Mazda TTCC007700-1155-0011H, TC070-15-01H Owner's Manual

LLEEVVEELL 11

Air Conditioning

Operation & Diagnosis

TTCC007700--1155--0011H

H

Student Guide

Mazda Motor Corporation

Technical Service Training

AIR CONDITIONING

SG00 - General

SG00-1

-

-

OUTLINE

Air conditioning operation & diagnosis course is 2-day training and centered on

Manual air conditioning system. Through this course, you can learn most frequent

services for air conditioning, such as Performance check, Refrigerant charge, and

Symptom troubleshooting.

The course begins with reviewing A/C Fundamentals (Mazda Masters Level F); you

are required to bring your textbook “A/C Fundamentals” to this training session.

Student guide and Student activity sheet are to be provided before the session starts.

In the Student guide and the Student activity sheet, you will find some questions and

tables that some information is intentionally removed. Try to answer to the question in

reference to what you have learnt so far and get information from relevant service

materials, such workshop manual and wiring diagram.

NOTE This course is developed based on the service materials of Mazda 3 included

in the CD-ESI (Electronic Service Information) 2/2004 Ver. 3.0 CD08-XX-04BE.

OBJECTIVES

After completing this course, you will be able to:

Describe a refrigeration cycle and what part the components play in the

cooling process.

Identify major components of a manual A/C system

Identify the components of Manual Air Conditioner and distinguish the

components from those of Full-auto Air Conditioner.

Describe a control system and how the system controls the Manual Air

Conditioner.

Identify major components of a manual A/C system

Locate A/C system protection devices

Explain the function of protection devices

Conduct A/C performance checks

Perform A/C refrigerant charging

Perform checks for A/C components

Isolate trouble cause based on Symptom based approach

AIR CONDITIONING

SG00 - General

SG00-2

-

-

CONTENTS

SG00 – General

SG01 – Basic System

Activity01 - Identifying A/C Components

Activity02 - Locating A/C Protection Devices

Activity03 - A/C performance Check

Activity04 - Refrigerant Charging

SG02 – Control System [Manual Air-conditioning]

Activity05 - Units and parts checks*

Activity06 - Symptom troubleshooting

AIR CONDITIONING

SG00 - General

SG00-3

-

-

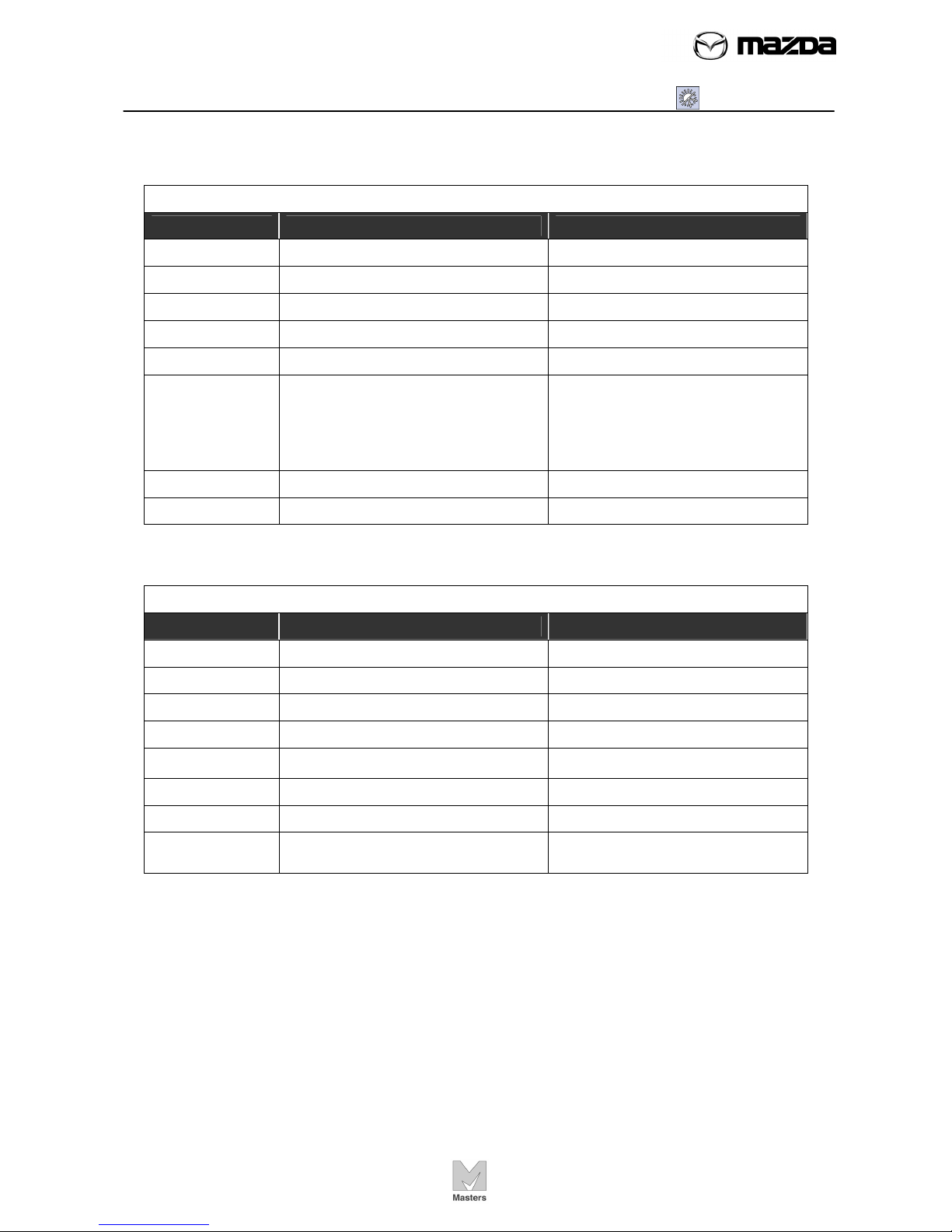

TIMETABLE

Day 1

Time Session Remark

8:30 – 9:00 Introductions

9:00 – 10:20 Review A/C Fundamentals A/C Fundamentals textbook

10:20 – 10:30 Break

10:30 – 11:50 Basic System SG (Classroom)

12:00 – 13:00 Lunch

13:00 – 14:50

Identifying AC Components

Locating AC Protection Devices

Refrigerant Pressure Check

SG Activity (Workshop)

14:50 – 15:00 Break

15:00 – 17:00 Performance Check SG Activity (Workshop)

Day 2

Time Session Remark

8:30 – 9:50 Control System SG (Classroom)

9:50 – 10:00 Break

10:00 – 11:50 Units and parts checks SG Activity (Workshop)

12:00 – 13:00 Lunch

13:00 – 14:50 Symptom troubleshooting SG Activity (Workshop)

14:50 – 15:00 Break

15:00 – 16:40 Course completion test

16:40 – 17:00

Session evaluation

Conclusion

Attendees satisfaction survey

This schedule is subject to change when necessary.

AIR CONDITIONING

SG00b - Pre-Test

SG00b-1

-

-

1. Technician A says the refrigerant used in the A/C system absorbs and releases

large amounts of heat as it changes from a liquid to a gas.

Technician B says as the refrigerant circulates through the tubes and hoses of an

operating A/C system, it constantly changes from a liquid to a gas and back to a

liquid again.

