Page 1

Mailer/inserter Model 45

Operator Manual

Mar 2000

Part No. 45866

Page 2

Table of contents

1. Introduction page

1.1 Operational safety 1-1

2. Getting to know the Model 45

2.1 Main components 2-1

2.2 The menus, flow chart 2-4

2.3 Explanation of the menus 2-5

3. Operator instructions

3.1 Setting up the Model 45 for different insert sizes 3-1

3.2 Adjusting the envelope feeder 3-3

3.3 Loading envelopes 3-4

3.4 Filling water 3-4

3.5 Setup a new job 3-5

3.6 Start inserting 3-6

4. Added features

5. Maintenance

6. Problem solving

7. Specifications

4.1 How to adjust the amount of sealing water 4-1

4.2 How to select language 4-1

4.3 Diagnosis 4-2

5.1 Cleaning the water tray 5-1

5.2 Cleaning the envelope sealing flap 5-2

5.3 Cleaning the envelope feed belts 5-3

5.4 GFI function test and resetting 5-3

6.1 Problem solving 6-1

7.1 Specifications 7-1

7.2 Insert and envelope specifications 7-2

Mailer/inserter Model 45 Operator Manual i

T10113 Mar 2000

Page 3

1. Introduction

The Model 45 is a mailer/inserter that can be

used on-line with the collators Model 306/310

and/or booklet feeder Model 46 or for handfeeding. This operator manual covers the

operation of the Model 45 both as a standalone unit or connected to the above mentioned collators. For on-line operation with

Model 46, also see Model 46 operator manual.

1.1 Operational safety

Attention to the following notes ensures the continued safe operation of your equipment.

Always connect the equipment to a properly

grounded power source receptacle. In doubt,

have the receptacle checked by a qualified

electrician.

WARNING: Improper connection of the equipment grounding conductor can result in electrical shock.

Always follow all warnings marked on, or

supplied with, the equipment.

Always locate the equipment on a solid support surface with adequate strength for the

weight of the machine.

Always exercise care in moving or relocating

the equipment.

Always keep magnets and all devices with

strong magnetic field away from the machine.

Never use a ground adapter plug to connect

the equipment to a power source receptacle

that lacks a ground connection terminal.

Never attempt any maintenance function that

is not specifically described in this documentation.

Never remove the covers or guards that are

fastened with screws.

Never install the unit near a radiator or any

other heat source.

Never override or “cheat” electrical or mechanical interlock devices.

Never operate the equipment if you notice

unusual noises or odours. Disconnect the

power cord from the power source receptacle

and call your customer service engineer to

correct the problem.

