MBA Instruments MLA 900 Operating Instruction

Title

MLA 900

Conductivity meter

for light petroleum products

Operation

Maintenance

Approvals

Operating Instructions

Document information

Document ID

Title: Operating Instructions MLA 900

Order No.: 8011381

Version: 2.0

Status: 2010-06

Subject

Product name: MLA 900

Software: Version 1.1

Manufacturer

MBA Instruments GmbH

Friedrich-List-Str. 7 · D-25451 Quickborn · Germany

Phone: +49 (0) 41 06 123 888-0

Fax: +49 (0) 41 06 123 888-9

E-Mail: info@mba-instruments.de

Trademarks

IBM is a trademark of the International Business Machine

Corporation.

MS-DOS and Windows are trademarks of the Microsoft

Corporation.

Other product names used in this document may also be

trademarks and are only used for identification purpose.

© MBA Instruments GmbH. All rights reserved.

Warning symbols

Hazard (general)

Hazard in explosion-hazardous locations

Hazard by explosive substances/mixtures

Warning levels / signal words

GEFAHR

Immediate hazard which will result in serious injury or death.

WARNUNG

Risk or hazardous situation which could result in serious injury or

death.

VORSICHT

Hazard or unsafe practice which may result in minor or moderate

personal injury.

NOTICE

Hazard or unsafe practice which could result in property

damage.

Information symbols

Important technical information for this product

Nice to know

Supplementary information

Link to information at another place

2

Operating Instructions 8011381 V2.0 © MBA Instruments GmbH

Contents

Contents

1 For your own safety … . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 General safety in hazardous locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2 Essential safety notes for the MLA 900 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Notes on application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Approved use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1.1 Designated use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1.2 Application restrictions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1.3 Regulations and standards fulfilled. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 Official approval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2.1 Definitions of terms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2.2 Approval for the MLA 900 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3 Preparing for operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.1 Supply schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.2 Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4 Handling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.1 Display unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.1.1 Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.1.2 Switching on and off. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.1.3 Measuring value displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.2 Fault/limit value displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.3 Performance test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.4 Measuring procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.5 Measures in the event of a fault/damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

5 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.1 Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.1.1 Cleaning the probe cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.1.2 Cleaning the measuring probe. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

5.1.3 Cleaning the display unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.2 Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.3 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6 Storage, transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.1 Correct storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.2 Short-distance transports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.3 Correct shipping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.4 Shipping for repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7 Approval certificate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

MLA 900 Operating Instructions V 2.0 8011381 © MBA Instruments GmbH 3

Contents

4 MLA 900 Operating Instructions V 2.0 8011381 © MBA Instruments GmbH

For your own safety …

MLA 900

1 For your own safety …

General safety

Essential safety notes

MLA 900 Operating Instructions V 2.0 8011381 © MBA Instruments GmbH 5

For your own safety …

1.1

General safety in hazardous locations

WARNUNG:

b

Before using the instrument for the first time in a hazardous location:

Observe all the safety instructions in these operating instructions.

1.2 Essential safety notes for the MLA 900

b

Observe the following safety notes when assembling and operating the instrument,

during maintenance and repair, and when exchanging parts – for your own protection.

The most important safety rules are:

VORSICHT: Risk of wrong measurements

b

Before using the MLA 900: carry out a performance test (→S. 21, §4.3) –

always to be done outside of the hazardous locations.

WARNUNG: Hazard when potential equalisation is missing:

b

Before the measuring probe is lowered into the liquid container: Safely

connect the ground clamp of the display unit with the liquid container

(potential equalisation).

WARNUNG: Hazard when enclosure is open

b

Never open the instrument enclosure as long as it is in a hazardous

location.

WARNUNG: Hazard by unsafe instrument

b

If there is any reason to assume that the instrument is no longer safe: shut

down the instrument and protected it against unauthorised use.

6 MLA 900 Operating Instructions V 2.0 8011381 © MBA Instruments GmbH

Notes on application

MLA 900

2 Notes on application

Designated use

Application restrictions

Official approval

MLA 900 Operating Instructions V 2.0 8011381 © MBA Instruments GmbH 7

Notes on application

2.1

2.1.1 Designated use

Approved use

Measuring function

The MLA 900 determines the electrical conductivity and the temperature of petroleum

products such as occur, for example, in aviation fuels and in other petroleum products.

During the filling process, pumping or filtering, these liquids may become electrostatically

charged. If, in addition, there is an inflammable gas mixture present in the ambient

atmosphere, there is a danger that the gas mixture will be ignited by a discharge spark,

which means that it may explode. To evaluate this risk, the electrical conductivity of the

liquid is measured (see German standard DIN 51 412-T02-79, »Determining electrical

conductivity, field procedure«).

