Page 1

Model ES-2000

User Manual

This manual provides detailed information on how to operate and maintain your

ES-2000.

Please read this manual before operating the machine in order to prevent any

damage caused by improper handling

Page 2

Introduction

Thank you for purchasing Paitec USA product.

This manual is prepared to provide you with guidelines on how to properly operate and

maintain the ES-2000 Pressure Sealer.

Copyright

Any of the contents should not be copied, re-printed or translated by other languages

without Paitec USA approval.

-2-

Page 3

ES-2000Specifications.

The ES-2000 offers a real office-friendly Pressure Sealer with

perfect sealing quality and extremely low noise level. It is

capable of processing 2,000 forms per hour.

Specifications:

• Form Size : A4 / Letter / Legal size

• Speed : 2,000 forms / hour

• Input Tray : up to 150* forms

• Form weight : 20#-28#

• Folding Setting : Z, C, V & Double, 14” uneven Z

• Noise Level : less than 45db

• weight : 49 lbs. (Without packaging)

• Dimension : 12.6” X 15.4” X 11”(WxLxH)

• *based on 20# paper weight.

-3-

Page 4

안전 테이프 및 보호 스티로폼 제거하기

안전 테이프 및 보호 스티로폼 제거하기

기기를 작동하기 전에 모든 안전 테이프와 보호 스티로폼을 제거 하십시요.

기기를 작동하기 전에 모든 안전 테이프와 보호 스티로폼을 제거 하십시요.

Unpacking Your Machine

Content

Please check if all of the following parts are included in the box

– Power cable, 1

ST

Fold Cassette, 2ndFold Cassette, Stacker, User

manual

st

Fold Cassette is already inserted onto the machines from the factory.)

( 1

[Box open]

[Remove the safety tape]

* Power connection : Please refer to the label for electric information which is located

at the back side of the machine. If it is not working properly, please contact your

local dealer for service

[2ndcassette, Stacker & Power cable]

[Power & on/off switch]

