MCC 50-2104, T50-2112 Service Manual

T-367 Manual

OPERATION/SERVICE MANUAL

© 2015 Mobile Climate Control

for

MCC Eco Xcel SERIES

T-367

REV. 05/2015

TABLE OF CONTENTS

SAFETY SUMMARY Safety--1.......................................................................

DESCRIPTION 1--1...............................................................................

1.1 INTRODUCTION 1--1.....................................................................

1.2 GENERAL DESCRIPTION 1--2.............................................................

1.2.1 Rooftop Unit 1--2......................................................................

1.2.2 Condensing Section 1--2...............................................................

1.2.3 Evaporator Sections 1--3...............................................................

1.2.4 MCC Microprocessor 1--3..............................................................

1.3 REFRIGERATION SYST EM COMPONENT SPECIFICATIONS 1-- 3.............................

1.4 ELECTRICAL SPECIFICATIONS -- MOTORS 1-- 3............................................

1.5 SAFETY DEVICES 1--4...................................................................

1.6 AIR CONDITIONING REFRIGERATION CYCLE 1--5..........................................

1.7 HEATING CYCLE 1--5....................................................................

OPERATION of MCC XCEL DRIVER DISPLAY 2--1...................................................

2.1 General Description 2--1...................................................................

2.2 STARTING, STOPPING AND OPERATING INSTRUCTIONS 2--1..............................

2.2.1 Starting 2--1..........................................................................

2.3 SEQUENCE OF OPERATION 2-- 2..........................................................

2.3.1 Function of Keys when “Engine On” and controller active: 2--2...............................

2.4 BASIC OPERATING INSTRUCTIONS 2--3..................................................

2.4.1 Display 2--3..........................................................................

2.4.2 Interior Set Point Temperature Control 2--3...............................................

2.4.3 Blower Speed Setting 2--3..............................................................

2.4.4 Mode Selection Descriptions 2--3........................................................

2.4.5 Capacity Control “Ladder” Diagrams 2--3.................................................

2.4.6 Display Settings 2--5...................................................................

2.4.7 HVAC Information Screens 2--6.........................................................

2.4.8 HVAC Diagnostics Screens 2--7.........................................................

2.4.9 HVAC Alarm Description 2--8...........................................................

2.5 MCC Eco NG Coolview 2-- 9...............................................................

2.5.1 Starting the MCC Coolview Application 2--10...............................................

2.5.2 Coolview Screen Layout 2--11...........................................................

2.5.3 Eco NG Display Pin out Description 2--16..................................................

2.5.4 Eco NG Controller Pin out Description 2--17...............................................

TROUBLESHOOTING 3--1.........................................................................

3.1 System Will Not Cool 3--1..............................................................

3.2 System Runs But Has Insufficient Cooling 3--1............................................

3.3 Abnormal Pressures 3--1...............................................................

3.4 Abnormal Noise Or Vibrations 3--1.......................................................

3.5 No Evaporator Air Flow Or Restricted Air Flow 3--2........................................

3.6 Expansion Valve Malfunction 3--2........................................................

3.7 Heating Malfunction 3--2...............................................................

SERVICE 4-1....................................................................................

4.1 MAINTENANCE SCHEDULE 4-1...........................................................

© 2015 Mobile Climate Control

1

T-367Rev . 05/2015

4.2 OPENING TOP COVER (EVAPORATORS) 4-2..............................................

4.3 REMOVING TOP COVERS (CONDENSER) 4-2.............................................

4.4 SUCTION AND DISCHARGE SERVICE VALVES 4-3.........................................

4.4.1 Installing R--134a Manifold Guage Set 4-4...............................................

4.4.2 SYSTEM PUMP DOWN FOR LOW SIDE REPAIR 4-6....................................

4.4.3. Removing Entire System Charge 4-7....................................................

4.5 REFRIGERANT LEAK CHECK 4-7.........................................................

4.6 EVACUATION AND DEHYDRATION 4-7....................................................

4.6.1 General 4-7..........................................................................

4.6.2 Preparation 4-7.......................................................................

4.6.3 Procedure for Evacuation and Dehydrating System (One Time Evacuation) 4-8...............

4.6.4 Procedure for Evacuation and Dehydrating System (Triple Evacuation) 4-8...................

4.7 CHECKING AND ADDING REFRIGERANT TO SYSTEM 4-8..................................

4.7.1 Checking Refrigerant Charge By Pressures 4-8...........................................

4.7.2 Checking Refrigerant Charge By Receiver Sight Glasses 4-9...............................

4.7.3 Adding Full Charge 4-9................................................................

4.7.4 Adding Partial Charge 4-11.............................................................

4.8 CHECKING SYSTEM FOR NON--CONDENSIBLES 4-11.......................................

4.9 CHECKING AND REPLACING HIGH OR LOW PRESSURE SWITCH 4-11.......................

4.10 FILTER--DRIER 4-12......................................................................

4.10.1 To Check Filter--Drier 4-12...............................................................

4.10.2 T o Replace Filter--Drier 4-12.............................................................

4.11 SERVICING THE LIQUID LINE SERVICE VALVE 4-12.........................................

4.11.1 Coil Replacement 4-13.................................................................

4.11.2 Internal Part Replacement 4-13..........................................................

4.11.3 Replace Entire LLS Valve 4-13...........................................................

4.12 THERMOSTATIC EXPANSION VALVE 4-14..................................................

4.12.1 Valve Replacement 4-14................................................................

4.12.2 Superheat Measurement 4-14...........................................................

4.13 REPLACING EVAPORATOR RETURN AIR FILTERS 4-15.....................................

4.14 COMPRESSOR MAINTENANCE 4-16.......................................................

4.14.1 Shaft Seal Reservoir 4-16...............................................................

4.14.2 Refrigerant Removal From An Inoperative Compressor. 4-16................................

4.14.3 Pump Down An Operable Compressor For Repair 4-16.....................................

4.14.4 Removing the Compressor 4-17.........................................................

4.14.5 Transferring Compressor Clutch 4-18.....................................................

4.14.6 Compressor Oil Level 4-19..............................................................

4.14.7 Checking Unloader Operation 4-19.......................................................

4.15 TEMPERATURE SENSOR CHECKOUT 4-21.................................................

4.16 PRESSURE TRANSDUCER CHECKOUT 4-21...............................................

4.17 REPLACING SENSORS AND TRANSDUCERS 4-21..........................................

ELECTRICAL 5--1................................................................................

