MBW Blitzscreed User Manual

OPERATOR’S SAFETY

AND SERVICE MANUAL

BLITZSCREED

CONCRETE SCREEDS

MBW, Inc.

250 Hartford Rd • PO Box 440

Slinger, WI 53086-0440

Phone: (262) 644-5234

Fax: (262) 644-5169

Email: mbw@mbw.com

Website: www.mbw.com

MBW (UK) Ltd.

Units 2 & 3 Cochrane Street

Bolton BL3 6BN, England

Phone: 01204 387784

Fax: 01204 387797

L2335 / 08.06.H

©MBW, Inc. 2006

Printed in the USA

TABLE OF CONTENTS

SAFETY PRECAUTIONS 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INTRODUCTION 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SAFETY NOTICE & DECALS 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SAFETY DECAL LOCATIONS 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WARRANTY 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MBW WAREHOUSE LOCATIONS 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BLITZSCREED SPECIFICATIONS 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SERIAL NUMBER LOCATION 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PARTS ORDERING PROCEDURE 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION ASSEMBLY 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ENGINE ASSEMBLY 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

END FRAME ASSEMBLY 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AIR DRIVE ASSEMBLY 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HYDRAULIC DRIVE ASSEMBLY 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OPERATING INSTRUCTIONS 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE & SERVICE, SCREED 21. . . . . . . . . . . . . . . . . . . . . . . . . . . .

A-FRAME REPLACEMENT 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BEARING REPLACEMENT 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DRIVE BELT REPLACEMENT 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GREASING BEARINGS 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LONG STORAGE 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TORQUE CHART 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BEARING LOCATIONS 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AIR EXCITER & GROMMET LOCATIONS 25. . . . . . . . . . . . . . . . . . . . . . .

MODEL MVS2 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MODEL MVS4 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MODEL MVS8 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ENGINE KITS 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5 HP HONDA ENGINE KIT 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.0 HP BRIGGS & STRATTON ENGINE KIT 35. . . . . . . . . . . . . . . . . . . . .

8.0 HP HONDA ENGINE KIT 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MODEL AVS2 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MODEL AVS4 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MODEL AVS8 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AIR REGULATOR KIT 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HAND WINCH KIT 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HYDRAULIC WINCH KIT 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WINCH ASSEMBLY 53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i

SAFETY PRECAUTIONS

READ AND STUDY THE FOLLOWING SAFETY INFORMATION BEFORE ATTEMPTING TO OPERĆ

ATE THIS EQUIPMENT. IN ADDITION, ENSURE THAT EVERY INDIVIDUAL WHO OPERATES OR

WORKS WITH THIS EQUIPMENT IS FAMILIAR WITH THESE SAFETY PRECAUTIONS.

W ARNING – LETHAL EXHAUST GAS!

An internal combustion engine discharges carbon monoxide, a poisonous, odorless invisible gas.

Death or serious illness may result if inhaled. Operate only in an area with good ventilation, NEVER IN

A CONFINED AREA!

W ARNING – DANGEROUS FUELS!

Use extreme caution when storing, handling and using fuels - they are highly volatile and explosive in

vapor state. Do not add fuel while engine is running. Stop and cool the engine before adding fuel. DO

NOT SMOKE!

SAFETY GUARDS

It is the owner's responsibility to ensure ALL GUARDS AND SHIELDS are in place and in working

order.

IGNITION SYSTEMS

Breakerless, magneto and battery ignition systems CAN CAUSE SEVERE ELECTRICAL SHOCKS.

Avoid contacting these units or their wiring.

SAFE DRESS

DO NOT WEAR loose clothing, rings, wristwatches, etc., near machinery.

NOISE PROTECTION

Wear O.S.H.A. specified hearing protection devices.

FOOT PROTECTION

Wear O.S.H.A. specified steel tip safety shoes.

HEAD PROTECTION

Wear O.S.H.A. specified safety helmets.

EYE PROTECTION

Wear O.S.H.A. specified eye shields, safety glasses, and sweat bands.

OPERATOR

Keep children and bystanders off and away from the equipment.

REFERENCES

For details on safety rules and regulations in the United States, contact your local Occupational Safety

and Health Administration (O.S.H.A.) office. Equipment operated in other countries must be operated

and serviced in accordance and compliance with any and all safety requirements of that country.The

publication of these safety precautions is done for your information. MBW Inc. does not by the publiĆ

cation of these precautions, imply or in any way represent that these are the sum of all dangers preĆ

sent near MBW equipment. If you are operating MBW Inc. equipment, it is your responsibility to insure

that such operation is in full accordance with all applicable safety requirements and codes. All reĆ

quirements of the United States Federal Occupational Safety and Healthy Administration Act must be

met when operated in areas that are under the jurisdiction of that United States Department.

1a

INTRODUCTION

MBW Inc. SCREED is intended for use in many applications. It offers the highest level of finishing consistency

available today. Precision machining of all components, combined with all bolted construction, are the key

factors for ease and speed of assembly and for true alignment job after job.

MBW Inc's exclusive 45 degree AĆframe cast aluminum design assures that all sections are exactly the same

and totally interchangeable. They come in 8'4", 4'4" and 2'4" lengths, so you can mix and match the length

you need up to 65 ft (20 m) for gas models and 65 ft (20 m) for air models.

The gasoline engine driven SCREED gives you a maximum eccentric speed of 2800 rpm, and permits idling of

the SCREED without stopping the engine. The air driven version gives you cycle vibration ranging from 5000

to 8000 VPM at 40 psi to 60 psi using about 4 CFM per vibrator.

The gasoline engine driven SCREED has winch kits available. The hand winch kit and the hydraulic winch kit.

The air powered SCREED offers the same fine features as our mechanical unit. It comes with optional handles

and an air system that includes filter, regulator and lubricator. It features an air line that is protected from damĆ

age by running inside the length of the AĆframe structure, and has flexible hose couplings between the air supĆ

ply tubes.

MBW Inc. has invested a great deal of time and effort in developing its SCREED. The equipment you have

purchased is built with a great deal of pride and designed to give you long life, efficient operation, durability and

dependability.

READ THIS MANUAL

The information in this manual has been written in an easy to read style. The design features makes it convenĆ

ient to operate and service your MBW Inc. SCREED through the use of this manual.

Read this manual carefully to learn how to operate and service your MBW Inc. SCREED correctly. Failure to do

so could result in personal injury or equipment damage.

Major points of safe operation are detailed on the SAFETY PRECAUTIONS page of this manual. The SAFETY

PRECAUTIONS page is located on page 1.

This manual should be considered a permanent part of your SCREED and should remain with the SCREED.

MEASUREMENTS

U.S. Units of measure and their metric equivalents are used in this manual.