Who is correct?

a. Technician A

b. Technician B

c. Both Technicians

d. Neither technician

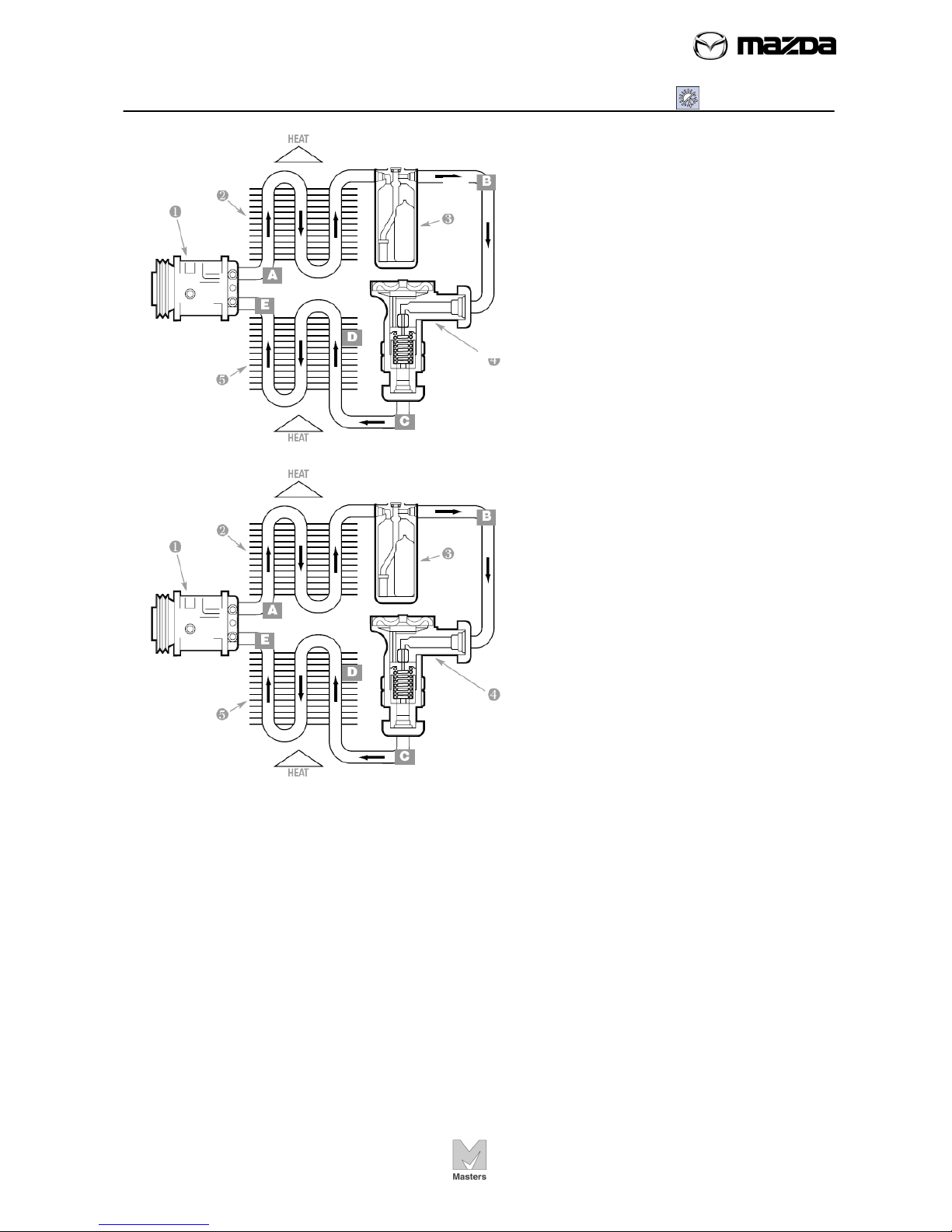

2. Technician A says that at point E in

this illustration the refrigerant is high

pressure vapor.

Technician B says at point E in this

illustration the refrigerant is a low

pressure vapor.

Who is correct?

a. Technician A

b. Technician B

c. Both Technicians

d. Neither technician

3. One BTU is the amount of heat needed at sea level to raise the temperature of

one pound of water;

a. One degree Centigrade

b. Ten degrees Centigrade

c. Ten degrees Fahrenheit

d. One degree Fahrenheit

4. Technician A says the latent heat applied to change a substance from a liquid to a

vapor is called the latent heat of vaporization.

Technician B says the latent heat applied to change a substance from a liquid to a

vapor is called the latent heat of condensation.

a. Technician A

b. Technician B

c. Both Technicians

d. Neither technician

AIR CONDITIONING

SG00b - Pre-Test

SG00b-2

-

-

5. Technician A says in a Mazda A/C system the refrigerant changes state from a

liquid to a vapor in the compressor while losing heat.

Technician B says the compressor acts as a pump for the refrigerant in an A/C

system.

Who is correct?

a. Technician A

b. Technician B

c. Both Technicians

d. Neither technician

6. Technician A says the compressor increases the temperature of the vaporized

refrigerant without adding heat.

Technician B says the compressor raises the pressure of the vaporized refrigerant

and not the temperature.

Who is correct?

a. Technician A

b. Technician B

c. Both Technicians

d. Neither technician

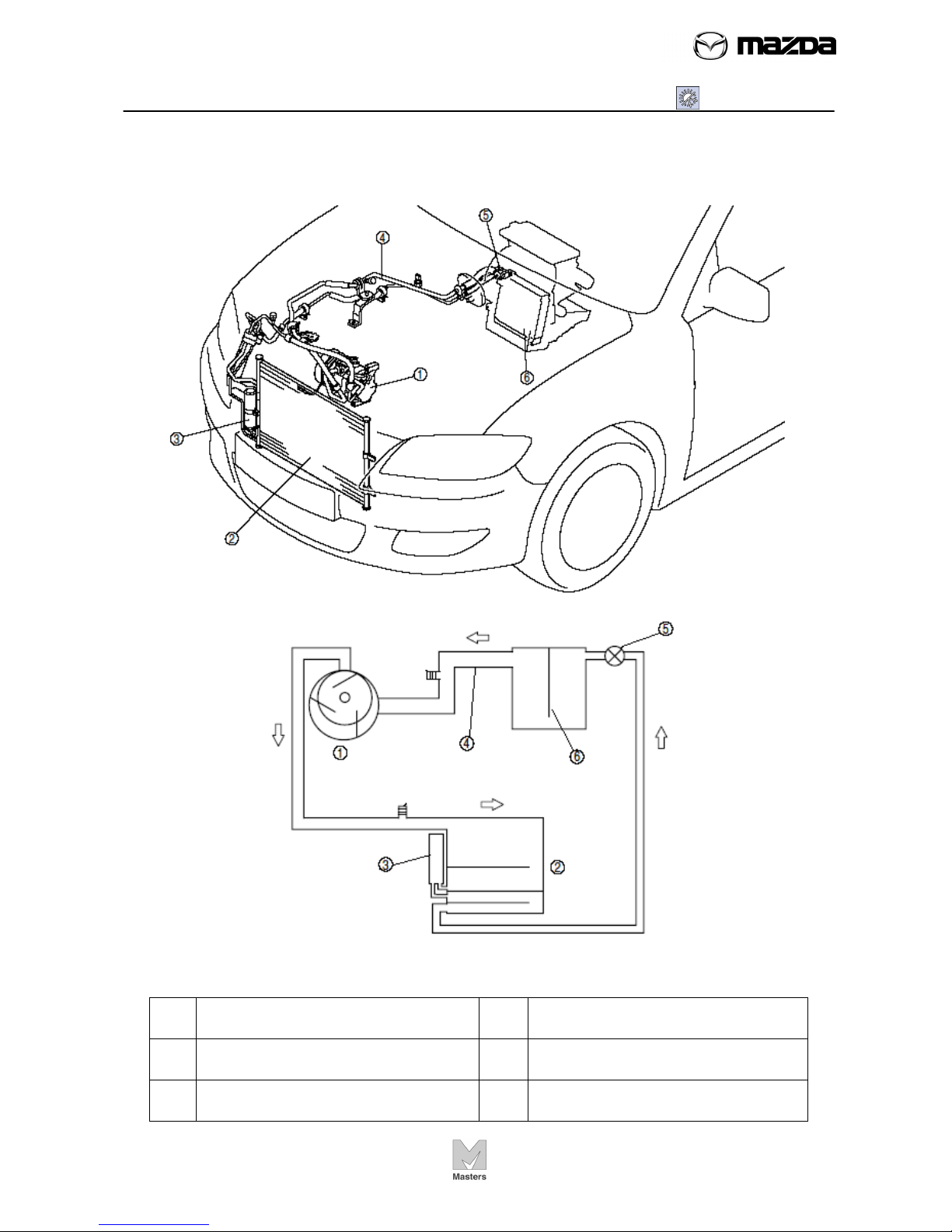

7. Which component in this

illustration receives hot, high

pressure refrigerant gas from the

compressor and transfers the heat to

the outside air.

a. 2

b. 3

c. 4

d. 5

8. Technician A says the expansion valve or orifice tube controls the amount of

refrigerant entering the evaporator.