5.1 INTRODUCTION 5--1.....................................................................

© 2015 Mobile Climate Control

2

T-367Rev . 05/2015

LIST OF TABLES

Table 1-- 1 Models 1--1.............................................................................

Table 1-- 2 Additional Support Manuals 1--1............................................................

Table 3-- 1 General System Troubleshooting Procedures 3--1............................................

Table 4-1 Temperature Sensor Resistance 4-21........................................................

Table 4-2 Pressure Transducer Voltage 4-22...........................................................

Table 4-3 R--134a Temperature -- Pressure Chart 4-23..................................................

LIST OF FIGURES

Figure1--1RooftopUnit(EcoXcel) 1--2.............................................................

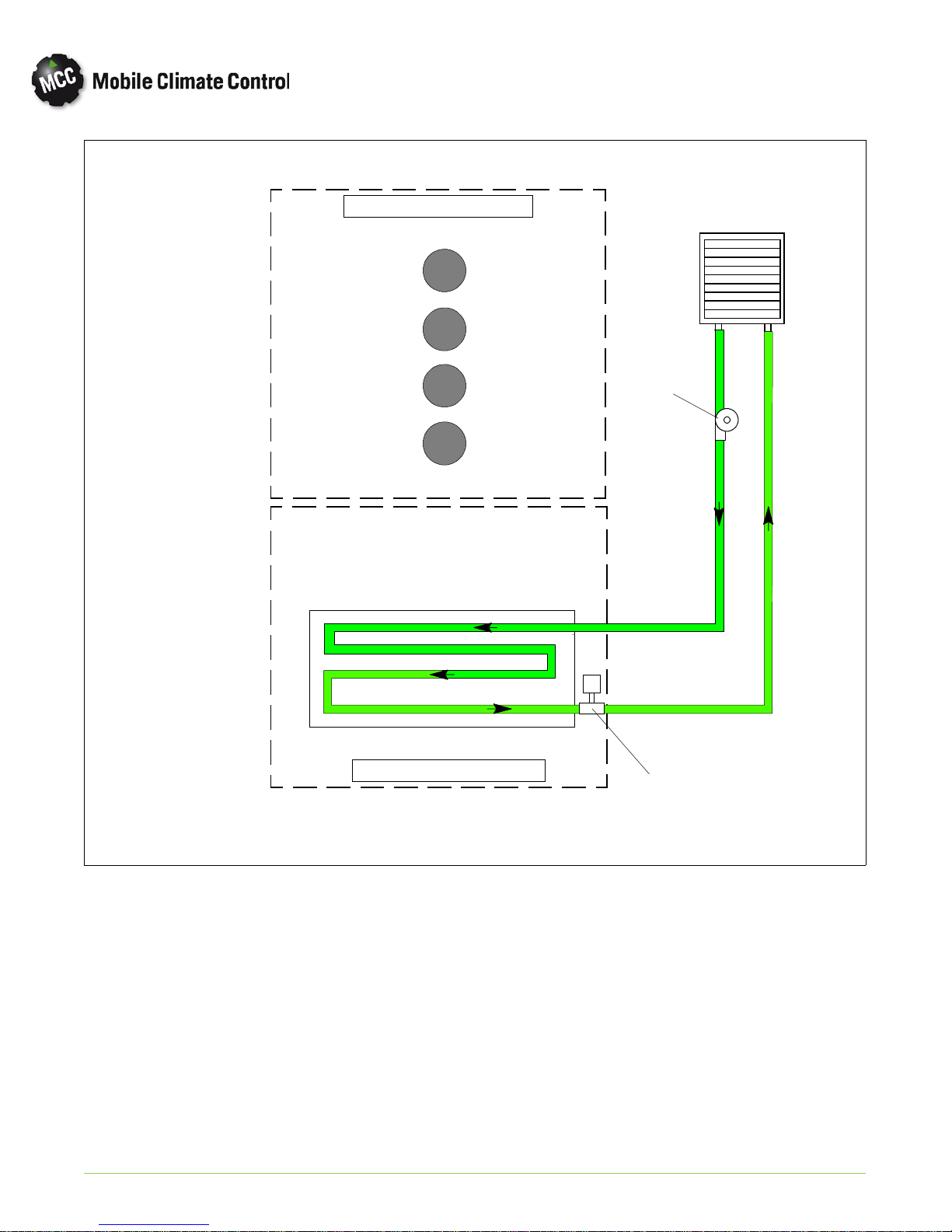

Figure 1--2 Refrigerant Flow Diagram 1--6...........................................................

Figure 1--3 Heat Flow Diagram 1--7.................................................................

Figure 2-1 Driver Display Module-- Control Layout 2--1................................................

Figure 2-2 Driver Display Module-- Display Layout 2--2................................................

Figure 2-3 Capacity Control Ladder Diagrams 2--4....................................................

Figure 2-4 HVAC DISPLAY SETTINGS 2--5..........................................................

Figure 2-5 HVAC INFORMATION SCREENS 2--6....................................................

Figure 2-6 HVAC DIAGNOSTIC SCREENS 2--7......................................................

Figure 2-7 MCC Eco NG Display Alarms 2--8........................................................

Figure 2-8 MCC Eco NG Coolview (Example Screenshot) 2--9.........................................

Figure 2-9 MCC Eco NG Coolview (VIEW Tab) 2--10...................................................

Figure 2-10 MCC Eco NG Coolview Inputs and Mode (VIEW Tab) 2--11..................................

Figure 2-11 MCC Eco NG Coolview Outputs (VIEW Tab) 2--12..........................................

