MBW 473-RP2, 473-SH2, 473-SH3, 473-SHX Maintenance Manual

Operation and

Maintenance Manual

V5.0

Dew Point Mirror 473

MBW 473 Manual English V5.0 i

Warranty

MBW Calibration AG. (MBW) guarantees that its products are manufactured to the highest quality of

material and workmanship specifications. MBW guarantees the reliability of its products for a period of

24 months from the date of initial shipment when operated in normal use and within the specified design limitations. Under this Warranty, MBW will, at its discretion, repair or replace any component that

upon examination by MBW or its duly authorized representatives proves to be defective during the

warranty period provided the system is returned to the factory for inspection and repair shipping prepaid. Improper or unauthorized maintenance, storage, repair, or alteration of any kind by personnel

other than MBW or its duly authorized representatives may void all warranties. Warranty may also be

voided for misuse, neglect, accident, corrosion, and improper installation. This Warranty is exclusive

and in lieu of any and all other warranties of merchantability, fitness for a particular purpose, or any

other warranty, expressed or implied, and all other liabilities and obligations on the part of MBW. MBW

will not be liable for any other claims or damages, either direct, indirect, or consequential arising out of

the use of its products.

Original manuals are supplied in English and German. Translations in other languages are available,

but in the event of any discrepancy, the German or English versions will be considered as the official

version.

Subject to change without notice.

For the latest version of this manual please visit our website.

Copyright © 2018

2018-04-30

MBW Calibration AG

Seminarstrasse 55/57

CH-5430 Wettingen / Switzerland

+41 56 437 28 30 phone

+41 56 437 28 40 fax

sales@mbw.ch

www.mbw.ch

ii MBW 473 Manual English V5.0

MBW 473 Manual English V5.0 iii

Table of Contents

WARRANTY ..................................................................................................... I

TABLE OF CONTENTS .................................................................................. III

1 SAFETY INSTRUCTIONS ........................................................................... 1

2 KEY FEATURES ........................................................................................ 3

3 QUICK START ........................................................................................... 5

3.1 Unpacking .......................................................................................................................................5

3.2 Installing the Measuring Heads ......................................................................................................6

3.3 Starting your 473 ............................................................................................................................7

3.4 Dew Point Measurement ................................................................................................................7

4 GET TO KNOW YOUR 473 ......................................................................... 9

4.1 Front Panel .....................................................................................................................................9

4.2 Touch Screen .............................................................................................................................. 12

4.3 Back Panel .................................................................................................................................. 13

4.4 Measuring Heads ........................................................................................................................ 18

4.5 Carrying Handle ........................................................................................................................... 23

5 SYSTEM CONFIGURATION ..................................................................... 25

5.1 The Menu .................................................................................................................................... 25

5.2 Selection of indicated Parameters ............................................................................................... 26

5.3 Selection of Numeric or Graphic Data Display ............................................................................ 27

5.4 Control Setup ............................................................................................................................... 30

5.5 Selection of Units......................................................................................................................... 35

5.6 Selection of Color ........................................................................................................................ 36

5.7 Configuration of Optional Analog Outputs ................................................................................... 37

5.8 Diagnostic Functions ................................................................................................................... 39

6 SET UP AND OPERATION ....................................................................... 43

6.1 Measurement Set Up................................................................................................................... 43

6.2 External Temperature .................................................................................................................. 44

6.3 Application Integration ................................................................................................................. 45

iv MBW 473 Manual English V5.0

7 REMOTE COMMUNICATION ................................ .................................... 49

7.1 Hardware Connection and Cabling .............................................................................................. 49

7.2 Communication Settings .............................................................................................................. 50

7.3 Command Syntax ........................................................................................................................ 50

7.4 Command Reference ................................................................................................................... 52

8 MAINTENANCE ........................................................................................ 55

8.1 Calibrate the Touch Screen ......................................................................................................... 55

8.2 Mirror Cleaning ............................................................................................................................ 56

8.3 Exterior Cleaning ......................................................................................................................... 57

8.4 Peltier Cooling Test ..................................................................................................................... 58

8.5 Periodic Maintenance Checks ..................................................................................................... 58

9 ERROR MESSAGES ................................................................................. 59

9.1 Reversible Error Messages ......................................................................................................... 59

9.2 Irreversible Error Messages......................................................................................................... 59

9.3 Fan failure SHX ........................................................................................................................... 60

10 SPECIFICATIONS ................................................................................. 61

11 DRAWINGS ........................................................................................... 63

11.1 Display Unit .................................................................................................................................. 63

11.2 Measuring Heads ......................................................................................................................... 65

12 FAQ’S ................................................................................................... 69

MBW 473 Manual English V5.0 1

1 Safety Instructions

• Disconnect power supply before opening

the instrument housing or connecting / disconnecting

sensors.

