Page 1

Engine

CONTENTS

Workshop

Manual

SKYACTIV-G 2.5

FOREWORD

This manual explains the service points for

the above-indicated automotive system.

This manual covers all models with the

above-indicated automotive system, not any

one specific model.

In order to do these procedures safely,

quickly, and correctly, you must first read

this manual and any other relevant service

materials carefully.

All the contents of this manual, including

drawings and specifications, are the latest

available at the time of printing.

As modifications affecting repair or

maintenance occur, relevant information

supplementary to this volume will be made

available at Mazda dealers. This manual

should be kept up-to-date.

Title Section

GENERAL INFORMATION 00

ENGINE

© 2012 Mazda Motor Corporation

PRINTED IN U.S.A., DECEMBER 2012

Form No. 1A36–1U–12L

Part No. 9999–95–EWPY–14

01

Mazda Motor Corporation reserves the right

to alter the specifications and contents of

this manual without obligation or advance

notice.

All rights reserved. No part of this book may

be reproduced or used in any form or by any

means, electronic or mechanical—including

photocopying and recording and the use of

any kind of information storage and retrieval

system—without permission in writing.

Mazda Motor Corporation

HIROSHIMA, JAPAN

Page 2

Page 3

WARNING

Servicing a vehicle can be dangerous. If you have not received

service-related training, the risks of injury, property damage, and

failure of servicing increase. The recommended servicing procedures

for the vehicle in this workshop manual were developed with

Mazda-trained technicians in mind. This manual may be useful to

non-Mazda trained technicians, but a technician with our

service-related training and experience will be at less risk when

performing service operations. However, all users of this manual are

expected to at least know general safety procedures.

This manual contains "Warnings" and "Cautions" applicable to risks

not normally encountered in a general technician's experience.

They should be followed to reduce the risk of injury and the risk

that improper service or repair may damage the vehicle or render it

unsafe. It is also important to understand that the "Warnings" and

"Cautions" are not exhaustive. It is impossible to warn of all

the hazardous consequences that might result from failure to follow

the procedures.

The procedures recommended and described in this manual are

effective methods of performing service and repair. Some require tools

specifically designed for a specific purpose. Persons using procedures

and tools which are not recommended by Mazda Motor Corporation

must satisfy themselves thoroughly that neither personal safety nor

safety of the vehicle will be jeopardized.

The contents of this manual, including drawings and specifications, are

the latest available at the time of printing, and

reserves the right to change the vehicle designs and alter the contents

of this manual without notice and without incurring obligation.

Parts should be replaced with genuine Mazda replacement parts or

with parts which match the quality of genuine Mazda replacement

parts. Persons using replacement parts of lesser quality than that of

genuine Mazda replacement parts must satisfy themselves thoroughly

that neither personal safety nor safety of the vehicle will be

jeopardized.

Mazda Motor Corporation is not responsible for any problems which

may arise from the use of this manual. The cause of such problems

includes but is not limited to insufficient service-related training, use of

improper tools, use of replacement parts of lesser quality than that of

genuine Mazda replacement parts, or not being aware of any revision

of this manual.

Mazda Motor Corporation

Page 4

GENERAL INFORMATION

Toc of SC T

GENERAL INFORMATION . . . .00-00

Toc of SC T

00-00 GENERAL INFORMATION

00

SECTION

00-00

HOW TO USE THIS MANUAL . . . . . . . . . 00-00–1

Range of Topics . . . . . . . . . . . . . . . . . . 00-00–1

Service Procedure . . . . . . . . . . . . . . . . 00-00–2

Symbols . . . . . . . . . . . . . . . . . . . . . . . . 00-00–4

Advisory Messages. . . . . . . . . . . . . . . . 00-00–4

UNITS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 00-00–5

Conversion From SI Units (Système

International d'Unités) . . . . . . . . . . . . . 00-00–5

Number Of Digits For

Converted Values . . . . . . . . . . . . . . . . 00-00–5

Converted Value Rounding Off And

Rounding Up/down . . . . . . . . . . . . . . . 00-00–5

ABBREVIATIONS. . . . . . . . . . . . . . . . . . . 00-00–6

FUNDAMENTAL PROCEDURES. . . . . . . 00-00–6

End of Toc

WM: GENERAL INFORMATION

HOW TO USE THIS MANUAL

Range of Topics

• This manual contains procedures for performing all required service operations. The procedures are divided

into the following basic operations:

— Removal/Installation

— Disassembly/Assembly

— Replacement

— Inspection

— Adjustment

• Simple operations which can be performed easily just by looking at the actual unit (i.e., removal/installation of

parts, cleaning of parts, and visual inspection) have been omitted.

Preparation of Tools and Measuring

Equipment . . . . . . . . . . . . . . . . . . . . . 00-00–6

Special Service Tools . . . . . . . . . . . . . . 00-00–6

Disassembly. . . . . . . . . . . . . . . . . . . . . 00-00–6

Inspection During Removal,

Disassembly. . . . . . . . . . . . . . . . . . . . 00-00–7

Arrangement of Parts . . . . . . . . . . . . . . 00-00–7

Cleaning of Parts . . . . . . . . . . . . . . . . . 00-00–7

Reassembly . . . . . . . . . . . . . . . . . . . . . 00-00–7

Adjustment . . . . . . . . . . . . . . . . . . . . . . 00-00–8

Rubber Parts and Tubing . . . . . . . . . . . 00-00–8

Torque Formulas . . . . . . . . . . . . . . . . . 00-00–8

Vise . . . . . . . . . . . . . . . . . . . . . . . . . . . 00-00–9

id000000000100

00-00–1

Page 5

GENERAL INFORMATION

Service Procedure

Inspection, adjustment

• Inspection and adjustment procedures are

divided into steps. Important points regarding the

location and contents of the procedures are

explained in detail and shown in the illustrations.

Fluid Pressure Inspection

1. Assemble the SSTs as shown in the figure.

49 1232 670A

SHOWS PROCEDURE ORDER

FOR SERVICE

Tightening torque

39—49 N·m {4.0—5.0 kgf·m, 29—36 ft·lbf}

49 H002 671

Caution

49 H032 322

Connect the gauge set from under

the vehicle to prevent contact with

the drive belt and the cooling fan.

SHOWS TIGHTENING

TORQUE

SPECIFICATIONS

bpe2ue00000101

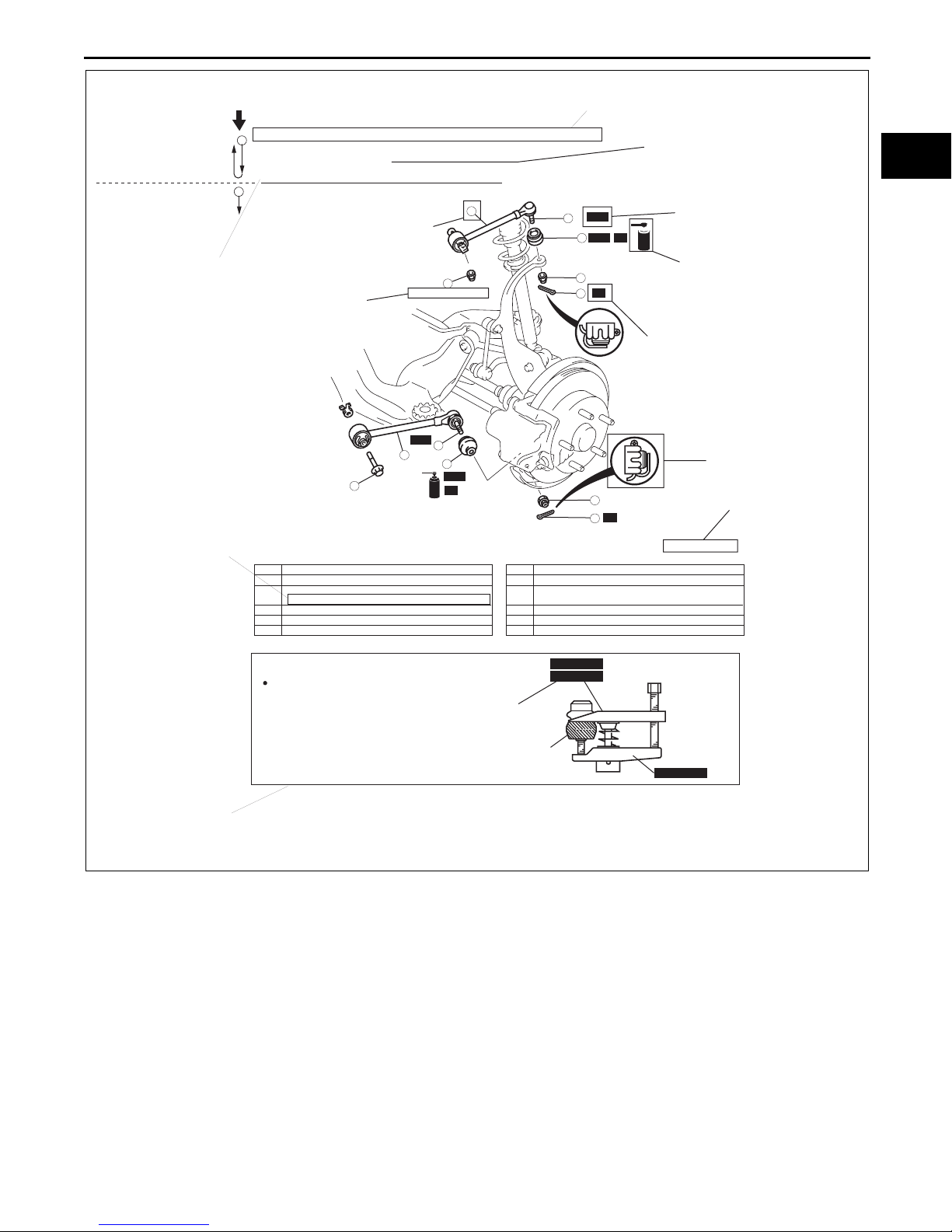

Repair procedure

1. Most repair operations begin with an overview illustration. It identifies the components, shows how the parts fit

together, and describes visual part inspection. However, only removal/installation procedures that need to be

performed methodically have written instructions.

2. Expendable parts, tightening torques, and symbols for oil, grease, and sealant are shown in the overview

illustration. In addition, symbols indicating parts requiring the use of special service tools or equivalent are also

shown.

3. Procedure steps are numbered and the part that is the main point of that procedure is shown in the illustration

with the corresponding number. Occasionally, there are important points or additional information concerning a

procedure. Refer to this information when servicing the related part.

00-00–2

Page 6

GENERAL INFORMATION

GREASE

GREASE

Procedure

"Removal/Installation"

Portion

"Inspection After

Installation" Portion

INSTALL THE PARTS BY

PERFORMING STEPS

—

1—3 IN REVERSE ORDER

SHOWS THERE

ARE REFERRAL

NOTES FOR SERVICE

LOWER TRAILING LINK, UPPER TRAILING LINK REMOVAL/INSTALLATION

1

1. Jack up the rear of the vehicle and suppor t it with safety stands.

2. Remove the undercover. (See 01-10-4 Undercover Removal)

3. Remove in the order indicated in the table.

4. Install in the reverse order of removal.

5. Inspect the rear wheel alignment and adjust it if necessary.

2

11

SHOWS PROCEDURE ORDER

FOR SERVICE

10

44—60 {4.4—6.2, 32—44}

SHOWS TIGHTENING

TORQUE

SPECIFICATIONS

SST

3

5

6

SST

4

94—116 {9.5—11.9, 69—86}

Split pin

1

Nut

2

Lower trailing link ball joint

3

(See 02-14-5 Lower Trailing Link Ball Joint Removal Note)

Bolt

4

Lower trailing link

5

Dust boot (lower trailing link)

6

GREASE

R

7

8 Nut

9 Upper trailing link ball joint

10

11

12

SHOWS SERVICE

ITEM (S)

INDICATES ANY RELEVANT

REFERENCES WHICH NEED

TO BE FOLLOWED DURING

INSTALLATION

SHOWS SPECIAL

SST

9

SST

12

43—56 {4.3—5.8, 32—41}

8

R

7

R

SERVICE TOOL (SST)

FOR SERVICE OPERATION

GREASE

SHOWS APPLICATION

POINTS OF GREASE, ETC.

SHOWS NON-REUSEABLE PARTS

SHOWS DETAILS

118—156 {12.0—16.0, 87—115}

2

R

1

N·m {kgf·m, ft·lbf}

Split pin

(See 02-14-5 Upper Trailing Link Ball Joint Removal Note)

Nut

Upper trailing link

Dust boot (upper trailing link)

00-00

SHOWS TIGHTENING

TORQUE UNITS

Lower Trailing Link Ball Joint, Upper Trailing Link

Ball Joint Removal Note

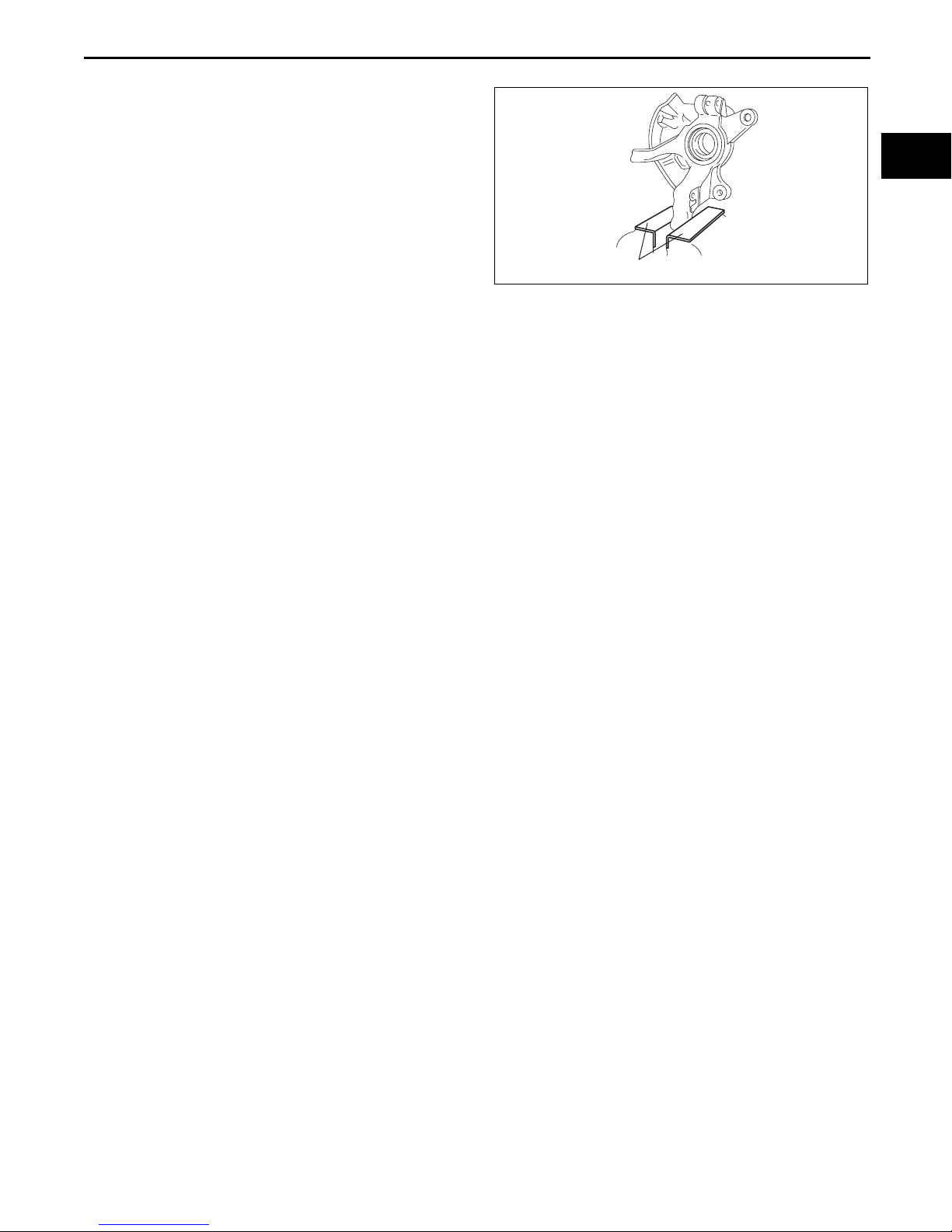

Remove the ball joint using the SSTs.

SHOWS REFERRAL

NOTES FOR

SERVICE

49 T028 304

49 T028 305

UPPER TRAILING LINK

LOWER TRAILING LINK

SHOWS SPECIAL

SERVICE TOOL (SST)

NO.

KNUCKLE

49 T028 303

bpe2ue00000001

00-00–3

Page 7

GENERAL INFORMATION

OIL

BRAKE

FLUID

ATF

GREASE

SEALANT

P

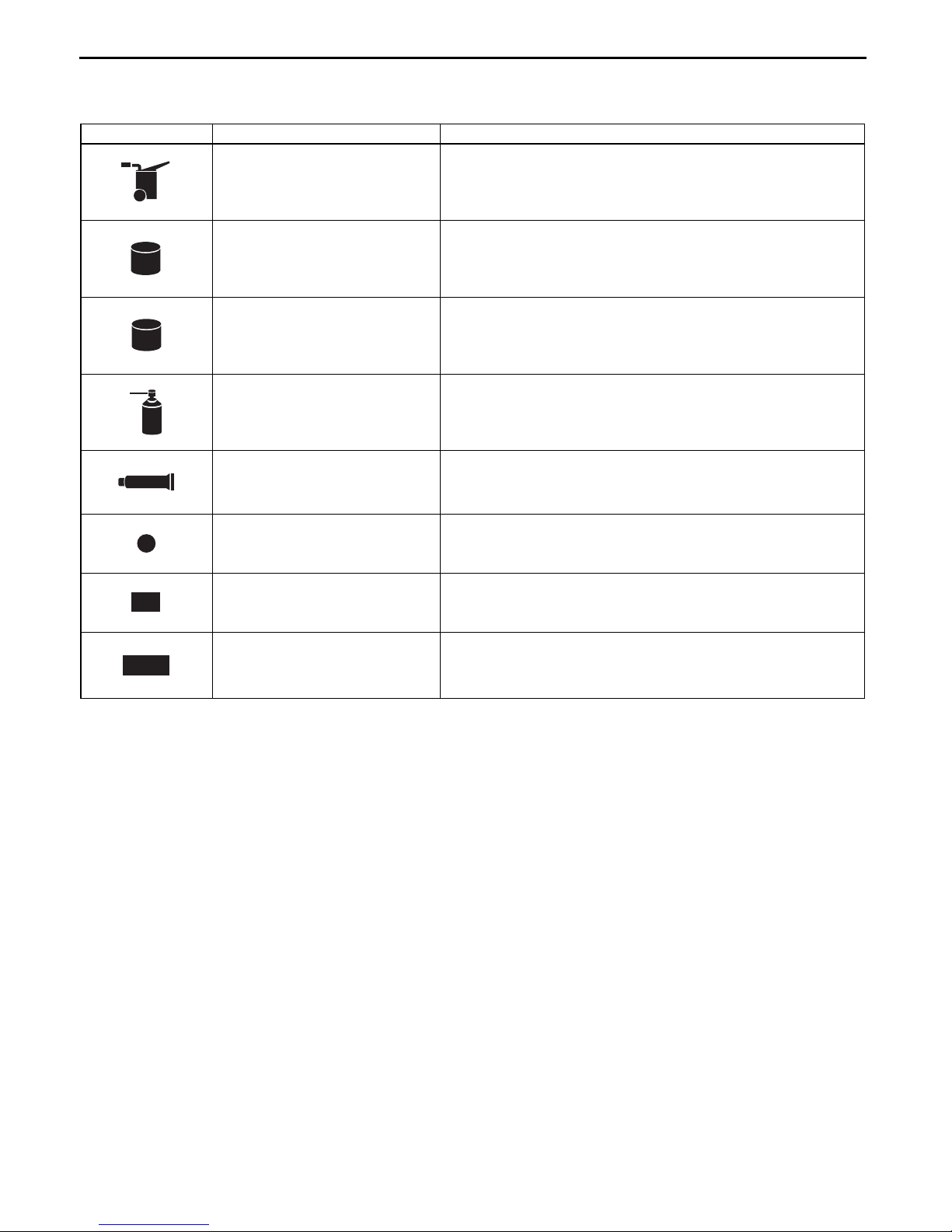

Symbols

• There are eight symbols indicating oil, grease, fluids, sealant, and the use of SST or equivalent. These symbols

show application points or use of these materials during service.

