Page 1

Air Feed Collator Model 100

Set Stacker Model 101

High Capacity Stacker Model 101

Operator Manual

November 2001

Part No. 14447

Page 2

Page 3

1. Introduction

Table of contents

1.1 Operational Safety

2. Getting to know the Model 100, 101, 101 HCS

2.1 Main Components, Model 100

2.2 Main Components, Model 101

2.3 Main Components, Model 101 HCS

3. Operator instructions

3.1 Adjusting the LCD display contrast

3.2 One, two or three collators

3.3 Setting up and loading Model 100

3.4 Docking the Lift

3.5 Using the fan

3.6 Running a job

4. The Menus

4.1 Programs

4.1.1 Alternate bin 1+2

4.1.2 Alternate bin mode

4.1.3 Block mode

4.1.4 Insertion sheet mode

4.1.5 Bin select mode

4.2 Statistics

4.3 Stored jobs

4.4 Preset counter

4.5 Reset

4.6 Added features

4.7 Select calibration mode

4.8 Error screens

1-1

2-1

2-4

2-5

3-1

3-1

3-2

3-4

3-4

3-5

4-1

4-1

4-2

4-2

4-3

4-3

4-4

4-4

4-5

4-6

4-6

4-7

4-8

5. Troubleshooting

5.1 Trouble shooting

6. Specifications

6.1 Specifications

Air Feed Collator Model 100, Stacker Model 101, Model 101 HCS Operator Manual

T10127 November 2001

5-1

6-1

i

Page 4

1. Introduction

1.1 Operational safety

Attention to the following notes ensures the continued safe operation of your

equipment.

Always connect the equipment to a

properly grounded power source receptacle. In doubt, have the receptacle

checked by a qualified electrician.

WARNING: Improper connection of the

equipment grounding conductor can

result in electrical shock.

Always follow all warnings marked on,

or supplied with, the equipment.

Always locate the equipment on a

solid support surface with adequate

strength for the weight of the machine.

Always exercise care in moving or

relocating the equipment.

Always keep magnets and all devices

with strong magnetic field away from

the machine.

Never use a ground adapter plug to

connect the equipment to a power

source receptacle that lacks a ground

connection terminal.

Never attempt any maintenance function that is not specifically described in

this documentation.

Never remove the covers or guards

that are fastened with screws.

Never install the unit near a radiator or

any other heat source.

Never override or “cheat” electrical or

mechanical interlock devices.

Never operate the equipment if you

notice unusual noises or odours. Disconnect the power cord from the power

source receptacle and call your customer service engineer to correct the

problem.

