Page 1

Pressure Sealer ES-5000

ES-5000

1

<Rev. 09-01-30>

Page 2

Pressure Sealer ES-5000

Table of Contents

1. Introduction

2. Installation

3. Features

1) Specifications

2) General views

4. How to Operate

1) Form Preparation

2) Loading forms

3) Start

4) Fold Setting

5) Operator Panel

6) Manual Feed

5. Maintenance

1) General Cleaning

2) Paper Dust

3) Cleaning Pickup and Fold Rollers

4) Cleaning Press Rollers

6. Trouble Shooting

1) Paper Jam

2) Double Feed

3) Mis-Feed

4) Skewed Fold

2

Page 3

Pressure Sealer ES-5000

1. Introduction

ES-5000 produces folded and sealed mailable documents with cut-sheet Pressure Seal

forms. Pressure activated adhesive applied forms provide and instantly secure seal on all

sides of the form, whether use a “C”, “V”, “Z” or “Double” fold.

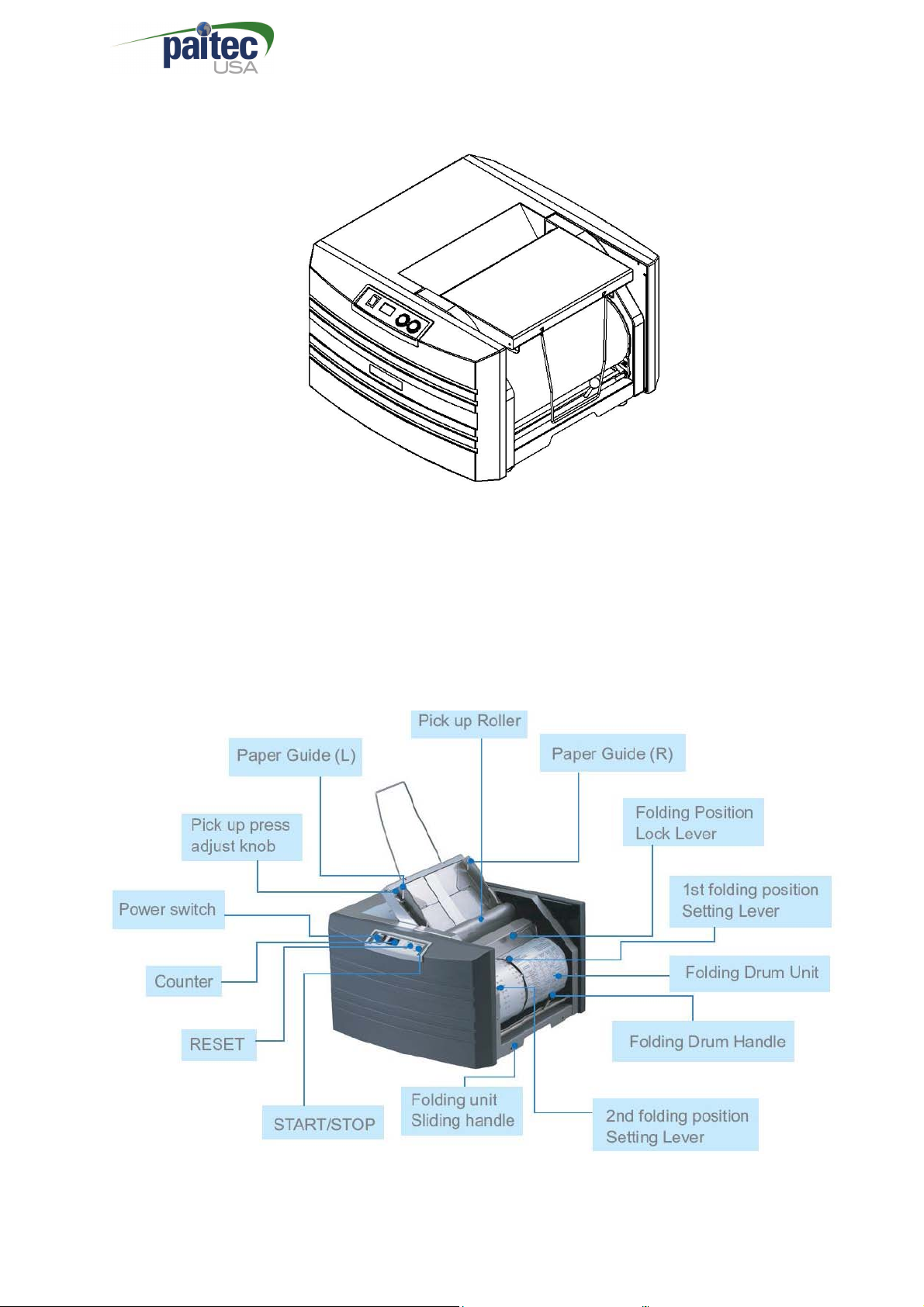

Names of each part

2.

