Page 1

Operator’s manual

Manuel d’utilisation

Bedienungsanvwisung

Manual de instrucciones

CS 330 CS 360

CS 370 CS 400

Please read the operator’s manual carefully and make sure you understand the instructions before using the machine.

Lire attentivement et bien assimiler le manual d’utilisation avant d’utiliser la machine.

Lesen Sie die Bedienungsanweisung sorgfältig durch med und machen Sie sich mit dem Inhalt vertraut,

bevor Sie des Gerät benutzen.

Lea detenidament el manual de instrucciones y asegúrese de entender su contenido antes de utilizar la máquina.

GB (2 - 21)

FR (22 - 43)

DE (44 - 65)

ES (66 - 87)

Page 2

87

DECLARACION DE CONFORMIDAD

Declaración de conformidad de la CE (Sólo aplicable en Europa)

Nosotros, Husqvarna AB, SE--561 82 Huskvarna, Suecia, con teléfono +46- -36- -146500, en

calidad de representante autorizado en la Comunidad, declara que la motosierra para servicio

forestal modeloMcCulloch CS 330, CS 360, CS 370, y CS 400 SAS---AV u a partir del número

de serie del año 2012 en adelante (el año se indica claramente en la placa de identificación,

seguido del número de serie), cumple con lo establecido por las estipulaciones de la

DIRECTIVA DEL CONSEJO:

2006/42/CE, “referente a máquinas”, del 17 de Mayo de 2006.

2004/108/CE, “referente a compatibilidad electromagnética”, del 15 de Diciembre de 2004,

y los suplementos válidos a la fecha.

2000/14/CE, “sobre emisiones sonoras en el entorno” del 8 de Mayo de 2000, según el

anexo V . Para más información sobre las emisiones sonoras, consulte el capítulo Datos

técnicos.

Se han aplicado las siguientes normas: ISO 12100:2010, CISPR 12:2007, ISO

11681-1:2011.

Organismo inscripto: 0404, SMP , Svensk Maskinprovning AB, Fyrisborgsgatan 3,

SE--754 50 Uppsala, Suecia, ha efectuado el examen CE de tipo conforme a la Directiva

sobre máquinas (2006/42/CE), artículo 12, apartado 3b. El certificado sobre el examen CE

de tipo conforme al Anexo IX tiene el número: 0404/09/2035.

La motosierra entregada coincide con el ejemplar que fue sometido al examen CE de tipo.

15--10--12

Ronnie E. Goldman, Director técnico

Presentante autorizado de Husqvarna AB y

responsable de la documentación técnica

TABLE OF CONTENTS

Introduction 2

Identification of Symbols 2

Identification (What is What?) 3

General Safety Precautions 4

Assembly 7

Fuel Handling 10

Starting and Stopping 11

Dear Customer,

Thank you for choosing a McCulloch product. You are thereby part of a story that started long

ago, when the McCulloch Corporation started its manufacturing of engines during WorldWar II. In

1949, when McCulloch introduced its first light one-man chain saw, woodworking would never be

the same again.

The line of innovative chain saws would continue over the decades, and business was expanded,

first by airplane and kart engines in the 1950s, then by mini chainsaws in the 1960s. Later, in the

1970s and 80s, trimmers and blower/vacs were added to the range.

Today, as a part of the Husqvarna group, McCulloch continues the tradition of powerful engines,

technical innovations, and strong designs that have been our hallmarks for more than half a century.

Lowering fuel consumption, emissions and noise levels are of top priority to us, as is improving safety

and user-friendliness.

We certainly hope that you will be satisfied with your McCulloch product, as it is designed to be

your companion for a long time. By following this operators manual’s advice on usage, service,

and maintenance, its lifespan can be extended. If you should need professional help with repair or

service, please use the Service Locator at www.mcculloch.com.

McCulloch has a policy of continuous product development and therefore reserves the right to

modify the design and appearance of products without prior notice.

This manual can also be downloaded at www.mcculloch.com.

INTRODUCTION

Working Techniques 12

Service and Adjustments 15

Storage 17

Troubleshooting Table 18

Technical Data 19

Declaration of Conformity 21

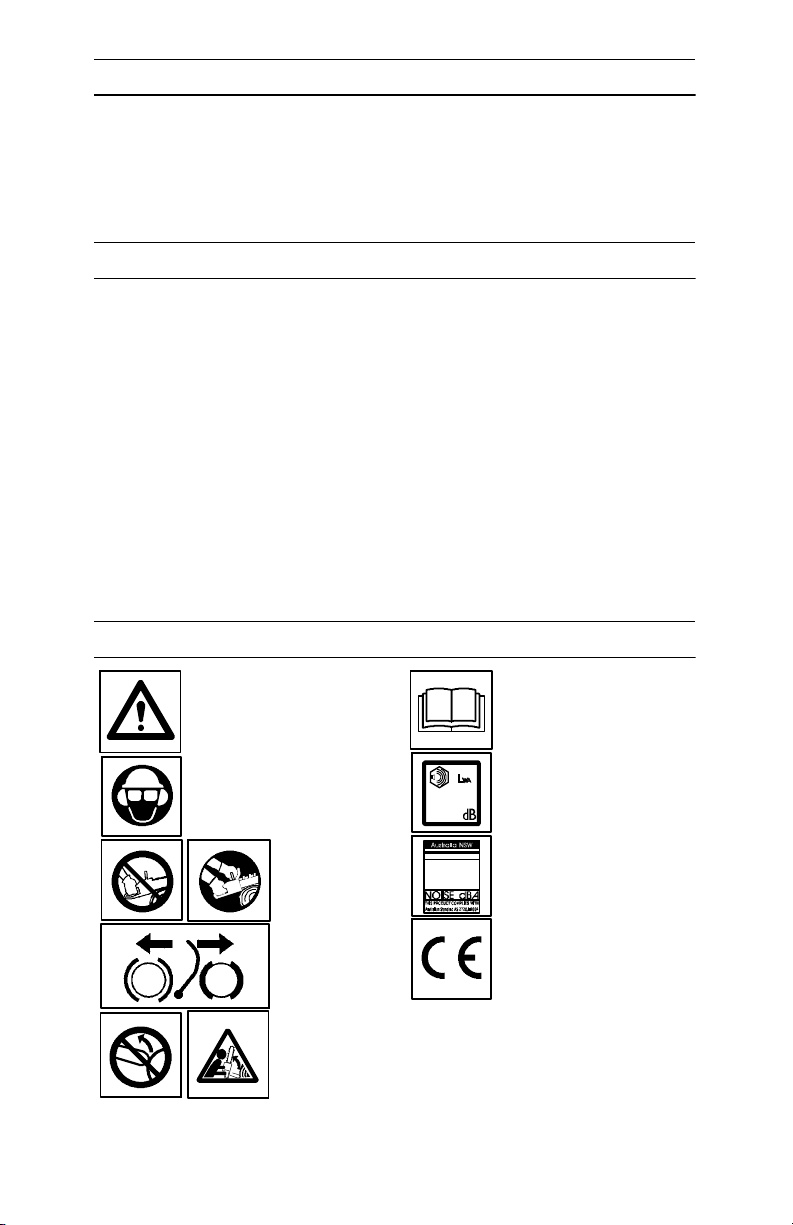

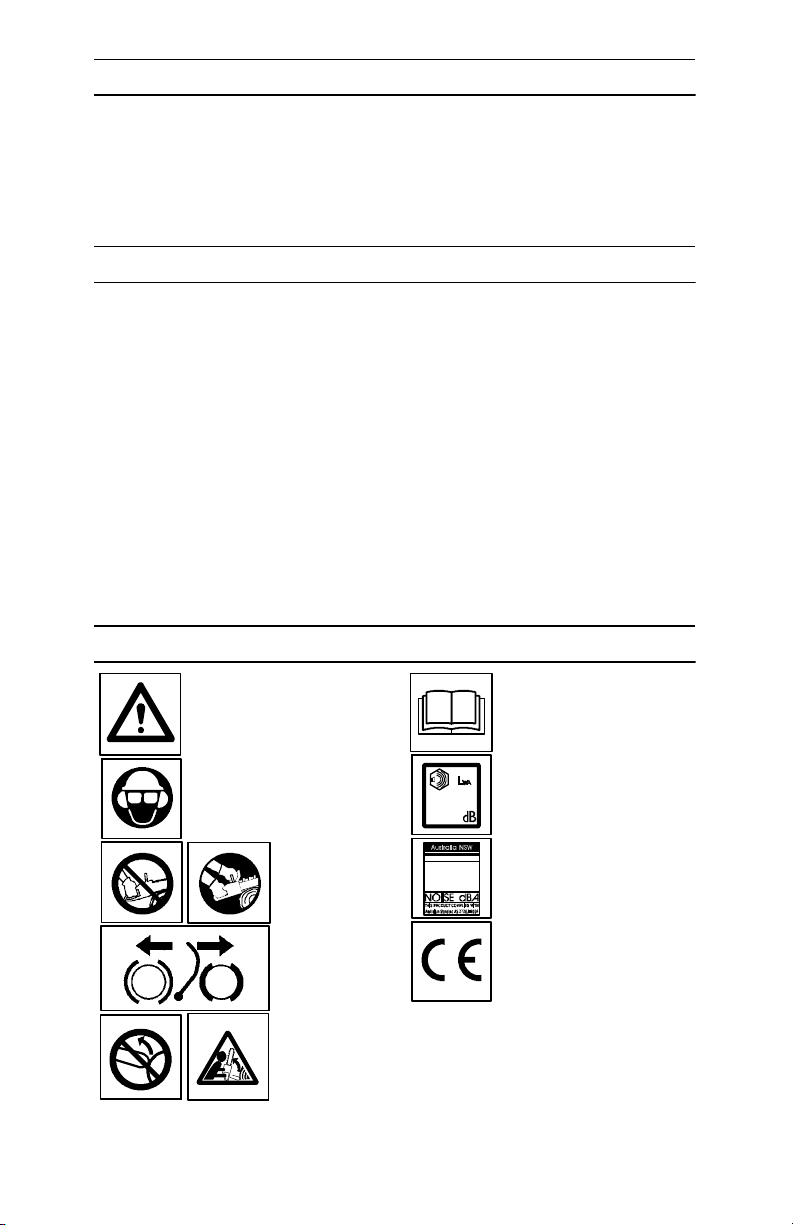

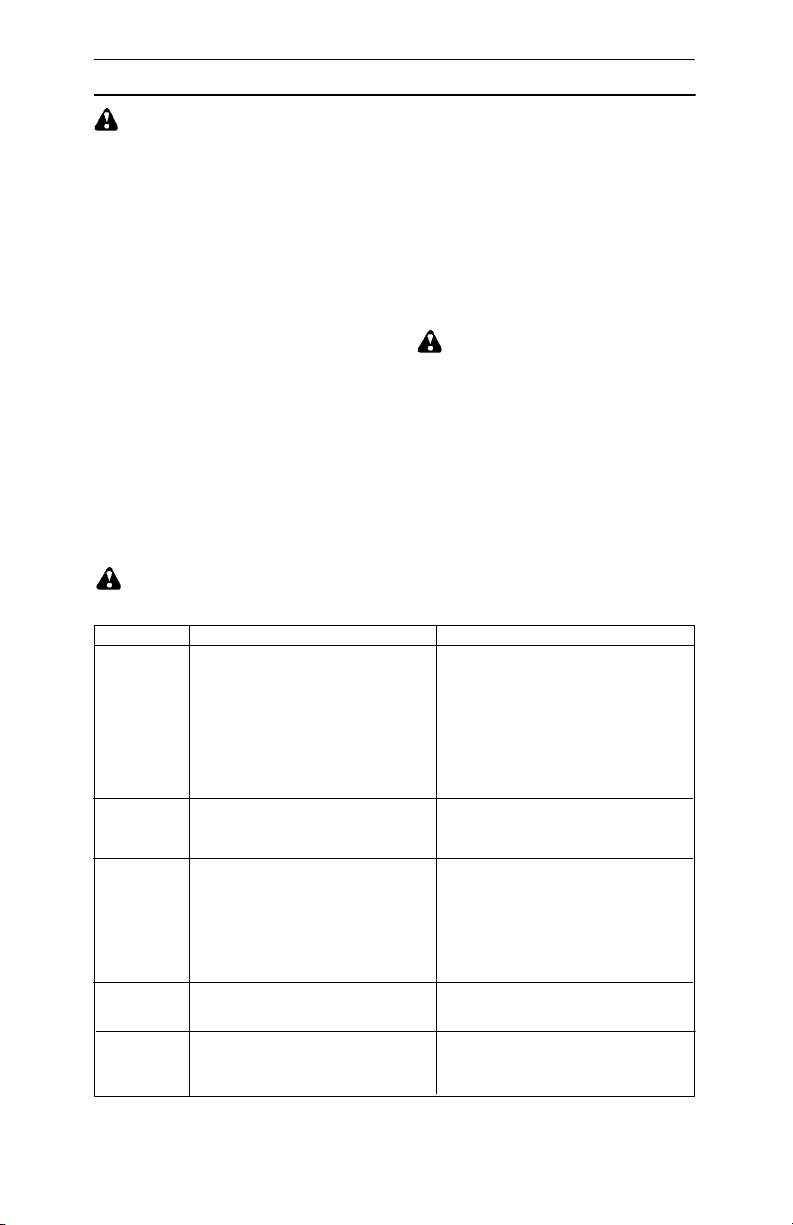

IDENTIFICATION OF SYMBOLS

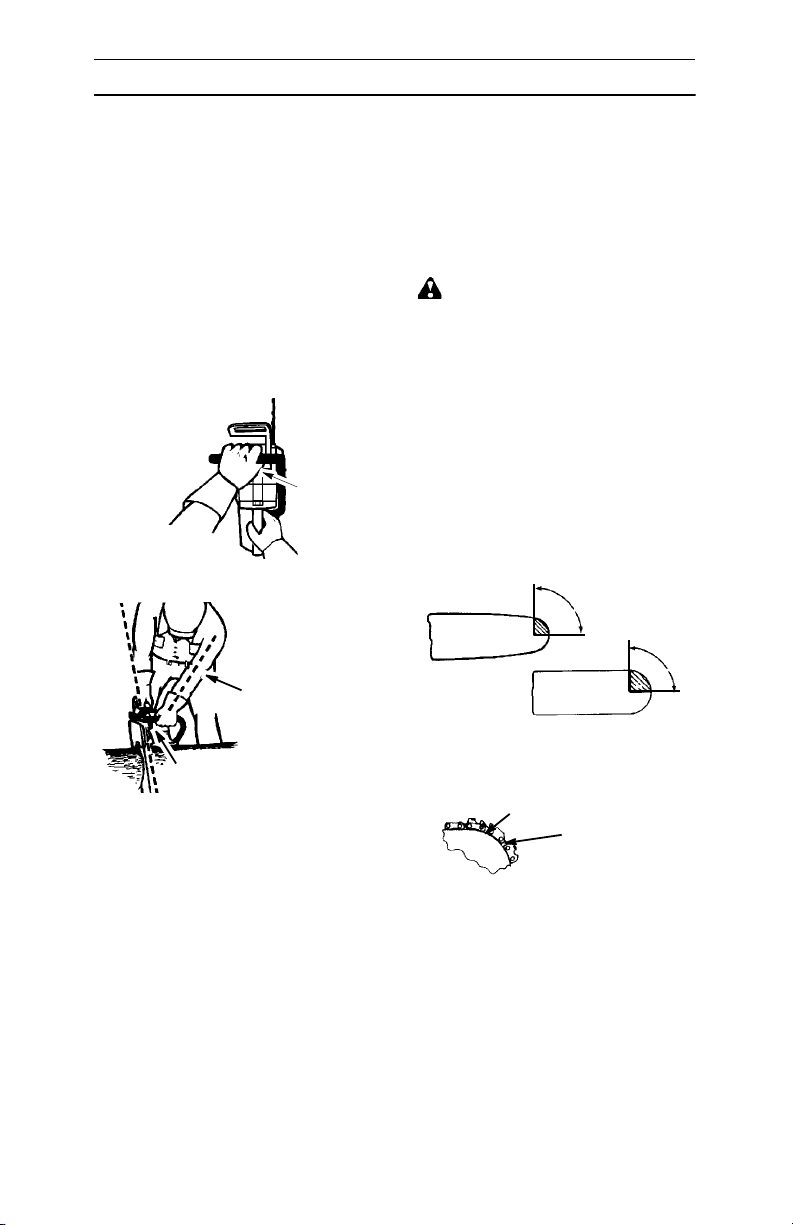

WARNING! This chain

saw can be dangerous! Careless or improper use can cause

serious or even fatal injury.

Read and understand the

instruction manual before

using the chain saw.

Always wear appropriate ear

protection, eye protection

and head protection.

Always use two

hands when

operating the

chain saw.

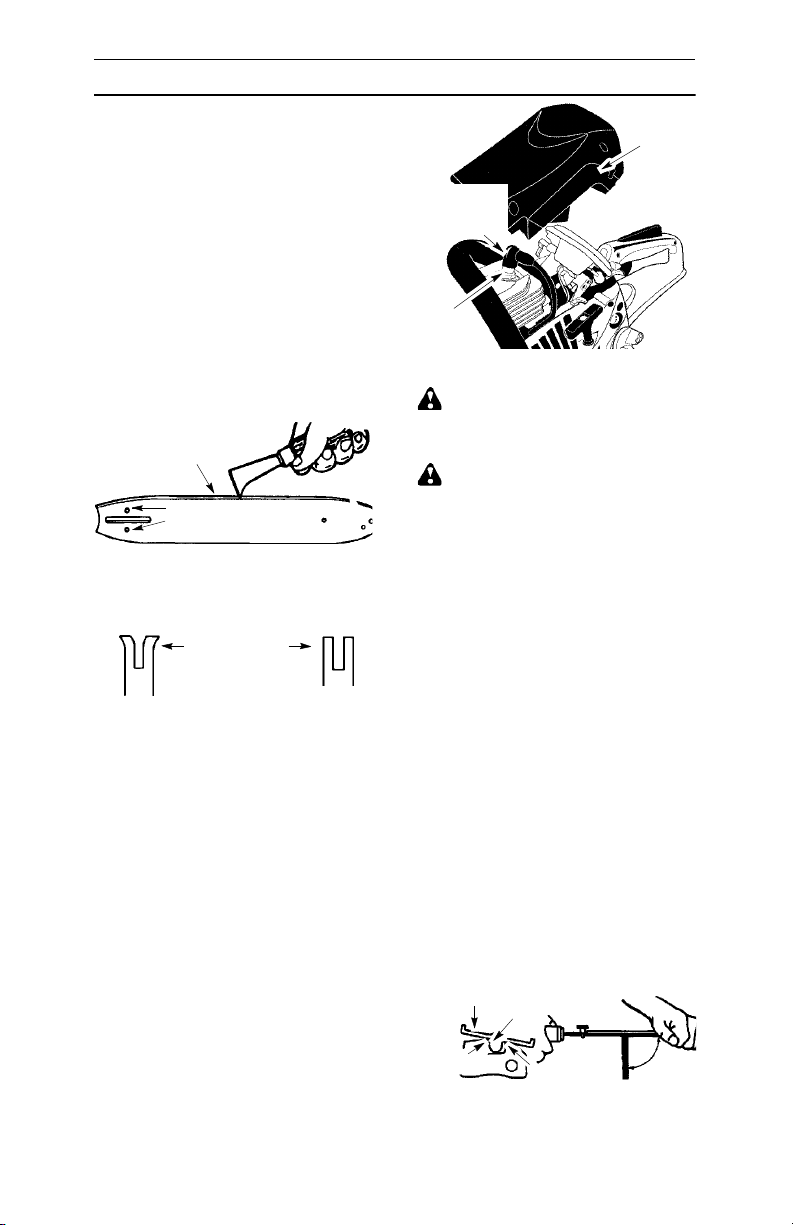

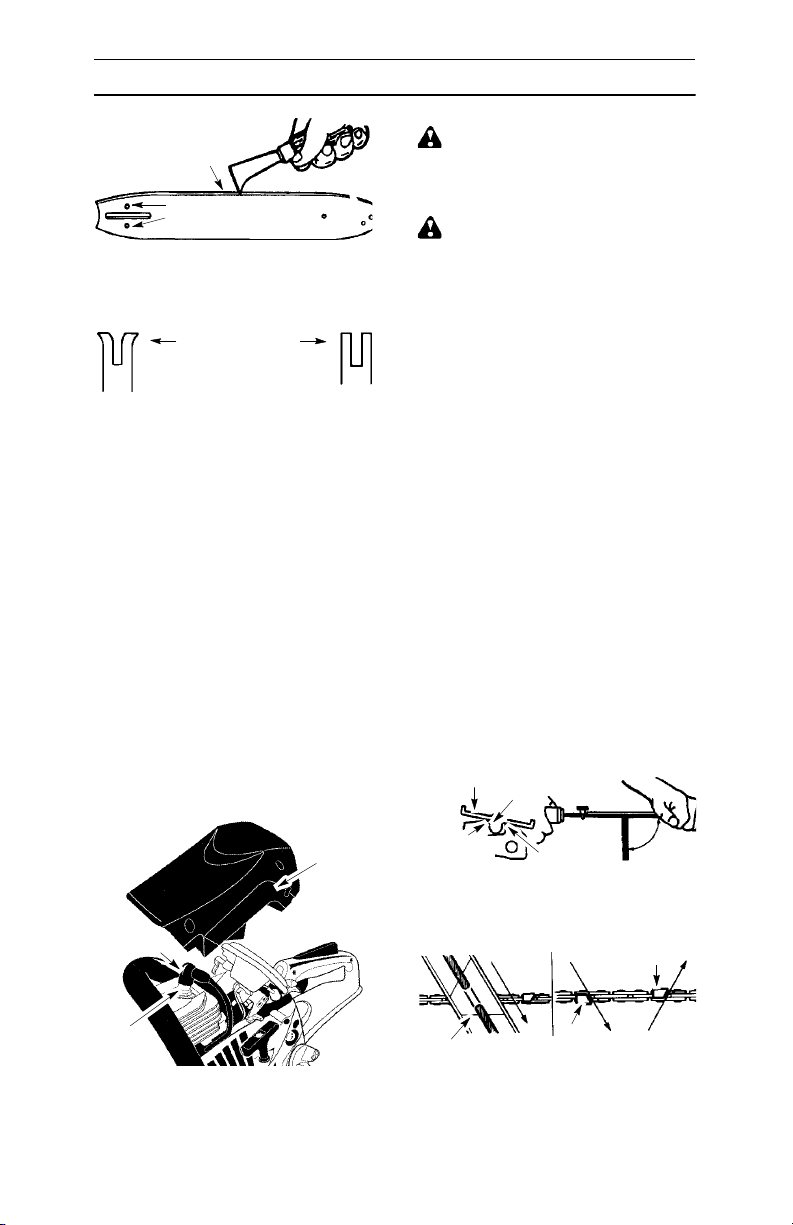

Chain brake,

activated (right)

Chain brake,

not activated (left)

WARNING! Contacting the guide bar tip with any object

should be avoided; tip contact may cause the guide bar to

move suddenly upward and backward, which may cause serious injury.

