Page 1

ISP

A Division Of Samuel Strapping Systems

Stitching & Bindery Products

MODEL

305

305-G

OWNERS

MANUAL

For Models With M2000 Stitching Heads

Bindery Mate Serial Numbers

5161 and higher

Page 2

CONTENTS

Section 1 INTRODUCTION

1. Model and Serial Number

2. Product Specifications

Section 2 SAFETY PRECAUTIONS

AND PROCEDURES

4. Safety

4. Safety Guards/Cover

Section 3 ASSEMBLY,

LUBRICATION,

INSTALLATION

5. Before Unpacking

5. After Unpacking

5. Assembly

6. Threading wire and adjusting wire

straightners

7. Lubrication-Felt Pads

8. Lubrication-Stitcher Head

9. External Lubrication

10. Internal Lubrication

Section 4 OPERATION

11. General Stitching

11. Table/Saddle Conversion

11. Table Stitching Using Work Trip

11. Table Stitching Using Foot Trip

11. Stitch Repeat

11. Hand Jog

12. Master and Secondary

12. Saddle Stitching-Foot Switch Only

12. Work Guides:

Side Guides

Corner Stitch Guides

12. Changing Work Thickness

Section 5 MAINTENANCE, TROUBLE

SHOOTING AND ADJUSTMENT

13. General

13. Recommended Spare Parts

13. Cleaning and oiling

13. Stitching Adjustments

13. To Equalize Both Legs of Stitch

14. Trouble Shooting-M2000 Head

17. Trouble Shooting-Drive

20. Insufficient or Excessive Compression

20. Table/Clincher Bracket Adjustment

20. Clincher

21. Clincher Point Height Adjustment

21. Reversing or Replacing Clincher Points

22. Head/Clincher Alignment

22. Bender bar

22. Bender bar Friction Plug

23. Driver Bar

24. Bender Bar Latch

24. Grip, Grip Release Slide and Faceplate

25. Wire Cutters

26. Wire cutter Operating Slide

26. Proper Wire

26. Rotator

27. Wire Straighteners

28. Supporter

28. Tension Pawl

28. Work Trip

29. Stitcher Head Disassembly

31. Drive/Frame Disassembly

Section 6 PARTS LIST

35. Drive/Frame

40. M2000 Head Stitcher

Section 7 ELECTRICAL

42. Electrical Schematic (115 V.A.C.)

43. Electrical Schematic (230 V.A.C.)

USE REPLACEMENT PARTS

DESIGNED AND

MANUFACTURED ONLY BY

INTERLAKE SPECIFICALLY FOR

YOUR M2000 STITCHER

Page 3

Section 1

INTRODUCTION

Here are the instructions on

how to install

operate, maintain, and make

repairs on your

MODEL 305, 305-G

BINDERY MATE

Bindery Mate Serial Number____________________

Bindery Mates M2000 Head Stitcher Serial Number____________________

When ordering parts or requesting information, please state: Quantity required, part number, part

name, model and serial number of your stitcher.

Your stitcher with the M2000 Stitching Head has been engineered and developed to provide you with the

finest equipment available for your stitching needs. With proper care and maintenance it will give you years

of satisfactory efficient service. This manual shows you how to get top performance from your stitcher and

is divided into 7 major sections.

Read the Bindery Mate Manual throughly. Study it carefully. Best stitching performance will be assured,

if all the adjustments are made as instructed, so that you get the following desired results.

1. Good Cut-Off

2. Uniform wire draw

3. Equal leg length

4. Proper clincher alignment

5. Sufficient compression

1

Page 4

BINDERY MATE

PRODUCT SPECIFICATIONS

Unit Weight: Overall: 30 Lbs.

Without Wire Spool: 25 Lbs.

Unit Envelope Size: Height Length Width

Overall: 27" 15" 10"

Without Tables and Wire Guide: 22" 12 1/2" 4"

Wire (Interlake 417-0025)

Wire Material: 120,000 to 150,000 p.s.i. tensile strength

tinned steel wire

Wire Size: 25 Gauge (.020" Diameter)

Wire Spool Weight: 5 Lb. Spool (Fully Loaded Wire)

Stitching Speed 173 stitches per minute, full load capacity.

199 stitches per minute, minimum load

capacity.

Stitching Capacity (20 Lb. Bond Paper)

Minimum Stitching thickness adjustment .94" Wire Draw, Approx. 57,000 stitches

per 5 Lb. coil.

Maximum Stitching thickness adjustment 1.24" Wire Draw, Approx. 43,000 stitches

per 5 Lb. Coil.

Maximum Stitching thickness: 1/4"

Stitcher: M2000 Head CTTT-2605-T3

(Equipped with faceplate adjustment lever)

Table (Flip-Up)/Saddle (Flip-Down)

Length: 10"

Width: 4 3/4"

Side Guides: Pop-Up/Pop Down pins in arms which adjust from 7/8" to 9 5/8" from center of clincher.

Corner Guides: Pop-Up/Pop Down pins in table for 45 degrees corner stitch.

2

Page 5

BINDERY MATE

PRODUCT SPECIFICATIONS

Auxiliary Rear Table (For flat work support when deep throat table stitching)

Length: 10"

Width: 3"

Throat Depth: 4" Max.

Stitch Modes:

Work Trip (For Table Mode): Plug foot switch into rear of housing.

Foot Trip (For Saddle or Table Mode): Manual Switch Control.

Master-Secondary (For use with Plug master into 2nd-3rd units for

multiple stacked unit): side by side multiple stitch (4 1/2 in.

min. centers).

Quick adjust for 3/16" to 4" throat depth.

Jog: Push in and turn knob, on rear of housing,

for manual forward or reverse operation.

Electrical

Input: 115 V.A.C. 60 HZ 230 V.A.C. 50 HZ

(Model 305) (Model 305-G)

Control Circuit: 12 V.D.C. 12 V.D.C.

Motor: 1/20 HP, 90 V.D.C. 1/20 HP, 180 V.D.C.

Circuit Breakers: 1 AMP for 115 V.A.C. Input 1/2 AMP for 230 V.A.C. Input

Mounting:

2 3/4"

Table

2 1/2" Max

1/2" Min

3

Page 6

Section 2

SAFETY PRECAUTIONS

AND PROCESURES

SAFETY

1. Make sure electrical power is turned off before

performing any adjustment or maintainence.

2. Keep hand, tools, hair, and clothing clear of

stitching area.

3. Become familiar with the moving components of

your machine. Keep fingers away from areas

that could pinch or cut.

4. Observe your plant safety rules.

5. Exert good housekeeping in your work area.

Keep it as clean and uncluttered as possible.

6. A well maintained machine is a safer machine.

Clean and lubricate the machine at regular

intervals. Check machine daily for broken or

worn parts. Replace as necessary. DO NOT

attempt to operate the machine if a part is broken.

7. Route all electrical cables away from pedestrian

transportation lanes.

8. See Safety Guards/Cover information. It points

out areas where additional caution should be

exercised. If you are unsure how to safely operate

or maintain your Stitcher, contact your Service

Representative.

CAUTION

THE SUPPLY CIRCUIT FOR ANY

305/306 SERIES UNIT MUST USE A

15 AMP MAXIMUM FUSE OR

CIRCUIT BREAKER. THE SHORT

CIRCUIT CAPACITY OF THE

SUPPLY CIRCUIT MUST NOT

EXCEED 2000 AMPS.

SAFETY GUARDS/COVER

A. Grey Plastic Cover: Covers frame, motor,

mechanical, and electrical components.

B. Front, Clear Plastic, Guard Assembly: A three

position guard. In the fully downward position

the guard is spring loaded to: cover the M2000

Head, and work trip adjustment knob; restrict

access to the stitching area; depress a limit

switch to allow the machine to operate. The

guard can be swung up to its first detent position

(about 70 deg.) to allow access to the work trip

adjustment knob and lower portion of the M2000

Head. The guard is swung up to its second

detent position (about 155 deg.) to allow total

access to the M2000 Head for faceplate

adjustment, lubrication, and wire threading.

DANGER

KEEP HANDS CLEAR OF

STITCHING AREA

ATTENTION

LE CIRCUIT D'ALIMENTATION DESTINE

A UNE UNITE DE LA SERIE 305/306 DOIT

COMPORTER UN FUSIBLE OU UNE

PROTECTION THERMIQUE CALIBREE A

15 AMP MAXIMUM. LA CAPACITE DE

COURT CIRCUIT DU RESEAU NE PEUT

PAS DEPASSER 2000 AMPS.

4

CAUTION

FOR YOUR SAFETY, MAKE SURE ALL

COVERS ARE PROPERLY IN PLACE

BEFORE OPERATING MACHINE

CAUTION

Do not operate stitcher until operating

instructions have been read and understooddo not operate stitcher at anytime without

work under the head.

Page 7

Section 3

ASSEMBLY, LUBRICATION

INSTALLATION

Wire Spool Washer

Wire Spool Stud

Support

Conical Spring

Note:

These instructions must be followed to insure

proper installation, efficient operation and the

prevention of serious damage to your stitcher.

Before Unpacking:

Examine the outside of the crate or carton for any

visible damage. If damaged DO NOT UNPACK

THE STITCHER. Notify the carrier who delivered

the stitcher.

After Unpacking:

Examine your stitcher carefully for any damage in

transit. If damaged, DO NOT INSTALL THE

STITCHER. Notify your nearest representative and

the carrier who delivered your stitcher.

