Page 1

CREASE MATIC

AUTO 50

Operators Manual

Page 2

Contents

Contents ……………………………………………………………………….. 2

Introduction ……………………………………………………………………. 3

Machine Components …………………………………………………………. 4

Setting Side Lays ………………………………………………………………. 5

Setting Outfeed Tray …………………………………………………………… 7

Changing Crease Matrix ……………………………………………………….. 8

Choke Adjustment and Rotating Cylinder …………………………………….. 9

Thin Gauge Paper Setting ……………………………………………………… 10

Heavy Gauge Paper……………………………………………………………... 10

Feed Gate Adjustment…………………………………………………………... 11

Horizontal Adjustment………………………………………………………….. 11

Vertical Adjustment…………………………………………………………….. 12

Perforation Wheels……………………………………………………………… 13

Top Shaft Alterations……………………………………………………………. 14

Bottom Shaft Alterations………………………………………………………... 15

Compressor/Vacuum Controls………………………………………………….. 16

Touch Screen Pages - Login Page…………………………………………….… 17

Run Page………………………………………………………………………… 18

Receipt Edit Page………………………………………………………………... 19

Crease Setting page 01……………………………………………..……………. 20

Crease Setting page 2-4……………………………………………………….…. 21

Service Menu ……………………………………………………………………. 22

Status Screen……………………………………………………………………… 23

Engineers Settings………………………………………………………………... 24

Factory Settings………………………………………………………………….. 25

Absolute and Incremental Programming…………………………………………. 26

Login Process…………………………………………………………………….. 27

Auto 50 Problem Solving………………………………………………………… 28

MBM Corporation

Michael Business Machines

3134 Industry Drive

North Charleston

South Carolina 29418

Customer Service - Tel: (800) 223 2508

Fax: (803) 552 2974

Parts & Service - Tel: (800) 223 2508

Fax: (803) 760 3814

Auto50-ops-touch screen usa 4/3/2013

2

Page 3

Introduction

Crease Matic Auto 50

Designed and manufactured in the U.K., the new Crease Matic Auto 50 is a fully

programmable high speed card creaser. Documents are suction fed and creased at up to

7000 sheets per hour. It is possible to crease Digital and Litho printed card, removing

cracking that may occur at the folding stage.

The CM Auto 50 is capable of accommodating stock from CD-SRA2 (500x700mm), with

a capability to program a maximum of 29 creases per sheet anywhere along its length.

A maximum of 99 different jobs can be programmed and saved to the machines internal

memory, making the selection and recall of common jobs quick and easy.

Jobs are programmed in Absolute mode. All crease positions are measured from the

leading edge and entered directly. Incremental mode may be used to make image shift

adjustments with one alteration.

The machine is supplied with rotary perforation that is adjustable across the width of the

document, and four widths of slide-out and turn crease matrix as standard.

