Page 1

Stapler Folder Model 102

Operator Manual

February 1999

Part No. 87499

Page 2

1. Introduction

Table of contents

1.1 Operational safety

2. Getting to know the Model 102

2.1 Main components

2.2 Control panel

3. Operator instructions

3.1 Switching on the Model 102

3.2 Setting up the Model 102

3.3 Feeding and adjusting a test set

3.4 Making fine adjustments

3.5 Beginning the production

3.6 Restoring the factory set A3, A4 or A5 program

3.7 Jam indications

4. Maintenance

4.1 Removal/replacement of the staple cartridge

4.2 Removal/replacement of the stapler head

4.3 Cleaning fold rolls

4.3 Lubrication of parts

1-1

2-1

2-4

3-1

3-2

3-5

3-7

3-8

3-9

3-10

4-1

4-4

4-6

4-7

5. Specifications

5.1 Specifications

Stapler Folder Model 102 Operator Manual

T10087 February 1999

5-1

i

Page 3

1. Introduction

1.1 Operational safety

Attention to the following notes ensures the continued safe operation of your equipment.

Always connect the equipment to a properly grounded power source receptacle. In

doubt, have the receptacle checked by a

qualified electrician.

WARNING: Improper connection of the

equipment grounding conductor can result

in electrical shock.

Always follow all warnings marked on, or

supplied with, the equipment.

Always locate the equipment on a solid

support surface with adequate strength for

the weight of the machine.

Always exercise care in moving or relocating the equipment.

Always keep magnets and all devices with

strong magnetic field away from the machine.

Never use a ground adapter plug to connect the equipment to a power source

receptacle that lacks a ground connection

terminal.

Never attempt any maintenance function

that is not specifically described in this

documentation.

Never remove the covers or guards that are

fastened with screws.

Never install the unit near a radiator or any

other heat source.

Never override or “cheat” electrical or

mechanical interlock devices.

Never operate the equipment if you notice

unusual noises or odours. Disconnect the

power cord from the power source receptacle and call your customer service engineer

to correct the problem.

