McCall 9036 Service Manual

Display Cases

Service and Installation Manual

Please read this manual completely before attempting to install or operate this equipment!

Notify carrier of damage! Inspect all components immediately. See page 2.

Model 724, 7000, and 9000 Series

Effective May 2002

Display Cases 724, 7000, 9000 Series Service and Installation Manual

Display Cases 724, 7000, 9000 Series Service and Installation Manual

3

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

CONTENTS

RECEIVING AND INSPECTING ..............................................3

INSTALLATION......................................................................3

WALL MOUNT INSTALLATION..............................................4

WIRING DIAGRAMS .............................................................5

OPERATION ..........................................................................6

MAINTENANCE .....................................................................6

REPLACEMENT PARTS

7000 SERIES .................................................................7

MODEL 724 ...................................................................7

PIKE®-STYLE DOORS ................................................ 8-9

9000 SERIES ...............................................................10

TROUBLESHOOTING REFERENCE ......................................11

STANDARD WARRANTIES ............................................ 12-13

AUTHORIZED PARTS DEPOTS...............................back cover

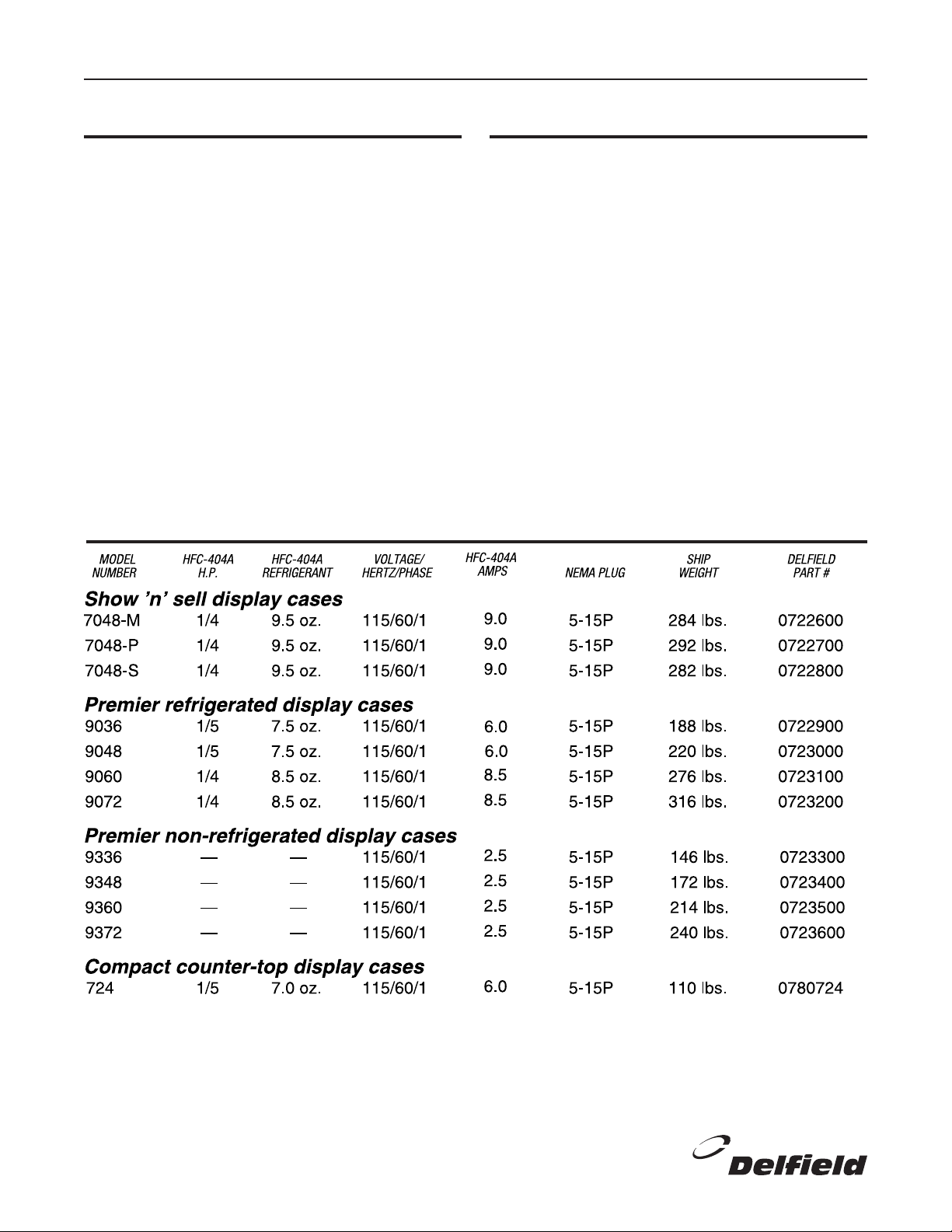

SPECIFICATIONS

SERIAL NUMBER LOCATION

724

Located on rear shroud panel below the power switches and

thermostat.

7000 & 9000

Located on the inside light xture on the right hand side.

Always have the serial number of your unit available when

calling for parts or service. A complete list of authorized parts

depots is shown on the back cover of this manual.

