Page 1

6-2013

WWW.MBMCORP.COM

icreaseAIR Digital Creaser

Operators Manual

Version 3.0

800-223-2508

Page 2

TABLE OF CONTENTS

SPECIFICATIONS…………………………………………………………………………………………….1a

SAFETY PROCEDURES/CARE & MAINTENANCE.………………………………………………….1b

COMPONENT IDENTIFICATION…………………………………………………………………………2

NOTES……………………………………………………………………………………………………..3

SETTING UP YOUR icreaseAIR………………………………………………………………………..4

Delivery Tray Assembly…………………………………………………………………………….4

Paper Stop Assemblies………………………………………………………………………….….5

MACHINE CONTROLS ………………………………………………………………………………………….6

PUMP CONTROLS……..............................................................................................6

PULSED FEED CONTROLS……………...…………………………………………………………………….7

TOUCH SCREEN CONTROLLE R..........................………………………………………………….8

Perf Mode..........................……………………………………………….………9

Feeder Mode........................ ..............…………………………….……...10

Crease Mode...................………………………………………….…….………10

Transport and Vacuum Operation Controls……………………………………………….………11

Programming for Crease Mod e.....………..…….........…...............................……12

Half Fold.....................................................................................12

Tri-fold................................................................................……12

Z Fold........................................................................................12

Letter Fold..................................................................................12

Roll Fold.....................................................................................12

Gate Fold....................................................................................13

Double Gate..................................... .... ......... ........ .... ...................13

Double Parallel..............................................................................13

Perfect Bind Double Hinge..............................................................13

Perfect Bind Single Hinge.......................... ....... ..............................14

Perfect Bind No Hinge............................... ....... ..............................14

Custom Crease Setups...................................................................14

Saving/Recalling Custom Jobs..........................................................15

Micro Adjusting the Crease Position...................................................15

Batch Counter..........…………………………………………………………………..16

FEED TABLE ASSEMBLY………………………………………………………………………………….17

Component Identification…….…………………………………………………….17

Adjusting Feed Rails………..……………………………………………….………18

Setting the Automatic Feeder…………………………………………………….19

Squaring the Feed Rails…………………………………………………………….19

Micro Skew Adjustment …………………………………………………………..19

Height Adjustment Caliper.………………………………………………….……20

Loading the Feeder.…………………………………………………………………21

Checking the Sensor…………………………………….……..............…..........……22

Perf Shaft & Strike Plate……………………………………………………………22

Removing the Perf Shaft to Change Configurations………………………23

ROTARY PERF & SCORE ASSEMBLY…………………………………………………………..24-27

Component Identification………………………………………………………….27

Perforation & Scoring Assemblies……………………………………………….27

Gripper Wheel Perf Score Mounting……………………………………………28

Folding Direction of Paper…………………………………………………………28

System (Rotary Actuated Creasing) Assembly……………………………………….29

RAC

Component Identification……………………………………………….………..29

Adjusting RAC rollers (depth of crease)…………………………………….. 30

Changing Lower Crease Die……………………………………………………... 30

TROUBLESHOOTING………………………………………………………………………………………..… 31

Page 3

ELECTRICAL SPECIFICATIONS

Power Requirement: 110v, 60 HZ, AC, or International 230v, 50/60HZ, AC

20 amp line required for models with pump

Circuit Protection: 3 AMP Circuit Breaker, 3 AMP Fuse

NOTE: Older buildings, overloaded lines, and bad grounds can affect the

operation of your IcreaseAIR. A regulated dedicated line is recommended.

Operating the machine through a power strip is not recommended.

OPERATING SPEEDS

MODE 8.5 X 11 Sheet(est)

Perf Mode 12,000

Crease Mode 5500

SPECIFICATIONS

Net Weight: icreaseAIR…………………………………………………..350 lbs

Overall Dimensions: …………………………………………………………………..32”Lx27”Wx26”D

Boxed Dimensions: …………………………………………………………………48”Lx48”Wx52”H

Min. Sheet Size: ………………………………………………………………..5”x5”

Max. Sheet Size: …………………………………………………………………18”x20”

NOTE: The icreaseAIR is capable o f handl ing many types of applications above and

beyond the standard specifications. It is possible to feed quite a variety of jobs, from

30” sheets to die cut stocks. Ho w ever, the performance of the icreaseAIR on these

special applicatio ns is directly related to the expe rience o f the operator.

1a

Page 4

BEFORE USE:

• Read through the owner’s manual. Follow instructions CAREFULLY.

• NEVER use a wet area. Electric shock could occur .

• Use a GROUNDED outlet and a GROUNDED circuit. Do no use ungrounded

equipment on the same circuit.

• Always use a dedicated line. DO NOT use with line splitt i ng surge protector.

DURING USE:

• Keep fingers and hands away from creasing bar, perf blades, and rubber

rollers.

• Keep cords clear of moving parts.

AFTER USE:

• Turn off machine at the top panel, then unplug the main power cord. This

will prevent damage to your machine by power/voltage spikes.

• To unplug cords, always grasp the plug body, never pull on cords to

disconnect. Wire fatigue and possible shock could result from improper

disconnect procedures.

BE ALERT! BE CAREFUL!

SAFETY PROCEDURES

CARE AND MAINTENANCE

The icreaseAIR is a preci sion machine. It is very important to keep it free of excessiv e

dust, dirt and foreign matter. We recommend that you keep the machine

when not in use.

BEARINGS/BUSHINGS: The bearing s ar e sealed roller b eari ng s and are designed to

be self lubricating, however dirt and dust can get into them causing clogging and dirt

build up. It is recommended to oil them daily under heavy use or monthly under light

use. The Bushings are Bronze and require lubrication more frequently. Oil these once a

week under heavy use.

STRIKE DIE: The groove in the lower die should be cleaned periodically using a

toothbrush to remove any dirt or build up.

SENSOR EYE: Clean the lower reflector tape located on the plate under the strike plate

of the machine. Dust will cause the beam to not reflect correctly. Clean when

necessary.

