Page 1

Automatic

CONTENTS

Transaxle and

Transfer

Workshop

Manual

AW6A–EL

AW6AX–EL

FOREWORD

This manual explains the service points for

the above-indicated automotive system.

This manual covers all models with the

above-indicated automotive system, not any

one specific model.

In order to do these procedures safely,

quickly, and correctly, you must first read

this manual and any other relevant service

materials carefully.

All the contents of this manual, including

drawings and specifications, are the latest

available at the time of printing.

As modifications affecting repair or

maintenance occur, relevant information

supplementary to this volume will be made

available at Mazda dealers.

This manual should be kept up-to-date.

Mazda Motor Corporation reserves the right

to alter the specifications and contents of

this manual without obligation or

advance notice.

All rights reserved.

No part of this book may be reproduced or

used in any form or by any means, electronic

or mechanical-including

photocopying and recording and the use of

any kind of information storage and retrieval

system-without permission in writing.

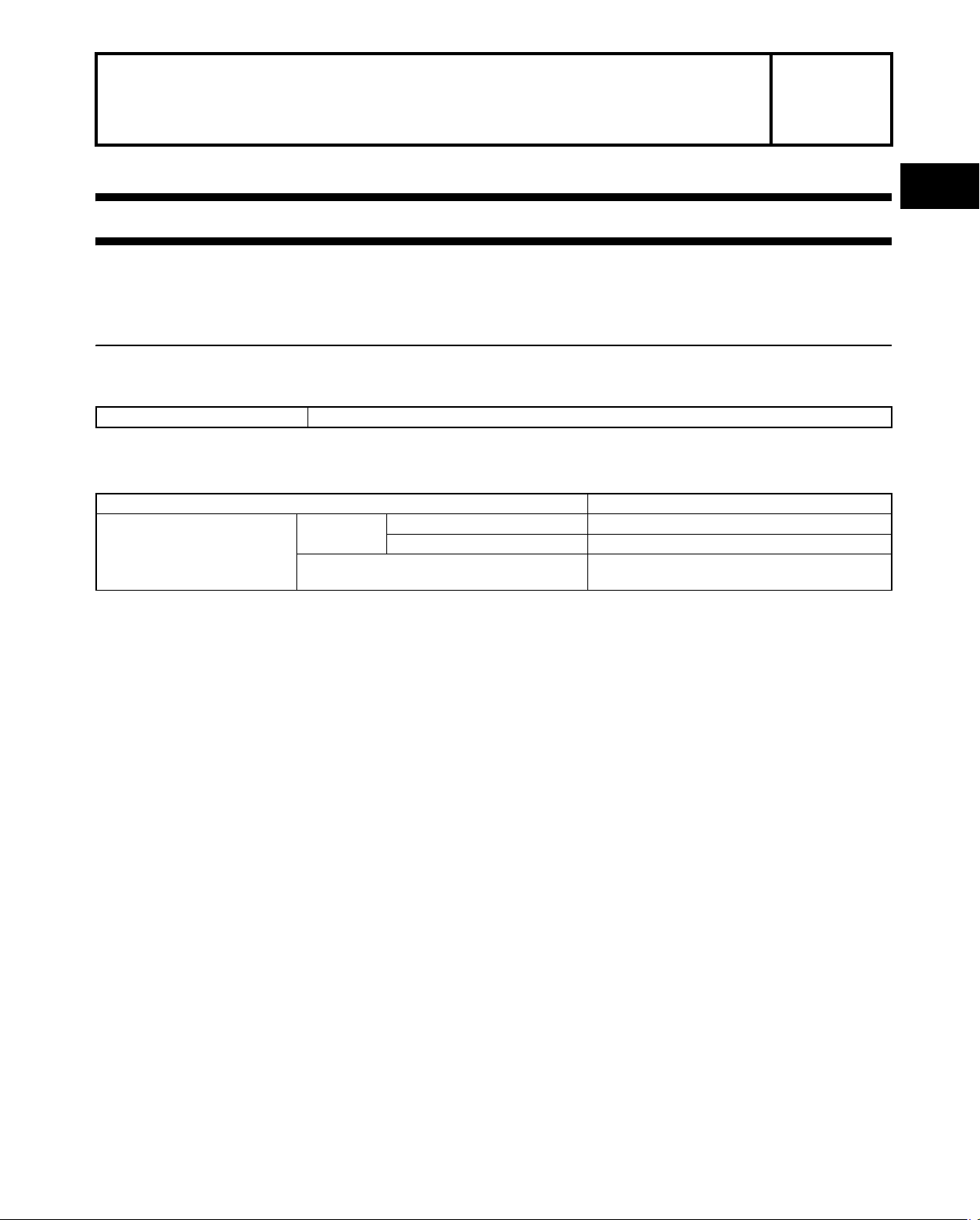

Title

GENERAL INFORMATION

DRIVELINE/AXLE

TRANSMISSION/TRANSAXLE

© 2006 Mazda Motor Corporation

PRINTED IN U.S.A., FEBRUARY 2006

Form No. 1874–1U–06B

Part No. 9999–95–0AW6–07

Section

FEATURES SERVICE

00 00

03 03

05 05

Mazda Motor Corporation

HIROSHIMA, JAPAN

Page 2

Page 3

FEATURES

Page 4

Page 5

DRIVELINE/AXLE

To c o f S C T

OUTLINE . . . . . . . . . . . . . . . . . . 03-00 TRANSFER . . . . . . . . . . . . . . . 03-16

To c o f S C T

03

SECTION

03-00 OUTLINE

DRIVELINE/AXLE FEATURES . . . . . . . . 03-00–1 DRIVELINE/AXLE SPECIFICATIONS. . . 03-00–1

End of Toc

NG: DRIVELINE/AXLE

DRIVELINE/AXLE FEATURES

Improved reliability • Separate oil pump and oil cooler have been adopted to the transfer

End Of Sie

DRIVELINE/AXLE SPECIFICATIONS

Item Specification

Grade API service GL-5

Viscosity SAE 80W-90

(L {US qt, Imp qt}) 1.2 {1.3,1.1}

Transfer oil

Ty p e

Oil capacity

(approx. quantity)