Air Feed Collator Model 100, Stacker Model 101, Model 101 HCS Operator Manual

T10127 November 2001

1-1

Page 5

2. Getting to know the Model 100, 101

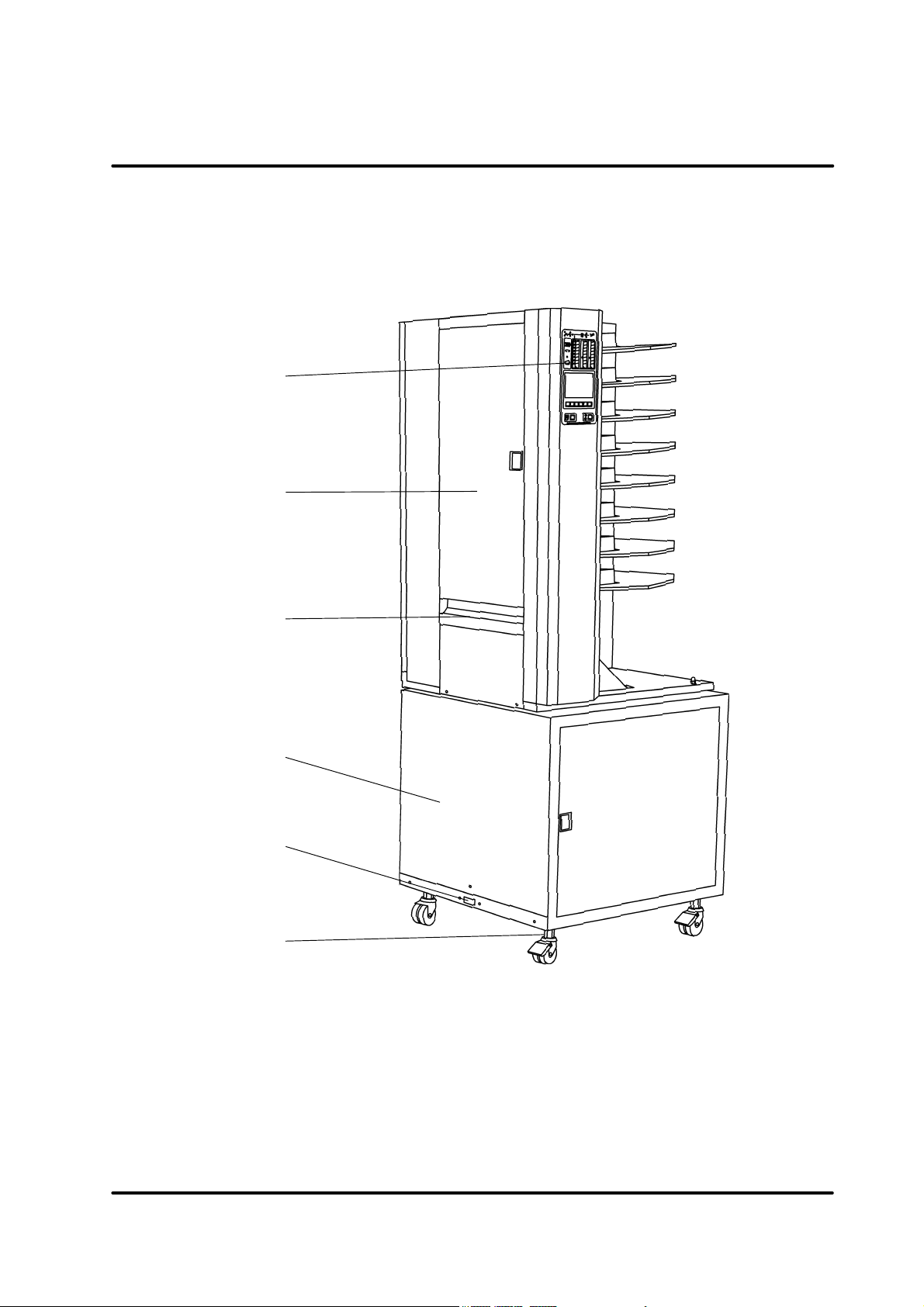

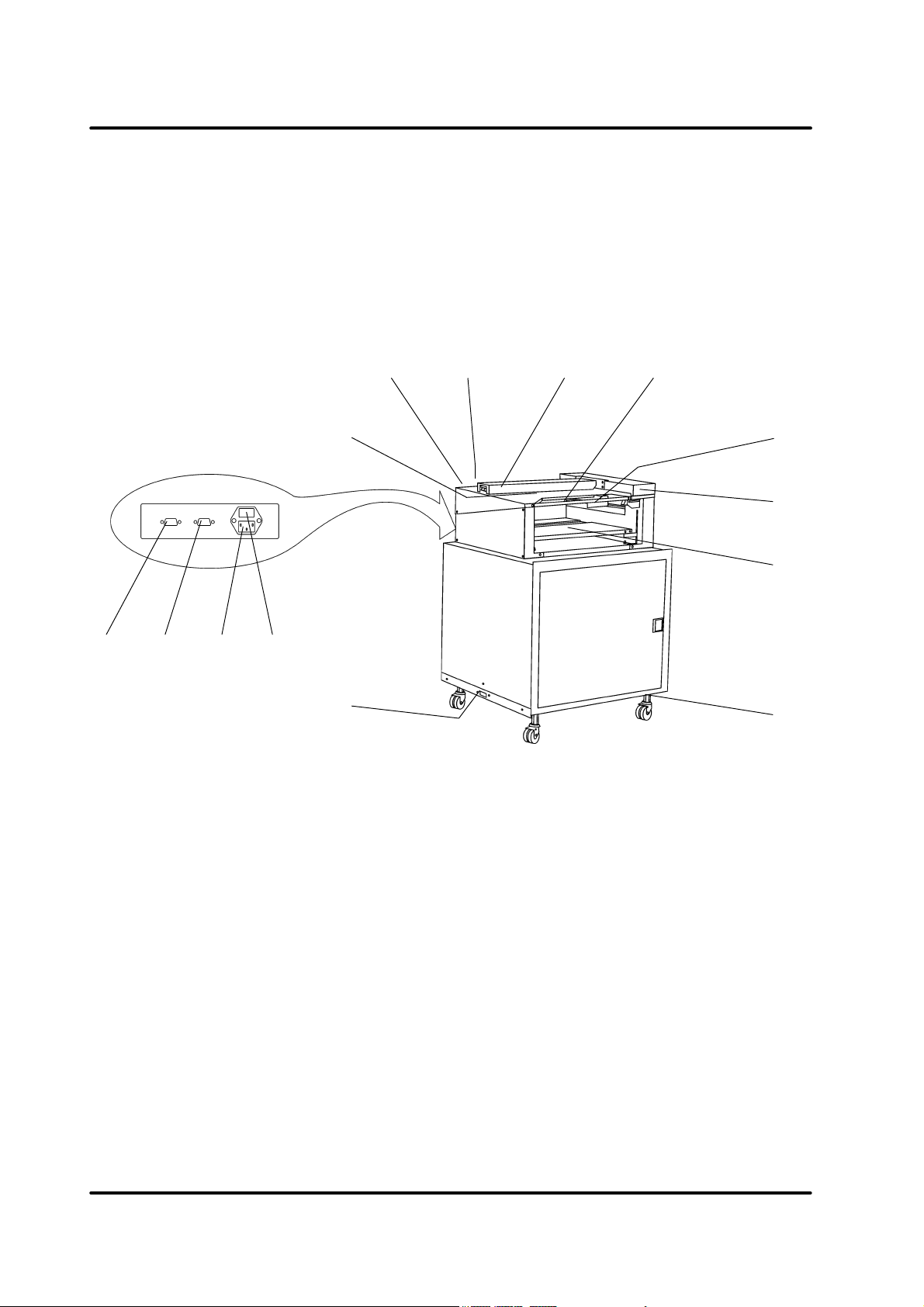

2.1 Main components, Model 100

1

2

3

4

5

6

1 Control panel (not present on second or third collator)

2 Conveyor door

3 Outfeed area

4 Base (optional)

5 Docking latch

6 Height adjustment

Air Feed Collator Model 100, Stacker Model 101, Model 101 HCS Operator Manual

T10127 November 2001

2-1

Page 6

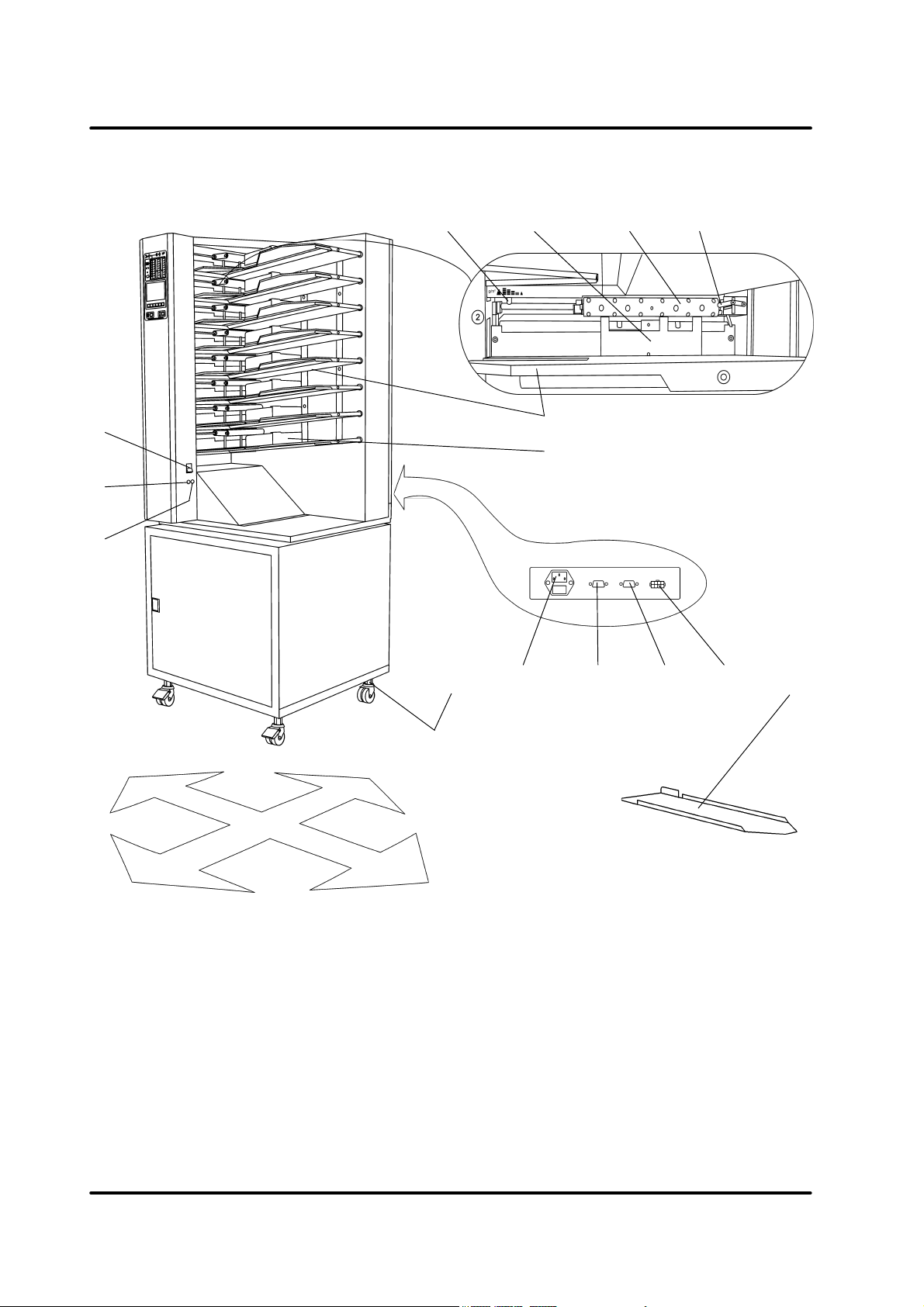

2.1 Main components, Model 100, cont.

465 7

1

2

3

left side

rear side

11

8

9

12 13

14 1510

front side

1 Main power switch

2 Fuse

3 Fuse

4 Stop fingers adjustment lever

5 Stop finger assembly

6 Suction belt

7 Bin height switch lever

8 Bin

9 Paper positioning stop

10 Height adjustment

11 Power cord receptacle

right side

12 Secondary unit connector

(i.e. secondary unit collator)

NOTE: If no secondary unit is used, jumper plug

part No. 140226 (female) has to be connected.

13 Third party device connector

(i.e. stacker, stapler/folder)

14 Power receptacle for conveyor bridge

(only on B and C collators in double or

tripple collator systems)

15 A5 (5.5”) plate

Air Feed Collator Model 100, Stacker Model 101, Model 101 HCS Operator Manual

T10127 November 2001

2-2

Page 7

2.1 Main components, Model 100, cont.

4

3

2

1

5

6

7

8

9

1 Set up guide button

2 Third party device error message

indicator

3 Double feed / paper jam symbol

(shown by bin indicator - firm light)

4 Bin indicator

5 Misfeed / empty bin symbol

(shown by bin indicator - flashing)

Air Feed Collator Model 100, Stacker Model 101, Model 101 HCS Operator Manual

T10127 November 2001

6 Second / third collator error

message indicator

7 LCD display

8 Multi function buttons

9 Start / stop button

2-3

Page 8

2.2 Main components, Model 101

132 4

7

6

9810

11

12

13

5

14

1 Collator connector

2 Third party device connector

(i.e. stapler/folder)

NOTE: If no third party device unit is used,

jumper plug part No. 140227 (male)

has to be connected.