Symbol Meaning Kind

OIL

BRAKE

FLUID

ATF

GREASE

SEALANT

P

R

Apply oil New appropriate engine oil or gear oil

Apply brake fluid New appropriate brake fluid

Apply automatic transaxle/

transmission fluid

New appropriate automatic

transaxle/

transmission fluid

Apply grease Appropriate grease

Apply sealant

Apply petroleum jelly

Appropriate

sealant

Appropriate

petroleum jelly

Replace part O-ring, gasket, etc.

SST

Use SST or

equivalent

Appropriate tools

Advisory Messages

• You will find several Warnings, Cautions, Notes, Specifications and Upper and Lower Limits in this

manual.

Warning

• A Warning indicates a situation in which serious injury or death could result if the warning is ignored.

Caution

• A Caution indicates a situation in which damage to the vehicle or parts could result if the caution is ignored.

Note

• A Note provides added information that will help you to complete a particular procedure.

Specification

• The values indicate the allowable range when performing inspections or adjustments.

Upper and lower limits

• The values indicate the upper and lower limits that must not be exceeded when performing inspections or

adjustments.

End Of Sie

00-00–4

Page 8

GENERAL INFORMATION

UNITS

Electric current A (ampere)

Electric power W (watt)

Electric resistance ohm

Electric voltage V (volt)

Length

Negative pressure

Positive pressure

Number of revolutions rpm (revolutions per minute)

To r qu e

Volum e

Weight

mm (millimeter)

in (inch)

kPa (kilo pascal)

mmHg (millimeters of mercury)

inHg (inches of mercury)

kPa (kilo pascal)

2

kgf/cm

psi (pounds per square inch)

N·m (Newton meter)

kgf·m (kilogram force meter)

kgf·cm (kilogram force centimeter)

ft·lbf (foot pound force)

in·lbf (inch pound force)

L (liter)

US qt (U.S. quart)

Imp qt (Imperial quart)

ml (milliliter)

cc (cubic centimeter)

cu in (cubic inch)

fl oz (fluid ounce)

g (gram)

oz (ounce)

(kilogram force per square centimeter)

id000000100400

00-00

Conversion From SI Units (Système International d'Unités)

• All numerical values in this manual are based on SI units. Numbers shown in conventional units are converted

from these values.

Number Of Digits For Converted Values

• The number digits for converted values is the same as the number of significant figures

*1

of the SI unit.

• For the torque value, the number of significant figures is, in principle, is 2 digits, in consideration of market

practicalities. However, if the number of decimal places at the upper and lower limits of the converted value

differs, the one with least number of decimal places is used. In addition, if the integer part is 3 digits or more,

the integer part becomes the significant number of figures.

*1 : The number of significant figures is the number of digits from the left-most non-zero digit to the right-most digit

including 0. (Example: 0.12 is 2 digits, 41.0 is 3 digits)

Converted Value Rounding Off And Rounding Up/down

• If there is no tolerance in the SI unit value, after conversion, rounding off is to within the number of significant

digits.

• If there is tolerance in the SI unit value and the figure after conversion indicates the upper limit, the number of

digits is rounded down to within the number of significant figures. If it indicates the lower limit, they are rounded

up to within the number of significant figures.

• Even if the SI unit value is the same, the converted value may differ based on whether that value is the upper or

lower limit.

End Of Sie

00-00–5

Page 9

GENERAL INFORMATION

ABBREVIATIONS

ATX Automatic Transaxle

EX Exhaust

HLA Hydraulic Lash Adjuster

IN Intake

MTX Manual Transaxle

OCV Oil Control Valve

TDC Top Dead Center

SST Special Service Tool

End Of Sie

GAIHAN: -

FUNDAMENTAL PROCEDURES

Preparation of Tools and Measuring Equipment

• Be sure that all necessary tools and measuring

equipment are available before starting any work.

id000000010100

id000000750100

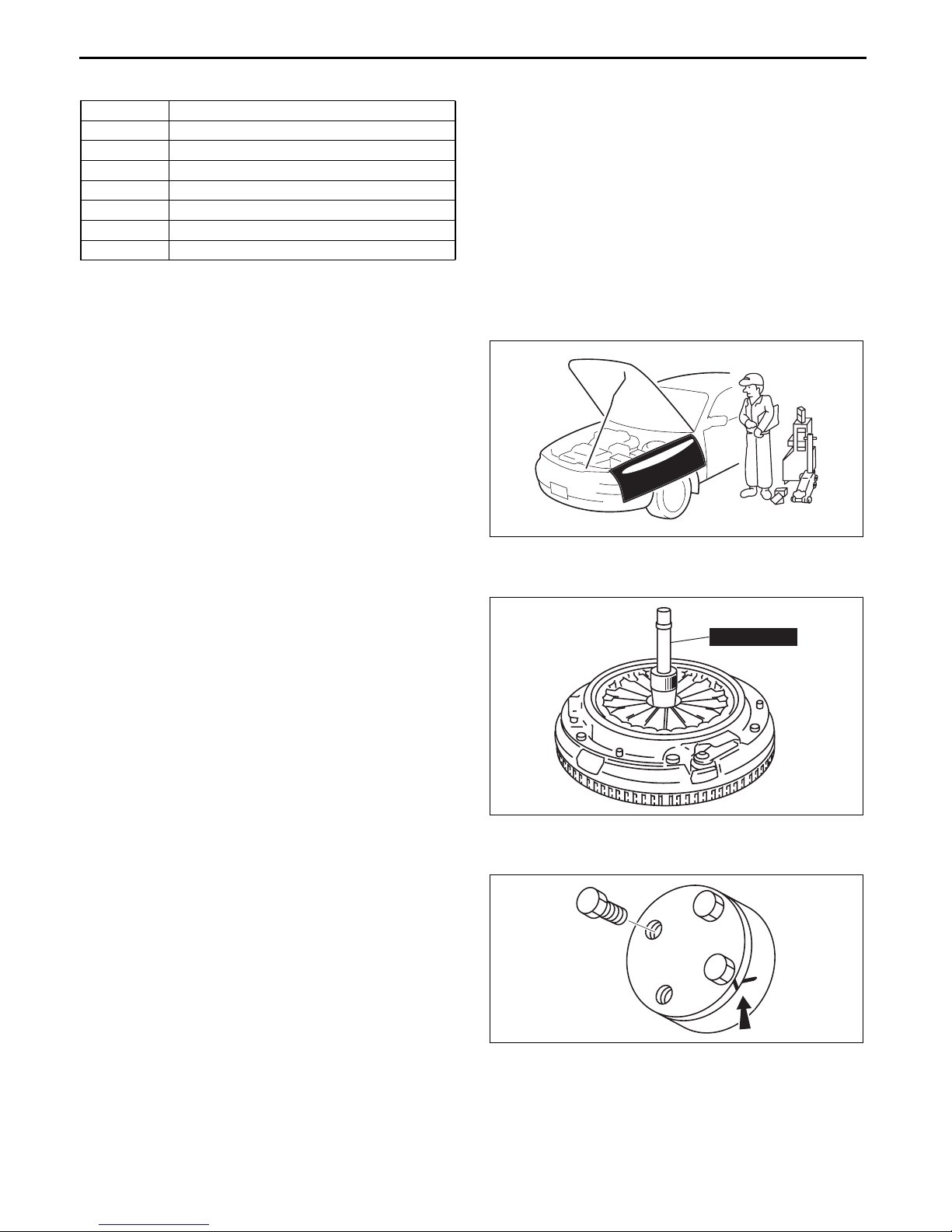

Special Service Tools

• Use special service tools or equivalent when they

are required.

Disassembly

• If the disassembly procedure is complex,

requiring many parts to be disassembled, all parts

should be marked in a place that will not affect

their performance or external appearance and

identified so that reassembly can be performed

easily and efficiently.

bpe2ue00000110

49 SE01 310

bpe2ue00000111

00-00–6

bpe2ue00000112

Page 10

GENERAL INFORMATION

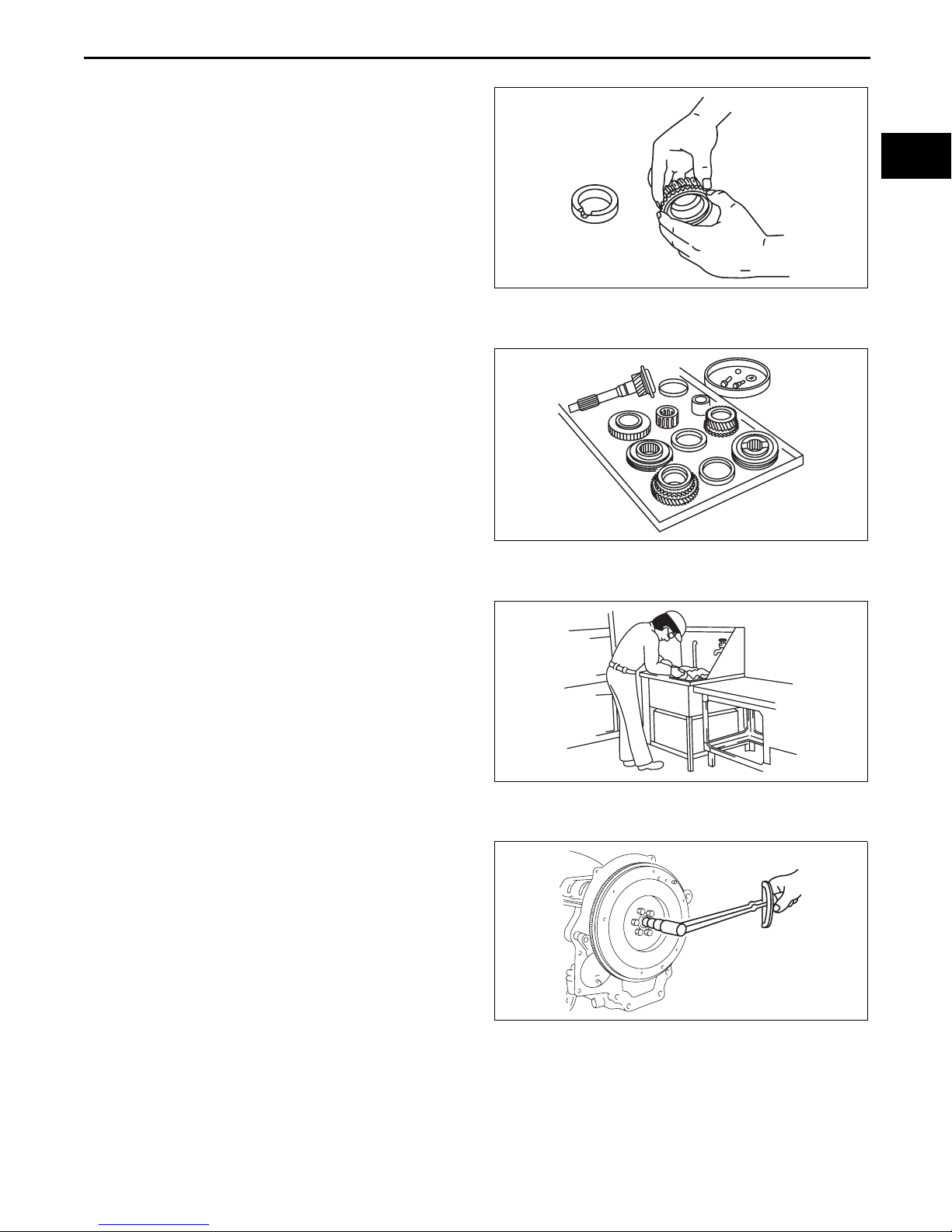

Inspection During Removal, Disassembly

• When removed, each part should be carefully

inspected for malfunction, deformation, damage

and other problems.

Arrangement of Parts

• All disassembled parts should be carefully

arranged for reassembly.

• Be sure to separate or otherwise identify the parts

to be replaced from those that will be reused.

00-00

bpe2ue00000113

Cleaning of Parts

• All parts to be reused should be carefully and

thoroughly cleaned in the appropriate method.

Warning

• Using compressed air can cause dirt and

other particles to fly out causing injury to

the eyes. Wear protective eye wear

whenever using compressed air.

Reassembly

• Standard values, such as torques and certain

adjustments, must be strictly observed in the

reassembly of all parts.

• If removed, the following parts should be replaced

with new ones:

— Oil seals

— Gaskets

— O-rings

— Lockwashers

— Cotter pins

— Nylon nuts

bpe2ue00000114

bpe2ue00000002

bpe2ue00000115

00-00–7

Page 11

• Depending on location:

— Sealant and gaskets, or both, should be

applied to specified locations. When sealant

is applied, parts should be installed before

sealant hardens to prevent leakage.

— Oil should be applied to the moving

components of parts.

— Specified oil or grease should be applied at

the prescribed locations (such as oil seals)

before reassembly.

Adjustment

• Use suitable gauges and testers when making

adjustments.

bpe2ue00000116

Rubber Parts and Tubing

• Prevent gasoline or oil from getting on rubber

parts or tubing.

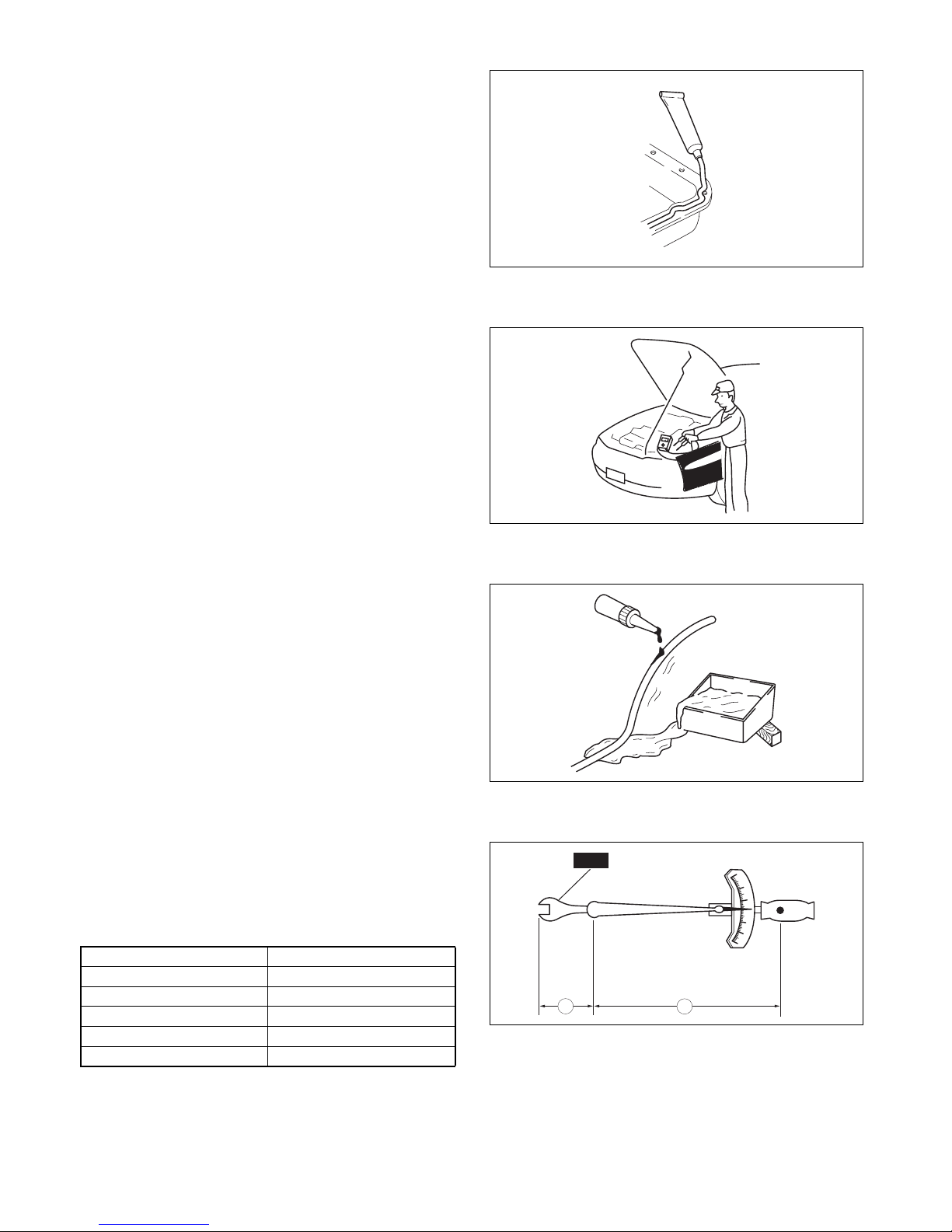

Torque Formulas

• When using a torque wrench-SST or equivalent

combination, the written torque must be

recalculated due to the extra length that the SST

or equivalent adds to the torque wrench.

Recalculate the torque by using the following

formulas. Choose the formula that applies to you.

Torque Unit Formula

N·m N·m × [L/(L+A)]

kgf·m kgf·m × [L/(L+A)]

kgf·cm kgf·cm × [L/(L+A)]

ft·lbf ft·lbf × [L/(L+A)]

in·lbf in·lbf × [L/(L+A)]

bpe2ue00000117

bpe2ue00000118

SST

A

L

3

2

1

0

1

2

3

bpe2ue00000119

A : The length of the SST past the torque wrench drive.

L : The length of the torque wrench.

Page 12

GENERAL INFORMATION

Vise

• When using a vise, put protective plates in the

jaws of the vise to prevent damage to parts.

