MBM SPRINT 3000 Operation Manual

SPRINT 3000

BOOKLETMAKER

OPERATION MANUAL

IMP

oper3500.doc Page 1 23/01/2004

CONTENTS

1. Introduction. 2

2. Specification. 2

3. Initial setting up. 3

4. Operation. 4

4.1 Loading staples. 5

4.2 Staple out system. 6

4.3 Staple jam. 6

4.4 Paper width settings. 7

4.3 Stapling / folding positions. 8

4.6 Changing stapling head positions. 10

5. Booklet making. 11

6. Corner and edge stapling 13

7. Counter. 14

8. Replacing stapling heads. 14

9. Aligning of stapling heads. 14

10. Problem solving. 15

Appendix A: Parts lists and drawings.

MBM Corporation

Michael Business Machines

3134 Industry Drive

North Charleston

South Carolina 29418

Customer Service - Tel: (800) 223 2508

oper3500.doc Page 2 23/01/2004

Fax: (803) 552 2974

Parts & Service - Tel: (800) 223 2508

Fax: (803) 760 3814

1 INTRODUCTION

• The Sprint 3000 Bookletmaker is a heavy duty machine for centre stapling and folding to make

booklets between 4¼“ x 5½“ and 8½“ x 11” with up to 100 pages. On each cycle of the machine

one set of sheets is stapled and the preceding set is folded and stacked on the conveyor belt.

• It is also possible to edge and corner staple up to 30 sheets of 20 lb bond 8½“x 11” paper.

• The machine can either be hand fed or placed on-line to one of the various desktop vertical

collators, using a KAS conveyor/ jogger link. A stand is also supplied to carry the collator so that

it is the correct height for feeding into the Bookletmaker.

• The Sprint 3000 is a floor standing machine fitted with sturdy castors and an integral conveyor

which can be folded up in order to occupy minimal floor space when not in use.

• This model has three stapling heads as standard and five stapling positions. The centre stapler is

fixed, whereas the outside heads may be moved to alternative positions depending upon the size of

paper.

• A low staple detector is fitted to one of the stapling heads, and the Bookletmaker will stop before

the stapling head runs out of staples.

2 SPECIFICATION

INPUT CAPACITY: 25 sheets of 20 lb bond

SHEET SIZES: 5½“ x 8” to 11½“ x 17½“

STAPLE LENGTH 6mm or 8mm

DIMENSIONS Width 23”

Height 36”

Length 20” (Conveyor stored).

Length 46” (Conveyor in use).

WEIGHT 205 lbs

POWER 115V 60Hz

Consumption approx. 180 Watts

oper3500.doc Page 3 23/01/2004

Fuse: 10 amp 115v.

3. INITIAL SETTING UP

1. Remove the bolts holding the machine to the pallet.

2. Castors are already fitted to the machine, lift from the pallet on to an even surface.

3. Remove packing from stapling section and from under fold stop beneath the conveyor.

4. Lower output conveyor, allowing the slotted ends on the support bars (part no. 6.06) to locate on

the protruding bolts provided. These bolts are located at the base of the machine.