The conductivity is stated in the physical unit »pS/m« (picosiemens per meter). This unit

corresponds to »c.u.« (conductivity unit), which is still commonly used in the petroleum

industry:

Ambient conditions

The MLA 900 is designed as a measuring instrument for outside use.

b

Use the MLA 900 at an ambient temperature of –20 °C … +60 °C (–4 … +140 °F).

Outside this temperature range it can no longer be guaranteed that the instrument will

function correctly.

pS

1

1c.u.=

m

● At temperatures above +60 °C (140 °F) there is a danger that caustic liquid

from the battery may escape and damage the electronics. Apart from this,

the LC displays may be damaged (irreversible blackening).

● At temperatures of below –20 °C (–4 °F), the LC displays in the display unit

may freeze, resulting in the LC display enclosure bursting.

● Low temperatures affect the flexibility of the probe cable.

b

Avoid bending the probe cables in low temperatures.

Otherwise the probe cable could brake due to the sheath becoming brittle.

2.1.2 Application restrictions

The MLA 900 may only be used to measure the conductivity and temperature of petroleum

products, such as petrol, kerosene and oils/greases. Other liquids such as acids or

solvents containing chlorinated hydrocarbons, for example, can damage the measuring

probe.

component clean with avoid contact with

measuring probe

probe cables

petrol

spirit (ethanol)

isopropanol

acids

chlorinated hydrocarbons (CHC)

methanol

acetone

8 MLA 900 Operating Instructions V 2.0 8011381 © MBA Instruments GmbH

Notes on application

2.1.3

Regulations and standards fulfilled

The MLA 900 measuring procedure corresponds to:

● German standard DIN 51 412-T02-79 (»Determining electrical conductivity, field

procedure«)

● ASTM 02624 »Standard Test Methods for Electrical Conductivity of Aviation and

Distaillate Fuels«

The technical design of the MLA 900 corresponds to:

● European standard EN 60079-0:2006

● European standard EN 60079-11:2007

● European standard EN 60079-26:2007

● European Council Directrive 94/9/EC (ATEX guideline)

● German »Ordinance on electrical appliances in hazardous locations« (»Verordnung

über elektrische Anlagen in explosionsgefährdeten Räumen«, ElexV) of 13 December

1996.

2.2 Official approval

2.2.1 Definitions of terms

● An explosive mixture is a mixture of gases, vapours, mists or dusts in which a reaction

continues independently after ignition.

● An explosive atmosphere contains explosive mixtures of gases, vapours, mists or dusts

with air, including usual admixtures (for example, humidity) under atmospheric

conditions. Atmospheric conditions are here defined as total pressures of 0.8 to 1.1 bar

and gas mixture temperatures of from –20 °C to +60 °C.

A dangerous explosive atmosphere occurs when in the event of an ignition injury may

be caused to persons as a direct or indirect result of the explosion.

● Hazardous locations are those areas in which a dangerous explosive atmosphere may

occur due to local and operational conditions.

Hazardous locations are divided into zones on the basis the probability (in terms of time

and place) of the presence of dangerous explosive atmospheres:

– Zone 0 includes areas in which a dangerous explosive atmosphere is present

»constantly or for longer periods«; for example, in tank facilities.

– Zone 1 covers areas in which a dangerous explosive atmosphere »occasionally«

occurs; for example, in the vicinity of refuelling nozzles.

MLA 900 Operating Instructions V 2.0 8011381 © MBA Instruments GmbH 9

Notes on application

2.2.2

Approval for the MLA 900

Approved area of application

The MLA 900 is approved for use in hazardous locations in which inflammable gases,

vapours or mists may occur (EEx ia IIB T6). The MLA 900 measuring probe is approved for

use in Zone 0, the display unit for use in Zone 1.

Prescribed operating conditions

The following applies for the use of the MLA 900 conductivity meter in the area of

application as defined in the »Ordinance on electrical appliances in hazardous locations

(ElexV)«:

WARNUNG: Hazards in explosions-hazardous locations

● The MLA 900 is intended exclusively for mobile use at different locations.

● The measuring probe of the MLA 900 is approved for use in containers for

inflammable liquids (Hazardous Location Zone 0).

● The display unit of the MLA 900 may only be used in Hazardous Location

Zone 1.

● The measuring probe may only be used in such liquids against which the

→

materials of which it is made offer adequate chemical resistance (

§2.1.2).

● Damaged measuring probes may not be used in Zone 0.

● Before the measuring probe is taken to Zone 0, all plug and threaded cable

connections must be checked.

● The measuring probe may only be used with the appropriate display unit.

● Before the measuring probe is lowered into the liquid container (tank), the

ground clamp of the display unit must be connected to the container to

equalize the electric potentials.