End Of Sie

00-00

PROTECTIVE PLATES

bpe2ue00000120

00-00–9

Page 13

Page 14

ENGINE

Toc of SC T

MECHANICAL. . . . . . . . . . . . . .01-10

TECHNICAL DATA . . . . . . . . . . 01-50

Toc of SC T

01-10 MECHANICAL

01

SECTION

01-10

SERVICE TOOLS . . . . . . . . . . . 01-60

ELECTRIC VARIABLE VALVE TIMING

MOTOR/DRIVER INSPECTION . . . . . . . 01-10–2

HYDRAULIC VARIABLE VALVE TIMING

ACTUATOR INSPECTION . . . . . . . . . . . 01-10–3

ELECTRIC VARIABLE VALVE TIMING

ACTUATOR INSPECTION . . . . . . . . . . . 01-10–3

OIL CONTROL VALVE (OCV)

INSPECTION . . . . . . . . . . . . . . . . . . . . . 01-10–4

Coil Resistance Inspection . . . . . . . . . . 01-10–4

Spool Valve Operation Inspection . . . . . 01-10–4

HYDRAULIC LASH ADJUSTER (HLA)

INSPECTION . . . . . . . . . . . . . . . . . . . . . 01-10–5

ROCKER ARM INSPECTION. . . . . . . . . . 01-10–5

ENGINE OVERHAUL SERVICE

WARNING. . . . . . . . . . . . . . . . . . . . . . . . 01-10–5

ENGINE MOUNTING/DISMOUNTING . . . 01-10–6

Mounting . . . . . . . . . . . . . . . . . . . . . . . . 01-10–6

Dismounting . . . . . . . . . . . . . . . . . . . . . 01-10–6

TIMING CHAIN DISASSEMBLY. . . . . . . . 01-10–7

Water Pump Pulley

Disassembly Note . . . . . . . . . . . . . . . . 01-10–9

Crankshaft Pulley Lock Bolt

Disassembly Note . . . . . . . . . . . . . . . . 01-10–10

Oil Pan Disassembly Note. . . . . . . . . . . 01-10–10

Engine Front Cover

Disassembly Note . . . . . . . . . . . . . . . . 01-10–10

Front Oil Seal Disassembly Note . . . . . 01-10–11

Chain Tensioner Disassembly Note . . . 01-10–11

Oil Pump Chain Disassembly Note. . . . 01-10–12

CYLINDER HEAD DISASSEMBLY (I) . . . 01-10–14

Electric Variable Valve Timing Actuator,

Hydraulic Variable Valve Timing

Actuator Disassembly Note. . . . . . . . . 01-10–16

Camshaft Cap Disassembly Note . . . . . 01-10–16

Rocker Arm Disassembly Note . . . . . . . 01-10–16

HLA Disassembly Note . . . . . . . . . . . . . 01-10–16

Cylinder Head Disassembly Note . . . . . 01-10–16

CYLINDER HEAD

DISASSEMBLY (II) . . . . . . . . . . . . . . . . . 01-10–17

Valve Keeper Disassembly Note . . . . . . 01-10–18

Valve Seal Disassembly Note . . . . . . . . 01-10–18

CYLINDER BLOCK

DISASSEMBLY (I) . . . . . . . . . . . . . . . . . 01-10–19

Dual-mass Flywheel (MTX)/ Drive

Plate (ATX) Installation Bolt

Disassembly Note . . . . . . . . . . . . . . . . 01-10–20

Dual-mass Flywheel

Disassembly Note (MTX) . . . . . . . . . . 01-10–21

Rear Oil Seal Disassembly Note . . . . . 01-10–21

CYLINDER BLOCK

DISASSEMBLY (II) . . . . . . . . . . . . . . . . 01-10–22

Pilot Bearing Disassembly Note. . . . . . 01-10–23

Connecting Rod Cap

Disassembly Note . . . . . . . . . . . . . . . 01-10–23

Connecting Rod Bearing

Disassembly Note . . . . . . . . . . . . . . . 01-10–23

Piston, Connecting Rod

Disassembly Note . . . . . . . . . . . . . . . 01-10–23

Snap Ring Disassembly Note. . . . . . . . 01-10–24

Lower Cylinder Block

Disassembly Note . . . . . . . . . . . . . . . 01-10–24

Thrust Bearing And Main Bearing

Disassembly Note . . . . . . . . . . . . . . . 01-10–25

Crankshaft Disassembly Note . . . . . . . 01-10–25

CYLINDER HEAD INSPECTION. . . . . . . 01-10–25

VALVE SEAT INSPECTION/REPAIR. . . . 01-10–26

VALVE, VALVE GUIDE

INSPECTION . . . . . . . . . . . . . . . . . . . . . 01-10–27

VALVE GUIDE REPLACEMENT . . . . . . . 01-10–29

Removal . . . . . . . . . . . . . . . . . . . . . . . . 01-10–29

Installation

VALVE SPRING INSPECTION . . . . . . . . 01-10–29

CAMSHAFT INSPECTION . . . . . . . . . . . 01-10–30

CYLINDER BLOCK INSPECTION . . . . . 01-10–32

OIL JET VALVE INSPECTION . . . . . . . . 01-10–32

PISTON INSPECTION . . . . . . . . . . . . . . . 01-10–32

PISTON RING INSPECTION . . . . . . . . . . 01-10–33

PISTON PIN INSPECTION . . . . . . . . . . . 01-10–34

PISTON AND CONNECTING ROD

INSPECTION . . . . . . . . . . . . . . . . . . . . . 01-10–35

CONNECTING ROD INSPECTION . . . . . 01-10–35

CONNECTING ROD CLEARANCE

INSPECTION . . . . . . . . . . . . . . . . . . . . . 01-10–35

CRANKSHAFT INSPECTION . . . . . . . . . 01-10–36

DUAL-MASS FLYWHEEL

INSPECTION . . . . . . . . . . . . . . . . . . . . . 01-10–37

Inspection Before Removal . . . . . . . . . 01-10–37

Inspection After Removal . . . . . . . . . . . 01-10–38

PILOT BEARING INSPECTION . . . . . . . 01-10–39

BOLT INSPECTION . . . . . . . . . . . . . . . . . 01-10–39

CYLINDER BLOCK ASSEMBLY (I) . . . . 01-10–40

Thrust Bearing And Main Bearing

Assembly Note . . . . . . . . . . . . . . . . . . 01-10–41

Plate Assembly Note . . . . . . . . . . . . . . 01-10–42

Lower Cylinder Block

Assembly Note . . . . . . . . . . . . . . . . . . 01-10–42

. . . . . . . . . . . . . . . . . . . . . . 01-10–29

01-10–1

Page 15

MECHANICAL

Piston Pin Assembly Note. . . . . . . . . . . 01-10–44

Snap Ring Assembly Note . . . . . . . . . . 01-10–44

Piston Ring Assembly Note. . . . . . . . . . 01-10–45

Connecting Rod Bearing

Assembly Note . . . . . . . . . . . . . . . . . . 01-10–46

Piston, Connecting Rod

Assembly Note . . . . . . . . . . . . . . . . . . 01-10–46

Connecting Rod Cap

Assembly Note . . . . . . . . . . . . . . . . . . 01-10–47

Pilot Bearing Assembly Note . . . . . . . . 01-10–47

CYLINDER BLOCK ASSEMBLY (II) . . . . 01-10–48

Balancer Unit Assembly Note . . . . . . . . 01-10–49

Oil Pump Assembly Note . . . . . . . . . . . 01-10–50

Water Pump Assembly Note . . . . . . . . . 01-10–51

Rear Oil Seal Assembly Note . . . . . . . . 01-10–52

End Plate Assembly Note . . . . . . . . . . . 01-10–53

Dual-mass Flywheel (MTX)/ Drive

Plate (ATX) Installation Bolt

Assembly Note . . . . . . . . . . . . . . . . . . 01-10–53

Knock Sensor (KS) Assembly Note . . . 01-10–54

CYLINDER HEAD ASSEMBLY (I) . . . . . . 01-10–55

Valve Seal Assembly Note . . . . . . . . . . 01-10–56

Valve Spring Assembly Note. . . . . . . . . 01-10–56

Valve Keeper Assembly Note . . . . . . . . 01-10–57

Thermostat Assembly Note . . . . . . . . . 01-10–58

CYLINDER HEAD ASSEMBLY (II) . . . . . 01-10–59

Cylinder Head Assembly Note . . . . . . . 01-10–61

Water Inlet Pipe Assembly Note. . . . . . 01-10–62

HLA Assembly Note . . . . . . . . . . . . . . . 01-10–63

Rocker Arm Assembly Note . . . . . . . . . 01-10–63

Camshaft Assembly Note. . . . . . . . . . . 01-10–64

Electric Variable Valve Timing Actuator,

Hydraulic Variable Valve Timing

Actuator Assembly Note. . . . . . . . . . . 01-10–66

TIMING CHAIN ASSEMBLY . . . . . . . . . . 01-10–67

Oil Pump Chain Assembly Note. . . . . . 01-10–69

Timing Chain Assembly Note. . . . . . . . 01-10–71

Engine Front Cover Assembly Note . . . 01-10–74

Oil Pan Assembly Note . . . . . . . . . . . . 01-10–77

Electric Variable Valve Timing Motor/

Driver Assembly Note. . . . . . . . . . . . . 01-10–79

Front Oil Seal Assembly Note . . . . . . . 01-10–80

Crankshaft Pulley Lock Bolt

Assembly Note . . . . . . . . . . . . . . . . . . 01-10–80

Water Pump Pulley Assembly Note . . . 01-10–81

Oil Shower Pipe Assembly Note . . . . . 01-10–81

Cylinder Head Cover

Assembly Note . . . . . . . . . . . . . . . . . . 01-10–82

Water Outlet Assembly Note. . . . . . . . . 01-10–57

End of Toc

WM: -

ELECTRIC VARIABLE VALVE TIMING MOTOR/DRIVER INSPECTION

id011000828100

Caution

• Do not disassemble the electric variable valve timing motor/driver because it is a precision unit.

• Do not apply excessive force when rotating the electric variable valve timing motor joint. If it is

rotated with excessive force, the electric variable valve timing motor could be damaged.

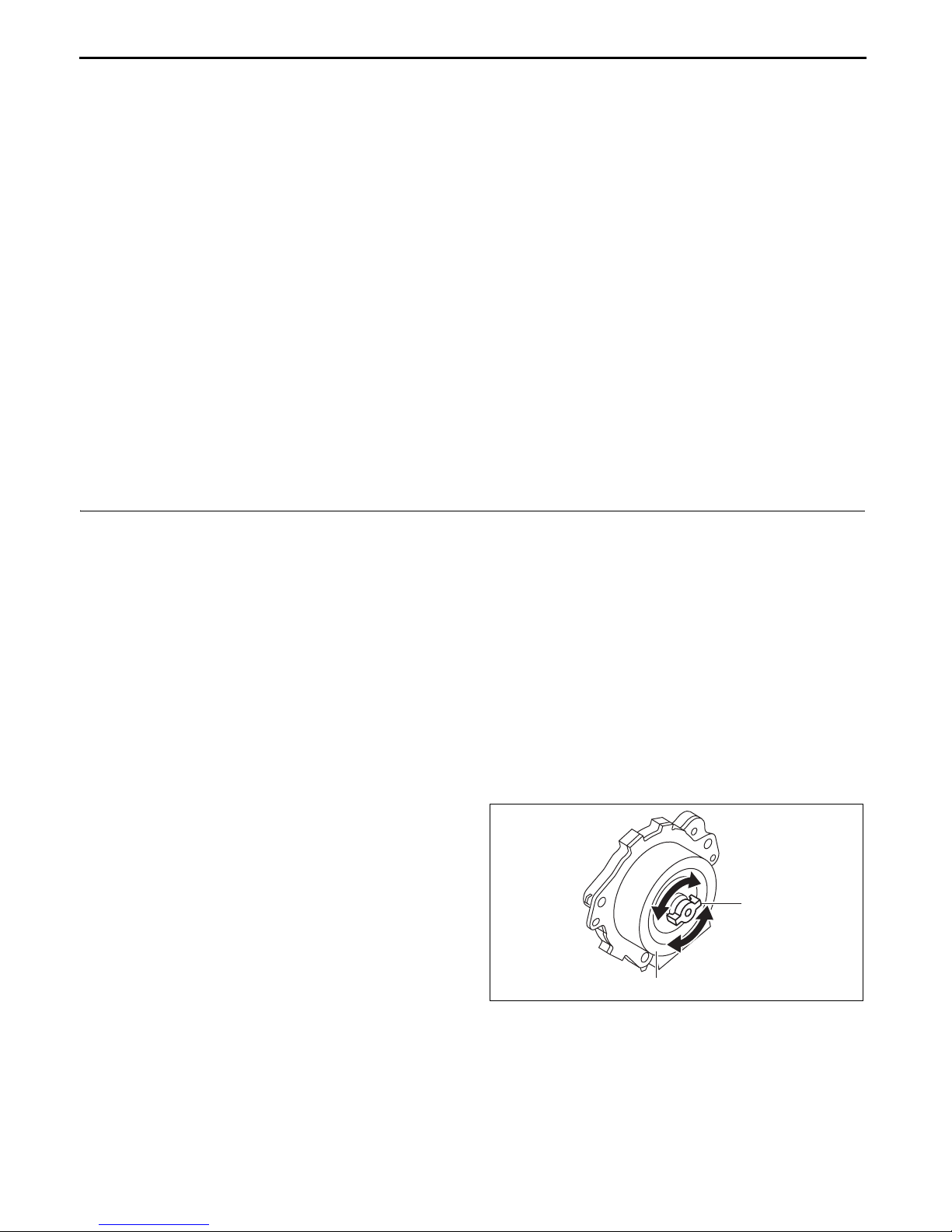

1. Rotate the electric variable valve timing motor joint to the left and right by your fingers and verify that it rotates

smoothly in 15° increments.

Note

• Rotate the joint area smoothly using only the tips of your fingers.

• The electric variable valve timing motor joint moves in 15° increments, and if the joint is moved 24 times, it

rotates one full rotation.

• If it does not rotate smoothly, replace the

electric variable valve timing motor/driver.

End Of Sie

WM: VARIABLE VALVE TIMING ACTUATOR

JOINT

ELECTRIC VARIABLE VALVE TIMING MOTOR

am3uuw00009048

01-10–2

Page 16

MECHANICAL

HYDRAULIC VARIABLE VALVE TIMING ACTUATOR INSPECTION

Caution

• Do not disassemble the hydraulic variable valve timing actuator because it is a precision unit.

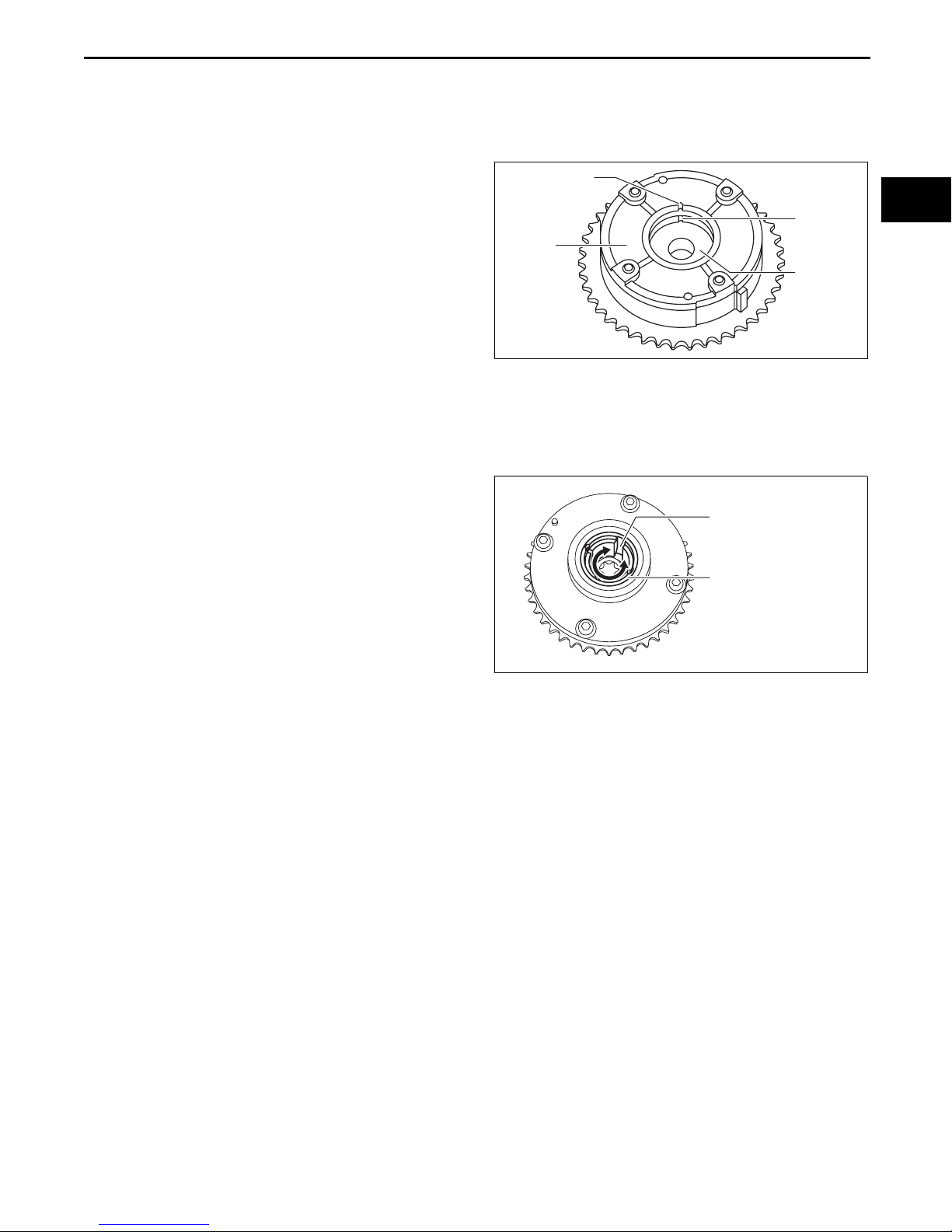

1. Verify that the notch of the rotor and projection of

the cover on the hydraulic variable valve timing

PROJECTION

actuator are aligned and fitted.

• If the projection and notch are not aligned,

rotate the rotor (camshaft installation) until a

click is heard and verify that they are aligned

COVER

and fixed in place.

— If the projection and notch are not aligned

or the rotor and cover are not secured

even if their projection and notch are

aligned, replace the hydraulic variable

valve timing actuator.

End Of Sie

ELECTRIC VARIABLE VALVE TIMING ACTUATOR INSPECTION

Caution

• Do not disassemble the electric variable valve timing actuator because it is a precision unit.

1. Rotate the eccentric shaft of the electric variable

valve timing actuator to the left and right by hand

and verify that it rotates smoothly.

• If it does not rotate smoothly, replace the

electric variable valve timing actuator.

JOINT GROOVE

id011000126800

01-10

NOTCH

ROTOR

bpe2ue00000012

id011000555500

Note

ECCENTRIC SHAFT

• Hook a finger onto the joint groove of the

eccentric shaft to rotate the shaft easily.

• The eccentric shaft stops rotating at the

maximum retard position when it is rotated

counterclockwise as viewed from the front,

and at the maximum advance position when

rotated clockwise.

• The eccentric shaft rotates 15.8 turns from the maximum retard position to the maximum advance

position.

