Page 1

OPERATION MANUAL

for

Scoring unit & Perforating unit

Read this operation manual carefully before

use. Keep this booklet handy for your

reference anytime.

A PRODUCT OF

CORPORATION

The Leader in Paper Handling Equipment

1-800-223-2508

www.mbmcorp.com

Nov.24 2009

1265-0043-00

Page 2

Before use

Read this operation manual carefully before use.

Keep this booklet handy for your reference anytime.

Specifications are subject to change without notice for product improvement.

Always refer the original manual which came with the delivered unit.

Index

1. Names of Parts

2. Preparation before use

3. How to use

1) Perforating Unit

3.1 Setting Perforating Block

3.2 Trial Perforation

3.3 Fine Adjustment of Perforating Line

3.4 Perforation, continues

3.5 Replacing Perforating Blade(with frame)

2) Scoring Unit

3.6 Setting Scoring Block

3.7 Trial Scoring

3.8 Fine Adjustment of Scoring Line

3.9 Scoring, continues

4. Adding 2nd Perforating or Scoring Unit to the same mounting shaft (= transport

shaft).

5. Installing Perforating Block in replacement of Scoring Block and vice versa

6. Replacing Transport Rubber Ring

7. Troubleshooting

8. Product Specifications

1

Page 3

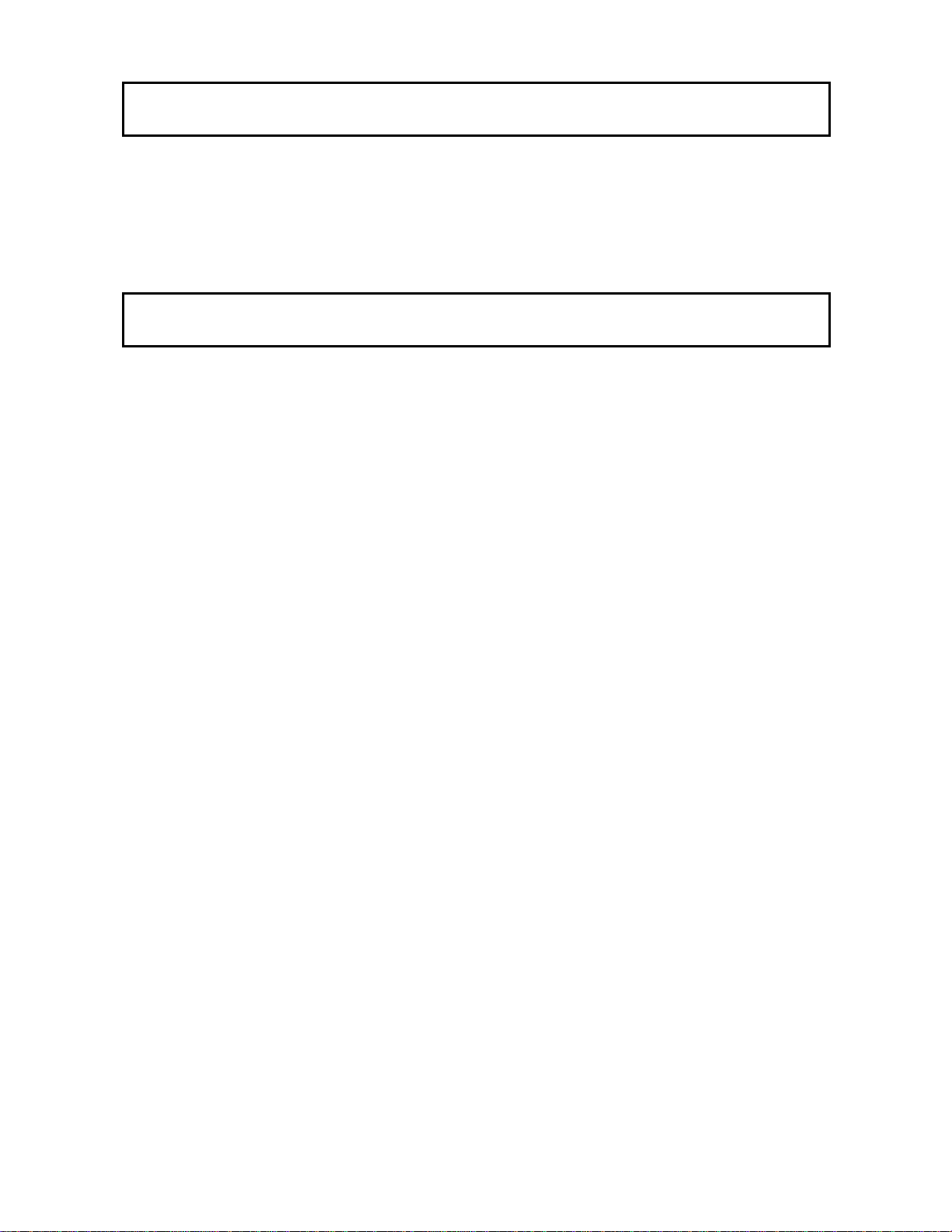

1. Name of Parts

1) Perforating Unit

Block Mounting Arm

Scale

Perforating Block

Block Mounting Arm

Transportation Shaft

Transport Roller Unit

Upper Transport Roller

Blade Receipt Roller

Lower Transport Roller

Perforating Blade

2

Page 4

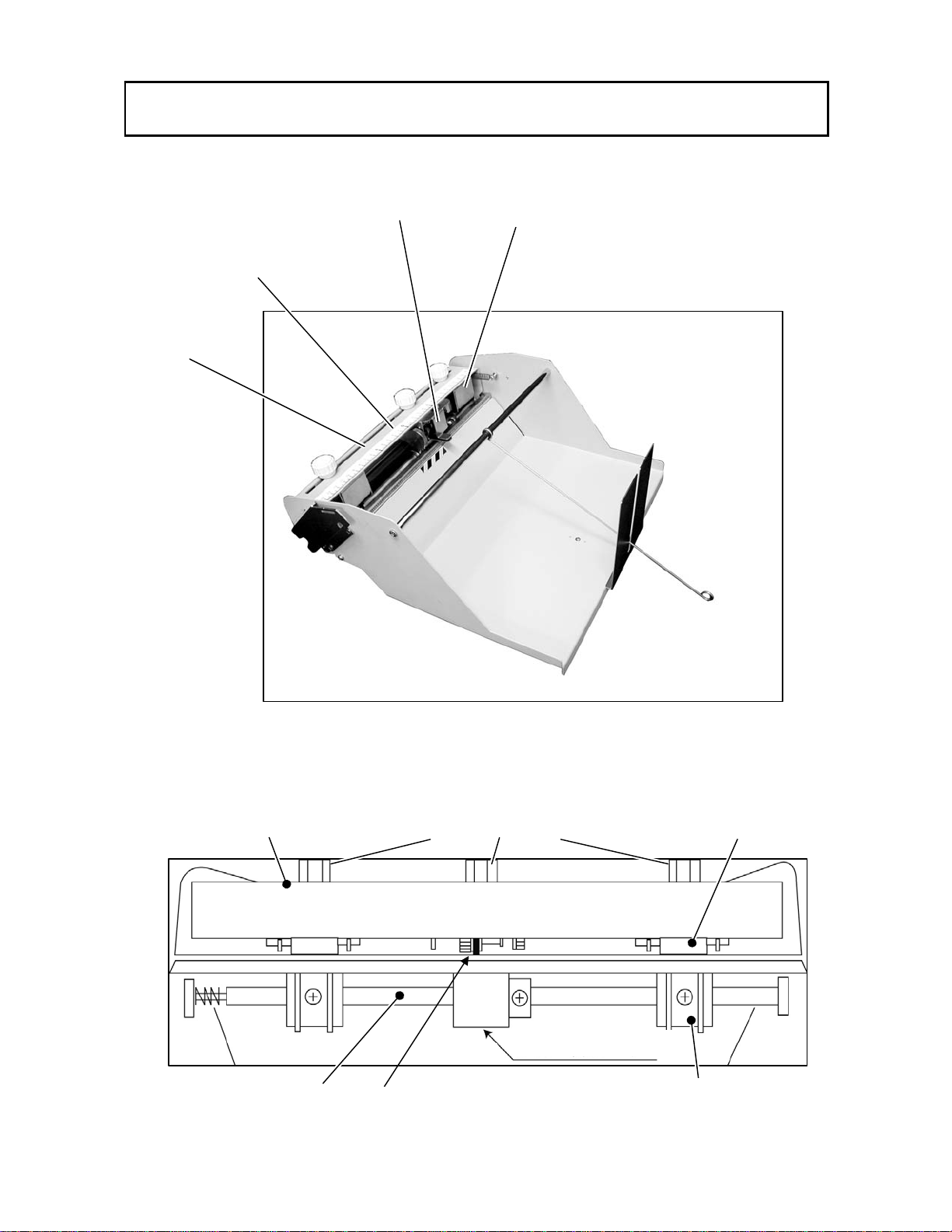

2. Preparation before use

(1) Remove 1st Folding Table to the

direction of arrow.

(2) Remove the connector of 2nd Folding

Table.

(3) Install Perforating / Scoring Unit to

the place where 1st Folding Table

was mounted.

