Page 1

Sheet Feeder Model 49

Operator Manual

Jan 2001

Part No. 49006

Page 2

Table of Contents

1. Introduction page

1.1 Operational Safety 1-1

2. Getting to Know the Model 49

2.1 Main Components 2-1

2.2 The Menus, Flow Chart 2-2

2.3 How to Read the Display 2-3

2.4 Explanation of the Menus 2-3

3. Operator Instructions

3.1 Setting up the Model 49 3-1

3.2 Adjusting the Separation 3-4

3.3 Loading 3-6

3.4 Programming the Model 49 3-7

3.5 Start Inserting 3-8

4. Diagnosis

5. Maintenance

6. Problem Solving

7. Specifications

8. OMR

4.1 Diagnosis 4-1

5.1 Cleaning the Feed Belts 4-1

6.1 Problem Solving 6-1

7.1 Specifications 7-1

7.2 Specifications for Placement 7-2

8.1 OMR mark Layout 8-1

8.2 OMR Positioning 8-2

8.3 How to Use the OMR marks 8-3

Sheet Feeder Model 49 Operator Manual

T10114 Jan 2001

i

Page 3

1. Introduction

1.1 Operational Safety

Attention to the following notes ensures the continued safe operation of your equipment.

Always connect the equipment to a properly

grounded power source receptacle. In doubt,

have the receptacle checked by a qualified

electrician.

WARNING: Improper connection of the equipment grounding conductor can result in electrical shock.

Always follow all warnings marked on, or

supplied with, the equipment.

Always locate the equipment on a solid support surface with adequate strength for the

weight of the machine.

Always exercise care in moving or relocating

the equipment.

Always keep magnets and all devices with

strong magnetic field away from the machine.

Never use a ground adapter plug to connect

the equipment to a power source receptacle

that lacks a ground connection terminal.

Never attempt any maintenance function that

is not specifically described in this documentation.

Never remove the covers or guards that are

fastened with screws.

Never install the unit near a radiator or any

other heat source.

Never override or “cheat” electrical or mechanical interlock devices.

Never operate the equipment if you notice

unusual noises or odours. Disconnect the

power cord from the power source receptacle

and call your customer service engineer to

correct the problem.

Sheet Feeder Model 49 Operator Manual

T10114 Jan 2001

1-1

Page 4

2.1 Main Components

2. Getting to know the Model 49

The Model 49 is a microprocessor controlled sheet

feeder designed to be used in a system together with

the mailer/inserter Model 45 and collator Model 306/

310.

Take a few minutes to become familiar with components of the Model 49.

1

2

3

4

5

rear

6

left

19 20 21 22

right

front

7

8

9

10

11

13 1412

18

23

15 16

17

1 Insert side guides

2 Insert front guide

3 Separator pads adjustment knob

4 Outfeed sensor

5 Paper deflector

6 Docking plate

7 Insert rear guide adjustment knob

8 Insert rear guide

9 Control panel

10 Insert feed belts

11 Insert sensor

12 Connection cable jack, female

13 Termination plug jack, male

Sheet Feeder Model 49 Operator Manual

T10114 Jan 2001

The Model 49 is powered from the Power

Pack mounted on the Model 45.

