MBW VS77M User Manual

OPERATOR’S SAFETY

AND SERVICE MANUAL

VIBRATION

SUPPRESSOR

& ERGOTAMP

This manual covers the following serial numbers

and higher for each model listed:

VS77...........1110640

VS77M........1110640

ErgoTamp....2110258

PROBLEM SOLVING TECHNOLOGIES

MBW, Inc.

250 Hartford Rd • PO Box 440

Slinger, WI 53086-0440

Phone: (262) 644-5234

Fax: (262) 644-5169

Email: mbw@mbw.com

Website: www.mbw.com

MBW (UK) Ltd.

Units 2&3 CochraneStreet

Bolton BL3 6BN

England, UK

Phone: 44 (0) 01204 387784

Fax: 44 (0) 01204 387797

E-mail: mbwuk@btinternet.com

MBW FRANCE S.A.R.L.

Z.A. d’Outreville

5 Rue Jean Baptiste Néron,

60540 BORNEL

France

Phone:+33 (0) 3 44 07 15 96

Fax: +33 (0) 3 44 07 41 28

Email: mbwfrance@free.fr

L18678 / 2.14L

©MBW, Inc. 2014

Printed in the USA

TABLE OF CONTENTS

Safety Information . . . . . . . . . . . . . . . . . . . . . . 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . 2

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Before Starting & Operating . . . . . . . . . . . . . . . . . . . . 3

Operating Ergo and Pole tamps . . . . . . . . . . . . . . . . . 4

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . 5

Fluid Levels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Tamper Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Vibration Suppressor Oil . . . . . . . . . . . . . . . . . . . . . . 5

Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Vibration Suppressor Disassembly . . . . . . . . . . . . . . 6

Vibration Suppressor Assembly . . . . . . . . . . . . . . . . . 6

Tamper Disassembly. . . . . . . . . . . . . . . . . . . . . . . . . 6

Tamper Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Suppressor Replacement Cycles and Tolerances . . . 7

Tamper Replacement Cycles and Tolerances . . . . . . 7

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . 9

Vibration Suppressor Assembly . . . . . . . . . . . . . . . . 10

Threaded Adapters. . . . . . . . . . . . . . . . . . . . . . . . . . 12

Tamper Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

This page intentionally left blank

SAFETY INFORMATION

WARNING

CAUTION

Introduction

This Safety Alert Symbol is used to call attention

to items or operations which may be dangerous

to those operating or working with this

equipment. The symbol can be found

throughout this manual and on the unit. Please read these

warnings and cautions, along with all decals, carefully

before attempting to operate the unit. Make sure every

individual who operates or works with this equipment is

familiar with all safety precautions.

GENERAL WARNING. Indicates information

important to the proper operation of the

equipment. Failure to observe may result in

damage to the equipment and/or severe bodily

injury or death.

GENERAL CAUTION. Indicates information

important to the proper operation of the

equipment. Failure to observe may result in

damage to the equipment.

Safety Precautions

LETHAL EXHAUST GAS: An internal

combustion engine discharges carbon

monoxide, a poisonous, odorless, invisible

gas. Death or serious illness may result if

inhaled. Operate only in an area with proper

ventilation. NEVER OPERATE IN A

CONFINED AREA!

SAFETY GUARDS: It is the owner's

responsibility to ensure that all guards and

shields are in place and in working order.

NOISE PROTECTION: Wear OSHA specified

hearing protection devices.

EYE PROTECTION: Wear OSHA specified

eye shields, safety glasses, and sweat bands.

FOOT PROTECTION: Wear OSHA specified

steel-tipped safety shoes.

HEAD PROTECTION: Wear OSHA specified

safety helmets.

DUST PROTECTION: Wear OSHA specified

dust mask or respirator.

OPERATOR: Keep children and bystanders

off and away from the equipment.

