Mazda MX-5 1994 User Manual

1994 Mazda MX-5 Miata

1994 Mazda MX-5 Miata

D - ADJUSTMENTS 1994 ENGINE PERFORMANCE Mazda - On-Vehicle Adjustments

D - ADJUSTMENTS 1994 ENGINE PERFORMANCE Mazda - On-Vehicle Adjustments

D - ADJUSTMENTS

1994 ENGINE PERFORMANCE Mazda - On-Vehicle Adjustments

ENGINE MECHANICAL

Before performing any on-vehicle adjustments to fuel or ignition systems, ensure engine mechanical condition

is okay.

VALVE CLEARANCE

NOTE: All piston engines are equipped with hydraulic valve lash adjusters. Valve

clearance is not adjustable.

IGNITION TIMING

NOTE: Before adjusting ignition timing, warm engine to normal operating temperature.

Turn off all accessories. Place transmission in Neutral (M/T) or Park (A/T).

Ensure idle speed is correct. See IDLE SPEED under IDLE SPEED & MIXTURE. If

timing is not within specification, loosen distributor or Crank Angle Sensor

(CAS) lock bolt. Rotate distributor or CAS until timing marks are aligned.

Tighten lock bolt.

1994 Mazda MX-5 Miata

D - ADJUSTMENTS 1994 ENGINE PERFORMANCE Mazda - On-Vehicle Adjustments

Courtesy of MAZDA MOTORS CORP.

NOTE: On Miata, use Blue 1-pin connector near airflow meter as a source of battery

power for positive lead of tachometer or timing light (battery is in trunk). DO

NOT ground this connector, or 20-amp WIPER fuse will blow.

1. Connect Diagnostic Tester (49 B019 9A0) to diagnostic connector and select SELF-TEST mode (position

1), or connect jumper wire between diagnostic connector terminals TEN and GND. See Fig. 2 .

2. Connect timing light. Set timing to specification. See IGNITION TIMING SPECIFICATIONS table.

See Fig. 1 . Disconnect diagnostic tester or jumper wire from diagnostic connector.

Fig. 2: Diagnostic Connector Terminal ID (Miata)

1994 Mazda MX-5 Miata

D - ADJUSTMENTS 1994 ENGINE PERFORMANCE Mazda - On-Vehicle Adjustments

Courtesy of MAZDA MOTORS CORP.

IGNITION TIMING SPECIFICATIONS

Application M/T

Miata

(2)

(1)

Place automatic transmission in Park.

(2)

Connect jumper wire between terminals TEN and GRN of diagnostic connector.

10 @ 850 10 @ 800

(1)

A/T

IDLE SPEED & MIXTURE

NOTE: Mixture adjustment is NOT a normal tune-up procedure. DO NOT adjust mixture

unless mixture control unit is replaced or vehicle fails emissions test.

NOTE: Idle mixture is not adjustable. If idle mixture is incorrect, see TESTS W/CODES

article in the ENGINE PERFORMANCE section.

IDLE SPEED

NOTE: Before adjusting idle speed, warm engine to normal operating temperature.

Turn off all accessories. Place transmission in Neutral (M/T) or Park (A/T).

Ensure ignition timing is adjusted. See IGNITION TIMING .

NOTE: On Miata, use Blue 1-pin connector near airflow meter as a source of battery

power for positive lead of tachometer or timing light (battery is in trunk). DO

NOT ground this connector, or 20-amp WIPER fuse will blow.

1. Connect Diagnostic Tester (49 B019 9A0) to diagnostic connector and select SELF-TEST mode, or

connect jumper wire between diagnostic connector terminals TEN and GND. See Fig. 2 . Connect

tachometer to diagnostic connector terminal IG (-).

2. If idle speed is not within specification, rotate idle air adjusting screw on throttle body. See IDLE SPEED

SPECIFICATIONS table. Disconnect jumper wire.

IDLE SPEED SPECIFICATIONS

Application M/T: RPM

Miata

(2)

(1)

Place automatic transmission in Park.

850 800

(1)

A/T: RPM

(2)

Connect jumper wire between terminals TEN and GRN of diagnostic connector.

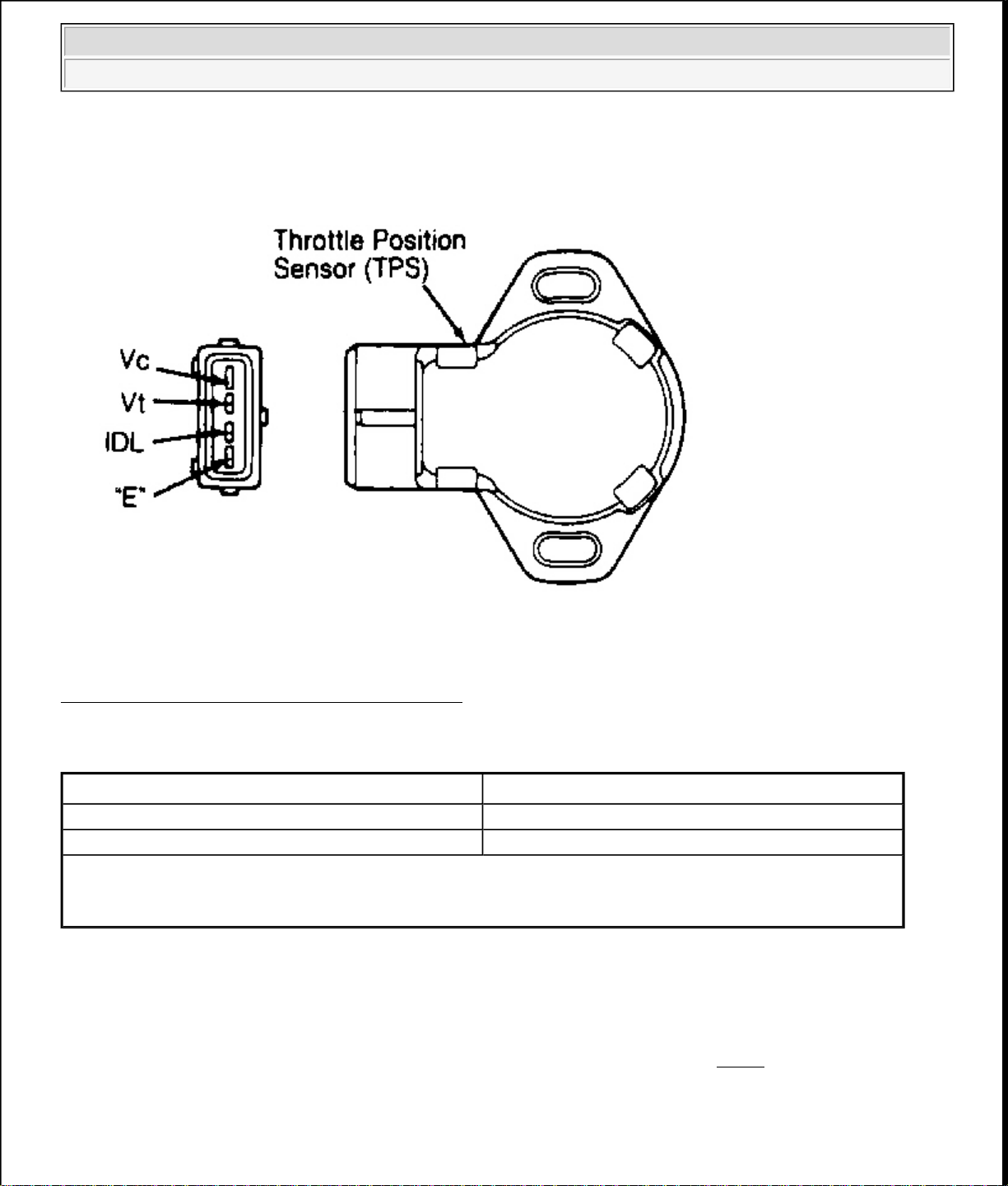

THROTTLE POSITION (TP) SENSOR

1994 Mazda MX-5 Miata

D - ADJUSTMENTS 1994 ENGINE PERFORMANCE Mazda - On-Vehicle Adjustments

INSPECTION (A/T)

1. Disconnect TP sensor connector. Connect ohmmeter between TP sensor connector terminals "E" and

IDL. See Fig. 3

. Insert feeler gauge of specified thickness between throttle lever and throttle stop screw.