2

Sound power level

Sound pressure level

at 7,5 meters

This product is in accordance with applicable

EC directives.

Page 3

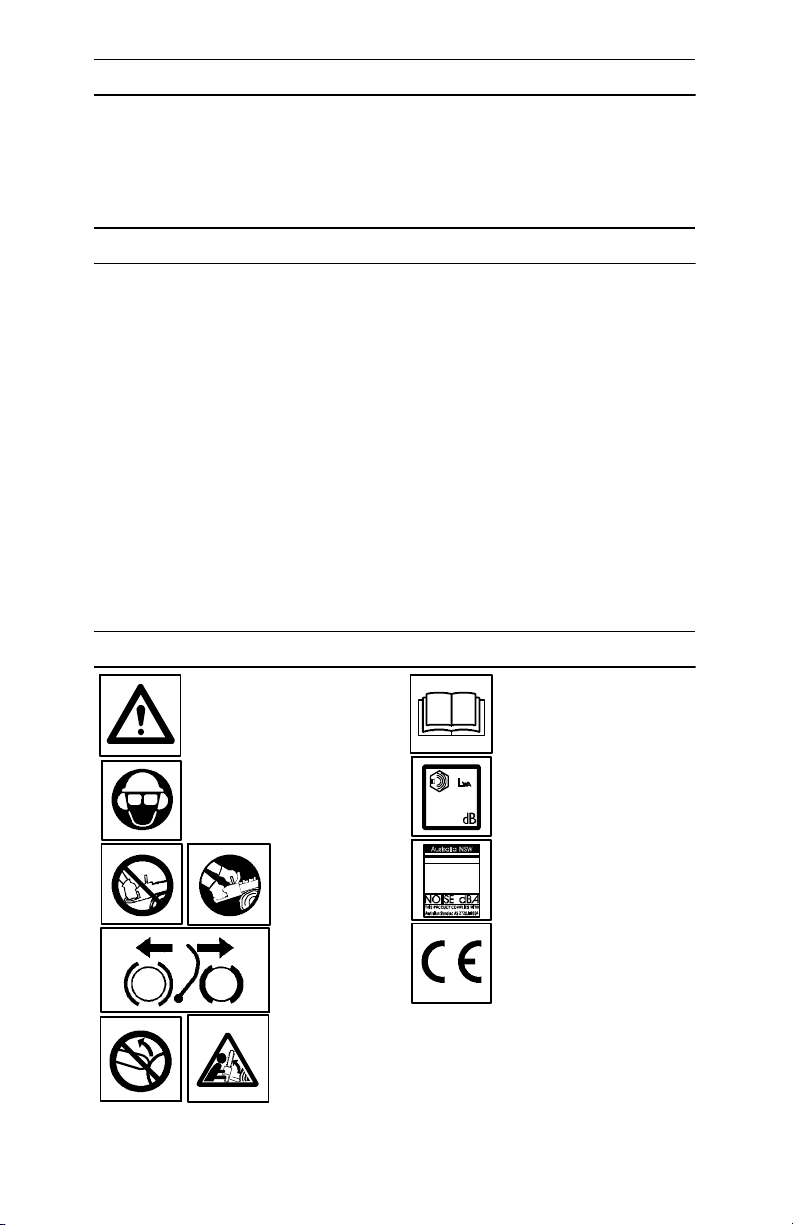

Starting Reminder

IDENTIFICATION OF SYMBOLS

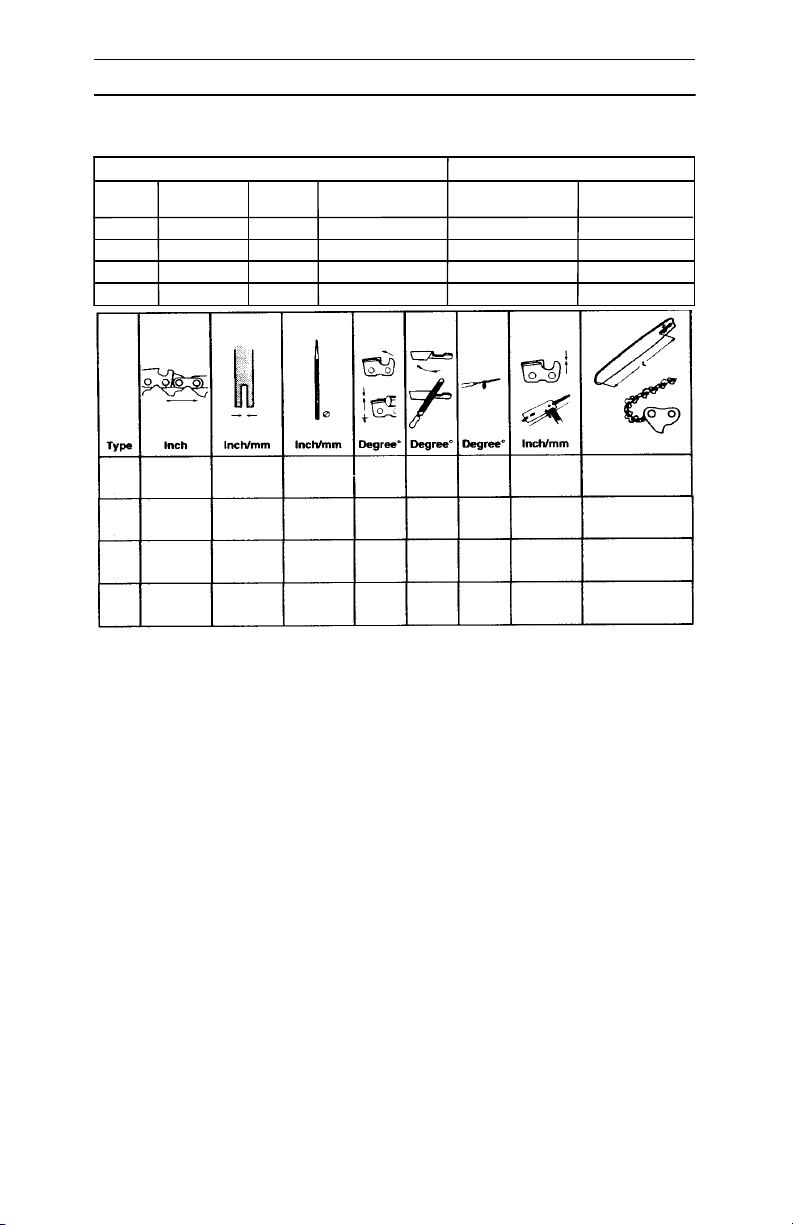

Chain

Adjustment Tool

(Bar Tool)

Move ON/STOP switch to

the ON position.

Slowly press primer bulb

6 times.

Pull choke/fast idle lever

out to the full extent (to

the FULL CHOKE position).

Starting a warm engine

Pull the starter rope

sharply with your right

hand until the engine fires.

Push the choke/fast idle

lever in to the HALF

CHOKE position.

Pull the starter rope sharply

with your right hand until

the engine starts.

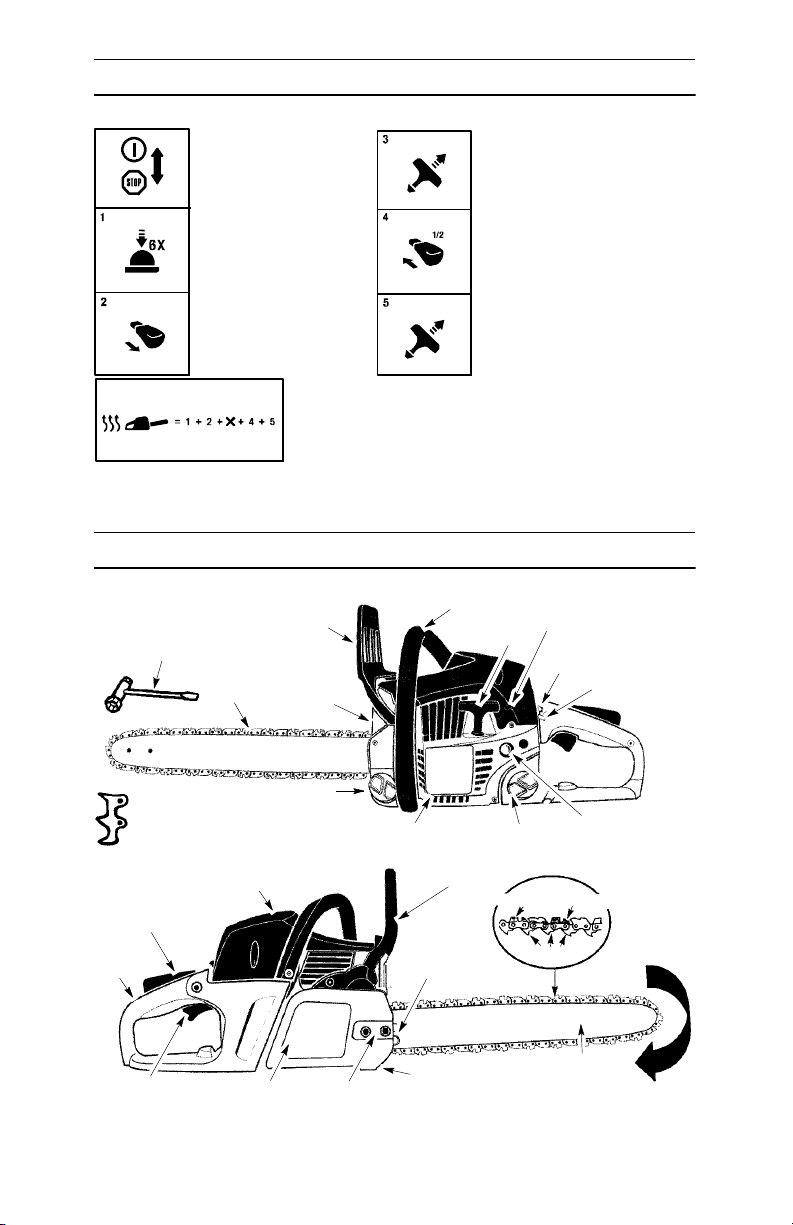

IDENTIFICATION (WHAT IS WHAT?)

Front Hand Guard

Chain

Muffler

Front Handle

Starter Rope

Idle Speed Screw

ON/STOP

Switch

Choke/

Fast Idle

Lever

Rear

Handle

Throttle

Trigger

Bumper

spike

Throttle

Lockout

Bar Oil Fill Cap

Cylinder Cover

Clutch Cover

Starter Housing

Bar Nuts

Fuel Mix Fill Cap

Chain

Brake

Adjusting Screw

Chain

Catcher

3

Primer Bulb

Guide Bar

Chain

Direction

of Travel

Page 4

GENERAL SAFETY PRECAUTIONS

85

DATOS TÉCNICOS

Datos técnicos

CS 330 CS 360 CS 370 CS 400

Motor

Cilindrada, cm

3

33 36 38 40

Carrera, mm 32 32 32 32

Régimen de ralentí, r.p.m. 3000 3000 3000 3000

Potencia, kW 1,2/9000 1,3/9000 1,4/9000 1,5/9000

Sistema de encendido

Bujía Champion Champion Champion Champion

RCJ--7Y RCJ--7Y RCJ--7Y RCJ --7Y

Distancia de electrodos, mm 0,5 0,5 0,5 0,5

Sistema de combustible y lubricación

Capacidad del depósito de gasolina, litros 0,3 0,3 0,3 0,3

Caudal de la bomba de aceite a 8.500 r.p.m.,

m l / m i n . 4 -- 8 4 -- 8 4 -- 8 4 -- 8

Capacidad del depósito de aceite, litros 0,2 0,2 0,2 0,2

Tipo de bomba de aceite Automática Automática Automática Automática

Peso

Motosierra sin espada ni cadena, con depósitos

vacíos, kg 5,5 5,5 5,5 5,5

Emisiones de ruido

(ver la nota 1)

Nivel de potencia acústica medido dB(A) 108,7 108,7 108,7 108,7

Nivel de potencia acústica garantizado L

WA

dB(A)113 113 113 113

Niveles acústicos

(vea la nota 2)

Nivel equivalente de presión acústica en el oído

del usuario, dB(A) 99,7 99,7 99,7 99,7

Niveles de vib ración equivalentes, a

hv,eq

(vea la nota 3)

Mango delantero, m/s

2

2,4 2,4 2,4 2,4

Mango trasero, m/s

2

2,4 2,4 2,4 2,4

Cadena/barra guía

Longitud de barra estándar, pulgadas/cm 14/35, 16/40, 18/45

Longitudes de barra recomendadas, pulgadas/cm 14--18 / 35--45

Longitud efectiva de corte, pulgadas/cm 13--17 / 34--44

Paso, pulgadas 0,375

Grosor del eslabón de arrastre, pulgadas/mm 0,050/1,3

Tipo de piñón de arrastre/número de dientes 6

Velocidad de la cadena a potencia máxima, m/s 18,5

Nota 1: Emisiones sonoras en el entorno medidas como potencia acústica (L

WA

) según la directiva CE

2000/14/CE.

Nota 2: el nivel de presión sonora equivalente, según la norma ISO 22868, se calcula como la suma

de energÌa, ponderada en el tiempo, de los niveles de presión sonor a en diferentes condiciones de

trabajo. La dispersión estadÌstica habitual del nivel de presión sonora equivalente es la desviación

tÌpica de 1 dB(A).

Nota 3: el nivel de vibración equivalente, según la norma ISO 22867, se calcula como la suma de

energÌa, ponderada en el tiempo, de los niveles de vibración en diferentes condiciones de trabajo. Los

datos referidos del nivel de vibración equivalente poseen una dispersión estadÌstica habitual (desvia-

ción tÌpica) de 1 m/s

2

.

WARNING: Always disconnect spark

plug wire and place wire where it cannot contact spark plug to prevent accidental starting

when setting up, transporting, adjusting or

making repairs except carburetor adjustments.

This chain saw for forest service is only designed for cutting wood. Because a chain saw

is a high-speed wood-cutting tool, special safety precautions must be observed to reduce the

risk of accidents. Careless or improper use of

this tool can cause serious injury.

PLAN AHEAD

S Read this manual carefully until you com-

pletely understand and can follow all safety

rules, precautions, and operating instructions before attempting to use the unit.

S Restrict the use of your saw to adult users

who understand and can follow safety

rules, precautions, and operating instructions found in this manual.

Hearing

Protection

Snug

Fitting

Clothing

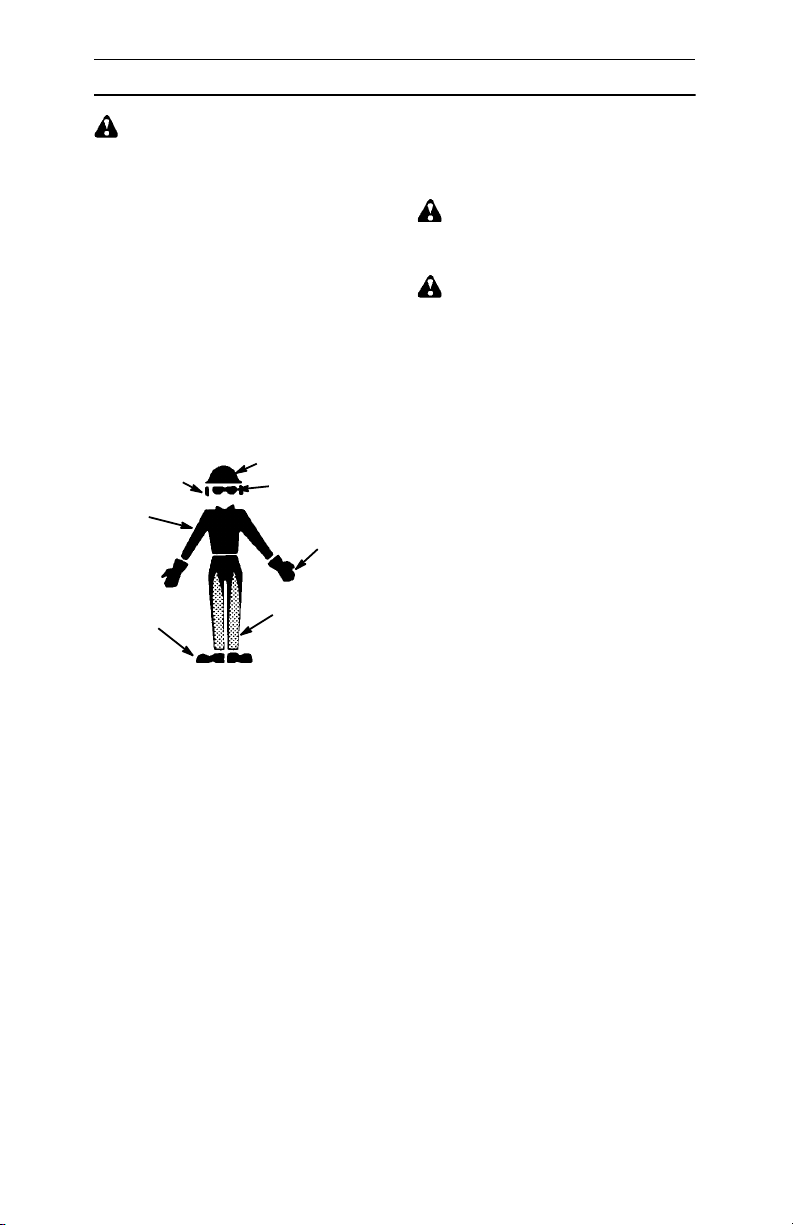

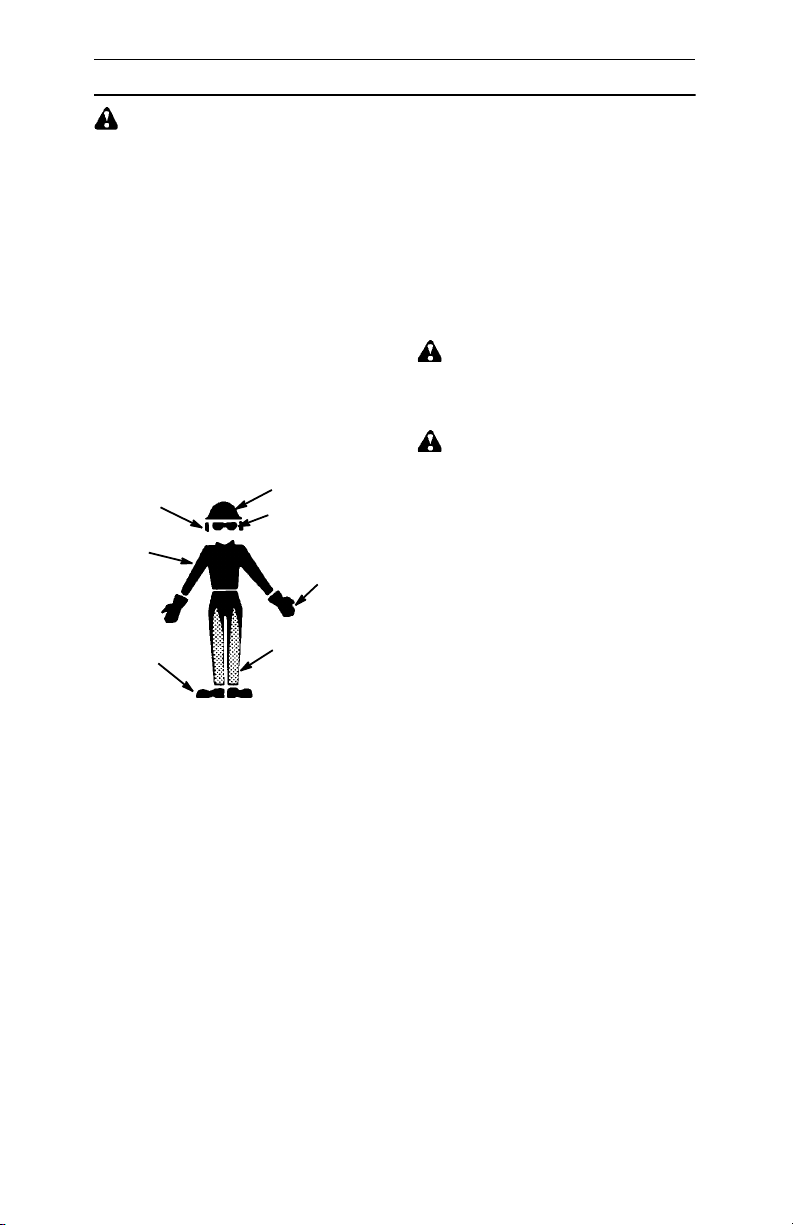

S Wear protective gear. Always use steel-toed

safety footwear with non-slip soles; snug-fitting clothing; heavy-duty, non-slip gloves;

eye protection such as non-fogging, vented

goggles or face screen; an approved safety

hard hat; and sound barriers (ear plugs or

mufflers) to protect your hearing. Secure hair

above shoulder length.

