Page 1

GENUINE ACCESSORIES

®

INSTALLATION INSTRUCTIONS

PART NUMBER (s):

0000-8F-M40

REMOTE START SYSTEM

APPLICABLE MODELS

2007-UP > MAZDA CX-7

ALL MODELS

NOTE: BOTH VEHICLE IGNITION KEYS ARE REQUIRED AT TIME OF

INSTALLATION. DO NOT BEGIN INSTALLATION WITHOUT BOTH

KEYS.

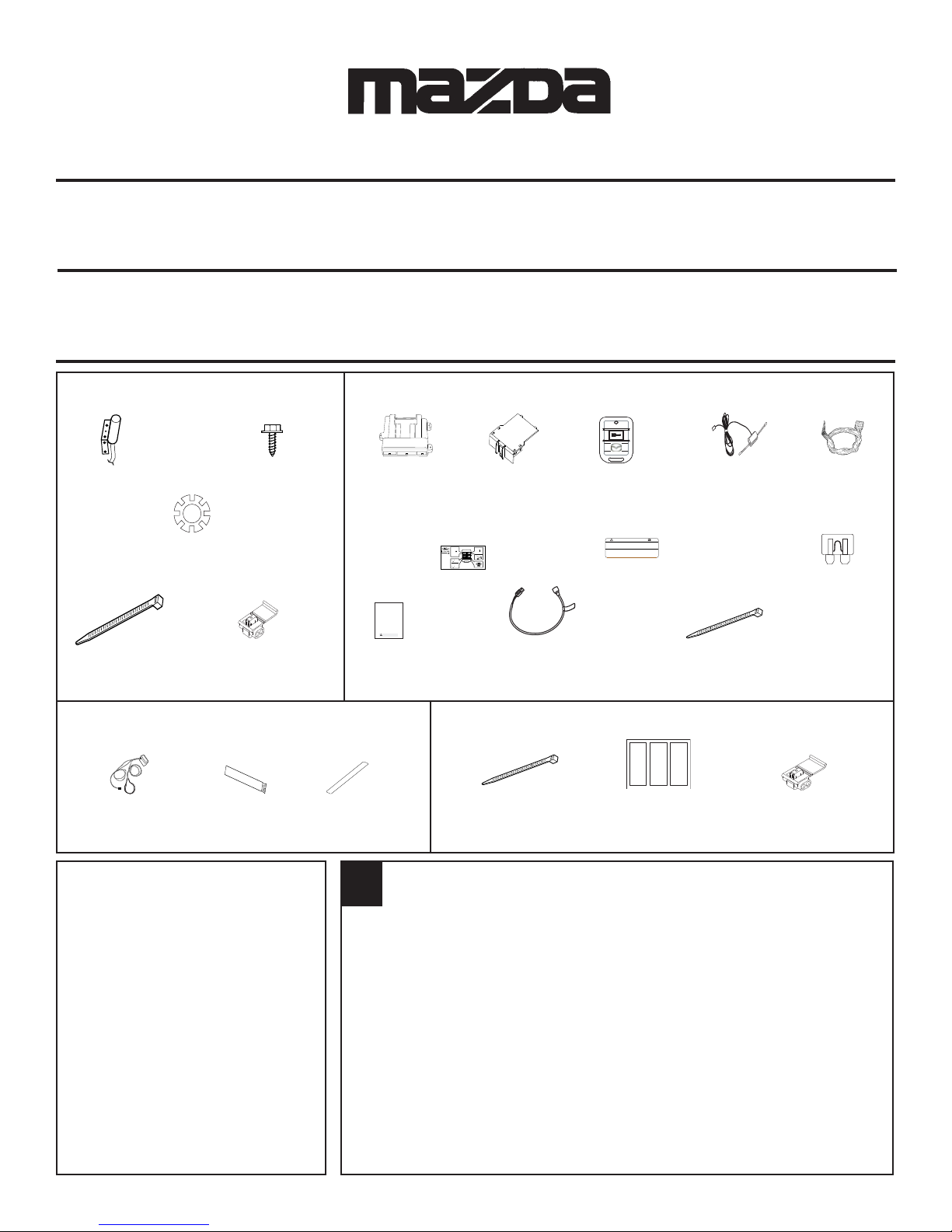

HOOD SAFETY SWITCH KIT CONTENTS

P/N: 0000-8F-H03

Hood Safety

Switch

(QTY 1)

Locking

Washer

(QTY 2)

Wire Tie

(QTY 2)

1/4” Self

Drilling Screws

(QTY 2)

IDC Wire Tap

(QTY 2)

Remote Start DNA Card Remote Start Dipole Antenna Remote Start

Control Module (QTY-1) Transmitters (QTY-1) Wire Harness

(QTY-1) (QTY-2) (QTY-1)

P/N: 0000-8F-Z01 P/N: 0000-8F-M21 P/N: 0000-8F-Z02 P/N: 0000-8F-Z10 P/N: 0000-8F-M41

2 sec.

5X

2 sec.

30

sec.

Wallet

Card

MAZDA

GENUINE ACCESSORIES

Vehicle Remote Start System

Owner's Manual

Featuring PowerCode Technology

TM

For the Ultimate in Comfort, Convenience and Security

(QTY 1)

TM

Owners

Manual

(QTY 1)

P/N: 0000-8F-Z03

KIT CONTENTS

Programming

Button

(QTY 1)

WARNING: / AVERTISSEMENT

This vehicle is equipped with a remote controlled engine starter.

To reduce the risk of serious Injury or death, switch engine starter

system into service mode and disconnect the vehicle battery

before performing any service on the vehicle.

Ce véhicule est doté d'un démarreur à distance. Pour réduire les

risques de blessures graves ou mortelles, mettre le démarreur à

distance en mode service et débrancher la batterie du véhicule

avant d'effectuer des travaux d'entretien sur celui-ci.

Underhood

Sticker

(QTY 1)

P/N: 0000-8F-Z12

Mini Fuses

(QTY - (1) 5 AMP)

(QTY - (7) 15 AMP)

Long Wire

Tie

(QTY 4)

IMMOBILIZER INTERFACE KIT CONTENTS

P/N: 0000-8F-H05A

Immobilizer Interface Adhesive Primer 2- Sided Tape

Module and Harness (QTY-1) (QTY-1)

(QTY-1)

TOOLS REQUIRED

0

SAFETY GLASSES

ELECTRICAL TAPE

WIRE CUTTERS

PLIERS

ALCOHOL or GLASS CLEANER

#2 PHILLIPS SCREWDRIVER

POWER DRILL

9/32” DRILL BIT

FIBER STICK

10 mm SOCKET AND RATCHET

1. CLEAN HANDS

2. OPEN DRIVER’S DOOR WINDOW

3. RECORD RADIO STATION PRESETS

4. SET PARKING BRAKE

5. ENSURE VEHICLE WILL START UTILIZING THE IGNITION KNOB & VALET

KEY (SMART-KEY EQUIPPED VEHICLES ONLY)

6. DISCONNECT AND ISOLATE NEGATIVE BATTERY TERMINAL

7. VEHICLE MUST BE AT ROOM TEMPERATURE

1/4” SOCKET AND DRIVE

3/8” DRIVE TORQUE WRENCH

3/8” DRIVE 10mm SOCKET

HI-TEMPERATURE SILICONE

PARTS BAG CONTENTS

Wire Tie

(QTY-10)

IDC Wire Tap

(QTY-8)

VEHICLE PREPARATION

PVC Foam

Tape

(QTY 1)

P/N: 0000-8F-Z13

1

4280246 Rev. B 11/10

Page 2

0

(

)

)

