MBW GPR57 Service Manual

OPERATOR’S SAFETY

Website: www.mbweurope.com

AND SERVICE MANUAL

GPR

is manual covers the following serial numbers

and higher for each model listed:

GPR78...........................................7800110

VIBRATORY PLATES

MBW, Inc.

250 Hartford Rd • PO Box 440

Slinger, WI 53086-0440

Phone: (262) 644-5234

Fax: (262) 644-5169

Email: mbw@mbw.com

Website: www.mbw.com

MBW Europe Ltd.

Units 2&3 CochraneStreet

Bolton BL3 6BN

England, UK

Phone: 44 (0) 01204 387784

Fax: 44 (0) 01204 387797

E-mail: PEZHXURSH#PEZFRP

MBW FR.R.L.

Z.A. d’Outreville

11 Rue Jean Baptiste

Néron,

60540 BORNEL

France

Email: mbwfrance@free.fr

Phone:+33 (0) 3 44 07 15 96

©

©MBW, Inc. 201

TABLE OF CONTENTS

Safety Information . . . . . . . . . . . . . . . . . . . . . . 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Parts Replacement Cycles and Tolerances . . . . . . . 7

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Decals: GPR78H (Decal Set #16031) . . . . . . . 3

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . .2

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Before Starting & Operating . . . . . . . . . . . . . . . . . . . . 3

Engine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Stopping Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Lifting/Transporting . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . 5

Fluid Levels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Engine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Engine Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Replacement Parts . . . . . . . . . . . . . . . . . . . . .8

9LEUDWLQJ3ODWH. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

%RG\. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . 11

9LEUDWRU$VVHPEO\. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . 13

+DQGOH$VVHPEO\ . . . . . . . . . . . . . . . . . . . . . . . . . . 14

. . . . . . . . . . . . . . . . . 15

+DQG3XPS$VVHPEO\

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

'HFODUDWLRQRI&RQIRUPLW\

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Torque Chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Service Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

CALIFORNIA PROPOSITION 65 WARNING

WARNING

Engine exhaust and some of its constituents are

known in the state of California to cause cancer, birth

defects, and other reproductive harm.

SAFETY INFORMATION

WARNING

CAUTION

Introduction

This Safety Alert Symbol is used to call attention

to items or operations which may be dangerous

to those operating or working with this

equipment. The symbol can be found

throughout this manual and on the unit. Please read these

warnings and cautions, along with all decals, carefully

before attempting to operate the unit. Make sure every

individual who operates or works with this equipment is

familiar with all safety precautions.

GENERAL WARNING. Indicates information

important to the proper operation of the

equipment. Failure to observe may result in

damage to the equipment and/or severe bodily

injury or death.

GENERAL CAUTION. Indicates information

important to the proper operation of the

equipment. Failure to observe may result in

damage to the equipment.

Safety Precautions

LETHAL EXHAUST GAS: An internal

combustion engine discharges carbon

monoxide, a poisonous, odorless, invisible

gas. Death or serious illness may result if

inhaled. Operate only in an area with proper

ventilation. NEVER OPERATE IN A

CONFINED AREA!

DANGEROUS FUELS: Use extreme caution

when storing, handling and using fuels, as

they are highly volatile and explosive in vapor

state. Do not add fuel while engine is running.

Stop and cool the engine before adding fuel.

DO NOT SMOKE!

SAFETY GUARDS: It is the owner's

responsibility to ensure that all guards and

shields are in place and in working order.

IGNITION SYSTEMS: Breakerless, magneto,

and battery ignition systems can cause severe

electrical shocks. Avoid contacting these

units or their wiring.

SAFE DRESS: Do not wear loose clothing,

rings, wristwatches, etc. near machinery.

NOISE PROTECTION: Wear OSHA specified

hearing protection devices.

EYE PROTECTION: Wear OSHA specified

eye shields, safety glasses, and sweat bands.

FOOT PROTECTION: Wear OSHA specified

steel-tipped safety shoes.

HEAD PROTECTION: Wear OSHA specified

safety helmets.

DUST PROTECTION: Wear OSHA specified

dust mask or respirator.

OPERATOR: Keep children and bystanders

off and away from the equipment.