• Measuring head may get hot during operation.

Instruments built for the SH3 measuring head

supply more power through the measuring head

cable. Therefore you must not connect an SH2

or RP2 measuring head to these display units,

as it will damage the measuring heads.

2 MBW 473 Manual English V5.0

MBW 473 Manual English V5.0 3

2 Key Features

Precise and Stable Humidity Measurement

With the 473 Dew Point Mirror you are able to perform precise dew point measurements as well as

measurements of other parameters such as relative humidity. The humidity measurement of the 473 is

based on chilled mirror condensation technology which provides highly precise, stable and repeatable

results.

Remote Measuring Heads with Temperature Probe

The 473 features remote cable mounted measuring head options, the RP2, SH2, SH3 and SHX. They

are designed for direct placement into applications. Measuring heads are available with a PRT for

precise temperature measurement and for the calculation of relative humidity.

Optional Pressure Measurement

Optionally, the 473 can be ordered with internal pressure measurement capability. This enables the

user to measure barometric pressure or pressure at the point of measurement.

LCD Display with Touch Panel

The 473 has a full color LCD touch panel with a high contrast ratio and a wide viewing angle for easy

readability. Data is displayed in large, easy-to-read fonts. Using the on-screen buttons and menus,

you can easily configure each line of the display for a variety of humidity, temperature, and pressure

parameters that may be viewed in either SI or non-SI units.

Calibration Check Function

Users can check the 473 calibration at any time using the built-in Ice Test function, which provides

instant verification of system accuracy and integrity.

Connect and Go

The system is ready for immediate use.

4 MBW 473 Manual English V5.0

MBW 473 Manual English V5.0 5

3 Quick Start

This section guides you through the set-up and the first steps using your 473. It is a summary and

should be used as a general overview and reference only. Do not use it as a substitute for the remainder of the manual. To understand your instrument thoroughly, please read the other sections carefully.

3.1 Unpacking

The 473-RP2, SH2 and SHX are delivered in a custom-fit foam-lined Peli 1550 transport case. The

473-SH3 is supplied in a cardboard carton and does not include the external PRT as standard.

The following items are included in the case:

• 473 Display Unit

• RP2, SH2, SH3 or SHX measuring head (as ordered)

• Temperature probe. Platinum Resistance Thermometer1 (PRT)

o The RP2 is supplied with a Ø3 x 30 mm PRT and a 0.5 m cable for extended connection

between the probe and the measuring head and a 3 m cable to connect the probe directly to the back panel of the instrument.

o The SH2 is supplied with a Ø2 x 100 mm PRT and a 0.5 m cable to connect the probe to

the measuring head and a 3 m cable to connect the probe directly to the back panel of

the instrument.

o The SHX is supplied with a Ø3 x 30 mm PRT and a 1 m cable for extended connection

between the probe and the measuring head.

o The SH3 does not include a PRT as standard.

• AC power cord

• External power supply (Input: 100-240 V AC, Output: 24 V DC)

• 2 m measuring head cable

• Operation and maintenance manual

• Calibration certificate

Before starting, carefully remove these items from the case and visually check for any

signs of damage. If you are missing any item or find them damaged, please call the

manufacturer or your local supplier. Make sure that the power rating on the back label

corresponds to your power supply specification.

1

In accordance with IEC 60571:2008 Industrial platinum resistance thermometers and platinum temperature

sensors

6 MBW 473 Manual English V5.0

The instrument is calibrated with the supplied measuring head. Please be aware that

the specific coefficients entered in the instruments correspond to the measuring head

supplied with the instrument. Should a different measuring head be connected to the

instrument, the coefficients must be changed accordingly.

3.2 Installing the Measuring Heads

The heart of the 473 Dew Point Mirror Instrument is a highly sensitive and accurate measuring head.

Depending on your order, the 473 is supplied with either of the following measuring heads:

SH2

SH3

SHX

RP2

Use the supplied measuring head cable (2 m) to connect the measuring head to the back panel of the 473.

For further information on the measuring heads, please refer to sections 4.4 ‘Measuring Heads’ and

8.2 ‘Mirror Cleaning’.