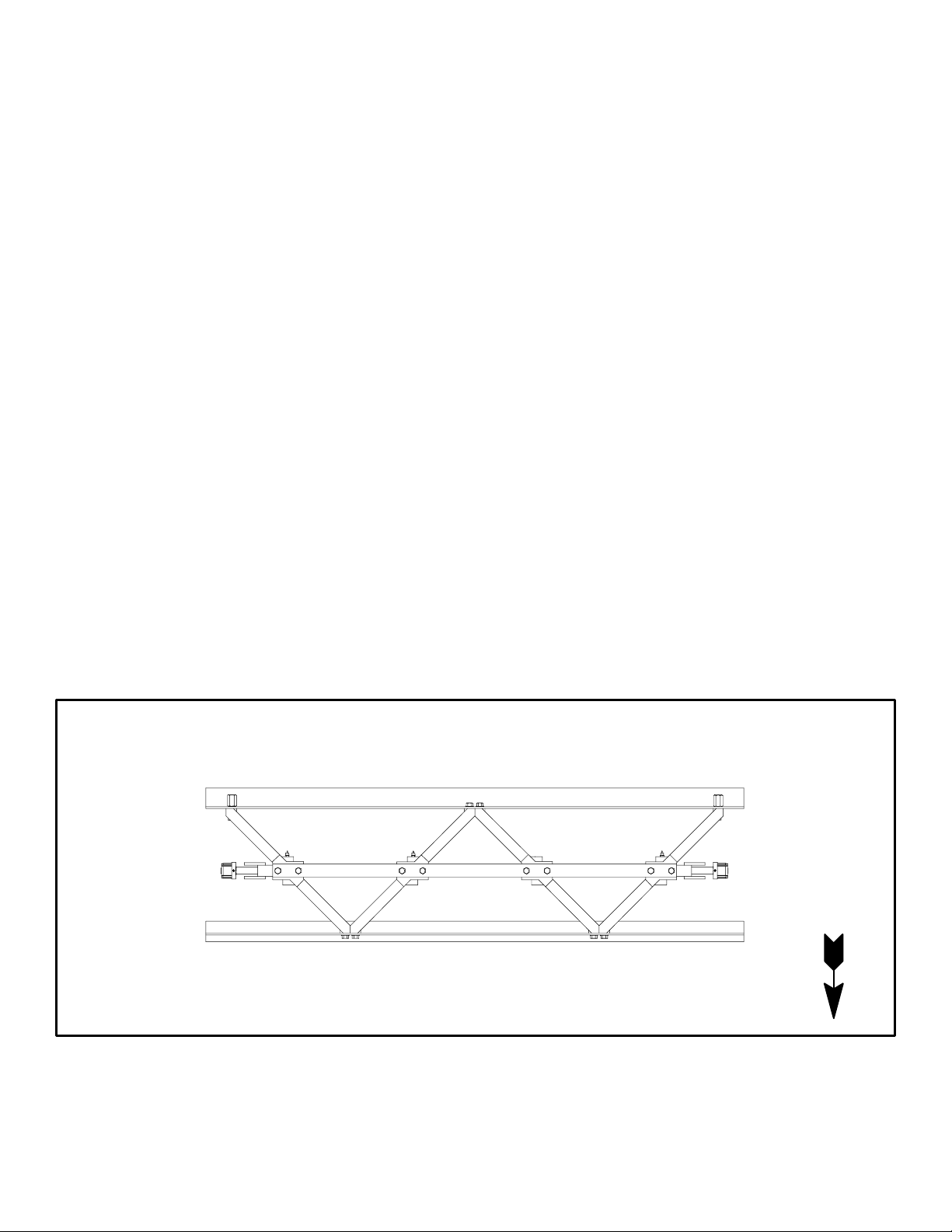

DIRECTIONS

Right and left sides of the screed are determined by facing the front (strikeoff) edging (T"

shaped edging). See Figure 1.

BACK (FLOAT)

LEFT

RIGHT

DIRECTION

FRONT (STRIKEOFF)

OF TRAVEL

FIGURE 1

WARRANTY

Warranty is provided as part of MBW Inc's support for customers who operate and maintain their

equipment as described in this manual. The warranty is stated on page 7.

MBW, Inc. reserves the right to make changes or improvements in the design or construction of any

part without incurring the obligation to install such changes on any piece of equipment previously

delivered.

2

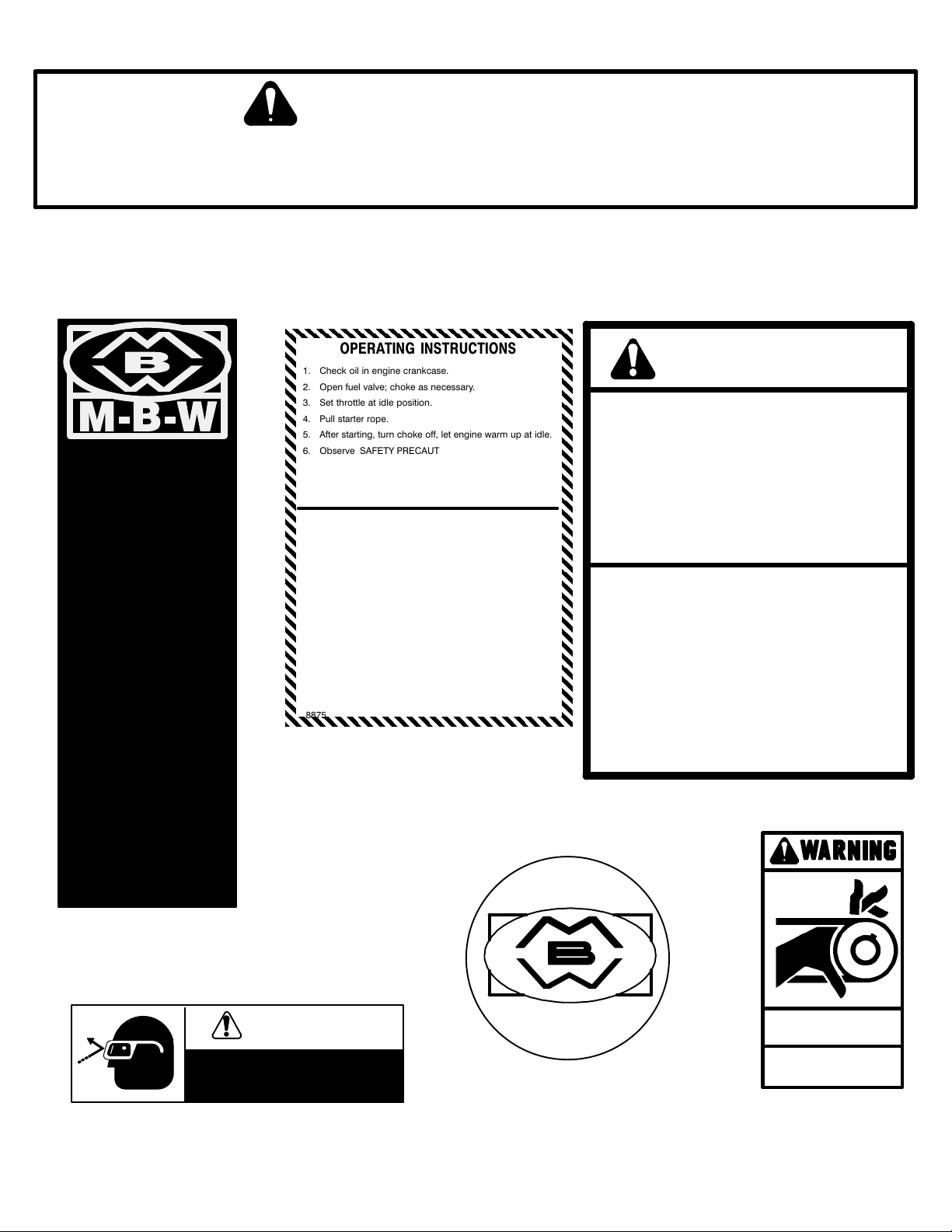

SAFETY NOTICE & DECALS

IMPORTANT NOTICE

The SAFETY ALERT SYMBOL" is used to call attention to items or operations that may be

dangerous to machine operators or others working with this equipment. The symbol can be

found throughout this manual and on the unit itself. Please read these messages carefully.

READ SAFETY DECALS CAREFULLY

Carefully read and follow all safety decals. Keep them in good condition. If decals become

damaged, replace as required. Decal Kits are available from authorized MBW Distributors.