Make certain that you get a signed copy of the Carrier

Inspectors Report of the damage incurred

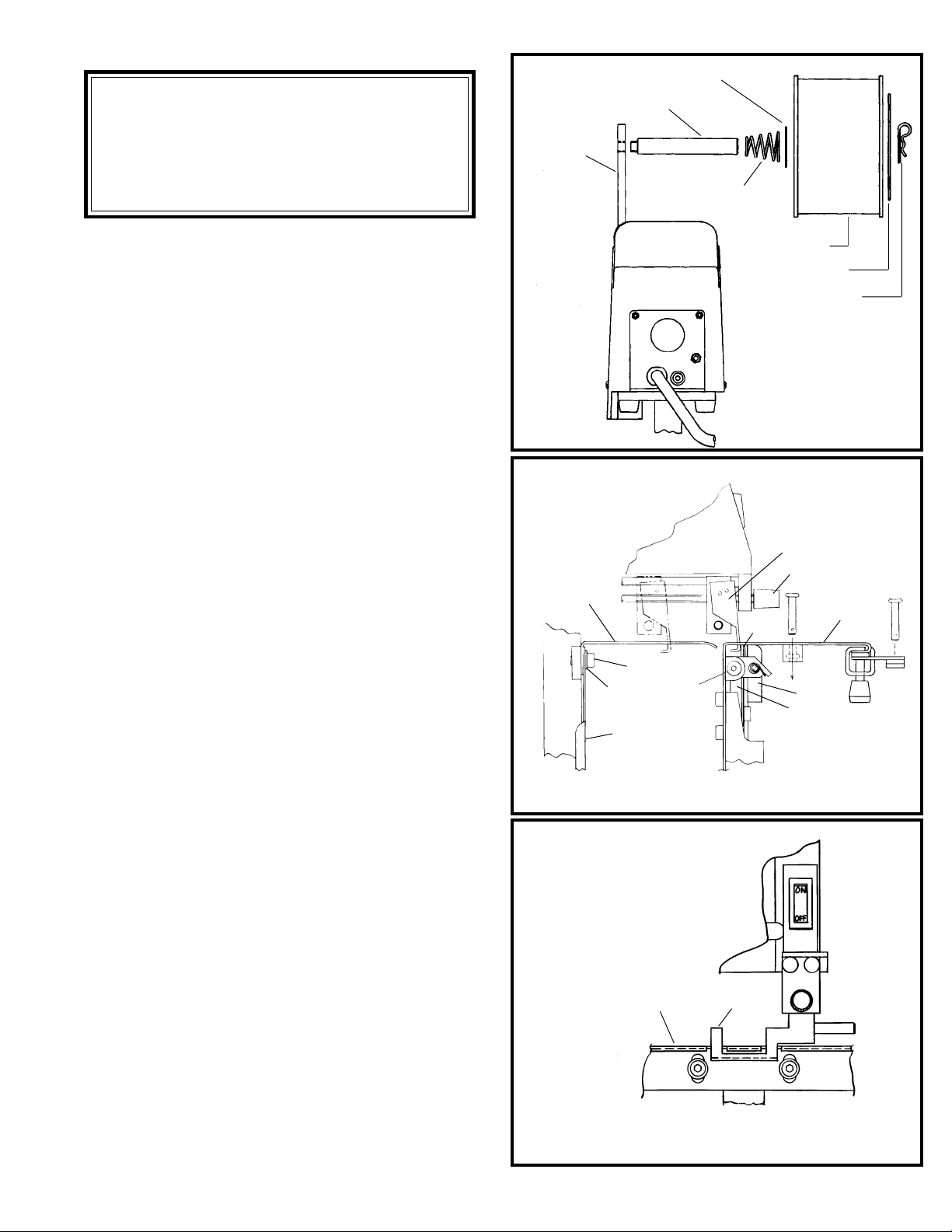

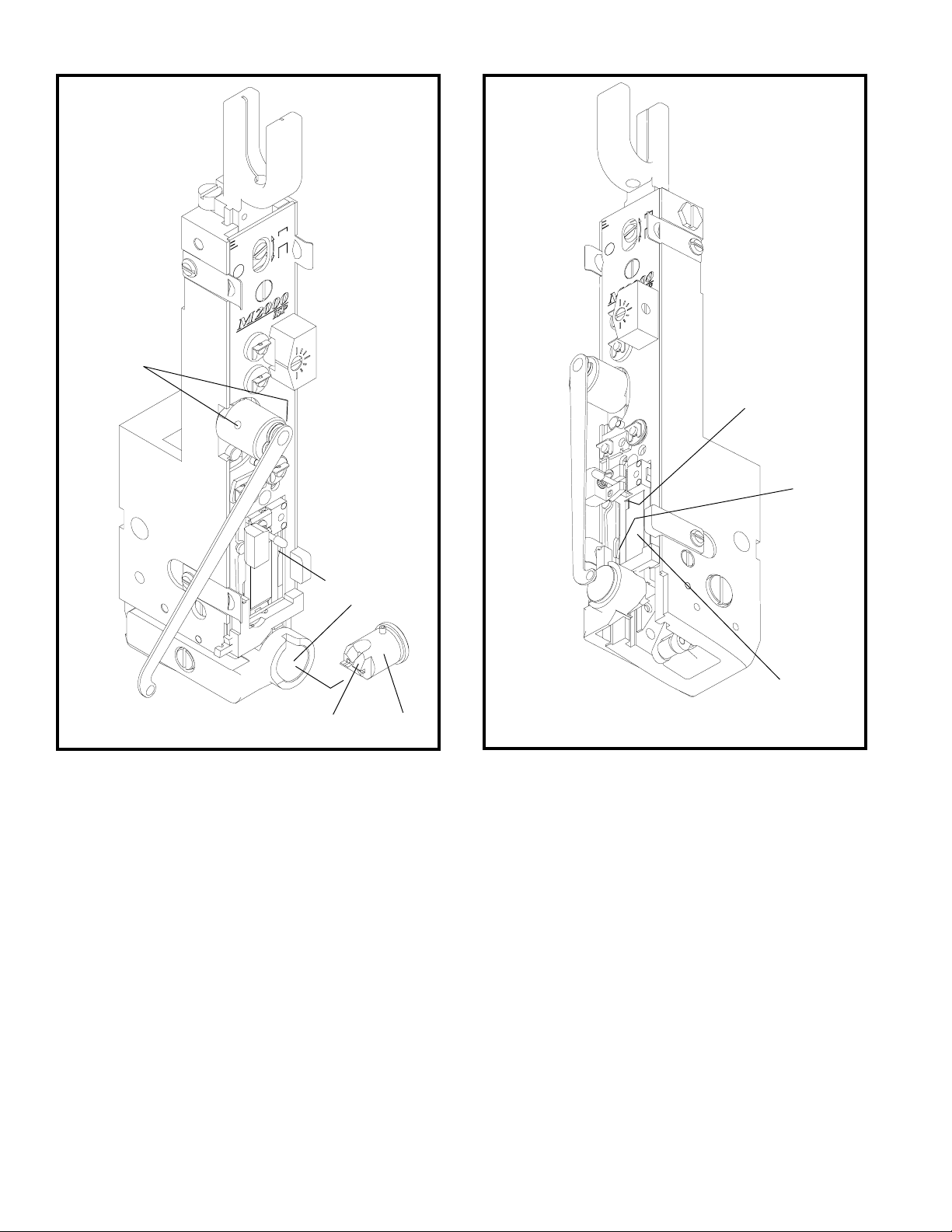

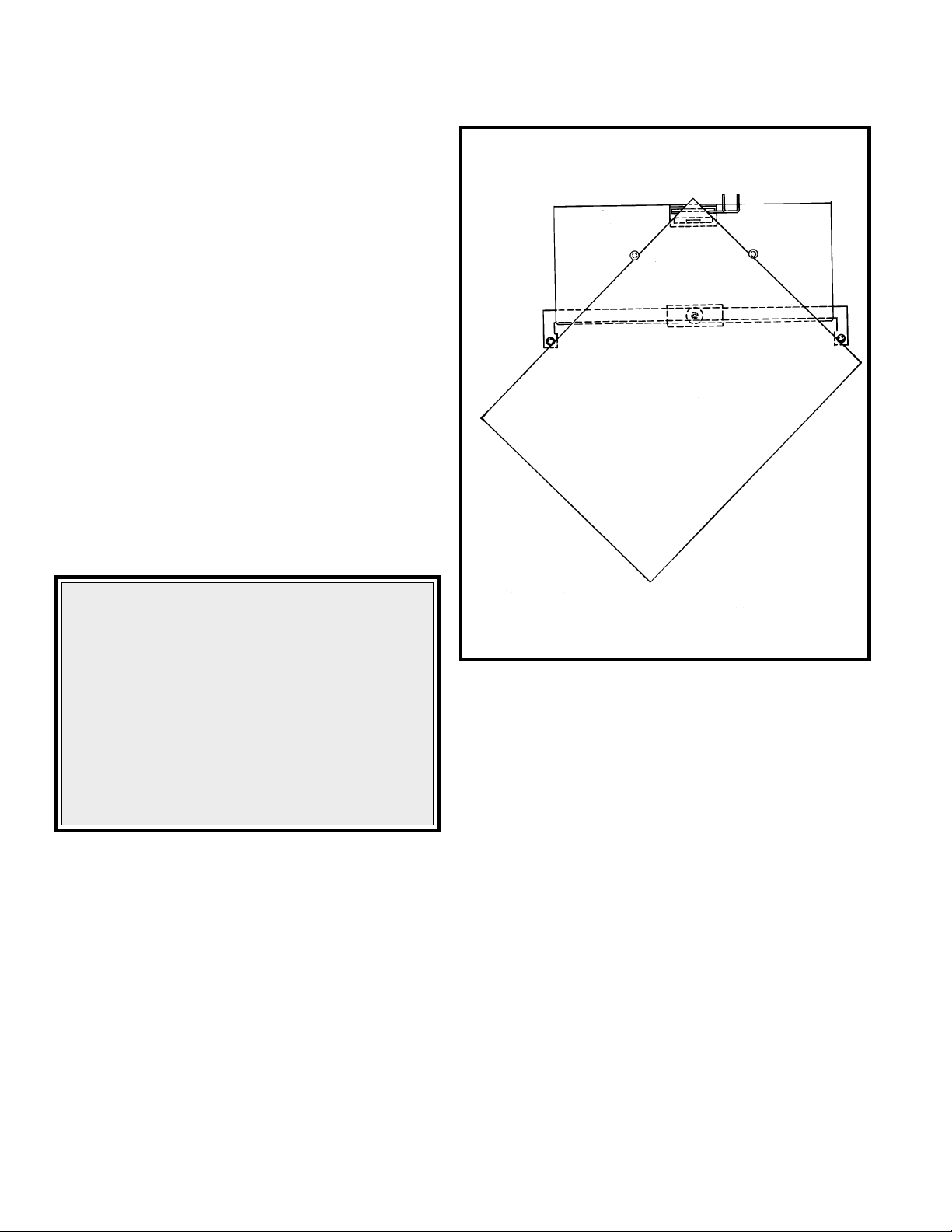

ASSEMBLY (FIGURES 1,2,3)

1. Clamp the Bindery Mate to a table or bench (see

"Mounting" page 3). Assemble per figure 1.

2. Install Table/Saddle (Index A) to Table and

Clincher Bracket (Index B) using the two

shoulder screws (Index C). Shoulder of screws

should extend through table and bottom out inside

of table/clincher bracket.

3. Turn Trip lever Knob (Index D) counter

clockwise and move the work trip (Index E) all

the way toward the clincher (Index F). Install

the Auxiliary Table (Index G) and Paper Guide

(Index K) to the stand using the two .25-28 x

.375 socket head cap screws and flat washers

(Index H,I). The top surface of the auxiliary

table should be at the same height as the main

table. NOTE: The auxiliary table MUST

NEVER TOUCH THE WORK TRIP OR

STITCHER WILL ACTIVATE (SEE

FIGURE 3).

4. Install Wire Guide Spring into wire guide bracket

of M2000 Head.

Figure 1

(QF27F1)

G

H

I

K

Figure 2

(QF27F2)

NOTE: AUXILIARY TABLE "G"

MUST NEVER TOUCH WORK

TRIP "E"

Figure 3

(QF27F3)

G

Coil of Wire

Spool Retainer

Hair Pin Cotter

NOTE: Slide coil of wire onto

spool stud so that the wire will

feed upward from the rear

E

D

A

F

C

J

B

E

5

Page 8

C

B

D

E

A

F

H

Figure 4

(CTTT2605T3 Scene 3, 4)