NOTE:

Fit the notches on the perforating unit to

the pins on the both sides of the folder

(4) Set the paper control wire onto the

bail and place the black rubber ring

on the both sides of the wire.

Pins

1st Folding Table

Connector

Notches

Perforating Unit

Black Rubber Rings

Bail

Paper Control

Wire

(5) Fix the bail on the body of perforating

unit with screws.

View after Perforating unit is mounted

3

Page 5

3. How to use

- PERFORATION UNIT

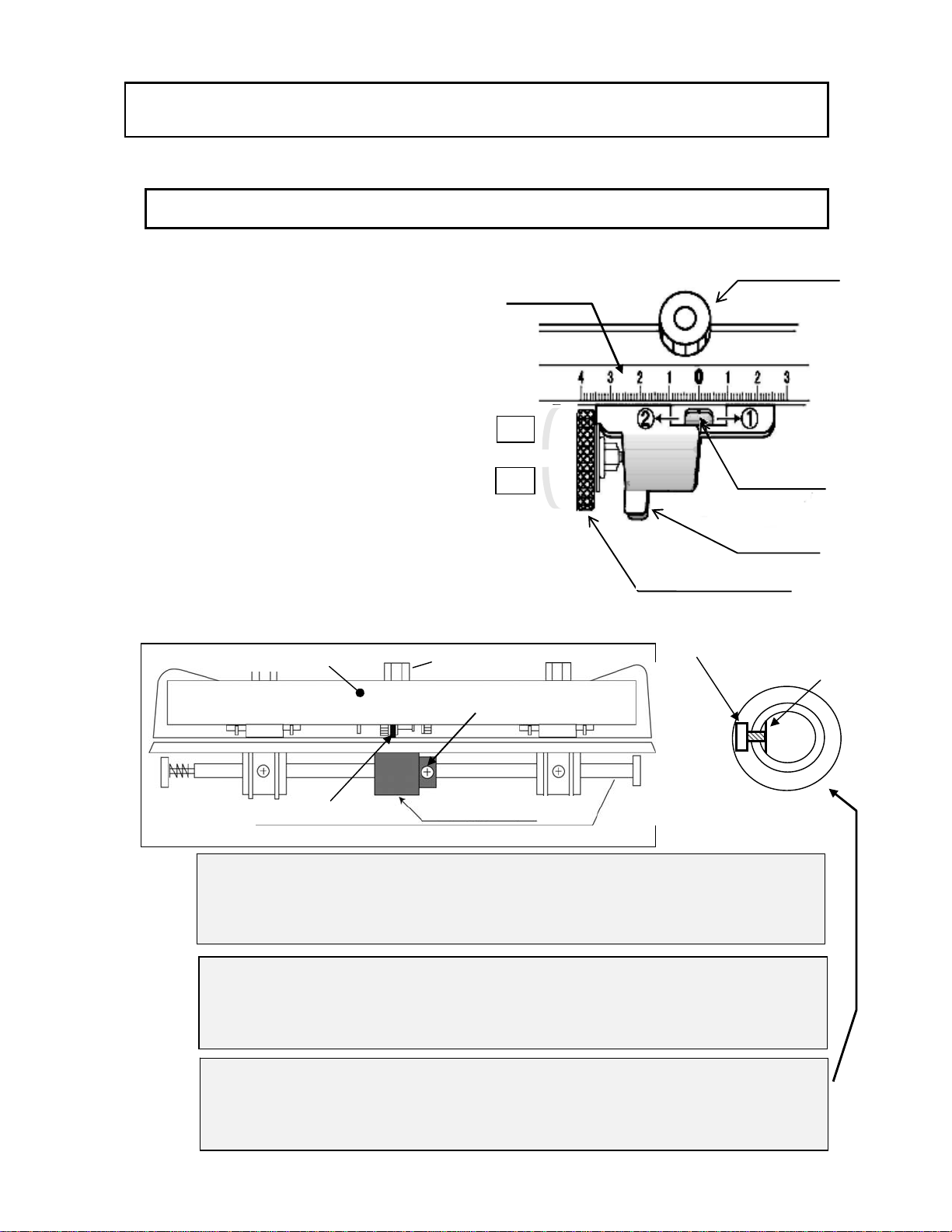

3.1 Setting Perforating Block

((1) Loosen Thumb Screw and squeeze

Release Levers with fingers to slide

Perforating Block right or left.

Refer to guide scale.

NOTE:

Before setting Perforating Block, make

sure to place Blade Position Reference at

center position so that fine adjustment

may be possible after the Block is

installed. Refer [3.3.1 Fine Adj. Dial]

(2) Fitting and fixing Blade Receipt Roller

- Loosen Roller Fixing Screw by Phillips Screw

Driver and place Blade Receipt Roller fit to the

Perforating Blade. Then fix Roller Fixing Screw.

