MBW BMS74, BMS75 Service Manual

OPERATOR’S SAFETY

AND SERVICE MANUAL

BMS74, BMS75 &

BMS95

This manual covers the following serial numbers

and higher for each model listed:

BMS74 . . . . . . . . . . . . . . . . . . . . . 0740100

BMS95 . . . . . . . . . . . . . . . . . . . . . 1060300

CONCRETE SPRAYERS:

FOR WATER BASE MATERIALS ONLY

MBW, Inc.

250 Hartford Rd • PO Box 440

Slinger, WI 53086-0440

Phone: (262) 644-5234

Fax: (262) 644-5169

Email: mbw@mbw.com

Website: www.mbw.com

MBW (UK) Ltd.

Units 2 & 3 Cochrane Street

Bolton BL3 6BN, England

Phone: 01204 387784

Fax: 01204 387797

MBW FRANCE S.A.R.L.

Phone: +33 (0) 3 44 07 15 96

Fax: +33 (0) 3 44 07 41 28

L18345 / 06.19.P

©MBW, Inc. 2015

Printed in the USA

TABLE OF CONTENTS

Safety Information . . . . . . . . . . . . . . . . . . . . . . 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . 3

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Before Starting & Operating . . . . . . . . . . . . . . . . . . . . 4

Starting Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Operating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Stopping Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . 5

Fluid Levels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Engine Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . 5

Engine Speed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Winterizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Torque Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

BMS 74. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

BMS 95. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . 8

BMS74 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

BMS 95. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Drum Cart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

OPTIONAL SPRAY EQUIPMENT:. . . . . . . . . . . . . . 16

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

CALIFORNIA PROPOSITION 65 WARNING

WARNING

Engine exhaust and some of its constituents are

known in the state of California to cause cancer,

birth defects, and other reproductive harm.

SAFETY INFORMATION

WARNING

CAUTION

Introduction

This Safety Alert Symbol is used to call attention

to items or operations which may be dangerous

to those operating or working with this

equipment. The symbol can be found

throughout this manual and on the unit. Please read these

warnings and cautions, along with all decals, carefully

before attempting to operate the unit. Make sure every

individual who operates or works with this equipment is

familiar with all safety precautions.

GENERAL WARNING. Indicates information

important to the proper operation of the

equipment. Failure to observe may result in

damage to the equipment and/or severe bodily

injury or death.

GENERAL CAUTION. Indicates information

important to the proper operation of the

equipment. Failure to observe may result in

damage to the equipment.

SAFE DRESS: Do not wear loose clothing,

rings, wristwatches, etc. near machinery.

NOISE PROTECTION: Wear OSHA specified

hearing protection devices.

EYE PROTECTION: Wear OSHA specified

eye shields, safety glasses, and sweat bands.

FOOT PROTECTION: Wear OSHA specified

steel-tipped safety shoes.

HEAD PROTECTION: Wear OSHA specified

safety helmets.

DUST PROTECTION: Wear OSHA specified

dust mask or respirator.

OPERATOR: Keep children and bystanders

off and away from the equipment.

EXPLOSION HAZARD: Use water based

material only. Do Not

use flammable material.

Safety Precautions

LETHAL EXHAUST GAS: An internal

combustion engine discharges carbon

monoxide, a poisonous, odorless, invisible

gas. Death or serious illness may result if

inhaled. Operate only in an area with proper

ventilation. NEVER OPERATE IN A

CONFINED AREA!

DANGEROUS FUELS: Use extreme caution

when storing, handling and using fuels, as

they are highly volatile and explosive in vapor

state. Do not add fuel while engine is running.

Stop and cool the engine before adding fuel.

DO NOT SMOKE!

SAFETY GUARDS: It is the owner's

responsibility to ensure that all guards and

shields are in place and in working order.

IGNITION SYSTEMS: Breakerless, magneto,

and battery ignition systems can cause severe

electrical shocks. Avoid contacting these

units or their wiring.