G

J

I

K

L

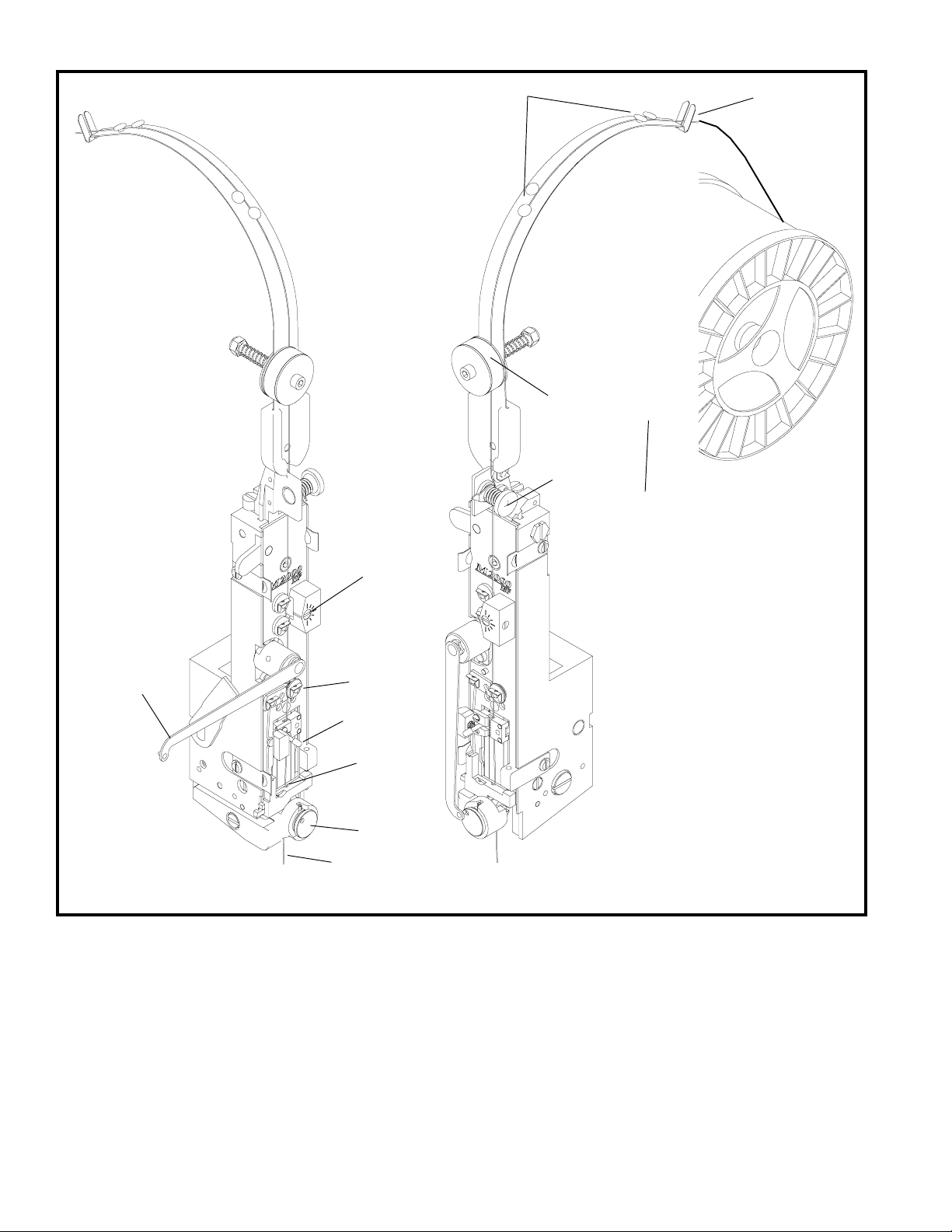

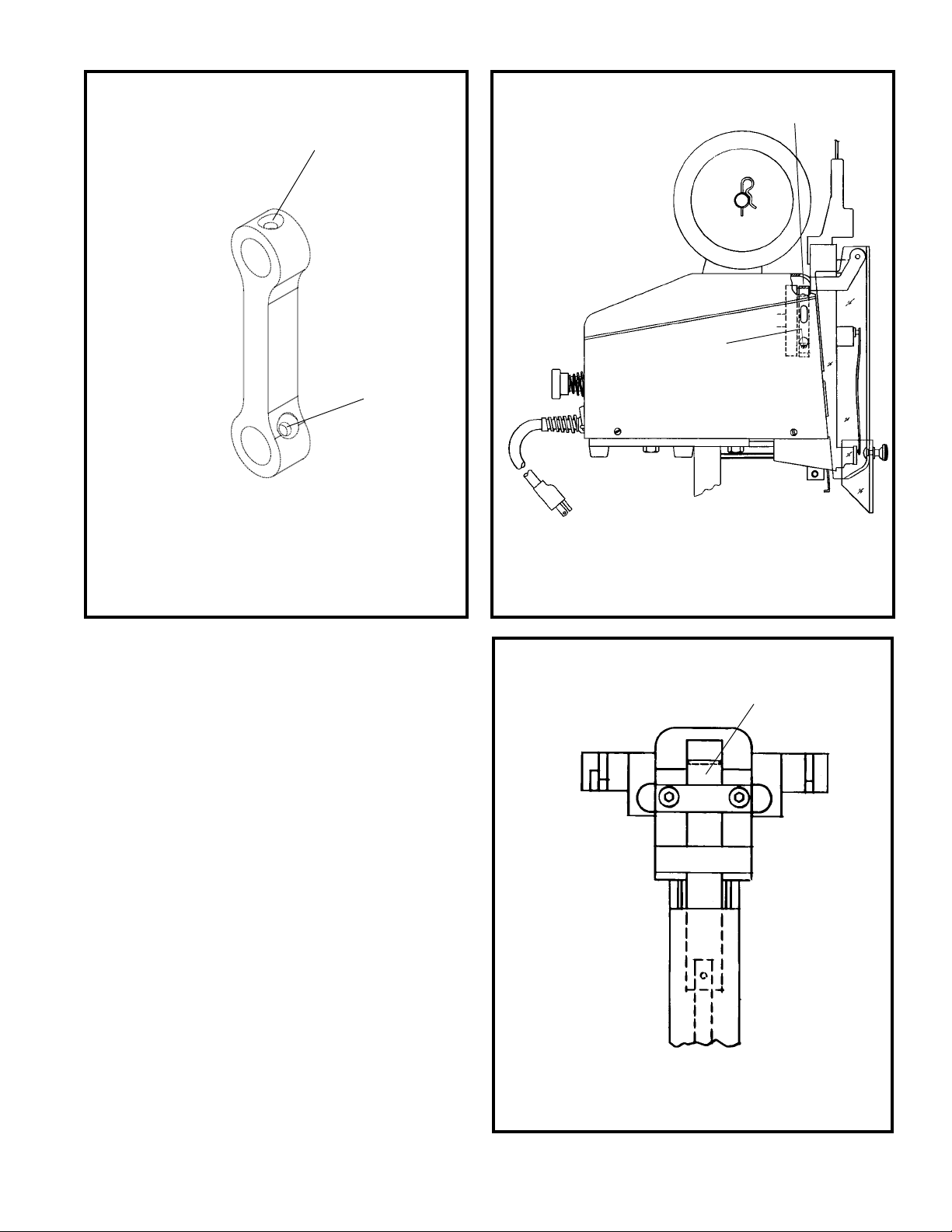

THREADING WIRE AND

ADJUSTING WIRE

STRAIGHTENERS (See fig. 4)

1. Draw wire by hand, from the the coil (Index A).

2. Thread the wire through the slot (Index B) at the

end of the wire guide spring, through the wire

guides (Index C), between the thin and thick felt

wire wipes (Index D), through the upper wire

straightener (Index E), and through the lower

wire straightener (Index F).

3. Release the rotator operating spring (Index H)

from the rotator and swing it to the left. Remove

Rotator (Index K).

4. Thread the wire between the tension pawl and

tension roll (Index G). Feed the wire through the

wire cutter lead-in hole (Index I) in the bottom

of the face plate.

5. Push grip post to left to open the grip (Index J).

Insert wire and release the post so that the grip

engages the wire for feeding into the rotator.

6

Page 9

6. To check adjustment, hold open grip (Index J

and pull about 1 1\2 feet of wire from below

face plate. Cycle machine once by hand to cut

wire. Cycle machine again by hand to observe

wire straightness. The wire (Index L) should

point straight down, prior to being cut, as shown

in Figure 4 .

7. Adjust the upper wire straightener, beginning at

position shown, (Index E, Figure 4) so that the

wire points straight down. Adjust the lower

wire straightener, beginning at the 3:00 o'clock

position, (Index F, Figures 4) so that the wire

(Index L, Figure 4) feeds straight down.

8. Replace the rotator and rotator operating spring.

NOTE:

When changing coils or wire sizes, check straightners

to insure proper wire feed.

FELT WIPE PADS

LUBRICATION

AND MAINTAINANCE:

(FIGURE 5)

IMPORTANT! In order for the stitchers to operate

properly, the felt wire wipes MUST be rotated and

dampened with SAE 20W oil before each new

spool of wire (50,000 to 70,000 stitches). Replace

felt pads when they become so dirty that they cannot

be rotated to a clean spot.

Figure 5

(CTTT2605T3 Scene 5)

1. After every wire

spool, rotate the dirty

area of the pads

slightly so that a clean

area can be used for

the next wire spool.

Rotate

2. Dampen both pads

(about 30 to 40 drops)

using an SAE 20W

oil.

Dirty area of pads has been

slightly rotated so that a clean

area of pads can be used for the

next wire spool.

7

Page 10

A

F

G

B

E

H

Figure 6

(CTTT2605 Scene 5)

D

C

STITCHING HEAD

LUBRICATION:

(FIGURES 6 & 7)

Typically, the 1/2 inch crown stitcher will run for

1,000,000 cycles without additional lubrication.

However, the following procedure used after each

spool of wire will assure optimum life and

performance. Use ISP lubricant #CA9640.

A. Inject lube into hole, or remove and lube shafts.

B. Wipe area clean and inject a small amount of

lube into cam area.

C. Remove rotator, wipe rotator clean and lube

rotator body.

D. Apply lube to rotator ramp.

E. Wipe clean inside of rotator holder.

Figure 7

(CTTT2605 Scene 6)

F. Inject a small amount of lube into cam area of

driver bar.

G. Inject lube into cutter operating slide.

H. Wipe driver clean, and apply a light coating of

lube.

After prolonged use (or storage) accumulations of

wire dust, dirt, or other contaminants can mix with

the stitcher lubricant. This will reduce the lubricant's

effectiveness. The following procedure is

recommended every 1,000,000 cycles.

1. Disassemble the head and clean all parts.

2. Lightly lube all sliding surfaces using ISP

lubricant #CA9640.

3. Double check lube points A through H.

8

Page 11

L

L

M

M

Figure 8

(CA44 Layout 2)

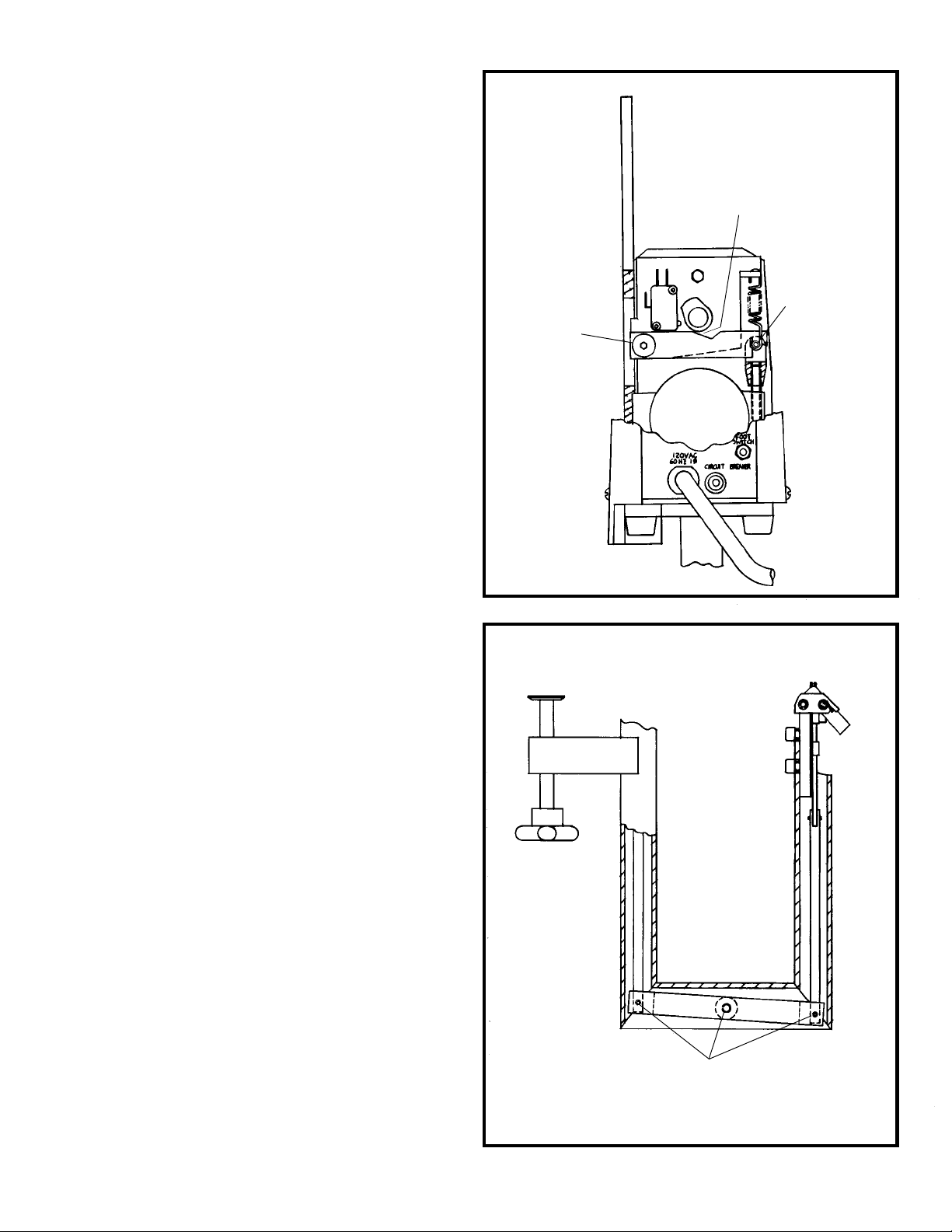

EXTERNAL LUBRICATION:

(FIGURES 8, 9, 10)

Lubricate the following points before each spool of

wire using SAE 20 oil.

L. One drop in top hole of head operating link.

Access through slot at top of cover behind stitcher

head.

M. One drop in lower/side hole of head operating

link. Access through round hole (while viewing

through slot immediately above round hole) in

side of cover.