Transportation

Shaft

Block Mounting Arm

Perforating Blade

CAUTION:

While fixing Thumb Screw, press Thumb Screw towards Block Mounting Arm so

that Perforating Block sets square to Block Mounting Arm. This helps the paper

to be fed straight.

CAUTION:

Perforating Blade is designed always to be pressed against Blade Receipt Roller.

Do not move the Roller without squeezing Release Levers. When Levers are

squeezed, they create a distance between Blade and Roller.

CAUTION:

Roller Fixing Screw must be fixed at the position where Transportation Shaft has

flat spot. Otherwise, the Blade Receipt Roller will not be fixed to the Shaft and

the Roller may be damaged.

Thumb Screw

Roller Fixing Screw

Blade Receipt Roller

Thumb Screw

Guide Scale

1

Blade Position

Reference

Release Lever

Fine Adjustment Dial

Fine Adjustment Dial

Roller Fixing Screw

Transportation Shaft

4

Page 6

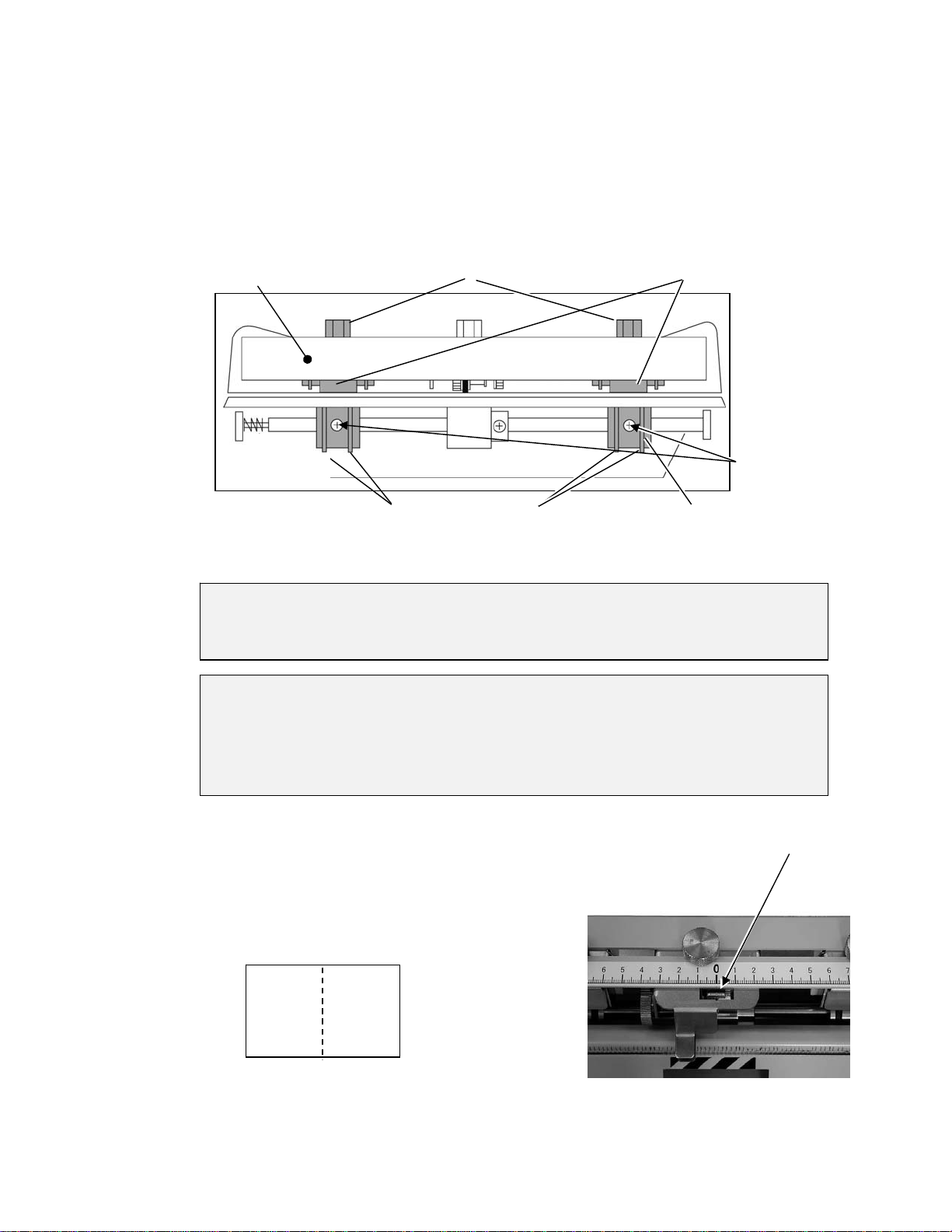

(3) Setting Paper Transport Rollers, Upper and Lower, at proper position

Place the Paper Transport Roller where they can grip paper positively.