Auto50-ops-touch screen usa 4/3/2013

3

Page 4

Machine Components

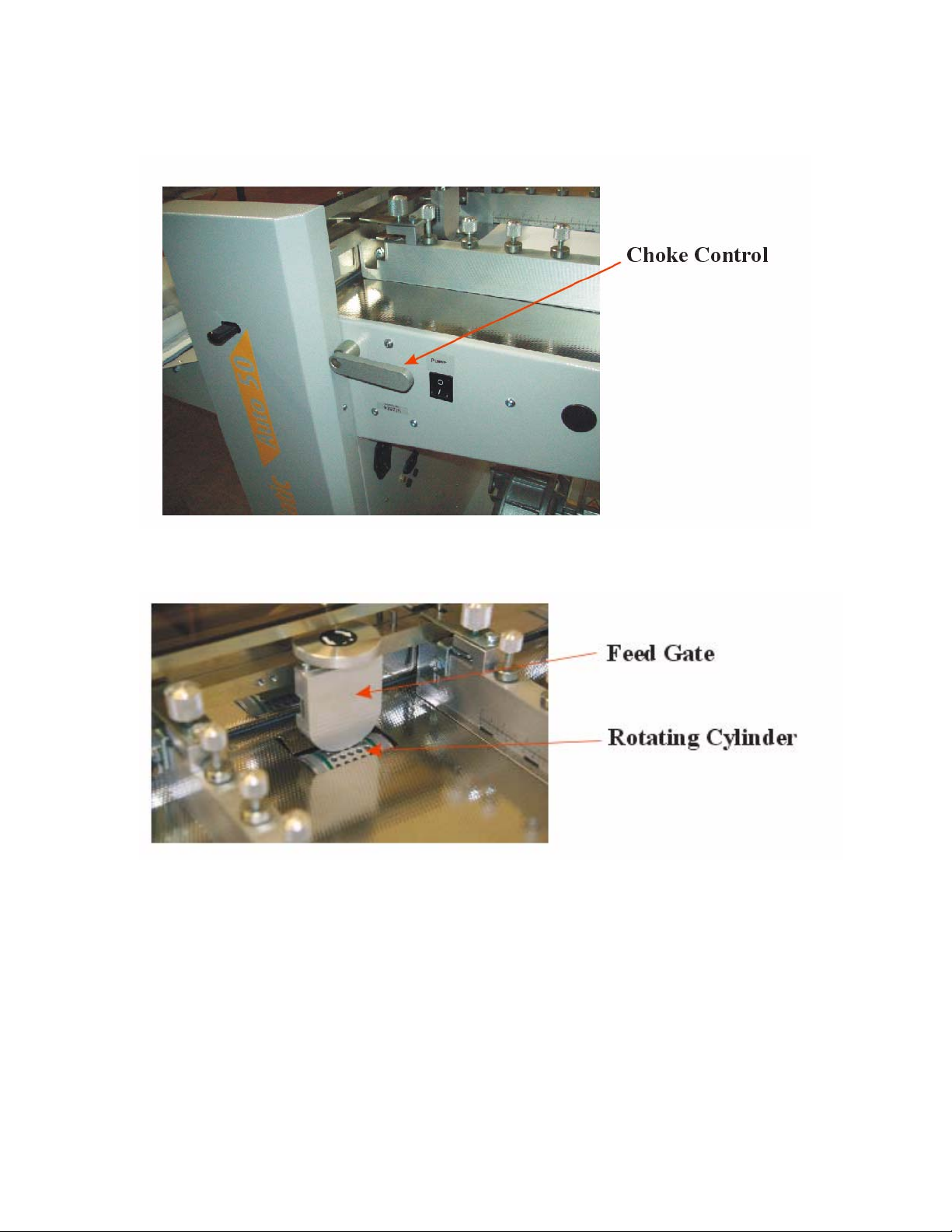

When installing the machine the supplied power cable should be plugged into the

switched power socket on the machine and then to the power supply socket. Switch the

machine on and the control screen will initialize. The compressor/vacuum unit has a

separate on/off switch located under the Choke Control Wheel. This allows the unit to be

switched off when not in use.

