MBM StitchFold Operation Manual

Operation

http://www.monomachines.com/

http://www.monomachines.com/

Bookletmaker

Manual

Bookletmaker

StitchFold

http://www.monomachines.com/

http://www.monomachines.com/

CONTENTS

Introduction........................................................ 3

Specifications ..................................................... 3

Safety ................................................................. 4

Assembly Drawing ............................................ 5

Installation .......................................................... 6

Preventive Maintenance ..................................... 6

Control Panel ..................................................... 7

Fuses .................................................................. 7

Operation & Setup............................................ 8

Side Stitching..................................................... 9

Corner Stitching................................................. 10

Adjustments ....................................................... 11

Trouble Shooting ............................................... 12

2

http://www.monomachines.com/

http://www.monomachines.com/

IVBVJ

CORPORATION

INTRODUCTION

Simple Operation: Just load your booklet and it is automatically jogged, stitched, folded, and discharged onto

an accumulating output conveyor. Side stitching, corner stitching, and folding projects, with or without stitching,

are easily accomplished.

Advanced Technology: StitchFold uses patented magnetic stitching head technology, providing the reliability

and economy of wire stitching. Dual sets of folding rollers assure consistent, professional results. For safety,

interlocked access guards prevent machine operation when open.

Improved Productivity: With StitchFold, you can jog, stitch, and fold more than 65,000 booklets at a maximum

speed of 2,300 finished booklets per hour - without stopping to reload staples. StitchFold's variable work

thickness capacity handles from 2 sheets to a one hundred page booklet with no setup changes or adjustments.

Lower Operating Costs: The StitchFold replaces expensive preformed staples with inexpensive bookbinding

wire; you save on material costs and nonproductive downtime.

BOOKLETMAKER SPECIFICATIONS

Unit Weight: 250 Pounds

Speed: Up to 2,300 booklets per hour

Capacity: 2 to 25 sheets of 20# bond (.100" thick before folding) (100 page book)

Re-load: 65,000 booklets per spool of wire

Paper Size: Min. 4.75" x 8.25" Max. 12.75" x 18.5" (also: A5 to A3)

Booklets: 4.25" x 5.5", 5.5" x 8.5", 8.5" x 11", 4.75" x 4.75 "CD", & metric sizes

Stitch Space: 5.5" on 8.5" or 11" tall books 2.75" on 5.5" tall books

Counter: Resettable 6-digit electronic counter

Folder: Knife folder with dual folding rollers

Squaring: Side jog plus full length tape feed

(All booklets with or without trim stock on one or three sides)

Output: Continuous conveyor

Footprint: 16.25" x 22.5"

Dimensions: Height 25" Width 21" Depth 52"

Modes: Stitch and Fold, Stitch, Fold, Corner Stitch, Side Stitch

Electrical: Standard outlet - 115 Volts, 60 Hz, 10 Amps (1/4 HP)

3

StitchFold

http://www.monomachines.com/

http://www.monomachines.com/

SAFETY

SAFETY PRECAUTIONS AND PROCEDURES

1. Make sure electrical power is turned off 4. A well maintained machine is a safer ma-

before performing any adjustment or maintenance.

2. Keep hands, hair, tools, and clothing clear

of stitching area.

chine. Clean and lubricate the machine at

regular intervals. Check machine daily for

broken or worn parts. Replace as necessary.

DO NOT attempt to operate the machine if a

part is broken.

3. Become familiar with the moving compo-

nents of your machine. Keep fingers away

from areas that could pinch or cut.

5. See "SAFETY GUARDS" below! If you are

unsure how to safely operate your Bookletmaker,

contact your Service Representative.

DANGER

KEEP HANDS CLEAR OF STITCHING AREA AND ANY MOVING PARTS!

NEVER OPERATE MACHINE WITHOUT ALL GUARDS IN PLACE!

SAFETY GUARDS

A. Front Guard: Blocks access to the stitching heads

and their point of operation. An electrical interlock keeps the machine turned off unless this

hinged guard is closed. Do not stick your fingers

under the front guard!

B. Top Guard: Blocks access to mechanism that

drives the stitching heads. An electrical interlock

keeps the machine turned off unless this guard is

closed. Do not stick your fingers under the top

guard!

E. Front Cover: Blocks access to dangerous elec-

F. Rear Cover: Blocks access to low voltage con-

G. Roller Guard: Blocks access to a pinch points.

tric voltage and mechanisms that can pinch or

cut. Be sure to disconnect electrical power before

removing this cover.

nections and mechanisms that can pinch or cut.

Do not stick your fingers beyond this cover!

