MBW SCS2 User Manual

OPERATOR’S SAFETY

AND SERVICE MANUAL

SCS2 & KEY

R

EADER

This manual covers the following serial numbers

and higher for each model listed:

SCS2.........................................6060007

SOIL COMPACTION SUPERVISOR 2 & KEY READER

MBW, Inc.

250 Hartford Rd • PO Box 440

Slinger, WI 53086-0440

Phone: (262) 644-5234

Fax: (262) 644-5169

Email: mbw@mbw.com

Website: www.mbw.com

MBW (UK) Ltd.

Units 2 & 3 Cochrane Street

Bolton BL3 6BN, England

Phone: 01204 387784

Fax: 01204 387797

MBW France S.A.R.L

Z.A. d’Outreville

11 rue Jean Baptiste Néron,

60540 BORNEL, France

Phone: 3 44 07 15 96

Fax: 3 44 07 41 28

L19035/ 04.09.E

©MBW, Inc. 2009

Printed in the USA

TABLE OF CONTENTS

Safety Precautions . . . . . . . . . . . . . . . . . . . . . 1

Noise Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Eye Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . 2

Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Using The Soil Compaction Supervisor . . . . 5

Power On/Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Inserting and Removing Key. . . . . . . . . . . . . . . . . . . . 5

Attaching/Removing Sensor . . . . . . . . . . . . . . . . . . . . 5

Monitoring Compaction. . . . . . . . . . . . . . . . . . . . . . . . 5

Toggling New Hole/New Lift . . . . . . . . . . . . . . . . . . . . 5

Data Management . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Example of Data Management . . . . . . . . . . . . . . . . . . 6

Error Lights and Troubleshooting . . . . . . . . . . . . . . . . 6

Data Location - Key vs. Meter . . . . . . . . . . . . . . . . . . 6

Memory Used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Transferring Data From the SCS2 to the Key . . . . . . 7

Updating the Date and Time in the SCS2 . . . . . . . . . 7

Replacing Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Using the USB Key Reader . . . . . . . . . . . . . . . 8

Minimum System Requirements . . . . . . . . . . . . . . . . 8

Software Installation . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Key Reader Installation . . . . . . . . . . . . . . . . . . . . . . . 8

Starting the Key Reader Software . . . . . . . . . . . . . . . 8

Inserting and Removing The Key . . . . . . . . . . . . . . . . 8

Key Reader Software Interface . . . . . . . . . . . . . . . . . 8

Reading Data from the Key . . . . . . . . . . . . . . . . . . . . 8

Erasing Data from the Key . . . . . . . . . . . . . . . . . . . . . 9

Read Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Data Content . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Updating Date and Time In the Meter . . . . . . . . . . . 10

Replacement Parts . . . . . . . . . . . . . . . . . . . . . 12

Soil Compaction Supervisor 2 Starter Kit . . . . . . . . . 13

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

SAFETY PRECAUTIONS

READ AND STUDY THE FOLLOWING SAFETY

INFORMATION BEFORE ATTEMPTING TO

OPERATE THIS EQUIPMENT. IN ADDITION,

ENSURE THAT EVERY INDIVIDUAL WHO

OPERATES OR WORKS WITH THIS EQUIPMENT IS

FAMILIAR WITH THESE SAFETY PRECAUTIONS.

Noise Protection

Wear O.S.H.A. specified hearing protection devices.

Eye Protection

Wear O.S.H.A. specified eye shields, safety glasses, and

sweat bands.

References

For details on safety rules and regulations in the United

States, contact your local Occupational Safety and Health

Administration (OSHA) office. Equipment operated in other

countries must be operated and serviced in accordance and

compliance with any and all safety requirements of that

country. The publication of these safety precautions is done

for your information. MBW does not by the publication of

these precautions, imply or in any way represent that these

are the sum of all dangers present near MBW equipment. If

you are operating MBW equipment, it is your responsibility

to insure that such operation is in full accordance with all

applicable safety requirement codes. All requirements of

the United States Federal Occupational Safety and Health

Administration Act must be met when operated in areas that

are under the jurisdiction of that United States Department.