3

Page 4

Pressure Sealer ES-5000

2. Installation

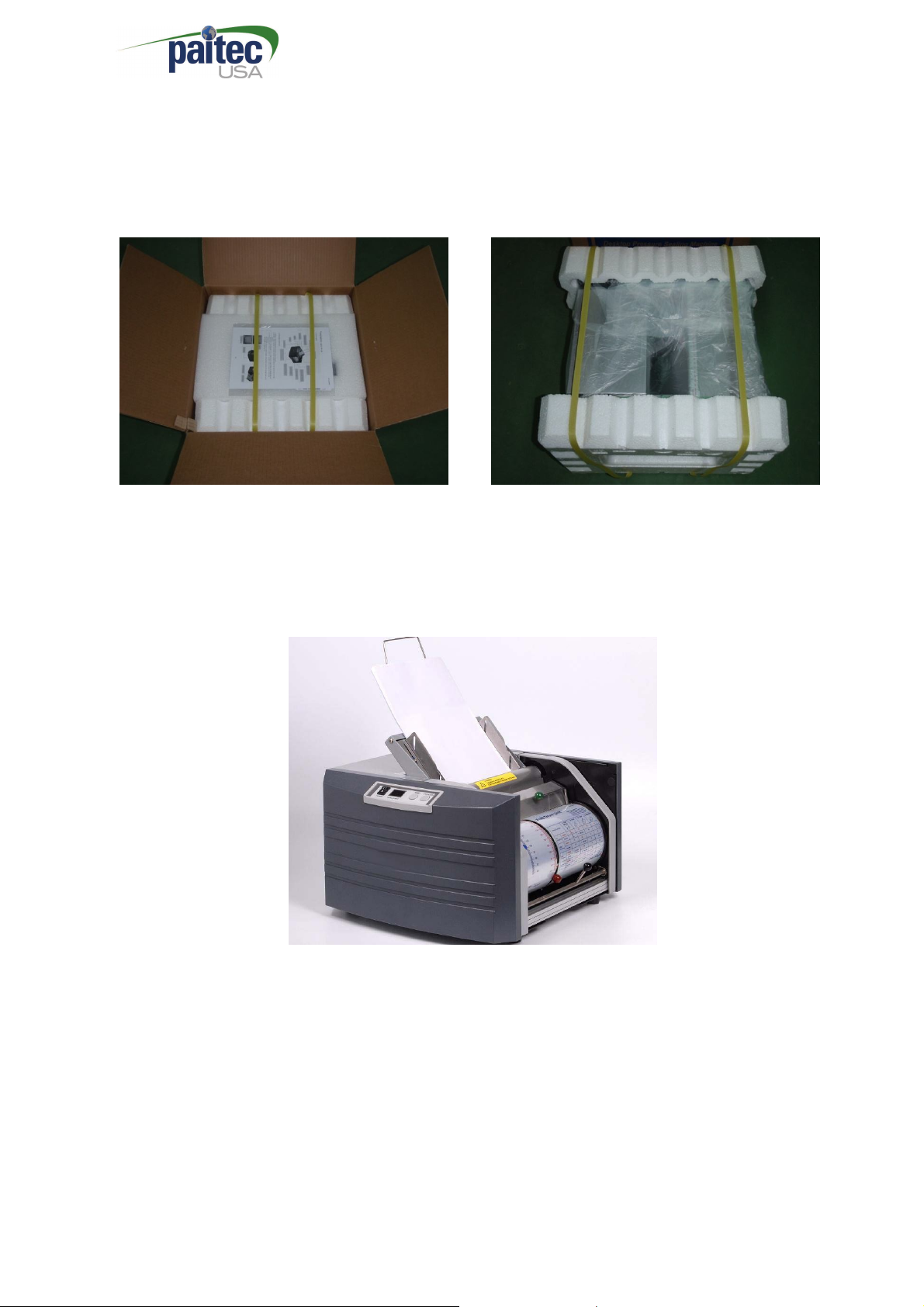

Locate the box right next to the location where the machine will be set up and operate.

Open Box, Remove the Operators Guide and set aside. Grasp the two Shipping Straps

and remove the unit from the box.