See TP SENSOR CONTINUITY (A/T) table.

2. If continuity is not as specified, adjust TP sensor. See ADJUSTMENT procedure. If continuity is as

specified, connect ohmmeter between TP sensor connector terminals Vt and "E". If resistance is less than

1000 ohms with throttle fully closed and about 5000 ohms with throttle wide open, TP sensor is adjusted.

If resistance is not as specified, adjust TP sensor. See ADJUSTMENT procedure.

NOTE: If ohmmeter reading indicates a rough transition anywhere in range between

lowest and highest readings, TP sensor potentiometer is faulty. Replace TP

sensor.

ADJUSTMENT

1. Disconnect TP sensor connector. Connect ohmmeter between TP sensor connector terminals "E" and

IDL. See Fig. 3

. Loosen TP sensor attaching screws.

2. Insert a .010" (.25 mm) feeler gauge between throttle lever and throttle stop screw. Rotate TP sensor

clockwise about 30 degrees, then rotate counterclockwise until ohmmeter indicates continuity.

3. Remove feeler gauge. Insert a .016" (.40 mm) feeler gauge between throttle lever and throttle stop screw.

If ohmmeter indicates no continuity, go to next step. If ohmmeter indicates continuity, repeat adjustment

procedure.

4. Tighten TP sensor attaching screws. Open throttle valve fully and verify resistance between terminals "E"

and Vt is about 5000 ohms.

1994 Mazda MX-5 Miata

D - ADJUSTMENTS 1994 ENGINE PERFORMANCE Mazda - On-Vehicle Adjustments

Fig. 3: TP Sensor Connector Terminal ID (A/T)

Courtesy of MAZDA MOTORS CORP.

TP SENSOR CONTINUITY

Test Condition

(1)

(2)

Continuity

.004" (.10 mm) Yes

.024" (.60 mm) No

(1)

Insert feeler gauge of specified thickness between throttle lever and throttle stop screw.

(2)

Check continuity with ohmmeter connected between TP sensor terminals "E" and IDL.

INSPECTION (M/T)

1. Disconnect TP sensor connector. Insert feeler gauge of specified thickness between throttle lever and

throttle stop screw. See TP SENSOR CONTINUITY (M/T) table.

2. Connect ohmmeter between specified terminals of TP sensor connector. See Fig. 4 . If continuity is not as

specified, adjust TP sensor. See ADJUSTMENT procedure.

ADJUSTMENT

1. Disconnect TP sensor connector. Connect ohmmeter between terminals IDL and TL/E of TP sensor

1994 Mazda MX-5 Miata

D - ADJUSTMENTS 1994 ENGINE PERFORMANCE Mazda - On-Vehicle Adjustments

connector. See Fig. 4 . Insert a .016" (.41 mm) feeler gauge between throttle lever and throttle stop screw.

2. Loosen TP sensor screws. Rotate TP sensor clockwise about 30 degrees, then rotate counterclockwise

until ohmmeter indicates continuity.

3. Remove feeler gauge. Insert a .027" (.69 mm) feeler gauge between throttle lever and throttle stop screw.

If ohmmeter indicates no continuity, go to next step. If ohmmeter indicates continuity, repeat adjustment

procedure.

4. Tighten TP sensor attaching screws. Open throttle valve fully a few times. Recheck TP sensor adjustment.

Fig. 4: TP Sensor Connector Terminal ID (M/T)

Courtesy of MAZDA MOTORS CORP.

TP SENSOR CONTINUITY

Condition

.016" (.41 mm)

.027" (.7 mm)

(1)

(1)

Continuity Between IDL

& TL/E

Yes No

No No

Continuity Between POW &

TL/E

WOT No Yes

Insert feeler gauge of specified thickness between throttle lever and throttle stop screw.

1994 Mazda MX-5 Miata

D - ADJUSTMENTS 1994 ENGINE PERFORMANCE Mazda - On-Vehicle Adjustments

(1)

THROTTLE (IDLE) SWITCH

NOTE: Throttle switch is either a part of TP sensor, which is adjusted automatically

when TP is adjusted, or a separate, nonadjustable switch on throttle body. See

THROTTLE POSITION (TP) SENSOR .

p

1994 Mazda MX-5 Miata

1994 Mazda MX-5 Miata

AIR BAG RESTRAINT SYSTEM 1994 ACCESSORIES/SAFETY EQUIPMENT Mazda Air Bags

AIR BAG RESTRAINT SYSTEM 1994 ACCESSORIES/SAFETY EQUIPMENT Mazda Air Bags

AIR BAG RESTRAINT SYSTEM

1994 ACCESSORIES/SAFETY EQUIPMENT Mazda Air Bags

DESCRIPTION & OPERATION

WARNING: To avoid injury from accidental air bag deployment, read and carefully

follow all WARNINGS and SERVICE PRECAUTIONS.

The Supplemental Restraint System (SRS), when used in conjunction with seat belt, provides increased

rotection for driver and passenger in a collision. The air bag restraint system consists of AIR BAG warning

light, driver's air bag module, passenger's air bag module, clockspring, diagnostic module, back-up battery

(located inside diagnostic module), 4 crash sensors and wiring harness. One crash sensor (S-sensor) is located

above heater unit in passenger compartment. Three other crash sensors (D-sensor) are located left front, right

front, and center front of vehicle. See Fig. 1 .

The air bag is designed to deploy when S-sensor (rear) and at least one D-sensor (front) close in a collision

when ignition is on. The back-up battery supplies current for the ignitor if the vehicle battery or fuses fail

during a collision.

The diagnostic module monitors the air bag system for failures. If diagnostic module detects a short between air

bag module and ground or a malfunction with S-sensor or any D-sensor, diagnostic module will melt system

fuse to prevent unintended air bag deployment. If a failure occurs, the diagnostic module turns on the AIR BAG

warning light. If AIR BAG warning light is burned out, diagnostic module will sound a buzzer to alert driver of

a system malfunction.

g

1994 Mazda MX-5 Miata

AIR BAG RESTRAINT SYSTEM 1994 ACCESSORIES/SAFETY EQUIPMENT Mazda Air Bags

Fig. 1: Identifying Air Bag System Components

Courtesy of MAZDA MOTORS CORP.

SERVICE PRECAUTIONS

Following precautions should be observed when working with air bag systems:

Disable SRS before servicing any SRS or steering column component. Failure to do this could result in

accidental air bag deployment and possible personal injury. See DISABLING & ACTIVATING AIR

BAG SYSTEM .

After an accident, all SRS components, including harness and brackets, must be inspected. If any

components are damaged or bent, they must be replaced, even if a deployment did not occur. Check

steering column, knee bolster, instrument panel steering column reinforcement plate and lower brace for

damage. DO NOT service any component or wiring. If components or wiring are damaged or defective,

replacement is necessary. DO NOT use components from another vehicle. Only use new replacement

parts.

After repairs, turn ignition on while ensuring any accidental air bag deployment will not cause injury.

Ensure SRS indicator li

ht is working properly and no system faults are indicated. See TESTING -

p

1994 Mazda MX-5 Miata

AIR BAG RESTRAINT SYSTEM 1994 ACCESSORIES/SAFETY EQUIPMENT Mazda Air Bags

SYSTEM OPERATION CHECK .

Always wear safety glasses when servicing or handling an air bag.

Air bag module must be stored in its original special container until used for service. It must be stored in

a clean, dry place, away from sources of extreme heat, sparks and high electrical energy.

When placing a live air bag module on a bench or other surface, always face air bag and trim cover up,

away from surface. This will reduce motion of module if it is accidentally deployed.

After deployment, air bag surface may contain deposits of sodium hydroxide, which can irritate skin.

Always wear safety glasses, rubber gloves and long-sleeved shirt during clean-up, and wash hands using

mild soap and water. Follow correct disposal procedures. See DISPOSAL PROCEDURES .

NEVER allow any electrical source near inflator on back of air bag module.

If the ignition is on, DO NOT bump the SRS unit. This could cause the air bags to deploy.

When carrying a live air bag module, trim cover should be pointed away from your body to minimize

injury in case of deployment.

DO NOT probe a wire through insulator; this will damage wire and eventually cause failure due to

corrosion.

When performing electrical tests, always use specified digital multimeter and SRS test harnesses

recommended by manufacturer. See SPECIAL TOOLS. DO NOT directly probe the component

connector pins or wires.