14 Power cord receptacle

15 Deflector band

16 Document side guides

17 Deflector band

18 Accumulator box

19 Display

20 Arrow buttons

21 Escape button

22 OK button

23 Main power switch

2-1

Page 5

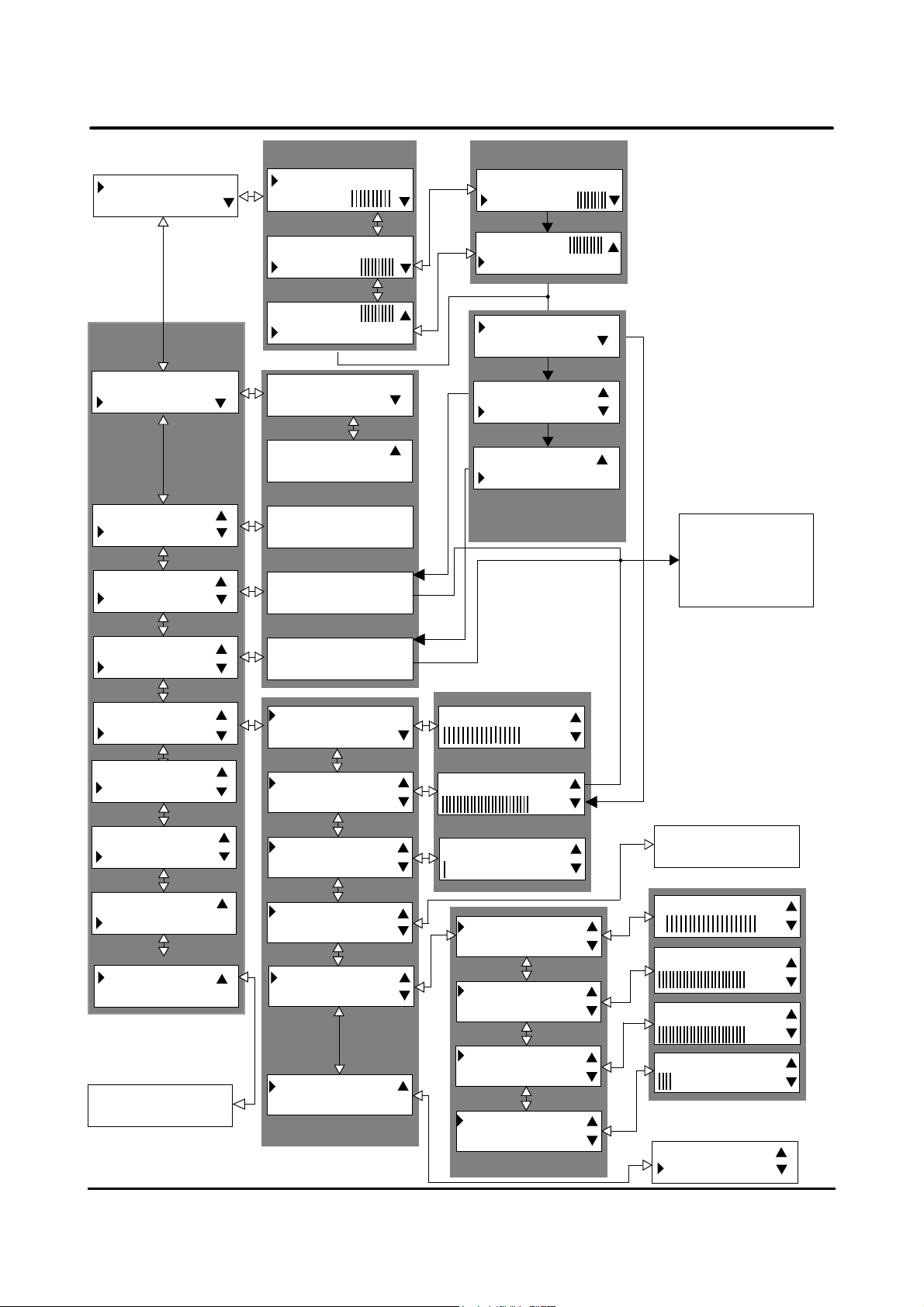

2.2 The Menus, Flow Chart

START 1

MODE On-line

Main Menu

Option

Menus

START 1

MODE On-line

MODE On-line

PROOF

PROOF

CLEAR COUNTER

Run Mode Menus

STOP 00075

PAUS

STOP 00075

PAUSE

PAUSE

ADJUST

On-Line

Off-Line

Off-Line

Stand Alone

Sheets/Set= 1

L=210mm BS=70%

Clear Counter

00075

Pause Mode Menus

STOP 00075

CONTINUE

CONTINUE

ADJUST

SETS PER HOUR

CLEAR COUNTER

SETS PER HOUR

CLEAR COUNTER

CLEAR COUNTER

PRESET COUNTER

Run Mode

Option Menus

To

Run Mode Menu

or

Pause Mode

CLEAR COUNTER

PRESET COUNTER

PRESET COUNTER

JOB SETUP

JOB SETUP

PLACEMENT (1)

PLACEMENT (1)

LANGUAGE

LANGUAGE

DIAGNOSIS

DIAGNOSIS

Run Diagnosis?

Diagnosis Menu

Counter :00100

Remaining :00025

LENGTH

SETS PER HOUR

SETS PER HOUR

SHEETS/SET

SHEET/SET

OMR

OMR

ADVANCED SETUP

ADVANCED SETUP

DEFAULT SETUP

DEFAULT SETUP

Adjustment Menus

Length: 200mm

SPH:2800

Sheets / Set 1

BELT SPEED

LUG SPEED

LUG SPEED

EJECT SPEED

EJECT SPEED

TRIG DELAY

TRIG DELAY

SETS PER HOUR

Adjustment Menus

OMR On

Off

BS: 80%

LS: 70%

ES: 100%

TD:50 ms

MODE On-line

PROOF

Sheet Feeder Model 49 Operator Manual

T10114 Jan 2001

2-2

Page 6

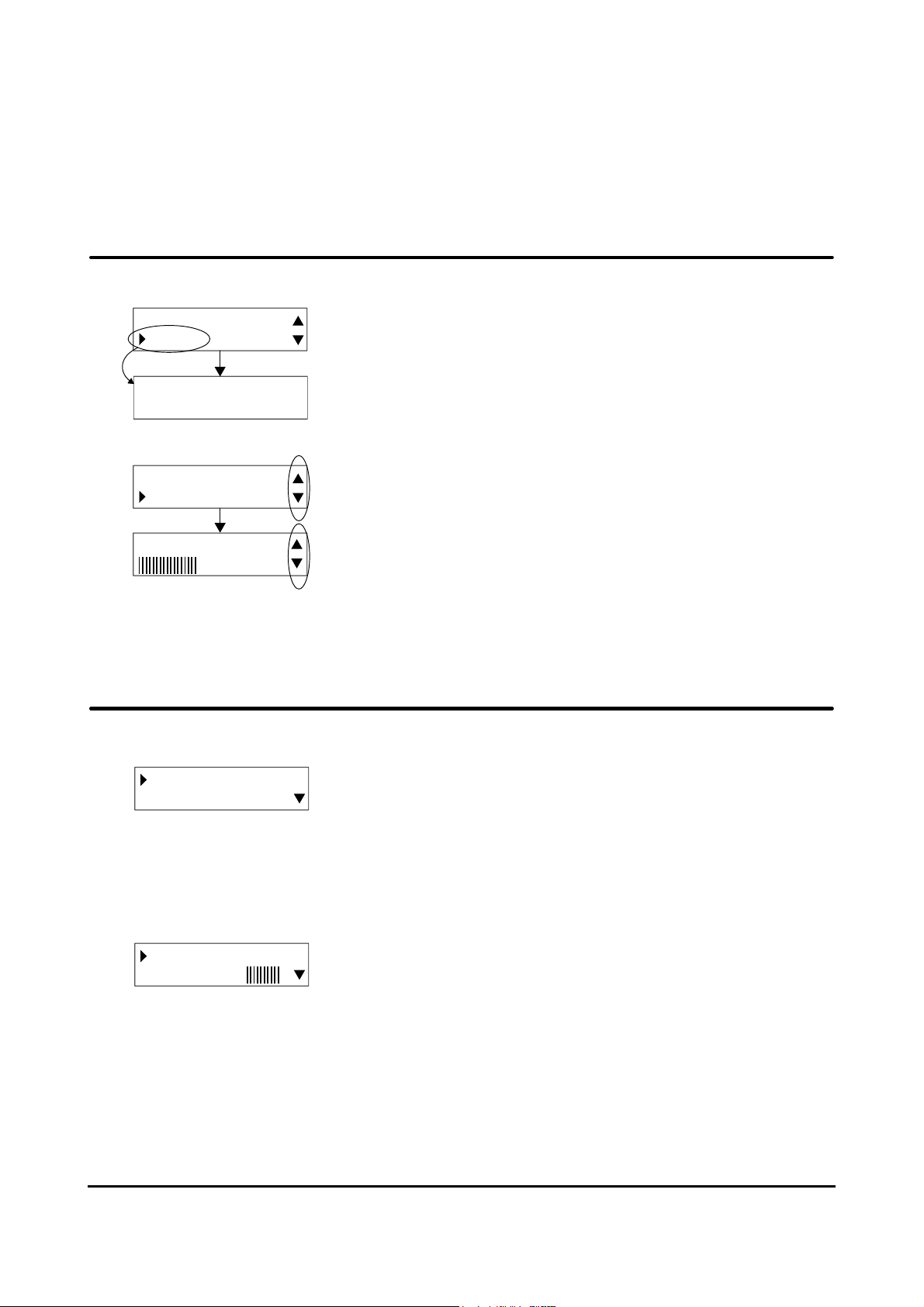

2.3 How to Read the Display

MODE On-line

PROOF

Sheets/Set= 1

L=210mm BS=70%

The arrow on the left side of the display shows option

currently selected.

