MBW AT84 User Manual

OPERATOR’S SAFETY

AND SERVICE MANUAL

AT73

AT84

This manual covers the following serial numbers

and higher for each model listed:

ATS73 . . . . . . . . . . . . . . . . . . . . 4070001

ATP73 . . . . . . . . . . . . . . . . . . . . 4070001

ATS84 . . . . . . . . . . . . . . . . . . . . 4080001

ATP84 . . . . . . . . . . . . . . . . . . . . 4080001

SKID-STEER ROLLER ATTACHMENTS

MBW, Inc.

250 Hartford Rd • PO Box 440

Slinger, WI 53086-0440

Phone: (262) 644-5234

Fax: (262) 644-5169

Email: mbw@mbw.com

Website: www.mbw.com

MBW (UK) Ltd.

Units 2 & 3 Cochrane Street

Bolton BL3 6BN, England

Phone: 44 (0) 01204 387784

Fax:44 (0) 01204 387797

MBW France S.A.R.L

Z.A. d’Outreville

5 rue Jean Baptiste Néron,

60540 BORNEL

France

Phone: +33 (0) 3 44 07 15 96

Fax: +33 (0) 3 44 07 41 28

L17993 / 05.11.E

©MBW, Inc. 2007

Printed in the USA

TABLE OF CONTENTS

Safety Information . . . . . . . . . . . . . . . . . . . . . . 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . 3

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Before Starting & Operating . . . . . . . . . . . . . . . . . . . . 4

Connecting to Loader . . . . . . . . . . . . . . . . . . . . . . . . . 4

Operating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . 5

Fluid Levels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Changing Exciter Oil . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Checking Exciter Oil . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Torque Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Service Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Replacing Shockmounts. . . . . . . . . . . . . . . . . . . . . . . 7

Replacing Input Seal . . . . . . . . . . . . . . . . . . . . . . . . . 7

Removing Drive Coupler . . . . . . . . . . . . . . . . . . . . . . 7

Installing Drive Coupler . . . . . . . . . . . . . . . . . . . . . . . 8

Removing Exciter Bearings and Shaft.. . . . . . . . . . . . 8

Installing Exciter Bearings and Shaft.. . . . . . . . . . . . . 8

Parts Replacement Cycles and Tolerances . . . . . . . . 9

Replacement Parts . . . . . . . . . . . . . . . . . . . . . 11

Drum Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Main Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Spider Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

WARNING

CALIFORNIA PROPOSITION 65 WARNING

Engine exhaust and some of its constituents are

known in the state of California to cause cancer,

birth defects, and other reproductive harm.

SAFETY INFORMATION

Introduction

This Safety Alert Symbol is used to call attention

to items or operations which may be dangerous

to those operating or working with this

equipment. The symbol can be found

throughout this manual and on the unit. Please read these

warnings and cautions, along with all decals, carefully

before attempting to operate the unit. Make sure every

individual who operates or works with this equipment is

familiar with all safety precautions.

WARNING

GENERAL WARNING. Indicates information

important to the proper operation of the

equipment. Failure to observe may result in

damage to the equipment and/or severe bodily

injury or death.

CAUTION

GENERAL CAUTION. Indicates information

important to the proper operation of the

equipment. Failure to observe may result in

damage to the equipment.

Safety Precautions

LETHAL EXHAUST GAS: An internal

combustion engine discharges carbon

monoxide, a poisonous, odorless, invisible

gas. Death or serious illness may result if

inhaled. Operate only in an area with proper

ventilation. NEVER OPERATE IN A

CONFINED AREA!

DANGEROUS FUELS: Use extreme caution

when storing, handling and using fuels, as

they are highly volatile and explosive in vapor

state. Do not add fuel while engine is running.

Stop and cool the engine before adding fuel.

DO NOT SMOKE!

SAFETY GUARDS: It is the owner's

responsibility to ensure that all guards and

shields are in place and in working order.

IGNITION SYSTEMS: Breakerless, magneto,

and battery ignition systems can cause severe

electrical shocks. Avoid contacting these

units or their wiring.

SAFE DRESS: Do not wear loose clothing,

rings, wristwatches, etc. near machinery.

NOISE PROTECTION: Wear OSHA specified

hearing protection devices.

EYE PROTECTION: Wear OSHA specified

eye shields, safety glasses, and sweat bands.

