MCC 68AC430-100, 68AC430-100-4, 68AC430-100-2, 68AC430-100-5, 68AC430-100-6 Service Manual

...

T-353 Manual

OPERATION/SERVICE

© 2012 Mobile Climate Control

for

68AC430-100

T-353

REV. 01/2013

TABLE OF CONTENTS

SAFETY SUMMARY Safety-1...............................................................

DESCRIPTION 1-1....................................................................

1.1 INTRODUCTION 1-1.......................................................

1.2 GENERAL DESCRIPTION 1-2...............................................

1.2.1 Rooftop Unit 1-2......................................................................

1.2.2 Condensing Section 1-2.................................................................

1.2.3 Evaporator Section 1-2..................................................................

1.2.4 BT-324 Microprocessor 1-3..............................................................

1.3 REFRIGERATION SYSTEM COMPONENT SPECIFICATIONS 1-3.................

1.4 ELECTRICAL SPECIFICATIONS - MOTORS 1-3................................

1.5 SAFETY DEVICES 1-3......................................................

1.6 AIR CONDITIONING REFRIGERATION CYCLE 1-4............................

1.7 HEATING CYCLE 1-4.......................................................

OPERATION BT324 Controller 2-1.........................................................

2.1 STARTING, STOPPING AND OPERATING INSTRUCTIONS 2-1..................

2.1.1 Starting 2-1...........................................................................

2.1.2 Stopping 2-1..........................................................................

2.2 PRE-TRIP INSPECTION 2-1..................................................

2.3 SEQUENCE OF OPERATION BT324 2-2.......................................

2.3.1 Function of Keys when “Engine On” and controller active: 2-2...................................

2.3.2 Illuminating Indications (Display) 2-2.......................................................

2.4 OPERATING INSTRUCTIONS BT324 2-2......................................

2.4.1 Display 2-2...........................................................................

2.4.2 Interior Temperature Control 2-2..........................................................

2.4.3 Ventilation 2-2........................................................................

2.4.4 Reheat (optional) 2-2....................................................................

2.4.5 Temperature Indication 2-2..............................................................

2.5 CHANGING BETWEEN °F (FAHRENHEIT) AND °C(CELCIUS) 2-2..............

TROUBLESHOOTING 3-1................................................................

3.1 System Will Not Cool 3-1................................................................

3.2 System Runs But Has Insufficient Cooling 3-1................................................

3.3 Abnormal Pressures 3-1.................................................................

3.4 Abnormal Noise Or Vibrations 3-1.........................................................

3.5 No Evaporator Air Flow Or Restricted Air Flow 3-2...........................................

3.6 Expansion Valve Malfunction 3-2..........................................................

3.7 Heating Malfunction 3-2.................................................................

© 2012 Mobile Climate Control T-353 Rev. 01/2013

i

TABLE OF CONTENTS (Continued)

SERVICE 4-1........................................................................

4.1 MAINTENANCE SCHEDULE 4-1.............................................

4.2 REMOVING COVER 4-1.....................................................

4.3 MANIFOLD GAUGE SET 4-1................................................

4.3.1 Installing R-134a Manifold Gauge/Hose Set 4-2..............................................

4.4 REMOVING THE REFRIGERANT CHARGE 4-3...............................

4.4.1 Removing Entire System Charge 4-3.......................................................

4.5 REFRIGERANT LEAK CHECK 4-3............................................

4.6 EVACUATION AND DEHYDRATION 4-3.....................................

4.6.1 General 4-3...........................................................................

4.6.2 Preparation 4-3........................................................................

4.6.3 Procedure for Evacuation and Dehydrating System 4-4.........................................

4.7 ADDING REFRIGERANT TO SYSTEM 4-4.....................................

4.7.1 Checking Refrigerant Charge 4-4..........................................................

4.7.2 Adding Full Charge 4-4.................................................................

4.8 CHECKING FOR NONCONDENSIBLES 4-4...................................

4.9 CHECKING AND REPLACING HIGH OR LOWPRESSURE CUTOUT SWITCH 4-4...

4.9.1 Replacing High Or Low Pressure Switches 4-4................................................

4.9.2 Checking High Pressure Switches 4-5......................................................

4.9.3 Checking Low Pressure Switches 4-5.......................................................

4.10 FILTER-DRIER 4-5.........................................................

4.10.1 To Check Filter-Drier 4-5................................................................

4.10.2 To Replace Filter-Drier Assembly 4-5......................................................

4.11 SERVICING THE HEAT VALVE 4-6..........................................

4.11.1 Coil Replacement 4-6...................................................................

4.11.2 Internal Part Replacement 4-6............................................................

4.11.3 Replace Entire Valve 4-6................................................................

4.12 SERVICE VALVES 4-7.......................................................

4.13 REPLACINGRETURNAIRFILTERS 4-7.......................................

4.14 THERMOSTATIC EXPANSION VALVE 4-8....................................

4.14.1 Valve Replacement 4-9..................................................................

4.14.2 Superheat Measurement 4-9..............................................................

ELECTRICAL 5-1......................................................................

