MBW GPR160 User Manual

OPERATOR’S SAFETY

AND SERVICE MANUAL

GPR160

This manual covers the following serial numbers

and higher for each model listed:

GPR160 . . . . . . . . . . . . . . . . . . 1600001

REVERSIBLE VIBRATORY PLATE

MBW, Inc.

250 Hartford Rd • PO Box 440

Slinger, WI 53086-0440

Phone: (262) 644-5234

Fax: (262) 644-5169

Email: mbw@mbw.com

Website: www.mbw.com

MBW (UK) Ltd.

Units 2 & 3 Cochrane Street

Bolton BL3 6BN, England

Phone: 01204 387784

Fax: 01204 387797

MBW FRANCE S.A.R.L.

Z.A. d’Outreville

11 rue Jean Baptiste Néron,

60540 BORNEL

FRANCE

Phone: +33 (0) 3 44 07 15 96

Fax: +33 (0) 3 44 07 41 28

Email: mbwfrance@free.fr

L20325 / 01.12.B

©MBW, Inc. 2011

Printed in the USA

TABLE OF CONTENTS

Safety Information . . . . . . . . . . . . . . . . . . . . . . 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . 3

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Before Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Engine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Starting Gasoline Engine . . . . . . . . . . . . . . . . . . . . . . 4

Starting Diesel Engine . . . . . . . . . . . . . . . . . . . . . . . . 4

Running Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Stopping Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Lifting/Transporting . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . 6

Fluid Levels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Engine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Cleaning Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Engine Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Battery Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . 7

Battery Charging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Belt Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Checking Hydraulic Fluid . . . . . . . . . . . . . . . . . . . . . . 7

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Service Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Main Disassembly Procedure (Diesel Engine) . . . . . . 8

Exciter Oil Change Procedure . . . . . . . . . . . . . . . . . . 9

Lower Hydraulic Seal Replacement . . . . . . . . . . . . . . 9

Bleeding And Adjustment of Hydraulic Controls. . . . 10

Baseplate Disassembly Procedure . . . . . . . . . . . . . 11

Handle Disassembly Procedure . . . . . . . . . . . . . . . . 12

Control Head Disassembly Procedure . . . . . . . . . . . 12

Baseplate Assembly Procedure . . . . . . . . . . . . . . . . 12

Control Head Assembly Procedure . . . . . . . . . . . . . 15

Handle Assembly Procedure . . . . . . . . . . . . . . . . . . 15

Final Assembly Procedure . . . . . . . . . . . . . . . . . . . . 16

Diesel Engine Throttle Adjustment . . . . . . . . . . . . . . 16

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Replacement Parts . . . . . . . . . . . . . . . . . . . . . 19

Main Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Baseplate Assembly. . . . . . . . . . . . . . . . . . . . . . . . . 22

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Lower Shaft Assembly . . . . . . . . . . . . . . . . . . . . . . . 24

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Handle Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Control Head Assembly . . . . . . . . . . . . . . . . . . . . . . 28

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Diesel Engine Assembly. . . . . . . . . . . . . . . . . . . . . . 30

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Torque Chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

WARNING

CALIFORNIA PROPOSITION 65 WARNING

Engine exhaust and some of its constituents are

known in the state of California to cause cancer,

birth defects, and other reproductive harm.

SAFETY INFORMATION

Introduction

This Safety Alert Symbol is used to call attention

to items or operations which may be dangerous

to those operating or working with this

equipment. The symbol can be found

throughout this manual and on the unit. Please read these

warnings and cautions, along with all decals, carefully

before attempting to operate the unit. Make sure every

individual who operates or works with this equipment is

familiar with all safety precautions.

WARNING

GENERAL WARNING. Indicates information

important to the proper operation of the

equipment. Failure to observe may result in

damage to the equipment and/or severe bodily

injury or death.

CAUTION

GENERAL CAUTION. Indicates information

important to the proper operation of the

equipment. Failure to observe may result in

damage to the equipment.

Safety Precautions

LETHAL EXHAUST GAS: An internal

combustion engine discharges carbon

monoxide, a poisonous, odorless, invisible

gas. Death or serious illness may result if

inhaled. Operate only in an area with proper

ventilation. NEVER OPERATE IN A

CONFINED AREA!

DANGEROUS FUELS: Use extreme caution

when storing, handling and using fuels, as

they are highly volatile and explosive in vapor

state. Do not add fuel while engine is running.

Stop and cool the engine before adding fuel.

DO NOT SMOKE!

SAFETY GUARDS: It is the owner's

responsibility to ensure that all guards and

shields are in place and in working order.

IGNITION SYSTEMS: Breakerless, magneto,

and battery ignition systems can cause severe

electrical shocks. Avoid contacting these

units or their wiring.

SAFE DRESS: Do not wear loose clothing,

rings, wristwatches, etc. near machinery.

NOISE PROTECTION: Wear OSHA specified

hearing protection devices.

EYE PROTECTION: Wear OSHA specified

eye shields, safety glasses, and sweat bands.

FOOT PROTECTION: Wear OSHA specified

steel-tipped safety shoes.

HEAD PROTECTION: Wear OSHA specified

safety helmets.

DUST PROTECTION: Wear OSHA specified

dust mask or respirator.

OPERATOR: Keep children and bystanders

off and away from the equipment.

