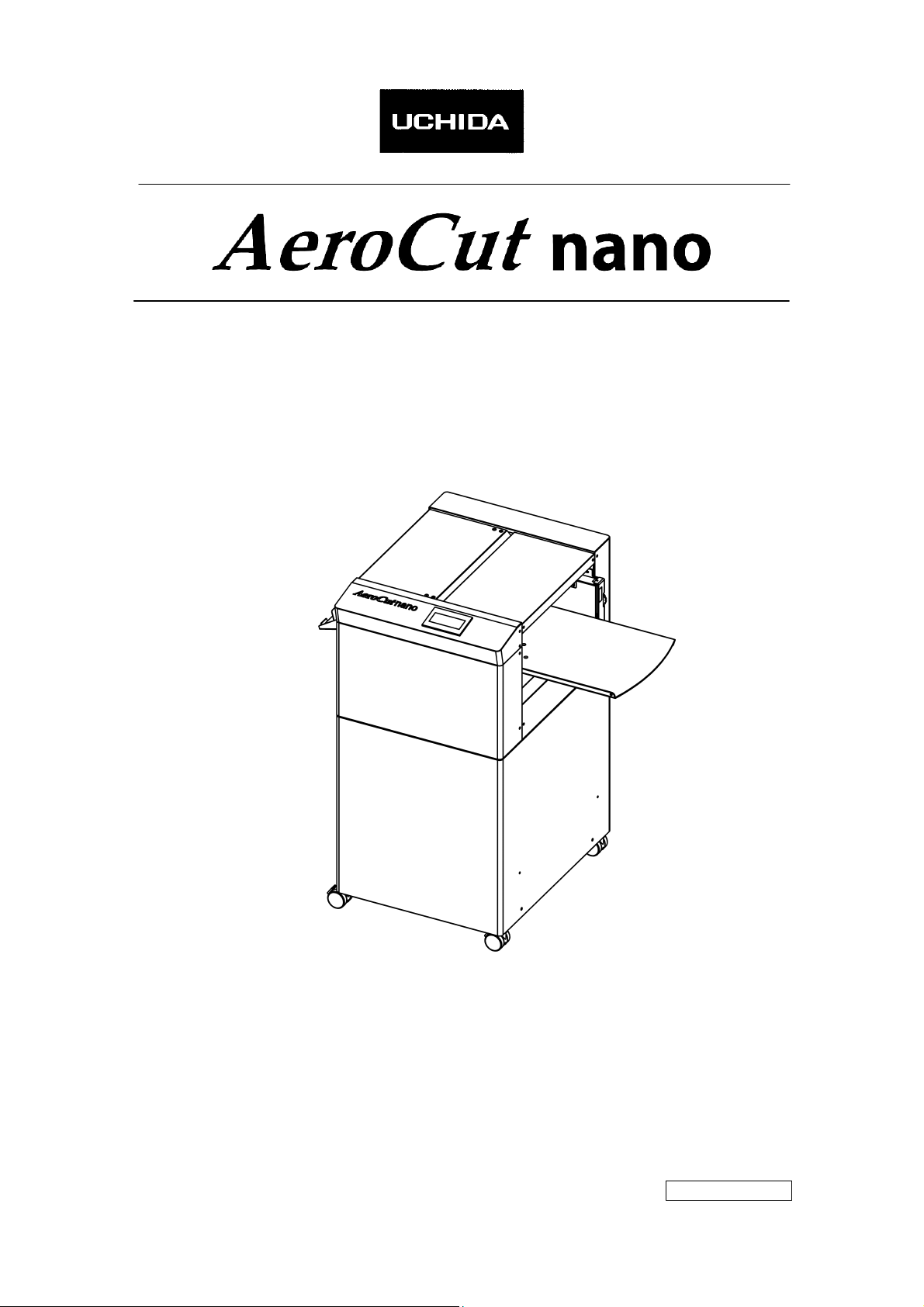

Page 1

OPERATION MANUAL

UCHIDA YOKO CO., LTD., TOKYO, JAPAN

77-872 US V1.01

Page 2

AeroCut nano OPERATION MANUAL

・Use machine only after reading the "Safety Instructions" given below carefully.

・These safety instructions are given to ensure that the machine will be used safely and

properly and to prevent operators from sustaining harm and injuries.

Definition of Symbols and Notes

In this manual the following names and signs stand for possible dangers.

Danger

This symbol stands for immediate danger threatening the life and health

of persons. Disregarding these instructions may cause severe damage

to health and even serious injuries.

Caution

This symbol stands for an endangering situation that may occur.