Figure 2-12 MCC Eco NG Coolview Error List (ERROR Tab) 2--12.......................................

Figure 2-13 MCC Eco NG Coolview Statistics (HOURS Tab) 2-- 13.......................................

Figure 2-14 MCC Eco NG Coolview Simulation Mode 2--14.............................................

Figure 2-15 MCC Eco NG Coolview Data Logger 2--15.................................................

Figure 2-16 MCC Eco NG Display Pinout 2--16........................................................

Figure 2-17 MCC Eco NG ControllerPinout 2--17......................................................

Figure 4-1 Opening Top Cover (Evaporator) 4-2......................................................

Figure 4-2 Removing Top Covers (Condenser) 4-2...................................................

Figure 4-3 Suction or Discharge Service Valve 4-3...................................................

Figure 4-4 Manifold Gauge Set (R--134a) 4-4........................................................

Figure 4-5 Service Connections 4-5................................................................

Figure 4-6 Rule of Thumb 4-8.....................................................................

Figure 4-7 Service Connections 4-10................................................................

Figure 4-8 Checking High Pressure Switch 4-11.......................................................

Figure 4-9 Filter--Drier Removal 4-12................................................................

Figure 4-10 Liquid Line Solenoid Valve 4-13..........................................................

Figure 4-11 Thermostatic Expansion Valve Bulb and Thermocouple 4-14.................................

Figure 4-12. Compressor Service Connections 4-16...................................................

Figure 4-13. Compressor Service Connections 4-16...................................................

Figure 4-14. Compressors 4-17.....................................................................

© 2015 Mobile Climate Control

3

T-367Rev . 05/2015

LIST OF FIGURES (Continued)

Figure 4-15. Removing Bypass Piston Plug 4-17......................................................

Figure 4-16. Compressor Clutch 4-18................................................................

Figure 4-17 Transducer Terminal Location 4-21.......................................................

Figure 5--1 Schematic 50--2104S 5--2...............................................................

Figure 5--2 Schematic T50--21 12S 5--3..............................................................

© 2015 Mobile Climate Control

4

T-367Rev . 05/2015

SAFETY SUMMARY

GENERAL SAFETY NOTICES

The following generalsafety notices supplement the specific warnings and cautions appearing elsewhere in

this manual. They are recommended precautions that must be understood and applied during operation

and maintenanceof the equipment covered herein. A listingof the specificwarningsand cautions appearing

elsewhere in the manual follows the general safety notices.

FIRST AID

An injury, no matter how slight, should never go unattended. Always obtain first aid or medical attention

immediately.

OPERATING PRECAUTIONS

Always wear safety glasses.

Keep hands, clothing and tools clear of the evaporator and condenser fans.

No work should be performed on the unit until all start-stop switches are placed in the OFF position, and

power supply is disconnected.

Always work in pairs. Never work on the equipment alone.

In case of severe vibration or unusual noise, stop the unit and investigate.

MAINTENANCE PRECAUTIONS

Beware of unannounced starting of the evaporator and condenser fans. Do not open the unit cover before

turning power off.

Be sure power is turned off before working on motors, controllers, solenoid valves and electrical controls.

Tag circuit breaker and power supply to prevent accidental energizing of circuit.

Do not bypass any electrical safety devices, e.g. bridging an overload, or using any sort of jumper wires.

Problems with the system should be diagnosed, and any necessary repairs performed by qualified service

personnel.

When performing any arc welding on the unit, disconnect all wire harness connectors from the modules in

the control box. Do not remove wire harness from the modules unless you are grounded to the unit frame

with a static-safe wrist strap.

In case of electrical fire, open circuit switch and extinguish with CO2(never use water).

© 2015 Mobile Climate Control

Safety--1

T-367 Rev. 05/2015

SPECIFIC WARNINGS AND CAUTIONS

WARNING

Use of an electro-magnetic valve as a means of positive shutoff for service is not recom

mended for safety, or good service practice.

WARNING

Be sure to observe warnings listed in the safety summary in the front of this manual be

fore performing maintenance on the hvac system

WARNING

Read the entire procedure before beginning work. Park the vehicle on a level surface,

with parking brake applied. Turn main electrical disconnect switch to the off position.

WARNING

Do Not Use A Nitrogen Cylinder Without A Pressure Regulator

WARNING

Do Not Use Oxygen In Or Near A Refrigeration System As An Explosion May Occur.

WARNING

The Filter-drier May Contain Liquid Refrigerant. Slowly Loosen The Connecting Nuts And Avoid Con

tact With Exposed Skin Or Eyes.

CAUTION

The 50-2104 Rooftop Systems have R134a service port couplings installed on the compressor and on the unit

piping.

CAUTION

To prevent trapping liquid refrigerant in the manifold gauge set be sure set is brought to suction pres

sure before disconnecting.

© 2015 Mobile Climate Control

Safety--2

T-367 Rev. 05/2015

SECTION 1

DESCRIPTION

1.1 INTRODUCTION

This manual contains Operating Instructions,

Service Instructions and Electrical Data for the

EcoXcel Model Air Conditioning and Heating

equipment furnished by Mobile Climate Control as

showninTable1-1.

The system is identified with a Model/Serial number

tag located inside the evaporator section, on the rear

bulkhead wall of the assembly. Example is shown in

Figure 1-1.

Models consists of a Rooftop unit containing the

condensing section, the evaporator sections and

Table 1-1 Models

Model

50-2104 24 VDC

T50-2112 24 VDC

Voltage Controller With Heat Single Loop W/Covers

MCC EcoTemp NG

Microprocessor

MCC EcoTemp NG

Microprocessor

engine compartment mounted compressor. To

complete the system, the air conditioning and

heating equipment interfaces, electrical cabling,

refrigerant piping, engine coolant piping (for

heating), duct work and other components

furnishedby Mobile Climate Control and/or the bus

manufacturer.

Additional support manuals are shown in Table 1-2.

Operation of the unit is controlled automatically by a

Mobile Climate Control Microprocessor based

controller. The controls maintain the vehicle's

interior temperature at the desired set point.