MBW 473 Manual English V5.0 7

3.3 Starting your 473

The 473 needs a source of AC power. It will work over a wide power range and will most likely operate

at your local voltage and frequency. Look at the back panel label for the power requirements of your

specific instrument.

1. Connect the AC power cord to the external power supply input and the external power supply

output to the back of the instrument.

2. Connect the measuring head and PRT

3. Turn the power switch to ON.

The display should become visible within a few seconds. If nothing happens, check the power source.

3.4 Dew Point Measurement

After connecting the measuring head or temperature probe, switch on the 473 and you will get an external temperature reading. If your instrument is equipped with a pressure sensor, the pressure reading will be displayed. To measure humidity (dew point, frost point, %RH, etc.), the Dew/Frost Control

mode must be enabled and gas must be flowing across the mirror. If %RH readings are required, an

external temperature probe must be connected. To connect the external temperature probe, see section ‘External Temperature Probe’ on page 16. Alternatively, a fixed external temperature value may

be entered via the touch screen. Please follow the instructions in section 6.2 ‘External Temperature’.

You can test the 473 dew point measurement by measuring the dew point temperature of the room.

First, make sure the measuring head is connected to the back panel of the 473.

Next, start the measurement by pressing the Dew/Frost Control key. This button

enables the system to cool the mirror to the dew or frost point temperature, monitor the thickness of the condensation layer on the mirror, and precisely adjust the

mirror temperature to maintain a stable condensation layer. When Dew/Frost Control is enabled, the indicator on the key will turn green and the dew or frost point

temperature display will begin to show the mirror temperature as it cools to the

condensation point.

See section 5.2 ‘Selection of indicated Parameters‘ for information on selecting

the parameters you wish to have displayed.