Disregarding these instructions may lead to slight injuries or damage to

property.

Note

This symbol stands for notes, operational hints, and other useful

information.

They are convenient for exploiting the machine’s functional abilities.

SAFETY INSTRUCTIONS

Explanations of the illustrations used in the Safety Instructions are given as follows:

Danger

1. Don't open the cover of the equipment. There is a danger of receiving an injury or electric

shock.

2. Don't touch any rotating part. There is a danger of receiving an injury.

Caution

1. Don't put a hand into the cover or a clearance between parts. There is a danger of

receiving an injury.

2. Don't bring a hand, face, hair, sleeves of clothes and the like close to the rotating parts of

the machine. There is a danger of receiving an injury.

2

Page 3

AeroCut nano OPERATION MANUAL

3. Don't touch the blade point of the cutter. There is a danger of receiving an injury.

4. Turn off the power supply beforehand when setting the feed table. There is a danger of

receiving an injury.

5. Turn off the power supply beforehand when removing paper scraps. There is a danger of

receiving an injury.

6. Do not exceed the MAX level when stacking the paper. Exceeding it may cause a

mechanical failure.

7. Turn off the power supply beforehand when starting maintenance or inspection. There is a

danger of receiving an injury.

8. When you install a machine, please install to a place with no dust, and the place which is

not influenced with a liquid. It becomes the cause of failure if the installation method is

mistaken.

9. When you put a machine into operation, please change into the state where all covers

were closed. If it works where a cover is opened, there is fear of an injury.

Before use

Read this "Operation Manual" carefully before use. In particular, be sure to read "Safety

Instructions" (page 2 to page 3) to ensure that the machine will be used properly.

Keep the manual at an appointed place with care so that it may be accessible whenever

necessary.

The specifications of this product are subject to change for improvement. Therefore, don't

mistake the "Operation Manual" of one product of the same model for that of another

because descriptions in the "Operation Manual" of products of the same model may differ.