Technician B says the accumulator regulates the refrigerant flow to the evaporator.

Who is correct?

a. Technician A

b. Technician B

c. Both Technicians

d. Neither technician

AIR CONDITIONING

SG00b - Pre-Test

SG00b-3

-

-

9. Which component in this

illustration removes heat from the

passenger compartment and

transfers it to the refrigerant?

a. 2

b. 3

c. 4

d. 5

10. At point A the refrigerant is;

a. High pressure liquid

b. High pressure vapor

c. Low pressure liquid

d. Low pressure vapor

11. Technician A says R-12 and R-134a system have different-sized service valves,

to prevent accidental mixing of refrigerants.

Technician B says R-134a systems use larger, metric-thread, quick connect service

valves.

Who is correct?

a. Technician A

b. Technician B

c. Both Technicians

d. Neither technician

123

4

5

AIR CONDITIONING

SG00b - Pre-Test

SG00b-4

-

-

12. Technician A says do not expose refrigerant to open flame. R-12 may produce

poisonous phosgene gas, and R-134a may support combustion.

Technician B says a propane torch style leak detector is the best type of detector for

R-12 and R134a systems.

Who is correct?

a. Technician A

b. Technician B

c. Both Technicians

d. Neither technician

13. Technician A says if refrigeration oil is not sealed properly, it will absorb moisture

from the air.

Technician B says you can reuse refrigeration oil removed from an operating A/C

system.

Who is correct?

a. Technician A

b. Technician B

c. Both Technicians

a. Neither technician

14. Technician A says after repairs have been performed, or if a system has been

open for a long period of time, the system must be evacuated to remove moisture

and ensure that it will hold a vacuum.

Technician B says the minimum time any system should be evacuated is 15 minutes.

The longer the system has been open, the longer it should be evacuated.

Who is correct?

a. Technician A

b. Technician B

c. Both Technicians

d. Neither technician

15. Technician A says all refrigerant should be recovered and recycled.

Technician B says only R-12 needs to be recovered and recycled.

Who is correct?

a. Technician A

b. Technician B

c. Both Technicians

d. Neither technician

AIR CONDITIONING

SG00b - Pre-Test

SG00b-5

-

-

16. Technician A says the accumulator traps liquid refrigerant allowing it time to

completely vaporize.

Technician B says if liquid refrigerant reaches the compressor it could be damaged.

Who is correct?

a. Technician A

b. Technician B

c. Both Technicians

d. Neither technician

17. Technician A says small refrigerant leaks are normal and the refrigerant should

be replaced once a year as a maintenance item.

Technician B says if the refrigerant has leaked out of an A/C system the technician

should charge the system with a small amount of refrigerant for leak testing purposes.

Who is correct?

a. Technician A

b. Technician B

c. Both Technicians

d. Neither technician

18. This method of charging an A/C system adds gaseous refrigerant through the

low-side service valve while the compressor is running.

a. Liquid charging

b. Vapor charging

c. Both answers a and b

d. Neither answer a or b

19. The component in this illustration divides the A/C system into high and low

pressure sides, what is it?

a. Fixed orifice tube

b. Expansion valve

c. Accumulator

d. Receiver dryer

AIR CONDITIONING

SG00b - Pre-Test

SG00b-6

-

-

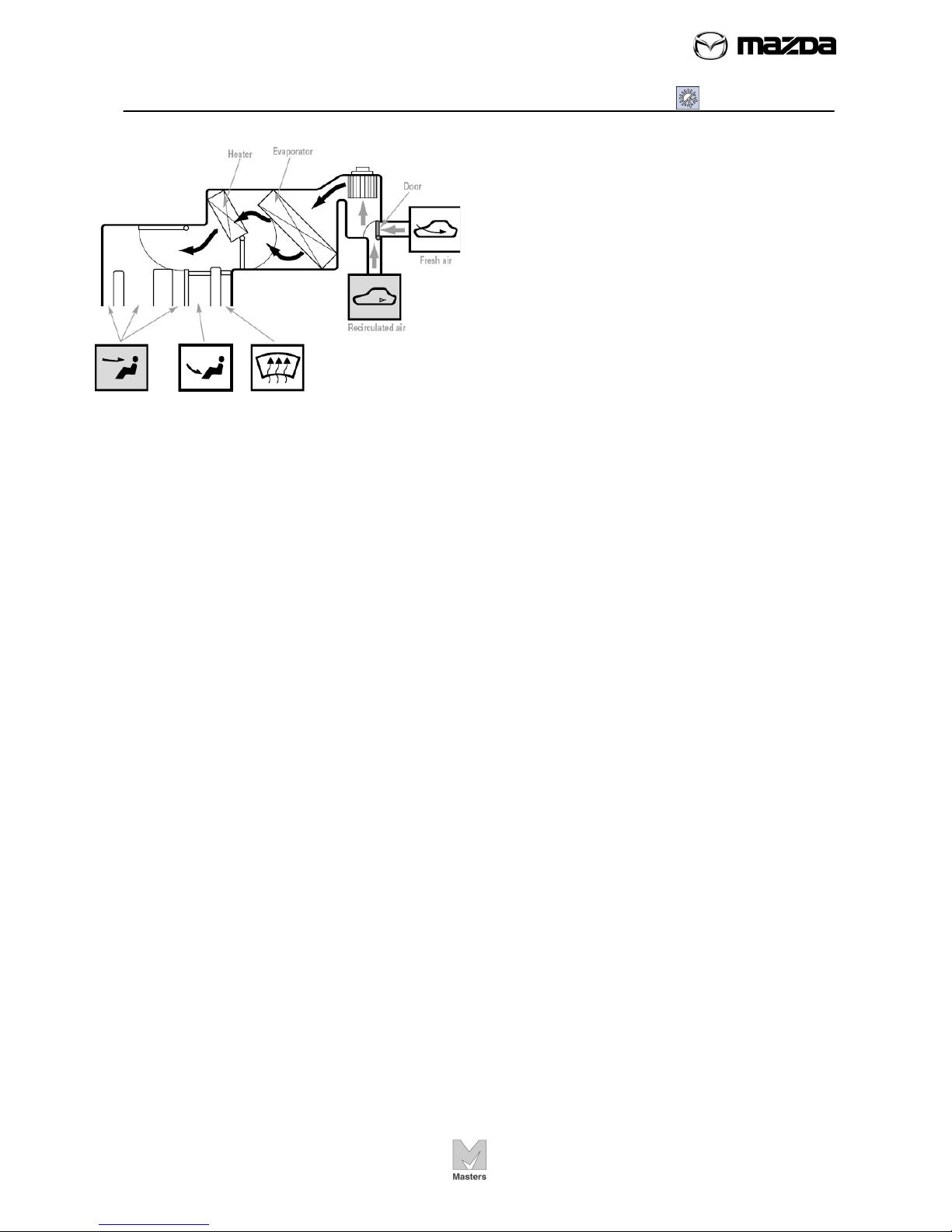

20. Which statement is true about this

climate control plenum assembly?

a. All air passes through the

evaporator

b. The air is being re-circulated

c. The temperature blend door is set

for max heat

d. All the above

AIR CONDITIONING

SG01 - Basic System

SG01-1

-

-

OBJECTIVES

After completing this section, you will be able to:

Describe a refrigeration cycle and what part the components play in the

cooling process.