N. One drop on clincher slide.

Figure 9

(QF27F4)

N

Figure 10

(QF27F5)

9

Page 12

INTERNAL LUBRICATION

(FIGURES 11, 12)

Frequency of Lubrication: Every 500,000 stitches

or once a year, which ever comes first.

Unplug power cord, remove grey plastic cover and

apply oil as follows:

O. Two drops to pivot point of clincher operating

lever.

P. One drop between cam and clincher operating

lever.

Q. One drop on roll pin.

R. One drop on each clincher rocker lever roll

P

Q

O

Figure 11

(QF27F6)

10

R

Figure 12

(QF27F7)

Page 13

Section 4

OPERATION

General:

After having properly installed and set up the

machine, it is now ready for stitching. It is

recommended that each operator be instructed as to

correct operating procedure and normal adjustments

necessary for varying work conditions.

WARNING

Prevent accidents by following these

rules:

1. Do not put your hands near area to

be stitched when machine is operating.

2. Turn the power off when the stitcher

is not in use.

Table/Saddle Conversion:

To convert from saddle to table fully raise front

sliding guard (Index 118, page 37), swing up front

of saddle until the two spring loaded table braces

(Index J, Fig.2) flip up to keep the table from

swinging back down.

To convert from table to saddle gently lift the front

of the table, pull forward at the bottom of one of the

table braces until the table can be gently swung

down to saddle position. Fully lower front sliding

guard (Index 118, page 37).

work trip to achieve the desired stitch location.

Swing down the front guard assembly. Switch power

on. Insert work, from the front, into the stitching

area until the work depresses the work trip, causing

stitch.

Table Stitching Using the Foot

switch:

Switch off power. Swing up front guard assembly.

Position table/saddle for saddle stitching. Turn the

trip lever knob counter clockwise and position the

work trip to serve as a back gauge or move work

trip completely back out of the way of the work.

Plug the foot switch cord into foot switch outlet on

rear control panel (work trip is then automatically

bypassed). Switch power on. Load work, from the

front, into the stitching area. Once the work is

positioned as desired step on foot switch to cause

a stitch.

Hand Jog:

A hand jog is located at the rear of the machine. To

manually cycle the Bindery Mate: switch off power;

push in and rotate knob counter clockwise to go

through a normal stitch cycle, or clockwise for a

reverse cycle.

Table Stitching Using the Work

Trip:

Position table/saddle for table stitching. Switch off

power. Swing up front guard assembly. Turn the

trip lever knob counter clockwise and position the

11

Page 14

Master Out and SecondaryUnit In:

These outlets are only for use with the "Multiple

Stitch Accessories".

Saddle Stitching-Foot Switch Use

Only:

Switch off power. Swing up front guard assembly.

Turn the trip lever knob counter clockwise, and

move the work trip all the way back. Position the

table/saddle for saddle stitching. Swing down the

front guard assembly. Slightly loosen the two knobs

(counter clockwise) securing the front sliding guard

to the front guard. Allow the front sliding guard to

drop to the saddle position. Retighten the two knobs.

Plug the foot switch cord into foot switch outlet on

rear control panel (work trip is then automatically

passed). Switch power on. Load work from either

side and step on foot switch to cause a stitch.

CAUTION

AVOID DAMAGE TO YOUR

STITCHER BY FOLLOWING THESE

RULES:

1. Never operate your stitcher with wire

feeding unless you have work material

between the clinchers and benderbar.

2. Do not drive one stitch on top of

another.

Work Guides:

A. Side Guides: To adjust side guides pop-up the

pins at the end of each guide, loosen the screw

knob beneath the table, position guides as desired,

and retighten the screw knob.

B. Corner Stitch Guides-Table Use Only: Pop Up

the pins located in the table and the pins located

at the end of each side guide. Using your work

as a set up tool, position and secure the side

Figure 13

(QF27F8)

guides as indicated in figure 13. Switch off

power, swing upfront guard assembly, and move

the work trip all the way forward. Swing front

guard assembly back down and switch on power.

Push work into corner guided area of table until

depression of work trip causes a stitch.

Changing Work Thickness:

Changing work thichness will probably require a

change of the wire draw length used to make a

stitch. This is done by raising or lowering the face

plate. To change face plate position switch off

power; swing front guard assembly up to the second

detente position; loosen the faceplate screw

(Located directly above M2000 on the face plate),

move the position lever up for more wire or down

for less wire, retighten faceplate screw, and swing

down front guard.

12

Page 15

Section 5

E

MAINTENANCE, TROUBLE

SHOOTING AND

ADJUSTMENTS

General

Every Bindery Mates M2000 Head Stitcher has a

friction-type head which depends on smooth sliding

friction and proper timing to function correctly.

Preventative maintenance will go far to insure

trouble-free operation. Avoid production down time

by keeping your stitcher in top working condition at

all times.

Recommended Spare Parts

Like any equipment that has moving parts, certain

parts of your stitcher will be subjected to more

wear than others and require replacement. The

following listing includes all the parts required for

minimum maintenance and good operation of your

Bindery Mate.

D

A

Figure 14

(CTTT2605T3 Scene 8)

Figure 15

(CTTT2605T3 Scene 9, 1)

Caution

MAKE ALL ADJUSTMENTS WITH

THE POWER OFF AND THE

STITCHING HEAD IN NEUTRAL

POSITION! (Fig. 14)

In neutral position, the wire grip assembly

(Index A) is stopped at the top of the slot

in the face plate.

C

PART NAME PART NO. QTY.

Wire Cutters CA9048 2

Grip CA9015D 1

Grip Spring CA168 1

Tension Roll Clip CA9124 2

Rotator CAA9038E 1

Clincher Points CA9083 2

Stitching Adjustments

Best stitching performance will be assured if all

adjustments are made so that you get the following

results:

1. Good Cut-Off

2. Uniform Wire Draw

3. Equal Leg Length

4. Proper Clincher Alignment

5. Sufficient Compression

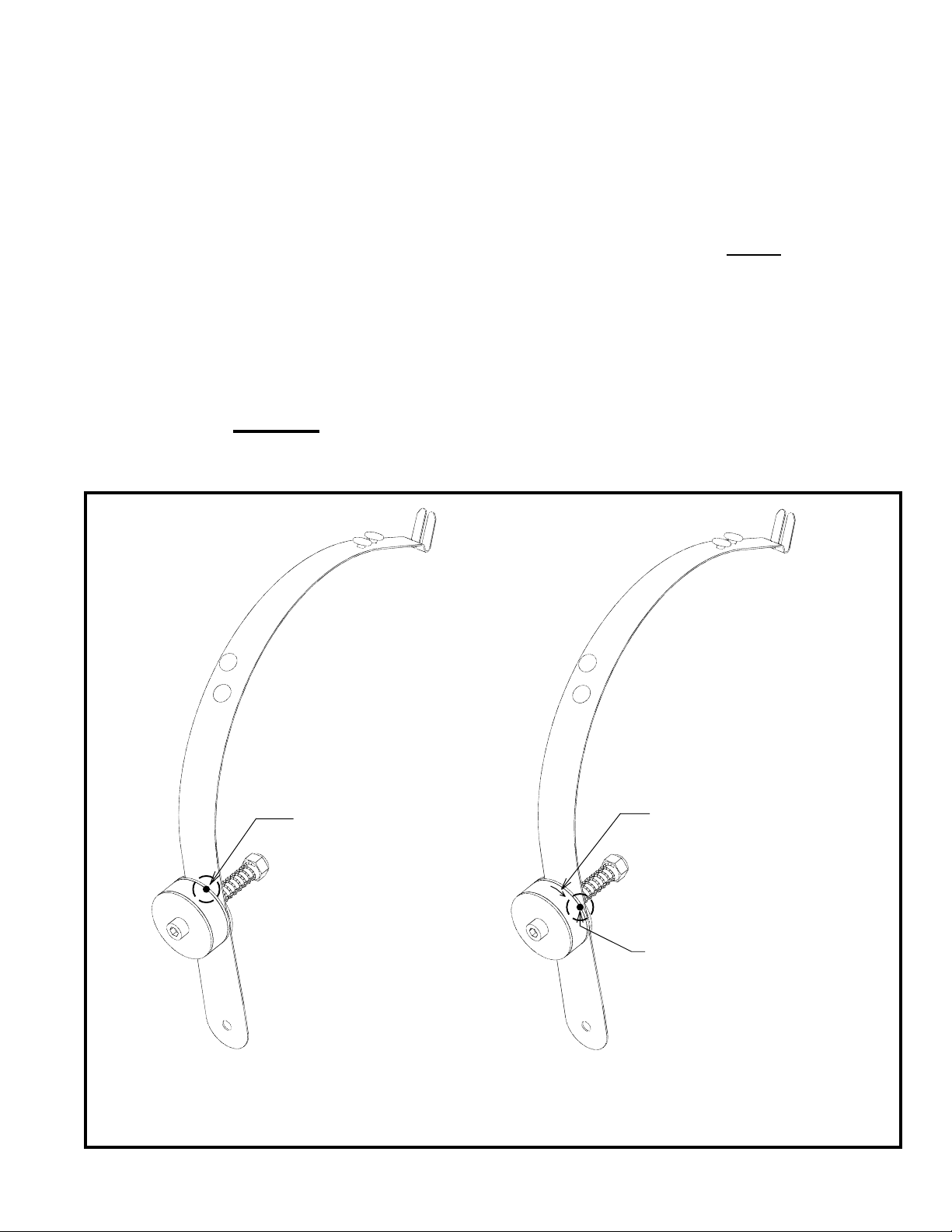

To Equalize Both Legs of Stitch

(Fig. 15)

1. Loosen the wire guide locking bolt (Index C).

2. Turn adjusting screw (Index D) clockwise to

shorten left leg of stitch; counter clockwise to

lenghten left leg.

3. Tap bracket (Index E) down before tightening

bolt (Index C).

13

Page 16

M2000 Head Trouble Shooting

HERE'S HOW A PERFECT STITCH LOOKS

Should stitches appear in any form other than illustrated, one or more

kinds of mechanical trouble may have caused the malformation. The

possible causes and remedies are given for each kind of mechanical trouble

and are listed under each section. The remedies are indexed to the

Adjustments Section which gives more detailed information about your

stitcher, the mechanical trouble that may occur and suggested remedies.

Unless you recognize the correct cause, check each possible cause given.

TROUBLE

A. Defective Stitches

1. One or both legs buckled.

NOTE: Since buckled legs are

often concealed in the work and

may appear the same as a short

leg, always remove two or more

stitches to see which is

occurring.

2. Wrinkled crown.

3. Length of one leg varies

POSSIBLE CAUSE

1. Clincher is worn or improperly

aligned.

2. Insufficient compression.

3. Unequal leg length

4. Burred stitch leg.

5. Incorrect wire size.

6. Worn bender bar.

1. Leg Lengths not adjusted

properly

2. Gripper is worn or dirty

3. Grip release slide is worn

4. Broken wire guide spring

(index 65H)

5. Excessive tension on wire

straightner

6. Worn Driver bar

7. Worn Tension Pawl or weak

tension pawl spring

8. Weak or broken grip spring

REMEDY

"C,F" Page 20,22

"A,B" Page 20

See "To Equalize Both Legs of

Stitch" Page 13

"L" Page 25

"N" Page 26

"G" Page 22

See "To Equalize Both Legs of

Stitch" Page 13

"K" Page 24

"K" Page 24

Page 40

"P" Page 27

"I" Page 23

"R" Page 28

"K" Page 24

14

Page 17

M2000 Head Trouble Shooting

TROUBLE

4. Corner of crown distorted or

fractured

5. Stitch crown not flat and legs

not bent into work

6. One or both legs turn out

7. Flat piece of wire

POSSIBLE CAUSE

1. Excessive compression

2. Broken driver bar end

3. Worn bender bar

4. Clincher improperly aligned

or worn

5. Incorrect wire size

1. Insufficient compression

1. Clincher improperly aligned

2. Dull cutters

1. Rotator is dirty

2. Improperly adjusted lower wire

straightener

3. Broken or worn rotator

4. Improperly aligned rotator

REMEDY

"A,B" Page 20

"I" Page 23

"G" Page 22

"C,F" Page 20,22

"N" Page 26

"A,B" Page 20

"F" Page 22

"L" Page 25

"O" Page 26,27

"P" Page 27

"O" Page 26,27

"O" page 26,27

8. Stitches come out in pieces

9. Both stitcher legs are either

too long or too short

1. Improperly aligned rotator

2. Weak rotator operating spring

3. Improperly adjusted upper wire

straightener

4. Incorrect wire size

5. Wire jammed in bender bar

grooves

Face plate not adjusted properly

"O" Page 26,27

"O" Page 26,27

"P" Page 27

"N" Page 26

"G,I" Page 22,23

See "Changing Work

Thichness" Page 12

15

Page 18

B. WIRE BUCKLES

M2000 Head Trouble Shooting

REMEDYPOSSIBLE CAUSETROUBLE

1. Wire buckles above the grip

and below the tension pawl

Figure 16

(CTTT2605 Scene 10VA)

2. Wire Buckles above the wire

cutters and below the grip

1. Worn driver bar

2. Worn bender bar latch

3. Worn or broken bender bar

friction plug and/or spring

1. Improperly aligned rotator

2. Worn or broken wire cutters

3. Burrs on rotator

4. Improperly adjusted lower

wire straightner

"I" Page 23

"J" Page 24

"H" Page 22

"O" Page 26,27

"L" Page 25

"O" Page 26,27

"P" Page 27

Figure 17

(CTTT2605 Scene10VB8)

C. GRIP

1. Grip does not close with

position lever up.

