MBM Corporation 46 Installation

T09120

INSTALLATION INSTRUCTION MODEL 46

UPGRADING THE MODEL 45 PCB

Before connecting a Model 46 to a Model 45 with machine No. 45033070 or lower, capacitor

C35 on the PCB PL45 need to be replaced.

CAUTION: Always handle the PCB, EEPROM, micro processor etc. in accordance with electro-

static discharge procedures (ESD). The PCB contains components that are sensitive to

ESD damage.

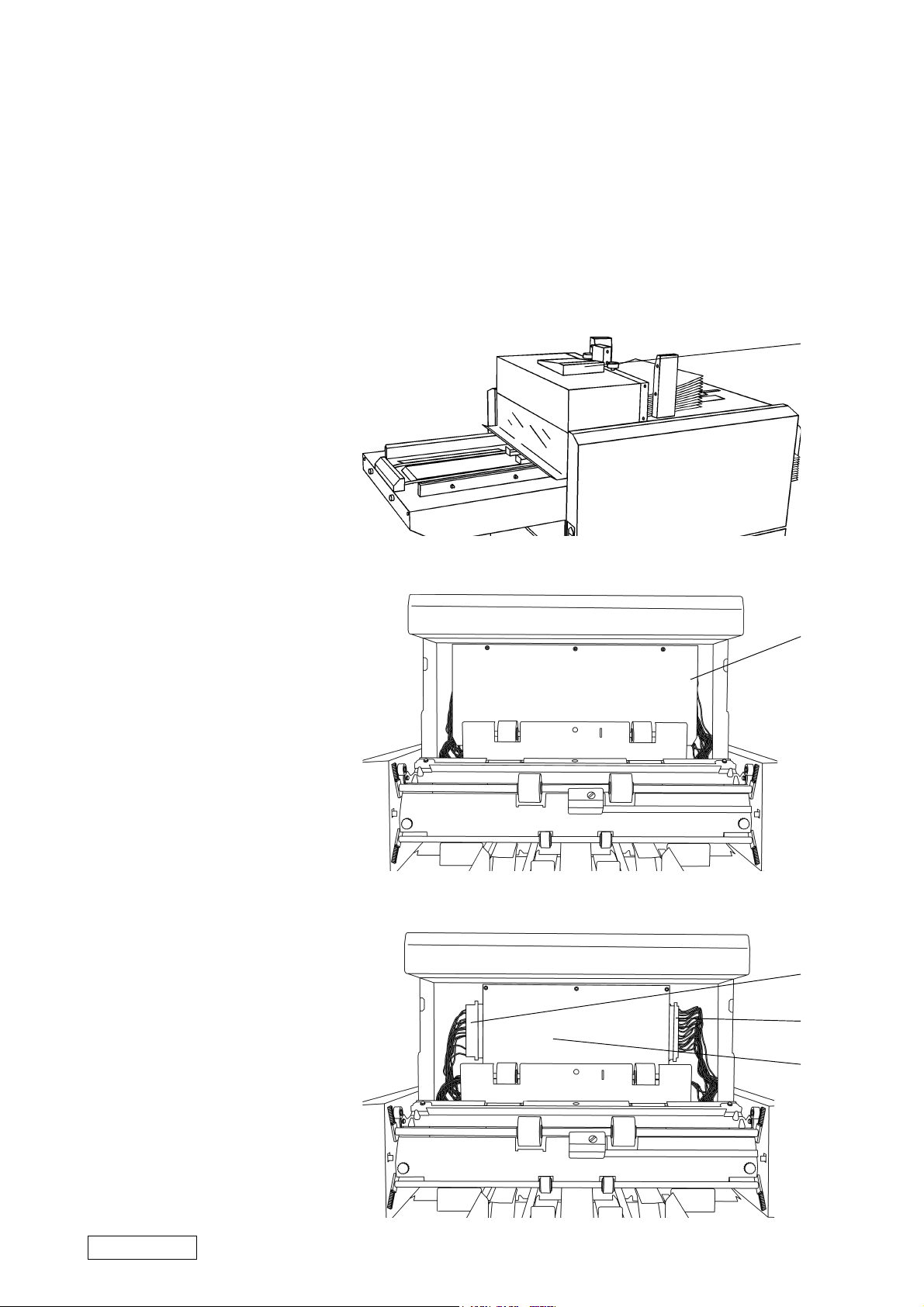

REMOVAL

1. Switch off the main power

switch and disconnect the

power cord.