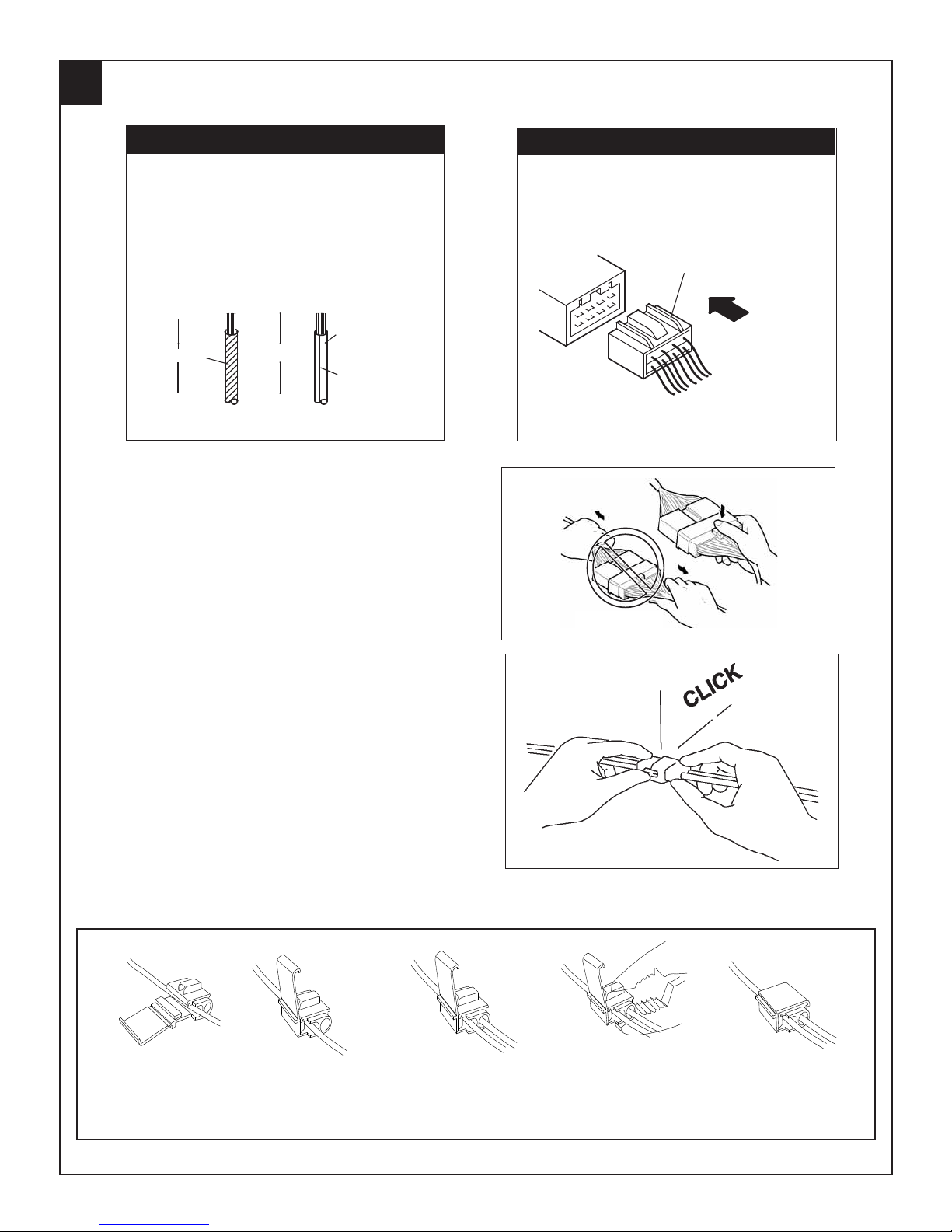

ELECTRICAL SYSTEM GENERAL PROCEDURES

W

irec

olorcode

Two-color wires are indicated by a two-letter

symbol.The first indicates the base color of the

wire, the second the color of the stripe.

For example:

W/R is a white wire with a red strip

BR/Y is a brown wire with a yellow strip

Symbol

(Example)

Solid color wire Striped wire

C

onn

Connector diagrams show connectors on the harness

side. The terminal indicates the view from the harness

side.

(Example)

ectordiagrams

Connector on harness side

White

Black

B

W/R

base color

Red(stripe

D

isconnect

When disconnecting connector, grasp the connectors,

not the wires.

L

ockingConnector

When locking connectors, listen for a click indicating

they are securely locked.

ingConnector

s

Unused terminals are indicated by ∗ .

N

OGOO

NO GOOD

D

View from harness side

IDC Wire Tap Procedure

Place IDC on vehicle

Close side of IDC.

wire.

Insert remote start

wire into IDC.

2

Crimp IDC metal tab

over both wires until

flush with top of IDC.

4280246 Rev. B 11/10

Close top of IDC.

Page 3

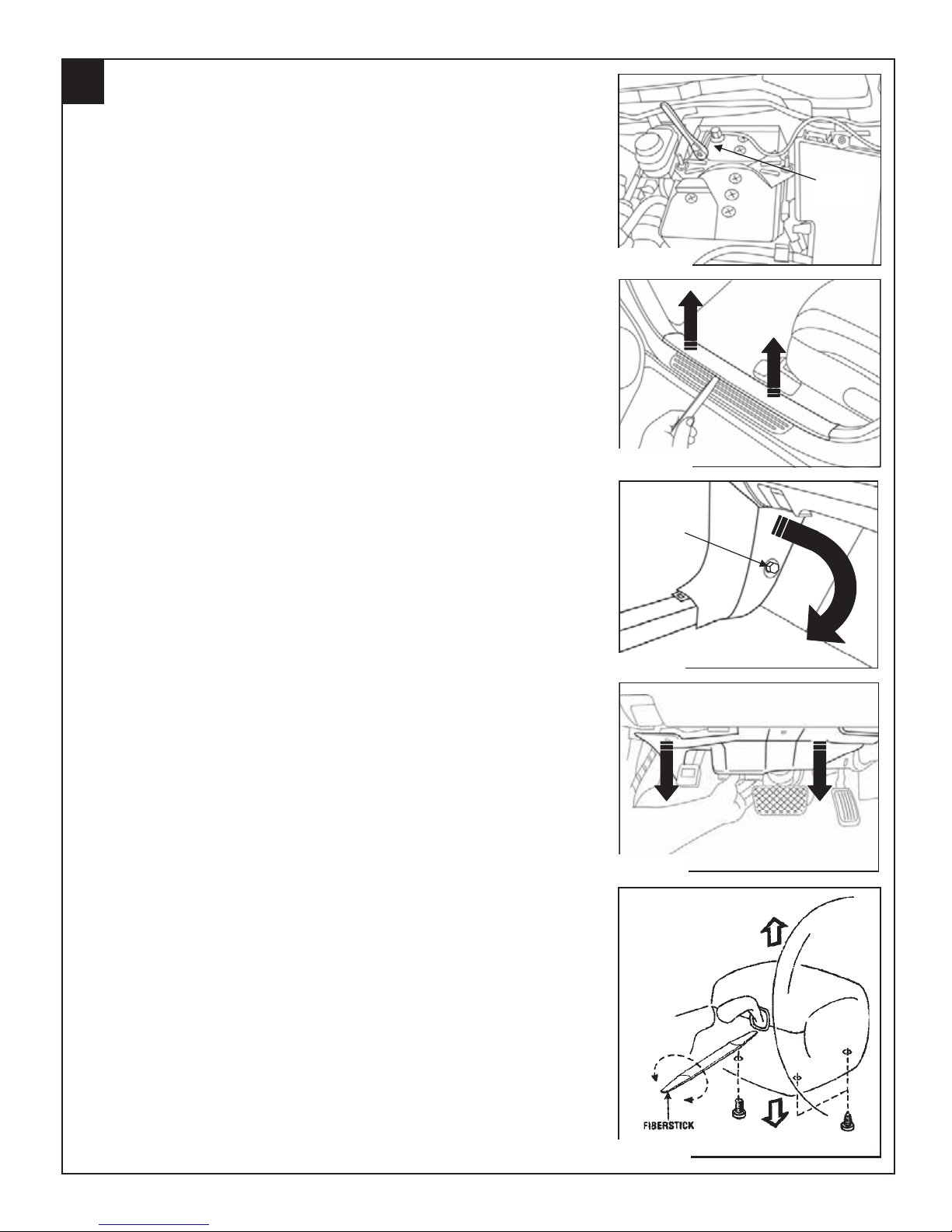

1

VEHICLE PREPARATION

1. Disconnect and Remove Battery

a. Disconnect and isolate the negative and positive battery

terminals. (FIGURE A)

b. Remove battery hold-down bracket assembly by loosen-

ing both 10 mm nuts and pivoting lower retainers toward

vehicle dashwall. (FIGURE A)

c. Carefully remove the battery from vehicle.

2. Remove the following components:

a. Using a fiber stick, remove the driver’s side scuff plate.

Panel is held by 3 clips. (FIGURE B)

10 mm

Socket

FIGURE A

FIGURE B

b. Remove the driver’s side kick panel by removing the plas-

tic nut. (FIGURE C) Partially peel back the rubber

weatherstrip away from the kick panel. Insert a fiber stick

between the body and kick panel to disengage the retaining clip. Gently pull the kick panel toward the rear of

the vehicle to remove.

c. Remove the black, lower dash panel by using a fiber stick

to pull the plastic center button of the plastic fastener out

to disengage. Use a fiber stick to disengage the two clips

located at the front of the panel and remove. (FIGURE D)

d. Remove the ignition knob by depressing both buttons on

either side of knob and pulling away from ignition switch.

