OPERATOR’S SAFETY

AND SERVICE MANUAL

SP80

SP125

SP160

This manual covers the following serial numbers

and higher for each model listed:

SP80 . . . . . . . . . . . . . . . . . . . . . 3830125

SP125 . . . . . . . . . . . . . . . . . . . . 3830125

SP160 . . . . . . . . . . . . . . . . . . . . 3830125

SOIL PICK

MBW, Inc.

250 Hartford Rd • PO Box 440

Slinger, WI 53086-0440

Phone: (262) 644-5234

Fax: (262) 644-5169

Email: mbw@mbw.com

Website: www.mbw.com

MBW (UK) Ltd.

Units 2 & 3 Cochrane Street

Bolton BL3 6BN, England

Phone: 01204 387784

Fax: 01204 387797

MBW France S.A.R.L

Z.A. d’Outreville

11 rue Jean Baptiste Néron,

60540 BORNEL

France

Phone: +33 (0) 3 44 07 15 96

Fax: +33 (0) 3 44 07 41 28

L3847 / 2.14.L

©MBW, Inc. 2014

Printed in the USA

TABLE OF CONTENTS

Safety Information . . . . . . . . . . . . . . . . . . . . . . 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . 3

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Before Starting & Operating . . . . . . . . . . . . . . . . . . . . 4

Connecting to Air Compressor . . . . . . . . . . . . . . . . . . 4

Starting Soil Pick. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Operating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Stopping Soil Pick. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Tips & Tricks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Torque Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Service Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Handle Disassembly. . . . . . . . . . . . . . . . . . . . . . . . . . 6

Handle Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Parts Replacement Cycles and Tolerances . . . . . . . . 7

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . 9

Main Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Handle Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

This page intentionally left blank.

SAFETY INFORMATION

WARNING

CAUTION

Introduction

This Safety Alert Symbol is used to call attention

to items or operations which may be dangerous

to those operating or working with this

equipment. The symbol can be found

throughout this manual and on the unit. Please read these

warnings and cautions, along with all decals, carefully

before attempting to operate the unit. Make sure every

individual who operates or works with this equipment is

familiar with all safety precautions.

GENERAL WARNING. Indicates information

important to the proper operation of the

equipment. Failure to observe may result in

damage to the equipment and/or severe bodily

injury or death.

GENERAL CAUTION. Indicates information

important to the proper operation of the

equipment. Failure to observe may result in

damage to the equipment.

Safety Precautions

LETHAL EXHAUST GAS: An internal

combustion engine discharges carbon

monoxide, a poisonous, odorless, invisible

gas. Death or serious illness may result if

inhaled. Operate only in an area with proper

ventilation. NEVER OPERATE IN A

CONFINED AREA!

DANGEROUS FUELS: Use extreme caution

when storing, handling and using fuels, as

they are highly volatile and explosive in vapor

state. Do not add fuel while engine is running.

Stop and cool the engine before adding fuel.

DO NOT SMOKE!

SAFETY GUARDS: It is the owner's

responsibility to ensure that all guards and

shields are in place and in working order.

IGNITION SYSTEMS: Breakerless, magneto,

and battery ignition systems can cause severe

electrical shocks. Avoid contacting these

units or their wiring.

SAFE DRESS: Do not wear loose clothing,

rings, wristwatches, etc. near machinery.

NOISE PROTECTION: Wear OSHA specified

hearing protection devices.

EYE PROTECTION: Wear OSHA specified

eye shields, safety glasses, and sweat bands.

FOOT PROTECTION: Wear OSHA specified

steel-tipped safety shoes.

HEAD PROTECTION: Wear OSHA specified

safety helmets.

DUST PROTECTION: Wear OSHA specified

dust mask or respirator.

OPERATOR: Keep children and bystanders

off and away from the equipment.

REFERENCES: For details on safety rules and regulations

in the United States, contact your local Occupational Safety

and Health Administration (OSHA) office. Equipment

operated in other countries must be operated and serviced

in accordance and compliance with any and all safety

requirements of that country. The publication of these

safety precautions is done for your information. MBW does

not by the publication of these precautions, imply or in any

way represent that these are the sum of all dangers present

near MBW equipment. If you are operating MBW

equipment, it is your responsibility to insure that such

operation is in full accordance with all applicable safety

requirements and codes. All requirements of the United

States Federal Occupational Safety and Health

Administration Act must be met when operated in areas that

are under the jurisdiction of that United States Department.