Mailer/inserter Model 45 Operator Manual 1-1

T10113 Mar 2000

Page 4

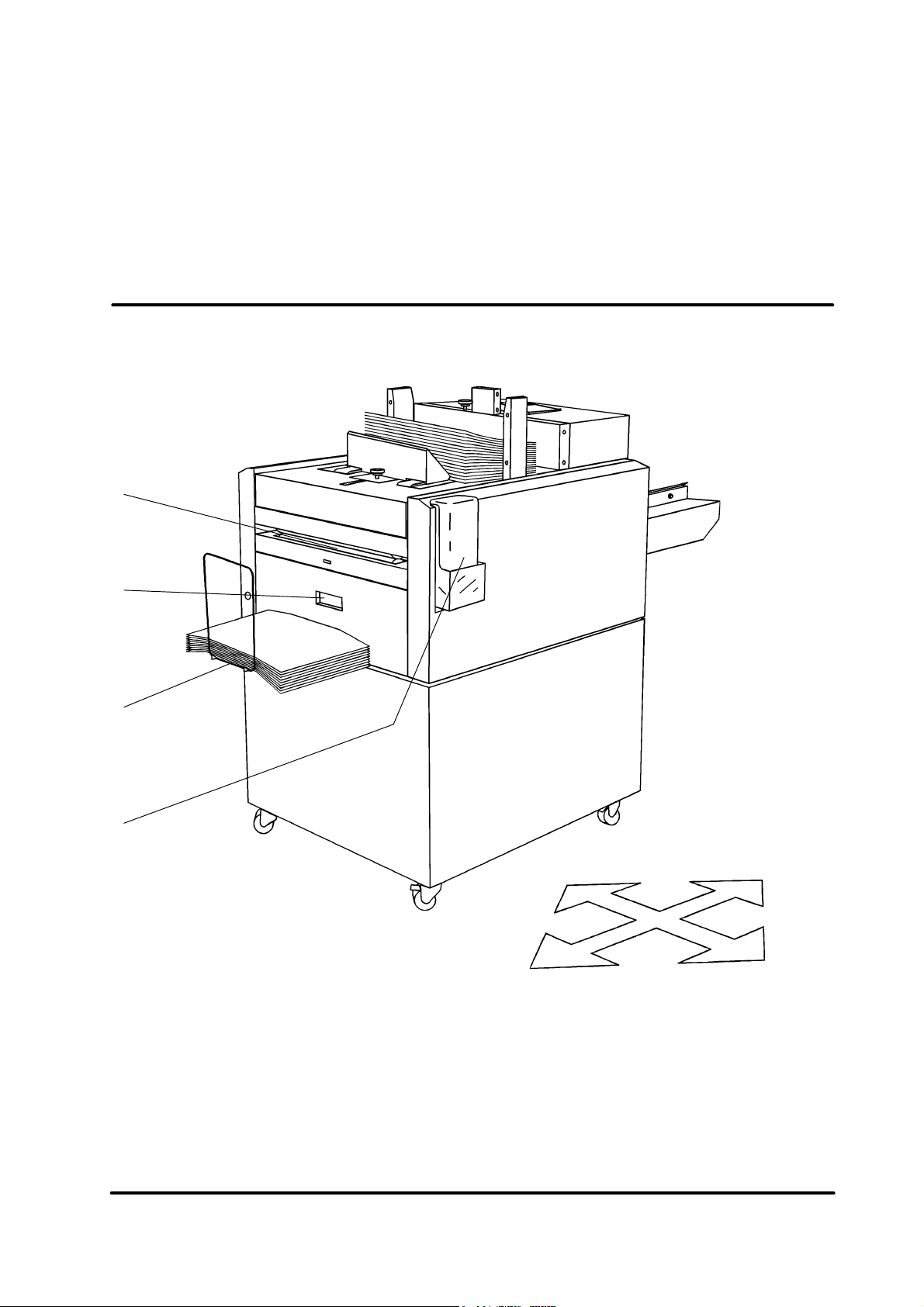

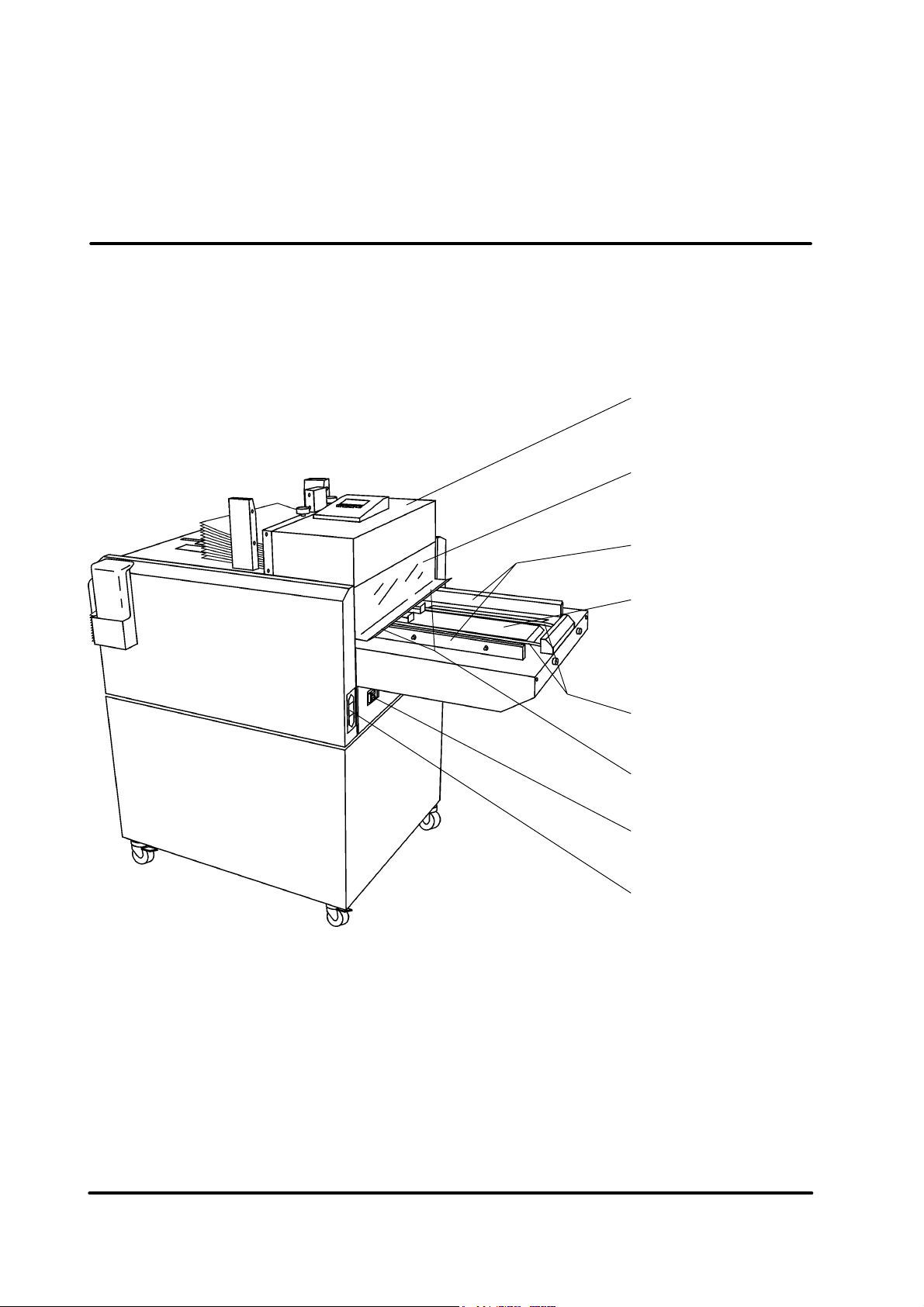

2.1 Main components

1

2. Getting to know the Model 45

The Model 45 is easy to use thanks to a fully microprocessor controlled operation. With the 4 buttons on

the control panel you can choose between the different

menus shown on the LCD display and do your settings.

Take a few minutes to become familiar with components of the Model 45.