REMOVEABLE SCREWS: When these show s i gns of wear or stripping, replace as soon

as possible. If these strip or hollow out they can be costly to remove. If you do keep

your icreaseAIR clean and in top condition, it will give you years of service.

1b

covered

Page 5

COMPONENT IDENTIFICATION

Air Feed Table Assembly

Delivery Tray

Pump with

Vacuum Valve

Perf and Score Assemblies

Crease Bar

Paper Stop

Touch Screen Pg. 8

Feed Rail Assembly

Touch Screen

Power Switch

REFERENCES

Feed Table Assemb l y Pg. 17

Delivery Tray Pg. 4

Pump with Vacuum Valve Pg. 6,7

Perf and Score Assemblies Pg. 24-27

Crease Bar Pg. 29

2

Page 6

NOTES:

3

Page 7

icreaseAIR

Install on top of the first

Tuck Lip up as shown

SETTING UP YOUR icreaseAIR

This machine is 99% ready to go when it arrives on your dock. There are only a few

items that need to be put into position before it is ready to use. Those 2 items are

below:

DELIVERY TRAY ASSEMBLY

INSTALLING THE DELIVERY TRAY

Position the tray to slide it under the dowel pins and rest it on the lower dowel pins.

Upper Position shown below

dowel pin and under the

second.

4

Page 8

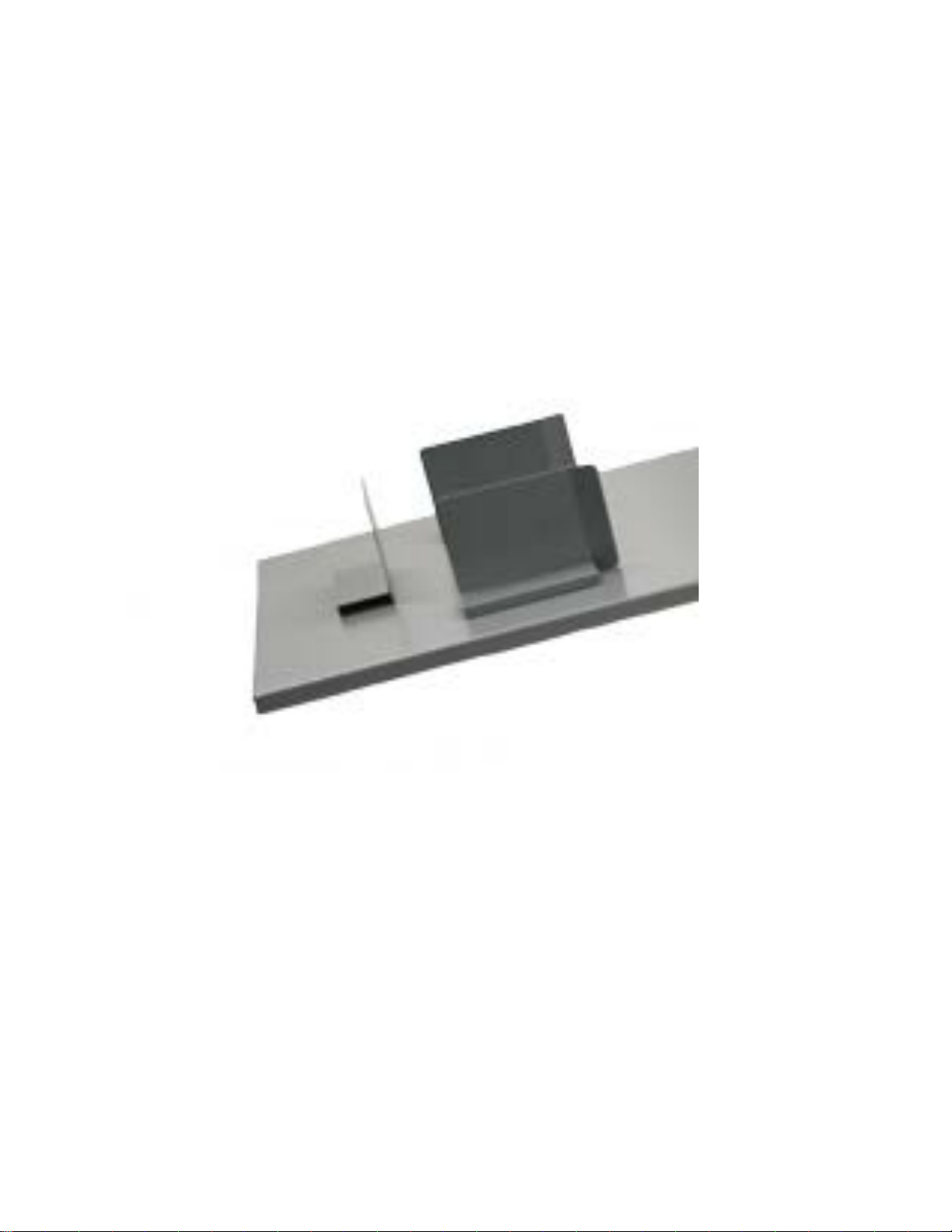

PAPER STOP ASSEMBLIES

INSTALLING THE PAPER STOPS

There are 3 different paper stops. 2 will have bends and 1 will be straight. The straight

paper stop is the rear or back paper stop. The other 2 are the right and left paper stop

and should be positioned as shown below. They hold their position using a magnet

which makes it easy for adjustment. The positions for the paper stops will change for

each individual job. If the paper stops are set to close the paper will hit them as it exits

the machine and will cause a paper jam. If they are set too loose the paper will stack in

an unorganized manner. Getting the position correct is imperative to smooth operation

of the machine.

Now that the Machine is setup, let's learn how to use the machine. The

sections below will guide you through the operation of the machine.

