MCC 68AC430-100, 68AC430-100-4, 68AC430-100-2, 68AC430-100-5, 68AC430-100-6 Service Manual

...

T-353 Manual

OPERATION/SERVICE

© 2012 Mobile Climate Control

for

68AC430-100

T-353

REV. 01/2013

TABLE OF CONTENTS

SAFETY SUMMARY Safety-1...............................................................

DESCRIPTION 1-1....................................................................

1.1 INTRODUCTION 1-1.......................................................

1.2 GENERAL DESCRIPTION 1-2...............................................

1.2.1 Rooftop Unit 1-2......................................................................

1.2.2 Condensing Section 1-2.................................................................

1.2.3 Evaporator Section 1-2..................................................................

1.2.4 BT-324 Microprocessor 1-3..............................................................

1.3 REFRIGERATION SYSTEM COMPONENT SPECIFICATIONS 1-3.................

1.4 ELECTRICAL SPECIFICATIONS - MOTORS 1-3................................

1.5 SAFETY DEVICES 1-3......................................................

1.6 AIR CONDITIONING REFRIGERATION CYCLE 1-4............................

1.7 HEATING CYCLE 1-4.......................................................

OPERATION BT324 Controller 2-1.........................................................

2.1 STARTING, STOPPING AND OPERATING INSTRUCTIONS 2-1..................

2.1.1 Starting 2-1...........................................................................

2.1.2 Stopping 2-1..........................................................................

2.2 PRE-TRIP INSPECTION 2-1..................................................

2.3 SEQUENCE OF OPERATION BT324 2-2.......................................

2.3.1 Function of Keys when “Engine On” and controller active: 2-2...................................

2.3.2 Illuminating Indications (Display) 2-2.......................................................

2.4 OPERATING INSTRUCTIONS BT324 2-2......................................

2.4.1 Display 2-2...........................................................................

2.4.2 Interior Temperature Control 2-2..........................................................

2.4.3 Ventilation 2-2........................................................................

2.4.4 Reheat (optional) 2-2....................................................................

2.4.5 Temperature Indication 2-2..............................................................

2.5 CHANGING BETWEEN °F (FAHRENHEIT) AND °C(CELCIUS) 2-2..............

TROUBLESHOOTING 3-1................................................................

3.1 System Will Not Cool 3-1................................................................

3.2 System Runs But Has Insufficient Cooling 3-1................................................

3.3 Abnormal Pressures 3-1.................................................................

3.4 Abnormal Noise Or Vibrations 3-1.........................................................

3.5 No Evaporator Air Flow Or Restricted Air Flow 3-2...........................................

3.6 Expansion Valve Malfunction 3-2..........................................................

3.7 Heating Malfunction 3-2.................................................................

© 2012 Mobile Climate Control T-353 Rev. 01/2013

i

TABLE OF CONTENTS (Continued)

SERVICE 4-1........................................................................

4.1 MAINTENANCE SCHEDULE 4-1.............................................

4.2 REMOVING COVER 4-1.....................................................

4.3 MANIFOLD GAUGE SET 4-1................................................

4.3.1 Installing R-134a Manifold Gauge/Hose Set 4-2..............................................

4.4 REMOVING THE REFRIGERANT CHARGE 4-3...............................

4.4.1 Removing Entire System Charge 4-3.......................................................

4.5 REFRIGERANT LEAK CHECK 4-3............................................

4.6 EVACUATION AND DEHYDRATION 4-3.....................................

4.6.1 General 4-3...........................................................................

4.6.2 Preparation 4-3........................................................................

4.6.3 Procedure for Evacuation and Dehydrating System 4-4.........................................

4.7 ADDING REFRIGERANT TO SYSTEM 4-4.....................................

4.7.1 Checking Refrigerant Charge 4-4..........................................................

4.7.2 Adding Full Charge 4-4.................................................................

4.8 CHECKING FOR NONCONDENSIBLES 4-4...................................

4.9 CHECKING AND REPLACING HIGH OR LOWPRESSURE CUTOUT SWITCH 4-4...

4.9.1 Replacing High Or Low Pressure Switches 4-4................................................

4.9.2 Checking High Pressure Switches 4-5......................................................

4.9.3 Checking Low Pressure Switches 4-5.......................................................

4.10 FILTER-DRIER 4-5.........................................................

4.10.1 To Check Filter-Drier 4-5................................................................

4.10.2 To Replace Filter-Drier Assembly 4-5......................................................

4.11 SERVICING THE HEAT VALVE 4-6..........................................

4.11.1 Coil Replacement 4-6...................................................................

4.11.2 Internal Part Replacement 4-6............................................................

4.11.3 Replace Entire Valve 4-6................................................................

4.12 SERVICE VALVES 4-7.......................................................

4.13 REPLACINGRETURNAIRFILTERS 4-7.......................................

4.14 THERMOSTATIC EXPANSION VALVE 4-8....................................

4.14.1 Valve Replacement 4-9..................................................................

4.14.2 Superheat Measurement 4-9..............................................................

ELECTRICAL 5-1......................................................................

