.

• Loss of engine power.

• Unnecessary wear to engine parts.

• Excessive fuel consumption.

ly cleaned to remove dust and

ked at the idle

aulty muffler. Regularly

To clean the air filter: (34)

1 Remov

2 Remove the air filter (D).

3 Clean the air filter.

- Wash the filter in clean, warm soapy water.

- Rinse in clean, cool water.

- Air dry completely.

4 Reassemble in reverse order. Make sure latch (E),

An air filter that has been in use for a long time cannot be

cleaned completely. The filter must therefore be replaced

with a new one at regular intervals. A damaged air filter

must always be replaced.

NOTE! It is advisable to have a supply of spare filters.

e the knob (A) holding the cylinder cover and

remove the cylinder cover (B).

latch (F) and cylinder cover fit properly. Tighten the

knob securely.

Spark plug

The spark plug condition is influenced by:

•

Incorrect carburettor adjustment.

• An incorrect fuel mixture (too much or incorrect type of

oil).

• A dirty air filter.

These factors cause deposits on the spark plug

electrodes, which may result in operating problems and