2

3

4

rear side

left side

1 Outfeed area

2 Outfeed cover

3 Receiving tray

4 Water bottle

right side

front side

Mailer/inserter Model 45 Operator Manual 2-1

T10113 Mar 2000

Page 5

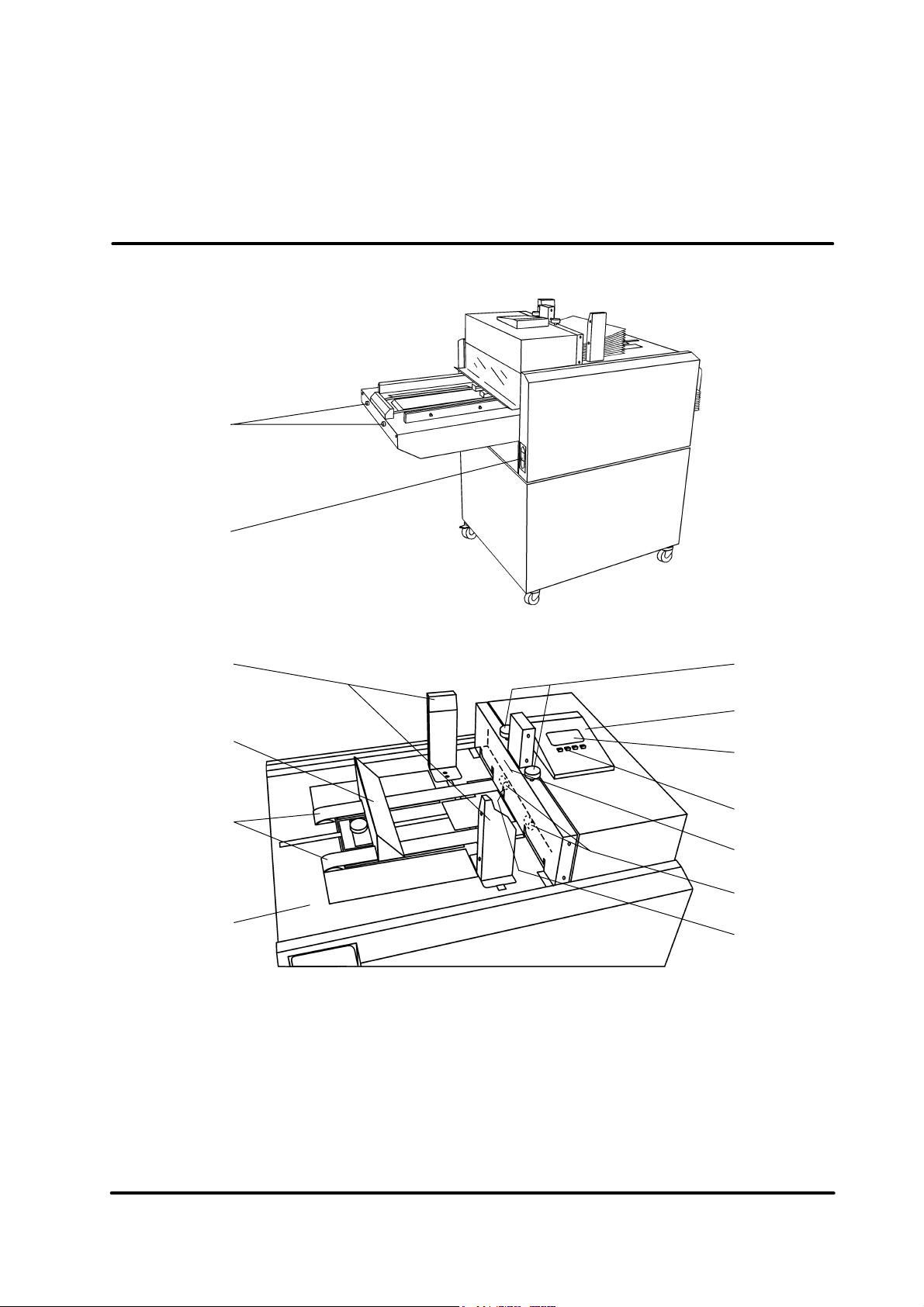

2.1 Main components, continues

1

2

3

4

5

6

7

8

1 Envelope feeding cover

2 Plastic cover

3 Document table side guides

4 Document table

5 Insert feed belts

6 Oversize envelope (B4) adjustment knobs

7 Ground fault interrupter (GFI)

8 Main power switch, power cord receptacle

and main fuse

Mailer/inserter Model 45 Operator Manual 2-2

T10113 Mar 2000

Page 6

2.1 Main components, continues

1

2

37

4

5

6

1 Studs

2 Connection cable jacks

3 Envelope side guides

4 Envelope rear guide

5 Envelope feed belts

6 Envelope feeding table

8

9

10

11

12

13

7 Envelope separator pads adjustment knobs

8 Control Panel

9 LCD display

10 Control buttons, multi function

11 Maximum load mark (red)

12 Envelope separator pads

13 Out of envelope sensor

Mailer/inserter Model 45 Operator Manual 2-3

T10113 Mar 2000

Page 7

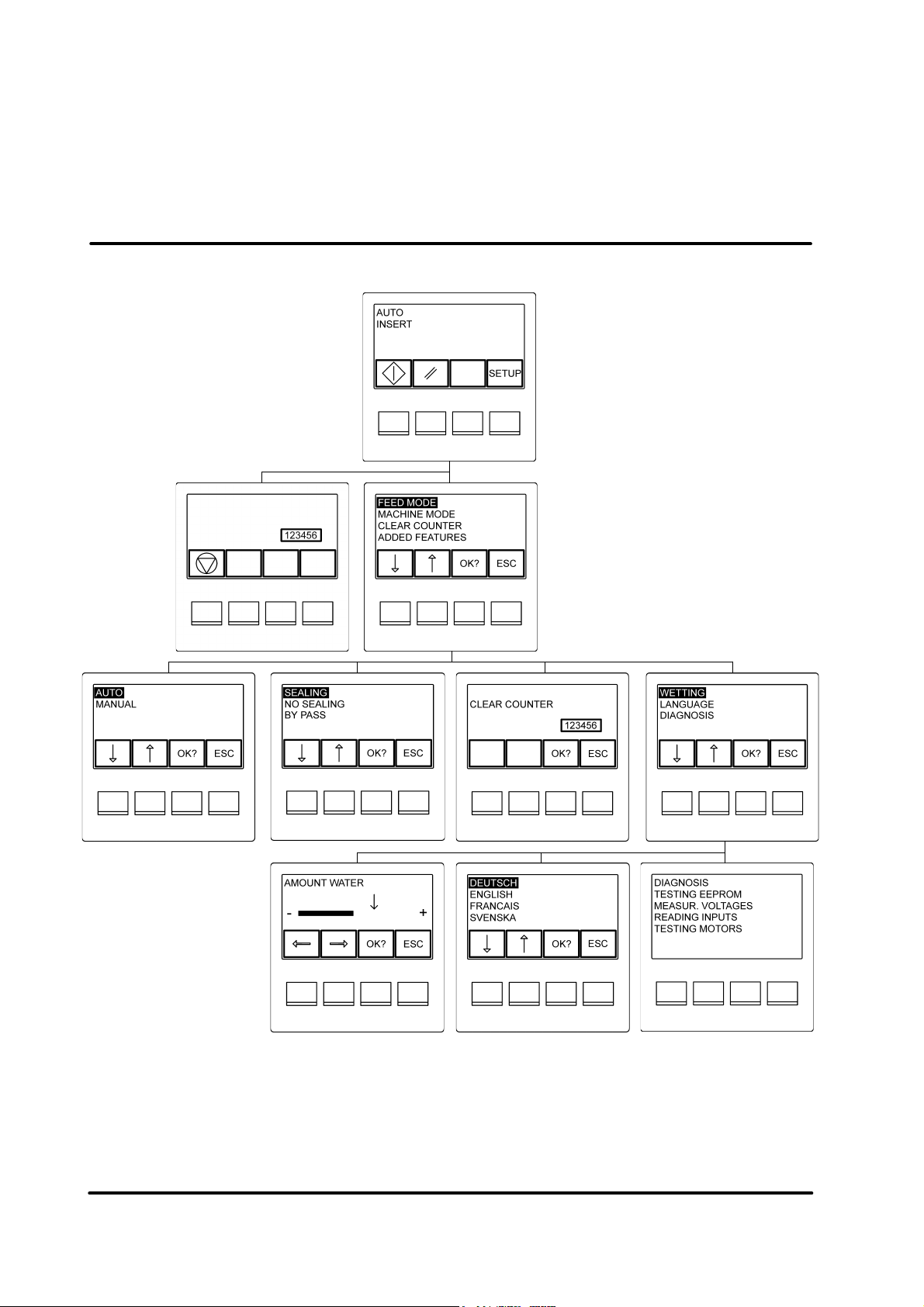

2.2 The menus, flow chart

Main Menu

Feed Mode Menu

Run Mode

Setup Menu