When installing SRS wiring harnesses, ensure they will not be pinched or interfere with other vehicle

components.

Inspect all ground connections. Ensure they are clean and tight.

DO not use any type of electrical equipment not specified by manufacturer. See SPECIAL TOOLS.

If SRS is not fully functional for any reason, vehicle should not be driven until system is repaired. DO

NOT remove any component or in any way disable system from operating normally. If SRS is not

functional, park vehicle until repairs can be made.

DISABLING & ACTIVATING AIR BAG SYSTEM

WARNING: After disabling air bag system, wait at least 10 minutes before servicing.

Air bag system voltage is maintained for about 10 minutes after system is

disabled. Failure to wait at least 10 minutes may cause accidental air bag

deployment and possible personal injury.

PROCEDURES

Disabling System

Cancel radio anti-theft function. See CANCELING & ACTIVATING RADIO ANTI-THEFT under

DISABLING & ACTIVATING AIR BAG SYSTEM. Disconnect and shield negative battery cable. Wait at

least 10 minutes for back-up power supply to be depleted. Remove cover panel below left side of instrument

anel. Disconnect Orange and Blue clockspring connectors for driver air bag. See Fig. 2 . Remove glove

compartment. Disconnect Orange and Blue passenger air bag module connectors. See Fig. 3

.

1994 Mazda MX-5 Miata

AIR BAG RESTRAINT SYSTEM 1994 ACCESSORIES/SAFETY EQUIPMENT Mazda Air Bags

Activating System

Ensure negative battery cable is disconnected. Connect Orange and Blue passenger air bag module connectors.

See Fig. 3

. Install glove compartment. Connect driver air bag Orange and Blue clockspring connectors. See

Fig. 2 . Install lower cover panel. Connect negative battery cable. See TESTING - SYSTEM OPERATION

CHECK . Activate radio anti-theft function. See CANCELING & ACTIVATING RADIO ANTI-THEFT

under DISABLING & ACTIVATING AIR BAG SYSTEM.

Fig. 2: Locating Driver Air Bag Clockspring Connectors

Courtesy of MAZDA MOTORS CORP.

1994 Mazda MX-5 Miata

AIR BAG RESTRAINT SYSTEM 1994 ACCESSORIES/SAFETY EQUIPMENT Mazda Air Bags

Fig. 3: Locating Passenger Air Bag Clockspring Connectors

Courtesy of MAZDA MOTORS CORP.

CANCELING & ACTIVATING RADIO ANTI-THEFT

Canceling

1. Obtain radio anti-theft code from vehicle owner. Turn ignition on. Push REW and FF until radio displays

bars. Use channel preset buttons 1-4 to enter current code number.

2. Use preset button 1 to enter first digit of code, preset button 2 to enter second digit of code, etc. After

entering all 4 digits of code, press and hold REW and FF for approximately 2 seconds until a beep is

heard.

3. Radio will display CODE for approximately 5 seconds, then disappear to indicate radio is operative with

anti-theft function by-passed. If radio displays ERR, repeat procedure.

NOTE: If 3 consecutive errors are made during activation of radio anti-theft, radio will

become completely inoperable. If this happens, contact Panasonic.

Activating

1994 Mazda MX-5 Miata

AIR BAG RESTRAINT SYSTEM 1994 ACCESSORIES/SAFETY EQUIPMENT Mazda Air Bags

1. Turn ignition on. Press REW and FF until radio displays bars. While radio is displaying bars, use channel

preset buttons 1-4 to enter code number.

2. Use preset button 1 to enter first digit of code, preset button 2 to enter second digit of code, etc. After

entering all 4 digits of code, press and hold REW and FF for approximately 2 seconds until a beep is

heard.

3. Radio will display COD with a backwards 9. This display will flash for 5 seconds, then disappear to

indicate radio is operational with anti-theft activated. If radio displays ERR, repeat procedure.

POST-COLLISION INSPECTION

If air bags deployed, replace air bag modules and clockspring. Whether air bags deployed or not, inspect the

following components and replace them if damaged: diagnostic module, impact sensors, instrument panel,

steering column, and steering wheel. DO NOT attempt to repair any component or wiring harness. After

replacing components as necessary, perform TESTING - SYSTEM OPERATION CHECK .

ADJUSTMENTS

CLOCKSPRING CENTERING

Set front wheels in straight-ahead position. Turn clockspring clockwise until it stops (DO NOT force). Return

clockspring 2 3/4 turns counterclockwise until mark on clockspring aligns with steering column cover mark.

DISPOSAL PROCEDURES

DEPLOYED AIR BAG

Wrap deployed air bag module in a plastic bag and dispose of as you would any other part. Wear gloves and

safety glasses when handling air bag module.

SCRAPPED VEHICLE

NOTE: When scrapping vehicles with an undeployed air bag(s), air bag(s) must be

deployed inside vehicle.

Driver Air Bag

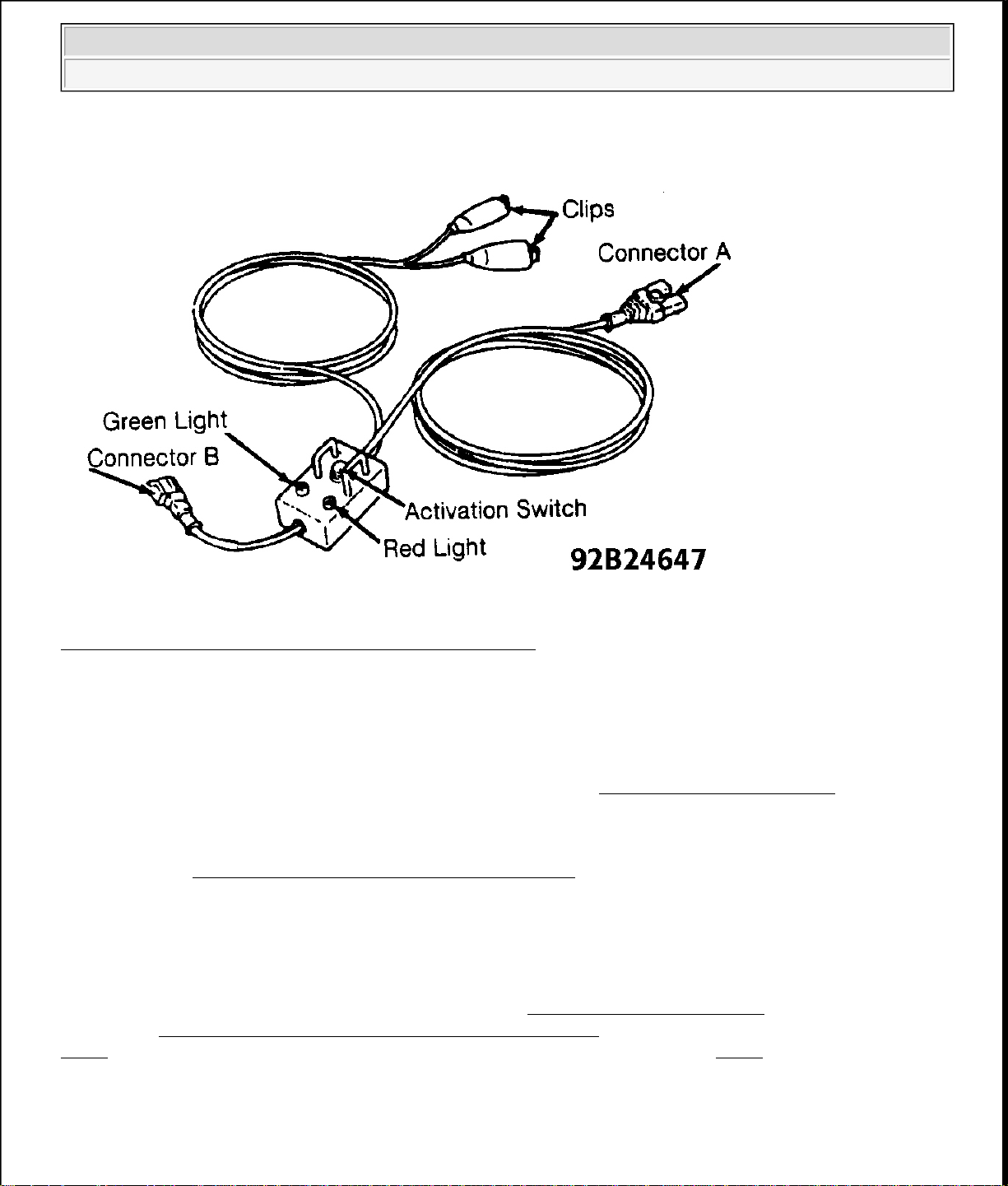

1. Before deploying air bag, inspect operating condition of Deployment Tool (49 H066 002). See

INSPECTING DEPLOYMENT TOOL

and away from other vehicles and people. Open doors. Open convertible top (if equipped). Disconnect

negative battery cable.