Identify major components of a manual A/C system

Activities To complete this section, you will perform the following activities:

Activity Title/Description Location

AC01 Identifying A/C Components Shop

AC02 Locating A/C Protection Devices Shop

AC03 A/C performance Check Shop

AC04 Refrigerant Charging Shop

In this section:

Basic System

A/C Components ........................................................................................... 2

A/C Unit construction/operation ..................................................................... 3

Evaporator ..................................................................................................... 4

Expansion valve ............................................................................................ 4

Air Mix Door Operation .................................................................................. 5

Airflow Mode Door Operation ........................................................................ 5

Air filter function ............................................................................................. 6

A/C compressor ............................................................................................. 6

Condenser ..................................................................................................... 7

Refrigerant life ............................................................................................... 7

Spring-lock Coupling ..................................................................................... 8

Gauge manifold reading ................................................................................ 9

Refrigerant System Service Warnings (Reference) ....................................... 10

Refrigerant System Service Cautions ............................................................ 10

AC abbreviation ............................................................................................. 12

Item Specification .......................................................................................... 12

Review Exercise ............................................................................................ 13

NOTE

This SG: Student Guide is developed based on Mazda 3.

AIR CONDITIONING

SG01 - Basic System

SG01-2

-

-

A/C Components

Name the components.

AIR CONDITIONING

SG01 - Basic System

SG01-3

-

-

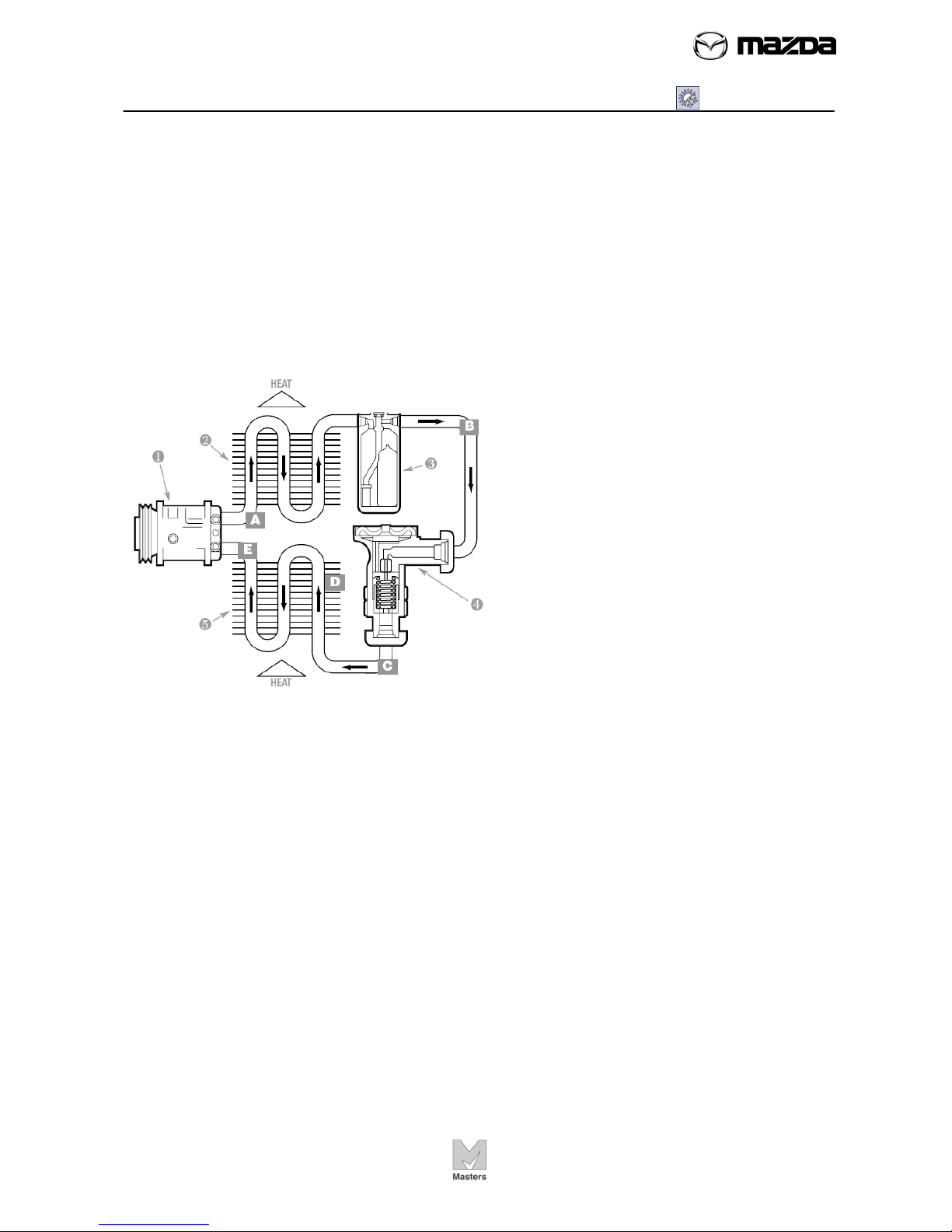

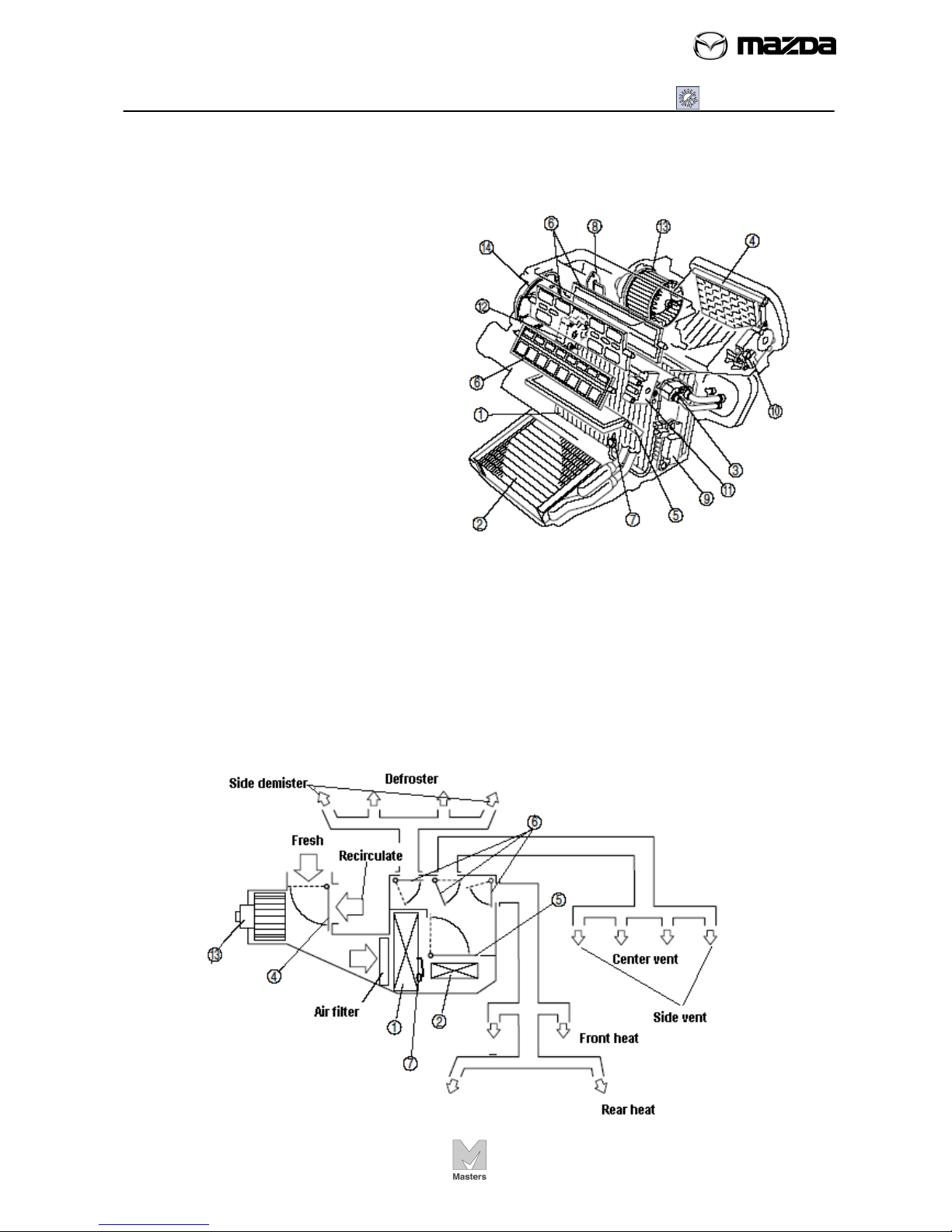

A/C unit construction/operation

• The figure below shows A/C unit which integrates the blower, cooling and heater

units.