3

Page 4

AeroCut nano OPERATION MANUAL

Contents

1 Introduction..................................................................................6

1.1 Names of parts......................................................... 6

1.2 Accessories............................................................ 6

1.3 Touch panel............................................................ 7

1.4 Paper weight / quality................................................. 7

2 Operating instructions .................................................................8

2.1 Lock a caster brake.................................................... 8

2.2 Turning the power on................................................... 8

2.3 Input ................................................................. 9

2.4 Gauge (InstaSet bar) setting.......................................... 10

2.5 Paper setting......................................................... 11

2.6 Stacker and Waste box settings........................................ 12

2.7 Start ................................................................13

2.8 Stop ................................................................. 13

2.9 Waste disposal........................................................ 13

2.10 Power off ............................................................ 14

3 Adjustment ................................................................................15

3.1 Speed change.......................................................... 15

3.2 Skew adjustment....................................................... 15

3.3 Adjustments on the paper feed section................................. 16

3.4 Feed size adjustment.................................................. 17

3.5 Slit position adjustment.............................................. 17

3.6 Cutting location adjustment (Guillotine).............................. 17

4 Cut pattern input........................................................................18

4.1 Outline .............................................................. 18

4.2 PRESET ............................................................... 18

4.3 MANUSET/ SAVE......................................................... 19

4.4 User program selection................................................ 22

5 Manual control...........................................................................23

5.1 Manual control screen................................................. 23

5.2 Paper jam ............................................................ 23

6 Error messages.........................................................................24

7 Troubleshooting.........................................................................27

8 Product specifications ...............................................................29

4

Page 5

AeroCut nano OPERATION MANUAL

5

Page 6

p

1 Introduction

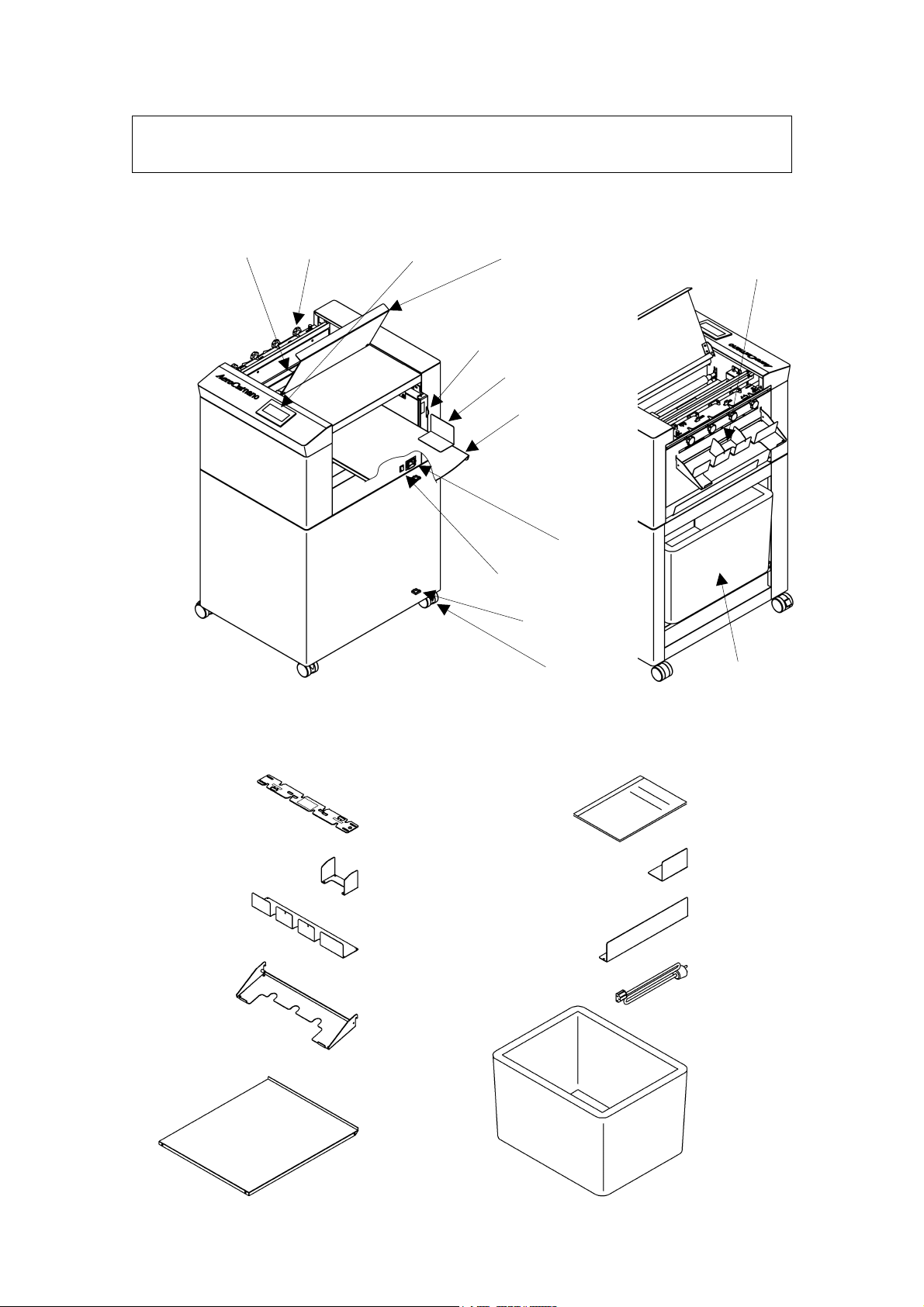

1.1 Names of parts

AeroCut nano OPERATION MANUAL

Guillotine

Slitter head

Touch panel

Skew adjustment dial

Safety cover

Paper guide

Feed table

Inlet

Power switch

Cable clip

Caster

Card

stacker

Waste box

1.2 Accessories

Gauge (InstaSet bar)

Business card

artition

Stacker end

Card stacker

Long stacker

Template

Paper guide

(Small)

Paper guide

(Large)

Electric

Power

cord

Waste box

x2

6

Page 7

A

1.3 Touch panel

AeroCut nano OPERATION MANUAL

Home screen

PRESET

Page 18

MANUSET

Page 19

START

Page 13

MANUSET screen

Manual control screen

SPEED

Page 15

BLOW

Page 16

Double feed

Page 16

1.4 Paper weight / quality

Clear

Page 13

Inching

Page 23

PAPER FEED WORK TIME

Page 16

Quantity

END Page 13

JOB

DJUST

Page 9

Page 22

Page 17

Manual control

Page 23

Cutmark

Page 9

STOP

Page 13

SAVE

Page 19

CUTTER

(Guillotine)

Page 23

TABLE

Page 23

Use suitable paper stocks which weight is

32 lbs (Bond) – 130 lbs (Cover stock)[120-350g/㎡].

These paper stocks are not suitable in use.

・Papers that has heavily electric static charged. It may cause miss-feed, double feed

or paper jam.

・Papers that are more than 0.125” curled or waved. It may cause miss-feed, double

feed or paper jam.

・Papers that have ink or toner not fused properly. It may cause contaminating the

work and the machine.