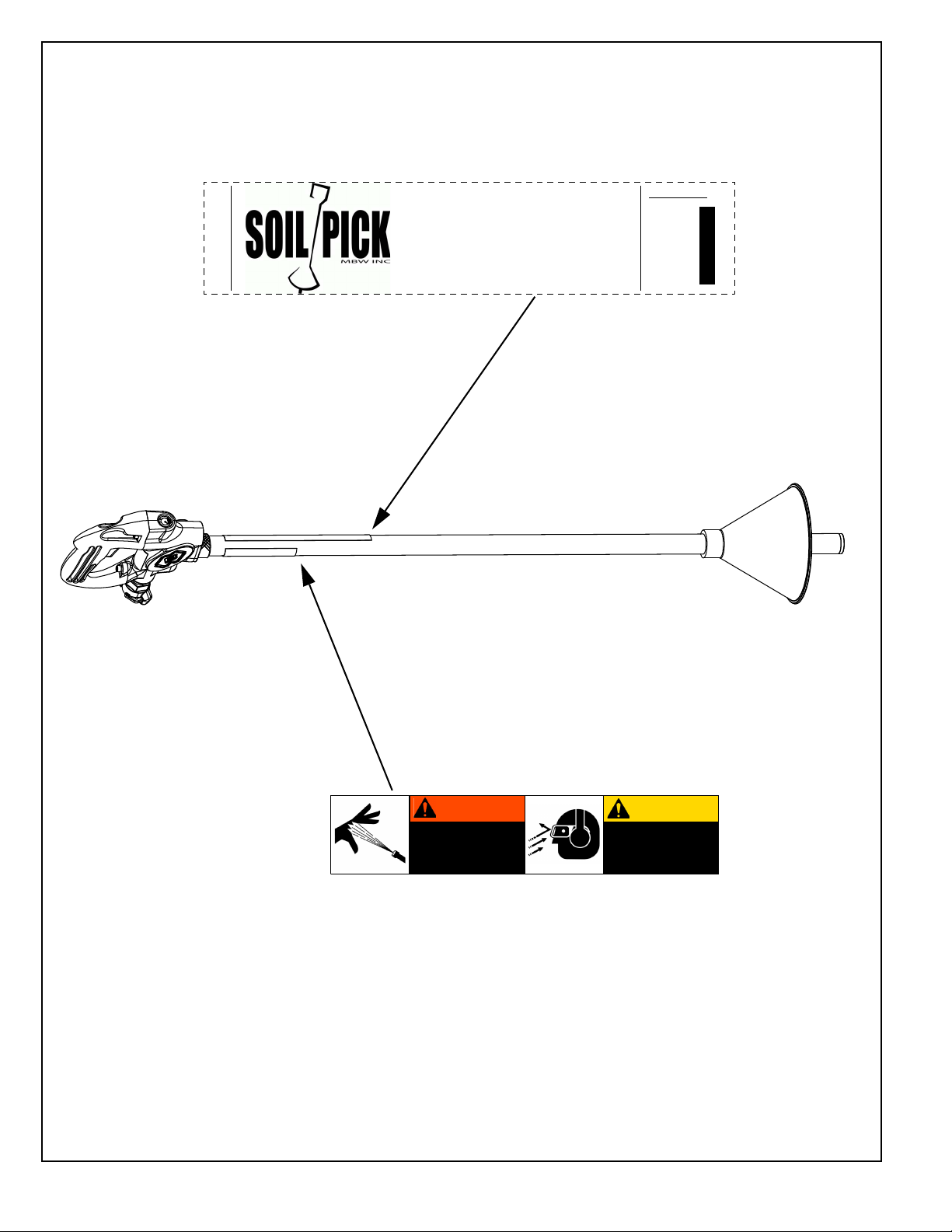

Safety Decals

Carefully read and follow all safety decals. Keep them in

good condition. If decals become damaged, replace as

required. If repainting the unit, replace all decals. Decals

are available from authorized MBW distributors. Order the

decal set listed on the following page(s).

- 1 -

17762

:$51,1*

&$87,21

MINIMIZE SCATTER BY KEEPING BOTTOM

OF DEFLECTOR SHIELD THREE INCHES (3)

ABOVE NOZZLE.

PULL TRIGGER AND CHECK PRESSURE

GAUGE. IF INDICATED PRESSURE IS NOT

BETWEEN 100 AND 125 PSI (INDICATED BY

A GREEN SECTION ON SOME GAUGES),

INCREASE AIR SUPPLY BEFORE

PROCEEDING.