End Of Sie

WM: OIL CONTROL VALVE (OCV)

bpe2ue00000097

01-10–3

Page 17

MECHANICAL

OIL CONTROL VALVE (OCV) INSPECTION

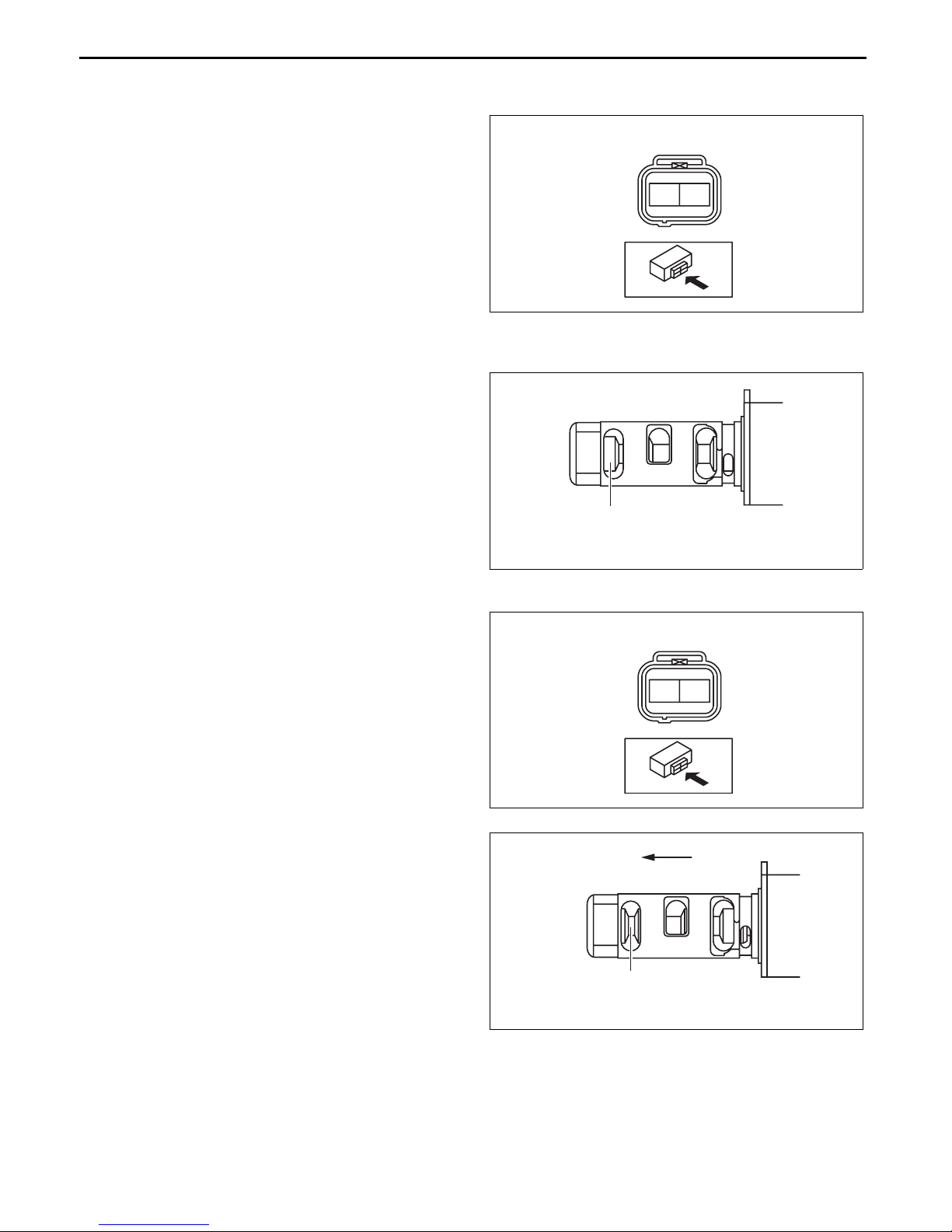

Coil Resistance Inspection

1. Measure the resistance between terminals A and

B using an ohmmeter.

OCV coil resistance

6.9—7.5 ohms [20°C {68°F}]

• If it is not within the specification, replace the

OCV.

Spool Valve Operation Inspection

1. Verify that the spool valve in the OCV is in the

maximum valve timing advance position as

indicated in the figure.

• If there is any malfunction, replace the OCV.

Note

• When applying battery positive voltage

between the OCV terminals, the connection

can be either of the following:

— Positive battery cable to terminal A,

negative battery cable to terminal B

— Positive battery cable to terminal B,

negative battery cable to terminal A

id011000801400

OIL CONTROL VALVE (OCV)

AB

bpe5ue00000015

SPOOL VALVE

(MAXIMUM VALVE TIMING

ADVANCE POSITION)

bpe1ze00000100

2. Apply battery positive voltage between the OCV

terminals and verify that the spool valve operates

and moves to the maximum valve timing retard

position.

• If there is any malfunction, replace the OCV.

3. Stop applying battery positive voltage and verify

that the spool valve returns to the maximum valve

timing advance position.

• If there is any malfunction, replace the OCV.

End Of Sie

WM: HYDRAULIC LASH ADJUSTER (HLA)

OIL CONTROL VALVE (OCV)

VALVE TIMING

RETARD

SPOOL VALVE

(MAXIMUM VALVE TIMING

RETARD POSITION)

AB

bpe5ue00000015

VALVE TIMING

ADVANCE

bpe1ze00000101

01-10–4

Page 18

MECHANICAL

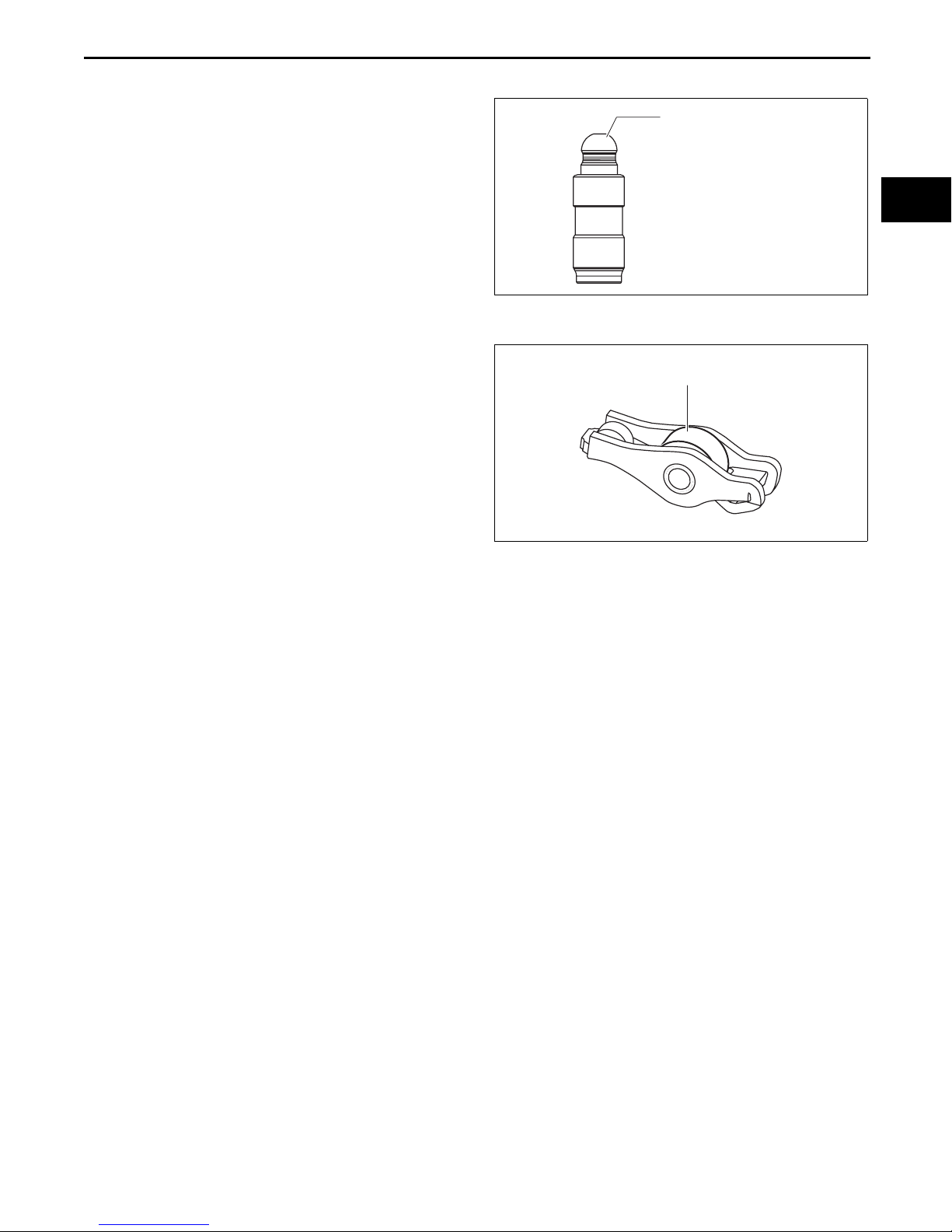

HYDRAULIC LASH ADJUSTER (HLA) INSPECTION

1. Visually inspect the HLA surface where it contacts

the rocker arm for wear or damage.

• If there is any malfunction, replace the HLA.

End Of Sie

WM: ROCKER ARM

ROCKER ARM INSPECTION

1. Rotate the roller or the rocker arm by hand and

verify that rotates smoothly.

• If it does not rotate smoothly, replace the

rocker arm.

2. Visually inspect the rocker arm surface where it

contacts the HLA and valve stem for wear or

damage.

• If there is any malfunction, replace the rocker

arm.

End Of Sie

EN: ENGINE COMPLETE

id011000805000

ROCKER ARM

CONTACT SURFACE

01-10

am3uuw00008989

id011000904800

ROLLER

ENGINE OVERHAUL SERVICE WARNING

Warning

• Continuous exposure to USED engine oil has been shown to cause skin cancer in laboratory mice.

Protect your skin by washing with soap and water immediately after performing work.

End Of Sie

bpe2ue00000096

id011000503900

01-10–5

Page 19

MECHANICAL

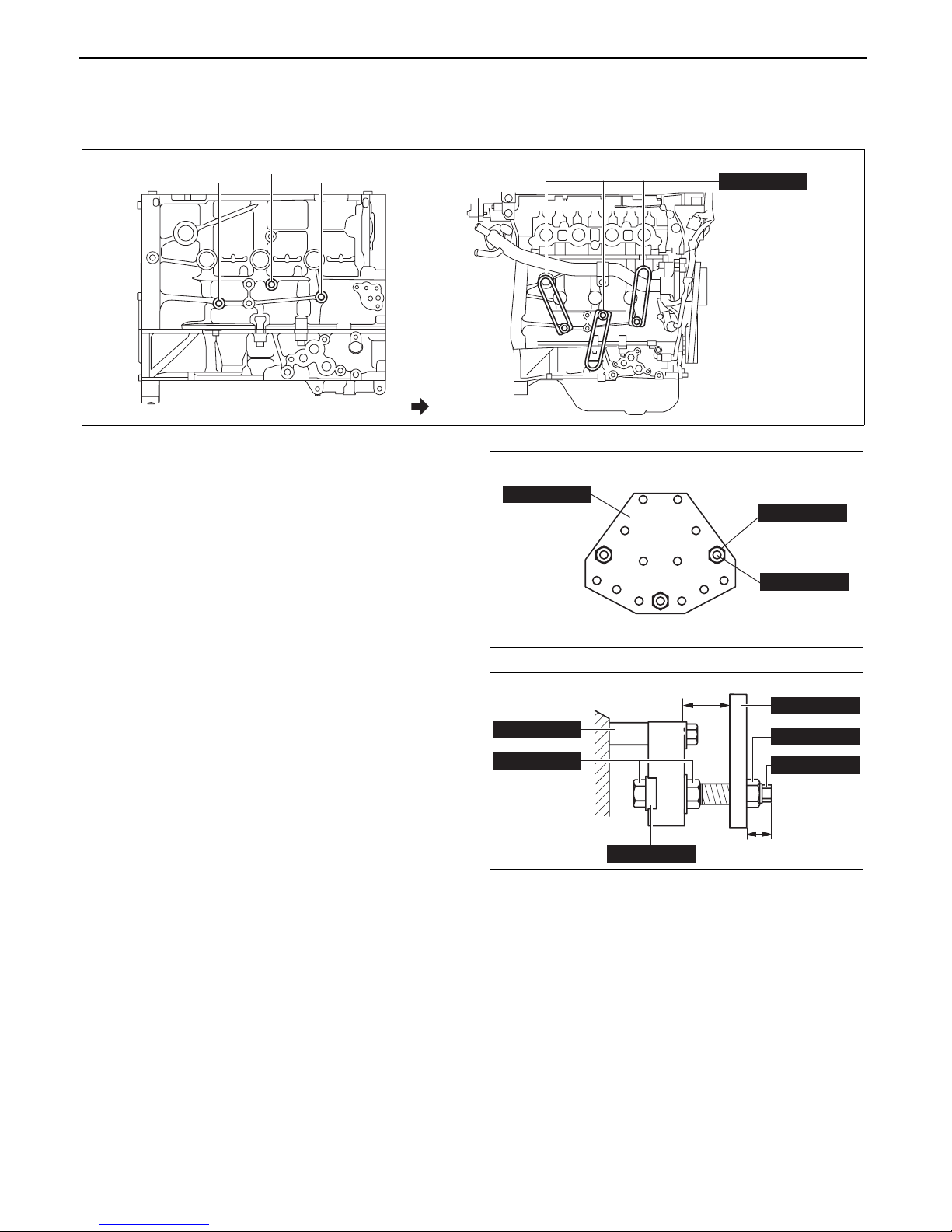

ENGINE MOUNTING/DISMOUNTING

id011000507000

Mounting

1. Install the SST (arms) to the three positions as shown in the figure and temporarily tighten the bolts (Part No.

9YA20-1003 or M10 × 1.5 length 90 mm {3.55 in}).

SST INSTALLATION HOLE

ENGINE FRONT

SST INSTALLED

49 L010 102

bpe1ze00000084

2. Install the SSTs (bolts and nuts) to the three

positions of the SST (plate) as shown in the

figure.

49 L010 101

49 L010 104

3. Install the SST (bolts, nuts and plate) set in Step 2

to the SST (arms) set in Step 1 using the SSTs

(hook and nuts).

4. Adjust the bolts so that approx. 20 mm {0.79 in}

of thread is exposed from the side of the plate.

5. Adjust the bolts and nuts so that the plate and

arms are parallel.

6. Tighten the SSTs (bolts and nuts) to affix the SST

firmly.

7. Install the engine to the SST (engine stand).

8. Remove the oil drain plug and drain the engine

oil.

9. Replace the gasket with a new one and install the

oil pan drain plug.

Tightening torque

30—41 N·m {3.1—4.1 kgf·m, 23—30 ft·lbf}

Dismounting

1. Dismount in the reverse order of mounting.

End Of Sie

49 L010 102

49 L010 104

ENGINE

PARALLEL

49 L010 103

49 L010 105

bp31je00000140

49 L010 101

49 L010 104

49 L010 105

APPROX. 20 mm {0.79 in}

bpe2ue00000089

01-10–6

Page 20

MECHANICAL

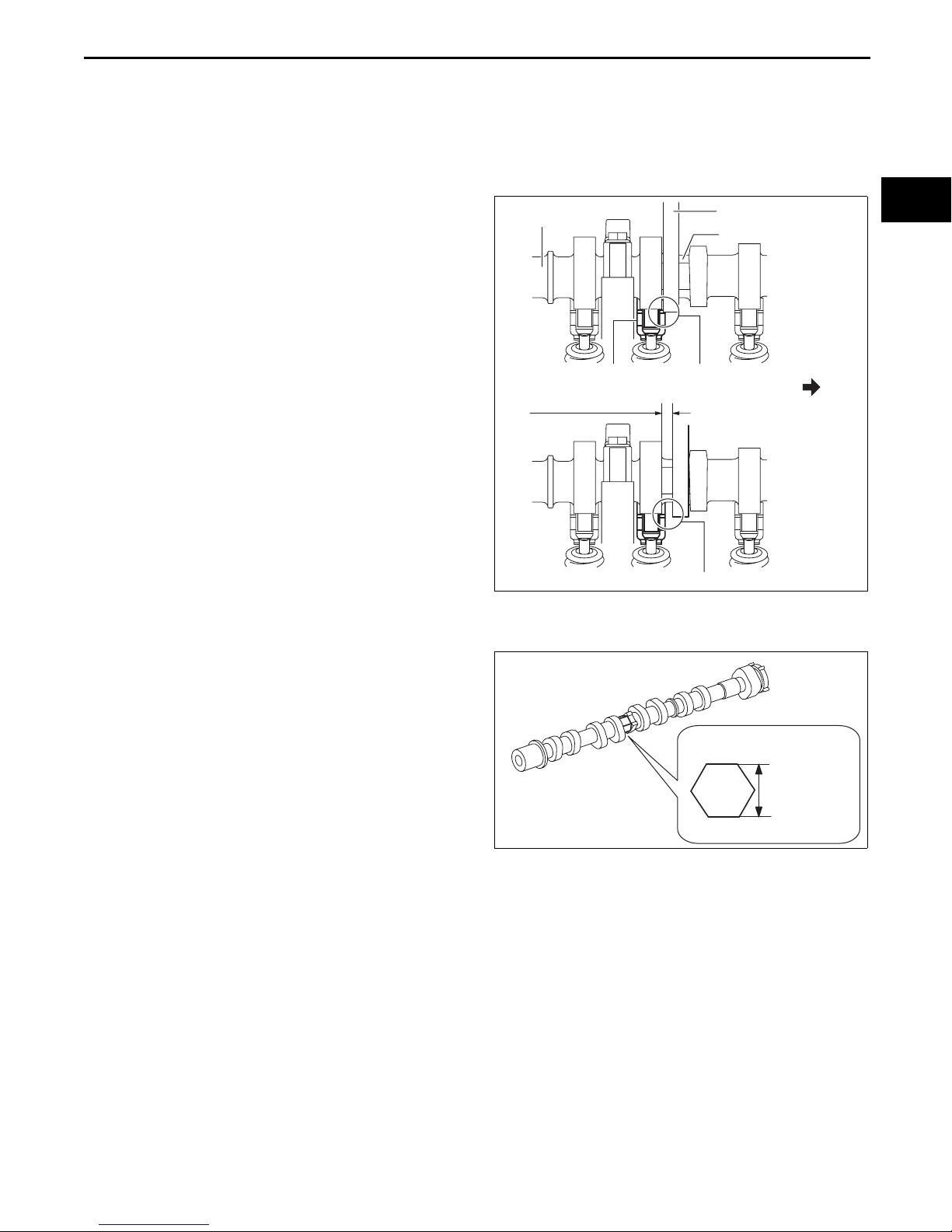

TIMING CHAIN DISASSEMBLY

Caution

• If the camshaft is rotated with the timing chain removed and the piston at the top dead center

position, the valve may contact the piston and the engine could be damaged. When rotating the

camshaft with the timing chain removed, rotate it after lowering the piston from the top dead

center position.

• When rotating the camshaft using a

wrench on the cast hexagon, the wrench

may contact the rocker arm and damage

CAMSHAFT

WRENCH

CAST HEXAGON

the rocker arm. To prevent damage to the

rocker arm when holding the camshaft on

the cast hexagon, use a wrench on the

rear side of the engine as shown in the

figure to secure a clearance between the

cam.