FOOT PROTECTION: Wear OSHA specified

steel-tipped safety shoes.

HEAD PROTECTION: Wear OSHA specified

safety helmets.

DUST PROTECTION: Wear OSHA specified

dust mask or respirator.

OPERATOR: Keep children and bystanders

off and away from the equipment.

REFERENCES: For details on safety rules and regulations

in the United States, contact your local Occupational Safety

and Health Administration (OSHA) office. Equipment

operated in other countries must be operated and serviced

in accordance and compliance with any and all safety

requirements of that country. The publication of these

safety precautions is done for your information. MBW does

not by the publication of these precautions, imply or in any

way represent that these are the sum of all dangers present

near MBW equipment. If you are operating MBW

equipment, it is your responsibility to insure that such

operation is in full accordance with all applicable safety

requirements and codes. All requirements of the United

States Federal Occupational Safety and Health

Administration Act must be met when operated in areas that

are under the jurisdiction of that United States Department.

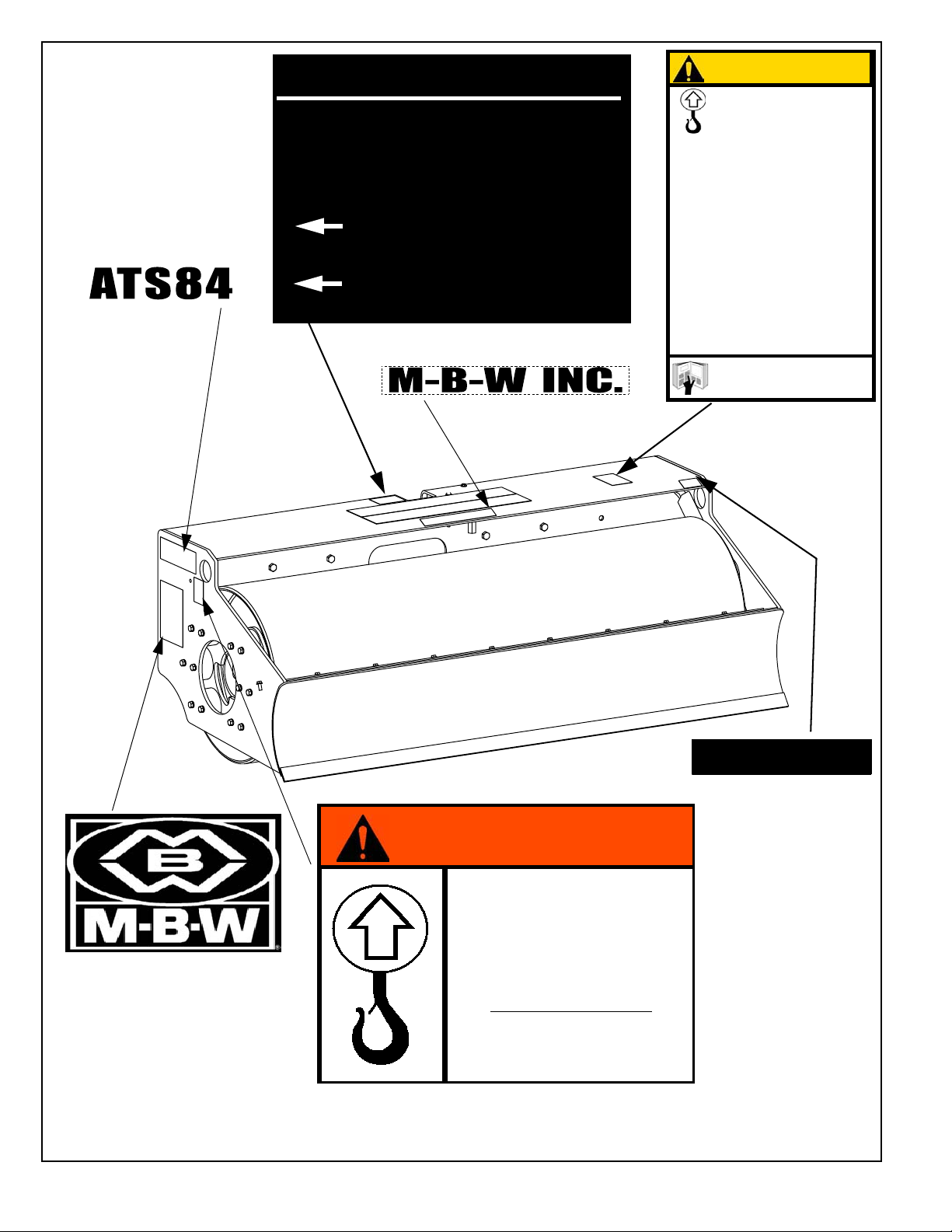

Safety Decals

Carefully read and follow all safety decals. Keep them in

good condition. If decals become damaged, replace as

required. If repainting the unit, replace all decals. Decals

are available from authorized MBW distributors. Order the

decal set listed on the following page(s).