US PATENT #5,170,943

Nozzle Size

65 CFM

80 CFM

125 CFM

160 CFM

17762

Safety Decals

- 2 -

03840

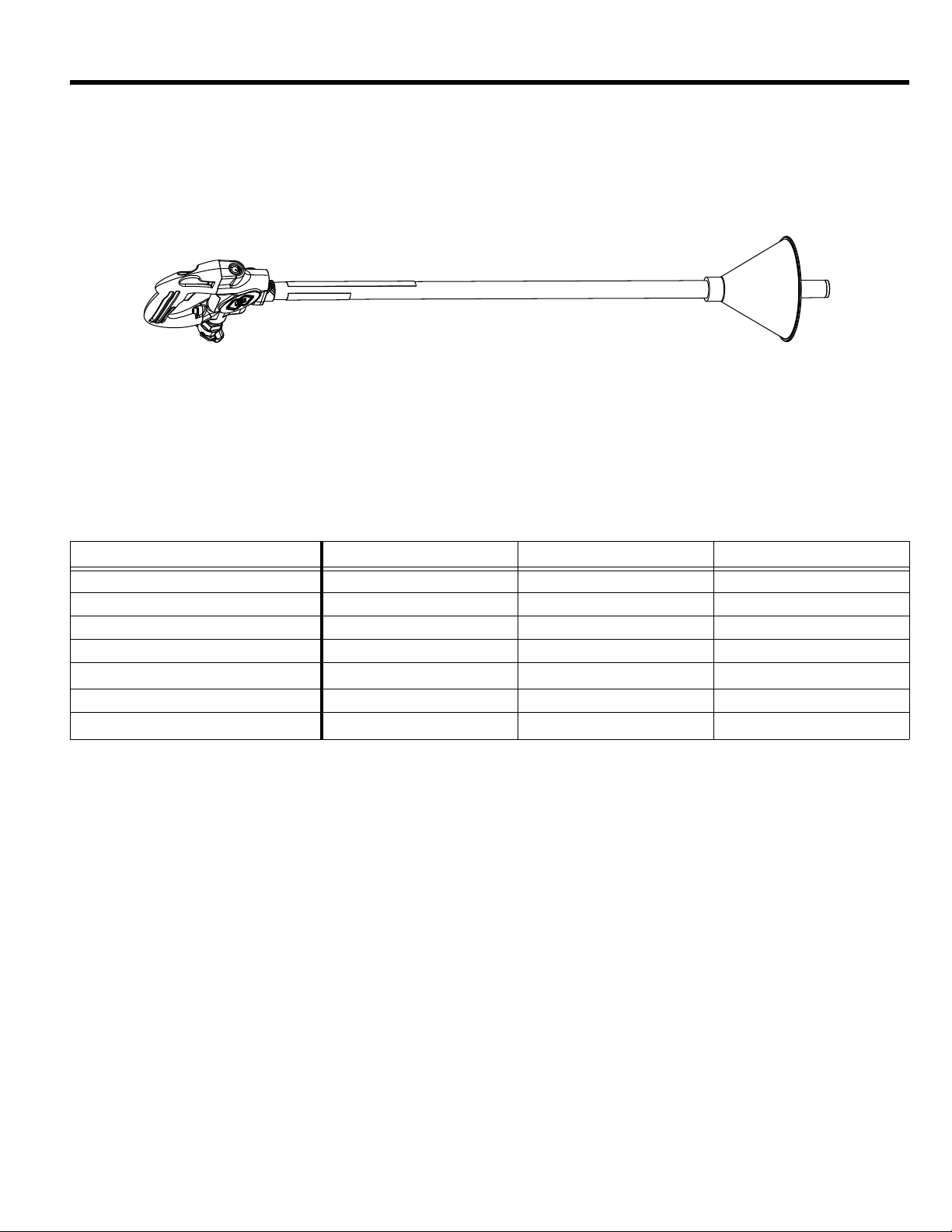

SPECIFICATIONS

63

SP80 SP125 SP160

Volu m e o f Air 80 cfm (38 L/s) 125 cfm (59 L/s) 160 cfm (76 L/s)

Minimum Operating Pressure 100 psi (689 kPa) 100 psi (689 kPa) 100 psi (689 kPa)

Maximum Operating Pressure 125 psi (862 kPa) 125 psi (862 kPa) 125 psi (862 kPa)

Exit Velocity 1476 mph (660 M/s) 1476 mph (660 M/s) 1476 mph (660 M/s)

Cutting Edge

Operating Weight 6.7 lbs (3.0 kg) 6.7 lbs (3.0 kg) 6.7 lbs (3.0 kg)

Noise Level

1. Cutting edge will vary with different soil conditions.

2. Noise levels based upon normal operating conditions.

Specifications subject to change without notice

1

2

4 in (10 cm) 4 in (10 cm) 8 in (20 cm)

100 dBA 100 dBA 100 dBA

- 3 -

Introduction

WARNING

WARNING

WARNING

OPERATION

This parts manual contains only standard parts. Variations

of these parts as well as other special parts are not included.