id030000100100

id030000100200

03-00

End Of Sie

03-00–1

Page 6

Page 7

03-16 TRANSFER

TRANSFER

TRANSFER STRUCTURAL VIEW . . . . . 03-16–1

TRANSFER CROSS-SECTIONAL

VIEW. . . . . . . . . . . . . . . . . . . . . . . . . . . 03-16–1

End of Toc

NG: TRANSFER

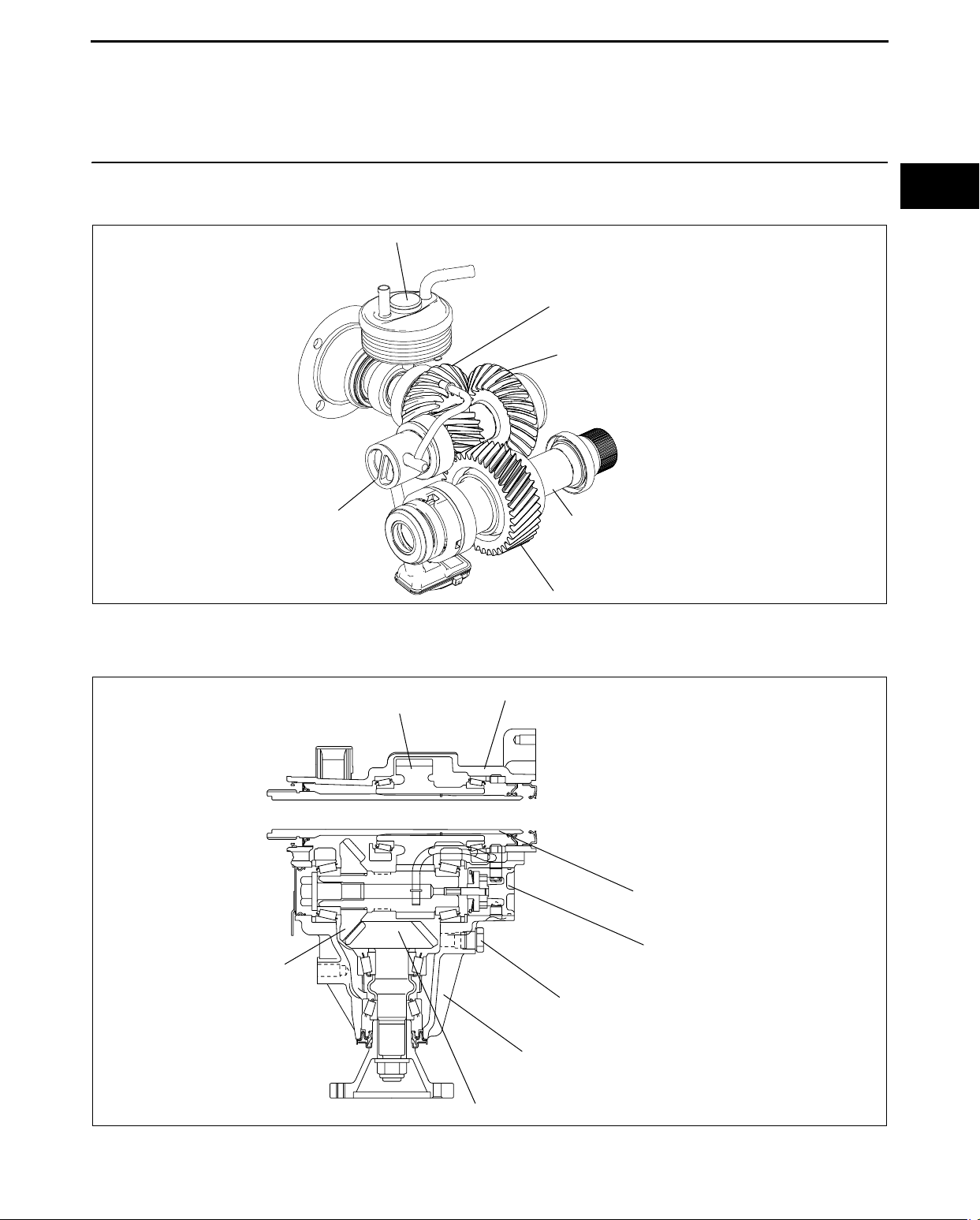

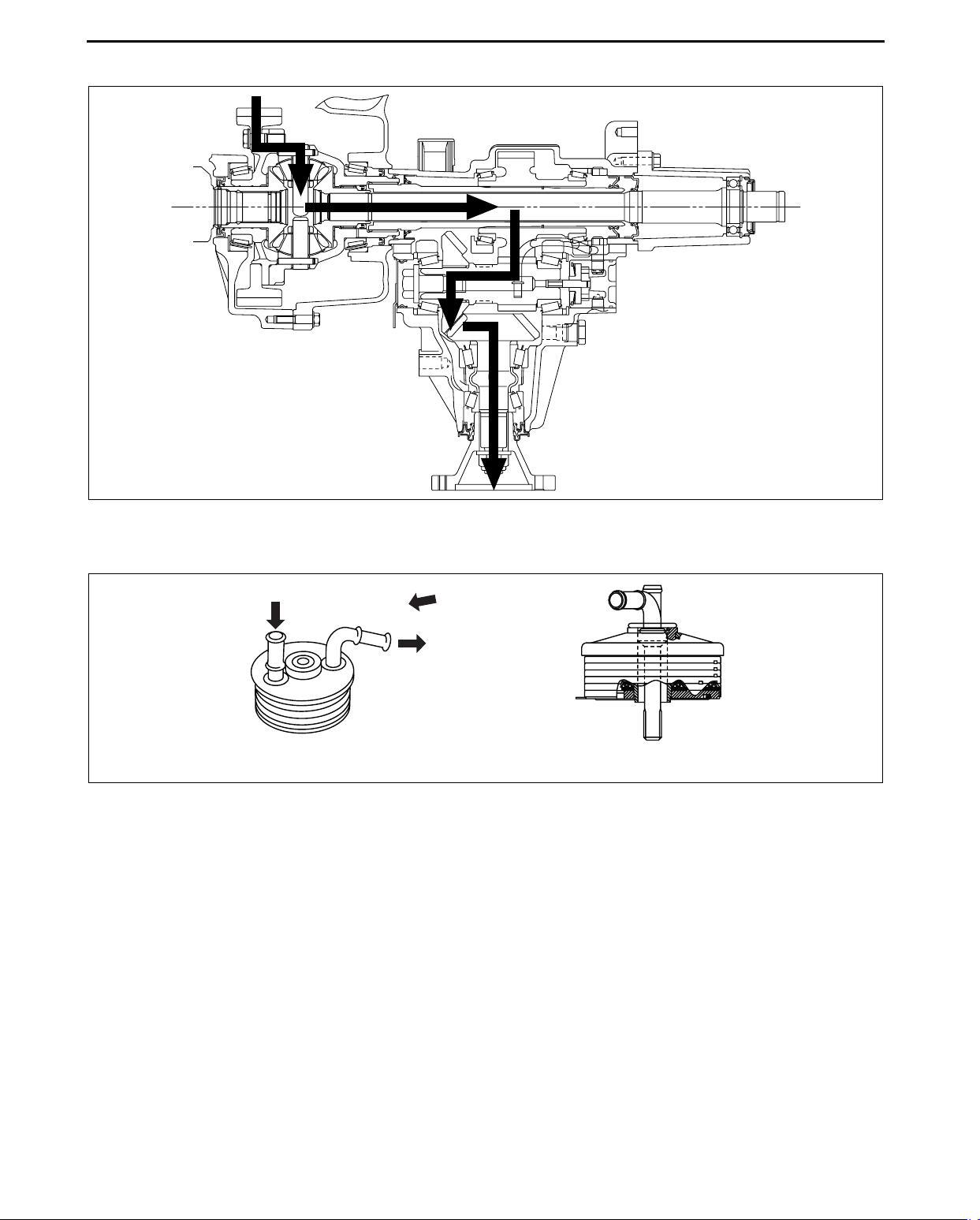

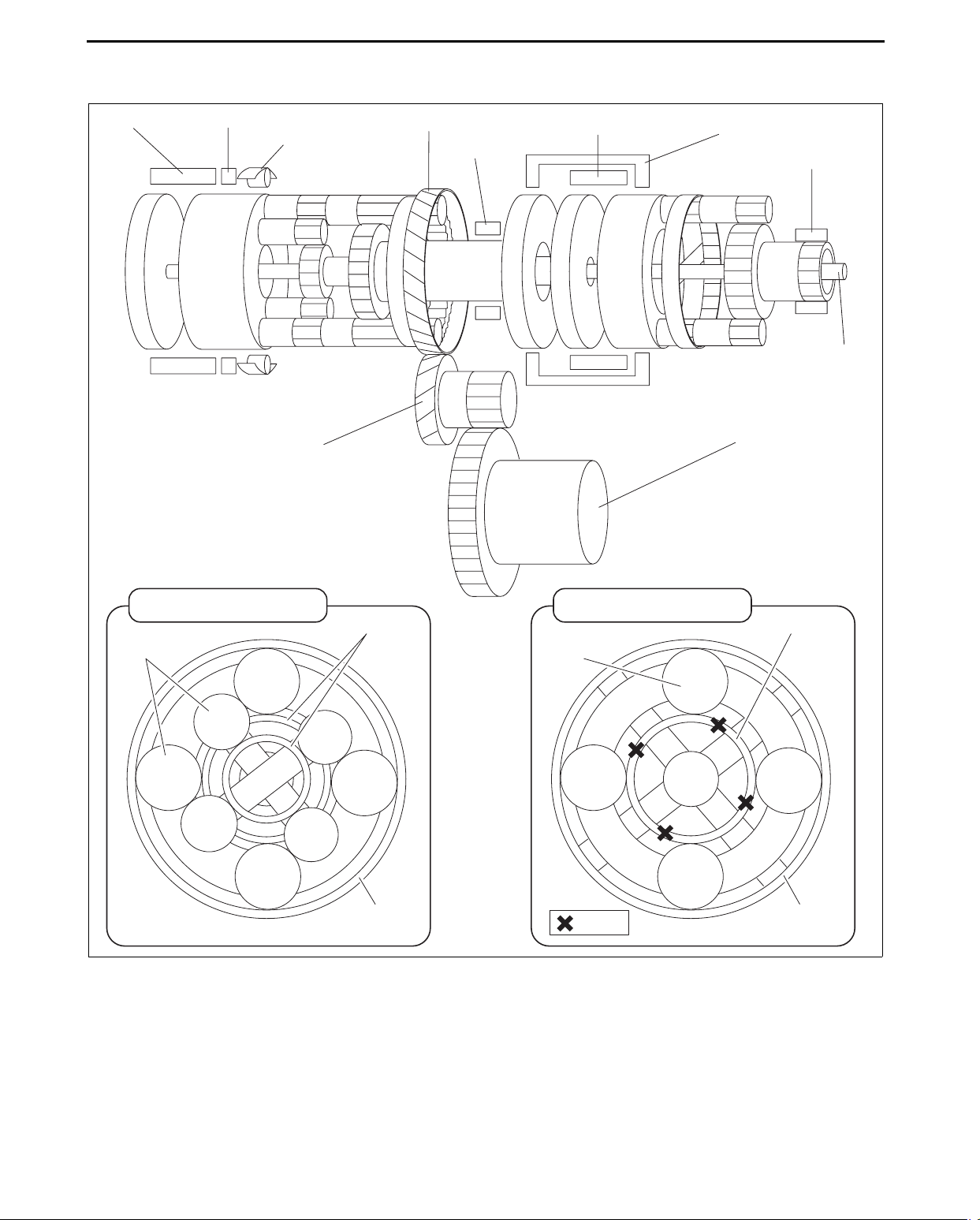

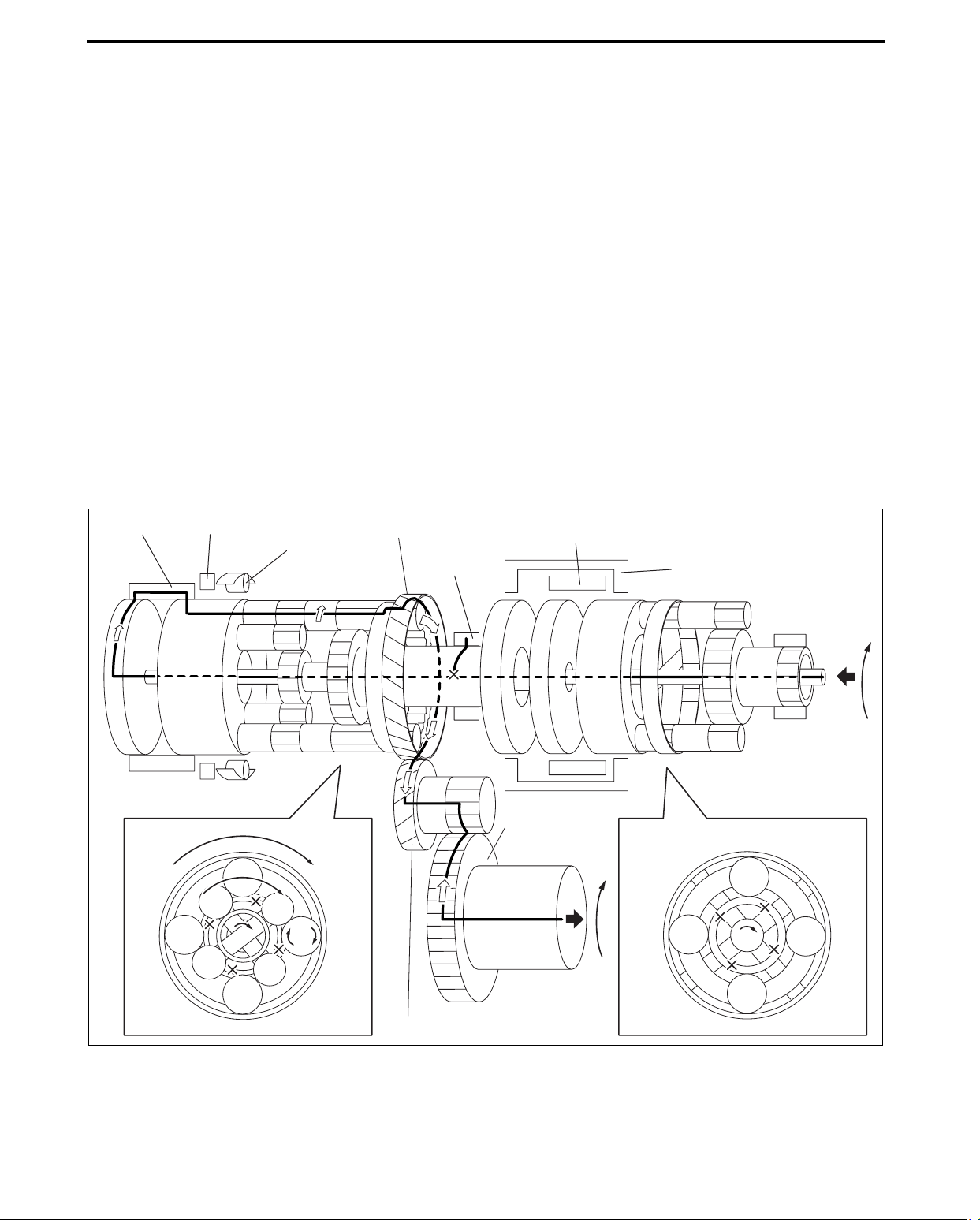

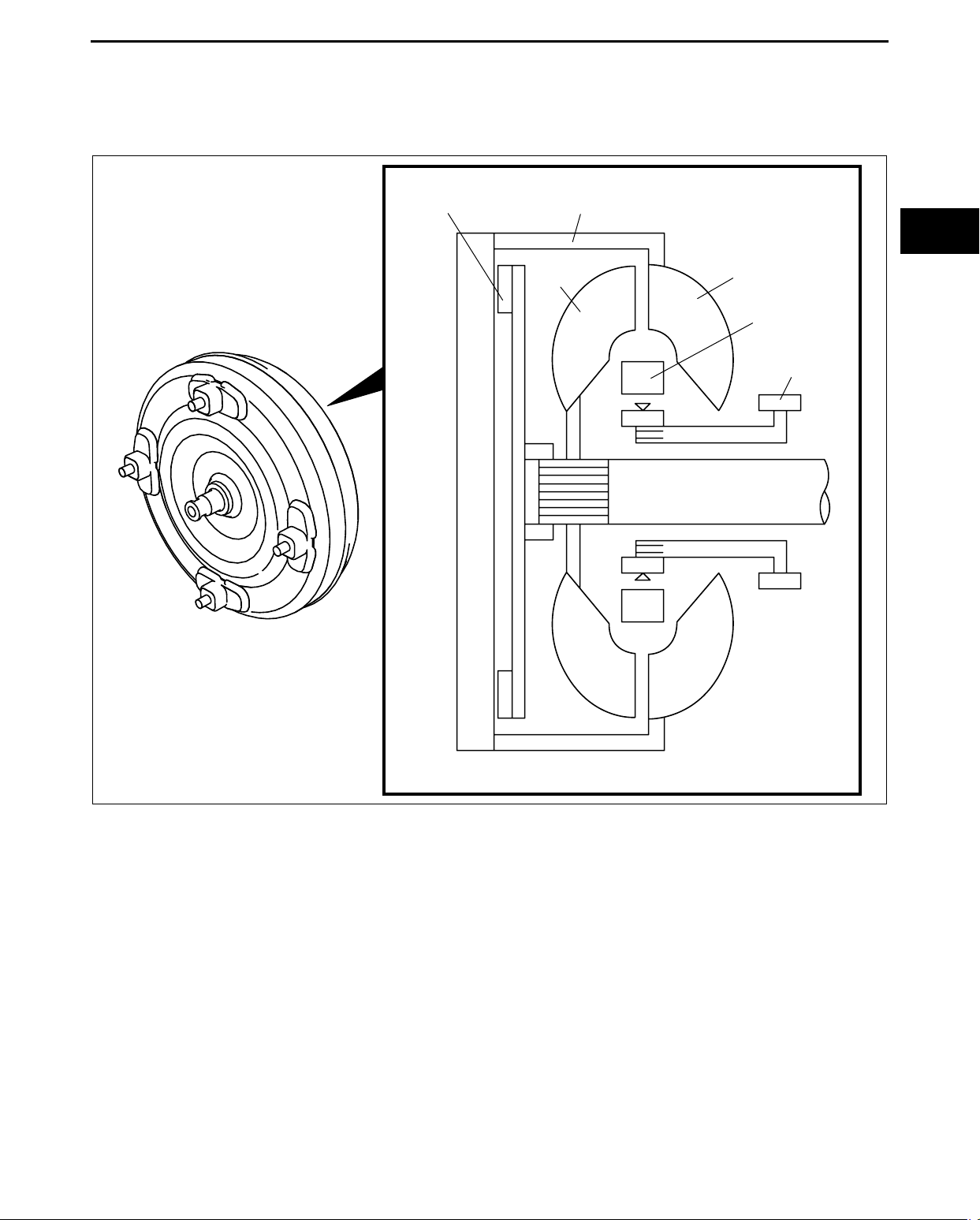

TRANSFER STRUCTURAL VIEW

OIL COOLER

OIL PUMP

TRANSFER POWER FLOW. . . . . . . . . . . 03-16–2

TRANSFER OIL COOLER

CONSTRUCTION . . . . . . . . . . . . . . . . . 03-16–2

03-16

id031600100100

DRIVE PINION GEAR

RING GEAR

DRIVE GEAR SHAFT

End Of Sie

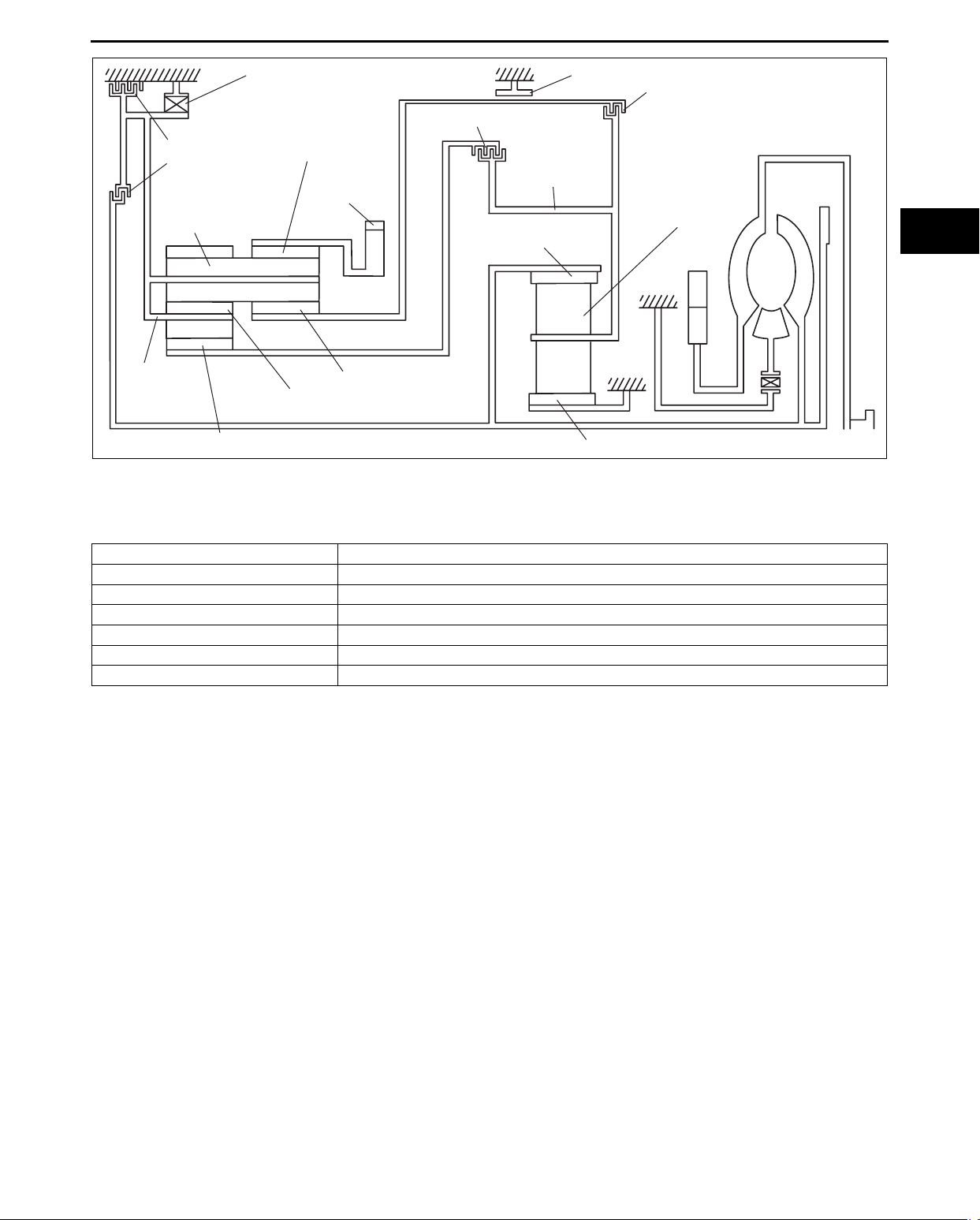

TRANSFER CROSS-SECTIONAL VIEW

DRIVE GEAR

RING GEAR

DRIVE GEAR

acxuun00000598

id031600100200

DRIVE GEAR CASE

DRIVE GEAR SHAFT

OIL PUMP

OIL LEVEL PLUG

End Of Sie

FRONT CARRIER

DRIVE PINION GEAR

acxuun00000599

03-16–1

Page 8

TRANSFER

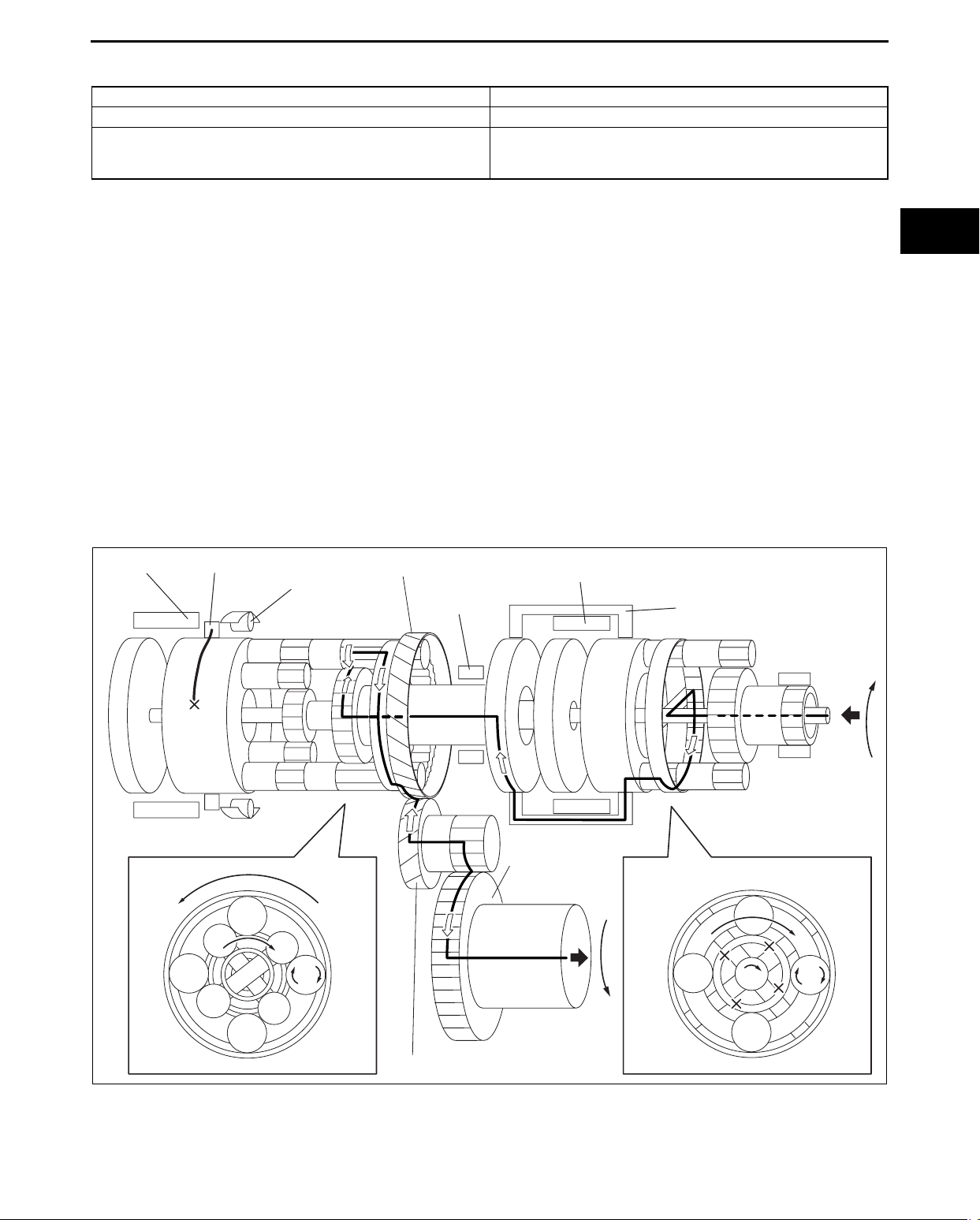

TRANSFER POWER FLOW

End Of Sie

TRANSFER OIL COOLER CONSTRUCTION

id031600100300

acxuun00000600

id031600100400

End Of Sie

WATER IN

VIEW A

WATER OUT

VIEW FROM A

acxuun00000601

03-16–2

Page 9

TRANSMISSION/TRANSAXLE

To c o f S C T

OUTLINE . . . . . . . . . . . . . . . . . . 05-00 AUTOMATIC TRANSAXLE . . . 05-17

05

SECTION