2. Ensure air bag module is firmly mounted to steering wheel. Remove cover panel below left side of

instrument panel. Disconnect Orange and Blue clockspring connectors for driver air bag. See Fig. 2

3. Connect deployment tool connector "A" to driver air bag clockspring connector. See Fig. 4

deployment tool clip to battery positive terminal. Connect Black deployment tool clip to battery negative

under DISPOSAL PROCEDURES. Ensure vehicle is outside

. Connect Red

.

1994 Mazda MX-5 Miata

AIR BAG RESTRAINT SYSTEM 1994 ACCESSORIES/SAFETY EQUIPMENT Mazda Air Bags

terminal. Verify deployment tool Red light is on.

4. Ensure all persons are at least 20 feet from vehicle. Press deployment tool activation switch to deploy air

bag. Because of heat generated from air bag deployment, wait at least 15 minutes before handling

deployed air bag module.

Passenger Air Bag

1. Before deploying air bag, inspect operating condition of Deployment Tool (49 H066 002). See

INSPECTING DEPLOYMENT TOOL under DISPOSAL PROCEDURES. Ensure vehicle is outside

and away from other vehicles and people. Open doors. Open convertible top (if equipped). Disconnect

negative battery cable.

2. Remove glove compartment. Disconnect Orange and Blue passenger air bag module connectors. See Fig.

3 . Connect deployment tool connector "A" to Orange and Blue passenger air bag connector. See Fig. 4 .

Connect Red deployment tool clip to battery positive terminal. Connect Black deployment tool clip to

battery negative terminal. Verify deployment tool Red light is on.

3. Ensure all persons are at least 20 feet from vehicle. Press deployment tool activation switch to deploy air

bag. Because of heat generated from air bag deployment, wait at least 15 minutes before handling

deployed air bag module.

INSPECTING DEPLOYMENT TOOL

NOTE: Deployment tool should always be inspected for proper operation before

deploying air bag.

1. Connect Red deployment tool clip to battery positive terminal. Connect Black deployment tool clip to

battery negative terminal. Observe deployment tool lights. Green light should be on with Red light off.

2. Connect deployment tool connector "A" to connector "B". See Fig. 4 . Green light should be off with Red

light on. Press deployment tool activation switch. Green light should be on with Red light off.

3. If deployment tool lights function as described, it is safe to use deployment tool to activate air bag. If

deployment tool lights do not function as described, DO NOT use deployment tool. Replace deployment

tool with another unit and repeat procedure.

1994 Mazda MX-5 Miata

AIR BAG RESTRAINT SYSTEM 1994 ACCESSORIES/SAFETY EQUIPMENT Mazda Air Bags

Fig. 4: Identifying Air Bag Deployment Tool Connectors

Courtesy of MAZDA MOTORS CORP.

REMOVAL & INSTALLATION

WARNING: Follow air bag service precautions to prevent accidental air bag

deployment and personal injury. See SERVICE PRECAUTIONS .

NOTE: After replacing components, check system to ensure proper operation. See

TESTING

DRIVER AIR BAG MODULE

Removal

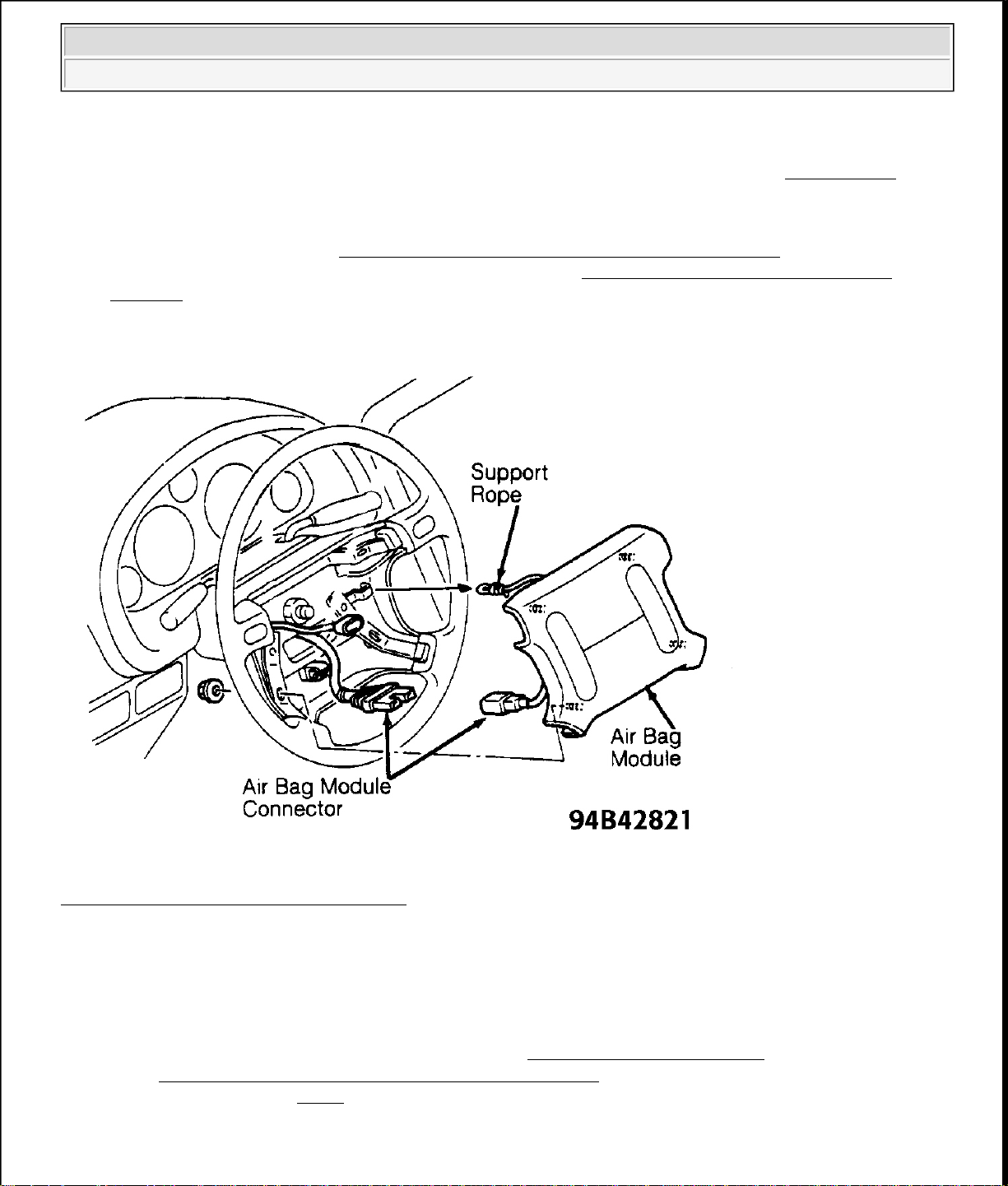

Before proceeding, follow air bag service precautions. See SERVICE PRECAUTIONS . Disable air bag

system. See DISABLING & ACTIVATING AIR BAG SYSTEM

. Disconnect driver air bag module connector. Disconnect support rope. See Fig. 5 . Remove driver air

Fig. 5

bag module.

Installation

- SYSTEM OPERATION CHECK .

. Remove 4 driver air bag module nuts. See

1. With driver air bag module removed from vehicle, connect Orange and Blue clockspring connectors

1994 Mazda MX-5 Miata

AIR BAG RESTRAINT SYSTEM 1994 ACCESSORIES/SAFETY EQUIPMENT Mazda Air Bags

located below left side of instrument panel. Connect negative battery cable. Turn ignition on. Observe

AIR BAG light. If code 32 is set, go to next step. If any code other than 32 is set, see DIAGNOSIS .