Machine Mode Menu Added Features Menu

Clear Counter Menu

Language MenuWater Amount Adjustment Menu

Diagnosis Menu

Mailer/inserter Model 45 Operator Manual 2-4

T10113 Mar 2000

Page 8

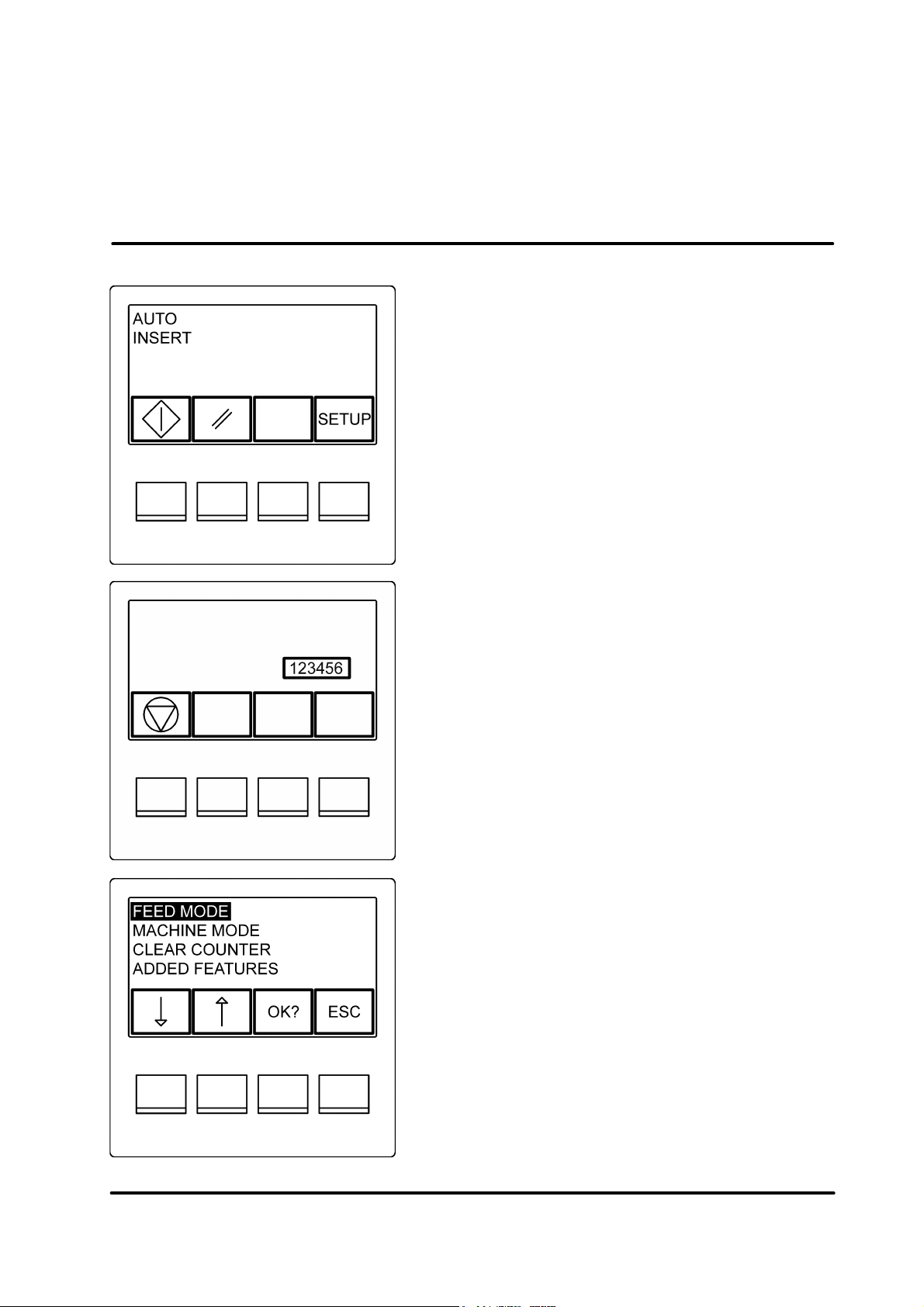

2.3 Explanation of the menus

The Main Menu appears after switching on the power.

This is also where you return before starting the job

after changing any settings. Use the left button (below

the start symbol) to initialize Run Mode. The next

button is the reset button which allows you to reset the

machine i.e. clear the machine from envelopes and

inserts. With the right button you can enter the Setup

Menu.

Start Reset

The Run Mode indicates that the Model 45 is ready for

use. Press the stop button to stop inserting and to

return to the Main Menu. If manual mode is chosen

from the Feed Mode Menu and no inserts are fed to

the document table within 15 seconds the Model 45 will

automatically return to the Main Menu.

Stop

In the Setup Menu you can scroll up and down with the

buttons below the arrow symbols. The chosen submenu will be shown with the text inverted. Confirm your

choice by pressing the “OK?” button.

To return to the Main Menu press the “ESC” button.