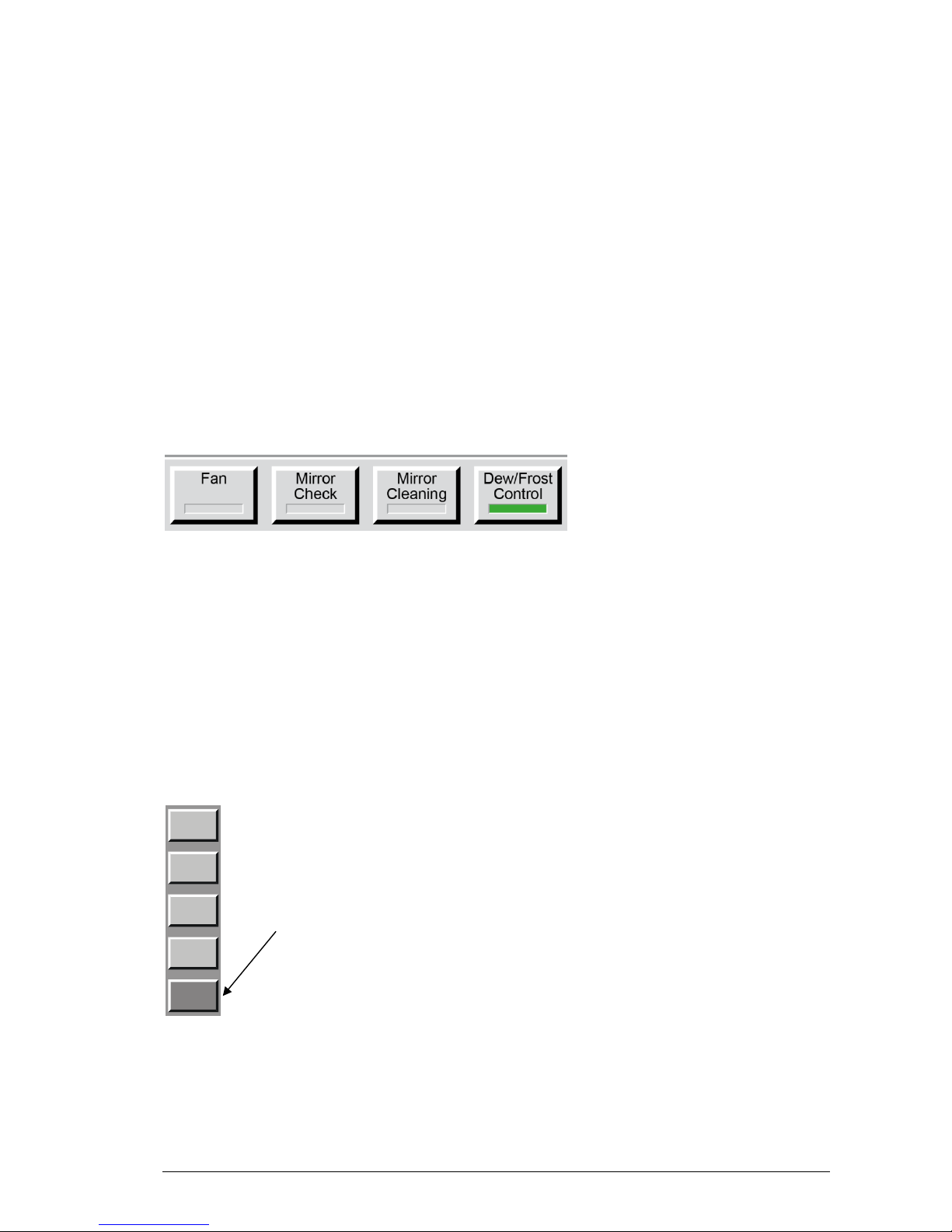

Fan

The SH2 and the SHX measuring head are equipped with a fan to pull a gas

sample through the measuring head. If you are using the SH2 or the SHX

measuring head, press the Fan key on the touch screen to turn the fan on/off. For

further information on the fan refer to section 4.4 ’Measuring Heads’.

8 MBW 473 Manual English V5.0

SH2

SHX

Fan

Fan

MBW 473 Manual English V5.0 9

4 Get to know your 473

4.1 Front Panel

The front panel of the 473 is equipped with a full color touch screen and a keypad for data entry. To

activate a menu option or toggle a function on or off, simply touch the desired key or object directly on

the screen.

When the 473 is turned on, the display will activate within a few seconds. A sample display configuration is shown below. The display configuration can be customized, so your display may look different.

The use and the functions of the display are described in the next chapter.

Menu

Keys

Status

Line

Fixed

Function Keys

Data

Lines

Keypad

10 MBW 473 Manual English V5.0

Data Lines

The first three lines of the display show a numeric or graphic representation of the measured data. We

will refer to these first three lines as Data Lines.

If numeric, a data line contains the value

to the left, with the parameter description

and units to the right.

If graphic, a data line shows a simple

graph of data over time.

Data can be displayed in different parameters and units either numerically or graphically. Please refer

to section 5, ‘System Configuration’ to learn how to configure your preferences.

Status Line

Balance

Although it is directly obtained from the intensity of the mirror’s reflected light signal, balance is effectively the first derivative of the dew thickness measurement. It indicates the rate of growth or reduction

of the condensation layer on the mirror. While the dew or frost layer on the mirror surface is growing,

the indicator will be above center. The faster the layer is growing, the higher the indication. Conversely, when the layer on the mirror surface is evaporating, the indicator will be below center. The faster it

disappears, the lower the indication. When the indicator is in the center, the thickness of the dew or

frost layer is neither growing nor evaporating, and the layer on the mirror surface is in equilibrium with

the sample gas. In this center position of the indicator, there is no net exchange of water vapor between the sample gas and the mirror surface. If the humidity of the gas sample is homogeneous and

of low enough variability for the control system to sense a steady value, the Balance indicator will

show a green Stable message, accompanied by a few short beeps.

Density

The Density Indicator graphically depicts the approximate thickness of the dew or frost layer on the

mirror surface. The 473 can automatically differentiate between dew and frost layers and the indicator

will display the current condensation state. The label in the density indicator will change from Layer

Density (when the state of the layer is uncertain) to either Dew Density or Frost Density (when either dew or frost is being measured). For more information regarding Dew/Frost point determination

see section ‘Dew / Frost Control’ on page 30.

Near the bottom of the display is the Status Line. The Status Line displays

Balance, Density, Contamination, and

Optic Power.

MBW 473 Manual English V5.0 11

Mirror Residue

The Mirror Residue Indicator graphically shows the amount of mirror contamination that was detected

during the last mirror check. If the bar covers more than a quarter of the space, we recommend that

you clean the mirror.

Optic Power

The optic power indicates the aging of the LED. When the instrument is used at higher measuring

head temperatures, the LED will age more quickly. When new, the optic condition bar graph will show

as ‘full’. When the indication starts to decrease, it provides the user with advanced notification that the

LED of the optical module may need service or replacement.

Fixed Function Keys

Menu Keys and Navigation

The menu selection is circular. Once you go past the last menu, the first one will appears again and

the process starts over. You can use the ± key on the keypad to move backward through the menus.

Use the Enter key to exit the menu.