REFERENCES: For details on safety rules and regulations

in the United States, contact your local Occupational Safety

and Health Administration (OSHA) office. Equipment

operated in other countries must be operated and serviced

in accordance and compliance with any and all safety

requirements of that country. The publication of these

safety precautions is done for your information. MBW does

not by the publication of these precautions, imply or in any

way represent that these are the sum of all dangers present

near MBW equipment. If you are operating MBW

equipment, it is your responsibility to insure that such

operation is in full accordance with all applicable safety

requirements and codes. All requirements of the United

States Federal Occupational Safety and Health

Administration Act must be met when operated in areas that

are under the jurisdiction of that United States Department.

SAFE DRESS: Do not wear loose clothing,

rings, wristwatches, etc. near machinery.

Safety Decals

The MBW Vibration Suppressor has a warning scribed into

the body tube of the device. If this warning becomes

damaged or unreadable, replace outer tube. This

component is available from authorized MBW distributors.

- 1 -

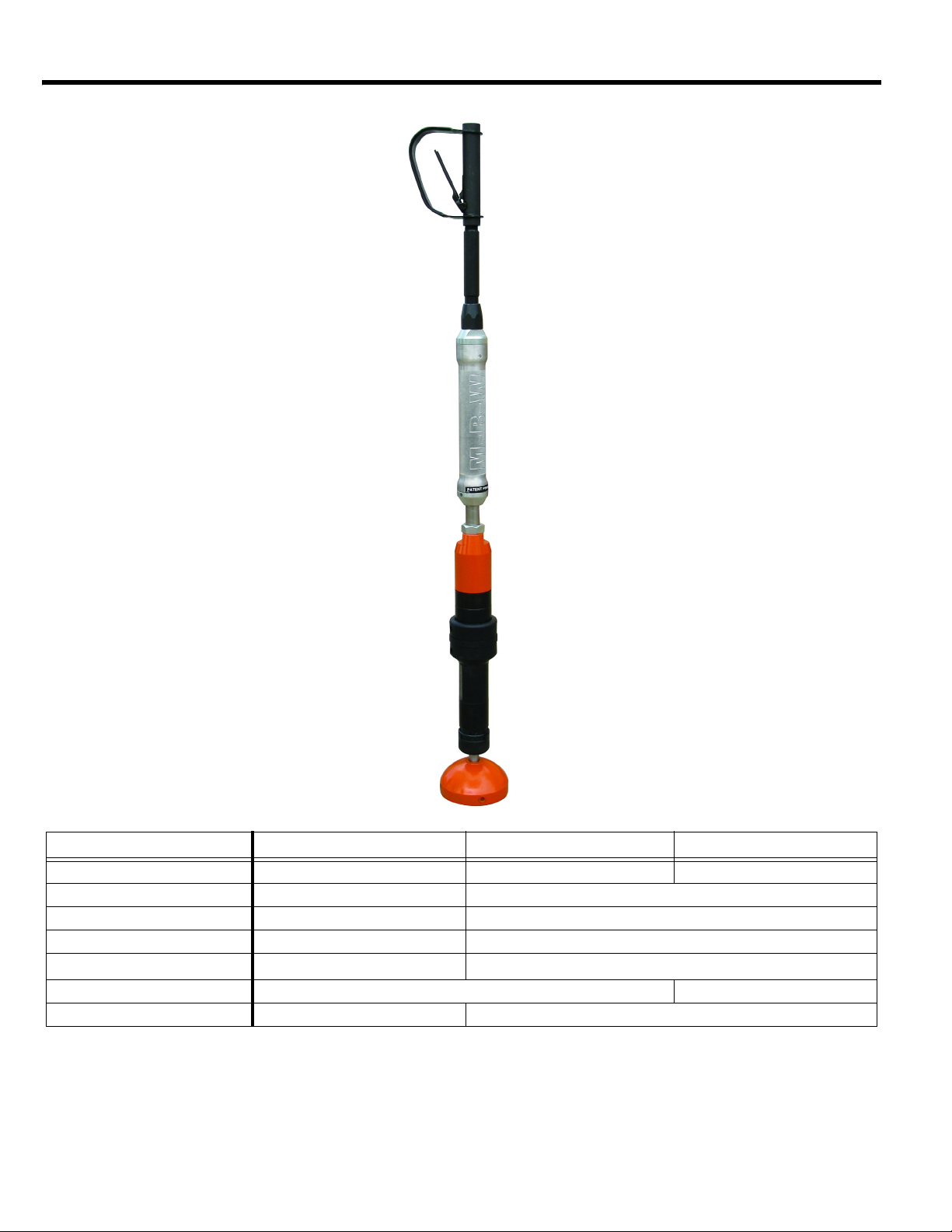

SPECIFICATIONS

VS77 Ergo-Tamp Pole-Tamp

Operating Weight 6.8 lb (3.1 kg) 48 lb (22 kg) 38 lb (17 kg)

Length 17 in (43 cm) 56 in (142 cm)

Foot Diameter -- 6.0 in (15 cm)

Maximum Pressure 140 psi (965 KPa) 90 psi (620 KPa)

Air Consumption --

Vibration Isolation up to 77%* None

Blows per Minute -- 800 @ 90 PSI

Specifications subject to change without notice

* Under ideal conditions, actual vibration isolation may vary with compactor type and compaction conditions

- 2 -

38.5 cfm (1.1 m

3

/m)