5

Page 9

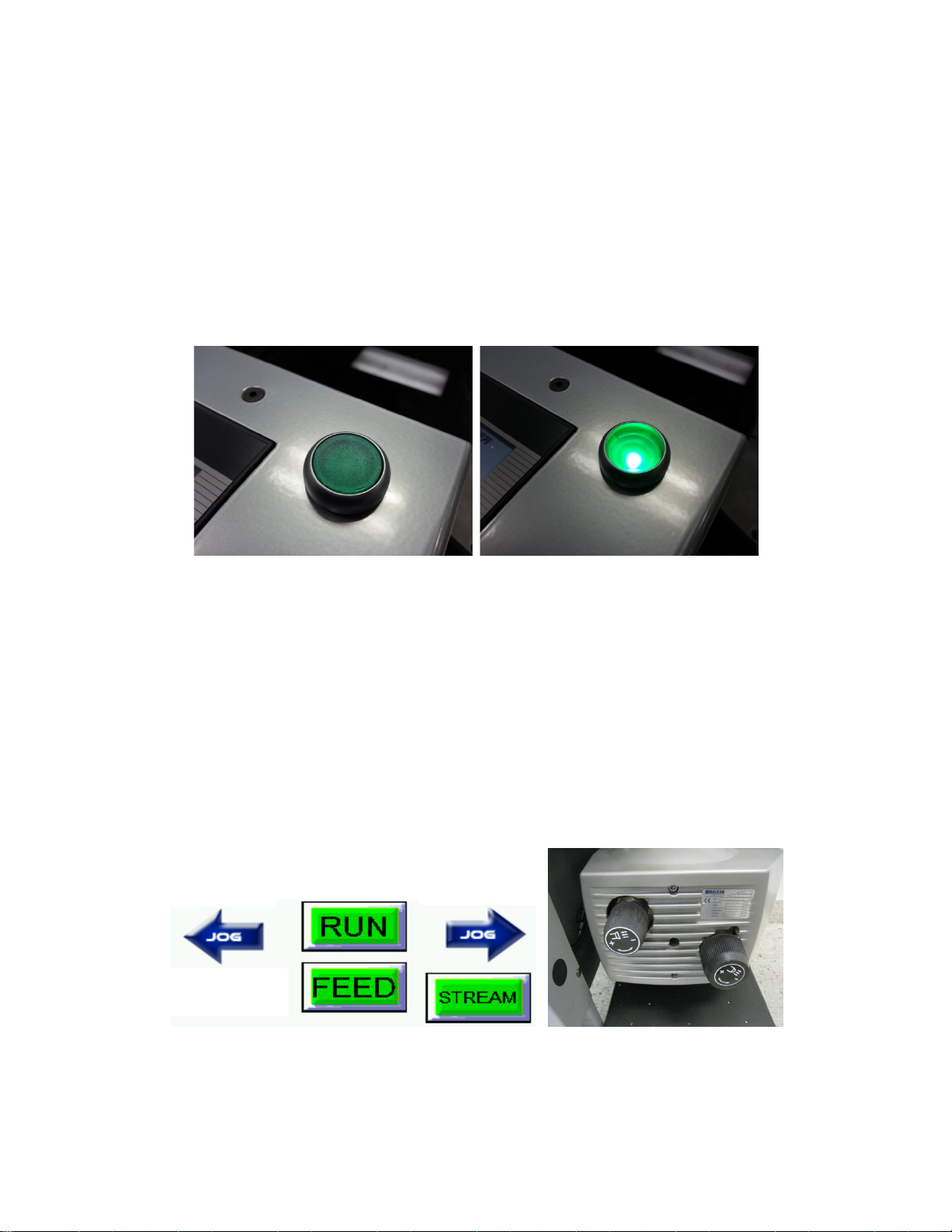

MACHINE CONTROLS

There is one switch on the icreaseAIR the main power. Everything else is controlled by

the Touch Screen.

MAIN POWER

On the operator side cover at the top o n the r i ght side is the main power button . This

is the on and off power for the machine. When pressed it will illuminate. This is how

you know the machine is on. Do not leave the machine on when not in use.

PUMP CONTROLS

The pump is controlled by the touch screen. Pressing t he run butto n the pump is

powered on. Use the knobs on the pump (pictured below right) to control the output of

the pressure and vacuum. As illustrated on the knobs you can control the suction and

the blow affecting the stock. Use care to not remove the pump knobs completely as they

have a directional specific spring for each knob. Depending on t he stock you are using

you will adjust these knobs to ensure proper feeding. The suction can be adjusted as

well as the vacuum pickup point to ensure enough suction to pull the bottom sheet. The

pressure will “fluff” the stack along the rails and make it easier to pull the bottom sheet

as well.