S Always use approved hearing protection.

Regular users should have hearing checked

regularly as chain saw noise can damage

hearing. Long--term exposure to noise can

result in permanent hearing impairment.

S Keep all parts of your body away from the

chain when the engine is running.

S Keep children, bystanders, and animals a

minimum of 10 meters away from the work

area. Do not allow other people or animals

to be near the chain saw when starting or

operating the chain saw.

S Do not handle or operate a chain saw when

you are fatigued, ill, or upset, or if you have

taken alcohol, drugs, or medication. Y ou

must be in good physical condition and mentally alert. Chain saw work is strenuous. If

you have any condition that might be aggravated by strenuous work, check with your

doctor before operating a chain saw.

Safety

Shoes

Safety Hat

Eye

Protection

Safety Chaps

Heavy Duty

Gloves

S Carefully plan your sawingoperation in ad-

vance. Donot start cutting until you have a

clear work area, secure footing, and, if you

are felling trees, a planned retreat path.

OPERATE YOUR SAW SAFELY

WARNING: Long term inhalation of

the engine’s exhaust fumes, chain oil mist and

dust from sawdust can result in serious personal injury.

WARNING: This machine produces

an electromagnetic field during operation. This

field may under some circumstances interfere

with active or passive medical implants. To reduce the risk of serious or fatal injury, we recommend persons with medical implants to

consult their physician and the medical implant

manufacturer before operating this machine.

S Do not operate a chain saw with one hand.

Serious injury to the operator, helpers, bystanders or any combination of these persons may result from one-handed operation.

A chain saw is intended for two-handed use.

S Operate the chain saw only in a well-venti-

lated outdoor area.

S Do not operate saw from a ladder or in a tree,

unless you are specifically trained to do so.

S Make sure the chain will not make contact

with any object while starting the engine.

Never try to start the saw when the guide bar

is in a cut.

S Do not put pressure on the saw at the end of

the cut. Applying pressure can cause you to

lose control of the chain saw when the cut is

completed and may cause serious personal

injury.

S Stop the engine before setting the saw down.

S Do not operate a chain saw that is damaged,

improperly adjusted, or not completely and

securely assembled. Always replace bar,

chain, hand guard, or chain brake immediately if it becomes damaged, broken or is

otherwise removed.

S With the engine stopped, hand carry the

chain saw with the muffler away from your

body, and the guide bar and chain to the rear,

preferably covered with a scabbard.

S Secure the machine during transport.

CHAIN SAW

SAFETY EQUIPMENT

NOTE: In this section, the safety feature s of

the chain saw and their function are explained.

For inspection and maintenance, see instructions in the CHECKING, MAINTAINING AND

SERVICING CHAIN SAW SAFETY EQUIPMENT section. See instructions under the

WHAT IS WHAT? section, to find where these

parts are located on your chain saw. The life

span of the machine can be reduced and the

risk of accidents can increase if machine maintenance is not carried out correctly and if service and/or repairs are not carried out professionally. If you need further information, please

contact your nearest service dealer.

4

Page 5

GENERAL SAFETY PRECAUTIONS

S Chain brake. Your chain saw is equipped

with a chain brake that is designed to stop

the chain from moving.

WARNING: The chain brake is de-

signed to stop the chain immediately if you get

a kickback. The chain brake reduces the risk of

accidents, but only you can prevent them. DO

NOT ASSUME THAT THE CHAIN BRAKE

WILL PROTECT YOU IN THE EVENT OF A

KICKBACK.

S Throttle trigger lock--out. The throttle

lock--out is designed to prevent accidental

operation of the throttle trigger.

S Chain catcher. The chain catcher is de-

signed to catch the saw chain if it breaks.

S Vibration damping system. Your chain

saw is equipped with a vibration damping

systemthat is designed to minimize vibration and make operation easier.

SAFETY NOTICE: Exposure to vibrations

through prolonged use of gasoline powered

hand tools could cause blood vessel or nerve

damage in the fingers, hands, and joints of people prone to circulation disorders or abnormal

swellings. Prolonged use in cold weather has

been linked to blood vessel damage in otherwise healthy people. If symptoms occur such

as numbness, pain, loss of strength, change in

skin color or texture, or loss of feeling in the fingers, hands, or joints, discontinue the use of

this tool and seek medical attention. An antivibration system does not guarantee the avoidance of these problems. Users who operate

power tools on a continual and regular basis

must monitor closely their physical condition

and the condition of this tool.

S ON/STOP switch. The ON/STOP switch

should be used to stop the engine.

CHECKING, MAINTAINING

AND SERVICING CHAIN SA W

SAFETY EQUIPMENT

WARNING: Never use a chain saw

with defective safety equipment. Safety

equipment must be inspected and maintained. If your chain saw does not pass inspection, take the saw to your nearest service dealer for repair.

S Chain brake. Brush off any wood dust, res-

in and dirt from the chain brake and clutch

drum. Dirt and wear can impair operation of

the brake. For additional information, see

OPERATING YOUR UNIT section.

S Throttle trigger lock--out. Check that the

throttle trigger can not be operated until the

throttle lock--out is pressed.

S Chain catcher. Check that the chain

catcher is not damaged and is firmly attached to the body of the chain saw.

S Vibration damping system. Regularly

check the vibration damping units for

cracks or deformation. Make sure the

vibration damping units are securely attached to the engine unit and handle unit.

S ON/STOP switch. Start the engine and

make sure the engine stops when you move

the ON/STOP switch to the STOP position.

MAINTAIN YOUR SAW IN

GOOD WORKING ORDER

S Have all chain saw service performed by a

qualified service dealer with the exception of

the items listed in the maintenance section of

this manual. For example, if improper tools

are used to remove or hold the flywheel

when servicing the clutch, structural damage

to the flywheel can occur and cause the flywheel to burst.

S Make certain the saw chain stops moving

when the throttle trigger is released. For

correction, refer to CARBURETOR ADJUSTMENTS.

S Never modify your saw in any way. Use

only attachments supplied or specifically

recommended by the manufacturer.

S Keep the handles dry, clean, and free of oil

or fuel mixture.

S Keep fuel and oil caps, screws, and fas-

teners securely tightened.

S Use only McCulloch accessories and re-

placement parts as recommended.

HANDLE FUEL WITH CAUTION

S Do not smoke while handling fuel or while

operating the saw.

S Eliminate all sources of sparks or flame in

the areas where fuel is mixed or poured.

There should be no smoking, open flames,

or work that could cause sparks. Allow engine to cool before refueling.

S Mix and pour fuel in an outdoor area on bare

ground; store fuel in a cool, dry, well ventilated place; and use an approved, marked

container for all fuel purposes. Wipe up all

fuel spills before starting saw.

S Move at least 10 feet (3 meters) from fuel-

ing site before starting engine.

S Turn the engine off and let saw cool in a

non-combustible area, not on dry leaves,

straw, paper, etc. Slowly remove fuel cap

and refuel unit.

S Store the unit and fuel in an area where fuel

vapors cannot reach sparks or open

flames from water heaters, electric motors

or switches, furnaces, etc.

KICKBACK

WARNING: Avoid kickback which

can result in serious injury. Kickback is the

backward, upward or sudden forward motion

of the guide bar occurring when the saw

chain near the upper tip of the guide bar contacts any object such as a log or branch, or

when the wood closes in and pinches the

saw chain in the cut. Contacting a foreign object in the wood can also result in loss of

chain saw control.

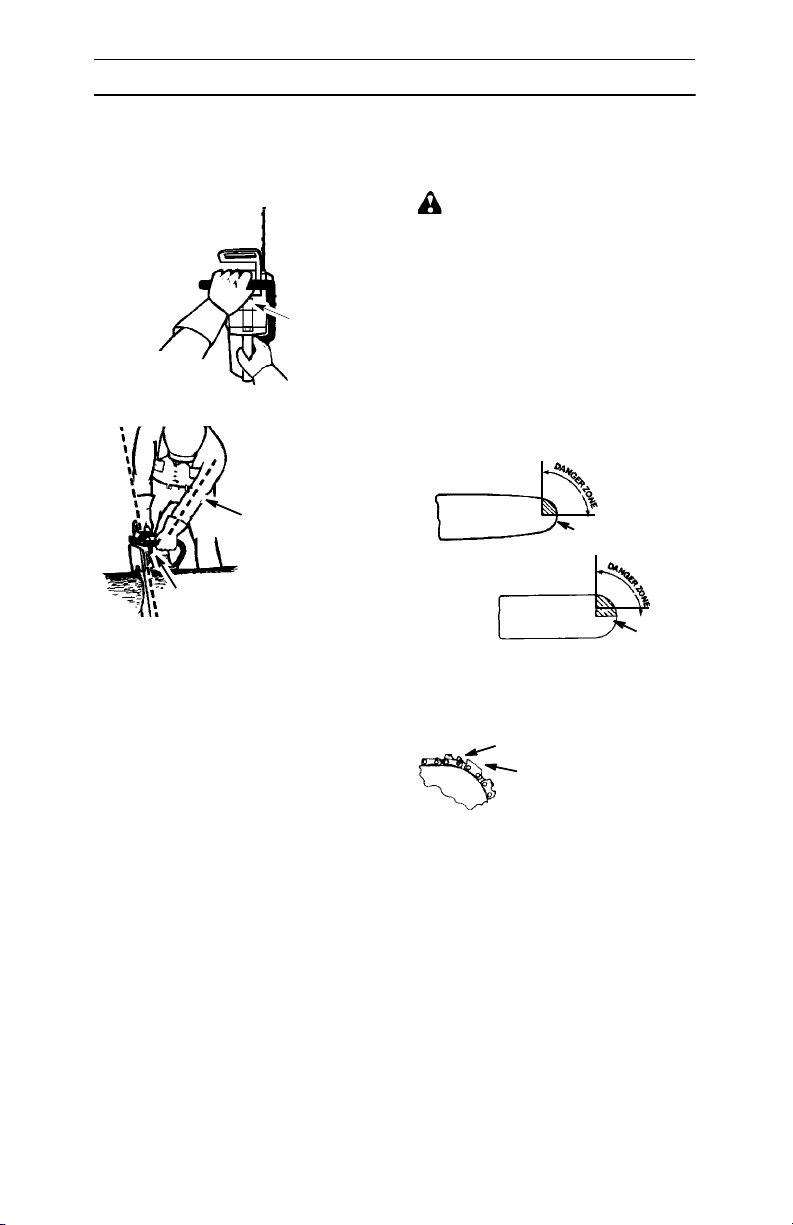

S Rotational Kickback can occur when the

moving chain contacts an object at the upper tip of the guide bar. This contact can

cause the chain to dig into the object,

5

Page 6

GENERAL SAFETY PRECAUTIONS

83

SERVICIO Y AJUSTES

S Limesólo el golpe de avance; use 2 o

3 golpes por borde de corte.

S Mantenga todas las cuchillas de la

misma longitud cuando las lima.

S Limelo suficiente como para eliminar

cualquier daño en los bordes de

corte (placa lateral y placa superior

de la cuchilla).

Cuchillas

igual longitud

Remueva daño

Placa

Superior

Placa

Lateral

S Lime la cadena según las

especificaciones, tal como se ilustra.

30°

80°

60°

Esquina

Redondeada

0,65 mm

Correcto

Ángulo de gancho

Incorrecto

Fuera Elevada el

Cuadrado Esquina

Ángulo del Gancho

Incorrecto

ADVERTENCIA: Mantenga el

ángulo de gancho correcto de acuerdo con las

especificaciones del fabricante de la cadena

que usa. Si el ángulo del gancho es incorrecto,

aumentan las probabilidades de reculadas,

que pueden producir lesiones graves.

4. Verifique y baje los marcadores de pro-

fundidad.

Herramienta marcadora

de profundidad

Lima

Marcador de

Profundidad

S Coloque la herramienta marcadora

sobre la cuchilla.

S Si el marcador de profundidad es más

alto que la herramienta marcadora de

profundidad, límelo para nivelarlo con

la parte superior de la herramienta

marcadora.

S Mantenga redondeada la esquina

delantera del marcador de

profundidad con una lima plana.

AVISO: El extremo superior del

marcador de profundidad debe ser

parejo con la mitad delantera,

redondeada con una lima plana.

Si nece sita más asistencia o no está seguro

sobre cómo llevar a cabo este procedimiento,

entre en contacto con su distribuidor

autorizado del servicio.

AJUSTE AL CARBURADOR

ADVERTENCIA: La cadena estará

en movimiento durante la mayor parte de

este prodecimiento. Use el equipo protector

y observe todad las precauciones de seguri-

dad. La cadena no debe moverse con el mo-

tor en marcha lenta.

El carburador ha sido ajustado cuidadosa-

mente en la fábrica. Posiblemente se hagan

necesarios ajustes si se nota cualquiera de las

siguientes condiciones:

S La cadena se mueve con el motor en mar-

cha lenta. Vea procedimiento de MARCHA

LENTA “T”.

S La sierra no anda a marcha lenta. Vea pro-

cedimiento de MARCHA LENTA “T”.

Marcha Lenta “T”

Deje que el motor trabaje en marcha lenta. Si

la cadena se mueve, la marcha lenta es de-

masiado. Si el motor se para, la marcha len-

ta es demasiado lenta. Ajuste las revolu-

ciones hasta que el motor se mantenga en

marcha sin que la cadena se mueva (la mar-

cha lenta es demasiado) o que el motor se

ahogue (la marcha lenta es demasiado len-

ta). El tornillo de la marcha lenta estásituado

arriba del bombeador y marcado con la “T”.

S Gire el tornillo de la marcha lenta “T” a la der-

echa (en el sentido del reloj) para aumentar

las revoluciones del motor.

S Gire el tornillo de la marcha lenta “T” a la iz-

quierda (en contra del sentido del reloj) para

bajar las revoluciones.

which stops the chain for an instant. The

result is a lightning fast, reverse reaction

which kicks the guide bar up and back toward the operator.

S Pinch-Kickback can occur when the the

wood closes in and pinches the moving

saw chain in the cut along the top of the

guide bar and the saw chain is suddenly

stopped. This sudden stopping of the

chain results in a reversal of the chain

force used to cut wood and causes the

saw to move in the opposite direction of the

chain rotation. The saw is driven straight

back toward the operator.

S Pull-In can occur when the moving chain

contacts a foreign object in the wood in the

cut along the bottom of the guide bar and the

saw chain is suddenly stopped. This sudden

stopping pulls the saw forward and away

from the operator and could easily cause the

operator to lose control of the saw.

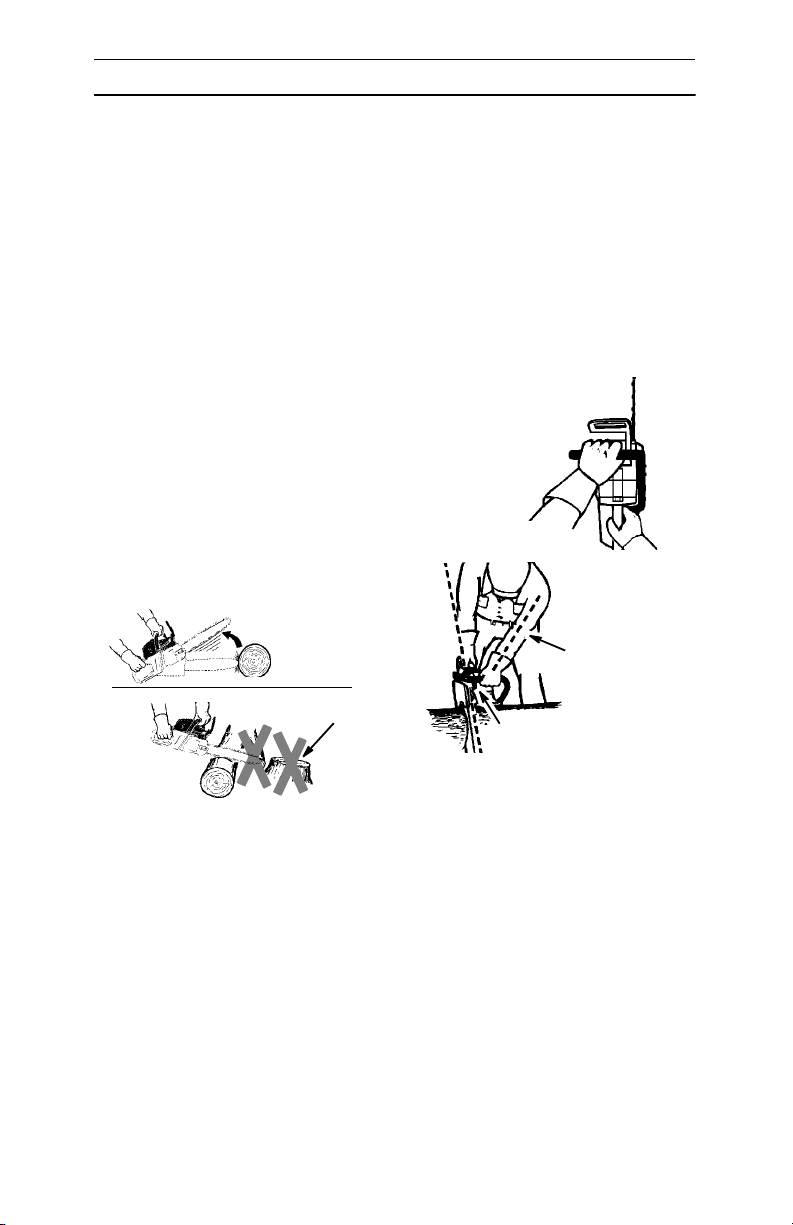

Avoid Pinch--Kickback:

S Be extremely aware of situations or obstruc-

tions that can cause material to pinch the top

of or otherwise stop the chain.

S Do not cut more than one log at a time.

S Do not twist the saw as the bar is with-

drawn from an undercut when bucking.

Avoid Pull --In:

S Always begin cutting with the engine at full

speed and the saw housing against wood.

S Use wedges made of plastic or wood.

Never use metal to hold the cut open.

Clear The

Working Area

REDUCE THE CHANCE OF

KICKBACK

S Recognize that kickback can happen.

With a basic understanding of kickback,

you can reduce the element of surprise

which contributes to accidents.

S Never let the moving chain contact any ob-

ject at the tip of the guide bar.

S Keep the working area free from obstruc-

tions such as other trees, branches, rocks,

fences, stumps, etc. Eliminate or avoid any

obstruction that your saw chain could hit

while you are cutting through a particular log

or branch.