5.1 INTRODUCTION 5-1.......................................................

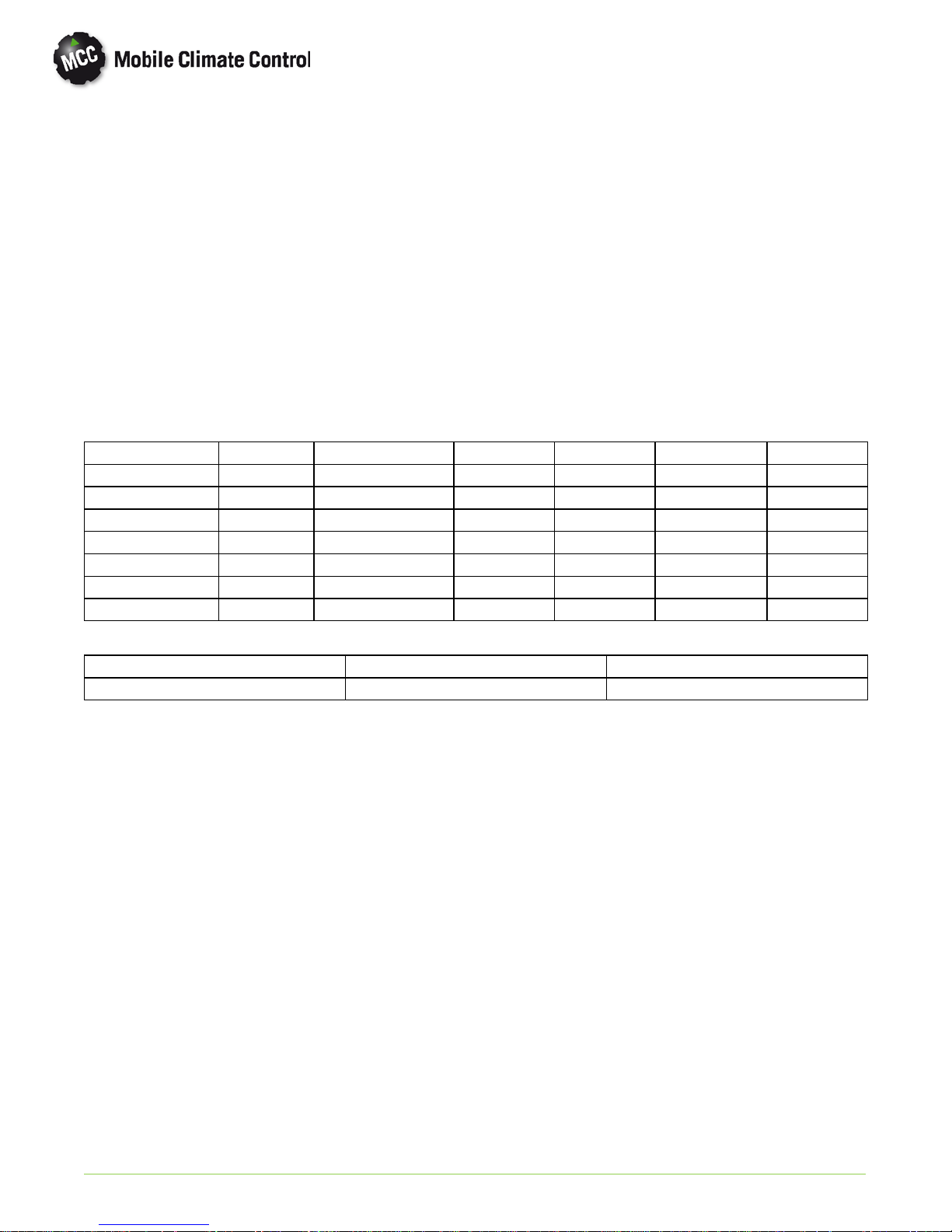

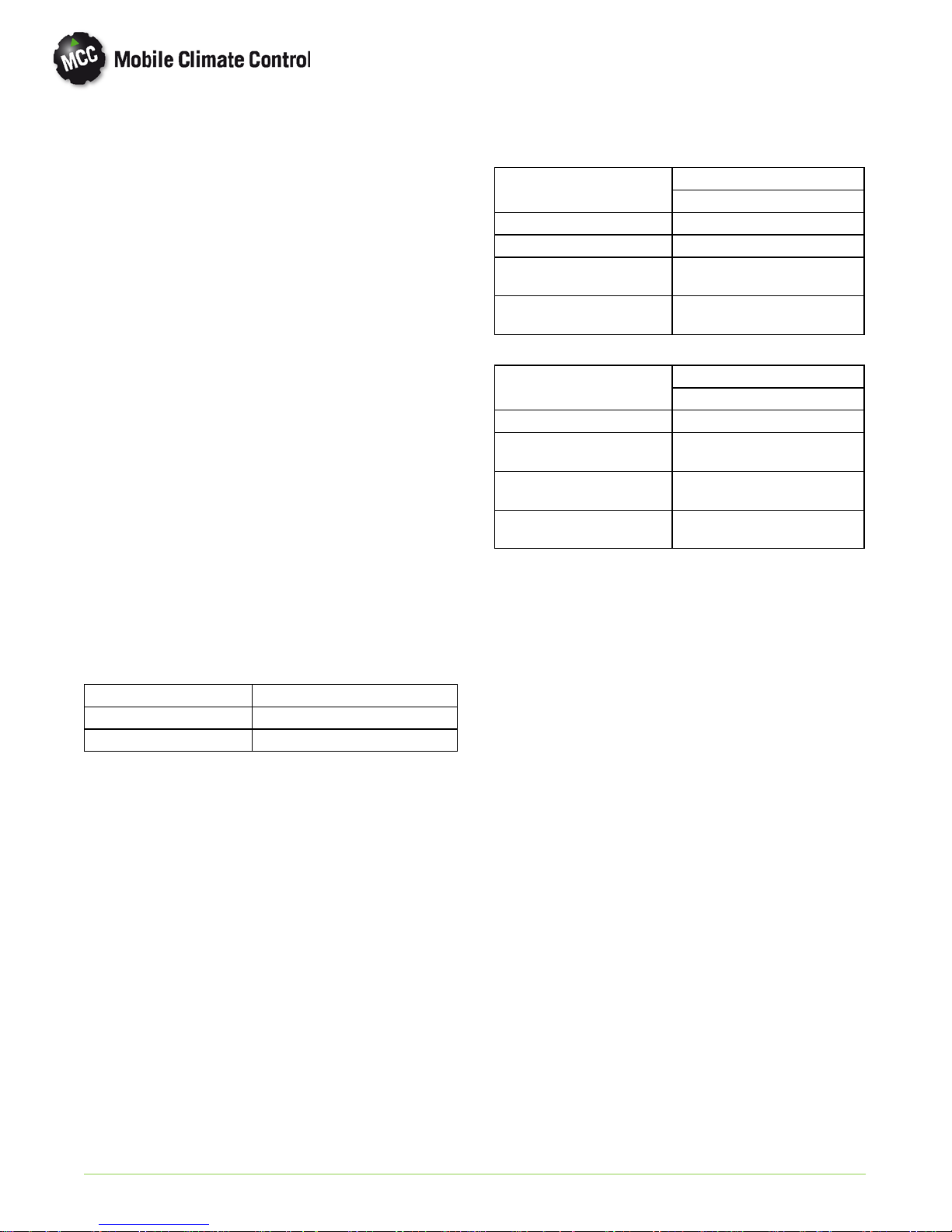

Table 1-1 68AC430 Models 1-1.........................................................

Table 1-2 Additional Support Manuals 1-1................................................

Table 3-1 General System Troubleshooting Procedures 3-1...................................

Table 4-1 R-134a Temperature - Pressure Chart 4-11.........................................

© 2012 Mobile Climate Control T-353 Rev. 01/2013

LIST OF TABLES

ii

LIST OF FIGURES

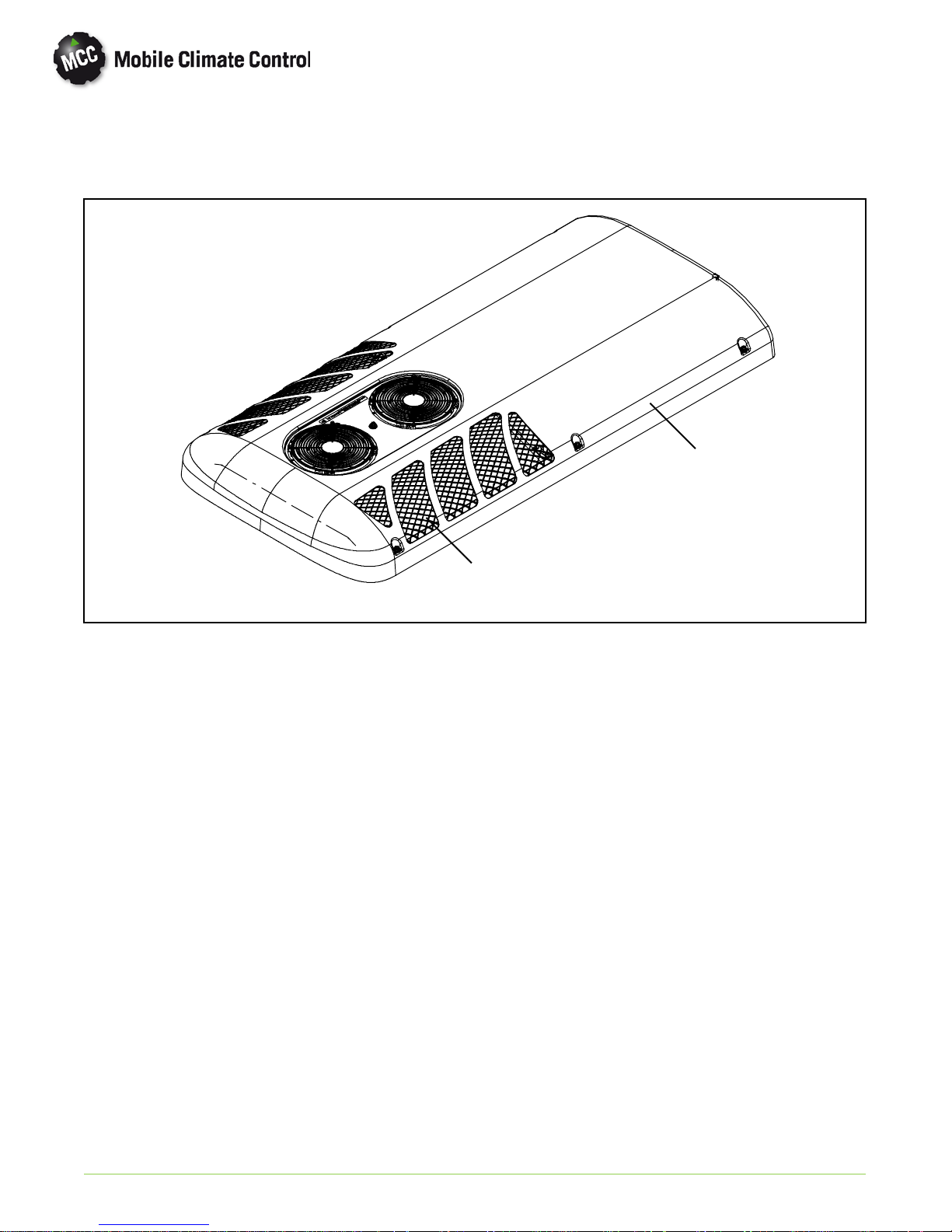

Figure 1-1 AC430 Rooftop Unit 1-2....................................................

Figure 1-2 Refrigerant/Heat Flow Diagram, AC430 1-5.....................................

Figure 1-3 AC430 With BT324 Control Board 1-6.........................................

Figure 3-1 BT324 Controller 2-1......................................................

Figure 4-1 Manifold Gauge Set (R-134a) 4-2..............................................

Figure 4-2 In-Line Service Connections 4-3..............................................

Figure 4-3 Checking High Pressure Switch 4-5............................................

Figure 4-4 Filter-Drier Removal 4-5....................................................

Figure 4-5 Heat Valve 4-7............................................................

Figure 4-6 Service Valve R134a (High Side) 4-7...........................................

Figure 4-7 Return Air Grill Assembly With Air Filter Showing 4-8.............................

Figure 4-8 Diffuser and Filter Element 4-8...............................................

Figure 4-9 Filter, Diffuser and Composite Frame 4-8.......................................

Figure 4-10 Return Air Grill Assembly With Diffuser And Composite Frame Showing 4-8..........

Figure 4-11 Thermostatic Expansion Valve 4-9...........................................

Figure 4-12 Thermostatic Expansion Valve Bulb and Thermocouple 4-9........................

Figure 5-2 Evaporator Motors 5-2.....................................................

Figure 5-3 Condenser Motors 5-3.....................................................

Figure 5-4 BT324 Controls With (1) Compressor 5-4.......................................

Figure 5-5 BT324 Control Circuit 5-5...................................................

Figure 5-6 AC430 With BT324 Control 5-6..............................................

Figure 5-7 AC430 With BT324 Control (Electrical Panel 91-62105-00) 5-7.......................

Figure 5-8 AC430 With BT324 Control (Electrical Panel 91-62105-00) 5-8.......................

© 2012 Mobile Climate Control T-353 Rev. 01/2013

iii

SAFETY SUMMARY

GENERAL SAFETY NOTICES

The following general safety notices supplement the specific warnings and cautions appearing elsewhere in this

manual. They are recommended precautions that must be understood and applied during operation and

maintenance of the equipment covered herein. A listing of the specific warnings and cautions appearing

elsewhere in the manual follows the general safety notices.

FIRST AID

An injury, no matter how slight, should never go unattended. Always obtain first aid or medical attention

immediately.

OPERATING PRECAUTIONS

Always wear safety glasses.

Keep hands, clothing and tools clear of the evaporator and condenser fans.

No workshouldbe performedon the unituntilall start-stop switchesare placed in the OFF position, and power

supply is disconnected.

Always work in pairs. Never work on the equipment alone.

In case of severe vibration or unusual noise, stop the unit and investigate.

MAINTENANCE PRECAUTIONS

Beware of unannounced starting of the evaporator and condenser fans. Do not open the unit cover before

turning power off.

Be sure power is turned off before working on motors, controllers, solenoid valves and electrical controls. Tag

circuit breaker and power supply to prevent accidental energizing of circuit.

Do not bypass any electrical safety devices, e.g. bridging an overload, or using any sort of jumper wires.

Problems with the system should be diagnosed, and any necessary repairs performed by qualified service

personnel.

When performing any arc welding on the unit, disconnect all wire harness connectors from the modules in the

control box. Do not remove wire harness from the modules unless you are grounded to the unit frame with a

static-safe wrist strap.

In case of electrical fire, open circuit switch and extinguish with CO2(never use water).

© 2012 Mobile Climate Control T-353 Rev. 01/2013

Safety--1

SPECIFIC WARNINGS AND CAUTIONS

WARNING

Be sure to observe warnings listed in the safety summary in the front of this manual before

performing maintenance on the hvac system

WARNING

Read the entire procedure before beginning work. Park the vehicle on a level surface, with

parking brake applied. Turn main electrical disconnect switch to the off position.

WARNING

Do Not Use A Nitrogen Cylinder Without A Pressure Regulator

WARNING

Do Not Use Oxygen In Or Near A Refrigeration System As An Explosion May Occur.

WARNING

The Filter-drier May Contain Liquid Refrigerant. S lowly Loosen The Connecting Nuts And

AvoidContactWithExposedSkinOrEyes.

CAUTION

The AC430 Rooftop Systems has R134a serviceport couplings installed on the compressor and

on the unit piping.

CAUTION

To prevent trapping liquid refrigerant in the manifold gauge set be sure set is brought to

suction pressure before disconnecting.

© 2012 Mobile Climate Control T-353 Rev. 01/2013

Safety--2

SECTION 1

DESCRIPTION

1.1 INTRODUCTION

This manual contains Operating Instructions,

Service Instructions and Electrical Data for the

Model 68AC430 Air Conditioning and Heating

equipment furnished by Mobile Climate Control as

showninTable1-1.

Model 68AC430 systems consists of a Rooftop unit

containing the condensing section, the evaporator

section and engine compartment mounted

compressor(s). To complete the system, the air

conditioning and heating equipment interfaces with

an optional drivers evaporator (dash-air), electrical

cabling, refrigerant piping, engine coolant piping (for

heating), duct work and other components

furnishedby Mobile Climate Control and/or the bus

manufacturer.