REFERENCES: For details on safety rules and regulations

in the United States, contact your local Occupational Safety

and Health Administration (OSHA) office. Equipment

operated in other countries must be operated and serviced

in accordance and compliance with any and all safety

requirements of that country. The publication of these

safety precautions is done for your information. MBW does

not by the publication of these precautions, imply or in any

way represent that these are the sum of all dangers present

near MBW equipment. If you are operating MBW

equipment, it is your responsibility to insure that such

operation is in full accordance with all applicable safety

requirements and codes. All requirements of the United

States Federal Occupational Safety and Health

Administration Act must be met when operated in areas that

are under the jurisdiction of that United States Department.

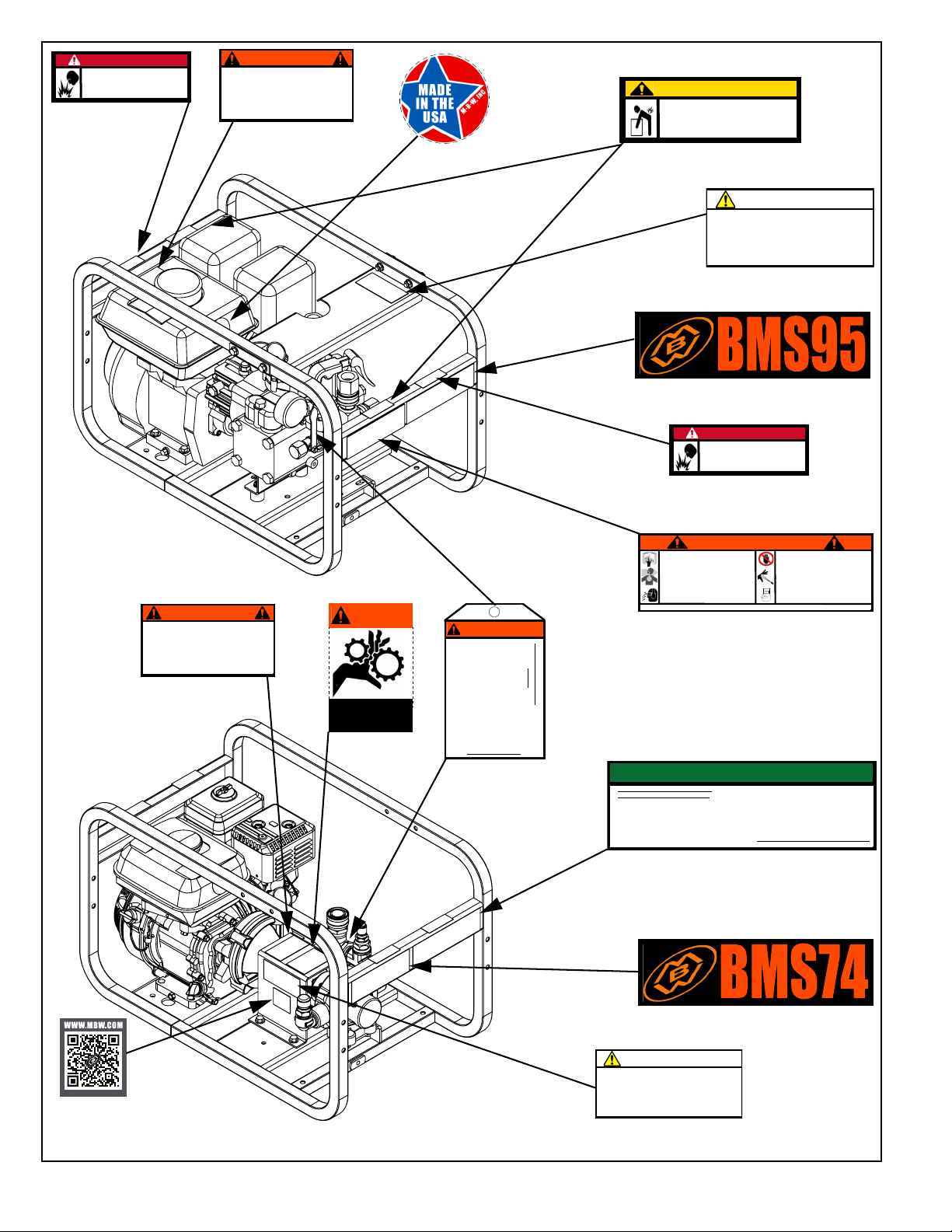

Safety Decals

Carefully read and follow all safety decals. Keep them in

good condition. If decals become damaged, replace as

required. If repainting the unit, replace all decals. Decals

are available from authorized MBW distributors. Order the

decal set listed on the following page(s).