-4-

Page 5

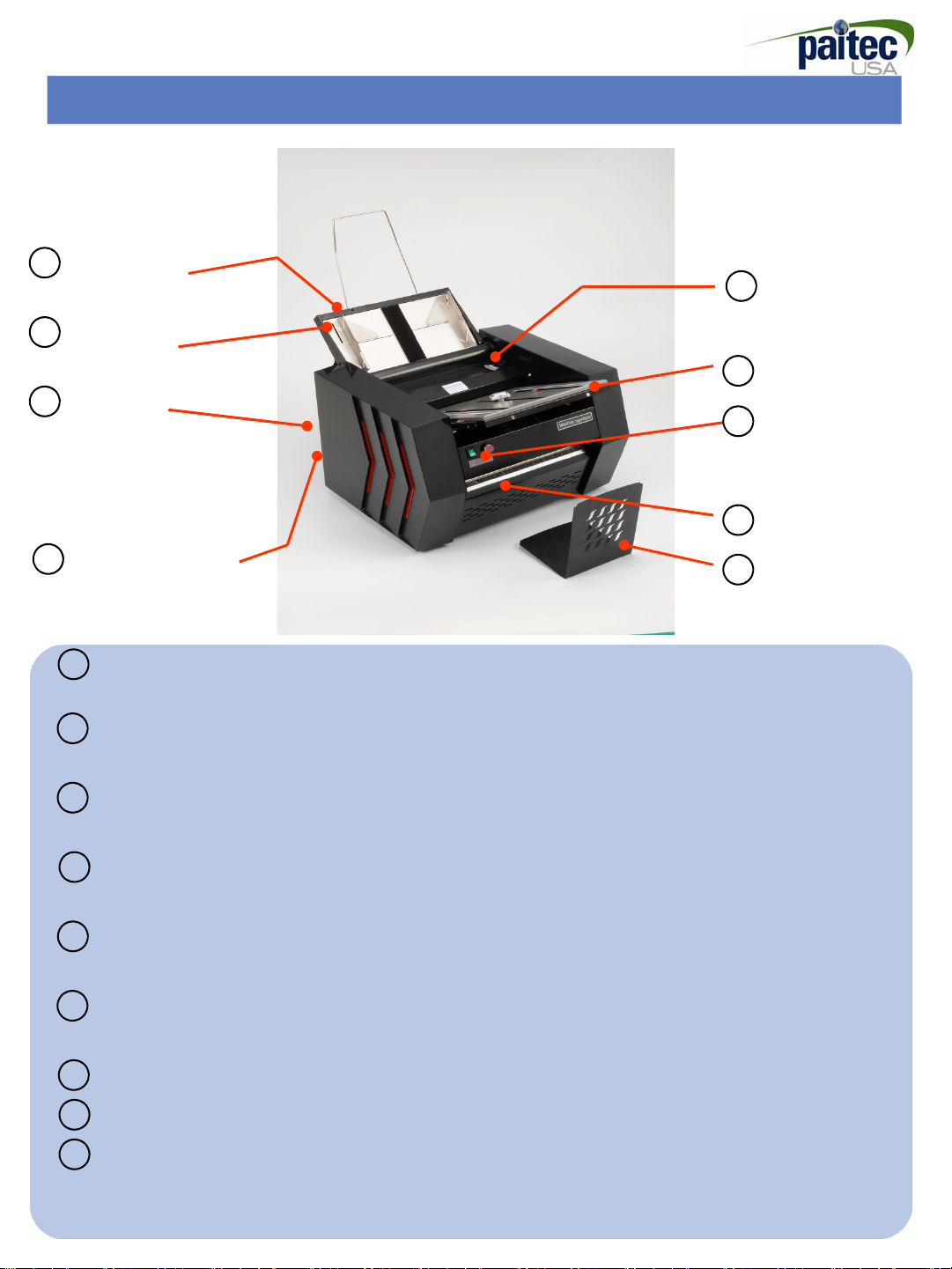

Identifying parts

1

Paper Guide

In-feed Pressure

2

adjustment

3

Power

socket

4

2ndFold

Cassette

Fold Roller Cover

5

st

1

6

Fold

Cassette

7

start/stop

8

Output

9

Stacker

Paper Guide

1

Adjust to fit into your form size (wide)

2

Press Adjustment

Adjust the pressure for the paper (Adjust sliders to suit paper weight).

3

Power socket

Main power socker located on the back of the machine.

nd

4

5

6

7

8

9

Fold Cassette

2

Insert the 2

Roller Cover

Open fold roller cover when jam occurs. (Please turn the Knob in clockwise rotation for unlock).

st

Fold Cassette

1

Insert the 1

Start/Stop

nd

Cassette on the back of the machine.

st

Cassette for first folding forms.

Output : Finished forms exit the front of the machine.

Stacker

-5-

Page 6

안전 테이프 및 보호 스티로폼 제거하기

안전 테이프 및 보호 스티로폼 제거하기

기기를 작동하기 전에 모든 안전 테이프와 보호 스티로폼을 제거 하십시요.

기기를 작동하기 전에 모든 안전 테이프와 보호 스티로폼을 제거 하십시요.

Folding Cassette Guide

A Fold cassette setting guide with ruler is attached on the front of the

hopper. Please select the folding type you require and adjust the 1

nd

cassette location based on this information.

2

st

and

If you want to process V -Fold documents (single fold) please

remove the 2

nd

fold cassette, rotate and replace

-6-

Page 7

안전 테이프 및 보호 스티로폼 제거하기

안전 테이프 및 보호 스티로폼 제거하기

기기를 작동하기 전에 모든 안전 테이프와 보호 스티로폼을 제거 하십시요.

기기를 작동하기 전에 모든 안전 테이프와 보호 스티로폼을 제거 하십시요.

How to install the Fold Cassettes

Please follow the these instructions to adjust the fold 1stand 2ndFold

Cassettes.

1. the 1stcassette is inserted

1stFold Cassette

on the front of the machine.

2. Insert the 2ndcassette on

the back of the machine.

2nd Fold Cassette

Adjusting the Fold Cassette

Turn the Knob to adjust the fold

cassette to the desired paper

size (Refer to fold assist label

on top of the in-feed tray.)

1stCassette

Knob for fold

cassette adjustment

2ndcassette

-7-

Page 8

안전 테이프 및 보호 스티로폼 제거하기

기기를 작동하기 전에 모든 안전 테이프와 보호 스티로폼을 제거 하십시요.

Different Folding cassettes for different paper sizes

The ES-2000 has a 3 different size of 1stfolding plate based on the

folding type required.