Contact your local MBW distributor for assistance in

identifying parts not included in this manual.

Before Starting & Operating

• REMEMBER! It is the owner’s responsibility to

communicate information on the safe use and proper

operation of this unit to the operators.

• Review ALL of the Safety Precautions listed on page 1 of

this manual.

• Familiarize yourself with the operation of the machine

and confirm that all controls function properly.

• Know how to STOP the machine in case of an

emergency.

• Make sure hands, feet, and clothing are at a safe

distance from any moving parts.

Connecting to Air Compressor

For proper operation, the air supply must deliver the volume

and pressure required for the Soil Pick model being used.

Refer to Specifications, page 3 for minimum requirements.

1. Start compressor and check pressure gage to verify

proper operation of the compressor.

2. Connect air hose to compressor outlet and install

safety clips if required.

3. Connect air hose to Soil Pick coupler and install

safety clips if required.

4. Open compressor valve to pressurize Soil Pick.

Starting Soil Pick

Do not operate the Soil Pick at a pressure greater

than 125 psi.

4. Adjust the rubber deflector so the bottom of the cone

is about three inches (3”) above the nozzle tip.

Operating

Always wear safety goggles and hearing

protection when operating Soil Pick.

1. If the area to be excavated is covered with grass or

other plant material, it may be easier to remove it with

a shovel or rake before proceeding with the Soil Pick.

2. Hold the Soil Pick perpendicular to the soil surface to

be worked.

3. With the nozzle in contact with the soil, pull the trigger

momentarily to break up the soil in immediate contact

with the nozzle tip.

4. While keeping the nozzle submerged in the loosened

soil, hold the trigger down and work the nozzle in a

circular motion.

5. As the soil is loosened and the Soil Pick is worked

deeper into the ground, move the deflector up the

barrel to minimize scatter.

6. After loosening the soil, it can be easily removed

using an industrial vacuum system or using

conventional methods.

Stopping Soil Pick

1. Close compressor valve to release supply pressure

to Soil Pick.

Never aim the Soil Pick at exposed skin or people.

1. Aim Soil Pick away from people, and pull the trigger.

2. If the pressure reading is less than 100 psi (indicated

as a red section on some gages), the air pressure at

the source must be increased.

3. If the pressure reading is greater than 125 psi, the air

pressure at the source must be decreased to prevent

damage and possible injury.

2. Aim Soil Pick away from people, and pull the trigger

to relieve all residual air pressure in the hose.

3. Disconnect air hose on both ends.

4. Turn compressor OFF.

5. Slowly open compressor valve to relieve air pressure

in the tank.

Tips & Tricks

1. The Soil Pick can be used alone for safe excavation

on small jobs, or used as an underground locating

and exposing tool in conjunction with higher

production excavators, backhoes, and trenchers.

- 4 -

2. The Soil Pick is not an elaborate blow pipe.

Conventional blow pipes produce subsonic air

stream velocities between 500 and 600 mph, and

cannot provide the cutting edge required for soil

excavation. Blow pipes can be used for moving loose

debris, but even then are outperformed by the Soil

Pick.

3. The Soil Pick is a selective excavator. The violent

decompression of air is sufficient to loosen porous

soil, but will have virtually no effect on non-porous

objects such as buried utilities or plant roots.

4. The Soil Pick has a cutting edge of four to eight

inches, depending on the model. This means the

nozzle must be kept close to the soil for the

decompression to be effective. Beyond the cutting

edge, substantial decompression has occurred and

the Soil Pick becomes a highly effective blower for

loose debris.

5. The Soil Pick will not cut through frost, but it will work

well below the frost line.

6. The Soil Pick works extremely well in all types of

granular soils and cohesive soils with a good granular

gradation. The effectiveness will drop off as the

granular component in cohesive soils decreases.

Wet clay soils may be too plastic to loosen.

7. The Soil Pick does not require lubrication. The air

supply must be free of oil to achieve proper

performance.