(Smart-Key equipped vehicles only)

Plastic Nut

Plastic Nut

Fig. 1-4

FIGURE C

FIGURE D

e. Remove the three (3) phillips head screws from the lower

steering column cover. (FIGURE E)

f. Insert a fiber stick between the combination switch and

the lower cover. Gently rotate the fiber stick until top and

bottom covers separate. (FIGURE E)

g. Gently unclip the ignition key light (Retractable Key

equipped vehicles only) and remove the lower cover.

FIGURE E

3

4280246 Rev. B 11/10

Page 4

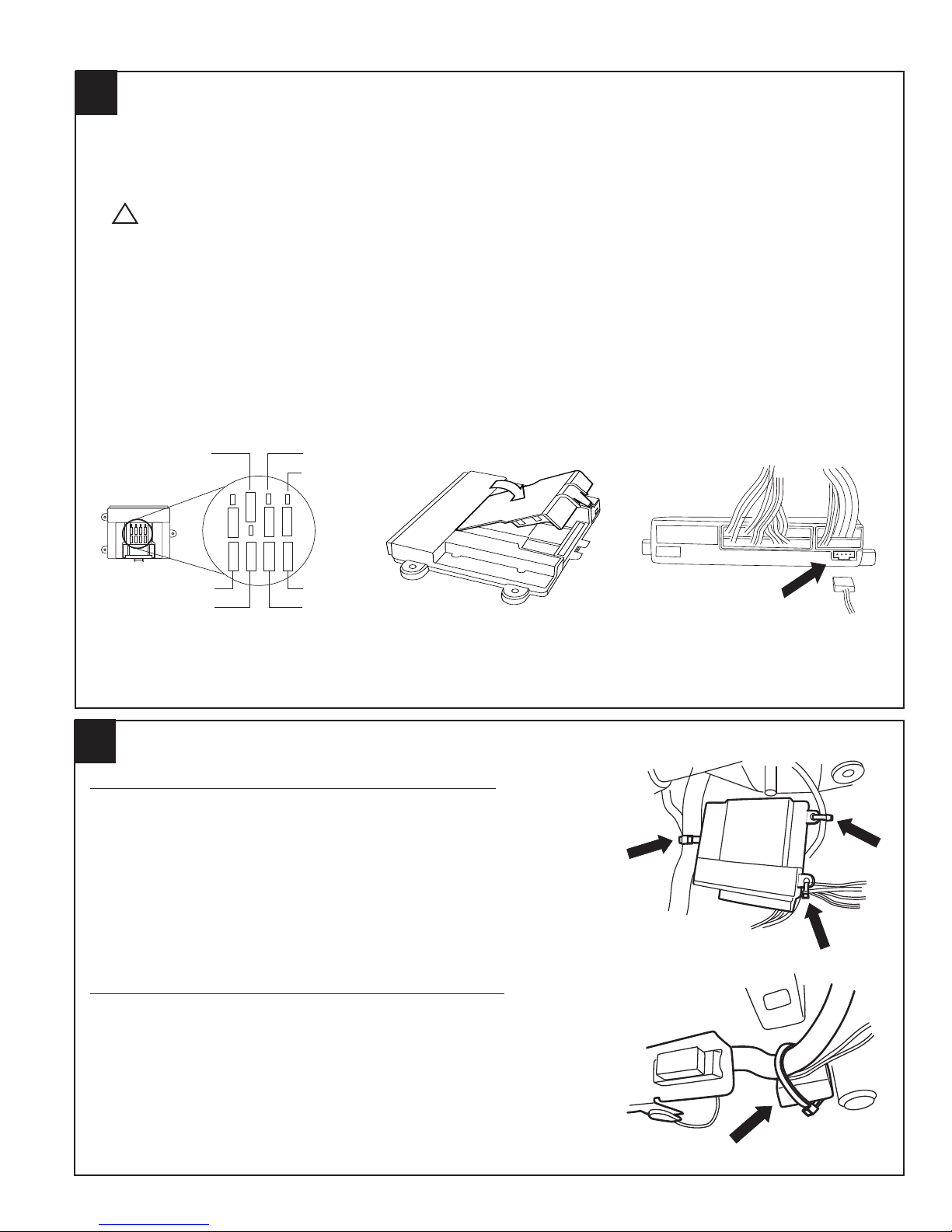

REMOTE START CONTROL MODULE PREPARATION

2

1. Insert the supplied fuses into the remote start control module as shown below. (FIGURE F)

The fuses fit tightly, so use the flat tip of a fiber stick to push them in place, if necessary.

2. Install DNA card into the remote start control module as shown below. (FIGURE G)

CAUTION: Use care to assure that both rows of the multi-pin connector are aligned and

!

seated properly.

3. Plug the supplied wire harness 10-way and 24-way connectors into the remote start control module. (FIGURE H) Make sure the connectors are seated completely. NOTE: The connectors will

only plug into the remote start control module one way.

4. Plug the supplied immobilizer interface 4-way connector into the remote start control module.

(FIGURE H)

NOTE: TAPE OFF THE WHITE WIRE (IF EQUIPPED) COMING FROM THE 4-WAY

CONNECTOR (THIS WIRE IS NOT USED ON THIS SYSTEM).

15

15

5

15

PK LIGHTS

DOOR LOCKS

-+

MAIN B+

IGNITION

FIGURE G

FIGURE H

DOME LIGHT

TRUNK RELEASE

15

15

HVAC 1

HVAC 2

-+

15

15

15

15

15

15

5

15

15

15

FIGURE F

REMOTE ENGINE START MODULE AND IMMOBILIZER INTERFACE MOUNTING

3

Tie Wraps

REMOTE ENGINE START MODULE MOUNTING

1. Locate the two large wire harnesses high up under the dashboard running near the vehicle dashwall.

2. Using (3) supplied long wire ties, secure the remote start control module to the wire harnesses. (FIGURE I)

IMMOBILIZER INTERFACE MODULE MOUNTING

1. Locate the large wire harness routed toward the diagnostic

conntector. (FIGURE J)