Standard

240mm plate 270mm plate

(148mm

plate)

Option Basic Option Option

Fold T ype Z Letter , A4,

LEGAL

V Letter , A4 Letter , A4,

C NA Letter , A4,

Uneven

NA NA Letter, A4,

C

Letter , A4,

LEGAL

LEGAL

LEGAL

Letter , A4,

LEGAL

Letter , A4,

LEGAL

Letter , A4,

LEGAL

LEGAL

Price Included Optional Extra Optional Extra

Remarks

sStandard 148mm S240mm Fold Cassette S270mm Fold Cassette

-8-

Page 9

안전 테이프 및 보호 스티로폼 제거하기

안전 테이프 및 보호 스티로폼 제거하기

기기를 작동하기 전에 모든 안전 테이프와 보호 스티로폼을 제거 하십시요.

기기를 작동하기 전에 모든 안전 테이프와 보호 스티로폼을 제거 하십시요.

Features

• Paper Jam Detection : This

sensor will detect a paper jam

and stop the machine.

• Please note you will have to

remove the jammed form before

restarting the machine.

* Limit sensor for fold roller

cover. The machine will not run

with this cover missing or if this

cover is removed while the

machine is running.

Paper Alignment Paddle.

Please do not remove this item.

Your machine will not function

properly without it

-9-

Page 10

안전 테이프 및 보호 스티로폼 제거하기

안전 테이프 및 보호 스티로폼 제거하기

기기를 작동하기 전에 모든 안전 테이프와 보호 스티로폼을 제거 하십시요.

기기를 작동하기 전에 모든 안전 테이프와 보호 스티로폼을 제거 하십시요.

Loading & Operation

Fan the pressure seal forms to separate and to eliminate any

static that may have been caused by the laser printer.

Place the forms into the paper tray in the correct orientation as

indicated by the chart below. The paper tray will hold up

to 100 sheets of pressure seal paper. To correctly place your

forms in the paper tray, square-off & neaten the stack and,

push the paper tray back so the forms will rest on the solid

plate and behind the feed roller. The paper tray is sprung-loaded

to apply the correct amount of pressure for proper

feeding.

It is always a good idea to fold one form to verify that the

fold-plate settings are correct and have not been changed.

Adjust if necessary and then proceed to load your forms in

the paper tray, press start button to fold and seal your forms.

-10-

Page 11

Loading the Paper Hopper

It is important that you load the paper hopper correctly to minimize the risk of paper jams

occurring.

Fan the pressure seal forms to separate and to eliminate any static that may have been

caused by the laser printer.

Adjusting the hopper paper guides to the correct location

Too much gap!

Good

Please note.

The hopper will take up to 150

printed forms. However please do

not overload the hopper . This will

result in miss-feeding

Paper Guide Tension

Insure that the side guides are

right up against the edge of the

form but not compressing the

form

-11-

Page 12

Jam removal

You can easily remove a paper jam as illustrated below .

If a paper jam has occurred, the machines will automatically stop after a few

seconds. After removing the paper jam, simply press the “red : start” button for the

machine to restart.

[Pull the 1stcassette back]

[[Locate the jam removal tool]

[Remove the fold roller cover]

[Insert the jam removal onto the hole of roller

and pull it down ]

• Caution : Please Remember to remove replace the jam removal tool back into its holder

once the paper jam has been cleared.

-12-

Page 13

안전 테이프 및 보호 스티로폼 제거하기

안전 테이프 및 보호 스티로폼 제거하기

기기를 작동하기 전에 모든 안전 테이프와 보호 스티로폼을 제거 하십시요.

기기를 작동하기 전에 모든 안전 테이프와 보호 스티로폼을 제거 하십시요.

Operator Maintenance

Since pressure seal forms leave paper dust as well as ink and

toner residues, it is very important to occasionally clean the

surface of the each roller to ensure optimum performance.

1. Paper Dust

Use small air cleaner or dust remover

2. Pick-up and Fold rollers

Clean the feed roller as well as the aluminum and rubber

rollers inside the folding unit with roller cleaning fluid. Do not

use oil as this will damage the surface of the rubber.

3. Sealing Rollers

With general use, toner will build up on the pressure rollers.

Check the rollers for build up of toner and clean on a regular

basis using a suitable roller cleaning fluid. The degree of build

up will vary according to the type of printer, toner & fuser used.

Caution : Do not use any other substance to clean the

surface of the fold rollers as it may damage the rubber.

Please contact your service tech for further details on

suitable cleaning solutions to be used.

-13-

Page 14

Division of Pai Trading, Inc.

This page intentionally left blank

Headquarter & Factory

st

15951 SW 41

Street #400

Davie, FL 33331

www.paitec.com

paitec@paitec.com

Loading...

Loading...