S. 8,

Approval document →S. 36

10 MLA 900 Operating Instructions V2.0 8011381 © MBA Instruments GmbH

Preparing for operation

MLA 900

3 Preparing for operation

Supplied parts

Assembly

MLA 900 Operating Instructions V 2.0 8011381 © MBA Instruments GmbH 11

Preparing for operation

Nr.: 930XXX

PTB02ATEX2201X

3.1

Supply schedule

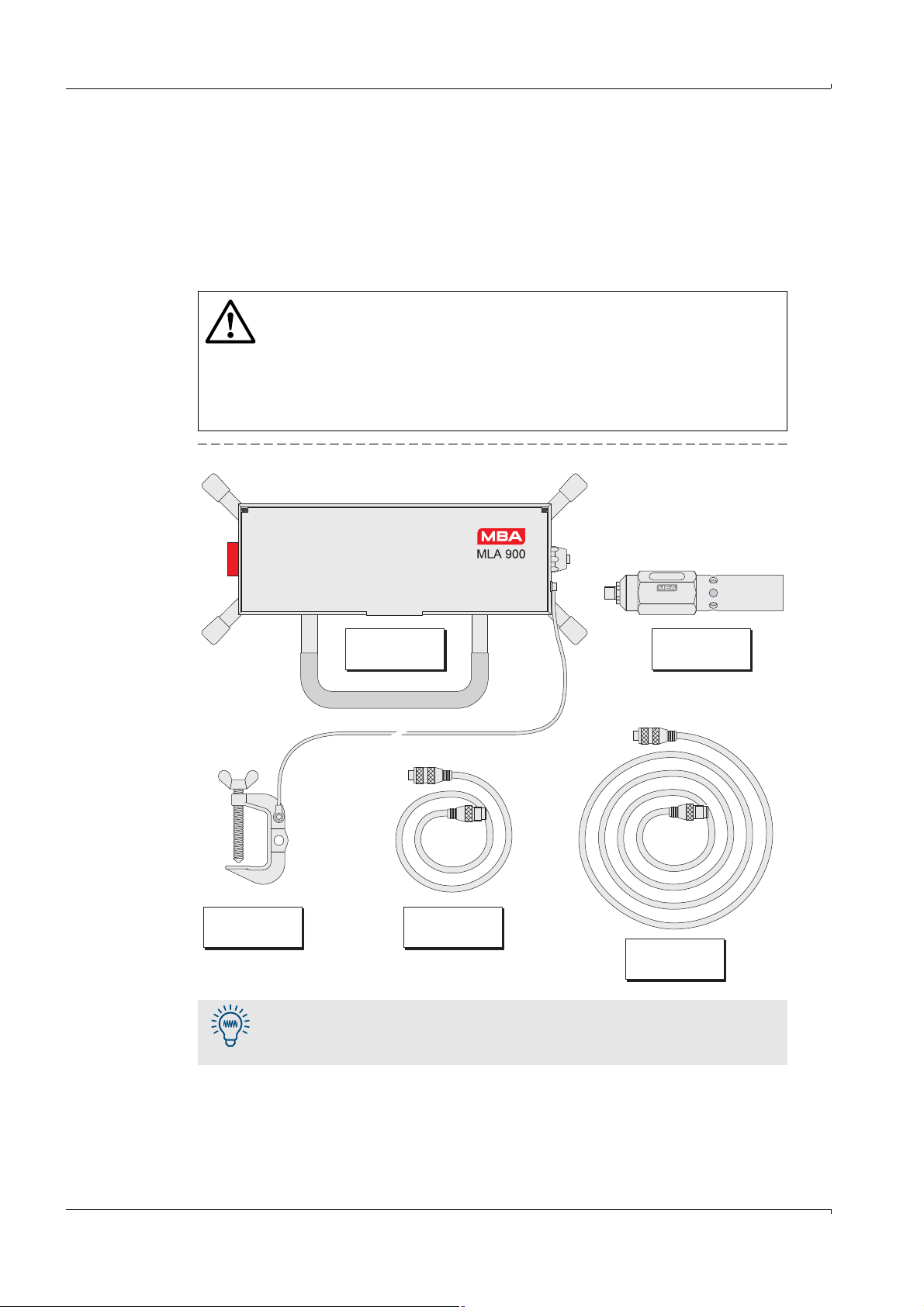

When delivered, the MLA 900 consists of:

● display unit with ground clamp

● measuring probe

● probe cable, 2 m long

● probe cable, 10 m long

● transport case

VORSICHT: Risk of damage

● Tight bending may damage the cable (cable breaks).

● Damaged cables must not be used in hazardous locations.

b

Never buckle the probe cable and do not bend the cables too far.

b

At temperatures below 0 °C (32 °F), treat the probe cable with particular

care – because the cable sheath may become brittle at these temperatures.

Avoid tight bending (risk of breakage).

Bild 1 MLA 900 supply schedule

ground clamp

● Keep the transport box even if you do not wish to use it when operating the

● List of spare parts

display unit

probe cable

2m

MLA 900. It may be useful as a shipping packaging.

→

S. 30, §5.3

measuring

probe

probe cable

10 m

12 MLA 900 Operating Instructions V2.0 8011381 © MBA Instruments GmbH

Loading...

Loading...