2. Using (1) supplied long wire tie, secure the immobilizer interface to the wire harness. (FIGURE J)

FIGURE I

FIGURE J

Tie Wraps

4

4280246 Rev. B 11/10

Page 5

FIGURE J

DIPOLE ANTENNA MOUNTING

4

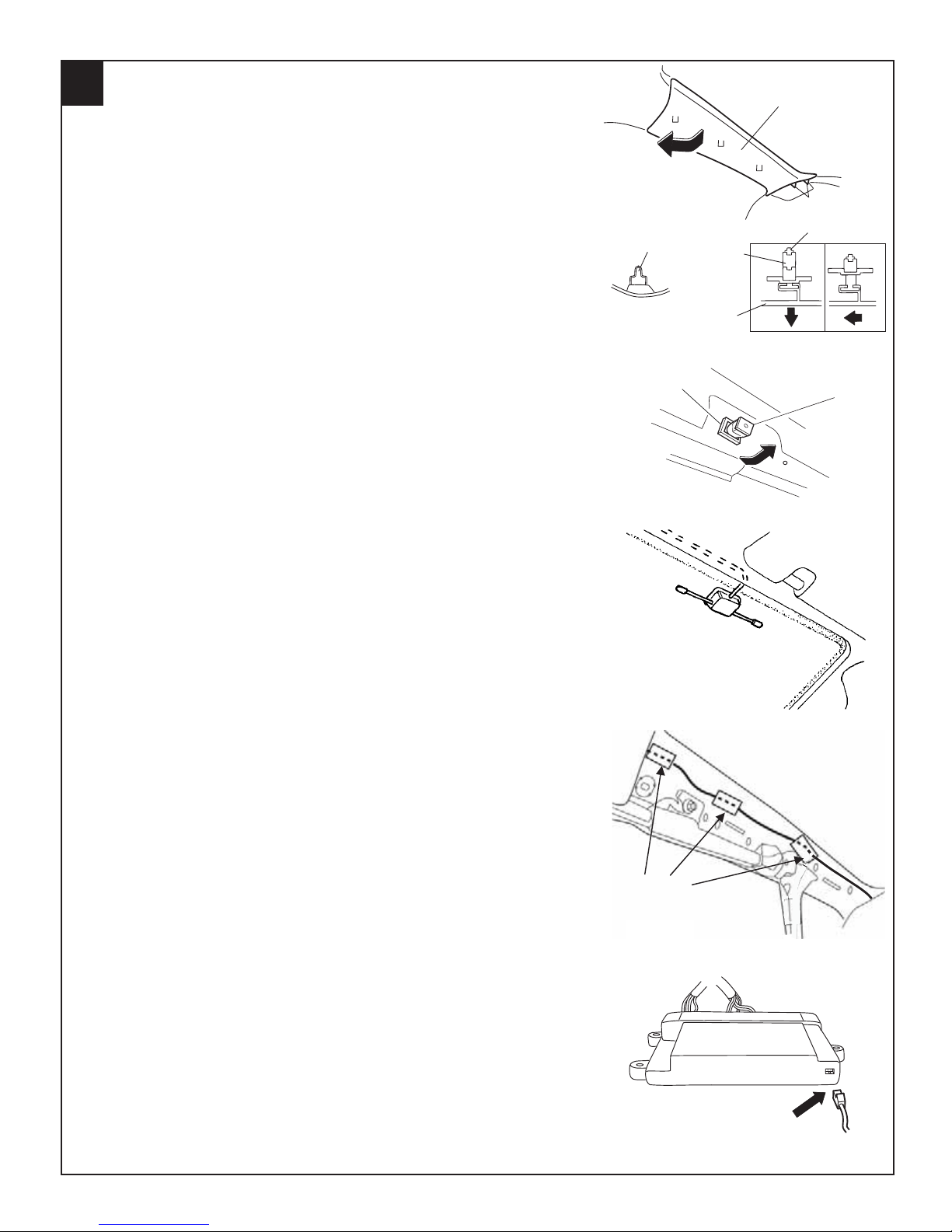

1. Driver’s A-Pillar Trim Removal/Installation

a. Partially peel back the rubber weatherstip away from the

A-pillar trim.

b. Pull the A-pillar trim, then disengage clips A. (FIGURE K)

c. Pull the A-pillar trim, then disengage clip B (1).

d. Pull the A-pillar trim upward, then disengage clip B from

the A-pillar trim (2).

e. Disengage the tabs from the dashboard, then remove the

A-pillar trim.

f. Pull clip B out, then rotate 45 degrees. (FIGURE L)

g. Remove clip B from the grommet by pulling it outward.

CLIP A

FIGURE K

GROMMET

FIGURE L

B

A

GROMMET

A-PILLAR

UPPER TRIM

A-PILLAR

UPPER TRIM

A

45

TAB

CLIP B

(1)

(2)

CLIP B

2. Clean mounting spot with an alcohol pad prior to mounting.

Mount the dipole antenna to the windshield 229 mm to the

right of the mirror base on the windshield, directly below the

black windshield frit. (FIGURE M)

3. Run the antenna wire above the headliner to the driver’s Apillar, using a fiber stick to secure under the headliner.

4. Route the antenna wire down the A-pillar securing it to the

existing metal pillar with (3) supplied pieces of foam tape.

(FIGURE N)

5. Route the antenna wire behind the left side of the dashboard

and over to the remote start control module. Plug the 2-pin

antenna connector into the 2-pin port on the bottom of the remote start control module. (FIGURE O)

FIGURE M

Foam Tape

FIGURE N

6. Re-install the driver’s side A-pillar panel and re-install the rubber weatherstrip along the A-pillar.

FIGURE O

5

4280246 Rev. B 11/10

Page 6

5

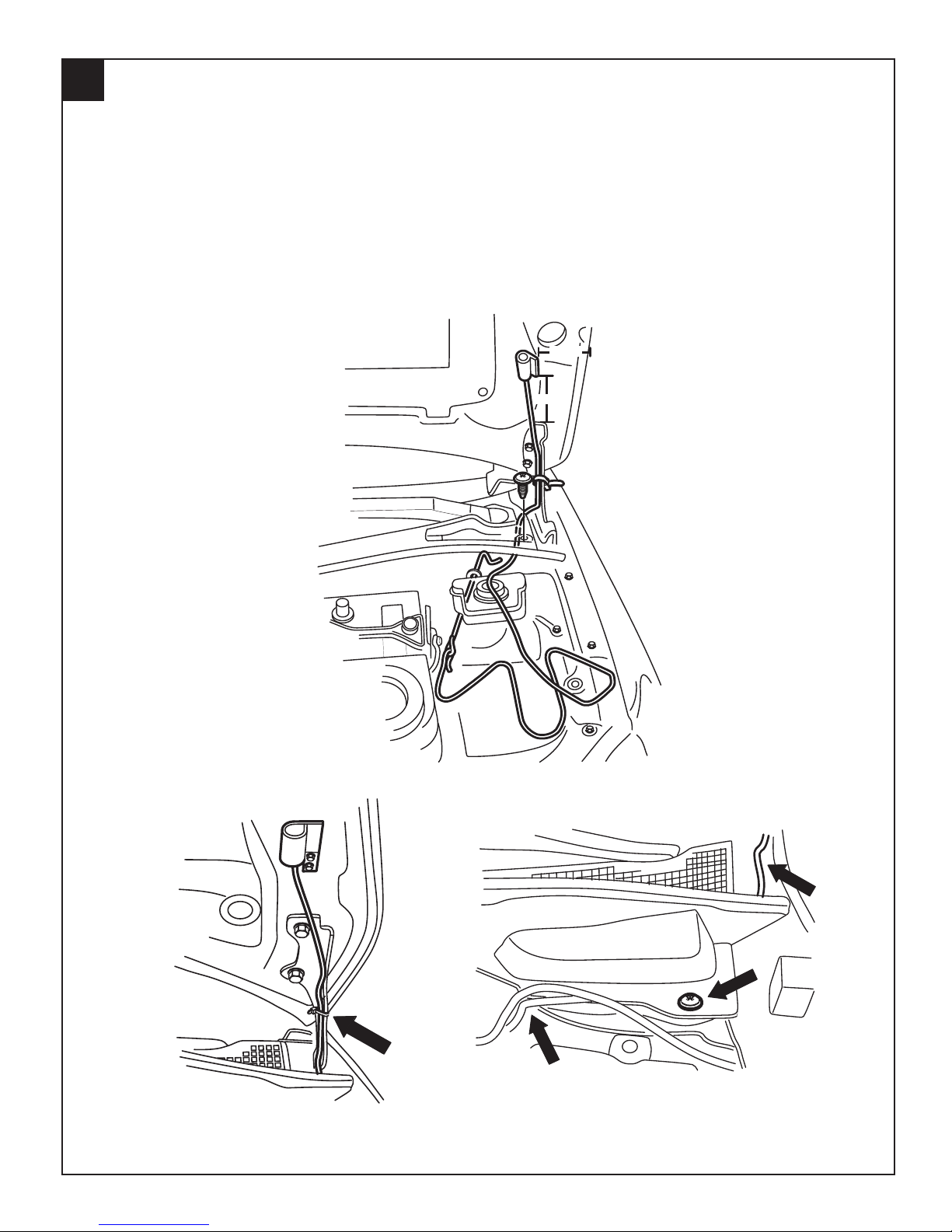

HOOD SAFETY SWITCH MOUNTING

1. Using (2) supplied 1/4” self drilling screws and (2) supplied lock washers, secure the hood safety

switch to the drivers side of the vehicle’s hood 62 mm above the top of the hood mounting bracket

and 62 mm from the side edge of the hood. (FIGURE P & Q)

2. Route the hood safety switch wiring down into the engine compartment along the inside of the

hood hinge and secure using (1) supplied, short wire tie. (FIGURE Q)

3. Remove plastic phillips screw in cowl panel to route the hood safety switch wiring underneath.

Gently lift the cowl panel and tuck hood saftey switch wiring under the cowl panel and into the

engine compartment. Continue routing toward the main wire harness grommet in the vehicle

dashwall. (FIGURE P & R)

62 mm

62 mm

FIGURE Q

FIGURE P

FIGURE R

6

4280246 Rev. B 11/10

Page 7

HOOD SAFETY SWITCH MOUNTING, continued

5

4. Using fish wire, pull the hood safety switch wiring and tach wire through the main wire harness

grommet:

a. From inside of the vehicle, bend approximately three (3) inches of tach wire at wire end.