5.1 INTRODUCTION 5-1.......................................................

Table 1-1 68AC430 Models 1-1.........................................................

Table 1-2 Additional Support Manuals 1-1................................................

Table 3-1 General System Troubleshooting Procedures 3-1...................................

Table 4-1 R-134a Temperature - Pressure Chart 4-11.........................................

© 2012 Mobile Climate Control T-353 Rev. 01/2013

LIST OF TABLES

ii

LIST OF FIGURES

Figure 1-1 AC430 Rooftop Unit 1-2....................................................

Figure 1-2 Refrigerant/Heat Flow Diagram, AC430 1-5.....................................

Figure 1-3 AC430 With BT324 Control Board 1-6.........................................

Figure 3-1 BT324 Controller 2-1......................................................

Figure 4-1 Manifold Gauge Set (R-134a) 4-2..............................................

Figure 4-2 In-Line Service Connections 4-3..............................................

Figure 4-3 Checking High Pressure Switch 4-5............................................

Figure 4-4 Filter-Drier Removal 4-5....................................................

Figure 4-5 Heat Valve 4-7............................................................

Figure 4-6 Service Valve R134a (High Side) 4-7...........................................

Figure 4-7 Return Air Grill Assembly With Air Filter Showing 4-8.............................

Figure 4-8 Diffuser and Filter Element 4-8...............................................

Figure 4-9 Filter, Diffuser and Composite Frame 4-8.......................................

Figure 4-10 Return Air Grill Assembly With Diffuser And Composite Frame Showing 4-8..........

Figure 4-11 Thermostatic Expansion Valve 4-9...........................................

Figure 4-12 Thermostatic Expansion Valve Bulb and Thermocouple 4-9........................

Figure 5-2 Evaporator Motors 5-2.....................................................

Figure 5-3 Condenser Motors 5-3.....................................................

Figure 5-4 BT324 Controls With (1) Compressor 5-4.......................................

Figure 5-5 BT324 Control Circuit 5-5...................................................

Figure 5-6 AC430 With BT324 Control 5-6..............................................

Figure 5-7 AC430 With BT324 Control (Electrical Panel 91-62105-00) 5-7.......................

Figure 5-8 AC430 With BT324 Control (Electrical Panel 91-62105-00) 5-8.......................

© 2012 Mobile Climate Control T-353 Rev. 01/2013

iii

SAFETY SUMMARY

GENERAL SAFETY NOTICES

The following general safety notices supplement the specific warnings and cautions appearing elsewhere in this

manual. They are recommended precautions that must be understood and applied during operation and

maintenance of the equipment covered herein. A listing of the specific warnings and cautions appearing

elsewhere in the manual follows the general safety notices.

FIRST AID

An injury, no matter how slight, should never go unattended. Always obtain first aid or medical attention

immediately.

OPERATING PRECAUTIONS

Always wear safety glasses.

Keep hands, clothing and tools clear of the evaporator and condenser fans.

No workshouldbe performedon the unituntilall start-stop switchesare placed in the OFF position, and power

supply is disconnected.

Always work in pairs. Never work on the equipment alone.

In case of severe vibration or unusual noise, stop the unit and investigate.

MAINTENANCE PRECAUTIONS

Beware of unannounced starting of the evaporator and condenser fans. Do not open the unit cover before

turning power off.

Be sure power is turned off before working on motors, controllers, solenoid valves and electrical controls. Tag

circuit breaker and power supply to prevent accidental energizing of circuit.

Do not bypass any electrical safety devices, e.g. bridging an overload, or using any sort of jumper wires.

Problems with the system should be diagnosed, and any necessary repairs performed by qualified service

personnel.

When performing any arc welding on the unit, disconnect all wire harness connectors from the modules in the

control box. Do not remove wire harness from the modules unless you are grounded to the unit frame with a

static-safe wrist strap.

In case of electrical fire, open circuit switch and extinguish with CO2(never use water).

© 2012 Mobile Climate Control T-353 Rev. 01/2013

Safety--1

SPECIFIC WARNINGS AND CAUTIONS

WARNING

Be sure to observe warnings listed in the safety summary in the front of this manual before

performing maintenance on the hvac system

WARNING

Read the entire procedure before beginning work. Park the vehicle on a level surface, with

parking brake applied. Turn main electrical disconnect switch to the off position.

WARNING

Do Not Use A Nitrogen Cylinder Without A Pressure Regulator

WARNING

Do Not Use Oxygen In Or Near A Refrigeration System As An Explosion May Occur.