Stapler Folder Model 102 Operator Manual

T10087 Febrary 1999

1-1

Page 4

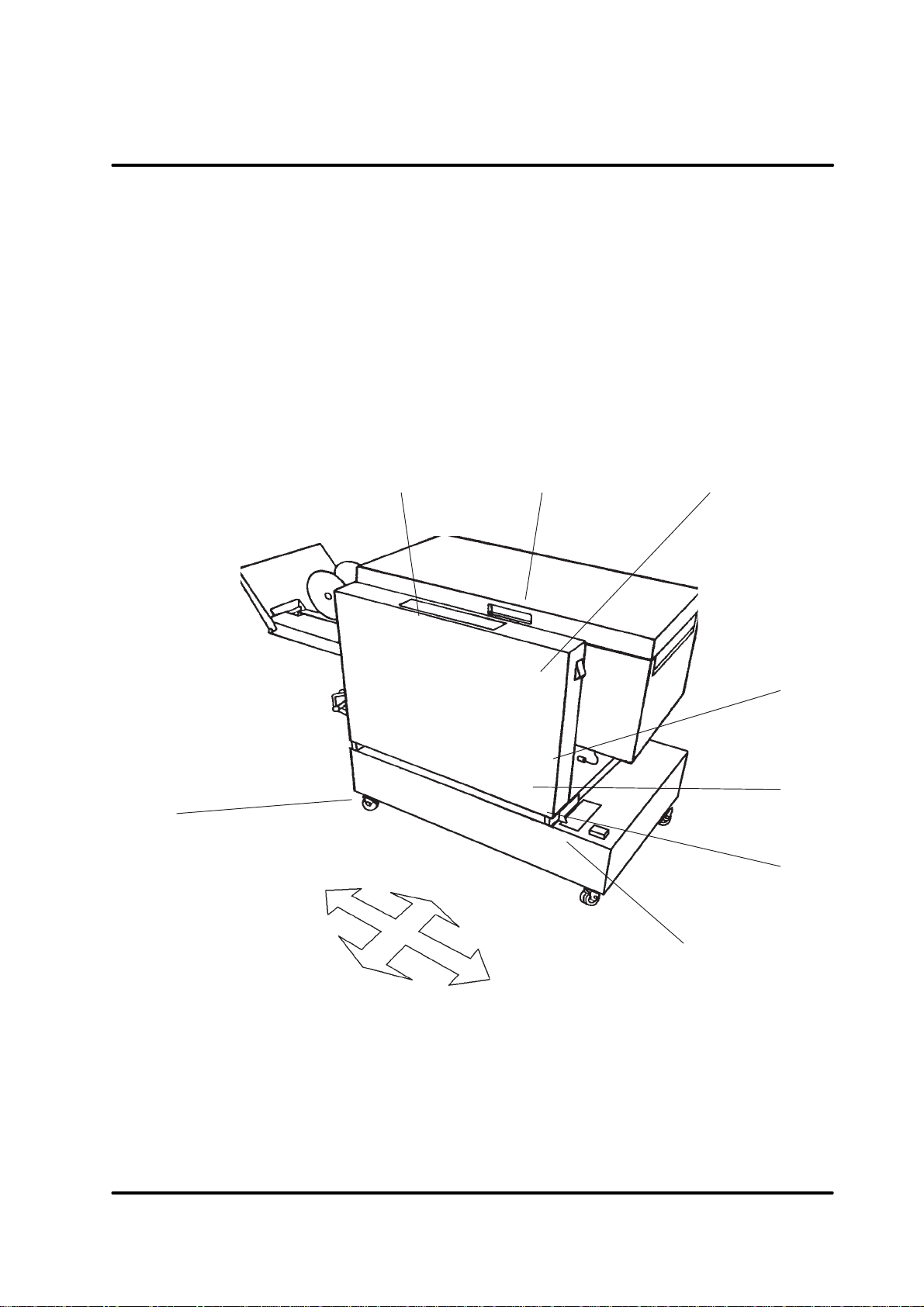

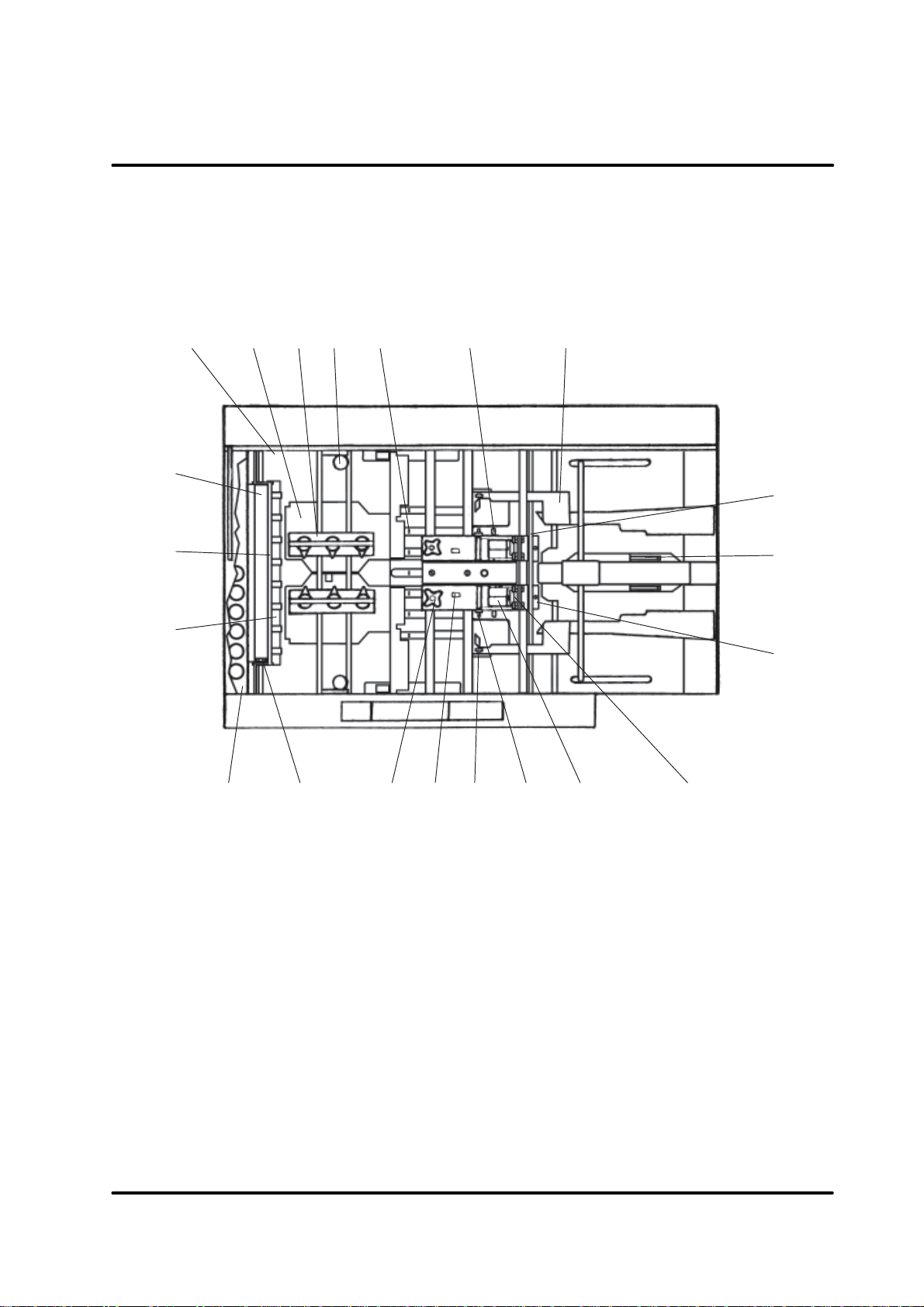

2. Getting to know the Model 102

2.1 Main components

The Model 102 can be quickly and easily connected to the Air Feed Collator Model 100 for

on-line booklet making. The Model 102 also makes an ideal manual hand feed booklet

maker with an optional manual feed tray .

The Model 102 is equipped with motor driven stapler heads (5000 staples per head), the

anvils are of the clinch type, ensuring professional flat staples. In addition, the operation

that fold the paper provide a sharp booklet fold.

T ake a few minutes to get familiar with the main components of the Model 102.