REFERENCES: For details on safety rules and regulations

in the United States, contact your local Occupational Safety

and Health Administration (OSHA) office. Equipment

operated in other countries must be operated and serviced

in accordance and compliance with any and all safety

requirements of that country. The publication of these

safety precautions is done for your information. MBW does

not by the publication of these precautions, imply or in any

way represent that these are the sum of all dangers present

near MBW equipment. If you are operating MBW

equipment, it is your responsibility to insure that such

operation is in full accordance with all applicable safety

requirements and codes. All requirements of the United

States Federal Occupational Safety and Health

Administration Act must be met when operated in areas that

are under the jurisdiction of that United States Department.

Safety Decals

Carefully read and follow all safety decals. Keep them in

good condition. If decals become damaged, replace as

required. If repainting the unit, replace all decals. Decals

are available from authorized MBW distributors. Order the

decal set listed on the following page(s).

- 1 -

CAUTION

13483

CAUTION

Wear approved hearing protection,

foot protection, eye protection and

head protection.

STOP

Read the Operating Instructions

before operating this piece of

equipment.

Keep unauthorized and untrained

people away from this

equipment.

ROTATING & MOVING PARTS!

Make sure all guards and safety

devices are in place.

Failure to comply could result in serious

bodily injury.

SHUT OFF the motor before servic-

ing or cleaning.

DO NOT RUN in an enclosed area.

The engine produces carbon

monoxide, a POISONOUS GAS.

1. Check engine oil level.

2. Check fuel level.

3. Set engine speed control in the middle position.

4. Move decompression lever (if equipped) to the up

position. (Located on top of the engine)

5. Use key (if equipped) or starting handle to start

engine (Refer to engine instruction book for proper

“Manual Starting” procedure.)

6. After starting return engine speed control to the idle

position and allow engine to reach operation

temperature.

7. During operation run engine at full throttle, when

excessive kickback is noticed maximum compaction

has been reached.

8. To stop, return throttle to the idle position and allow

engine to idle for one minute then move control to

stop position.

DIESEL PLATE

OPERATING INSTRUCTIONS

15832

Machine may fall and cause injury or damage if lifted

improperly. All weights shown are with 6” wings.

Lift only by lift hook.

GPR135H = 878 lbs (398 kg)

GPR135DE = 940 lbs (426 kg)

#15853

#20324

GPR160H = 906 lbs (411 kg)

GPR160DE = 985 lbs (447 kg)

15853

DIESEL MODEL

WARNING

OPERATION OF THIS EQUIPMENT MAY

CREATE SPARKS THAT CAN START FIRES

AROUND DRY VEGETATION. A SPARK

ARRESTER MAY BE REQUIRED. THE

OPERATOR SHOULD CONTACT LOCAL FIRE

AGENCIES FOR LAWS OR REGULATIONS

RELATING TO FIRE PREVENTION

#19791

19791

HYDRAULIC OIL

15844

IDLE STO P RUN

THROTTLE

19493

#19493

#15844

FORWARD

20324

REVERSE

14665

#14665

20323

#20323

#15874

WARNING

ROTATING PARTS

can crush and cut.

Keep hands away!

12573

#12573

U.S. PATENT 7,165,469

19326 HYDRAULIC PLATE

#19326

20322

#20322

#15832

Safety Decals (Decal Set #16031)