2. Turn ignition off. Disconnect negative battery cable. Disconnect Orange and Blue clockspring connectors

located below left side of instrument panel. To install, reverse removal procedure.

3. Activate air bag system. See DISABLING & ACTIVATING AIR BAG SYSTEM . Check AIR BAG

warning light to ensure system is functioning properly. See TESTING

- SYSTEM OPERATION

CHECK .

Fig. 5: Removing Driver Air Bag Module

Courtesy of MAZDA MOTORS CORP.

PASSENGER AIR BAG MODULE

Removal

Before proceeding, follow air bag service precautions. See SERVICE PRECAUTIONS . Disable air bag

system. See DISABLING & ACTIVATING AIR BAG SYSTEM . Remove 4 passenger air bag module nuts.

Disconnect support rope. See Fig. 6

Installation

. Remove passenger air bag module.

1994 Mazda MX-5 Miata

AIR BAG RESTRAINT SYSTEM 1994 ACCESSORIES/SAFETY EQUIPMENT Mazda Air Bags

1. With passenger air bag module removed from vehicle, connect Orange and Blue passenger air bag

module connectors. Connect negative battery cable. Turn ignition on. Observe AIR BAG light. If code 33

is set, go to next step. If any code other than 33 is set, see DIAGNOSIS

.

2. Turn ignition off. Disconnect negative battery cable. Disconnect Orange and Blue passenger air bag

module connectors. To install, reverse removal procedure.

3. Activate air bag system. See DISABLING & ACTIVATING AIR BAG SYSTEM

. Check AIR BAG

warning light to ensure system is functioning properly. See TESTING - SYSTEM OPERATION

CHECK .

Fig. 6: Removing Passenger Air Bag Module

Courtesy of MAZDA MOTORS CORP.

CLOCKSPRING

NOTE: Clockspring is part of combination switch. When replacing clockspring, replace

clockspring and combination switch as an assembly.

Removal

1994 Mazda MX-5 Miata

AIR BAG RESTRAINT SYSTEM 1994 ACCESSORIES/SAFETY EQUIPMENT Mazda Air Bags

1. Set front wheels in straight-ahead position. Before proceeding, follow air bag service precautions. See

SERVICE PRECAUTIONS . Disable air bag system. See DISABLING & ACTIVATING AIR BAG

SYSTEM .

2. Remove driver air bag module. See DRIVER AIR BAG MODULE . Remove steering wheel nut. Using

a puller, remove steering wheel. Remove steering column covers. Remove clockspring screws. Remove

clockspring and combination switch as an assembly.

Installation

1. To install, reverse removal procedure. Before installing steering wheel, center clockspring. See

CLOCKSPRING CENTERING under ADJUSTMENTS. Tighten steering wheel nut to specification.

See TORQUE SPECIFICATIONS TABLE at the end of this article.

2. After installation, activate air bag system. See DISABLING & ACTIVATING AIR BAG SYSTEM .

Check AIR BAG warning light to ensure system is functioning properly. See TESTING - SYSTEM

OPERATION CHECK .

CRASH SENSORS

WARNING: Crash sensor orientation and mounting is important for proper operation.

All sensors must be positioned so arrow points forward. If sheet metal

damage exists near sensor mounting point, inspect body structure at

sensor mounting point for deformation. If structure is damaged, restore it

to original shape.

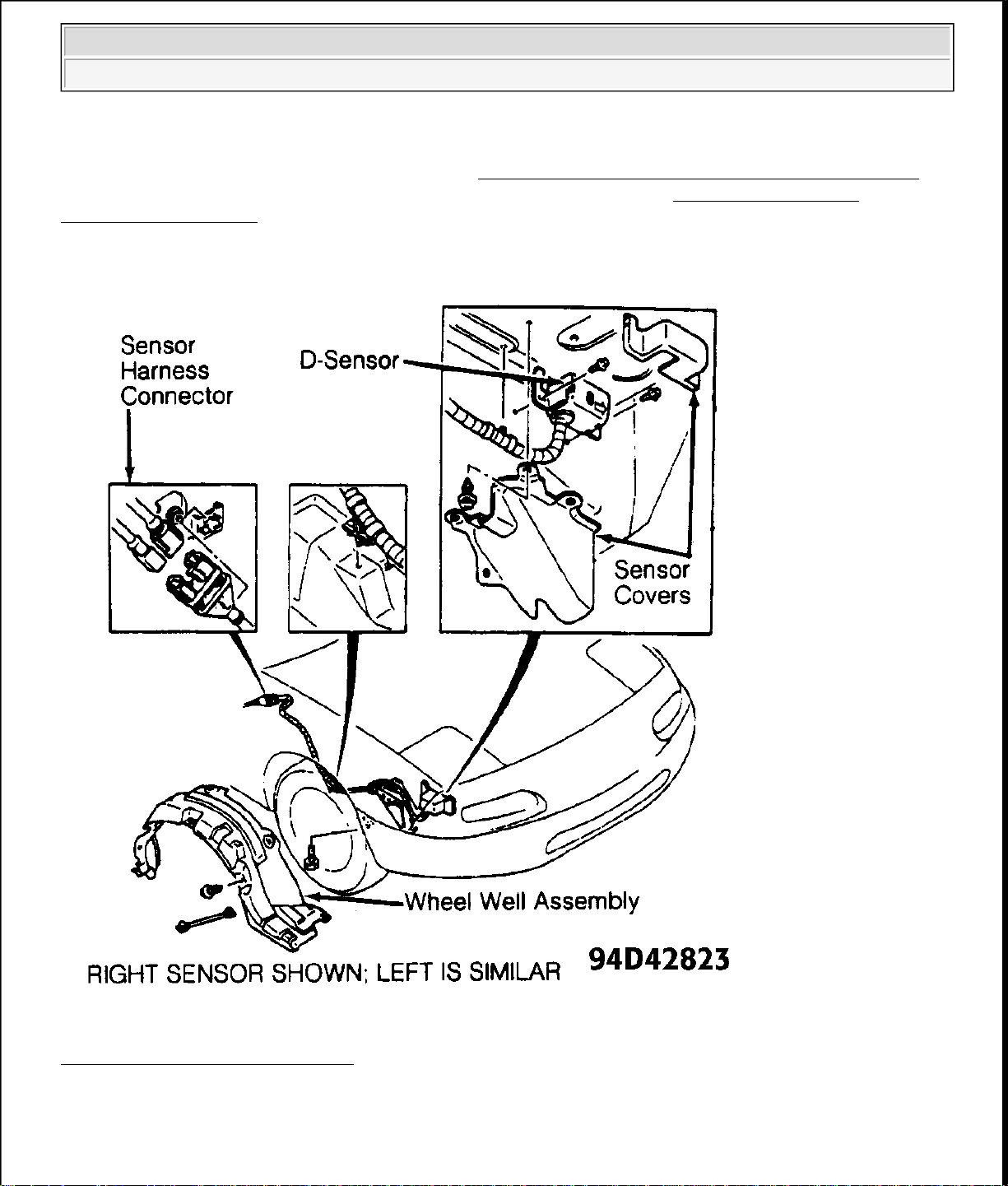

Removal (Front D-Sensors)

1. Before proceeding, follow air bag service precautions. See SERVICE PRECAUTIONS . Disable air bag

system. See DISABLING & ACTIVATING AIR BAG SYSTEM .

2. To remove center sensor, go to step 4). To remove left or right sensor, raise and support front of vehicle.

Remove wheel and tire assembly. Remove wheel well assembly to access sensor.

3. Remove 2 sensor covers. Unbolt sensor from vehicle. Disconnect sensor harness connector located in

front of door jamb area. Remove sensor and harness from vehicle. See Fig. 7

.

4. To remove center sensor, remove top cover located forward of radiator to access sensor. Remove sensor

cover. Unbolt sensor from vehicle. Disconnect sensor harness connector located on top of left wheel well

in engine compartment. Remove sensor and harness from vehicle.

Removal (Rear S-Sensor)

Before proceeding, follow air bag service precautions. See SERVICE PRECAUTIONS . Disable the air bag

system. See DISABLING & ACTIVATING AIR BAG SYSTEM

in passenger compartment. See Fig. 1

. Remove driver and passenger air bag modules. See DRIVER AIR BAG

. Rear S-sensor is located above heater unit

MODULE and PASSENGER AIR BAG MODULE. Remove dashboard assembly to access sensor. Unbolt

sensor from vehicle. Disconnect electrical connectors. Remove sensor from vehicle.