Remove all packing materials from around the unit and place the folder on a sturdy

surface.

Open Infeeder Chute and Pull out Paper Stopper

Set up fold drum and run at least 50 documents through the machine. Show customer

how to run the machine.

4

Page 5

Pressure Sealer ES-5000

1) Features

1) Specifications

Processing Speed 4,200 forms per hour

Automatic jam recovery system

No adjustment required for varying paper thickness

Fold plate setting can be changed in seconds

Manual feeder for single form processing

Folding unit slides out for easy access and maintenance

Digital reset counter

Exceptionally quiet – approximately 45db

Infeeder capacity-150(24#), 120(28#)

Form Size: Letter, Legal(14” Z-fold available option)

Z,C,V & double fold

Paper Weights: 16 lb to 28 lb

Counter: reset counter

Jam Removal: folder unit slides out and opens

Size: 17.3 x 16.5 x 19 inches (L x W x H)

Weight: 80 lbs

Power: 120V/60Hz

2) General Views

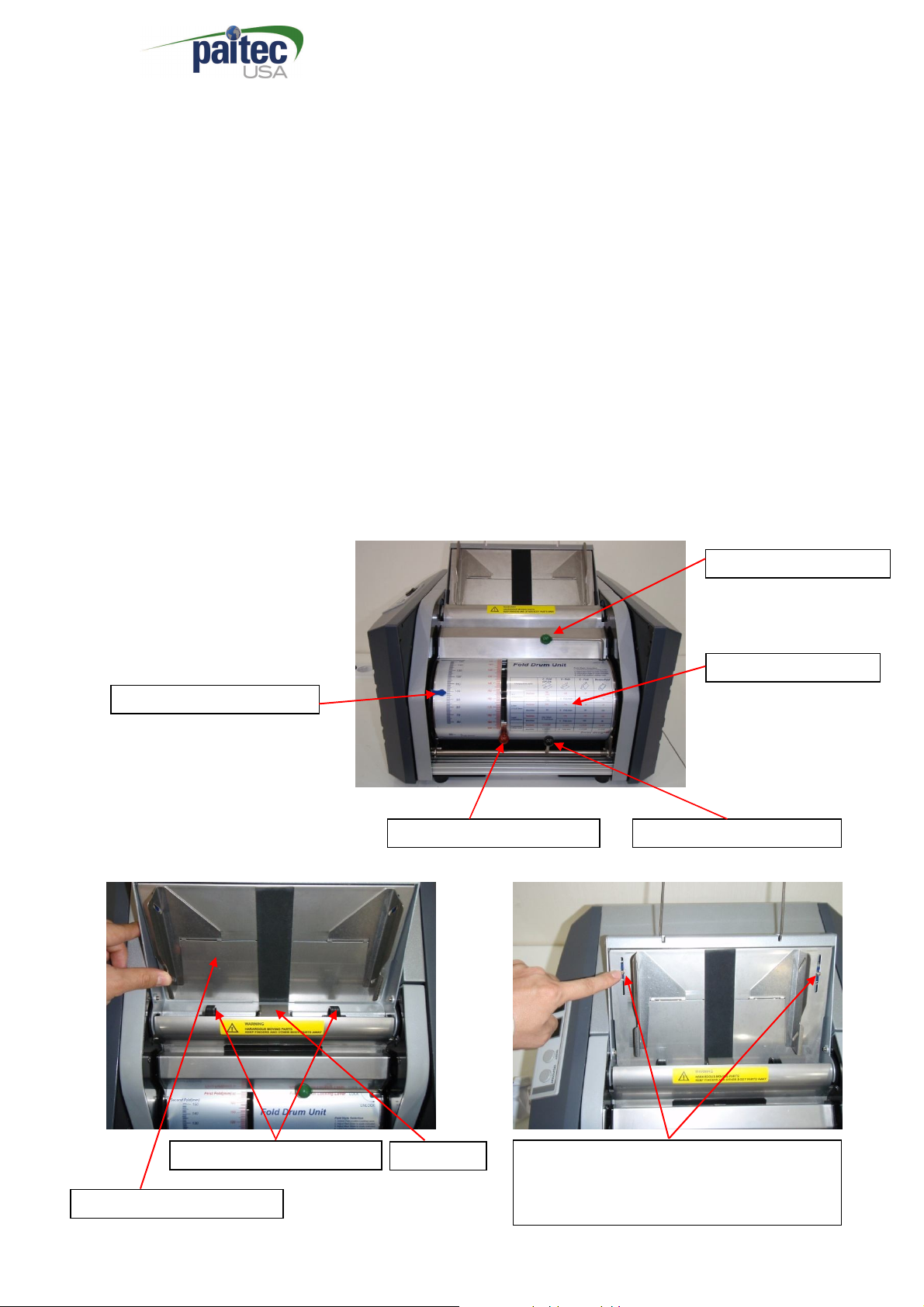

2.1) Folding Drum

Fold Position Lock Lever

Fold Type/Setting Chart

2nd Fold position Setting Lever

1st Fold position Setting Lever

Folding Drum Release Handle

2.2) Feeding Unit

Spring-loaded Feed Table

Movable Paper Guide Rollers

Feed Roller

Slide these Tab up or down to decrease or

increase Feed Table spring lift tension to Aid in

feeding documents. Factory Preset Value is right

in the middle as shown above

5

Page 6

Pressure Sealer ES-5000

2.3) Exit Tray

Stopper for Exit Tray

2.4) Label & Fuse

AC Socket

5 Amp 250V Mini Fuse in a 1/4

Turn Fuse Holder

Manufacturer’s Label with

Serial No.

2.5) How to Open the Fold Unit (Please follow the pictures below in order)

6

Folding Unit Pulls out by grasping the hand hold

and pull out

Page 7

Pressure Sealer ES-5000

2.6) How to open the Fold Drum (Please follow the pictures below in order)

Folding Drum handle

in the Unlock(down)

position

Folding Drum in the

partially open position

Folding Drum in the open position.

Access the Folding Drum for clearing jams

7

Page 8

Pressure Sealer ES-5000

3. How to operate

1) Form preparation

Forms must be fanned properly on both sides to separate and eliminate any static that

may have been induced by the laser printer

2) Loading forms

Place the paper in the Paper tray in the correct orientation as indicated in the chart