Yes X X

Yes X X

Table 1-2 Additional Support Manuals

MANUAL NUMBER

T-367PL Eco Xcel Models Service Replacement Parts List

EQUIPMENT COVERED TYPE OF MANUAL

© 2015 Mobile Climate Control

1--1

T-367Rev. 05/2015

1.2 GENERAL DESCRIPTION

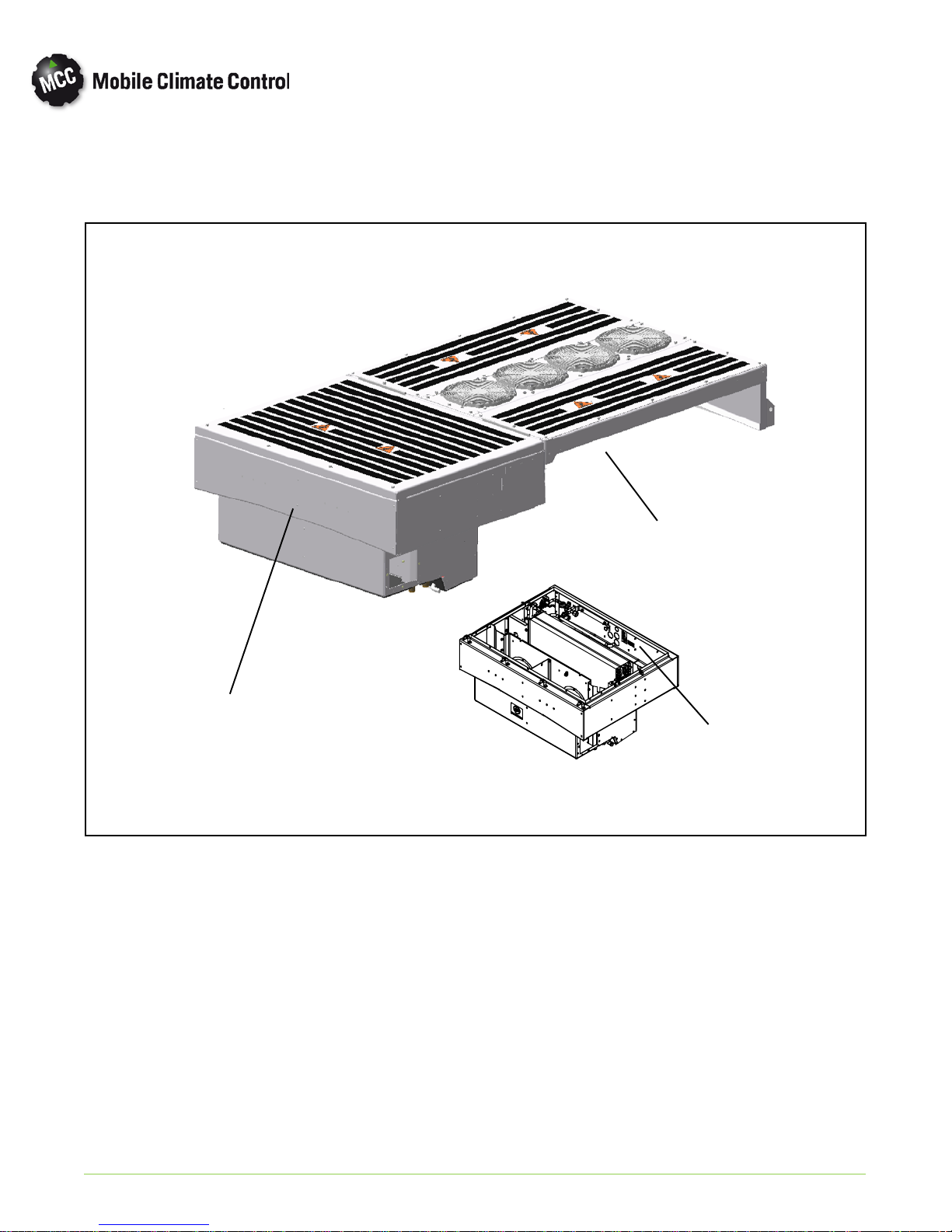

1.2.1 Rooftop Unit

The rooftop unit includes the condenser section and the evaporator sections (See Figure 1-1).

Condenser Section

Evaporator Section

Figure 1-1 Rooftop Unit (Eco Xcel)

1.2.2 Condensing Section

The condensing section includes 2 micro-channel

condenser coils, four (4) fan and motor assemblies

and receiver tank assembly with sight glasses,

moisture indicator and fusible plug

The condenser coils provideheat transfer surface for

condensing refrigerant gas at a high temperature and

pressure into a liquid at high temperature and

pressure. The condenser fans circulate ambient air

across the outside of the condenser tubes at a

temperature lower than refrigerant circulating inside

the tubes; this results in condensation of the

refrigerant into a liquid. The receiver tank is also

EVAPORATOR SECTION

Interior Location

Model/Serial Number Plate

equipped with a pressure relief valve (fusible plug)

which protects the system from unsafe high pressure

conditions. The filter-drier,located in the evaporator

section,removes moisture and debris from the liquid

refrigerant before it enters the thermostatic

expansion valve in the evaporator assembly.

a. Condenser fan operation

Low Speed ON: 150 psig (10.31 bar)

Low Speed OFF: 120 psig (8.27 bar)

High Speed ON: 225 psig (15.51 bar)

High Speed OFF: 165 psig (11.38 bar)

© 2015 Mobile Climate Control T-367Rev. 05/2015

1--2

1.2.3 Evaporator Sections

The evaporator section includes the evaporator coil,

two (2) blower motor assemblies, thermostatic

expansion valve, heater coil assembly, heater valve,

filter/drier, service valves and condensate drain

connections.