Installation (D-Sensor & S-Sensor)

1994 Mazda MX-5 Miata

AIR BAG RESTRAINT SYSTEM 1994 ACCESSORIES/SAFETY EQUIPMENT Mazda Air Bags

To install, reverse removal procedure. Position sensor with arrow toward front of vehicle. Install air bag

modules (if necessary). Activate air bag system. See DISABLING & ACTIVATING AIR BAG SYSTEM .

Check AIR BAG warning light to ensure system is functioning properly. See TESTING - SYSTEM

OPERATION CHECK .

Fig. 7: Removing Front (D

-Sensor)

Courtesy of MAZDA MOTORS CORP.

DIAGNOSTIC MODULE

Removal & Installation

y

1994 Mazda MX-5 Miata

AIR BAG RESTRAINT SYSTEM 1994 ACCESSORIES/SAFETY EQUIPMENT Mazda Air Bags

1. Before proceeding, follow air bag service precautions. See SERVICE PRECAUTIONS . Disable air bag

system. See DISABLING & ACTIVATING AIR BAG SYSTEM .

2. Diagnostic module is located under left side of instrument panel. See Fig. 1

module connectors. Remove 2 diagnostic module mounting nuts. Remove diagnostic module.

3. To install, reverse removal procedure. After diagnostic module is installed, activate air bag system. See

DISABLING & ACTIVATING AIR BAG SYSTEM

is functioning properly. See TESTING - SYSTEM OPERATION CHECK .

. Check AIR BAG warning light to ensure system

. Disconnect diagnostic

TESTING - SYSTEM OPERATION CHECK

Turn ignition on. AIR BAG warning light in instrument cluster should glow for 4-8 seconds and then turn off. If

AIR BAG warning light does not function as described, a failure has occurred in Supplemental Restraint

System (SRS). Repair malfunctioning SRS. See SERVICE PRECAUTIONS . See DIAGNOSIS .

WIRE REPAIR

DO NOT repair air bag system wiring. If a problem is found with air bag system wiring, replace faulty wiring.

DIAGNOSIS

WARNING: Follow air bag service precautions to prevent accidental air bag

deployment and personal injury. See SERVICE PRECAUTIONS .

SELF-DIAGNOSTIC SYSTEM

NOTE: If AIR BAG warning light does not come on and buzzer sounds when ignition is

turned on, check and repair warning light circuit first.

Diagnostic module will only display one code at a time. Diagnostic module will always display highest code

first. As an example, diagnostic module displays Code 23. After repairing Code 23, if any other codes are

stored, diagnostic module will display next code. Next code displayed will be Code 22 or less. After repairing

system, perform TESTING

during TESTING - SYSTEM OPERATION CHECK , record code displayed. Repair system as necessary.

Retrieving & Clearing Codes

If codes are stored, AIR BAG warning light will flash or remain on when ignition is turned on. Codes are

automatically cleared when fault is corrected.

AIR BAG Warning Light Flashes

AIR BAG warning light indicates fault codes by flashing. Count the number of flashes between pauses to

determine code. See AIR BAG CODES table. Codes are prioritized. If 2 or more faults are present, diagnostic

module will displa

highest code number first. After identifying code, go to appropriate code test.

- SYSTEM OPERATION CHECK . If AIR BAG warning light is still flashing

1994 Mazda MX-5 Miata

AIR BAG RESTRAINT SYSTEM 1994 ACCESSORIES/SAFETY EQUIPMENT Mazda Air Bags

AIR BAG Warning Light Remains On

AIR BAG warning light on all the time when ignition is turned on indicates a Code 0 (zero). See AIR BAG

CODES table.

AIR BAG Warning Light Does Not Come On

Check for blown fuses, burned-out bulb, disconnected diagnostic module or open circuit between warning light

and diagnostic module.

AIR BAG CODES

Code Possible Cause

0

(1)

Poor Connection At Diagnostic Module

12 Open Circuit Or Poor Connection Of Power Source

13 Damaged D-Sensor (D-Sensor On)

21 Poor Installation Of S-Sensor

22 Damaged S-Sensor (S-Sensor On)

23 Open Circuit In S-Sensor Feed Circuit

24 S-Sensor Diagnostic Circuit Open

32 High Resistance Or Open Circuit In Driver Air Bag

Module Circuit

33 High Resistance Or Open Circuit In Passenger Air

Bag Module Circuit

34 Low Resistance In Driver Air Bag Module Circuit

35 Low Resistance In Passenger Air Bag Module

Circuit

41 Open Circuit Between Diagnostic Module And D-

Sensor

44 Poor Installation Of Right D-Sensor

45 Poor Installation Of Center D-Sensor

46 Poor Installation Of Left D-Sensor

51 System Down (Fuse Open)

52 Damaged Back-Up Battery

53 Damaged Diagnostic Module

(2)

99

(1)

AIR BAG warning light remains on all the time indicating a Code 0 (zero).

Poor Connection Of All D-Sensors

(2)

AIR BAG warning light will flash quickly and continuously, indicating Code 99.

CODE 0

Warning Light Remains On

1994 Mazda MX-5 Miata

AIR BAG RESTRAINT SYSTEM 1994 ACCESSORIES/SAFETY EQUIPMENT Mazda Air Bags

1. Disable air bag system. See DISABLING & ACTIVATING AIR BAG SYSTEM . Ensure diagnostic

module connectors are properly connected. Verify that shorting bar is in fully retracted position. Repair as

necessary. If diagnostic module connectors and shorting bar are okay, go to next step.

2. Disconnect diagnostic module connector (with shorting bar). Remove shorting bar from diagnostic

module connector. Observe AIR BAG warning light. If AIR BAG warning light is on, repair wiring

harness between instrument cluster and diagnostic module connector. Perform TESTING

- SYSTEM

OPERATION CHECK . If AIR BAG warning light is off, replace diagnostic module. Perform

TESTING - SYSTEM OPERATION CHECK .

CODE 12

NOTE: For connector terminal identification, see WIRING DIAGRAM .

1. Disable air bag system. See DISABLING & ACTIVATING AIR BAG SYSTEM

. Check INJ fuse (30

amp) located in engine compartment fuse panel. If fuse is okay, go to next step. If fuse is open, go to step

3).

2. Disconnect diagnostic module connectors. Connect negative battery cable. Using a DVOM, measure

voltage on diagnostic module connector terminal 1L. If battery voltage is present, replace diagnostic

module. Perform TESTING

- SYSTEM OPERATION CHECK . If battery voltage is not present,

repair wiring harness between air bag fuse and diagnostic module connector. Perform TESTING -

SYSTEM OPERATION CHECK .

3. Disconnect diagnostic module connectors. Using a DVOM, check for continuity between diagnostic

module connector terminal 1L and ground. If continuity is not present, go to next step. If continuity is

present, replace INJ fuse and repair wiring harness between INJ fuse and diagnostic module connector.

Perform TESTING - SYSTEM OPERATION CHECK .

4. Using a DVOM, check for continuity between diagnostic module connector terminal 1H and ground. If

continuity is present, go to next step. If continuity is not present, replace diagnostic module. Perform

TESTING - SYSTEM OPERATION CHECK .

5. Disconnect S-sensor connector. Using a DVOM, check for continuity between diagnostic module

connector terminal 1H and ground. If continuity is present, replace S-sensor. Perform TESTING -

SYSTEM OPERATION CHECK

. If continuity is not present, replace wiring harness. Perform

TESTING - SYSTEM OPERATION CHECK .

CODE 13

NOTE: For connector terminal identification, see WIRING DIAGRAM

1. Disable air bag system. See DISABLING & ACTIVATING AIR BAG SYSTEM

.

. Connect negative

battery cable. Turn ignition on. Observe AIR BAG warning light. If AIR BAG warning light displays

Code 13, go to step 4). If AIR BAG warning light displays a code other than 13, go to next step.

