MBM FGMD107, FGMD207, FGMD67, FGMD107SC, FGMD67SC Maintenance Manual

...

- 1 -

LAST REVISION: 27/06/00 IMFOC 00230

INSTALLATION, OPERATION AND

MAINTENANCE INSTRUCTIONS

DIRECT”COMBINED”ANALOGUEELECTRONICGASOVEN

TO STANDARDS EN 437 and EN 203 Part I

EN 60335 - I and EN 60335 - II - 42

FGMD67

FGMD107

FGMD207

FGMD67SC

FGMD107SC

FGMD207SC

- 2 -

CONTENTS

SECTION DESCRIPTION PAGE

1. Warnings ............................................................................................................................................ 3

1.1 General warnings ............................................................................................................................... 3

2. Technical data ................................................................................................................................... 4

2.1 Gas appliances................................................................................................................................... 4

3. Installation diagrams ......................................................................................................................... 5

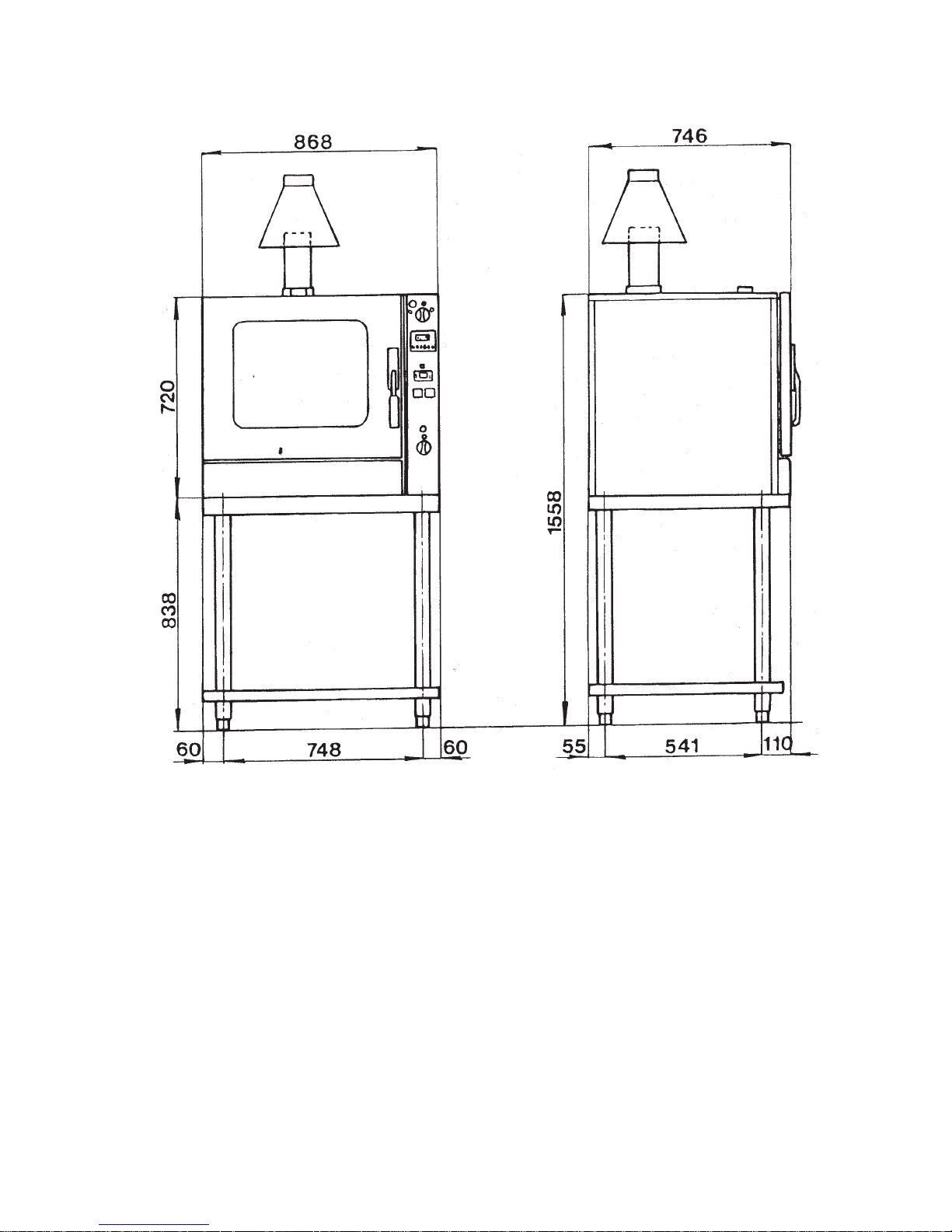

3.1 Direct ”Combined” gas oven FGMD67/FGMD67SC....................................................................... 5

3.2 Direct ”Combined” gas oven FGMD67/FGMD67SC with stand SF3 .............................................. 7

3.3 Direct ”Combined” gas oven FGMD107/FGMD107SC with cabinet SF A - SFRU .......................... 8

3.4 Direct ”Combined” gas oven FGMD207/FGMD207SC with stand SF2.......................................... 9

4. Installation instructions .................................................................................................................... 10