ROCKER ARM CONTACT

SECURE CLEARANCE

id011000505500

01-10

ENGINE REAR

Note

• Width at the cast hexagon of the camshaft is

22—24 mm {0.87—0.94 in}.

CAMSHAFT

DOES NOT CONTACT

CAST HEXAGON

22—24 mm

{0.87

am3uuw00008837

—0.94 in}

am3uuw00009029

01-10–7

Page 21

MECHANICAL

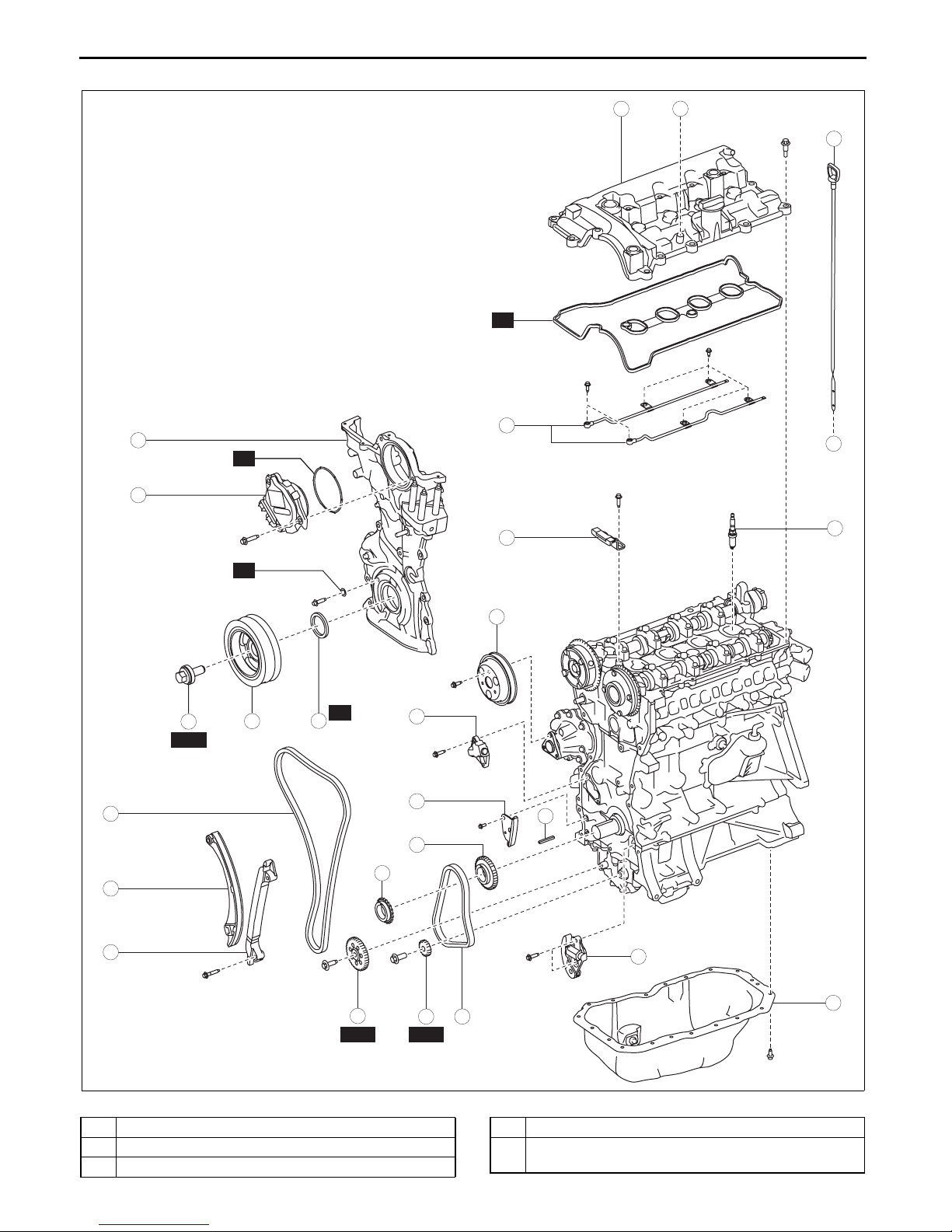

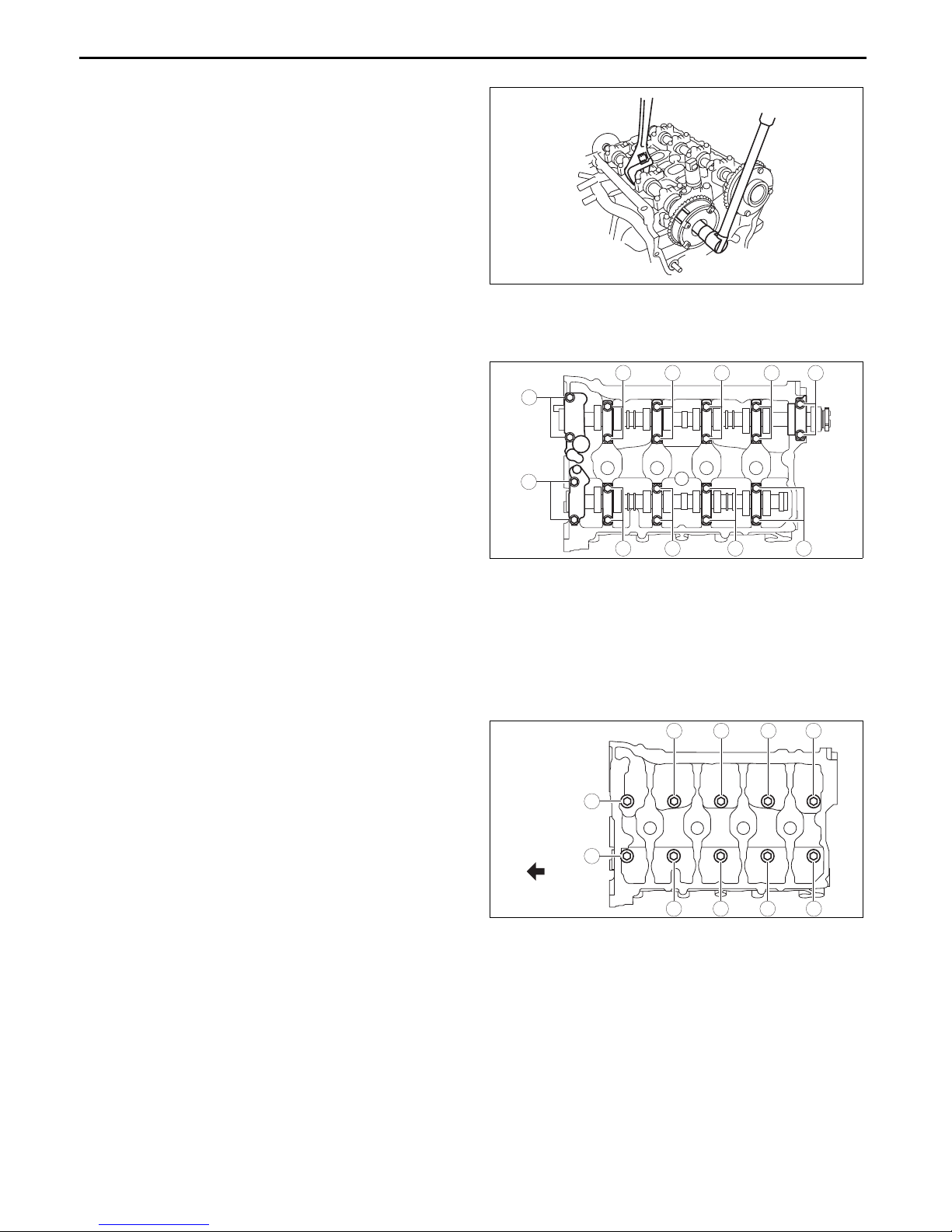

1. Disassemble in the order indicated in the table.

10

8

2

A

1

R

3

A

R

12

4

15

14

16

6

SST

R

5

7

11

R

13

22

24

23

17

18

9

21

SST SST

19

20

.

1 Dipstick

2 Cylinder head cover

3 Oil shower pipe

01-10–8

bpe1ze00000062

4 Spark plug

5 Water pump pulley

(See 01-10-9 Water Pump Pulley Disassembly Note.)

Page 22

MECHANICAL

6 Crankshaft pulley lock bolt

(See 01-10-10 Crankshaft Pulley Lock Bolt

Disassembly Note.)

7 Crankshaft pulley

8 Electric variable valve timing motor/driver

9Oil pan

(See 01-10-10 Oil Pan Disassembly Note.)

10 Engine front cover

(See 01-10-10 Engine Front Cover Disassembly

Note.)

11 Front oil seal

(See 01-10-11 Front Oil Seal Disassembly Note.)

12 Chain guide (No.1)

13 Chain tensioner

(See 01-10-11 Chain Tensioner Disassembly Note.)

14 Tensioner arm

15 Timing chain

16 Chain guide (No.2)

17 Crankshaft sprocket

18 Oil pump chain tensioner

(See 01-10-12 Oil Pump Chain Disassembly Note.)

19 Balancer shaft sprocket

(See 01-10-12 Oil Pump Chain Disassembly Note.)

20 Oil pump chain

(See 01-10-12 Oil Pump Chain Disassembly Note.)

21 Oil pump driven sprocket

(See 01-10-12 Oil Pump Chain Disassembly Note.)

22 Oil pump chain guide

23 Oil pump drive sprocket

24 Key

Water Pump Pulley Disassembly Note

Caution

• Be careful not to damage the belt groove and surface of the water pump pulley when using tools,

otherwise it will cause wear, breakage, abnormal noise of the drive belt (stretch belt), damage to

the pulley, and rust.

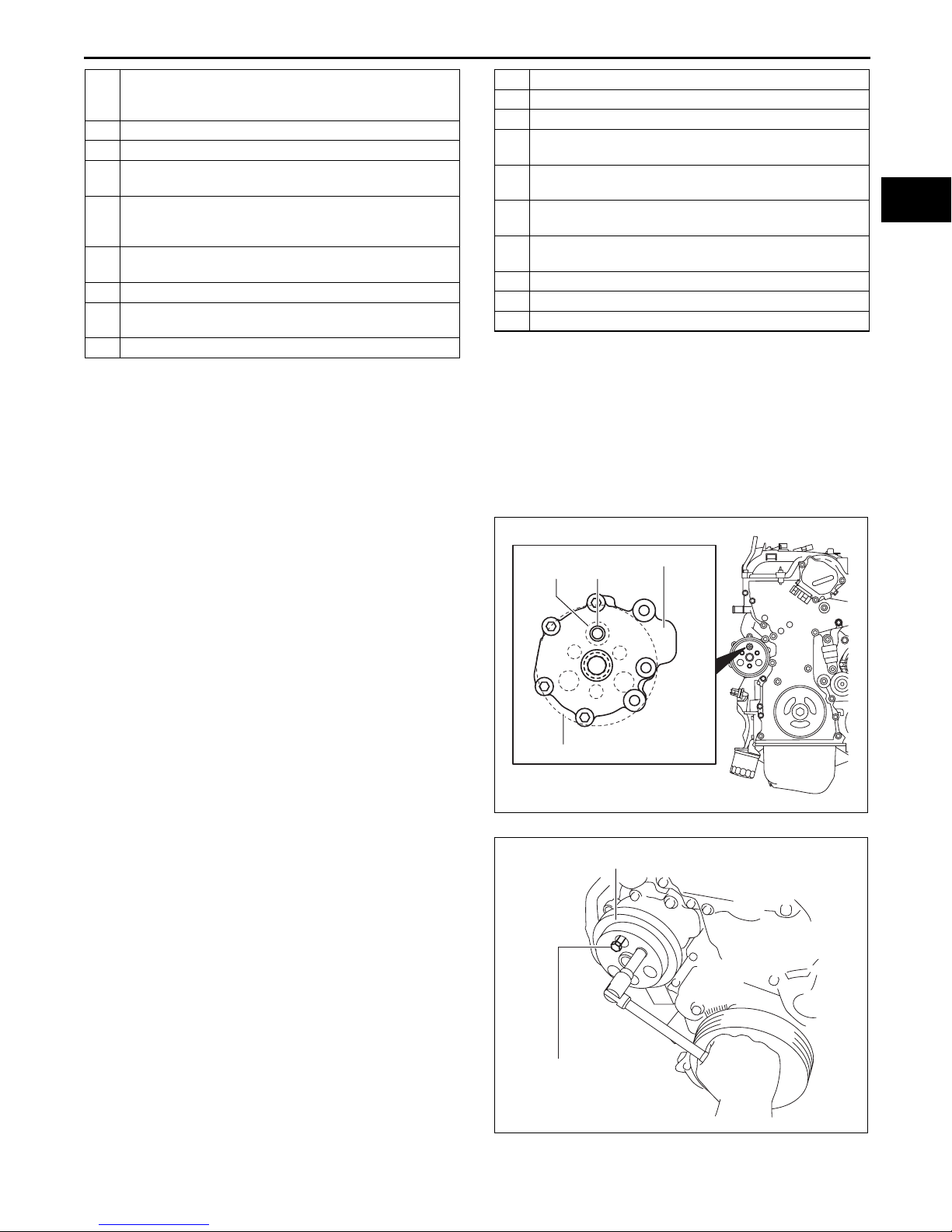

1. Align the water pump pulley hole with the water

pump hole as shown in the figure.

WATER PUMP

HOLEHOLE

01-10

2. Insert an appropriate bolt (length approx. 70 mm

{2.8 in}) into the water pump hole as shown in the

figure, and lock the water pump pulley against

rotation.

3. Remove the water pump pulley.

4. Remove the bolt used for locking the water pump

pulley against rotation.

WATER PUMP PULLEY

am3uuw00008841

WATER PUMP PULLEY

BOLT

am3uuw00008842

01-10–9

Page 23

MECHANICAL

Crankshaft Pulley Lock Bolt Disassembly Note

1. Hold the crankshaft using the SST.

2. Remove the crankshaft pulley lock bolt.

Oil Pan Disassembly Note

1. Remove the oil pan using a separator tool.

49 E011 1A0

bpe1ze00000063

Engine Front Cover Disassembly Note

1. Remove the engine front cover installation bolts.

2.

Using a screwdriver wrapped in a cloth, peel the

sealant away a little at a time, and remove the

engine front cover.

Caution

• Do not apply excessive force to the

screwdriver. Otherwise, the engine front

cover could be damaged.

• Be careful not to scratch or damage the

seal surface. Otherwise, it could cause

oil leakage.

CLOTH

adejjw00003946

CLOTH

am3uuw00008851

01-10–10

CLOTH

am3uuw00008852

Page 24

MECHANICAL

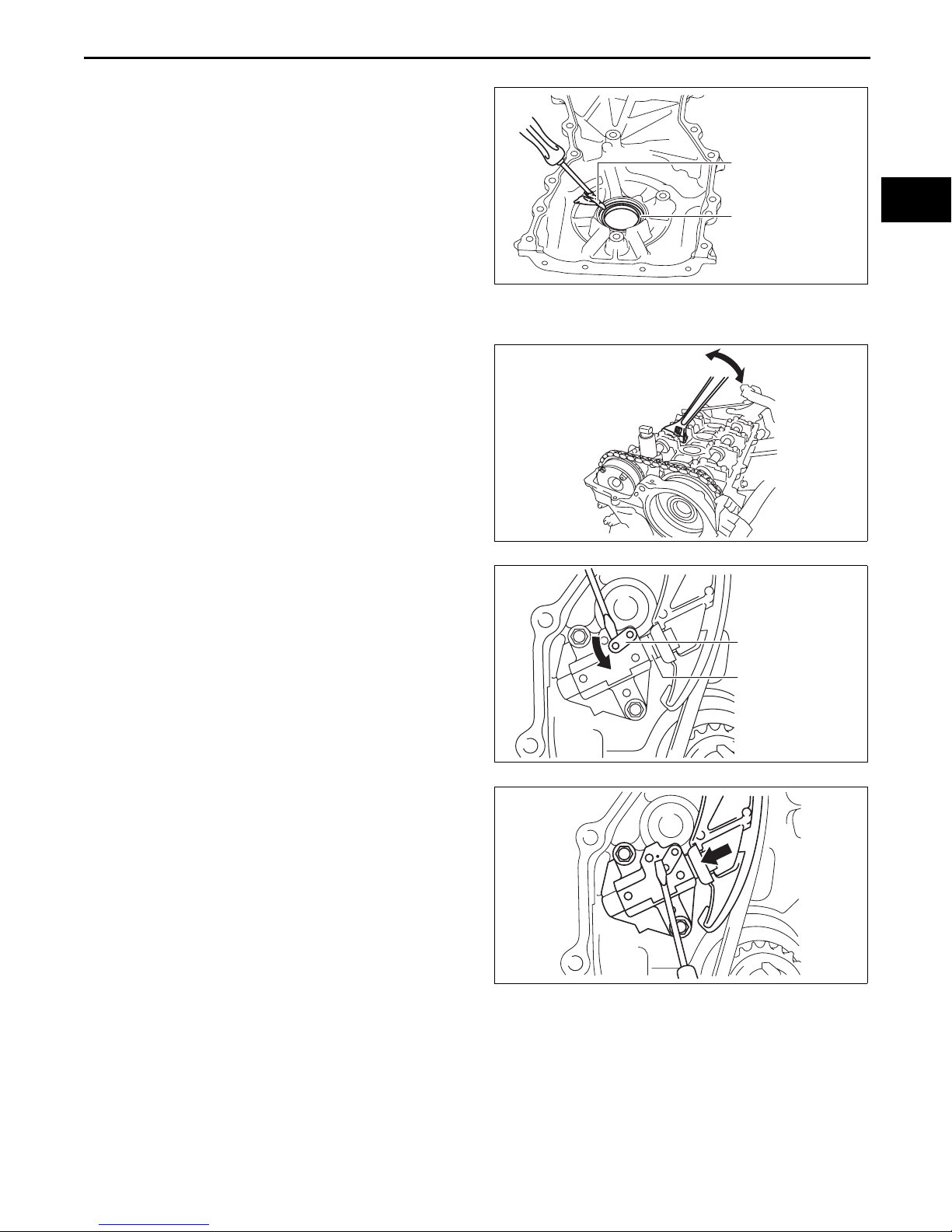

Front Oil Seal Disassembly Note

1. Remove the oil seal using a flathead screwdriver

with the tip protected by a clean cloth.