23 4

1

left side

1 Castor lock

2 Control panel

3 T op cover

4 Power switch

front side

5

6

7

rear side

8

right side

5 Ground fault interrupter

6 Power receptacle/main fuse

7 Machine positioning scale

8 Foot pedal

Stapler Folder Model 102 Operator Manual

T10087 February 1999

2-1

Page 5

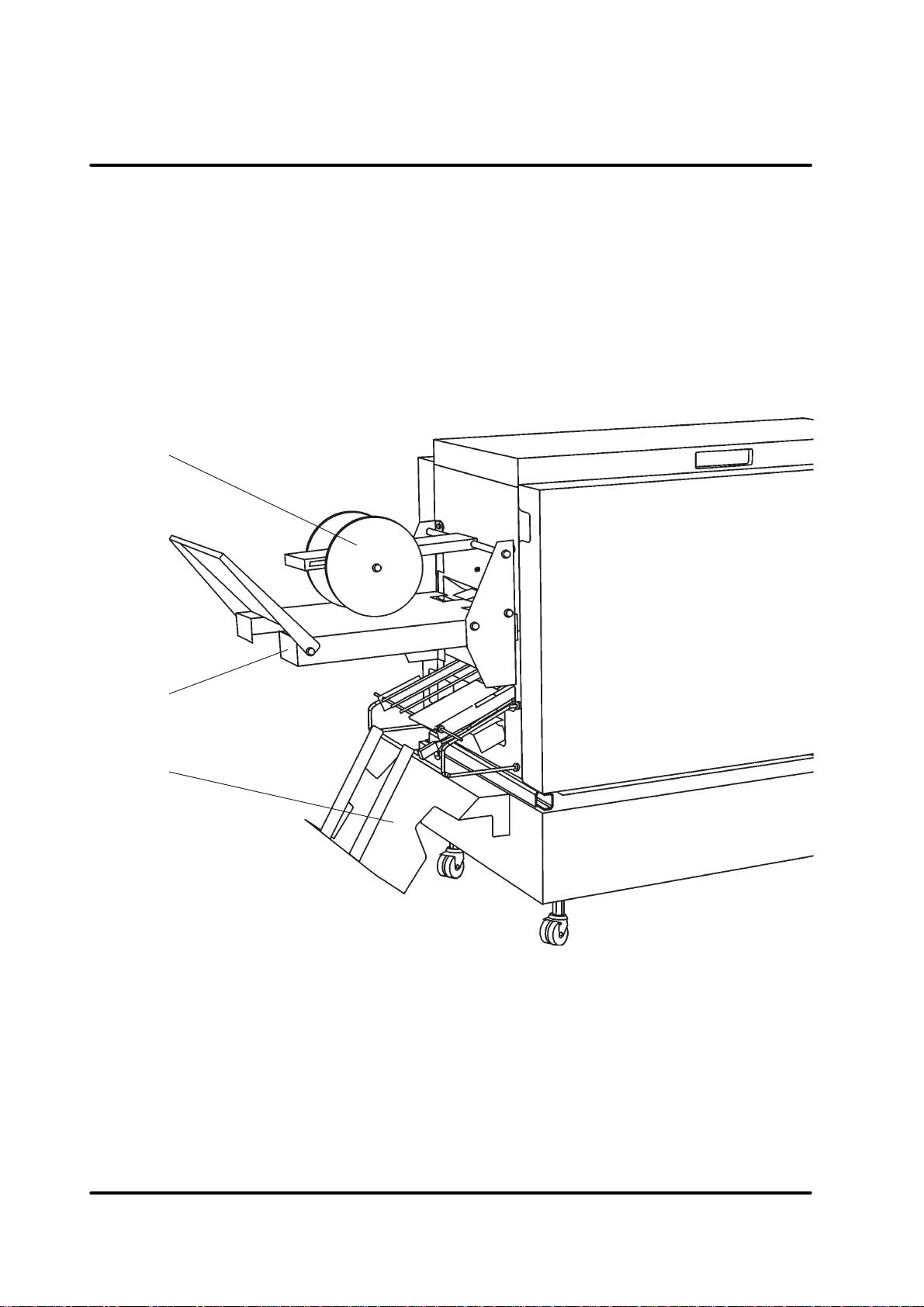

2.1 Main components, continues

The belt stacker is used when stapling/folding or folding only is selected. The function of the

belt stacker is the same whether the feed is automatic or manual.

The back of the belt stacker is normally angled upward (about 15 degrees to horizontal),

but can be lowered to allow booklets to drop into a box.

The output wheels should be positioned at the innermost notch for A4, A5 ( 8.5”x14”,

8.5”x1 1”) and similar sizes, at the middle notch for A3 (1 1”x17”) and similar sizes, and at

the outermost notch for storage. Using customized formats the output wheels should be

positioned approximately 50mm from the leading edge of the first set.

1

2

3

1 Set output wheel

2 Belt stacker

3 Delivery tray (optional)

The optional delivery tray is used for side or corner stapling if there is no trimmer attached.

When side or corner stapling is selected, the fold stop moves away automatically and the

stapled sets are delivered onto the tray .

Stapler Folder Model 102 Operator Manual 2-2

T10087 Febrary 1999

Page 6

2.1 Main components, continues

The Model 102 interior has parts that you will come in contact with when making the fine

adjustments to the booklet or when performing maintenance.