Firstly, loosen Lower Philips Fixing Screws on both sides. Slide and position

them to the appropriate location and fix them.

Then, loosen Thumb Screws of Upper Transport Rollers on both sides. Slide and

position them so that Upper Transport Rollers ride on the Lower Transport Rubber

Rings.

Block Mounting Arm

Thumb Screw

Upper Transport Roller

Transportation

Shaft

Transport Rubber Rings

Lower Transport Roller

CAUTION:

Press Thumb Screw to Block Mounting Arm when fixing the Perforating Block.

This helps the paper to be fed straightly.

CAUTION:

Depending location of perforating line, it may not always be possible to place

Upper Transport Roller riding on the two Rubber Rings. In this case, use single

Rubber Ring. However, as much as possible, try to use two Rubber Rings at both

sides for stable paper feeding.

(Perforation Examples )

(1) Perforating at the center of a sheet

Place Blade Position Reference to 0 (Zero)

position of the scale

Blade Position Reference

Roller Fixing

Screw

5

Page 7

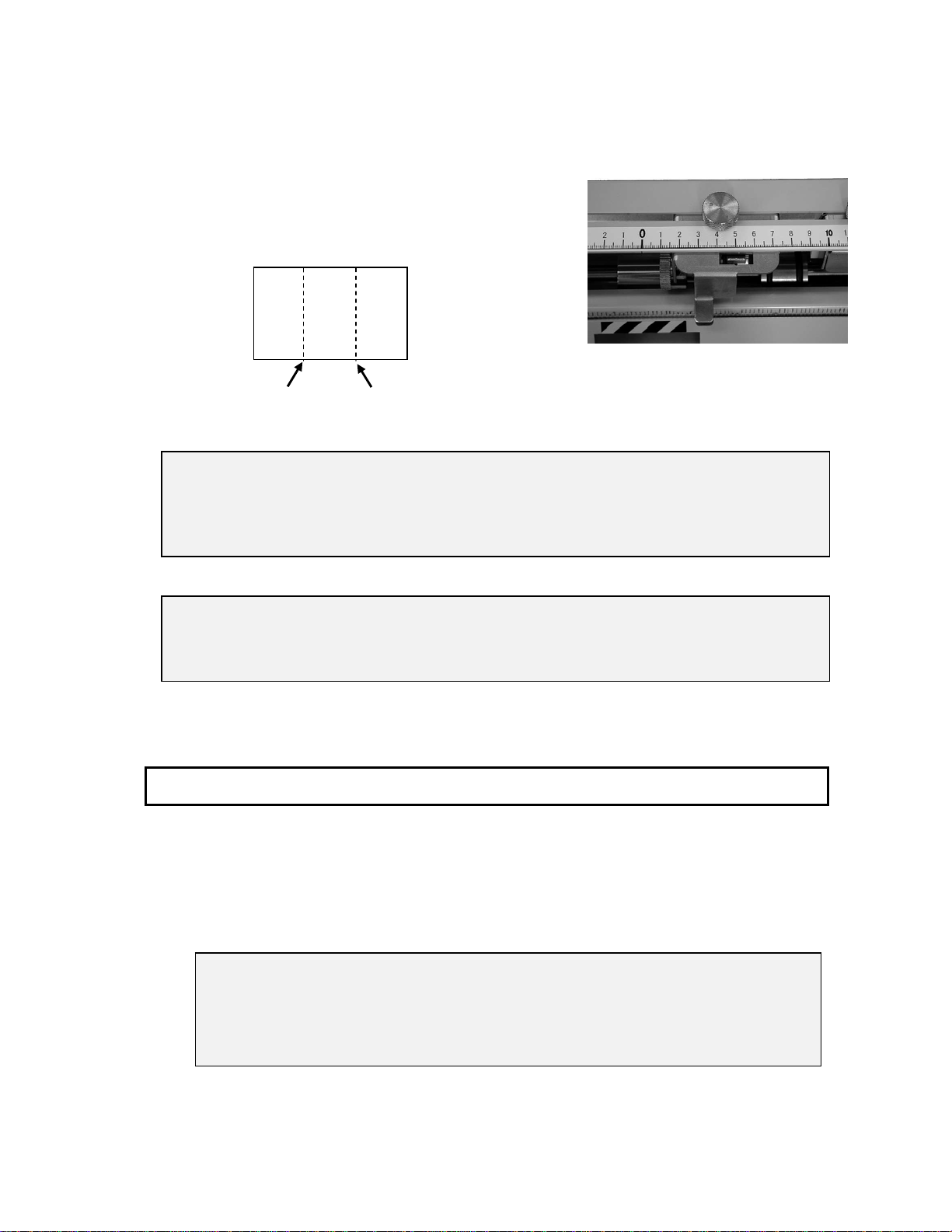

(2) Perforating two lines on a sheet by single

perforation block.