2. Loosen the screw (1) on the

back side of the control panel.

3. Push the control panel towards

the rear side and lift it.

4. Remove the ground wire and

the ribbon cable.

5. Slide the envelope feeding

table open.

6. Open the envelope feeding

cover.

7. Remove the five screws

holding the PCB cover plate

(2).

1

2

8. Remove the PCB cover plate.

9. Remove the plugs P1 (3) and

P2 (4).

10. Remove the PCB cover plate

stand-offs.

11. Remove the PCB (5).

3

4

5

Page 1 (13) Art. nr 45961 Sep 2000

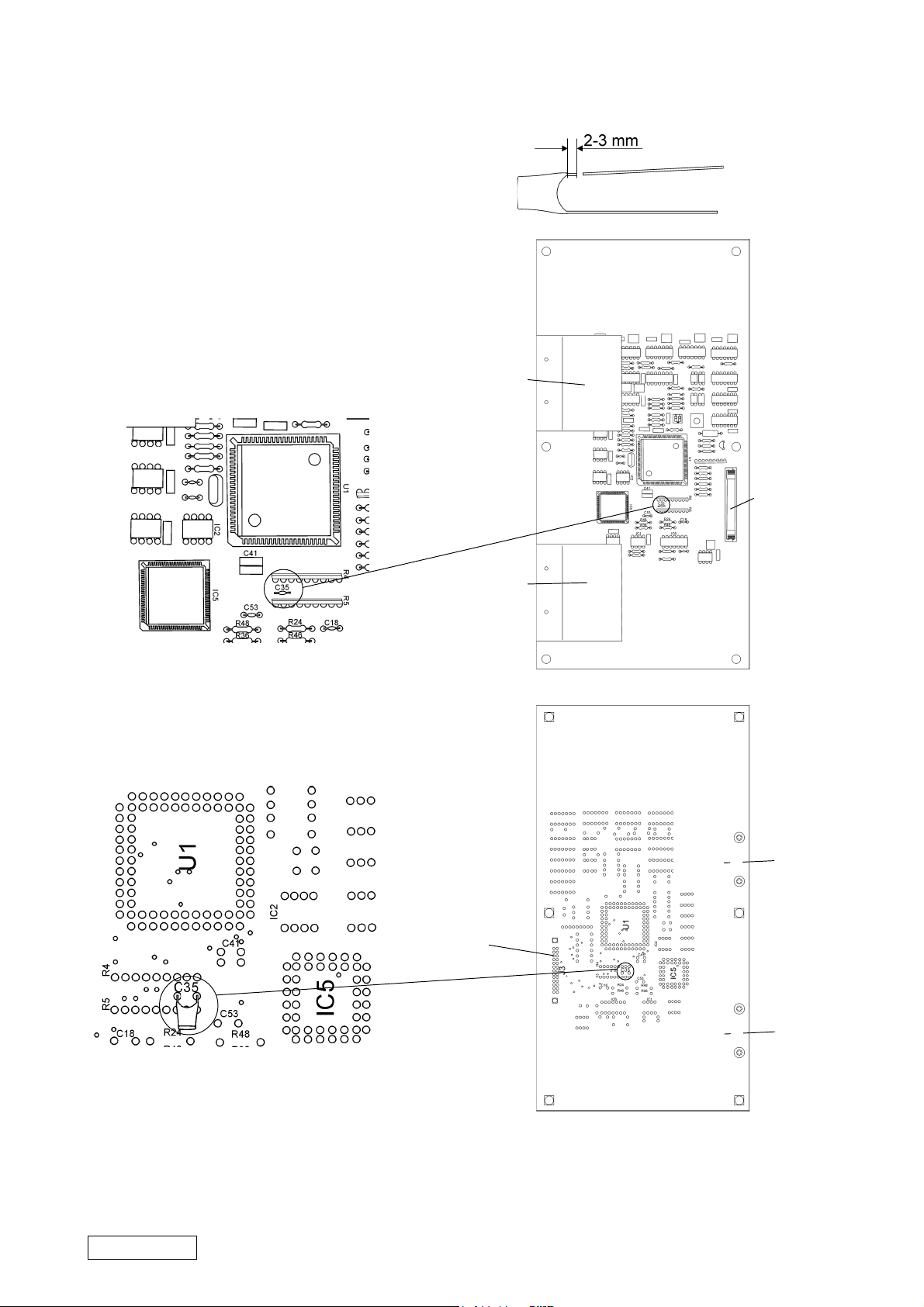

REPLACING THE CAPACITOR

1. Cut off the legs of the new

capacitor so that 2-3 mm

remains.

2. Place the PCB face up with the

heat sinks to the left and

connector J3 to the right.

Capacitor C35 is located

between R4 and R5 just below

the processor. Cut off the

capacitor.

T09120

heat

sink

connector

J3

3. Turn the PCB over. Locate the

legs of the original capacitor.

Solder the new capacitor onto

the legs of the old one.

heat

sink

heat

sink

connector

J3

heat

sink

REINSTALLING

Installation is an exact reversed

procedudre of removal

Art. nr 45961 Sep 2000

Page 2 (13)

T09120

UPGRADING SOFTWARE IN MODEL 45 AND MODEL 306/310

In order to run a system containing a Model 45, a Model 306/310 and a Model 46, the Model

45 and Model 306/310 requires certain software versions. This instruction describes how to

upgrade the Model 45 Mailer to software version 1.16 (or greater) and Collator Model 306/

310 to software version PL90 M 1.00 (or greater).

CHECK SOFTWARE VERSION MODEL 45

The actual software version is showed in the display on the control panel when the Model 45

is powered on.