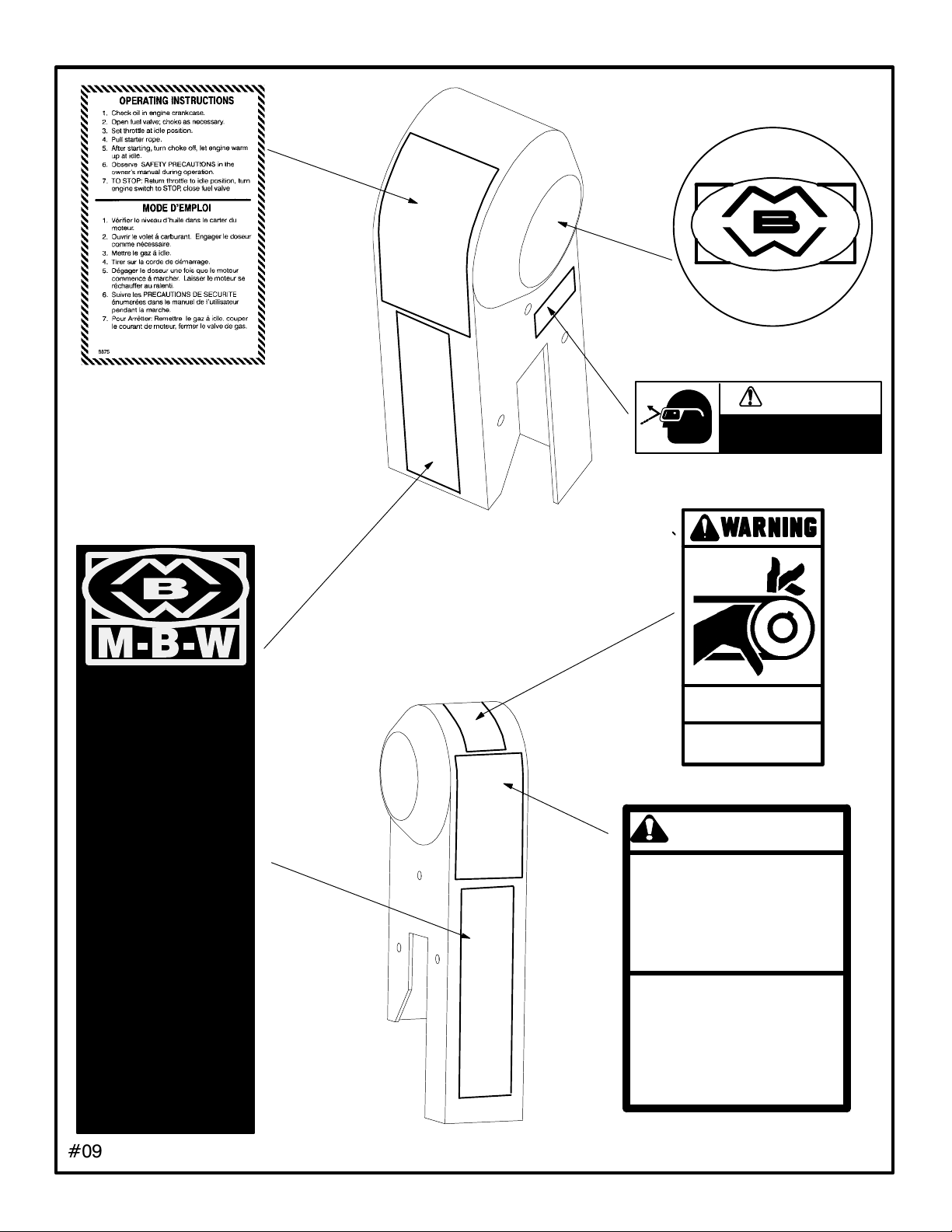

-Decals shown below are located on the engine belt guard.

OPERATING INSTRUCTIONS

CAUTION

L

I

T

Z

S

C

R

1. Check oil in engine crankcase.

2. Open fuel valve; choke as necessary.

3. Set throttle at idle position.

4. Pull starter rope.

5. After starting, turn choke off, let engine warm up at idle.

6. Observe SAFETY PRECAUTIONS in the owner's

manual during operation.

7. TO STOP: Return throttle to idle position, turn engine

switch to STOP, close fuel valve

MODE D'EMPLOI

1. Vérifier le niveau d'huile dans le carter du moteur.

2. Ouvrir le volet á carburant. Engager le doseur

comme nécessaire.

3. Mettre le gaz á idle.

4. Tirer sur la corde de démarrage.

5. Dégager le doseur une fois que le moteur commence

á marcher. Laisser le moteur se réchauffer au ralenti.

6. Suivre les PRECAUTIONS DE SECURITE énumerées

dans le manuel de I'utilisateur pendant la marche.

7. Pour Arrêtter: Remettre le gaz á idle, couper le

courant de moteur, fermer le valve de ga

8875

s.

#08875, Belt Guard

Read the operating instructions before operating this piece of

equipment.

Keep unauthorized, inexperienced, untrained people away from

this equipment.

CHECK saftey switch frequently for proper operation.

ROTATING & MOVING PARTS! Make sure all guards and safety

devices are in place.

DO NOT RUN this machine in an enclosed area. The engine

produces carbon monoxide, a POISONOUS gas.

SHUT OFF the engine before servicing , cleaning or adding fuel.

Failure to comply could result in serious bodly injury.

Lire le Mode d'Emploi avant de faire fonctionner le matériel

Eloigner toute personne non formée, non autorisée et inexpérimentée

du matériel.

VERIFIER fréquemment I'interrupteur de sécurité pour un bon

fonctionnement.

PIECES TOURNANTES ET MOBILES! S'assurer que tous les

protecteurs et les dispositifs de sécurité sont en place.

NE PAS FAIRE FONCTIONNER le matériel dans les lieux clos. Le

moteur produit de l'oxyde de carbone, un gaz TOXIQUE.

ARRETER le moteur avant d'entretenir ou de nettoyer, et avant d'y

ajouter de l'essence.

L'inobservation des consignes de sécurité risque de provoquer de

graves blessures corporelles.

1447

E

#01447, Belt Guard

E

ą

D

09095

#09095, Belt Guard

15459

#15459, Belt Guard

CAUTION

WEAR EYE PROTECTION

WHEN

OPERATING EQUIPMENT

MĆBĆW

INC.

1060E

#01060E, Belt Guard

3

PIECES ROTATIVES

Ne pas toucher!

ROTATING PARTS

Keep hands away!