Mailer/inserter Model 45 Operator Manual 2-5

T10113 Mar 2000

Page 9

2.3 Explanation of the menus, continues

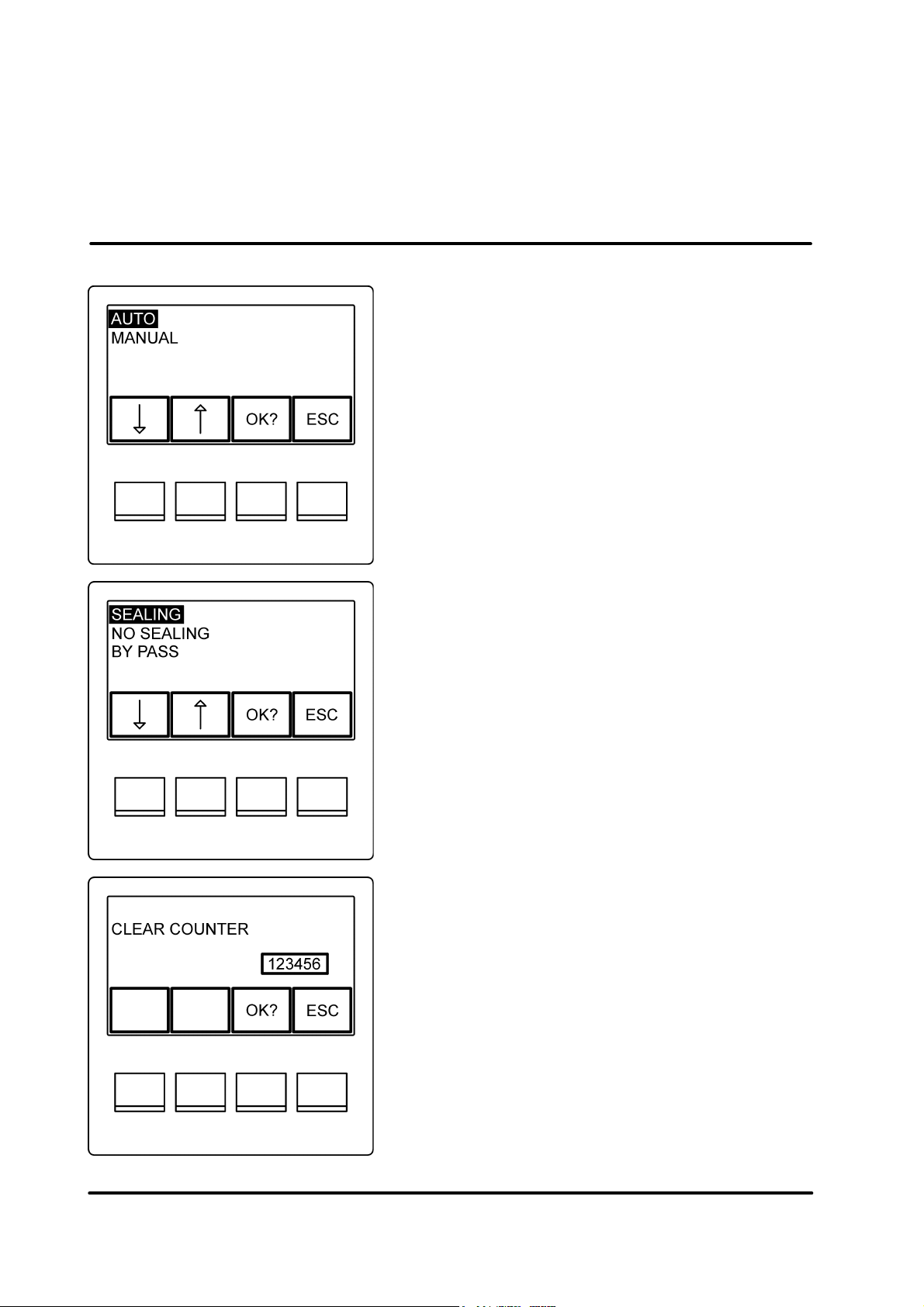

In the Feed Mode Menu you can choose between

manual feeding or automatic feeding from a collator

and/or booklet feeder. The chosen item will be shown

with the text inverted. Confirm your choice by pressing

the “OK?” button or cancel with the “ESC” button to

return to the Setup Menu.

In the Machine Mode Menu you can choose between

inserting with sealing, inserting and no sealing or just to

let the Model 45 feed your inserts through the machine

(without any envelopes as a bypass function). The

chosen mode will be shown with the text inverted.

Confirm your choice by pressing the “OK?” button or

cancel with the “ESC” button to return to the Setup

Menu.

In the Clear Counter Menu you can reset the counter.

Confirm your choice by pressing the “OK?” button or

cancel with the “ESC” button to return to the Setup

Menu.

Mailer/inserter Model 45 Operator Manual 2-6

T10113 Mar 2000

Page 10

2.3 Explanation of the menus, continues

In the Added Features Menu you can access the

Water Amount Adjustment Menu, the Language

Menu or start the self test program, Diagnosis. The

chosen item will be shown with the text inverted. Confirm your choice by pressing the “OK?” button or cancel

with the “ESC” button to return to the Setup Menu.

NOTE: Choosing “DIAGNOSIS” will immediately start

the built in self test program. Before performing

a diagnosis it is very important to read “4.3

Diagnosis” in the section “4 Added Features”.

In the Water Amount Adjustment Menu you can

adjust the amount of sealing water in the wetting system by pressing the corresponding arrow button. The

previous setting is indicated by an arrow. Confirm your

choice by pressing the “OK?” button or cancel with the

“ESC” button to return to the Added Features Menu.

In the Language Menu you can scroll/select which

language you want to be displayed using the arrow

buttons. The chosen language will be shown with the

text inverted. Confirm your choice by pressing the

“OK?” button or cancel with the “ESC ” button to return

to the Added Features Menu.

Mailer/inserter Model 45 Operator Manual 2-7

T10113 Mar 2000

Page 11

2.3 Explanation of the menus, continues

After choosing “DIAGNOSIS” the display will show what

type of self test that is currently performed. During the

test you will hear sounds when components are tested.

NOTE: Before performing a diagnosis it is very impor-

tant to read “4.3 Diagnosis” in the section “4

Added Features”.

Normally the message “NO FAULTS FOUND” should

be displayed. Press the reset button (

the Added Features Menu.

If the self test program would find any errors the display will show the faulty component, its actual status

and a fault code. In case of multiple errors there will be

an arrow button and a cancel button visible. Scroll with

the arrow button and press the “ESC” button to return

to the Added Features Menu.

) to return to

Mailer/inserter Model 45 Operator Manual 2-8

T10113 Mar 2000

Page 12

3. Operator instructions

3.1 Setting up the Model 45 for different insert sizes

The holes in the docking plate allows you to move the

Model 45 to the front or to the rear depending on the

size of the inserts.

A5 Landscape

A4 Portrait

A4 Landscape

Move the Model 45 to the front for portrait A4 size

inserts and to the rear for landscape A4 or portrait A5

size inserts.