・Papers that are too slippery. It may cause miss-feed or inaccurate results.

・Prints that are shrank, stretched or skewed inconsistently. It may cause inaccurate

results.

7

Page 8

AeroCut nano OPERATION MANUAL

A

2 Operating instructions

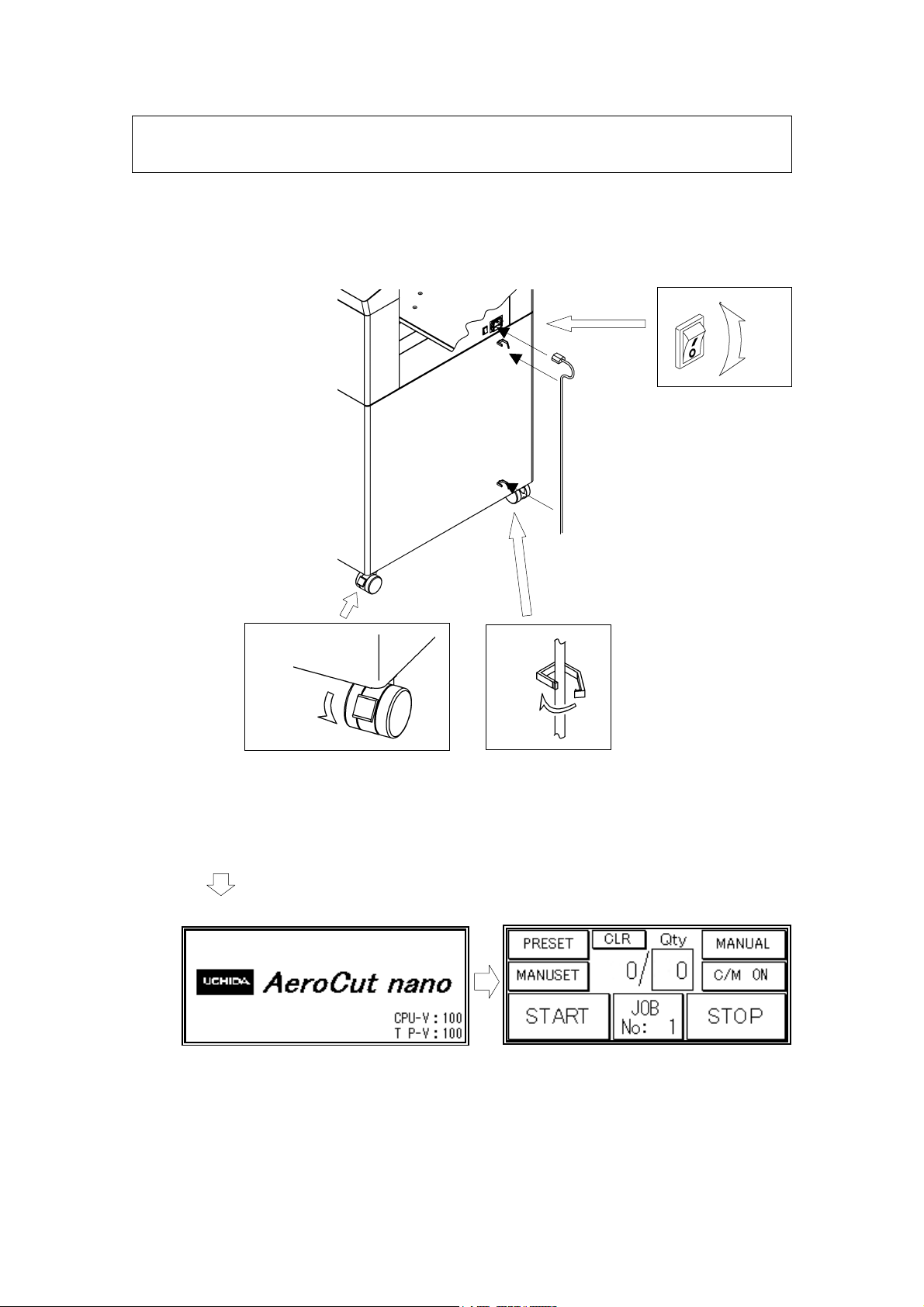

2.1 Lock a caster brake

2.2 Turning the power on

ON

OFF

Unlock

Lock

Caster

Lock

Cable clip

Electric power

cord

C 100-240V

50/60Hz

100W

Power switch

Power on

Opening screen

Home screen

8

Page 9

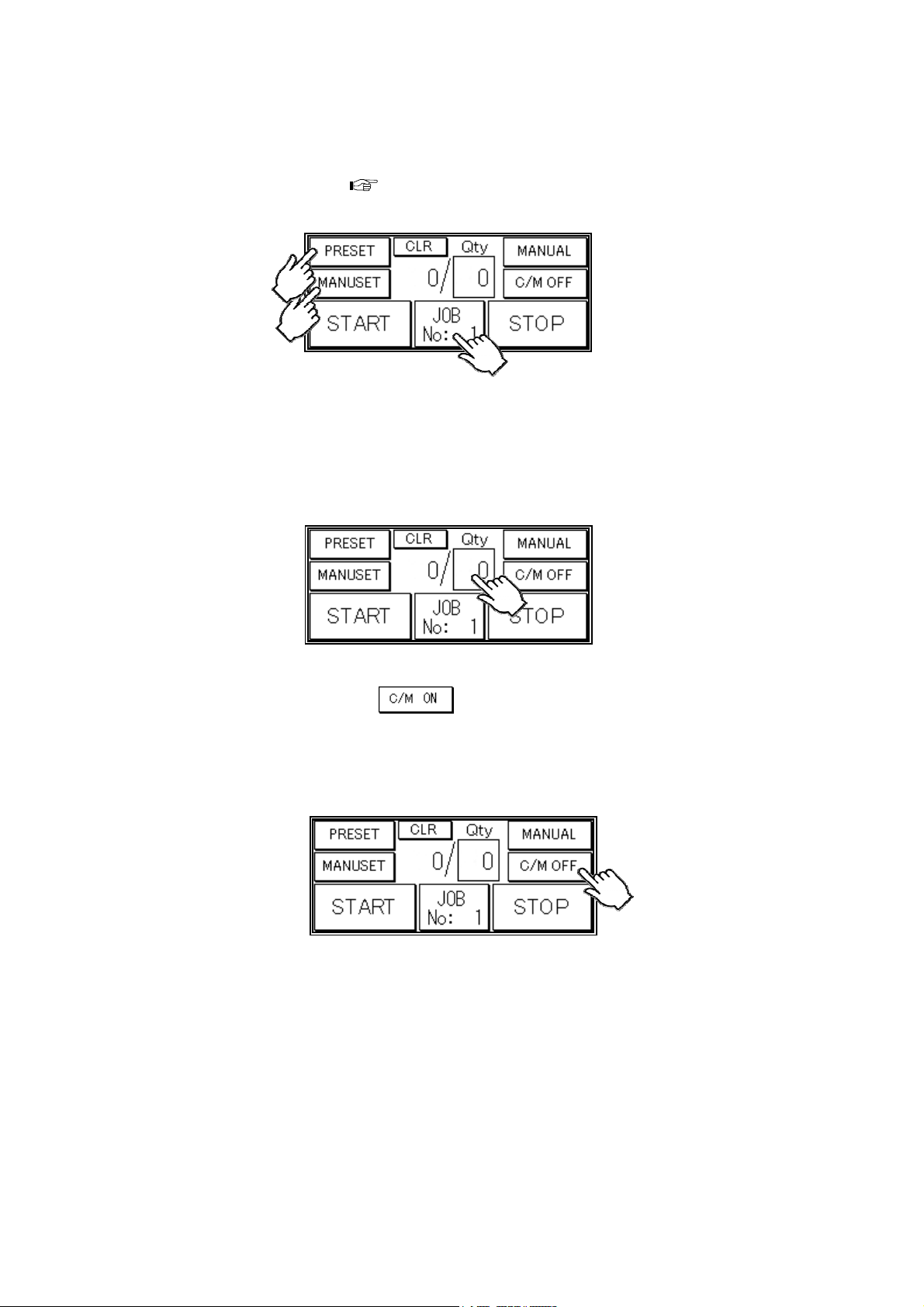

2.3 Input

AeroCut nano OPERATION MANUAL

① Enter the cut pattern.

② Enter the number of sheets for operation.

All the sheets on the feed table will feed in case 0 is entered in Qty.

Home screen

Home screen

Page 18

③ Touch the screen to have

When it is on, the machine register the cut-mark and cross cuts at proper positions

even the image is drifted.

Note.

Cut-mark sensor detects the black mark by infrared light.

Some types of toner or ink may reflect the infrared light and cause the sensor not

reading the cut-mark. Please inactivate the cut-mark registration in such cases.

Home screen

to activate cut-mark registration.

9

Page 10

AeroCut nano OPERATION MANUAL

2.4 Gauge (InstaSet bar) setting

・Select the right InstaSet bar

according to desired cut pattern.