1. Evaporator*

2. Heater core*

3. Expansion valve

4. Air intake door*

5. Air mix door*

6. Airflow mode door*

7. Evaporator temperature

sensor*

8. Resistor (manual air conditioner)

9. Power MOS FET (full-auto air conditioner)

10. Air intake actuator

11. Air mix actuator (full-auto air conditioner)

12. Airflow mode actuator (full-auto air conditioner)

13. Blower motor*

14. Airflow mode main link

* Also refer to the figure below “Ventilation System”

Ventilation System

AIR CONDITIONING

SG01 - Basic System

SG01-4

-

-

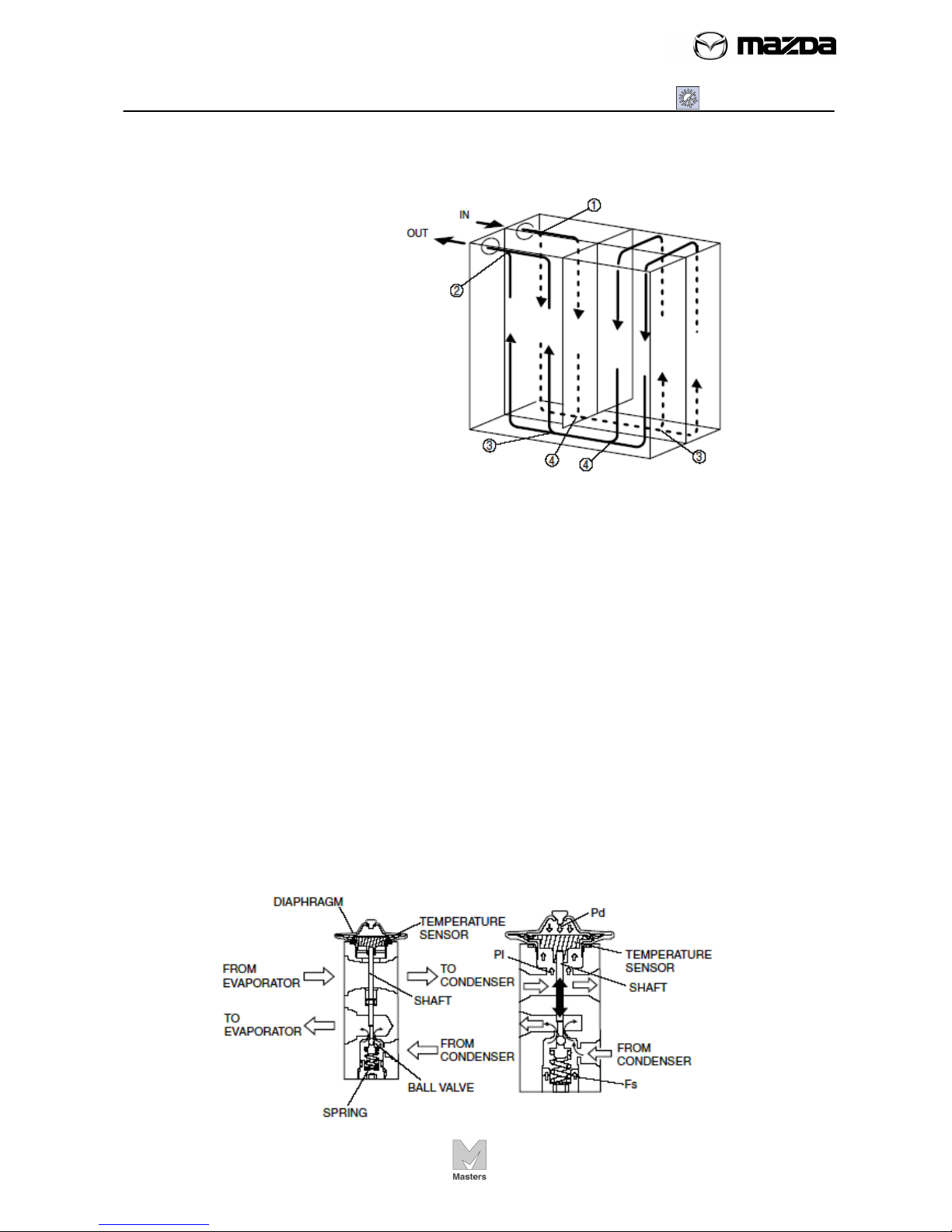

Evaporator

• The figure below shows a double-tank drawn cup.

1. Separation part

2. Rejoining point

3. Separation part

4. Rejoining point

Expansion valve

• The liquid refrigerant of about 1.5 MPa is sprayed at the expansion valve. The

splayed refrigerant is, then, expanded its volume that causes its pressure decreased

to about 0.2 MPa. This makes the refrigerant to be vaporized causing reduction of

temperature. The expansion valve regulates the flow volume of the refrigerant.

• The amount of refrigerant delivered to the evaporator is adjusted by the opening

angle of the ball valve in the expansion valve.

• Opening angle is adjusted by a balance of the R-134a pressure (Pd) in the

diaphragm, and a composite force of evaporator discharge pressure (PI) against the

lower part of the diaphragm and spring force (Fs) pushing up the ball valve. When

PI increases, the temperature of the temperature sensor near the diaphragm rises

and the Pd heated by the R-134a in the diaphragm increases. When the Pd

increases more than PI + Fs, the diaphragm is pushed down, and the shaft attached

to end of the temperature sensor rod pushes down the ball valve, increasing the

amount of liquid refrigerant flow. When the evaporator discharge refrigerant

temperature decreases, PI + Fs increases more than Pd, the ball valve is pushed

up, and the amount of liquid refrigerant flow decreases.