©2000 The Delfield Company. All rights reserved. Reproduction without

written permission is prohibited.

“Delfield” is a registered trademarks of The Delfield Company.

2

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

Display Cases 724, 7000, 9000 Series Service and Installation Manual

RECEIVING AND INSPECTING THE EQUIPMENT

Even though most equipment is shipped crated, care should be

taken during unloading so the equipment is not damaged while

being moved into the building.

Carefully check for any visible signs of damage to the cartons or

containers. If evidence of damage exists, the package should be

opened immediately and a joint inventory and examination of the

contents should be made by you and the driver. Sign delivery

receipt as damaged. Example— if (2) pieces of (5) are damaged, you must indicate the number of units damaged.

Concealed damage

If a concealed loss or damage is discovered after you have

given the carrier a clear delivery receipt, notify the carrier

in writing immediately or within 10 days from the delivery

INSTALLATION

Location

Deleld 7000 and 9000 Series and Model 724 display cases

should be installed on a level surface away from any source

of intense heat such as ovens or ranges. Do not install 9000

Series units closer than 6" (15.2 cm) from the ceiling or

counter. This will allow air ow to the machine compartment.

The 724 should be installed on legs as provided (4" [10.2 cm]

from the counter).

When using a Model 724 display case, never obstruct the

ow of air to the top of the cabinet. Do not place or store any

items on top surface of unit. Obstruction of air may cause

damage to the compressor.

On 7000 Series pass-through or see-through units, the cabinet can be installed with the machine compartment side ush

against a wall or obstruction as long as both the front and

the rear louvers are unobstructed. Do not install 7000 Series

mirrored units closer than 6" (15.2 cm) from the wall.