ENGINE

OIL DRAIN

#15845

- 2 -

15845

#13483

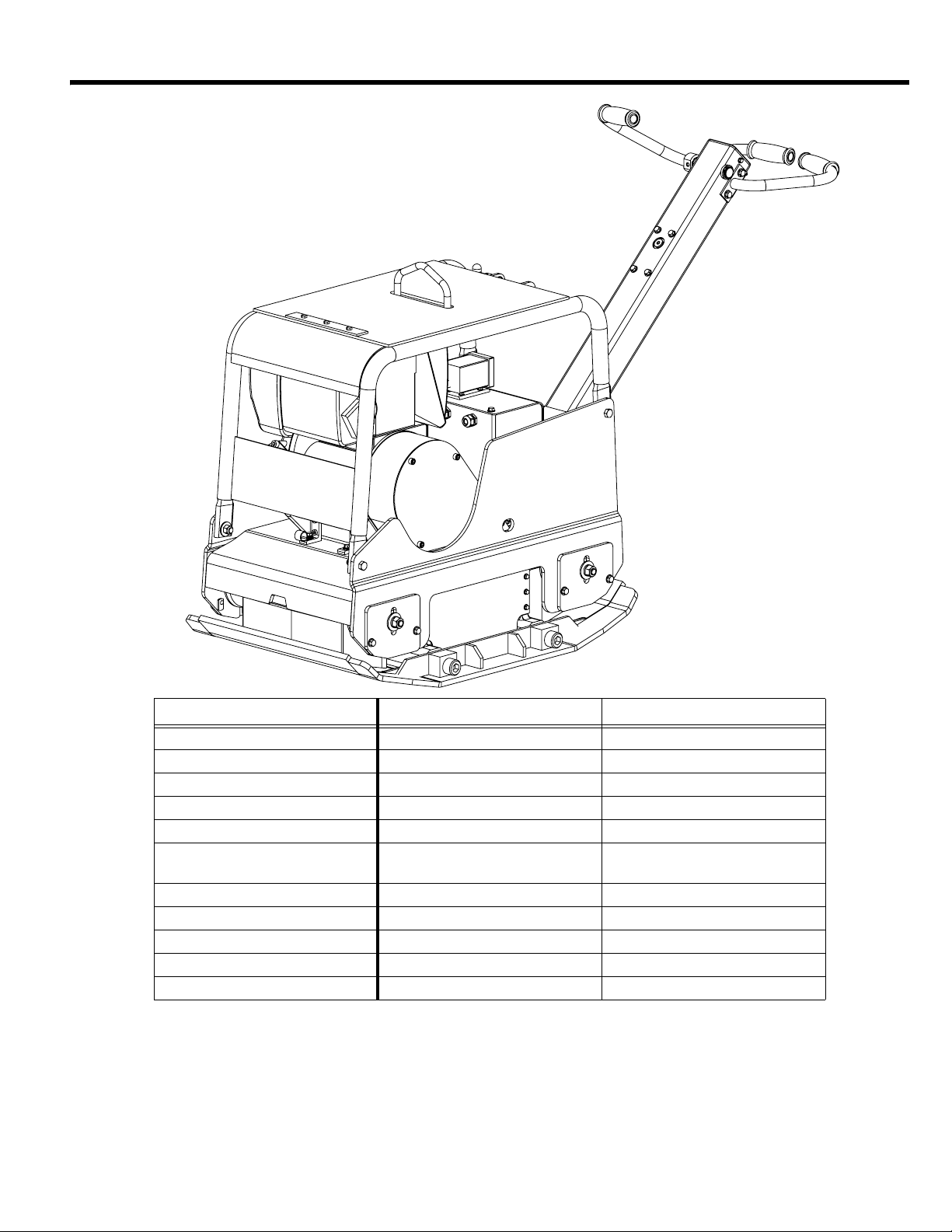

SPECIFICATIONS

GPR160DE

CENTRIFUGAL FORCE 16000 LBF (71 kN)

EXCITER (VPM) 3840 vpm

TRAVEL SPEED 80 ft./min. (24 m/min.)

COMPACTION DEPTH 28 in (71 cm)

WIDTH x LENGTH 25.6 x 37.3 in. (65 x 95 cm)

OPERATING WEIGHT

ENGINE Hatz 1B40 28.2 in.³ (462 cm³)

FUEL Diesel

ENGINE SPEED 3600 rpm

STARTER SYSTEM Electric Start with Recoil

OPTIONAL PLATE EXTENSIONS 6 in. (15.2 cm)

Specifications subject to change without notice

No universal method or formula has been accepted for determining “Compaction Force”. All manufactures employ their

own method or formula.

950 lb. (431 kg)

983 lb. (446 kg) 6” Wings

- 3 -

OPERATION

Introduction

MBW Inc. equipment is intended for use in very severe

applications. They are powered by four cycle engines and

are available in different sizes and a selection of engines.

The MBW Reversible Plate Compactor is intended to

compact various soil types. Recommended soil types

include granular soils, gravel/sand mixtures, and semigranular cohesive soils.

The MBW Reversible Plate Compactor is not

recommended for use in cohesive soils nor for very hard

surfaces such as concrete or asphalt.

This parts manual contains only standard parts.

Variations of these parts as well as other special parts are

not included. Contact your local MBW Inc. Distributor for

assistance in identifying parts not included in this manual.

Before Operation

After receiving your new MBW Inc. Reversible Plate

Compactor, inspect it for any visible damage done during

shipment. Make sure the engine throttle works properly.

Contact your nearest MBW Inc. Distributor if there are any

problems.

Your new MBW Inc. Reversible Plate Compactor is

shipped complete and ready for use.

• REMEMBER It is the owner’s responsibility to

communicate information on the safe use and proper

operation of this unit to all operators.

• Review All of the Safety Precautions listed on page 1 of

this manual.

• Familiarize yourself with the operation of the equipment

and confirm that all controls function properly.

diesel fuel or unleaded gasoline dependent on engine

type. (See Engine “Owner’s Manual”)

• FUEL FILTER - If clogged or damaged, replace.

Engine

Refer to the engine manual for location of all controls and

features.

Starting Gasoline Engine

1. Open fuel valve.

2. Turn engine switch to on position.

3. Set throttle to idle position.

4. Choke engine if necessary, (you may not need to

choke a warm engine).

5. Pull starter rope repeatedly until engine starts.

6. Move choke to the off or open position.

7. Allow engine to warm up for one or two minutes.

Starting Diesel Engine

For detailed instructions refer to the engine Manual.

1. When starting the engine, the throttle lever on the

handle must be in the idle position.

2. The engine has an automatic decompression

system, however it is recommended to slowly pull the

starter rope until you feel a slight resistance. Let the

starter rope recoil completely and pull the starter rope

quickly, do not jerk the starter handle, until the engine

starts.

3. Let the engine warm up in the idle position for one or

two minutes.

• Know how to STOP the equipment in case of an

emergency.

• Make sure hands, feet, and clothing are at a safe

distance from any moving parts.

• OIL LEVEL - Check the oil level in the engine. For more

information see “Lubrication” under the respective

engine’s “Owner’s Manual” or the MAINTENANCE

section of this manual.

• AIR CLEANER - Check to ensure element is in good

condition and properly installed.

• FUEL SUPPLY - The engines on MBW Inc. Compaction

equipment require an automotive grade of clean, fresh,

Running Engine

1. After the engine warms up, fully open throttle.

2. The compactor will begin vibrating and moving in a

forward direction. Never leave compactor idling

unattended.

3. The MBW Reversible Plate Compactor is designed to

slowly move forward without application of the control

lever. The number of passes needed to reach the

compaction level desired will depend on soil type and

moisture. Maximum compaction of the soil has been

reached when excessive kickback is noticed in the

compactor.

- 4 -

/,)76(&85(+(5(

Stopping Engine

WARNING

Always stop the engine before:

1. To stop the compactor from traveling forward, return

the engine throttle to idle position.