8. The Soil Pick is not designed as an impact or prying

tool. The barrel is manufactured of a composite

material designed to withstand high internal

pressure. It is not designed to withstand prying or

impact forces.

9. The Soil Pick is an effective excavation tool even

when there is no concerns of buried utilities. In most

cases, productivity is enhanced dramatically

compared to pick and shovel work.

10. The Soil Pick is highly effective when used to clean

saw joints and cracks in concrete. It can grossly

outperform a blow pipe, and provide a very clean

surface for excellent sealant adhesion.

11. The Soil Pick is an effective tool for nursery

applications. Because it is a selective excavator, it

will not damage roots. Because it is an air tool, it is

also aerating the soil while digging.

12. The Soil Pick has an almost endless list of uses. It

can effectively clean barges, railroad cars,

construction equipment, and more. It can be used for

shallow trenching, post hole digging, stump removal,

pothole preparation prior to patching, and many more

unique applications.

- 5 -

SERVICE

Assembly and disassembly should be performed by a

service technician who has been factory trained on MBW

equipment. The unit should be clean and free of debris.

Pressure washing before disassembly is recommended.

• Prior to assembly, wash all parts in a suitable cleaner or

solvent.

• Check moving parts for wear and failure. Refer to the

Replacement section in this manual for tolerance and

replacement cycles.

• All shafts and housings should be oiled prior to pressing

bearings. Also, ensure that the bearings are pressed

square and are seated properly.

• All bearings should be replaced when rebuilding any

exciter or gearbox.

• All gaskets and seals should be replaced after any

disassembly.

Torque Chart

SIZE GRADE 2 GRADE 5 GRADE 8

1/4-20 49 in

1/4-28 56 in

5/16-18 8 ft

5/16-24 9 ft

3/8-16 15 ft

3/8-24 17 ft

7/16-14 24 ft

7/16-20 27 ft

1/2-13 37 ft

1/2-20 41 ft

9/16-12 53 ft

5/8-11 73 ft

5/8-18 83 ft

3/4-16 144 ft

1-8 188 ft

1-14 210 ft

1-1/2-6 652 ft

M 6 3 ft

M 8 6 ft

M 10 10 ft

•lbs 76 in•lbs 9 ft•lbs

•lbs 87 in•lbs 10 ft•lbs

•lbs 13 ft•lbs 18 ft•lbs

•lbs 14 ft•lbs 20 ft•lbs

•lbs 23 ft•lbs 33 ft•lbs

•lbs 26 ft•lbs 37 ft•lbs

•lbs 37 ft•lbs 52 ft•lbs

•lbs 41 ft•lbs 58 ft•lbs

•lbs 57 ft•lbs 80 ft•lbs

•lbs 64 ft•lbs 90 ft•lbs

•lbs 82 ft•lbs 115 ft•lbs

•lbs 112 ft•lbs 159 ft•lbs

•lbs 112 ft•lbs 180 ft•lbs

•lbs 200 ft•lbs 315 ft•lbs

•lbs 483 ft•lbs 682 ft•lbs

•lbs 541 ft•lbs 764 ft•lbs

•lbs 1462 ft•lbs 2371 ft•lbs

•lbs 4 ft•lbs 7 ft•lbs

•lbs 10 ft•lbs 18 ft•lbs

•lbs 20 ft•lbs 30 ft•lbs

CONVERSIONS

•lbs x 0.083 = ft•lbs

in

•lbs x 12 = in•lbs

ft

•lbs x 0.1383 = kg•m

ft

•lbs x 1.3558 = N•m

ft

Service Tools

Part No. Description

20563 VALVE GREASE, SILICONE,.21 oz

20565 REBUILD KIT, SOIL PICK

Handle Disassembly

Refer to Handle Assembly, page 12.

1. Remove three screws (#18) securing handle and

remove, taking care to not lose spring (#10).

2. Remove two screws (#15) holding bottom cover (#5)

and remove cover.

3. Using a wrench across flats on valve spool (#4),

loosen and remove screw securing trigger (#8).

4. Use a pick or small screwdriver, remove shaft wiper

(#2).

5. Remove snap ring (#15).

6. Using a wrench across the flats on valve spool (# 4),

remove screw securing lower spool (#7).

7. Pull spool (#4) our the top of the body. Guide (#6) will

come out with spool.

8. Push lower valve spool (#7) out the bottom of the

valve body (#9).

9. Insert a long standard bladed screwdriver through the

inlet of the valve body to unscrew the gage (#11).

Handle Assembly

Refer to Handle Assembly, page 12.