- Place Blade Position Reference to adequate

position and perforate.

- After first perforation done, reload the sheet

to Paper Feed Tray reversing the paper

position. Then perforate 2nd line again.

1st Perforation 2nd Perforation

Further information:

If desired to perforate two lines by one operation, add one additional perforating block

(optional) to the transport shaft. Note due to frame size of perforating block,

perforating too closed lines or too far apart lines may be limited.

Refer page 13, how to add another perforating unit.

NOTE:

Scale graduation and Blade Position Reference are for guidance only. To perforate at

the accurate position, use fine adjustment mechanism. Refer page 8, fine adjustment

of perforating blade location.

3.2 Trial Perforation

(1) To activate Perforation Unit, turn on the Power Switch while pressing the SELECT

Key. Release the Key as “PERFORATION MODE LAMP” is illuminated.

To operate with normal Folding Mode, Turn power switch off. Install Folding

Table and connect Folding Table Plug to Machine. Then, turn on Power Switch.

CAUTION:

When the machine is turned on, it automatically sets for medium running speed.

Use the machine middle to lower speed. For perforation/scoring, machine is

designed to be used at middle to lower speed to avoid possibility of tearing the

perforating paper.

(2) Set papers on Paper Feed Tray, set Counter to “1” and press “START” Key.

(3) Evaluate if the perforation is done properly as desired.

6

Page 8

y

3.3 Fine Adjustment of Perforating Line

3.3.1 Adjusting line location

– If the line is extremely out of desired location,

Perforating Unit must be relocated.

- If the line is away for approximately 5mm or

less from desired position, fine adjustment

may be possible without changing Perforating

Block set up.

NOTE:

Before fixing Perforating Block, make sure

to place Blade Position Reference to center

position so that fine adjustment may be

possible after the Block is fixed.

Fine Adjustment Dial:

While squeezing release levers, turn Fine Adjustment Dial to direction (1) and

Perforation position moves to right.

When it is turned towards direction (2), Perforator position moves to left.

3.3.2 Adjustment of perforating angle

CAUTION:

Before making any adjustment, make

sure that the paper is tightly placed

without play between the Paper Guides

in the Paper Feed Tray of Folder.

Otherwise, right angle of perforation is

not available in an

event.

In case perforation is not performed in the

right angle, adjustment of angle may be

possible.

- In case finishing of perforation is angled

to right A, turn Slant Adjustment Dial to

the direction of 1.

- In case finishing of perforation is angled

to left B, turn Slant Adjustment Dial to

the direction of 2.

1

2

Slant Adjust Dial

Angled to right

Angled to left

A

Paper

direction

B

Thumb Screw

Blade Position

Fine Adjustment Dial

Reference

Release Lever

Indicator

2

Slant Adjust Dial

1

7

Page 9

3.4 Perforation, continuous

(1) Press “C” Key and clear the counter setting to “0 (Zero)”.

(2) Perforate all the sheets loaded:

Load paper to Paper Feed Tray and press “START” Key.

Machine perforates up to the end of paper stack.

(3) Perforate designated number of sheets:

Load paper to Paper Feed Tray and preset quantity of sheet desired to perforate.

Then, press “START”.

Machine perforates up to the designated quantity of sheet and stops.

3.5 Replacing Perforating Blade (with frame)

(1) While squeezing levers, loosen Thumb Screw and remove Perforating Block.

Thumb Screw

Perforating Block

Release Levers

Rubber Ring

(2) While holding Rubber Ring, loosen Fixing Wheel.

(3) Remove Fixing Wheel, Washer and framed Perforating Blade.

(4) Replace the Framed Perforating Blade with new one and fix the parts in order.

Blade Mount Boss

Washer

Fixing

Wheel

CAUTION:

1) Fit Blade Hole to Blade Mount Boss when

setting Framed Perforating Blade.

2) Also make sure that UP DIRECTION

indicated on Frame of Perforating Blade

directs upward.

3) While tighten Fixing Wheel, hold Rubber

Ring so that the Framed Perforating

Blade is fixed tightly.