2. Whenever possible, it is recommended to let the

engine idle for one or two minutes before stopping.

3. Gas engines: Turn the switch on the engine to

“STOP” position.

Diesel engines: Move the throttle control to the

“STOP” position.

4. Turn off the fuel valve where applicable.

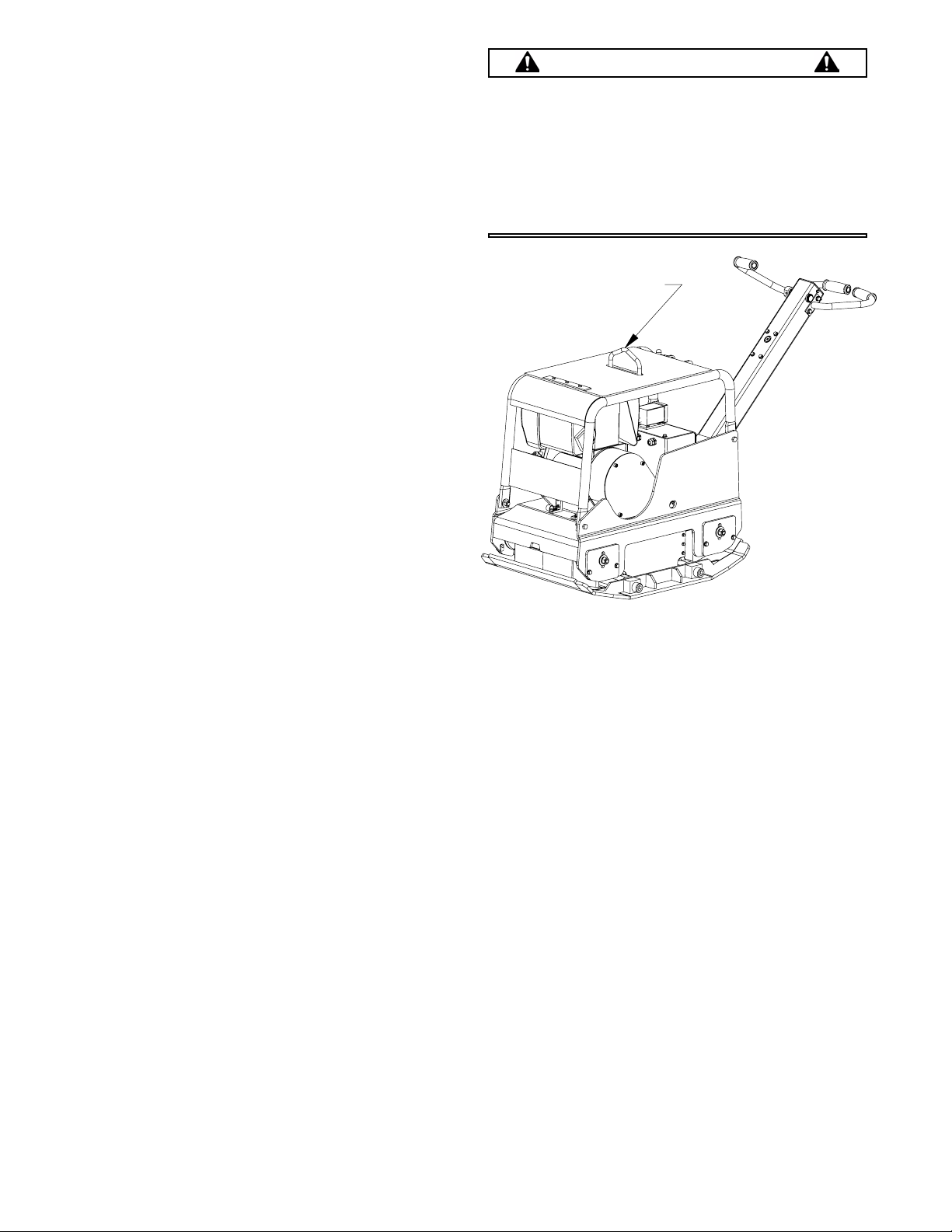

Lifting/Transporting

1. Lift unit by center lifting eye on rollcage.

2. The unit must be transported in the upright position.

DO NOT lay machine on its side.

3. Secure or tiedown unit using lift eye or roll cage when

transporting.

Adding fuel.

Leaving the equipment unattended, even if only

for a minute.

Before making any repairs or adjustments to the

machine.

- 5 -

MAINTENANCE

WARNING

Always exercise the stopping procedure before

servicing or lubricating the unit.

After servicing the unit, replace and fasten all

guards, shields, and covers to their original

positions before resuming operation.

Always verify fluid levels and check for leaks after

changing fluids.

Do not drain oil onto ground, into open streams,

or down sewage drains.