Auto50-ops-touch screen usa 4/3/2013

4

Page 5

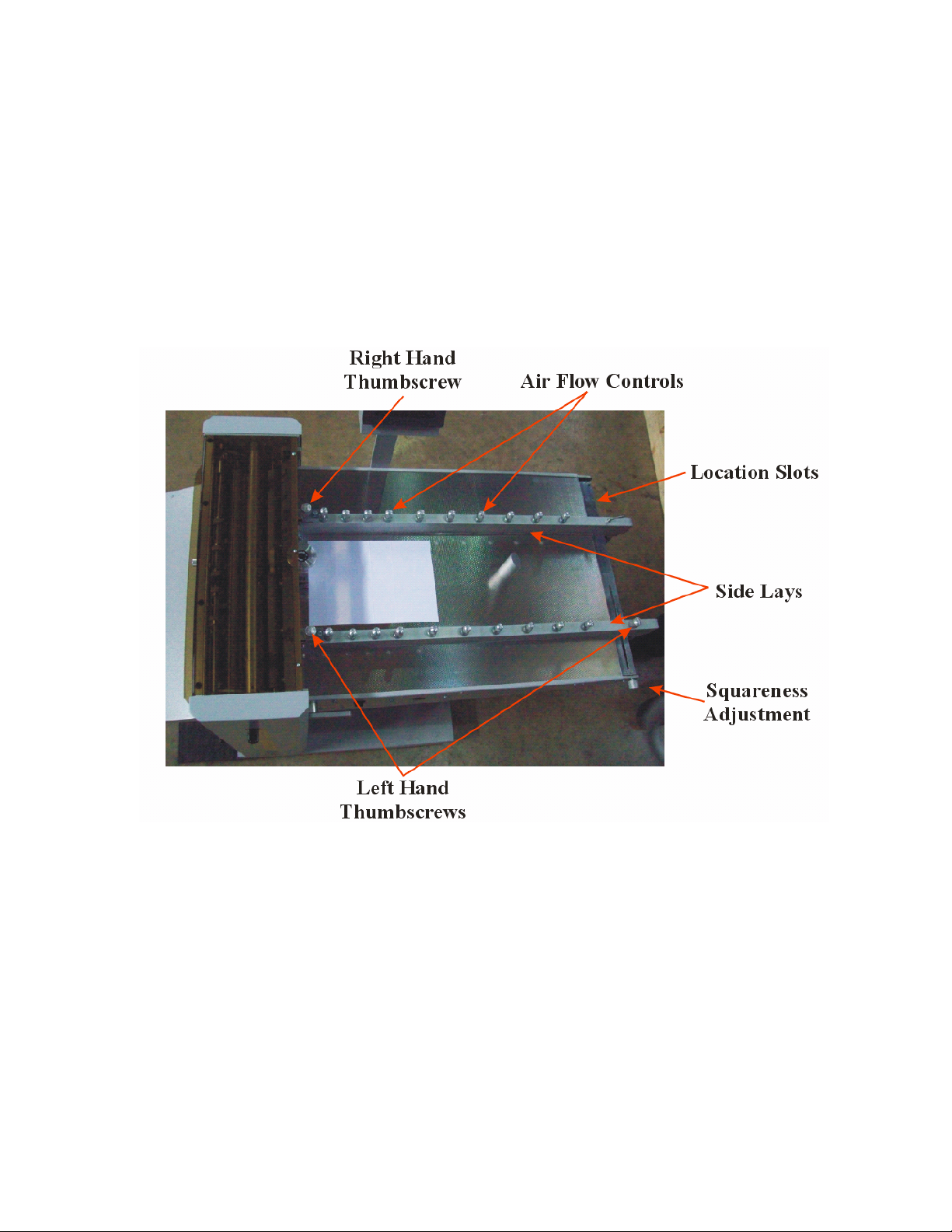

Setting Side Lays

There are two side lays on the machine which sit at each side of the paper on the infeed

section. Their purpose is to guide the paper under the feed gate and into the feed rolls

accurately, to ensure a square crease is made across the document. They also supply air to

the underside of the paper stack, by way of thin slots, in order to make the paper “float”

before the bottom sheet is vacuum fed away under the feed gate.

On the CM Auto 50 there is also the capability to adjust the lays out of squareness to

accommodate for non square crease lines, although this adjustment is minimal.

Firstly, ensure that the squareness adjustment is set to its central position by aligning the

two marks on the machine bed.

The right hand side lay has four location positions. By releasing the thumbscrews at the

feed gate end, the lay may be extracted from one slot and repositioned in another, using

the thumbscrew to secure it. This position must be selected with the paper size being fed

in mind, in order to keep the feed gate as central as possible to the paper centre line.

Once the right hand lay is in position, loosen the two thumbscrews at either end of the left

hand side lay and with a single sheet in the machine, push it across to the correct width of

document. The lays should not pinch the document and the paper must sit on top of the

protruding edge at the base of the lay. Secure the thumbscrews when in position.

Auto50-ops-touch screen usa 4/3/2013

5

Page 6

Setting Side Lays cont.