6

Page 10

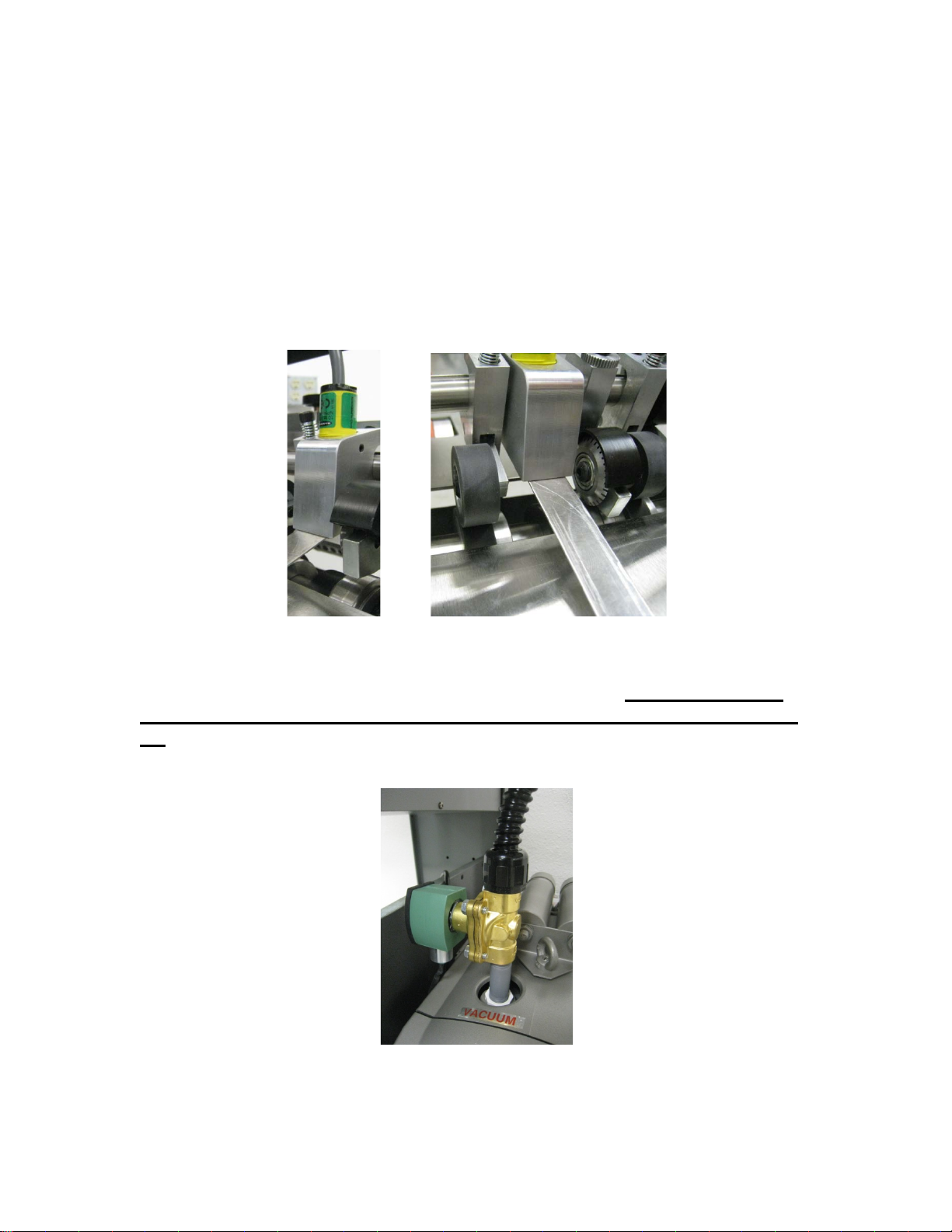

PULSED FEED CONTROLS

The feed button is the control of a pulsed suctio n valve that allows the machine to fully

control the feed of the paper. This mode of operations is a much more consistent way

to run the machine. While the output speed is slower the end result is much more user

friendly feed. To use the pulse suction press the FEED button on t he Touch Screen.

When using the pulsed feed it is very important that the proximity sensor is adjusted

correctly. See the images below to identify the pulse senso r and position it needs to be

in.

Note: Make sure nothing is below the proximity sensor and it is

positioned between the sheet metal and perf shaft. If this position is

not correct the pulse feed will not work and the suction valve will stay

off.

Air Valve Assembly

7

Page 11

icreaseAIR

1 2 3

4

MBM Corporation 800-223-2508

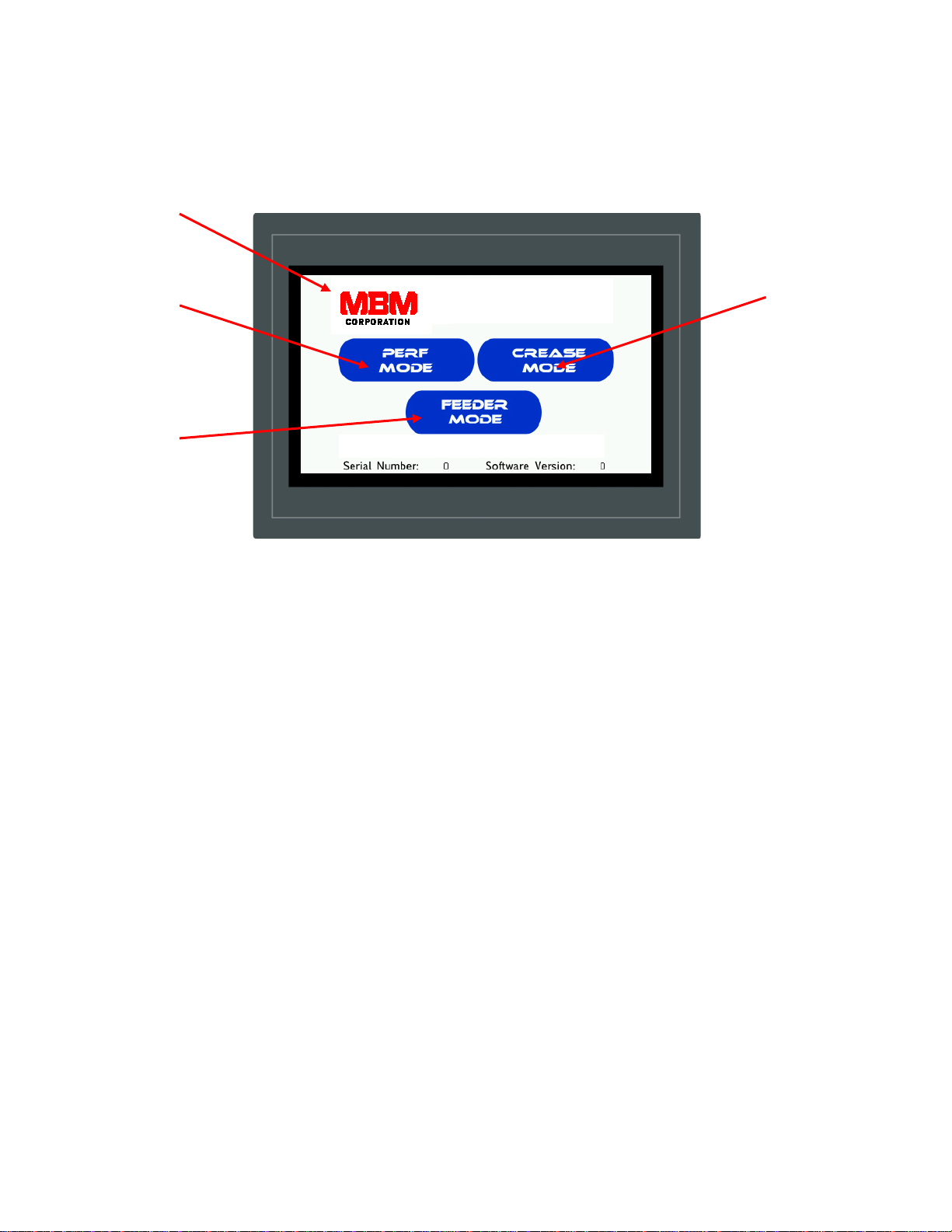

TOUCH SCREEN CONTROLLER

icreaseAIR

THE TOUCH SCREEN CONSISTS OF FOUR SECTIONS:

1. MBM Logo and Service Access

2. P erf Mode

3 . Feeder Mode

4. Crease mode

Touch Screen Operation

When the machine is turned on the display may take up to 7 seconds for the home

screen to display. There is a screen saver that will turn the display off if the machine is

not touched within 30 minutes. The power light will stay illuminated letting you know

the machine is still on.

MBM logo and Service Access

If the logo is pressed a password screen is displayed. This is for factory and service

access only. This Screen is for internal use only. The password is not given out.

8

Page 12

Perf Mode

From the home screen press t he perf mode button the perf mode screen will be

displayed.

Home: Takes you back to the home scr e en.

Counter Reset: Resets the displayed counter to 0.

Jog Left and Right: Slowly advances the rollers left or right.

Batch Counter: Allows for stopping the machine after a batch number is reached.

Run: Turns on the transport.

Feed: Starts the feeding of paper in pulse mode.

Stream : Turns off pulsed feed and continuously feeds the sheets of paper.

When the run button is pressed the graphic will change red and the button will flash.

This is the indicator the machine is in running. When the feed button is pressed the

graphics will change red and the paper will start to feed.

9

Page 13

Feeder Mode

Feed mode is the mode to run your IcreaseAIR as a feed er into our CountCoat UV Coater. It

runs much slower than the other mode s giving the sheets enough spacing to move through the

UV coater.

Home: Takes you back to the home screen.

Counter Reset: Resets the displayed counter to 0.

Jog Left and Right: Slowly advances the rollers left or right.

Batch Counter: Allows for stopping the machine after a batch number is reached.

Run: Turns on the transport.

Feed: Starts the feeding o f p a per in pulse mode.

Crease mode

Crease mode is used to apply a Compression Crease/Score to a piece of paper. In this mode

there are several Automatic Setup selections or you can do a custom selection and enter the

distance in mm.

Crease selections include half, tri-fold, z fold, letter fold, roll fold, gate fold, double gate, double

parallel, 3 perfect bind selections and 12 custom crea se locations.

10

Page 14

TRANSPORT AND VACUUM OPERATION

• The Run Button will start the Transport in any given mode. When

pressed it will also turn the air portion of the pressure pump on.

Press it again to stop the transport and turn of the pump. Each Mode

has a timeout feature to preserve the life of the machine.

• The Feed Button is what controls the suction portion of the feeder.

Press it once to turn pulse feed action. This is controlled by a sensor

just before the perf shaft that tells the machine to turn the suction off

until the end of the sheet is reached. The concep t of this is that the

machine will only feed one sheet at a time. Providi ng better

registration when in Crease Mode.

• The Stream Button is designed as a turbo button for when in perf

mode and running faster. This button opens the valve and provides

continuous suction.

• A document may be slowly advanced through the transport by

pushing and holding one of these buttons. These will not turn on the

pump.

EXAMPLE:

The motor should advance transport at slow speed and stop

whenever your finger is lifted.

• Controls on-off function of motor.

EXAMPLE:

Machine will run at mode and speed previously selected.

• Machine will stop.

11

Page 15

PROGRAMMING FOR CREASE MODE

Half Fold: Press the Crease Mode Button > Half > Start Measuring > Physically Run a

sheet through the machine for the sensor to measure > Accept > Run > Feed.

EXAMPLE:

Tri-Fold: Press the Creas e Mode Button > Tri-Fold > Start Measuring > Physically Run

a sheet through the machine for the sensor to measure > Accept > Run > Feed.

EXAMPLE:

Z-Fold: Press the Crease Mod e Bu tt on > Z-Fold > Start Measuring > Physically Run a

sheet through the machine for the sensor to measure > Accept > Run > Feed.

EXAMPLE:

Letter Fold: Press the Crease Mode Button > Letter > Start Measuri ng > Physically Run

a sheet through the machine for the sensor to measure > Accept > Run > Feed.

EXAMPLE:

Roll Fold: Press the Crease Mode Button > More > Roll > Start Measuring > Physically

Run a sheet through the machine for the sensor to measure > Accept > Run > Feed.

EXAMPLE:

12

Page 16

Gate Fold: Press the Crease Mode Button > More > Gate > Start Measuring >

Physically Run a sheet through the machine for the sensor to measure > Accept > Run

> Feed.

EXAMPLE:

Double Gate Fold : Press the Crease Mode Button > More > Double Gate > Start

Measuring > Physically Run a sheet through the machine for the sensor to measure >

Accept > Run > Feed.

EXAMPLE:

Double Parallel Fold: Press the Crease Mode Button > More > Double Parallel > Start

Measuring > Physically Run a sheet through the machine for the sensor to measure >

Accept > Run > Feed.

EXAMPLE:

Perfect Bind Double Hinge: Press the Crease Mode Button > More > Perfect Binding

Score > Enter The Book Thickness > Double Hinge > Start Measuring > Physically Run

a sheet through the machine for the sensor to measure > Accept > Run > Feed.

EXAMPLE:

13

Page 17

Perfect Bind Single Hinge: Press the Crease Mode Button > More > Perfect Binding

Score > Enter The Book Thickness > Single Hinge > Start Measuring > Physically Run a

sheet through the machine for the sensor to measure > Accept > Run > Feed.

EXAMPLE:

Perfect Bind No Hinge: Press the Crease Mo de Button > More > Perfect Binding

Score > Enter The Book Thicknes s > No Hinge > Start Measuring > Physically Run a

sheet through the machine for the sensor to measure > Accept > Run > Feed.