To c o f S C T

05-00 OUTLINE

05-00

TRANSMISSION/TRANSAXLE

FEATURES . . . . . . . . . . . . . . . . . . . . . . 05-00–1

End of Toc

NG: TRANSMISSION/TRANSAXLE

TRANSMISSION/TRANSAXLE FEATURES

ATX [AW6A-EL, AW6AX-EL]

Superior shift quality • Centrifugal hydraulic pressure cancel clutch has been adopted.

End Of Sie

AUTOMATIC TRANSAXLE SPECIFICATIONS

Item Specifications

Transaxle type AW6A-EL, AW6AX-EL

1GR 4.148

2GR 2.370

3GR 1.555

Gear ratio

Final gear ratio 3.749

AT F

Torque converter stall torque ratio 2.15

Hydraulic system

(Number of drive/driven plates)

Band servo

(mm {in})

Front planetary gear

(Number of teeth)

Rear planetary gear

(Number of teeth)

Counter drive gear (Number of teeth) 52

Counter gear (Number of teeth)

Ring gear (Number of teeth) 53

• The example of automatic transaxle specifications. (specifications of the CX-7)

End Of Sie

4GR 1.154

5GR 0.859

6GR 0.685

Reverse 3.393

Type JWS3309

Capacity (approx. quantity)

C1 clutch 7/7

C2 clutch 4/4

C3 clutch 4/4

B2 brake 7/6

Servo diameter (piston outer dia./retainer

outer dia.)

Ring gear 81

Sun gear 45

Pinion gear 17

Ring gear 72

Middle sun gear 33

Rear sun gear 27

Long pinion gear 18

Short pinion gear 17

Driven gear 49

Drive gear 15

AUTOMATIC TRANSAXLE

SPECIFICATIONS . . . . . . . . . . . . . . . . 05-00–1

(L {US qt, Imp qt})

7.0 {7.4, 6.2}

61.3/66.0

{2.41/2.60}

id050000100200