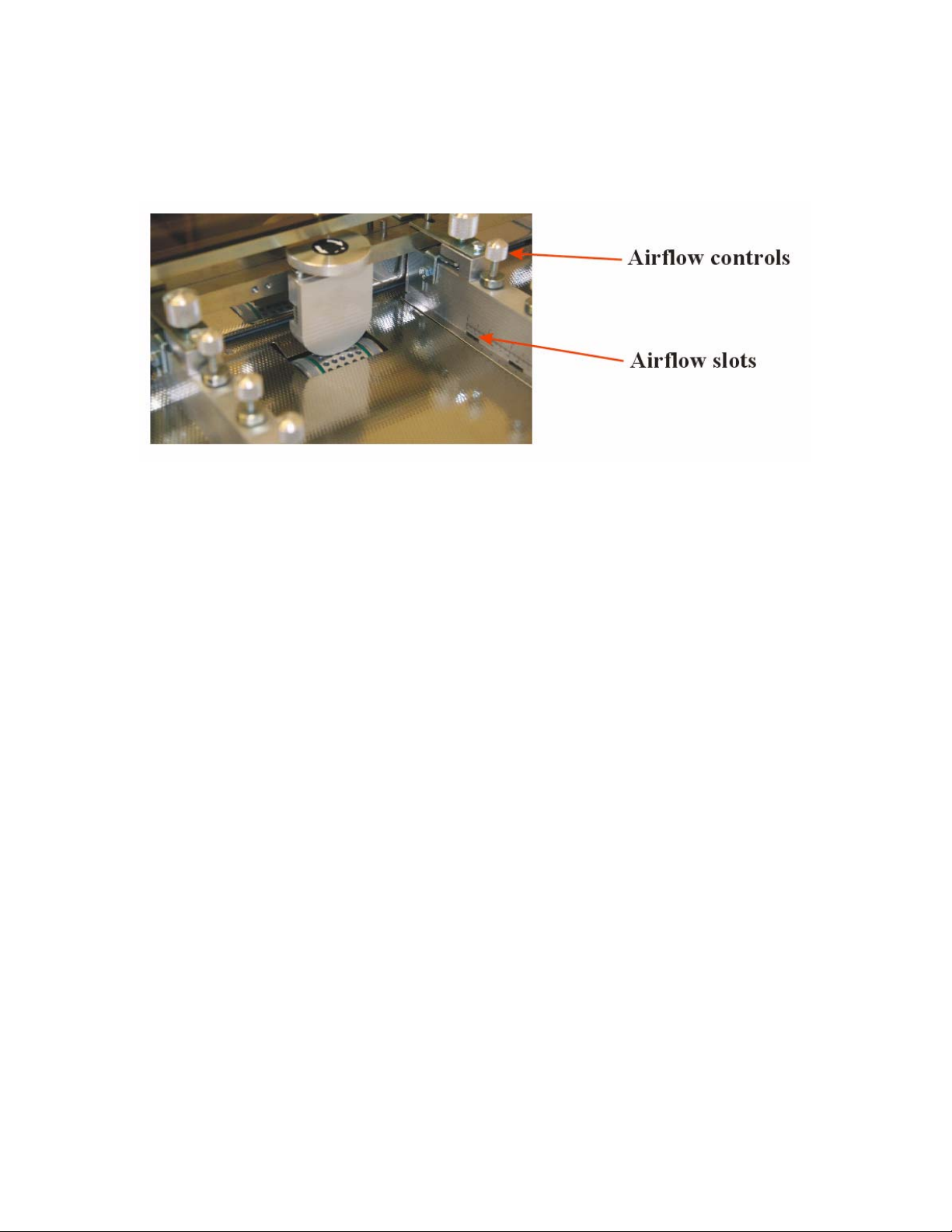

Air flow to the slots is controlled using the thumbscrews running along the top edge of

each lay. By screwing them down (clockwise) all the way the flow of air will be stopped.

This should be done if the document does not cover the slots. Screwing them up will

allow air to pass through the slot. The thumbscrews are fitted with anti-vibration devices,

to prevent the settings from altering during normal operation. After placing the paper

onto the machine, the magnetic backstop should be placed behind the stack to prevent it

from moving.