5. Worn or broken wire cutter

operating slide

6. Wire cutter slot in face plate

worn

Face plate is too high Loosen face plate screw, turn

"M" Page 26

"L" Page 25

set screw (item 36H, page 40)

downward slightly in face plate

clip (item 35H, page 40),

retighten face plate screw.

16

Page 19

Drive Trouble Shooting

POSSIBLE CAUSETROUBLE REMEDY

On/Off switch does not light

when switched on

Stitcher drive does not operate

with work trip

Power cord unplugged

Circuit breaker is blown

Faulty electrical connection

Safety switch is not being

depressed by front guard

Foot switch is plugged in Unplug foot switch

Circuit breaker is blown

Faulty foot switch jack

Plug in power cord

Press in extended circuit

breaker

NOTE: If recently blown, wait

10 min. before pressing in

Use electrical schematic page

42, 43 to check wiring

Adjust front guard and/or safety

switch bracket

Press in the extended citcuit

breaker. NOTE: If recently

blown, wait 10 min. before

pressing in

Repair or replace foot switch

jack

See foot switch schematic pages

42 and 43 for reference

Contaminants on electrical

contacts of trip mechanism

Faulty electrical contact of trip

machanism. (Pressing the trip

should break the circuit between

the round trip locating rod, Item

25 page 35, and the hexagonal

paper trip rod, Item 24 page 35)

Faulty electrical connections

Faulty safety switch

Faulty motor (test using 90 vdc)

Faulty circuit board

Turn trip lever knob counter

clockwise and move trip mechanism from front to back a few

times

Remove trip machanism, clean,

repair, or replace contaminated

or damaged items

Use electrical schematic page

42, 43 to check wiring

Replace switch

Replace motor

Replace circuit board

17

Page 20

Drive Trouble Shooting

TROUBLE POSSIBLE CAUSE

Stitcher drive does not operate

when foot switch is depressed

Safety Switch is not being

depressed by front guard

Circuit breaker is blown

Faulty foot switch (pressing foot

switch should break contacts of

switch inside Footswitch

assembly)

Faulty electrical connections

Faulty safety switch

Faulty motor (test using 90 vdc)

REMEDY

Adjust front guard and/or safety

switch bracket

Press in the extended circuit

breaker. NOTE: If recently

blown, wait 10 min. before

pressing in.

Replace footswitch

Use electrical schematic page

42, 43 to check wiring

Replace switch

Replace motor

Stitcher keeps cycling, without

depressing footswitch or work

trip, until power is shut off

Faulty circuit board

Faulty cam switch

Faulty electrical connections

Replace circuit board

replace switch

Use electrical schematic page

42, 43 to check wiring

18

Page 21

NOTES

19

Page 22

CAUTION

Turn Power OFF Before making Any

Adjustments

A. Insufficient or Excessive

Compression

Proper compression of work between the clincher

and the bender bars is necessary so that the stitch

penetrates the work material and clinches correctly.

To test for compression, drive several stitches into

sample work material. With proper compression,

stitches hold the work together firmly and the clinched

legs do not overlap. In the following instances,

either one or all of the conditions may exist: with

insufficient compression, stitch legs overlap, crown

of the stitch is fractured, and the work mutilated.

To change compression adjust the table/clincher

bracket.

D

B

A

C

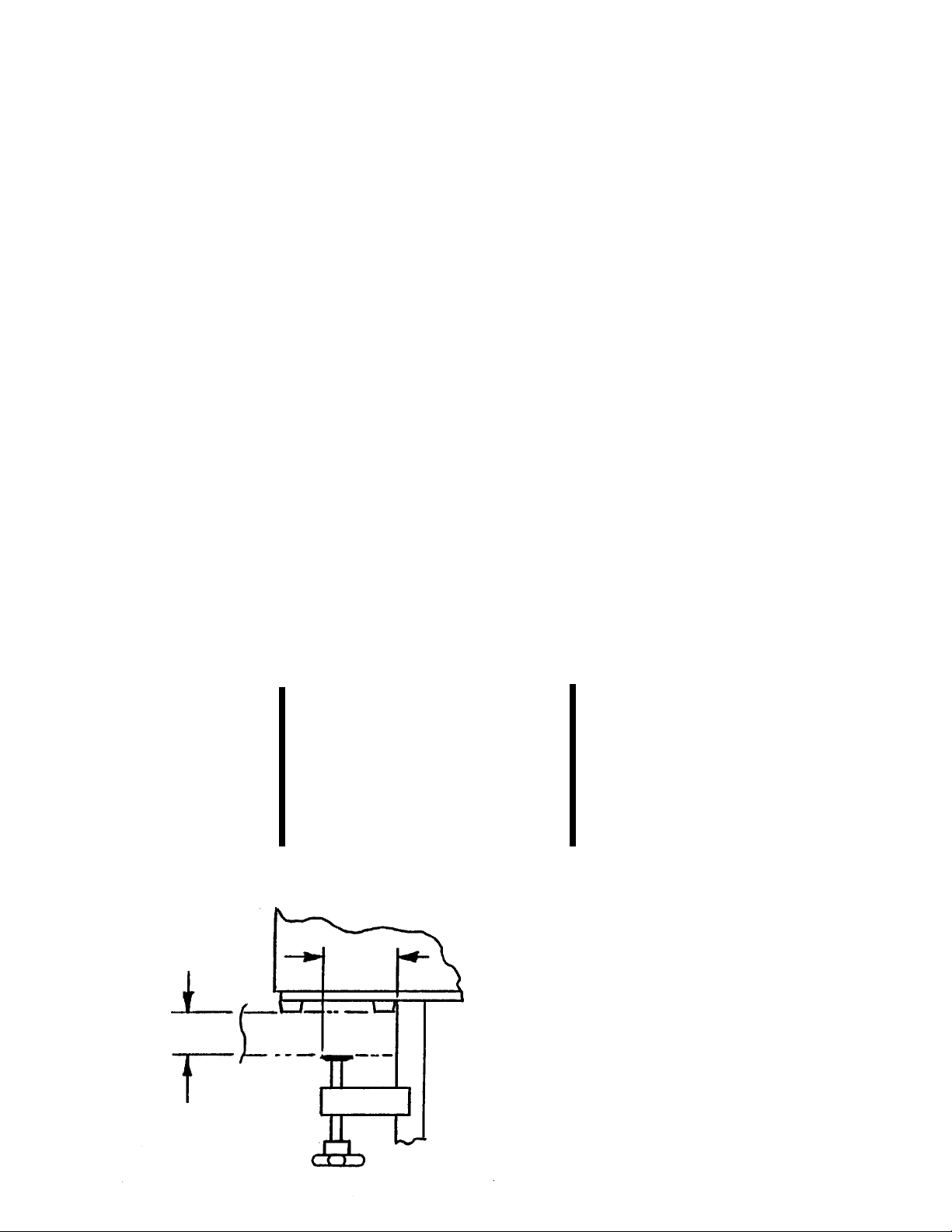

B. Table/Clincher Bracket

Adjustment (Figure 18)

1. Remove wire from rotator, and turn the jog knob

clockwise until the bender bar is fully down.

2. Loosen the two screws (Index A) securing the

table/clincher bracket (Index B) to the stand

(Index C).

3. Move the table/clincher bracket up until the top

of the clincher assembly squarely touches the

bottom of the fully lowered bender bar. (Index

D)

4. Retighten the two screws.

C. Clincher (Figure 19)

The purpose of the clincher is to turn the legs of the

stitch back after they have penetrated the work

material.

With the Activated (moving) Type clincher, the stitch

legs must enter the clincher at the same time and

with equal spacing from each side. When the stitch

legs have penetrated the work material, the moving

clinchers are raised to bend the legs towards each

other and up flat against the work. The clincher

Figure 18

(QF27F9)

points must bend both legs of the stitch against the

work with the same force. Clincher points must

always move freely and not bind. Dirt, wire chips,

etc. will cause the points to bind.

The clincher points are in a retracted position in the

clincher box until the stitch legs penetrate the work

material. After the legs penetrate, the clincher points

move upward to give a neat, flat clinch against the

bottom surface of the work material. If the clincher

points remain in the up position, the legs of the next

stitch cannot penetrate the work material, causing

the stitch legs to buckle and/or the corners of the

crown to fracture. Examine the clincher points,

clincher slide for possible binding. Clean and oil.

If clincher points rise to high, they fracture the stitch

legs and/or mar the work. If the points do not rise

high enough, the legs will not clinch flat. Adjust the

height of the clincher points.

20

Page 23

A

Stitch

Figure 19

(SK852F)

D. To Adjust Clincher Points

Height (Figure 20)

1. Turn off power and unplug power cord.

2. Remove wire coil, washer, compression spring

and stud.

3. Swing up front guard assembly to 1st detent

position.

4. Unscrew the four screws securing cover and

remove cover.

5. Unhook and remove the extension spring (Index

A).

6. Lift clincher operating lever (Index B) away

from clevis (Index C) and turn clevis clockwise

to lower the clinchers, counterclockwise to raise

the clinchers. Note: clinchers will raise or lower

.025" per 360 degree turn of clevis.

7. Reassemble unit.

Figure 20

(QF27F10)

Figure 21

(QF27F11)

C

B

C

D

A

B

If the clinchers points are broken, the stitch legs

will not clinch and/or be deformed. Reverse or

replace the clincher points.

E. To Reverse or Replace Clincher

Points (Figure 21)

1. Remove the two screws (Index A) securing the

clincher slide brace (Index B). Remove brace.

2. Move clincher slide away from clincher points

(Index C).

3. Raise the clincher points, and reverse or replace.

4. When reassembling, push the clincher points

down so that the top lip of the clincher slide

(Index D) will engage the center of the clincher

points. Note: Clincher slide must move freely

up and down after reassembly.

The proper alignment of the clincher under the

formers is one of the most critical adjustments on

the stitcher. Therefore, extreme care should be

taken to align the clincher so that both legs of the

stitch strike the clincher at the same time with equal

spacing from the outside edges of the grooves (See

Figure 19). Also, the clincher must be aligned with

the bender bar grooves of the head from front to

rear so that the legs enter the clincher at the widest

section of the clincher grooves.

21

Page 24

B

A

C

Figure 22

(QF27F12)

B

C

A

Figure 23

(QF27F13)

F. Head/Clincher Alignment

(Figures 22, 23)

Figure 24

(SK852I)

G. Bender Bar (Figure 24)

The bender bar bends the wire over the rotator and

forms it into an unclinched stitch. The legs of the

stitch are guided towards the work material by the

bender bar grooves. The legs of the unclinched

stitch should be perpendicular to the crown. When

the bender bar grooves become worn, the legs tend

to flare out (Figure 24) as they emerge from the

grooves. This causes the legs to strike the clincher

improperly. As a result, one or both legs will

crumple and a broken driver bar or a broken bender

bar can result. If the lower end of the bender bar

groove becomes chipped, it will not support the

wire and may cause the stitch to break at the crown.

Replace the bender bar assembly (See Section H or

Fig. 25). Other bender bar functions are related to

wire cutting (Section L), and driving (Section I).