EXAMPLE:

Custom Crease Job: Press the Crease Mode Button > Custom > Enter In Distance For

each Crease in mm > Accept > Run > Feed.

14

Page 18

Saving Custom Crease Jobs: Press the Crease Mode Button > Custom > Enter In

Distance For each Crease in mm > Save > Select Position to save in 1, 2, 3, or 4.

Recalling Custom Crease Jobs: P ress the Crease Mode Button > Custom > Recall >

Accept > Run > Feed.

Micro Adjusting the Crease Position: Press the adjust button from the run screen.

You can micro adjust each crease by pressing the arrow keys each direction. Each press

will adjust by 1/9th of a mm. Each adjustment is relative to the one before it so if you

adjust crease 1 by 3 clicks it w i l l als o move all the creases after it i n the same direction.

To keep the subsequent creases in their same locations you would then need to adjust

them each back the number of clicks you adjusted the previous location, in this case 3

clicks.

15

Page 19

Batch Counter: Press the Batch Counter button from the run screen in any mode and

it will take you to the Batch Count Screen.

Press the Enter Batch Amount Button to enter in the number you want to run per batch.

Press the Reset Batch Button to start from 0. Press the On Button. The button turns red

as shown below.

As you are running and the batch number is reached the screen will display "Batch

Complete".

16

Page 20

FEED TABLE COMPONENT IDENTIFICATION

1

2

3 4 5 6 7

8

9

10

11

1. Height Adjustment Caliper

2. Feed Rail Lock Knob Front

3. Paper Back Stop

4. Feed Rails

5. O-ring Caliper Assembly

6. Vacuum Pickup Point Adjustment Knob

7. Micro Skew Adjustment Knob

8. Feed Rail Lock Knob Rear

9. Vacuum Wheel O-ring

10. Vacuum Wheel

11. Vacuum Wheel O-ring Drive Belt

17

Page 21

ADJUSTING THE FEED RAILS

The feed rails on your icreaseAIR are designed to adjust easily in case of a problem wit h

crooked feeding. By loosening the feed rail alignment lock knobs you can move each rail

independently to square them to your stock. To maintain an accurate perf or score, it is

important to get the rails as aligned and snug to the sheet as possible without

“squeezing” the sheet, as this will create drag and cause the sheets to hang up in the

rails. If your crease locations are slightly inconsistent the rails being too snug or tight.

Loosening the rails slightly may be an easy solution to correct this.

To adjust this correctly, use one rail as your reference, t he l e ft (operator side). Pl a ce

your stock squarely against it and then bring your right rail in and tighten, looking down

at it from the rear. Adjust the rail with the skew adjustment knob so it is squared to the

sheet. Then tighten the lock knob, and place your icreaseAIR in perf mode. Set a sheet

in the feeder, and under the feed wheels, then press run.

Check perf by folding over and aligning the perfed edge.

Perf holes should line up within a blade’s width. If they do not line up, adjust rails

accordingly, moving your left rail first and then adjusting the right rail to square the

sheet. This may take a few attempts, but this adjustment is important to produce quality

perf and score jobs.

EXAMPLE:

18

Page 22

Lock Knob

Adjustment Knob

SQUARING THE FEED RAILS

The constant fine tuning of the rails will make it necessary to bring the rails back to true

“square”. To do this, take a sheet of 8 1/2 x 11” cover stock and place it in the feed

table against the operator side guide. Pressing the sheet against the rail, slide the rail

over so that the front edge of the stock lines up to the front edge of the feed table.

Loosen the feed rail adjustment lock knob, and use the skew adjustment knob to adjust

the rail so that the sheet is aligned with the left to right with the edge. Once this is

done, slide the opposit e sid e guide into position and adjust it to the ed ge of the sheet.

Your rails should now feed the sheet perfectly aligned providing a straight perf or score.

MICRO SKEW ADJUSTMENT

The micro skew adjustment will allow for the rear adjustment of the feed rails. It

adjusts both of the rear feed rails at the same time. This makes it easier to adjust for

and straighten the perf or score.

SETTING THE AUT OM A T IC FEEDER

For efficient Auto-feeding, the setting of the caliper to the vacuum wheel is very

important. Use a piece of the s tock to be run as a “feeler gauge”. Place a

sheet under the feed wheels, turn the feed wheel adjustment screw

(Counterclockwise to raise, clockwise to lower) s o th at the paper can slip freely under

the wheels. The feed wheels should be barely touching the stock. If during the feeding

you begin to get doubles, lower the feed wheels just enough to stop the double

sheeting. The paper between the friction plate and the auto feed wheel must move

freely and should not be gripped.

19

Page 23

HEIGHT ADJUSTMENT CALIPER

Height Adjustment Knob

Caliper Disk Lock Knob

The caliper setting is what ensures the feeding of one sheet and prevents the feeding of

double sheets. It is very important that this caliper be set correctly. To set the caliper

take one sheet of the stock you are running and slide it between the caliper and vacuum

wheel. Take a second sheet and slide it back and forth, in and out while lowering the

height adjustment until the second sheet cannot slide under the caliper. DO NOT

OVERTIGHTEN! It is very important that the sheet is not pinched in anyway.

There are 2 different calipers; the o-ring and the metal caliper. The metal caliper is

designed to work better with heavy stock and the o-ring caliper is designed to work with

lighter stocks. Use the o-ring caliper when running any multi-part forms.

20

Page 24

LOADING THE FEEDER

Take the paper and load the feed tray. DO NOT OVER LOAD. The weight and size for

the stock you are running will determine how much can be loaded in the feed rails. The

paper should sit snug between the caliper and back stop. Do not pinch the paper as it

will affect the feeding consistency.

FEEDING NOTE S

• When set properly, the feed is very efficient and flexible. When neglected it ca n

become very frustrating to run even the simplest job. The adjustments

previously discussed are ver y important.