Auto50-ops-touch screen usa 4/3/2013

6

Page 7

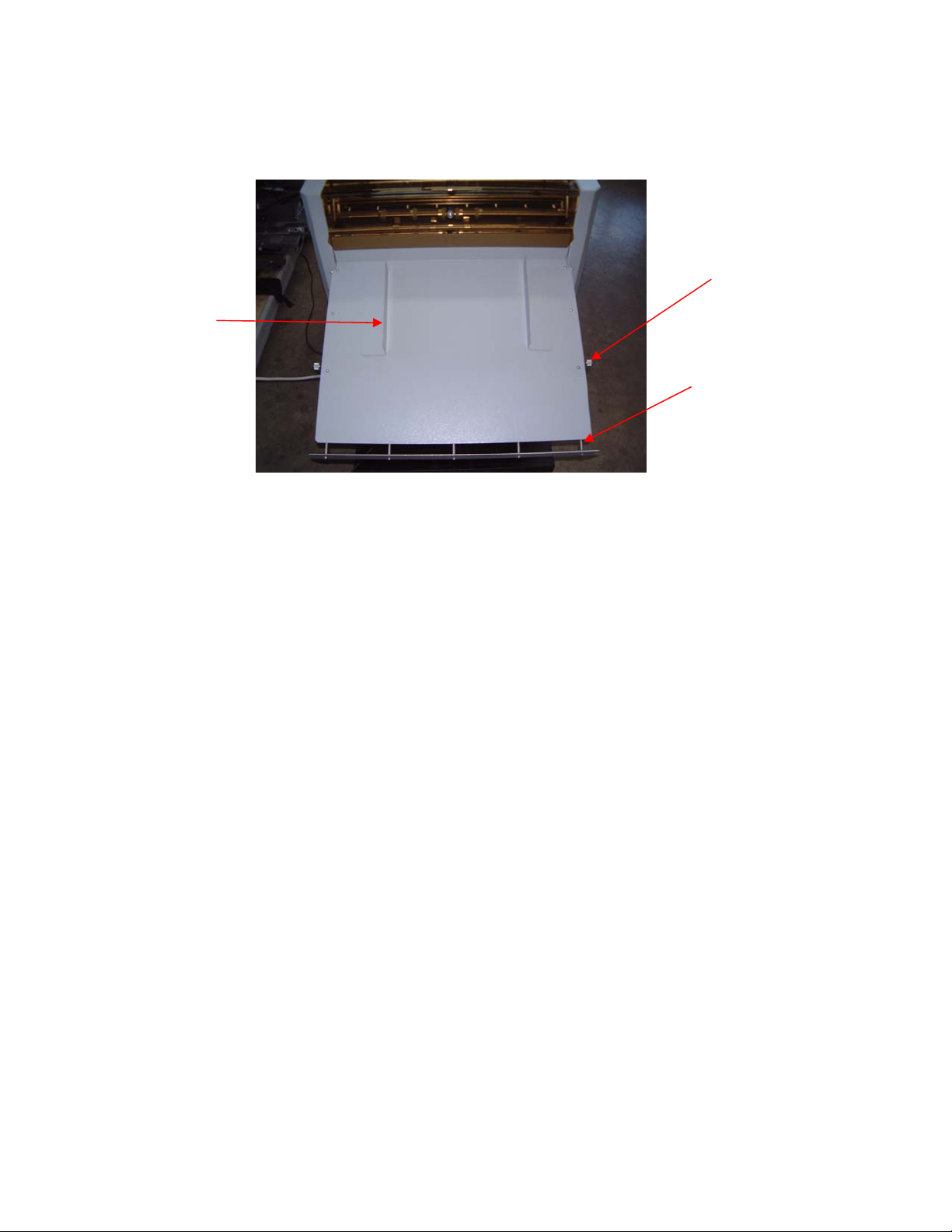

Setting Outfeed Tray

Thumbscrews

Magnetic

Side Lays

Bottom

Stop Plate

The outfeed tray has two thumbscrews , one on each side. By loosening the thumbscrews

the bottom stop plate may be extended to allow larger sheets to be collected without

damage.

The magnetic side plates may be positioned to keep fed documents stacked accurately.

The outfeed tray can be removed in order to adjust the lower perforation wheel shaft.

Auto50-ops-touch screen usa 4/3/2013

7

Page 8

Changing Crease Matrix

The machine is supplied with two crease matrix bars that have different widths of slot on

either side. One of these slots allows the operator to use replaceable self adhesive matrix

bars, the other three may be changed depending on the thickness of the material to be

creased.

The bar must only be changed while the machine is in its rest position with the knife at its

highest point. Withdraw the bar from the slot, turn or replace with the correct size slot,

and slid the bar into the machine until it stops.

Auto50-ops-touch screen usa 4/3/2013

8

Page 9

Choke Adjustment and Rotating Cylinder

The choke is used to control the amount of vacuum applied to the front edge of the paper

through the rotating cylinder holes.

The amount of vacuum needed is dependant on the type of paper being fed. Thin gauge

paper, 80gsm to 90gsm will tend to wrap around the cylinder easier than thick gauge

paper, and will need less vacuum to feed.

By rotating the choke control wheel clockwise, more area of slot inside the cylinder is

exposed through the holes and so more of the front edge of the document is sucked onto

the wheel.

Auto50-ops-touch screen usa 4/3/2013

9

Page 10

Thin Gauge Paper Setting.

Rotate the choke adjustment knob anticlockwise until the slot inside the cylinder is tilted

towards the feed gate. This adjustment may be fine tuned during operation.