AIR CONDITIONING

SG01 - Basic System

SG01-5

-

-

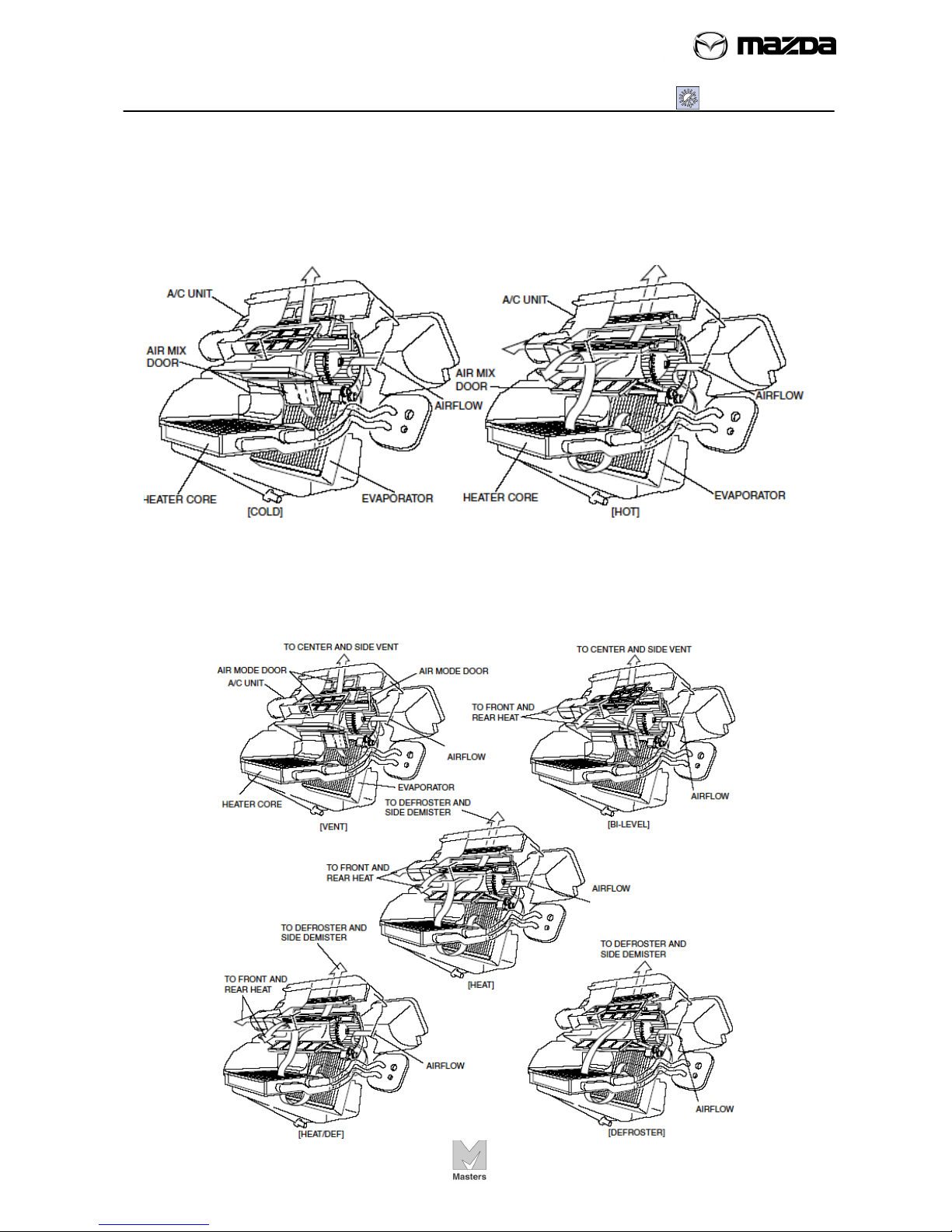

Air Mix Door Operation

• The air mix door, installed in the A/C unit, controls HOT or COLD position,

depending on the position of the temperature control dial. As a result, airflow

distribution changes, and the airflow temperature is controlled.

Airflow Mode Door Operation

• The airflow mode doors move to VENT, BI-LEVEL, HEAT, HEAT/DEF, or

DEFROSTER position, depending on the position of the airflow mode selector dial.

AIR CONDITIONING

SG01 - Basic System

SG01-6

-

-

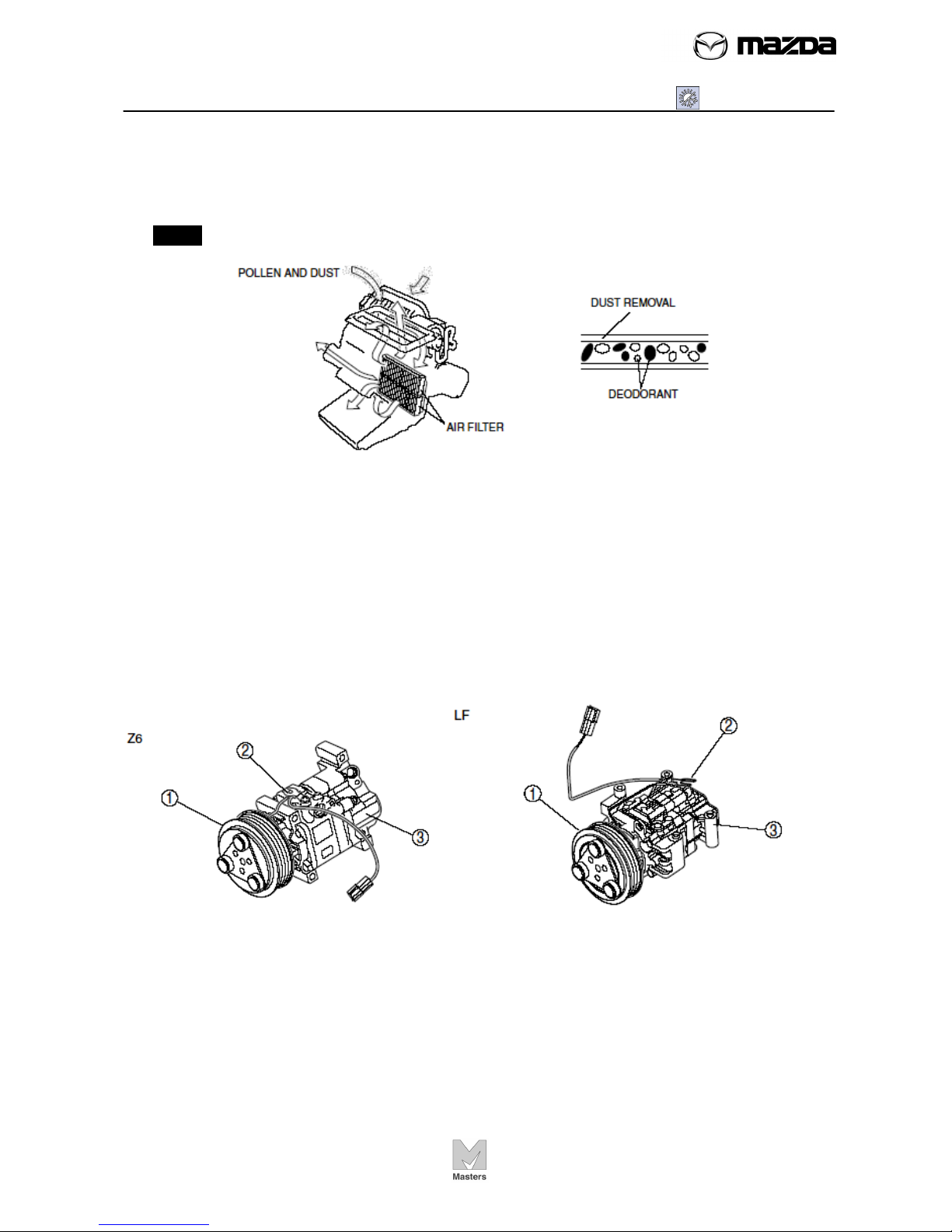

Air filter function

• The figure below shows air filter that can remove pollen and dust has been added.

• The air filter cannot be reused and must be replaced periodically.

NOTE Even new air filters are gray; be careful not to mistake the gray color as dirt.

A/C compressor

• A rotary-vane type (H12A1) A/C compressor body has been adopted for size,

weight, and operation vibration reduction.