The evaporator coil provides heat transfer surface

for transferring heat from air circulating over the

outside of the coil to refrigerant circulating inside the

tubes; thus providing cooling. The heating coils

provide a heat transfer surface for transferring heat

from engine coolant water circulating inside the

tubes to air circulatingover the outside surface of the

tubes, thus providing heating. The fans circulate the

air over the coils. The air filters (OEM supplied)

remove dirt particles from the air before it passes

over the coils. The thermostatic expansion valve

meters the flow o f refrigerant entering the

evaporator coils. The heat valve controls the flow of

engine coolant t o the heating coils upon receipt of a

signal from the controller. The condensate drain

connections provide a means for connecting tubing

for disposing of con densate collected on the

evaporator coils during cooling operation.

1.2.4 MCC Microprocessor

The MCC controller maintains desired temperature

set point by controlling compressor capacity, fan

speeds and heat valve operation. Refer to Section 2,

for operational sequences.

1.3 REFRIGERATION SYSTEM COMPONENT SPECIFICATIONS

a.System Capacity: Cooling - 120,000 Btu/Hr (35 kW)

Heating - 126,000 Btu/Hr (37 kW)

b. Refrigerant Charge R-134a (Approximate)

NOTE

Refrigerant charge will depend on hose

lengths and diameters; or if there is an InDash unit (front evaporator). The following

should only be used as a guideline.

c. Compressor

Compressor

No. Of Cylinders 6

Weight, (Dry) With Clutch 145 Lbs. (66 kg)

Oil Charge

d. Thermostatic Expansion Valve:

7 Ton Capacity- Adjustable

e. High Pressure Switch (HPS)

Opens at: 360 ±10 psig (24.82 ±0.68bar)

Closes at: 285 ±15 psig (19.65 ±0.68bar)

f. Low Pressure Switch (LPS)

Opens at: 6 ±3psig (0.41 ±0.20 bar)

Closes at: 25 ±3psig(1.7±0.20 bar)

g. Water Temperature Switch (WTS) (If Equipped)

[Bus Manufacturer Supplied - Suggested close on tempera

ture rise at 105°F(41°C)]

Normally Closed

Normally Open

05G

5.5 pints

(2.6 liters)

1.4 ELECTRICAL SPECIFICATIONS - MOTORS

a. Evaporator Blower/Motor

Evaporator Motor

Full Load Amps (FLA) ~25

Bearing L ubrication

b. Condenser Fan Motor

Condenser Motor

Full Load Amps (FLA) ~7

Bearing L ubrication

c. Temperature Sensors (All)

Input Range: -40 to 167° F(-40to75°C)

Output: NTC 10K ohms at 77° F(25°C)

d. Ambient Sensor (Controls Compressor Outputs)

Brushless

24 VDC

Factory Lubricated

(additional grease not required)

Brushless

24 VDC

Factory Lubricated

(additional grease not required)

50-2104 with 05G Compressor

13 ± 0.5 Pounds (5.9 ± 0.23 kg)

© 2015 Mobile Climate Control

1--3

Opens at: 43° F(6.1°C)

Closes at: 47° F(8.3°C)

T-367Rev. 05/2015

1.5 SAFETY DEVICES

System components are protected from damage

caused by unsafe operating conditions with safety

devices. Safety devices with Mo b ile Climate Contro l

supplied equipment include high pressure switch

(HPS), low pressure switch (LPS), fusible plug,

circuit breakers and fuses.

a. Pressure Switches

High Pressure Switch (HPS)

During the air conditioning cycle, compressor clutch

operation will automatically stop if the HPS switch

contacts open due to an unsafe operating condition.

Opening HPS contacts de-energizes the compressor

clutch shutting down the compressor. The high

pressure switch (HPS) is installed at the compressor

assembly. See paragraph 1.3 for specifications.

Low Pressure Switch (LPS)

The low pressure switch is installed on the

compressor assembly and opens on a pressure drop

to shut down the system when a low p ressure

condition occurs. See paragraph 1.3 for

specifications.

Defrost Mode

Opens Compressor Output at: 28° F(-2.2°C)

Closes Compressor Output at: 32° F(0°C)

The ambient tem p erature sensor measures the

condenser inlet air temperature. These settings

protect the compressor from damage caused by

operation at low pressures.

d. Unloader Operation

The compressor is equipped with two unloaders to

allow compressor operation at 33%, 66% or 100%

capacity.

Low Pressure Control

Energizes Unloader Output 1 (Unloads) at: 25 psig (1.7

bars)

De-energizes Unloader Output1 (Loads) at: 32 psig (2.2

bars)

Energizes Unloader Output 2 (Unloads) at: 21 psig (1.4

bars)

De-energizes Unloader Output1 (Loads) at: 28 psig (1.9

bars)

b. Fuses and Circuit Breakers

The Relay Bo ard is protected against high current by

an OEM supplied circuit breaker or fuse located in

the bus battery compartment (100 Amp for 24 VDC

systems is recommended). Independent fuses and

circuit breakers protect electrical circuits from high

current conditions. During a high current condition,

the circuit protection may open.

c. Ambient Lockout

Auto Mode

Opens Compressor Output at: 43° F(6.1°C)

Closes Compressor Output at: 47° F(8.3°C)

High Pressure Control (below 87 F (30.8C)

Energizes Unloader Output (Unloads) at: 300 psig (20.7

bars)

High Pressure Control (above 92 F (33.6C)

Energizes Unloader Output (Unloads) at: 320 psig (23.4

bars)

In response to the high pressure conditions

above, the unloader remains energized for 2

minutes. Once the pressures return below the

parameters listed, the unloader circuit will de-en

ergize.