4.1 Preparing for installation .................................................................................................. ................. 10

4.1.1 Laws, regulations and technical directives ....................................................................................... 10

4.1.2 Plate to E.U. standards....................................................................................................................... 10

4.2 Positioning ........................................................................................................................................ 11

4.3 Cold water connection ...................................................................................................................... 11

4.4 Waste water outlet ............................................................................................................................. 11

4.5 Electrical connection ........................................................................................................................ 12

4.5.1 Earthing ............................................................................................................................................. 12

4.5.2 Equipotential system ......................................................................................................................... 12

4.5.3 Power supply cable............................................................................................................................ 12

4.5.4 Cable wiring to terminal block ......................................................................................................... 1 2

4.6.0 Table I gas, pressure and classes in different countries ..................................................................... 13

4.6 Hook-up with the gas system ............................................................................................................ 14

4.6.1 Transformation for operation with a different type of gas ................................................................ 14

4.6.1.1 Replacing burner nozzle (FGMD67, FGMD67SC, FGMD107 and FGMD107SC) ......................... 14

4.6.1.2 Replacing burner nozzle (FGMD207 and FGMD207SC) ................................................................ 15

4.6.1.3 Adjusting gas pressure at the burner ................................................................................................. 15

4.6.1.4.1a Table II: gas burner injectors for direct ovens................................................................................... 18

4.6.1.4.1b Table III: gas burner injectors for direct ovens.................................................................................. 19

4.6.1.4.1c Table IV: gas burner injectors for direct ovens.................................................................................. 20

4.6.1.5 Checking heat capacity by means of pressure .................................................................................. 21

4.6.1.6 Discharging the products of combustion under a suction hood ....................................................... 2 1

4.6.1.7 Discharging the products of combustion using a flue ......................................................................21

4.6.1.8 Type of installation for discharging the products of combustion .................................................... 21

4.6.1.9 Other outlets ...................................................................................................................................... 2 3

4.7 Room ventilation .............................................................................................................................. 23

5. Use ..................................................................................................................................................... 23

5.1 User instructions: commissioning..................................................................................................... 2 3

6. Using the electronic oven ................................................................................................................. 25

6.1 Cooking selection ............................................................................................................................. 25

6.2 Vent valve in cooking chamber ........................................................................................................ 25

6.3 Humidifier ......................................................................................................................................... 2 6

6.4 Chamber light.................................................................................................................................... 26

6.5 Fan speed ........................................................................................................................................... 26

6.6 Cooking chamber temperature.......................................................................................................... 26

6.7 Cooking time and starting the oven ................................................................................................. 26

6.8 Core probe ......................................................................................................................................... 27

6.9 Cook & Hold ..................................................................................................................................... 2 7

6.10 Displaying and modifying cooking parameters ............................................................................... 2 7

6.11 Messages and alarms ......................................................................................................................... 28

7. Cleaning and Maintenance ............................................................................................................... 28

7.1 Cleaning ............................................................................................................................................ 2 8

7.1.1 Cleaning after cooking and at the end of the day............................................................................. 28

7.1.2 Troubleshooting................................................................................................................................29

7.2 Maintenance...................................................................................................................................... 2 9

7.2.1 Replacing components ...................................................................................................................... 2 9

A) Electric components and electronic card ..................................................................................... 29

B) Burners.......................................................................................................................................... 29

C) Detection device........................................................................................................................... 29

D) Ignition devices ............................................................................................................................ 29

E) Gas multi-functional valves.......................................................................................................... 29

F) Oven lamp ..................................................................................................................................... 30

G) Oven door gasket.......................................................................................................................... 30

H) Cleaning solenoid valve filters .................................................................................................... 3 0

7.2.2 Yearly maintenance ........................................................................................................................... 3 1

7.2.3 Safety devices Equipment control and safety systems .................................................................... 31

7.3 Switching off in the event of equipment faults.............................................................................. ... 31

7.3.1 Precautions if the oven is not to be used for a lengthy period.......................................................... 32

- 3 -

The manufacturer disclaims all responsibility for any inaccuracies in this booklet that may be due to typing or printing

mistakes. The manufacturer, moreover, reserves the right to make the modifications to the product it considers useful or

necessary, without affecting its basic features.