12 5 7

4

3

6

11

12

13

8

9

10

14 15 16 17 18 19 20

1 T otal set counter

2 Paper guide

3 Ball cage

4 Fold adjust lever

5 Staple stop

6 Lock pin

7 Side jogger

8 Anvil position scale

9 Back jogger

10 Anvil

11 Upper fold roll

12 Fold roller guide cassette

Stapler Folder Model 102 Operator Manual

T10087 February 1999

21

13 Lower fold roll

14 T ool box including balls, allen key

and open end wrench

15 Hex grip, upper fold roll

16 Thumb screw for stapler assembly

17 Staple detection switch

18 Side jogger incorrectly positioned

actuator

19 Side jogger incorrectly positioned

switch

20 Staple cartridge

21 Stapler head

2-3

Page 7

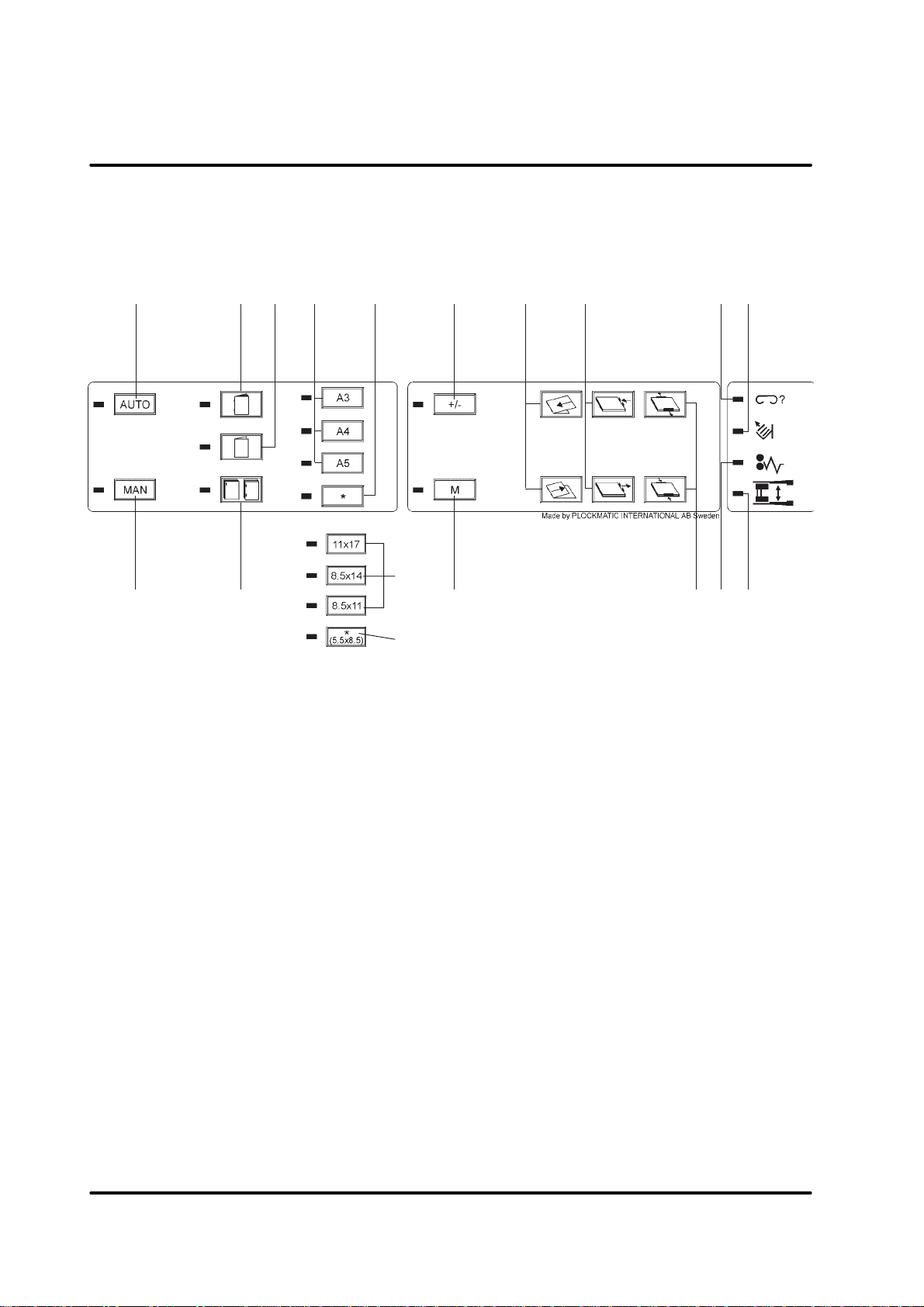

2.2 Control panel

1

43

7a6

8

11

1413

6

2

5

9

12

151016

7b

U.S. paper sizes

1 Automatic set feed mode

2 Manual set feed mode

3 Stapling and folding

4 Folding only

5 Side stapling or corner stapling

6 Factory preprogrammed paper size

(Can also be used to store customer

programmable paper size)

7a Customer programmable paper size

7b Factory preprogrammed paper size/

Customer programmable paper size

8 Programming access/format ad-

justment access

9 Memory

10 Fold position adjustment

11 Back jogger position adjustment

12 Side jogger position adjustment

13 Staple(s) missing indicator

14 Stacker full Indicator

15 Paper jam indicator

16 Staplers or side jogger incorrectly

positioned indicator

Stapler Folder Model 102 Operator Manual 2-4

T10087 Febrary 1999

Page 8

3. Operator instructions

3.1 Switching on the Model 102

This chapter explains the operations for making the booklets, whether the Model 102 is in

automatic or manual mode.

The following steps apply to both automatic and manual

feed.

1 Plug the Model 102 into the wall outlet.

2 Set ON/OFF switch to ON position.

2

3 Wait until there is steady illumination of the paper size

indicator. If you previously used the Model 102, the

paper size that was last used will illuminate.

Stapler Folder Model 102 Operator Manual

T10087 February 1999

3-1

Page 9

3.2 Setting up the Model 102

This section explains how to set up the Model 102 and do a test run. After the test run you

can do fine adjustments of the settings, if necessary . When you are satisfied with the test

run you can begin production.

Select a paper feed mode

1 If the papers are fed from a collator , press the AUT O button.

NOTE: Make sure the Model 102 is correctly positioned on the base. Press

the green foot pedal on the base and move the Model 102 to the

corresponding format according to the machine positioning scale.

2 Or, if the p apers are fed manually , press the MANUAL button.

Select the type of finishing

Y ou can select staple and fold, fold only , corner st apling or side stapling for

your booklets.

NOTE: For corner stapling and side stapling an optional delivery tray is

necessary if a trimmer is not installed. If a trimmer is present,

consult the trimmer operator manual.

Pressing any of the following buttons will start the paper size program

indicators to light up in sequence (running light), waiting for you to select

the correct paper size program.

3 Press this button for stapled and folded booklets.

4 Press this button for non stapled, folded booklets.

5 Press this button for corner stapling or side stapling. Disable either

stapler by removing it according to section 4.2, and switch off the

staple detection switch if corner stapling is chosen.

NOTE: Side stapling or corner stapling of A3 paper format is not possi-

ble.