S Keep your saw chain sharp and properly

tensioned. A loose or dull chain can increase

the chance of kickback occurring. Follow

manufacturer’s chain sharpening and maintenance instructions. Check tension at regu-

Kickback Path

Avoid Obstructions

lar intervals with the engine stopped, never

with the engine running. Make sure the bar

clamp nuts are securely tightened after tensioning the chain.

S Begin and continue cutting at full speed. If

the chain is moving at a slower speed, there

is greater chance of kickback occurring.

S Cut one log at a time.

S Use extreme caution when re-entering a

previous cut.

S Do not attempt cuts starting with the tip of

the bar (plunge cuts).

S Watch for shifting logs or other forces that

could close a cut and pinch or fall into chain.

S Use the Reduced- -Kickback Guide Bar and

Low- -Kickback Chain specified for your saw.

MAINTAIN CONTROL

Stand to the left of

the saw

Never reverse

hand positions

S Keep a good, firm grip on the saw with both

hands when the engine is running and don’t

let go. A firm grip will help you reduce kickback and maintain control of the saw. Keep

the fingers of your left hand encircling and

your left thumb under the front handlebar.

Keep your right hand completely around the

rear handle whether your are right handed or

left handed. Keep your left arm straight with

the elbow locked.

S Position your left hand on the front handle-

bar so it is in a straight line with your right

hand on the rear handle when making

bucking cuts. Never reverse right and left

hand positions for any type of cutting.

S Stand with your weight evenly balanced on

both feet.

S Stand slightly to the left side of the saw to

keep your body from being in a direct line

with the cutting chain.

S Do not overreach. You could be drawn or

thrown off balance and lose control of the

saw.

6

Elbow locked

Thumb on underside of

handlebar

Page 7

GENERAL SAFETY PRECAUTIONS

L

S Do not cut above shoulder height. It is diffi-

cult to maintain control of saw above

shoulder height.I

KICKBACK SAFETY FEATURES

WARNING: The following features

are included on your saw to help reduce the

hazard of kickback; however, such features will

not totally eliminate this dangerous reaction.

As a chain saw user, do not rely only on safety

devices. You must follow all safety precautions, instructions, and maintenance in this

manual to help avoid kickback and other forces

which can result in serious injury.

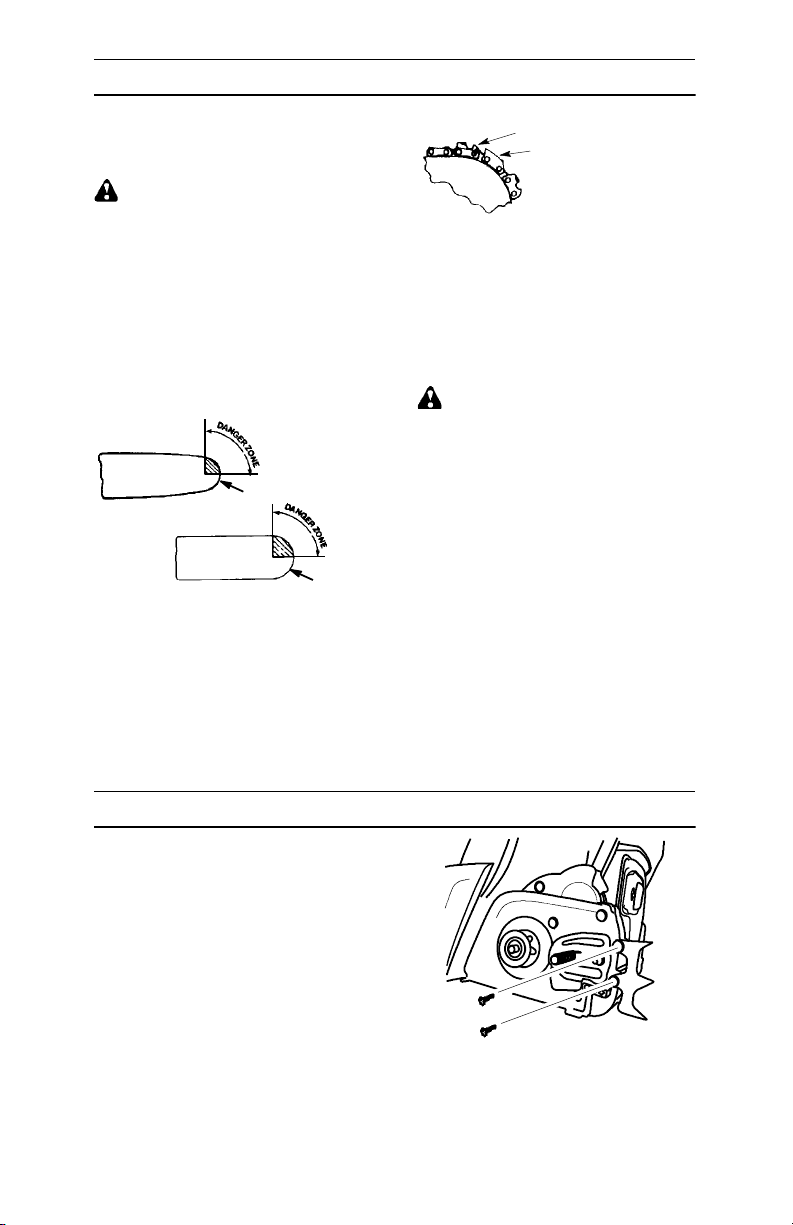

S Reduced--Kickback Guide Bar, designed

with a small radius tip which reduces the

size of the kickback danger zone on the

bar tip. A Reduced- -Kickback Guide Bar has

been demonstrated to significantly reduce

the number and seriousness of kickbacks.

Reduced Kickback

Symmetrical

Guide Bar

Symmetrical Guide Bar

S Low--Kickback Chain, designed with a

contoured depth gauge and guard link

which deflect kickback force and allow

wood to gradually ride into the cutter.

Small Radius Tip

Large Radius Tip

ow-Kickback Chain

S Handguard, designed to reduce the chance

of your left hand contacting the chain if your

hand slips off the front handlebar.

S Position of front and rear handlebars, de-

signed with distance between handles and

“in-line” with each other. The spread and

“in-line” position of the hands provided by

this design work together to give balance

and resistance in controlling the pivot of

the saw back toward the operator if kickback occurs.

WARNING: DO NOT RELY UPON

ANY OF THE DEVICES BUILTINTO YOUR

SAW. YOU SHOULD USE THE SAW

PROPERLY AND CAREFULLY TO AVOID

KICKBACK. Reduced--kickback guide bars

and low--kickback saw chains reduce the

chance and magnitude of kickback and are

recommended. Yoursaw has a low kickback

chain and bar as original equipment. Repairs

on a chain brake should be made by an authorized servicing dealer. Take your unit to

the place of purchase if purchased from a

servicing dealer, or to the nearest authorized

master service dealer.

S Tip contact in some cases may cause a light-

ning fast reverse REACTION, kicking the

guide bar up and back toward the operator.

S Pinching the saw chain along the top of the

guide bar may push the guide bar rapidly

back toward the operator.

S Either of these reactions may cause you to

lose control of the saw which could result

in serious injury. Do not rely exclusively

uponthe safety devices builtinto your saw.

Contoured Depth Gauge

Elongated Guard Link

Deflects Kickback

Force And Allows

Wood To Gradually

Ride Into Cutter

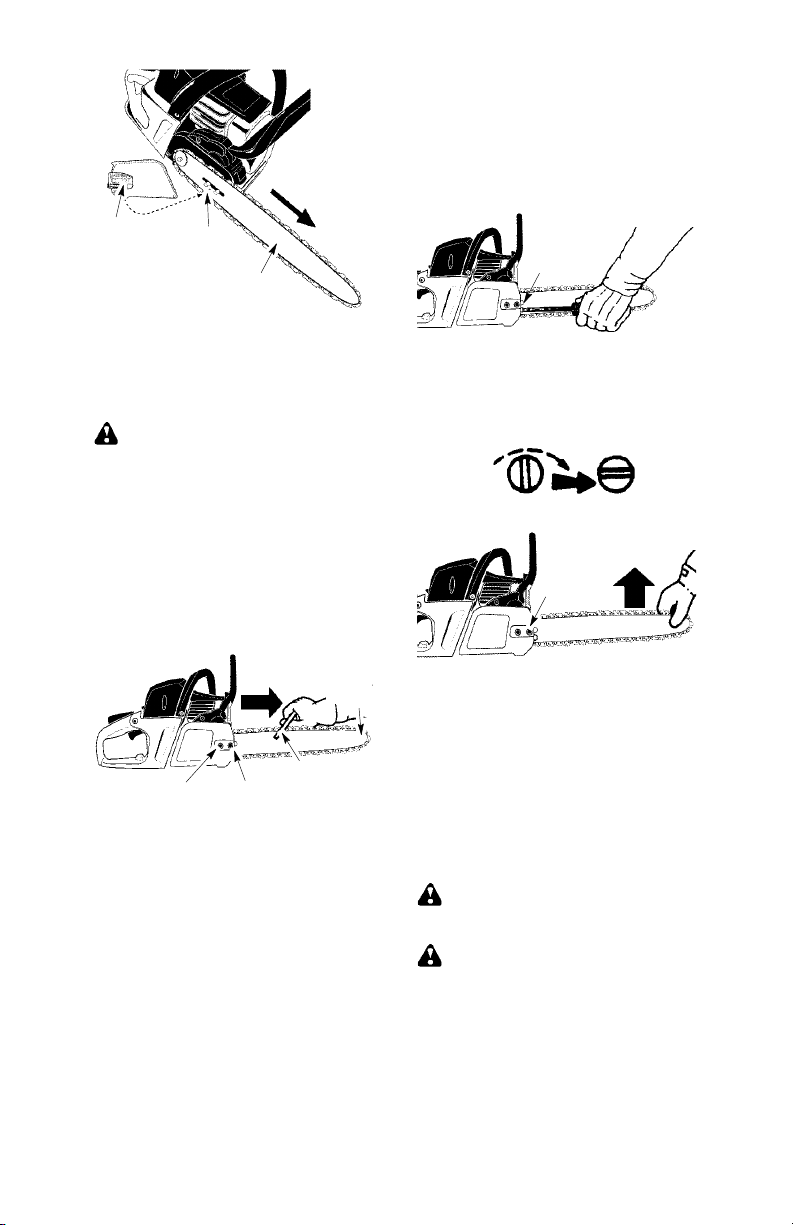

ASSEMBLY

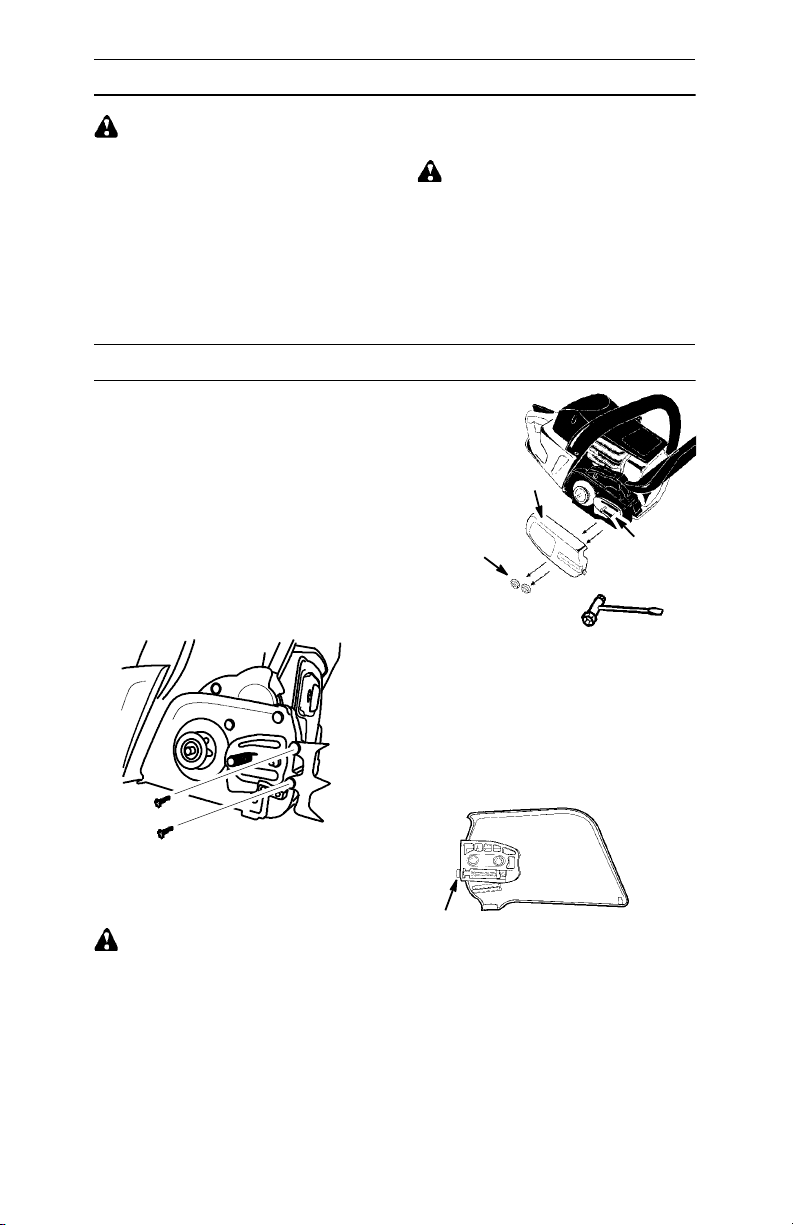

Protective gloves (not provided) should be

worn during assembly.

ATT ACHING THE BUMPER

SPIKE (if not already attached)

The bumper spike may be used as a pivot

when making a cut.

1. Loosen and remove the bar nuts and the

clutch cover from the saw.

2. Attach the bumper spike with the two

screws as illustrated.

7

Page 8

ASSEMBLY

A

81

SERVICIO Y AJUSTES

ADVERTENCIA: El mantenimiento

incorrecto podía causar daño serio al motor o a

graves lesiones al operador.

ADVERTENCIA: Desconecte la

bujía antes de hacer cualquier mantenimiento,

con la excepción de los ajustes al carburador.

Se recomienda que confíe todas las repara-

ciones y ajustes no descritos en el manual a

su Distribuidor Autorizado.

PLANILLA DE MANTENIMIENTO

Verifique:

Elniveldecombustible Antesdecadauso-.

Lubricacióndelabarra Antesdecadauso.

Tensión de la cadena Antes de cada uso...

Afilación de la cadena Antes de cada uso..

Piezas dañadas Antes de cada uso.......

Tapas sueltas Antes de cada uso.........

Fijadores sueltas Antes de cada uso......

Piezas sueltas Antes de cada uso

Inspeccionar y Limpiar:

barra guía Antes de cada uso.............

Sierra completa Después de cada........

uso

Filtro de aire Cada 5 horas*..........

Freno de cadena Cada 5 horas*......

Rejilla antichispas y

silenciador Cada 25 horas*............

Cambiar la bujia Anualmente......

Cambiar el filtro de

combustible Anualmente..........

* Horas de uso

FRENO DE CADENA

ADVERTENCIA: La banda del

freno podrá romperse al activar el freno si ésta

se encuentra demasiado usada y fina. Si la

banda del freno se encuentra rota, el freno de

cadena no detendrá la cadena. El freno de

cadena debe ser substituido si cualquier parte

se desgasta menos de 0,5 mm densamente.

Cualquier reparación en un freno de cadena

deber ser realizada por el distribuidor

autorizado. Si compró la máquina a un

distribuidor,acudaconsumáquinaaésteoala

oficina principal del distribuidor autorizado.

CONTROL DEL FRENO

PRECAUCION: El freno de cadena debe

probarse varias veces al día. Al hacer esta

inspección, el motor siempre debe estar

prendido.

Coloque la sierra en suelo firme. Sostenga la

mango trasera con la mano derecha y la

mango delantera con la mano izquierda.

Aplique a la velocidad máxima presionando el

gatillo del acelerador. Active el freno de

cadena dando vuelta a su muñeca izquierda

contra el protector de mano delantera sin soltar

la mango delantera. La cadena deberá

detenerse inmediatamente.

FILTRO DE AIRE

ADVERTENCIA: No limpie el filtro

con gasolina ni con otros disolventes infla-

mables para evitar el peligro de incendio o

emisiones de vapores nocivos.

Limpieza del filtro de aire:

Un filtro de aire sucio reduce el rendimiento

del motor y aumenta el consumo de combus-

tible y las emisiones nocivas. Siempre limpie

el filtro cada 5 horas de funcionamiento.

1. Limpie la cubierta y la zona que la rodea

para evitar que se introduzca suciedad y

serrín en la cámara del carburador cuan-

do se extraiga la cubierta.

2. Retire las piezas que se ilustran abajo.

3. Lave el filtro con agua y jabón. Enjuague

biencon agua clara y fría. Séquelo al aire

totalmente antes de reinstalarlo.

4. Aplique varias gotas de aceite al filtro;

apriete el filtro para distribuir el aceite.

5. Reinstale las piezas.

Filtro de

Aire

Tapa del

Cilindro

Cubierta

del Filtro

de Aire

MANTENIMIENTO DE LA

BARRA GUÍA

Si la sierra de cadena sólo corta por un lado,

tiene que forzarla para cortar o ha estado

funcionando con una cantidad inadecuada

de lubricante, puede que necesite revisarla.

Una barra guía desgastada puede dañar la

cadena y dificultar el corte.

Después de usar, asegúrese el interruptor ON/

STOP está en posición STOP, luego limpie

todo el aserrín y cualquier otro escombro de la

ranura de la barra guía y del orificio del engra-

naje.

Para mantener la barra guía:

S Mueva el interruptor ON/STOP en posición

STOP.

S Afloje y retire las tuercas del freno de cadena

y el freno de cadena. Retire la barra guía y la

cadena del aparato.

S Limpie los orificios del aceite y el ranura de la

barra guía después de cada 5 horas de la

operación.