• The icreaseAIR is capable of running 20lb. single sheets, 4-part forms and 100 lb

cover. It is also very capable of handling gloss, coated, and even laminated

stocks. Its flexibil i ty is directly related to the opera tor’s experience.

• All carbonless sets are fed into the icreaseAIR with as little air pressure as

possible. Use just enough pressure to pull a single multi-part form.

21

Page 25

CHECKING THE SENSORS

1. Turn machine power on and allow screen to turn on

2. There should be 2 lights on the sensor; a green indicating power is getting to the

sensor and orange that is the reflecting signal. If both lights are not on there is a

problem and must be fixed before you are able to run.

3. Make sure the sensor reflector tape is located on the base plate and the red beam

from the sensor is hitting the tape. If not loosen the screws on the sensor and adjust

the beam until it is on the tape.

4. If all above steps work corre ctly, the sensor is working properly, if not, contact the

MBM Corporation service department.

DRIVE CHAIN TENSION

The chain that drives the upper crease die in time will stretch. This is a common

occurrence in chains. The spring tensioner bracket will automatically adjust the tension.

It is important that this chain remain taut and free of any play. It is recommended to

check this periodically. If there is play in the chain drive, make sure the adjustment

spring is in the correct location.

PERF SHAFT & STRI KE PL ATE

22

Page 26

REMOVING THE PERF SHAFT

1. Loosen Both Screws,

3. Remove Belt

2. Remove Belt

(Changing the position of the lower assemblies)

Turn the power off and unplug the machine. You may want to remove the upper assemblies

before you begin to get them out of the way as the rollers are spring loaded and will give

pressure on the lower rollers. Loosen the set screws on all of the lower assemblies. Loo sen the

2 set screws on the bearing hub located on the inside of the o perator side frame as shown

below.

Next, remove the non-operator side cover. DO NOT REMOVE ANY PULLEY'S! Loosen the

screws on the belt tensioned idler pulley (as shown below).

Slide Bracket Down

You do not need to remove the screws as loosening them will allow enough movement to remove

the belt. Remove the belt. Now remove the belt from the motor by turning the pulley by hand

and walking the belt off the pulley with no flanges on the perf shaft. Once removed there should

be no more belts on the perf shaft and the perf shaft should slide out easily. Slide the perf shaft

out the pulley side 6-8 inches the allow it to rest on the hole in the fra me.

It is only necessary to slide the shaft out about 6 to 8 inches. With the shaft slid to the side, you

can access the lower hubs and reconfigure them as needed from under the fro nt of the machine.

After you have con fi gured the lower sha ft, replace the shaft into its bearing and tighten the set

screws on the bearing hub. The shaft should be tight and not be able to move side to side. With

both drive belts back in position, re-tension the belt idler and tighten while applying const ant firm

pressure on the bel ts by pushing down on the tops of the brackets with the large T-handle

wrench supplied. Replace cover. Align upper assemblies accordingly.

23

Page 27

PERFORATI NG AND S COR I N G

Your icreaseAIR will come equipped with 1 Perf and 1 Score assembly standard. Up to 4

perf or score assemblies can be used at the same time. Perf and Score assemblies

require the corresponding Perf or Score lower hub assembly in order to function

properly.

PERFORATING

To perforate on your icreaseAIR you will lower the perf blade on the upper assembly

down onto the lower perf assembly. The upper perf assembly will look similar to the

score assembly in design, but will have a black protective guard covering the blade as

illustrated below. The lower perf assembly is made of hardened steel. See the image in

the Perorating and Scoring Section below for detail.

will see a line dead center on the lower assembly and this is where you should lower the

blade located on the upper assembly down onto the lower assembly.

Note: The lower perf assembly has a rubber core which is designed to

have some give so that when the perf blade is set against the hardened

steel lower you are not wearing away your perf blade. Because of this

fact; if you set the perf blade anywhere but center on the lower

assembly the lower assembly will “lean” to the right or left and not

give you the ideal perf quality or straightness.

From our quality control testing you

24

Page 28

Setting the Perf Blade

When locating the perf blade to where you would like to perf you must make sure that

you can move the lower assembly and upper assembly to the location you want to perf.

This may require moving the rubber gripper wheels or other upper and lower

assemblies. The lower assemblies all have a single set screw that once broken loose will

slide along the lower shaft. These are placed in line with each other for easier access. If

you cannot see the lower assembly set screws rotate the lower shaft until they become

accessible. The upper assemblies have one set screw on the upper shaft that when

broken loose will allow you to slide or move them to the desired location.

Make sure that you have even distribution of gripper wheels across the width of your

sheet when setting your perf up. While your sheet size may not require all 4 gripper

wheels to securely guide the sheet you will want as even distribution and uniform

pressure on all the gripper whe el s.

With the corresponding T-Handle wrench provided with your machine, lower the perf

blade down until the blade just touches the hardened steel lower. Then turn the THandle ½ turn and hand screw the lock down to lock the blade into the down position.

You are now ready to perf. Remember, depending on the thickness of stock you may

need to adjust the perf blade up or down to fine tune your perforation.

Important: When you lower a perf or score assembly you are putting

downward force on the lower shaft. These are self tightening and

should automatically adjust. However, if you have multiple perf

assemblies operating at the same time you may need to make fine tune

adjustments to ensure matching perf depth.

25

Page 29

SCORING

Just as in setting the perforation on your machine setting the score may require you to

move around gripper wheels and other assemblies in order to set up your score in the

proper location.

The score upper assembly will look similar to the perf upper assembly without a safety

guard covering the blade. See the image in the Perorating and Scoring Section below for

detail. The lower assembly for the score will be a solid dark colored lower with 3 grooves

located towards the ed ges of the assembly. These grov es correspond to the depth and

the width of the score as well as the ability to score thicker stocks. A wider groove will

allow for scoring of heavier stock or a deeper score than a thinner groove.