2. Disconnect negative battery cable. Remove driver air bag module. See DRIVER AIR BAG MODULE

under REMOVAL & INSTALLATION. Connect driver air bag module Orange and Blue clockspring

connectors. Connect negative battery cable. Turn ignition on. Observe AIR BAG warning light. If AIR

BAG warning light displays Code 13, replace clockspring assembly. Perform TESTING - SYSTEM

1994 Mazda MX-5 Miata

AIR BAG RESTRAINT SYSTEM 1994 ACCESSORIES/SAFETY EQUIPMENT Mazda Air Bags

3. Turn ignition off. Disconnect negative battery cable. Connect passenger air bag module Orange and Blue

clockspring connectors. Connect negative battery cable. Turn ignition on. Observe AIR BAG warning

light. If AIR BAG warning light displays Code 13, replace passenger air bag module. Perform TESTING

- SYSTEM OPERATION CHECK . If AIR BAG warning light displays a code other than 13, replace

driver air bag module. Perform TESTING - SYSTEM OPERATION CHECK .

4. Turn ignition off. Disconnect diagnostic module connectors. Using a DVOM, check for continuity

between diagnostic module connector terminal 2F and ground. If continuity is not present, got to next

step. If continuity is present, replace wiring harness. Perform TESTING - SYSTEM OPERATION

CHECK .

5. Using a DVOM, check for continuity between diagnostic module connector terminal 2G and ground. If

continuity is not present, go step XX). If continuity is present, go to next step.

6. Using a DVOM, check for continuity between diagnostic module connector terminal 2D and ground. If

continuity is present, go to next step. If continuity is not present, go to step 8).

7. Disconnect S-sensor connector. Using a DVOM, check for continuity between S-sensor connector (sensor

side) terminal "C" and ground. If continuity is present, replace S-sensor. Perform TESTING - SYSTEM

OPERATION CHECK . If continuity is not present, replace wiring harness. Perform TESTING SYSTEM OPERATION CHECK .

8. Using a DVOM, check resistance between diagnostic module connector terminals 1C, 1A, 2L and ground

one at a time. If resistance on all terminals was 1.18 k-ohms, replace diagnostic module. Perform

TESTING - SYSTEM OPERATION CHECK . If resistance was not 1.18 k-ohms, on one or more

terminals, test suspect D-sensor. See SENSOR IDENTIFICATION table. Go to next step.

SENSOR IDENTIFICATION

Diagnostic Module

Connector Terminal D-Sensor

1A Center

1C Right

2L Left

9. Using a DVOM, check resistance between suspect D-sensor connector (sensor side) terminal "A" and

ground. See Fig. 8 . If resistance is 1.18 k-ohms, replace wiring harness. Perform TESTING - SYSTEM

OPERATION CHECK . If resistance is not 1.18 k-ohms, replace suspect D-sensor. Perform TESTING

- SYSTEM OPERATION CHECK .

1994 Mazda MX-5 Miata

AIR BAG RESTRAINT SYSTEM 1994 ACCESSORIES/SAFETY EQUIPMENT Mazda Air Bags

Fig. 8: Identifying D-Sensor Terminal "A"

Courtesy of MAZDA MOTORS CORP.

CODE 21

NOTE: For connector terminal identification, see WIRING DIAGRAM .

1. Disable air bag system. See DISABLING & ACTIVATING AIR BAG SYSTEM . Disconnect

diagnostic module connectors. Using a DVOM, check for continuity between diagnostic module

connector terminal 1E and ground. If continuity is present, replace diagnostic module. Perform

TESTING

- SYSTEM OPERATION CHECK . If continuity is not present, go to next step.

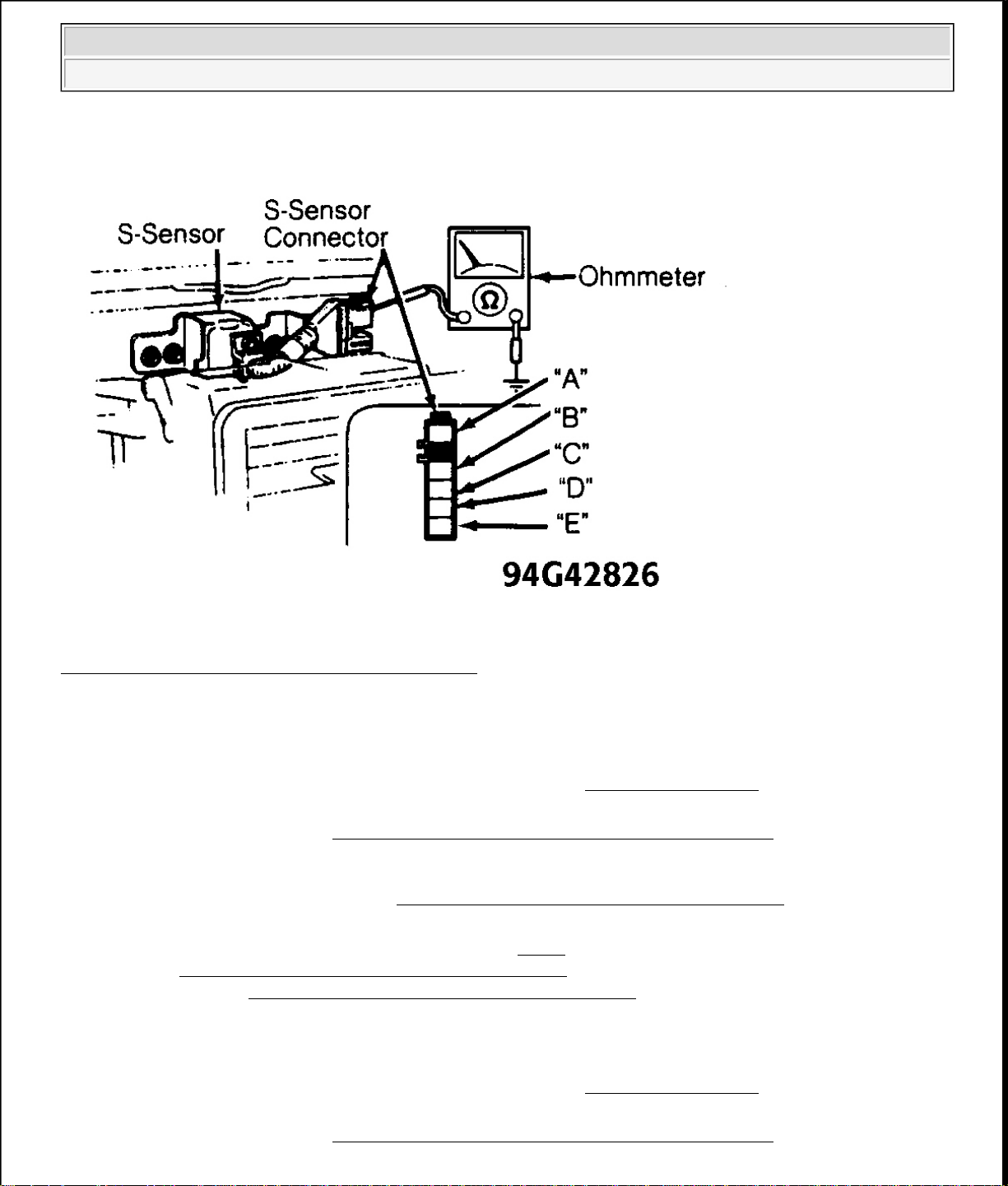

2. Disconnect Orange and Blue S-sensor connector. Using a DVOM, check for continuity between S-sensor

connector (sensor side) terminal "A" and ground. See Fig. 9

harness. Perform TESTING

- SYSTEM OPERATION CHECK . If continuity is not present, replace S-

. If continuity is present, replace wiring

sensor. Perform TESTING - SYSTEM OPERATION CHECK .

1994 Mazda MX-5 Miata

AIR BAG RESTRAINT SYSTEM 1994 ACCESSORIES/SAFETY EQUIPMENT Mazda Air Bags

Fig. 9: Identifying S-Sensor Connector Terminals

Courtesy of MAZDA MOTORS CORP.

CODE 22

NOTE: For connector terminal identification, see WIRING DIAGRAM .

1. Disable air bag system. See DISABLING & ACTIVATING AIR BAG SYSTEM

. Disconnect

diagnostic module connectors. Using a DVOM, check for continuity between diagnostic module

connector terminals 1H and 2D. If continuity is present, go to next step. If continuity is not present,

replace diagnostic module. Perform TESTING - SYSTEM OPERATION CHECK .

2. Disconnect Orange and Blue S-sensor connector. Using a DVOM, check for continuity between S-sensor

connector (sensor side) terminals "B" and "D". See Fig. 9 . If continuity is present, replace S-sensor.