Fixing Wheel

Framed Perforating Blade

Framed Perforating Blade

with UP DIRECTION

8

Page 10

SCORING UNIT

3.6 Setting Scoring Block

Upper Scoring Roller

Lower Scoring Roller

(1) Scoring Position

Move V-Groove of Lower Scoring Roller to the place where scoring. Then, fix the Roller

by Philips Screw Driver. Press “Test” Key as leading edge of paper comes close to Lower

Scoring Roller so that scoring position is determined. Do not feed paper yet to the

rollers.

(2) Positioning of Upper Scoring Roller

Loosen (turn) Release/Fix screw (left) on the left side for 2 to 3 rounds. Turn

Shallow/Deeper screw counterclockwise 2 to 3 rounds. Slide the Upper Scoring Roller

right above the lower V-Groove. Turn Shallow/Deeper screw clockwise till Roller comes

down in to the bottom of V-Groove. Then, Fix the Scoring Block turning Release/Fix

screw clockwise. Now, Upper Blade and Lower Groove position is mechanically matched.

(3) Adjusting shallowness/depth of Upper Scoring Roller

Turn Shallower/Deeper screw counterclockwise for 2 to 3 turns. Then, fix the height by

Fix/Release screw.

Fix / Release

Height

V-Groove

Scoring Block

BLADE HEIGHT CONTROL

(Screw on right side)

Shallower

Deeper

9

Page 11

(4) Adjusting positions of Feed Rollers

Place Lower Transport Rollers to the positions where both of them stay on the paper

positively. Then, fix Upper Transport Rollers by Phillips Screw Driver where Upper

Rollers fit on the 2 Rubber Bands of Lower Transport Rollers.

Upper Transport

搬送ローラー 搬送ローラー

Roller

3.7 Trial Scoring

(1) To activate Scoring Unit, turn on the Power Switch while pressing the SELECT

Key. Release the Key as “PERFORATION MODE LAMP” is illuminated.

To operate with normal Folding Mode, Turn power switch off. Install Folding

Table and connect Folding Table Plug to Machine. Then, turn on Power Switch.

CAUTION:

When the machine is turned on, it automatically sets for medium running speed.

Use the machine middle to lower speed. For scoring/perforating, machine is

designed to be used at middle to lower speed to avoid possibility of tearing the

scoring paper.

(2) Set papers on Paper Feed Tray, set Counter to “1” and press “START” Key.

(3) Evaluate if the scoring is done properly as desired.

3.8 Fine Adjustment of Scoring Line

3.8.1 Shallower/Deeper Fine Adjustment

By turning Shallower/Deeper Screw, scoring depth is adjustable. Loosen Release/Fix

Screw first and make shallower/deeper adjustment. After adjustment, fix it by

Release/Fix Screw.

スジ入れキット

Scoring Block

Upper Transport

Roller

10

Page 12

3.8.2 Adjusting scoring line location

Slide and move Lower Scoring Roller first, then slide Upper Scoring Roller. Make

sure to fix both Rollers by Phillips Screw Driver after moved.

3.8.3 Adjusting scoring Angle

In case scoring is not made in square, refer [3.3.2 Adjustment of perforating angle]

(page 8.).

3.9 Scoring, continuous

(1) Press “C” Key and clear the counter setting to “0 (Zero)”.

(2) Perforate all the sheets loaded:

Load paper to Paper Feed Tray and press “START” Key.

Machine scores up to the end of paper stack.

(3) Perforate designated number of sheets:

Load paper to Paper Feed Tray and preset quantity of sheet desired to scores.

Then, press “START”.

Machine scores up to the designated quantity of sheets and stops.

11

Page 13

4.Adding Perforation Unit

(1) Remove Transportation Shaft from Perforation Unit

(2) Remove a Phillips screw from the end of Transportation Shaft.

Transportation Shaft

(3) Remove Lower Transportation Roller from the Shaft after loosening Lower Fixing Screw.

NOTE:

When removing Transportation

Shaft, rotate Block Mounting Arm

toward the direction of arrow. It

makes wider opening and easier to

take out Transportation Shaft.

Lower Transport Roller

Blade Receipt Roller

Roller Fixing Screw

Block Mounting Arm

Transportation Shaft

12

Page 14

(4) Add another Blade Receipt Roller to the Shaft and re-mount Lower Transportation

Roller. Then, fix Rollers by screws. Fix the Phillips Screw at end of the Shaft.

(5) Add another Perforation Unit to the Block Mounting Arm and fix by Thumb Screw.

(6) Place Transportation Rollers where they grip perforating sheet positively.

The two Perforation Units should not touch each other.

NOTE:

Position where perforation can be done is only between the two Lower

Transportation Rollers.

Seen as two Perforation Units are mounted.

Seen as two Perforation Units are mounted.

13

Page 15

5. Exchanging Perforation Unit to Scoring Unit.

Perforation Unit can be exchanged to Scoring Unit and Scoring Unit can be exchanged to

Perforating Unit.