3 Power cord receptacle

4 Fuse

5 Docking latch

6 Bypass paper path

7 Bar

8 Main power switch

9 Idler roller bar

10 Opening handle

11 Paper guide (man. adjust.)

12 Top cover

13 Document table

14 Height adjustment

Air Feed Collator Model 100, Stacker Model 101, Model 101 HCS Operator Manual

T10127 November 2001

2-4

Page 9

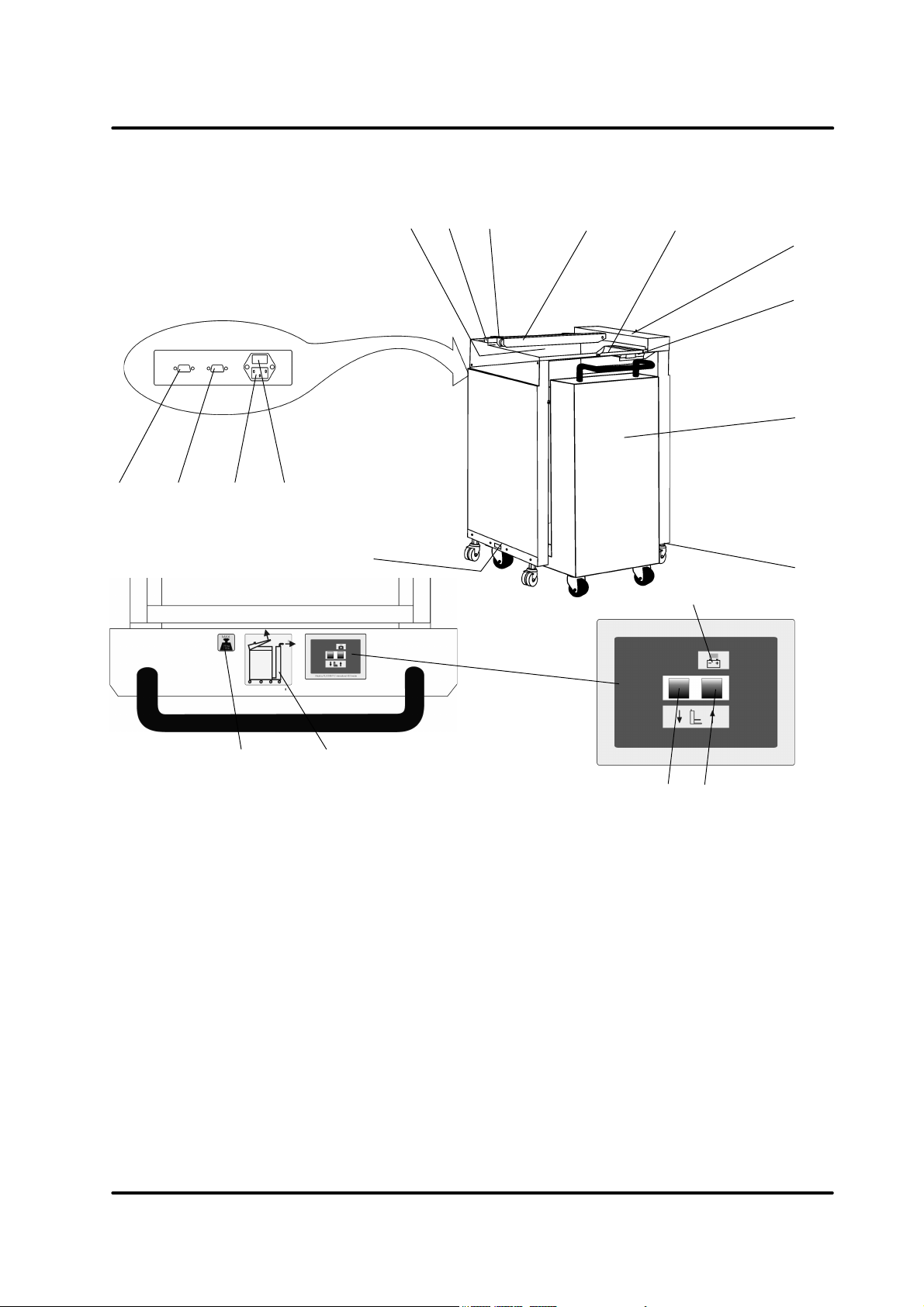

2.3 Main components, High Capacity Stacker Model 101

7

6

132 4

8

9

10

11

12

13

5

15

16

1 Collator connector

2 Third party device connector

(i.e. stapler/folder)

NOTE: If no third party device unit is used,

jumper plug part No. 140227 (male)

has to be connected.

3 Power cord receptacle

4 Fuse

5 Docking latch

6 Bypass paper path

7 Bar

8 Main power switch

17

19

18

9 Idler roller bar

10 Opening handle

11 Top cover

12 Paper guide (man. adjust.)

13 Lift, document table including

14 Height adjustment

15 Maximum load sign

16 Docking instruction sign

17 Lowering Lift button

18 Elevating Lift button

19 Battery indicator

14

Air Feed Collator Model 100, Stacker Model 101, Model 101 HCS Operator Manual

T10127 November 2001

2-5

Page 10

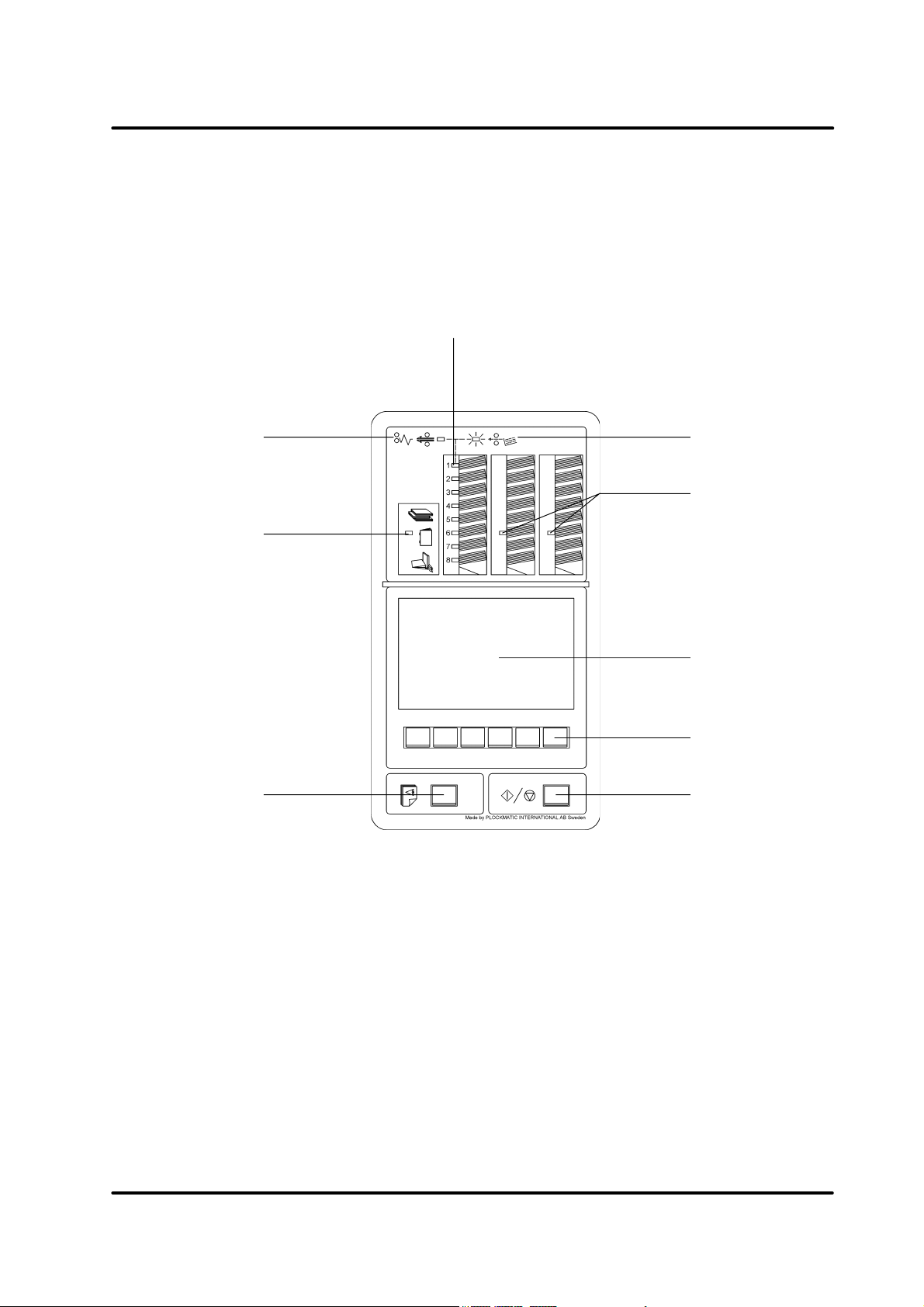

3. Operator instructions

Most settings and adjustments are operated from the control panel using the multi function