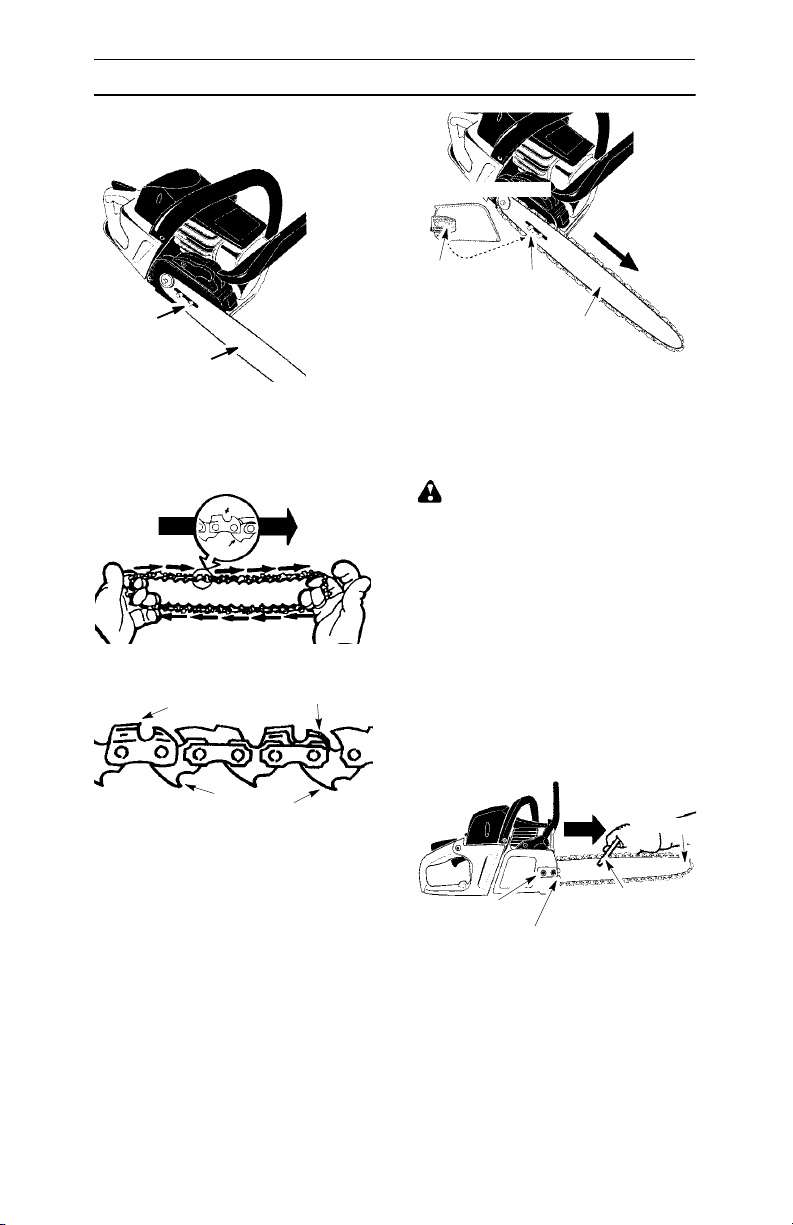

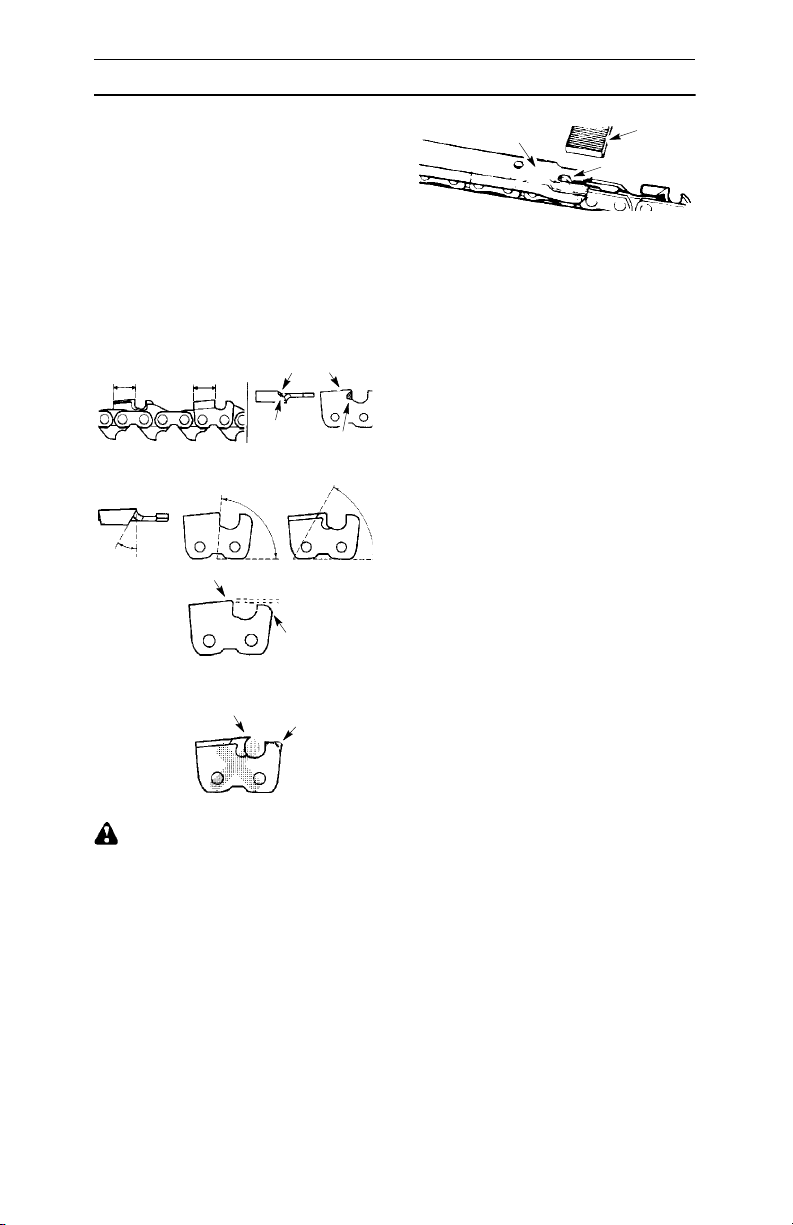

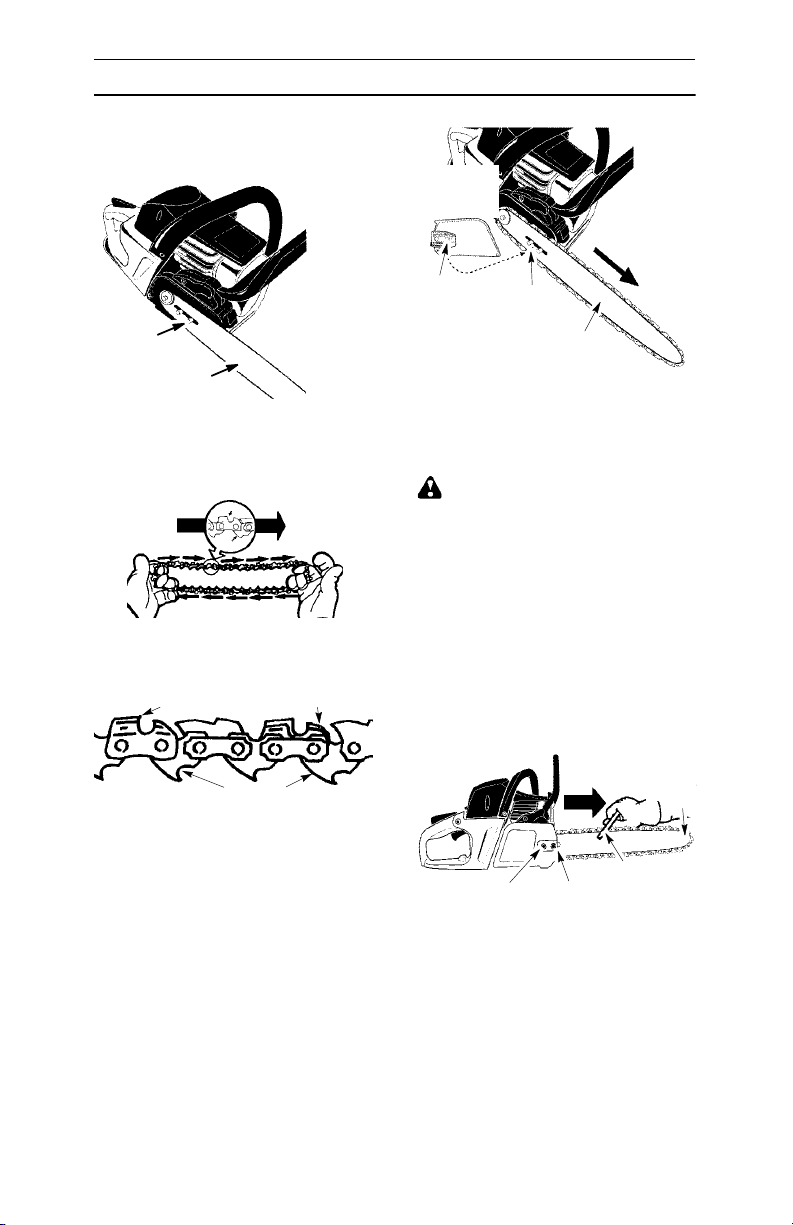

WARNING: Recheck each assem-

bly step if the saw is received assembled. Always wear gloves when handling the chain.

The chain is sharp and can cut you even

when it is not moving!

1. Loosen and remove the bar nuts and the

clutch cover from the saw.

2. Remove the plastic shipping spacer (if

present).

Clutch cover

Bar nuts

Chain adjustment tool

(Bar Tool)

3. An adjusting pin and screw is used to adjust the tension of the chain. It is very important when assembling the bar, that the

pin located on the adjusting screw aligns

into a hole in the bar. Turning the screw will

move the adjustment pin up and down the

screw. Locate this adjustment before you

begin mounting the bar onto the saw. See

following illustration.

Adjustment located on clutch cover

4. Turn the adjusting screw by hand counterclockwise until the adjusting pin just

touches the stop. This should allow the

pin to be near the correct position.

5. Slide guide bar on bar bolts until guide bar

stops against clutch drum sprocket.

Location of

shipping

spacer

Inside

view of

clutch

cover

Bar bolts

Guide bar

6. Carefully remove the chain from the package. Hold chain with the drive links as

shown.

CUTTERS MUST FACE IN

DIIRECTION OF ROT

Cutters

7. Place chain over and behind clutch retainer, fitting the drive links in the clutch

drum sprocket.

8. Fit bottom of drive links between the

teeth in the sprocket in the nose of the

guide bar.

9. Fit chain drive links into bar groove.

10. Pull guide bar forward until chain is snug

in guide bar groove. Ensure all drive links

are in the bar groove.

11. Now,install clutch cover making sure the

adjusting pin is positioned in the lower

hole in the guide bar. Remember this pin

moves the bar forward and backward as

the screw is turned.

8

Drive Links

Tip of

Bar

TION

Depth Gauge

Page 9

Clutch

e

Cover

Adjusting Pin

12. Install bar nuts and finger tighten only.

Once the chain is tensioned, you will

need to tighten bar nuts.

Lower

Hole

Guide Bar

CHAIN TENSION (Including units

with chain already installed)

WARNING: Wear protective gloves

when handling chain. The chain is sharpand

can cut you even when it is not moving.

NOTE: When adjusting chain tension,

make sure the bar nuts are finger tight only.

Attempting to tension the chain when the bar

nuts are tight can cause damage.

Checking the tension:

Use the screwdriver end of the chain adjustment tool (bar tool) to move chain around

guide bar. If the chain does not rotate, it is too

tight. If the chain is too loose, it will sag below

the bar.

Guid

Bar

Chain Adjustment

Bar Nuts

Adjusting

Screw

Tool

(Bar Tool)

Adjusting the tension:

Chain tension is very important. Chains

stretch during use. This is especially true

during the first few times you use your saw.

Always check chain tension each time you

use and refuel your saw.

1. Loosen bar nuts until they are finger tight

against the clutch cover.

2. Turn adjusting screw clockwise until chain

solidly contacts bottom of guide bar rail.

Adjusting

Screw

3. Using bar tool, roll chain around guide bar

to ensure all links are in bar groove.

4. Lift up tip of guide bar to check for sag.

Release tip of guide bar,then turn adjusting screw

til sag does not exist.

5. While lifting tip of guide bar, tighten bar

nuts securely with the bar tool.

6. Use the screwdriver end of the bar tool to

move chain around guide bar.

7. If chain does not rotate, it is too tight.

Slightly loosen bar nuts and loosen chain

by turning the adjusting screw

counterclockwise. Retighten bar nuts.

8. If chain is too loose, it will sag below the

guidebar. DO NOT operate the saw if the

chain is loose.

NOTE: The chain is tensioned correctly

when the weight of the chain does not cause it

to sag below the guide bar (with the chain saw

sitting in an upright position), but the chain still

moves.

WARNING: If the saw is operated

with a loose chain, the chain could jump off

the guide bar and result in serious injury.

WARNING: Muffler is very hotduring

and after use. Do not touch the muffler or allow combustible material such as dry grass

or fuel to do so.

1

/4turn clockwise. Repeat un-

Bar Nuts

1

/4Turn

Adjusting Screw --

1

/4turn

9

Page 10

FUEL HANDLING

79

TÉCNICA DE TRABAJO

Apertura

del corte de

tala

Cierre del

cachado

La bisagra sostiene el

á

rbol en el tocón,

ayudando a controlar la caída

NOTA: Antes de completar el corte de

talado, utilice cuñas para abrir el corte cuando

sea necesario controlar la dirección de caída.

Utilice cuñas de madera o de plástico, pero

nunca de acero o hierro, que podrían causar

rebotes y daños en la cadena.

S Preste atención a los indicios de que el ár-

bol está a punto de caer: crujidos, ensan-

chamiento del corte de talado o movimien-

tos en las ramas superiores.

S Cuando el árbol comience a caer, detenga

la sierra, déjela en el suelo y aléjese rápi-

damente a una zona despejada.

S NO CORTE con la sierra un árbol parcial-

mente caído. Extreme las precauciones con

los árboles parcialmente caídos, ya que

pueden caer con facilidad al no disponer de

apoyo. Si el árbol no cae completamente,

deje la sierra y tire de él con un cabrestante

de cables, bloque y polea o un tractor.

CORTE DE UN ÁRBOL CAÍDO

(TRONZADO)

El término ”tronzado” se utiliza para designar la

tala de árboles a la altura del tronco deseada.

ADVERTENCIA: No se apoye so-

bre el tronco que está cortando. Podría des-

prenderse un trozo provocando la pérdida de

equilibrio y control. No permanezca cuesta

abajo respecto al tronco que está cortando.

Puntos importantes

S No corte más de un tronco simultánea-

mente.

S Corte con cuidado la madera astillada, ya

que las astillas pueden salir despedidas

hacia el operador.

S Utilice un caballete para cortar los troncos

pequeños. Al cortar un tronco, no lo sujete

con el pié o con la mano, ni permita que

otra persona haga lo mismo.

S No corte en zonas en las que se los troncos,

raíces y ramas estén enredados. Arrastre

los troncos a una zona despejada y corte pri-

mero los que están más visibles y limpios.

TIPOSDECORTEUTILIZADOS

PAR A EL TRONZADO

ADVERTENCIA: Si la sierra se que-

da atascada o enganchada en un tronco, no in-

tente sacarla por la fuerza. Podría perder el

control de la herramienta y dañarla o sufrir ac-

cidentes. Pare el motor e inserte una cuña de

plástico o de madera en el corte hasta que

pueda extraer fácilmente la sierra. Vuelva a en-

cenderla y corte con cuidado por el mismo lu-

gar. No intente conectar la sierra estando atas-

cada o enganchada en un tronco.

Apague la sierra OFF y utilice una cuña

de plástico o de madera para abrir más

el corte.

El corte por arriba empieza en la parte su-

perior del tronco apoyando la sierra contra el

mismo. Cuando vaya a cortar por arriba, pre-

sione la sierra hacia abajo.

Corte descendiente

Corte ascendiente

El corte por debajo implica cortar desde la

parte inferior del tronco apoyando la sierra

contra el mismo. Cuando vaya a cortar por

debajo, empuje la sierra hacia arriba. Sujete

la sierra con firmeza para mantenerla bajo

control. La sierra tenderá a caer hacia abajo

y a ejercer presión contra el operador.

ADVERTENCIA: No dé la vuelta a

la sierra para cortar por debajo. En esa posi-

ción no la podrá controlar.

Segundo corte

Primer corte en el lado de

presión del tronco

Primercorteenelladodepresión

del tronco

Segundo corte

TRONZADO SIN SOPORTE

S Corte por arriba de 1/3 del diámetro del

tronco.

S Gire el tronco y termine el serrado hacien-

do un segundo corte.

S Preste mucha atención a los troncos retorci-

dos para evitar que la sierra quede atasca-

da. Realice el primer corte en el lado retorci-

do del tronco para eliminarlo parcialmente.

FUEL

Note! The machine is equipped with a twostroke engine and must always be run using

a mixture of petrol and two-stroke oil. It is important to accurately measure the amount of

oil to be mixed to ensure that the correct mixture is obtained. When mixing small amounts

of fuel, even small inaccuracies can drastically affect the ratio of the mixture.

WARNING: Always ensure there is

adequate ventilation when handling fuel.

PETROL

S Use good quality unleaded or leaded petrol.

S The lowest recommended octane grade is

90 (RON).

S If you run the engine on a lower octane grade

than 90 so- -called knocking can occur. This

gives rise to a high engine temperature and

increased bearing load, which can result in

serious engine damage.

S When working with continuous high revs

(e.g. limbing) a higher octane is recommended.

Running--in

AvoId running at a too high speed for extended periods during the first 10 hours.

TWO-STROKE OIL

S For best results and performance use Uni-

versal, Universal powered by McCulloch

two--stroke engine oil, which is specially

formulated for our air cooled two--stroke

engines.

S Never use two-stroke oil intended for water-

cooled engines, sometimes referred to as

outboard oil (rated TCW).

S Never use oil intended for four--stroke en-

gines.

S A poor oil quality and/or too high oil/fuel ra-

tio may jeopardise function and decrease

the lifetme of catalytic converters.

MIXING RATIO

1:50 (2%) with Universal, Universal powered

by McCulloch two-stroke oil.

1:33 (3%) with oils class JASO FB or ISO EGB

formulated for air-cooled, two-stroke engines.

Petrol, litre Two--Stroke Oil, litre

5 0,10 0,15

10 0,20 0,30

15 0,30 0,45

20 0,40 0,60

2% (1:50) 3% (1:33)

MIXING

S Always mix the petrol and oil in a clean

container intended for fuel.

S Always start by filling half the amount of the

petrol to be used. Then add the entire

amount of oil. Mix (shake) the fuel mixture.

Add the remaining amount of petrol.

S Mix (shake) the fuel mixture thoroughly be-

fore filling the machine’s fuel tank.

S Do not mix more than one month’s supply

of fuel at a time.

S If the machine is not used for some time

the fuel tank should be emptied and

cleaned.

CHAIN OIL

S We recommend the use of special oil

(chain oil) with good adhesion characteristics.

S Never use waste oil. This results in dam-

age to the oil pump, the bar and the chain.

S It is important to use oil of the right grade

(suitable viscosity range) to suit the air

temperature.

S In temperatures below 0°C(32°F) some

oils become too viscous. This can overload the oil pump and result in damage to

the oil pump components.

S Contact your service dealer when choos-

ing chain oil.

FUELING

WARNING: Taking the following pre-

cautions will lessen the risk of fire: do not

smoke and do not place any hot objects in

the vicinity of fuel; always stop the engine

and let it cool for a few minutes before refueling; when refueling, open the fuel cap slowly

so that any excess pressure is released

gently; tighten the fuel cap carefully after refueling; always move the machine away

from the refueling area and source before

starting.

Clean the area around the fuel cap. Clean

the fuel and chainoil tanks regularly. The fuel

filter must be replaced at least once a year.

Contamination in the tanks causes malfunction. Make sure the fuel is well mixed by

shaking the container before refuelling. The

capacities of the chain oil tank and fuel tank

are carefully matched. You should therefore

always fill the chain oil tank and fuel tank at

the same time.

WARNING: Fuel and fuel vapour are

highly flammable. Take care when handling

fuel and chain oil. Be aware of the risks of

fire, explosion and those associated with inhalation.

10

Page 11

STARTING AND STOPPING

WARNING: The chain must not

move when the engine runs at idle speed. If

the chain moves at idle speed refer to CARBURETOR ADJUSTMENT within this

manual. Avoid contact with the muffler. A hot

muffler can cause serious burns.

To stop the engine, move the ON/STOP

switch to the STOP position.

To start the engine, hold the saw firmly on

the ground as illustrated below. Make sure

the chain is free to turn without contacting

any object.

Use only 40 --- 45 cm of rope per pull.

Hold saw firmly while pulling starter rope.

Starter Rope Handle

Left Hand

on Front

Handle

Right Foot Through Rear Handle

IMPORTANT POINTS TO

REMEMBER

When pulling the starter rope, do not use the full

extent of the rope as this can cause the rope to

break. Do not let starter rope snap back. Hold

the handle and let the rope rewind slowly.

For cold weather starting, start the unit at full

choke; allow the engine to warm up before

squeezing the throttle trigger.

NOTE: Do not cut material with the choke/

fast idle lever at the FULL CHOKE position.

STARTING A COLD ENGINE

(orawarmengineafterrunning out of fuel)

NOTE:

choke/fast idle lever is pulled out to the full

extent, the correct throttle setting for starting

is set automatically.

1. Move ON/STOPswitch to the ON position.

2. Slowly press primer bulb 6 times.

In the following steps, when the

IGNITION

SWITCH

ON

STOP

Choke

Lever

3. Pull out choke/fast idle to the full extent

(to the FULL CHOKE position).

4. Pull the starter rope sharply with your

right hand until the engine fires, which

can be heard through a “puff” sound.

Then, proceed to the next step.

NOTE: If the engine sounds as if it is trying

to start before the 5th pull, stop pulling and

immediately proceed to the next step.

5. Push the choke/fast idle lever in to the

HALF CHOKE position.

CHOKE/FAST IDLE LEVER

OFF

HALF

FULL

6. Pull the starter rope sharply with your

right hand until the engine starts.

7. Allow the engine to run for approximately

30 seconds. Then, squeeze and release

throttle trigger to allow engineto return to

idle speed.

There is a simplified start reminder with

illustrations to describe each step on the

rear edge of the chain saw.

STARTING A WARM ENGINE

1. Move ON/STOPswitch to the ON position.

2. Pull the choke/fast idle lever out to the

FULL CHOKE position to set the fast

idle, then push the lever in to the HALF

CHOKE position.

3. Slowly press the primer bulb 6 times.

4. Pull the starter rope sharply with your

right hand until the engine starts.

5. Squeeze and release throttle trigger to

allow engine to return to idle speed.

DIFFICULT STARTING (or starting a flooded engine)

The engine may be flooded with too much

fuel if it has not started after 10 pulls.

Flooded engines can be cleared of excess

fuel by pushing the choke/fast idle lever in

completely (to the OFF CHOKE position)

and then following the warm engine starting

procedure listed above. Ensure the ON/

STOP switch is in the ON position.

Starting could require pulling the starter rope

handle many times depending on how badly

the unit is flooded. If engine fails to start, refer to the TROUBLESHOOTING TABLE.

11

Page 12

WORKING TECHNIQUES

77

ARRANQUE Y PARADA

1. Mueva el interruptor ON/STOP a la posi-

ción ON.

2. Lentamente, oprima el bombeador 6

veces.

3. Tire de la palanca del cebador/marcha

lenta rapida a la posición HALF CHOKE.