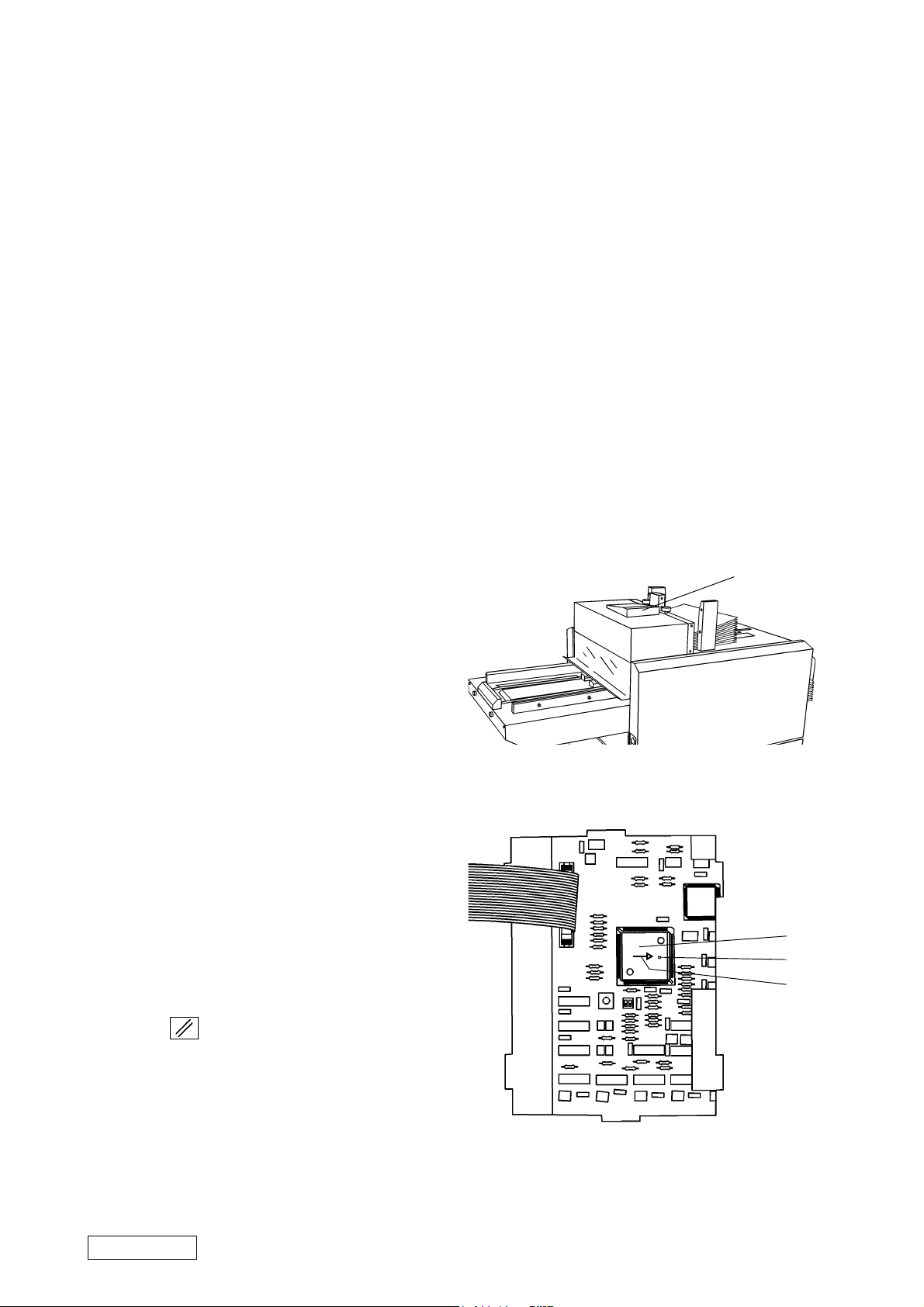

CHANGING PROCESSOR MODEL 45

CAUTION: Always handle the PCB, EEPROM, micro processor etc. in accordance with electrostatic

discharge procedures (ESD). The PCB contains components that are sensitive to ESD

damage.

1. Switch off the main power switch and

disconnect power cord and connection

cable (if present).

2. Loosen the screw (1) on the back side of

the control panel.

3. Push the control panel towards the rear

side and lift it.

4. Remove the processor (2) using the

extractor tool (part No. 95147).

5. Install the new processor (software

version 1.16 or greater) by applying an

even pressure on the processor until it

is fully inserted.

NOTE 1: On the socket under the processor there

is an arrow (4). Install the processor so

that the arrow will be pointing towards

the small dent (3) on the processor.

NOTE 2: There is no need to manually reset the

EEPROM. The new software does that

automatically. However, when powered

up the first time after processor

replacement, press the reset button

( ) when called for.

6. Install the control panel in reversed

order.