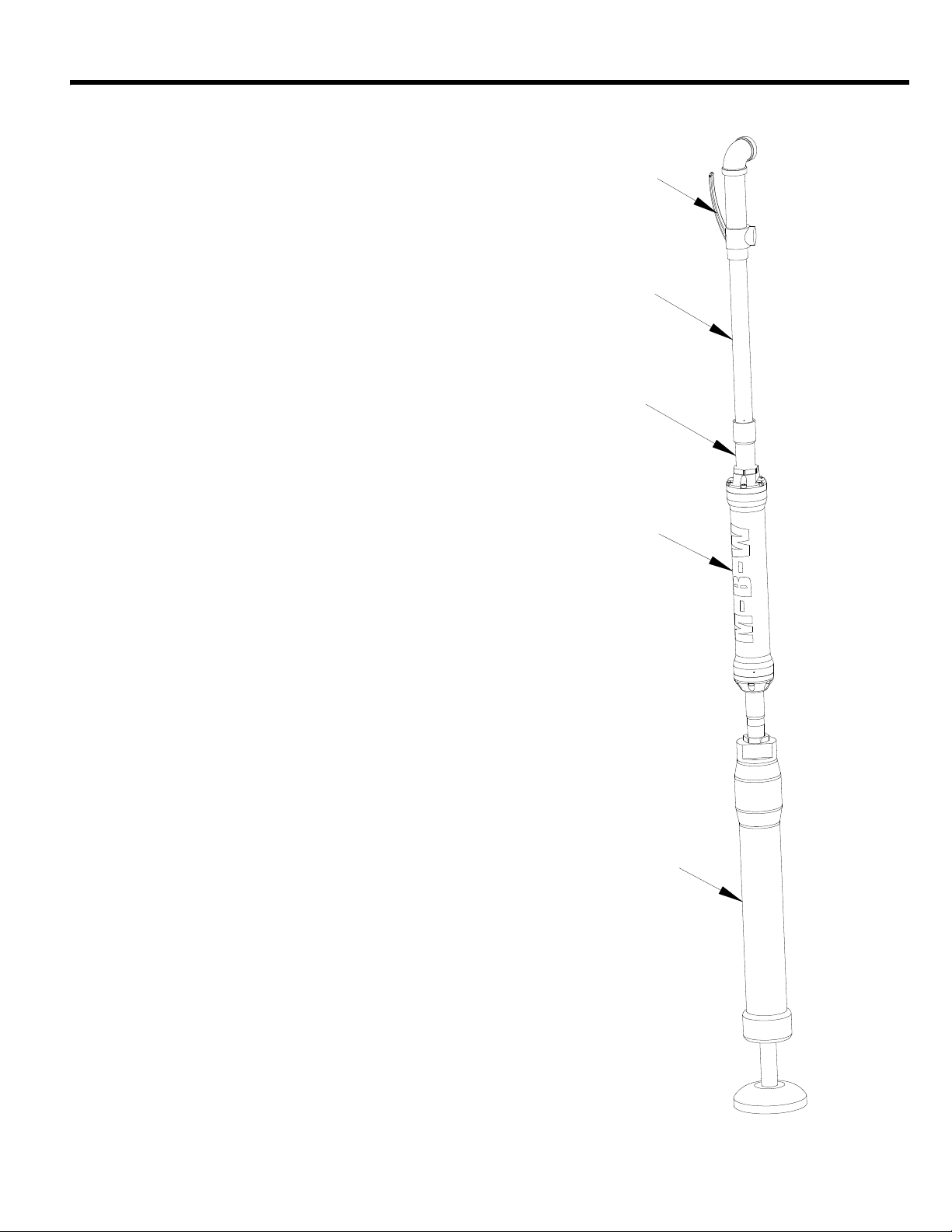

OPERATION

75,**(5

$66(0%/<

(;7(16,21

3,3(

$'$37(5

9,%5$7,21

68335(6625

3(5&866,21

81,7

Introduction

MBW equipment is intended for use in very severe

applications. The Vibration Suppressor is available in a

variety of configurations.

This parts manual contains only standard parts. Variations

of these parts as well as other special parts are not included.

Contact your local MBW distributor for assistance in

identifying parts not included in this manual.

Installation

• The MBW Vibration suppressor is intended to be

installed on a variety of pneumatic pole tampers.

• Connection adapters are included with some models to

add flexibility to installation

1. Disconnect air supply to tool and make sure all air

pressure is released

2. Unscrew connector pipe between trigger assembly

and main percussion unit

3. Attach “ROD” end of the Vibration Suppressor to the

main percussion unit. Tighten connection using a

supplied lock-nut

4. Attach trigger assembly to other end of the Vibration

Suppressor. Tighten connection using a supplied

lock-nut

• Depending on Pole Tamper style, adapters may be

needed to make connections

• To ensure connections stay tight, MBW recommends

using a medium strength thread locker on all

connections

• To lengthen the pole tamper assembly, it is

recommended that the added pipe section be placed

above the Vibration Suppressor

Before Starting & Operating

• REMEMBER! It is the owner’s responsibility to

communicate information on the safe use and proper

operation of this unit to the operators.

• Review ALL of the Safety Precautions listed on page 1 of

this manual.