4. Firmemente, tire de la cuerda de arran-

que con su mano derecha hasta que el

motor se ponga en marcha.

5. Apriete y suelte el gatillo acelerador para

para permitir que el motor regrese a mar-

cha lenta.

ARRANQUE DIFICIL (o arran-

que de motor ahogado)

El motor puede encontrarse ahogado con

demasiado combustible si no se ha puesto en

marcha después del 10 tirón. Un motor que se

encuentre ahogado puede ser aclarado del

exceso de combustible empujando la palanca

del cebador/marcha lenta rapida en totalmente

(a la posición OFF CHOKE) y luego siguiendo

el procedimiento de puesta en marcha para

motores calientes que se has indicado

anteriormente. Asegúrese de que el interruptor

ON/STOP se encuentre en la posición ON.

Que el motor se ponga en marcha puede

requerir que se tire de la cuerda de arranque

muchas veces, dependiendo cuán ahogado

se encuentre el motor. Si el motor no arranca,

refiérase a la TABLA DIAGNÓSTICA.

TÉCNICA DE TRABAJO

FRENO DE CADENA

ADVERTENCIA: Asegúrese el fre-

no de cadena se disactiva tirando el protector

de mano delantero hacia atrás, acercándolo a

la manija delantera todo lo que sea posible. Es

necesario desactivar el freno de cadena para

cortar con la sierra.

S Esta sierra está equipada con un freno de

cadena diseñada para detener la cadena en

el caso de rebote.

S El freno de cadena inercia- -activado se

activa si el protector delantero de mano es

empujado hacia adelante ya sea

manualmente (a mano) o automáticamente

(por el movimiento repentino).

S Si el freno ya está activado, se lo desactiva

tirando el protector de mano delantero hacia

ánoà, acercándolo a la mango delantera

todo lo que sea posible.

S Para cortar con la sierra, es necesario

desactivar el freno de cadena.

Activado

Desactivado

PUNTOS IMPORTANTES

ADVERTENCIA: A veces las astil-

las quedan atrapadas en la cubierta del em-

brague, lo que hace que la cadena se atas-

que. Pare siempre el motor antes de limpiar

la máquina.

S Verifique la tensión de la cadena antes del

primer uso y después de un minuto de fun-

cionamiento. Vea TENSION DE LA CADE-

NA en la sección de MONTAGE.

S Corte únicamente madera. No corte mate-

riales metálicos, plásticos, de albañilería,

materiales de construcción que no sean

de madera, etc.

S La espiga de tope se puede utilizar como eje

central al realizar un corte.

S Detenga la sierra en caso de que la cadena

toque un objeto extraño. Inspeccione la sie-

rra y cambie las piezas que sean necesa-

rias.

S Mantenga la cadena apartada de tierra y

suciedad. Incluso una pequeña cantidad

de suciedad desafilará rápidamente la ca-

dena y aumentará el riesgo de rebotes.

S Practique cortando algunos troncos pe-

queños empleando las siguientes técni-

cas y así familiarizarse con la sierra antes

de comenzar trabajos de serrado más im-

portantes.

S Pulse el gatillo del acelerador y deje

que el motor alcance la máxima veloci-

dad antes de comenzar a cortar.

S Comience a realizar cortes con el bas-

tidor de la sierra contra el tronco.

S Mantenga el motor con la máxima velo-

cidad durante todo el tiempo en el que

esté cortando.

S Deje que la cadena corte por usted.

Únicamente ejerza un ligera presión.

S Libere el gatillo del acelerador tan pronto

como se haya terminado el corte, permi-

tiendo que el motor funcione en ralentí. Si

utiliza la sierra con la máxima aceleración

sin una carga de corte, puede producirse

un desgaste innecesario.

S Para evitar perder el control, no ejerza

presión al final del corte.

S Apague el motor antes de dejar la motosie-

rra en el suelo.

CHAIN BRAKE

WARNING: Ensure chain brake is

disengaged by pulling the front hand guard

back toward the front handle as far as possible.

The chain brake must be disengaged before

cuttingwiththesaw.

S This saw is equipped with a chain brake.

The brake is designed to stop the chain if

kickback occurs.

S The inertia activated chain brake is activated

if the front hand guard is pushed forward, either manually or by centrifugal force.

S If the brake is already activated, it is disen-

gaged by pulling the front hand guard back

toward the front handle as far as possible.

S When cutting with the saw,the chain brake

must be disengaged.

Disengaged

Engaged

IMPORTANT POINTS

WARNING: Sometimes wood chips

get stuck in the clutch cover causing the chain

to jam. Always stop the engine before cleaning.

S Check chain tension before first use and af-

ter 1 minute of operation. See CHAIN TENSION in the ASSEMBLY section.

S Cut wood only. Do not cut metal, plastics,

masonry, non-wood building materials, etc.

S The bumper spike may be used as a pivot

when making a cut.

S Stop the saw if the chain strikes a foreign

object. Inspect thesaw and repair parts as

necessary.

S Keep the chain out of dirt and sand. Even a

small amount of dirt will quickly dull a chain

and increase the possibility of kickback.

S Practice cutting a few small logs using the

following techniques to get the “feel” of using your saw before you begin a major

sawing operation.

S Squeeze the throttle trigger and allow the

engine to reach full speed before cutting.

S Begin cutting with the saw frame

against the log.

S Keep the engine at full speed the entire

time you are cutting.

S Allow the chain to cut for you. Exert only

light downward pressure.

S Release the throttle trigger as soon as

the cut is completed, allowing the engine to idle. If you run the saw at full

throttle without a cutting load, unnecessary wear can occur.

S To avoid losing control when cut is com-

plete, do not put pressure on saw at end

of cut.

S Stop the engine before setting the saw down.

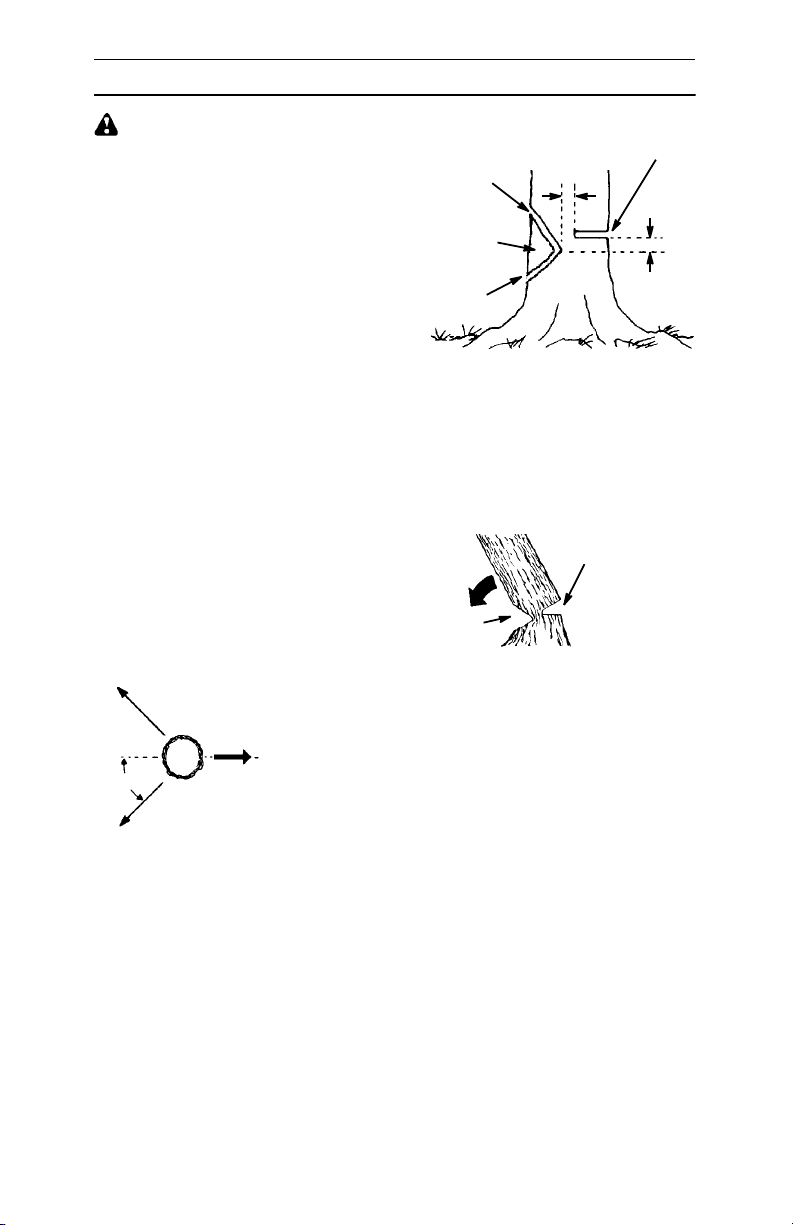

TREE FELLING TECHNIQUES

WARNING: Felling a tree requires

chain saw skills and experience. Inexperienced users should not fell trees. Do not attempt any task that makes you feel uncomfortable or unsure.

WARNING: Do not cut near buildings

or electrical wires if you do not know the direction of tree fall, at night since you will not be able

to see well, or during bad weather such as rain,

snow, or strong winds. as fall is unpredictable.

Carefully plan your sawing operation in advance. You need a clear area all around the

tree so you can have secure footing. Check

for broken or dead branches which can fall

on you causing serious injury.

Natural conditions that can cause a tree to

fall in a particular direction include:

S The wind direction and speed.

S The lean of the tree. The lean of a tree

might not be apparent due to uneven or

sloping terrain. Use a plumb or level to determine the direction of tree lean.

S Weight and branches on one side.

S Surrounding trees and obstacles.

Look for decay and rot. If the trunk is rotted, it

can snap and fall toward the operator. Make

sure there is enough room for the tree to fall.

Maintain a distance of

the nearest person or other objects. Engine

noise can drown out a warning call. Remove

dirt, stones, loose bark, nails, staples, and wire

from the tree where cuts are to be made.

45_

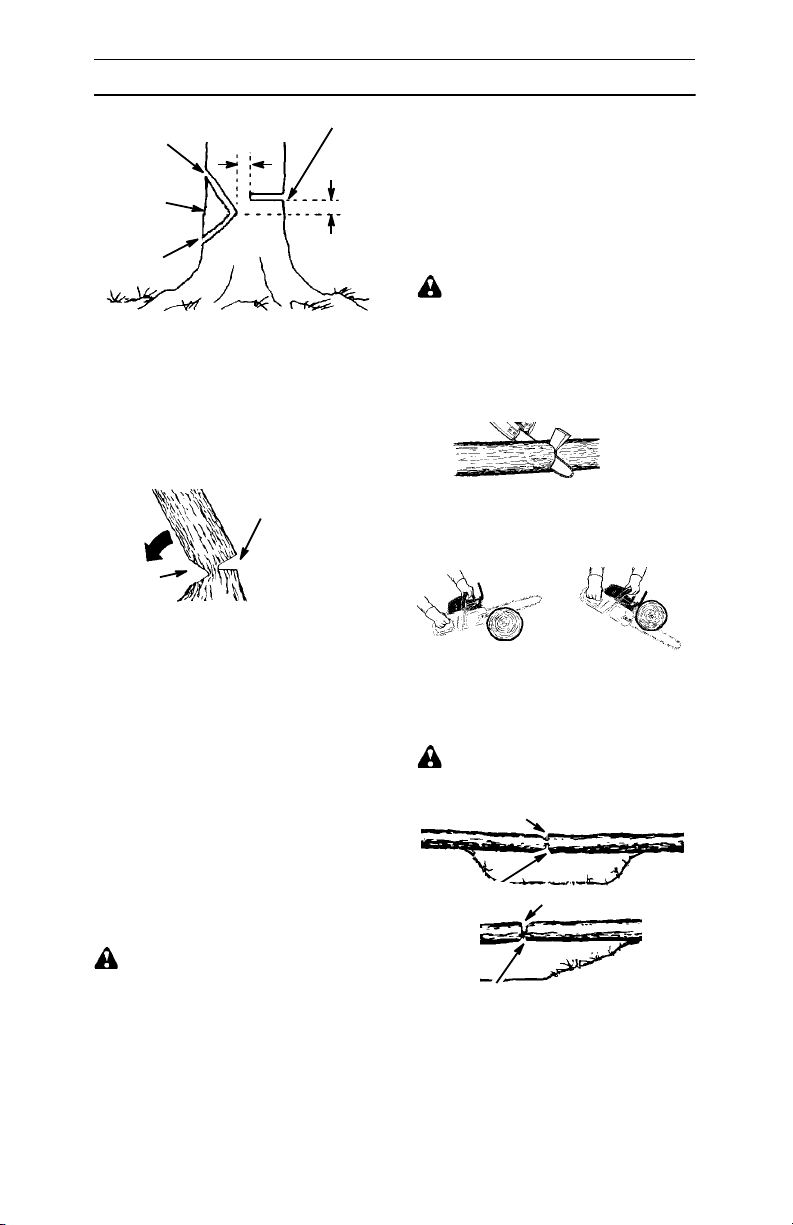

FELLING LARGE TREES

(15 cm in diameter or larger)

The notch method is used to fell large trees.

A notch is cut on the side of the tree in the desired direction of fall. After a felling cut is

made on the opposite side of tree, the tree

will tend to fall into the notch.

NOTCH CUT AND FELLING THE

TREE

S Make notch cut by cutting the top of the

notch first. Cut through

of the tree. Next complete the notch by cutting the bottom of the notch. See illustration. Once the notch is cut remove the

notch of wood from the tree.

12

2-1/2 tree lengths from

Plan a clear retreat path

Direction of Fall

1/3 of the diameter

Page 13

WORKING TECHNIQUES

Final cut here. 5 cm above

First cut

Notch

Second cut

S After removing the wood from the notch,

make the felling cut on the opposite side of

the notch. This is done by making a cut about

5 cm higher than the center of the notch.

This will leave enough uncut wood between

the felling cut and the notch to form a hinge.

This hinge will help prevent the tree from falling in the wrong direction.

Hinge holds tree on stump and helps

control fall

Closing

of notch

NOTE: Before felling cut is complete, use

wedges to open the cut when necessary to

control the directionof fall. Toavoid kickback

or chain damage, use wood or plastic

wedges, but never steel or iron wedges.

S Be alert to signs that the tree is ready to fall:

cracking sounds, widening of the felling cut,

or movement in the upper branches.

S As tree starts to fall, stop saw, put it down,

and get away quickly on your planned retreat path.

S DO NOT cut down a partially fallen tree with

your saw. Be extremely cautious with partially fallen trees that may be poorly supported. When a tree doesn’t fall completely,

set the saw aside and pull down the tree with

a cable winch, block and tackle, or tractor.

center of notch.