The bottom line of the display

contains a row of fixed function

keys. These keys are used to

start and stop the gas flow fan

(only for SH2 and SHX), initiate

a mirror check, initiate mirror

cleaning, and switch dew/frost

control on or off. For further

information on the fan see

section 4.4, for the other

funcitons see section 5.4.

On the right hand side of the display there is a column of

menu keys. The bottom, dark gray key changes the current menu by cycling to the next menu. Each of the light

gray keys changes their label and function based on the

menu that is currently selected.

Use the dark grey

key on the bottom

(menu selection key)

to move between

menus.

12 MBW 473 Manual English V5.0

4.2 Touch Screen

The 473 dew point mirror is operated using the touch screen. To make a menu selection or switch

functions on or off, touch the screen where appropriate with your finger or a stylus. Never use sharp

objects, as damage may occur.

Before using the 473 for the first time or when several users operate this unit, the touch screen can be

calibrated to suit the user. The procedure is described in chapter 8.1 ‘Calibrate the Touch Screen’ on

page 55.

MBW 473 Manual English V5.0 13

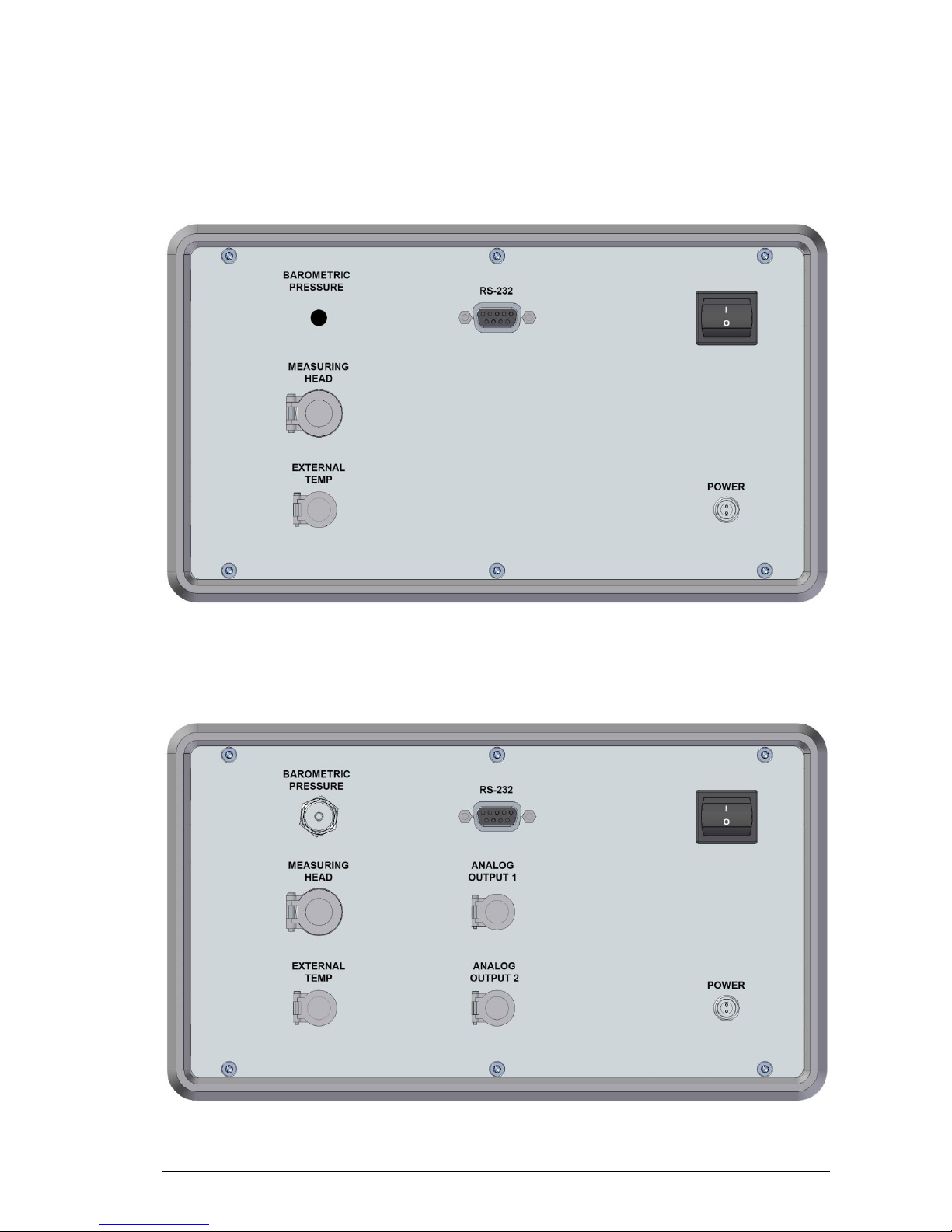

4.3 Back Panel

Without Options

With Barometric Pressure and Analog Output Options

14 MBW 473 Manual English V5.0

Power Switch

The main power switch is on the back panel above the power connection. The external power supply