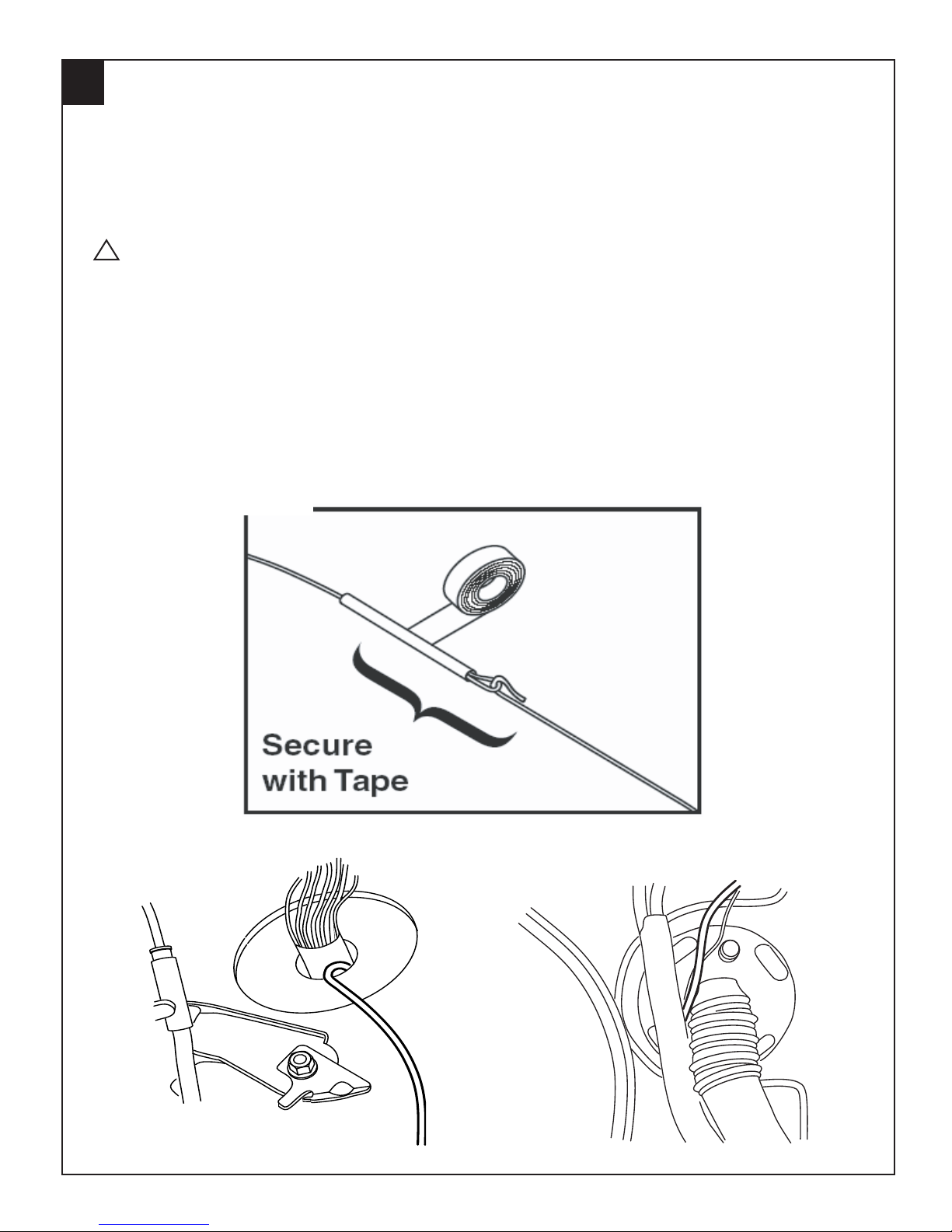

b. Using electrical tape, secure fish wire to tach wire as shown. (FIGURE S)

c. Insert the fish wire along with tach wire through the main wire harness grommet into the

engine compartment. (FIGURE T & U)

!

CAUTION: Do not pierce the main wire harness with fish wire when pulling through

main grommet.

d. Disconnect tach wire from fish wire and pull remaining slack of tach wire from the inside

of the vehicle out into the engine compartment.

e. Bend approximately three (3) inches of hood safety switch wiring at wire end.

f. Using electrical tape, secure fish wire to hood safety switch wiring as shown.

(FIGURE S)

g. Pull fish wire and hood safety switch wiring back through main wire harness grommet

into the vehicle. (FIGURE T & U)

h. Disconnect hood safety switch wiring from fish wire and pull remaining slack of hood

safety switch wiring from the engine compartment into the vehicle.

FIGURE S

FIGURE T

FIGURE U

7

4280246 Rev. B 11/10

Page 8

6

1. Locate the BLACK/ORANGE and GRAY/RED wires from the remote start system harness.

2. Using the (2) supplied IDC wire taps (in hood safety switch parts bag), connect the wires listed

HOOD SAFETY SWITCH WIRE CONNECTIONS

below together and crimp the IDC wire taps in place using pliers. Ensure that a complete and

secure connection is made.

HOOD SAFETY SWITCH WIRE REMOTE START HARNESS WIRE

Dk. GRAY GRAY/RED

Dk. GRAY BLACK/ORANGE

NOTE: Switch is not polarity sensitive.

NOTE: Refer to Page 2 for IDC Wire Tap Procedure and Wire color code information.

GROUND CONNECTION

7

1. Locate the 10 mm factory bolt located at the bottom left of the metal

brace supporting the diagnostic connector. (FIGURE V)

2. Using a 10 mm ratchet remove the 10 mm lug bolt.

3. Re-secure the factory ground ringlet and remote start harness

BLACK/ORANGE ground wire with ringlet and tighten with a 10 mm

ratchet.

NOTE: USING A 3/8” DRIVE TORQUE WRENCH MAKE SURE

THAT THE 10 mm GROUND LUG BOLT IS SECURELY

TIGHTENED TO 78-121 INCH/POUNDS.

FIGURE V

8

4280246 Rev. B 11/10

Page 9

8

IMMOBILIZER INTERFACE RIBBON CABLE MOUNTING

1. Route the immobilizer interface ribbon cable to the ignition switch.

2. Following the instructions on the supplied adhesive primer stick,

apply a thin coating to the entire immobilizer antenna coil (black

plastic ring around ignition switch and to the ribbon cable.

(FIGURE W)

3. Remove the backing from one side of the supplied 2-way tape and

apply tape around the immobilizer antenna coil (black plastic ring

around ignition switch) keeping the tape off of the rounded part of

the ignition switch face and trimming excess 2-way tape, if necessary. (FIGURE X & Y)

FIGURE W

FIGURE X

Smart-Key

FIGURE Y

Retractable Key

4. Remove the remaining backing on the 2-way tape and position the

ribbon cable around the immobilizer antenna coil, with the red

striped side facing the ignition key opening. (FIGURE Z)

5. Separate approximately 100 mm of the twisted red ribbon cable.

(FIGURE AA)

6. Create a second loop around the immobilizer antenna coil directly

in front of the first loop. (FIGURE BB & CC)

7. Using a supplied, short wire tie, secure the antenna coil.

(FIGURE BB & CC)

First Loop

Second Loop

First Loop

Second Loop

FIGURE Z

FIGURE AA

100 mm

Retractable Key

FIGURE BB

CAUTION: This is a critical step that must be followed precisely for proper remote start operation.

!

Wire Tie

FIGURE CC

Smart-Key

9

Wire Tie

4280246 Rev. B 11/10

Page 10

WIRE HARNESS CONNECTIONS - STEERING COLUMN

9

IGNITION SWITCH CONNECTOR

1. Route the remote start ignition harness with 6-pin male and female ignition connectors over the factory harness, along the

left side of the steering column. Do not secure harness at this

time.

2. Locate the 6-pin WHITE ignition connector, on the left side of

the steering column.

3. Release the red secondary lock and disconnect the 6-pin WHITE

ignition connector by pulling outward. ( CAUTION: DO NOT

!

PULL ON WIRES TO DISCONNECT CONNECTOR.)

4. Plug the 6-pin female remote start harness connector into the

factory ignition switch and engage the red secondary lock.

(FIGURE DD)

5. Plug the 6-pin male remote start harness connector into the 6pin female factory ignition connector and engage the red secondary lock. (FIGURE DD)

PARKING LIGHT CONNECTION

1. Locate the 17-pin multifunction switch connector on the left side

of the steering column (plugged into the turn signal assembly).

(FIGURE EE)

2. Using a razor knife carefully cut back 1”-2” of the electrical tape

to expose the wiring. ( CAUTION: BE EXTREMELY CARE-

!

FUL NOT TO DAMAGE ANY OF THE WIRES.)

3. Using (1) supplied IDC wire tap, connect the wires listed below

and crimp the IDC wire tap in place using pliers. Ensure that a

complete and secure connection is made. Refer to FIGURE EE

& FF for proper connector and pin location.

FIGURE DD

FIGURE EE

2010 MODELS

QO

B/R B/O

B/G

VIEW FROM HARNESS SIDE

FIGURE FF

B/L

JH DL

B/R

&B/R

B/L

B

B/R

VEHICLE’S PARKING LIGHT WIRE REMOTE START HARNESS WIRE

2010 MODELS - BLACK/BLUE BLACK/RED

2007-2009 MODELS - BLACK/RED BLACK/RED

NOTE: Refer to Page 2 for IDC Wire Tap Procedure and Wire color code information.