- 1 -

17906 - ATS73

CAUTION

HEAVY

ATTACHMENT

14434

READ OPERATORS MANUAL

BEFORE USING ATTACHMENT

Overloading skid loader

could cause loader to pitch

or tip forward.

Check lifting capacity of skid

loader before hooking onto

attachment.

Do not lift attachment over

12” (30cm) above ground

level.

09867

17907 - ATP73

17908 - ATS84

17909 - ATP84

(NOT IN DECAL SET)

Hydraulic Requirements

PRESSURE: 1500-3000 psi

(103-207 bar)

FLOW: 10-50 gpm

(38-190 l/m)

Return

Pressure

14435

14435

02355

02355

(NOT IN DECAL SET)

14434

Safety Decals (Decal Set #14436)

(NOT IN DECAL SET)

09867

11922

WARNING

Machine may fall and cause

serious damage or injury if

lifted improperly.

Lift only by holes in frame

above.

MACHINE WEIGHT

ATS84- 2300 lbs (1043 kg)

ATP84- 2450lbs (1111 kg)

18075

18075-AT84

18074-AT74 (Not Shown)

- 2 -

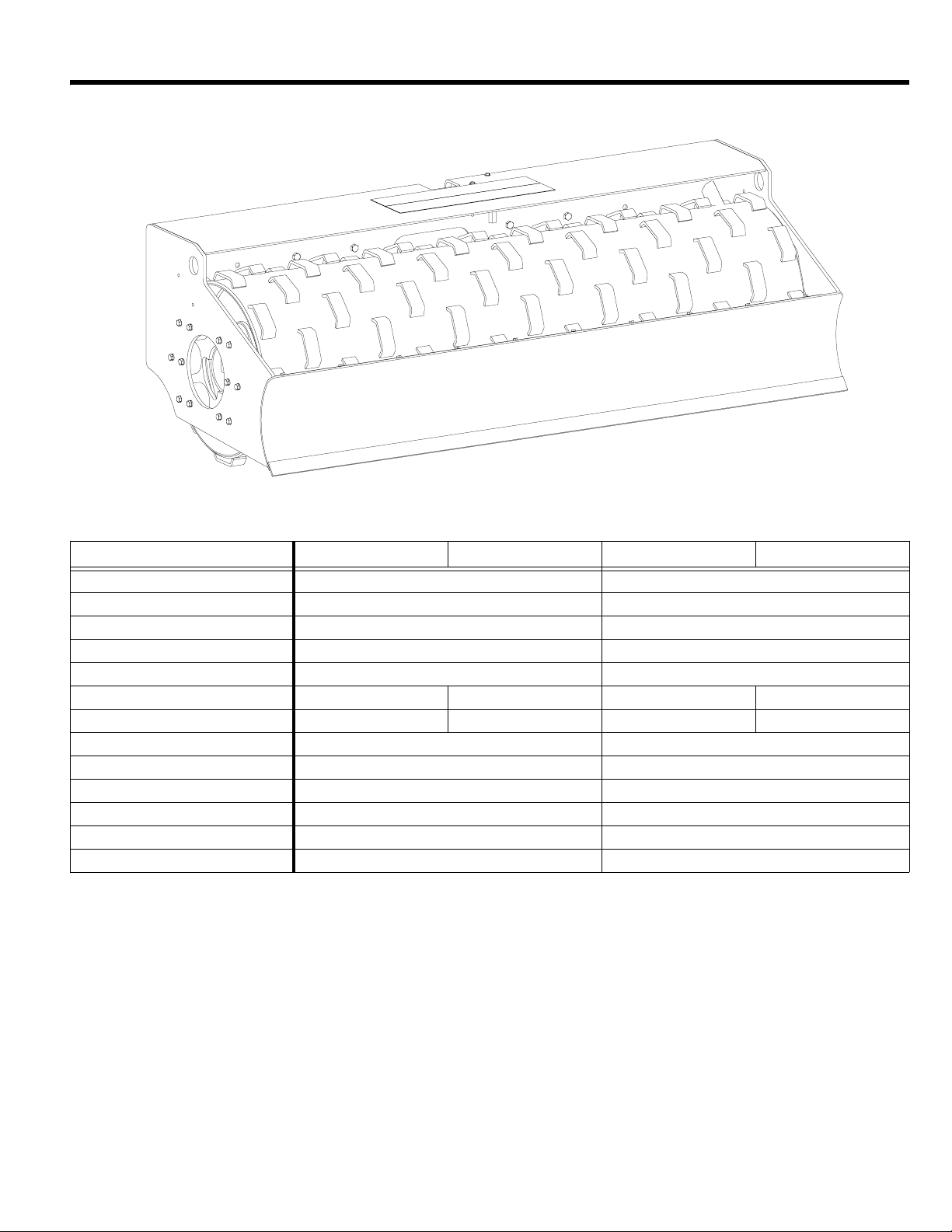

SPECIFICATIONS

ATP84

ATS73 ATP73 ATS84 ATP84

Centrifugal Force 8850 lbs (4014 kg) 9765 lbs (4429 kg)

Exciter Speed 3000 rpm 3000 rpm

Dynamic Linear Force 121 lb/in (21.7 kg/cm) 116 lb/in (20.8 kg/cm)

Amplitude --

Length 43.3 in (110 cm) 43.3 in (110 cm)

Height 29 in (74 cm) 30 in (76 cm) 29 in (74 cm) 30 in (76 cm)

Weight 2070 lbs (939kg) 2210 lbs (1002 kg) 2300 lbs (1043 kg) 2450 lbs (1111 kg)

Width, Working 73 in (185 cm) 84 in (213 cm)

Width, Overall 78 in (198 cm) 89 in (226 cm)

Sound Pressure Level 85 dBa 85 dBa

Pressure Requirement 1500 - 3000 psi (10.3 - 20.7 MPa) 1500 - 3000 psi (10.3 - 20.7 MPa)

Flow Rate Requirement 10 - 50 GPM (38 - 176 LPM) 10 - 50 GPM (38 - 176 LPM)

Connection 1/2” Flat-face Quick Coupling 1/2” Flat-face Quick Coupling

Specifications subject to change without notice

- 3 -

OPERATION

Introduction

MBW equipment is intended for use in very severe

applications.

This parts manual contains only standard parts. Variations