11640

#11640, Belt Guard

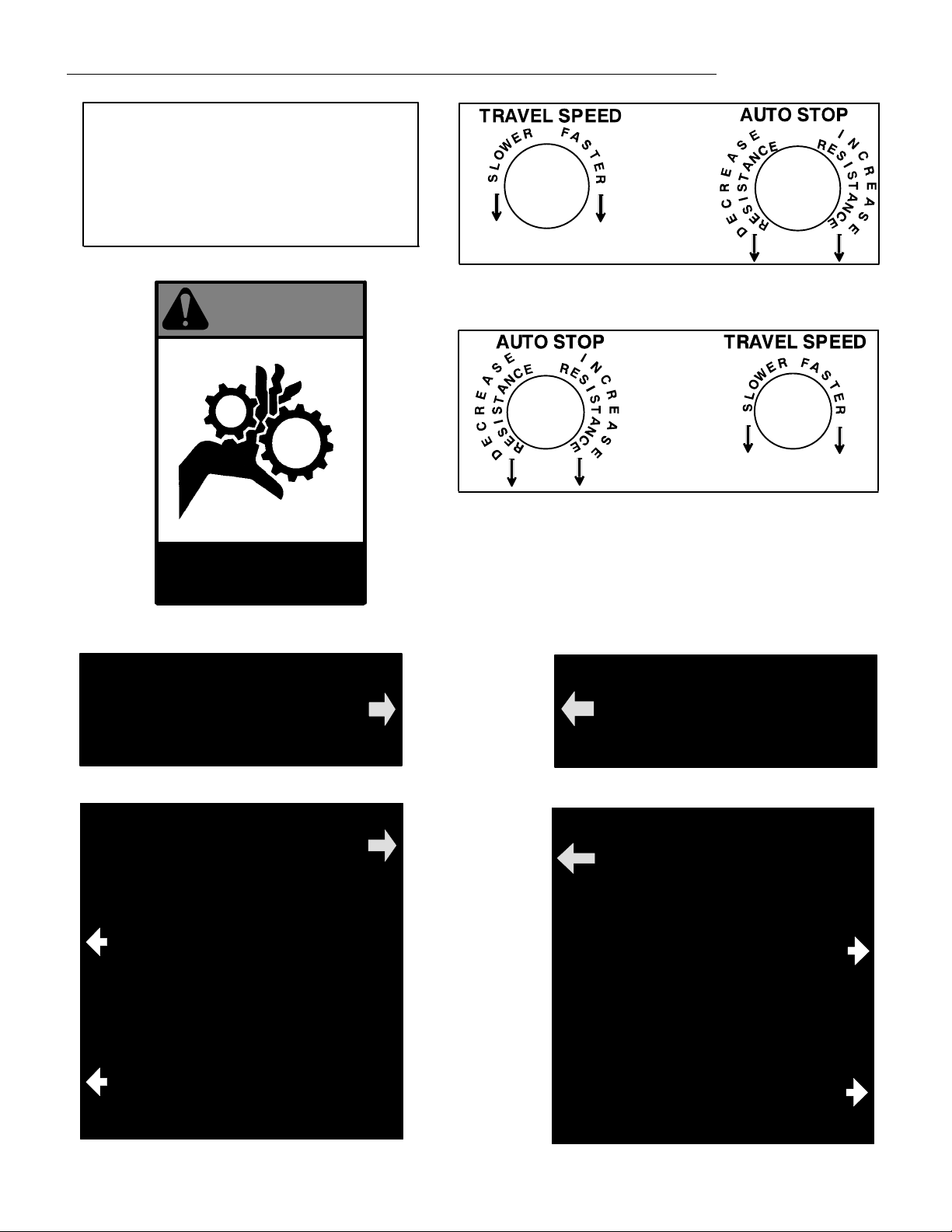

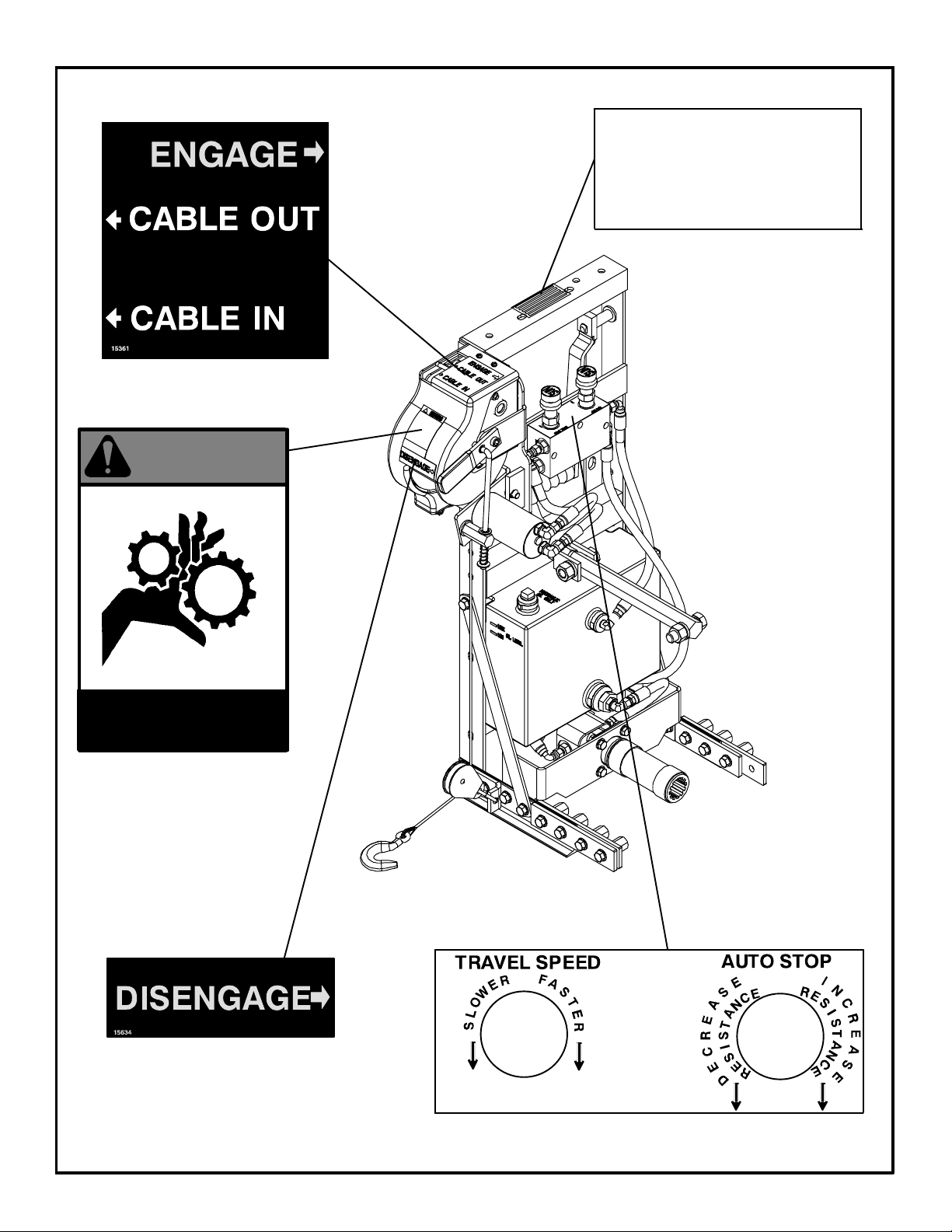

Decals shown below are located only on the hydraulic winches.

AUTO STOP MUST BE ADJUSTED EACH

TIME SCREED LENGTH OR OPERATING

CONDITIONS CHANGE. SET TRAVEL

SPEED, THEN INCREASE OR DECREASE

AUTO STOP RESISTANCE TO A POINT

SLIGHTLY HIGHER THAN REQUIRED TO

MAINTAIN DESIRED TRAVEL SPEED.

#15399 (TOP OF SUPPORT FRAME)

15399

15400

#15400 (TOP OF VALVE BLOCK, RIGHT)

WARNING

15401

#15401 (TOP OF VALVE BLOCK, LEFT)

ROTATING PARTS

Keep hands away!

15518

#15518 (WINCH COVER)

DISENGAGE

15634

#15634 (WINCH COVER, LEFT)

ENGAGE

CABLE OUT

DISENGAGE

15398

#15398 (WINCH COVER, RIGHT)

ENGAGE

CABLE OUT

CABLE IN

15361

#15631 (WINCH COVER, LEFT)

CABLE IN

15632

#15632 (WINCH COVER, RIGHT)

4

SAFETY DECAL LOCATIONS

#08875, On Belt Guard

MĆBĆW

INC.

1060E

#01060E, On Belt Guard

CAUTION

WEAR EYE PROTECTION

WHEN

OPERATING EQUIPMENT

15459

#15459, On Belt Guard

L

I

T

Z

S

C

R

E

E

ą

D

09095

#09095, On Belt Guard

PIECES ROTATIVES

Ne pas toucher!

ROTATING PARTS

Keep hands away!

11640

#11640, On Belt Guard

CAUTION

Read the operating instructions before operating this piece of

equipment.

Keep unauthorized, inexperienced, untrained people away from

this equipment.

CHECK saftey switch frequently for proper operation.

ROTATING & MOVING PARTS! Make sure all guards and safety

devices are in place.

DO NOT RUN this machine in an enclosed area. The engine

produces carbon monoxide, a POISONOUS gas.

SHUT OFF the engine before servicing , cleaning or adding fuel.

Failure to comply could result in serious bodly injury.

Lire le Mode d'Emploi avant de faire fonctionner le matériel

Eloigner toute personne non formée, non autorisée et

inexpérimentée du matériel.

VERIFIER fréquemment I'interrupteur de sécurité pour un bon

fonctionnement.

PIECES TOURNANTES ET MOBILES! S'assurer que tous les

protecteurs et les dispositifs de sécurité sont en place.

NE PAS FAIRE FONCTIONNER le matériel dans les lieux clos.

Le moteur produit de l'oxyde de carbone, un gaz TOXIQUE.

ARRETER le moteur avant d'entretenir ou de nettoyer, et avant

d'y ajouter de l'essence.

L'inobservation des consignes de sécurité risque de

provoquer de graves blessures corporelles.

#01447, On Belt Guard

ą

1447

5

SAFETY DECAL LOCATIONS

WARNING

AUTO STOP MUST BE ADJUSTED EACH

TIME SCREED LENGTH OR OPERATING

CONDITIONS CHANGE. SET TRAVEL

SPEED, THEN INCREASE OR DECREASE

AUTO STOP RESISTANCE TO A POINT

SLIGHTLY HIGHER THAN REQUIRED TO

MAINTAIN DESIRED TRAVEL SPEED.

15399

ROTATING PARTS

Keep hands away!

15518

15400

6

WARRANTY

WARRANTY

THIS IS YOUR WARRANTY - PLEASE READ AND SAVE

1. MBW INC, Slinger Wisconsin, warrants each new machine against defects in material and workmanship

under normal use and service for a period of six (6) months. This warranty commences the first day the

machine is sold, assigned to a rental fleet, or otherwise put to first use.

2. The obligation under this warranty is limited to the replacement or repair of parts and/or machine at MBW

INC factory branches or at authorized MBW INC Distributors.

3. Machines altered or modified without MBW INC written consent voids this warranty. Misuse, negligence,

accidents or the operation of machines in any way other than recommended by MBW INC will void this

warranty. This warranty shall not apply to machines repaired by other than MBW INC factory branches or

authorized MBW INC Distributors.

4. This warranty includes labor on all MBW INC products. Labor must be performed at an authorized MBW INC

Distributor.

5. The cost of transportation and other expenses connected therewith are not covered by this warranty.

6. Written authorization for the return of merchandise under warranty must be obtained from MBW INC,

Slinger, Wisconsin. In England: MBW (UK) LIMITED, Bradley Fold Trading Estate Unit 6, Radcliffe Moor

Road, Bolton BL2 6RT.