Note: All o-rings and seals should be replaced after any

disassembly.

1. Thread gage (#11) into body (#9) using a long

standard blade screwdriver and thread sealing

compound.

2. Place o-rings (#12, 14) into grooves on valve spool

(#4). Coat o-rings with grease and insert spool (#4)

into body (#9).

3. Place o-ring (#14) into groove on lower valve spool

(#7), coat o-ring with grease, and insert into bottom of

body. Secure to valve spool (#14) with screw (#17).

Use wrench across flats on valve spool to tighten

screw.

4. Place o-ring in groove on upper guide (#6), coat with

grease, and insert into main body over the valve

spool.

- 6 -

5. Insert retaining ring (#15) and make certain it is fully

seated in groove.

6. Coat the inner diameter of the dust wiper (#2) with

grease and insert into main body. The lip of the seal

should be facing out, and the shoulder should be

flush with the surface of the body.

7. Attach trigger (#8) to valve spool with screw (#17). Do

not overtighten screw. place spring in the well of the

trigger (#8).

Parts Replacement Cycles and Tolerances

8. Attach Handle (#3) to body with three screws (#17).

Use Medium strength loctite on these screws.

9. Assemble lower cover (#5) to body with two screws

(#15)

10. Test action of trigger to ensure complete closing of

valve after trigger is released.

Bearings

Hardware

Safety Decals Replace if they become damaged or illegible.

Seals & Gaskets Replace if a leak is detected and at every overhaul or teardown.

Replace anytime a bearing is rough, binding, discolored or removed from housing or

shaft.

Replace any worn or damaged hardware as needed. Replacement hardware should

be grade 5 and zinc plated unless otherwise specified.

- 7 -

This page intentionally left blank.

- 8 -

REPLACEMENT PARTS

Write Model Number here

Write Serial Number here

'(&$//2&$7,21

The warranty is stated in this book on page 14. Failure to

return the Warranty Registration Card renders the warranty

null and void.

MBW has established a network of reputable distributors/

dealers with trained mechanics and full facilities for

maintenance and rebuilding, and to carry an adequate parts

stock in all areas of the country. Their sales engineers are

available for professional consultation. If you cannot locate

an MBW distributor in your area, contact MBW or one of our

Sales Branches listed below.

When ordering replacement parts, be sure to have the

following information available:

• Model and Serial Number of machine when ordering

MBW parts

• Model and Serial Number of engine when ordering

engine parts

• Part Number, Description, and Quantity

• Company Name, Address, Zip Code, and Purchase

Order Number

• Preferred method of shipping

REMEMBER - You own the best! If repairs are needed,

use only MBW parts purchased from authorized

MBW distributors.

The unit’s serial number can be found in the following

locations:

• The serial number decal is located on the handle body

adjacent to the pressure gage.

Contact Information

MBW, Inc.

250 Hartford Rd • PO Box 440

Slinger, WI 53086-0440

Phone: (262) 644-5234

Fax: (262) 644-5169

Email: mbw@mbw.com

Website: www.mbw.com

MBW (UK) Ltd.