Adjust the document table side guides by sliding them

towards or from each other by gripping the side guides

by the green dots. Adjust them to the scale mark corresponding the insert size. Normal setting is a 2-3 mm

play between the inserts and the side guides. If measurement “C” (see section 7.2) is large, a larger play has

to be accepted, otherwise the envelopes will not be

opened for insertion.

CAUTION • Before adjusting the side guides press

the reset button from the Main Menu to

avoid damages on the inserting tools.

Mailer/inserter Model 45 Operator Manual 3-1

T10113 Mar 2000

Page 13

3.1 Setting up the Model 45 for different insert sizes, continues

When B4 envelopes (extra wide) is used to

accomodate a large packing thickness, the oversize

envelope adjustment knobs should be set to their

outermost positions to aviod damages to the envelopes. Loosen the knobs to adjust.

CAUTION • Only perform the adjustment when the

document table side guides are in their

outermost position.

NOTE • If B4 envelopes (extra wide) not is used,

the oversize envelope adjustment knobs

oversize envelope adjustment knobs

shown in their outermost position

Depending on the actual packing thickness, the outfeed

rollers need to be adjusted. Open the outfeed cover and

position the two levers, one on each side, to the required position as shown in the figure.

should be set to their innermost positions.

0 - 7 mm

position

5 - 12 mm

position

Mailer/inserter Model 45 Operator Manual 3-2

T10113 Mar 2000

Page 14

3.2 Adjusting the envelope feeder

NOTE: It is important for the envelope feeding that the

gap between the envelope separator pads and the

envelope feed belts is correct and equal!

Default setting:

Press the envelope feed belt downwards at the arrow

and thighten the envelope separation adjustment knob

envelope

feed belt

envelope

separator pad

until there is no gap between the separator pad and the

feed belt. Then loosen the adjustment knob one and a

half turn. To facilitate adjustment, use a flash light and/

or a 0.05 mm feeler gauge.

If double feed occurs: Thighten the adjustment knobs.

If miss feed occurs: Loosen the adjustment knobs.

B

A

NOTE: The friction between the envelopes and the

envelope feed belts is also essential for proper

envelope feeding. Therefore the rear envelope

guide (B) must be adjusted properly.

Envelopes

Place one envelope on the envelope feeder so the right

edge stops against the envelope separator pads (A).

Loosen the knob on the rear envelope guide (B) and

slide it so that it is in line with the left edge of the envelope.

Bags

Place one bag on the envelope feeder so the right edge

stops against the envelope separator pads (A). Loosen

the knob on the rear envelope guide (B) and slide it so

that the left edge of the bag reaches the top of the

slope.

Mailer/inserter Model 45 Operator Manual 3-3

T10113 Mar 2000

Page 15

3.3 Loading envelopes

envelope low symbol

Slide the envelope feeder side guides away from each

other. Load the rest of the envelopes, not higher than up

to the red mark, with the flap up and to the left. Slide

the envelope feeder side guides towards each other

against the envelopes without squeezing.

The right side of the envelope stack should be straight

and make sure the envelope low symbol disappears

from the display.

NOTE: • Before loading the envelopes, fan them

properly to make sure they are not glued

together.

3.4 Filling water

• Also bend the envelopes perpendicular to

the feed direction, to make sure the

envelopes have proper contact with the

envelope feed belts.

• When running, make sure one or two

envelopes falls down to the feed belts and

the rest of the stack should lay onto the

rear envelope guide. Adjust the rear guide

if necessary.

The water bottle is mounted upside down and fills water

into the wetting system through holes in the cap.

Press down the water bottle slightly. Remove the bottle

by turning it over and lifting it out. Fill the bottle with

fresh water and tighten the cap. Put the bottle back in

the same position.

Mailer/inserter Model 45 Operator Manual 3-4

T10113 Mar 2000

Page 16

3.5 Setup a new job

Switch on the power and enter the Setup Menu.

Enter the Feed Mode Menu.

Choose “AUTO” to feed your inserts from a collator or a

booklet feeder. Follow instructions in the collator and/or

booklet feeder operator manual to setup the collator

and/or booklet feeder properly. Choose “MANUAL” to

feed your inserts manually. Confirm your choice by

pressing the “OK?” button.

Enter the Machine Mode Menu.

Choose the desired machine mode; “INSERT”, “NO

SEALING” or “BY PASS”.

Confirm your choice by pressing the “OK?” button

If you wish to clear the counter, choose “CLEAR

COUNTER” and confirm by pressing the “OK?” button.

Press the “ESC” button to return to the Main Menu.

Mailer/inserter Model 45 Operator Manual 3-5

T10113 Mar 2000

Page 17

3.6 Start inserting

Start the Model 45 by pressing the start button.

The Run Mode indicates that the Model 45 is ready for

use. Depending of the chosen machine mode continue

as follows:

Insert

sensor

“AUTO” mode: Press the calibration test button on

the collator. One set will be fed to

the document table and the system

will stop. Check that the inserts fed

to the document table are correct

and put them back. Make sure that

the inserts blocks the infeed sensor.

Press the start button on the Model

45 and then the start button on the

collator.

“MANUAL” mode: Begin inserting by feeding your

inserts manually to the document

table. Make sure that the inserts

blocks the infeed sensor.

Inserts can be “married together” by choosing “AUTO”

mode combined with hand feeding. Reduce the speed

on the collator (1000 sets per hour). Feed the document you want to add before the inserts are fed from

the collator.

To stop inserting press the stop button on the Model 45.

CAUTION: The insert feed belts will start to travel in

about 0.7 seconds after the insert sensor is

blocked.

NOTE: If the insert sensor is not blocked within 15

seconds in “MANUAL” mode the Model 45

will return from run mode to the Main Menu.

Mailer/inserter Model 45 Operator Manual 3-6

T10113 Mar 2000

Page 18

4. Added features

4.1 How to adjust the amount of sealing water

• Enter the Setup Menu.

• Enter the Added Features Menu.

• Enter the Water Amount Adjustment Menu.

Adjust the amount of sealing water by pressing the

corresponding arrow button. The previous setting is

indicated by an arrow. Confirm your choice by pressing

the “OK?” button or cancel with the “CANCEL” button to

return to the Added Features Menu.

• Press the “CANCEL” button to return to the Setup

Menu.

4.2 How to select language

• Press the “ESC” button to return to the Main Menu.

• Enter the Setup Menu.