CAUTION

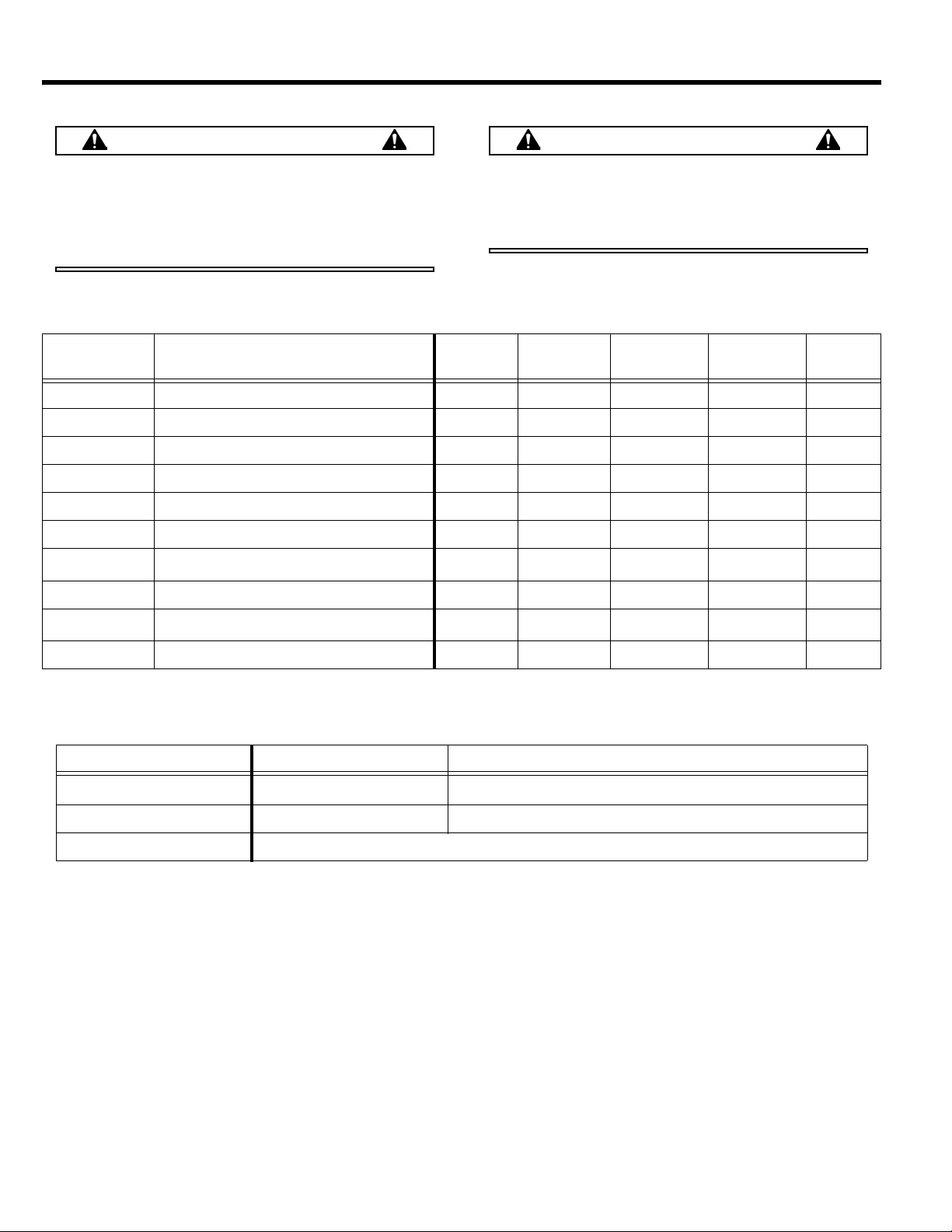

Maintenance Schedule

SYSTEM MAINTENANCE

Engine Refer to engine operator/owner manual X

Clean cooling fins XX

Belts Check for wear and retighten X

Exciter Check oil level X

Check for oil leaks X

Change oil XX

Tighten Bolts

1

EACH

USE

EVERY 50

HOURS

XX

EVERY 100

HOURS

EVERY 250

HOURS

YEARLY

Hydraulics Check level and refill X

Hardware

Shockmounts

1. Check all hardware after the first 5 hours of use, then follow the maintenance schedule.

Check and tighten as needed

Check for cracks or tears XX

1

XX

Fluid Levels

SYSTEM FLUID VOLUME RECOMMENDED OIL

Exciter 32 oz. (0.95 Liter)

Hydraulic Oil 5 oz. (.24 Liter) Chevron AW ISO32 or Rykon 32

Engine Refer to engine operator/owner manual

1. MBW #01058---- 6-Pack (8 oz bottles)

MBW #17320---- 1 quart (32 oz)

Engine Maintenance

Refer to the engine owner’s manual for maintenance

intervals and procedures.

Cleaning Plate

Remove any excess debris which may get into the housing

of the unit.

Engine Speed

MBW Ground Pounder

1. Engine speed is factory set according to the speeds

listed in the Specifications section of this manual. Do

not tamper with the governor setting. The governor

establishes safe operating limits which must not be

exceeded.

2. Refer to the engine Owner’s Manual for procedure on

setting operating and idle speeds.

®

Exciter Oil

1

3. The engine operating speed should be set to 3600

RPM.

- 6 -

4. The engine idle speed must not exceed 1800 RPM. If

the idle speed is greater than 1800 RPM the clutch

may not disengage.

Battery Maintenance

3. Tighten the belt by lifting the engine deck to provide

3/8 - 3/4 inch of “play” on one side of the belt. Be

sure to keep the engine deck level with the

baseplate when adjusting the belt.

4. Retighten the four hex nuts securing the engine deck.

1. Loose or corroded battery terminals will lead to weak

starts and poor charging. Clean posts and connectors

with a wire brush for best connection. Remove dirt

from case using a solution of (2) teaspoons baking

soda and (1) pint of water. Dry completely.

2. Always recycle old battery when replacing. Improper

disposal of batteries can lead to contamination of soil

and ground water.

Battery Charging

1. If unit is not routinely used, charging your battery may

be necessary. An unused battery will self-discharge

over time. Under charged batteries may suffer

permanent damage and premature failure.