Pressing the OK button on the control panel confirms your

selection and the corresponding submenu will appear in the

display.

SHEETS PER SET

LENGTH

Length: 210mm

On the right side of the display, up and / or down arrows

appear if other options can be selected.

These arrows are also displayed when the value of the

selected option can be increased / decreased, using the

arrow buttons. Use the up/down buttons on the control

panel for selecting, scrolling or adjustment.

2.4 Explanation of the Menus

START 1

MODE On-line

Main Menu

The ”Main Menu” shows ”START” when the Model 49 is

switched on. The information shows the Model 49 is ready to

start, this example on-line with the system. The number 1 in

the display indicate “Placement” of the machine.

For more information about “Placement” see table on page

7.2.

Press the OK button on the control panel to confirm your

STOP 00075

PAUSE

Run Mode Menu

selection and the Model 49 will start. When the Model 49 is

installed in a system with a Mailer/Inserter Model 45 and a

Feeder Model 306/310, the complete system can be started

from any start button on any of the units. The ”Main Menu” will

be replaced with the ”Run Mode Menu” as soon as the

Model 49/system is started.

Sheet Feeder Model 49 Operator Manual

T10114 Jan 2001

2-3

Page 7

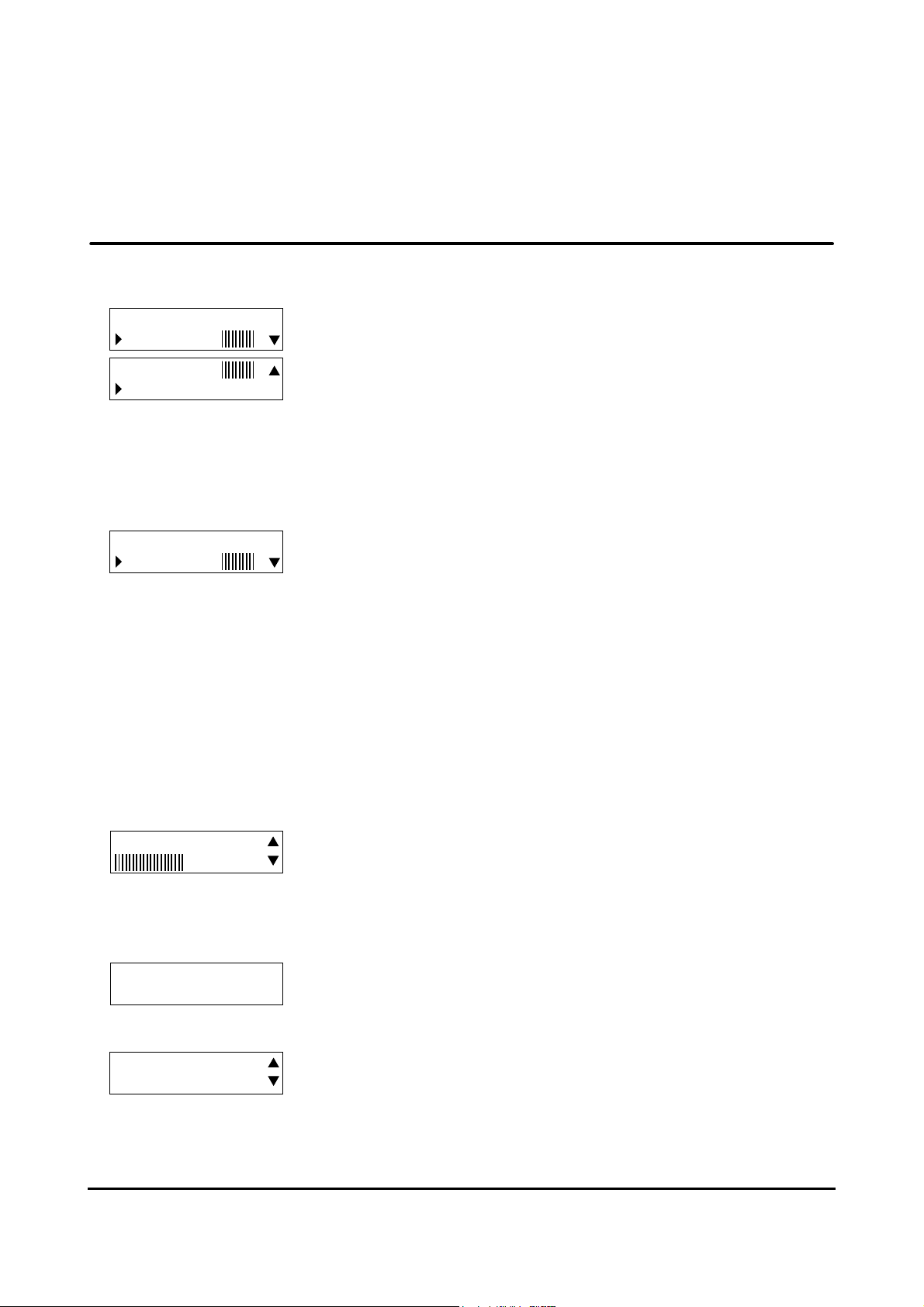

2.4 Explanation of the Menus, cont.

The ”Run Mode Menu” is displayed when the Model 49 is

STOP 00075

PAUSE

PAUSE

ADJUST

Run Mode Menu

STOP 00075

CONTINUE

Pause Mode Menu

started. In the ”Run Mode Menu” there are three options:

”STOP”, ”PAUSE” and ”ADJUST”. Scroll / select option with

the arrow buttons and confirm with the OK button.

”STOP”: The Model 49 (and attached units) completes the

already started set and then stops. You will be returned to

the ”Main Menu”.

