MBW MM60, MM80 Service Manual

OPERATOR’S SAFETY

AND SERVICE MANUAL

MM60

MM80

MM90

This manual covers the following serial numbers

and higher for each model listed:

MM60 . . . . . . . . . . . . . . . . . . . . 7011600

MM80 . . . . . . . . . . . . . . . . . . . . 7032000

MM90 . . . . . . . . . . . . . . . . . . . . 7051100

MORTAR & PLASTER MIXERS

MBW, Inc.

250 Hartford Rd • PO Box 440

Slinger, WI 53086-0440

Phone: (262) 644-5234

Fax: (262) 644-5169

Email: mbw@mbw.com

Website: www.mbw.com

MBW (UK) Ltd.

Units 2 & 3 Cochrane Street

Bolton BL3 6BN, England

Phone: 01204 387784

Fax: 01204 387797

MBW FRANCE S.A.R.L.

Z.A. d’Outreville

11 rue Jean Baptiste Néron,

60540 BORNEL

FRANCE

Phone: +33 (0) 3 44 07 15 96

Fax: +33 (0) 3 44 07 41 28

Email: mbwfrance@free.fr

L16746. 04.14.T

©MBW, Inc. 2005

Printed in the USA

TABLE OF CONTENTS

Safety Information . . . . . . . . . . . . . . . . . . . . . . 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . 5

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Before Starting & Operating . . . . . . . . . . . . . . . . . . . . 6

Wiring Electric Motor. . . . . . . . . . . . . . . . . . . . . . . . . . 6

Starting Gas Engine . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Starting Electric Motor . . . . . . . . . . . . . . . . . . . . . . . . 6

Operating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Stopping Gas Engine . . . . . . . . . . . . . . . . . . . . . . . . . 6

Stopping Electric Motor. . . . . . . . . . . . . . . . . . . . . . . . 7

Towing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . 8

Engine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Engine Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Belt Guides. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Greasing Wheel Bearings . . . . . . . . . . . . . . . . . . . . . 9

Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Engine Shroud Removal . . . . . . . . . . . . . . . . . . . . . 10

Engine Shroud Installation . . . . . . . . . . . . . . . . . . . . 10

Drum Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Drum Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Drum Bearing & Seals Replacement . . . . . . . . . . . . 11

Engine Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Engine Installation . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Parts Replacement Cycles and Tolerances . . . . . . . 12

Replacement Parts . . . . . . . . . . . . . . . . . . . . . 13

Drum Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Drivetrain Assembly . . . . . . . . . . . . . . . . . . . . . . . . . 16

Electric Motor Drivetrain Assembly . . . . . . . . . . . . . 18

Idler Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Air Mixer Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . 22

Frame & Axle Assembly . . . . . . . . . . . . . . . . . . . . . . 24

Paddle Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

CALIFORNIA PROPOSITION 65 WARNING

WARNING

Engine exhaust and some of its constituents are

known in the state of California to cause cancer, birth

defects, and other reproductive harm.