Feed Gate

Cylinder

Paper

Choke

Heavy Gauge Paper.

Rotate the choke clockwise until the slot is in an upright position.

Feed Gate

Cylinder

Paper

Choke

Auto50-ops-touch screen usa 4/3/2013

10

Page 11

Feed Gate Adjustment

The feed gate is set to allow only one document past at a time. This is achieved by

altering the gap and position of the bottom edge of the gate to the rotating cylinder. There

are two thumbscrew adjustments. One on top, to allow the vertical movement of the gate,

and one under the top cover, to allow horizontal movement. Adjustment of the gate

carried out along with adjustment of the choke.

Horizontal Adjustment

Firstly, set the choke to the correct position for the thickness of document about to be fed.

Then, using the smaller thumbscrew, align the front face of the feed gate to the left hand

edge of the choke slot, seen inside the rotating drum.

Front Face

Auto50-ops-touch screen usa 4/3/2013

11

Page 12

Vertical Adjustment

The vertical adjustment is used to achieve the correct gap between drum and feed gate

dependant on paper thickness being fed.

Place a stack of paper onto the machine feed table. With the machine and compressor

turned on, adjust the vertical thumbscrew until only one document is taken from the base

of the stack at a time.

Auto50-ops-touch screen usa 4/3/2013

12

Page 13

Perforation Wheels

Top Wheel

Control Wheels

Spring

Bottom Wheel

The perforation wheels are located under the top cover of the machine. The outfeed tray

may be lifted clear of the machine in order to gain access to the lower shaft. By altering

the position of the wheels along their shafts, perforations can be made at any point across

the documents width. You can use the perforation wheels without needing to crease the

documents. There are also feed wheels on these shafts, and it may be necessary to alter

their positions to achieve the correct perforation position. To perform perforations away

from the centre of the paper, the order of the feed wheels and perforation wheels on the

shaft must be changed to maintain drive across the width of the document.

Location

Holes

Sprung

Locator

Top Shaft

and Collar

The wheels may be raised or lowered using the sprung locator to the left end of the top

shaft. Two location holes allow easy positioning of the shaft in either the up or down

position. The shaft must be in its up position to make any alterations to the perforation

position. When lowering the top shaft, the perforation wheel must be pulled against the

spring until it is located, so that the wheels are in contact when the spring is released.

Auto50-ops-touch screen usa 4/3/2013

13

Page 14

Top Shaft Alterations

Top Shaft and

Perforation Wheel

The top shaft must be in its raised position to be removed. It is removed by undoing the

grub screw in the collar on the left hand end and sliding the collar to the right and out of

the bush, allowing the end of the shaft to come towards you. It can then be removed from

its location on the right hand side. The components on the shaft can then be loosened,

slide off and repositioned in the desired order.

Note. The perforation wheel is positioned between two drive wheels and is sprung

loaded. This arrangement must stay the same wherever you position the perforation wheel

along the shaft.

All screws should be tightened onto the machined flat so that the shaft is not damaged.

Refitting is the opposite of removing. Locate the right hand end of the shaft in the bush

on the right side of the machine, line up the left hand side and slide the collar into the

bush. Tighten the screw to secure.

Accurate setting of this wheel can only be achieved when a test document is run, and

final adjustments to measurements should be made at this stage.

Auto50-ops-touch screen usa 4/3/2013

14

Page 15

Bottom Shaft Alterations

Collar and

Grub Screw

The bottom shaft can not be removed from the machine but can be slid across to allow

components to be removed and repositioned.

Note. The drive wheels on the bottom shaft must stay in line with the wheels on the top

shaft.

Bottom Shaft

Collar and Gap

Undo the grub screw in the collar on the left hand end of the shaft. Slide the shaft to the

right until there is a big enough gap near the collar to remove the drive wheels.

Reposition the desired components opposite the wheels on the top shaft and tighten in

position. Slide the shaft back into the collar and tighten the grub screw onto the flat.

Accurate adjustments and alignment may be made with the top shaft down.

Auto50-ops-touch screen usa 4/3/2013

15

Page 16

Compressor/Vacuum Controls

Where the compressor/vacuum unit has two controls. The right hand control wheel

increases and decreases the supply of air to the machines side lays. The left hand control

alters the amount of vacuum supplied to the choke. This may need to be decreased when

using light or thin paper.