- 1 -

Read the Operating Instructions before

operating this piece of equipment.

WARNING

18418

Wear approved hearing protection, foot

protection, eye protection and head protection.

STOP

Contents under HIGH PRESSURE! Shut off

engine and relieve pressure before

disconnecting hoses. Always point spray gun in

a safe direction.

Failure to comply could result in serious bodily injury.

SHUT OFF the motor before servicing or clean-

ing.

DO NOT RUN in an enclosed area. The engine

produces carbon monoxide, a POISONOUS

GAS.

Keep unauthorized and untrained people away

from this equipment.

18423

20249

OPERATING INSTRUCTIONS

1.IMPORTANT: All materials must be

thoroughly agitated before spaying.

2.Check fuel level and open fuel valve.

3.Set throttle at idle position.

4.Choke engine. A warm engine may not need

to be choked.

5.Pull starter rope.

6.After starting, open choke gradually and let

engine warm up at idle.

7.To start spraying: open throttle fully.

8.To increase pressure turn T handle, on

pressure relief valve, clockwise. To decrease

pressure turn T counter-clockwise.

9.To stop: return throttle to idle and allow engine

to run for a few minutes before turning off.

10.Turn engine switch to off and close fuel

valve.

11. Clean sprayer thoroughly after every use

.

18365

WARNING

Keep hands away!

15518

ROTATING PARTS

Can crush and cut

- EXPLOSION HAZARD: Use water base

materials ONLY.

Use of other material

may void warranty

- All materials must be thoroughly agitated

before spraying.

- Pump must be properly cleaned

immediately after every use.

- Follow chemical suppliers procedures

for proper cleaning of equipment.

- Failure to properly clean sprayer

voids warranty

WARNING

18420

DO NOT REMOVE

19791

WARNING

OPERATION OF THIS EQUIPMENT MAY

CREATE SPARKS THAT CAN START FIRES

AROUND DRY VEGETATION. A SPARK

ARRESTER MAY BE REQUIRED. THE

OPERATOR SHOULD CONTACT LOCAL FIRE

AGENCIES FOR LAWS OR REGULATIONS

RELATING TO FIRE PREVENTION

EXPLOSION HAZARD: Do not

spray flammable material.

Failure to comply could result in

serious bodily injury.

DANGER

18421

LIFTING HAZARD. Single person lift

could cause injury. Use assistance

when lifting or moving.

Failure to comply could result in serious

bodily injury.

CAUTION

18426

18421

19791

WARNING

OPERATION OF THIS EQUIPMENT MAY

CREATE SPARKS THAT CAN START FIRES

AROUND DRY VEGETATION. A SPARK

ARRESTER MAY BE REQUIRED. THE

OPERATOR SHOULD CONTACT LOCAL FIRE

AGENCIES FOR LAWS OR REGULATIONS

RELATING TO FIRE PREVENTION

WARNING

Operating, servicing and maintaining this equipment

can expose you to chemicals, including engine

exhaust, phthalates and lead, which are known to the

state of California to cause cancer and birth defects or

other reproductive harm. Avoid breathing engine

exhaust. Do not operate equipment in confined areas.

For more information go to

www.P65Warnings.ca.gov

21820

EXPLOSION HAZARD: Do not

spray flammable material.

Failure to comply could result in

serious bodily injury.

DANGER

18421

21738

WARNING

Operating, servicing and maintaining this equipment

can expose you to chemicals, including engine

exhaust, phthalates and lead, which are known to the

state of California to cause cancer and birth defects or

other reproductive harm. Avoid breathing engine

exhaust. Do not operate equipment in confined areas.