© 2015 Mobile Climate Control T-367Rev. 05/2015

1--4

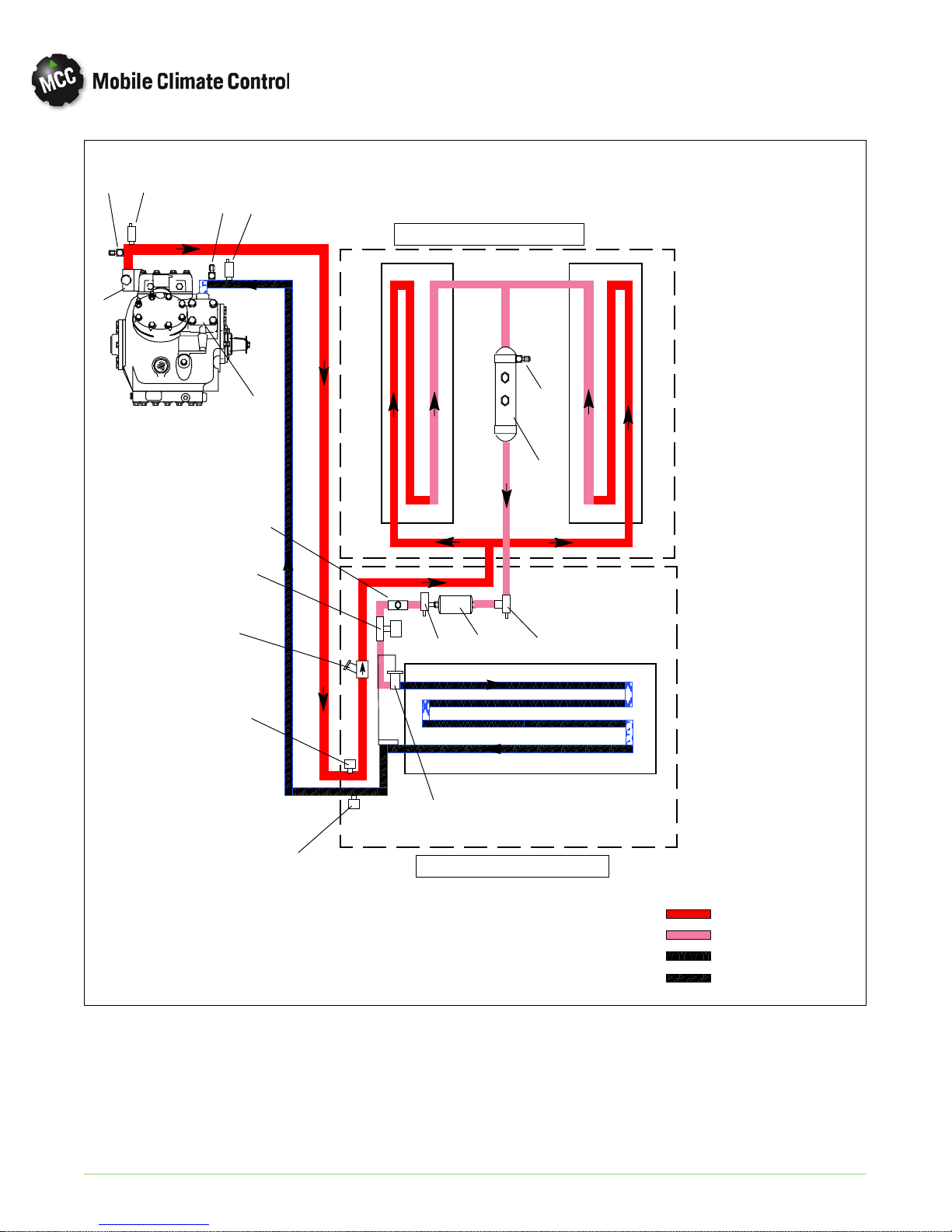

1.6 AIR CONDITIONING REFRIGERATION CYCLE

When air conditioning (cooling) is selected by the

controller, the unit operates as a vapor compression

system using R-134a as a refrigerant (See Figure 1-2

refrigerant flow diagram). The main components of

the system are the A/C compressor, air-cooled

condenser coils, filter-drier, thermostatic expansion

valve, liquid line solenoid valve and evaporator coils.

The compressor raises the pressure and the

temperature of the refrigerant and forces it into the

condenser tubes. The condenser fan circulates

surrounding air (which is at a temperature lower than

the refrigerant) over the outside of the condenser

tubes. Heat transfer is established from the

refrigerant (inside the tubes) to the condenser air

(flowing over the tubes). The condenser tubes have

fins designed to improve the transfer of heat from

the refrigerant gas to the air; this removal of heat

causes the refrigerant to liquefy, thus liquid

refrigerant leaves the condenser and flows to the

filter-drier.

The refrigerant passes through a filter-drier where a

desiccant keeps the refrigerant clean and dry.

From the filter-drier,the liquid refrigerantthen flows

through the liquid line to the sight-glass and then to

the thermostatic expansion valve. The thermal

expansion valvereduces pressure and temperature of

the liquid and meters the flow of liquid refrigerant to

the evaporator to obtain maximum use of the

evaporator heat transfer surface.

The low pressure, low temperature liquid that flows

into the evaporator tubes is colder than the air that is

circulated over the evaporator tubes by the

evaporatorfans. Heat transferis established from the

evaporator air (flowing over the tubes) to the

refrigerant (flowing inside the tubes). The

evaporator tubes have aluminum fins to increase

heat transfer from the air to the refrigerant;therefore

the cooler air is circulated to the interior of the bus.

The transfer of heat from the air to the low

temperature liquid refrigerant in the evaporator

causes the liquid to vaporize. This low temperature,

low pressure vapor passes through the suction line

and returns to the compressor where the cycle

repeats.

1.7 HEATING CYCLE

Heating circuit (See Figure 1-3) components

furnished by Mobile Climate Control include the

heater cores and solenoid operated heat valve.

Components furnished by the bus manufacturer

may include a water temperature switch (WTS),

boost water pump and floor blower convectors.

The controller automatically controls the heat valves

during the heating mode to maintain required

temperatures inside the bus. Engine coolant (glycol

solution) is circulated through the heating circuit by

the engine and an auxiliary boost water pump. When

the heat valve solenoids are energized, the valves will

open to allow engine coolant to flow through the

heater coils. The valves are normally closed.

NOTE: In order to ensure water is entering the

heater coils sufficiently heated, it is suggested that the

OEM supplied Water Temperature Switch (WTS),

(If equipped) close on temperature rise at 105°F

(40.5°C).