Additional support manuals are shown in Table 1-2.

Operation of the unit is controlled automatically by

an electronic thermostat. The controls maintain the

vehicle'sinterior temperature at the desired set point.

Table 1-1 68AC430 Models

Model Voltage Controller With Heat Dual Loop Single Loop Roof Radius

68AC430-100 12 VDC BT324 Yes X 4.6M

68AC430-100-2 12 VDC BT324 No X 4.6M

68AC430-100-4 12 VDC BT324 Yes X 4.6M

68AC430-100-5 12 VDC BT324 No X 4.6M

68AC430-100-6 12 VDC BT324 Yes X 7.8M

68AC430-100-7 12 VDC BT324 No X 7.8M

68AC430-100-8 * 12 VDC BT324 No X 7.8M

Table 1-2 Additional Support Manuals

MANUAL NUMBER EQUIPMENT COVERED TYPE OF MANUAL

T-353PL 68AC-430-100 Service Parts List

* Denotes Special Packaging

© 2012 Mobile Climate Control T-353 Rev. 01/2013

1--1

1.2 GENERAL DESCRIPTION

1.2.1 Rooftop Unit

The rooftop unit includes the condenser section and the evaporator section (See Figure 1-1).

Evaporator Section

Figure 1-1 AC430 Rooftop Unit

1.2.2 Condensing Section

The condensing section includes the condenser

coils, two (2)fan and mot or assemblies, receiver,

filter-drier and filter-drier service valves.

The condenser coils provide heat transfer surface for

condensing refrigerant gas at a high temperature and

pressure into a liquid at high temperature and

pressure. The condenser fans circulate ambient air

across the outside of the condenser tubes at a

temperature lower than refrigerant circulating inside

the tubes; this results in condensation of the

refrigerant into a liquid. The receiver collects and

stores liquid refrigerant. The receiver is also fitted

with a pressure relief valve which protects the system

from unsafe high pressure conditions. The

filter-drier removes moisture and debris from the

liquid refrigerant before it enters the thermostatic

expansion valve in the evaporator assembly. The

service valves enable isolation of the filter-drier for

service.

Condenser Section

1.2.3 Evaporator Section

The evaporatorsection includesthe evaporatorcoils,

two (2) single-shaftedblower/motor assemblies,two

(optional) heater coil assemblies, a thermostatic

expansion valve and condensate drain connections.

The evaporator coils provide heat transfer surface

for transferring heat from air circulating over the

outside of the coil to refrigerant circulating inside the

tubes; thus providing cooling. The heating coils (if

equipped) provide a heat transfer surface for

transferring heat from engine coolant water

circulating inside the tubes to air circulating over the

outside surface of the tubes, thus providing heating.

The fans circulate the air over the coils. The air filters

remove dirt particles from the air before it passes

over the coils. The thermostatic expansion valve

meters the flow of refrigerant entering the

evaporator coils. The heat valve controls the flow of

engine coolant to the heating co ils upon receipt of a

signal from the controller. The condensate drain

connections provide a means for connecting tubing

for disposing of condensate collected on the

evaporator coils during cooling operation.

© 2012 Mobile Climate Control T-353 Rev. 01/2013

1--2

1.2.4 BT-324 Microprocessor

1.4 ELECTRICAL SPECIFICATIONS - MOTORS

This BT-324 controller has three (3) modes, Auto,

Vent (Cycle clutch type) and Heat.

In the auto mode the compressor is energized while

the evaporator and condenser fans are operated to

providerefrigerationas required. The compressor(s)

capacity is matched to the bus requirements. Once

interior temperature reaches the desired set po int,

the compressor(s) is de-energized.

In the heat mode the heat valves are opened to allow

a flow of engine coolant through the heat coils

located in the evaporator section. The evaporator

fans operate to circulate air over the heat coils in the

same manner as the cooling mode.

1.3 REFRIGERATION SYSTEM COMPONENT SPECIFICATIONS

a. Refrigerant Charge R-134a (Approximate)

NOTE

Refrigerant charge will depend on hose

lengths and diameters; or if there is an InDash unit (front evaporator). The following

should only be used as a guideline.

AC430 Single Loop TM-21 Compressor

11 Pounds (5 kg)

b. Compressors

Compressor

Weight, (Dry) 7.5 Lbs. (3.4 kg)

Oil Charge 6.1 Oz. (180 cc) PAG

c. Thermostatic Expansion Valves:

TDEN 5.8 TR

Superheat Setting Factory Set at 12°F(±1.8°F)

6.7°C (±1°C)

TGEN 4.5

Superheat Setting Factory Set at 7.2°F(4°C)

MOP70psig(4.8bar)

TM-21

a. Evaporator Blower/Motor

Evaporator Motor

Horsepower (kW) .375 (.28)

Full Load Amps (FLA) 20.7

Operating Speed

High(RPM)

Bearing Lubrication

b. Condenser Fan Motor

Condenser Motor

Horsepower (kW) 1/4 (.18)

Full Load Amps (FLA) @

13.5 VDC

Operating Speed

High(RPM)

Bearing Lubrication

c. Return Air Sensor

Input Range: -40 to 176° F(-40to80°C)

Output: 20K ohms at 77° F(25°C)

d. Ambient Sensor (location chosen by Installer)

Input Range: -40 to 302° F (-40 to 150°C)

Output: 20K ohms at 77° F(25°C)

Opens at: 25° F(10°C)

Closes at: 35° F(1.7°C)

Brushless

12 VDC

3250

Factory Lubricated

(additional grease not required)

Permanent Magnet

12 VDC

14.4

3222

Factory Lubricated

(additional grease not required)

1.5 SAFETY DEVICES

System components are protected from damage

caused by unsafe operating conditions with safety

devices. Safety devices with Mobile Climate Control

supplied equipment include high pressure switch

(HPS), low pressure switch (LPS), circuit breakers

and fuses.

d. High Pressure Switch (HPS)

Opens at: 360 ±10 psig (20.41 ±0.68bar)

Closes at: 280 ±10 psig (13.61 ±0.68bar)

e. Low Pressure Switch (LPS)

Opens at: 6 ±3psig (0.41 ±0.20 bar)

Closes at: 25 ±3psig(1.7±0.20 bar)

© 2012 Mobile Climate Control T-353 Rev. 01/2013

Normally Closed

Normally Open

a. Pressure Switches

High Pressure Switch (HPS)

During the air co nditioning cycle, compressor clutch

operation will automatically stop if the HPS switch

contacts open due to an unsafe operating condition.

Opening HPS contacts de-energizes the compressor

clutch shutting down the compressor. The high

pressure switch (HPS) is installed in the condenser

section.

1--3

Low Pressure Switch (LPS)

The low pressure switch is installedin the evaporator

section and opens on a pressure drop to shut down

the system when a low pressure condition occurs.

b. Fuses and Circuit Breakers

The Relay Board is p ro tected against high current by

an OEM supplied circuit breaker or fuse located in

the bus battery compartment (150 Amp for 12 VDC

systems). Independen t 20 Amp, 12 VDC fuses

protect each condenser motor. Independent 25

Amp, 12 VDC fuses protect each evaporator motor.

Output circuits are pro tected by additional 2,3,5 and

10 Amp fuses according to circuit loads. During a

high current condition, the fuse may open.

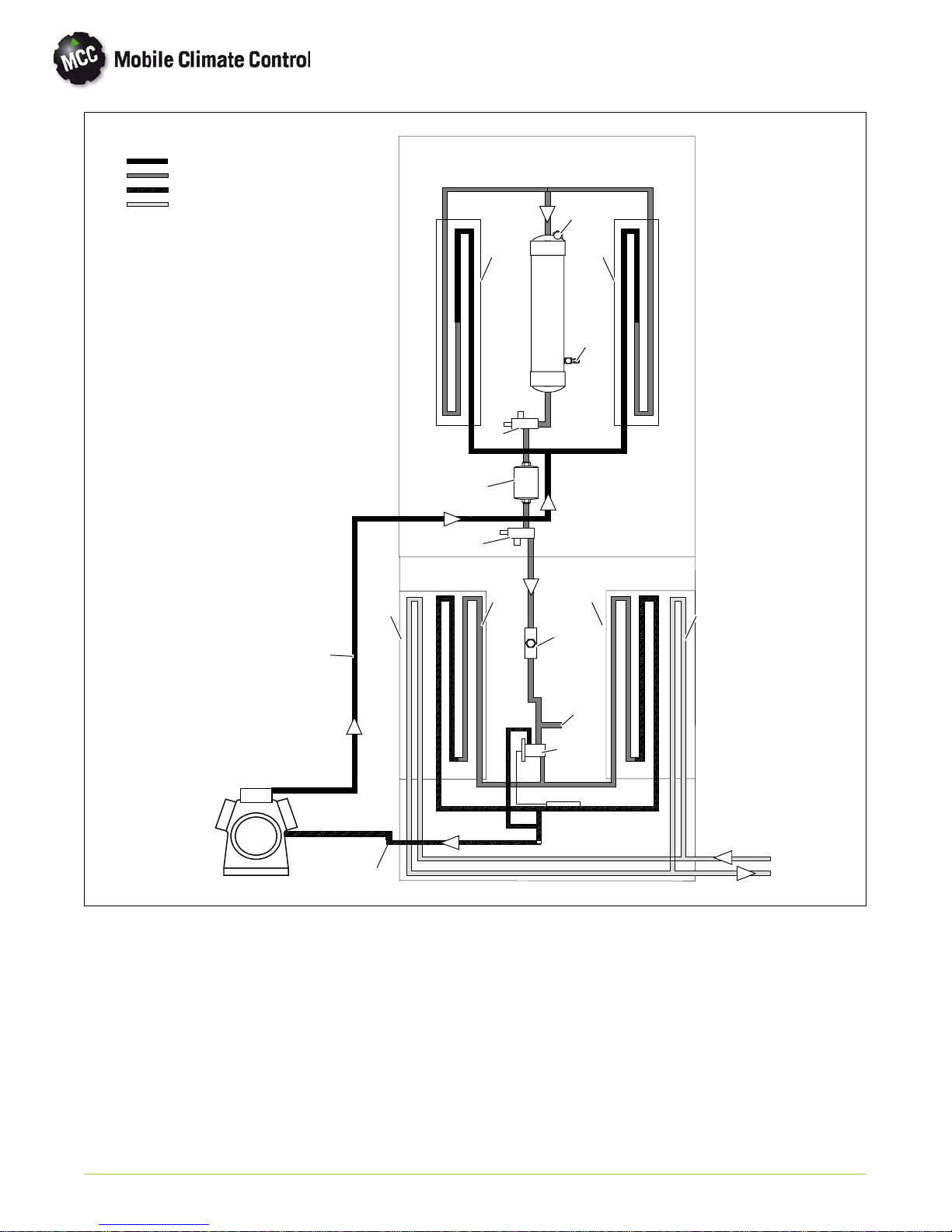

1.6 AIR CONDITIONING REFRIGERATION CYCLE

When air conditioning (cooling) is selected by the

controller, the unit operates as a vapor compression

system using R-134a as a refrigerant (See Figure 1-2

refrigerant flow diagram). The main components of

the system are the A/C compressor, air-cooled

condenser coils, receiver, filter-drier, th ermo static

expansion valve, liquid line solenoid valve (if

equipped), and evaporator coils.