Belt Adjustment

If any belt stretch develops follow these steps:

Refer to Main Assembly, page 20.

1. Remove the belt guard, refer to engine assembly

pages.

2. Loosen (do not remove) the four hex nuts (#31)

securing the engine deck to the baseplate.

5. Reinstall the beltguard, refer to engine assembly

pages.

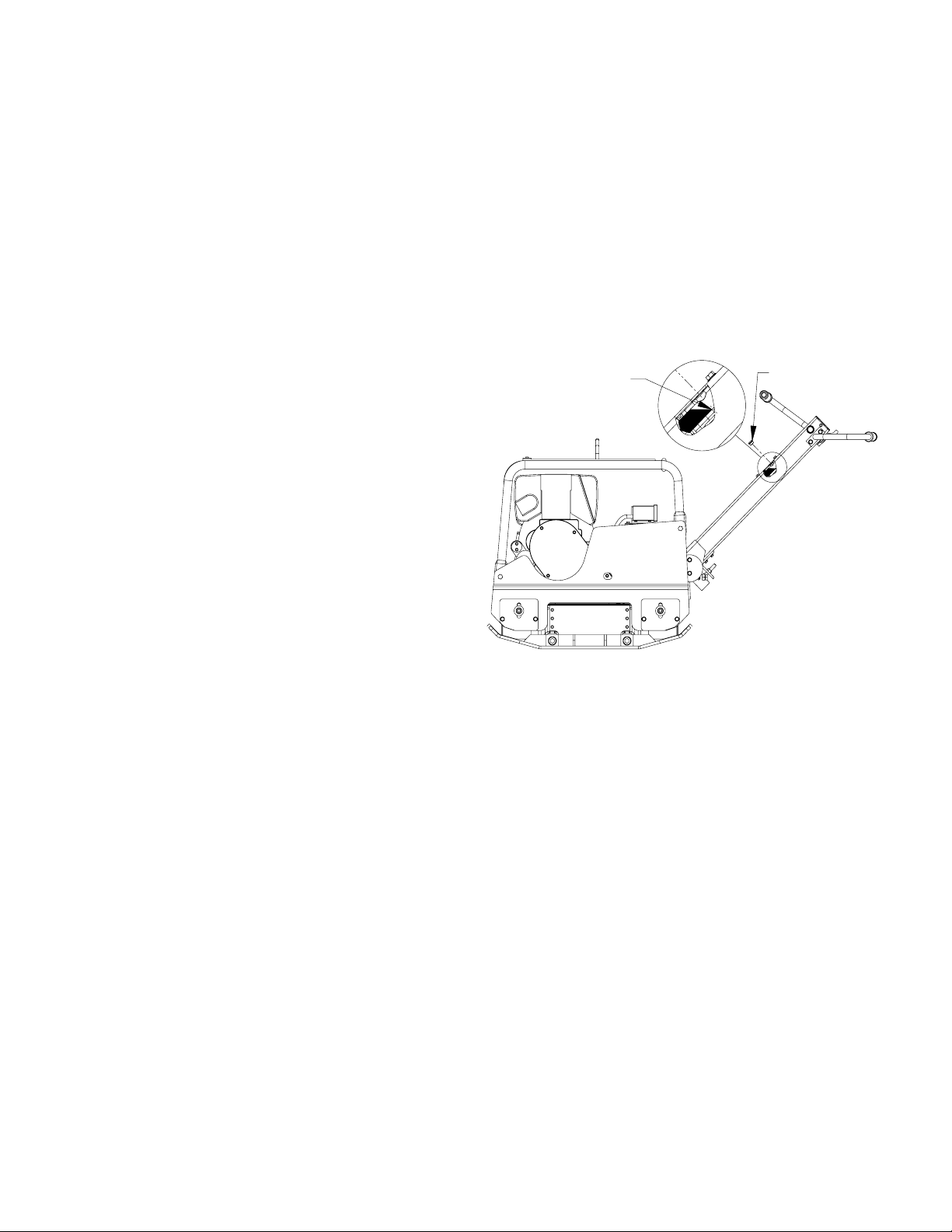

Checking Hydraulic Fluid

1. To avoid contaminating the hydraulic oil clean all dirt

& debris from around the fill plug on handle.

2. Remove fill plug. With handle in operating position

and the shift lever in the forward position, oil level to

be at bottom edge of inside hole as shown.

)/8,'/(9(/72%(83

72%27720('*(2)

,16,'(+2/(

),//3/8*

- 7 -

SERVICE

Assembly and disassembly should be preformed by a

service technician who has been factory trained on MBW

equipment. the unit should be clean and free of debris.

Pressure washing before disassembly is recommended.

• Prior to assembly, wash all parts in a suitable cleaner or

solvent.

• Check moving parts for wear and failure. Refer to the

Replacement Section of this manual for tolerances and

replacement cycles.

• All shafts and housings should be oiled prior to pressing

bearings. Also ensure that bearings are pressed square

and are seated properly.

• All bearings should be replaced when rebuilding any

exciter or gearbox.

• All gaskets and seals should be replaced after any

disassembly.