5cm

Opening

of felling

cut

5cm

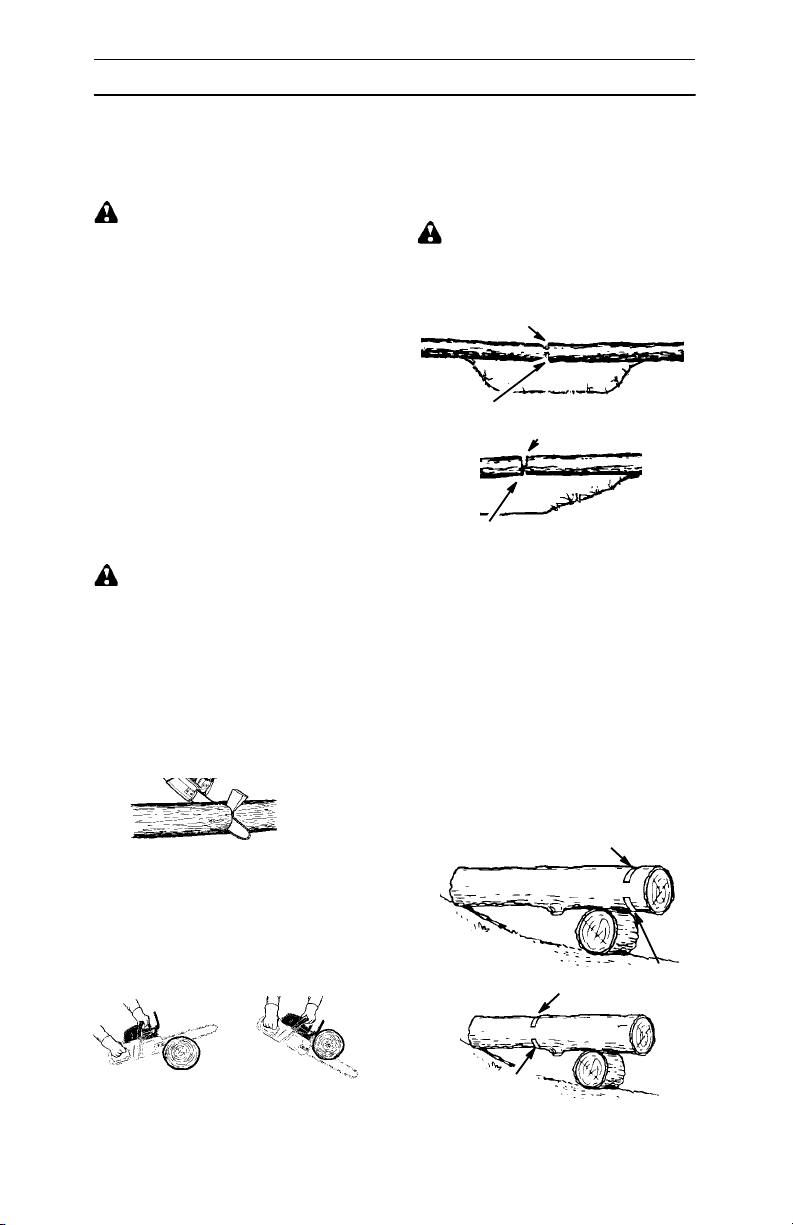

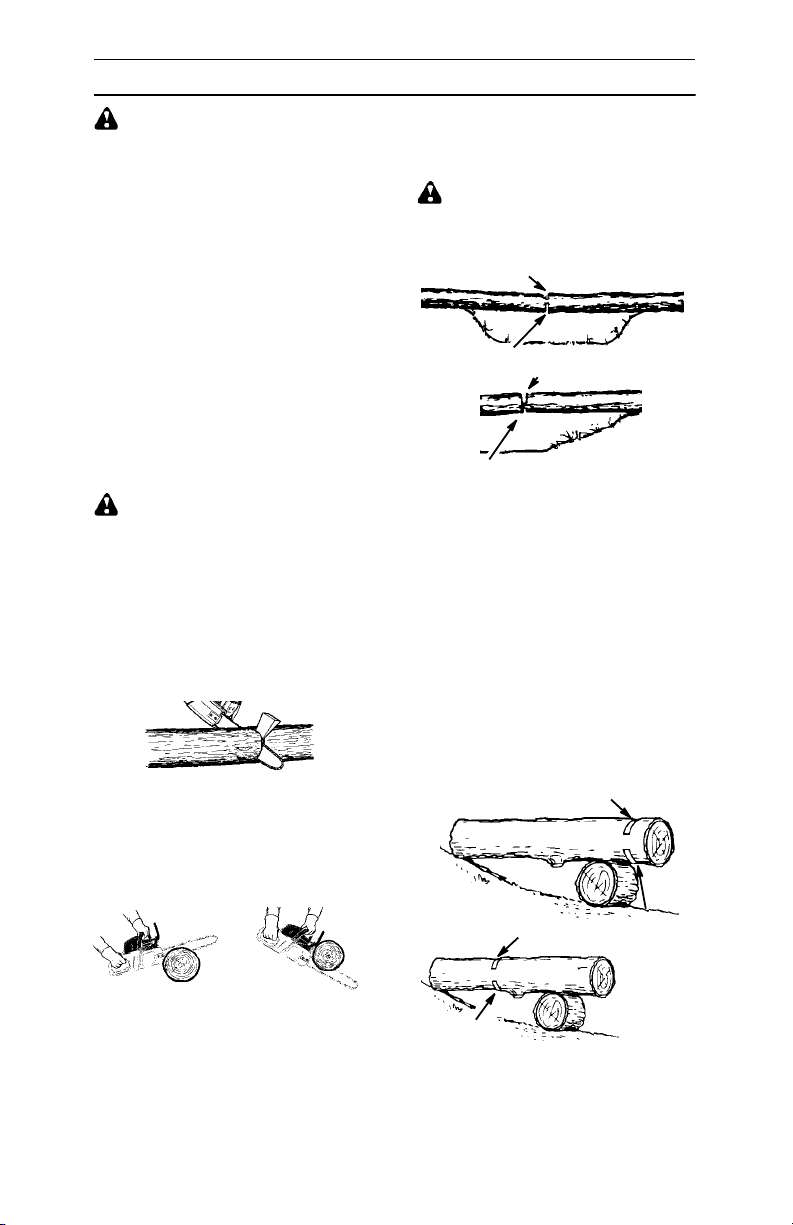

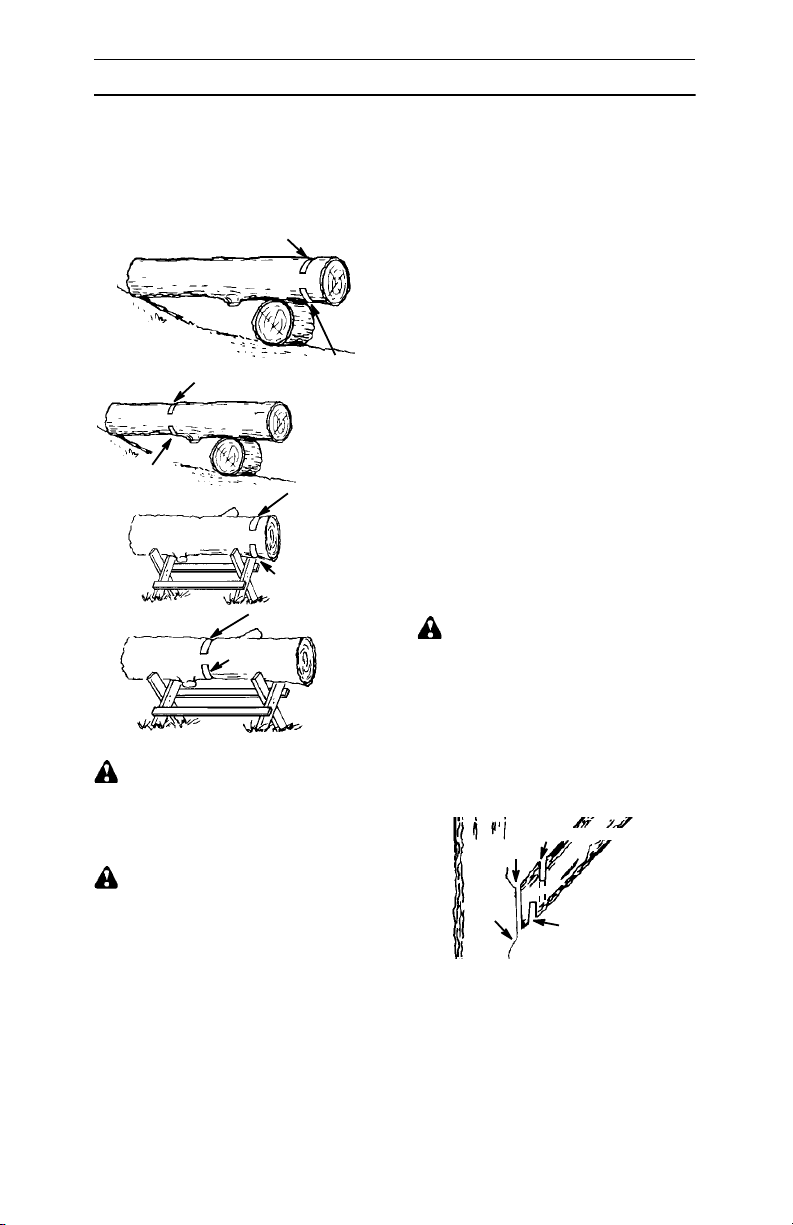

CUTTING A FALLEN TREE

(BUCKING)

Bucking is the term used for cutting a fallen

tree to the desired log length.

WARNING: Do not stand on the log

being cut. Any portion can roll causing loss

of footing and control. Do not stand downhill

of the log being cut.

Important points

S Cut only one log at a time.

S Cut shattered wood very carefully; sharp

pieces of wood could be flung toward operator.

S Use a sawhorse to cut small logs. Never

allow another person to hold the log while

cutting and never hold the log with your leg

or foot.

S Do not cut in an area where logs, limbs,

and roots are tangled. Drag the logs into a

clear area before cutting by pulling out exposed and cleared logs first.

TYPES OF CUTTING USED

FOR BUCKING

WARNING: If saw becomes pinched

or hung in a log, don’t try to force it out. You

can lose control of the saw resulting in injury

and/or damage to the saw. Stop the saw,

drive a wedge of plastic or wood into the cut

until the saw can be removed easily. Restart

the saw and carefully reenter the cut. Do not

attempt to restart your saw when it is pinched

or hung in a log.

Turn saw OFF and use a plastic or

wooden wedge to force cut open.

Overcutting begins on the top side of the log

with the saw against the log. When overcutting use light downward pressure.

Overcutting

Undercutting

Undercuttinginvolves cutting on the underside of the log with top of saw against the log.

When undercutting use light upward pressure. Hold saw firmly and maintain control.

The saw will tend to push back toward you.

WARNING: Never turn saw upside

down to undercut. The saw cannot be controlled in this position.

First cut on pressure side of log

Second cut

First cut on pressure side of log

Second cut

BUCKING WITHOUT A

SUPPORT

S Overcut through 1/3 of the diameter of the

log.

S Roll the log over and finish with a second

overcut.

13

Page 14

WORKING TECHNIQUES

75

MANIPULACION DEL COMBUSTIBLE

ACEITE PARA MOTORES DE

DOS TIEMPOS

S Para un resultado y prestaciones óptimos,

utilice aceite para motores de dos tiempos

Universal, Universal powered by McCulloch,

especialmente fabricado para motores de

dos tiempos refrigerados por aire.

S No utilice nunca aceite para motores de

dos tiempos fuera borda refrigerados por

agua (llamado outboard oil), con desig-

nación TCW.

S No utilice nunca aceite para motores de

cuatro tiempos.

S Un aceite de calidad deficiente o una

mezcla de aceite/combustible demasiado

rica puede perjudicar el funcionamiento

del catalizador y reducir su vida útil.

MEZCLA

1:50 (2%) con aceite para motores de dos

tiempos Universal, Universal powered by

McCulloch.

1:33 (3%) con otros aceites para motores de

dos tiempos refrigerados por aire y clasifica-

dos para JASO FB/ISO EGB.

Aceite para motores de

Gasolina, litros dos tiempos, litros

2% (1:50) 3% (1:33)

5 0,10 0,15

10 0,20 0,30

15 0,30 0,45

20 0,40 0,60

MEZCLA

S Siempre haga la mezcla de gasolina y

aceite en un recipiente limpio, homo-

logado para gasolina.

S Primero, ponga la mitad de la gasolina que

se va a mezclar. Luego, añada todo el

aceite y agite la mezcla. A continuación,

añada el resto de la gasolina.

S Agite bien la mezcla de combustible antes

de ponerla en el depósito de combustible

de la máquina.

S No mezcle más combustible que el ne-

cesario para utilizar un mes como máximo.

S Si no se ha utilizado la máquina por un

tiempo prolongado, vacíe el depósito de

combustible y límpielo.

ACEITE PARA CADENA

• Para lubricar se recomienda un aceite es-

pecial (aceite para lubricar cadenas) con

buena aptitud adherente.

S No utilice nunca aceite residual. Puede

ocasionar averías en la bomba de aceite,

la espada y la cadena.

S Es importante utilizar un aceite adecuado

para la temperatura ambiente (con la vis-

cosidad correcta).

S Con temperaturas bajo cero, algunos

aceites se espesan. Ello puede causar

sobrecargas en la bomba de aceite, con

averías subsiguientes de las piezas de la

bomba.

S Para la selección de aceite lubricante de

cadena, consulte con su taller de servicio.

REPOSTAJE

ADVERTENCIA: Las siguientes

medidas preventivas reducen el riesgo de

incendio: no fume ni ponga objetos calientes

cerca del combustible; apague el motor y de-

je que se enfríe unos minutos antes de re-

postar; para repostar, abra despacio la tapa

del depósito de combustible para evacuar

lentamente la eventual sobrepresión; des-

pués de repostar, apriete bien la tapa del de-

pósito de combustible; antes de arrancar,

aparte siempre la máquina del lugar y de la

fuente de repostaje.

Seque minuciosamente alrededor de las

tapas de los depósitos. Limpie regularmente

los depósitos de combustible y de aceite

para cadena. Cambie el filtro de combustible

una vez al año como mínimo. La suciedad en

los depósitos produce perturbaciones del

funcionamiento. Asegúrese de que el com-

bustible esté bien mezclado, agitando el re-

cipiente antes de repostar. Las capacidades

de los depósitos de combustible y aceite

para cadena están adaptadas entre sí. Por

consiguiente, haga el repostaje de ambos al

mismo tiempo.

ADVERTENCIA: El combustible y

los vapores de combustible son muy inflam-

ables. Proceda con cuidado en la manipula-

ción del combustible y el aceite de cadena.

Tenga en cuenta el riesgo de incendio, ex-

plosión e inhalación.

S Give special attention to logs under strain

to prevent the saw from pinching. Make

the first cut on the pressure side to relieve

the stress on the log.

BUCKING USING A LOG OR

SUPPORT STAND

S Remember your first cut is always on the

pressure side of the log.

S Your first cut should extend

diameter of the log.

S Finish with your second cut.

Usingalogforsupport

2ndCut

Using a support stand

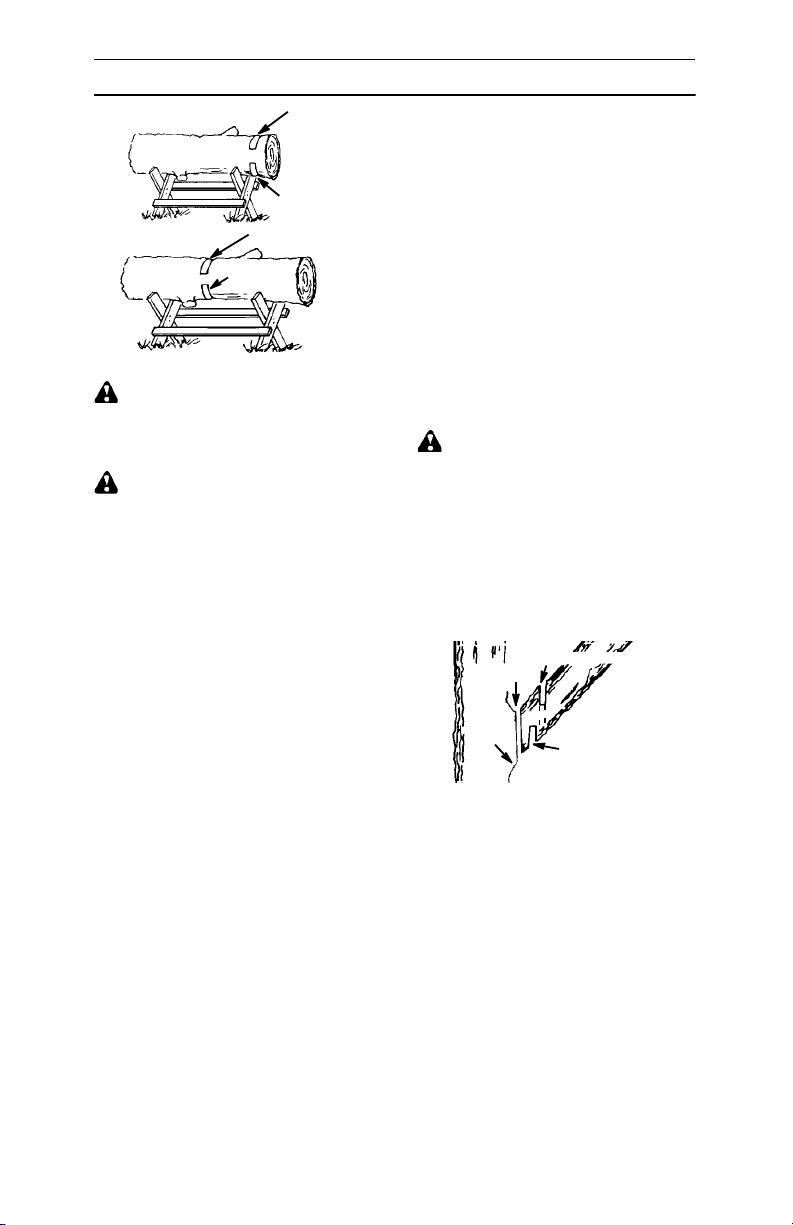

LIMBING AND PRUNING

WARNING: Be alert for and guard

against kickback. Do not allow the moving

chain to contact any other branched or objects

at the nose of the guide bar when limbing or

pruning. Allowing such contact can result in

serious injury.

nd

2

st

1

nd

2

nd

2

1/3 of the

Cut

1stCut

Cut

Cut

1stCut

1stCut

Cut

WARNING: Never climb into a tree to

limb or prune. Do not stand on ladders, platforms, a log, or in any position which can cause

you to lose your balance or control of the saw.

IMPORTANT POINTS

S Watch out for springpoles. Use extreme

caution when cutting small size limbs. Slender material may catch the saw chain and be

whipped toward you or pull you off balance.

S Be alert for springback. Watch out for

branches that are bent or under pressure.

Avoid being struck by the branch or the

saw when the tension in the wood fibers is

released.

S Keep a clear work area. Frequently clear

branches out of the way to avoid tripping

over them.

LIMBING

S Always limb a treeafter it is cut down. Only

then can limbing be done safely and properly.

S Leave the larger limbs underneath the

felled tree to support the tree as you work.

S Start at base of the felled tree and work to-

ward the top, cutting branches and limbs.

Remove small limbs with one cut.

S Keep the tree between you and the chain

as much as possible.

S Remove larger, supporting branches with

the cutting techniques described in BUCKING WITHOUT A SUPPORT.

S Always use an overcut to cut small and

freely hanging limbs. Undercutting could

cause limbs to fall and pinch saw.

PRUNING

WARNING: Limit pruning to limbs

shoulder height or below. Do not cut if

branches are higher than your shoulder.Get

a professional to do the job.

S Make your fist cut

the bottom of the limb.

S Next make a 2nd cut all the way through

the limb. Then cut a third overcut leaving

a 3 to 5 cm collar from the trunk of the tree.

Third cut

Collar

1/3 of the way through

Second cut

First cut

Pruning technique

14

Page 15

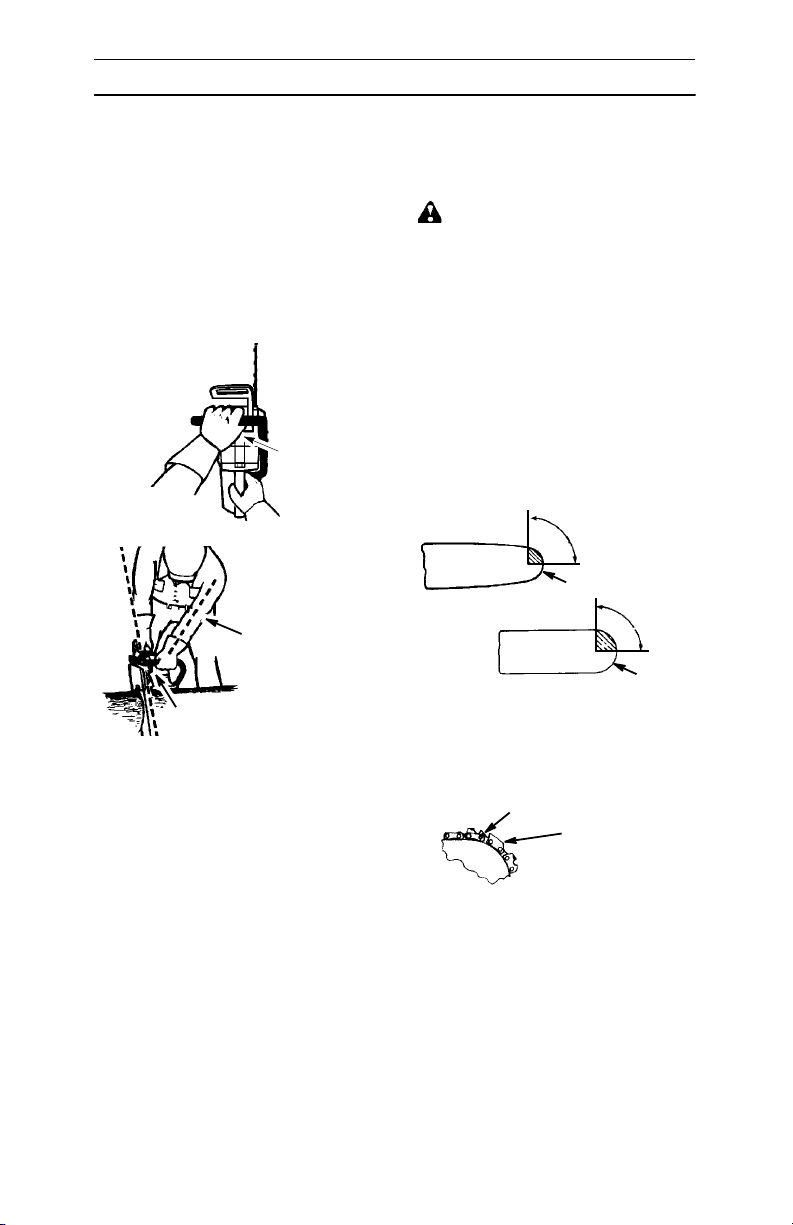

SERVICE AND ADJUSTMENTS

WARNING: Improper maintenance

could result in serious engine damage or in serious injury.

WARNING: Disconnect the spark

plug before performing maintenance, except

for carburetor adjustments.

We recommend all service and adjustments

not listed in this manual be performed by an

Authorized Service Dealer.