① Loosen the slitter head lock knobs.

② Slide the slitter head with holding the knob.

Adjust the positions of the slitters so that their pins fit to the U-notches on the

InstaSet bar. Snap the InstaSet bar with the labeled side on top and adjust it so that

its pointer points 0.

③ Tighten the screws.

④ Tighten the slitter head lock knobs.

Gauge

(InstaSet bar)

Slitter head

Pin

U-notch

Pointer

③

Screws x2

②

Gauge

(InstaSet bar)

・Some cut p atterns do not require to use

all the slitter units.

In such cases, slide the unnecessary

slitter head(s) to side trench and tighten

the slitter head lock knob(s).

④

Tight

Loose

①

Slitter head lock knob

Lock knob

Scale

Don’t use the head

10

Page 11

2.5 Paper setting

AeroCut nano OPERATION MANUAL

① Press the

7) if the feed table is in upper position. The feed table

moves down to the lower dead point.

② Flip through the sheets well before you put them on the

feed table.

③ Set the sheets on the feed table. Use the pager guide

(Large) and paper guides (Small) to fix the sheets.

button on the home screen ( Page

Pager guide (Large)

Pager guide (Small)

Pager

Pager guide (Small)

・Paper loading capacity is 1.2”.

・Make sure that the paper stack does not

exceed the MAX label.

・It affects finishing accuracy if there is a

gap between the side guide and the

sheets.

・If the print is skew on the sheets, the angle of the side guide can be adjusted.

Page 15

Side guide

Gap

Paper

11

Page 12

AeroCut nano OPERATION MANUAL

2.6 Stacker and Waste box settings

Stacker end

Card stacker

Waste box

Long stacker

Business card

partition

・Change the settings of the stacker according to the cut pattern.

Business card

Business card partition

Stacker end

Post card

Stacker end

Put the long stacker in the storage

underneath the waste box while

not in use.

Stacker end

Sheet

Card stacker

Card stacker

12

Card stacker

Long stacker

Page 13

AeroCut nano OPERATION MANUAL

2.7 Start

Home screen

・ After processing the entered number of sheets in

automatically.

・Do not open the Safety cover (

Page 6) while the machine is running. Machine will

stop immediately.

2.8 Stop

Home screen (While Running)

, the machine stops

・Press ST OP and the machine will make an EMERGENCY stop even if the operation is

underway.

・Press END if you wish to stop the machine when the current sheet is completed.

・ The counter indicates the number of

finished sheet when the machine is

stopped with STOP or END button.

Press

to reset the counter to 0.

Counter

・If paper is left in the machine, remove it by inching. ( Page 23)

2.9 Waste disposal

・Dispose the wastes in the waste box appropriately.

・Overloading wastes causes errors or a breakdown.

13

Waste box

Page 14

AeroCut nano OPERATION MANUAL

2.10 Power off

・Make sure that the machine is stopped.

・Return to the Home screen.

・Turn off the Power switch.

Home screen

14

Page 15

3 Adjustment

3.1 Speed change

AeroCut nano OPERATION MANUAL

Home screen

・In case of finishing thick paper, slow down

the speed.

・ If finished sizes are inaccurate or

inconsistent, there is a possibility that

the running speed is too fast. Slow down

the speed.

・Note. The reference of the paper thickness and speed.

- 0.006” (0.15mm) 4

0.006” - 0.01”(0.25mm) 3

MANUAL CONTROL screen

SPEED screen

Slow

Fast

0.01” - 2

3.2 Skew adjustment

・If print is skew on the sheet, the angle of

the side guide can be adjusted.

・The angle of the side guide changes as

the skew adjustment dial is turned.

Set the sheets again.

Page 11

Skew adjustment

dial

Side guide

15

Page 16

AeroCut nano OPERATION MANUAL

3.3 Adjustments on the paper feed section

・ Adjustments are required when the

machine is likely to feed double or skew.

・Air blow adjustment

Default

Reduce double feed

Home screen

MANUAL CONTROL screen

Reduce skew

・PAPER FEED WORK TIME adjustment

0.0 1.0 2.0 3.0 4.0 5.0

Reduce skew

・Sensitivity of Double feed sensor

Default

High sensitive

・If the machine detects double feed even

with a single sheet, lower the sensitivity of

the detection sensor.

・The detection sensor detects double feed

Default

Reduce double feed

Low sensitive

Detection area

by checking the edge of sheets as shown

on the drawing. It is recommended not to

Paper feed

direction

print on the sheet edge.