The compressor raises the pressure and the

temperature of the refrigerant and forces it into the

condenser tub es. The condenser fan circulates

surrounding air (which is at atemperature lower than

the refrigerant) over the outside of the condenser

tubes. Heat transfer is established from the

refrigerant (inside the tubes) to the condenser air

(flowing over the tubes). The condenser tubes have

fins designed to improve the transfer of heat from

the refrigerant gas to the air; this removal of heat

causes the refrigerant to liquefy, thus liquid

refrigerant leaves the condenser and flows to the

receiver.

The refrigerant leaves the receiver and passes

through the receiver outlet/service valve, th rou gh a

filter-drier where a desiccant keeps t h e refrigerant

clean and dry.

From the filter-drier, the liquidrefrigerant then flows

through the liquid line to the sight-glass and then to

the thermostatic expansion valve. The thermal

expansion valvereduces pressure and t em p erature of

the liquid and meters the flow of liquid refrigerant to

the evaporator to obtain maximum use of the

evaporator heat transfer surface.

The low pressure, low temperature liquid that flows

into the evaporator tubes is colder than the air that is

circulated over the evaporator tubes by the

evaporator fans (fans). Heat transfer is established

from the evaporator air (flowing over the tubes) to

the refrigerant (flowing inside the tubes). The

evaporator tubes have aluminum fins to increase

heat transfer from the air to the refrigerant;therefore

the cooler air is circulated to the interior of the bus.

The transfer of heat from the air to the low

temperature liquid refrigerant in the evaporator

causes the liquid to vaporize. This low temperature,

low pressure vapor passes through the suction line

and returns to the compressor where the cycle

repeats.

1.7 HEATING CYCLE

Heating circuit (See Figure 1-2) components

furnished by Mobile Climate Control include the

heater cores and solenoid operated heat valves.

Components furnished by the bus manufacturer

may include a water temperature switch (WTS) and

boost water pump.

The controller automatically controls the heat valves

during the heating mode to maintain required

temperatures inside the bus. Engine coolant (glycol

solution) is circulated through the heating circuit by

the engine and an auxiliary boost water pump. When

the heat valve solenoids are energized, the valves will

open to allow engine coolant to flow through the

heater coils. The valves are normally closed so that if

a failure occurs, the system will be able to cool.

© 2012 Mobile Climate Control T-353 Rev. 01/2013

1--4

Discharge

Liquid

Suction

Coolant

14

11

11

13

3

10

12

CONDENSER

10

EVAPORATOR

8

77

8

2

6

9

Figure 1-2 Refrigerant/Heat Flow Diagram, AC430

1. Thermal Expansion Valve

2. Liquid Line Sight Glass

3. Fusible Plug

4. Dash Air Liquid Line

5. Suction Line

6. Discharge Line

7. Heater Coil

4

1

5

8. Evaporator Coil

9. Compressor

10. Service Valve

11. Condenser Coil

12. Filter-Drier

13. Receiver

14. Receiver Liquid Level Sight Glass

© 2012 Mobile Climate Control T-353 Rev. 01/2013

1--5

13

4

121110987

6

1

3

17

5

14

15

16

2

22

20

18

19

21

23

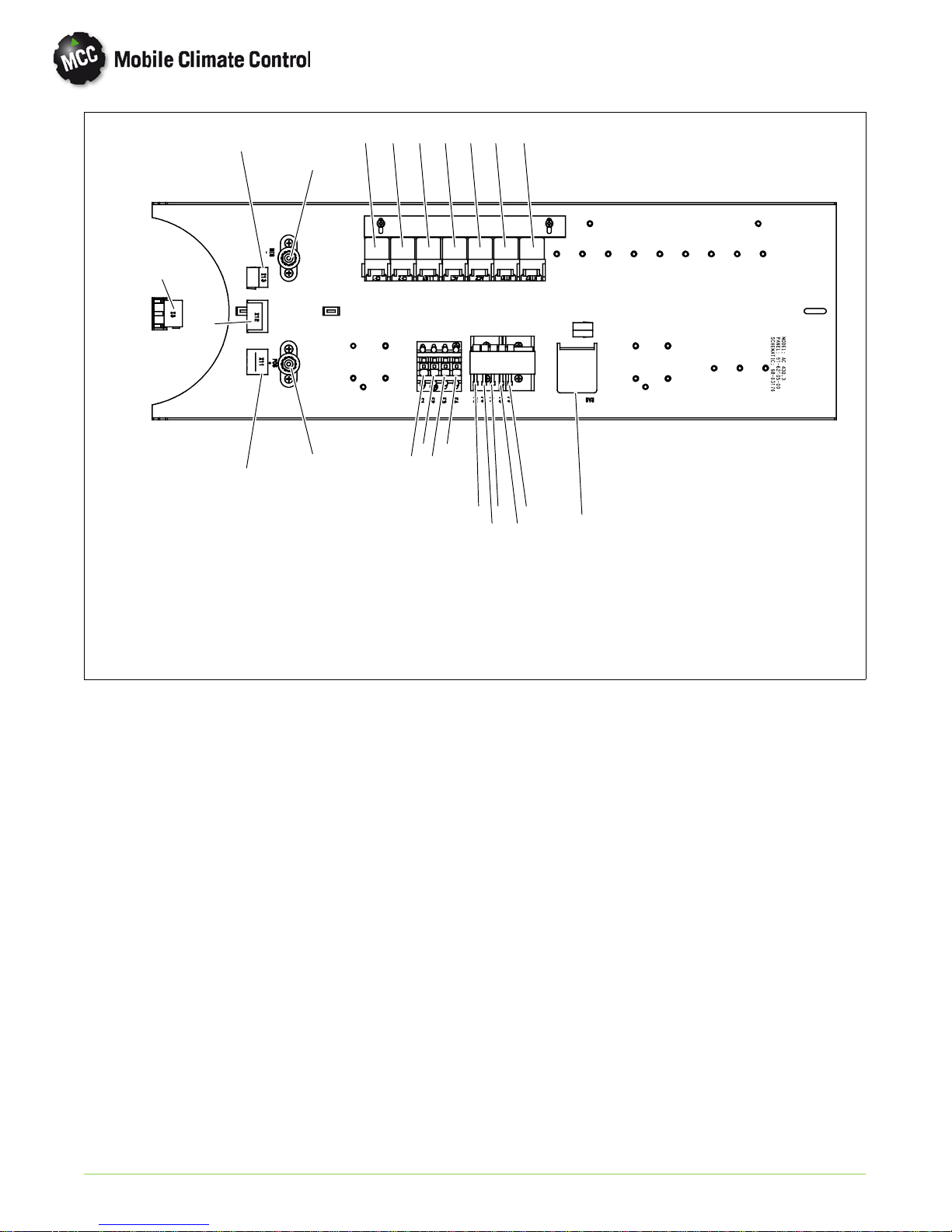

Figure 1-3 AC430 With BT324 Control Board

1. X3, Connector, Controller/Driver Display

2. X11, Connector, Evaporator Blower Motors

3. X12, Connector, Condenser Fan Motors/

High Pressure Switch

4. X13, Connector, Low Pressure Switch, Fresh

Air Flap

5. POS, 12VDCPower Connection

6. NEG, Ground Connection

7. CF1, Condenser Fan Relay 1

8. CF2, Condenser Fan Relay 2

9. LLSV, Liquid Line Solenoid Valve Relay

10. AC1, Condenser Fan On Relay

11. AC2, Condenser Fan On Relay

12. HTR1, Relay, Evaporator High Speed

13. HTR2, Relay, Evaporator Low Speed

14. F1, Fuse, Evaporator Motor

15. F2, Fuse, Evaporator Motor

16. F3, Fuse, Condenser Motor

17. F4, Fuse, Condenser Motor

18. F5, Fuse, LLSV

19. F6, Fuse, Condenser Fan Relay

20. F7, Fuse, Pressure Switch Relay

21. F8, Fuse, Heat Valve/ Pump Relay

22. F9, Fuse, Heat Valve/Floor Relay

23. RAS, Return Air Sensor

© 2012 Mobile Climate Control T-353 Rev. 01/2013

1--6

SECTION 2

OPERATION BT324 CONTROLLER

2.1 STARTING, STOPPING AND OPERATING INSTRUCTIONS

The BT324 Digital Display is marked with

international symbols (See Figure 3-1).

2.1.1 Starting

a. If the engine is not running, start the engine.

b. When the 12VDC power is applied, the driver dis

play will illuminate and show return air set point.

Press the A/C key (Item 5 Figure 3-1) on the dis

play to trigger the start up sequence.

c. After the pre-trip inspection is completed, the

switches may be set in accordance with the desired

control modes.

1

6

Before starting, electrical power must be available

from the bus power supply.

A fuse located in the battery compartment passes

power for the clutch, evaporator and condenser

assemblies.

2.1.2 Stopping

Toggling the A/C key (Item 5 Figure 3-1) on the

display again will stop the system operation.

2.2 PRE-TRIP INSPECTION

After starting system, allow system to stabilize for ten

to fifteen minutes and check for the following:

a. Listen for abnormal noises in compressor or fan

motors.

b. Check refrigerant charge. (Refer to section 4.7.1 )

KEYS

1. Plus Key

2. Minus Key

3. Recirculate/Fresh Air Key

4. Blower Control Key

5. Automatic Climate Control (A/C)

© 2012 Mobile Climate Control T-353 Rev. 01/2013

5432

10987

Figure 3-1 BT324 Controller

LEDS

6. Display

7. Fresh Air Operation (Green)

8. Manual Blower Control 'ON' (Green)

9. Heating Mode (Green)

10. Malfunction Light (Red)

2--1

2.3 SEQUENCE OF OPERATION BT324

2.3.1 Function of Keys when “Engine On” and controller

active:

a. PlusKey - Increases interior temperature set point

by 1° per stroke or increasesmanual blower speed,

depending on displayed mode.

b. Minus Key - Decreases interior temp erature set

point by 1° per stroke or decreases manual b lower

speed, depending on displayed mode.

c. Recirculating Air/Fresh Air - Switches from Recir

culating Air to Fresh Air and vice-versa.

d. Blower Control - Switches on the manual blower

control.

e. Automatic Climate Con t ro l - Switches o n the Au

tomatic Temperature Control.

f. Temperature Indicator (Key2+Key3)- Shows

the inside temperature for 10 seconds. If pressed a

second time shows the outside temperature for 10

seconds (optional).

g. Reheat (optional) (Key3+Key5)- Starts Reheat

mode for 3 minutes (duration adjustable).

h. Controller Off (A/C Switch To Off) -Switches

off all control functions and the display.