(1) Remove Transportation Shaft from Perforation Unit

(2) Remove a Phillips screw from the end of Transportation Shaft.

Transportation Shaft

NOTE:

When removing Transportation

Shaft, rotate Block Mounting Arm

toward the direction of arrow. It

makes wider opening and easier to

take out Transportation Shaft.

Blade Receipt Roller

Roller Fixing Screw

Block Mounting Arm

14

Transportation Shaft

Lower Transport Roller

Page 16

(3) Remove Lower Transport Roller from the Shaft after loosening Lower Fixing Screw.

(4) Replace with Lower Transport Roller, Blade Receipt Roller, etc. Fix the Phillips screw

at end of the Shaft.

Seen as two Perforation Units are mounted.

(5) Mount Lower Transport Roller and fix it. Then, re-mount Transportation Shaft to

the Perforation Unit.

(6) Place Scoring Block or Perforating Block as desired.

The two Perforation Units, if any, should not touch each other.

(7) Refer [3. How to use]( page 5.)

NOTE:

Position where perforation can be done is only between the two Lower Transport

Rollers.

15

Page 17

6. Replacing Transport Rubber Ring

(1) Remove Transportation Shaft from Perforation/Scoring Unit

(2) Remove a Phillips screw from the end of Transportation

Transportation Shaft

Blade Receipt Roller

NOTE:

When removing Transportation

Shaft, rotate Block Mounting Arm

toward the direction of arrow. It

makes wider opening and easier to

take out Transportation Shaft.

Lower Transport Roller

Roller Fixing Screw

Transportation Shaft

Block Mounting Arm

16

Page 18

(3) Remove Lower Transport Roller from the Shaft after loosening Roller Fixing Screw.

(4) Remove worn/old Rubber Rings from the Lower Transport Roller.

(5) Mount new Rubber Ring

(6) Re-mount Lower Transport Roller in the reversed procedures.

17

Page 19

y

p

g

g sp

y

j

g

g

p

p

7. Troubleshooting

Symptom

Paper Slippage

Paper Jam

Slanting

Not sufficient

perforation

Torn scoring

Not sufficient

scoring

8. Specifications

- Replace Paper Separator.

- Re

lace Paper Feed Roller.

- Remove jammed paper by removing Perforation/Scoring Unit from

Foldin

- Remove jammed paper. Then adjust mounting location of

Roller. Make the Transport Rollers grip perforating/scoring paper

at the both sides.

- Slow down runnin

- Make no play to the paper placed between the Paper Guides in the Paper

Feed Tra

- Ad

- Adjust mounting location of Transport Roller.

Make the Transport Rollers grip perforating/scoring paper at the both

sides.

- Re-mount Perforatin

- Make sure to ride Perforatin

- Re

- Upper Scoring Roller is too deep. Lift the Scoring Roller by

Shallower/Dee

- Upper Scoring Roller is not matching with V-Grooved Lower Scoring

Roller. Match the Upper Scoring Roller to V-Groove by Fine Adjustment

Dial.

- Upper Scoring Roller is too shallow against V-Grooved Lower Scoring

Roller. Lower the Scoring Roller by Height Adjustment Screw.

Machine.

of the Folding Machine.

ust by Slant Adjustment Dial.

lace used/old Framed Perforating Blade to new one.

Remed

eed.

/Scoring Unit firmly to Block Mounting Arm.

Blade on Blade Receipt Roller.

er Adjustment Screw.

Paper Weight

Paper Quality Offset paper / Coated paper Offset paper / Coated paper

Running speed

Location of perforation

and scoring line

Perforating pitch

Machine Dimensions

(Both Perforation and

Scoring Units)

Unit Weight

(Both Perforation and

Scoring Units)

Perforation

Scoring

60 to 85 sheets/minute

(3600 to 5100 sheets/hour)

Centering

0.35mm(perforation),

0.20mm(non-perforation),

continuous

W480 x D380 x H200 mm (In

Use)

W380 x D380 x H200 mm (Not in

Use)

Approx. 4.8 kg Approx. 10.6 lbs

: 64~127.9 g/㎡

: 64~157 g/㎡

18

lbs (Bond)

lbs (Bond)

A4 landscape

In case A4 paper, landscape,

+ or - 50mm (1.96")

when transportation rollers

are

placed at paper sides

0.014"(perforation),

0.008"(non-perforation),

continuous

W18.9 x D15.0 x H7.9" (In Use)

W15.0 x D15.0 x H7.9" (Not in

Use)

Page 20

Intentionally left blank

JaCIcOn

19

Page 21

MBM Corporation

20

Loading...

Loading...