Perform TESTING

harness. Perform TESTING

- SYSTEM OPERATION CHECK . If continuity is not present, replace wiring

- SYSTEM OPERATION CHECK .

CODE 23

NOTE: For connector terminal identification, see WIRING DIAGRAM .

1. Disable air bag system. See DISABLING & ACTIVATING AIR BAG SYSTEM

. Disconnect

diagnostic module connectors. Using a DVOM, check for continuity between diagnostic module

connector terminals 1H and 2C. If continuity is present, replace diagnostic module. Perform TESTING -

1994 Mazda MX-5 Miata

AIR BAG RESTRAINT SYSTEM 1994 ACCESSORIES/SAFETY EQUIPMENT Mazda Air Bags

SYSTEM OPERATION CHECK . If continuity is not present, go to next step.

2. Disconnect Orange and Blue S-sensor connector. Using a DVOM, check for continuity between S-sensor

connector (sensor side) terminals "B" and "E". See Fig. 9

Perform TESTING

- SYSTEM OPERATION CHECK . If continuity is not present, replace S-sensor.

. If continuity is present, replace wiring harness.

Perform TESTING - SYSTEM OPERATION CHECK .

CODE 24

NOTE: For connector terminal identification, see WIRING DIAGRAM .

Disable air bag system. See DISABLING & ACTIVATING AIR BAG SYSTEM . Disconnect diagnostic

module connectors. Using a DVOM, check for continuity between diagnostic module connector terminals 2B

and 2D. If continuity is present, replace diagnostic module. Perform TESTING - SYSTEM OPERATION

CHECK . If continuity is not present, replace wiring harness. Perform TESTING - SYSTEM OPERATION

CHECK .

CODE 32

NOTE: For connector terminal identification, see WIRING DIAGRAM .

1. Disable air bag system. See DISABLING & ACTIVATING AIR BAG SYSTEM . Connect a jumper

wire between driver air bag module clockspring connector (harness side) terminals "B" and "C". See Fig.

10 . Connect negative battery cable. Turn ignition on. Observe AIR BAG warning light. If AIR BAG

warning light displays Code 32, go to step 4). If AIR BAG warning light displays a code other than 32, go

to next step.

1994 Mazda MX-5 Miata

AIR BAG RESTRAINT SYSTEM 1994 ACCESSORIES/SAFETY EQUIPMENT Mazda Air Bags

Fig. 10: Clockspring Connector Terminal ID (Harness Side)

Courtesy of MAZDA MOTORS CORP.

2. Turn ignition off. Disconnect negative battery cable. Remove driver air bag module. See DRIVER AIR

BAG MODULE under REMOVAL & INSTALLATION. Remove jumper wire from driver air bag

module clockspring connector (harness side). Connect driver air bag module Orange and Blue

clockspring connectors. Connect a jumper wire between driver air bag module clockspring connector

terminals "B" and "C". See Fig. 11 .

1994 Mazda MX-5 Miata

AIR BAG RESTRAINT SYSTEM 1994 ACCESSORIES/SAFETY EQUIPMENT Mazda Air Bags

Fig. 11: Identifying Clockspring Connector Terminals

Courtesy of MAZDA MOTORS CORP.

3. Connect negative battery cable. Turn ignition on. Observe AIR BAG warning light. If AIR BAG warning

light displays Code 32, replace clockspring assembly. Perform TESTING

- SYSTEM OPERATION

CHECK . If AIR BAG warning light displays a code other than 32, replace driver air bag module.

Perform TESTING - SYSTEM OPERATION CHECK .

4. Turn ignition off. Disconnect negative battery cable. Disconnect diagnostic module connectors. Using a

DVOM, check for continuity between diagnostic module connector terminals 2D and 2F. If continuity is

present, replace diagnostic module. Perform TESTING - SYSTEM OPERATION CHECK . If

continuity is not present, replace wiring harness. Perform TESTING - SYSTEM OPERATION

CHECK .

CODE 33

NOTE: For connector terminal identification, see WIRING DIAGRAM .

1. Disable air bag system. See DISABLING & ACTIVATING AIR BAG SYSTEM

. Connect a one ohm

resistor (rated power one watt) between driver air bag module clockspring connector (harness side)

terminals "B" and "C". See Fig. 10

. Connect a jumper wire between passenger air bag module connector

1994 Mazda MX-5 Miata

AIR BAG RESTRAINT SYSTEM 1994 ACCESSORIES/SAFETY EQUIPMENT Mazda Air Bags

(harness side) terminals "B" and "C". See Fig. 12 .

2. Connect negative battery cable. Turn ignition on. Observe AIR BAG warning light. If AIR BAG warning

light displays Code 33, go to next step. If AIR BAG warning light displays a code other than 33, replace

passenger air bag module. Perform TESTING - SYSTEM OPERATION CHECK .

Fig. 12: Passenger Air Bag Module Connector Terminal ID (Harness Side)

Courtesy of MAZDA MOTORS CORP.

3. Turn ignition off. Disconnect negative battery cable. Disconnect diagnostic module connectors. Using a

DVOM, check for continuity between diagnostic module connector terminals 2D and 2G. If continuity is

present, replace diagnostic module. Perform TESTING - SYSTEM OPERATION CHECK . If

continuity is not present, replace wiring harness. Perform TESTING

- SYSTEM OPERATION

CHECK .

CODE 34

1994 Mazda MX-5 Miata

AIR BAG RESTRAINT SYSTEM 1994 ACCESSORIES/SAFETY EQUIPMENT Mazda Air Bags

NOTE: For connector terminal identification, see WIRING DIAGRAM

.

1. Disable air bag system. See DISABLING & ACTIVATING AIR BAG SYSTEM . Connect a one ohm

resistor (rated power one watt) between passenger air bag module connector (harness side) terminals "B"

and "C". See Fig. 12 .

2. Connect negative battery cable. Turn ignition on. Observe AIR BAG warning light. If AIR BAG warning

light displays Code 34, go to next step. If AIR BAG warning light displays a code other than 34, go to

step 4).

3. Turn ignition off. Disconnect negative battery cable. Disconnect diagnostic module connectors. Using a

DVOM, check for continuity between diagnostic module connector terminals 2D and 2F. If continuity is

present, replace wiring harness. Perform TESTING

- SYSTEM OPERATION CHECK . If continuity

is not present, replace diagnostic module. Perform TESTING - SYSTEM OPERATION CHECK .

4. Turn ignition off. Disconnect negative battery cable. Remove driver air bag module. See DRIVER AIR

BAG MODULE under REMOVAL & INSTALLATION. Inspect clockspring connector for broken pins.

If clockspring connector pins are okay, go to next step. If clockspring connector pins are broken, replace

clockspring assembly. Perform TESTING - SYSTEM OPERATION CHECK .

5. Connect clockspring connector. Turn ignition on. Observe AIR BAG warning light. If AIR BAG warning

light displays Code 34, replace clockspring assembly. Perform TESTING - SYSTEM OPERATION

CHECK . If AIR BAG warning light does not display Code 34, replace driver air bag module. Perform

TESTING - SYSTEM OPERATION CHECK .

CODE 35

NOTE: For connector terminal identification, see WIRING DIAGRAM .

1. Disable air bag system. See DISABLING & ACTIVATING AIR BAG SYSTEM . Inspect clockspring

connector for broken pins. If clockspring connector pins are okay, go to next step. If clockspring

connector pins are broken, replace clockspring assembly. Perform TESTING - SYSTEM OPERATION

CHECK .

2. Connect a one ohm resistor (rated power one watt) between driver air bag module clockspring connector

(harness side) terminals "B" and "C". See Fig. 10

. Connect negative battery cable. Turn ignition on.

Observe AIR BAG warning light.

3. If AIR BAG warning light displays Code 35, go to next step. If AIR BAG warning light displays a code

other than 35, replace passenger air bag module. Perform TESTING - SYSTEM OPERATION

CHECK .

4. Turn ignition off. Disconnect negative battery cable. Disconnect diagnostic module connectors. Using a

DVOM, check for continuity between diagnostic module connector terminals 2D and 2G. If continuity is

present, replace wiring harness. Perform TESTING

is not present, replace diagnostic module. Perform TESTING

- SYSTEM OPERATION CHECK . If continuity

- SYSTEM OPERATION CHECK .

CODE 41

NOTE: For connector terminal identification, see WIRING DIAGRAM

.

Loading...

Loading...