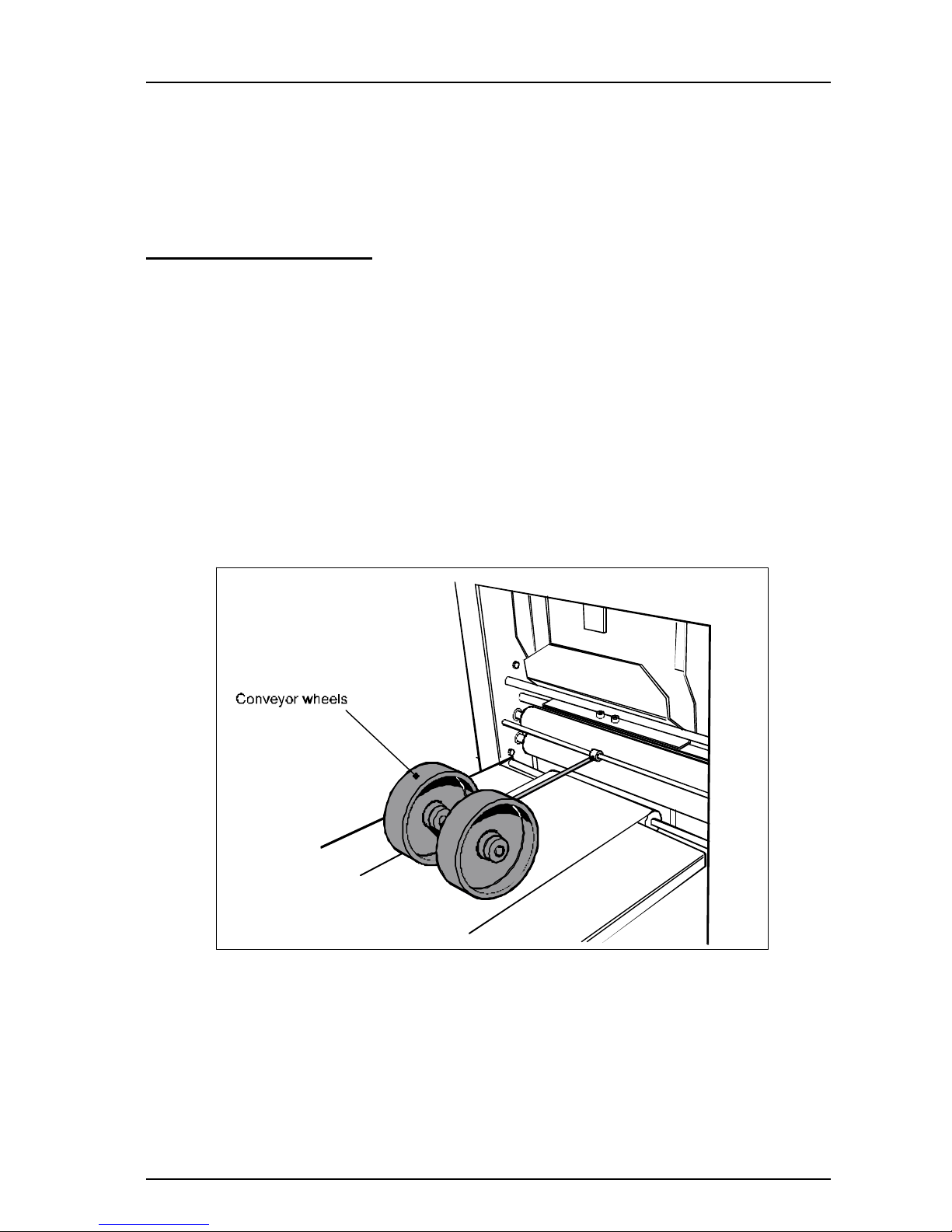

5. Fit the conveyor wheels.

Figure 2 - Conveyor setup.

6. Insert the conveyor end stop (part no. 6.11) at the far end of the conveyor, making sure it does not

infringe the belt. It is held in position by a flat magnet.

7. Position the machine near to a suitable socket outlet and ensure outlet is not covered and is easily

accessible.

oper3500.doc Page 4 23/01/2004

8. Check that the power supply is of the correct voltage for the machine. Once connected, the

machine is ready for use.

oper3500.doc Page 5 23/01/2004

4. OPERATION

Figure 1 - Control layout (centre head removed for clarity)

1 Fold stop lock thumbscrew 8 Staple position fine adjustment screw

2 Stapling head locking levers 9 On / off button

3 10 Staple delay knob

4 Side guide clamping thumbscrew 11 Staple/fold stop indicator

5 Staple low indicator / reset 12 Fold stop tilt adjustment thumbscrew

6 Stapling head cartridge eject 13 Staple & fold stops adjustment wheel

7 Anvil 14 Counter

Loading...

Loading...