In the event of the user or the installation technician failing to observe the instructions given in this manual, the Firm

disclaims all responsibility thereof and cannot be held liable for any accidents or trouble caused by such non-observance.

1. WARNINGS

- Installation, start-up and maintenance of the oven are to be carried out only by skilled personnel authorized by our firm

or by licensed installers.

- Read the instructions contained in this manual carefully as they provide important information on the correct installation,

operation and maintenance procedures.

- Store this manual carefully for future reference by the operators.

- After removing the packing, check the integrity of the equipment.

- In the event of equipment failure or trouble, do not operate the equipment, call professionally qualified personnel.

- Packaging elements (plastic bags, polystyrene foam, nails, etc.) are potentially dangerous and should not be left within the

reach of children.

- Before connecting the equipment, make sure that the data reported on the plate correspond to those of the gas, electric and

water supply networks.

- The plate is located on the base inside the panel, under the oven door.

- The equipment is to be operated by specifically trained staff only.

- This equipment must only be used for the purposes for which it was designed, i.e. cooking or warming up food; any other use

is to be considered improper and therefore dangerous.

- Do not obstruct air vents or heat dissipation openings.

- Switch off the oven after use.

1.1 GENERAL WARNINGS

- 4 -

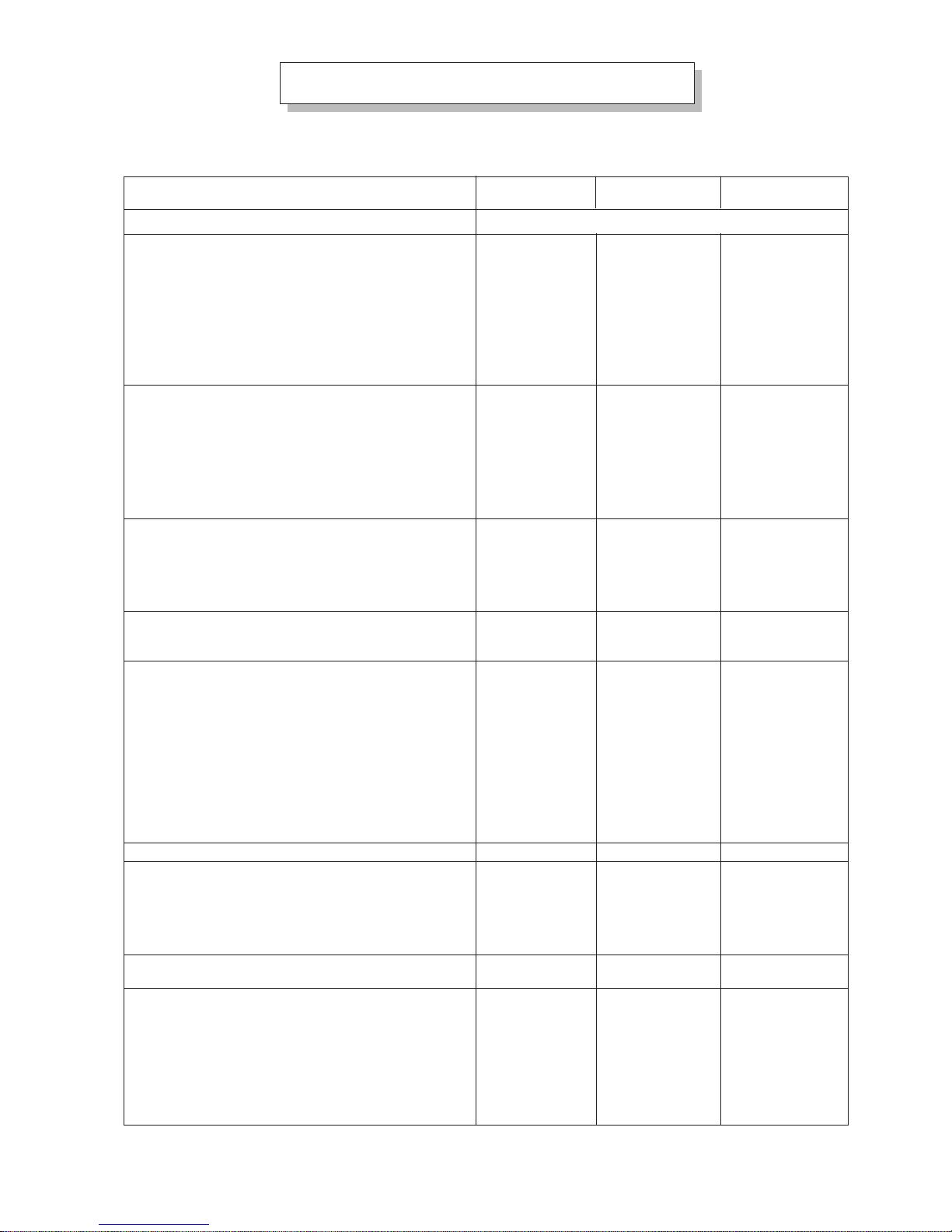

2. TECHNICAL DATA

2.1 GAS APPLIANCES

MODEL

Standards

Outside dimensions

Width

Depth

Height

Height

Full height type A

Full height type B

Outlet type A

Outlet type B

Net weight

Cooking chamber dimensions

Width

Depth

Height

Useful volume

Capacity No. Grilles GN 1/1-2/1

Oven load capacity