id050000100300

05-00–1

Page 10

Page 11

AUTOMATIC TRANSAXLE

05-17 AUTOMATIC TRANSAXLE

AUTOMATIC TRANSAXLE OUTLINE . . 05-17–1

AUTOMATIC TRANSAXLE

CROSS-SECTIONAL VIEW . . . . . . . . . 05-17–2

POWERFLOW STRUCTURE . . . . . . . . . 05-17–4

Description of Components . . . . . . . . . 05-17–4

POWERFLOW OPERATION . . . . . . . . . . 05-17–5

1GR (D range) . . . . . . . . . . . . . . . . . . . 05-17–6

1GR (M range) . . . . . . . . . . . . . . . . . . . 05-17–7

2GR . . . . . . . . . . . . . . . . . . . . . . . . . . . 05-17–8

3GR. . . . . . . . . . . . . . . . . . . . . . . . . . . . 05-17–9

4GR. . . . . . . . . . . . . . . . . . . . . . . . . . . . 05-17–10

5GR. . . . . . . . . . . . . . . . . . . . . . . . . . . . 05-17–11

6GR. . . . . . . . . . . . . . . . . . . . . . . . . . . . 05-17–12

R position . . . . . . . . . . . . . . . . . . . . . . . 05-17–13

CENTRIFUGAL HYDRAULIC PRESSURE

CANCEL CLUTCH OUTLINE . . . . . . . . 05-17–15

TORQUE CONVERTER OUTLINE. . . . . . 05-17–17

End of Toc

NG: AUTOMATIC TRANSAXLE

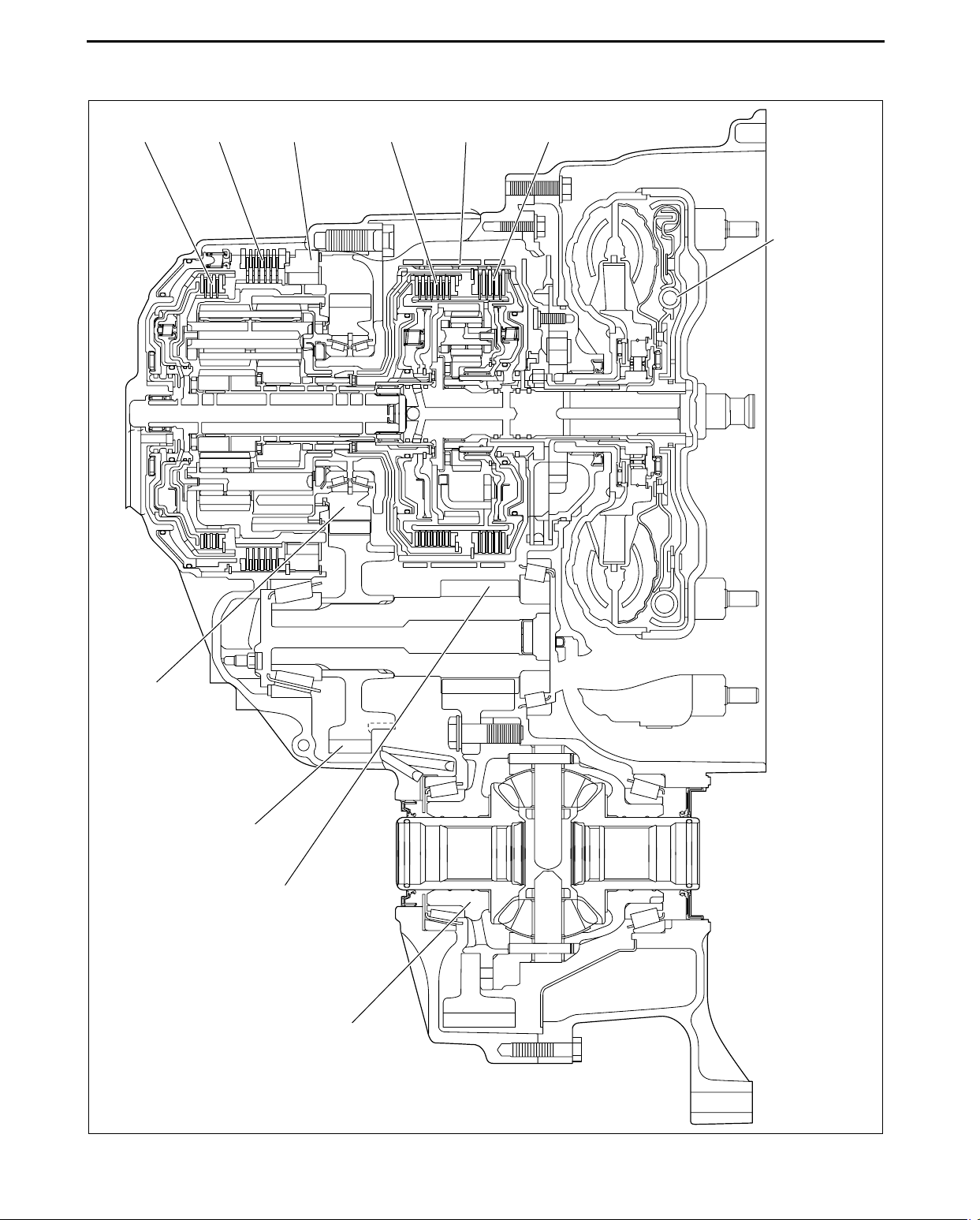

AUTOMATIC TRANSAXLE OUTLINE

• The AW6A (X) -EL automatic transaxle is a compact, lightweight, next-generation electronically controlled FF 6speed automatic transaxle that employs a Ravigneaux-type planetary gear. It employs a high-precision clutch

hydraulic control system for smooth, highly responsive gear shift feel.