buttons. The actual function of the buttons in each menu will be indicated by an icon above the

corresponding button.

Note: The settings for the last job will be erased when switching off the power or changing to a

different job. Store the job in order to easily recover your settings.

3.1 Adjusting the LCD display contrast

Switch on the power with the main power switch. The Main

Menu will appear in the LCD display. Increase/decrease the

contrast of the LCD display by pressing the contrast adjustment buttons.

contrast adjustment

buttons

3.2 One, two or three collators

Several menus, for example the BLOCK MODE menu,

shows that there is a possibility to use two or three collators.

Until additional collators are installed in the system, these

options will be displayed in grey to show that they are not

accessible.

The collator closest to the stacker or bookletmaker is called

the A tower. All programming, for the two or three collator

system, is done from this A tower that is the only collator in

the system with a display.

Air Feed Collator Model 100, Stacker Model 101, Model 101 HCS Operator Manual

T10127 November 2001

3-1

Page 11

3.3 Setting up and loading Model 100

Before loading the bins make sure that the sheets are well

fanned, aligned and that the ink has dried out. Load the

sheets into the bins so that all the sheets are in contact with

the stop finger assembly (left side) and the main frame (rear

side). Place the paper positioning stops as shown in the

figure.

bi n sheets paper positioning

stop

A5 plate

Stop finger adjustment lever

The suction area should be limited when running A5 (5.5” x 8.5”)

by inserting the A5 plate inbetween the suction belt and the

suction belt assembly on the bottom side.

132

Air Feed Collator Model 100, Stacker Model 101, Model 101 HCS Operator Manual

T10127 November 2001

3-2

Page 12

3.3 Setting up and loading Model 100, cont.

Recommendations in table below are only guide lines to get started. The adjustments can vary a

lot depending on paper quality, print quality, air humidity etc.

senilediuGpu-teS

ezisrepaPytilauQthgiewrepaPolfriAw noitisopregnifpotShctiwsthgiehniB

5ArepapypoCmsg08%561 lamroN

4ArepapypoCmsg08%061 lamroN

epacsdnaL4ArepapypoCmsg08%561 lamroN

3AkcotskcihTmsg042%0014 reppU

3ARSrepapypoCmsg08%061 lamroN

-dnaL"11x"5.8

dnoBbl02%551 lamroN

tiartrop/epacs

"41x"5.8repapypoCmsg08%061 lamroN

"71x"11repapypoCmsg06%551 lamroN

"71x"11kcotsdetaoCmsg001%0012/11lamroN

If miss or double feeding occurs when a job is set up according to table, adjust according to

below:

Air flow

• Increase if miss feeding

• Decrease if double feeding

Stop finger position

• Increase gap by moving the lever to the left if misfeeding

• Decrease gap by moving the lever to the right if

doublefeeding

stop fingers in position 3

For mixed jobs

papers are loaded

* - move lever to the left in bins where thicker

Bin height switch

• Move lever upwards if misfeeding

• Move lever downwards if doublefeeding

For mixed jobs

papers are loaded

bin height switch in normal position

Air Feed Collator Model 100, Stacker Model 101, Model 101 HCS Operator Manual

T10127 November 2001

*The difference in paper weight between cover sheets and

bodysheets should not exceed 100 gsm.

* - move lever upwards in bins where heavier

3-3

Page 13

3.4 Docking the Lift

When pushing the lift into the Model 101 HCS, it is not

necessary to open the top cover. The lift will automatically lock to the Model 101 HCS while pushed in.

However, make sure that the lift is not in the uppermost position to avoid damaging the paper guide in

the cover. Also be careful while pushing in the lift in to

avoid damaging the electrical connector located on

the right leg of the lift.

To pull out the lift,first lift the top cover on the Model

101 HCS.

Note: When not using the

Model 101 HCS for longer

time, leave the Lift docked

to the Model 101 HCS. Do

not disconnect the power

cord, otherwise the compensation charge does not

work.

3.5 Using the fan

Normally the fan should be switched off.

Switch on the fan to facilitate stacking of static

sheets.

Lift the top cover to access the switch located on the

right side (1) of the Model 101 HCS.

The fan only operates when the system is running.

1

Air Feed Collator Model 100, Stacker Model 101, Model 101 HCS Operator Manual 3-4

T10127 November 2001

Page 14

3.6 Running a job

To ensure that any earlier program settings does not interfere

with your job, reset according to section 4.5.

Note: Do not reset if you have started programming according to

section 4.1 or loaded a stored job according to section 4.3.

To start a job - just press the yellow set up guide button from

the main menu.

Select calibrate mode by using the arrow buttons and press

the ”OK” button. For details, see section 4.7.

Note: The calibration set does not affect the insertion sheet

counter, preset counter or set counter.

Select standard format by using the left/right arrow buttons.

To use custom format or to change direction between landscape/portrait, select item with the up/down arrow buttons

and adjust with the left/right arrow buttons.

Press the ”OK” button.

If calibrate mode “STRAIGHT STACKING” or “OFFSET

STACKING” is selected calibration will start.

If calibrate mode ”STRAIGHT STACKING” or ”OFFSET STACKING” was selected

The calibrated set will stop on the bypass paper path of the

Model 101/101 HCS.

Viewed from above, slide the paper guide so that there will

bee a slight gap between the innermost edge of the paper

guide and the outermost edge of the set.