Guide c/c distance GN 1/1

Tray depth

Power supply voltage

AC 230 V 50 Hz (or 60 Hz)

External residual

current device

T otal absorbed electric power

Motor absorbed electric power

Power supply

Power supply cable type H07RN-F

Cable no. 3 wires Cross-section

Class according to EN 203 part 1

Outlet type

Nom. outlet diameter

Height type A

Height type B

Nominal heat capacity (min-max)

Gas consumption (15°C)

G30 - 29/50 mbar

G31 - 30/37/50/67 mbar

G20 - 20 mbar

G25 - 25 mbar

Gas supply

W ater supply

Softened water (min÷max)

Consumption

Steam generation

Steam elimination

* NB : 1 bar = 100 kPa

W aste water outlet

T emperature

Oven performance

Oven air temperature range

Steam temperature range

Core probe temperature range

Time to reach 200°C

Consumption to keep average 180°C

Fan speed

868

746

720

807

1097

1237

100

110

120

590

335

430

85

6/18

60

20

x

10

0.55

0.5

1.5

II

A or B

100/110

290

430

8/11.4

0.897

0.885

1.21

1.40

G 3/4”

G 3/4”

0.5÷4

7.5

90

40

100

20 ÷ 270

20 ÷ 100

20 ÷ 99

7

1.8

1400

2800

mm

mm

min.mm

max.mm

max.mm

max.mm

Ø mm

Ø mm

kg

mm

mm

mm

dm

3

max.kg

mm

min.mm

A/ph

kW

kW

mim.mm

2

Ø mm

mm

mm

kW

kW

kg/h

kg/h

m

3

/h

m

3

/h

“R”

min÷max bar*

l/h

l/h

Ø mm

max.°C

°C

°C

°C

min.

kWh

min.g/min

max.g/min

EN 437 and EN 203 part 1

EN 60335 - I and EN 60335 - II - 42

FGMD67

FGMD67SC

FGMD107

FGMD107SC

Gas

Electric

940

900

1045

1095

1365

1575

130

150

175

640

465

670

199

10/-

30÷40

60

20

x

10

0.65

0.6

1.5

II

A or B

130/150

270

480

11.2/15.5

1.26

1.243

1.694

1.97

G 3/4”

G 3/4”

0.5÷4

10

140

40

100

20 ÷ 270

20 ÷ 100

20 ÷ 99

8

2.1

700

1400

1340

995

960

1010

1270

1525

160

180

250

638

850

670

363

10-20

60÷80

60

20

x

10

0.7

0.65

1.5

II

A or B

160/180

260

515

19.6/28.0

2.205

2.175

2.964

3.447

G 3/4”

(2x) G 3/4”