of these parts as well as other special parts are not included.

Contact your local MBW distributor for assistance in

identifying parts not included in this manual.

Before Starting & Operating

• REMEMBER! It is the owner’s responsibility to

communicate information on the safe use and proper

operation of this unit to the operators.

• Review ALL of the Safety Precautions listed on page 1 of

this manual.

• Familiarize yourself with the operation of the machine

and confirm that all controls function properly.

• Know how to STOP the machine in case of an

emergency.

• Make sure hands, feet, and clothing are at a safe

distance from any moving parts.

4. Lower the roller, and engage the loaders’ arms into

their float mode.

5. Engage the auxiliary hydraulics and allow the vibrator

to come up to speed.

Operating

• Check for loose hardware every 20 hours of operation.

• Do not run exciter when roller is not in contact with the

ground.

• Check that rated capacity of skid steer loader meets or

exceeds weight of roller attachment.

• The operating pressure supplied to the control valve

must fall in the range of 1500 to 3000 psi.

• The minimum volume requirement supplied to the control

valve is 10 gpm, but do not exceed 50 gpm.

• Do not use excessive down pressure when compacting

soil.

WARNING

Always stop the engine before:

Connecting to Loader

1. Attach the roller to the skid steer loader with the

universal bracket. Be sure that the wedges and

levers are fully engaged and locked.

2. Connect the hydraulic hoses to the skid steer loader’s

auxiliary hydraulics supply using the quick couplers.

3. If skid loader is equipped with a high flow and low flow

ports, it is recommended to use the low flow side.

Adding fuel.

Leaving the equipment unattended for any

amount of time.

Before making any repairs or adjustments to the

machine.

- 4 -

Loading...

Loading...