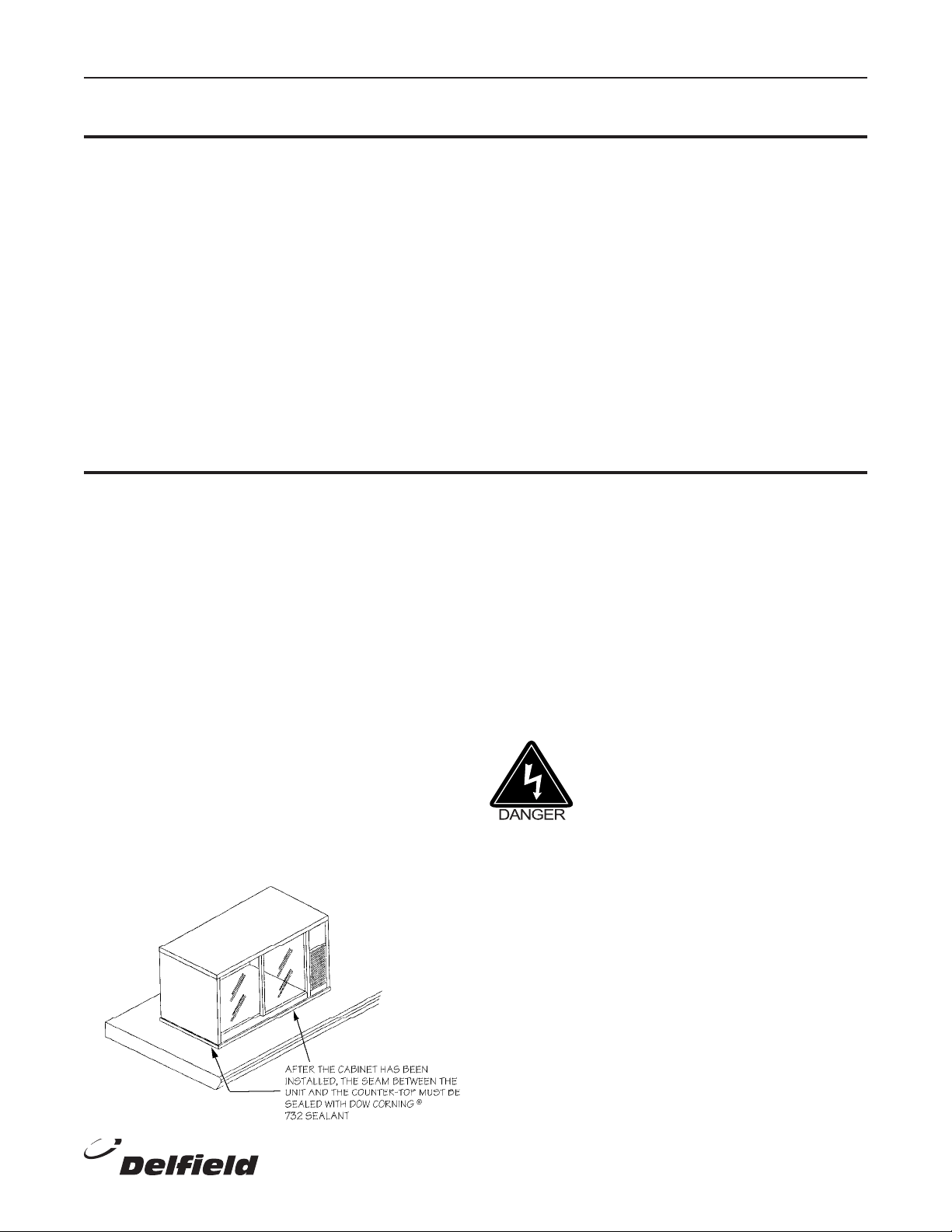

If installing a 7000 Series display case into a counter-top, you

must seal the perimeter of the equipment with silicone sealant (see diagram below).

date. If you phone the carrier, you must follow up the call

in writing to protect your rights. You can only improve your

position as a claimant by promptly reporting such loss or

damage. You should also retain all cartons or containers,

including packing material, until an inspection has been

made or waived.

Filing a claim

Notation of loss or damage does not constitute the ling of

a claim. You should le your claim in writing with the carrier

immediately!

Carriers will furnish the necessary form upon request. You

should also request an inspection. If a claim is led by phone,

always follow up immediately in writing.

For the most efcient refrigeration, be sure to provide good

air circulation inside and out. Take care not to block air ow

to the fans and allow space along the sides.

Do not pack the interior of the display case so full that air

cannot circulate.

Leveling

A level cabinet looks better and will perform better because

the doors will line up with the door frames properly, and the

cabinet will not be subject to unnecessary strain.

Electrical connection

Refer to the amperage data on page 2 or the

serial tag data and your local code or the

National Electrical Code to be sure the unit

is connected to the proper power source. A

protected circuit of the correct voltage and

amperage must be run for connection of the

line cord or permanent connection to the

unit.

The power should be disconnected whenever performing maintenance or repair

functions. Failure to observe this warning

may result in electrical shock and personal

injury!

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

3

Display Cases 724, 7000, 9000 Series Service and Installation Manual

Display Cases 724, 7000, 9000 Series Service and Installation Manual

5

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

ST PE S

S

T PE

S

WALL MOUNT INSTALLATION

7000 Series

The optional wall mount kit is designed to securely hold a

7000 Series unit to a structurally sound wall. It meets the

requirements as established by Underwriter’s Laboratories

of withstanding a static load of four times the weight of the

cabinet alone.