id051700101700

End Of Sie

05-17

05-17–1

Page 12

AUTOMATIC TRANSAXLE

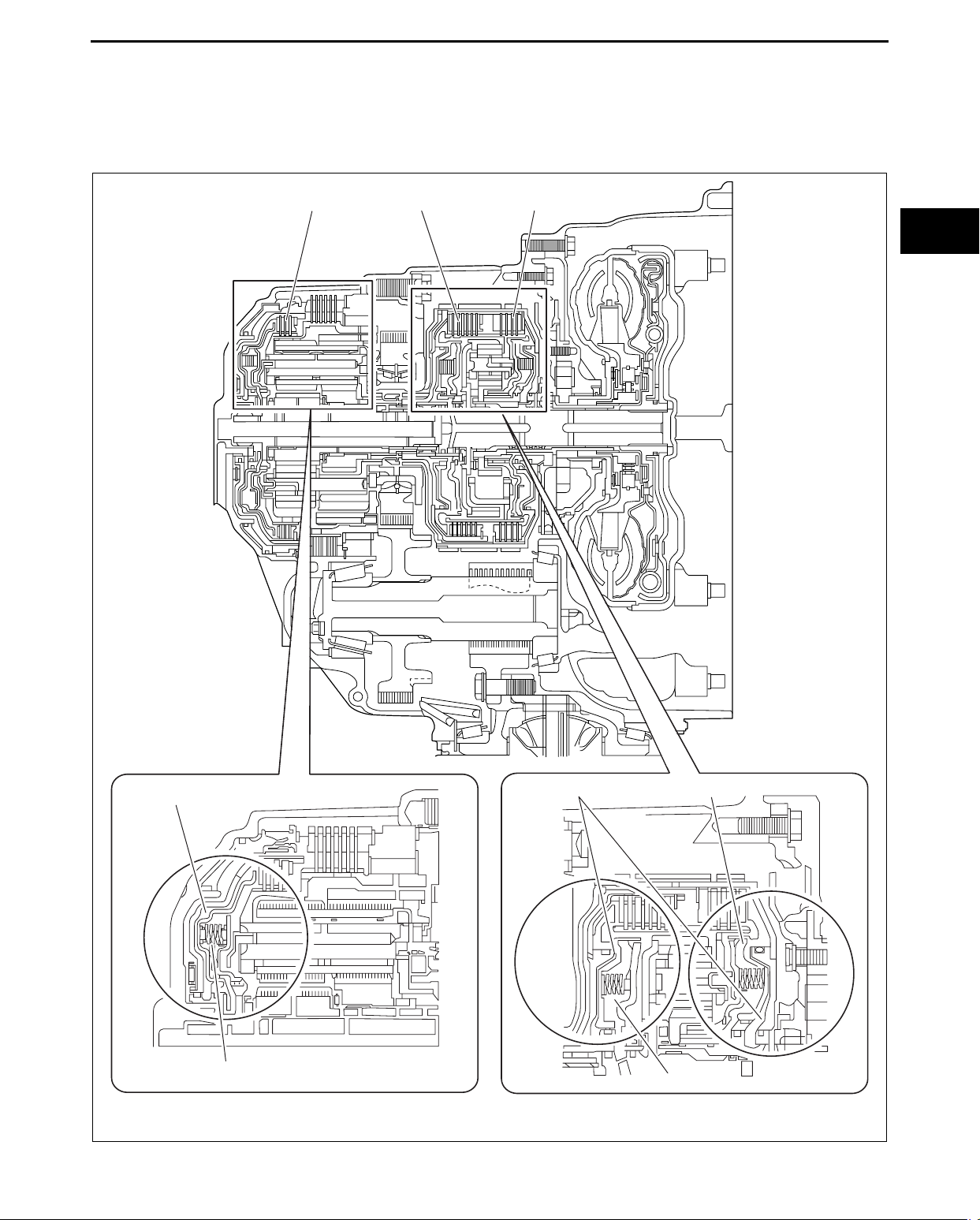

AUTOMATIC TRANSAXLE CROSS-SECTIONAL VIEW

AW6A-EL

C2 CLUTCH C1 CLUTCH C3 CLUTCHB2 BRAKE B1 BRAKE

ONE-WAY

CLUTCH

id051700101900

TORQUE

CONVERTER

COUNTER

DRIVE GEAR

COUNTER GEAR

(DRIVEN)

COUNTER GEAR

(DRIVE)

DIFFERENTIAL

acxuun00000612

05-17–2

Page 13

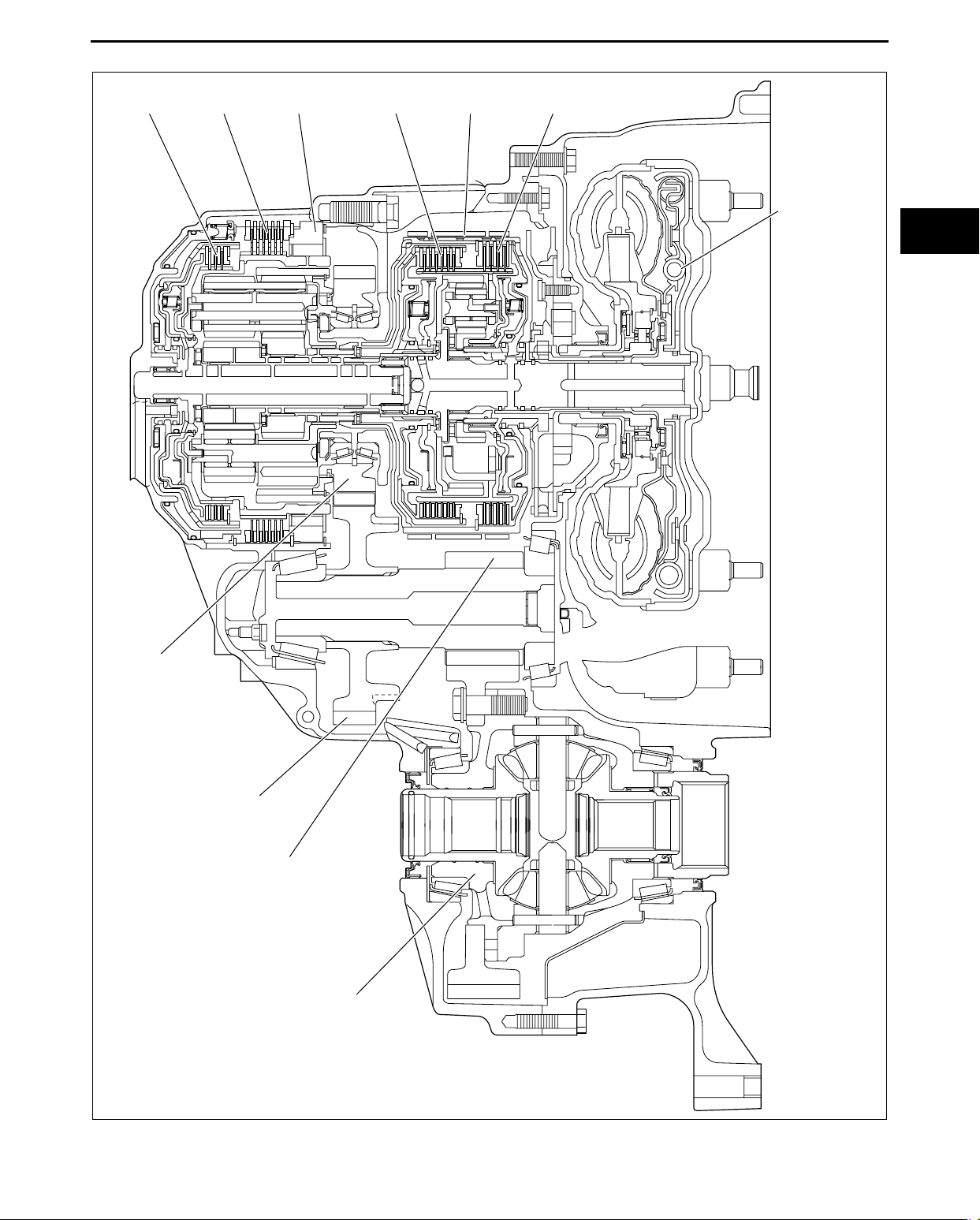

AW6AX-EL

AUTOMATIC TRANSAXLE

C2 CLUTCH C1 CLUTCH C3 CLUTCHB2 BRAKE B1 BRAKE

ONE-WAY

CLUTCH

TORQUE

CONVERTER

05-17

COUNTER

DRIVE GEAR

COUNTER GEAR

(DRIVEN)

COUNTER GEAR

(DRIVE)

DIFFERENTIAL

End Of Sie

acxuun00000613

05-17–3

Page 14

AUTOMATIC TRANSAXLE

POWERFLOW STRUCTURE

Description of Components

C2 CLUTCH B2 BRAKE

ONE-WAY

CLUTCH

COUNTER GEAR

COUNTER DRIVE GEAR

B1 BRAKE

C1 CLUTCH

id051700102200

C3 CLUTCH

OIL PUMP

INPUT

SHAFT

DIFFERENTIAL

REAR PLANETARY GEAR

SUN GEAR

PINION GEAR

RING GEAR

FRONT PLANETARY GEAR

PINION GEAR

INPUT

SHAFT

: LOCK

• The number of pinion gears differs depending on the engine displacement and vehicle.