NOTE

The following blower steps are disabled

when the automatic climate control is on:

2-, 3-step blower: Off

Continuously adjustable blower: Off

2.3.2 Illuminating Indications (Display)

With “Engine-On” and Controller active

2.4 OPERATING INSTRUCTIONS BT324

When the engine is running, toggle the A/C Switch

to on to activate the Air Conditioning Unit.

2.4.1 Display

The temperature can be adjusted between 64° F(18°

C) and 82° F(28° C).

When the outside temperatures are below 35° F(2°

C) (adjustable parameter), the cooling function

remains disabled.

2.4.3 Ventilation

When the unit is operating in Automatic Climate

Control mode, the blower speed is controlled based

on the room temperature.

However, the blowers may be switched to manual

mode of operation by pressing the blower key.

Press the Plus o r Minus keys to select different

blower steps. The b lowers can not be switched OFF

when Automatic Climate Control is ON.

When Automatic Climate Control is OFF, the

blowers stop when the manual control is turned to

zero.

2.4.4 Reheat (optional)

The Reheat mode is used to remo ve air humidity and

to help defog the windshield. Press Key 3

(Recirculating Air/Fresh Air) and Key 5 (Automatic

Climate Control) at the same time to activate Reheat.

Heating and cooling will be energized on for 3

minutes (adjustable parameter). In addition, the

blowers are switched to maximum speed and the

fresh air flap is closed. At the end of the pre-set

duration of time, the functions return to the

previously selected settings.

Reheat mode is disabled with the outside

temperature is below 35° F(2° C) (adjustable

parameter), when the sensor is not installed, or when

there is a sensor failure.

2.4.5 Temperature Indication

Press key 2 (minus) and key 3 (Recirculating

Air/Fresh Air) at the same time to display the inside

temperature for 10 seconds.

Optionally, the outside temperature may be

displayed when pressing the keys a second time.

A sensor malfunction is displayed by “i --” or “o --”.

When the unit is ON, the display shows the interior

set point temperature. When selecting individual

functions, the display shows the corresponding

information for a short period of time. The display is

dark when the engine and control unit are OFF.

2.4.2 Interior Temperature Control

Press the Plus (1) or Minus (2) keys to set the desired

interior temperature.

© 2012 Mobile Climate Control T-353 Rev. 01/2013

2.5 CHANGING BETWEEN °F (FAHRENHEIT) AND °C

(CELCIUS )

Procedures for changing the BT324 Controller

between Fahrenheit and Celsius is as follows:

a. Engine “OFF” & Ignition “ON”.

b. Press Key 1 (plus) an d Key 2 (minus) at the same

time until the display shows the word “Code”.

2--2

NOTE

After the display shows the word “Code”

you have 5 seconds to enter the correct ac

cess code.

c. Press Key 1 (Plus Key) one time and release.

e. Press Key 4 (blower control) one time and release.

The display will show the mode “Fah” for

temperatures in °F or the mode “Cel” for

temperatures in °C.

f. Press Key 1 (plus) or Key 2 (minus) to change the

temperature mode.

d. Press Key 3 (Recirculating Air/Fresh Air) one

time and release.

g. Press Key 5 (automatic climate control) one time

to end the program.

© 2012 Mobile Climate Control T-353 Rev. 01/2013

2--3

SECTION 3

TROUBLESHOOTING

Table 3-1 General System Troubleshooting Procedures

INDICATION -

TROUBLE

POSSIBLE CAUSES

REFERENCE

SECTION

3.1 System Will Not Cool

Compressor will not run Drive-Belt loose or defective

Clutch coil defective

Clutch malfunction

Compressor malfunction

Electrical malfunction Coach power source defective

Circuit Breaker/safety device open

Check

Check/Replace

Check/Replace

See Table 1-2

Check/Repair

Check/Reset

3.2 System Runs But Has Insufficient Cooling

Compressor Drive-Belt loose or defective

Compressor valves defective

Refrigeration system Abnormal pressures

No or restricted evaporator air flow

Expansion valve malfunction

Restricted refrigerant flow

Low refrigerant charge

Service valves partially closed

Safety device open

Restricted air flow No evaporator air flow or restriction 3.5

Heating system Heat valve stuck open 3.7

Check

See Table 1-2

3.3

3.5

3.6

4.10

4.7

Open

1.5

3.3 Abnormal Pressures

High discharge pressure Refrigerant overcharge

Low discharge pressure Compressorvalve(s)wornorbroken

High suction pressure Compressorvalve(s)wornorbroken See Table 1-2

Low suction pressure Suction service valve partially closed

Suction and discharge pressures tend

to equalize when system is operating

Noncondensable in system

Condenser motor failure

Condenser coil dirty

Low refrigerant charge

Filter-drier inlet valve partially closed

Filter-drier partially plugged

Low refrigerant charge

Expansion valve malfunction

Restricted air flow

Compressor valve defective See Table 1-2

4.7.1

Check

Check

Clean

See Table 1-2

4.7

Open

Check/Open

4.10

4.7

3.6

3.5

3.4 Abnormal Noise Or Vibrations

Compressor Loose mounting hardware

Worn bearings

Worn or broken valves

Liquid slugging

Insufficient oil

Clutch loose, rubbing or is defective

Drive-Belt cracked, worn or loose

Dirt or debris on fan blades

Check/Tighten

See Table 1-2

SeeTable 1-2

3.6

1.3

Repair/Replace

Adjust/Replace

Clean

© 2012 Mobile Climate Control T-353 Rev. 01/2013

3--1

Table 3-1 General System Troubleshooting Procedures - Continued

INDICATION -

TROUBLE

POSSIBLE CAUSES

REFERENCE

SECTION

3.4 Abnormal Noise Or Vibrations - Continued

Condenser or evaporator fans Loose mounting hardware

Defective bearings

Blade interference

Blade missing or broken

Check/Tighten

Replace

Check

Check/Replace

3.5 No Evaporator Air Flow Or Restricted Air Flow

Air flow through coil blocked Coil frosted over

Dirty coil

Dirty filter

No or partial evaporator air flow Motor(s) defective

Motor brushes defective

Evaporator fan loose or defective

Fan damaged

Return air filter dirty

Icing of coil

Fan relay(s) defective

Safety device open

Fan rotation incorrect

Defrost coil

Clean

Clean/Replace

Repair/Replace

Replace

Repair/Replace

Repair/Replace

Clean/Replace

Clean/Defrost

Check/Replace

1.5

Check

3.6 Expansion Valve Malfunction

Low suction pressure with high super

heat

Low superheat and liquid slugging in

the compressor

Side to side temperature difference

(Warm Coil)

Low refrigerant charge

Wax, oil or dirt plugging valve orifice

Ice formation at valve seat

Power assembly failure

Loss of bulb charge

Broken capillary tube

Bulb is loose or not installed.

Superheat setting too low

Ice or other foreign material holding valve open

Wax, oil or dirt plugging valve orifice

Ice formation at valve seat

Power assembly failure

Loss of bulb charge

Broken capillary

4.7

Check

4.6

Replace

Replace

4.14

4.14

4.14

Check

4.6

Replace

Replace

4.14

3.7 Heating Malfunction

Insufficient heating Dirtyorpluggedheatercore

Coolant solenoid valve(s) malfunctioning or plugged

Low coolant level

Strainer(s) plugged

Hand valve(s) closed

Water pumps defective

Auxiliary Heater malfunctioning.

No Heating Coolant solenoid valve(s) malfunctioning or plugged

Controller malfunction

Pump(s) malfunctioning

Safety device open

Continuous Heating Coolant solenoid valve stuck open 4.11

Clean

Check/Replace

Check

Clean

Open

Repair/Replace

Repair/Replace

Check/Replace

Replace

Repair/Replace

1.5

© 2012 Mobile Climate Control T-353 Rev. 01/2013

3--2

SECTION 4

SERVICE

WARNING

Be sure to observe warnings listed in the safety summary in the front of this manual before per

forming maintenance on the hvac system

WARNING

Read the entire procedure before beginning work. Park the coach on a level surface, with park

ing brake applied. Turn main electrical d isconnect switch to the off position.

NOTE

To avoid damage to the earth's o zone layer, use a refrigerantreco very system whenever remo ving refrig

erant. When working with refrigerants you must comply with all local government environmental laws.

4.1 MAINTENANCE SCHEDULE

SYSTEM

ON OFF

a. Daily Maintenance

X

b. Weekly Inspection

X

c. Monthly Inspection and Maintenance

Pre-trip Inspection - after starting

X

Check tension and condition of drive belts.

X

Perform daily inspection

X

Check condenser, evaporator coils and air filters for cleanliness

X

Check refrigerant hoses, fittings and component connections for leaks

Feel filter-drier for excessive temperature drop across drier

X

Perform weekly inspection and maintenance

X

Clean evaporator drain pans and hoses

X

Check wire harnesses for chafing and loose terminals

X

Check fan motor bearings

X

Check compressor mounting bolts for tightness

SYSTEM

4.2 REMOVING COVER

To remove the cover do the following:

1. Turn all the 1/4 turn cam locks counterclockwise.

2. Using two people carefully grasp the cover under

the bottom edge and lift up.

REFERENCE

SECTION

2.2

None

See above

None

4.5

4.10

See above

None

Replace/Tighten

None

None

4.3 MANIFOLD GAUGE SET

A manifold gauge set can be used to determine

system operating pressures, add charge, equalize or

evacuate system.

When the suction pressure hand valve is front seated

(turned all the way in), th e suction (low) pressure can

be read. When the discharge pressure hand valve is

front seated, discharge (high) pressure can be read.

© 2012 Mobile Climate Control T-353 Rev. 01/2013

4--1

When both valves are open (turned

counterclockwise),high pressure vapor willflow into

the low side. When only the low pressure valve is

open, the system can be charged or evacuated.

CAUTION

the manifold gauge set. Mid-seat both hand valves on

the manifold gauge set and allow the pressure in the

manifold gauge set to be drawn down to low side

pressure. This returns any liquid that may be in the

high side hose to the system.

The AC430 Rooftop Systems has R134a

service port couplings installed on the

unit piping.