0.5÷4

15

140

40

100

20 ÷ 270

20 ÷ 100

20 ÷ 99

5.7

4.0

700

1400

FGMD207

FGMD207SC

- 5 -

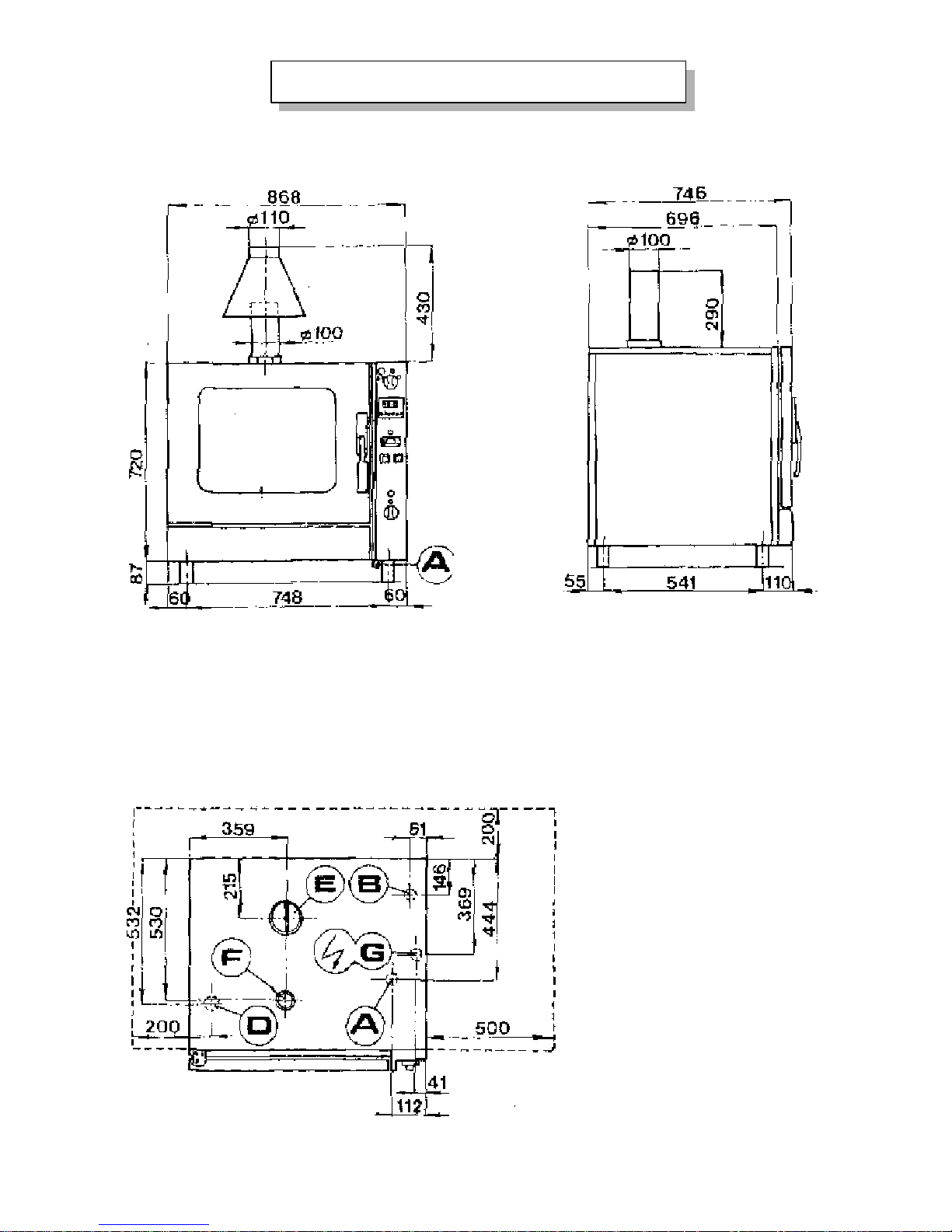

3. INSTALLATION DIAGRAMS

3.1 DIRECT ”COMBINED” GAS OVEN FGMD67/FGMD67SC

B) Softened water inlet G 3/4”

D) Water outlet Ø 40 mm

F) Vent pipe Ø 50 mm

G) Power supply cable input

A) Gas connection G 3/4”

E) Chamber flue Ø 100 mm

- 6 -

DIRECT “COMBINED” GAS OVEN FGMD107/FGMD107SC

B) Softened water inlet G 3/4”

D) Water outlet Ø 40 mm

F) Vent pipe Ø 50 mm

G) Power supply cable input

A) Gas connection G 3/4”