1. Magnetic clutch

2. Thermal protector

3. A/C compressor

AIR CONDITIONING

SG01 - Basic System

SG01-7

-

-

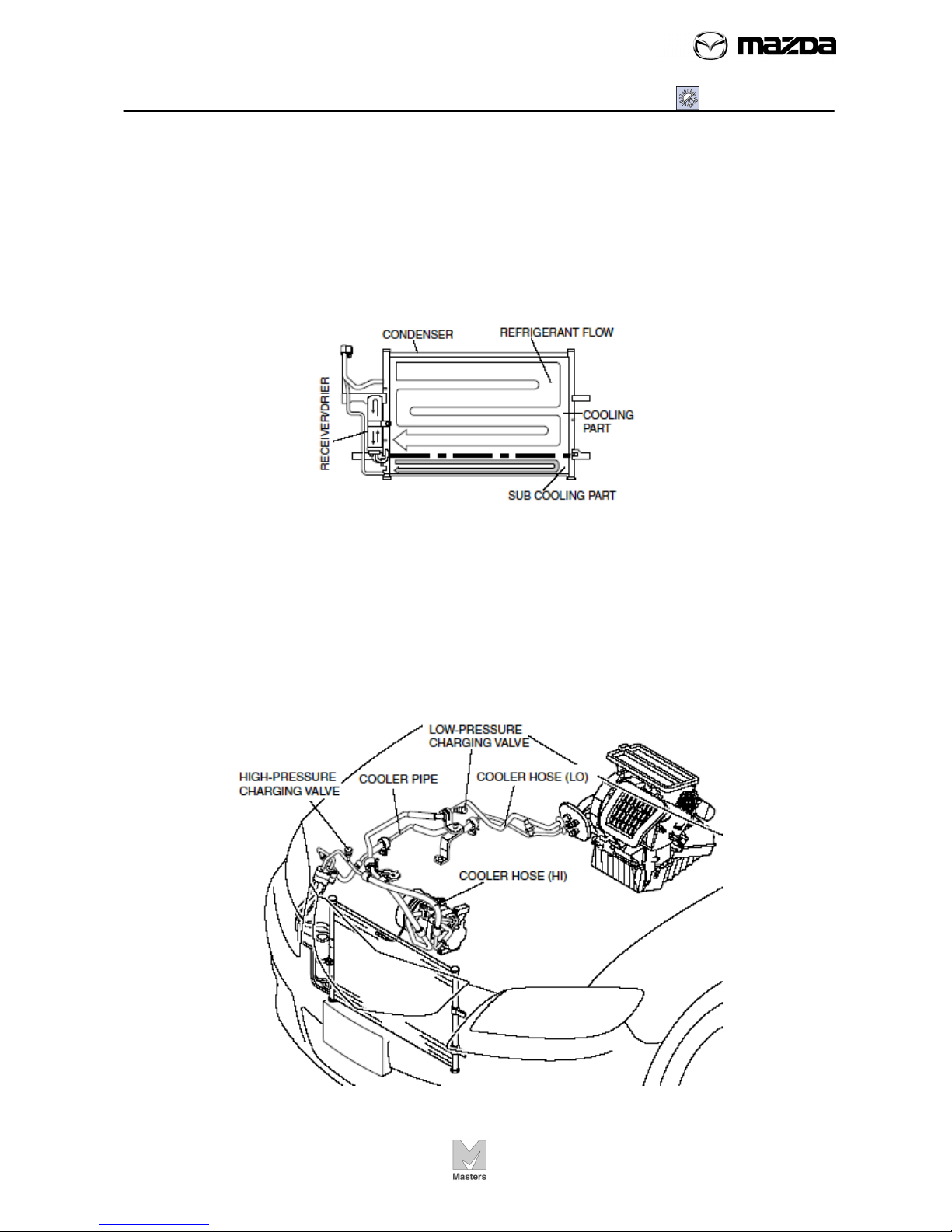

Condenser

• The figure below shows a sub cool condenser. It is a multi-flow condenser which is

equipped with a sub cooling part and integrated with a receiver/drier.

• The sub cool condenser separates liquid-gas refrigerant initially cooled at the

condenser via the receiver/drier, where it returns again to the condenser sub cooling

part and is cooled, accelerating liquefaction and improving cooling capacity.

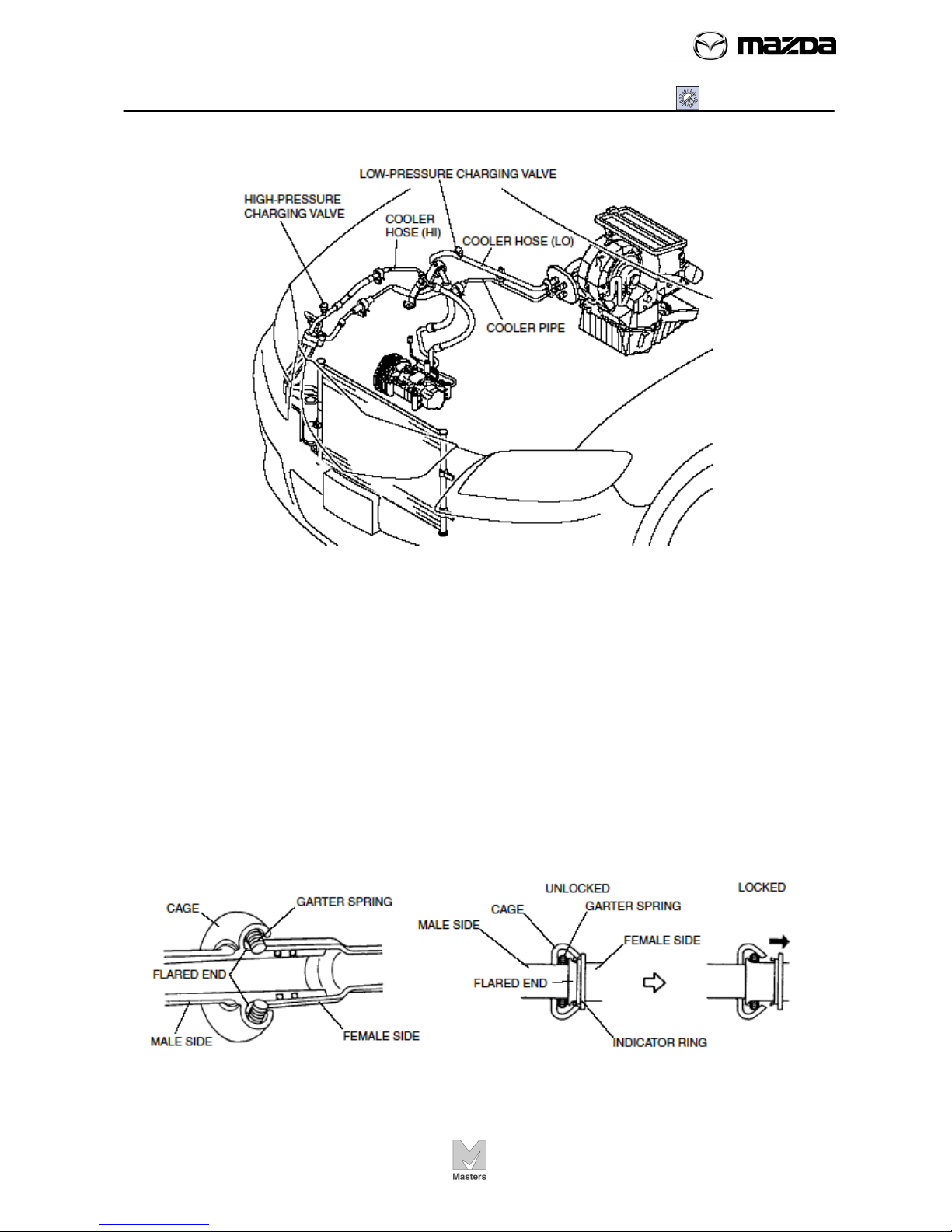

Refrigerant life

• The pipes in the refrigerant lines are made of aluminum alloy and the hoses are

made of rubber (flexible hose).

• A high-pressure charging valve is located on the cooler hose (HI) and a lowpressure charging valve is located on the cooler hose (LO).

Z6

AIR CONDITIONING

SG01 - Basic System

SG01-8

-

-

LF

Spring-lock Coupling

• Spring-lock coupling is used for pipe-to-pipe connections. As a result, pipes can be

connected easily, maintenance of torque is unnecessary, and serviceability is

improved.

• There is a garter spring in the cage on the male side (cooler pipe or cooler hose

(LO)) of spring-lock coupling type and the end of the pipe on the female side (A/C

unit) is flared. When the pipes are being connected, the flared end of the female

side forces the garter spring on the female side to expand, and by fully inserting the

male side into the female side, the flared end is locked by the garter spring. When

the cooler pipe or cooler hose (LO) is replaced, the additional indicator ring comes

out after connecting; indicating that the flared end is locked.