Do not stick your fingers beyond this cover!

C. Right Side Cover: Blocks access to mechanisms

that can pinch or cut.

D. Left Side Cover: Blocks access to dangerous

electric voltage and mechanisms that can pinch

or cut. Be sure to disconnect electrical power

4

before removing this cover.

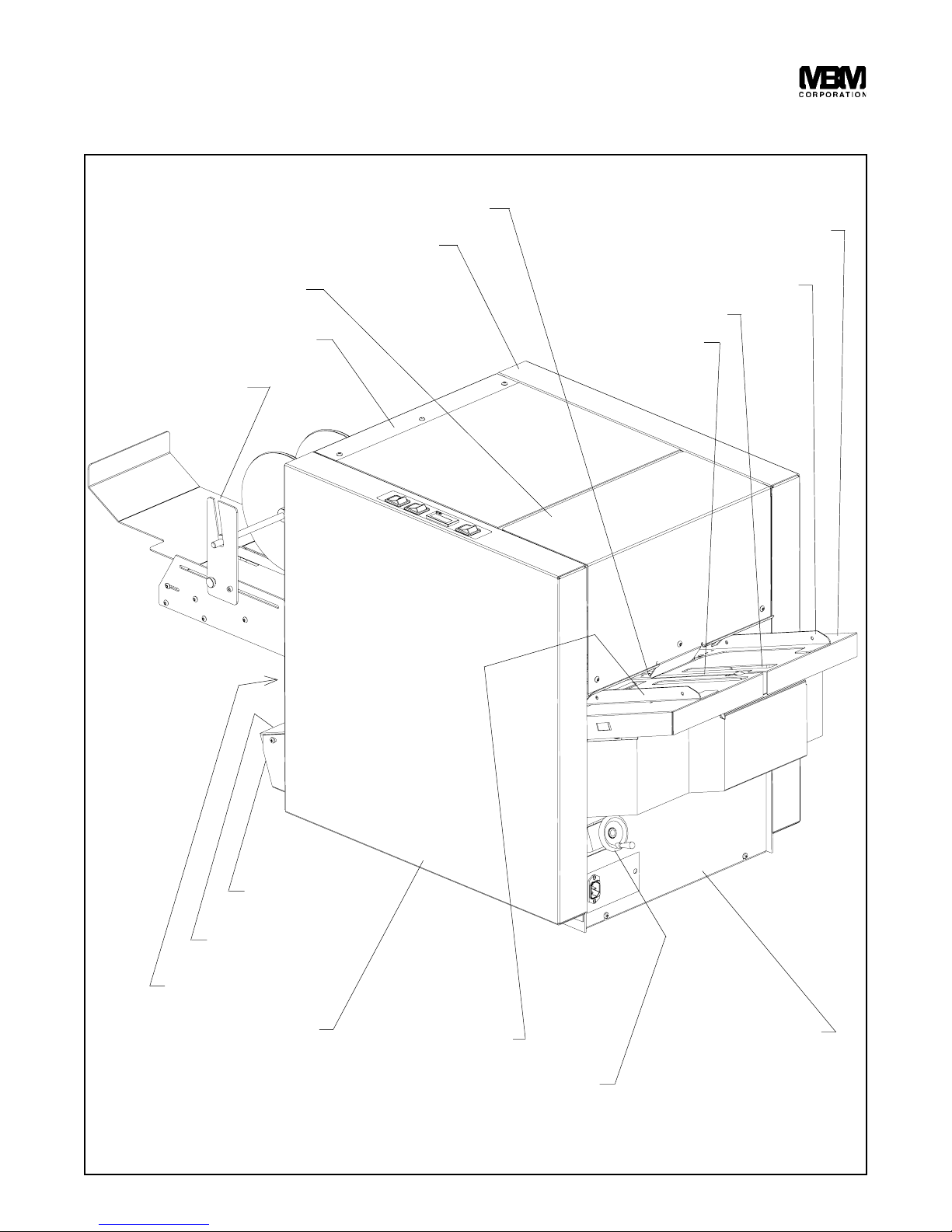

ASSEMBLY DRAWING

http://www.monomachines.com/

http://www.monomachines.com/

C. Right Side Cover

Ski

IVBVJ

CORPORATION

Main Table

A. Front Guard

B. Top Guard

Delivery Table

Right Side Guide

Jog Fingers

Main Table Belt

F. Rear Cover

Secondary Table

G. Roller Guard

D. Left Side Cover

Left Side Guide

(RBM1000A Scene 1)

E. Front Cover

Hand Crank

5

Loading...

Loading...