4.3.1 Installing R-134a Manifold Gauge/Hose Set

An R-134a manifold gauge/hose set with self-sealing

hoses is pictured in Figure 4-1. The manifold

gauge/hose set is available from Mobile Climate

Control. (Mobile Climate Control P/N 07-00294-00,

which includes items 1 through 6, Figure 4-1). To

perform service using the manifold gauge/hose set,

do the following:

a. Preparing Manifold Gauge/Hose Set for use.

1. If the manifold gauge/hose set is new or was ex

posed to the atmosphere it will need to be evacu

ated to remove contaminants and air as follows:

2. Back-seat (turn counterclockwise) both field ser

vice couplers (see Figure 4-1) and mid-seat both

hand valves.

3. Connect the yellow hose to a vacuum pump and

an R-134a cylinder.

CAUTION

To prevent trapping liquid refrigerant in

the manifold gauge set be sure set is

brought to suction pressure before dis

connecting.

2. Back-seat the low side field service coupler and

front-seat both manifold set hand valves. Back

seat the in-line system access valves(if applicable).

Remove the coup lers from the in-line access

valves.

3. Install both in-line access valve caps.

SUCTION

PRESSURE

GAUGE

OPENED

(Backseated )

HAND VALVE

1.

DISCHARGE

PRESSURE

GAUGE

CLOSED

(Frontseated)

HAND VALVE

4. Evacuate to 10 inches of vacuum and then charge

with R134a to slightly positive pressure of 1.0

psig.

5. Front-seat both manifold gauge set hand valves

and disconnect from cylinder. The gauge set is

now ready for use.

b. Connecting the Manifold Gauge Gauge/Hose

Set.

To connect the manifold gauge/hose set for reading

pressures, do the following:

1. Connect the field service couplers (see

Figure 4-1) to the high and low in-line service ports.

2. Turn the field service coupling knobs clockwise,

which will open the system to the gauge set.

3. Read the system pressures.

c. Removing the Manifold Gauge Set.

1. While the compressor is still ON, backseat (coun

terclockwise) the high side field service coupler on

To Low Side

Access Valve

BLUE

6.

Blue Knob

3.

2.

4.

To Refrigerant Tank

or Vacuum Pump

2.

3.

YELLOW

Figure 4-1 Manifold Gauge Set (R-134a)

1. Manifold Gauge Set

2.. Hose Fitting (0.5-16 Acme)

3.. Refrigeration and/or Evacuation Hose

. (SAE J2196/R-134a)

4.. Hose Fitting w/O-ring (M14 x 1.5)

5.. High Side Field Service Coupling

6.. Low Side Field Service Coupling

To High Side

Access Valve

3.

RED

4.

5.

Red Knob

© 2012 Mobile Climate Control T-353 Rev. 01/2013

4--2

4.4 REMOVING THE REFRIGERANT CHARGE

NOTE

To avoid damage to the earth's ozone layer,

use a refrigerant recovery system whenever

removing refrigerant.

NOTE

It must be emphasized that only the correct

refrigerant should be used to pressurize the

system. Use of any other refrigerant will con

taminate the system, and require additional

evacuation.

4.4.1 Removing Entire System Charge

To remove the entire refrigerant charge, do the

following:

a. Connect a manifold gauge set to the system as

showninFigure4-2.

b. Con n ect a reclaimer to the center manifold gauge

set connection.

c. Recover refrigerant in accordance with reclaimer

manufacturers instructions.

1.

To Compressor

7.

D

2.

6.

3.

S

4.

5.

Figure 4-2 In-Line Service Connections

1. Discharge Service

Port

2. Suction Service

Port

3. Manifold Gauge

Set

4. Vacuum Pump

5. Reclaimer

6. Refrigerant Cylinder

7. Thermistor Vacuum

Gauge

a. Ensure filter drier service and solenoid valves(if

equipped) are open.

1. Filter drier service valves shou ld be back seated.

b. If system is without refrigerant, charge system

with refrigerant vapor to build up pressure be

tween 20 to 30 psig (1.36 to 2.04 bar).

c. Add sufficient nitrogen t o raise system pressure to

150 to 200 psig (10.21 to 13.61 bar).

d. Check for leaks. The recommended pro cedure for

finding leaks in a system is with an electronic leak

detector. Testing joints with soapsudsissatisfacto

ry only for locating large leaks.

e. Remove test gas and replace filter-drier.

f. Evacuate and dehydrate the system. (Refer to

paragraph 4.6.)

g. Charge the unit. (Refer to paragraph 4.7.)

4.6 EVACUATION AND DEHYDRATION

4.6.1 General

The presence of moisture in a refrigeration system

can have many undesirable effects. The most

common are copper plating, acid sludge formation,

“freezing-up” of metering devices by free water, and

formation of acids, resulting in metal corrosion. An

evacuation should take place after a system repair

(replacement of filter drier. expansion valve,

solenoid valve, etc).

4.6.2 Preparation

NOTE

Usinga compound gauge(manifold gauge) for

determination of vacuum level is not recom

mended because of its inherent inaccuracy.

4.5 REFRIGERANT LEAK CHECK

A refrigerant leak check should always be performed

after the system has been opened to replace or repair

a component.

To check for leaks in the refrigeration system,

perform the following procedure:

© 2012 Mobile Climate Control T-353 Rev. 01/2013

a. Evacuate and dehydrate only after pressure leak

test. (Refer to p aragraph 4.5)

b. Essential tools to properly evacuate and dehydrate

any system include a good vacuum pump with a

minimum of 5 cfm (8.5 m3/hr) volume displace

ment, (MCC P/N 07-00176-11), and a good mi

cron gauge (MCC P/N 07-00414-00).

4--3

c. Keep the ambient temperature above 60°F

(15.6°C) to speed evaporation o f moisture. If am

bient temperature is lower than 60°F (15.6°C),ice

may form before moisture removal is complete.

f. When correct charge has been added (refer to

paragraph1.3, refrigerantspecifications), close cyl

inder valve and front seat manifold discharge

valve.

4.6.3 Procedure for Evacuation and Dehydrating System

a. Remove refrigerant using a refrigerant recovery

system. Refer to paragraph 4.4.1

b. The recommended method is connecting 3/8”

OD refrigerant hoses designed for vacuum service

asshowninFigure5-1.

c. Make sure vacuum pump valve is open.

d. Start vacuum pump. Slowly open valves halfway

and then open vacuum gauge valve.

e. Evacuate unit until vacuum gauge indicates 500

microns Hg vacuum. Close gauge valve, vacuum

pump valve, and stop vacuum pump.

f. Wait five minutes to see if vacuum holds.

g. Charge system. Refer to paragraph 4.7.2

4.7 ADDING REFRIGERANT TO SYSTEM

4.7.1 Checking Refrigerant Charge

The following conditions must be met to accurately

check the refrigerant ch arge.

g. Prepare the cylinder as required to allow vapor

charging. Backseat the manifold suction valve and

charge vapor until the correct charge has been

added. Close cylinder valve and front seat suction

manifold set.

h. Check charge level in accordance with the proce

dures of paragraph 4.7.1.

4.8 CHECKING FOR NONCONDENSIBLES

To check for non co ndensibles, proceed as follows:

a. Stabilize system to equalize pressure between the

suction and discharge side of the system.

b. Check temperature at the condenser and receiver.

c. Check pressure at the discharge (in-line) service

port.

d. Check saturation pressure as it corresponds to the

condenser/receiver temperature. See tempera

ture-Pressure chart Table Table 4-1 for R134a.

a. Bus engine operating at high idle.

b. Unit operating in cool mode for 15 minutes.

c. Compressor discharge pressure at least 150 psig

(10.21 bar). (It may be necessary to block condens

er air flow to raise discharge pressure.)

d. Under the above conditions, the system is proper

ly charged when the float ball in the receiver tank

sight glass is showing ½ to ¾ level.

4.7.2 Adding Full Charge

a. Install manifold gauge set at the in-line suction and

discharge service ports.

b. Evacuate and dehydrate system. (Refer to para

graph 4.6)

c. Place appropriate refrigerant cylinder on scales.

Prepare to charge liquid refrigerant by connecting

charging hose from container to center connec

tion on gage manifold. Purge air from hoses.

d. Note weight of refrigerant and cylinder.

e. Open cylinder valve, backseat discharge valve on

gauge manifold and allow liquidrefrigerant to flow

into the high side of the system

e. If gauge reading is 3 psig or more than the calcu

lated P/T pressure in step d., non-condensables

are present.

f. Remove refrigerant using a refrigerant recovery

system.

g. Evacuate and dehydrate the system. (Refer to

paragraph 4.6.)

h. Charge the unit. (Refer to paragraph 4.7.2.)

4.9 CHECKING AND REPLACING HIGH OR LOWPRESSURE CUTOUT SWITCH

4.9.1 Replacing High Or Low Pressure Switches

a. The high and low pressure switches are equipped

with Schreader valves to allow removal and instal

lation without recovering the refrigerant charge.

b. Disconnect wiring from defective switch.

c. Installnew cutout switch after verifying switch set

tings.

© 2012 Mobile Climate Control T-353 Rev. 01/2013

4--4

4.9.2 Checking High Pressure Switches

WARNING

Do not use a nitrogen cylinder without a

pressure regulator

WARNING

Do n o t use oxygen in or near a refrigeration

system as an explosion may occur.

a. Disconnect wiring and remove switch from sys

tem.

b. Connect an ohmmeter across switch terminals. If

the switch is good, the ohmmeter will indicate no

resistance, indicating that the contacts are closed.

c. Connect switch to a cylinder of dry nitrogen.

(SeeFigure 4-3).

1.

4.

2.

5.

point, the switch contacts should close, indicating

no resistance (continuity) on the ohmmeter.

g. Replace switch if it does not function as outlined

above.

4.9.3 Checking Low Pressure Switches

a. Disconnect wiring and remove switch from sys

tem.

b. Connect an ohmmeter across switch terminals. If

the switch is good, the ohmmeter will indicate an

infinite reading on an ohmmeter (no continuity).

c. Connect switch to a cylinder of dry nitrogen.

(SeeFigure 4-3).

d. Set nitrogen pressure regulator higher than switch

cutout setting. (refer to paragraph 1.3.)

e. Open cylinder valve. Slowly open the regulator

valve to increase the p ressure until it reaches cut in

point. The switch should close, which is indicated

by no resistance on an ohmmeter (continuity).

f. Close cylinder valve and release pressure through

the bleed-off valve. As p ressure drops to cut-out

point, the switch contacts should open, indicating

infinite resistance (no continuity) on the ohmme

ter.

4.10 FILTER-DRIER

6.

3.