Setting the Score Blade

To set the score into posit i on lock the upper score assembly into place with the single

set screw into the groove on the upper shaft. Loosen the set screw o n the lower

assembly on the perf shaft and slide whichever groove your job requires under the score

blade. Then lower the score blade down and into the lower score assembly groo ve. Take

a strip of the stock you are scoring (approximately 1/2 to 1 inch) and press the advance

button to advance this strip into the score assembly. This will self-center the bottom

score assembly to the s core b lade. With the stock still in the score tighten the bottom

assembly set screw and your score is set. Advance the remaining stock out and you are

ready to score. Remember yo u m ay need to adjust the depth of the score bl a de to avoid

slitting the sheet or scoring too lightly. This will depend on the stock and will require

some fine tuning to achieve the score results you are looking for.

26

Page 30

Part No. Description

For removing and old blade and attaching a new blade to the pressure adjust mounting

bracket, remove the (1) button head cap screw. BE SURE TO TIGHTEN THE SET

SCREW SECURELY TO THE BAR. Once you have the upper and lower perf assemblies

in place, you can tighten the half dog screw.

Complete: #S-APP-0129 Com plete: #S-APP-0139

PERFORATING AND SC ORI N G ASSE M BL IE S

H-0215 Screw-10-32x1/2” button head

socket

H-0250 Screw-10-32x 1 1/2”socket cap

H-0270 Screw-1/4”-20x1/4” socket set

H-0275 Screw-1/4-20x1/4” socket set

H-0278 Screw-1/4-20x1/4” socket half

dog

H-0456 Washer – flat .20

H-0580 Compression spring 1 ½”

S-AAM-0930 Upper Wheel Assemlby

S-AM-0931 Lower Forwarding Roller Assy

S-AAM-0933 MOLDED ROLLER WHEEL

ASSEMBLY COMPLETE

S-APP-0131 Score blade assembly

S-APP-0143 9-1 Perf blade assembly

S-APP-0132 Lower score hub assy.Hub ap

S-APP-0133 Lower perf assy. Hub app

S-APP-0622 Bracket-perf/score pres,adj.

assy

27

Page 31

GRIPPER WHEEL PERF-SCORE MOUNTING

Score Wheel

Rubber Grip Wheel Position

Position your score blade as desired. Scores should be made so that the blade runs on

the side of the sheet that will be on the inside of the finished fold. Scores may be made

on the icreaseAIR in three different ways using the different groo v es on the lower score

assembly.

FOLDING DIRECTION OF PAPER

There is a correct and incorrect way to fold a creased paper. Following the diagram

below will show you the correct di r e ction the paper should be folded.

28

Page 32

A B C D E H I

RAC System (Rotary Actuated Creasing)

Assembly

Component ID

A. RAC drive motor

B. Eccentric Drive Shaft

C. Upper crease die

D. Pressure Adjust beari ng blocks (RAC Rollers)

E. Lower crease die

F. Drive chain & tensioner SEE DRIVE CHAIN TENSIONER ON PAGE 13

G. Return springs SEE SERVICE DIAGRAM A ON PAGE 21

H. Compression bracket RAC locknut F-2640

I. Compression Bra cket Adjust Screw A ssy

29

Page 33

ADJUSTING THE RAC ROLLERS

The RAC rollers are set from the factory and it is NOT recommended to make any

adjustments to this without consulting with MBM’s tech-support department.

Should an adjustment be necessary, please follow the steps below.

Loosen the small bearing block lock screws. This allows very slight adjustments of the

bearing block to be made by loosening the thumb lock and turning the height

adjustment screw in the middle of the bearing block. This is a very fine thread and is

capable of making very slight adjustments. Turning the adjustment screw clockwise will

increase the bar pressur e , as counterclockwise will dec r ea se the pressure. Once the

adjustment to the bar has been made, slightly tighten the thumb lock and re-set the

block set-screws.

CHANGING THE LOWER CREASE DIE

The Lower crease die can easily be changed to accommodate thicke r s to cks by removing

the non-operator side cover, slide the bar out and flip it over to use the wider die

channel. Please note, custom die’s are available upon request.

30

Page 34

TROUBLE SHOOTING

• POWER DOES NOT TURN ON

1. Check circuit bre aker on rear panel.

2. Check outlet for pow er.

• TRANSPORT “LOCKS UP” AFTER CREASING

1. Turn the crease bar over to wide groove.

2. Increase pressure of forwarding rollers by tur n the shaft clockwise to

increase the pressure.

3. Check pulleys to make sure they are securely tightened on shafts.

• FEED TABLE NOT FEEDING CORRECTLY

1. Clean feed wheel rollers.

2. Feed wheels do not have equal pressure on them, check adjustment.

3. Contact strip is worn and will not gap the stack.

• SHEETS NOT FEEDING STRAIGHT

1. Unequal feed wheel pressure.

2. Align feed rails “check for squareness”. This can be checked by the lead edge

of the paper feeding into the machine should li ne up with the front edge of the

feed plate.

3. Not enough pressure on forwarding rollers.

4. Clean ALL rubber rollers.

• PERF IS NOT STRAIGHT

1. Check for equal pressure on all grip wheels and that none are hanging up.

2. Recheck all steps under (SHEET NOT FEEDING STRAIGHT)

• PERFORATION IS NOT CLEAN OR CUTS SHEETS

1. Not enough pressure on perf wheel.

2. Perf blade is worn.

• CREASE NOT REGISTERING ON SHEET

1. Clean all Rubber Rollers

2. Turn crease bar over for any stock o ver 9pt .009"

3. Check pressure on grip wheels. If these are not down firmly, your registration

will be off.

4. Check all pulleys to make sure they are securely tensioned on shafts.

5. Check to see that machine transport turns fr eely.

• CREASE APPEARS WEAK

1. Crease bar not level.

2. Not enough pressure, adjust RAC rollers with height adjustment screw.

3. Too much pre s s ure, motor cannot make full stro ke. Motor damage will occur.

4. Crease bar not tightened properly on bracket.

• CREASE BAR DOES NOT ROTATE

1. Crease bar set too low, cannot make full stroke.

2. Crease bar is dirty. Clean with damp cloth and wipe clean.

3. May need to send crease bar in to headquarters for service.

31

Loading...

Loading...