16

Page 17

AeroCut nano OPERATION MANUAL

3.4 Feed size adjustment

・Adjust through MANUSET screen.

Page 19

3.5 Slit position adjustment

Slit position

Feed size

・Adjust the positions of the slitter heads

by moving the gauge (InstaSet bar).

・The gaps between the slitter heads are

not adjustable.

3.6 Cutting location adjustment (Guillotine)

Home screen

MANUAL CONTROL screen

Slitter head

Gauge

(InstaSet bar)

Between Cutmark and

1st cut. [inch]

Between paper edge and

1st cut. [inch]

Input balance between the entered value in MANUSET and the actual finished size.

i.e. MANUSET:1.00”, Actual size:1.02” = Input -0.02”

ADJUST screen

Stretch or shrink

Reset to factory

settings.

17

Page 18

4 Cut pattern input

4.1 Outline

AeroCut nano OPERATION MANUAL

・

・

・

4.2 PRESET

① Press PRESET.

PRESET is a series of cut patterns that are already stored in the

machine. (

In MANUSET mode, user programs can be created and stored into the

machine.

Recall the stored user progr ams.

Home screen

Templ at e)

Home screen

② Press the size of the original sheets.

② Press the cut size.

18

Page 19

AeroCut nano OPERATION MANUAL

③ The machine recalls the preset

pattern and automatically returns to the

home screen.

④ To check the details of selected job,

press the MANUSET.

Press the START to get the machine

started.

4.3 MANUSET/ SAVE

① Press MANUSET.

② The screen displays the current cut

pattern.

The program shown in the picture is for

the below cut pattern.

Card size Gutter size

Front margin

size

Home screen

MANUSET screen

Paper size

8 cards

Back margin

size

Cutmark

Position

Paper feed direction

19

Page 20

AeroCut nano OPERATION MANUAL

③ Press the number to change the value.

The values that can be changed and the limits are as shown in the figure below.

Front margin size [inch]

It doesn't make the first cut if 0 is entered.

Paper size [inch]

8.25”-19.25”

Cut size

1.975”-

Back margin [inch ]

Not manually

changeable

Paper feed

direction

Cutmark Position [inch]

Only smaller number than the

front margin can be entered.

Gutter size[inch] 0.075- (Depending on paper)

When 0 is entered, the machine makes single

cuts.

Number of cards

・If an error message is displayed.

Page 24

④ Can store the contents of the MANUSET Press the .

40 user program can be registered.

MANUSET screen

User program selection screen

20

Page 21

AeroCut nano OPERATION MANUAL

User program detail screen

Enter the name for registration.

MANUSET screen

Note.

Press

to delete the user program.

User program detail screen

21

Page 22

AeroCut nano OPERATION MANUAL

4.4 User program selection

Home screen

User program selection screen

The screen indicates the user program number.

User program detail screen

Home screen

22

Page 23

AeroCut nano OPERATION MANUAL

5 Manual control

5.1 Manual control screen

Home screen

MANUAL CONTROL screen

・

Inching

・

・

Feed roller will rotate.

Guillotine will move once.

Feed table will move.

5.2 Paper jam

① Enter MANUAL CONTROL screen,

press < > buttons to inch the rollers

forward/backward and remove the

jammed paper.

If paper is stuck around the guillotine

MANUAL CONTROL screen

section, press CUTTER to cycle the

guillotine to chop jammed paper.

② If the Main motor doesn't rotate, slow

down the speed.

MANUAL CONTROL screen

23

Page 24

6 Error messages

AeroCut nano OPERATION MANUAL

1.

2. Timeout error 1

3.

Safety cover ( Page 6) might be

open.

Make sure to close the Safety cover

closed.

Paper was not fed within a set time

period.

Check the paper feeder.

Timeout error 2

Paper did not pass through within a set

time period.

Remove the paper remaining inside the

machine.

4.

5.

Check the paper or paper path.

Cutmark was unable to be detected.

Check the cut mark.

Eject the paper inside the machine.

Note.

Cut-mark sensor detects the black mark

by infrared light. Some types of toner

or ink may reflect the infrared light and

cause the sensor not reading the

cut-mark. Please inactivate the

cut-mark registration in such cases.

24

Page 25

AeroCut nano OPERATION MANUAL

6.

7.

8.

Paper remains inside the machine.

Remove the paper.

Overload error 1

Cutting did not complete within a set

time period.

Remove the paper remaining inside the

machine.

Overload error 2

An overloading error occurred at the

feed table.

Check the feed table.

9.

Communication with the touch panel is

not possible.