Figure 4-3 Checking High Pressure Switch

1. Cylinder Valve and Gauge

2. Pressure Regulator

3. Nitrogen Cylinder

4. Pressure Gauge (0 to 400 psig = 0 to 27.22 bar)

5. Bleed-Off Valve

6. 1/4 inch Connection

d. Set nitrogen pressure regulator higher than switch

cutout setting. (refer to paragraph 1.3.)

e. Open cylinder valve. Slowly open the regulator

valve to increase the pressure until it reaches cut

out point. The switch should open, which is indi

cated by an infinite reading on an ohmmeter (no

continuity).

f. Close cylinder valve and release pressure through

the bleed-off valve. As pressure drops to cut-in

1.

2. 3. 4.

3.

2.

6.

5.

Figure 4-4 Filter-Drier Removal

1. Filter--Drier Inlet

Service Valve

2. Valve Service Port

3. Flare Nut

4. Filter--Drier

5. Liquid Line

Solenoid Valve

6. Filter--Drier Outlet

Service Valve

4.10.1 To Check Filter-Drier

The filter-drier (See Figure 4-4) mu st be ch anged if

the system has been opened, (for any reason), or the

filter drier is partially restricted. Restriction can be

identified by either the outlet frosting or a

temperature difference between the inlet and outlet.

4.10.2 To Replace Filter-Drier Assembly

Filter D rier replacement can be accomplished by

performing the following procedure.

a. Turn the driver's A/C switch to “OFF” position.

b. Front seat the filter-drier service valves on both

sides of the filter drier.

© 2012 Mobile Climate Control T-353 Rev. 01/2013

4--5

c. Connect manifold gauge set and reclaimer to the

filter drier service valve access p o rts and reclaim

any refrigerant contained in the filter drier.

d. Place a new filter-drier near the unit for immediate

installation.

WARNING

The filter-drier may contain liquid refrig

erant. Slowly loosen the connecting nuts

and avoid contact with exposed skin or

eyes.

e. Using t wo open end wrenches, slowly crack open

the connecting nuts on each side of the filter-drier

assembly. Remove the filter-drier assembly.

f. Remove seal caps from the new filter-drier. Apply

a light coat of mineral oil to the filter-drier connec

tions.

g. Assemble th e new filter-drierto lines ensuring that

the arrow on the body of the filter-drier points in

the direction of the refrigerant flow (refrigerant

flows from the receiver to the evaporator). Finger

tighten the connecting nuts.

h. Tighten filter-drier connecting nuts using two

open end wrenches.

i. Connect vacuum pump to manifold gauge set and

evacuate filter to 500 microns. Close gauge valve,

vacuum pump valve, and stop vacuum pump.

j. Backseat (fully close) b o th service valve ports and

replace valve caps.

k. Remove Gauges.

4.11 SERVICING THE HEAT VALVE

The heat valve (Figure 4-5) requires no maintenance

unless a malfunction to the internal parts or coil

occurs. This may be caused by foreign material such

as: dirt, scale, or sludge in the coolant system, or

improper voltage to the coil.

NOTE

The OEM supplied heating (hot water) Sole

noid Valve is normally located outside of the

AC430 rooftop air conditioning system.

There are only three possiblevalvemalfunctions:coil

burnout, failure to open, or failure to close.

Coil burnout may be caused by the following:

1. Improper voltage

2. Continuous over-voltage, more than 10% or Un

der-voltageofmorethan15%.

3. Incomplete magnetic circuit due to the omission

of the coil housing or plunger.

4. Mechanical interference with movement of plung

er which m ay be caused by a deformed enclosing

tube.

Failure to open may be caused by the following:

1.Coil burned out or an open circuit to coil connec

tions.

2. Improper voltage.

3. Torn diaphragm.

4. Defective plunger or deformed valve b o dy assem

bly.

Failure to close may be caused by the following:

1. Defective plunger or deformed valve body as

sembly.

2. Foreign material in the valve.

3. Torn diaphragm.

4.11.1 Coil Replacement

a. It is not necessary to drain the coolant from the

system.

b. Place main battery disconnect switch in OFF posi

tion and lock.

c. Disconnect wire leads to coil.

d. Remove coil retaining screw and nameplate.

e. Lift burned-out coil from enclosing tube and re

place.

f. Connect wire leads and test operation.

4.11.2 Internal Part Replacement

a. Disconnect system from bus battery.

b. Open the vent fitting at the top of the outlet head

er of the heater coil.

c. Drain coil by opening the drain-cock on the inlet

tube.

d. Disassemble valve and replace defective parts.

e. Assemble valve, refill and bleed coolant lines.

4.11.3 Replace Entire Valve

a. Disconnect system from bus battery.

b. Drain coolant from lines as previously described

and disconnect hoses to valve .

c. Disconnect wire leads to coil.

d. Remove valve assembly from bracket.

e. Install new valve and re-connect hoses. It is not

necessary to disassemble the valve when installing.

© 2012 Mobile Climate Control T-353 Rev. 01/2013

4--6

f. Refill and bleed coolant lines.

f

f

g. Connect wire leads and test operation.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

TO LIQUID LINE

TO FILTER/DRYER

Service Valve

Frontseated

(clockwise)

SERVICE

PORT

Service Valve

Backseated

(counterclockwise)

VALVE CAP

VALVE

STEM

Figure 4-5 Heat Valve

1. Coil Retaining Screw

2. Nameplate

3. Coil Housing

Assembly

4. Enclosing Tube &

Bonnet Assembly

5 . K i c k --- O

6. Plunger

7. Closing Spring

8. D iaphra gm

9. O ---Ring

10. Valve Body

Spring

4.12 SERVICE VALVES

The filter/drier (High Side) service valves

(Figure 4-6) are provided with a double seat and a

gauge port, which allows servicing of the filter drier

assembly.

Turning the valvestem counterclockwise (all the way

out) will backseat the valve to open the line to the

system and close off the gauge port. In normal

operation, the valve is backseated to allow full flow

through the valve. The valve should always be

backseated before removing the service port cap.

Turning the valve stem clockwise (all the way

forward) will frontseat the valve to isolate the system

and open the service port.

Figure 4-6 Service Valve R134a (High Side)

4.13 REPLACING RETURN AIR FILTERS

The return air filters are located behind the return air

grill, inside the vehicle.

The filters shou ld be checked for cleanliness

periodically depending on operating conditions. A

dirty filter will restrict air flow over the evaporator

coil which may cause insufficient cooling or heating

and possiblefrost buildupon the coil. To remove the

filters, do the following.

a. Insure air conditioning system is in the off posi

tion.

b. Remove the return air grille with the filter-diffuser

assembly, by turning the six 1/4 turn fasteners

counterclockwise.

© 2012 Mobile Climate Control T-353 Rev. 01/2013

4--7

Composite Frame

Return Air Filter

Figure 4-7 Return Air Grill Assembly

With Air Filter Showing

c. Remove diffuser from the bus composite frame.

Diffuser

Diffuser

Air Filter

Composite Frame

Figure 4-9

Filter, Diffuser and Composite Frame

g. Place filter and diffuser into composite frame, with

filter element down (See Figure 4-9).

Return Air Filter

Figure 4-8 Diffuser and Filter Element

d. Remove and replace the filter element.

e. Center diffuser on filter element.

f. Pull filter element appro ximately 1/4 inch over

ends of the diffuser.

Captive 1/4 Fasteners

Figure 4-10 Return Air Grill Assembly

With Diffuser And Composite Frame Showing

h. Insert filter-diffuser assembly into composite

frame on bus with the six captive 1/4 fasteners.

(See Figure 4-10)

i. Lock the six captive 1/4 turns in place by rotating

clockwise.

4.14 THERMOSTATIC EXPANSION VALVE

The thermostat expansion valve (Figure 4-11) is an

automatic device which maintains constant

superheat of the refrigerant gas leaving the

© 2012 Mobile Climate Control T-353 Rev. 01/2013

4--8

evaporator regardless of suction pressure. The valve

functions are: (a) automatic control of refrigerant

flow to match the evaporator load and (b)

prevention of liquid refrigerant entering the

compressor. Unless the valve is defective, it seldom

requires any maintenance.

1.

2.

j. Run the coach for approximately 30 minutes on

fast idle.

k.Check refrigerant charge. (Refer to 4.7.1)

4.14.2 Superheat Measurement

NOTE

All readings must be taken from the TXV

bulb location and out of the direct air stream.

3.

Figure 4-11 Thermostatic Expansion Valve

1.. Power Head Assembly

2.. Equalizer Connection

3.. Bulb

4.14.1 Valve Replacement

a. Recover and recycle refrigerant from the sys

tem.(refer to 4.4.1)

b. Remove insulation from expansion valve bulb.

(See Figure 4-11 and Figure 4-12.)

c. Loosen retaining straps holding bulb to suction

line and detach bulb from the suction line.

d. Loosen flare nuts on equalizer line and disconnect

equalizer line from the expansion valve.

e. Check, clean and remove any foreign material

from the valve body, valve seat and mating sur

faces. I f required, replace the valve.

NOTE

R-134a valves are adjustable. Valves are pre

setatthefactory.

f. The thermal bulb is installed below the center of

the suction line (four or eight o'clock position).

This area must be clean to ensure positive bulb

contact. Strap thermal bulb to suction line. Ensure

that retaining straps are tight and renew insulation.

g. Fasten equalizer line to the expansion valve.

h. Leak check the new valve (Refer to paragraph 4.5)

i. Evacuate and recharge the system. (Refer to para

graph 4.6.)

3.

2.

1.

4.

5.

Figure 4-12 Thermostatic Expansion Valve Bulb and

Thermocouple

1.. Suction Line

(section view)

2.. TXV Bulb Clamp

3.. Nut & Bolt (clamp)

4.. Thermocouple

5.. TXV Bulb (Shown

in the 4’clock

position)

a. Open top cover.

b. Remove Presstite insulation from expansion valve

bulb and suction line.

c. Loosen one TXV bulb clamp and make sure area

under clamp is clean.

d. Place temperature thermocouple in contact with

the suction tube and parallel to the TXV bulb, and

then secure loosened clamp making sure b o t h

bulb and thermocouple are firmly secured to suc

tion line. (See Figure 4-12). Reinstall insulation

around the bulb.

e. Connect an accurate low p ressure gauge to t h e low

pressure port.

f. Close top cover being careful to ro u te thermocou

ple sensing wire and gauge hose outside the unit.

g. Start bus and run on fast idle until unit has stabi

lized, about 20 to 30 minutes.

NOTE

When conducting this test, the suction pres

sure must be at least 6 psig (0.41 bar) below

the expansion valve maximum operating

pressure (MOP). Refer to paragraph 1.3 for

MOP.

© 2012 Mobile Climate Control T-353 Rev. 01/2013

4--9

h. From the temperature/pressure chart, determine

the saturation temperature corresponding to the

evaporator outlet pressure.

i. Note the temperature of the suction gas at the ex

pansion valve bulb. Subtract the saturation tem

perature from this temperature. The difference is

the superheat of the suction gas.

j. The superheat may cycle from a low to high read

ing. Monitor the superheat taking readings every

3-5 minutes for a total of 5-6 readings. Calculate

the superheats, add the readings and divide by the

number of readings taken to determine average su

perheat. The superheat should be 12 ± 1.8°F.

k. If superheat is not within tolerance, replace the

valve.