1

2

3

4

Page 3 (13) Art. nr 45961 Sep 2000

T09120

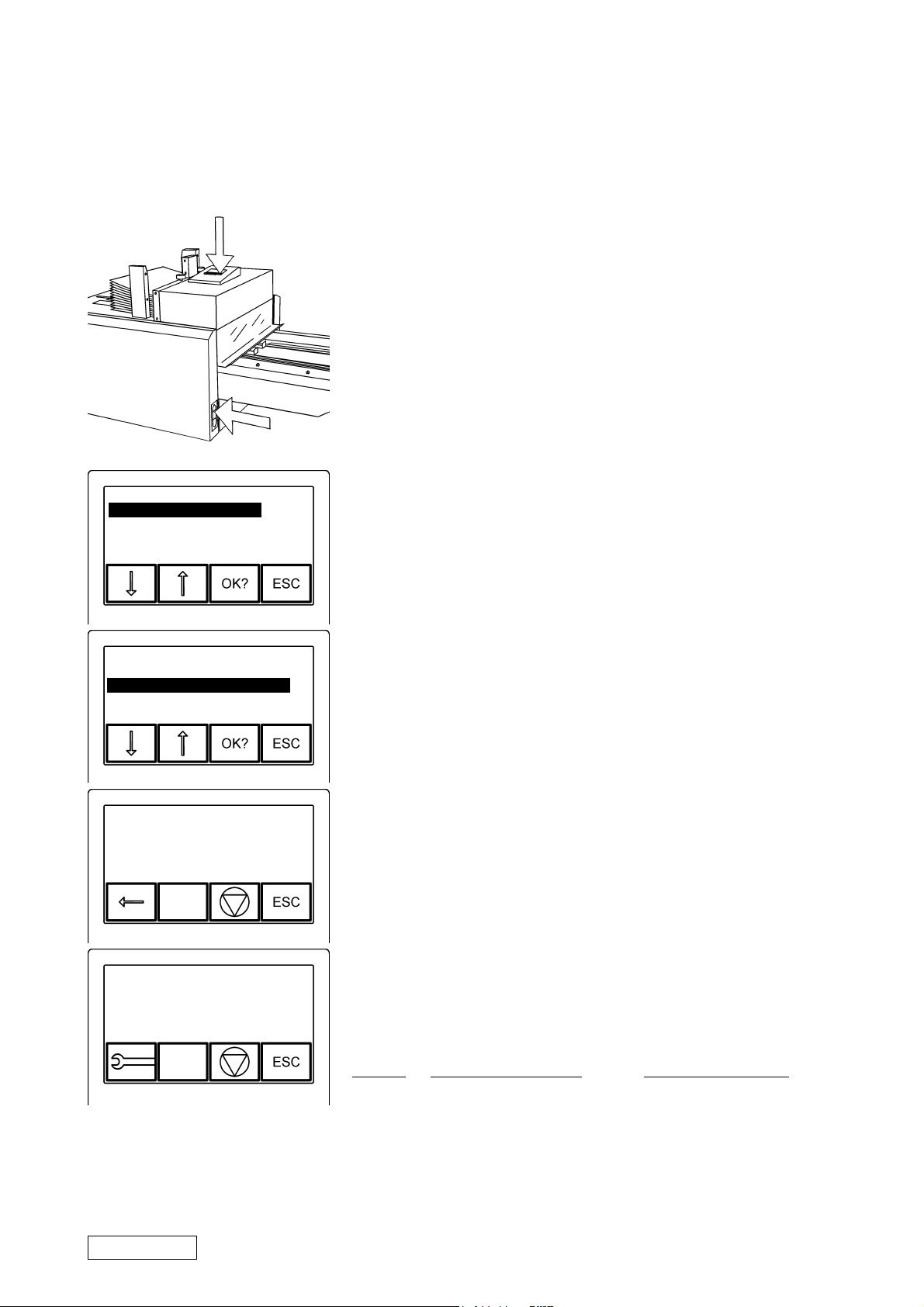

CALIBRATING MOTORS

After upgrading the software motors 3, 5 and 8 needs to be calibrated. Motors should allways

be allowed to cool off (if used) before calibration.

1

2

SELF DIAGNOSIS

CHECK MOTORS

CHECK SENSORS

VOLTMETER

ACTIVE STOP POS.

M1 RESERVED

M2 ENV. FLAP OP.

M3 ENV. POSITION

M4 ENV. OPNER

M5 PAPER TRANSP.

Enter the service mode by:

1. Pressing and holding the rightmost button pressed on

the control panel.

2. Switching on the power.

3. Choose “CHECK MOTORS” and press the “OK”

button.

4. Select motor and press the “OK” button

SPEED = 2.00 M/S

SPEED = 2.00 M/S

Art. nr 45961 Sep 2000

5. Run the motor by pressing the directional arrow

button.

6. Press the wrench button if the motor does not run at

the specified speed. The Model 45 will automatically

adjust the speed. Press the stop button to store

value.

Motor Normal reading Description

M3 SPEED=2,00 M/S ENV. POSITION

M5 SPEED=2,80 M/S PAPER TRANSP

M8 SPEED=2,90 M/S ENV. SEALING

7. After calibration, press the ”ESC” button one time

Page 4 (13)

Loading...

Loading...