”PAUSE”: The model 49 (and attached units) is paused

immediately. The text ”PAUSE” will be replaced with the text

”CONTINUE”. Select ”CONTINUE” and confirm with the OK

button when you want to leave the pause mode and start the

system. Or, select ”STOP” and confirm with the OK button

when you want to leave the pause mode and stop the system.

SPH: 2800

Adjustment Menu

Clear Counter

00075

Adjustment Menu

Counter :00100

Remaining :00025

Adjustment Menu

”ADJUST”: The “Run Mode Option Menus” can be reached

both when the Model 49 is paused and while it is running. In

the “Run Mode Option” menu there are three options: “SETS

PER HOUR”, “CLEAR COUNTER” and “PRESET COUNTER”. Scroll/select option with the arrow buttons and confirm

with the OK button.

“SETS PER HOUR”: To adjust speed use the arrow buttons.

The range is 1000 to 3600 sets per hour. Default value is

1800. The speed will, however, be limited to match units

attached.

“CLEAR COUNTER”: Clears the set counter when the OK

button is pressed.

“PRESET COUNTER”: To set the preset counter use the arrow

buttons. Default value is 0. This menu can also be used to

check the setting of the preset counter and the number of sets

to go before the job is completed.

NOTE: When checking, use the “ESC” button to leave the menu

without changing the settings.

Sheet Feeder Model 49 Operator Manual

T10114 Jan 2001

2-4

Page 8

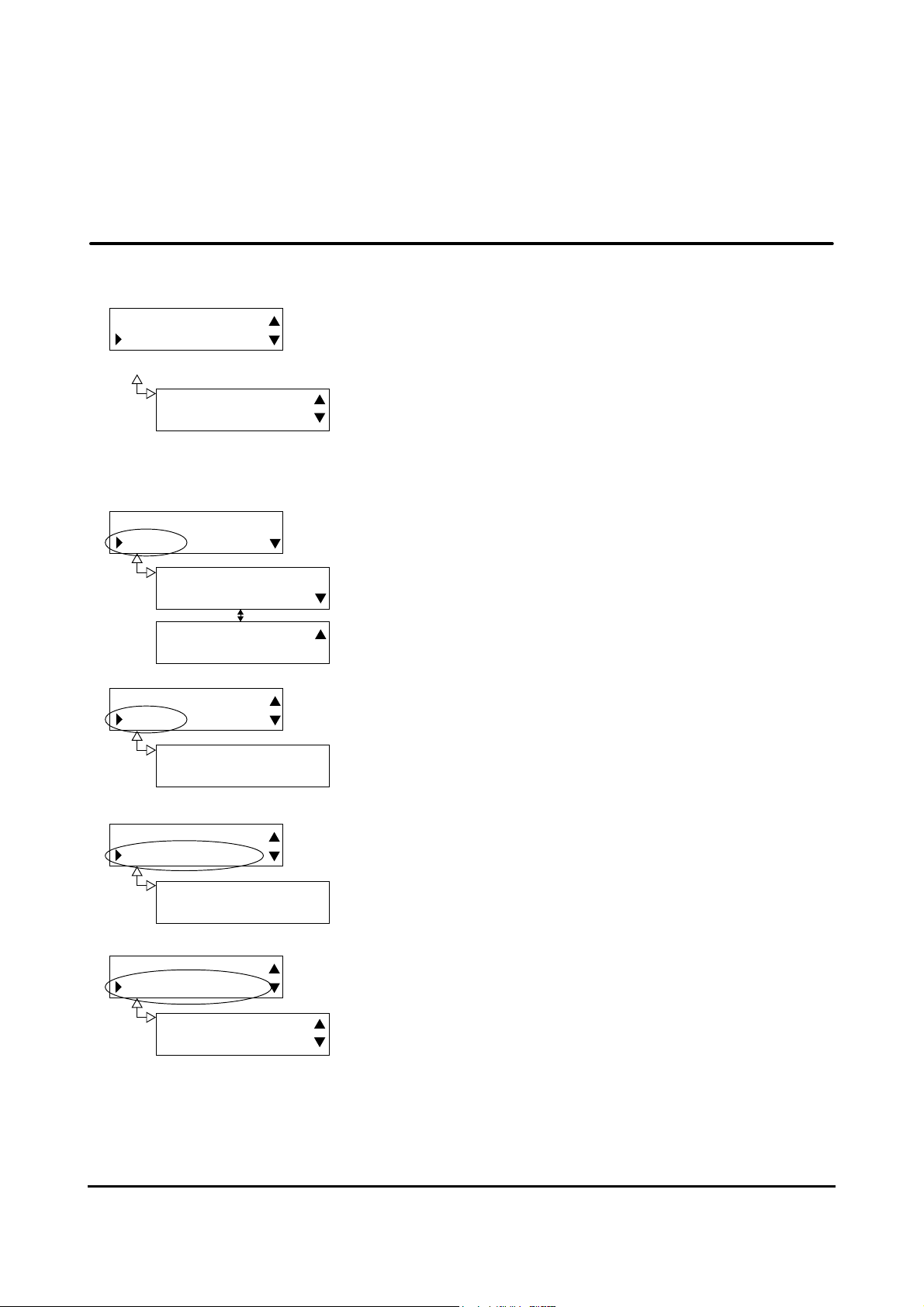

2.4 Explanation of the Menus, cont.

CLEAR COUNTER

PRESET COUNTER

Option Menu

Counter :00100

Remaining :00025

Adjustment Menu

START 00075

MODE On-line

On-Line

Off-Line

Off-Line

Stand Alone

MODE On-line

PROOF

Sheets/Set= 1

L=210mm BS=70%

Scrolling down from the ”Start Menu”, using the arrow buttons, you will find several options. Press the OK button at the

desired option to enter the corresponding ”Adjustment

Menu” as illustrated in the figure to the left. How each adjustment menu works in detail will be described later on in this

text. After adjustments press the OK button to confirm

changes or the ESC button to cancel. In either case you will

be returned to the ”Option Menu’s”.

Decide whether the Model 49 should be on-line or off-line

with the system or be operated as a stand alone unit.

This menu provides information of basic settings, number of

sheets per set, insert length and belt speed. No changes

can be made here.