6. Depending of the actual paper size and/or the selected booklet form

you might want to change the position of the staples.

Use the allen key to loosen the anvil(s). Move the anvil(s) to the desired position and tighten the screw(s). Loosen the thumb screw(s) for

the stapler assembly . Centre the stapler assembly over the anvils and

thighten the thumb screw(s).

Stapler Folder Model 102 Operator Manual

T10087 Febrary 1999

3-2

Page 10

3.2 Setting up the Model 102, continues

min 8 mm

min 8 mm

NOTE1:If the distance between the stapler and the side jogger is to

narrow, the staplers or side joggers incorrectly positioned indicator will be illuminated (also see section 3.7.). Make sure the

distance between the actuator and the switch is no less than 8

mm.

NOTE2:Depending of the previous job setup you might have to select

paper size program before you move the staplers apart.

The anvil position scale indicates the distance, in millimetres, from centre

to centre (cc) of the staples.

T ype of finishing Paper format Setting (cc)

booklet making 5,5”, CD 98

booklet making A5 105

booklet making 8,5”, A4 120

booklet making 11”, A3 120 or 200

side stapling 1 1”, A4 144 (Recommended)

corner stapling 11” 255 (Recommended)

corner stapling A4 273 (Recommended)

NOTE: Using other settings could result in poor staple/fold result.

lead

edge

trail

edge

U.S. paper

sizes

Select a paper size program

For your convenience, the A3, A4 and A5 (8.5"x1 1", 8.5x14", 11"x17" and

5.5”x8.5”) paper size programs were factory set with appropriate jogging,

staple position and fold line position. The jogging, staple position and the

fold line position may need fine adjustments depending on the type of

paper used.

NOTE: If you want to use a custom format, select the next bigger (dis-

tance between the lead edge and the trail edge) paper size program. Fine adjustments will be explained in section 3.3 and 3.4.

7 Press the appropriate button to select paper size program.

The A3 button for 297 x 420 mm. - Position the output wheel at the

middle notch.

The A4 button for 297 x 210 mm. - Position the output wheel at the

or

The A5 button for 148 x 210 mm. - Position the output wheel at the

The * button for customised size. - Position the set output wheel

innermost notch.

innermost notch.

appro. 50 mm from the leading

edge of the first set.

Stapler Folder Model 102 Operator Manual

T10087 February 1999

3-3

Page 11

3.2 Setting up the Model 102, continues

8. When selecting staple and fold, or fold only the configuration of the

balls in the ball cage is important. The purpose is to apply enough

pressure on the set to ensure proper alignement against the fold stop

before the set is being folded. By doing that the set will be correctly

folded at the middle of the set. The Model 102 is delivered with glass

balls at the left side and plastic balls at the right side of the ball cage

which should cover most jobs.

Depending on the number of sheets in each set and the stiffness of the

papers used you might need to change the configuration. In the tool

box you can find 2 steel balls, 2 glass balls and 2 plastic balls.

The heaviest configuration, for several sheets with high stiffness, is 2

steel balls at the left side and 2 glass balls at the right side. The lightest configuration, when running just a few sheets with low stiffness, is

plastic balls at the left only .

If your booklets comes out with the staples on the back of the booklet

the configuration is to heavy . T o many and/or to heavy balls allowed the

set to buckle (travel too far) before it was folded.

123

If your booklets comes out with the staples on the front, and/or with a

skew fold, the configuration is to light. By using not enough and/or to

light balls the set did not travel all the way down to the fold stop and

was not aligned correctly .

senilediugnoitarugifnocllaB

htiwgnidlofylnosteehsegralelgniS

ssenffits/thgiewrepapwol

wolhtiwstesteehswefdedlof-delpatS

ssenffits/thgiewrepap

noitarugifnocdradnatSssalG- citsalP

steehsdedlof-delpatslareveSssalG- ssalG

steehsdedlof-delpatsdrahlareveSleetS- ssalG

123

citsalP--

citsalP-citsalP

123

steehs

Stapler Folder Model 102 Operator Manual

T10087 Febrary 1999

dlofretnecehtnosruccosgnikramfI

dedlof-elpatslarevesgninnurnehw

ssalGcitsalPcitsalP

3-4

Page 12

3.3 Feeding and adjusting a test set

The first time you use the Model 102, or when you change to a different paper size program, you run one test set and make necessary adjustments before you begin production.

Y ou can use automatic feed from the collator , using the calibration option or manual feed.

Coarse adjustment

Y ou have already selected either automatic or manual operation, type of

finishing, and paper size program.

1 Press the program access button.

2 Open the cover.

3 Look at the side jogger scale.

back jogger arm

side jogger scalestaple/fold line scale

4 Press and hold the side jogger button until the side jogger reaches the

position on the side jogger scale for the test set.

5 Look at the staple/fold line scale.

6 Press and hold the back jogger button until the back jogger reaches

the position on the staple/ fold line scale for the test set.

(Manually lift the back jogger arms)

NOTE: The staple/fold line scale does not show the correct position for

the set when corner stapling or side stapling is chosen.

Stapler Folder Model 102 Operator Manual 3-5

T10087 February 1999

Page 13

3.3 Feeding and adjusting a test set, continues

7 Close the top cover.

8 Feed one set of the chosen paper size into the model 102 (The ma-

chine will repeatedly make a jog cycle).

9 Open the top cover.

moving the

staple stop

towards the

infeed

moving the

staple stop

towards the

outfeed

10 Press and hold the staple stop adjustment button until the trail edge of

the set reaches the paper size mark on the staple fold/line scale. If the

required paper size mark not is visible (the set is to close to the

infeed), press the staple stop adjustment button until the set passes

the required paper size mark (towards the outfeed). Ensure that the

set is aligned against the staple stop and press the staple stop adjustment button until the trail edge of the set reaches the paper size mark

on the staple fold/line scale.