B/Y

10

2007-2009 MODELS

QO

B/R B/O

B/G

VIEW FROM HARNESS SIDE

B/R

JH DL

B/R

B/Y

B/L

B

&B/R

B/R

4280246 Rev. B 11/10

Page 11

9

WIRE HARNESS CONNECTIONS - STEERING COLUMN, continued

KEY-IN-SENSE & PUSH WIRE ROUTING

1. Route the remote start harness Red/Black and White/Green wires

along with the immobilizer interface ribbon cable between the

vehicle’s yellow shielded harness and steering column harness

to protect the wires from any potential damage from the steering

column cover and tilt steering wheel mechanism. (FIGURE GG)

2. Using supplied, short wire ties, secure the remote start harness

wires to the vehicle’s harness. (FIGURE GG)

CAUTION: FAILURE TO ROUTE THE REMOTE START HAR-

!

NESS WIRES PROPERLY COULD RESULT IN DAMAGE TO THE

WIRES DURING RE-ASSEMBLY. IF THE RED/BLACK OR WHITE/

GREEN WIRES ARE SHORTED TO GROUND, THE SMART-KEY

SUBSET WILL GET DAMAGED AND NEED TO BE REPLACED.

KEY-IN-SENSE CONNECTION

1. Locate the 12-pin (Smart-Key equipped) or 2-pin (Retractable

Key equipped) WHITE key-in-sense connector under the ignition switch. (FIGURE HH)

Wire Tie

FIGURE GG

Yellow Shielded

Harness

Wire Tie

2. Using a razor knife carefully cut back 1”-2” of the electrical tape

to expose the wiring. ( CAUTION: BE EXTREMELY CARE-

!

FUL NOT TO DAMAGE ANY OF THE WIRES.)

FIGURE HH

3. Using (1) supplied IDC wire tap, connect the wires listed below

and crimp the IDC wire tap in place using pliers. Ensure that a

complete and secure connection is made. Refer to FIGURE

HH & II for proper connector and pin location.

2007-2009 MODELS

R

BR/G

CIG AE

B/LW/GY/G

RR

VIEW FROM HARNESS SIDE

BDFHJL

FIGURE II

2010 MODELS

CI

E

K

L

G

BR

J

VIEW FROM HARNESS SIDE

DF

H

A

O/B

B

K

B/G

VEHICLE’S KEY-IN SENSE WIRE REMOTE START HARNESS WIRE

2010 MODELS

BROWN (SMART-KEY) RED/BLACK

ORANGE/BLACK (RETRACTABLE KEY)

2007-2009 MODELS

BROWN/GREEN (SMART-KEY) RED/BLACK

RED/BLACK (RETRACTABLE KEY)

R/B R

NOTE: Refer to Page 2 for IDC Wire Tap Procedure and Wire color code information.

11

4280246 Rev. B 11/10

Page 12

9

WIRE HARNESS CONNECTIONS - STEERING COLUMN, continued

PUSH-WIRE CONNECTION (Smart-Key equipped vehicles only)

NOTE: If performing the installation on a

Retractable Key equipped vehicle, tape

off the Remote Start Harness

White/Green wire (This wire is not used

on this vehicle).

1. Locate the 12-pin WHITE key-in-sense connector under the ignition switch. (FIGURE JJ)

2. Using a razor knife carefully cut back 1”-2” of the electrical tape

to expose the wiring. ( CAUTION: BE EXTREMELY CAREFUL NOT TO DAMAGE ANY OF THE WIRES.)

3. Using (1) supplied IDC wire tap, connect the wires listed below

and crimp the IDC wire tap in place using pliers. Ensure that a

complete and secure connection is made. Refer to FIGURE JJ

& KK for proper connector and pin location.

!

FIGURE JJ

K

I

Y/G

L

JH

B/G

FIGURE KK

G

R

BR/G W/G

*

*

VIEW FROM HARNESS SIDE

C

E

F

R

A

B/L

D

*

B

R

*

VEHICLE’S PUSH WIRE REMOTE START HARNESS WIRE

WHITE/GREEN WHITE/GREEN

NOTE: Refer to Page 2 for IDC Wire Tap Procedure and Wire color code information.

4. Using (1) supplied, short wire tie secure the remote start wiring and

immobilizer interface wiring to the vehicle’s factory ignition wiring.

(FIGURE LL)

NOTE: IT IS EXTREMELY IMPORTANT THAT THE WIRING

IS SECURED IN A MANNER THAT WILL ALLOW THE TILT

STEERING WHEEL TO MOVE FREELY AND STILL ALLOW

FOR REASSEMBLY OF THE STEERING COLUMN SHROUD.

CHECK FUNCTIONALITY OF THE TILT STEERING WHEEL

PRIOR TO REASSEMBLY.

FIGURE LL

12

4280246 Rev. B 11/10

Page 13

10

WIRE HARNESS CONNECTIONS - BRAKE SWITCH

BRAKE SWITCH CONNECTION

1. Locate the 4-pin WHITE brake switch connector at the top of the

brake pedal. (FIGURE MM)

2. Using a razor knife carefully cut back 1”-2” of the electrical tape to

expose the wiring. ( CAUTION: BE EXTREMELY CAREFUL

NOT TO DAMAGE ANY OF THE WIRES.)

3. Route the red/white remote start harness brake wire between the

dashwall and steering column to the brake switch connector.

!

FIGURE MM

4. Using (1) supplied IDC wire tap, connect the wires listed below

and crimp the IDC wire tap in place using pliers. Ensure that a

complete and secure connection is made. Refer to FIGURE MM

& NN for proper connector and pin location.

FIGURE NN

BB/Y

VIEW FROM HARNESS SIDE

VEHICLE’S BRAKE WIRE REMOTE START HARNESS WIRE

RED/WHITE RED/WHITE

NOTE: Refer to Page 2 for IDC Wire Tap Procedure and Wire color code information.

11

1. Locate the 6-pin WHITE connector at the Body Control Mod-

2. Using a razor knife carefully cut back 1”-2” of the electrical

WIRE HARNESS CONNECTIONS - DRIVER’S KICK PANEL

DOME LIGHT CONNECTION

ule mounted in the left kick panel area. (FIGURE OO)

tape to expose the wiring. ( CAUTION: BE EXTREMELY

CAREFUL NOT TO DAMAGE ANY OF THE WIRES.)

!

RR/W

3. Using (1) supplied IDC wire tap, connect the wires listed below and crimp the IDC wire tap in place using pliers. Ensure

that a complete and secure connection is made. Refer to

FIGURE OO & PP for proper connector and pin location.

6E 6C 6A

Y/B W/R B

6F 6D 6B

VIEW FROM HARNESS SIDE

FIGURE PP

VEHICLE’S DOME LIGHT WIRE REMOTE START HARNESS WIRE

BLACK/BLUE BLACK/BLUE

NOTE: Refer to Page 2 for IDC Wire Tap Procedure and Wire color code information.

RW/B B/L

13

FIGURE OO

4280246 Rev. B 11/10

Page 14

11

WIRE HARNESS CONNECTIONS - DRIVER’S KICK PANEL, continued

DOOR UNLOCK CONNECTION

1. Locate the 30-pin WHITE connector at the Body Control Module mounted in the left kick panel area. (FIGURE QQ)

2. Using a razor knife carefully cut back 1”-2” of the electrical

tape to expose the wiring. ( CAUTION: BE EXTREMELY

!

CAREFUL NOT TO DAMAGE ANY OF THE WIRES.)

3. Using (1) supplied IDC wire tap, connect the wires listed below and crimp the IDC wire tap in place using pliers. Ensure

that a complete and secure connection is made. Refer to

FIGURE QQ & RR for proper connector and pin location.

2010 MODELS

FIGURE QQ

2007-2009 MODELS

5Y 5V 5S 5P 5M

5AB

B/Y

5AD

G/BG/O

5G 5D 5A

5Q 5K 5B5E5H5AC 5N5Z 5T5W

B/R

B/L

G/R

5O5AA 5U5X

L

L/R

B/OB/L

B/G

VIEW FROM HARNESS SIDE

B/G

GY/R

5I 5F5J5C5L5R

B/O

B/L

L/R

B/O

B/G

GY/R

B/W

L/R

5Y 5V 5S 5P 5M

5AB

B/Y

5AD

G/BG/O

VIEW FROM HARNESS SIDE

B/OB/L

B/G

B/R

5Q 5K 5B5E5H5AC 5N5Z 5T5W

G/R

5O5AA 5U5X

L

B/L

L/R

B/G

GY/R

5G 5D 5A

B/O

B/O

B/G

B/L

5I 5F5J5C5L5R

GY/R

L/R

B/W

W/L

L/R

FIGURE RR

VEHICLE’S DOOR UNLOCK WIRE REMOTE START HARNESS WIRE

BLACK/WHITE BLACK/WHITE

NOTE: Refer to Page 2 for IDC Wire Tap Procedure and Wire color code information.