PROOF

CLEAR COUNTER

Clear Counter

00075

CLEAR COUNTER

PRESET COUNTER

Clears the set counter when the OK button is pressed.

Enter the number of sets for the desired preset value using

the arrow buttons. Default value is 0. This menu can also be

used to check the setting of the preset counter and the

Counter :00100

Remaining :00025

number of sets to go before the job is completed.

NOTE: When checking, use the “ESC” button to leave the menu

without changing the settings.

Sheet Feeder Model 49 Operator Manual

T10114 Jan 2001

2-5

Page 9

2.4 Explanation of the menus, cont.

PRESET COUNTER

JOB SETUP

LENGTH

SETS PER HOUR

Length: 210mm

SETS PER HOUR

SHEETS/SET

SPH: 2800%

SHEETS/SET

OMR

BS: 100%

OMR

ADVANCED SETUP

OMR: On

Off

The menu “JOB SETUP” contains the main group of

settings.

Enter the length of the inserts (in the feed direction) using the

arrow buttons. The range is 100 to 310 mm. Default value is

200 mm.

Enter the number of sets per hour using the arrow buttons.

The range is 1000 to 3600 sets per hour. Default value is

1800. The speed will however be limited to match units

attached. When running the machine do not adjust speed

more than 1000 SPH at a time, If so, it could cause interruption per set.

Enter the number of sheets that should be fed from the

Model 49 per set using the arrow buttons. The range is 1 to

50 sheets per set. Defalut value is 1.

Enter OMR by pressing the OK button. Select OMR On or

Off.

See page (8.1) more for information .

ADVANCED SETUP

DEFAULT SETUP

The menu “Advanced Setup” contains settings of Belt

speed, Lug Speed, Eject Speed and Trig Delay.

Sheet Feeder Model 49 Operator Manual 2-6

T10114 Jan 2001

Page 10

2.4 Explanation of the Menus, cont.

BELT SPEED

LUG SPEED

BS: 100%

LUG SPEED

EJECT SPEED

LS: 70%

EJECT SPEED

TRIG DELAY

ES: 100%

TRIG DELAY

SETS PER HOUR

TD: 50 ms

Belt speed is how fast each document will be fed. Enter a

percentage using the arrow buttons. The range is 60 to

100%. Default value is 80%. If the belt speed is too slow the

documents might have problems to ”leave” the Model 49. If

the belt speed is too high, single sheets might turn over

when they are fed and booklets might bounce back.

Lug speed is how fast each set of documents will be fed

into Model 45. The range is 30 -140%. Default value is

70%.

Eject speed is a speed up function of the Lug speed. The

range is 30-140%. Default value is 100%. The value should

not be set under the “Lug Speed” value.

Trig Delay is a delay of the signal, which is sent as a start

signal to next machine in order. The range is 30-1000 ms.

Default value is 50 ms.

DEFAULT SETUP

BELT SPEED

When entering the menu “Default setup” and pressing the

OK button the “Belt Speed”, “Lug speed”, “Eject speed” and

“Trig Delay” will have their default values.

PLACEMENT (1)

LANGUAGE

Enter the “Placement” with OK button to set the place of the

machine in the line. The placement number of the machine

is depending on how many machines are in use.

See chapter 7.2 for more information.

LANGUAGE

DIAGNOSIS

Select language by pressing OK button. The languages

available in the system are Deutsch, English, Francais and

Svenska.

Default language is English.

Sheet Feeder Model 49 Operator Manual

T10114 Jan 2001

2-7

Page 11

3. Operator Instructions

3.1 Setting up the Model 49

Feeder Model 306/310

Mailer/inserter Model 45

Booklet feeder Model 46

Sheet feeder Model 49

When transporting the Model 49 the document table should

be flipped down. Flip up the document table, release the

securing plate on both sides of the document table by

holding the document table down a little bit when pushing

them away. The document table is now in its working

position.

Open the docking plate on Model 45 and position the Model

49 to the Model 45. Lock the Model 49 to the Model 45. If a

Model 306/310 is present in the system it should be positioned whith Model 49, square with the document table and

as close to the document table as possible. While calibrating the collator, adjust the paper deflector so that the leading

edge of the sheets lands between the insert feed belts on

Model 49 docking plate

the Model 45.

Sheet Feeder Model 49 Operator Manual

T10114 Jan 2001

3-1

Page 12

3.1 Setting up the Model 49, cont.

The docking plate is placed under the document table. When

the Model 49 is docked to Model 45 it is possible to push

the machine forward and backward by loosen the locking

screw.

Sheet Feeder Model 49 Operator Manual

T10114 Jan 2001

3-2

Page 13

3.1 Setting up the Model 49, cont.

paper feeder

To exclude the Model 49 from the system, just select “Offline” in the “Mode” menu.

To reactivate, select “On-line” in the “Mode” menu.

To exclude the Model 306/310 from the system, just select

“Stacking mode” on the control panel.

To reactivate, select “Third party device mode” on the

control panel.

paper deflector

Sheet Feeder Model 49 Operator Manual

T10114 Jan 2001

3-3

Page 14

3.2 Adjusting the Separation

separator pads

adjustment knob

separator pads

feed beltrollers

The drawing to the left shows schematically how the

separation works and the name of the different parts.

Tightening the separator pads adjustment knob, moves the

rollers and the separator pads closer to the feed belt. Adjust

the separation as follows.

Documents over 3 mm thickness.

Place the document between the rollers and the feed belts

as shown. Tighten the separator pads adjustment knob until

the feed belts moves when the booklet is pulled back and

forth.

Documents up to 3 mm thickness.

Place the document between the separator pads and the

feed belt as shown. Tighten the separator pads adjustment

knob so the next booklet stays in front of the separator pad

when the first one is fed.

Single sheets.

Place two sheets between the separator pads and the feed

belt as shown. Tighten the separator pads adjustment knob.

Then release until the top sheet can be pulled out.

Check adjustment in the proof menu. Press the up arrow

button to feed step by step. To feed an entire set, press the

OK button.

Sheet Feeder Model 49 Operator Manual

T10114 Jan 2001

3-4

Page 15

3.3 Loading

side guide adjustment

Slide the insert side guides away from each other. Load the

inserts. Slide the guides towards each other so that there

will be a play of 1-2 mm between the inserts and the side

guides.