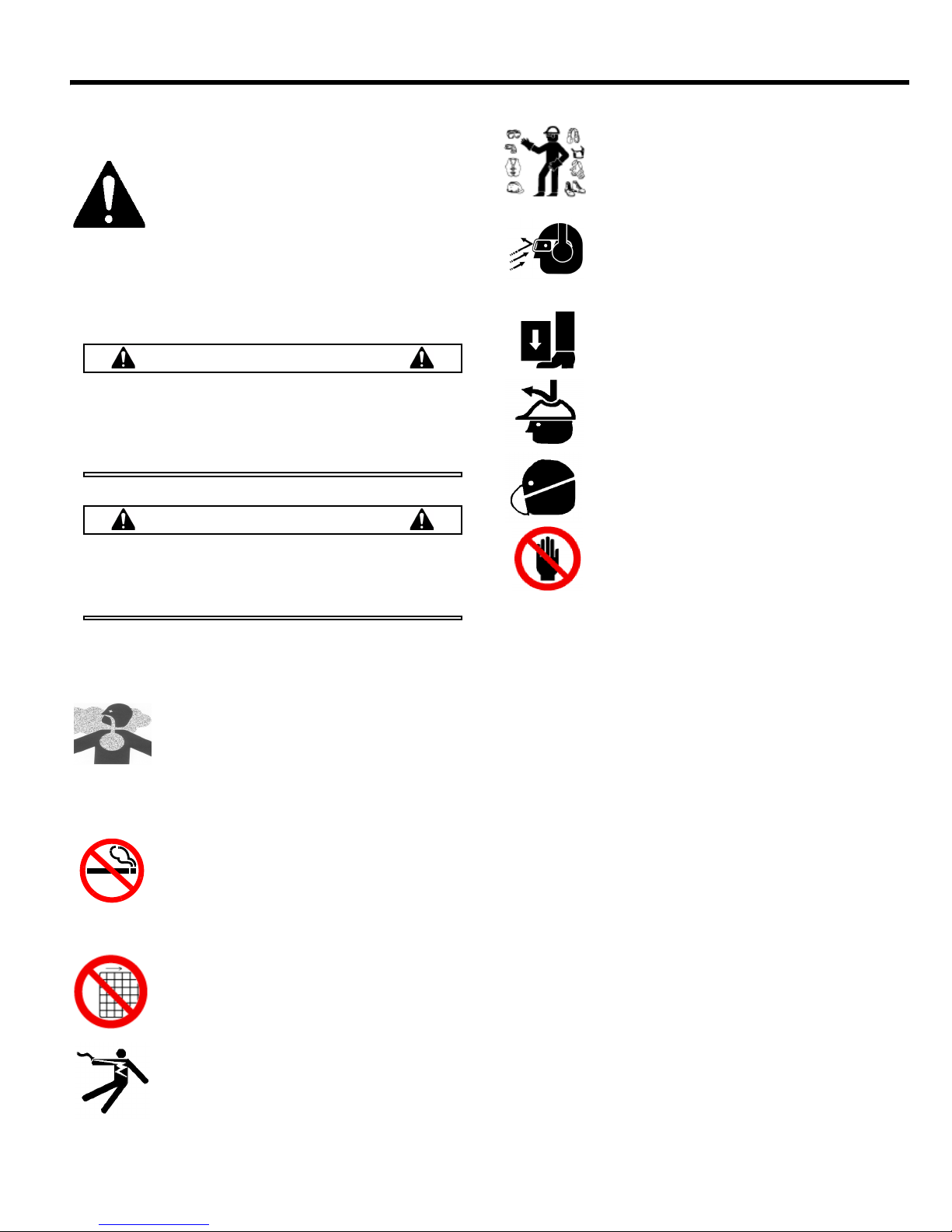

SAFETY INFORMATION

WARNING

CAUTION

Introduction

This Safety Alert Symbol is used to call attention

to items or operations which may be dangerous

to those operating or working with this

equipment. The symbol can be found

throughout this manual and on the unit. Please read these

warnings and cautions, along with all decals, carefully

before attempting to operate the unit. Make sure every

individual who operates or works with this equipment is

familiar with all safety precautions.

GENERAL WARNING. Indicates information

important to the proper operation of the

equipment. Failure to observe may result in

damage to the equipment and/or severe bodily

injury or death.

GENERAL CAUTION. Indicates information

important to the proper operation of the

equipment. Failure to observe may result in

damage to the equipment.

Safety Precautions

LETHAL EXHAUST GAS: An internal

combustion engine discharges carbon

monoxide, a poisonous, odorless, invisible

gas. Death or serious illness may result if

inhaled. Operate only in an area with proper

ventilation. NEVER OPERATE IN A

CONFINED AREA!

DANGEROUS FUELS: Use extreme caution

when storing, handling and using fuels, as

they are highly volatile and explosive in vapor

state. Do not add fuel while engine is running.

Stop and cool the engine before adding fuel.

DO NOT SMOKE!

SAFETY GUARDS: It is the owner's

responsibility to ensure that all guards and

shields are in place and in working order.

IGNITION SYSTEMS: Breakerless, magneto,

and battery ignition systems can cause severe

electrical shocks. Avoid contacting these

units or their wiring.

SAFE DRESS: Do not wear loose clothing,

rings, wristwatches, etc. near machinery.

NOISE PROTECTION: Wear OSHA specified

hearing protection devices.

EYE PROTECTION: Wear OSHA specified

eye shields, safety glasses, and sweat bands.

FOOT PROTECTION: Wear OSHA specified

steel-tipped safety shoes.

HEAD PROTECTION: Wear OSHA specified

safety helmets.

DUST PROTECTION: Wear OSHA specified

dust mask or respirator.

OPERATOR: Keep children and bystanders

off and away from the equipment.