11 Press the side jogger button until the side joggers jogg the set firmly

without making a buckle in the set.

12 Press and hold the back jogger button until the back jogger is approxi-

mately 1 mm from the set.

13 T o store your settings:

• press the format adjustment access button (the +/- button) to keep your

settings temporarily . Y our settings are not stored but will remain until a

paper size format button is pressed even if the power is switched off.

• press the memory button to store your settings on the actual paper

size button, earlier selected according to section 3.2.

• or, select any other paper size program button and then press the

memory button.

NOTE1:Side stapling or corner stapling of A3 paper format (or similar

sizes) is not possible.

NOTE2:You can store 4+4 different settings. Four in the staple/fold or

fold only finishing mode, and four in the corner or side stapling

finishing mode.

14 Close the top cover. The paper set moves to the belt stacker .

15 In booklet finishing mode: If the cover is torn from the body sheets

increase the gap between the fold rolls by adjusting the fold adjust

levers from the factory setting 1 to a higher number.

Stapler Folder Model 102 Operator Manual 3-6

T10087 Febrary 1999

Page 14

3.4 Making fine adjustments

This section shows you how to make fine adjustments of the booklet.

The test run has just been completed and the Model 102 is switched ON.

Y our selection for paper size program is still in effect.

1 Press the program access button.

2 Feed one set.

3 Open the top cover.

MELBORPNOITCERROCNOTTUB

ehtfosegdeedisehT

nevetonerasteehs

ehtfosegdeedisehT

demrofederasteehs

fosegdemottob/potehT

nevetonerasteehs

ehtfokcabrorevocehT

degamaderastelkoob

,deretnectonsidlofehT

sitelkoobehtfopoteht

trohsoot

,deretnectonsidlofehT

sitelkoobehtfopoteht

gnoloot

NOTE: Pressing the adjustment buttons shortly will increase/decrease

the position with approximately 0.5 mm.

resolc

trapa

sreggojedisehtevoM

sreggojedisehtevoM

reggojkcabehtevoM

tesehtotresolc

reggojkcabehtevoM

tesehtmorfyawa

.rehgihpotsdlofehtteS

tsumreggojkcabehT

uoyretfadetsujdaereb

noitisopdlofehttsujda

.rewolpotsdlofehtteS

tsumreggojkcabehT

uoyretfadetsujdaereb

noitisopdlofehttsujda

4 Store your settings according to section 3.3, item 13.

5 Close the top cover. The booklet transport s to the set output tray .

6 Check the booklet. If it is still not good, repeat the fine adjustment.

Otherwise go to section 3.5 Beginning the production.