The adjustment of the rear guide affects the friction between

the inserts and the feed belt. Adjustment therefore depends

on paper weight, structure and printing method as well as

what type of inserts that are fed. Proper adjustment is more

significant when running single sheets. Loosen the knob

and slide the rear guide to adjust. Tighten after adjustment.

Adjusting the rear guide too much to the left may cause

inserts not to be fed due to lack of friction. The error message ”Belt overload” will be shown in the display. Move the

rear guide to the right to increase the friction.

rear guide adjustment

front guide in rightmost position

extra weight

Adjusting the rear guide too much to the right may cause the

next insert to follow directly after the first one. The error

message ”Paper jam” will be shown in the display. Move the

rear guide to the left to decrease the friction.

Proper adjustment of the rear guide demands that the separation is properly adjusted.

The insert front guide should be positioned in its rightmost

position when booklets over 3mm are fed. For single sheets

and booklets up to 3mm position the front guide should be

positioned in its leftmost position. Lift the front guide to

adjust.

Extra weight to put upon the documents, to get a proper

separation.

front guide in leftmost position

Sheet Feeder Model 49 Operator Manual

T10114 Jan 2001

3-5

Page 16

3.3 Loading, cont.

scale

Slide the document side guides away from each other. Read

the scale on the bottom of the document board, and set the

same width as the loaded inserts.

When feeding longedge the short paper deflector should be

placed on the edge of the cover, and the long paper

deflector should hang down on the document table. When

feeding short edge, the short paper deflector should be

placed in the hole at the top of the cover, and the long paper

deflector should also be placed in the same hole.

Sheet Feeder Model 49 Operator Manual

T10114 Jan 2001

3-6

Page 17

3.4 Programming the Model 49

Switch on the power. Select ”Mode” and press the OK button. Choose ”On-line” if the Model

49 is used together with a feeder Model 306/310 and/or a mailer/inserter Model 45 and/or

Booklet Feeder Model 46. Choose ”Stand Alone” to use the Model 49 as a stand alone

document feeder. If the Model 49 should be inactivated choose ”Off-line”. Confirm your

choice by pressing the OK button.

Select “Job Set” and press the OK button. From “Adjustment Menu” it is possible to scroll and

enter any of the adjustable parameters.

Select ”Length” and press the OK button. Enter the length of the inserts (in the feed direction)

using the arrow buttons. The range is 100 to 310 mm. Default value is 200 mm. Confirm by

pressing the OK button.

Select ”Sets per hour” and press the OK button. Enter the number of sets per hour using the

arrow buttons. The range is 1000 to 3600 sets per hour. Default value is 1800. The speed will

however be limited to match units attached. Confirm by pressing the OK button.

Select ”Sheets per set” and press the OK button. Enter number of sheets per set using the

arrow buttons. The range is 1 to 50 sheets per set. Default value is 1. Confirm by pressing the

OK button.

Select “Advanced Setup” and press the OK button.

Select ”Belt speed” and press the OK button. Enter a percentage using the arrow buttons.

The range is 60 to 100%. Default value is 80%. Confirm by pressing the OK button.

Select “Lug Speed” and press the OK button. Enter a percentage using the arrow buttons.

The range is 30 to 140%. Default value is 70%. Confirm by pressing the OK button.

Select “Eject Speed” and press the Ok button. Enter a percentage using the arrow buttons.

The range is 30 to 140%. Default value is 100%. Confirm by pressing the OK button.

Select “Trig Delay” and press the OK button. Enter the time (millisecond) using the arrow

buttons. The range is 30 to 1000 ms. Default value is 50 ms. Confirm by pressing the OK

button.

Sheet Feeder Model 49 Operator Manual 3-7

T10114 Jan 2001

Page 18

3.4 Programming the Model 49, cont.

If you wish to reset the set counter select ”Clear counter” and press the OK button. The next

menu shows the actual value of the set counter. Clear the set counter by pressing the OK

button.

If you wish to program a specific number sets for a job, select ”Preset counter” and press

the OK button. The next menu shows the actual value of the preset counter and how many

more sets to go to finish the job. Enter a new value using the arrow buttons.

Default value is 0. Confirm by pressing the OK button.

3.5 Start inserting

After the setting up of attached units according to their respective operator instructions, the

system is ready to be started. The system can be started and stopped using the start and

stop buttons on any unit in the system.