To test alignment: Drive several stitches into a

section of material identical to that which is to be

stitched. The clinched legs should be identical and

aligned with each other. If the legs are not in

alignment, make the following adjustments:

1. With power off, press in and turn the jog knob

clockwise until the legs of the stitch (Index A,

Fig. 22) appear just below the bender bar (Index

B).

2. Loosen the four bolts (Index A, Fig. 23) securing

the base (Index B) to the stand (Index C).

3. Move the base until the legs of the stitch line

up with the clincher points (Index C, Fig. 22).

4. Tighten the four base mounting bolts.

22

H. Bender Bar Friction Plug

And/Or Spring (Fig. 25)

Two parts furnish pressure to coordinate movement

of driver bar and bender bar. If pressure is

insufficient, proper timing is not maintained for the

action of the grip. As a result, wire feeds backwards.

Replace the plug and/or spring.

To replace bender bar friction plug and/or bender

bar friction spring:

1. Remove bender bar assembly by following steps

1 through 23 of "Removing and Dismantling

M2000 Head", Pages 29 and 30.

Page 25

A

B

C

B

Figure 25

(CTTT2605 Scene 13)

2. Remove bender bar friction bushing (Index A).

Bender bar friction plug (Index C) and spring

(Index B) will be released forward from bender

bar assembly.

3. Replace plug and/or spring and reassemble.

I. Driver Bar (Figure 26)

The driver bar (Index A) has several functions:

1. It imparts the downward thrust from the driving

slide assembly (Index B) to the bender bar

assembly (Index C).

2. It returns these parts to the neutral position on

the upstroke.

3. In conjunction with the grip release slide (Index

D), it controls the movement of the bender bar

latch (Index E) that opens and closes the grip

(Index F).

If the notches (Index G) at the top left side of the

driver bar become worn, the grip will not remain

open on the upstroke. As a result the wire feeds

backwards and buckles above the grip and below

the tension pawl. Worn notches can also cause

uneven wire draw. Replace the driver bar.

The notches shown on left side of driver bar play

an important part in function of bender bar assembly

therefore, corners should be free of dirt and notches

not marred.

The driver bar rides within the bender bar grooves

as part of the bender bar assembly. As this assembly

reaches the lower contact point of the cam in the

D

Figure 26

(CTTT2605T3 Scene 10, CA9012M)

grip release slide, the bender bar latch is forced

inward, releasing the wire grip and permitting the

bender bar assembly to continue downward with the

end of the driver bar riding on top of the formed

stitch. When the bender bar is stopped against the

work material, the driver bar continues downward

to exert pressure on the crown of the stitch, driving

it through the work material.

If the end of the driver bar is chipped it allows the

legs of the stitch to back up into the broken area.

This causes the corner of the crown to fracture or

a "spike" section to protrude above the crown. A

chipped driver bar is usually the result of driving a

stitch on top of another stitch. A worn driver bar

often causes deformed stitches or fracturing at the

corners of the crown.

A

G

F

E

C

23

Page 26

E

F

D

B

Figure 27

(CTTT2605T3 Scene 11)

J. Bender Bar Latch

The bender bar latch opens and closes and is actuated

by the grip release slide and driver bar. If the

contact points of the latch become worn, timing of

the grip is erratic and uneven wire feed results. A

dirty latch will decrease pressure of the grip on the

wire. This causes wire slippage. Clean or replace

the latch.

X

C

A

K. Grip, Grip Release Slide and

Face Plate: (Figure 27)

The grip spring (Index A) exerts pressure on the

benderbar latch (Index B) to close the grip (Index

C) at the start of the down stroke. The grip release

slide (Index D) actuates the bender bar latch at

point X to open the grip after the correct amount of

wire has been fed to make a stitch. The serrated

teeth on the grip must be sharp or slippage will

occur, producing uneven wire draw.

24

Page 27

L. Wire Cutters: (Figure 28)

The purpose of the wire cutters is to shear the wire

cleanly. There are two wire cutters, upper and

lower. The upper wire cutter (Index A) recieves

wire from the grip through the wire cutter lead-inhole (Index B). It also serves as the cut-off die.

The lower wire cutter (Index C) is the cutting knife.

If the cutter breaks, it will cover the lead-in hole.

M

E

D

I

A

H

This prevents the wire from feeding into the rotator.

If the cutting surfaces become worn, burrs will result on the end of the wire. This prevents the wire

from feeding into the rotator. As a result, the wire

buckles between the cutters and the wire grip. Reverse, interchange or replace the cutters.

To Reverse, Interchange or

F

L

C

K

N

Figure 28

(CTTT2605T3 Scene 12)

When the face plate (Index E) is adjusted (See

"Changing Work Thickness", page 12) a pivotal

action (at point F) changes the position of the grip

slide. When the face plate is raised, it moves the

grip release slide down. The gripper can then remain

closed longer, on the downstroke, feeding more wire

for the stitch. When the face plate is lowered, it

moves the grip release slide up. The gripper will

open sooner on the downstroke, feeding less wire

for the stitch.

If the grip is weak, uneven wire draw will result.

Replace the grip spring. If the contact points on the

grip release slide and/or the bender bar latch are

worn, wire adjustment will not remain accurate.

The face plate stops the bender bar assembly at the

top of its stroke and allows the bender bar latch to

close the grip. When the face plate is too high, too

much of the upstroke has been used before the bender

bar hits the face plate. In the remaining portion of

the upstroke, the driver bar cannot continue upward

enough to release the bender bar latch so that it can

close the grip.

J

B

G

Replace the Wire Cutters:

1. Loosen both face plate retaining clips (Index D)

at bottom of bonnet.

2. Spring the face plate out 1/8" while holding the

cutter clide in position (Index E).

3. Slide the cutters out to the left.

4. Reverse, interchange or replace the cutters.

NOTE

While installing the cutters, make sure that (1):

lip on upper cutter (Index F) fits into the recess

behind the face plate (Index G) and (2):that the

lip on the bottom cutter fits into the slot (Index

H) in the wire cutter operating slide (Index I).

The wire cutter operating slide actuates the lower

wire cutter. If the slide is worn or broken, the wire

cutter is not actuated. Replace the operating slide.

The slot in the lower part of the face plate contains

the wire cutter and maintains a close fit for wire

shearing. If this slot becomes oversized, the wire

will not be cut off. Replace face plate. To Replace

Face Plate (See Steps 1 through 10, Section M)

NOTE: (Figure 29)

The lug (Index C) in the faceplate must match

the slot (Index D) in the grip release adjusting

lever (Index E) or damage to the head may result.

25

Page 28

D

G

C

A

9. Position grip spring housing (Index G) between

tension pawl spring retainer (Index H) and cutter

housing (Index I).

10. Remove face plate (Index B) by sliding face

plate to the left and lifting up.

11. Remove the cutter operating slide (Index I, Figure

E

F

28).

12. Insert a new cutter operating slide.

13. Reassemble

N. Proper Wire

The Bindery Mate is designed to use 25 gauge (.020"

diameter) 120,000 to 159,000 psi tensile strength

bookbinders wire.

If the wire used is larger than the bender bar grooves

were designed for, it will fracture at the stitch corners

B

H

and come out in pieces. Also, serious damage to

the stitcher may result. If the wire used is smaller

than the bender bar grooves were designed for, the

legs of the stitch do not fit snugly in the grooves and

may tend to buckle when they strike the work material

because they are not fully supported.

Figure 29

(CTTT2605T3 Scene 13)

I

M. Wire Cutter Operating Slide

The wire cutter operating slide actuates the lower

wire cutter which acts as the cutting knife. If the

slide is worn or broken, the wire cutter is not

actuated. Replace the operating slide.

To Replace The Wire Cutter Operating Slide:

1. Cut the wire at the bracket and pull the loose

end out.

2. Remove the stitcher head assembly.

3. Lift end of spring (Index L, Figure 28) out of

rotator.

4. Swing the spring up to disengage it and lift out.

5. Slip the rotator operating cam (Index M, Figure

28) forward and off the stud.

6. Pull the rotator forward.

7. Loosen the two face plate retaining clips (Index

A, Figure 29) and rotate them downward.

8. Push two face plate retaining clips (Index F)

outward while lifting face plate up, or remove

retaining clips to release face plate.

O. Rotator (Figure 28)

The rotator (Index J) (1) recieves the wire from the

cut-off die, (2) holds the wire while it is being cut,

then (3) turns it to a horizontal position, moves it

under the bender bar grooves and (4) supports the

wire while it is being formed into a "U-shaped"

stitch.

The wire lead-in-funnel of the rotator must be aligned

with the wire as it comes through the wire cutters.

If the rotator is improperly aligned, the wire hits the

rotator and buckles. Adjust upper two wire

straightners until wire slips past rotator. Burrs on

the rotator prevent the wire from entering the rotator.

This causes wire buckling. Remove the rotator and

polish the lead-in radius.

The magnets in the rotator hold the wire firmly in

the rotator. If a magnet is broken or chipped the

wire may fall out. To determine if the rotator has

the proper holding strength, remove the rotator and

insert a cut length of wire in the rotator. Hold

rotator between thumb and forefinger. Attempt to

jar wire loose by hitting heel on hand on top of

table or against other hand. With proper magnetic

holding force wire will remain in rotator. With

26

Page 29

insufficient holding force wire

will fall from rotator. Replace

the rotator.

The rotator holder and rotator

operating spring are responsible

for alignment of the wire beneath

the bender bar grooves. The

position of the rotator holder

determines how far the rotator

is pushed forward under the

bender bar by the rotator

operating spring (Index L). A

weak spring will not push the

rotator in far enough and with

this improper alignment the

bender bar will knock the wire

from the rotator or will shear

the wire into pieces. To secure

proper alignment, check the

position of the rotator operating

spring. Make any necessary

adjustment of the rotator holder

or replace the rotator operating

spring if weak.

The wire is fed into the rotator

and held for forming. If the

rotator is dirty, the wire is not

gripped securely enough and drops out. Remove

and clean the rotator. If the edges over which the

wire is formed are sharp, the corners of the stitch

crown will fracture. Remove the rotator and polish

the edges with a fine emery cloth.

To remove, Adjust or Replace the Rotator Holder:

1. Swing the rotator operating spring to the left.

2. Remove the rotator.

3. Loosen the rotator holder screw (Index N).

4. Adjust the rotator holder screw.

5. Re-assemble.

Figure 30

(CTTT2605T3 Scene 3, 4)

P. Wire Straighteners: (Figure 30)

All coils of stitching wire have a certain amount of

bundle curve. The purpose of a wire straightener

is to remove this curve. There is both an upper

wire straightener (Index A) and a lower wire

straightener (Index B) on all M2000 Model Stitchers.

See "Threading Wire and Adjusting Wire

Straighteners" page 6.

The upper wire straightener should feed wire parallel

A

B

D

C

to the faceplate. This insures that the wire will

properly enter the rotator and will be aligned with

the grooves in the bender bar. If the wire is not

parallel to the face plate the wire is sheared in the

rotator as the bender bar descends. Adjust the

upper wire straightener.

The lower wire straightener directs the wire straight

down so that it enters the rotator (Index C). If the

wire is not straight enough it hits the rotator and

buckles. Adjust the lower wire straightener so that

the wire points straight down as in figure 30.

Improper straightening of the wire can also cause

the stitch legs to buckle or turn out because they

strike the clincher improperly. Excessive tension

on the wire straightener prevents the grip (Index D)

from feeding the wire smoothly. This causes

variation in leg length.

NOTE:

Check the wire straighteners when changing the

coils to insure the accurate feeding of wire.

27

Page 30

D

A

Figure 31

C

B

Q. Supporter

The supporter furnishes the necessary

support to the inside

surface of the stitch

so that it does not

buckle as it is being

driven into the work

material. A lack of

(or insufficient) support will often cause

the stitch crown to

wrinkle or the legs

of the stitch to

buckle. Tighten the

supporter spring

bushing (Index A,

Figure 33) or re-

place the spring.

If the corners of the top surface of the supporter are

too sharp, or nicked, the corners of the stitch crown

will fracture. To inspect the supporter:

1. Turn the jog knob clockwise until the bender

bars touch the work material and the legs of the

stitch are about to leave the bender bar grooves.

At this point, the supporter should be touching

the underside of the crown. DO NOT TURN

THE MOTOR ON

2. Continue turning the jog knob until the stitch is

completely driven. Although the supporter is

gradually retracted by the driver, it should remain

under the crown of the stitch until the last instant

before the crown touches the work material.