Stapler Folder Model 102 Operator Manual

T10087 February 1999

3-7

Page 15

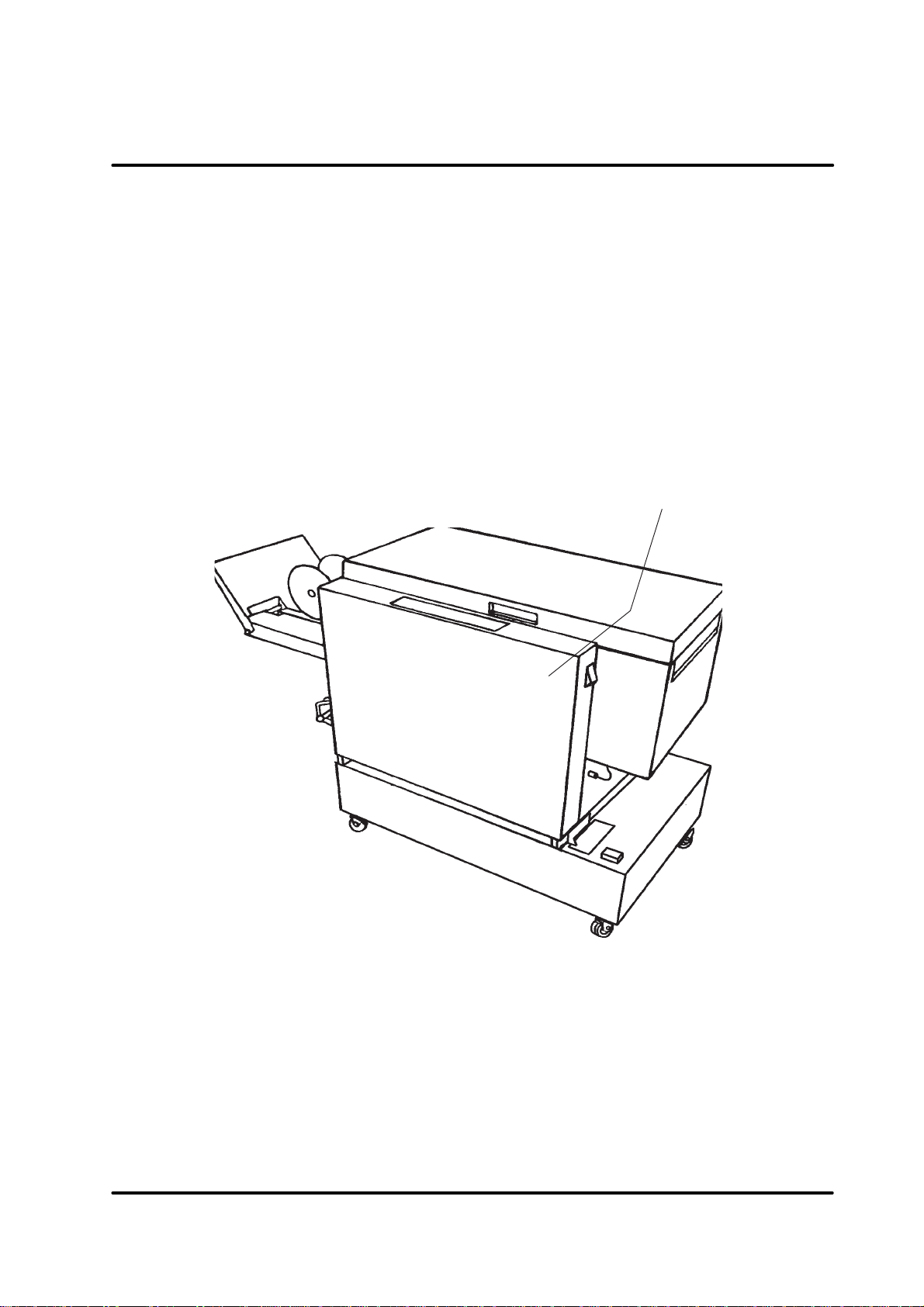

3.5 Beginning the production

This section shows you how to begin production. Y ou have run a test set

and made necessary adjustments.

The Model 102 is switched ON.

Automatic operation

1 Verify that the indicator light s, associated with the paper size button

(example showing A3 selected) and type of finishing (example showing stapling and folding) that you selected, is on.

2 Check that the Model is correctly positioned on the base according to

the machine positioning scale.

3 Start your collator . The set s are automatically fed into the Model 102

and the booklets appear on the belt stacker .

NOTE: After a successful booklet production, if you change the paper

size or weight, you may need to go back to section 3.3 Feeding

and adjusting a test set.

Manual operation

1 Verify that the indicator light s, associated with the paper size button

(example showing A4 selected) and type of finishing (example showing side/corner stapling) that you selected, is on.

2 Check that the optional delivery tray for side/corner stapling is in-

stalled. Or , if a trimmer is present, consult the trimmer operator

manual.

T o facilitate hand feeding, use an optional feeding tray as shown in the

drawing below .

Stapler Folder Model 102 Operator Manual 3-8

T10087 Febrary 1999

Page 16

3.6 Restoring the factory set A3, A4 or A5 program

This section shows you how to restore the factory set program.

Y ou might want to do this after you made fine adjustments of the A3, A4 or

A5 program but no longer need those adjustments.

1 Select the type of finishing and paper size format, for which you want

to restore the factory preset paper size program.

2 Press and hold the paper size button until the indicator light goes off

and then comes back on after approximately 7 seconds.

3 Again, press the type of finishing button. The factory set program is

restored and the Model 102 will set up the retrieved format.

Example:

Restoring the factory setting for side stapling of A4 paper size.

1 Press the side/corner stapling button. The paper size program indica-

tors will now lit up in sequence (running light). Press the A4 button.

Wait until the Model 102 is finished setting up the “old” adjustments.

2 Press and hold the A4 button until the indicator light goes off and then

comes back on after approximately 7 seconds. The type of finishing

indicators will now lit up in sequence (running light).

3 Press the side/corner stapling button. The factory set program is

restored and the Model 102 will set up the retrieved format.

Stapler Folder Model 102 Operator Manual

T10087 February 1999

3-9

Page 17

3.7 Jam indications

Staple(s) missing indicator

The staple(s) missing indicator is illuminated when a set is missing one or

two staples. The model 102 will automatically shut down the on-line system

when this indicator is lit. Check/replace the staple cartridge(s) according

to section 4.1.

Stacker full indicator

The stacker full indicator is illuminated when the belt stacker is full. Remove the completed sets.

Paper jam indicator

The paper jam indicator is illuminated when an operation in the Model 102

is not done within the preset time. Open the top cover and remove the

jammed sets reachable.

If necessary:

• Lift the fold roll guide cassette.

• Turn the upper fold roll using the open end wrench at the hex grip at the

front side of the roll. The Model 102 is delivered with an open end

wrench for that purpose in the tool box.

• Press the staple stop down and move the paper guides apart.

• Fold down the fold roller guide cassette and reposition the paper

guides. There is a magnetic lock holding the paper guides together .

Close the top cover and the model 102 will automatically purge remaining

jammed sets.

Staplers or side joggers incorrectly positioned indicator

The staplers or side joggers incorrectly positioned indicator is illuminated

when the distance between the side jogger and the stapler is to narrow .

Check/adjust the position of the staplers according to section 3.2. Switch

the power off and then on again to reset the position of the side joggers.

Stapler Folder Model 102 Operator Manual

T10087 Febrary 1999

3-10

Page 18

4. Maintenance

This chapter explains how to do routine maintenance of the Model 102.

Maintenance of the Model 102 consists of removal and replacement of the stapler head

and the staple cartridge, and lubrication of the parts associated with the staplers and

joggers. The steps for how to do this are given next.

4.1 Removal/replacement of the staple cartridge

Y ou may remove and replace the staple cartridge while the stapler head

assembly is in place.

1 Open the top cover.

2 Raise the staple cartridge locking lever as indicated in the drawing

below.

3 Gently twist the staple cartridge from side to side, and pull out the

staple cartridge from the stapler head.

32

Stapler Folder Model 102 Operator Manual

T10087 February 1999

4-1

Page 19

4.1 Removal/replacement of the staple cartridge, continues

4 If the staple cartridge is empty , discard it and replace it with a new

one. Before replacing the cartridge, pull at least 20 mm of the staples

out and tear off at the staple tear line which is marked on the cartridge.

If there has been a miss-feed, and the cartridge still contains staples,

pull 20 mm of staples out of the cartridge and tear off at the stapler

tear line. Check that the first staple is flat. If not, tear off another 20

mm, using less force.

4

5 Insert the cartridge into the stapler head with the staples facing to-

wards the head mechanism. The cartridge should be placed flat on

the slide on the bottom of the stapler head and pushed firmly into the

stapler head.