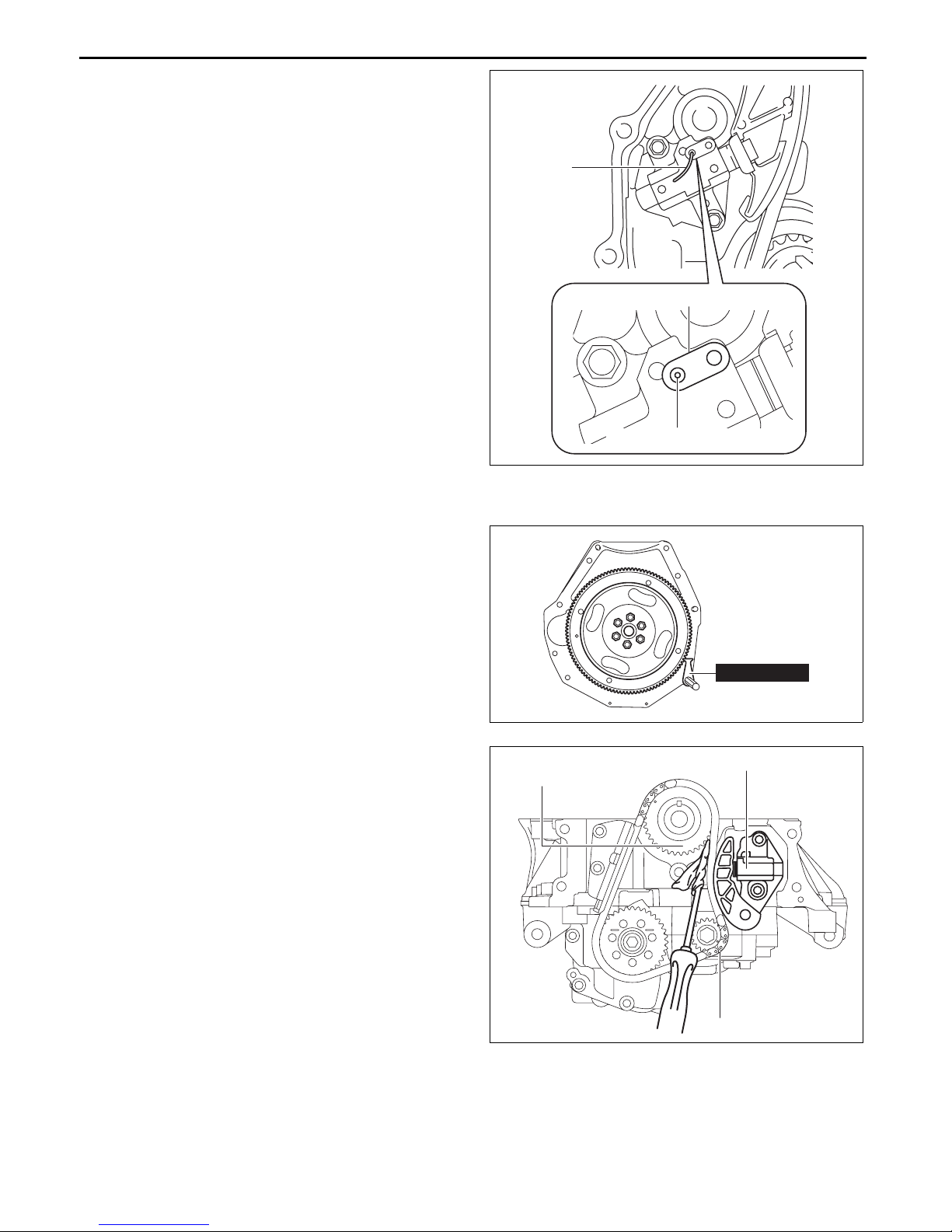

Chain Tensioner Disassembly Note

1. While moving the exhaust camshaft back and

forth in the direction of the arrow using a wrench

on the cast hexagon, press down the link plate of

the timing chain tensioner using a precision

screwdriver and release the plunger lock.

CLOTH

01-10

FRONT OIL SEAL

bpe2ue00000100

Note

• When moving the exhaust camshaft back

and forth, the timing chain pushes the

plunger in the chain tensioner making it

easier to operate the link plate.

2. Push back the plunger slowly in the direction

shown in the figure with the link plate still pushed

down.

3. Remove the screwdriver from the link plate with

the plunger still pushed down.

4. Release the force slightly from the plunger, and

move it back and forth 2—3 mm {0.08—0.11 in}.

bp31je00000104

LINK PLATE

PLUNGER

am3uuw00008854

am3uuw00008855

01-10–11

Page 25

MECHANICAL

5. Insert a wire with an approx. diameter of 1.5 mm

{0.059 in} or a paper clip where the link plate hole

and the tensioner body hole overlap to secure the

link plate and lock the plunger.

6. Remove the chain tensioner.

WIRE OR

PAPER CLIP

LINK PLATE

TENSIONER BODY HOLE

am3uuw00008856

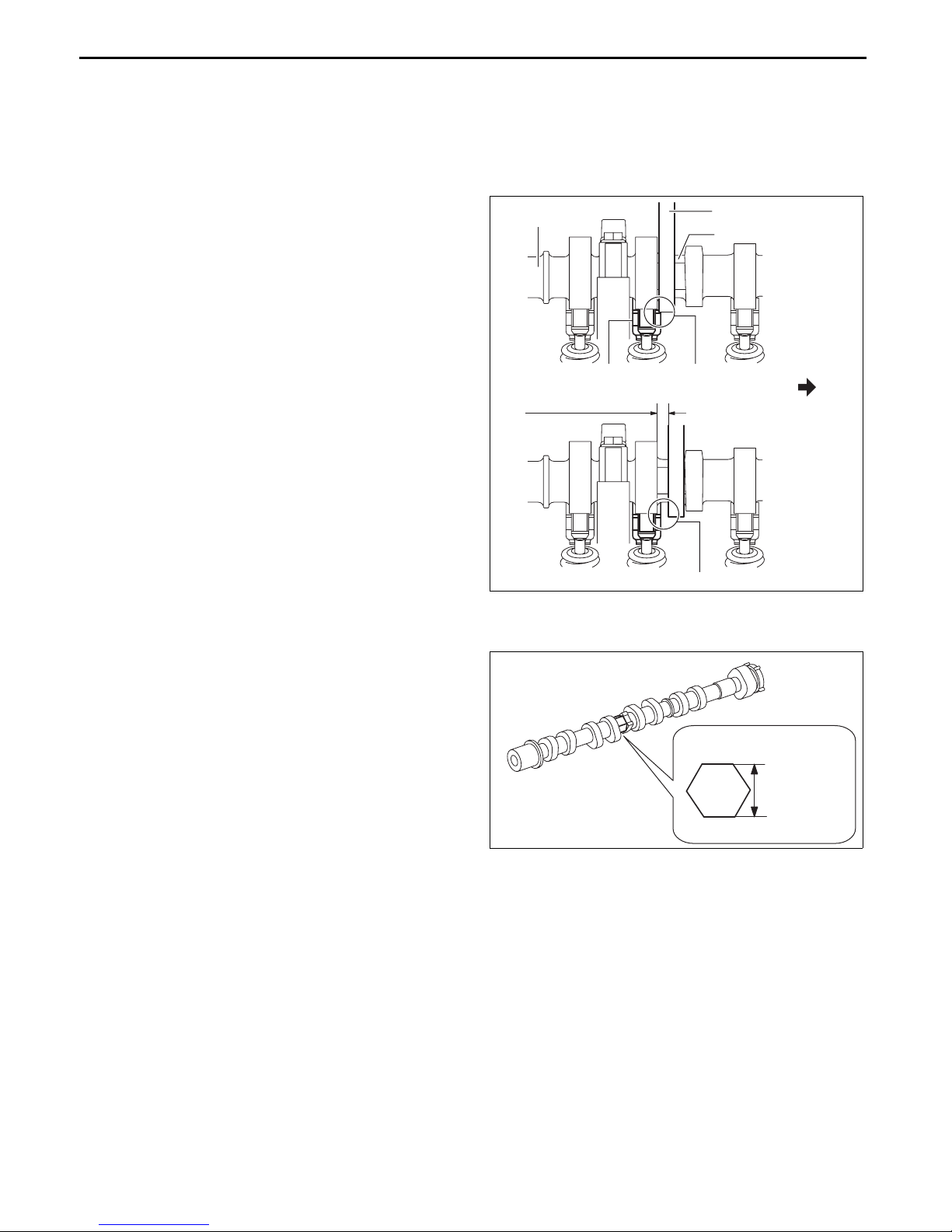

Oil Pump Chain Disassembly Note

1. Hold the crankshaft using the SST.

2. Slightly loosen the balancer shaft sprocket and oil

pump driven sprocket installation bolts.

Note

• At this stage, only loosen the installation

bolts, do not remove them. Remove the bolts

after removing the oil pump chain tensioner.

3. Set a cloth wrapped flathead screwdriver in the

gap between the oil pump drive sprocket and the

oil pump chain as shown in the figure.

OIL PUMP DRIVE

SPROCKET

49 E011 1A0

bpe1ze00000095

OIL PUMP CHAIN TENSIONER

01-10–12

OIL PUMP CHAIN

bpe1ze00000064

Page 26

MECHANICAL

4. Move the screwdriver in the direction of the arrow and press the oil pump chain, and then press on the plunger

of the oil pump chain tensioner.

OIL PUMP CHAIN

OIL PUMP DRIVE

SPROCKET

OIL PUMP CHAIN TENSIONER

01-10

BEFORE PRESSING AFTER PRESSING

PLUNGER

OIL PUMP CHAIN TENSIONER

5. Insert a wire with an approx. diameter of 1.4 mm

{0.055 in} or a paper clip into the body hole of the

oil pump chain tensioner with the plunger

pressed.

OIL PUMP CHAIN TENSIONER

bpe1ze00000065

Note

• The wire or paper clip secures the plunger,

and the tension can be released.

6. Remove the oil pump chain tensioner.

7. Remove the oil pump chain and balancer shaft

sprocket as a single unit.

8. Remove the oil pump driven sprocket.

End Of Sie

WIRE OR

PAPER CLIP

bpe1ze00000066

01-10–13

Page 27

MECHANICAL

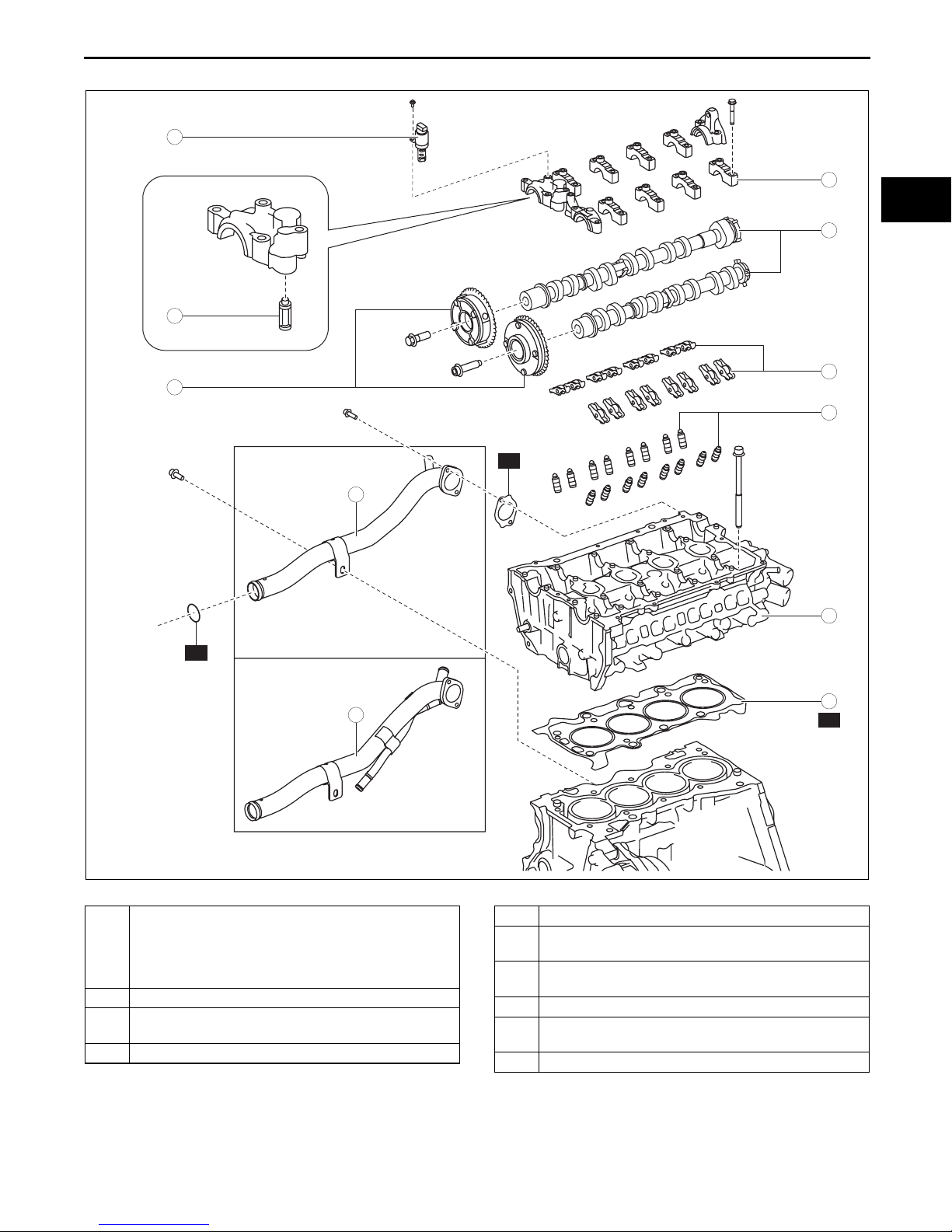

CYLINDER HEAD DISASSEMBLY (I)

Caution

• If the camshaft is rotated with the timing chain removed and the piston at the top dead center

position, the valve may contact the piston and the engine could be damaged. When rotating the

camshaft with the timing chain removed, rotate it after lowering the piston from the top dead

center position.

• When rotating the camshaft using a

wrench on the cast hexagon, the wrench

may contact the rocker arm and damage

CAMSHAFT

WRENCH

CAST HEXAGON

the rocker arm. To prevent damage to the

rocker arm when holding the camshaft on

the cast hexagon, use a wrench on the

rear side of the engine as shown in the

figure to secure a clearance between the

cam.

ROCKER ARM CONTACT

SECURE CLEARANCE

id011000500400

ENGINE REAR

Note

• Width at the cast hexagon of the camshaft is

22—24 mm {0.87—0.94 in}.

CAMSHAFT

DOES NOT CONTACT

CAST HEXAGON

22—24 mm

{0.87

am3uuw00008837

—0.94 in}

am3uuw00009029

01-10–14

Page 28

MECHANICAL

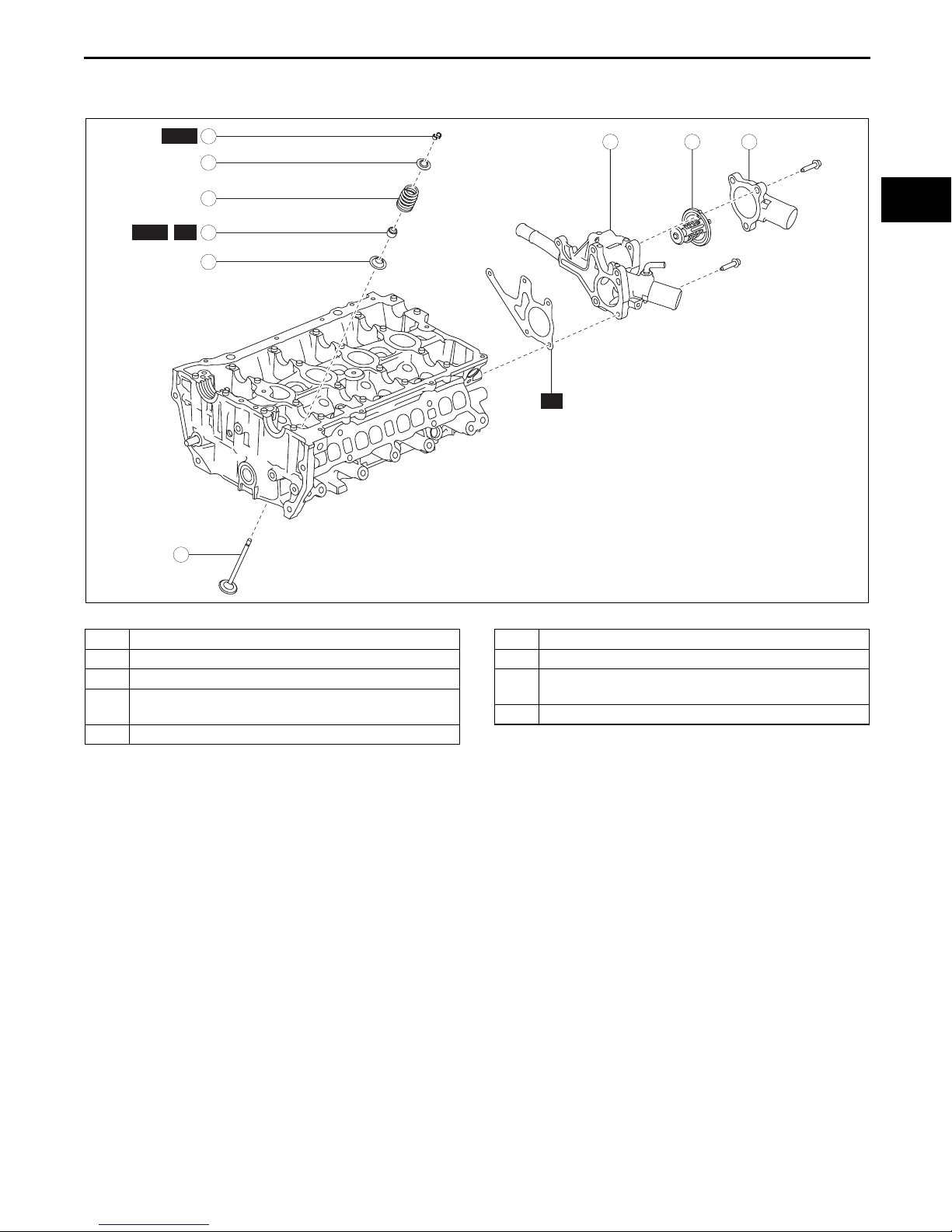

1. Disassemble in the order indicated in the table.

2

5

1

3

01-10

4

6

7

WITHOUT OIL COOLER

8

WATER

PUMP

R

WITH OIL COOLER

8

.

1 Electric variable valve timing actuator, hydraulic

variable valve timing actuator

(See 01-10-16 Electric Variable Valve Timing

Actuator, Hydraulic Variable Valve Timing Actuator

Disassembly Note.)

2OCV

3 Camshaft cap

(See 01-10-16 Camshaft Cap Disassembly Note.)

4 Camshaft

R

9

10

R

bpe5ue00000001

5 OCV oil filter

6 Rocker arm

(See 01-10-16 Rocker Arm Disassembly Note.)

7HLA

(See 01-10-16 HLA Disassembly Note.)

8 Water inlet pipe

9 Cylinder head

(See 01-10-16 Cylinder Head Disassembly Note.)

10 Cylinder head gasket

01-10–15

Page 29

MECHANICAL

Electric Variable Valve Timing Actuator, Hydraulic Variable Valve Timing Actuator Disassembly Note

1. Hold the camshaft using a wrench on the cast

hexagon and loosen the actuator installation bolt.

bp31je00000161

Camshaft Cap Disassembly Note

1. Before removing the camshaft cap, Inspect the camshaft end play. (See 01-10-30 CAMSHAFT INSPECTION.)

2. Loosen the camshaft cap installation bolts in two

or three passes in the order shown in the figure

and remove the camshaft caps.