Units 2 & 3 Cochrane Street

Bolton BL3 6BN, England

Phone: 01204 387784

Fax: 01204 387797

- 9 -

MBW France S.A.R.L

Z.A. d’Outreville

11 rue Jean Baptiste Néron,

60540 BORNEL

France

Phone: +33 (0) 3 44 07 15 96

Fax: +33 (0) 3 44 07 41 28

ACCESSORIES

Main Assembly

- 10 -

ITEM PART NO. DESCRIPTION QTY

1. 01291 CABLE TIE 1

2. 03820 BARREL ASSEMBLY, 80 CFM (Includes 1,3,4) 1

03813 BARREL ASSEMBLY, 125 CFM (Includes 1,3,4) 1

17594 BARREL ASSEMBLY, 160 CFM (Includes 1,3,4) 1

3. 03817 O-RING 1

4. 03829 DEFLECTOR 1

5. 03841 FITTING, COUPLER DIXON AM-7 (CLAW COUPLER) 1

17599 FITTING, COUPLER, DIXON DML12 (QUICK CONNECT) 1

6. 03848 BARREL ASM, 42” EXTENSION 1

03849 BARREL ASM, 21” EXTENSION 1

7. 11540 WHEEL 2

8. 11541 CART, WELDMENT 1

9. 11542 KIT, SOIL PICK CART (INCLUDES 7, 8, 14,15,16) 1

10. 17748 NOZZLE, 80CFM, 45 DEG 1

17749 NOZZLE, 125CFM, 45 DEG 1

17750 NOZZLE, 160CFM, 45 DEG 1

11. 19358 KIT, CASE, SOIL PICK 1

12. 19750 NOZZLE, 65 CFM, 90 DEG 1

19751 NOZZLE, 80 CFM, 90 DEG 1

19749 NOZZLE, 125 CFM, 90 DEG 1

19752 NOZZLE, 160 CFM, 90 DEG 1

13. 20450 HANDLE ASM, ERGO 1

14. F042004TS SCREW, THUMB, 1/4-20 X 1/2 1

15. F0208CP PIN, COTTER 1/8 X 1 2

16. F08LW WASHER 1/2” 2

1

- 11 -

Handle Assembly

- 12 -

ITEM PART NO. DESCRIPTION QTY

1. 17250 FITTING, PLUG 1

2. 19430 SHAFT WIPER SEAL, 3/4 ID X 1-1/8 OD 1

3. 20451 HANDLE, SOIL PICK 1

4. 20452 VALVE SPOOL 1

5. 20453 COVER, BOTTOM 1

6. 20454 GUIDE, TOP 1

7. 20455 BOTTOM SPOOL (20455: before SN 3830125 use 20677) 1

8. 20456 TRIGGER 1

9. 20457 VALVE BODY, MACHINED 1

10. 20459 SPRING, TRIGGER 1

11. 20460 GAGE, SLOTTED 1

12. 20461 O-RING, 9/16 ID X .125 1

13. 20462 O-RING, 1 ID X .0625 1

14. 20463 O-RING, 5/8 ID X .0625 2

15. 20587 RETAINING RING, INT. 1.125 1

16. F023202BCS BCS, TORX, #8-32 X 1/4” 2

17. F033205BCS BCS, TORX, #10-32 X 5/8” 2

18. F042006BCS BCS, TORX, 1/4-20 X 3/4” 3

20565 REBUILD KIT, SOIL PICK (CONTAINS 2, 12, 13, 14)

- 13 -

WARRANTY

WHAT DOES THIS WARRANTY COVER? MBW, Incorporated (MBW)

warrants each New Machine against defects in material and workmanship

for a period of twelve (12) months. "New Machine" means a machine

shipped directly from MBW or authorized MBW dealer to the end user. This

warranty commences on the first day the machine is sold, assigned to a

rental fleet, or otherwise put to first use.

MBW warrants each Demonstration Machine against defects in material

and workmanship for a period of six (6) months. "Demonstration Machine"

means a machine used by MBW or its agents for promotional purposes.

This warranty commences on the first day the machine is sold, assigned to

a rental fleet, or otherwise put to first use.

This warranty covers the labor cost for replacement or repair of parts,

components, or equipment on New Machines or Demonstration Machines,

and MBW shall pay labor costs at MBW's prevailing rate to affect the

warranted repair or replacement. MBW reserves the right to adjust labor

claims on a claim-by-claim basis.

This warranty covers the shipping cost of replacement parts, components,

or equipment via common ground carriers from MBW to an authorized

MBW dealer. Air freight is considered only in cases where ground

transportation is not practical.

MAY THIS WARRANTY BE TRANSFERRED? This warranty is nontransferable and only applies to the original end user of a new machine or

demonstration machine.

WHAT DOES THIS WARRANTY NOT COVER?

1.This warranty does not cover any Used Equipment. "Used Equipment"

means any MBW machine or equipment that is not a New Machine or a

Demonstration Machine. All Used Equipment is sold AS IS/WHERE IS

WITH ALL FAULTS.

2.This warranty does not cover any New Machine, Demonstration

Machine, or their equipment, parts, or components altered or modified in

any way without MBW's prior written consent. This warranty does not

cover the use of parts not specifically approved by MBW for use on MBW

products. This warranty does not cover misuse, neglect, shipping damage,

accidents, acts of God, the operation of any New Machine or

Demonstration Machine in any way other than recommended by MBW in

accordance with its specifications, or any other circumstances beyond

MBW's control. This warranty does not cover any New Machine or

Demonstration Machine repaired by anyone other than MBW factory

branches or authorized MBW distributors.

3.This warranty does not cover, and MBW affirmatively disclaims, liability

for any damage or injury resulting directly or indirectly from design,

materials, or operation of a New Machine or Demonstration Machine or any

other MBW product. MBW's liability with respect to any breach of warranty

shall be limited to the provisions of this document and in no event shall

exceed an amount equal to the purchase price of the New Machine or

Demonstration Machine purchased from MBW.