REFERENCES: For details on safety rules and regulations

in the United States, contact your local Occupational Safety

and Health Administration (OSHA) office. Equipment

operated in other countries must be operated and serviced

in accordance and compliance with any and all safety

requirements of that country. The publication of these

safety precautions is done for your information. MBW does

not by the publication of these precautions, imply or in any

way represent that these are the sum of all dangers present

near MBW equipment. If you are operating MBW

equipment, it is your responsibility to insure that such

operation is in full accordance with all applicable safety

requirements and codes. All requirements of the United

States Federal Occupational Safety and Health

Administration Act must be met when operated in areas that

are under the jurisdiction of that United States Department.

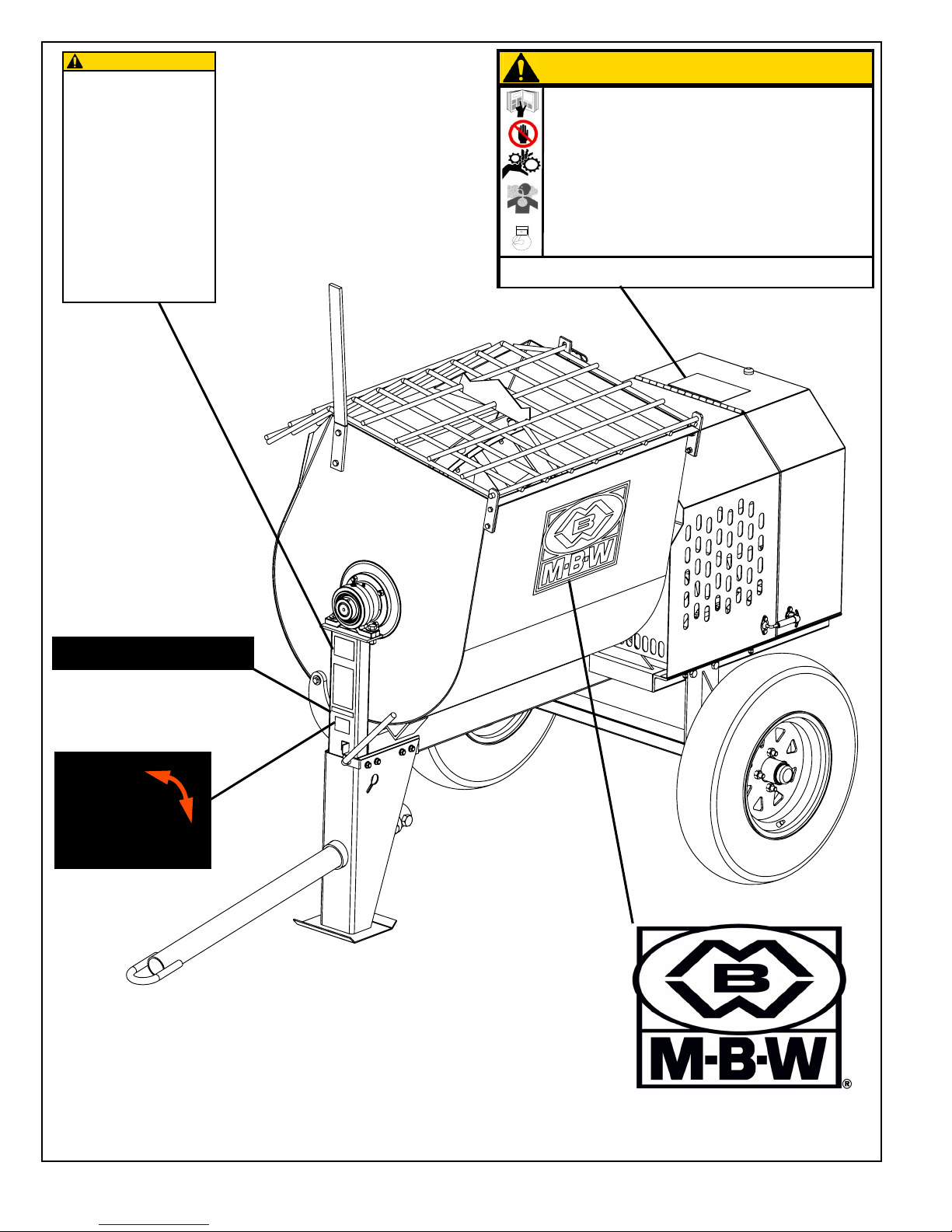

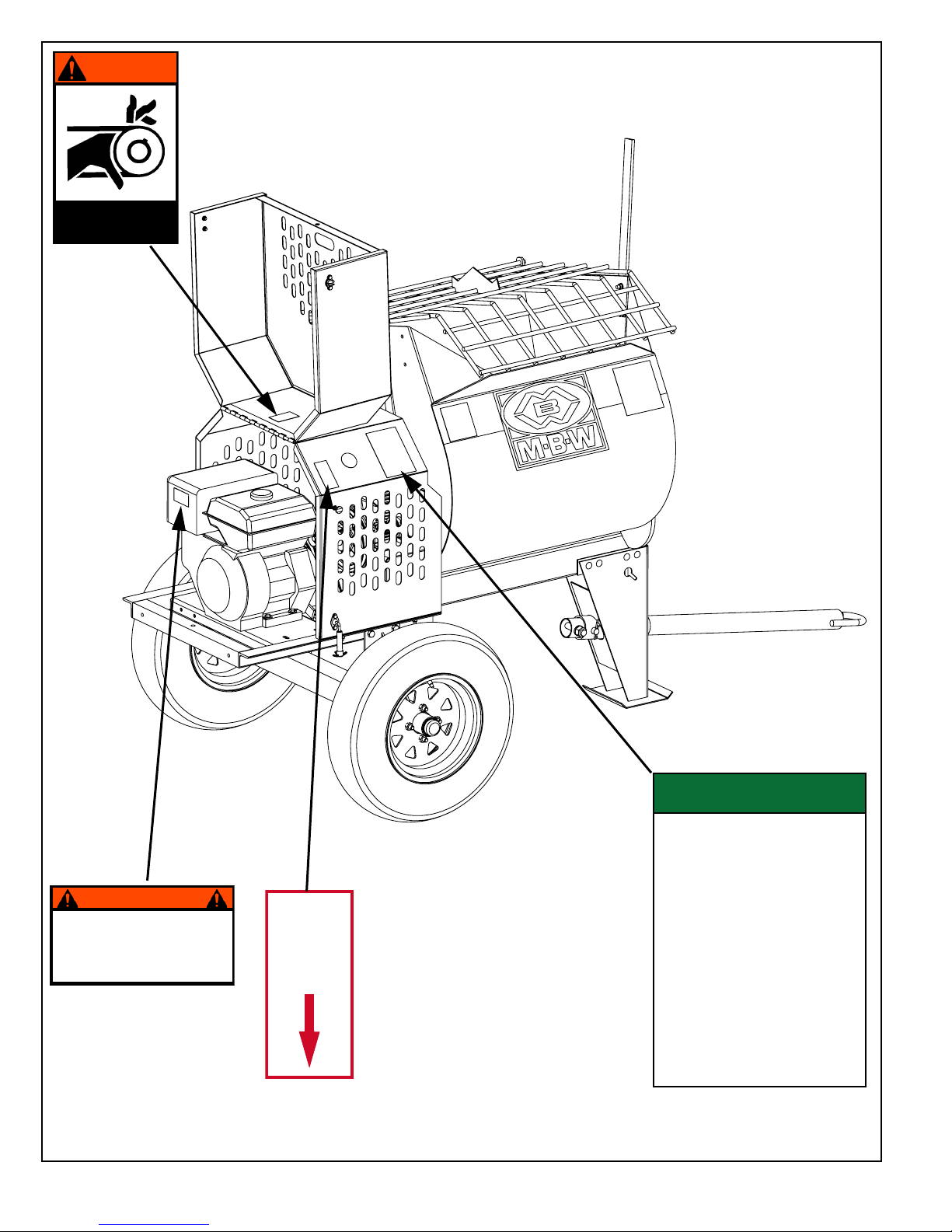

Safety Decals

Carefully read and follow all safety decals. Keep them in

good condition. If decals become damaged, replace as

required. If repainting the unit, replace all decals. Decals

are available from authorized MBW distributors. Order the

decal set listed on the following page(s).

- 1 -

U.S. PATENT 6,695,467

17949

Before Towing:

1. Check running gear and tow bar.

2. Lock drum in tow position.

3. Check tow pin for proper instal-lation

and good condition.

4. USE SAFETY CHAINS when towing.

MAXIMUM TOW SPEED: 50 mph

Improper towing can lead to

damage or injury.

CAUTION(PRECAUCIÓN)

15072

Un remolque incorrecto

puede provocar daños

materiales o lesiones.

Antes del remolque:

1. Revise el funcionamiento de los

engranajes y de la barra de remolque.

2. Bloquee el tambor en la posición de

remolque.

3. Verifique que el pasador de remolque

esté bien instalado y en buen estado.

4. USE CADENAS DE SEGURIDAD al

remolcar la máquina.