WARNING

The Filter-drier May Contain Liquid Refrigerant. S lowly Loosen The Connecting Nuts And

AvoidContactWithExposedSkinOrEyes.

CAUTION

The AC430 Rooftop Systems has R134a serviceport couplings installed on the compressor and

on the unit piping.

CAUTION

To prevent trapping liquid refrigerant in the manifold gauge set be sure set is brought to

suction pressure before disconnecting.

© 2012 Mobile Climate Control T-353 Rev. 01/2013

Safety--2

SECTION 1

DESCRIPTION

1.1 INTRODUCTION

This manual contains Operating Instructions,

Service Instructions and Electrical Data for the

Model 68AC430 Air Conditioning and Heating

equipment furnished by Mobile Climate Control as

showninTable1-1.

Model 68AC430 systems consists of a Rooftop unit

containing the condensing section, the evaporator

section and engine compartment mounted

compressor(s). To complete the system, the air

conditioning and heating equipment interfaces with

an optional drivers evaporator (dash-air), electrical

cabling, refrigerant piping, engine coolant piping (for

heating), duct work and other components

furnishedby Mobile Climate Control and/or the bus

manufacturer.

Additional support manuals are shown in Table 1-2.

Operation of the unit is controlled automatically by

an electronic thermostat. The controls maintain the

vehicle'sinterior temperature at the desired set point.