Turn off the power, and turn it on again

after 5 seconds or longer.

10.

Paper size error

Correct the paper size to fit in the value

range below.

11. Back margin error

Correct the back margin to fit in the

value specified below.

25

Page 26

AeroCut nano OPERATION MANUAL

12.

13.

14.

Final cutting measurement error

Correct the final cutting measurement to

exceed the value specified below.

Leading edge margin and cut mark

margin warning

Correct the measurement so that the

leading margin becomes larger than the

cut mark margin.

Cutting measurement error

Correct the cutting measurement to fit in

the value range below.

The maximum value is subject to

change depending on the entered paper

15

size.

Cut piece number error

Correct the number of cut pieces to be

in the value range below.

The maximum number of pieces is

subject to change depending on the

operation.

26

Page 27

7 Troubleshooting

1. Papers are not fed well.

・Check if the paper guides on the feed table hold sheets too tight.

・Make sure that the paper edges are not curled or waved.

・Make sure that the papers are not heavily electric static charged.

AeroCut nano OPERATION MANUAL

・Shorten the PAPER FEED WORK TIME. i.e. 1.0 (

・Lengthen the air blow adjustment. (

2. The machine feeds double-sheets.

・Make sure that the papers are not heavily electric static charged.

・Lengthen the air blow adjustment. (

・Lengthen the PAPER FEED WORK TIME. i.e. 3.0 (

3. The machine doesn’t detect double-feed properly.

・The machine detects the density of the first fed sheet and compares the density of

the next sheet to the first one. Therefore, the machine cannot detect double-feed

when it occurs with the first fed sheet.

・Adjust the sensitivity of the double-feed detection sensor. (

・The detection sensor detects double feed by checking the edge of sheets as shown

on the drawing. It is recommended not to print on the sheet edge. (

4. The machine detects double-feed mistakenly.

Page 16)

Page 16)

Page 16)

Page 16)

Page 16)

Page 16)

・Adjust the sensitivity of the double-feed detection sensor. (

・The detection sensor detects double feed by checking the edge of sheets as shown

on the drawing. It is recommended not to print on the sheet edge. (

5. Cut skewing

① Make sure that the stock is put on the feed table correctly. (

② Check whether the skewings are consistent or inconsistent.

If skewings are consistent :

+ Make the skewing adjust via the skew adjustment dial. (

+ Set the paper guides without play.

Do not set them too tight as the sheet may not be fed well.

If skewings are inconsistent :

+ Make the blower and separation time adjustments properly. (

+ Make sure that the sheets are printed consistently and aligned well.

27

Page 16)

Page 16)

Page 11)

Page 15)

Page 16)

Page 28

AeroCut nano OPERATION MANUAL

6. Paper jam often occurs.

・Make sure that papers, paper strips or paper dusts not remain inside of the machine.

・Check the conditions of the paper stock.(

Page 7)

28

Page 29

AeroCut nano OPERATION MANUAL

8 Product specifications

Specifications

Slitter 4 sets (6 slitter blades)

Guillotine 1 set

Maximum paper size 13” x 19”

Minimum paper size 8.25” x 8.25”

Minimum work size 3.5” x 2”

Paper weight

Maximum paper curl size 0.125”

Paper type Offset, Coat, UVcoat, Glossy, Laminate

Paper feeding method Air Suction

Input tray capacity MAX1.2”

Speed

Machine dimensions

Net weight 154lb (70kg)

Power supply Single phase 100- 240VAC, 50/60Hz,

Power consumption 100W

Use temperature -5℃~+40℃

Preservation temperature -25℃~+65℃

32 lbs (Bond) – 130 lbs (Cover stock)

(120-350g/㎡)

6 sheets per minute

(21 business cards from A3)

W22.2”x D24.9”x H37.9”

(Occupancy area: W46.9”x D24.9”x H46.5”)

Use temperature humidity 45~85%RH

Preservation humidity 25~100%RH

Use the uplands ~1000M

One’s tolerance level 100~240V +6%, -10%

Over voltage category Category Ⅱ according to IEC60664-1

Pollution degree Degree 3 according to IEC60664-1

29

Page 30

AeroCut nano OPERATION MANUAL

r

r

Keep this “Operation Manual” at an appointed place with care so that it may be

available whenever required.

If this “Operation Manual” is stained or lost, make contact with the distributor o

our salesman or customer service section to ask for a new operation manual afte

making sure of its contents.

When ordering consumables or parts, be sure to specify the machine model.

UCHIDA YOKO CO., LTD., TOKYO, JAPAN

30

Loading...

Loading...