has a built-in fuse and will automatically switch off in case of overload. To restart power, the main

power switch must be switched off and on again.

Power Supply

The output of the supplied external 24 VDC power supply is connected to the power connection on the

instrument back panel. The supported input voltage for the power supply is 100-120 VAC / 200-240

VAC at 50 to 60Hz.

RS-232

The RS-232 port can be used to connect the 473 to a desktop or laptop computer. The necessary 9pin RS-232 (serial) extender cable is a common accessory and can easily be obtained at any computer store.

Measuring Head Connection

The 473 can be ordered with different types of measuring heads; the RP2, SH2, SH3 and SHX. These

measuring heads are connected to the back panel of the corresponding 473 display unit. The 473RP2, SH2 and SH3 are supplied with a 19-pin measuring head cable, while the 473-SHX is supplied

with a 30-pin measuring head cable.

Internal Barometric Pressure Sensor

As an option you can order an internal barometric pressure sensor to measure ambient pressure. To

measure chamber pressure or to calibrate the sensor, connect a 3 mm tube with a Swagelok fitting to

the pressure sensor port on the back panel.

Optional Analog Outputs

The 473 can be ordered with two optional analog outputs which are independently configurable. For

each of the analog outputs, you can choose which parameter to transmit and scale its range. Please

refer to section 5.7 ‘Configuration of Optional Analog Outputs‘ on page 37 to learn how to configure

the analog outputs.