Figure 33

(CTTT2605T3 Scene 14)

A

A

B

Figure 32

(CTTT2605T3 Scene 15)

R. Tension Pawl: (Figure 32)

The tension pawl (Index A) and spring (Index B)

apply pressure on the wire to prevent back feed. If

the pawl becomes worn or the spring becomes weak,

the wire feeds backwards. Reverse or replace the

tension pawl and/or spring.

S. Work Trip: (Figure 31)

The amount of work trip lever overtravel can be

slightly increased or decreased by turning the

overtravel adjustment screw (Index A) located at

the rear of the trip lever guide.

1. Turn screw counterclockwise to increase trip

lever overtravel.

2. Turn screw clockwise to decrease trip lever

overtravel., NOTE: A small amount of trip lever

overtravel is always required or work trip will

not function properly.

NOTE:

Trip lever must NOT touch the clincher assembly

(Index B) when moved fully forward or the rear

table when moved fully back, or unit will not

work properly. If the trip lever touches clincher

decrease overtravel or loosen set screw in front

bumper (Index C) and reposition and secure

further back. If the lever touches rear table

loosen set screw in rear bumber (Index D) and

reposition and secure further forward.

28

Page 31

REMOVING AND DISMANTLING M2000 HEAD

A

2. Slip tension spring

5. Loosen the top two

3. Lift Bonnet Clamp

(QF27F14)

Note: Before removing head use hand jog to make sure bender

bar is all the way up.

from bracket.

clip screws, and

remove clear guard

assembly.

lever as shown.

1. Cut wire at bracket

and secure.

4. Pull head froward

and off stitcher.

CAUTION

As a precautionary measure-When removing

the head from any stitching machine make

SURE that the power to the machine has been

turned OFF or disconnected.

C

10. Remove

the upper

face plate

clips.

13. Remove the

face plate by

sliding face

plate to the left

and lifting up.

12. Position grip

spring housing

between

tension pawl

spring retainer

and cutter

housing.

11. Remove the lower face plate clips.

(CTTT2605T3 Scene 17)

B

8. Slip rotator operating cam

off.

CAUTION

The rotator operating cam can be

installed backwards. Be sure to

read fand follow the instructions

on page 30 before reassembling.

9. Pull

rotator

forward.

D

17. Remove

grip

release

slide.

14. Remove the cutter

operating slide.

7. Swing spring up

to disengage.

Lift out.

15. Remove the friction

plug and spring.

16. Remove rotator holder.

6. Lift end of spring

(CTTT2605T3 Scene 16) (CTTT2605T3 Scene 18)

out of rotator.

29

Page 32

REMOVING AND DISMANTLING M2000 HEAD

E

21. Slide tension spring bracket

and adjusting lever from top.

23. Slide the driving slide and bender

bar assemblies from the top. When

reassembling, hook bender bar to

driving slide before sliding into

place. This must be assembled as

a complete unit.

22. Loosen face plate clamp screw and slide out face plate

locating block.

20. Remove

screw

18. Remove

rotator

operating

cam stud

screw.

19. Remove

rotator

operating

cam

stud.

(CTTT2605T3 Scene 19)

F

DO NOT

REMOVE

OR ADJUST

THESE TWO

SCREWS.

The screws

are factory set

to control the

supporter

lever location.

G

How to Install rotator

operating cam

When reassembling,

make certain that pin

(Index A) is visible and is

A

B

C

aligned with slot (Index

B) of rotator operating

cam (Index C). If not

assembled in this way,

the bonnet casting will

crack or break on the

next cycle under power.

It is recommended that

the stitcher be cycled by

hand to test that proper

reassembly procedure

has been followed.

Caution

(CTTT2605T3 Scene 21) (CTTT2605T3 Scene 20)

30

Page 33

DISMANTLING DRIVE

A

NOTE: Head must be removed prior

to dismantling drive

6. Remove wire

spool stud.

5. Remove conical

spring.

4. Remove wire

spool washer.

3. Remove coil

of wire.

8. Remove cover.

2. Remove spool retainer.

7. Remove cover screws.

1. Remove hairpin cotter

CAUTION

Disconnect power to the machine

before any disassembly.

B

Circuit board

Circuit board support

Note: If replacing circuit board, unplug

connector terminal from circuit board after

removing board.

9. Remove circuit board by gently

sqreezing here and then lift off

circuit board.

(QF27F15)

C

11. Unplug cam switch

terminals.

(QF27F16)

13. Unscrew flat head bolts (4) and

remove motor.

12. Remove extension spring.

10. Remove circuit board

bracket.

14. Unplug motor terminals.

(QF27F17)

31

Page 34

DISMANTLING DRIVE

D

NOTE: Rear table must be removed prior

to trip mechanism disassemblly.

ON/OFF

SWITCH

BRACKET

15. Remove screws securing

ON/OFF switch bracket.

17. Hold front glide bracket in

place while removing the top

screw.

(QF27F18)

16. Remove two screws

from front glide

bracket

TRIP LOCATING ROD

FRONT GLIDE BRACKET

PAPER TRIP ROD/KNOB

18. Hold the paper trip rod/knob in place

while gently pulling the front glide

bracket off of the trip locating rod.

32

Page 35

E

DISMANTLING DRIVE

TRIP LOCATING ROD

COMPRESSION

SPRING

PAPER TRIP ROD

19. Gently lower trip mechanism until it is clear of the trip locating

rod. Do not yet pull away from rear glide bracket.

20. Rotate trip mechanism, with paper trip rod, clockwise to

unwrap the torsion spring. The trip mechanism with

paper rod can now be withdrawn from the rear glide bracket.

Reverse procedure for reassembly.

REAR

GLIDE

BRACKET

TORSION SPRING

(QF27F19)

33

Page 36

DISMANTLING DRIVE

Note: Remove saddle/table prior to

removing clincher slide

24. Remove clincher brace

screws.

25. Remove clincher brace.

26. Slide out front clincher

rod with clincher slide.

23. Remove roll pin.

21. Remove roll pin.

22. Lower clincher rocker lever.

Note: After reassembly, clincher slide must move freely up and down

in clincher assembly.

(QF27F20)

34

Page 37

Section 6

PARTS LIST

53

52

51

50

54

49

33

34

36

35

37

124

38

32

40

31

28

41

42

127

29

43

28

44

27

45

26

1

25 24

48

2

3

47

46

4

5

124

6

55

7

(QF27F21)

20

30

19

18

17

13

16

23

123

22

15

21

22

14

11

9

125

10

8

12

13

35

Page 38

33

56

37

57

58

59

71

67

73

72

68

66

75

74

53

76

70

69

65

128

61

62

63

28

60

86

77

78

79

80

81

82

83

84

85

(QF27F22)

36

64

Page 39

88

89

110

104

103

102

75

126

109

108

39

93

107

106

105

42

91

92

90

42

94

93

84

95

96

97

111

112

93

113

114

115

116

(QF27F23)

100

99

98

118

117

55

101

119

122

120

121

37

Page 40

MODEL 305

PARTS LIST

(See Pages 40 & 41 for M2000 HEAD Parts List.)

ITEM PART NO. DESCRIPTION QTY REF.

PAGE

1 CK-138 SUPPORT 1 35

2 CG-115-A GEARMOTOR, 90 VDC (115 V.A.C.) 1 35

CG-115-B GEARMOTOR, 180 VDC (230 V.A.C.) 1 3 5

3 CKK-81-B CRANK ASSEMBLY, DRIVE SHAFT 1 3 5

CKK-81-A CRANK ASSEMBLY, DRIVE SHAFT 1 35

(FOR BINDERY MATE PRIOR TO SERIAL # 700)

4 D-23940-F PIN, ROLL, .125 x .88 Lg. (CRANK) 1 35

5 CA-44-E HEAD OPERATING LINK 1 35

CA-44 HEAD OPERATING LINK 1 35

(FOR BINDERY MATE PRIOR TO SERIAL # 700)

6 CKK-154 SADDLE AND TABLE ASSEMBLY 1 35

7 CK-158 PIN, CLEVIS, COTTERLESS 4 35

8 CB-1253 KNOB 1 35

9 CK-150 BRACE, TABLE 2 35

10 CK-180-B SPRING, TORSION, TABLE 1 35

11 CK-152 BAR, PIVOT, TABLE BRACE 1 35

12 CK-148 ROD, CLINCHER, FRONT 1 35

13 D-37769-F PIN, ROLL, .125 x .500 2 35

14 CT-199 WASHER, .25 ID x .625 OD x .093 2 35

15 CB-835-Z PIN, ROLL, .250 X 1.00 SST 1 35

16 CK-145 LEVER, CLINCHER, ROCKER 1 35

17 CK-147 ROD, CLINCHER, REAR 1 35

18 CKK-137 STAND W/MT. 1 35

19 CKK-193 CLAMP, ASSEMBLY 1 35

20 CBB-283-J CORD, POWER (115 V.A.C.) 1 35

CBB-283-S CORD, POWER (230 V.A.C.) 1 35

21 CK-151 BRACKET, TABLE AND CLINCHER 1 35

22 D-41440-F SCREW, .25-28 x .375 SOC. HD. CAP 4 35

23 CB-806 WASHER, FLAT, .250 2 35

24 CK-157 ROD, TRIP, PAPER 1 35

25 CK-136 ROD, LOCATING TRIP 1 35

26 CK-180-C SPRING, TORSION 1 35

27 CB-284-A PIN, DOWEL, .1875 X .75 1 35

28 CB-401 SCREW 8-32 X .375 RD. HD. 10 35,36

29 D-25947-F SCREW, .375-16 X .75 HEX HD. 4 35

30 CK-168 DISC, CLAMP 1 35

31 CP-3-A BUMPER, POLYLASTOMER 4 35

32 CG-162-B BUSHING, STRAIN RELIEF 1 35

33 CK-180 SPRING, COMP., CONICAL 2 35,36

34 CKK-193-C KNOB ASSEMBLY 1 35

35 CB-837-L RING, RETAINING 1 35

36 CB-835-K2 PIN, ROLL, .093 x .437 LG. 1 35

37 CA-114-A WASHER, FLAT, .625 ID x 1.5 OD x .04 2 35,36

38 CK-230 WASHER, .562 ID, .75 OD x .030 FLAT 1 37

39 CG-14-A SCREW, 4-40 x .50 RD. HD. 2 37

40 CK-182 BRACKET, CIRCUIT BOARD 1 35

41 CK-162 BOARD, CIRCUIT (115 V.A.C.) 1 35

CK-162-A BOARD, CIRCUIT (230 V.A.C.) 1 35

42 CB-206 SCREW, 8-32 x .375 FL. HD. 4 35,37

43 CK-183 SUPPORT, PC BOARD 4 35

44 CK-174 COVER 1 35

45 CK-176 COTTER, HAIRPIN 1 35

46 CK-170 GLIDE, LEVER, TRIP 1 35

47 CA-9077 SCREW, 6-32 UNC 2B x .500 SET 1 35

48 CK-156 WASHER, ECCENTRIC 1 35

49 CB-835-J2 PIN, ROLL, .093 X .562, SST 1 35

50 CA-5108-B SPRING, COMP. 1 35

51 CK-175 PIN, TRIP LEVER 1 35

52 CB-434-A BUMPER, TRIP 2 35

53 D-31028-F SCREW, 6-32 X .25 SET 3 35,37

54 CK-193-B KNOB, TRIP LEVER 1 35

55 CB-835-T PIN, ROLL, .062 x .312 2 35,37

56 CA-45-B STUD, SPOOL WIRE 1 36

57 CA-139 SPOOL RETAINER 1 36

58 CB-56-R SCREW, 4-40 x .75 SOC. HD. CAP 2 36

59 CB-1070-A SCREW, 10-32 x .375 HEX HD. 3 36

60 CK-149 C AM 1 36

61 CK-180-A SPRING, EXTENSION 1 36

62 D-30610-F PIN, ROLL, .187 x .625 LG. 1 36

63 CK-146 CLEVIS 1 36

64 CK-153 TABLE, AUXILIARY 1 36

65 CK-166 BRACKET, GLIDE, REAR 1 36

66 CB-56-S SCREW, 5-40 x .50 SOC. HD, CAP 2 36

ITEM PART NO. DESCRIPTION QTY REF.