© 2012 Mobile Climate Control T-353 Rev. 01/2013

4--10

Table 4-1 R-134a Temperature - Pressure Chart

Temperature Vacuum

°F °C

“/hg cm/hg kg/cm@ bar

-40 -40 14.6 49.4 37.08 0.49

.35 .37 12.3 41.6 31.25 0.42

-30 -34 9.7 32.8 24.64 0.33

-25 -32 6.7 22.7 17.00 0.23

-20 -29 3.5 11.9 8.89 0.12

-18 -28 2.1 7.1 5.33 0.07

-16 -27 0.6 2.0 1.52 0.02

Temperature Pressure

°F °C

psig kPa kg/cm@ bar

-14 -26 0.4 1.1 0.03 0.03

-12 -24 1.2 8.3 0.08 0.08

-10 -23 2.0 13.8 0.14 0.14

-8 -22 2.9 20.0 0.20 0.20

-6 -21 3.7 25.5 0.26 0.26

-4 -20 4.6 31.7 0.32 0.32

-2 -19 5.6 36.6 0.39 0.39

0 -18 6.5 44.8 0.46 0.45

2 -17 7.6 52.4 0.53 0.52

4 -16 8.6 59.3 0.60 0.59

6 -14 9.7 66.9 0.68 0.67

8 -13 10.8 74.5 0.76 0.74

10 -12 12.0 82.7 0.84 0.83

12 -11 13.2 91.0 0.93 0.91

14 -10 14.5 100.0 1.02 1.00

16 -9 15.8 108.9 1.11 1.09

18 -8 17.1 117.9 1.20 1.18

20 -7 18.5 127.6 1.30 1.28

22 -6 19.9 137.2 1.40 1.37

24 -4 21.4 147.6 1.50 1.48

26 -3 22.9 157.9 1.61 1.58

Temperature Pressure

°F °C

psig kPa kg/cm@ bar

28 -2 24.5 168.9 1.72 1.69

30 -1 26.1 180.0 1.84 1.80

32 0 27.8 191.7 1.95 1.92

34 1 29.6 204.1 2.08 2.04

36 2 31.3 215.8 2.20 2.16

38 3 33.2 228.9 2.33 2.29

40 4 35.1 242.0 2.47 2.42

45 7 40.1 276.5 2.82 2.76

50 10 45.5 313.7 3.20 3.14

55 13 51.2 353.0 3.60 3.53

60 16 57.4 395.8 4.04 3.96

65 18 64.1 441.0 4.51 4.42

70 21 71.1 490.2 5.00 4.90

75 24 78.7 542.6 5.53 5.43

80 27 86.7 597.8 6.10 5.98

85 29 95.3 657.1 6.70 6.57

90 32 104.3 719.1 7.33 7.19

95 35 114.0 786.0 8.01 7.86

100 38 124.2 856.4 8.73 8.56

105 41 135.0 930.8 9.49 9.31

110 43 146.4 1009 10.29 10.09

115 46 158.4 1092 11.14 10.92

120 49 171.2 1180 12.04 11.80

125 52 184.6 1273 12.98 12.73

130 54 198.7 1370 13.97 13.70

135 57 213.6 1473 15.02 14.73

140 60 229.2 1580 16.11 15.80

145 63 245.6 1693 17.27 16.93

150 66 262.9 1813 18.48 18.13

155 68 281.1 1938 19.76 19.37

© 2012 Mobile Climate Control T-353 Rev. 01/2013

4--11

SECTION 5

ELECTRICAL

5.1 INTRODUCTION

conditioning units which are fitted with two (2)

double-shafted evaporator blower/motor

This section includes electrical wiring schematics.

The schematics shown in this section provides

information for the AC430 model rooftop air

UNIT CONTROLLER FIGURE NUMBERS

68AC430 BT324 Figure 5-1 Thru Figure 5-6

68AC430 (Electrical Panel 91-62105-00) BT324 Figure 5-7 Thru Figure 5-8

assemblies and two (2) condenser fan motors.

Figure 5-2 thru Figure 5-6 shows the BT324

controller used with the AC430 system.

© 2012 Mobile Climate Control T-353 Rev. 01/2013

5--1

98--67037--00

© 2012 Mobile Climate Control

5--2

Figure 5-2 Evaporator Motors

T-353 Rev. 01/2013

© 2012 Mobile Climate Control

5--3

Figure 5-3 Condenser Motors

98--67037--00

T-353 Rev. 01/2013

98--67037--00

© 2012 Mobile Climate Control

5--4

Figure 5-4 BT324 Controls With (1) Compressor

T-353 Rev. 01/2013

© 2012 Mobile Climate Control

5--5

Figure 5-5 BT324 Control Circuit

98--67037--00

T-353 Rev. 01/2013

98--67037--00

Figure 5-6 AC430 With BT324 Control

© 2012 Mobile Climate Control

5--6

T-353 Rev. 01/2013

Figure 5-7 AC430 With BT324 Control (Electrical Panel 91-62105-00)

INDICATES RELAY CONTACTS (NORMALLY CLOSED)

INDICATES RELAY CONTACTS (NORMALLY OPEN)

INDICATES A CONNECTOR (VARIOUS STYLES)

INDICATES A TERMINAL CONNECTION

INDICATES A WIRE GROUND

INDICATES OPTIONAL WIRING OR FEATURE

INDICATES OPTIONAL UNIT WIRING O R FEATURE

INDICATES WIRING EXTERNAL TO UNIT

INDICATES WIRING INTERNAL TO UNIT

SYMBOL DESCRIPTION

© 2012 Mobile Climate Control

GRD

HIGHPRESSURESWITCH

FUSE,3AMP

FUSE,5AMP

A/CRELAY

ACR1--ACR2

CONDENSERFANRELAY

CFR1--CFR2

F1-- F2 FUSE,25AMP

ATS AMBIENTTEMPERATURESENSOR

DESCRIPTION

INDICATES AMBIENT TEMPERATURE SENSOR (ATS)

INDICATES FUSE WITH MANUAL RESET

INDICATES FUSE

INDICATES ELECTRICAL COMPONENT

INDICATES RELAY COIL

86 85

ATS

SYMBOL

FUSE,10AMP

HPS

F5

F6-- F7

F8-- F9

F3-- F4 FUSE,20AMP

HTR1--HTR1 HEAT RELAY

5--7

RETURNAIRSENSOR

LOWPRESSURESWITCH

LIQUIDLINESOLENOIDVALVE

RAS

LPS

LLSV

LLSR LIQUIDLINESOLENOIDRELAY

T-353 Rev. 01/2013

POS

(+)

NEG

(--)

F7

F8

F9

ATS

OPTIONAL

DIMMER

12V(+)

IGNITION

12V (+)

ALTERNATOR

12V (+)

CHASSIS

GROUND

5AMP

10 AMP

10 AMP

GREY

LOOM

BLU

2AMP

3AMP

2AMP

BRN

WHT

30

30

30

ACR2

HTR1

HTR2

BT--7

BT--3

BT--5

BT--1

BT--9

LLSV

85

87

X12--5

HPS

B

X12--6

A

X13--1

X3--14

87

87

BT--13

BT--18

BT--10

BT--6

BT--15

BT--11

BT324CONTROLLER

BT--14

BT--8

BT--17

BT--4

X3--15

X3--16

X3--10 (NOT USED)

DRIVERCONTROLHARNESS

X3--11

X3--9

X3--6

X3--4

X3--3

X3--2

X3--1

X3--7

X3--8 (NOT USED)BT--2

86

X13--3

X13--4

86

HTR1

ACR1

A

B

X11--5

85

85

A

RETURN AIR

LPS

RAS

SENSOR

M1- -PWM

X13--2

B

COMP

CLUTCH

A B

HTR2

85

86

COOLANT

PUMP

RELAY

A B

COOLANT

VALVE

RELAY

A B

FRESH AIR

MOTOR

86

F1

25 AMP

F2

25 AMP

F3

20 AMP

F4

20 AMP

F5

3AMP

F6

5AMP

30

30

30

30

CFR1

87

CFR2

87

LSVR

87

ACR1

87

98--63176

© 2012 Mobile Climate Control

X11--1

X11--3

X12--1

X12--7

5--8

M1- -1

M2- -PWM

M2- -1

M1- -A

M2- -AX12--2

LV --1

EVAP

MTR 1

EVAP

MTR 2

COND

MTR 1

COND

MTR 2

LLSV

86

86

86

ACR2

CFR1

CFR2

85

M1- -2

M2- -2

M1- -B

M2- -B

LV --1 2

85

85

X11--2

Figure 5-8 AC430 With BT324 Control (Electrical Panel 91-62105-00)

X11--4

T-353 Rev. 01/2013

INDEX

A

Air Filters, 4-7

Apex Unit, 1-2

C

Circuit Breaker, 1-4

Compressor, 1-3

Condenser Fan, 1-3

Condensing Section, 1-2

D

DESCRIPTION, 1-1

E

M

Maintenance Schedule, 4-1

Manifold Gauge Set, 4-2

N

Noncondensibles, 4-4

O

Operating Instructions, 2-1

OPERATION, 2-1

P

Pre-Trip Inspection, 2-1

Pump Down, 4-3

ELECTRICAL, 5-1

Evacuation, 4-3, 4-4

Evaporator, 1-2

Evaporator Fan, 1-3

F

Filter-Drier, 4-5

Fuse, 1-4

H

Heat Valve, 4-6

Heating Cycle, 1-4

High Pressure Switch, 1-3

L

R

Refrigerant Charge, 1-3, 4-3, 4-4

Refrigerant Removal, 4-3

Refrigeration Cycle, 1-4

S

SERVICE, 4-1

Starting, 2-1

Stopping, 2-1

Superheat, 4-9

T

Temperature Pressure Chart, 4-11

Temperature Sensor, 1-3

Thermostatic Expansion Valve, 1-3, 4-8

Low Pressure Switch, 1-3, 1-4

© 2012 Mobile Climate Control T-353 Rev. 01/2013

TROUBLESHOOTING, 3-1

Index --1

Every driver deserves the best possible

vehicle climate with MCC products

MCC provides exceptional performance in mobile climate comfort.

Specifications subject to change without notice. MCC is a registered trademark.

© 2012 Mobile Climate Control

Member of MCC Group S Certified ISO 9001 and ISO 1 4001.

www.mcc-hvac.com

3189 Farmtrail Road

York PA 17406 USA

Tel: 1--800--673--2431

Fax: 1--717--764--0401

T-353 Rev. 01/2013

Loading...

Loading...