• Familiarize yourself with the operation of the machine

and confirm that all controls function properly.

• Know how to STOP the machine in case of an

emergency.

- 3 -

• Make sure hands, feet, and clothing are at a safe

WARNING

WARNING

CAUTION

distance from any moving parts.

• The MBW Vibration Suppressor should only be run with

clean and dry compressed air. The use of an oil mist

lubrication system will improve the life of both the

Vibration Suppressor and the pole tamper

• Verify that all joints are tight

Operating Ergo and Pole tamps

Follow all recommended operating procedures of

pole tamper manufacturer. Failure to do so could

result in serious bodily injury or death.

1. Connect air supply hose to trigger assembly

2. Grasp pole tamper assembly on the main body of the

Vibration Suppressor or anywhere above

3. Depress trigger to begin tamping.

4. Release trigger to stop device.

PINCH HAZARD: Avoid placing hands below main

body of the MBW Vibration Suppressor

• The MBW Vibration Suppressor is a spring loaded

device. Efficiency of isolation will depend on many

factors including air pressure, pole tamper type and

operator input. When operating, try to find the correct

down pressure that results in the least amount of

transmitted vibration.

Storage

• The MBW Vibration Suppressor is made of high quality

corrosive resistant components. To lengthen the life of

the entire tamper assembly, drop a small amount of light

oil into trigger assembly and run device for a minute

before long term storage.

Do not place any part of body above pole tamper

assembly. Device will “Jump” when air is

activated.

- 4 -

Loading...

Loading...