Sheet Feeder Model 49 Operator Manual 3-8

T10114 Jan 2001

Page 19

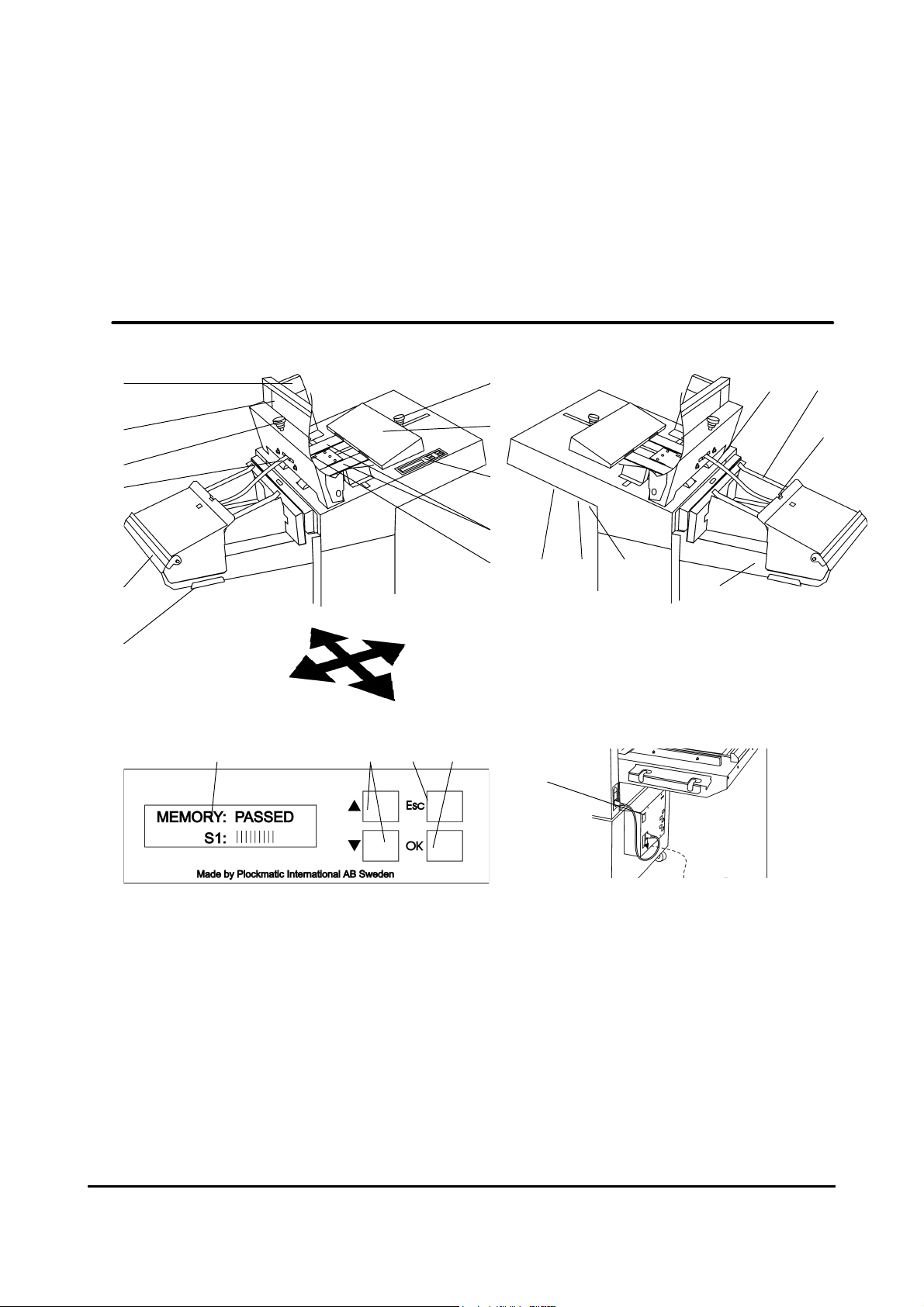

4.1 Diagnosis

4. Diagnosis

Note: Before starting the diagnosis, all inserts must be removed.

LANGUAGE

DIAGNOSIS

Run Diagnosis?

MEMORY:PASSED

S1:

Exemple: Display shows that

the Model 49 passed the

memory test and testing of

sensor S1 in progress.

Select ”DIAGNOSIS” from the ”Options Menu” and press the

OK button at the ”Diagnosis Menu” to start the self test.

The self test will check: memory, insert sensor (S1), outfeed

sensor (S2), set sensor (S3), lug belt senor (S4),voltage

supplied from the power pack and feed belt motor (M1),set

delivery motor (M2) and (OMR) if it is connected to the

system. During the test, the display will show which part that

currently is tested. After the test you can scroll with the arrow

buttons to check that all parts diagnosed, passed the test.

If any tested part did not pass the test.

If any of the sensors should fail the self test, check if sensors

are blocked with paper dust. If so, clean them and perform

the self test again. If cleaning does not correct the problem,

or if any other of the parts checked fails the test, have the

Model 46 checked by a qualified technician.

5. Maintenance

5.1 Cleaning the Feed Belts

Clean the insert feed belts using a mild soap detergent every

10 000 feeds or earlier if needed.

Sheet Feeder Model 49 Operator Manual

T10114 Jan 2001

4-1

Page 20

6.1 Problem Solving

6. Problem solving

egassemdeyalpsiDsesuacelbissoP

WARNING

Comm. Error

ERROR Purge

Paper Jam

noitca/noitanalpxE

-ffonidetrats94ledoM.1

nehwedomenil-noroenil

.ffoderewopsi54ledoM

elbacnoitacinummoC.2

dna54ledoMneewteb

rodetcennocton94ledoM

.evitcefed

xobnoitacinummoC.3

.evitcefed

si013/603ledoMehT.4

-mmoCehtroffodehctiws

.detcennoctonsixob

htgneltresnitcerrocnI.1

.deretne

foesuacebdeefelbuoD.2

detsujdayltcerrocni

.noitarapes

rosnesdeeftuO.3

.detanimatnocroevitcefed

.xob-mmoc

.elbattnemucod54

.naicinhcet

.no54ledoMehthctiwS.1

.unemtratsehtretne

ehtnistinuehtneewtebnoitacinummoC

.dehsilbatseebtondluocmetsys

.elbacnoitacinummocecalper/kcehC.2

metsys/xobnoitacinummocehtevaH.3

.naicinhcetdeifilauqaybdekcehc

ehttesdna013/603ledoMehtnonruT.4

ehttcennoC.enil-FFOroenil.NOenihcam

ledoMehtotylreporpdefdetropertons/tresnI

ni,htgneltresnitcerrocehtretnE.1

.4.2noitcesotgnidrocca,sretemillim

.4.2noitcesotgnidroccanoitarapestsujdA.2

.tsudhtiwdetanimatnocebyamrosneS.3

nuR.rosnesdeeftuoehtnaelc/kcehC

ehtfI.rosnesfosutatsyfirevot"sisongaiD"

,evitcefedsirosnesehttahtseifirevtsetfles

deifilauqaybdekcehc94ledoMehtevah

ehtegrupotnottubworrapuehtsserP

retneotecnonottubcsEehtsserP.s/tresni

tahthtgneltresnitahwkcehC.unemfoorpeht

oteromecnonottubcsEehtsserP.deretnesi

ERROR Purge

Belt over load

.noitarapes

.evitcefed

Sheet Feeder Model 49 Operator Manual

T10114 Jan 2001

esuacebdefstresnioN.1

detsujdayltcerrocnifo

rosnesdeeftuO.2

.evitcefedrotomdeeF.3

.rosnesdeeftuo

sirosnesehttahtseifirevtsetfleseht

.naicinhcetdeifilauq

.naicinhcetdeifilauq

ehtegrupotnottubworrapuehtsserP

.unemtratsehtretneoterom

ehtsehcaerstresniynatahtderetsigertonsitI

.4.2noitcesotgnidroccanoitarapestsujdA.1

fI.rosnesfosutatsyfirevot"sisongaiD"nuR.2

aybdekcehc94ledoMehtevah,evitcefed

deeffosutatsyfirevot"sisongaiD"nuR.3

sirotomehttahtseifirevtsetflesehtfI.rotom

aybdekcehc94ledoMehtevah,evitcefed

retneotecnonottubcsEehtsserP.s/tresni

ecnonottubcsEehtsserP.unemfoorpeht

6-1

Page 21

6.1 Problem Solving

egassemdeyalpsiDsesuacelbissoPnoitca/noitanalpxE

6. Problem Solving

WARNING Purge

Feeder is empty

System ERROR

Interlock at (X)