REFERENCES: For details on safety rules and regulations

in the United States, contact your local Occupational Safety

and Health Administration (OSHA) office. Equipment

operated in other countries must be operated and serviced

in accordance and compliance with any and all safety

requirements of that country. The publication of these

safety precautions is done for your information. MBW does

not by the publication of these precautions, imply or in any

way represent that these are the sum of all dangers present

near MBW equipment. If you are operating MBW

equipment, it is your responsibility to insure that such

operation is in full accordance with all applicable safety

requirements and codes. All requirements of the United

States Federal Occupational Safety and Health

Administration Act must be met when operated in areas that

are under the jurisdiction of that United States Department.

Safety Decals

Carefully read and follow all safety decals. Keep them in

good condition. If decals become damaged, replace as

required. If repainting the unit, replace all decals. Decals

are available from authorized MBW distributors. Order the

decal set listed on the following page(s).

- 1 -

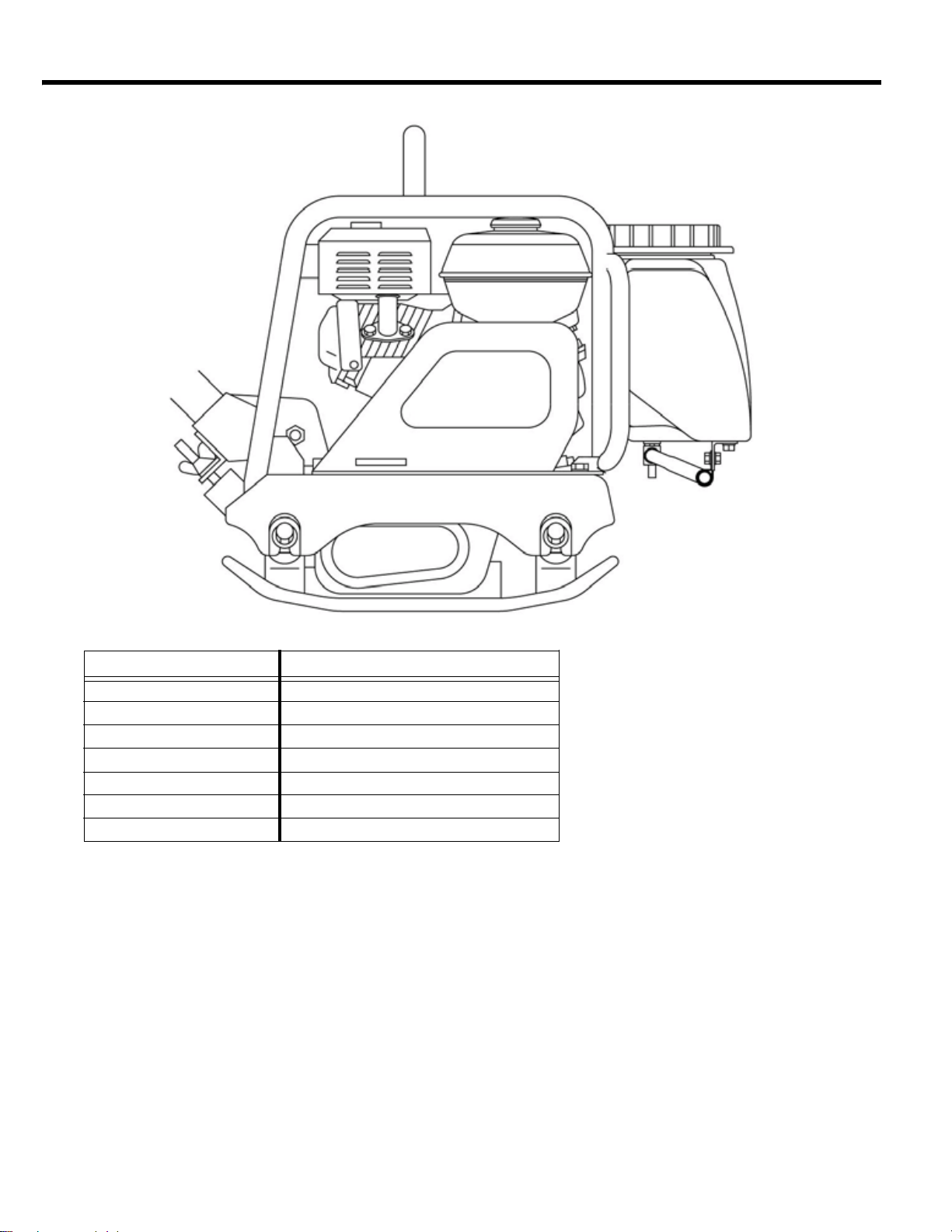

SPECIFICATIONS

GRP

CENTRIFUGAL FORCE ϮϳϱϬ kgf (Ϯϳ kN)

EXCITER (VPM) vpm +]

TRAVEL SPEED 82 ft./min. (25 m/min.)

WIDTH x LENGTH ϰϯ X ϭϭϯ cm

OPERATING WEIGHT kg

ENGINE <DQPDU/

FUEL Diesel

Specifications subject to change without notice.

No universal method or formula has been accepted for determining “Compaction Force”. All manufactures employ their

own method or formula.

- 2 -

OPERATION

Introduction

MBW equipment is intended for use in very severe

applications. They are powered by four cycle engines and

are available in different sizes and a selection of engines.

The MBW Reversible Plate Compactor is intended to

compact various soil types. Recommended soil types

include granular soils, gravel/sand mixtures, and semigranular cohesive soils.

The MBW Reversible Plate Compactor is not recommended

for use in cohesive soils nor for very hard surfaces such as

concrete or asphalt.

This parts manual contains only standard parts. Variations

of these parts as well as other special parts are not included.

Contact your local MBW distributor for assistance in

identifying parts not included in this manual.

Before Starting & Operating

After receiving your new MBW Inc. Reversible Plate

Compactor, inspect it for any visible damage done during

shipment. Make sure the engine throttle works properly.