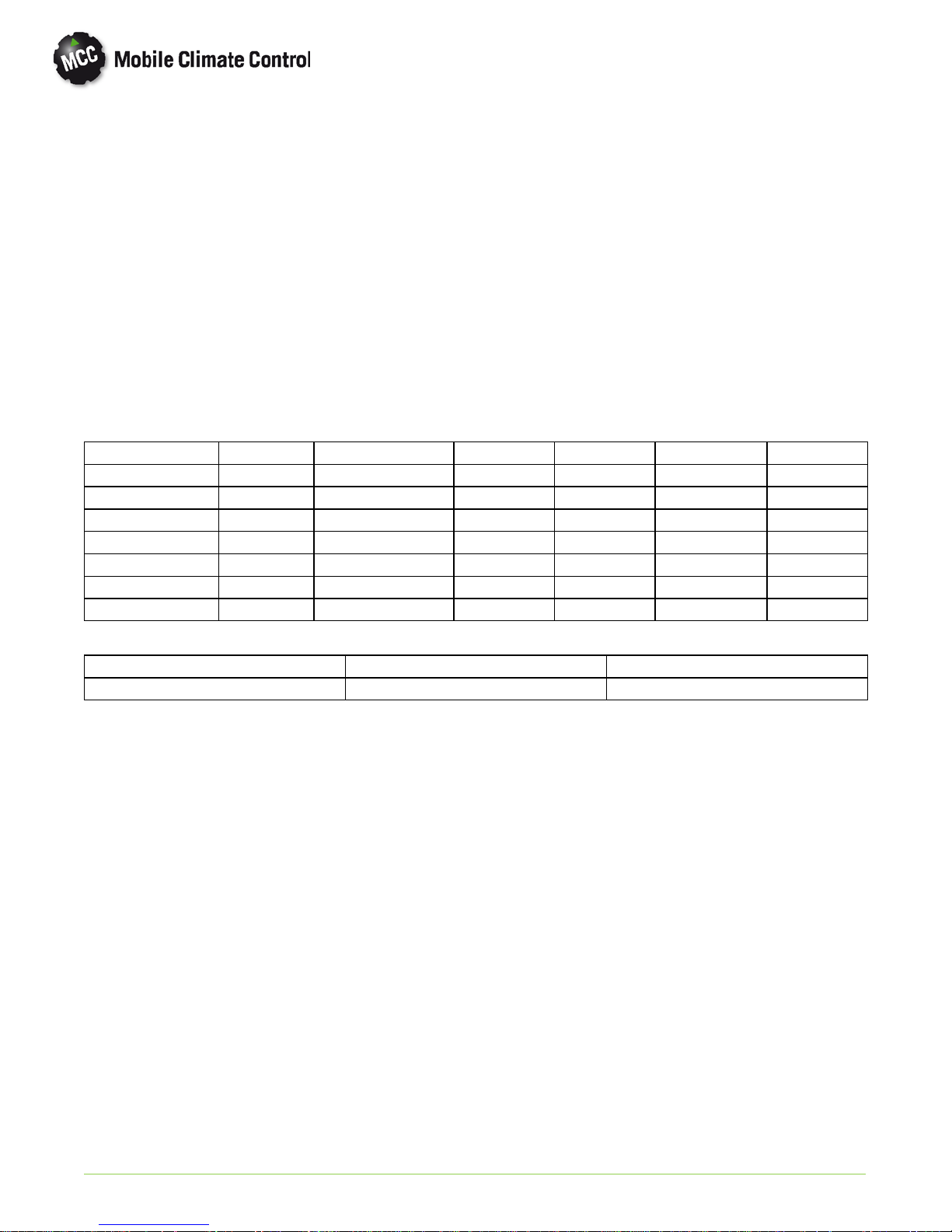

Table 1-1 68AC430 Models

Model Voltage Controller With Heat Dual Loop Single Loop Roof Radius

68AC430-100 12 VDC BT324 Yes X 4.6M

68AC430-100-2 12 VDC BT324 No X 4.6M

68AC430-100-4 12 VDC BT324 Yes X 4.6M

68AC430-100-5 12 VDC BT324 No X 4.6M

68AC430-100-6 12 VDC BT324 Yes X 7.8M

68AC430-100-7 12 VDC BT324 No X 7.8M

68AC430-100-8 * 12 VDC BT324 No X 7.8M

Table 1-2 Additional Support Manuals

MANUAL NUMBER EQUIPMENT COVERED TYPE OF MANUAL

T-353PL 68AC-430-100 Service Parts List

* Denotes Special Packaging

© 2012 Mobile Climate Control T-353 Rev. 01/2013

1--1

1.2 GENERAL DESCRIPTION

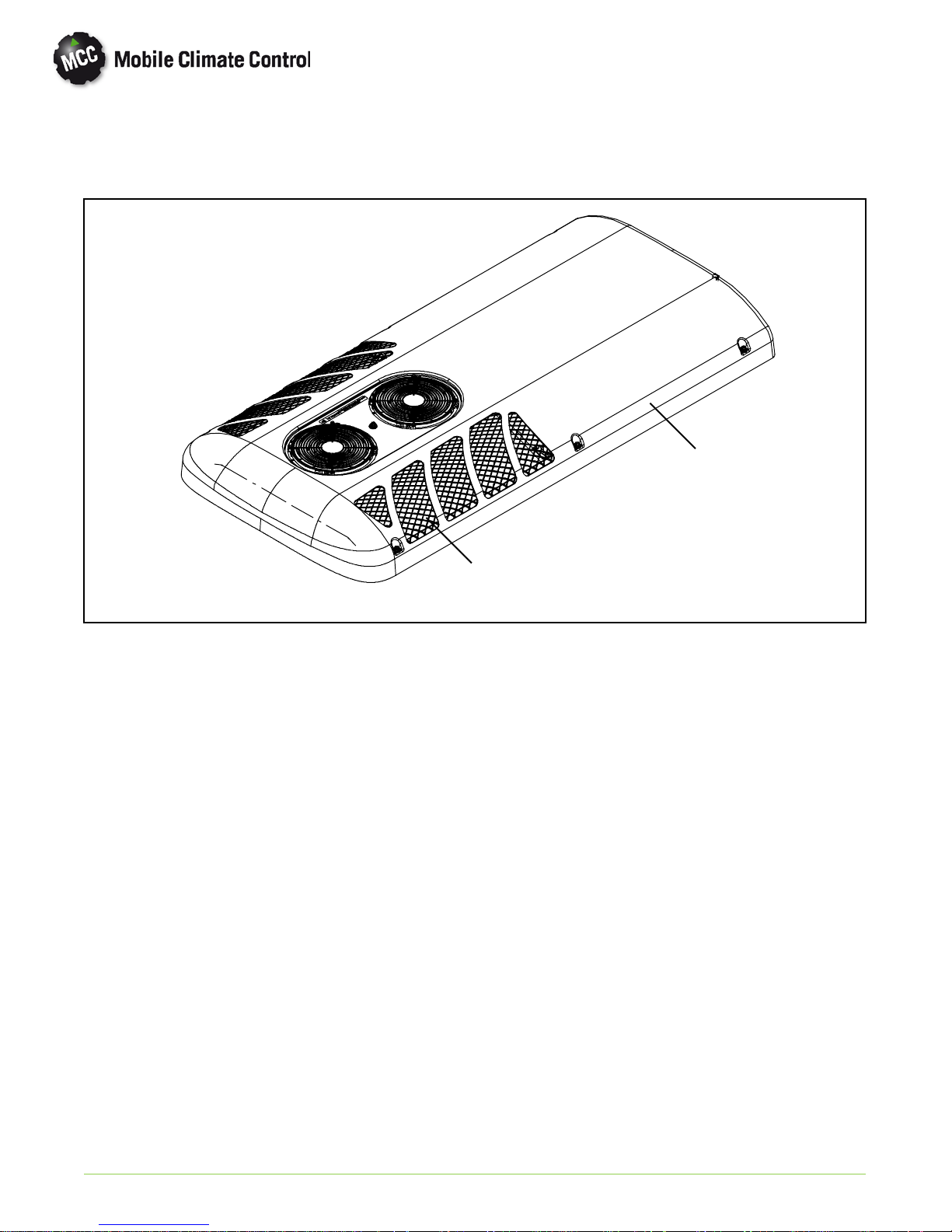

1.2.1 Rooftop Unit

The rooftop unit includes the condenser section and the evaporator section (See Figure 1-1).