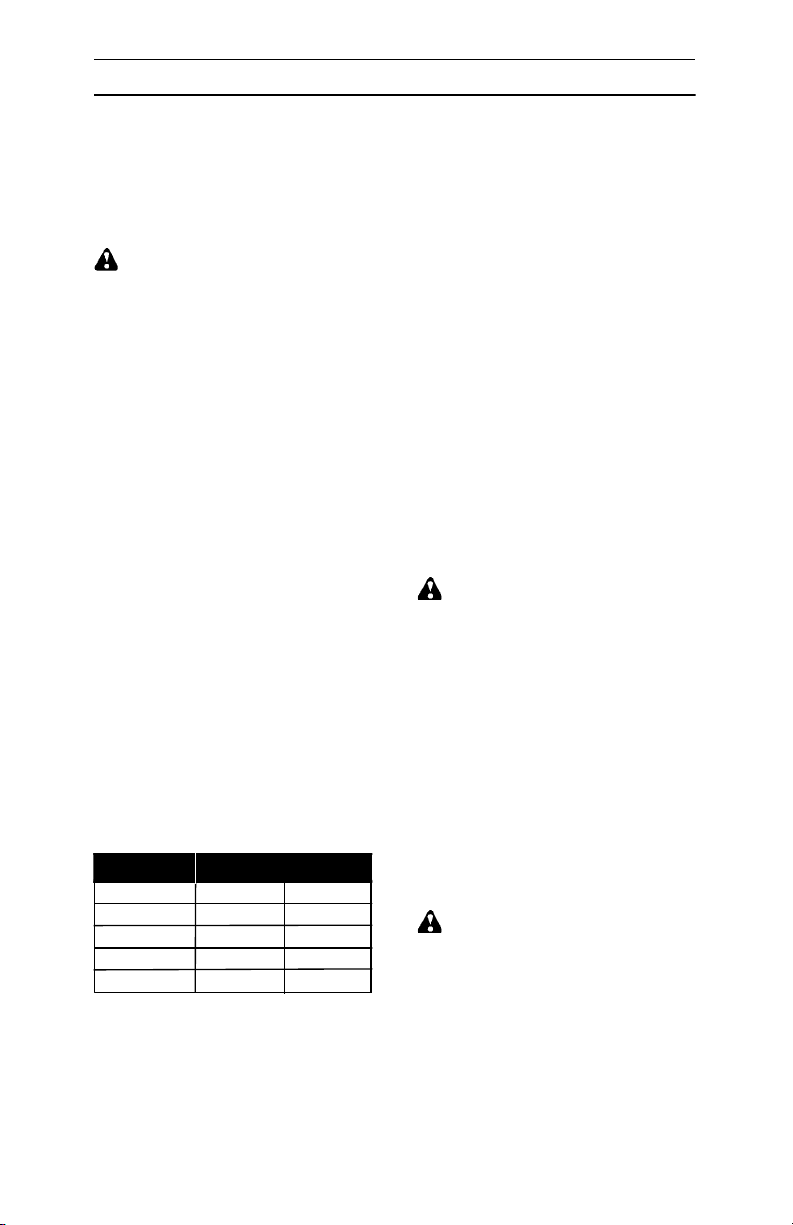

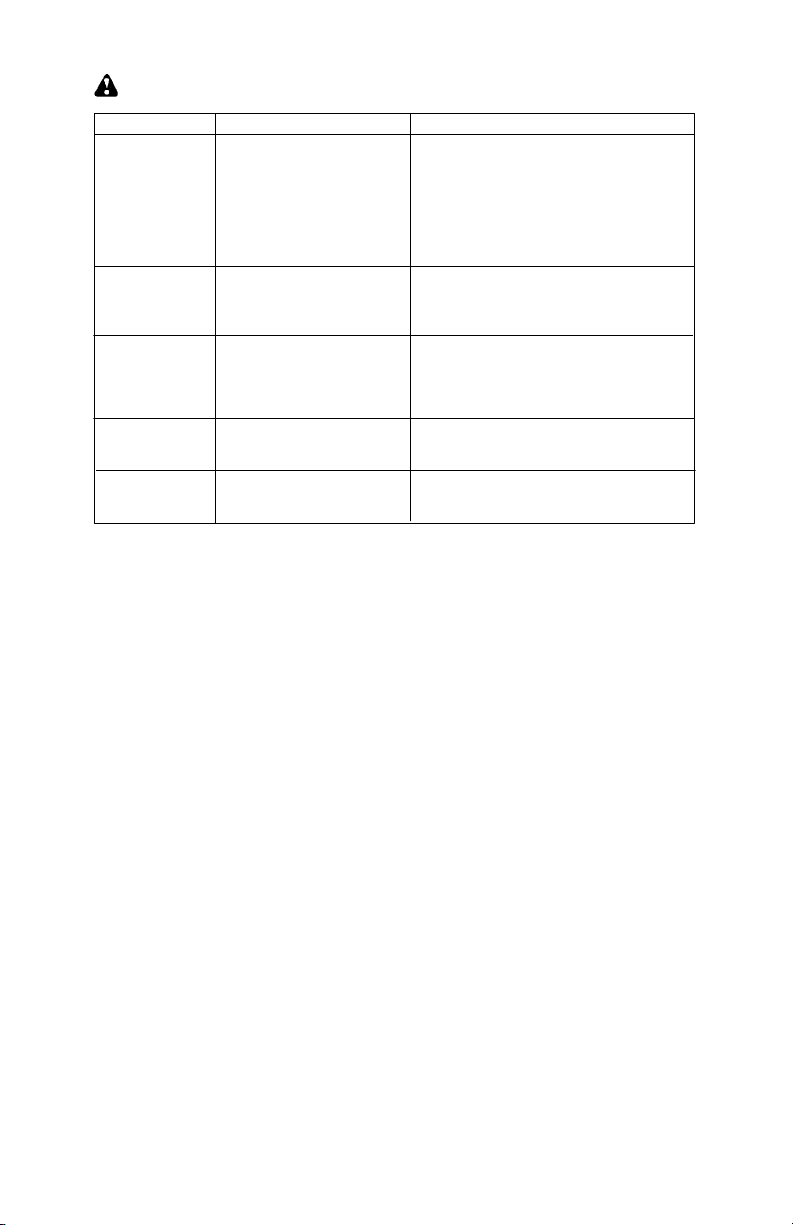

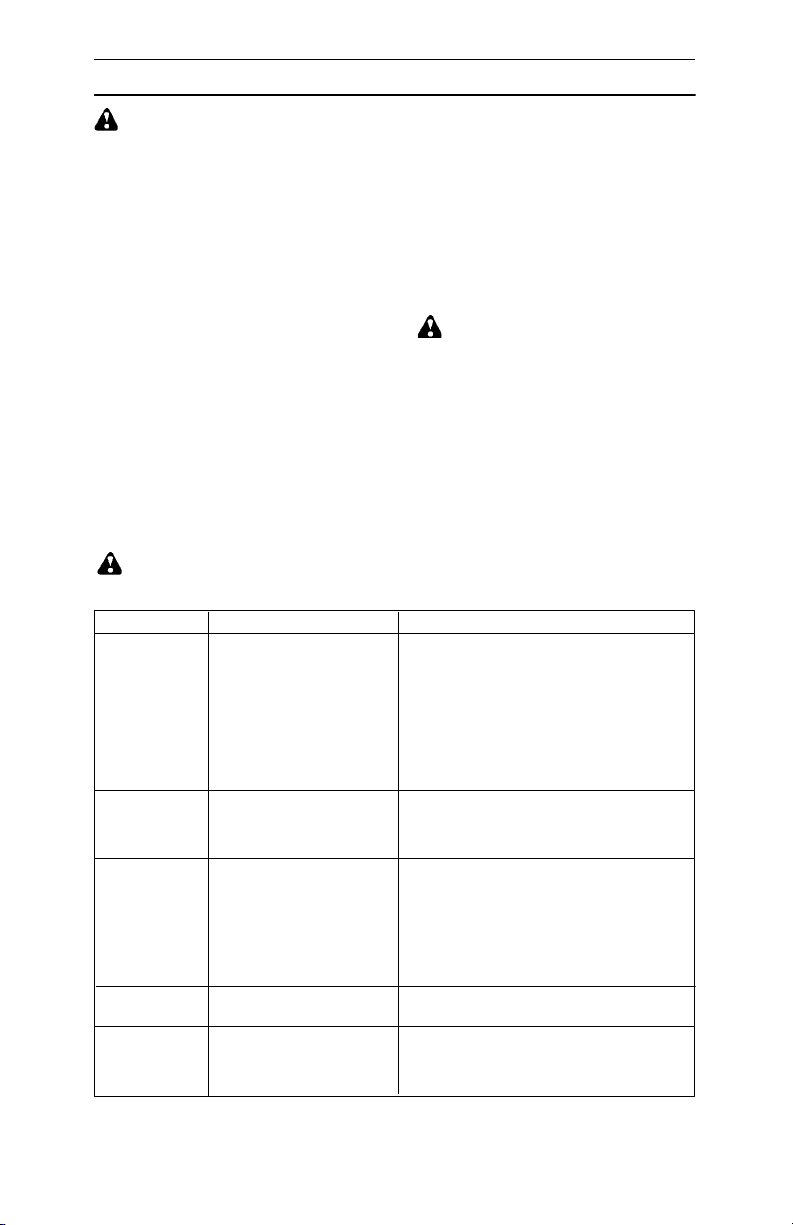

MAINTENANCE SCHEDULE

Check:

Fuel mixture level Before each use....

Bar lubrication Before each use.......

Chain tension Before each use.......

Chain sharpness Before each use....

For damaged parts Before each use..

For loose caps Before each use......

For loose fasteners Before each use...

For loose parts Before each use......

Inspect and Clean:

Bar Before each use................

Complete saw After each use.......

Air filter Every 5 hours*.............

Chain brake Every 5 hours*........

Spark arresting screen

and muffler Every 25 hours*.........

Replace spark plug Yearly.

Replace fuel filter Yea r ly...

*HoursofOperation

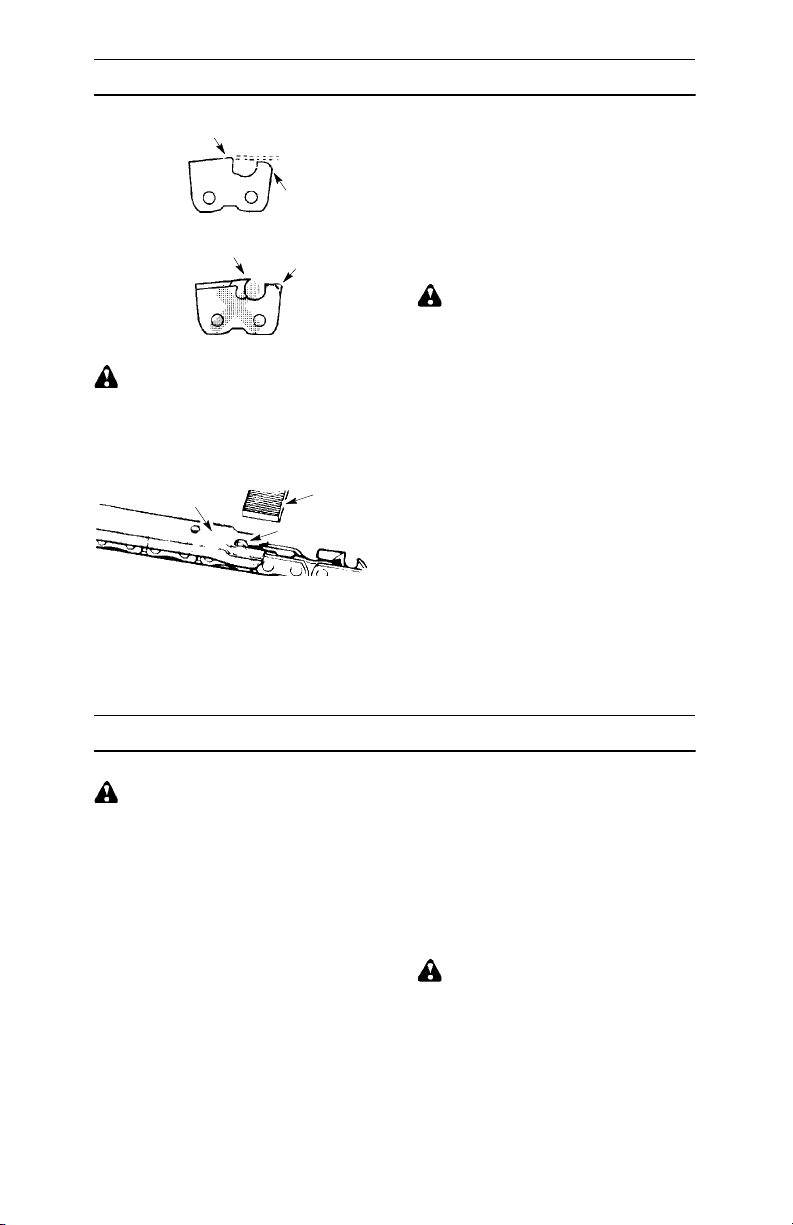

CHAIN BRAKE

WARNING: If the brake band is worn

too thin it may break when the chain brake is

triggered. With a broken brake band, the chain

brake will not stop the chain. The chain brake

should be replaced by an authorized service

dealer if any part is worn to less than 0,02″ (0,5

mm) thick. Repairs on a chain brake should be

made by an authorized service dealer. T ake

your unit to the place of purchase if purchased

from a servicing dealer, or to the nearest authorized master service dealer.

BRAKING FUNCTION CONTROL

CAUTION: The chain brake must be

checked several times daily. The engine

must be running when performing this procedure. This is the only instance when the saw

should be placed on the ground with the engine running.

Place the saw on firm ground. Grip the rear

handlewith your right hand and the front handle with your left hand. Apply full throttle by

fully depressing the throttle trigger. Activate

the chain brake by turning your left wrist

against the hand guard without releasing

your grip around the front handle. The chain

should stop immediately.

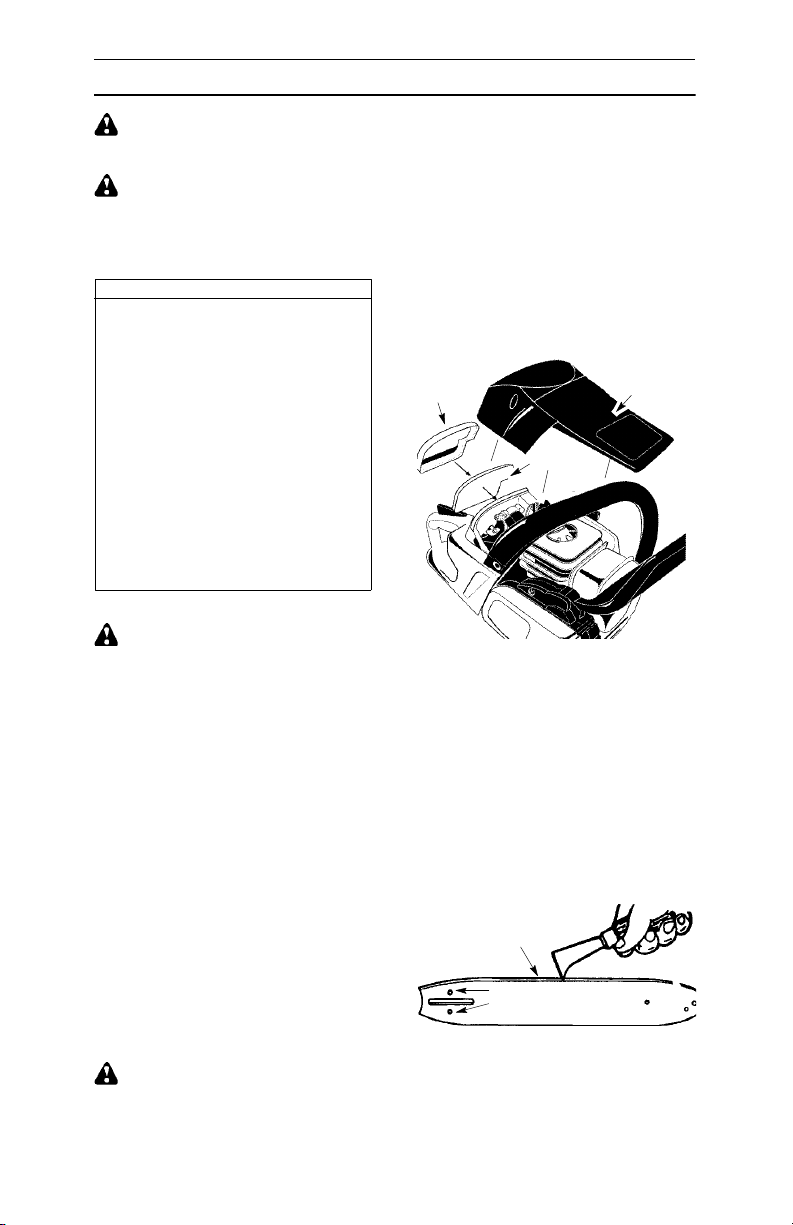

AIR FILTER

CAUTION: Do not clean filter in gaso-

line or other flammable solvent to avoid

creating a fire hazard or producing harmful

evaporative emissions.

Cleaning the air filter:

A dirty air filter decreases engine performance and increases fuel consumption and

harmful emissions. Always clean after every

5 hours of operation.

1. Clean the cover and the area around it to

keep dirt and sawdust from falling into

the carburetor chamber when the cover

is removed.

2. Remove the parts as illustrated.

3. Wash the filter in soap and water. Rinse

in clean cool water. Air dry completely

before reinstalling.

4. Reinstall parts.

Air Filter

Cover

Air Filter

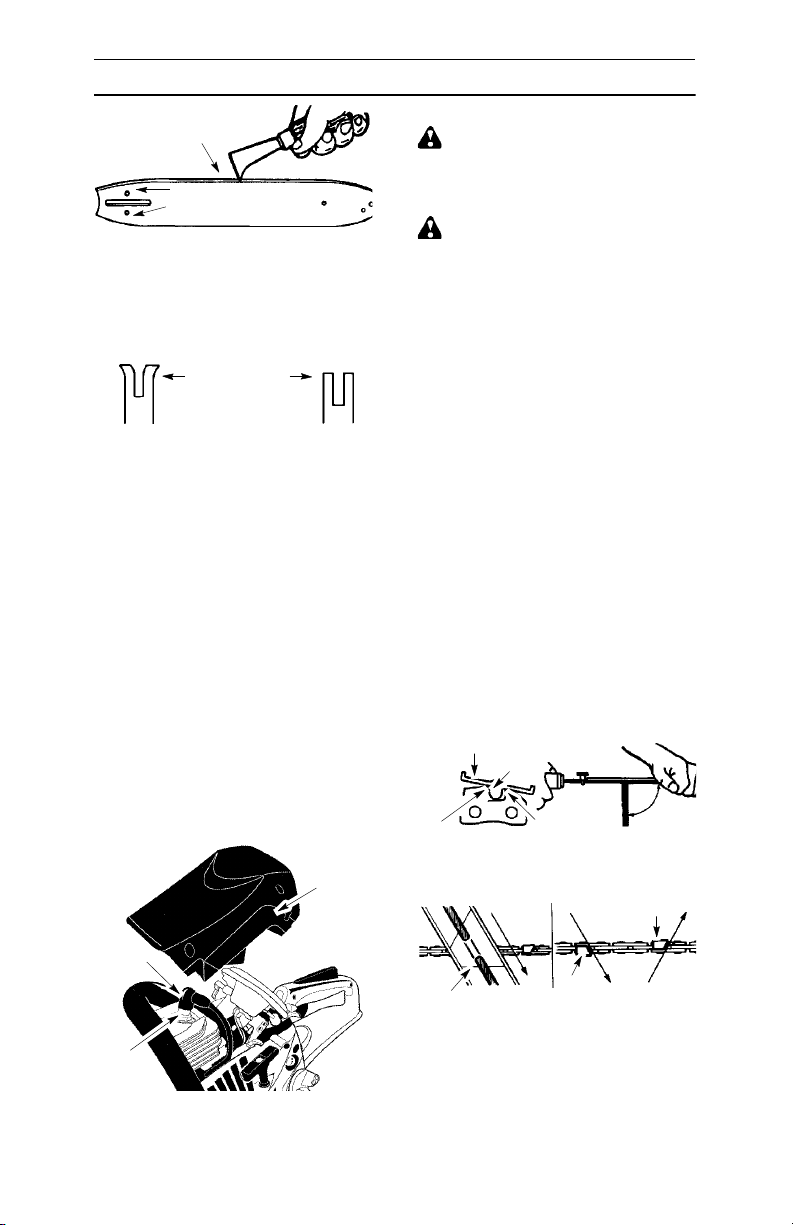

BAR MAINTENANCE

If your saw cuts to one side, has to be forced

through the cut, or been run with an improper

amount of bar lubrication it may be necessary to service your bar. A worn bar will damage your chain and make cutting difficult.

After each use, ensure ON/STOP switch is

in the STOP position, then clean all sawdust

from the guide bar and sprocket hole.

To maintain guide bar:

S Move ON/STOP switch to the STOP posi-

tion.

S Loosen and remove bar nuts and chain

brake. Remove bar and chain from saw.

S Clean the oil holes and bar groove after each

5 hours of operation.

Remove Sawdust From

Guide Bar Groove

Oil Holes

S Burring of guide bar rails is a normal

process of rail wear. Remove these burrs

with a flat file.

S When rail top is uneven, use a flat file to re-

store square edges and sides.

Cylinder

Cover

15

Page 16

SERVICE AND ADJUSTMENTS

A

73

MONTAJE

5. Haga deslizar la barra en los pernos de la

barra hasta que la barra se detenga al to-

car el engranaje del cilindro del em-

brague.

Barra g uía

Pernos de

la barra

6. Retire muy cuidadosamente la cadena

delpaquete. Sostenga la cadena con los

eslabones de impulsión orientados

como se ve en la ilustración.

Punta de

la Barra

Cuchillas

Eslabones

LAS CUCHILLAS

DEBERAN APUNTAR EN

DIRECCION A LA ROTACION

Cuchillas

Marcador de Profundidad

Eslabones de Funcionamiento

7. Coloque la cadena por encima y detrás del

seguidor del embrague, ponga las esla-

bones de funcionamiento en el cilindro del

embrague.

8. Coloque los eslabones de propulsión

entre los dientes del engranaje en la

punta de la barra.

9. Coloque los eslabones de propulsión en

la ranura de la barra.

10. Tire la barra hacia adelante hasta que la

cadena quede tirante en la ranura de la

barra. Asegure que todas los eslabones

depropulsión se encuentren en el ranura

de la barra.

11. Ahora instale la cubierta del embrague

asegurándose que la clavija de ajuste

esté posicionada en el orificio inferior en

la barra guía.

Barra guía

Orificio

inferior

Clavija

Cubierta

del

embrague

12. Instale las tuercas de la barra y ajústelas

a mano únicamente. Ajuste las tuercas

dela barra después de que la cadena es-

té tensionada.

TENSION DE LA CADENA (inclusive

losaparatosconlacadenayainstalada)

ADVERTENCIA: Use guantes

protectores para tocar la cadena. Lacadena

es muy filosa y puede cortar aun no estando

en movimiento.

NOTA: Al hacer ajuste a la tensión de la

cadena, asegúrese que las tuercas de la

barra estén ajustadas a mano únicamente.

Si intenta tensionar la cadena con las tuer-

cas de la barra ajustadas, puede dañar el

aparato.

Para verificar la tensión:

Use la punta destornilladora de la

herramienta doble para hacer girar la

cadena alrededor de la barra. Si la cadena

no gira, está demasiado tirante. Si está

demasiado floja, se la verá colgar separada

de la parte inferior de la barra.

Barra

guía

Tuercas de

la barra

Tornillo de

ajuste

Herramienta

de Ajuste de

la Cadena

(Herramienta

de la Barra)

Para ajustar la tensión:

La tensión de la cadena es muy importante. La

cadena se va estirando con el uso,

especialmente durante las primeras veces que

usa la sierra. V erifique sin falta la tensión de la

cadena caga vez que use la sierra y cada vez

que la abastezca de combustible.

Replace guide bar when the groove is worn,

the guide bar is bent or cracked, or when

excess heating or burring of the rails occurs.