— Mazda6

• Front: 3 pinions

• Rear: 3 pinions

— CX-7

• Front: 5 pinions

• Rear: 3 pinions

SUN GEAR

RING GEAR

acxuun00000680

05-17–4

Page 15

AUTOMATIC TRANSAXLE

ONE-WAY CLUTCH

B2 BRAKE

C2 CLUTCH

REAR PLANETARY

LONG PINION

GEAR

REAR

PLANETARY

CARRIER

REAR PLANETARY

RING GEAR

REAR PLANETARY SHORT

PINION GEAR

REAR PLANETARY REAR SUN GEAR

End Of Sie

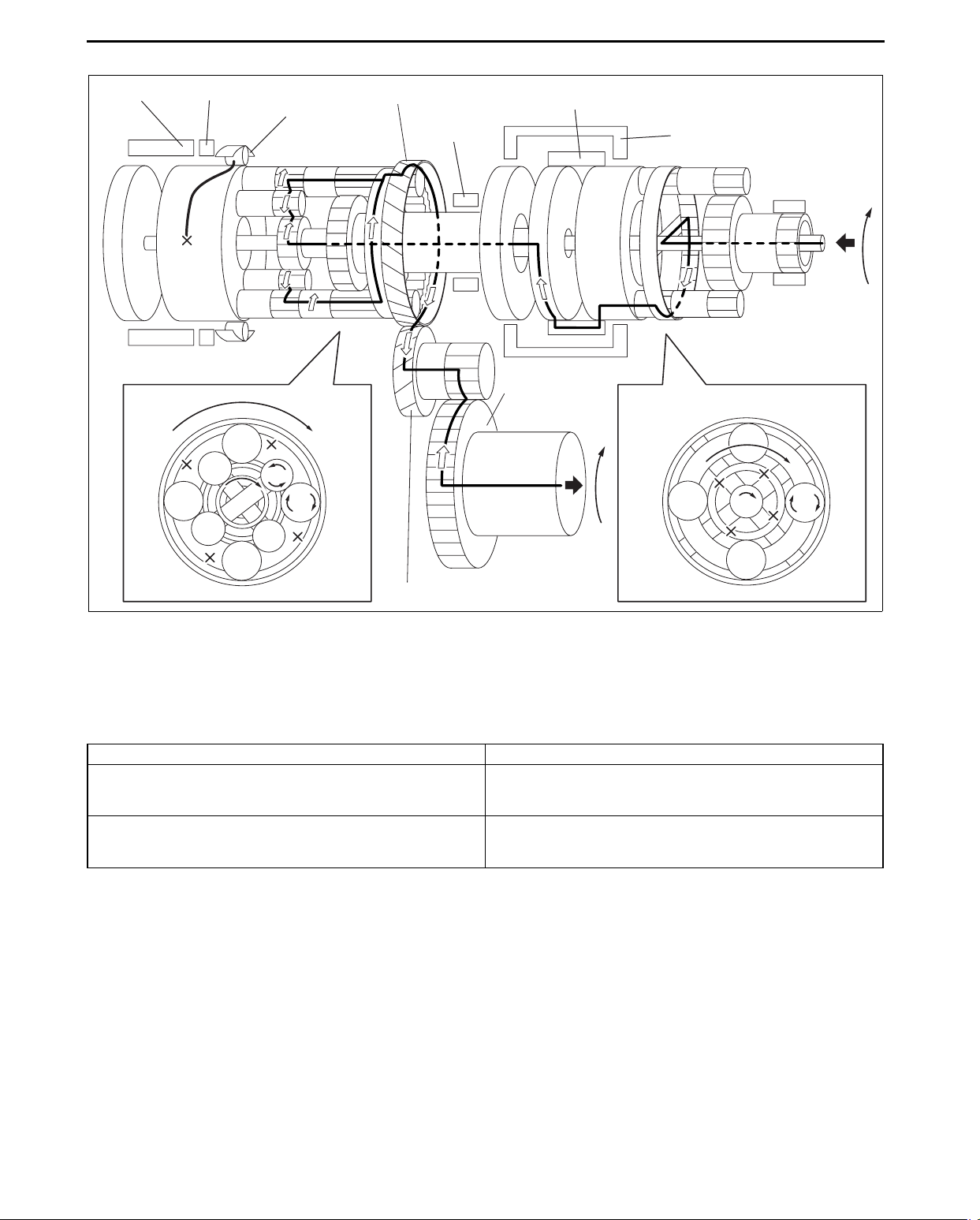

POWERFLOW OPERATION

List of operating components

Clutch / Brake Operation

C1 clutch • Connects front planetary carrier to rear planetary rear sun gear

C2 clutch • Connects intermediate shaft to rear planetary carrier

C3 clutch • Connects front planetary carrier to rear planetary middle sun gear

B1 brake • Locks rear planetary middle sun gear

B2 brake • Locks rear planetary carrier

One-way clutch • Locks counterclockwise rotation of rear planetary carrier

COUNTER

DRIVE GEAR

REAR PLANETARY

MIDDLE SUN GEAR

C1 CLUTCH

FRONT

PLANETARY

RING GEAR

B1 BRAKE

FRONT

PLANETARY

CARRIER

FRONT PLANETARY SUN GEAR

C3 CLUTCH

FRONT

PLANETARY

PINION GEAR

05-17

acxuun00000681

id051700102300

05-17–5

Page 16

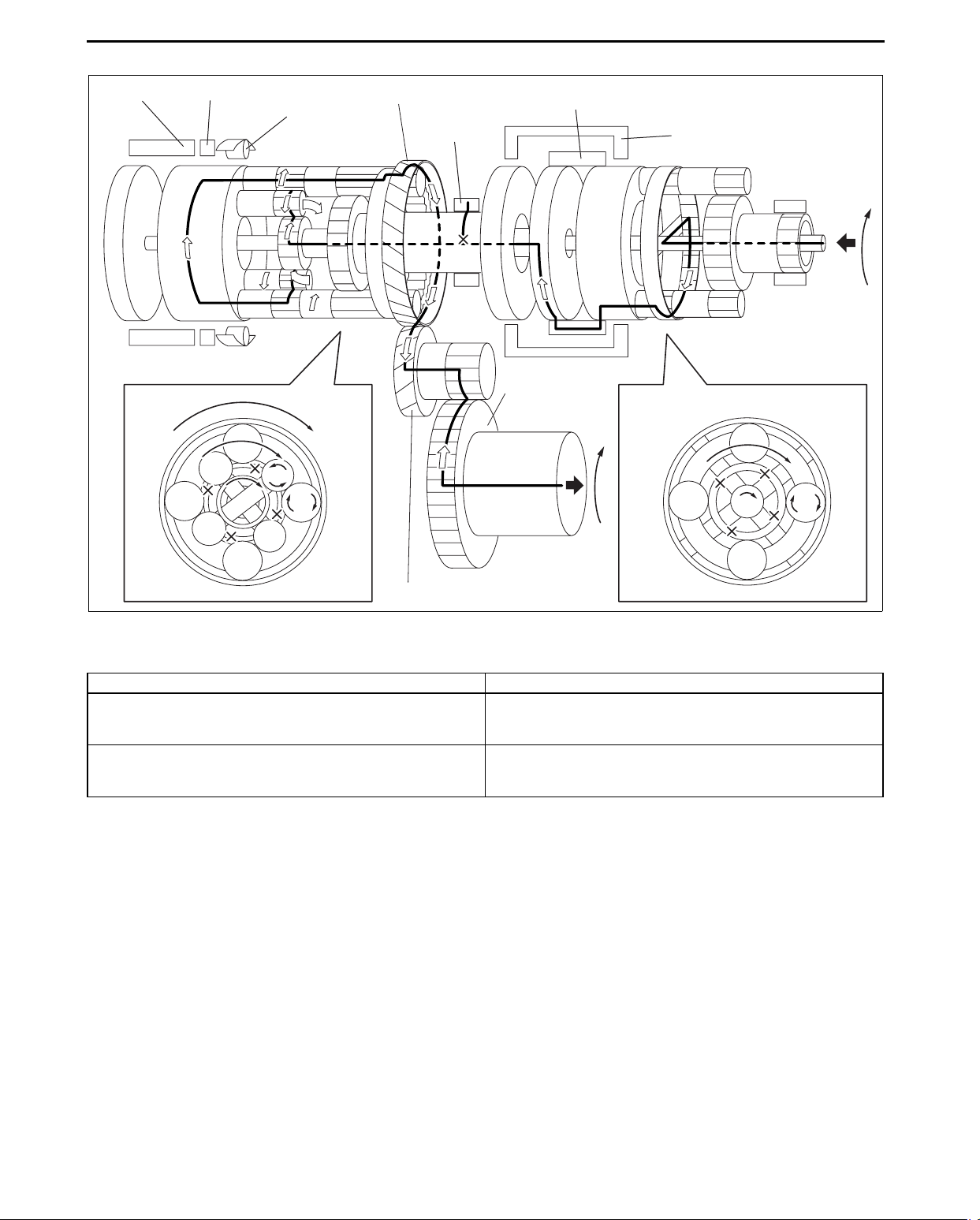

1GR (D range)

AUTOMATIC TRANSAXLE

C2 CLUTCH B2 BRAKE

ONE-WAY

CLUTCH

COUNTER DRIVE GEAR

B1 BRAKE

C1 CLUTCH

C3 CLUTCH

RING GEAR

(DIFFERENTIAL)

COUNTER GEAR

acxuun00000620

Power transmission pathway

[Operating components: C1 clutch, One-way clutch]

• Operating components:

C1 clutch, One-way clutch (counterclockwise rotation is locked), B2 brake (ON when engine brake is operating)

Planetary gear unit Input, Locked, Output

Front

Rear

Input: Ring gear

Locked: Sun gear

Output: Carrier

Input: Rear sun gear

Locked: Carrier

Output: Ring gear

1. Input shaft (rotates clockwise) [same revolutions as the torque converter’s turbine runner]

2. Front planetary ring gear (rotates clockwise) [same revolutions as the input shaft]

3. Front planetary pinion gear (rotates clockwise on its axis, orbits clockwise)

[because the front planetary sun gear is locked by the oil pump, it is pressed against the front planetary ring

gear and orbits the sun gear while rotating on its axis (because the front planetary ring gear has internal gears,

the rotational direction does not change)]

4. Front planetary carrier (rotates clockwise)

[reduction: same revolution as the front planetary pinion gear orbit revolution]

5. C1 clutch (rotates clockwise) [connects the front planetary carrier and the rear planetary rear sun gear]

6. Rear planetary rear sun gear (rotates clockwise) [same revolution as the front planetary carrier]

7. Rear planetary short pinion gear (rotates counterclockwise on its axis)

[the rear planetary carrier tries to rotate counterclockwise, but the counterclockwise rotation is locked by oneway clutch.]

8. Rear planetary long pinion gear (rotates clockwise on its axis)

[the rear planetary middle sun gear rotates counterclockwise (idling)]

05-17–6

Page 17

AUTOMATIC TRANSAXLE

9. Rear planetary ring gear (rotates clockwise)

[the rear planetary ring gear is rotated by the rear planetary long pinion gear (because the rear planetary ring

gear has internal gears, the rotational direction does not change)]

10. Counter drive gear (rotates clockwise)

[because the rear planetary ring gear is installed on the counter drive gear, the rotational direction and the

revolution are the same as the rear planetary ring gear]