System ERROR

Jam at (X)

.stresnioN.1

revoctonseodstresnI.2

tresniehtnorosneseht

.elbat

evitcefedrosnestresnI.3

tinutahctiwskcolretnI.1

si"X"rebmunDIhtiw

.detautca

.yrtiucricninoitpurretnI.2

DIhtiwtinutamaJ.1

.detautcasi"X"rebmun

.yrtiucricninoitcnuflaM.2

.elbattresnieht

.daoleR.1

.3.3noitcesotgnidrocca

sirosnesehttahtseifirevtsetfleseht

.naicinhcetdeifilauq

.melborpehtgnisuac

.naicinhcet

.ylreporpdetcennoc

sitahttinuhcihwyfitnediot4.2noitces

.melborpehtgnisuac

.ylreporpdetcennoc

nostresniynaeraerehttahtderetsigertonsitI

ylreporpdedaolerastresniehttahtkcehC.2

fI.rosnesfosutatsyfirevot"sisongaiD"nuR.3

aybdekcehc94ledoMehtevah,evitcefed

sitahttinuhcihwyfitnediot4.2noitceseeS

eratonsehctiwskcolretniehttahtkcehC.1

,detcerrocebnactonmelborpfI.detautca

deifilauqaybdekcehctinu/metsysehtevah

eraselbacnoitacinummocehttahtkcehC.2

ehtevah,detcerrocebnactonmelborpfI

.naicinhcetdeifilauqaybdekcehctinu/metsys

ees,yrassecenfI."X"tinutamajraelC.1

eraselbacnoitacinummocehttahtkcehC.2

ehtevah,detcerrocebnactonmelborpfI

.naicinhcetdeifilauqaybdekcehctinu/metsys

Sheet Feeder Model 49 Operator Manual

T10114 Jan 2001

6-2

Page 22

7.1 Specifications

ezisrepaP.niMmm002x*001

thgiewrepaP.niMmsg06

:sdeepS

7. Specifications

NOITACIFICEPS94LEDOM

.xaMmm503x*523

.xaM

:noitatsrotalumuccaotnI

tes/steehs2,*FES,4A

tes/steehs3,*FEL,4A

tes/steehs4,*FEL,5A

:noitatsrotalumuccamorF

ruoh/steehs0027otpU

ruoh/steehs00821otpU

ruoh/steehs00441otpU

ruoh/stes0063otpU

ssenkcihttnemucodxaMmm8

thgiehkcatS.xaMmm071

noitceteddeefssiMseY

noitcetedmaJseY

thgieHmm0211

htdiWmm065

htpeDmm084

thgieWgk25

egatloV 54ledoMnokcaPrewoPmorfdeilppuS

* 100 mm in the fedding direction

* 325 mm in the feeding direction

* Rear Guide not effective below 140 mm

* SEF = Short edge feed

* LEF = Long edge feed

Sheet Feeder Model 49 Operator Manual

T10114 Jan 2001

7-1

Page 23

7.2 Specifications for Placement

The settings of placement gives the operator an opportunity to select the working position

of the machines. The table below show the available state of placement for each machine.

The machine with number 1 feeds first then number 2 and so on. The Model 45 is always

the last machine in the line. Placement can be selected from each machine, follow the

operator instruction for each machine.

54ledoM64ledoM94ledoM013/603ledoM

4321

4213

4132

321 esuniton

312 esuniton

3esuniton21

3esuniton12

31 esuniton2

32 esuniton1

21 esunitonesuniton

2esuniton1esuniton

2esunitonesuniton1

Sheet Feeder Model 49 Operator Manual

T10114 Jan 2001

7-2

Page 24

8. OMR

8.1 OMR mark Layout

The thickness of the marks should be between 0,5 to 0,8 mm (1½ – 2 pt). The length of the

marks should be 5 mm or more. The distance between the marks should be 3 mm. The length

of the total number of marks should be 15 mm ± 0,4 mm.

8.2 OMR Positioning

The OMR marks must not be printed within 10 mm from leading edge or 40 mm from trailing edge

of the sheet. Beside these limitations the OMR marks can be placed anywhere on the sheet. The

area covered by the OMR reader, between the leading edge and the OMR marks must be free from

text, images, and holes or similar in order not to confuse the reading procedure. Exception: A single

line before the OMR field, at least 10 mm away from the gate marks, will be ignored. Any print after

the OMR field will also be ignored. It is suggested that the margins on either side should be used for

placing the OMR marks. It is also advisable to place the OMR code closer to the leading edge

rather than the trailing edge, because of line-up reasons.

Area covered by OMR reader

Sheet Feeder Model 49 Operator Manual 8-1

T10114 Jan 2001

Page 25

8.3 How to Use the OMR Marks

Mark Structure

Gate 1

Gate 2

E. O. S.

Parity

Seq. 1

Seq. 2

Gate 1, Gate 2

The Gate 1 and Gate 2 act as start - reading - marks. Each mark

sequense must always include the two Gate marks. If not, the sheet

will be detected as blank.

Sequence 1 - 2

The “Seq1” & “Seq2” marks are needed for the OMR reader to detect

that the sheets in a set are fed in the right order. The sequence is: No

marks, S1 mark, S2 mark, S1 and S2 mark, no mark and so on. Each

new group shall start with the sequence number 0 (no marks), see

examples below.

End Of Set (E.O.S)

To indicate the last sheet in a set, an ”End Of Set” mark is required.

Parity

There must allways be an even number of marks on each sheet. When

needed, add the parity mark.

The example below illustrates a set containing eight sheet.

Page

1 2 3 4 5 6 7 8

G1

G2

EOS

P

S1

S2

The example below illustrates a set containing five sheets.

Page

1 2 3 4 5

Sheet Feeder Model 49 Operator Manual 8-2

T10114 Jan 2001

Page 26

Notes

Loading...

Loading...