E) Chamber flue Ø 130 mm

- 7 -

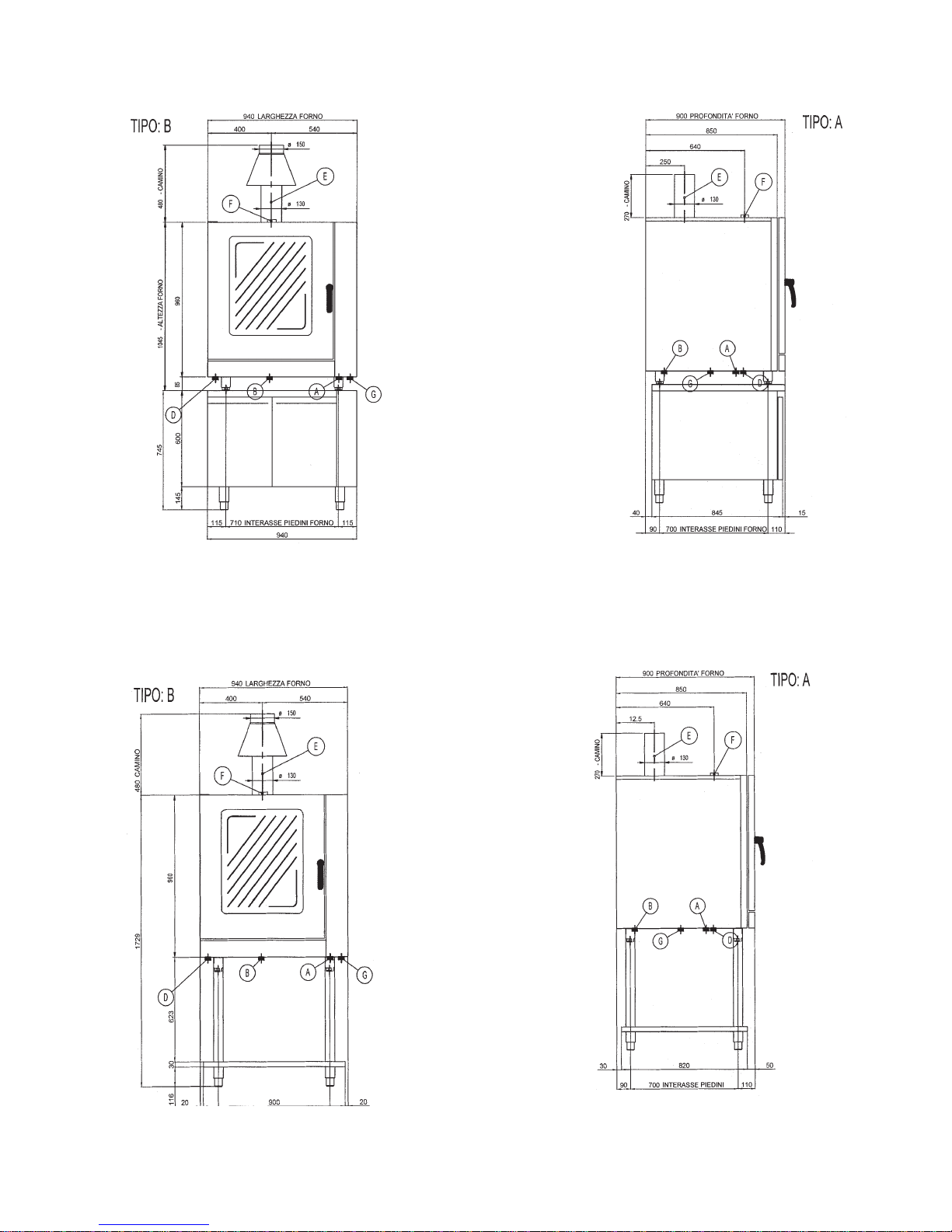

3.2 DIRECT ”COMBINED” GAS OVEN FGMD67/FGMD67SC WITH STAND SF3

- 8 -

3. 3 DIRECT “COMBINED” GAS OVEN FGMD107/FGMD107SC

WITH CABINET SFA - SFRU

DIRECT “COMBINED” GAS OVEN FGMD107/FGMD107SC WITH STAND SFCV

A) Gas connection G 3/4”

B) Softened water inlet G 3/4”

D) W ater outlet Ø 40 mm

E) Chamber flue Ø 130 mm

F) Vent pipe Ø 50 mm

G) Power supply cable entry

A) Gas connection G 3/4”

B) Softened water inlet G 3/4”