The Deleld Company cannot assume

any responsibility for damage to a wall

or injury of any persons should the wall

fail as a result of the unit’s weight. Nor

will The Deleld Company assume any

responsibility for damage or injury as a

result of the wall mount xture failing if it is

determined that the installation instructions

were not properly followed.

List of materials

2 — 2" x 2" x 3/16" (5.1 cm x 5.1 cm x 0.2 cm) angled

aluminum brackets, 48" (121.9 cm) long

12 — #10 x 7/8" type A hex head metal screws

6 — 1/4" x 2–1/2" lag bolts

2 — stainless steel trim pieces

1 Position the prepunched aluminum bracket

on the top of the unit, flush with the back

edge, and mark the location of the holes

on the unit. There should be one hole

approximately 5/8" (1.6 cm) from each end

of the cabinet, and a third hole 8.75" (22.2

cm) from the right end of the cabinet. Be

sure to use the prepunched holes; screws

in these locations tie into the internal

support structure of the unit.

2 Drill 9/64" (3.6 mm) holes at the locations

as marked. Attach the bracket to the unit

with three of the #10 sheet metal screws.

3 Mount the bottom bracket to the wall.

On a stud wall, the bottom bracket should be screwed into a

minimum of three studs with the provided 1/4" x 2–1/2" lag

bolts. On a masonry block wall, the bottom bracket should be

screwed into the wall at a minimum of three evenly spaced

locations with 1/4" diameter toggle bolts (not provided).

When positioning the bottom bracket, be sure to allow at

least 6" (15.2 cm) of clearance above and below the unit. Be

sure the bottom bracket is level before continuing.

4 Position the unit on the bottom bracket and

attach the top bracket to the wall using the

same method as in step 3.

5 Attach the bottom bracket to the unit using

the prepunched holes and three of the #10

sheet metal screws.

6 Attach the stainless steel trim strips to the

left and right sides of the cabinet using

three #10 metal screws on each side.

9000 Series

The Deleld Company cannot assume

any responsibility for damage to a wall

or injury of any persons should the wall

fail as a result of the unit’s weight. Nor

will The Deleld Company assume any

responsibility for damage or injury as a

result of the wall brackets failing if it is

determined that the installation instructions

were not properly followed.

When choosing a location to mount your 9000 Series display

case, keep in mind that the entire unit must be removed from

the wall in order to clean the condenser. This must be done

on a regular basis, in most cases not longer than every three

months. Install the equipment in a location that will allow

easy removal for cleaning.

1 Two wall brackets are supplied with 36" and 48"

long units; three brackets are supplied with 60"

and 72" long units. Lag bolts are not supplied

(see below for recommended sizes). Use all

brackets provided for a secure installation.

On a stud wall, the brackets should be screwed into two

studs with 1/4" lag bolts so that 2.50" (6.4 cm) of the lag

bolt engages the stud. On a masonry block wall, the brackets

should be screwed into the wall at two evenly spaced locations with 1/4" diameter toggle bolts.

When positioning the brackets, be sure to allow at least 6"

(15.2 cm) of clearance above and below the unit.

2 After the brackets are attached to the wall

with one bolt in each, check that they are

level. Finish mounting the brackets.

3 Once the brackets are secure, lift the unit

into place and engage the angle bracket on

the back of the unit into the wall brackets.