Remove the set and check that it is OK .

Note 1 : If the calibrated set does not have the correct number

of sheets, restart the calibration by pressing the yellow

setup guide button.

Note 2: When the job is started and the sets are fed into the

stacker, the gap should be minimized, but not to

narrow to avoid paper jam.

paper guide

If calibrate mode ”BOOKLET MAKING” was selected

A message on the display will appear asking:

”IS BOOKLETMAKER SETUP PERFORMED?”. Check that

the booklet maker is adjusted to correct paper size. If necessary, check booklet maker operator manual for details. Press

the ”OK” button to start calibration.

Air Feed Collator Model 100, Stacker Model 101, Model 101 HCS Operator Manual

T10127 November 2001

3-5

Page 15

3.6 Running a job, cont.

If calibrate mode ”BOOKLET MAKING” was selected, cont.

The calibrated set will stop in the bookletmaker before it has been stapled and folded. You have

two ways to check the calibrated set.

A Press the purge button on the display of the Model 100. The set will be stapled,

folded and ejected from the booklet maker. Check the calibrated set.

B Open the top cover of the booklet maker to check/remove the calibrated set.

Note: If the calibrated set does not have the correct number of sheets, restart the calibration

by pressing the yellow setup guide button.

Regardless of which calibrate mode was selected

If running a slightly absorbing paper, such as a thick paper, a

message “CHECK SET. IS SET OK?” can appear on the

display. Check the calibrated set according to above. If the

set is OK, press the “YES” button and a second calibration

will be performed. Check the second calibrated set according

to above. If the set is not OK, press the “NO” button and the

calibration will be repeated.

Note: The message “DSD Off”can be displayed if an extremely

light absorbing and/or thick paper is used. This means that the

optical double sheet detection now is limited. However, the

lengthwise double sheet detection is still fully functional.

After a successfully performed calibration the message

”CALIBRATION DONE” will be shown. Press the ”ST” button

if you want to store the calibrated job now. You can also store

the job later after the job is finished or during* the job, until

the “ESC” button is pressed.

To run the job, press the green start/stop button.

*To store the running job, first press the green button to stop

the job.

Frequently used settings can be stored as “jobs”. Up to 100

different jobs can be stored. This menu shows you jobs that

are already programmed and positions that still are free. Use

the arrow buttons to select “EMPTY” to store or “PROGRAMMED” to overwrite an old job. Press the “OK” button to

confirm. If you want to see information about a certain job,

press the “info” button. Press the “info” button again to return

to the previous menu. To delete a stored job, press the “C”

button.

Air Feed Collator Model 100, Stacker Model 101, Model 101 HCS Operator Manual

T10127 November 2001

3-6

Page 16

4. The menus

4.1 Programs

To access the different programming possibilities select

“PROGRAMS” menu from the MAIN MENU and press the

“OK” button.

From the PROGRAMS

menu you can select

which actions you want

to use. Select and

press the “OK” button

to enter the corresponding submenu.

4.1.1 Alternate bin 1+2

Note: After selecting/changing any action the yellow or the

green button can be pressed to calibrate or to start the

job.

Enter the ALTERNATE BIN MODE 1+2 menu.

This program doubles the loading capacity of covers by

allowing you to load the cover sheets in both bin 1 and bin 2.

Use this program when the covers have a higher paper

weight than the body sheets. Select alternate bin mode 1+2

with the arrow buttons. Press the “OK” button to confirm.

Follow the procedure in “3.6 Running a job” to calibrate and

start the job.

Air Feed Collator Model 100, Stacker Model 101, Model 101 HCS Operator Manual

T10127 November 2001

4-1

Page 17

4.1.2 Alternate bin mode

Enter the ALTERNATE BIN MODE menu.

This program allows you to reload the collator while running

by loading the same sheet in two bins. As soon as any bin is

empty the collator automatically switches to the alternate

bins. With one collator it is possible to load up to 4 sheets per

set (with two collators - 8 sheets and with three collators up

to 12 sheets). Mark the total No. of bins to be used with the

arrow buttons. The marked bins will be shown inverted.

Press the “OK” button to confirm. Follow the procedure in

“3.6 Running a job” to calibrate and start the job.

Note 1: Load sheet one in bin 1 and bin 2, sheet two in bin 3

Note 2: After reloading, press the up arrow button to activate

and bin 4 and so on.

the reloaded bin/s to achieve continuous running.

4.1.3 Block mode

Enter the BLOCK MODE menu.

This program allows you to reload the collator while running

by loading the set twice in two separate blocks. When any of

the bins in one block become empty, the collator automatically switches to the other block. With one collator it is possible load up to 4 sheets per set (with two collators - 8 sheets

and with three collators up to 12 sheets).

Mark the number of bins to be used (i.e. the No. of sheets in

the set) in the first block with the arrow buttons. The marked

bins will be shown inverted. Press the “OK” button to confirm.

When the “OK” button is pressed the collator will suggest the

next bins to be used by showing them inverted. You may

select other bins than the suggested by moving the block

with the arrow buttons. Press the “OK” button to confirm.

Follow the procedure in “3.6 Running a job” to calibrate and

start the job.

Note 1: The example is shows how to run a set of two sheets.

Load sheet one in bin 1 (first block) and bin 3 (second

block). Sheet two should consequently be loaded in

bin 2 and bin 4.

Note 2: After reloading, press the up arrow button to activate

the reloaded bin/s and achieve continuous running.

Air Feed Collator Model 100, Stacker Model 101, Model 101 HCS Operator Manual

T10127 November 2001

4-2

Page 18

4.1.4 Insertion sheet mode

Enter the INSERTION SHEET MODE menu.

This program allows you to separate a stack of sets by using

an insertion sheet. Select the digit you want to change with

the left/right arrow buttons. The selected digit will be shown

inverted. With the up/down arrow buttons you can enter a

number between 0 - 9. Press the “OK” button to confirm.

Follow the procedure in “3.6 Running a job” to calibrate and

start the job. The calibration set does not affect the insertion

sheet mode counter. Insertion sheet mode can be combined

with any other program.