11. Counter gear (rotates counterclockwise)

12. Differential ring gear (rotates clockwise)

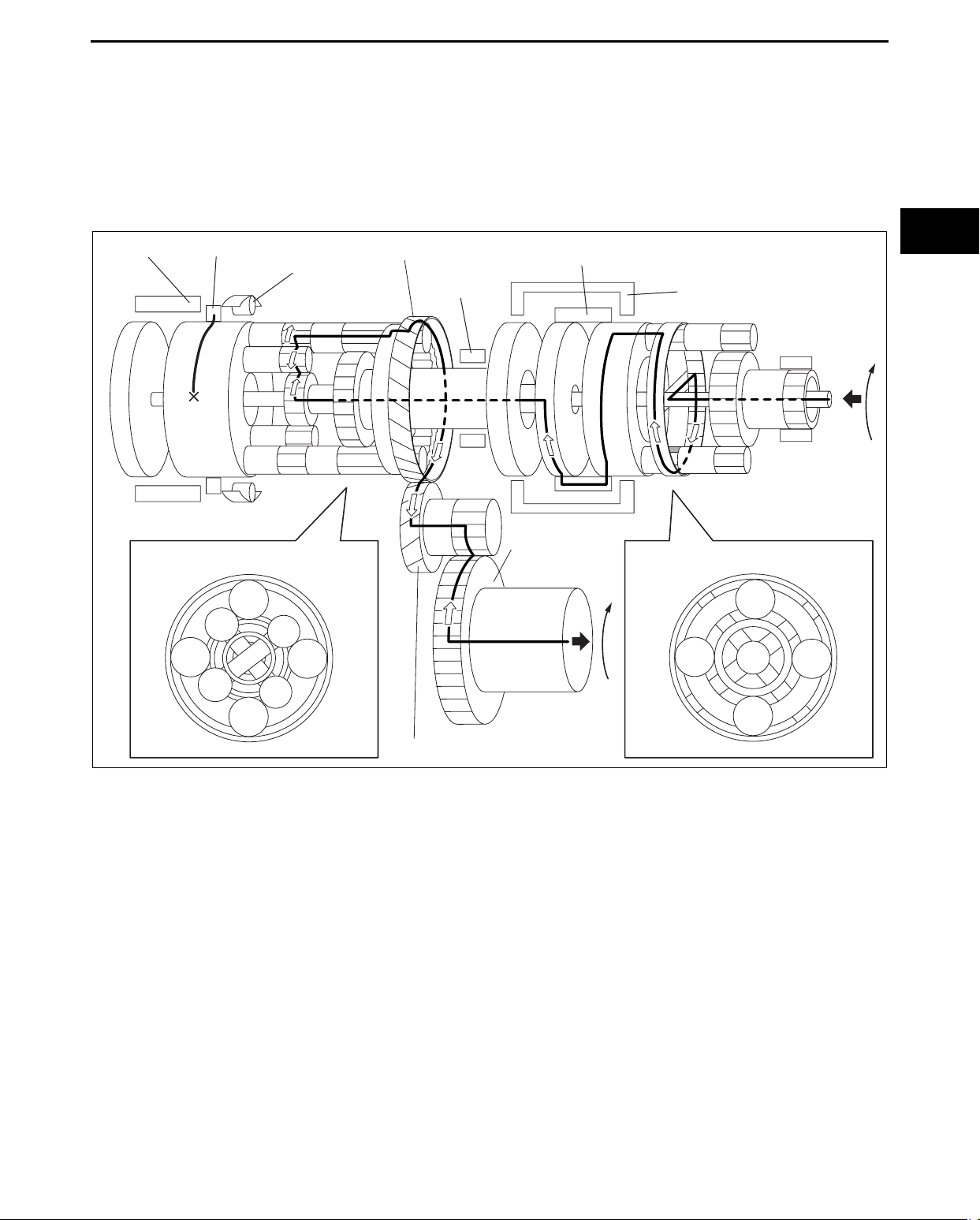

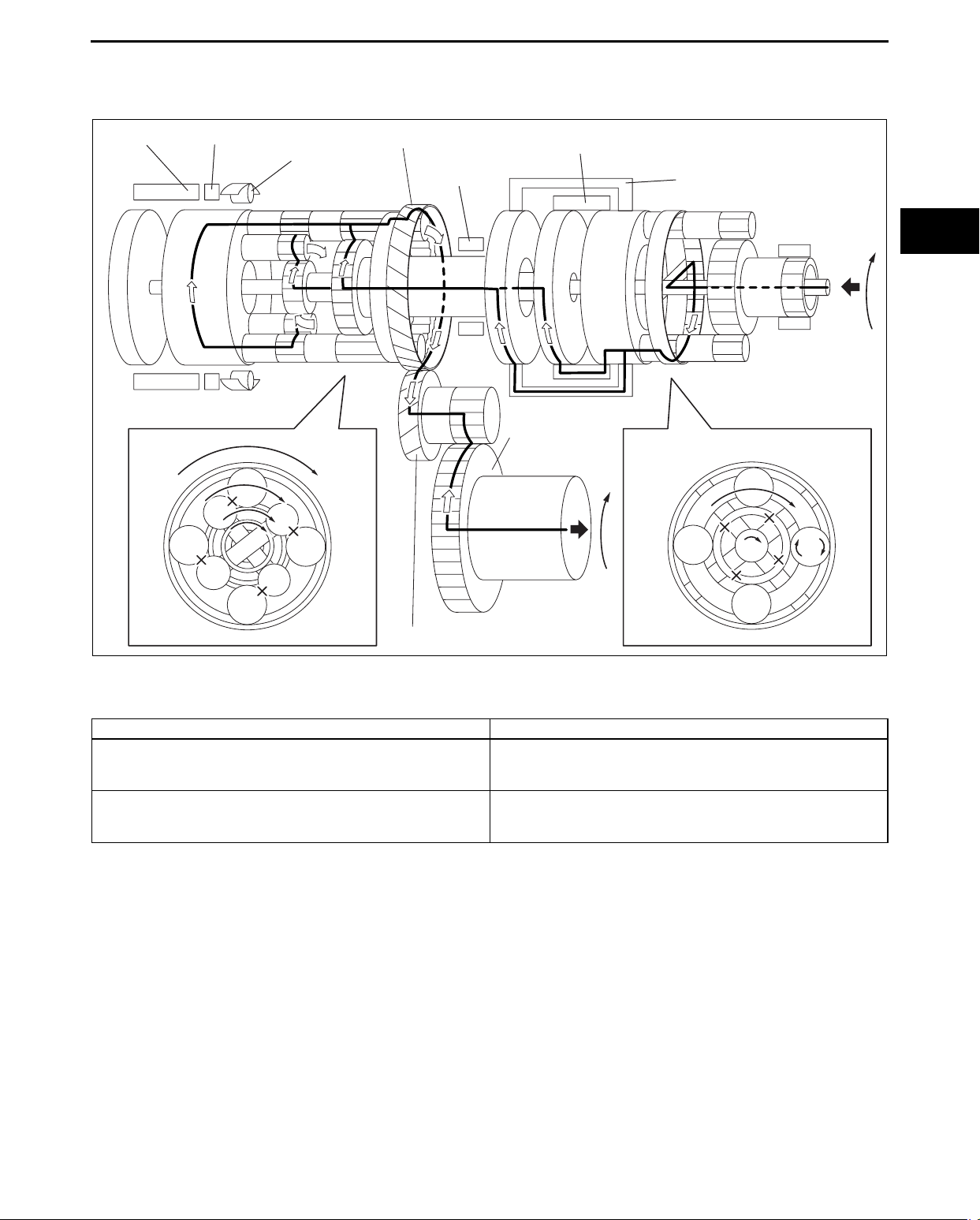

1GR (M range)

C2 CLUTCH B2 BRAKE

ONE-WAY

CLUTCH

COUNTER DRIVE GEAR

B1 BRAKE

05-17

C1 CLUTCH

C3 CLUTCH

RING GEAR

(DIFFERENTIAL)

COUNTER GEAR

acxuun00000621

[Operating components: C1 clutch, B2 brake]

• When the engine brake is operating, driving force is transmitted from the tires. Because the rear planetary

carrier, which is locked in its counterclockwise rotation by the one-way clutch, tries to rotate clockwise, B2 brake

is turned ON and the rear planetary carrier is locked, and kinematic energy is transmitted from the tires to the

engine.

05-17–7

Page 18

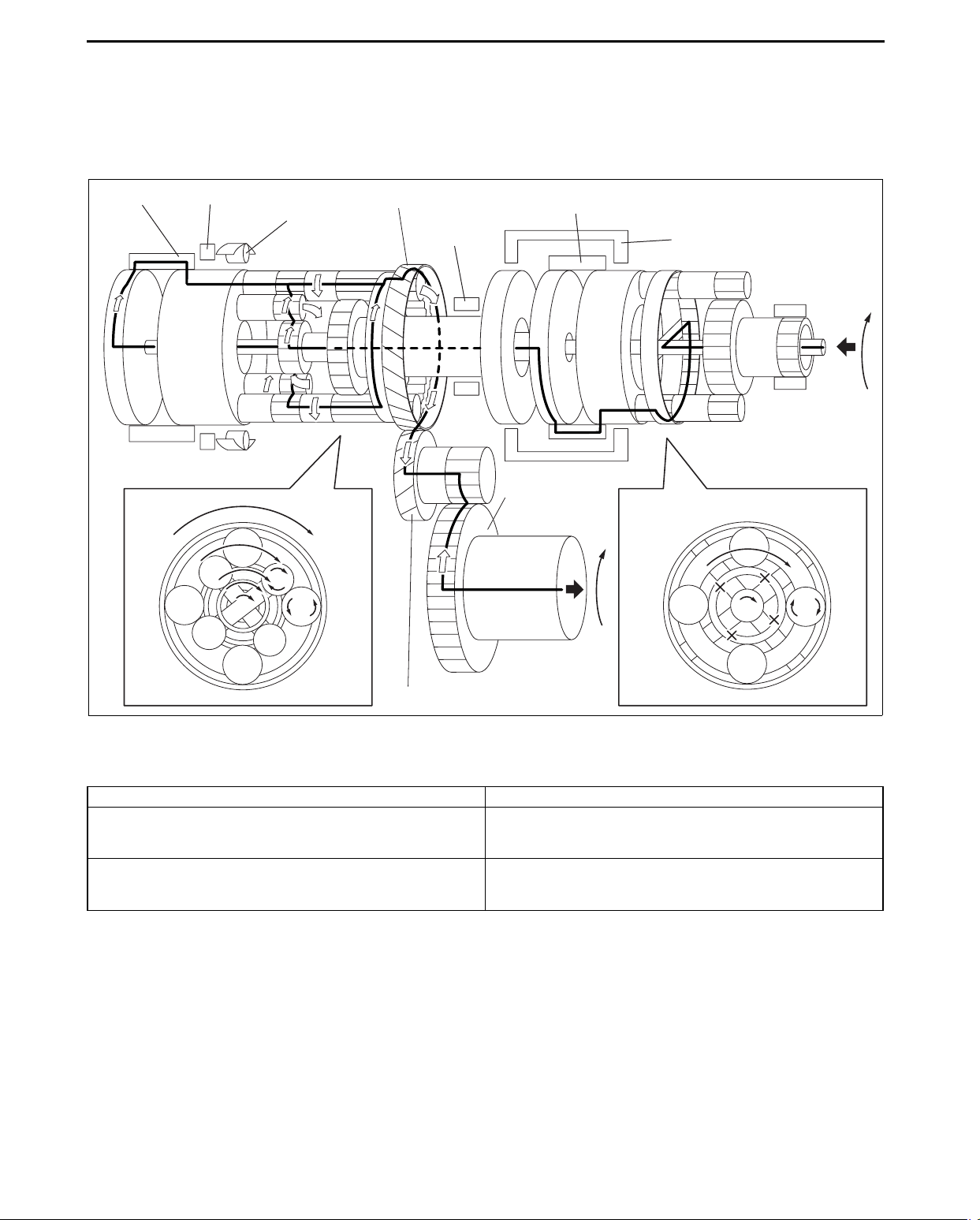

2GR

AUTOMATIC TRANSAXLE

C2 CLUTCH B2 BRAKE

ONE-WAY

CLUTCH

COUNTER DRIVE GEAR

B1 BRAKE

C1 CLUTCH

C3 CLUTCH

RING GEAR

(DIFFERENTIAL)

COUNTER GEAR

acxuun00000622

Power transmission pathway

[Operating components: C1 clutch, B1 brake]

Planetary gear unit Input, Locked, Output

Front

Rear

Input: Ring gear

Locked: Sun gear

Output: Carrier

Input: Rear Sun gear

Locked: Middle Sun gear

Output: Ring gear

1. Input shaft (rotates clockwise) [same revolutions as the torque converter’s turbine runner]

2. Front planetary ring gear (rotates clockwise) [same revolution as the input shaft]

3. Front planetary pinion gear (rotates clockwise on its axis, orbits clockwise)

[because the front planetary sun gear is locked by the oil pump, it is pressed against the front planetary ring

gear and orbits the sun gear while rotating on its axis (because the front planetary ring gear has internal gears,

the rotational direction does not change)]

4. Front planetary carrier (rotates clockwise)

[reduction: same revolution as the front planetary pinion gear orbit revolution]

5. C1 clutch (rotates clockwise) [connects the front planetary carrier and the rear planetary rear sun gear]

6. Rear planetary rear sun gear (rotates clockwise) [same revolution as the front planetary carrier]

7. Rear planetary middle sun gear is locked by B1 brake

8. Rear planetary short pinion gear (rotates counterclockwise on its axis, orbits clockwise)

9. Rear planetary long pinion gear (rotates clockwise on its axis, orbits clockwise)

10. Rear planetary ring gear (rotates clockwise)

[the rear planetary ring gear is rotated by the rear planetary long pinion gear (because the rear planetary ring

gear has internal gears, the rotational direction does not change)]

11. Counter drive gear (rotates clockwise)

[because the rear planetary ring gear is installed on the counter drive gear, the rotational direction and the

revolution are the same as the rear planetary ring gear]

12. Counter gear (rotates counterclockwise)

13. Differential ring gear (rotates clockwise)

05-17–8

Page 19

AUTOMATIC TRANSAXLE

Engine brake

• When the engine brake is operating, driving force is transmitted from the tires.