MBW 473 Manual English V5.0 15

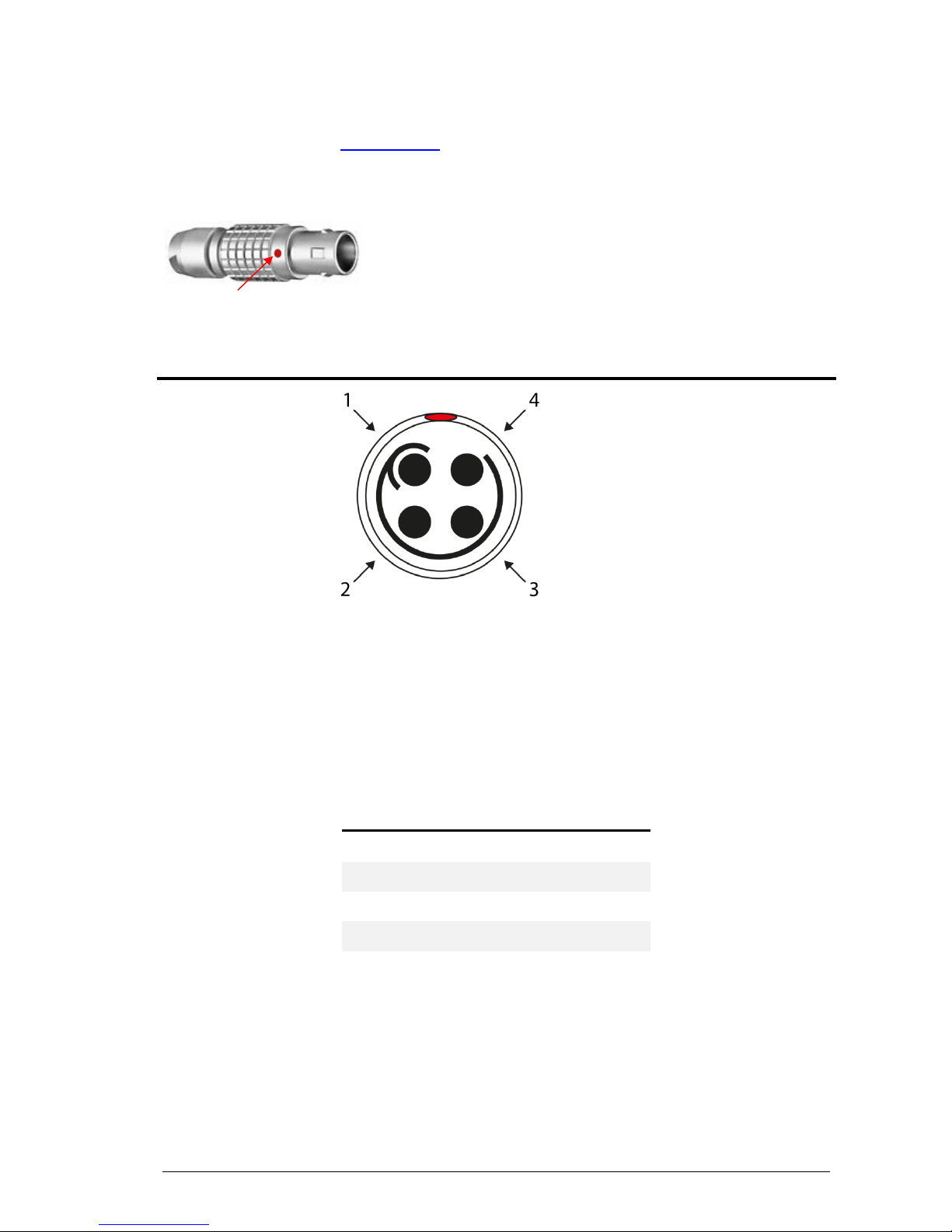

If the instrument is ordered with the optional analog outputs, two 4-pin LEMO connectors (Part Number: FGG.1B.304.CLAD52 www.lemo.com) will be supplied with the instrument. These can be used to

make up a custom cable for your installation.

When the 4-pin LEMO connector is properly assembled, the red

dot of the connector housing should be between pin 1 and 4.

The 473 allows both a voltage and a current output signal. As shown in the illustration above, pins 1 and

2 supply the voltage signal (V), and pins 3 and 4 supply the current signal (I). Inside the instrument, the

output signal is connected to a D/A converter and then split into a voltage and a current signal. Therefore, you may use either a volt or current meter to receive the analog signal. The maximum voltage output range is -10…+10 V. See the following table to identify the corresponding current signal.

Voltage

[V]

Current

[mA]

+10

20 2 4 0 0

-10

N/A

Pin

Signal

Position

Description

1

+V

When viewing the solder tabs of a

disassembled 4-pin LEMO connector,

pin 1 is usually identified with a full or

partial circle drawn around it. Pin 4

should have no identifier. When wiring

the cable, note that the pin numbering

of the socket in the back panel of the

instrument starts at the top left (pin 1)

and goes counter-clockwise (as

viewed from the rear of the unit).

2

-V

3

+I

4

-I

The red dot is between pin 1 and 4

16 MBW 473 Manual English V5.0

External Temperature Probe

The external temperature probe is used to measure the temperature of the environment that is being

measured. To obtain certain humidity parameters, such as %rh, an external temperature measurement is necessary. External temperature measurements are not required for dew or frost point measurements.

• The SH2 is supplied with a Ø2 x 100 mm PRT temperature probe. The probe can be connect-

ed to the 473 in the following ways:

1. Use the supplied 4-pin 0.5 m cable to connect the probe to the measuring head.

2. Use the supplied 5-pin 3 m cable to connect the probe to the back panel of the instrument.

• The RP2 is supplied with a Ø3 x 30 mm PRT temperature probe. The probe can be connected

to the 473 in the following ways:

1. Plug the temperature probe directly into the connector on the top of the RP2

measuring head.

2. Use the supplied 4-pin 0.5 m cable to connect the probe to the measuring head.

3. Use the supplied 5-pin 3 m cable to connect the probe directly to the back panel

of the instrument.

• The SHX is supplied with a Ø3 x 30 mm PRT temperature probe. The probe can be connected

to the 473 in the following way:

1. Use the supplied 4-pin 1 m cable to connect the probe to the measuring head.

• The SH3 is not supplied with a temperature probe as standard, but where one has been speci-

fied it is connected directly to the back panel of the 473 External Temp connector.

Use your own External Temperature Sensor

The External Temperature plug on the back panel is used for the connection of an external temperature probe. External temperature measurements are required if certain humidity parameters, such as

%RH, are to be computed. External temperature measurements are not required for dew or frost point

measurements.