For more information go to

www.P65Warnings.ca.gov

21820

19791

12500

18426

21820

18423 - BMS95

20249 - BMS74

18421

19791

18418

15518

18420

18419 - BMS95

18365 - BMS75

18423 - BMS95

20249 - BMS74

21738

Safety Decals (Decal Set #18344)

21820

- 2 -

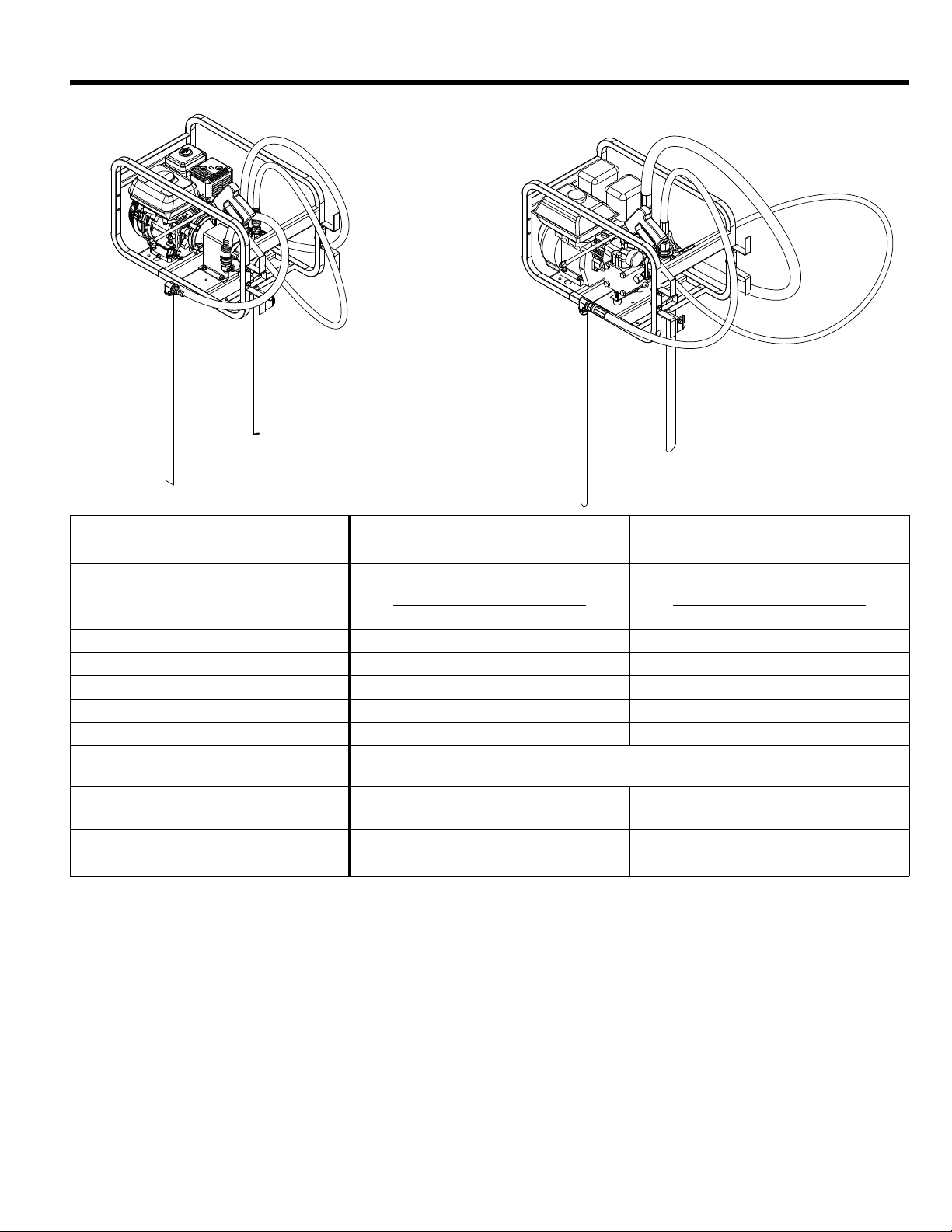

SPECIFICATIONS

BMS74/75

BMS95

BMS74

(W/ 25’ HOSE & WAND)