D) W ater outlet Ø 40 mm

E) Chamber flue Ø 130 mm

F) Vent pipe Ø 50 mm

G) Power supply cable entry

- 9 -

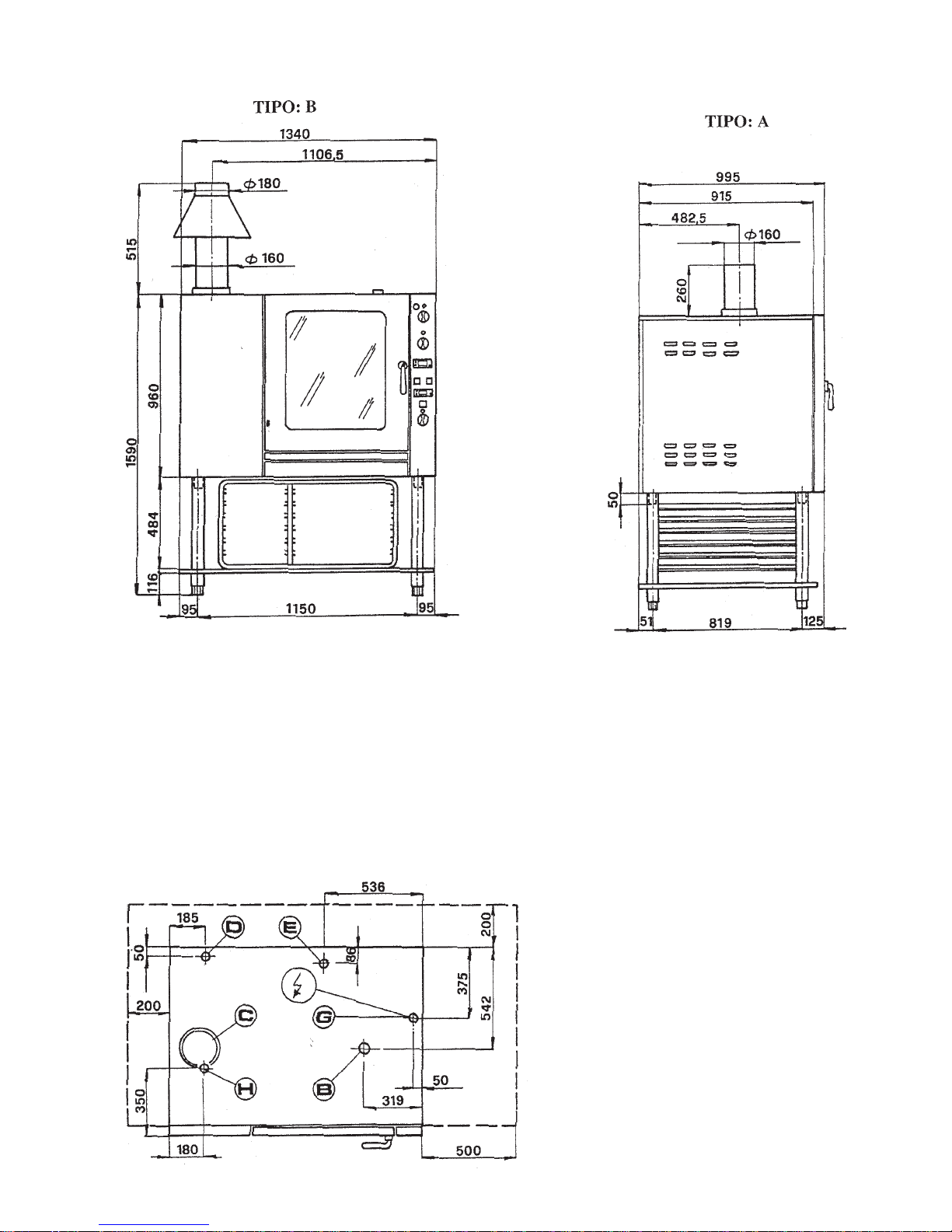

3.4 DIRECT ”COMBINED” GAS OVEN FGMD207/FGMD207SC WITH STAND SF2

E) Water outlet Ø 40 mm

G) Power supply cable input

B) Adjustable top condensate outlet Ø 50 mm

C) Chamber flue Ø 160 mm

D) Humidifier water and steam

reduction inlet G 3/4”

H) Gas connection G 3/4”

- 10 -

4. INSTALLATION INSTRUCTIONS

Installation and adjustment operations are to be carried out by qualified personnel according to the norms in force.

(See technical specification tables on page 4).

WARNINGS:

- If the oven is installed against a wall, the wall needs to withstand temperatures of 80°C and must be incombustible.

- Inlets (water and electricity) and outlets (waste water, steam etc.) are signalled by dedicated tags.

- The top of the oven is not to be used to store goods!

4.1 PREPARING FOR INSTALLATION

Before proceeding to installation, remove the protective plastic film and eliminate any adhesive residues by means of a

suitable product for cleaning stainless steel.

4.1.1 LAWS, REGULATIONS AND TECHNICAL DIRECTIVES

The following regulations must be observed during installation:

- Fire regulations.