7. MBW INC reserves the right to inspect and render final decision on each warranty case.

8. MBW INC reserves the right to improve or make product changes without incurring any obligation to

update, refit, or install the same on machines previously sold.

9. MBW INC is not responsible for any liability or damage or injury directly or indirectly from design, material or

operation of its products.

10. Warranty card must be returned to MBW INC, P.O. Box 440, Slinger, Wisconsin 53086-0440, within 10 days

after purchase, assignment to a rental fleet, or first use. In England: MBW (UK) LIMITED, Bradley Fold

Trading Estate Unit 6, Radcliffe Moor Road, Bolton BL2 6RT. Failure to return warranty card as specified

renders the warranty null and void.

11. Requests for warranty must be submitted in writing within 30 days after machine failure to MBW INC, P.O.

Box 440, Slinger, Wisconsin 53086-0440. In England: MBW (UK) LIMITED, Bradley Fold Trading Estate

Unit 6, Radcliffe Moor Road, Bolton BL2 6RT.

12. THE FOREGOING WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR

IMPLIED, INCLUDING THE WARRANTIES OF MERCHANTABILITY AND FITNESS FOR USE, AND OF ALL

OTHER OBLIGATION OR LIABILITIES ON OUR PART, AND WE NEITHER ASSUME NOR AUTHORIZE ANY

OTHER PERSON TO ASSUME FOR US ANY OTHER LIABILITY OR WARRANTY IN CONNECTION WITH

THE SALE OR SERVICE OF ANY OF OUR PRODUCTS. LIKEWISE, THIS WARRANTY SHALL NOT APPLY

WITH RESPECT TO ENGINES, MOTORS AND OTHER COMPONENT PARTS PRODUCED BY OTHER

MANUFACTURERS AND USED ON MBW PRODUCTS, BUT SUCH ITEMS SHALL HAVE SUCH

WARRANTIES AS MAY BE PROVIDED BY THE MANUFACTURER THEREOF.

MBW INC.

250 HARTFORD ROAD P.O. BOX 440

SLINGER, WI 53086-0440

PHONE: (262) 644-5234 FAX (262) 644-5169

MBW CORPORATE INTERNET ADDRESS

E-MAIL: mbw@mbw.com WEB SITE: www.mbw.com

IN ENGLAND:

MBW (UK) LIMITED

Units 2 & 3 Cochrane Street

Bolton

BL3 6BN

Phone: 01204 387784 FAX: 01204 387797

7

MBW WAREHOUSE LOCATIONS

is at your service

MBW Inc. has established a network of reputable Distributors with trained mechanics and full facilities

for maintenance and rebuilding, and to carry an adequate parts stock in all areas of the country. Their

sales engineers are available for professional consultation. If you cannot locate an MBW Inc. Distributor

in your area, contact one of our Sales Branches or MBW Inc. The locations and phone numbers of the

Sales Branches are listed below.

Remember - you own the best. If repairs are needed use only MBW Inc. parts purchased from

Authorized MBW Inc. Distributors.

Sales Branches:

1. MBW Inc.

250 Hartford Rd.

P.O. Box 440

Slinger, WI 53086Ć0440

Phone: (262) 644Ć5234

FAX: (262) 644-5169

E-MAIL ON THE WORLD WIDE WEB mbw@mbw.com

WEB SITE ON THE INTERNET www.mbw.com

2. MBW (UK) LIMITED

Units 2 & 3 Cochrane Street

Bolton

BL3 6BN

Phone: 01204 387784

FAX: 01204 387797

1

Great Britain

2

8

BLITZSCREED SPECIFICATIONS

Mechanical

Section Length

Model Section Length

MVS8 8 ft. 4 in. (2.54 m). . . . . . . . . . . . . . . . . .

MVS4 4 ft. 4 in. (1.32 m). . . . . . . . . . . . . . . . . .

MVS2 2 ft. 4 in. (0.71 m). . . . . . . . . . . . . . . . . .

Screed Blades

Front (Strikeoff)

T" Profile Blade Standard. . . . . . . .

L" Profile Blade Optional. . . . . . . . .

Plow Blade Optional. . . . . . . . . . . . .

Tamper Blade Optional. . . . . . . . . . .

(Float)

Rear

L" Profile Blade Standard. . . . . . . . .

Truss Dimensions

Height 16in (40.7cm). . . . . . . . . . . . . . . . .

Width 15in (38.1mm). . . . . . . . . . . . . . . . . .

Weight approx. (excluding engine)

All Models 8.3 lbs./ft. (12 kg/m). . . . . . . . . . . . . .

Air Powered

Section Length

Model Section Length

AVS8 8 ft. 4 in. (2.54 m). . . . . . . . . . . . . . . . . .

AVS4 4 ft. 4 in. (1.32 m). . . . . . . . . . . . . . . . . .

AVS2 2 ft. 4 in. (0.71 m). . . . . . . . . . . . . . . . . .

Screed Blades

Front (Strikeoff)

T" Profile Blade Standard. . . . . . . .

L" Profile Blade Optional. . . . . . . . .

Plow Blade Optional. . . . . . . . . . . . .

Tamper Blade Optional. . . . . . . . . . .

(Float)

Rear

L" Profile Blade Standard. . . . . . . . .

Truss Dimensions

Height 16in (40.7cm). . . . . . . . . . . . . . . . .

Width 15in (38.1cm). . . . . . . . . . . . . . . . . .

Weight approx. (excluding regulator kit)

All Models 8.9 lbs./ft. (13.2 kg/m). . . . . . . . . . . . . .

Engines

Model Rated Power

Briggs & Stratton

Model 135232 5.0hp / 3.7kW. . . . . . . . . .

Honda

Model GX160K1QX 5.5hp / 4.1kW. . . . . .

Honda

GX240K1QA2 8.0hp / 6.0kW. . . . . . . . . . .

Vibrations per minute

All Models 5000-8000. . . . . . . . . . . . . .

Air Operating Pressure

All Models 40 - 60 psi (0.28 - 0.41 MPa). . . . . . .

Air Usage

All Models 4 cfm (0.11 m3/min.) / vibrator. . . . . . .

Engine Speed (max.)

All models 2800 RPM. . . . . . . . . . . . . .

Eccentric Shaft Speed (max.)

All models 2800 RPM. . . . . . . . . . . . . .

Centrifugal Force / Unit Length

All models 15.0 lbs. / ft ( 220 N/m). . . . . . . . . . . . . .

@ 2800 RPM

Width 9.75 in (24.8cm). . . . . . . . . . . .

Hydraulic Winch

(For Mechanical Screeds)

Noise Level 89 dba. . . . . . . . . .

Weight 82 lbs./side (37 kg/side). . . . . . . . . . . . . .

Length 10 in (25.4cm). . . . . . . . . . . . . .

Height 34 in (86.4cm). . . . . . . . . . . . .

Oil Capacity 1.7 gal (6.4 l). . . . . . . .

Speed ........... 0-16.7 ft/min (0-5.1 m/min)

9

SERIAL NUMBER LOCATION

SCREED AND HYDRAULIC WINCH SERIAL NUMBERS

The serial number for each screed section is located on the side of the left most A-Frame.

The serial number is also stamped into the top of each A-Frame.

HYDRAULIC WINCHSCREED FRAME

SERIAL# (Stamped)

SERIAL# DECAL

PARTS ORDERING PROCEDURE

The Warranty is stated in this book on page 7. Failure to return the Warranty Registration Card

renders the Warranty null and void.

PARTS ORDERING:

MBW Inc. parts are available worldwide and must be ordered through your local MBW Inc. DisĆ

tributor. If you cannot locate an MBW Inc. Distributor in your area, refer to page 8 of this manual,

locate the MBW Inc. Sales Branch nearest you and call for assistance.

ALWAYS INCLUDE:

1. Model and Serial Number of Machine when ordering MBW Inc Parts.

2. Item Part Number, Description, and Quantity.

3. Company Name, Address, Zip Code and Purchase Order Number.

4. Preferred method of shipping.

REMEMBER - you own the best. If repairs are needed use only MBW Inc. parts purchased

from Authorized MBW Inc. Distributors.