If the compressor/vacuum unit is not fitted with air flow controls, the volume of air

delivered to the paper stack may be reduced by opening the uncovered air flow controls

in the side lay.

Auto50-ops-touch screen usa 4/3/2013

16

Page 17

Screen Sequence.

Logon Page:

Press the open padlock sign to logon.

Press within the dotted area to proceed to the ‘Recipe Select Page’.

Recipe Select Page:

Press any of the default setups to go to the ‘Run’ page. Default recipes may only be

adjusted from the Run screen Edit button if the user is logged in as ENGR or FACT.

Press RECIPE to manage customer created recipes.

Auto50-ops-touch screen usa 4/3/2013

17

Page 18

Run Page:

Edit: Press to edit the job directly.

Load: Press to load changes from ‘Edit’ to the controller.

Act Sheet: ‘Reset’ will clear the Act Sheet if pressed for 3 seconds.

Set Sheet: Job counter. Press to set max number of pages to be processed.

Speed: Press number to enter speed setting, select speed and press enter.

Auto50-ops-touch screen usa 4/3/2013

18

Page 19

Recipe Edit Page:

Edit: Proceeds to ‘Crease Setting Page 01’ for the recipe selected.

Load: Proceeds to the ‘Run’ screen.

Delete: Deletes the recipe selected.

Create: Create a new recipe. In the recipe pull down menu, a new recipe is created and

named to a default name, for example “r7”. Press this name to change it. Then press

‘Save & Load’. A pop up box will then appear allowing the user to configure the job in

Inches or Millimetres, Incremental or Absolute. ‘Cont..’ will proceed to ‘Crease Setting

Page 01’.

Auto50-ops-touch screen usa 4/3/2013

19

Page 20

Crease Setting Page 01:

Auto50-ops-touch screen usa 4/3/2013

20

Page 21

Crease Setting Pages 2 to 4:

Auto50-ops-touch screen usa 4/3/2013

21

Page 22

Service Menus:

Visibility dependent on login code:

Manager - MNGR (5138)

Engineer - ENGR ()

Factory - FACT ()

Auto50-ops-touch screen usa 4/3/2013

22

Page 23

Status Screen:

Information only.

Auto50-ops-touch screen usa 4/3/2013

23

Page 24

Engineer Settings:

Sheet Tolerance: The length of every sheet passed through the machine is measured for

error detection. Adjust this value to regulate stoppages.

Photo to Knife Offset: Distance from the paper detection photocell to the knife. This

setting can be adjusted to give the correct first crease position from the leading edge of

the paper.

Feed Timeout: Feed distance of paper feed roll before a Paper Jam Error is made. This

may be disabled by the button below.

Default Settings are:

Sheet Tolerance - 50

Photo to Knife offset - 23.5

Feed Timeout - 800

Auto50-ops-touch screen usa 4/3/2013

24

Page 25

Factory Setting:

Default Settings are:

Acceleration - 28000

Deceleration - 40000

KPn - 0.0651

TNn - 16.00

TAUnref - 1.0

TAUiref - 0.2

Trim Factr - -2.0

Min Speed: Roll speed at Speed 0 - 100

Max Speed: Roll speed at Speed 9 - 2400

Auto50-ops-touch screen usa 4/3/2013

25

Page 26

Absolute and Incremental Programming

t

d

The main difference between the two types of programming system is that Absolute

measurements are taken from the leading edge of the document, and Incremental

measurements are taken from the previous crease line.

The machine is not meant to be programmed initially in Incremental mode!

It is intended that the initial program should be entered in Absolute. I.e. all measurements

are taken from the leading edge. Then if an adjustment is required because the print

registration has changed to the leading edge, select “Incremental”, then enter program

mode and any change to any crease position will also affect any following crease

positions by the same amount.

Example.

A document requires three creases, the first is 100mm from the leading edge, the second

is 150mm from the leading edge and the third is 175mm from the leading edge as shown

below.

