MBW F30 Operator's Safety And Service Manual

OPERATOR’S SAFETY

AND SERVICE MANUAL

F30

This manual covers the following serial numbers

and higher for each model listed:

F30..............................1460000

MBW, Inc.

250 Hartford Rd • PO Box 440

Slinger, WI 53086-0440

Phone: (262) 644-5234

Fax: (262) 644-5169

Email: mbw@mbw.com

Website: www.mbw.com

MBW (UK) Ltd.

Units 2&3 CochraneStreet

Bolton BL3 6BN

England, UK

Phone: 44 (0) 01204 387784

Fax: 44 (0) 01204 387797

E-mail: mbwuk@btinternet.com

MBW FRANCE S.A.R.L.

Phone:+33 (0) 3 44 07 15 96

Fax: +33 (0) 3 44 07 41 28

L F30/ 10.18.A

©MBW, Inc. 2018

Printed in the USA

Instruction and Maintenance Manual Moskito gasoline C4-75 PAGE 2 of 16

Thank you for purchasing a MBW Trowel.

This handbook contains operating and maintenance instructions of the Moskito Edging Trowel,

model C4-75.

Please keep it in a safe place. You may need to refer to it at a later date.

Follow these instructions carefully in order to become familiar with the trowel and to avoid

problems caused by improper use.

To conform to the safety procedures it is recommended that the operator wears safety devices such

as safety shoes, soundproof devices, safety helmet and heavy duty leather working gloves.

The manufacturer reserves the right to change the contents of the handbook to improve the quality

of the trowel without notice.

Table of contents:

Sections

Description

Page

1.

Introduction........................................................................

4

2.

Technical details.................................................................

4

3.

General instructions...........................................................

5

3.1

Power to the trowel.............................................................

5

3.2

Safety precautions for the operator...................................

5

4.

Starting machine................................................................

6

4.1

Assembly.............................................................................

6

4.2

Before starting....................................................................

7

4.3

Starting...............................................................................

7

4.4

Using the trowel..................................................................

7

4.5

Stopping the trowel............................................................

7

5.

General use.........................................................................

7

5.1

Preparation of the concrete surface...................................

7

5.2

Floating operation..............................................................

7

5.3

Finishing operation............................................................

8

5.4

Machine cleaning................................................................

8

Instruction and Maintenance Manual Moskito gasoline C4-75 PAGE 3 of 16

5.5

Moving the trowel..............................................................

8

6.

Maintenance.......................................................................

8

6.1

General maintenance..........................................................

9

6.2

Changing floating disc........................................................

9

6.3

Changing blades.................................................................

9

6.4

Changing V-belts................................................................

9

7.

Trouble shooting and repair..............................................

10

8.

Warranty............................................................................

11

9.

Marking and certificate......................................................

11

Attached: declaration of conformity, electrical schedule

and spare parts list

Instruction and Maintenance Manual Moskito gasoline C4-75 PAGE 4 of 16

1. I N T R O D U C T I O N

The machine described in this instruction and maintenance manual is a patented mini trowel

provided with a free wheel for floating and finishing concrete, epoxy floors and sub floors.

The trowel is equipped with 4 blades.

The power is transmitted from a gasoline engine through a centrifugal clutch connected by a V-belt

with the gearbox.