Contact your nearest MBW Inc. Distributor if there are any

problems.

Your new MBW Inc. Reversible Plate Compactor is

shipped complete and ready for use.

• REMEMBER! It is the owner’s responsibility to

communicate information on the safe use and proper

operation of this unit to the operators.

• Review ALL of the Safety Precautions listed on page 1 of

this manual.

• Familiarize yourself with the operation of the machine

and confirm that all controls function properly.

diesel fuel or unleaded gasoline dependent on engine

type. (See Engine “Owner’s Manual”)

• FUEL FILTER - If clogged or damaged, replace.

Engine

Refer to the engine manual for location of all controls and

features.

Starting Gasoline Engine

1. Open fuel valve.

2. Turn engine switch to “ON” position.

3. Set throttle to idle position.

4. Choke engine if necessary (you may not need to

choke a warm engine).

5. Pull starter rope repeatedly until engine starts.

6. Move choke lever to off or open position.

7. Allow engine to warm up for one or two minutes.

Starting Diesel Engine

For detailed instructions refer to the engine Manual.

1. When starting the engine, the throttle lever on the

handle must be in the idle position.

2. The engine has an automatic decompression

system, however it is recommended to slowly pull the

starter rope until you feel a slight resistance. Let the

starter rope recoil completely and pull the starter rope

quickly.

3. Let the engine warm up in the idle position for one or

two minutes.

• Know how to STOP the machine in case of an

emergency.

• Make sure hands, feet, and clothing are at a safe

distance from any moving parts.

• OIL LEVEL - Check the oil level in the engine. For more

information see “Lubrication” under the respective

engine’s “Owners Manual” or the Maintenance section of

this manual.

• AIR CLEANER - Check to ensure element is in good

condition and properly installed.

• FUEL SUPPLY - The engines on MBW Inc. compaction

equipment require an automotive grade of clean, fresh,

Operating

1. After the engine warms up, fully open throttle.

2. The compactor will begin vibrating and moving in a

forward direction. Never leave compactor idling

unattended.

3. The MBW Reversible Plate Compactor is designed to

shift into forward automaticly when control lever is

released. The number of passes needed to reach the

compaction level desired will depend on soil type and

moisture. Maximum compaction of the soil has been

reached when excessive kickback is noticed in the

compactor.

- 3 -

Loading...

Loading...