4 3

6

2

E2

E3

1

I2

I3

E4

I4

5

E5

I5

1

2

4

Rocker Arm Disassembly Note

1. Keep the rocker arms in the order of removal to enable reassembly in their original positions.

HLA Disassembly Note

1. Keep the HLAs in the order of removal to enable reassembly in their original positions.

Cylinder Head Disassembly Note

1. Loosen the cylinder head installation bolts in two

or three passes in the order shown in the figure

7

and remove them.

End Of Sie

3

4

ENGINE

FRONT

8

10

5

3

am3uuw00008985

26

159

bpe2ue00000014

01-10–16

Page 30

MECHANICAL

CYLINDER HEAD DISASSEMBLY (II)

1. Disassemble in the order indicated in the table.

SST

4

5

6

SST

R

8

9

id011000500500

3

2

1

01-10

R

7

.

1 Thermostat cover

2 Thermostat

3 Water outlet

4 Valve keeper

(See 01-10-18 Valve Keeper Disassembly Note.)

5 Upper valve spring seat

bpe1ze00000013

6Valve spring

7Valve

8 Valve seal

(See 01-10-18 Valve Seal Disassembly Note.)

9 Lower valve spring seat

01-10–17

Page 31

Valve Keeper Disassembly Note

1. Remove the valve keeper using the SSTs.

MECHANICAL

49 B012 0A2A

49 0636 100B

bpe1ze00000014

Valve Seal Disassembly Note

1. Remove the valve seal using the SST or pliers.

End Of Sie

49 S120 170

VALVE SEAL

VALVE GUIDE

bpe1ze00000015

VALVE SEAL

bpe1ze00000016

01-10–18

Page 32

MECHANICAL

CYLINDER BLOCK DISASSEMBLY (I)

Caution

• Do not disassemble the oil pump, water pump and balancer unit because it is a precision unit.

1. Disassemble in the order indicated in the table.

AT X

R

7 6

8

R

5

MTX

5

1

4

id011000500600

SST

R

3

SST

R

3

01-10

10

R

.

1 Knock sensor (KS)

2 Oil separator

3 Dual-mass flywheel (MTX)/ drive plate (ATX)

installation bolt

(See 01-10-20 Dual-mass Flywheel (MTX)/ Drive

Plate (ATX) Installation Bolt Disassembly Note.)

4 Backing plate (ATX)

5 Dual-mass flywheel (MTX), drive plate (ATX)

(See 01-10-21 Dual-mass Flywheel Disassembly

Note (MTX).)

11

R

2

9

bpe5ue00000002

6 End plate

7 Rear oil seal

(See 01-10-21 Rear Oil Seal Disassembly Note.)

8 Water pump

9Oil strainer

10 Oil pump

11 Balancer unit

01-10–19

Page 33

MECHANICAL

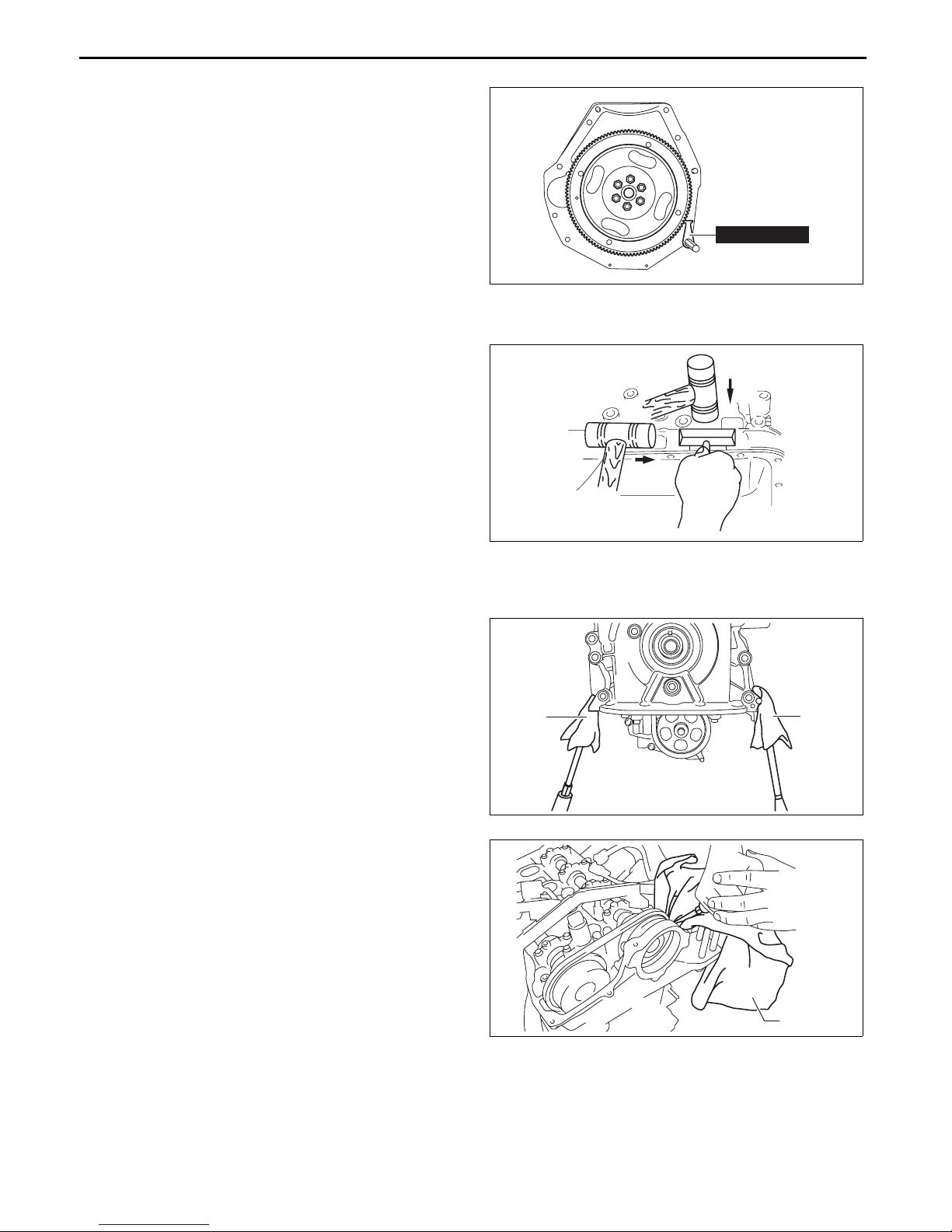

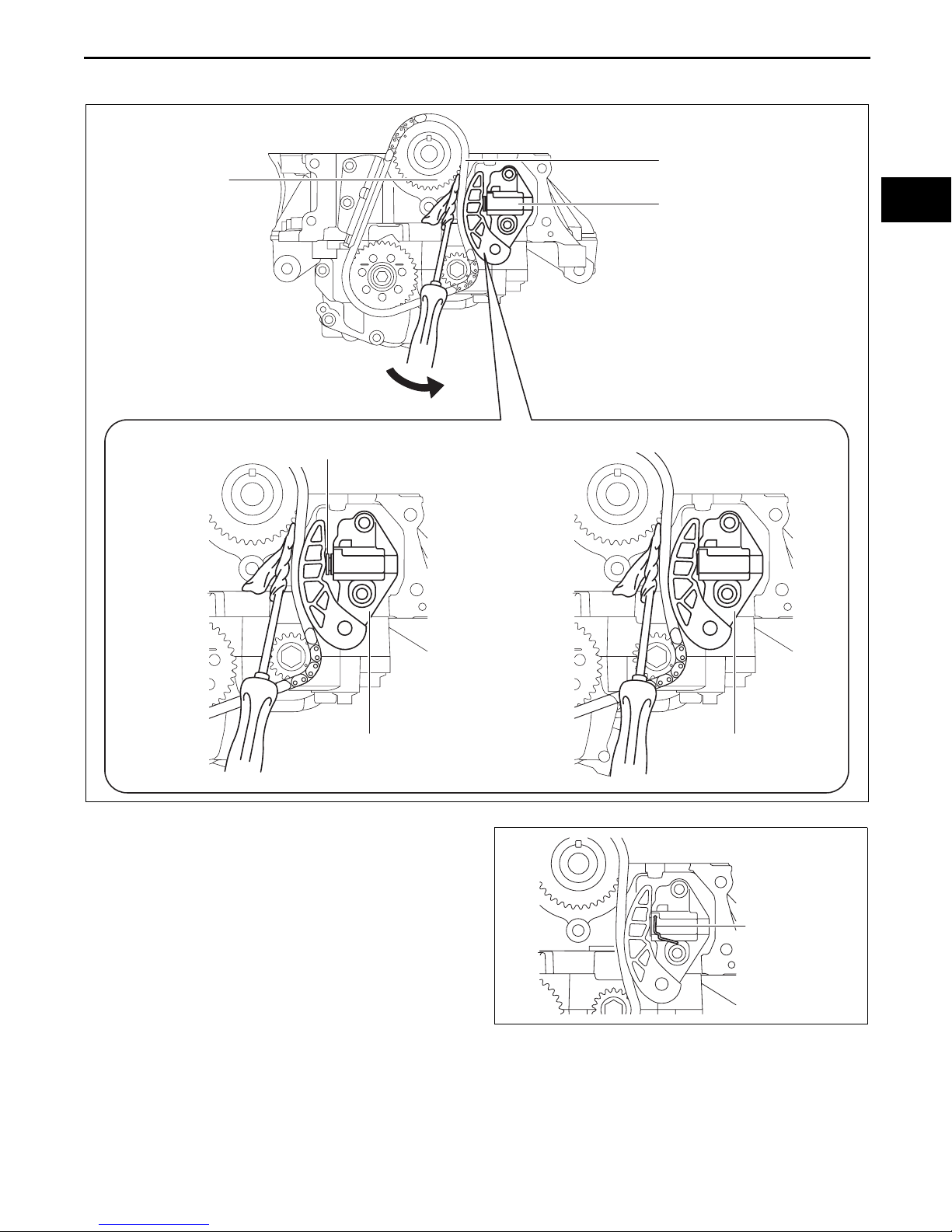

Dual-mass Flywheel (MTX)/ Drive Plate (ATX) Installation Bolt Disassembly Note

Dual-mass flywheel installation bolt (MTX)

1. Hold the crankshaft using the SST (49 E011 1A0).

2. Loosen the bolts uniformly and gradually in the

order shown in the figure.

Note

• If the bolt installation holes are not

positioned properly, perform the following

procedure:

(1) Install the SST (49 S120 710) to the dual-

mass flywheel.

(2) Rotate the dual-mass flywheel (secondary

flywheel side) using the SST (49 S120 710).

(3) When the bolt installation holes are positioned

properly, hold the position and remove one of

the bolts.

(4) After removing the bolt, set up the SST (49

G033 102) to lock the dual-mass flywheel

(secondary flywheel side) against rotation.

49 E011 1A0

49 E011 1A0

49 E011 1A0

49 S120 710

8

1

3

5

6

4

2

7

ac5wzw00005660

am6xuw00005540

Warning

• If all of the bolts are removed without

locking the dual-mass flywheel

(secondary flywheel side) against

rotation, the dual-mass flywheel (primary

or secondary flywheel side) may rotate,

resulting in injury. Therefore, always set

up the SST (49 G033 102).

• When the bolts are removed from the

dual-mass flywheel, always cover the bolt

holes using tape. If the SST (49 G033 102) is removed while the operator’s finger is inserted in the

bolt hole, the dual-mass flywheel may rotate and the operator could be injured.

(5) Remove the remaining bolts.

Drive plate installation bolt (ATX)

1. Hold the crankshaft using the SST.

2. Loosen the bolts uniformly and gradually in the

order shown in the figure.

49 G033 102

49 S120 710

am6xuw00005541

49 E011 1A0

01-10–20

bpe1ze00000092

Page 34

MECHANICAL

Dual-mass Flywheel Disassembly Note (MTX)

Note

• When reusing the dual-mass flywheel, do not remove the SST (49 G033 102) locking the dual-mass

flywheel (secondary flywheel side) against rotation.

Rear Oil Seal Disassembly Note

1. Cut the oil seal lip using a utility knife.

2. Remove the oil seal using a flathead screwdriver

with the tip protected by a clean cloth to prevent

damage to the oil seal sliding part of the

crankshaft.

End Of Sie

01-10

REAR OIL

SEAL

CLOTH

bpe5ue00000003

01-10–21

Page 35

MECHANICAL

CYLINDER BLOCK DISASSEMBLY (II)

1. Disassemble in the order indicated in the table.

4

6

9

7

R

7

R

8

10

5

16

id011000500700

18

17

15

1

R

SST

13

3

2

.

1 Pilot bearing (MTX)

(See 01-10-23 Pilot Bearing Disassembly Note.)

2 Connecting rod cap

(See 01-10-23 Connecting Rod Cap Disassembly

Note.)

3 Lower connecting rod bearing

(See 01-10-23 Connecting Rod Bearing

Disassembly Note.)

4 Piston, connecting rod

(See 01-10-23 Piston, Connecting Rod Disassembly

Note.)

5 Upper connecting rod bearing

(See 01-10-23 Connecting Rod Bearing

Disassembly Note.)

12

11

14

bpe1ze00000038

6 Piston ring

7 Snap ring

(See 01-10-24 Snap Ring Disassembly Note.)

8 Piston pin

9Piston

10 Connecting rod

11 Lower cylinder block

(See 01-10-24 Lower Cylinder Block Disassembly

Note.)

12 Lower main bearing

(See 01-10-25 Thrust Bearing And Main Bearing

Disassembly Note.)

01-10–22

Page 36

MECHANICAL

13 Crankshaft

(See 01-10-25 Crankshaft Disassembly Note.)

14 Plate

15 Upper main bearing

(See 01-10-25 Thrust Bearing And Main Bearing

Disassembly Note.)

16 Thrust bearing

(See 01-10-25 Thrust Bearing And Main Bearing

Disassembly Note.)

17 Oil jet valve

18 Upper cylinder block

Pilot Bearing Disassembly Note

Note

• The pilot bearing does not need to be removed unless you are replacing it.

1. Use the SST to remove the pilot bearing.

49 1285 071

01-10

bpe2ue00000021

Connecting Rod Cap Disassembly Note

1. Before removing the connecting rod cap, inspect

the connecting rod side clearance. (See 01-10-35

CONNECTING ROD CLEARANCE

INSPECTION.)

2. The removed connecting rod caps are to be kept

so that they can be assembled to the same

positions and in the direction as before removal.

bp31je00000044

Connecting Rod Bearing Disassembly Note

1. The removed connecting rod bearings are to be kept so that they can be assembled to the same positions and

in the direction as before removal.

Piston, Connecting Rod Disassembly Note

1. Before removing the piston and connecting rod, remove the carbon in the cylinder.

2. Before removing the piston and connecting rod, inspect the oil clearance at the large end of the connecting rod.

(See 01-10-35 CONNECTING ROD CLEARANCE INSPECTION.)

01-10–23

Page 37

MECHANICAL

Snap Ring Disassembly Note

1. Before removing the snap ring, verify that the large end of connecting rod drops under its own weight with no

resistance. (See 01-10-35 PISTON AND CONNECTING ROD INSPECTION.)

2. Remove the snap ring using a flathead

screwdriver.

SNAP RING

bpe2ue00000022

Lower Cylinder Block Disassembly Note

1. Before removing the lower cylinder block, inspect the crankshaft end play. (See 01-10-36 CRANKSHAFT

INSPECTION.)

2. Loosen the lower cylinder block installation bolts

B in two or three passes in the order shown in the

figure and remove them.

1

5

9

8

BBBBB

4

3. Loosen the lower cylinder block installation bolts

A in two or three passes in the order shown in the

figure and remove them.

ENGINE

FRONT

ENGINE

FRONT

2

1

2

6

10

5

6

9

10

7

AAAA

7

AAAA

3

BBBBB

bpe1ze00000039

A

48

3

A

bpe1ze00000040

01-10–24

Page 38

MECHANICAL

4. Using a screwdriver wrapped in a cloth, peel the

sealant away a little at a time, and remove the

LOWER CYLINDER BLOCK

lower cylinder block.

Caution

• Do not apply excessive force to the

screwdriver. Otherwise, the lower

cylinder block could be damaged.

• Be careful not to scratch or damage the

seal surface. Otherwise, it could cause

oil leakage.

CLOTH

bpe2ue00000025

Thrust Bearing And Main Bearing Disassembly Note

1. The removed thrust bearings and main bearings are to be kept so that they can be assembled to the same

positions and in the direction as before removal.

Crankshaft Disassembly Note

Caution

• Placing the crankshaft on a disassembly bench will deform or damage it because the plate for the

crankshaft position sensor signal detection installed to the crankshaft is larger than the

counterweight. Therefore, set wood blocks or similar objects on the both sides of the crankshaft

so that the plate does not contact the disassembly bench directly when placing the crankshaft on

the bench.

01-10

CLOTH

End Of Sie

CYLINDER HEAD INSPECTION

1. Inspect the cylinder head surface for cracks and other damage using a red dye penetrant.

• If there is a malfunction, replace the cylinder head.

2. Measure the combustion chamber side of the

cylinder head for distortion in six directions as

shown in the figure using a straight edge and

feeler gauge.

• If the distortion exceeds the maximum

specification, replace the cylinder head. Do

not attempt to repair the cylinder head by

milling or grinding.

Maximum distortion, head gasket side of the

cylinder head

0.05 mm {0.002 in}

id011000507100

bpe1ze00000003

01-10–25

Page 39

MECHANICAL

3. Inspect the contact surface of the exhaust

manifold and the intake manifold for distortion by

measuring as shown in the figure using a straight

edge and feeler gauge.

• If the distortion on the intake manifold side

exceeds the maximum specification, replace

the cylinder head.

• If the distortion on the exhaust manifold side

exceeds the maximum specification, grind the

surface or replace the cylinder head.

Maximum distortion, manifold side

IN: 0.10 mm {0.0039 in}

EX: 0.05 mm {0.002 in}

Maximum cutting length, manifold side

IN: Cutting not authorized

EX: 0.20 mm {0.0079 in}

End Of Sie

VALVE SEAT INSPECTION/REPAIR

1. Measure the contact width of the valve face and

the valve seat using the valve lapping compound.

• If it is not within the specification, resurface

the valve seat using the 45° valve seat cutter.

Standard valve seat contact width

1.37—1.84 mm {0.0540—0.0724 in}

IN

EX

bpe1ze00000004

id011000501300

SEAT CONTACT

WIDTH

Valve seat angle

45°

2. Verify that the area where the valve seat contacts

the valve face is centered.

• If the seating position is too high, correct the

valve seat using a 70° (IN) 70° (EX) valve seat

cutter and a 45° valve seat cutter.

• If the seating position is too low, correct as

follows:

— IN: Correct the valve seat using a 20°

valve seat cutter and then using a 45°

valve cutter.

— EX: Correct the valve seat using a 45°

valve seat cutter.

EX

45

bpe1ze00000102

IN

°

70

°

°

70

°

45

°

20

VALVE SEATVALVE SEAT

01-10–26

COMBUSTION CHAMBER

bpe1ze00000103

Page 40

MECHANICAL

3. Inspect the valve seat for sinkage. Measure the

protruding length (dimension L) of the valve stem

using a valve of standard length.