- 1 -

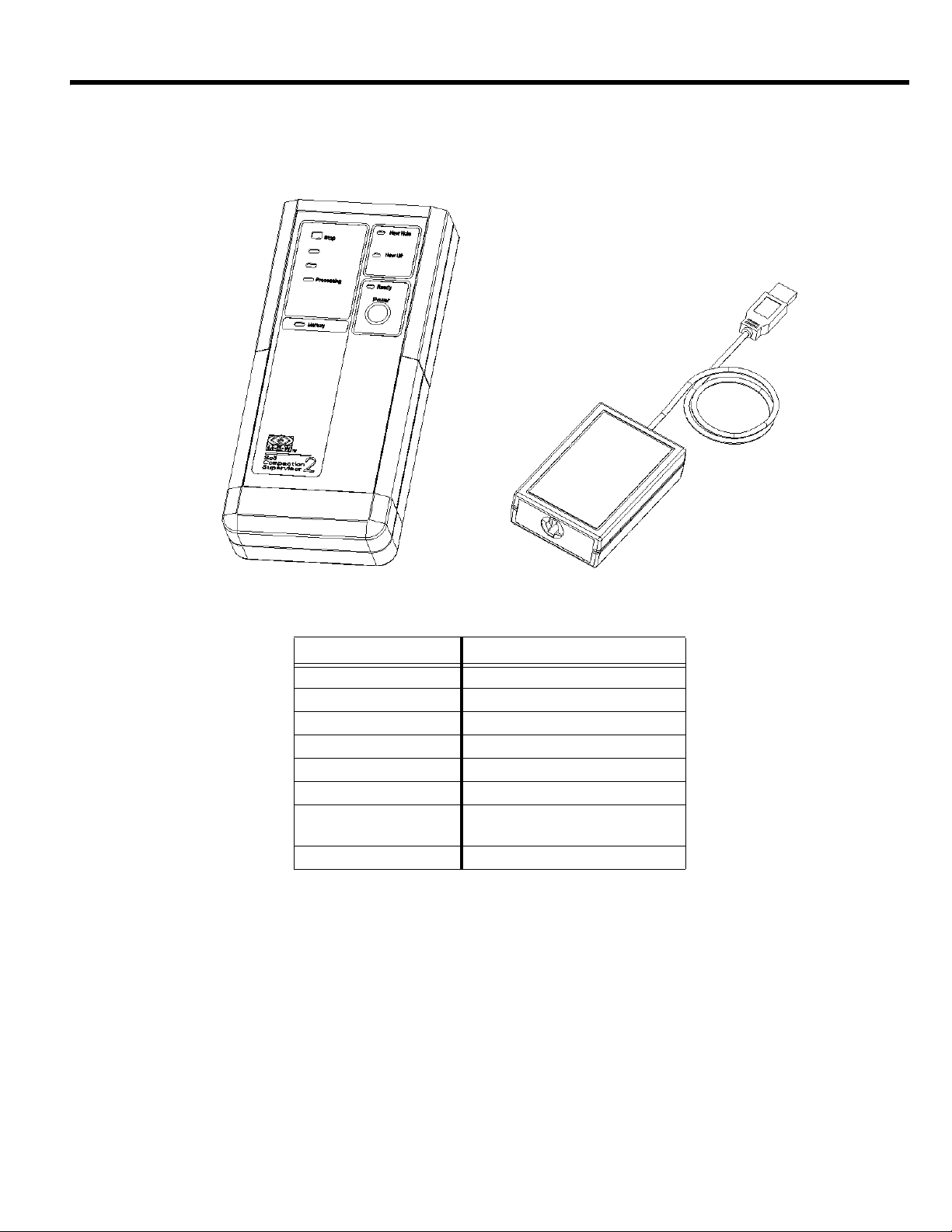

SPECIFICATIONS

Automatic Power Off After 10 minutes of inactivity

Meter Memory Capacity 90 records

Key Memory Capacity 200 records

Key Memory Life 10 years minimum

Key Contact Life

Specifications subject to change without notice

SCS2

Batteries 4 “AA” type alkaline

Battery Life Up to 40 hours of continuous use

15,000 insertion/removal cycles

minimum

Clock Internal with 10-year battery

- 2 -

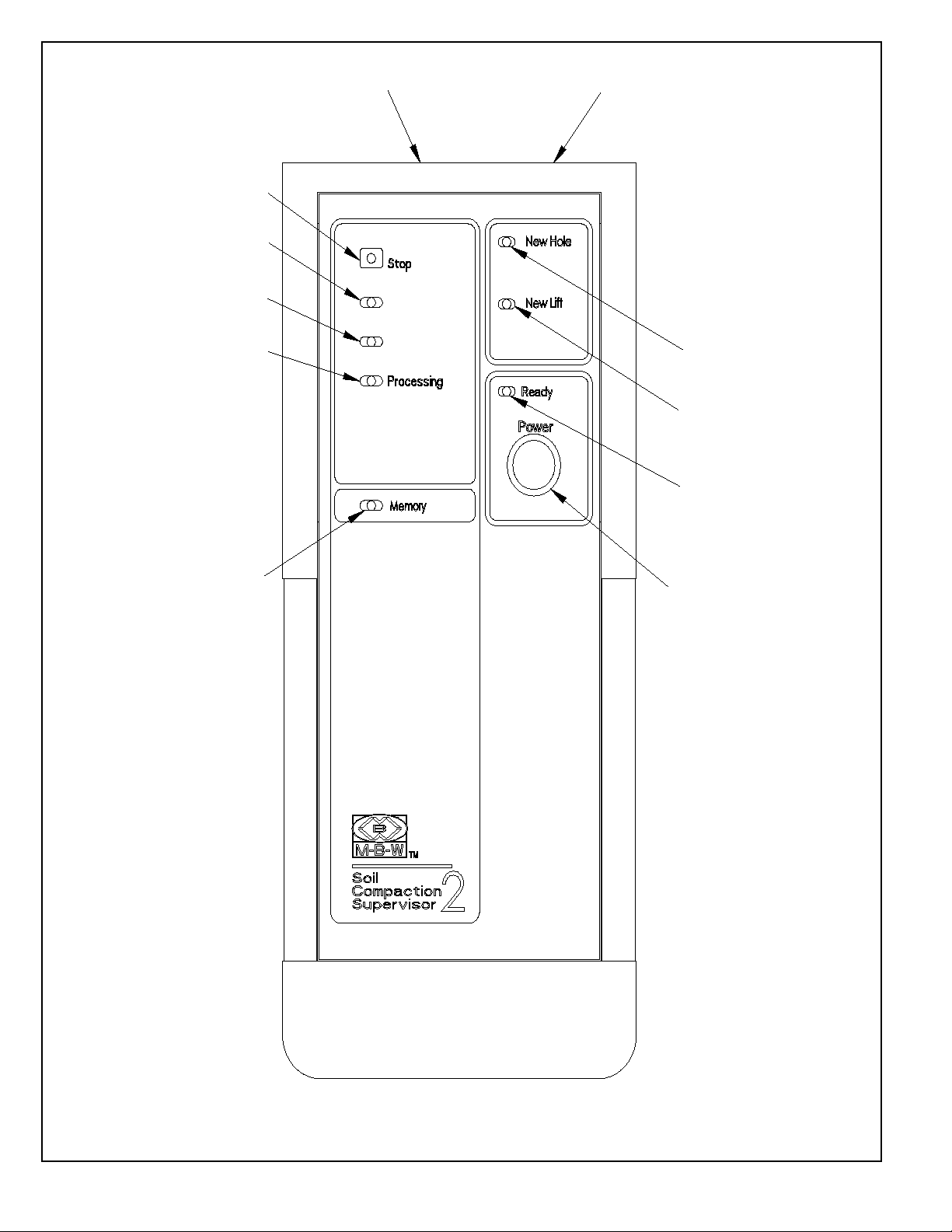

.(<5(&(37,&/(

6723/,*+7

&203$&7,21

,1',&$725

&203$&7,21

,1',&$725

6(16255(&(37,&/(

352&(66,1*

/,*+7

0(025<

/,*+7

1(:+2/(/,*+7

1(:/,)7/,*+7

5($'</,*+7

32:(5%87721

Layout

- 3 -

INTRODUCTION

CAUTION

The Soil Compaction Supervisor 2 is a low cost, easy to use

instrument that assists with optimizing the compaction of

backfill by eliminating over and under compaction. The Soil

Compaction Supervisor 2 also provides the ability to record

compaction data for analysis and quality control.

The system consists of a portable, battery powered Soil

Compaction Supervisor 2, a disposable sensor, and a

reusable data key. In use, the sensor is placed in the bottom

of the excavation and its cable is connected to the Soil

compaction Supervisor 2. As each lift is compacted the

sensor sends a signal to the Soil Compaction Supervisor 2

which determines when the maximum compaction has been

achieved under the current conditions. When the lift has

been compacted to the optimum level, the Soil Compaction

Supervisor 2 signals the user to stop and the data for that lift

is recorded. The Soil Compaction Supervisor 2 has internal

memory, so it can record data either with or without the data

key in place. This data can later be downloaded to a

personal computer with the MBW Key Reader

The use of the SCS2 (Soil Compaction

Supervisor 2) does not, in any way lessen

the importance of following good soil reinstatement practices. Backfill soils

MUST be acceptable for specific backfill

purposes. Lift thickness MUST be controlled relative to soil type and capacity of

the compaction device. Soils MUST have

moisture contents in a reasonable range

relative to optimum. The compaction

equipment MUST be in good operating

condition. Failure to consistently apply

the accepted principles of good soil reinstatement can result in failure, with or

without the use of quality control instrumentation.

- 4 -

Loading...

Loading...