below. The Paper tray can hold up to about 120 sheets of pressure forms. To correctly

place your forms in the Paper tray, jog the forms so the stack is neat, push the Paper

tray back so the forms will rest on the solid plate and behind the feed roller. The Paper

tray is spring-loaded to apply the correct amount of pressure for proper feeding.

It is always a good idea to fold one form to verify that the fold settings are OK and have

not been changed. Adjust if necessary and then proceed to load your forms in the Paper

tray.

Form Load in Paper

tray

Z-Fold Address leading,

Face Up

Z-Fold Address Trailing,

Face Down

C-Fold Address Trailing,

Face Down

V-Fold Address Trailing,

Face Down

3) Start (Press Start button to fold & seal)

3.1 ) If the output is acceptable, Run the job

3.2 ) If the folded position is not correct, reset the fold position by readjusting the fold

guide.(Please use plain paper for a test run in order to find out more accurate the

fold position and compare the folded position with the perforation line on the forms)

Forms will deliver

Address side will be face up and document

sequence will be reversed from the

sequence in the Paper tray

Address side will be face down and

document sequence will be reversed from

the sequence in the Paper tray

Address side will be face up and document

sequence will be the same as the

sequence in the Paper tray

Address side will be face down and

document sequence will be the same as

the sequence in the Paper tray

8

Page 9

Pressure Sealer ES-5000

4) Fold Setting

4.1) Standard Folding Drum

4.1.1) Unlock the green release lever to set the fold position

4.1.2) Move the red arrow, First fold on the red knob to the fold position required

according to the manual on the fold drum

4.1.3) Move blue arrow, Second fold according to the manual on the fold drum

4.1.4) Once the fold position properly is done, lock back the green release lever

(Red knob is the first fold setting, Blue know is the second fold setting)

Ex 1) “Z” fold with 8 1/2" x 11"

- Red knob “186”(First fold 186mm), blue knob “93”(Second fold 93mm)

Ex 2) “C” fold with Letter

- Red knob “92”(First fold 92mm), blue knob “94”(Second fold 94mm)

Ex 3) “V” fold with 8 1/2" x 11"

- Red knob “140”(First fold 140mm), blue knob “0”(Fully down, No Second

fold)