Note 1: The insertion sheets must be loaded in the next bin

Note 2: If “BLOCK MODE” is selected two bins with insertion

below the loaded set.

sheets must be used. Load the insertion sheets in the

next following bins of each block.

4.1.5 Bin select mode

cross button tick button

Enter the BIN SELECT MODE menu.

This program allows you to use empty bins for new jobs

without removing already loaded sheets. Use the arrow

buttons and press the “tick” button to activate the bins you

want to use for the new job. Selected bins will be shown

inverted. To deselect a bin, use the arrow buttons and press

the “cross” button. Load the sheets into the empty bins.

Press the “OK” button to confirm. Follow the procedure in

“3.6 Running a job” to calibrate and start the job.

Air Feed Collator Model 100, Stacker Model 101, Model 101 HCS Operator Manual

T10127 November 2001

4-3

Page 19

4.2 Statistics

Enter the STATISTICS menu.

This menu shows

statistics of the last

job.

Press the “ESC”

button to return to the

MAIN MENU. Each

calibration resets the

statistics.

4.3 Stored jobs

Enter the STORED JOBS menu.

Frequently used settings can be stored as “jobs”. Up to 100

different job can be

stored. This menu

shows you which

jobs that are already

programmed and

which positions that

still are free. Select

job with the arrow

buttons. Press the

“OK” button to load a

job. Follow the

procedure in “3.6

Running a job” to

calibrate and start the job.Press the “C” button to delete a

stored job.

Air Feed Collator Model 100, Stacker Model 101, Model 101 HCS Operator Manual

T10127 November 2001

4-4

Page 20

4.3 Stored jobs, continues

If you want to see information about a certain job, press the

“info” button from the STORED JOBS menu.

Press the “info”

button again to return

to the STORED

JOBS MENU or the

“C” button to erase

the job.

4.4 Preset counter

info button

To erase the job, confirm by pressing the ”OK” button.

Enter the PRESET COUNTER menu.

This program allows

you to stop the collator

after a certain number

of sets. Select the

digit you want to

change with the left/

right arrow buttons.

The digit subject to

change will be shown

inverted. With the up/

down arrow buttons

you can enter a

number between 0 - 9.

The calibration set does not affect the preset counter.

Press the “OK” button to confirm.

Air Feed Collator Model 100, Stacker Model 101, Model 101 HCS Operator Manual

T10127 November 2001

4-5

Page 21

4.5 Reset

4.6 Added features

Enter the “RESET” menu.

From this menu you

can choose to reset

”PROGRAMS”, ”PRESET COUNTER”, ”SET

COUNTER” or all three.

Press the ”ESC” button

to return to the MAIN

MENU or select item to

reset and press the

”OK” button.

To reset according to

selection, confirm by

pressing the ”OK” button.

Note 1: Do not reset if you have started programming accord-

ing to section 4.1 or loaded a stored job according to

section 4.3.

Note 2: Resetting “PROGRAMS” will erase the currently loaded

job or programmed settings.

Note 3: Resetting “PROGRAMS or resetting “ALL” does not

affect stored jobs.

Enter the ADDED FEATURES menu.

From this menu you can

adjust the speed, the air

flow, the overlap, change

the user interface language

and select double sheet

detection ON or OFF.

Select the item you want to

adjust with the up/down

arrow buttons. Change

setting with the left/right

arrow buttons. Collating

speed can be adjusted

from 1000 sph (sets per hour) to 3800 sph. Check the specification for the connected machines before changing the

speed. Air flow can be adjusted from 30% to 100%. If “AIR

FLOW A” is selected, also tower B and C will be adjusted.

Select “AIR FLOW B” and/ or “AIR FLOW C” to set the B and

C collators air flow individually.

NOTE: Also see section 3.6 and 5.1 for recommendations and

trouble shooting .

Air Feed Collator Model 100, Stacker Model 101, Model 101 HCS Operator Manual

T10127 November 2001

4-6

Page 22

4.6 Added features, continues

Overlap can be adjusted from -2 to 50, where 50 gives the

largest length in the set. Default value is 0. If problems are

experienced when jogging the sets in the booklet maker or

external unit, the overlap value can be changed.

For static sheets run into stacker, decrease value to -2 to get

a better stacking result.

For static sheets run into booklet maker, increase value if

sheets are not properly jogged.

small overlap value

large overlap value

If the opacity of the sheets varies so much that the Model 100

indicates false doubles, the detection can be switched OFF. If

switched OFF all bin are effected. The length double

detection are still functioning though.

NOTE: If a thin line is located exactly at the position of the

4.7 Select calibration mode

This menu appears when the yellow Setup Guide button is

pressed

sensor (17mm from inner edge) the Model 100 can also

indicate false double. In that case the sheets in the bin

can be turned 180 degrees, rather than switing the

double detection OFF.

Select “BOOKLETMAKING” to deliver the set to the booklet

maker.

Select “STRAIGHT STACKING” or “OFFSET STACKING” to

deliver the set to the stacker.

“EXTERNAL UNIT” should be selected to deliver the set to

any other, to the system not connected unit.

Air Feed Collator Model 100, Stacker Model 101, Model 101 HCS Operator Manual

T10127 November 2001

4-7

Page 23

4.8 Error screens

This example error screen shows that at collator No. 1 (the A

tower), a number of errors has occurred.

Double feed from bin 1, misfeed from bin 3 and jam in bin 5.

See section 5.1 for how to correct these problems before the

the system is restarted.

You can also see that bin 8 is empty and need to be reloaded.

This error screen tells you that the stacker is full. Open the

top cover, empty the stacker before the system is restarted.

This error screen tells you that there is a jam in the stacker.

Open the top cover and clear the stacker from jammed

sheets.

• Check that the stacker is properly set up according to

section 3.6 and restart the system.

• If the problem persists, the machines may have been

misaligned (moved) after installation and therefore causes

the set to jam. Call service to have the system aligned

according to the installation instruction.

This error screen tells you that there is jam at the booklet

maker or trimmer. Check the control panels at the booklet

maker and trimmer to see what caused the problem. If necessary, consult the booklet maker and/or trimmer operator

manual for how to correct the problem.