Evaporator Section

Figure 1-1 AC430 Rooftop Unit

1.2.2 Condensing Section

The condensing section includes the condenser

coils, two (2)fan and mot or assemblies, receiver,

filter-drier and filter-drier service valves.

The condenser coils provide heat transfer surface for

condensing refrigerant gas at a high temperature and

pressure into a liquid at high temperature and

pressure. The condenser fans circulate ambient air

across the outside of the condenser tubes at a

temperature lower than refrigerant circulating inside

the tubes; this results in condensation of the

refrigerant into a liquid. The receiver collects and

stores liquid refrigerant. The receiver is also fitted

with a pressure relief valve which protects the system

from unsafe high pressure conditions. The

filter-drier removes moisture and debris from the

liquid refrigerant before it enters the thermostatic

expansion valve in the evaporator assembly. The

service valves enable isolation of the filter-drier for

service.

Condenser Section

1.2.3 Evaporator Section

The evaporatorsection includesthe evaporatorcoils,

two (2) single-shaftedblower/motor assemblies,two

(optional) heater coil assemblies, a thermostatic

expansion valve and condensate drain connections.

The evaporator coils provide heat transfer surface

for transferring heat from air circulating over the

outside of the coil to refrigerant circulating inside the

tubes; thus providing cooling. The heating coils (if

equipped) provide a heat transfer surface for

transferring heat from engine coolant water

circulating inside the tubes to air circulating over the

outside surface of the tubes, thus providing heating.

The fans circulate the air over the coils. The air filters

remove dirt particles from the air before it passes

over the coils. The thermostatic expansion valve

meters the flow of refrigerant entering the

evaporator coils. The heat valve controls the flow of

engine coolant to the heating co ils upon receipt of a

signal from the controller. The condensate drain

connections provide a means for connecting tubing

for disposing of condensate collected on the

evaporator coils during cooling operation.

© 2012 Mobile Climate Control T-353 Rev. 01/2013

1--2

1.2.4 BT-324 Microprocessor

1.4 ELECTRICAL SPECIFICATIONS - MOTORS

This BT-324 controller has three (3) modes, Auto,

Vent (Cycle clutch type) and Heat.

In the auto mode the compressor is energized while

the evaporator and condenser fans are operated to

providerefrigerationas required. The compressor(s)

capacity is matched to the bus requirements. Once

interior temperature reaches the desired set po int,

the compressor(s) is de-energized.

In the heat mode the heat valves are opened to allow

a flow of engine coolant through the heat coils

located in the evaporator section. The evaporator

fans operate to circulate air over the heat coils in the

same manner as the cooling mode.

1.3 REFRIGERATION SYSTEM COMPONENT SPECIFICATIONS

a. Refrigerant Charge R-134a (Approximate)

NOTE

Refrigerant charge will depend on hose

lengths and diameters; or if there is an InDash unit (front evaporator). The following

should only be used as a guideline.

AC430 Single Loop TM-21 Compressor

11 Pounds (5 kg)

b. Compressors

Compressor

Weight, (Dry) 7.5 Lbs. (3.4 kg)

Oil Charge 6.1 Oz. (180 cc) PAG

c. Thermostatic Expansion Valves:

TDEN 5.8 TR

Superheat Setting Factory Set at 12°F(±1.8°F)

6.7°C (±1°C)

TGEN 4.5

Superheat Setting Factory Set at 7.2°F(4°C)

MOP70psig(4.8bar)

TM-21

a. Evaporator Blower/Motor

Evaporator Motor

Horsepower (kW) .375 (.28)

Full Load Amps (FLA) 20.7

Operating Speed

High(RPM)

Bearing Lubrication

b. Condenser Fan Motor

Condenser Motor

Horsepower (kW) 1/4 (.18)

Full Load Amps (FLA) @

13.5 VDC

Operating Speed

High(RPM)

Bearing Lubrication

c. Return Air Sensor

Input Range: -40 to 176° F(-40to80°C)

Output: 20K ohms at 77° F(25°C)

d. Ambient Sensor (location chosen by Installer)

Input Range: -40 to 302° F (-40 to 150°C)

Output: 20K ohms at 77° F(25°C)

Opens at: 25° F(10°C)

Closes at: 35° F(1.7°C)

Brushless

12 VDC

3250

Factory Lubricated

(additional grease not required)