Torque Chart

SIZE GRADE 2 GRADE 5 GRADE 8

1/4-20 49 in

1/4-28 56 in

5/16-18 8 ft

5/16-24 9 ft

3/8-16 15 ft

3/8-24 17 ft

7/16-14 24 ft

7/16-20 27 ft

1/2-13 37 ft

1/2-20 41 ft

9/16-12 53 ft

5/8-11 73 ft

5/8-18 83 ft

3/4-16 144 ft

1-8 188 ft

1-14 210 ft

1-1/2-6 652 ft

M 6 3 ft

M 8 6 ft

M 10 10 ft

•lbs 76 in•lbs 9 ft•lbs

•lbs 87 in•lbs 10 ft•lbs

•lbs 13 ft•lbs 18 ft•lbs

•lbs 14 ft•lbs 20 ft•lbs

•lbs 23 ft•lbs 33 ft•lbs

•lbs 26 ft•lbs 37 ft•lbs

•lbs 37 ft•lbs 52 ft•lbs

•lbs 41 ft•lbs 58 ft•lbs

•lbs 57 ft•lbs 80 ft•lbs

•lbs 64 ft•lbs 90 ft•lbs

•lbs 82 ft•lbs 115 ft•lbs

•lbs 112 ft•lbs 159 ft•lbs

•lbs 112 ft•lbs 180 ft•lbs

•lbs 200 ft•lbs 315 ft•lbs

•lbs 483 ft•lbs 682 ft•lbs

•lbs 541 ft•lbs 764 ft•lbs

•lbs 1462 ft•lbs 2371 ft•lbs

•lbs 4 ft•lbs 7 ft•lbs

•lbs 10 ft•lbs 18 ft•lbs

•lbs 20 ft•lbs 30 ft•lbs

CONVERSIONS

in

•lbs x 0.083 = ft•lbs

ft

•lbs x 12 = in•lbs

ft

•lbs x 0.1383 = kg•m

ft

•lbs x 1.3558 = N•m

Service Tools

Part No. Description

16129 Rubber Test Mat

16031 Decal Set

17368 Kit, Rebuild, Lower Hydraulic

19606 Kit, Rebuild, Upper Hydraulic

Main Disassembly Procedure (Diesel Engine)

Refer to Main Assembly, page 20. for disassembly.

1. Clean all visible debris from the machine before

servicing.

2. Remove the four hex nuts (#31), lock washers (#32)

and washers (#33). Use caution as the engine deck

will drop down.

3. Remove flange head screws (26) and plates (#19)

securing the engine deck (#18) to the baseplate

(#17).

Refer to Diesel Engine Assembly, page 30. Sections of

this manual for belt guard & belt removal, step 3 & 4.

4. Remove the four socket head capscrews (#32)

securing the belt guard (11) to the mount plate (#16)

on the engine (#14) and remove the beltguard.

5. Slide the belt (#3) off the clutch (#6).

6. Remove the two flange screws (#22) securing the

bellows retainer (#11), and remove the retainer.

7. Push the lip of the bellows (#3) through the hole in the

engine deck.

8. Disconnect the hydraulic line (#16) from the control

head in the handle assembly. Keep the end of the

hydraulic line and control head fitting free of dirt and

debris by using tape. Be careful to use a drain pan

to catch the hydraulic oil.

9. Use the main lift hook on the rollcage (#15) to

separate the engine deck from the baseplate. Be

careful to guide the hydraulic line through the

handle assembly and engine deck as the

subassemblies are separated to prevent damage

to components. If further disassembly of the engine

deck is required proceed to step 9. If baseplate

service is required refer to the Baseplate

Disassembly Procedure section of this manual.

10. Disconnect the throttle cable (#14) from the engine.

11. Remove the handle assembly by removing the four

flange screws (#26) securing the handle mount (#4)

to the engine deck (#18).

- 8 -

12. Remove the four hex head capscrews (#28), washers

(#30) and lock nut (#29) securing the rollcage to the

engine deck and remove the rollcage.

Refer to Diesel Engine Assembly, page 30.

13. Remove the three 6mm bolts (#35) securing the

ignition box to the mount (#13).

14. Remove four flange head screws (#27) securing

cover (#19) to battery box (#18) and remove cover.

15. Disconnect the negative “black” battery cable (#9)

from the batter (#22).

16. Disconnect the positive “red” battery cable (#10) from

the battery (#22).

17. Loosen hex lock nuts (#25) and remove battery (#22)

from battery box (#18).

18. Remove negative cable (#9) from engine mounting

bolt (#29).

19. Remove positive battery cable (#10) from engine

starter.

20. Remove the four hex head screws (#34) and lock

washers (#37) securing the battery box (#18) to

shockmounts (#15), remove battery box and cables.

Then remove four hex head flange screws (#28) and

mounting brackets (#20).

21. Remove the four hex head capscrews (#29) securing

the engine to the engine deck and remove the engine

(#14) & engine shims If required.