Front Edge

100mm

s

1

50mm

nd

2

25mm

r

To program this job in Absolute, all of the measurements are taken from the front edge,

1st crease at 100mm

2nd crease at 150mm

3rd crease at 175mm

To program with Incremental measurements, the first distance is taken from the front

edge, the second is taken from the first crease, and the third from the second crease.

st

crease at 100mm

1

nd

2

crease at 50mm

rd

crease at 25mm

3

Auto50-ops-touch screen usa 4/3/2013

26

Page 27

Login Process:

Four login modes are available:

0 User – access to crease positions on all jobs (5)

1 Manager - as above plus access to default speed (8191)

2 Engineer - as above plus access to photocell offset and languages (xxxx)

3 Factory - as above plus access to motor parameters (xxxx)

The LED to the felt of the display indicates the login level.

Access to anything other than crease positions is only available on program 1.

To login:

From start up, press continue at any time to start. If a valid code is not entered, login

defaults to ‘user’.

To login adjust the present digit with the ‘up’ and ’down’ keys, when correct press the

‘right’ key to advance to the next digit. When the last (forth) digit is correct, press the

‘continue’ key.

Auto50-ops-touch screen usa 4/3/2013

27

Page 28

Auto 50 problem solving:

1. ‘Knife error’ or ‘stop’ showing on screen.

1.1. Machine jamming with card

1.2. Knife out of position.

Try a different matrix tool

1.3. Knife pulley loose on motor shaft

2. Knife does not always cycle or behaves erratically:

2.1. Ensure knife flag is aligned with and passes through the slotted photocell.

2.2. With age and use the knife may over run at the end of cycle. Ensure that at the

end of cycle the flag is still obscuring the slotted photocell.

2.3. Check output from photocell. Place positive probe (red) of meter (set to 24v DC

range) on orange at local terminal strip and place other probe (black) on pin 29

(white/red wire) of the green IDC connector. When the photocell beam is broken

(knife flag) the meter should read 5volts, other wise 0volts should be shown.

2.4. Check and change as necessary R4, the knife motor run relay.

2.5. Knife pulley loose on motor shaft

3. Paper feeds through machine without being creased:

3.1. Ensure a crease position is set.

3.2. Check output from photocell. Place positive probe (red) of meter (set to 24v DC

range) on orange at local terminal strip and place other probe (black) on pin 31

(white/blue wire) of the green IDC connector. When the photocell beam is

broken (paper present) the meter should read 5volts, other wise 0volts should be

shown.

4. Feed motor does not run:

4.1. Ensure cover is closed (white/brown wire).

4.2. Ensure catch tray is properly attached.

4.3. Ensure main (large 11 pin relay) is actuated. Contacts are in up position.

4.4. Ensure motor inverter shows green LED (enabled). If LED is red, motor is not

enabled.

Auto50-ops-touch screen usa 4/3/2013

28

Page 29

5. Paper does not feed:

5.1. Ensure compressor is on.

5.2. Ensure side lay are not too tight

5.3. Ensure paper stack is “floating”.

5.4. Check gate position.

5.5. Check throttle position.

5.6. Ensure suction relay (leftmost small relay) has actuated. Relay with grey wire to

right of 11 pin. Contacts are up.

5.7. Ensure suction valve has operated. I.e. solenoid has “pulled in”

5.8. Check setting of solenoid for suction valve. Release valve body cap (two 5mm

set screws) to allow a 1mm gap between the cap and the body. Loosen the the

hex bolts holding the solenoid block to the cover plate. Pull the solenoid block

away from the valve until there is no slack in the system. Tighten hex bolts. Now

tighten set screws in cap. This last action will force the solenoid bolt out of the

solenoid.

From

To Wheel

Compressor

Valve Body

Spring Stop

Auto50-ops-touch screen usa 4/3/2013

Return Spring

29

Page 30

6. Crease position is not accurate.

Set a new job with 1 crease. Turn the air off. Remove stack from feeder. Feed a single

sheet several times through the Creaser. Does the crease line move? If yes:

Side lays set too loose, feed restricted.

6.1.1. Side lays set too tight, page twisting.

Set a new job with 4 creases set at 50, 100, 150 and 200mm. Run 8 pages. Line up the

leading edges together. Are the first creases in line? No:

Feed Gate set too wide, over feeding.

Ensure the job is feeding consistently and not overfeeding.

Line up the first creases together. Are the second, third and forth creases in line?

Check entry roll pressure. Release screws in roll bearings. Ensure roll is free to lift. Feed

two 1” strips of 80gsm (20 lb) paper at extreme ends of roll. Tighten locking screws.

Check tension of 180xl belt on rollers and tighten as necessary.

Auto50-ops-touch screen usa 4/3/2013

30

Loading...

Loading...