MÁX. VELOCIDAD DE REMOLQUE:

80 KPH

STOP

CAUTION(PRECAUCIÓN)

15070

Failure to comply could result in serious bodily injury

El no cumplir con estas instrucciones puede producir como resultado lesiones corporales graves.

Read the operating instructions before operating this piece of equipment.

Lea las Instrucciones Operativas antes de hacer funcionar esta parte del equipo.

Keep unauthorized, inexperienced, untrained people away from this equipment.

Mantenga a las personas no autorizadas y sin entrenamiento alejadas de este equipo.

ROTATING AND MOVING PARTS! Make sure all guards and safety devices are in

place.

¡HAY PIEZAS ROTATIVAS Y MÓVILES! Asegúrese de que todas las guardas y

dispositivos de seguridad estén colocados en sus lugares.

DO NOT RUN this machine in an exnclosed area. The engine produces carbon

monoxide, a POISONOUS gas.

NO HAGA FUNCIONAR esta máquina en una zona encerrada. El motor produce

monóxido de carbono, un GAS VENENOSO.

SHUT OFF the engine before servicing, cleaning or adding fuel to engine or machine.

APAQUE el motor antes de hacerle el servicio, limiarlo o agregarle combustible.

MI

X

IDLE

17129

RALENTÍ

MEZCLA

15072

17949 - Not included

with decal set

15070

17129

Safety Decals (Decal Set #15074)