Permanent Magnet

12 VDC

14.4

3222

Factory Lubricated

(additional grease not required)

1.5 SAFETY DEVICES

System components are protected from damage

caused by unsafe operating conditions with safety

devices. Safety devices with Mobile Climate Control

supplied equipment include high pressure switch

(HPS), low pressure switch (LPS), circuit breakers

and fuses.

d. High Pressure Switch (HPS)

Opens at: 360 ±10 psig (20.41 ±0.68bar)

Closes at: 280 ±10 psig (13.61 ±0.68bar)

e. Low Pressure Switch (LPS)

Opens at: 6 ±3psig (0.41 ±0.20 bar)

Closes at: 25 ±3psig(1.7±0.20 bar)

© 2012 Mobile Climate Control T-353 Rev. 01/2013

Normally Closed

Normally Open

a. Pressure Switches

High Pressure Switch (HPS)

During the air co nditioning cycle, compressor clutch

operation will automatically stop if the HPS switch

contacts open due to an unsafe operating condition.

Opening HPS contacts de-energizes the compressor

clutch shutting down the compressor. The high

pressure switch (HPS) is installed in the condenser

section.

1--3

Low Pressure Switch (LPS)

The low pressure switch is installedin the evaporator

section and opens on a pressure drop to shut down

the system when a low pressure condition occurs.

b. Fuses and Circuit Breakers

The Relay Board is p ro tected against high current by

an OEM supplied circuit breaker or fuse located in

the bus battery compartment (150 Amp for 12 VDC

systems). Independen t 20 Amp, 12 VDC fuses

protect each condenser motor. Independent 25

Amp, 12 VDC fuses protect each evaporator motor.

Output circuits are pro tected by additional 2,3,5 and

10 Amp fuses according to circuit loads. During a

high current condition, the fuse may open.