Pump Roller 7560C-R Diaphragm

Solids Content

(high efficiency / max.rating)

Maximum Flow 7.5 gpm (28.3 lpm) 9.5 gpm (36 lpm)

Maximum Pressure 300 psi (20.7 bar) 550 psi (38 bar)

Adjustable Pressure Settings Ye s Yes

Standard Operating Pressure 100 psi (6.8 bar) 100 psi (6.8 bar)

Weight 95 lbs (43 kg) 115 lbs (52 kg)

Dimensions (L x W x H)

Engine

Max Engine RPM 3600 rpm 3600rpm

Quick Disconnect Fittings Yes Ye s

Specifications subject to change without notice

(Water Based Materials Only)

25% / 30%

HONDA GX120

7.2 cu. in. (118 cm

3

)

27 x 15.5 x 17in.

(69 x 39 x 43cm)

(W/ 25’ HOSE & WAND)

(Water Based Materials Only)

BMS95

HONDA GX160

9.9 cu. in. (163 cm3)

35%

- 3 -

OPERATION

WARNING

CAUTION

WARNING

Introduction

MBW equipment is intended for use in very severe

applications. They are powered by four cycle engines and

are available in different sizes and a selection of engines.

This parts manual contains only standard parts. Variations of

these parts as well as other special parts are not included.

Contact your local MBW distributor for assistance in

identifying parts not included in this manual.

Before Starting & Operating

• Use water based material only. Do not use flammable

material. Failure to comply could result in serious bodily

and or equipment damage and void warranty.

• Thoroughly agitate materials to be sprayed. High solid

content from bottom of container can cause pump failure,

voiding warranty

• REMEMBER! It is the owner’s responsibility to

communicate information on the safe use and proper

operation of this unit to the operators.

• Review ALL of the Safety Precautions listed on page 1 of

this manual.

• Familiarize yourself with the operation of the machine

and confirm that all controls function properly.

• Know how to STOP the machine in case of an

emergency.

• Make sure hands, feet, and clothing are at a safe distance

from any moving parts.

• OIL LEVEL - Check the oil level in the engine, gear

reducer and pump. For more information see

“Lubrication” under the respective engine’s/pump’s

Owners Manual.

.

Starting Engine

1. Check fuel level and open fuel valve.

2. Set throttle at idle position.

3. Choke engine and pull starter rope. A warm engine

may not need to be choked

4. After starting, open choke gradually and let engine

warm up at idle.

Operating

1. All materials to be sprayed MUST be thoroughly

agitated. Failure to properly mix product before

spaying can result in damage to pump voiding

warranty.

2. To start spraying, open throttle fully & squeeze trigger.

3. Follow all manufactures specifications for product

application, cure time and clean-up for all materials

applied with this equipment.

4. Do not allow pump to run dry. Stop engine before the

pump runs out of fluid.

Stopping Engine

1. Return throttle to idle and allow engine to run for a few

minutes before turning off.

2. Turn engine switch to off and close fuel valve.

3. Clean pump after each use. Refer to Cleaning, page

4 for proper cleaning procedure.

Failure to clean pump after each use could result

in damage to the pump and personal injury.

• AIR CLEANER - Check to ensure element is in good

condition and properly installed.

• FUEL SUPPLY - The engines on MBW equipment require

an automotive grade of clean, fresh, unleaded gasoline.

• FUEL FILTER - If clogged or damaged, replace.

• Inspect unit for loose or missing hardware or guards and

cracked or damaged hoses. Tighten or replace any loose

or missing hardware. DO NOT OPERATE SPRAYER

damaged hoses or missing guards. Replace damaged

hoses or missing guards before operating unit.

• SPRAY GUN - Check spray gun nozzle and all hoses &

fittings to ensure they are free of all debris or blockage.

with

Freezing fluids can cause damage to the pump. If

unit is likely to be stored in freezing temperatures,

always exercise the winterizing procedure.

Always stop the engine before: Adding fuel.

Leaving the equipment unattended for any amount

of time.

Before making any repairs or adjustments to the

machine.

- 4 -

Loading...

Loading...