01554 - Not included

with decal set

- 2 -

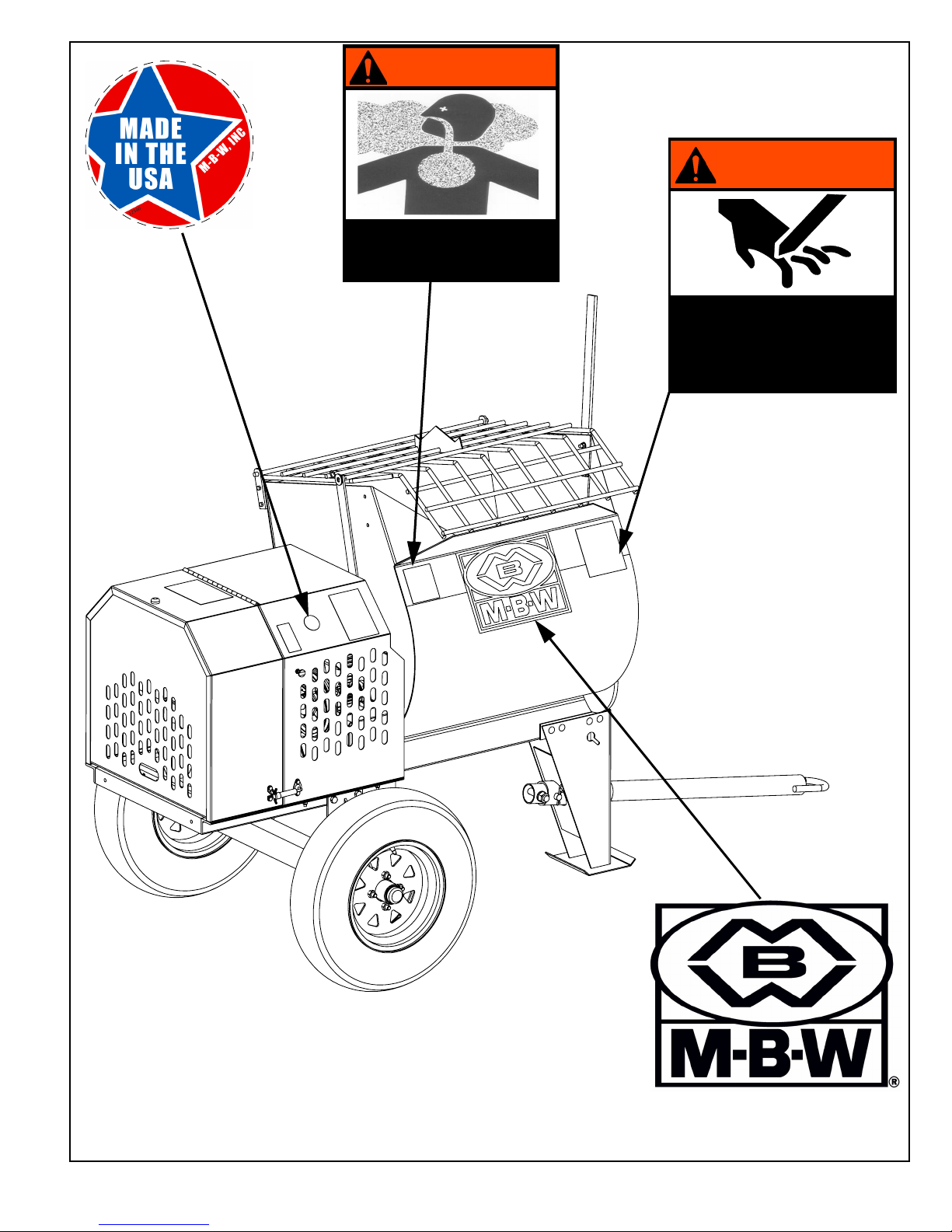

WARNING

ENGINE EXHAUST IS HAZARDOUS IF INHALED

USE ONLY IN A WELL VENTILATED AREA

15076

EL GAS DEL ESCAPE DEL MOTOR ES

PELIGROSO SI SE INHALA

USE LA MÁQUINA SÓLO EN UNA ZONA BIEN

VENTILADA

ADVERTENCIA

WARNING

LAS PIEZAS MÓVILES PUEDEN IMPACTAR Y CORTAR

¡MANTENGA ALEJADAS SUS MANOS!

APAGUE EL MOTOR ANTES DEL SERVICIO.

15069

MOVING PARTS CAN CRUSH AND CUT

KEEP HANDS CLEAR!

SHUT OFF ENGINE OR MOTOR

BEFORE SERVICING.

ADVERTENCIA

12500

15076

15069

Safety Decals (Decal Set #15074)

01554 - Not included with decal set

- 3 -

MIXER(MEZCLADORA)

OPERATING INSTRUCTIONS

1. Check oil in engine crankcase.

2. MAKE SURE grid is CLOSED before starting and during operation.

3. Place engage lever in IDLE position before starting engine.

4. Open fuel valve.

5. Close choke on engine. A warm engine may not need to be choked.

6. Open throttle to FAST position.

7. Pull starter rope.

8. After starting, turn choke off, let engine warm up at idle.

9. Open throttle to FAST position, CLOSE SHROUD! Place

engagement lever in MIX position, charge mixer.

10. TO STOP: Place engagement lever in IDLE position, return throttle

to idle, close fuel valve, press stop button.

11. Before towing, check that drum is locked in towing position, and tow

pin is properly installed and in good condition.

MAXIMUM TOW SPEED: 50 MPH

MÁX. VELOCIDAD DE REMOLQUE: 80 KPH

15071

INSTRUCCIONES DE OPERACIÓN

1. Revise el aceite en el cárter del motor.

2. CERCIÓRESE de que la rejilla esté CERRADA antes del arranque y durante la

operación.

3. Coloque la palanca de engranaje en la posición de RALENTÍ antes de arrancar

el motor.

4. Abra la válvula de combustible.

5. Cierre el estrangulador del motor. Si el motor está tibio, puede que no requiera

estrangulamiento.

6. Abra el acelerador a la posición RÁPIDA.

7. Tire de la cuerda de arranque.

8. Tras el arranque, apague el estrangulador y deje que el motor se caliente en

ralentí.

9. Abra el acelerador y póngalo en la posición RÁPIDA, ¡CIERRE LA CUBIERTA!

Coloque la palanca de engranaje en la posición de MEZCLA, cargue la

mezcladora.

10. PARA DETENERLA: Coloque la palanca de engranaje en la posición RALENTÍ,

vuelva el acelerador a ralentí, cierre la válvula de combustible y pulse el botón de

parada.

11. Antes del remolque, verifique que el tambor esté bloqueado en la posición de

remolque, y que el perno esté correctamente instalado y en buen estado.

PUSH

TO

STOP

16546

PULSE PARA

DETENER

12573

19791

WARNING

OPERATION OF THIS EQUIPMENT MAY

CREATE SPARKS THAT CAN START FIRES

AROUND DRY VEGETATION. A SPARK

ARRESTER MAY BE REQUIRED. THE

OPERATOR SHOULD CONTACT LOCAL FIRE

AGENCIES FOR LAWS OR REGULATIONS

RELATING TO FIRE PREVENTION

19791

Safety Decals (Decal Set #15074)