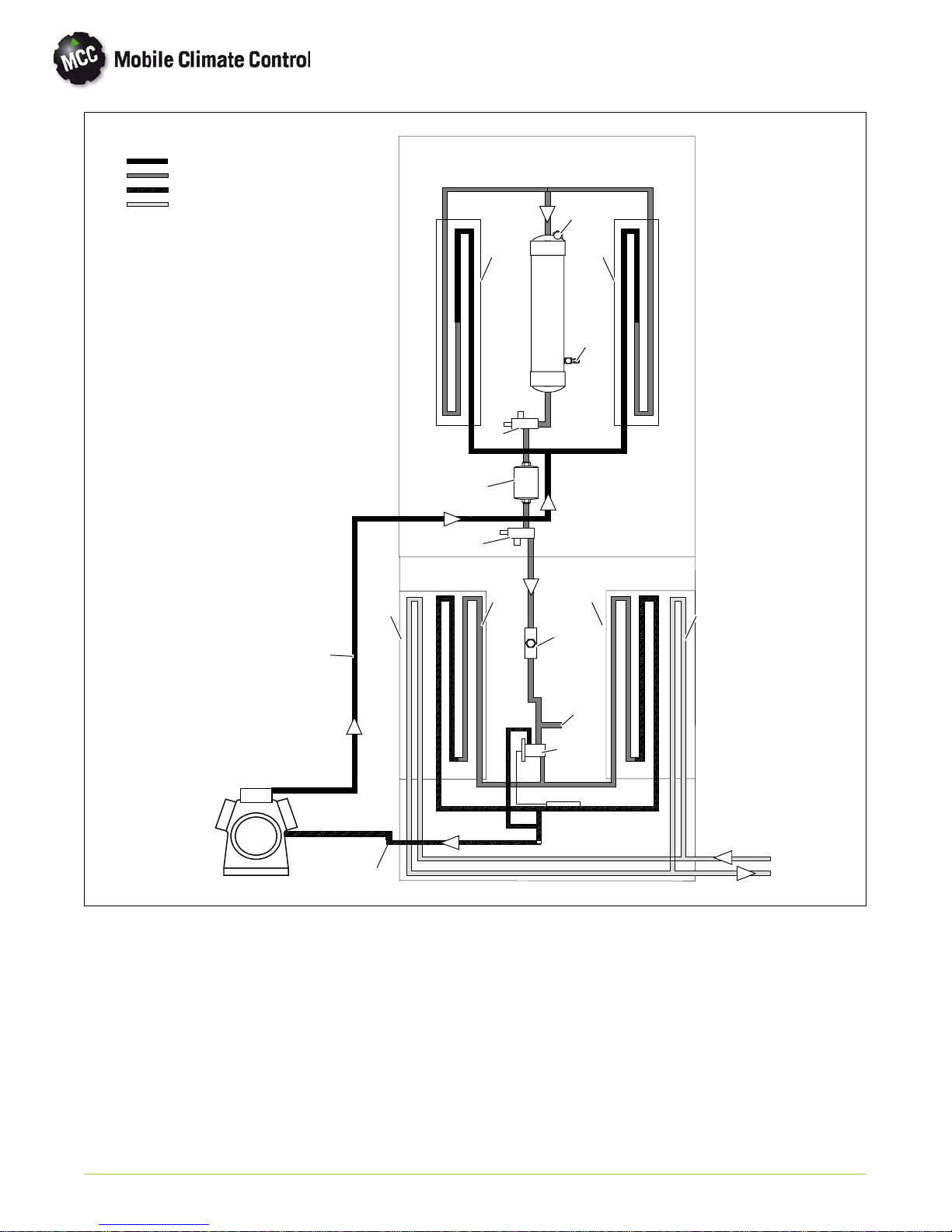

1.6 AIR CONDITIONING REFRIGERATION CYCLE

When air conditioning (cooling) is selected by the

controller, the unit operates as a vapor compression

system using R-134a as a refrigerant (See Figure 1-2

refrigerant flow diagram). The main components of

the system are the A/C compressor, air-cooled

condenser coils, receiver, filter-drier, th ermo static

expansion valve, liquid line solenoid valve (if

equipped), and evaporator coils.

The compressor raises the pressure and the

temperature of the refrigerant and forces it into the

condenser tub es. The condenser fan circulates

surrounding air (which is at atemperature lower than

the refrigerant) over the outside of the condenser

tubes. Heat transfer is established from the

refrigerant (inside the tubes) to the condenser air

(flowing over the tubes). The condenser tubes have

fins designed to improve the transfer of heat from

the refrigerant gas to the air; this removal of heat

causes the refrigerant to liquefy, thus liquid

refrigerant leaves the condenser and flows to the

receiver.

The refrigerant leaves the receiver and passes

through the receiver outlet/service valve, th rou gh a

filter-drier where a desiccant keeps t h e refrigerant

clean and dry.

From the filter-drier, the liquidrefrigerant then flows

through the liquid line to the sight-glass and then to

the thermostatic expansion valve. The thermal

expansion valvereduces pressure and t em p erature of

the liquid and meters the flow of liquid refrigerant to

the evaporator to obtain maximum use of the

evaporator heat transfer surface.

The low pressure, low temperature liquid that flows

into the evaporator tubes is colder than the air that is

circulated over the evaporator tubes by the

evaporator fans (fans). Heat transfer is established

from the evaporator air (flowing over the tubes) to

the refrigerant (flowing inside the tubes). The

evaporator tubes have aluminum fins to increase

heat transfer from the air to the refrigerant;therefore

the cooler air is circulated to the interior of the bus.

The transfer of heat from the air to the low

temperature liquid refrigerant in the evaporator

causes the liquid to vaporize. This low temperature,

low pressure vapor passes through the suction line

and returns to the compressor where the cycle

repeats.

1.7 HEATING CYCLE

Heating circuit (See Figure 1-2) components

furnished by Mobile Climate Control include the

heater cores and solenoid operated heat valves.

Components furnished by the bus manufacturer

may include a water temperature switch (WTS) and

boost water pump.

The controller automatically controls the heat valves

during the heating mode to maintain required

temperatures inside the bus. Engine coolant (glycol

solution) is circulated through the heating circuit by

the engine and an auxiliary boost water pump. When

the heat valve solenoids are energized, the valves will

open to allow engine coolant to flow through the

heater coils. The valves are normally closed so that if

a failure occurs, the system will be able to cool.