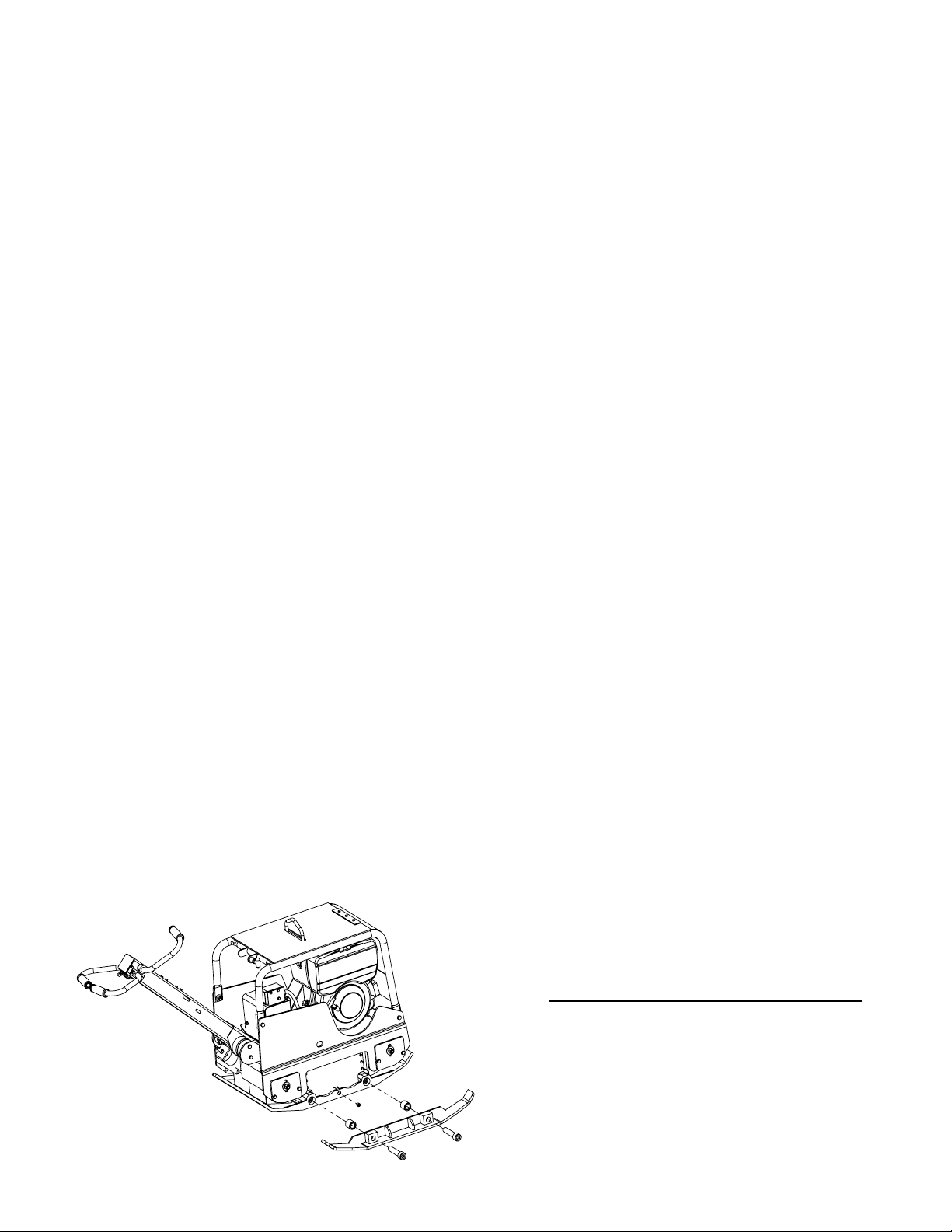

Exciter Oil Change Procedure

Refer to Figure 1

1. If possible run unit for approximately 5 minutes to

warm oil before draining.

2. Clean all dirt and debris from baseplate before

disassembly to prevent contamination of exciter oil.

Refer to Baseplate Assembly, page 22.

3. Remove the two socket head capscrews (#29) and

bushings (#19) securing the baseplate extensions

(#18) to the baseplate (#15) from the recoil/oil drain

side of the baseplate. (See figure 1)

),*85(

4. Tilt the plate toward a drain pan to aid in the removal

of all used oil and particles.

5. Remove the socket head pipe plug (#28) from the

baseplate and drain the oil. Examine the oil for

metal chips as a precaution to future troubles.

6. Tip the plate opposite the drain hole, and fill the

baseplate through the pipe plug opening with exciter

oil to level specified in the Fluid Levels section of this

manual. Use only MBW Ground Pounder Exciter Oil.

7. Reinstall the socket head pipe plug (#28) using

sealant (LOCTITE #565).

8. Reinstall the bushings (#19), using antisieze lubricant

(LOCTITE #767), baseplate extensions (#18) and

socket head cap screws (#29).

Lower Hydraulic Seal Replacement

Refer to Lower Shaft Assembly, page 24.

Note: The seals (#6), guide ring (#4), and gaskets (#17

and #18) should be replaced as a set. MBW

recommends purchasing rebuild kit #17368 for ease

of repairs (Seals are pre-assembled to the spool).

1. Position the handle in locked position and set the lock

pin.

Refer to Main Assembly, page 20. for side cover

removal.

2. Remove the six flange screws (21) securing the side

cover (#8) to the recoil/oil drain side of the baseplate.

Loosen hex nuts (#31) on the oil drain side only. Lift

the engine deck up to allow the side cover to be

removed.

3. Remove fill plug (page 28, #6 ) from the control head

housing.

4. Remove the hydraulic line (page 20 #16) from the 90

degree fitting (page 25, #13) on the hydraulic

housing. Be careful to use a drain pan to catch the

hydraulic oil.

5. Remove the four flange screws (#22) securing the

hydraulic housing (#16) and cylinder mount plate

(#20) to the input shaft cover (#12) and remove the

hydraulic housing.

6. Remove the shift spool (#15) from the shift shaft (#10)

by rotating the input shaft counter clockwise to push

the shift spool out of the baseplate. Holding shaft

(#10) secure while un-threading the shift spool (#15).

NOTE: This connection is left hand thread.

(;&,7(52,/'5$,1

7. If you purchased the rebuild kit (MBW Part Number

17368) go to step #12.

8. Remove the seal guide ring (#4) from the shift spool.

9. Remove the damaged or worn seals (#6) from the

shift spool (#15). Note the orientation of the

sealing lips of the seals to be replaced. Be careful

- 9 -

Loading...

Loading...