5

6 Hold the staple cartridge firmly in place and push down the cartridge

locking lever .

NOTE: If the cartridge is allowed to move away from the stapler head

before the locking lever is in engaged, remove cartridge and tear

off 20 mm of staples level with the staple tear line.

Stapler Folder Model 102 Operator Manual 4-2

T10087 Febrary 1999

Page 20

4.1 Removal/replacement of the staple cartridge, continues

NOTE: The staples will not be fed until a few booklets have passed

through the Model 102.

7 Move the staple detection switch to the disable position to prevent the

Model 102 from shutting down when it detects missing staples in the

first few booklets. Reset the staple detection switch to normal position

to enable future staple miss-feed indications, after checking that there

are two staples in the booklet.

8 Continue production.

Stapler Folder Model 102 Operator Manual 4-3

T10087 February 1999

Page 21

4.2 Removal/replacement of the stapler head

1 Select the A3 (11"x17") position to ensure that the side joggers are

away from the stapler head.

2 Loosen the thumb screw . Rotate the lock spring towards the thumb-

screws and remove the lock pin from the stapler head assembly .

3 Disconnect the red wire. Push the stapler head towards the in-feed

side, out of the stapler head assembly .

NOTE: Whenever you remove a stapler head, be sure to manually eject

some staples before replacing it in the Model 102. To do this,

rest the stapler head on a firm surface (for example, the top of a

table or the Model 102) and actuate the staple driver post up/

down through full travel. Do this a number of times to ensure

that the staples are ejected on each down movement. If you need

to change the staple cartridge, see previous section, removal/

replacement of staple cartridge.

WARNING: When manually ejecting the stapler, stay clear from stapler

output area.

Stapler Folder Model 102 Operator Manual

T10087 Febrary 1999

4-4

Page 22

4.2 Removal/replacement of the stapler head, continues

4 Before inserting the stapler head, centre the movable carrier over the

area that will receive the stapler head. Ensure that the staple driver

post is in its uppermost position.

5 Place the stapler head back into the Model 102. The front tab of the

stapler assembly must be placed under the nylon tension spring and

the driver post arm placed into the carrier .

4

driver post arm

5

CAUTION: If the driver post arm is not correctly positioned into the

carrier (4) it will cause permanent damage to the stapler

head as well as the carrier. Subsequently, also future correctly mounted stapler heads will be damaged.

6 Press on the lower front edge of the stapler head to align the hole in

the stapler bracket with the hole in the stapler head. Insert the lock

spring so that it engages the stapler head and the metal sides of the

stapler assembly .

8

7 Lock the pin by rotating it towards the in-feed side. Check that the

stapler head is correctly mounted by pushing the stapler head towards

the infeed area.

8 Insert the red wire into its outlet.

Stapler Folder Model 102 Operator Manual

T10087 February 1999

6

4-5

Page 23

4.3 Cleaning fold rolls

The fold rolls will eventually need cleaning due to colour deposits from the

print-out. Especially the upper fold rolls. How often depends of the printing

method but you will notice that when you can see marks or deposits on the

cover of the booklets.

The fold rolls guide cassette can be folded up for better access. At the

front end of the upper fold roll you will find a hex grip. Use the open end

wrench delivered with the Model 102 in the tool box to turn the fold rolls.

Use the same procedure to clean the lower fold rolls.

Stapler Folder Model 102 Operator Manual 4-6

T10087 Febrary 1999

Page 24

4.3 Lubrication of parts

Lubrication of parts

The parts that need lubrication are shown in the table below .

Drive post Stapler drive bar Stapler drive carrier

Staple driver Clincher

TRAPYCNEUQERFNOITACOLTRAP

srehcnilCstelkoobK02yrevE

stsopevirDstelkoobK02yrevE)esaerg(egirtracelpatS

rabevirdrelpatSstelkoobK02yrevE

evirdrelpatS

reirrac

stelkoobK02yrevE

revirdelpatSstelkoobK02yrevE)lioniht(revirdelpatS

daehrelpatsehthtaeneB

)lioniht(ylbmessa

daehelpatsehtevobA

)esaerg(

daehelpatsehtevobA

)esaerg(

Stapler Folder Model 102 Operator Manual

T10087 February 1999

4-7

Page 25

5. Specifications

5.1 Specifications

yticapaC msg57steehs42otpU

sedoM gnidlofdnagnilpatselddaS

deepS

gnidlofdnagnilpatselddaS

gnilpatsrenrocdnaediS

201ledoMredloFrelpatS

ylnognidloF

gnilpatsediS

gnilpatsrenroC

ruohrepstelkoobdezis)"52.4x"5.5(6A0082otpU

ruohrepstelkoobdezis)"5.8x"5.5(5A0062otpU

ruohrepstelkoobdezis)"11x"5.8(4A0022otpU

ruohrepstelkoobdezis)"11x"5.8(4A0012otpU

ezisrepaPniM

xaM

sthgiewrepaPniM

xaM

selpatS detnioplesihc0005x2

dnanoitcetedytpmerelpatS

noitcetedmaj

semmargorpteserP dna"11x"5.8,"41x"5.8,"71x"11/5Adna4A,3A

gnirotstamrofrepapmotsuC

seitilbissop

)DxWxH(snoisnemiD 026x5841x549

thgieW gk741

egatloV zH06-05V042/032

mm012x021

mm754x023

msg06

msg002

seY

"5.8x"5.5

yraropmet1,tnenamrep4+4

zH06V511

ecitontuohtiwegnahcottcejbuserasnoitacificepsdnangisedenihcamehT

Stapler Folder Model 102 Operator Manual

T10087 Febrary 1999

5-1

Page 26

Notes

Loading...

Loading...