Note: Please note that although we suggest that you follow the fold

setting according to the manual, however the scale on the drum is NOT

100% accurate

9

Page 10

Pressure Sealer ES-5000

5) Operator Panel

5.1) Power Switch: Power On/Off

5.2) Reset: Reset button will clear

the display count

5.3) Start/Stop: Start/Stop button

will start or stop the Feed cycle

5.4) Counter: Display will show the

total page count/resettable as

well as Firmware Rev. Level at

Start-up, Fold unit open and

Jam condition, please see the

pictures as below for the details

6) Manual Feed

10

6.1) Fold the form manually and insert the form to the manual feeder

6.2) Press Start button to run the machine

Note: This is ideal for the poorly sealed forms owing to evaporation of the glue

Page 11

Pickup roller in Gray color

Aluminum & Rubber rollers

Pressure Sealer ES-5000

5. Maintenance

1) General Cleaning

Be sure that the room is well ventilated, Switch off the mains power and unplug or

disconnect from the mains, Pull out the fold drum and the fold unit, Remove as much

paper dust as possible using a soft brush

2) Paper Dust

With general use, paper dust will build up inside the machine and can be cleared by

suing an can of invertible Air Duster, which will apply a short burst of compressed

air and clear any paper dust that may be present.

3) Cleaning Pick up and Fold rollers

Clean the pickup roller, aluminum and rubber roller in the Fold unit with roller

cleaning fluid such as an alcohol solution.

11

Caution:

Please do not use any gasolinic oils since it may damage the surface of the rubber

rollers!

Avoid breathing the fumes or getting the solution in an open wound or other sensitive

areas such as the eyes or mouth!

Page 12

Pressure Sealer ES-5000

4) Cleaning Press Rollers

With general use, toner will build up on the Press rollers. Check the rollers for build

up and clean on a regular basis with roller cleaning fluid. Depending on the type of

laser printer, toner and fuser, the degree of build up will vary.

Clean both Upper & Lower Press

12

Page 13

Pressure Sealer ES-5000

6. Trouble Shooting

1) Paper Jam

1.1) Feeding Unit Jam

Do not pull the document backward in the

event of jam in the Infeeder.

Open the Fold Drum Unit by pushing

down the Fold Drum handle as the

direction of the red arrow in the picture

on the right

Pull the paper to the direction of the red

arrow as shown in the picture on the right

1.2) Folding Unit Jam

Open the Fold Drum Unit by pushing

down the Fold Drum handle as shown in

the direction of the red arrow in the

picture on the right

Remove the document from the Folding

Drum as shown in the picture on the right

13

Page 14

Pressure Sealer ES-5000

1.3) Press Unit Jam

Fully extend the Folding Unit to the

direction of the red arrow in the picture on

the right

Use the Jam Removal Tool to rotate the

rollers by placing the tool into the jam

Removal holes as shown in the picture on

the right

Turn it downward. Remove the jam as

shown in the picture on the right

Tips: Correct any mis-folds and run the

form through the manual feed (please refer

to Chapter 4-6 for the details of the

manual feed)

1.4) Out Feed Jam

In the event of jam in the Out-feed, the

display blinks

Push down the lower plate (with the

rollers) and remove the jam as shown in

the picture on the right.

14

Page 15

Pressure Sealer ES-5000

2) Double Feed

2.1) Clean the Pickup rollers and pad with an

alcoholic solution(In case the problem

persists, then go to 2.2)

2.2) Slide In-feed tray tension adjusters

upwards (Manufacturer’s default position:

middle). Both tension adjusters must be in

the same position as shown in the picture

on the right(In case the problem persists,

then go to 2.3)

2.3) Replace in-feed roller and or Separator(Pad Base)

3) Mis-Feed

3.1) Clean In-feed roller and pad with an

alcoholic solution(In case the problem

persists, then go to 3.2)

3.2) Move the In-feed tray tension adjusters

downwards until miss-feeding is resolved

as shown in the picture on the right(in case

of no improvement, then go to 3.3)

3.3) Replace in-feed roller and/or Separator

(Pad Base)

4) Skewed Fold

4.1) Clean the In-feed roller and pad with an alcoholic solution

4.2) Check to make sure the side guides are not bent in any ways

4.3) Insure that there shouldn’t be too much gap between paper and the side guides as

shown in the picture below

4.4) On adjustment screws are set correctly

4.5) Insure that the side guides are right up against the edge of the form but not

compressing the form

4.6) Look for foreign materials in the folding drum assembly

15

Page 16

Pressure Sealer ES-5000

Division of Pai Trading, Inc.

Headquaters & Factory

15951 SW 41st Street. Suite 400

Davie, FL 33331

Email: paitec@paitec.com

www.paitec.com

4.7) Clean the fold rollers with an alcoholic solution

4.8) Examine and replace any folding roller with imperfections such as flat spots or

swelling

4.9) Replace or exchange from side to side the folding roller compression springs

16

Loading...

Loading...