67 CB-720 NUT, 6-32 HEX 2 36

68 CK-178 SCREW, 6-32 x 1.00 SET 1 36

69 CBB-283-K WIRE ASSEM., TRIGGER/FT. JACK 1 36

70 CK-144 LEVER, CLINCHER OPERATING 1 36

71 CB-102-A NUT, .312-18 UNC 2B HEX 1 36

72 CK-181 WASHER, .390 ID x .625 OD x .062 7 36

73 CB-1421-G SHOULDER SCR., .375 DIA. x .75 LG. 1 3 6

74 CG-17 SPACER, LIMIT SWITCH 3 36

75 CG-15 SWITCH, LIMIT 2 36,37

76 CK-143 BRACKET, SWITCH, CAM 1 36

77 CG-190-A PHONE JACK, .097 DIA. 2 36

78 CK-164-A WASHER, SWEDGED FIBRE, .097 DIA. 2 36

79 CK-164-C WASHER, FLAT PHENOLIC, .097 DIA. 2 36

80 CK-167 PANEL, CONTROL, REAR (115 V.A.C.) 1 36

CK-167-B PANEL, CONTROL, REAR (230 V.A.C.) 1 36

81 CG-190-B PHONE JACK, .141 DIA. 1 36

82 CK-164 WASHER, SWEDGED FIBRE, .141 DIA. 1 36

83 CK-164-B WASHER, FLAT PHENOLIC, .141 DIA. 1 36

84 CB-206-B SCREW, 8-32 x .625 FL. HD. 4 36,37

85 CK-163 CIRCUIT BRKR ASSEM. (115 V.A.C.) 1 36

CK-163-A CIRCUIT BRKR ASSEM. (230 V.A.C.) 1 36

86 CB-55-F SCREW, 4-40 x .375 FL. HD. 3 36

88 CK-135 PLATE, MOTOR, MTG. 1 37

89 CB-587 SCREW, .250-20 x .75 FL. HD. 4 37

90 CB-56-P SCREW, 5-40 x .75 SOC. HD 8 37

91 CK-172 BRACKET, SWITCH, ON-OFF 1 37

92 CB-2 8 5-P2 SWITCH, ON-OFF ILLUM. (115 V.A.C.) 1 37

CB-2 8 5-S2 SWITCH, ON-OFF ILLUM. (230 V.A.C.) 1 37

93 CB-287-B SCREW, 6-32 X .312 RD. HD. 8 37

94 CK-165 BRACKET, GLIDE, FRONT 1 37

95 CB-835-Y PIN, .250 x 1.50 SST 1 3 7

96 CB-1421-E SCREW, SHOULDER 2 37

97 CB-561 SCREW, 10-32 x .50 SOC. HD. CAP 2 37

98 CTT-9086 CLINCHER PLATE ASSEMBLY 1 37

99 CA-2095-J CLINCHER SLIDE 1 37

100 CK-160 GUIDE, PAPER L.H. 1 37

101 CK-161 GUIDE, PAPER R.H. 1 37

102 CA-9085-H BRACE, SLIDE, CLINCHER 1 37

103 CA-9083 CLINCHER POINTS 2 37

104 CK-155 TRIP, LEVER, PAPER 1 37

105 CK-179 PLATE, RETAINER 1 37

106 CTT-9002 BONNET CLAMP ASSEMBLY 1 37

107 CB-619 SCREW, .250-20 x 1 FL. HD. 2 37

108 CK-134 BASE 1 37

109 CK-190 BRACKET, SW., SAFETY 1 37

110 CK-192 PIN, PIVOT, BLOCK 2 37

111 CK-191 BLOCK, PIVOT, GUARD 1 37

112 CF-1989 WASHER, #6 FLAT 2 37

113 CK-186 SPRING/SUPPORT, GUARD 1 37

114 CK-187 GUARD, FRONT 1 37

115 CB-1262 WASHER, #10, FLAT 2 37

116 CA-9067-B NUT, ECCENTRIC, WIRE STR. 2 37

117 CK-189 BOLT, 10-24 x .50 CARRIAGE 2 37

118 CK-188 GUARD, SLIDING, FRONT 1 37

119 CB-2095-D GUARD, FOOTSWITCH 1 37

120 CB-502-M FOOT SWITCH 1 37

121 CK-177 SCREW, NO. 4 THR'D. FORMING 2 3 7

122 CBB-502-M FOOTSWITCH ASSEMBLY 1 37

123 CK-196 GUIDE, PAPER 1 35

124 CG-14 SCREW, 4-40 X .250 RD. HD. 4 35

125 CK-198 BRACKET, PAPER, GUIDE 1 35

126 CK-229 GUIDE, GUARD 2 37

127 CKK-234 RESISTOR ASSEMBLY 1 35

128 D-38063-F PIN, ROLL .125 x .625 1 35

PAGE

38

Page 41

NOTES

39

Page 42

11H

9H

68H

67H

66H

Note: See Section

F page 30 before

assembling.

62H

69H

(10H)

65H

(9H)

51H

52H

50H

67H

49H

64H

(39H)

53H

2H

70H

34H

37H

37H

1H

12H

46H

13H

31H

34H

47H

14H

30H

8H

33H

38H

10H

3H

4H

5H

6H

7H

32H

34H

37H

40H

39H

36H

37H

63H

(CTTT2605T3 Manual)

40

60H

56H

61H

55H

54H

58H

59H

29H

20H

28H

27H

57H

19H

45H

48H

25H

21H

16H

26H

42H

22H

18H

41H

43H

23H

35H

44H

15H

24H

17H

Page 43

M2000 HEAD

PARTS LIST

The following parts listing (from index numbers 1H through 70H) is for the

Bindery Mate's M2000 Head, CTTT-2605-T3.

ITEM PART NO. DESCRIPTION QTY

1H CAAA9074A2 WIRE GUIDE BRACKET ASSEMBLY 1

NOTE: The above Wire Guide Bracket Assembly includes the

following items through item 11H:

1H CAA9074A2 WIRE GUIDE BRACKET SUB-ASSEMBLY 1

2H CA9146A ECCENTRIC SCREW 1

3H CA9068 ECCENTRIC FRICTION BUSHING 1

4H CA9065 ECCENTRIC ROLL 1

5H CA9070 ECCENTRIC POINTER 1

6H CA9069 ECCENTRIC SPRING 1

7H CA9067 ECCENTRIC NUT 1

8H D31028F SET SCREW 1

9H CA9103C WIRE STRAIGHTENER ROLL 2

10H CA9124 TENSION ROLL CLIP 2

11H CA9076 WIRE GUIDE SPRING BRKT ADJ SCREW 1

12H CB77 FACE PLATE LOCATING BLOCK SCREW 1

13H CT2606 FACE PLATE LOCATING CLAMP 1

14H CT2607 FACE PLATE LOCATING BLOCK 1

15H CAA2623C DRIVING SLIDE ASSEMBLY 1

NOTE: The above assembly includes the following parts:

CA2623B DRIVING SLIDE (ONLY)

CA2007A DRIVING SLIDE SPRING PLUNGER

CA9006A DRIVING SLIDE SPRING

D37327F DRIVING SLIDE SPRING PIN

CA9028 DRIVING SLIDE ROTATOR OPERATING PIN

16H CAAA9013Z2 BENDER BAR ASS'Y COMPLETE 1

1/2" CROWN #25 TO #30 RD. WIRE

NOTE: The above Bender Bar Assembly includes the following items

through item 29H

16H CAA9013U BENDER BAR SUB ASSEMBLY

1/2" CROWN #25 TO #30 RD. WIRE

17H CAA9026 SUPPORTER ASSEMBLY 1/2" CROWN 1

18H CA9029 SUPPORTER PIVOT PIN 1

19H CAA9014J BENDER BAR LATCH ASSEMBLY 1

20H CA173 PLASTIC CAP 1

21H CA9012M DRIVER BAR ASSEMBLY 1/2" CROWN 1

22H CA9112A BENDER BAR FRICTION PLUG 1

23H CA9113A BENDER BAR FRICTION PLUG SPRING 1

24H CA9115 BENDER BAR FRICTION BUSHING 1

25H CA9015D GRIP 1

26H CA168 GRIP SPRING 1

27H CT413A SPRING HOUSING 1

28H CB371K LOCKWASHER 1

29H CA9024A GRIP RETAINING CLIP SCREW 1

30H CTT2604N BONNET CASTING SUB ASSEMBLY 1

31H CA9127 ROTATOR OPERATING CAM STUD 1

32H CA9058 ROTATOR OPERATINGCAM STUD SCREW 1

33H CA9075 WIRE GUIDE BRACKET SCREW 1

34H CA9056C FACE PLATE RETAINING CLIP 3

35H CA9056D FACE PLATE RETAINING CLIP 1

36H CK213 SCREW, 4-40 X.500 SOC. HD. SET 1

37H CA2081 FACE PLATE RETAINING CLIP SCREW 4

38H CT9109 BONNET ALIGNMENT SCREW 1

39H CA9032C SUPPORTER SPRING 1

40H CA9037 SUPPORTER SPRING BUSHING 1

41H CA9081 SUPPORTER GUIDE PLATE SCREW 2

42H CA9030 SUPPORTER GUIDE PLATE 2

ITEM PART NO. DESCRIPTION QTY

43H CAA9036B SUPPORTER SPRING LEVER 1

44H CA9034 SUPPORTER SPRING LEVER SCREW 1

45H CA9049A WIRE CUTTER OPERATING SLIDE 1/2" CR. 1

46H CA9050A WIRE CUTTER OP. SLIDE FRICTION 1

PLUG

47H CA9051A WIRE CUTTER OP. SLIDE FRICTION 1

PLUG SPRING

48H CA9022J GRIP RELEASE SLIDE 1/2" CROWN 1

49H CA9025F FACE PLATE ADJUSTING LEVER 1

50H CAAA2132W FACE PLATE ASSY. 1/2" CROWN #22 TO 1

#30 RD. WIRE

NOTE:The above Face Plate Assembly includes the following items

through item 56H

(9H) CA9103C WIRE STRAIGHTENER ROLL 2

(10H)CA9124 TENSION ROLL CLIP 4

50H CAA2132W FACE PLATE SUB ASSY. 1/2" CROWN 1

#22 TO #30 RD. WIRE

51H CA9065A WIRE STRAIGHTENER ECCENTRIC ROLL 1

52H CA9066A WIRE STRAIGHTENER ECCENTRIC 1

53H CA172 ECCENTRIC FRICTION LOCKING SCREW 1

54H CA9098 TENSION PAWL 1

55H CA9103A CHECK PAWL ROLLER 1

56H CA9134 TENSION PAWL SPRING 1

57H CA9048 WIRE CUTTER 2

58H CA9043M ROTATOR HOLDER #25 TO #30 RD. WIRE 1

59H CB75B KEY, WOODRUFF 1

60H CA9044A ROTATOR HOLDER SCREW 1

61H CAA9038E ROTATOR ASSEMBLY COMPLETE, 1/2" CR. 1

62H CA9163C ROTATOR OPERATING CAM 1

63H CAA9046D ROTATOR OPERATING SPRING ASSEMBLY 1

64H CTT9003D BONNET CLAMP ECCENTRIC 1

65H CTTT2133C2 WIRE GUIDE ASSEMBLY 1

NOTE: The above Wire Guide Assembly includes the following items

through item 70H:

(39H)CA9032C SUPPORTER SPRING 1

65H CTT2133C2 WIRE GUIDE SUB-ASSEMBLY 1

66H CB651E SCREW 1

67H CA9651 WASHER 2

68H CA9652 FELT WASHER, THICK 1

69H CA9653 FELT WASHER, THIN 1

70H CB860B NUT 1

41

Page 44

42

ELECTRICAL SCHEMATIC 115 V.A.C.

(SK828)

Section 7

ELECTRICAL

Page 45

ELECTRICAL SCHEMATIC 230 V.A.C.

(SK828B)

43

Page 46

BINDERY MATE

WHEN ORDERING PARTS, PLEASE STATE: QUANTITY REQUIRED, PART

NUMBER, PART NAME, WIRE SIZE AND CROWN WIDTH OF YOUR STITCHER.

ISP

A Division Of Samuel Strapping Systems

USA:

3911 S. Memorial Dr. Racine, WI 53403

1-800-345-6641 1-262-589-5421

Fax: 1-262-598-5426

www.ispstitching.com

Stitching & Bindery Products

FORM QF27D 7-9-02

Loading...

Loading...