4

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

Display Cases 724, 7000, 9000 Series Service and Installation Manual

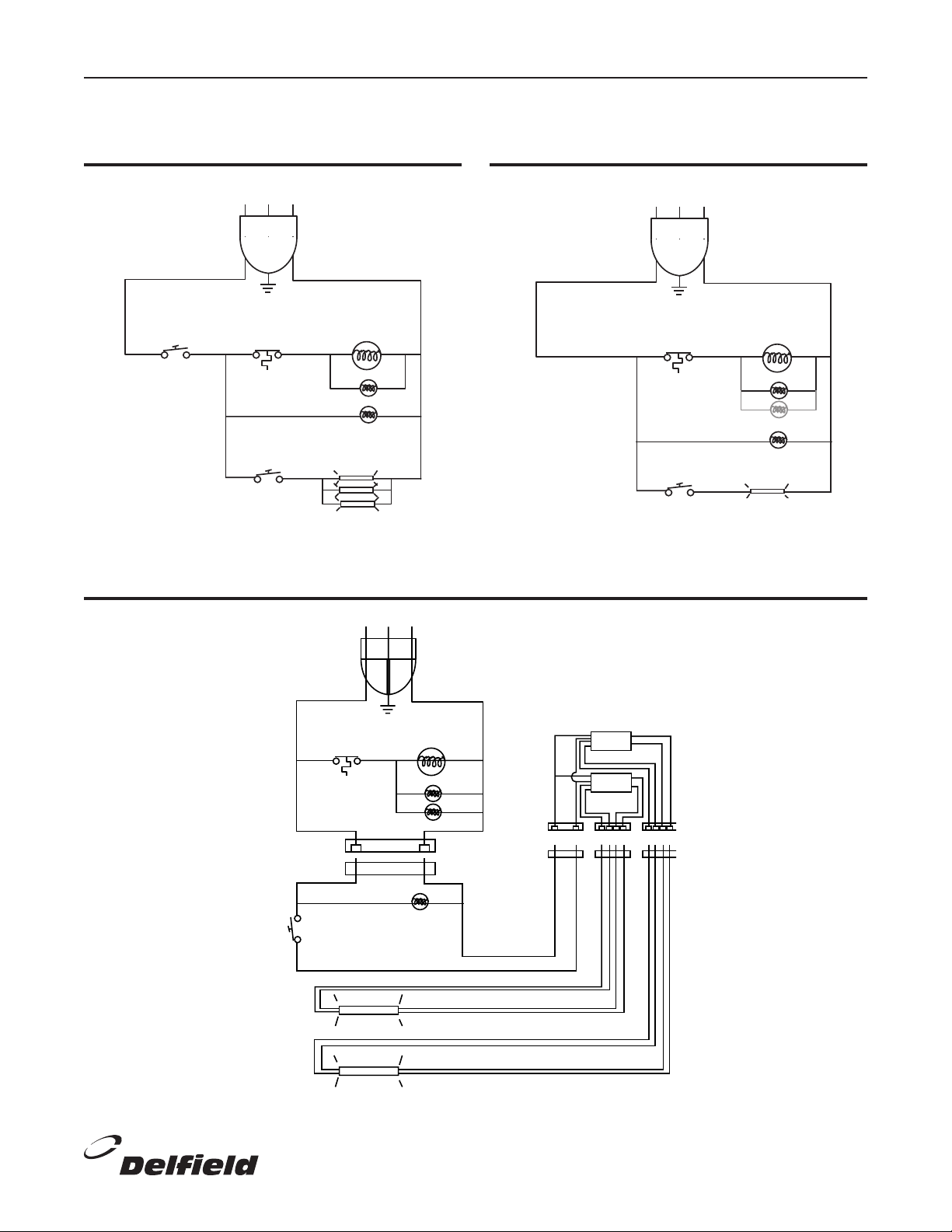

G

COMPRESSOR

WIRING

DIAGRAM FOR

115V/60Hz/1 ph

9000 SERIES

BLACK

WHITE

CONDENSER FANS

(2 on 9060 & 9072)

EVAPORATOR FAN

TEMPERATURE

CONTROL

LIGHT SWITCH

LIGHT

LIGHTS

G

COMPRESSOR

WIRING

DIAGRAM FOR

115V/60Hz/1 ph

MODEL 724

POWER

SWITCH

BLACK

WHITE

CONDENSER FAN

EVAPORATOR FAN

TEMPERATURE

CONTROL

LIGHT

SWITCH

G

COMPRESSOR

WIRING

DIAGRAM FOR

115V/60Hz/1 ph

7000 SERIES

BLACK WHITE

CONDENSER FANS

EVAPORATOR FAN

TEMPERATURE

CONTROL

LIGHT SWITCH

FLUORESCENT LAMPS

WHITE

BLACK

WALL

PLUG

BALLASTS

WALL

PLUGS

WIRING DIAGRAM—

MODEL 724

WIRING DIAGRAM—

9000 SERIES

WIRING DIAGRAM—7000 SERIES

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

5

Loading...

Loading...