Air Feed Collator Model 100, Stacker Model 101, Model 101 HCS Operator Manual 4-8

T10127 November 2001

Page 24

4.8 Error screens cont.

This error message will be displayed if the Model 100 or

Model 101 has a malfunction.

Note which machine has the malfunction (i.e. PL100) and the

malfunction code (i.e. 030).

• Malfuntion code 009-014 can be generated by a temporar-

ily low voltage supply. Switch off the machines and try

switching them on later on or try using another wall outlet.

• Malfunction code 040-047 can be generated by strong

incoming light. Block or redirect light sources such as sun

light, spot lights etc.

If above does not correct the problem - call service and

report which machine and malfunction code that was

displayed.

This error screen tells you that the Lift is not docked into

Model 101 HCS. Check that the Lift is correctly docked to the

Model 101 HCS.

Air Feed Collator Model 100, Stacker Model 101, Model 101 HCS Operator Manual

T10127 November 2001

4-9

Page 25

5. Trouble shooting

5.1 Trouble shooting

melborPesuacelbissoPnoitcA

rognideefsiM

.maj

.dedaol

.wol

.wolfriawolooTehtniriafotnuomaehtesaercnI SERUTAEFDEDDA

.unem

sregnifpotS

ootdetsujda

ehtotesolc

.tlebnoitcus

.setalp5A5Agninnurnehwdesuebtsumsetalp5AehT

repaphcumooT

kcotsrepaP

.dedaolylroop

.srepapdelkcuBtnereffidneewtebkcotsrepapehtgnivomdoivA

ootthgiehniB

.tfelehtotrevel

.decuder

.ecivresdeenyam

tnemtsujdasregnifpotSehtgnivomybpagehtesaercnI

nehwdevomerebtsumdnatamrofrepap)"5.8x"5.5(

.repap)rediw(regralgninnur

thgiewyvaehyllaicepse,seitilauqrepapemosroF

ebotdeenyamdedaolrepapfotnuomaehtrepap

erasteehsllatahtosdengilallewkcotsrepapehtdaoL

ehtdna)tfel(ylbmessasregnifpotsehthtiwtcatnocni

.ecalpnisipotsrepapehterusekaM.)raer(emarfniam

ledoMehT.gnitnirpehtretfadnaerofebhtobsetamilc

retnirpehtsamooremasehtnidetacolebdluohs001

retnirpeht,seunitnocmelborpfI.melborpsihtdoivaot

.sdrawpurevelhctiwsthgiehnibehtevoM

gnideefelbuoD.wolfriahgihooTehtniriafotnuomaehtesaerceD SERUTAEFDEDDA

.unem

sregnifpotS

rafootdetsujda

ehtmorftrapa

.tlebnoitcus

repaptnereffiD

dedaolseitilauq

.nibemasehtni

kcotsrepaP

dedaolylroop

ootthgiehniB

.hgih

dekcodnutfiL

detacidni

.dekcod

yltcerroctontfiL

.thgirehtotrevel

.teehsotteehsmorfdengilalleweboslatsum

.sdrawnwodrevelhctiwsthgiehnibehtevoM

noitcennocoN

tfiLneewteb

.gnikcodnehw

tnemtsujdasregnifpotsehtgnivomybpagehtesaerceD

emasehtfoeranibehtnisrepapehttahterusekaM

tnirpehT.tnirpemasehtsahdnathgiewrepap,ezis

erasteehsllatahtosdengilallewkcotsrepapehtdaoL

ehtdna)tfel(ylbmessasregnifpotsehthtiwtcatnocni

.ecalpnisipotsrepapehterusekaM.)raer(emarfniam

kcehC.dekcodyltcerrocsitfiLehttahterusekaM

.tfiLehtfogelthgirehtnorotcennocehttaegamad

gnithgilsipmalrotacidniyrettabehttahtkcehC

SCHdna

tcerrocnI

ehtrognikcats

tonodsteehs

laicepsgnisU

rokciht,repap

.edisdnah

thgirehtnonafehtnonrutdnarevocehtnepO

.repapniht

repapehthcaer

.pots

Air Feed Collator Model 100, Stacker Model 101, Model 101 HCS Operator Manual

T10127 November 2001

5-1

Page 26

6. Specifications

6.1 Specifications

SNOITACIFICEPS001LEDOM

snibforebmuN 8

yticapacniB "1mm04

ezisteehSniM

xaM

thgiewrepaPniM

xaM

deepS otpuelbatsujdA

rotceteddeefelbuoD seY

rotceteddeefssiM seY

rotcetednibytpmE seY

rotcetedmajrepaP seY

retnuocteS stigid5

retnuocteserP seY

sdomrotalloC 5

msinahcemgnideeF tlebmuucaV

)DxWxH(snoisnemiD mm716x946x9001

thgieW bl022gk001

SNOITACIFICEPSSCH101/101ledoM

gnikcatS thgiarts/tesffO

9

/

61

1

"5mm012x041

/2"8x1/

4

3

"11mm074x523

/

"81x1/

4

2

msg05

msg042

ruoh/stes0083

3

/

"52x1/2"42x5/

"93

4

61

yticapaC

101ledoM

SCH101ledoM

ezisrepaPniM

xaM

thgiewrepaPniM

xaM

noitcnufssapyB seY

yllacitamotuA

gnidiecer

)DxWxH(snoisnemiD

101ledoM

SCH101ledoM

dekcodnutfiL

dekcodtfiL

thgieW

101ledoM

SCH101ledoM

egatloV zH06-05V521/511/001

msg06

seY

3

"73

/4"32x5/

3

"73

/4"32x5/

3

"73

/4"32x5/

"4mm001

3

"51mm044-004

3

"5mm012x841

/4"8x1/

5

"21mm754x023

5

/

"71-

/

4

/

8

61

4

"81x

msg042

mm515x006x052

"02x5/

8

61

mm515x006x069

"02x5/

8

61

mm017x006x069

"82x

8

bl55gk52

tfiL.lcnibl091gk68

zH06-05V042/032/022

egatloV zH06-05V521/511/001

zH06-05V042/032/022

Air Feed Collator Model 100, Stacker Model 101, Model 101 HCS Operator Manual

T10127 November 2001

6-1

Page 27

Loading...

Loading...