© 2015 Mobile Climate Control

1--5

T-367Rev. 05/2015

1

6

2

7

CONDENSER SECTION

3

4

10

14

5

11

13

12

9

16

15

12

8

1. High Pressure Switch

2. Low Pressure Switch

3. Discharge Service Valve

4. Suction Service Valve

5. Discharge Check Valve

6. Service Port, (High Side)

7. Service Port, (Low Side)

8. Pressure Transducer (SPT)

© 2015 Mobile Climate Control T-367Rev. 05/2015

EVAPORATOR SECTION

9. Thermal Expansion Valve (TXV)

10. Liquid Line Sight Glass

11. Pressure Transducer (DPT)

12. Filter Drier Service Valve

13. Filter Drier

14. Liquid Li ne Solenoid Valve

15. Receiver Tank

16. Fusible Plug

Figure 1-2 Refrigerant Flow Diagram

1--6

HT HP SHV

HT HP SCL

LT LP SM

LT LP SHV

CONDENSER SECTION

MAIN ENGINE

RADIATOR

Boost

Pump

INLET

EVAPORATOR SECTION

Figure 1-3 Heat Flow Diagram

OUTLET

Heat Valve

(N.C.)

© 2015 Mobile Climate Control

1--7

T-367Rev. 05/2015

SECTION 2

OPERATION of MCC EcoXcel DRIVER DISPLAY

2.1 General Description

Operation of the MCC Eco Xcel unit is controlled

through the MCC Driver's display.

When the MCC Displayis used to control operation,

the Mode selection is selected using the “Mode”

button ( item 3) on display, shown in Figure 2-1.

Ability to view system pressures, sensor

temperatures, component status, etc. is available

Through the MCC Display Module.

2.2 STARTING, STOPPING AND OPERATING INSTRUCTIONS

The MCC Drivers Display Module is marked with

international symbols (See Figure 2-1).

Before starting, electrical power must be available

from the bus power supply.

A circuit b reaker/fuse in the battery com partment

passes power for the clutch, evaporator and

condenser assemblies.

2.2.1 Starting

a. If the engine is not running, start the engine.

b. When the 24VDC power is applied, the driver dis

play will be ready to except req u est for system op

eration. Press the On/Off key (Item 1, Figure 2-1)

on the displayto triggerthe start up sequence, con

trolled by the MCC D rivers display module.

2.2.2 Stopping

Toggling the On/Off key (Item 1, Figure 2-1) on the

display again will stop the system operation

controlled by the MCC D rivers display module.

2

1

5

Figure 2-1 Driver Display Module- Control Layout

© 2015 Mobile Climate Control

1. On/Off

2. Temperature Set Point Control

3. Cursor and Mode Selection

4. Information/Display Settings

5. Alarm Indicator

2--1

3

4

T-367Re v. 05/2015

2

1

5

3

1. Operation Mode

2. Temperature Set Point

3. Fan Speed Indicator

4. Interior/Exterior Temperatures

5.. Alarm Indicator Symbol

Figure 2-2 Driver Display Module- Display Layout

2.3 SEQUENCE OF OPERATION

2.3.1 Function of Keys when “Engine On” and controller

active:

a. On/Off Key - Turns HVAC unit On or Off, un

less OEM supplied switches are installed. It also is

used to exit diagnostic men u .

b. Temperature Set Point Control Keys -These

buttons increase or decrease the tem perature set

point for the passenger area HVAC unit.

c. Cursor/Mode Selection Key- Used to toggle

through parameter settings in diagnostic mode or

set the operating mode to Auto, Heat, Vent, Cool,

and Defrost in normal display mode.

4

d. Information/Display Settings Key - Allows ac

cess to display settings and system diagnostics.

2.3.2 Illuminating Indications (Display)

With “Engine-On” and Controller active by the

On/Off button.

NOTE:

Depending on Customer specification, the

modes of operation may be controlled

strictly through manual switches provided in

the driver's area.

© 2015 Mobile Climate Control

2--2

T-367Rev05/2015

2.4 BASIC OPERATING INSTRUCTIONS

When the engine is running, press the On/Off

buttonondisplay.

2.4.1 Display

When the unit is ON, the display shows the interior

set point temperature, current blower speed setting,

mode selection and Interior/Exterior temperatures.

2.4.2 Interior Set Point Temperature Control

Press the UP (Red) or Do wn (Blue) keys to set the

desired interior temperature.

The t em perature can be adjusted between 62° F(16°

C) and 82° F(28° C).

2.4.3 Blower Speed Setting

Blower speed operation will be set for high or low

speed operation automatically through software, or

can be set through manual switches provided at the

driver area.

2.4.4 Mode Selection Descriptions

a. Auto - In the auto mode, the ECC node willadjust

the individual components to maintain the desired

set point temperature.

In the auto mode, the evaporator fans will operate

in an “Ultra” high speed to achieve desired set

point faster, when the interior temperature is

greater than 5.4°F (3°C), from desired set point.

In the auto mode, the A/C system will continue to

operate when set point is reached, and will ener

gize the boost pump and de-energize the heat

solenoid valve to maintain temperature. This is re

ferred to as Reheat mode, to provide additionalde

humidification of interior space.

The reheat mode will be disabledif the outsideam

bient air temperature is below 43° F(6.1° C).

b. Cooling - In the cooling mode, the Compressor,

condenser fans and evaporator fans will be ener

gized. The heater solenoid valve will be energized

(closed), to provide full cooling.

The compressor and condenser fans will be de-en

ergized 2 degrees F below set point. The evaporat

or fans willcontinue to operateto circulateinterior

air.

c. Heating - In the heating mode, the compressor

and condenser fans will remain de-energized.

Evaporator fans will be energized. The boost

pump willbe energized,andthe heat solenoidvalve

will be de-energized (opened), to allow engine

coolant to flow through the heater coils. If the in

terior temperature is more than 5° F(3° C) below

set point, the floor blowers (if equipped) will also

be energized.

d. Defrost - In the defrost mode, the boost pump

will be energized to pro vide engine coolant flow to

the drivers unit to allow defogging of the wind

shield.