© 2012 Mobile Climate Control T-353 Rev. 01/2013

1--4

Discharge

Liquid

Suction

Coolant

14

11

11

13

3

10

12

CONDENSER

10

EVAPORATOR

8

77

8

2

6

9

Figure 1-2 Refrigerant/Heat Flow Diagram, AC430

1. Thermal Expansion Valve

2. Liquid Line Sight Glass

3. Fusible Plug

4. Dash Air Liquid Line

5. Suction Line

6. Discharge Line

7. Heater Coil

4

1

5

8. Evaporator Coil

9. Compressor

10. Service Valve

11. Condenser Coil

12. Filter-Drier

13. Receiver

14. Receiver Liquid Level Sight Glass

© 2012 Mobile Climate Control T-353 Rev. 01/2013

1--5

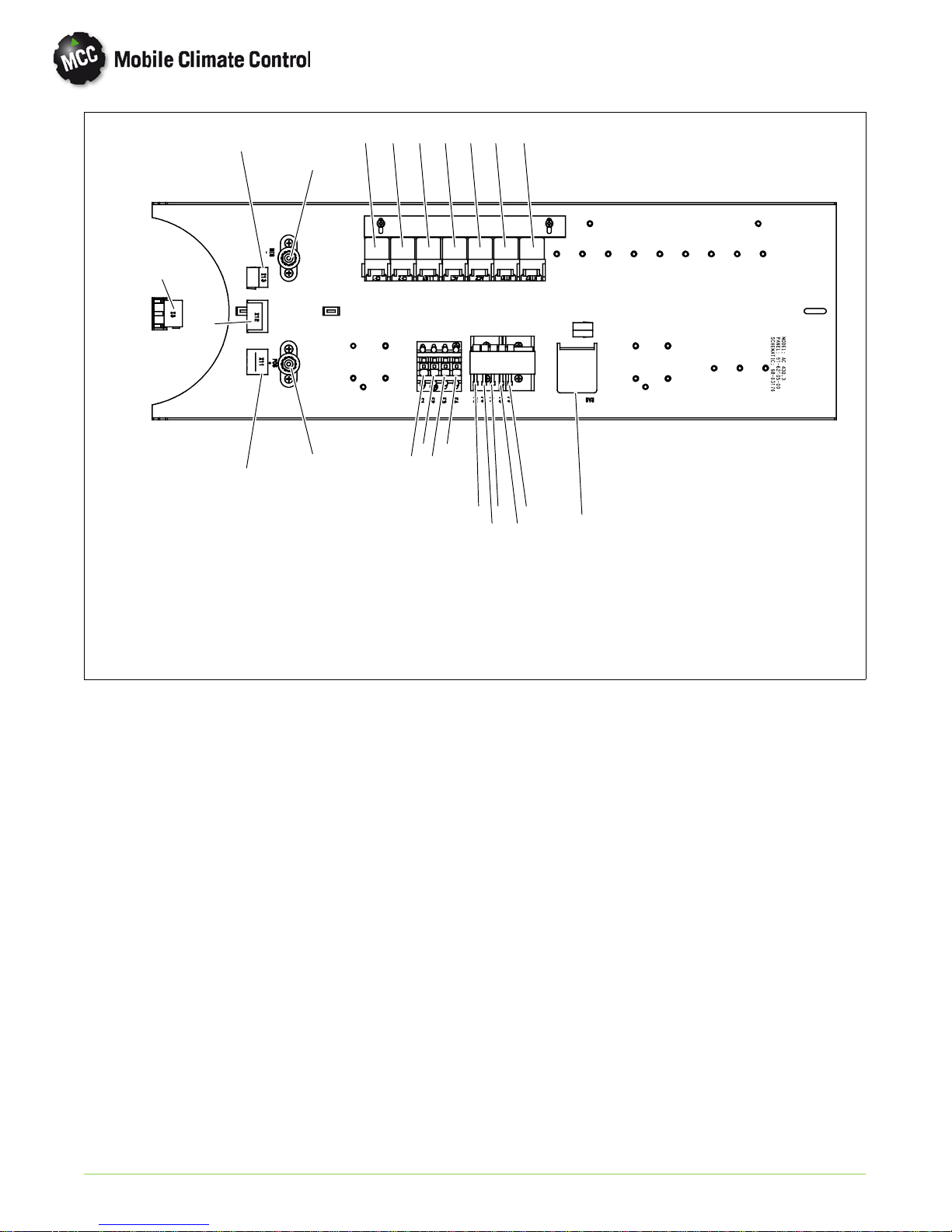

13

4

121110987

6

1

3

17

5

14

15

16

2

22

20

18

19

21

23

Figure 1-3 AC430 With BT324 Control Board

1. X3, Connector, Controller/Driver Display

2. X11, Connector, Evaporator Blower Motors

3. X12, Connector, Condenser Fan Motors/

High Pressure Switch

4. X13, Connector, Low Pressure Switch, Fresh

Air Flap

5. POS, 12VDCPower Connection

6. NEG, Ground Connection

7. CF1, Condenser Fan Relay 1

8. CF2, Condenser Fan Relay 2

9. LLSV, Liquid Line Solenoid Valve Relay

10. AC1, Condenser Fan On Relay

11. AC2, Condenser Fan On Relay

12. HTR1, Relay, Evaporator High Speed

13. HTR2, Relay, Evaporator Low Speed

14. F1, Fuse, Evaporator Motor

15. F2, Fuse, Evaporator Motor

16. F3, Fuse, Condenser Motor

17. F4, Fuse, Condenser Motor

18. F5, Fuse, LLSV

19. F6, Fuse, Condenser Fan Relay

20. F7, Fuse, Pressure Switch Relay

21. F8, Fuse, Heat Valve/ Pump Relay

22. F9, Fuse, Heat Valve/Floor Relay

23. RAS, Return Air Sensor

© 2012 Mobile Climate Control T-353 Rev. 01/2013

1--6

Loading...

Loading...