6.This warranty does not cover any updates to any New Machine,

Demonstration Machine, or any other MBW product. MBW reserves the

right to improve or make product changes without incurring any obligation

to update, refit, or install the same on New Machines or Demonstration

Machines previously sold.

WHAT MUST YOU DO TO OBTAIN WARRANTY COVERAGE? Each

New Machine or Demonstration Machine is accompanied by a Warranty

Registration Card. You must sign, date, and return the Warranty

Registration Card to the place of origin of the New Machine or

Demonstration Machine, either to MBW, Inc. at P.O. Box 440, Slinger,

Wisconsin 53086, MBW (UK), Ltd. at Units 2 & 3 Cochrane Street, Bolton

BL3 6BN, United Kingdom or MBW FRANCE SARL at

ZA D'Outreville, 5 Rue Jean Baptiste Neron, Bornel 60540 France, within

ten (10) days after purchase, assignment to a rental fleet, or first use. This

signed warranty card is the buyer's affirmation that he has read,

understood, and accepted the warranty at the time of purchase. Failure to

return the warranty card as specified herein renders the warranty null and

void. In order to receive warranty coverage consideration, warranty claims

must be submitted within thirty (30) days after the New Machine or

Demonstration Machine fails. Warranty claims must be submitted to MBW,

Inc., MBW (UK), Ltd. or MBW FRANCE SARL, and written authorization for

the return of merchandise or parts under the warranty must be obtained

before shipment to MBW.

WHAT WILL MBW DO? MBW's obligation under this warranty is limited to

the replacement or repair of parts for a New Machine or Demonstration

Machine at MBW factory branches or at authorized MBW distributors, and

such replacement or repair is the exclusive remedy provided hereunder.

Labor must be performed at an authorized MBW distributor. MBW

reserves the right to inspect and render a final decision on each warranty

case, and MBW's repair or replacement is solely within the discretion of

MBW.

S EXPRESSLY AGREED THAT THIS SHALL BE THE SOLE AND

IT I

EXCLUSIVE REMEDY UNDER THIS WARRANTY. UNDER NO

CIRCUMSTANCES SHALL MBW BE LIABLE FOR ANY COSTS, LOSS,

EXPENSE, DAMAGES, SPECIAL DAMAGES, INCIDENTAL DAMAGES,

OR PUNITIVE DAMAGES ARISING DIRECTLY OR INDIRECTLY FROM

THE USE OF THE NEW MACHINE OR DEMONSTRATION MACHINE

WHETHER BASED UPON WARRANTY, CONTRACT, NEGLIGENCE,

STRICT LIABILITY, OR ANY OTHER LEGAL THEORY.

THE FOREGOING WARRANTY IS EXPRESSLY IN LIEU OF ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING THE

WARRANTIES OF MERCHANTABILITY, FITNESS FOR USE, AND

FITNESS FOR A PARTICULAR PURPOSE, AND ALL OTHER

OBLIGATIONS OR LIABILITY ON MBW'S PART. MBW NEITHER

ASSUMES NOR AUTHORIZES ANY OTHER PERSON TO ASSUME ON

BEHALF OF MBW ANY OTHER LIABILITY OR WARRANTY IN

CONNECTION WITH THE SALE OR SERVICE OF ANY NEW MACHINE,

DEMONSTRATION MACHINE , OR ANY OTHER MBW PRODUCT.

4.This warranty does not cover engines, motors, and other assemblies or

components produced by other manufacturers and used on a New

Machine or Demonstration Machine, as said engines, motors, and other

assemblies or components may have warranties provided by the

manufacturer thereof. This warranty does not apply to consumable items,

such as v-belts, filters, trowel and screed blades, seals, shock mounts,

batteries, and the like, all of which are sold AS IS/WHERE IS WITH ALL

FAULTS.

5.This warranty does not cover the cost of transportation and other

expenses which may be connected with warranty service but not

specifically mentioned herein.

EXTENDED RAMMER WARRANTY - MODELS R422, R442,

R482 & R483.

This extended warranty commences on the last day of MBW’s standard,

one year, “limited warranty” and runs for an additional four years

(48 months). This extended warranty is limited to part replacement and

shipping costs of rammer bellows and non-metallic slide bearings only.

This extended warranty does not cover labor, down time, or any other cost

beyond that of component replacement and freight. This extended

warranty is subject to all limitations set fourth in MBW’s “limited warranty”,

above.

- 14 -

Loading...

Loading...