Defrost Override - In the event the main HVAC

system is “OFF”, the ability of the OEM to

provide a signal to the controller to energize the

Boost Pump to provide engine coolant flow for

the Drivers Defroster is provided.

e. Vent- In the vent mode, the evaporator blowers

are operated to circulate air in the bus.

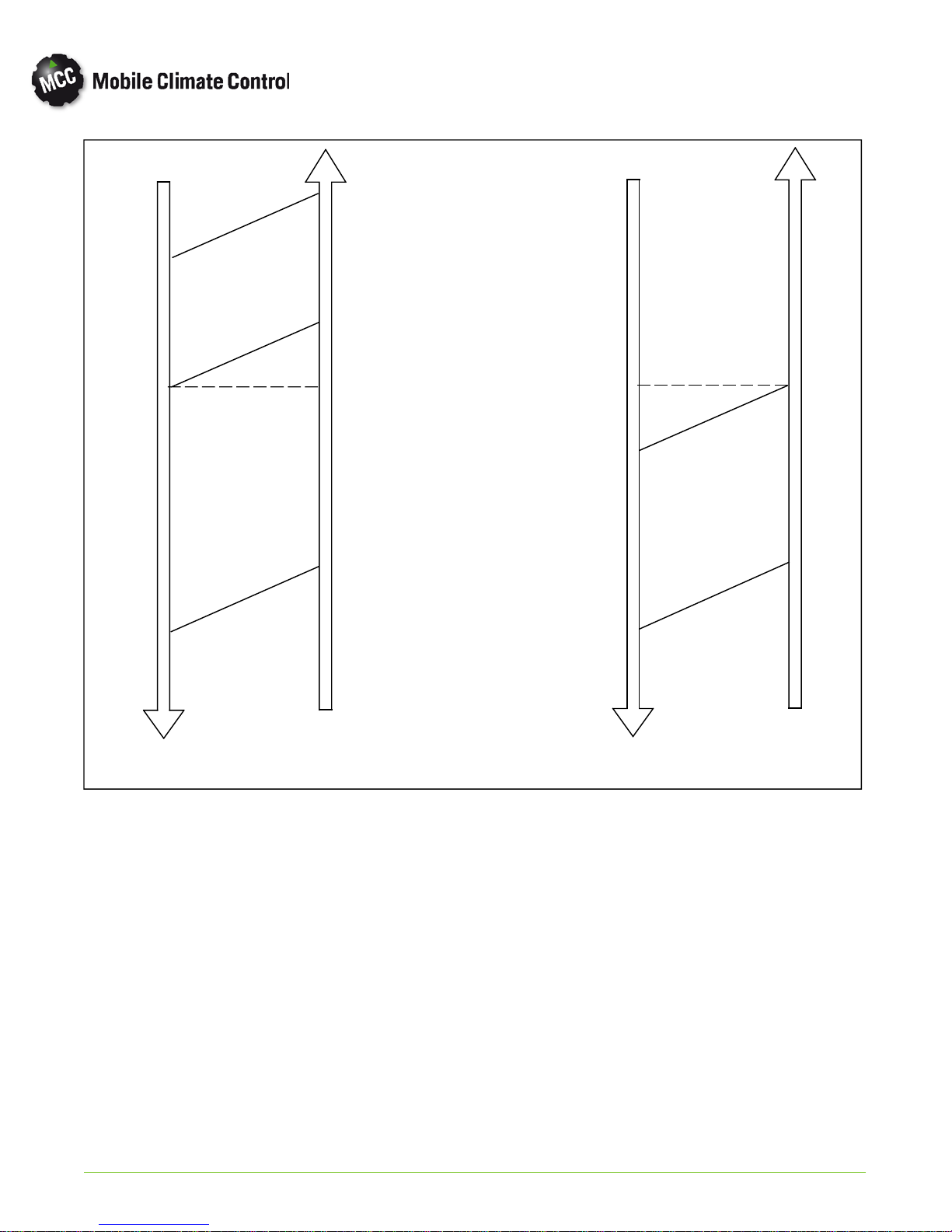

2.4.5 Capacity Control “Ladder” Diagrams

Ladder diagrams showing system operational

control logic for Auto/ Cool (Reheat system), and

Heat, can be seen in Figure 2-3.

© 2015 Mobile Climate Control

2--3

T-367Re v. 05/2015

3°F

COOL

4 CYLINDER

3°F

2°F

1°F

SETPOINT

-- 1 °F

-- 2 °F

-- 3 °F

-- 4 °F

-- 5 °F

COOL

2CYLINDERS

REHEAT DUTY CYCLE

0-- 100%

2 CYLINDERS

HEAT

2°F

1°F

SETPOINT

-- 1 °F

-- 2 °F

-- 3 °F

-- 4 °F

-- 5 °F

VENT

HEAT

FLOOR BLOWERS

OFF

HEAT

WITH

FLOOR BLOWERS

AUTO/COOL

(Reheat)

© 2015 Mobile Climate Control

Figure 2-3 Capacity Control Ladder Diagrams

2--4

HEAT

T-367Rev05/2015

2.4.6 Display Settings

To adjust display settings, from the main menu:

c. To adjust settings, press the up or down cursor

keys to scroll to desired parameter (Item 3 in

Figure 2-1).

a. Press the “Information” button to enter the

“View” screen (Item 4 in Figure 2-1).

b. Press and releaseboth “Temperature Control UP”

and “Cursor UP” buttons (Items 3 in Figure 2-4)

to access the display set- up screen.

Main Menu Screen

Temperature

Control UP

d. To adjust settings, press the up or down temperat

ure control keys to scroll to adjust parameter

e. After adjustment, press “Information” button

(Item 4 in Figure 2-1) to exit set-up screen.

Info Button

Cursor UP

© 2015 Mobile Climate Control

View Screen

Display Set-Up Screen

Figure 2-4 HVAC DISPLAY SETTINGS

2--5

T-367Re v. 05/2015

Loading...

Loading...