• Enter the Added Features Menu.

• Enter the Language Menu.

Select language by scrolling with the arrow buttons.

The chosen language will be shown with the text inverted. Confirm your choice by pressing the “OK?”

button or cancel with the “CANCEL” button to return to

the Added Features Menu.

• Press the “CANCEL” button to return to the Setup

Menu.

• Press the “ESC” button to return to the Main Menu.

Mailer/inserter Model 45 Operator Manual 4-1

T10113 Mar 2000

Page 19

4.3 Diagnosis

The diagnosis is a self test program the operator can

run in order to verify the status of the Model 45 if some

problems are experienced. The self test program will

perform a test of the EEPROM, sensors, motors and

circuits as well as checking of different voltages.

NOTE: Choosing “DIAGNOSIS” will immediately start

the self test program. Before performing a

diagnosis it is very important to:

• Remove all envelopes from the envelope

feeding table.

• Remove all inserts from the document table.

• Press the reset button from the Main Menu to

clear the Model 45 from envelopes and in

serts inside.

• Empty the receiving tray

Reset

CAUTION: Do not attempt to stop the self test program

before it is finished.

To start the self test program from the Main Menu:

• Enter the Setup Menu.

• Enter the Added Features Menu.

• Choose “DIAGNOSIS” and press the “OK” button.

After choosing “DIAGNOSIS” the display will show what

type of self test that is currently performed. During the

test you will hear sounds when components are tested.

Normally the message “NO FAULTS FOUND” should

be displayed. If the self test program would find any

errors the display will show the faulty component, its

actual status and a fault code. In case of multiple errors

you can scroll with the arrow button.

• Press the “CANCEL” button to return to the Added

Features Menu.

• Press the “CANCEL” button to return to the Setup

Menu.

• Press the “ESC” button to return to the Main Menu.

Mailer/inserter Model 45 Operator Manual 4-2

T10113 Mar 2000

Page 20

4.3 Diagnosis, continues

Fault code Error message Explanation

1 EEPROM ERROR The EEP ROM is defective.

The unregulated voltage supplied to the

2 UNR. VOLTA GE LOW

3 UNR. VOLTA GE HIGH

4 REG. VOLTAGE LOW The regulated voltage is too low.

5 REG. VOLTAGE HIGH The regulated voltage is too high.

Model 45 is too low and/or the

transformer is defective.

The unregulated voltage supplied to the

Model 45 is too high a nd/or the

transformer is defective.

6 - 19 SENSOR S# ACTUATED

20 COVER OPEN The envelope feeding table is open.

21 INTERLOCK

22 SENSOR S17 ACTUATED Water level low.

31 - 49

(odd No.s only)

32 - 50

(even No.s only)

51 - 56 SE NSOR S# NOT RES PONDING

57 INTERLOCK RE LAY Int er lock relay defec tive.

MOTOR M# OPEN CIRCUIT

MOTOR M# SHORT CIRCUIT

Foreign object is covering the mentioned

sensor.

The interlock switch in the envelope

feeding cover is actuated.

Interruptio n in the mentioned motor

circuit.

Sho rt circuit in the mentio ned motor

circuit.

Interrup ti on in the mentioned sensor

circuit.

Mailer/inserter Model 45 Operator Manual 4-3

T10113 Mar 2000

Page 21

5.1 Cleaning the water tray

open

closed

5. Maintenance

The water tray should be cleaned at least every other

week.

• Remove the water bottle.

• Pull out and remove the receiving tray.

• Open and remove the outfeed cover.

• Pull out the hose, open the tap and empty the water

tray.

• Close the tap and put the hose back in position.

• Unlock the water tray by pushing it to the left and fold

it downwards.

• Clean the water tray.

• Hold the guide plate in the correct position (see

picture on next page) while folding the water tray

upwards until it snaps into locked position.

Caution: Check that the guide plate behind the water

tray is in the correct position. Incorrect position causes sealing jam.

Mailer/inserter Model 45 Operator Manual 5-1

T10113 Mar 2000

Page 22

5.1 Cleaning the water tray, continues

guide plate

correct position

water tray

5.2 Cleaning the envelope sealing flap

lift painted

plate here

envelope

sealing flap

1

2

The envelope sealing flap (stainless steel) and a guide

plate (stainless steel) under it, aswell as the painted

plate under the two leftmost rollers will eventually need

cleaning due to glue build-up.

• Clean the envelope sealing flap and the guide plate

by lifting app. 10mm at the green dot. To facilitate

cleaning, the rightmost roller can be removed. Press

down the envelope sealing flap and remove the roller

by pushing it to the rear (1) and lifting the front end (2).

• Clean the painted plate under the rollers. If neces-

sary remove the painted plate by lifting the rightmost

edge as shown in figure (and same place opposite

side). Close the envelope feeding table and pull the

plate out towards the receiving tray.

incorrectly positioned

guide plate

Mailer/inserter Model 45 Operator Manual 5-2

T10113 Mar 2000

Page 23

5.3 Cleaning the envelope feed belts

Clean the envelope feed belts using a mild soap detergent every 10 000 feeds or earlier if needed.

envelope feed belts

5.4 GFI function test and resetting

WARNING: DO NOT use the Model 45 if the following

test fails. No additional testing should be

performed. Call for service.

window

black

button

red

button

When testing the Ground Fault Interruptor (GFI ), the

Model 45 power cord must be connected to the wall

receptacle and the main power switch in the ON (1)

position.

• Press the red ”TEST”- button.

• Press the black ”RESET”-button. A red flag should

appear in the window of the GFI.

• Press the red ”TEST”- button. The red flag should

disappear.

• Press the black ”RESET”-button again. The Model

45 should now be ready to use.

Mailer/inserter Model 45 Operator Manual 5-3

T10113 Mar 2000

Page 24

6.1 Problem solving

6. Problem solving

This section explains possible causes and what actions to take if an error message should appear in the

display.

Allways remove envelopes and inserts in the same

direction as they travel through the Model 45.

If problem could not be solved - call for service.

Displayed message/symbol Explanation/Possible

causes

Water level low Fill water according to section 3.4.

Stacker full. Stop signal

sent to collator and/or

booklet feeder (if

attached).

Envelope feeder empty.

Stop si gnal sent to

collator and/or booklet

feed er (if a ttached) .

Envelope co uld not be

fed fr om envelo pe feed er.