AIR CONDITIONING

SG01 - Basic System

SG01-9

-

-

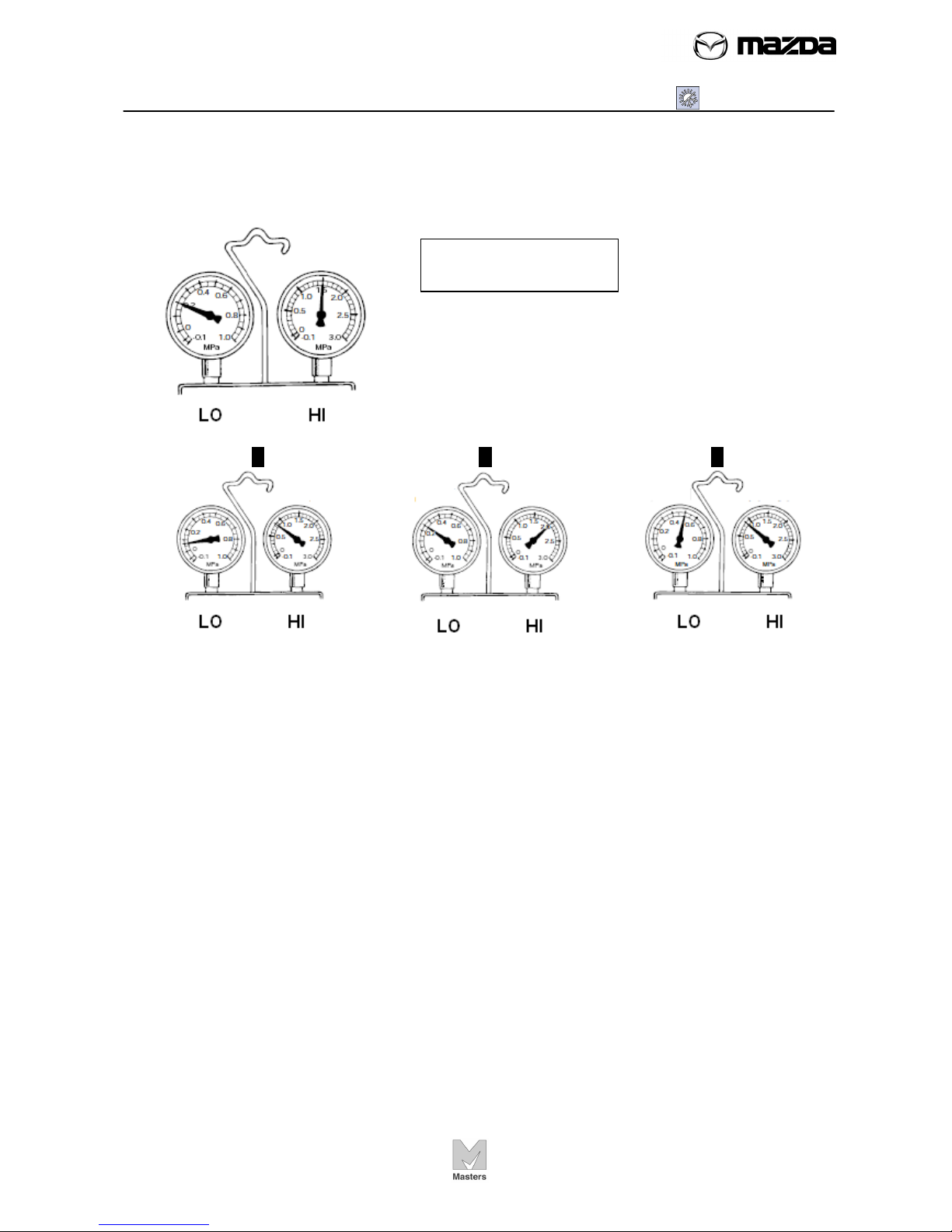

Gauge manifold reading

Normal

LO: 0.15 – 0.25 MPa

HI: 1.37 – 1.57 MPa

It may vary under the different condition.

A B C

A: Insufficient refrigerant

B: Excessive refrigerant or insufficient cooling

C: Compressor failure

AIR CONDITIONING

SG01 - Basic System

SG01-10

-

-

Refrigerant System Service Warnings (Reference)

Handling Refrigerant

• Avoid breathing air conditioning refrigerant or lubricant vapor. Exposure may irritate

eyes, nose and throat. Also, due to environmental concerns, we urge use of

recovery/recycling/recharging equipment when draining R-134a from the air

conditioning system. If accidental system discharge occurs, ventilate work area

before resuming service.

• Do not perform pressure test or leak test for R-134a service equipment and/or

vehicle air conditioning system using compressed air. Some mixtures of air and R134a have been shown to be combustible at elevated pressures. These mixtures, if

ignited, may cause injury or property damage. Additional health and safety

information may be obtained from refrigerant manufacturers.

• Do not allow the refrigerant to leak near fire or any kind of heat. A poisonous gas

may be generated if the refrigerant gas contacts fire or heat such as from cigarettes

and heaters. When carrying out any operation that can cause refrigerant leakage,

extinguish or remove the above-mentioned heat sources and maintain adequate

ventilation.

• Handling liquid refrigerant is dangerous. A drop of it on the skin can result in

localized frostbite. When handling the refrigerant, wear gloves and safety goggles. If

refrigerant splashes into the eyes, immediately wash them with clean water and

consult a doctor.

Storing Refrigerant

• The refrigerant container is highly pressurized. If it is subjected to high heat, it could

explode, scattering metal fragments and liquid refrigerant that can seriously injure

you. Store the refrigerant at temperatures below 40 °C {104 °F}.

Refrigerant System Service Cautions

Handling Insufficient Refrigerant Level

• If an insufficient refrigerant level is detected at troubleshooting, do not charge (add)

the refrigerant. Because an accurate amount of refrigerant cannot be determined

from the pressure indicated on the manifold gauge, never charge the refrigerant. If

there is too much or too little refrigerant from the refilling, there may be secondary

problems such as damage to the refrigerant cycle parts, or a decrease of cooling

performance. Therefore, if it is determined that the refrigerant level is insufficient,

completely remove refrigerant from the refrigerant cycle and refill with refrigerant to

the specified amount.

AIR CONDITIONING

SG01 - Basic System

SG01-11

-

-

Handling Compressor Oil

• Use only ATMOS GU10 compressor oil for this vehicle. Using a PAG oil other than

ATMOS GU10 compressor oil can damage the A/C compressor.

• Do not spill ATMOS GU10 compressor oil on the vehicle. A drop of compressor oil

on the vehicle surface can eat away at the paint. If oil gets on the vehicle, wipe it off

immediately.

• ATMOS GU10 compressor oil (PAG oil) has higher moisture absorption efficiency

than the previously used mineral oil. If moisture mixes with the compressor oil, the

refrigerant system could be damaged. Therefore, install caps immediately after

using the compressor oil or removing refrigerant system parts to prevent moisture

absorption.

Moisture Absorption

0

• If the refrigerant gas is completely discharged from the system for reasons such as

a malfunction during A/C operation, repair or replace the malfunctioning part, charge

the refrigerant to the specified amount and always add 60 ml {60 cc, 2.03 fl oz} of

compressor. If the compressor oil is not adequately replenished, the A/C

compressor may quickly deteriorate, abnormal noise may develop, cooling

performance may be affected or, in the worst case, the A/C compressor may seize.

AIR CONDITIONING

SG01 - Basic System

SG01-12

-

-

HVAC ABBREVIATION

A/C: Air Conditioning

B+: Battery Positive Voltage

CAN: Control Area Network

CPU: Central Processing Unit

HI: High

IG: Ignition

ISO: International Organization for Standardization

LO: Low

M: Motor

MAX: Maximum

OFF: Switch Off

ON: Switch On

PCM: Powertrain Control Module

REC: Recirculate

SW: Switch

Item Specification (Mazda 3)

Heating capacity (kW {kcal/h}): 4.550 {3,913}

Cooling capacity (kW {kcal/h}): 3.960 {3,406}

Refrigerant

Type: R-134a

Regular amount: (approx. quantity) (g {oz}) 525 {18.5}

A/C compressor

Type: Vane-rotary

Discharge capacity (ml {cc, fl oz}): 120 {120, 4.06}

Max. allowable speed (rpm): 6,400/Z6, 7,200/LF

Lube oil

Type: ATMOS GU10

Sealed volume (approx. quantity) (ml {cc, fl oz}): 120 {120, 4.06}/Z6,

150 {150, 5.07}: LF

Condenser

Type: Multi-flow (sub-cooling type)

Radiated heat (kW {kcal/h}): 6.600 {5,680}

Receiver/drier capacity (ml {cc, fl oz}): 180 {180, 6.08}

Desiccant: Synthetic zeolite

Expansion valve type: Block type

Evaporator type: Double-tank drawn cup

Temperature control: Reheat full air mix type

Loading...

Loading...