HORN CONNECTION

1. Locate the 24-pin connector at the Body Control Module mounted

in the left kick panel area. (FIGURE SS)

2. Using a razor knife carefully cut back 1”-2” of the electrical tape

to expose the wiring. ( CAUTION: BE EXTREMELY CAREFUL NOT TO DAMAGE ANY OF THE WIRES.)

3. Using (1) supplied IDC wire tap, connect the wires listed below

and crimp the IDC wire tap in place using pliers. Ensure that a

complete and secure connection is made. Refer to FIGURE SS

& TT for proper connector and pin location.

!

2010 MODELS

3W 3U 3O 3M

3X 3V 3P 3N

GY/R

3S 3Q

B/RL/R R

3T 3R

B/L B/W B/L

B/O

W/L W/G W/B W

VIEW FROM HARNESS SIDE

FIGURE TT

3K 3I 3C 3A

3L 3J 3D 3B

BR/L W/R

B/Y B/O

3G 3E

3H 3F

BB

VEHICLE’S HORN WIRE REMOTE START HARNESS WIRE

BLACK BLACK

NOTE: Refer to Page 2 for IDC Wire Tap Procedure and Wire color code information.

B/L R/B BR/L

{R}

14

FIGURE SS

2007-2009 MODELS

3W 3U 3O 3M

3X 3V 3P 3N

GY/R

3S 3Q

B/RL/R R

B/O

W/L W/G W/B W

3T 3R

B/L B/W B/L

VIEW FROM HARNESS SIDE

BR/L W/R

B/Y B/O

3G 3E

B/L R/B BR/L

3H 3F

{R}

BB

3K 3I 3C 3A

3L 3J 3D 3B

4280246 Rev. B 11/10

Page 15

12

WIRE HARNESS CONNECTIONS - ENGINE COMPARTMENT

TACHOMETER CONNECTION

1. Locate the lower 60-pin WHITE connector at the Powertrain

Control Module mounted to the backside of the driver’s side

strut tower in the engine compartment. (FIGURE UU)

2. Using a razor knife carefully cut back 1”-2” of the electrical tape

to expose the wiring. ( CAUTION: BE EXTREMELY CARE-

!

FUL NOT TO DAMAGE ANY OF THE WIRES.)

3. Using (1) supplied IDC wire tap, connect the wires listed below

and crimp the IDC wire tap in place using pliers. Ensure that a

complete and secure connection is made. Apply silicone to

both ends of IDC wire tap to seal the connections from potential moisture. Refer to FIGURE UU & VV for proper connector

and pin location.

2AC

2Y

2BA

2BE

R/L

2BB

2BF

R/L

BWBR

2AS 2AO

2AW

W/V

B/L W/RY

2AX

2AP

2AT

W/GW/L W/BW/LW/B

2AK

2AG

G/W Y/L

2AH 2V

2AL

2AD

BR/L

2U

BR/Y

2Z

2R 2N

2I

2M2Q

G/R

W

BR/G

2E 2A

YWW

2F

2J

W/LG/O

2B

Y/LG/W

TURBO

Models

2BC

2BG

2BD

2BH

FIGURE VV

2AY

2AU

BR/R

2AV

2AZ

BBYB B

2AM

2AQ

Y/GY/V W/BB/W B/Y G/BB/R L/R

2AN

2AR

B/O B/G

2AE 2W

2AI 2AA

L

2AF

GY

VIEW FROM HARNESS SIDE

2X 2D

2AB

GY/BGY/PBR/W

2O2S

2T 2P2AJ 2H2L

L/W BR

2K 2G

2C

B/OW

BB/R

NON-TURBO Models

FIGURE UU

VEHICLE’S TACHOMETER WIRE REMOTE START HARNESS WIRE

WHITE WHITE

NOTE: Refer to Page 2 for IDC Wire Tap Procedure and Wire color code information.

13

1. Locate the previously removed driver’s side kick panel cover.

2. Drill a 9/32” hole at the top of the panel, exactly 20 mm down and 40 mm from the far edge.

3. Route the emergency override/programming button from the remote start harness down to the kick

4. Mount the emergency override/programming button in the drilled hole from behind and screw the mounting

EMERGENCY OVERRIDE/PROGRAMMING BUTTON MOUNTING

panel.

cap in place. (FIGURE WW)

NOTE: DISCARD THE LOCK WASHER FROM THE EMERGENCY OVERRIDE/PROGRAMMING BUTTON, IT IS NOT USED ON THIS MODEL.

15

20 mm

40 mm

FIGURE WW

4280246 Rev. B 11/10

Page 16

14

RE-ASSEMBLY

1. Re-install the following components:

a. Plug the ignition key light back into the lower steering

column cover (Retractable Key equipped vehicles only)

and carefully snap the steering column cover halves back

together. (FIGURE XX)

b. Re-install the (3) phillips head screws. Verify operation

of the tilt steering wheel.

CAUTION: Do not pierce the remote start wiring with the

!

steering column cover halves or phillips head screws dur

ing reassembly.

c. Replace the ignition knob by pushing toward the ignition

switch until it snaps in place. (Smart-Key equipped vehicles only)

d. Re-install the black, lower dash panel by engaging the

two clips located at the front of the panel. Re-install the

plastic fastener and push the plastic center button down

until flush with fastener to engage. (FIGURE YY)

FIGURE XX

FIGURE YY

e. Re-install the driver’s side kick panel by engaging the

retaining clip on the panel. Re-install the plastic nut and

rubber weatherstrip on the kick panel. (FIGURE ZZ)

f. Re-install the driver’s side scuff plate by engaging all three

clips. (FIGURE AAA)

2. Re-install and Reconnect Battery:

a. Carefully re-install battery into vehicle’s battery tray.

Plastic Nut

FIGURE ZZ

FIGURE AAA

b. Re-install battery hold-down bracket by engaging lower

retainers into battery tray, away from vehicle dashwall and

tightening both 10 mm nuts. (FIGURE BBB)

c. Reconnect the positive and negative battery terminals.

(FIGURE BBB)

16

10 mm

Socket

FIGURE BBB

4280246 Rev. B 11/10

Page 17

15

1. Verify that all connections are secure as per installation instructions.

2. Ensure 15 amp Room fuse is properly installed in dash fuse panel.

3. Turn the ignition key to the RUN position.

4. Reconnect the negative battery terminal.

5. Turn the ignition key to the OFF position.

SYSTEM POWER-UP

16

1. Open the engine hood and find a suitable mounting location in the engine compartment that will be in plain

2. Using an alcohol pad, clean the mounting surface thoroughly.

3. Remove the backing on the underhood sticker and mount in place.

4. Close engine hood.

17

1. Tachometer Programming - Make sure engine hood is closed!

UNDERHOOD WARNING LABEL MOUNTING

sight when the hood is open (on the radiator cowl).

TACHOMETER PROGRAMMING

a. Turn the ignition key to the ON or RUN position.

b. Press and hold the programming button. After 10 seconds the horn will beep 3 times.

c. Release the programming button.

d. Press and release the programming button a second time.

The horn will beep 4 times, indicating that the system has entered option learn mode.

e. Press and release the brake pedal. The horn will beep 1 time indicating that the system has

entered tachometer learn mode.

f. Start the vehicle with the ignition key and let engine warm up to a normal idle rate. (Less than

1000 RPMs)

The horn will beep 1 time every 3 seconds indicating the system is monitoring the idle rate.

g. Once the vehicle’s engine has warmed up, press and release the programming button.

The horn will beep 4 times, indicating that the system has learned the current idle rate.

h. Turn the ignition key to the OFF position.

17

4280246 Rev. B 11/10

Page 18

18

IMMOBILIZER INTERFACE PROGRAMMING

NOTE: IF YOU DID NOT PROGRAM THE TACHOMETER SIGNAL AS INSTRUCTED IN SECTION 17, THEN THE

VEHICLE WILL NOT ATTEMPT TO START. INSTEAD, YOU WILL GET FOUR ADDITIONAL BEEPS FROM THE HORN.

THE TACHOMETER SIGNAL MUST BE PROGRAMMED TO THE DNA CARD FOR THE REMOTE ENGINE START

FUNCTION TO OPERATE. (READ ENTIRE PROGRAMMING PROCEDURE PRIOR TO PROGRAMMING.)