10

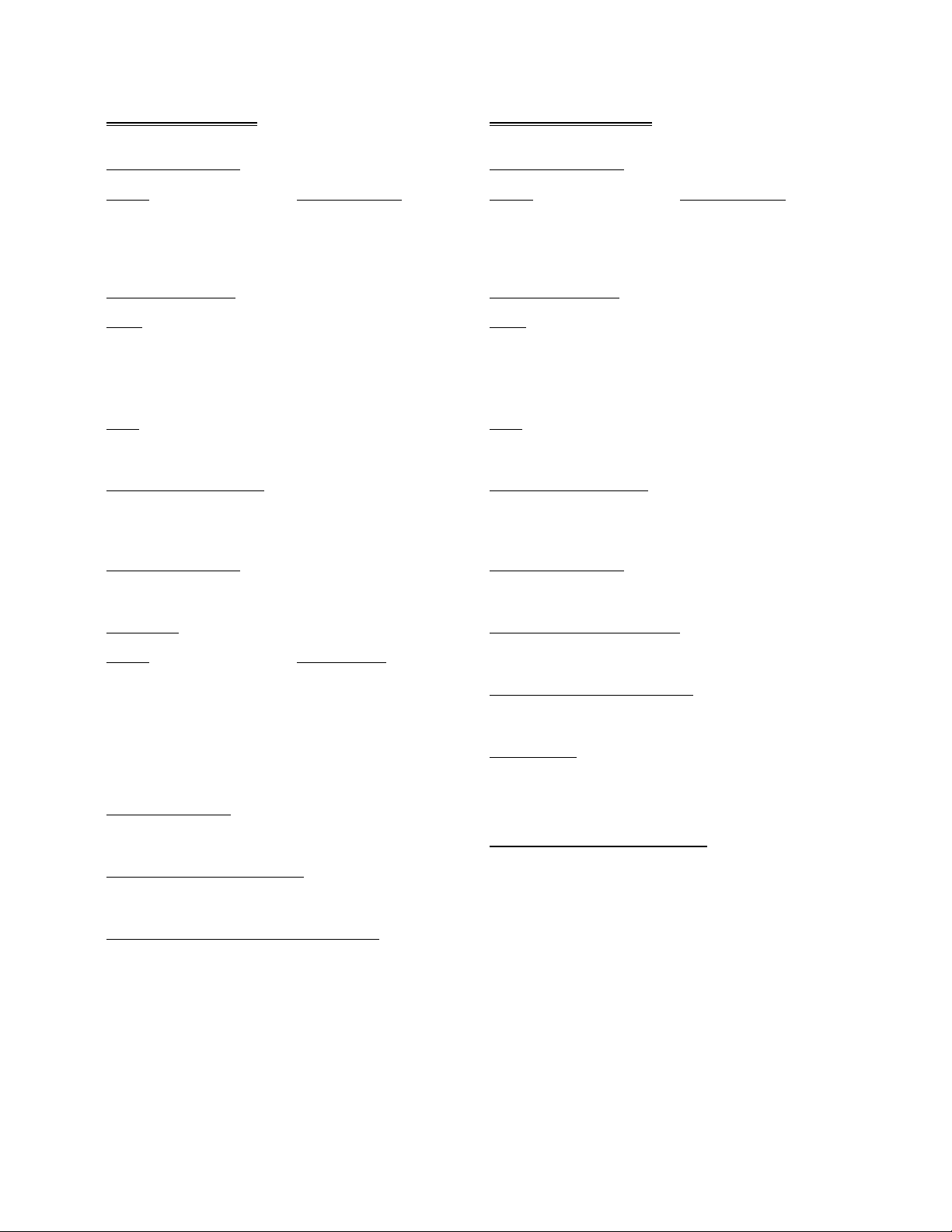

SECTION ASSEMBLY

GENERAL

The following describes the assembly procedure of screed sections for both Mechanical

and Air Screeds. Most figures shown are of a Mechanical Screed. Section assembly of an

Air Screed is identical except where otherwise stated. It is essential to follow the proper

set-up sequence when assembling the screed for optimum performance.

IMPORTANT!

For steps 1-10, the screed sections

must be on a flat surface.

1. Determine the number of sections reĆ

quired to obtained the proper screed

length. Arrange the sections so the lonĆ

ger sections are in the middle and the

shorter sections are at the ends.

2. For the mechanical screed affix an enĆ

gine kit to one of the end sections or to

the middle section. Refer to Engine

Assembly for engine kit installation.

3. If an air screed is being used, refer to

Air Drive Assembly for instruction on

assembling air drive and end frames.

4. Assemble end frames and winches to

the end sections. Refer to End Frame

Assembly for installation of end

frames.

FIGURE 2

For the air screed join the threaded

manifold ends with a manifold hose.

Use a pipe wrench to prevent the manĆ

ifold from turning while the hose ends

are tightened onto the manifold ends

(see Figure 3). Assemble all sections in

this manner. Sight down top tubes of all

sections joined and straighten sections

if necessary.

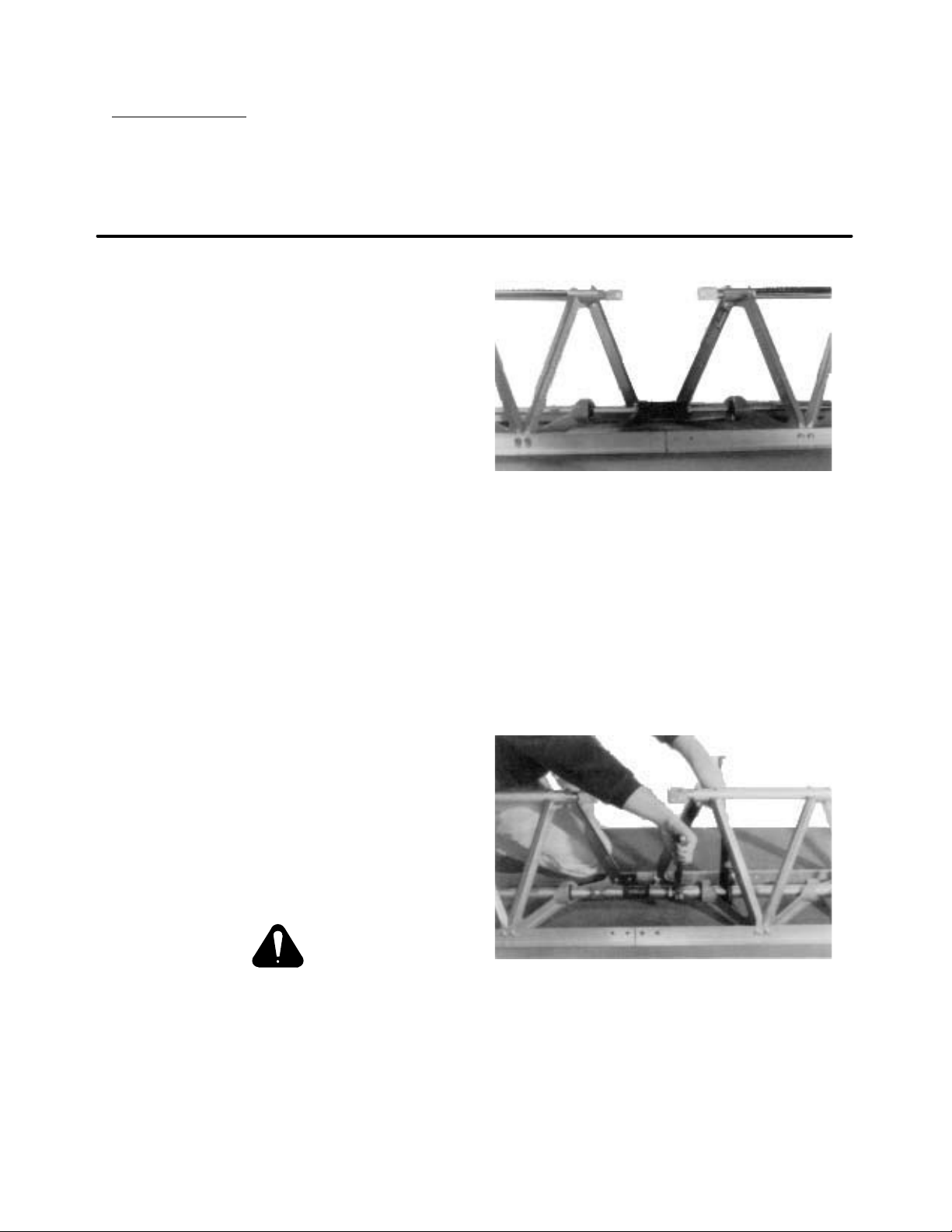

5. Start assembling sections at one end of

the screed. For mechanical screeds

place a flex coupling along with two flex

coupling collars between the two couĆ

pling drivers of adjoining sections. ColĆ

lars should be slid out to the ends of the

flex coupling (see Figure 2).