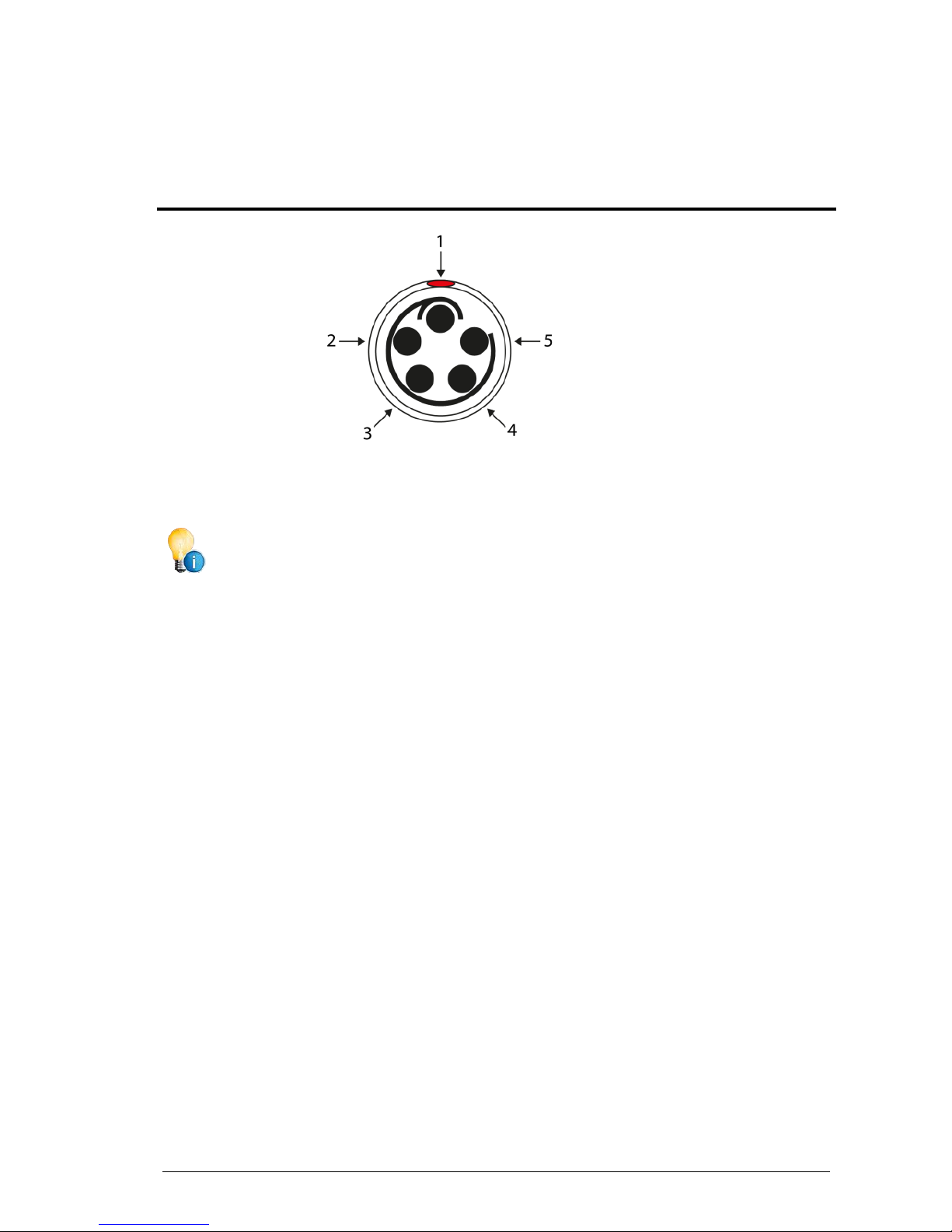

If you wish to make your own thermometer cable, the 473 requires a 5 pin LEMO connector (www.lemo.ch), part number FGG

1B 305 CLAD 52.

Red Dot aligns with Pin 1

MBW 473 Manual English V5.0 17

After identifying pin 1, follow the line counter-clockwise from pin 1 to all other pins in succession. Wire

the cable according to the following scheme:

When the 5-pin LEMO connector is properly assembled, the red dot of the connector housing

is located directly above pin 1.

Pin

Signal

Position

Description

1

Shield

When viewing the solder tabs of a

disassembled 5-pin LEMO connector,

pin 1 is usually identified with a full or

partial circle drawn around it. Pin 5

should have no identifier. When wiring

the cable, note that the pin numbering

of the socket in the back panel of the

instrument starts at the top left (pin 1)

and goes counter-clockwise (as

viewed from the rear of the unit).

2

+I 3 +V

4

-V

5

-I

Loading...

Loading...