1. Transponder interface programming:

NOTE: Two programmed ignition keys are required for this step and hood must be closed. For

Smart-Key equipped vehicles, remove keys from Smart-Key transmitters and place transmitters

at least 10 feet away from vehicle during programming.

a. Sitting in the driver seat, be prepared to press the brake pedal to shut down the remote starter

system.

b. Using the first key, turn the ignition on, wait for the THEFT light to turn off, then turn the ignition off and

remove key from the ignition switch.

c. Using the second key within 5 seconds, turn the ignition on, wait for the THEFT light to turn off, then

turn the ignition off and remove key from the ignition switch.

d. Activate the remote start function by pressing the START button (2) times within 5 seconds.

The system should flash the parking lights and chirp the horn one time, pause for four seconds then

start the engine.

e. After the engine is started. Press the brake pedal to shut down the engine. The Immobilizer

interface is now programmed.

f. Attach new Remote Engine Start transmitters to the retractable keys.

19

TRANSMITTER PROGRAMMING

NOTE: THE FOLLOWING STEPS ARE ONLY NECESSARY IF YOU NEED TO PROGRAM ADDITIONAL

TRANSMITTERS.

1. Transmitter Programming

NOTE: The transmitters shipped with the remote start system are pre-programmed to the DNA

card, and do not need to be reprogrammed.

a. Turn the ignition key to the ON or RUN position.

b. Press and hold the programming button.

After 10 seconds the horn will beep 3 times, indicating that the system is now in transmitter learn

mode.

c. Release the programming button.

d. If programming transmitters at this time, press the START button once on each transmitter to be

programmed.

The horn will beep 1 time to indicate that the transmitter has been learned.

NOTE: Up to a total of 8 transmitters can be programmed to the DNA card.

18

4280246 Rev. B 11/10

Page 19

20

FUNCTION TEST

Car Find

1. Press and hold START button - Horn should beep six times and parking lights should flash six times.

Remote Engine Start Functions

1. REMOTE ENGINE START - Make sure the key is removed from the ignition switch and the engine hood is

closed. Press the START button twice within 3 seconds. The parking lights should flash one time, the horn

should beep once, then the vehicle should crank and start. Once started, the parking lights will turn on and

stay on signifying the vehicle is running.

2. UNLOCK DOORS - While the vehicle is running on the remote engine start, press the START button once to

unlock the driver’s door. Press the START button a second time within 3 seconds of first button press to unlock

all doors. The Factory transmitters will not unlock all doors during remote engine start.

3. BRAKE PEDAL SAFETY - Enter the vehicle and press the brake pedal. The vehicle should shut off.

4. KEY-IN-SENSE - Insert the ignition key into the ignition switch but keep in the off position. Activate the remote

engine start. The vehicle should flash the lights once as if it is going to start, but then the horn should beep

twice and the remote engine start does not attempt to start the vehicle since it senses the key in the ignition.

5. HOOD SAFETY SWITCH - Open the engine hood and activate the remote engine start. The horn should beep

two additional times signifying that hood safety switch is engaged and the vehicle will not start. (Reference

20

section 23 if adjustment is needed.)

NOTE: IF ANY OF THE ABOVE FUNCTIONS DO NOT PERFORM AS DIRECTED, SEE TROUBLESHOOTING GUIDE (SECTION 21).

FUNCTIONAL TESTING IS NOW COMPLETE.

19

4280246 Rev. B 11/10

Page 20

21

TROUBLESHOOTING GUIDE

1. Horn honks 4 times & vehicle does not remote start - No tachometer signal learned to DNA card.

a. Ensure good connection and correct vehicle wire at PCM in engine compartment (See Section 12).

b. Re-program tachometer signal (See Section 17).

2. Starter cranks too long during remote start operation.

a. Re-program tachometer signal (See Section 17) and allow engine to warm up to a normal idle rate (Less than 1000

RPMs).

3. Ignition turns on, then horn honks 2 times & vehicle does not remote start - Key-in-sense circuit activated.

a. Remove ignition key from ignition cylinder.

b. Ensure good connection and correct vehicle wire at Key-in-sense connector (See Section 9).

4. Horn honks 2 times & vehicle does not remote start - Safety input activated.

a. Ensure hood is closed and hood switch is adjusted properly (See Section 23).

b. Ensure brake pedal is not depressed.

c. Ensure good connection and correct vehicle wire at Brake switch (See Section 10).

5. Horn honks 3 times & vehicle does not remote start - Service/Valet Mode engaged.

a. Disengage Service/Valet Mode (Refer to page 5 in Owner’s Manual).

6. Ignition turns on, Theft indicator is flashing & vehicle does not remote start - Immobilizer Interface issue.

a. Ensure 4-pin connector is engaged into the remote start control module properly (See Section 2).

b. Ensure Immobilizer Interface Ribbon Cable is installed properly (See Section 8).

c. Double-wrap the Immobilizer Interface Ribbon Cable to create two loops around the immobilizer antenna coil

(See Section 8).

d. Re-program immobilizer interface (See Section 18).

7. Vehicle does not remote start unless Smart-Key transmitters are in or near the vehicle.

a. Re-program immobilizer interface using valet keys and place Smart-Key transmitters at least 10 feet away

from vehicle (See Section 18).

8. Unlock feature does not operate properly during remote start operation.

a. Ensure good connection and correct vehicle wire at Body Control Module (See Section 11).

20

4280246 Rev. B 11/10

Page 21

22

FINALIZING THE INSTALLATION

1. NOTE: After reassembling the vehicle parts, check for any dirt. Clean any dirty parts.

2. NOTE: After completing the installation, refer to the vehicle Owner’s Manual for instructions on how to reset the clock

and preset radio stations.

!

3. CAUTION: Disconnecting the battery causes the DSC indicator light to become inoperable. (The DSC OFF

indicator light flashes and the TCS/DSC indicator light is illuminated.)

Perform the following procedure to restore the DSC to an operable condition:

a. Start the vehicle with the key.

b. Turn the steering wheel completely to the right and then completely to the left.

c. Verify that the DSC OFF indicator light turns off.

d. Turn the ignition switch to the OFF position and then turn it to the ON position again.

e. Verify that the TCS/DSC indicator light turns off.

!

4. CAUTION: When the battery is disconnected, the windows will not fully open and close automatically.

Perform the following procedure to the driver and passenger front windows to resume operation:

a. Turn the ignition switch to the ON position.

b. Press down the window switch on the front passenger’s side door panel and fully open the window.

c. Pull up the window switch on the front passenger’s side door panel and continue holding for approximately 3

seconds to fully close the window.

d. Press down both front window switches on the driver’s door panel and fully open the windows.

e. Pull up both front window switches on the driver’s door panel and continue holding for approximately 3 seconds to

fully close the windows.

f. Turn the ignition switch to the OFF position.

21

4280246 Rev. B 11/10

Page 22

23

HOOD SAFETY SWITCH ADJUSTMENT

The hood safety will need to be adjusted to shutdown the vehicle when the hood is raised to the full upright position

1. Raise and prop the vehicle’s hood.

2. The hood switch cylinder should be bend away from the hood to approximately 15 degrees above parallel with the

ground. (FIGURE CCC)

3. After the adjustment has been made verify that remote start system does not engage when the vehicle’s hood is

open.

4. If the remote start system engages with the hood in the full upright position, the switch will need to be bent closer to

the hood.

NOTE: IT IS VERY IMPORTANT TO VERIFY THAT THE HOOD

SAFETY SWITCH PREVENTS THE REMOTE ENGINE START

SYSTEM FROM ENGAGING WHEN THE VEHICLE’S HOOD IS

IN THE FULL UPRIGHT POSITION

FIGURE CCC

24

SERVICE PART NUMBER LIST

Part Number Description

0000-8F-H03 Hood Safety Switch Kit Service Part

0000-8F-H05A Mazda Immobilizer Interface Service Part

0000-8F-M21 Mazda CX-7 DNA Card Software Service Part

0000-8F-M41 Mazda CX-7 Remote Start Wire Harness Service Part

0000-8F-Z01 Remote Start Control Module Service Part

0000-8F-Z02 Mazda 1-Button Remote Start Transmitter Service Part

0000-8F-Z03 Emergency Override/Programming Button Service Part

0000-8F-Z10 Dipole Antenna Service Part

0000-8F-Z12 Underhood Warning Label Service Part

0000-8F-Z13 PVC Foam Tape Service Part

PowerCode®, IT-s®, Real Panic Sound® and Progressive Find® are registered trademarks of Code Systems, Inc.

22

4280246 Rev. B 11/10

Page 23

SYSTEM LAYOUT

23

4280246 Rev. B 11/10

Loading...

Loading...