IMPORTANT !

Check that the two vibrating shaft

offsets are in line.

Assemble all sections in this manner.

Sight down top tubes of all sections

joined and straighten sections if necesĆ

sary.

FIGURE 3

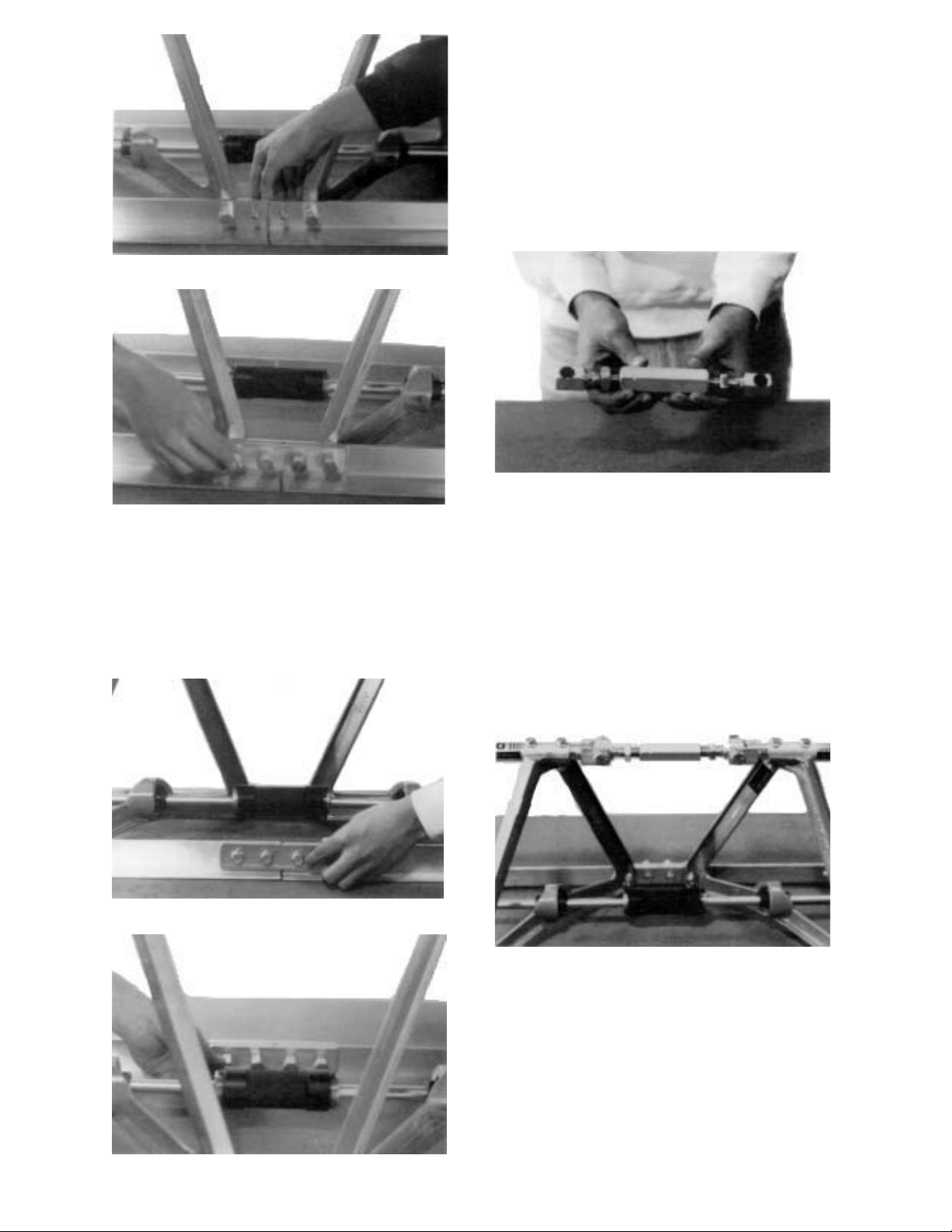

6. Install a two bolt splice plate thru float

edging. Install a four hole splice plate

on the outside of edging and loosely

install four blind nuts (see Figures 4 and

5).

11

FIGURE 4

8. Make sure the bottom of the four edgĆ

ings are in the same plane. Tighten

both splice plates hard.

9. Take a right turnbuckle eye and install a

right-hand jam nut about three quarĆ

ters of the way up the shaft. Now install

the eye onto the turnbuckle a little over

half way. Do the same with the left turnĆ

buckle eye (see Figure 8).

FIGURE 8

FIGURE 5

7. Install a four bolt splice plate thru the

strikeoff edging. Install a four hole

splice plate on the inside of the edging

and loosely install 4 blind nuts (see FigĆ

ures 6 and 7).

FIGURE 6

10.Loosely install the turnbuckle assembly

directly above the flex coupling to both

clevises using a 5/8-18 X 2-1/2 bolt,

lockwasher, and a hex nut (see Figure

9). Install all the turnbuckles in the

same direction as you progress

down the screed. There is a notch cut

on one end of the turnbuckle to indicate

its direction. Remember, do not tighten

the turnbuckle hardware yet.

FIGURE 7

FIGURE 9

12

REPEAT STEPS 6 - 10 UNTIL ENTIRE SCREED IS ASSEMBLED.

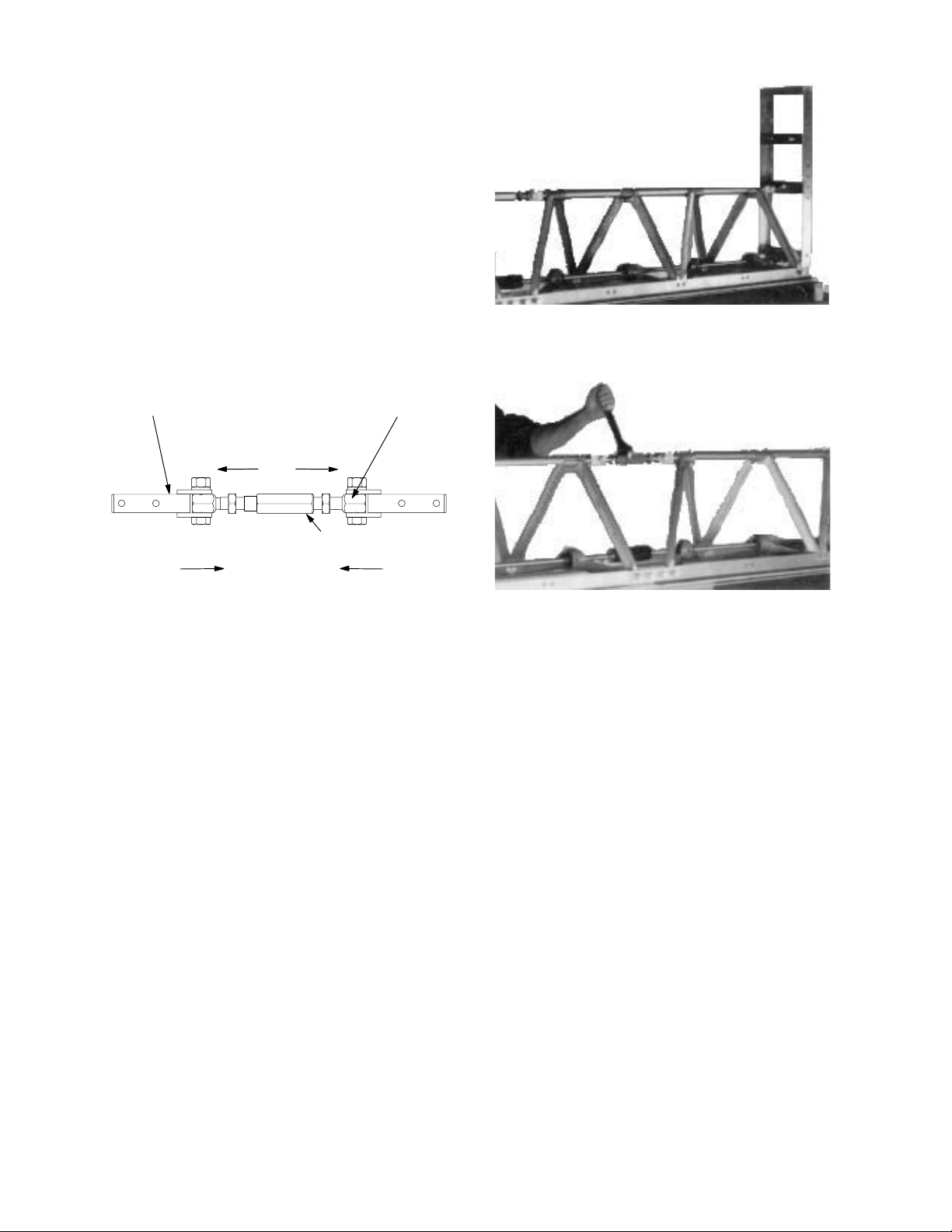

After all needed sections are assembled

the edging can be trued horizontally.