- Current accident-prevention regulations.

- The regulations of the gas board.

- “Gas system installation” standards.

- “Electric system installation” standards.

- The regulations of the electricity board.

- The regulations of the water board.

- Local ”municipal” norms on the drainage of waste water.

- Health regulations.

- Italian law no.46 05/03/1990.

- Safety standards UNI-CIG 8723 and Italian Ministerial Decree D.M. no. 74 dated 12/04/96.

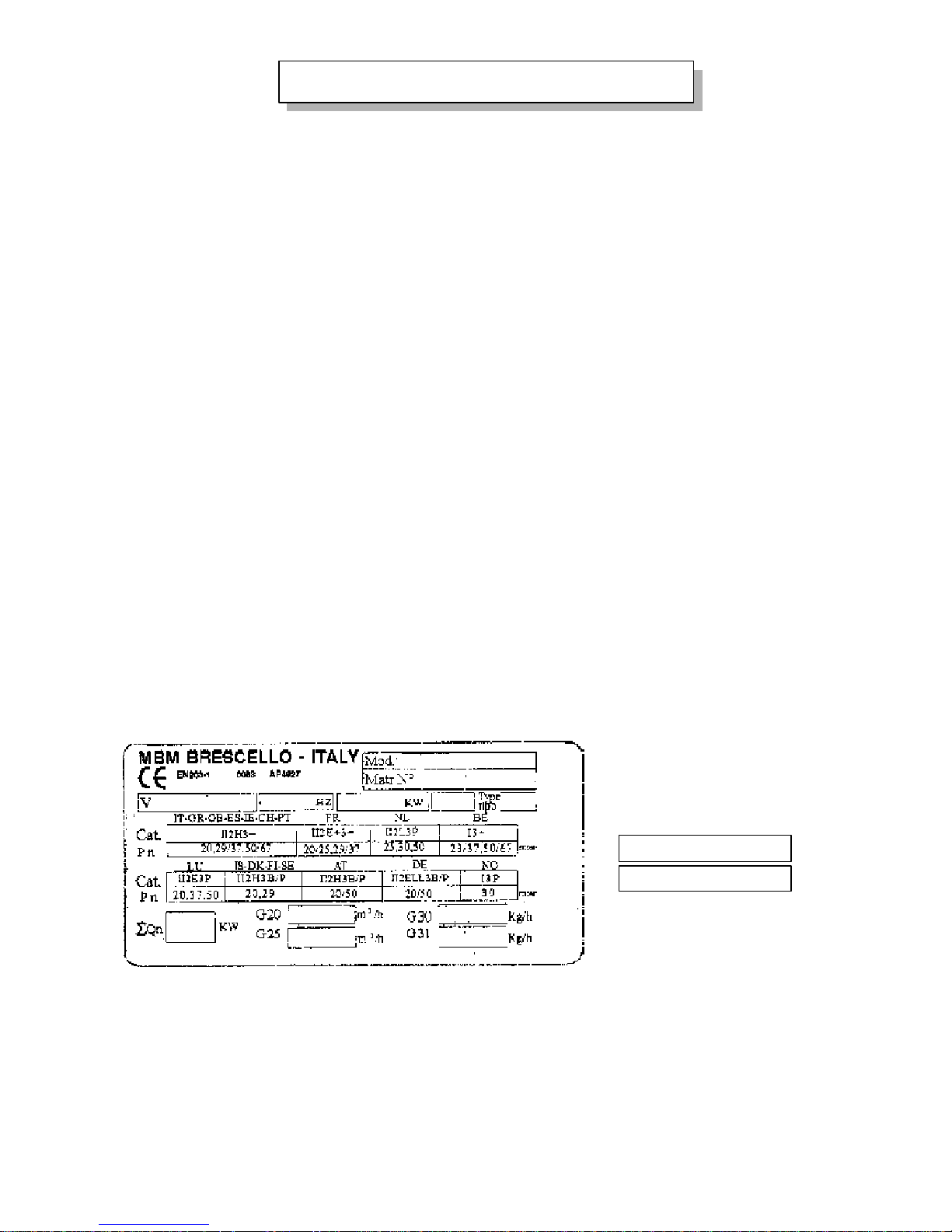

4.1.2 PLATE TO E.U. STANDARDS

TO STANDARDS EN 437 and EN 203 Part 1

ADHESIVE PLATES

GAS FITTING

G 20 20 mbar

G 30/31 29/37 mbar

Loading...

Loading...