Envelope miss occurs

when the envelope s does

not have proper contact

wi th the envelo pe feed

belts (i.e. when the

ENVELOPE MISS

REMOVE SET FROM

INFEED TABLE

friction is to low).

The collator has stopped

due to some error or

calibration.

Actio n

Empty the receiving tray.

Load more envelopes.

1. Check that the envelope s are bent

according to section 3.3.

2. Check adjustment of the envelope

separation pads according to section 3.2.

3. C heck the ad justme nt of the envelope

rear guide according to section 3.2.

Check/clean the feed belts a ccord ing to

section 5.3.

See collator operator manual and Model

45 operator manual 3.6.

The interlock switch in the

plastic cover is actuated.

INTERLOC K

NOTE: These symbols can appear allthough action as above is not

necessary. For instance, an air buble in the water hose could

cause the water level symbol to appear intermittently. Once the

air buble disappears, water level warning symbol extinguishes

automatically. If problem percists for certain amount of time,

the machine stops.

Above means when attending a stoped machine, fault message

may already have been corrected.

1. Re move obstac le. If nece ss a ry slide t he

envelope feeding table open and open the

envelope feeding cover.

2. If a collator is attached, check that the

paper feeder on the collator does not have

contact with the plastic cover on the Model

45.

3. After obstacle is removed, follow on

screen instruction.

Mailer/inserter Model 45 Operator Manual 6-1

T10113 Mar 2000

Page 25

6.1 Problem solving, continues

Disp layed message/symbo l Explanation/Possible

causes

The interlock switch in the

plastic cover was

actuated but obstacle is

INTERLOC K

RESET SYSTEM

THE TOP C OV E R IS

OPEN

FLAP OPENER MISS

SEALING JAM

no longer actuating the

interlock switch.

The envelope feeding

table i s open.

1. The flap on the

envelope could not be

opened when the

envelope was positi oned

before i nserting.

2. The flap on the

envelope was already

open when the envelope

was fed.

Malfunction when sealing. Slide the envelope feeding table open.

Actio n

Press the reset button. Press the start

button. Start the collator (if attached).

Close the envelope feeding table.

Slide the envelope feeding table open.

Remove the envelope . Close the envelope

feeding table. Press the reset button.

1. Check that the envelopes are loaded

with the flap up, closed and towards the

envelope rear guide according to section

3.3.

2. Check that the envelopes not already

are accidentally sealed.

3. Check that the flap not is to he avi ly

curved .P ress the start b utton. Start the

collator (if attached).

Remove the envelope . Close the envelope

feeding table. Press the reset button.

1. Check/fill water according to section 3.4.

2. Check that the gui de plate is in the

correct po s i ti on according to s e ctio n 5.1 .

3. Check/clean according to sections 5.1

and 5.2.

P ress the start button. Start the c ollator (i f

attached).

Mailer/inserter Model 45 Operator Manual 6-2

T10113 Mar 2000

Page 26

6.1 Problem solving, continues

Displayed message/symbol Explanation/Possible

causes

Malfuncti on when

inserting.

INSERTER ERROR

Envelope jam under the

envelope

feeding cover.

FEED ERROR

Insert(s) or e nvelope

inside the machine .

REMOVE PAPER

Actio n

Clear the d o cument table. Slide the

envelope feeding table open. Remove

envelope and i nserts. Close the envelope

feeding table. Press the reset button.

Check the ad justme nt of the document

table side guides according to section 3.1.

If the inserts a re clos e t o mi nimum

recommended specifi ca ti ons for actual

envelope size (see section 7.2) you might

have to exceed the recommended play of

2-3 mm.

Press the start button. Start the collator (if

attached).

Slide the envelope feeding table open.

Open the envelope feedi ng cover. Remo ve

the envelope. Close the envelop e feeding

cover. Close the envelope feeding table.

Press the reset button. Press the start

button. S tart the collator (if attached).

Slide the envelope feeding table open.

Remove envelope and inse rts. Close the

envelope feeding table. Press the reset

button. S tart the collator (if attached).

If problem continues, check that the

enve lope s fed not are to heavily curved .

1. Envelope is not

removed after a feed

error.

2. Double feed ing of

envelopes.

REMOVE ENVELOPE

Jam in unit feeding Model

45.

FEEDER JAM

Slide the envelope feeding table open.

Open the envelope feedi ng cover. Remo ve

the envelope. Close the envelop e feeding

cover. Close the envelope feeding table.

Press the reset button. Press the start

button. S tart the collator (if attached).

Follow actual operator manual to clear jam.

Press the reset button. Press the start

button. S tart the collator (if attached).

Mailer/inserter Model 45 Operator Manual 6-3

T10113 Mar 2000

Page 27

7.1 Specifications

SPE CIFICATIONS MODEL 45

Envelope size Min. See next page

Envelope loading c a pa city 100 mm

Paper size Min. See next page

Paper weight Min. 60 gsm

7. Specifications

Max. See next page

Max. See next page

Max. -

Maximum speed Up to 3600 e nvelopes/hour

Max packing thickness 12 mm

Misfee d d etecti on Yes

Jam detection Yes

Envelope low detection Yes

Stacker full detection Yes

Availibility factor

Height 560 mm

Width 1150 mm

Depth 640 mm

80% at 36 00 envelope s/hour

(2 minutes stop / 10 minute period)

Weight 83 kg

Volta ge 105 /115 /1 25/220 /2 30 /2 40 volt, 50-60 Hz

Mailer/inserter Model 45 Operator Manual 7-1

T10113 Mar 2000

Page 28

7.2 Insert and envelope specifications

Mailer/inserter Model 45 Operator Manual 7-2

T10113 Mar 2000

Page 29

7.2 Insert and envelope specifications, continues

OK!

OK!

AVOID

OK!

OK!

mailpoint or pointed type flap with window

positioned off center of envelope

The envelopes should have edge-tight gluing on windows to avoid jam and inserts getting caught

between the edge of the patch and the window. Use envelopes where the window is positioned

off centre of the envelope to avoid the pointed part of the flap to getting caught in the window.

Avoid using envelopes with square types of flaps, the

straight edge of the flap could easily get caught in the

window.

mailpoint or pointed type flap with window

positioned across center of envelope

AVOID

AVOID

AVOID

wallet or square type flap

Mailer/inserter Model 45 Operator Manual 7-3

T10113 Mar 2000

Loading...

Loading...