11.If the pour surface is to be crowned or

flat, rotate the turnbuckles so the turnĆ

buckle eyes are pushed away from

each other taking out the slack at the

clevis connections. If the pour surface

is a valley, rotate the turnbuckles so the

turnbuckle eyes are drawn towards

each other taking out the slack at the

clevis connections (see Figure 10).

Tighten down the 5/8 bolts going

through the clevises and turnbuckle

eyes HARD once the slack is removed.

FIGURE 11

Clevis

Crowned or Flat

Valley

Turnbuckle Eye

Turnbuckle

FIGURE 10

12. The screed is now ready for grade adĆ

justment. Place the assembled screed

on blocks or forms. String a taut chalk

line across the back of the float edge of

the screed (see Figure 11). Start with

the centermost turnbuckle and adjust it

so the bottom edge of the screed

moves up or down until it is adjusted to

the desired grade (see Figure 12). AdĆ

just each turnbuckle, working out from

the center, until the desired grade is

achieved. As the turnbuckles are adĆ

justed from the center out, previously

adjusted turnbuckles may need to be

readjusted to grade. Readjust the cenĆ

termost turnbuckles and continue adĆ

justing outward. When all adjustments

are completed, hold the turnbuckle

from further movement and tighten the

jam nuts.

FIGURE 12

CAUTION!

If there is a significant difference beĆ

tween the ambient temperature at set up

and the temperature of the concrete to

be screeded, the edgings may warp due

to thermal expansion. Recheck the

grade of the screed if this is the case.

13

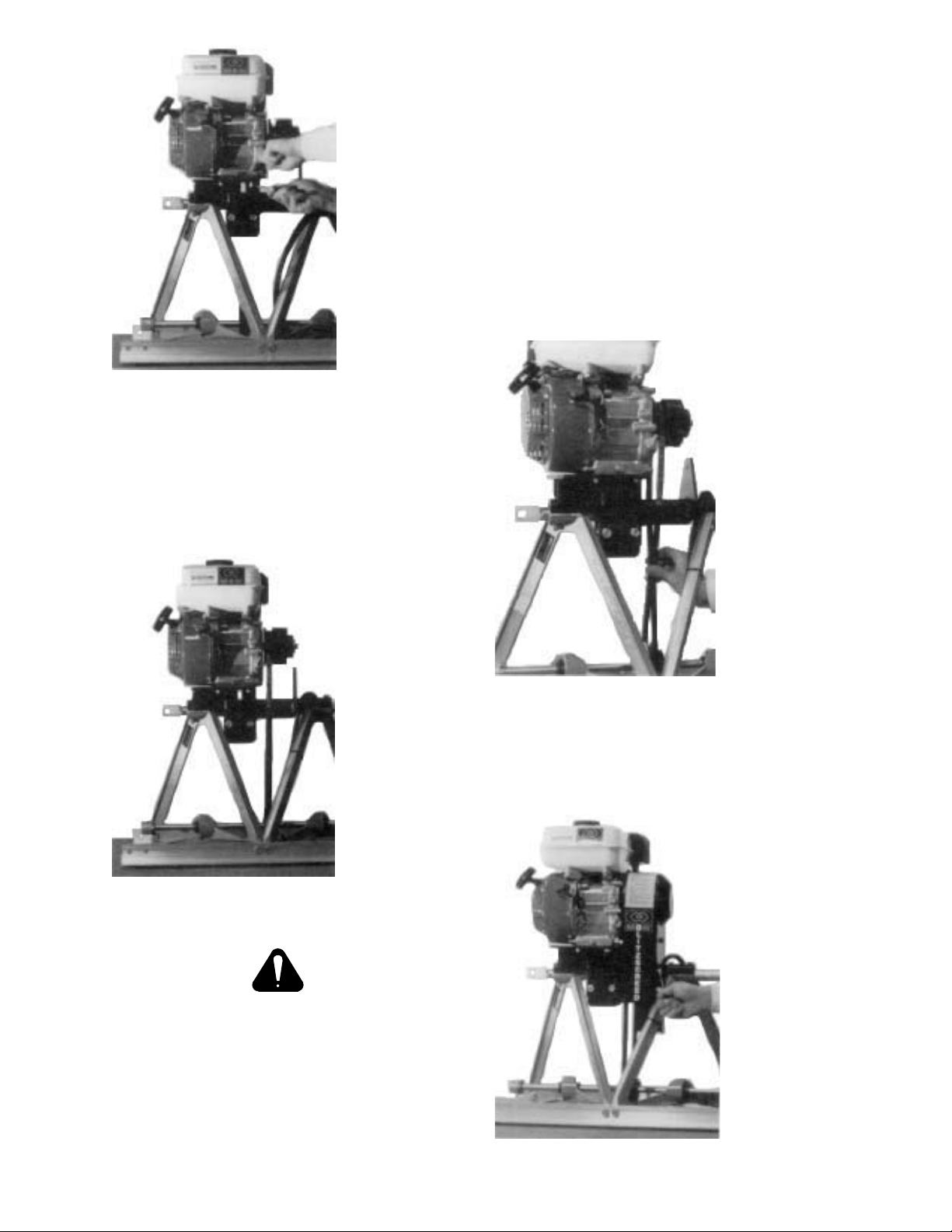

ENGINE ASSEMBLY

GENERAL

The engine can be put on any mechanical screed section on the left end where there are

bearings in two adjacent A-frames.

1. To install sheave, first remove left couĆ

pling driver. Support end of shaft when

driving out the spiral pin. Now remove

left end A-frame and clevis. Slide

#09126 sheave onto main shaft. Also

put both V-belts, supplied with engine

kit, around main shaft and over top of

the top tube (see Figure 13). ReassemĆ

ble left A-frame, clevis and coupling

driver (see Figure 14). Do not install the

top tube bolts at this time.

FIGURE 13

ing bracket thru holes aligned above

(See Figure 15). These bolts replace

the original 3/8-16 X 2 bolts that were

removed earlier.

FIGURE 15

3. Place engine mounting deck (#09787)

on top of mounting bracket installed in

Step 2. Loosely install engine mountĆ

ing deck using four whiz-lock bolts

and flange nuts thru slots in mounting

deck and thru holes in mounting brackĆ

et (see Figure 16). The mounting deck

should be in its lowest position.

FIGURE 14

2. Remove the two top tube bolts from

right A-frame next to left A-frame reĆ

moved in Step 1. Set #09090 mounting

bracket on top tube and align holes up

over the two A-frames. Use four

3/8-16 X 2-1/2 bolts to secure mountĆ

FIGURE 16

4. Bolt engine tight to the mounting deck

using four engine mounting bolts,

washers and flange nuts (see Figure

17).

14

FIGURE 17

5. Slip one V-belt over engine clutch.

Place V-belt on sheave and align

sheave with engine clutch. Secure

spare V-belt to an A-frame using tie

wraps (see Figure 18).

7. Adjust belt tension by sliding engine

mounting deck upward in slots. Check

belt tension by pinching belt between

your fingers.

Single Belt - The two sides of the belt

should touch or go slightly past each

other (see Figure 19).

Dual Belt - A 2" gap should remain beĆ

tween the two sides of both belts.

Tighten the four whiz-lock bolts holding

the engine mounting deck to the

mounting bracket. NOTE: Do not over

tighten belt.

FIGURE 18

Make sure the shaft is rotated to its

lowest position at this time. (set

screws in bearings are up).

6. Rotate pulley so the thick side of bore

is on top of the shaft. Tighten sheave

onto shaft by tightening the two screws

in the tapered bushing of sheave.

FIGURE 19

8. Bolt the belt guard to the mounting

bracket using three 5/16-18 X 1/2

screws (see Figure 20).

FIGURE 20

15

Loading...

Loading...