16546

15071

- 4 -

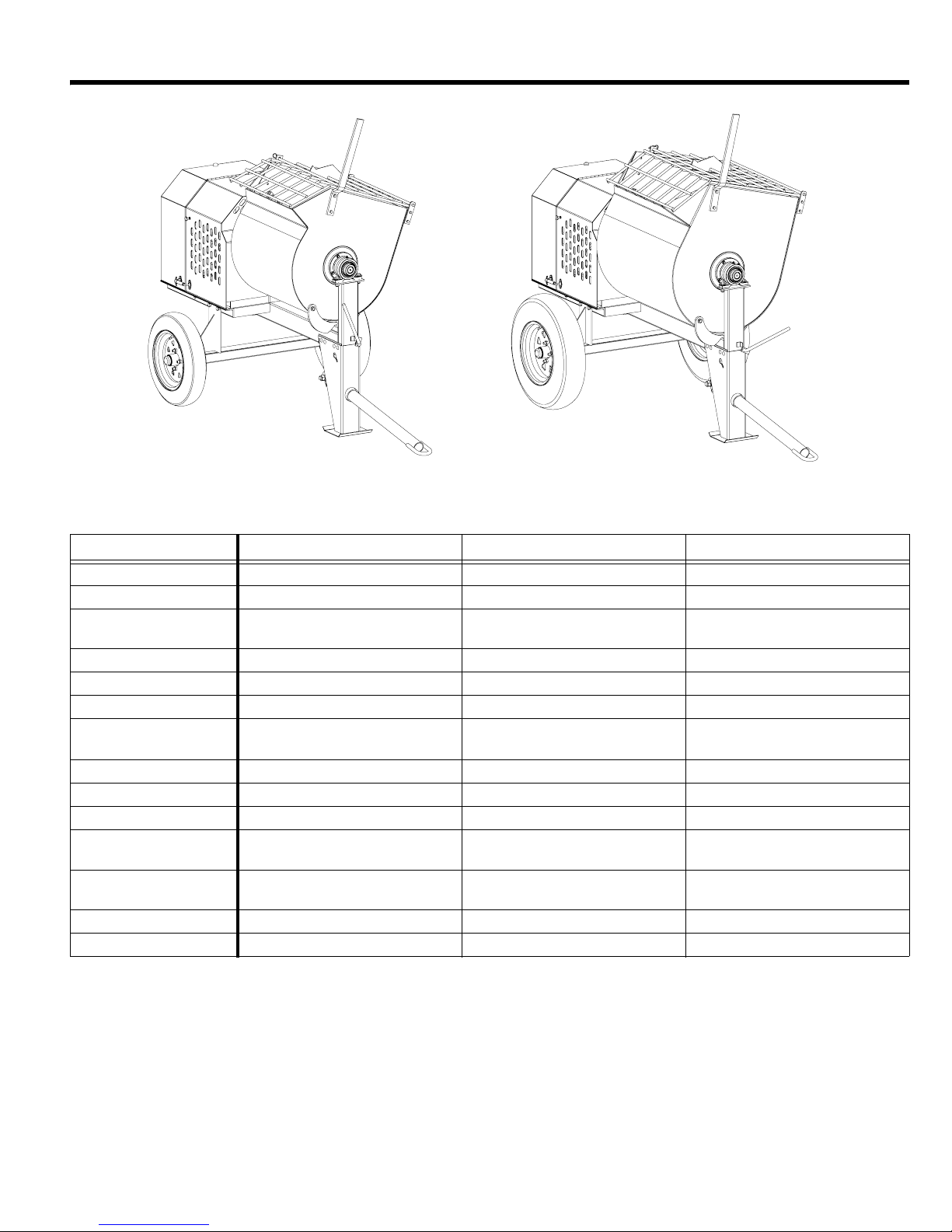

SPECIFICATIONS

MM90

MM60

MM60 MM80 MM90

Batch Capacity 6 cu. ft (.17 cu. m) 8 cu. ft (0.23 cu. m) 9 cu. ft (0.26 cu. m)

Batch Size 2 bags 2.5 - 3 bags 3 - 3.5 bags

Gas Engines

Engine Speed 3500 rpm 3300 rpm 3300 rpm

Drivetrain V-belts to Gears V-belts to Gears V-belts to Gears

Electric Motors Baldor 1.5 hp (1-phase) Baldor 2 hp (1-phase) Baldor 3 hp (1-phase)

Motor Draw

Motor Speed 1725 rpm 1725 rpm 1725 rpm

Drivetrain Chain to V-belts to Gears Chain to V-belts to Gears Chain to V-belts to Gears

Axle 46” Solid Axle 46” Solid Axle 46” Solid Axle

Wheels

Size - W x L x H

Weight 650 lbs (295 kg) 715 lbs (324 kg) 730 lbs (331 kg)