• If it is not within the specification, replace the

cylinder head.

Standard valve seat sinkage amount

(Dimension L)

IN: 48.93—50.17 mm {1.927—1.975 in}

EX: 48.87—50.11 mm {1.925—1.972 in}

End Of Sie

VALVE, VALVE GUIDE INSPECTION

1. Measure the valve head margin thickness using a

vernier caliper.

• If it is less than the standard specification,

replace the valve.

Standard valve head margin thickness

IN: 1.75—1.95 mm {0.0689—0.0767 in}

EX: 1.95—2.15 mm {0.0768—0.0846 in}

2. Measure the length of the each valve using a

vernier caliper.

• If it is less than the minimum specification,

replace the valve.

IN : 34.0 mm {1.34 in}

EX : 29.0 mm {1.14 in}

MARGIN THICKNESS

L

01-10

bpe1ze00000104

id011000506200

bpe5ue00000012

Standard valve length

IN: 107.00—107.60 mm {4.2127—4.2362 in}

EX: 117.09—117.69 mm {4.6099—4.6334 in}

Minimum valve length

IN: 106.78 mm {4.2039 in}

EX: 116.87 mm {4.6012 in}.

3. Measure the valve stem diameter of each valve

using the micrometer. Measurement positions

total six and are in the X and Y directions, at three

points (A, B, and C) as shown in the figure.

• If it is less than the minimum specification,

replace the valve.

Standard valve stem diameter

IN: 5.470—5.485 mm {0.2154—0.2159 in}

EX: 5.465—5.480 mm {0.2152—0.2157 in}

Minimum valve stem diameter

IN: 5.424 mm {0.2135 in}

EX: 5.419 mm {0.2133 in}

bez0je00000017

X

Y

A

B

C

bpe2ue00000084

01-10–27

Page 41

MECHANICAL

4. Measure the inner diameter of each valve guide

using the caliper gauge. Measurement positions

total six and are in the X and Y directions, at three

points (A, B, and C) as shown in the figure.

• If it is not within the specification, replace the

valve guide.

Standard valve guide inner diameter

IN: 5.510—5.530 mm {0.2170—0.2177 in}

EX: 5.510—5.530 mm {0.2170—0.2177 in}

5. Calculate the clearance between the valve stem

and the valve guide by subtracting the inner

diameter of the valve guide from the outer

diameter of the corresponding valve stem.

• If it exceeds the maximum specification,

replace the valve or valve guide.

Standard clearance between valve stem and

guide

IN: 0.025—0.060 mm {0.0010—0.0023 in}

EX: 0.030—0.065 mm {0.0012—0.0025 in}

Maximum clearance between valve stem and

guide

0.10 mm {0.0039 in}

X

Y

A

B

C

bpe2ue00000085

VALVE STEM

VALVE GUIDE

CLEARANCE

bpe2ue00000086

6. Measure the projection height (dimension A) of

each valve guide using the vernier caliper.

• If it is not within the specification, replace the

valve guide.

Standard valve guide projection height

IN: 16.4—17.0 mm {0.646—0.669 in}

EX: 16.4—17.0 mm {0.646—0.669 in}

End Of Sie

A

VALVE GUIDE

CYLINDER HEAD

bpe2ue00000087

01-10–28

Page 42

MECHANICAL

VALVE GUIDE REPLACEMENT

Removal

1. Tap the valve guide out from combustion chamber

side using the SST.

Installation

1. Apply clean engine oil to the valve guide.

2. Tap the valve guide from the camshaft side using

the SST so that the projection height (dimension

A) is within the specification.

Standard valve guide projection height

IN: 16.4—17.0 mm {0.646—0.669 in}

EX: 16.4—17.0 mm {0.646—0.669 in}

End Of Sie

id011000501200

49 B012 015

01-10

VALVE GUIDE

bpe2ue00000026

49 B012 015

A

VALVE GUIDE

VALVE SPRING INSPECTION

Caution

• The valve springs differ depending on the

IN and EX sides.Therefore, verify the free

length or identification paint beforehand

and inspect the valve springs.

CYLINDER HEAD

bpe2ue00000027

id011000501400

IN

48.96 mm {1.928 in}

PURPLE PAINT

EX

50.07 mm {1.971 in}

NOT PAINTED

bpe1ze00000041

01-10–29

Page 43

MECHANICAL

1. Measure the valve spring height using the spring

tester.

• If it is not within the specification, replace the

valve spring.

Valve spring installation height

When pressurized with spring force of 228—

252 N {23.3—25.6 kgf, 51.3—56.6 lbf},

spring height is 38.0 mm {1.50 in}

2. Measure the amount of off-square on the valve

spring using a square.

(1) Rotate the valve spring one full turn and

measure A at the point where the gap is the

largest.

• If it exceeds the maximum specification,

replace the valve spring.

Maximum valve spring off-square

IN: 2.0 ° (1.7 mm {0.067 in})

EX: 2.0 ° (1.7 mm {0.067 in})

End Of Sie

CAMSHAFT INSPECTION

1. Set the No.1 and No.5 journals of the camshaft on V-blocks.

2. Measure the camshaft runout using the dial

gauge.

• If it exceeds the maximum specification,

replace the camshaft.

bp31je00000053

A

UPPER

LOWER

beltze00000017

id011000501500

Maximum camshaft runout

0.030 mm {0.0012 in}

3. Measure the cam height using the micrometer as

shown in the figure.

• If it is less than the minimum specification,

replace the camshaft.

Standard cam height

IN: 42.34 mm {1.667 in}

EX: 40.37 mm {1.589 in}

Minimum cam height

IN: 42.27 mm {1.664 in}

EX: 40.30 mm {1.587 in}

bpe2ue00000031

bp31je00000171

01-10–30

Page 44

4. Measure the journal diameter using the

micrometer. Measurement positions total four and

are in the X and Y directions, at two points (A and

B) as shown in the figure.

• If it is less than the minimum specification,

replace the camshaft.

MECHANICAL

A B

Standard camshaft journal diameter

24.96—24.98 mm {0.9827—0.9834 in}

Y

Minimum camshaft journal diameter

24.93 mm {0.9815 in}

5. Measure the camshaft journal oil clearance using

the following procedure:

(1) Clean the camshaft journal and the journal receptacle part.

(2) Put the camshaft on the cylinder head with the rocker arm detached.

(3) Cut the plastigauge to the same length as the

journal width and position it parallel to the

camshaft.

(4) Install the camshaft caps. (See 01-10-59

CYLINDER HEAD ASSEMBLY (II).)

(5) Remove the camshaft caps. (See 01-10-14

CYLINDER HEAD DISASSEMBLY (I).)

(6) Measure the camshaft journal oil clearance.

• If it exceeds the maximum specification,

replace the cylinder head.

Standard camshaft journal oil clearance

0.035—0.080 mm {0.0014—0.0031 in}

Maximum camshaft journal oil clearance

0.090 mm {0.0035 in}

X

01-10

bp31je00000172

PLASTIGAUGE

bpe2ue00000032

6. Measure the camshaft end play using a dial

gauge.

• If it exceeds the maximum specification,

replace the cylinder head or camshaft.

Standard camshaft end play

0.07—0.22 mm {0.003—0.008 in}

Maximum camshaft end play

0.23 mm {0.0091 in}

End Of Sie

bp31je00000173

01-10–31

Page 45

MECHANICAL

CYLINDER BLOCK INSPECTION

1. Measure the cylinder block for distortion in six

directions as shown in the figure using a straight

edge and feeler gauge.

• If it exceeds the maximum specification,

replace the cylinder block.

Maximum distortion, head gasket side of the

cylinder block

0.10 mm {0.0039 in}

2. Measure the cylinder bore diameter using the

cylinder gauge. The measurement position is in

the X and Y directions at a point 43.9 mm {1.73

in} below the top surface of the cylinder as shown

in the figure.

• If it is not within the specification, replace the

cylinder block.

Standard cylinder bore diameter

89.000—89.030 mm {3.5040—3.5051 in}

End Of Sie

OIL JET VALVE INSPECTION

1. Apply compressed air to oil jet valve A and verify

that air passes through oil jet valve B.

• If air does not flow, replace the oil jet valve.

• If there is air flow with air compressor of less

than 180 kPa {1.84 kgf/cm

replace the oil jet valve.

2

, 26.1 psi},

id011000507200

bp31je00000144

X

Y

43.9 mm {1.73 in}

bpe2ue00000098

id011000505900

B

A

Oil jet valve opening pressure

180—220 kPa {1.84—2.24 kgf/cm

2

, 26.2—

31.9 psi}

End Of Sie

PISTON INSPECTION

Caution

• If the piston is replaced, replace the piston, piston pin, and the snap ring as a single component.

1. Measure the piston outer diameter using the

micrometer. The measurement position is 8.0 mm

{0.31 in} from the lower end of the piston (area

with no coating on the piston skirt) and in the

thrust direction.

• If it is not within the specification, replace the

piston.

Standard piston outer diameter

88.965—88.995 mm {3.5026—3.5037 in}

2. Measure the cylinder bore diameter. (See 01-1032 CYLINDER BLOCK INSPECTION.)

bp31je00000131

id011000502100

bpe1ze00000097

01-10–32

Page 46

MECHANICAL

3. Calculate the cylinder-to-piston clearance from the cylinder bore diameter and the piston outer diameter.

• If the clearance exceeds the maximum specification, replace the piston or cylinder block.

Standard clearance between piston and cylinder

0.025—0.045 mm {0.0010—0.0017 in}

Maximum clearance between piston and cylinder

0.066 mm {0.0026 in}

4. Measure the piston-to-ring groove clearance

along the perimeter using a feeler gauge. For the

O-ring, measure the clearance with the O-ring

assembled to the piston.

• If the clearance exceeds the maximum

specification, replace the piston or piston ring.

Standard clearance between piston ring and

ring groove

Top: 0.04—0.08 mm {0.002—0.003 in}

Second: 0.03—0.07 mm {0.0012—0.0027 in}

Oil: 0.04—0.12 mm {0.002—0.004 in}

Maximum clearance between piston ring and

ring groove

Top: 0.12 mm {0.0047 in}

Second: 0.10 mm {0.0039 in}

Oil: 0.17 mm {0.0067 in}

bpe1ze00000098

01-10

End Of Sie

PISTON RING INSPECTION

1. Using the piston, press the piston ring parallel into

the cylinder to 43.9 mm {1.73 in} from the upper

end of the cylinder block.

2. Measure the piston ring end gap using a feeler

gauge.

• If it exceeds the maximum specification,

replace the piston ring.

Standard piston ring end gap

Top: 0.13—0.18 mm {0.0052—0.0070 in}

Second: 0.18—0.28 mm {0.008—0.011 in}

Oil (Rail): 0.10—0.35 mm {0.004—0.013 in}

Maximum piston ring end gap

Top: 0.35 mm {0.014 in}

Second: 0.45 mm {0.018 in}

Oil (Rail): 0.52 mm {0.020 in}

43.9 mm {1.73 in}

id011000592300

PISTON

CYLINDER BLOCK

PISTON RING

bpe2ue00000094

PISTON RING

bpe2ue00000095

End Of Sie

01-10–33

Page 47

MECHANICAL

C

PISTON PIN INSPECTION

Caution

• If the piston or piston pin is replaced, replace the piston, piston pin and the snap ring as a single

component.

1. Measure the piston pin outer diameter using the

micrometer. Measurement positions total eight

and are in the X and Y directions, at four points

(A, B, C, and D) as shown in the figure.

Standard piston pin outer diameter

20.995—21.000 mm {0.82658—0.82677 in}

2. Measure the piston pin hole diameter using the

caliper gauge. Measurement positions total eight

and are in the X and Y directions, at four points

X

(A, B, C, and D) as shown in the figure.

Standard piston pin hole diameter

21.004—21.008 mm {0.82693—0.82708 in}

A

B

3. Calculate the clearance between the piston pin

hole diameter and the piston pin outer diameter.

• If it is not within the specification, replace the

piston or the piston pin.

C

D

Standard clearance between piston pin hole

diameter and piston pin outer diameter

0.004—0.013 mm {0.0002—0.0005 in}

id011000507500

X

Y

A

B

D

adj2224e255

Y

bpe1ze00000085

4. Measure the inner diameter on the small end of

the connecting rod using the caliper gauge in the

X and Y directions as shown in the figure.

Standard connecting rod small end inner

diameter

21.002—21.013 mm {0.82686—0.82728 in}

5. Calculate the clearance between the inner

diameter on the small end of the connecting rod

and the piston pin outer diameter.

• If it is not within the specification, replace the

CONNECTING ROD

connecting rod or the piston pin.

Standard clearance between connecting rod small end inner diameter and piston pin outer diameter

0.002—0.018 mm {0.00008—0.00070 in}

End Of Sie

X

Y

bpe2ue00000092

01-10–34

Page 48

MECHANICAL

PISTON AND CONNECTING ROD INSPECTION

1. Check the oscillation torque as shown in the

figure. Verify that the large end drops under its

own weight with no resistance.

• If the piston shakes heavily or unsmoothly,

disassemble the piston and connecting rod,

then inspect the following: (See 01-10-34

PISTON PIN INSPECTION.)

— Clearance between piston pin outer

diameter and piston pin hole diameter.

— Clearance between piston pin outer

diameter and connecting rod small end

inner diameter.

End Of Sie

CONNECTING ROD INSPECTION

1. Inspect the connecting rod for bending and

distortion using the connecting rod aligner.

• If it exceeds the maximum specification,

replace the connecting rod.

Maximum connecting rod bending

0.050 mm {0.0020 in}

Maximum connecting rod distortion

0.050 mm {0.0020 in}

id011000503100

01-10

bp31je00000061

id011000502800

Connecting rod center-to-center distance

154.8 mm {6.094 in}

End Of Sie

CONNECTING ROD CLEARANCE INSPECTION

1. Measure the side clearance at the large end of

the connecting rod using a feeler gauge.

• If it exceeds the maximum specification,

replace the connecting rod or crankshaft.

Standard side clearance at the large end of

connecting rod

0.14—0.36 mm {0.006—0.014 in}

Maximum side clearance at the large end of

connecting rod

0.465 mm {0.0183 in}

2. Measure the oil clearance at the large end of the

connecting rod using the following procedure:

(1) Cut the plastigauge as wide as the connecting

rod bearing width, place it parallel to the

crankshaft, avoiding the oil hole.

(2) Install the lower connecting rod bearing and

connecting rod cap. (See 01-10-40

CYLINDER BLOCK ASSEMBLY (I).)

(3) Remove the connecting rod cap. (See 01-10-

22 CYLINDER BLOCK DISASSEMBLY (II).)

(4) Measure the oil clearance at the large end of

the connecting rod.

• If it exceeds the maximum specification,

replace the bearing or grind the crank pin

and use oversize bearings so that the

specified clearance is obtained.

bpe2ue00000036

id011000507600

bp31je00000148

PLASTIGAUGE

bpe2ue00000093

01-10–35

Page 49

MECHANICAL

Standard bearing oil clearance at the large end of the connecting rod

0.026—0.052 mm {0.0011—0.0020 in}

Maximum bearing oil clearance at the large end of the connecting rod

0.10 mm {0.0039 in}

Connecting rod bearing size

STD: 1.502—1.519 mm {0.05914—0.05980 in}

OS 0.25: 1.628—1.631 mm {0.06410—0.06421 in}

OS 0.50: 1.753—1.756 mm {0.06902—0.06913 in}

End Of Sie

CRANKSHAFT INSPECTION

1. Measure the crankshaft end play using a dial

gauge.

• If it exceeds the maximum specification,

replace the crankshaft or grind the thrust side

of crankshaft and use the oversize thrust

bearing so that the specified end play is

obtained.

Standard crankshaft end play

0.08—0.29 mm {0.004—0.011 in}

id011000502500

Maximum crankshaft end play

0.30 mm {0.012 in}

Thrust bearing size

STD: 2.500—2.550 mm {0.0985—0.1003 in}

OS 0.25: 2.625—2.675 mm {0.1034—0.1053

in}

2. Measure the runout of the main journal using a Vblock and dial gauge.

• If it exceeds the maximum specification,

replace the crankshaft.

Maximum main journal runout

0.10 mm {0.0039 in}

3. Inspect the main journal diameter and crank pin

diameter. Measurement positions total four and

are in the X and Y directions, at two points (A and

B) as shown in the figure.

• If it is not within the specification or if it

exceeds the maximum off-round, grind the

journal with an oversized bearing.

bp31je00000217

bpe2ue00000035

AB

X

Y

Standard main journal diameter

49.980—50.000 mm {1.9678—1.9685 in}

Maximum main journal off-round

0.005 mm {0.0002 in}

Standard crank pin diameter

49.980—50.000 mm {1.9678—1.9685 in}

Maximum crank pin off-round

0.005 mm {0.0002 in}

01-10–36

b3e0110e085

Page 50

MECHANICAL

4. Inspect the main journal oil clearance using the following procedure:

(1) Install the thrust bearing, upper main bearing and crankshaft.

(2) Position a plastigauge on the journals.

(3) Install the lower main bearing and lower cylinder block. (See 01-10-40 CYLINDER BLOCK ASSEMBLY (I).)

(4) Remove the lower cylinder block. (See 01-10-22 CYLINDER BLOCK DISASSEMBLY (II).)

(5) Measure the main journal oil clearance.

• If it exceeds the maximum specification,

replace the main bearing, or grind the

main journal and use oversized bearings

so that the specified oil clearance is

obtained.

Standard main journal oil clearance

0.016—0.039 mm {0.0007—0.0015 in}

Maximum main journal oil clearance

0.084 mm {0.0033 in}

Main bearing size

STD: 2.489—2.510 mm {0.0980—0.0988 in}

OS 0.25: 2.614—2.617 mm {0.10292—0.10303 in}

OS 0.50: 2.739—2.742 mm {0.10784—0.10795 in}

End Of Sie

DUAL-MASS FLYWHEEL INSPECTION

bp31je00000152

id011000501900

01-10

Caution

• Do not rework the dual-mass flywheel if it is distorted.

• Do not clean the dual-mass flywheel with any kind of fluid. Clean the dual-mass flywheel with a dry

cloth only.

• Do not clean the gap between the primary and secondary mass. Only clean the bolt connection

surface and the clutch surface.

Inspection Before Removal

1. Rotate the dual-mass flywheel or attempt to move

it up and down, and left and right to verify that the

center of the dual-mass flywheel does not move.

• If there is any movement as indicated by the

arrows in the figure, replace the dual-mass

flywheel.

2. Verify that the secondary mass does not rotate by

15 teeth or more.

• If it rotates by 15 teeth or more, replace the

dual-mass flywheel.

ac5wzw00005672

ac5wzw00005673

01-10–37

Page 51

MECHANICAL

3. Measure the amount of guide pin projection of the

dual-mass flywheel.

• If it exceeds the maximum amount, replace

the dual-mass flywheel.

Dual-mass flywheel guide pin projection

maximum amount

11.0—12.0 mm {0.434—0.472 in}

4. Using a dial indicator, measure the dual-mass

flywheel runout.

• If it exceeds the maximum runout, replace the

dual-mass flywheel.