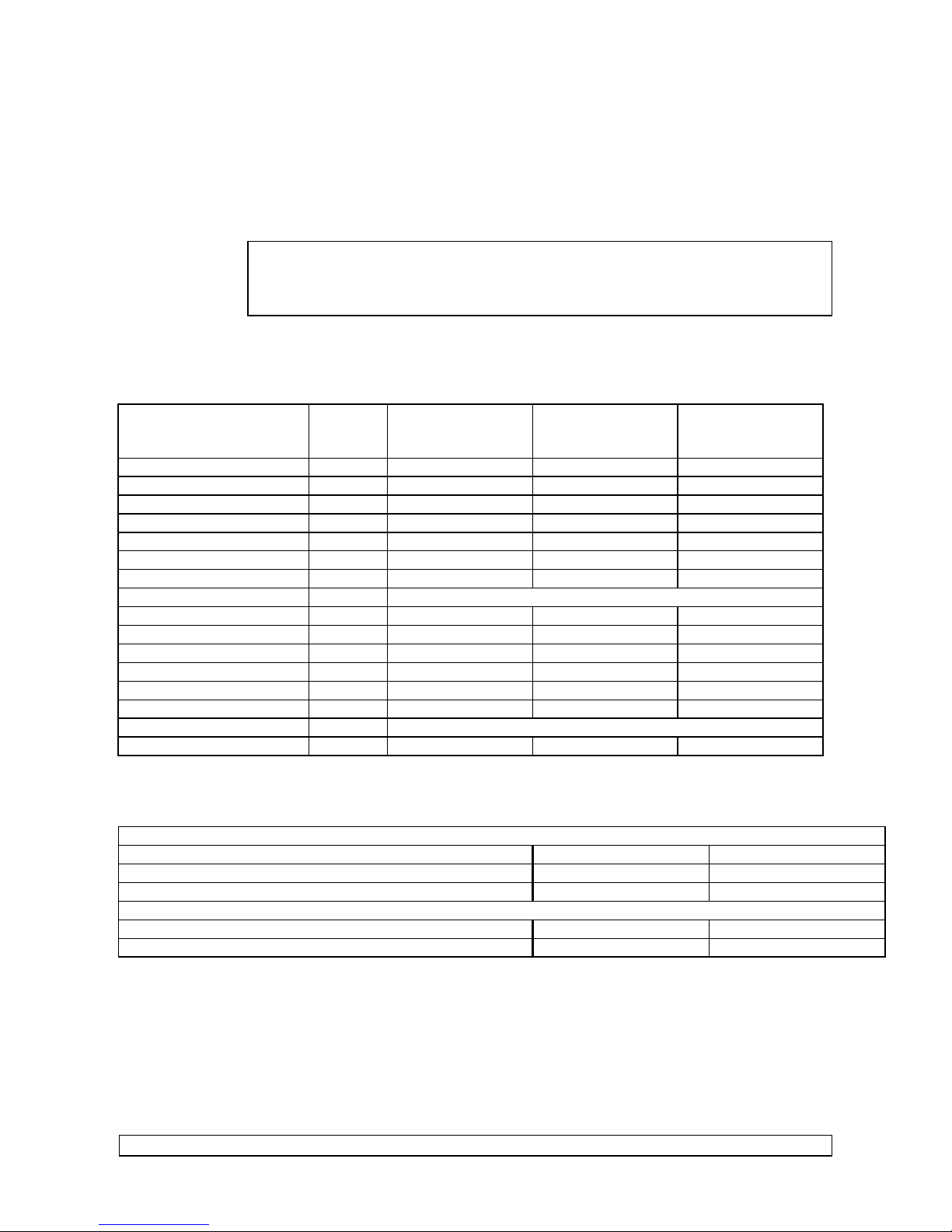

2. T E C H N I C A L D E T A I L S

DESCRIPTION

Unit

Measure

C4-75/B

B&S. V.

85432

C4-75/H

HONDA

GX120

C4-75/H1

HONDA

GX160

Overall dimensions

mm

750 x 1490 x 910

750 x 1490 x 910

750 x 1490 x 910

Shipping dimensions

mm

1000 x 1020 x 790

1000 x 1020 x 790

1000 x 1020 x 790

Operating weight

Kg

56,6

53,5

55,5

Shipping weight

Kg

74

71

73

Disc diameter

mm

750

750

750

Number of blades

Nr

4 4 4

Gearbox oil

Type

SHELL TIVELA COMPOUNDS A or similar type - 0,3lt.

Engine

Type

Gasoline

Gasoline

Gasoline

Power

Kw / HP

2,94 (4HP)

2,94 (4HP)

4,04 (5,5HP)

Engine Speed

RPM

3600

3600

3600

Cooling AIR

AIR

AIR

Starting

Type

Recoil starter

Recoil starter

Recoil starter

Machine speed

RPM

90

90

90

Blade speed

RPM

minimum - maximum 70 - 125

Tank capacity

LT 3 2,5

3,6

Tests have been undertaken to determine noise and vibration levels and to evaluate the effect on the

operator. The results are.

Noise and vibration levels in working condition

Average acoustic pressure

dbA

88,8

Average acoustic power

dbA

103,2

Acoustic pressure on operator

dbA

89,1

Value of vibration

Vibration value on the handle

aw

7,0

It is recommended not to use the trowel for any other purpose than for what

it is designed for, unless you have a written authorisation from BARIKELL.

In case of disposal of the machine it is necessary to respect the local

environmental law.

Instruction and Maintenance Manual Moskito gasoline C4-75 PAGE 5 of 16

3. G E N E R A L I N S T R U C T I O N S

3.1 Power to the trowel

The power must be supplied to the trowel as described in the BARIKELL handbook. For safety

keep the following points in mind:

- The engine is an air-cooled gasoline engine.

The trowel can be equipped with different types of engines as indicated in the technical

details. The engine is started by rope start. The fuel is gasoline, and is conveyed from the

tank to the carburettor after flowing through a filter.

- The rotation of the blades is transmitted from the engine to a centrifugal clutch, connected by a

V-belt to the gearbox of the rotor.

3.2 Safety precautions for t he operator

Never start any maintenance or repair while the engine is still running or hot. Be sure the spark

plug is disconnected.

Make sure that nobody stands near the trowel when operating. To avoid unexpected contact with

the rotating parts it is recommended to keep a minimum distance of 2 meters from the operator and

the trowel.

Before every working day check the trowel thoroughly, and pay special attention for loose bolts and

nuts. Be sure that the deadman switches on the trowel are working correctly.

Use the trowel always on a flat level surface.

Do not wear untied clothes, bracelets or other flying objects during the working cycle.

Always wear protective devices such as gloves, safety helmet, safety shoes and others which

conform to the safety regulations.

To avoid slipping and loss of control of the trowel, when starting the engine,

the operator must always maintain good footing. Be sure to maintain

control at all times, to avoid possible damage or operator injury.

Be careful when changing old blades for new. Due to the way the blades

wear, the old blades become sharp like razor blades. Always wear heavy

duty working gloves during this operation and pay special attention to the

position of the blades.

Keep hands and feet away from rotating parts and make sure all safety

protection is in place.

When finishing concrete above ground level or on floors with holes larger

than 20x20cm, barriers should be installed as a protective measure. The

barrier should be such that it will stop the trowel from riding over the edge

of the slab in case of loss of control.

Never lift the trowel by the rotating ring; use the lifting handle provided on

the trowel.

Exhaust fumes are harmful. Always operate in well illuminated and

ventilated areas.

Loading...

Loading...