Charging Height 47 in (119 cm) 49 in (124 cm) 49 in (124 cm)

Specifications subject to change without notice

Honda GX160

Honda GX240

115V - 18A

230V - 9A

4.80 x 12

High-Speed

46 x 64 x 56 in

(117 x 163 x 142 cm)

Honda GX240 Honda GX240

230V - 14A 230V - 15.5A

ST175/80D13

High-Speed

46 x 67 x 57 in

(117 x 170 x 145 cm)

ST175/80D13

High-Speed

46 x 71 x 57 in

(117 x 180 x 145 cm)

- 5 -

OPERATION

WARNING

WARNING

CAUTION

Introduction

MBW equipment is intended for use in very severe

applications. They are powered by four cycle engines and

are available in different sizes and a selection of engines.

This parts manual contains only standard parts. Variations

of these parts as well as other special parts are not included.

Contact your local MBW distributor for assistance in

identifying parts not included in this manual.

Before Starting & Operating

• REMEMBER! It is the owner’s responsibility to

communicate information on the safe use and proper

operation of this unit to the operators.

• Review ALL of the Safety Precautions listed on page 1 of

this manual.

• Familiarize yourself with the operation of the machine

and confirm that all controls function properly.

• Know how to STOP the machine in case of an

emergency.

• Make sure hands, feet, and clothing are at a safe

distance from any moving parts.

• OIL LEVEL - Check the oil level in the engine. For more

information see “Lubrication” under the respective

engine’s “Owners Manual” or the Maintenance section of

this manual.

• AIR CLEANER - Check to ensure element is in good

condition and properly installed.

• FUEL SUPPLY - The engines on MBW equipment

require an automotive grade of clean, fresh, unleaded

gasoline.

• FUEL FILTER - If clogged or damaged, replace.

Wiring Electric Motor

3. Pull out the stop switch on the engine shroud.

4. Move the engine throttle lever to the “FAST” position.

5. Choke the engine if necessary. (You may not need to

choke a warm engine).

6. Pull the starter rope repeatedly until engine starts.

7. Move choke lever to open position and throttle lever

to the “IDLE” position

8. Allow engine to warm up for one or two minutes.

Starting Electric Motor

1. Move mixer engagement lever to “IDLE” position.

2. Plug the motor into a suitable power source.

3. Move the switch on the motor to the “ON” position.

Operating

1. Close the engine shroud.

Do not operate the mixer with the shroud open.

2. Move engagement lever to the “MIX” position.

3. Add half of the required amount of sand and water for

the batch to be mixed.

4. Add the total required amount of mortar mix.

5. Add the remaining amounts of sand and water and allow time to mix properly.

6. Unlock the drum by rotating the locking bar out of engagement with the frame.

7. Tip the drum forward to discharge the batch.

8. Return drum to mixing position and check that it is

locked in place.

9. If another batch is to be mixed, add water for the next

batch.

All electric motors come with a 12” pigtail which must be

wired with a plug for your application.

Wiring must be done by certified electrician.

Starting Gas Engine

1. Move mixer engagement lever to “IDLE” position.

2. Open the fuel valve.

Always clean the drum after each day’s operation.

See Cleaning, page 8.

Stopping Gas Engine

1. Move mixer engagement lever to the “IDLE” position.

2. Whenever possible it is recommended to let the engine idle before stopping.

3. Push in the engine stop switch on the engine shroud.

- 6 -

4. Close the fuel valve.

WARNING

WARNING

Stopping Electric Motor

1. Move mixer engagement lever to the “IDLE” position.

2. Move the switch on the motor to the “OFF” position.

Always STOP the engine before adding fuel.

Always STOP the engine or motor before leaving

the equipment unattended for any amount of time.

Always STOP the engine or motor and disconnect

spark plug wire or power cord before making any

repairs or adjustments to the machine.

Towing

1. Stop the engine or electric motor.

2. Close and latch the engine shroud.

3. Rotate the drum into the locked position, and check

that it is locked in place.

4. Secure the mixer hitch and safety chains to the vehicle.

Always check that axle, front leg, and tow bar

hardware is tight before towing.

Make sure safety bolt is in place.

Check the condition of the pin on the tow bar and

make sure it is secure.

Remove any loose debris from the mixer before

towing on roads.

Check that safety chains cross each other when

attached.

MAXIMUM TOW SPEED: 50 mph

- 7 -

Loading...

Loading...