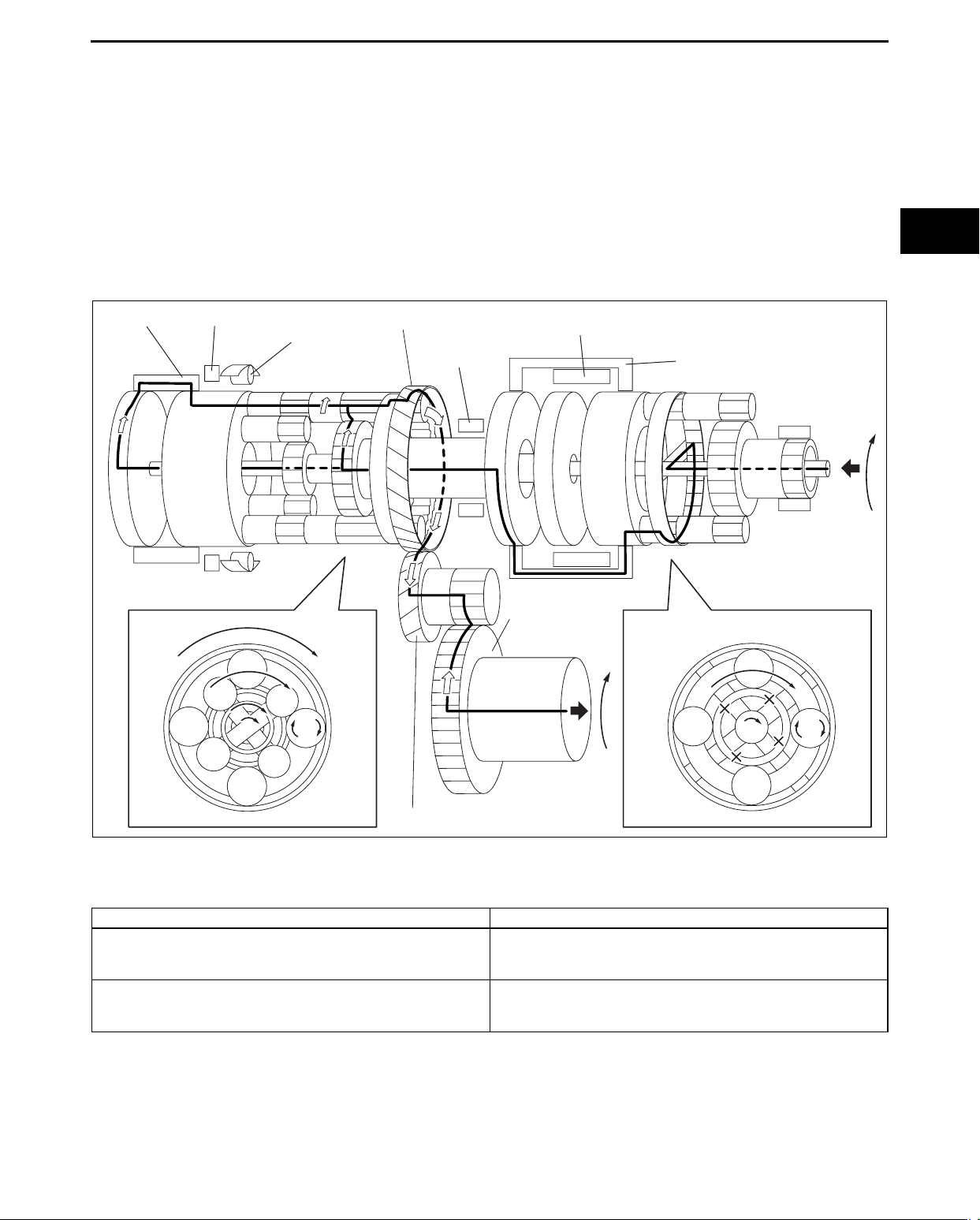

3GR

C2 CLUTCH B2 BRAKE

ONE-WAY

CLUTCH

COUNTER DRIVE GEAR

B1 BRAKE

C1 CLUTCH

C3 CLUTCH

05-17

RING GEAR

(DIFFERENTIAL)

COUNTER GEAR

acxuun00000623

Power transmission pathway

[Operating components: C1 clutch, C3 clutch]

Planetary gear unit Input, Locked, Output

Input: Ring gear

Front

Input: Rear Sun gear, Middle Sun gear

Rear

Locked: Sun gear

Output: Carrier

Locked: -

Output: Ring gear

1. Input shaft (rotates clockwise) [same revolution as the torque converter’s turbine runner]

2. Front planetary ring gear (rotates clockwise) [same revolution as the input shaft]

3. Front planetary pinion gear (rotates clockwise on its axis, orbits clockwise)

[because the front planetary sun gear is locked by the oil pump, it is pressed against the front planetary ring

gear and orbits the sun gear while rotating on its axis (because the front planetary ring gear has internal gears,

the rotational direction does not change)]

4. Front planetary carrier (rotates clockwise)

[reduction: same revolution as the front planetary pinion gear orbit revolution]

5. C1 clutch (rotates clockwise) [connects the front planetary carrier and the rear planetary rear sun gear]

6. C3 clutch (rotates clockwise) [connects the front planetary carrier and the rear planetary middle sun gear]

7. Rear planetary gear component (rotates clockwise)

[because the rear planetary short pinion gear and the rear planetary long pinion gear are engaged, both the

pinion gears are locked due to the difference in the rotational directions, and kinematic energy of the rear

planetary sun gear and rear planetary middle sun gear is transmitted to the rear planetary ring gear]

8. Rear planetary ring gear (rotates clockwise) [same revolution as the rear planetary carrier]

9. Counter drive gear (rotates clockwise)

[because the rear planetary ring gear is installed on the counter drive gear, the rotational direction and the

revolution are same as the rear planetary ring gear]

05-17–9

Page 20

AUTOMATIC TRANSAXLE

10. Counter gear (rotates counterclockwise)

11. Differential ring gear (rotates clockwise)

Engine brake

• When the engine brake is operating, driving force is transmitted from the tires.

4GR

C2 CLUTCH B2 BRAKE

ONE-WAY

CLUTCH

COUNTER DRIVE GEAR

B1 BRAKE

C1 CLUTCH

C3 CLUTCH

RING GEAR

(DIFFERENTIAL)

COUNTER GEAR

acxuun00000624

Power transmission pathway

[Operating components: C1 clutch, C2 clutch]

Planetary gear unit Input, Locked, Output

Front

Rear

Input: Ring gear

Locked: Sun gear

Output: Carrier

Input: Rear Sun gear, Carrier

Locked: -

Output: Ring gear

1. Input shaft (rotates clockwise) [same revolution as the torque converter’s turbine runner]

2. Front planetary ring gear (rotates clockwise) [same revolution as the input shaft]

3. Front planetary pinion gear (rotates clockwise on its axis, orbits clockwise)

[because the front planetary sun gear is locked by the oil pump, it is pressed against the front planetary ring

gear and orbits the sun gear while rotating on its axis (because the front planetary ring gear has internal gears,

the rotational direction does not change)]

4. Front planetary carrier (rotates clockwise)

[reduction: same revolution as the front planetary pinion gear orbit revolution]

5. C1 clutch (rotates clockwise) [connects the front planetary carrier and the rear planetary rear sun gear]

6. Intermediate shaft (rotates clockwise) [same revolution as the input shaft]

7. C2 clutch (rotates clockwise) [same revolution as the intermediate shaft]

8. Rear planetary carrier (rotates clockwise) [same revolution as the intermediate shaft]

9. Rear planetary short pinion gear (rotates clockwise on its axis, orbits clockwise)

[because the rear planetary carrier rotates faster than the rear planetary sun gear]

05-17–10

Page 21

AUTOMATIC TRANSAXLE

10. Rear planetary long pinion gear (rotates counterclockwise on its axis, orbits clockwise)

11. Rear planetary ring gear (rotates clockwise)

[because the rear planetary long pinion gear’s rotation is subtracted from the rear planetary carrier revolution,

the rear planetary ring gear revolution is slower than those of the rear planetary carrier]

12. Counter drive gear (rotates clockwise)

[because the rear planetary ring gear is installed on the counter drive gear, the rotational direction and the

revolution is the same as the rear planetary ring gear]

13. Counter gear (rotates counterclockwise)

14. Differential ring gear (rotates clockwise)

Engine brake

• When the engine brake is operating, driving force is transmitted from the tires.

5GR

C2 CLUTCH B2 BRAKE

ONE-WAY

CLUTCH

COUNTER DRIVE GEAR

B1 BRAKE

C1 CLUTCH

RING GEAR

(DIFFERENTIAL)

05-17

C3 CLUTCH

COUNTER GEAR

acxuun00000625

Power transmission pathway

[Operating components: C2 clutch, C3 clutch]

Planetary gear unit Input, Locked, Output

Input: Ring gear

Front

Rear

Locked: Sun gear

Output: Carrier

Input: Carrier, Middle Sun gear

Locked: -

Output: Ring gear

1. Input shaft (rotates clockwise) [same revolutions as torque converter’s turbine runner]

2. Front planetary ring gear (rotates clockwise) [same revolution as the input shaft]

3. Front planetary pinion gear (rotates clockwise on its axis, orbits clockwise)

[because the front planetary sun gear is locked by the oil pump, it is pressed against the front planetary ring

gear and orbits the sun gear while rotating on its axis (because the front planetary ring gear has internal gears,

the rotational direction does not change)]

05-17–11

Page 22

AUTOMATIC TRANSAXLE

4. Front planetary carrier (rotates clockwise)

[reduction: same revolution as the front planetary pinion gear orbit revolution]

5. C3 clutch (rotates clockwise) [connects the front planetary carrier and the rear planetary middle sun gear]

6. Rear planetary middle sun gear (rotates clockwise)

[same revolution as C3 clutch (decelerates by the front planetary gear, so the revolutions are slower than the

input shaft)]

7. Intermediate shaft (rotates clockwise) [same revolution as the input shaft]

8. C2 clutch (rotates clockwise) [same revolution as the intermediate shaft]

9. Rear planetary carrier (rotates clockwise) [same revolutions as intermediate shaft]

10. Rear planetary long pinion gear (rotates clockwise on its axis, orbits clockwise)

[because the rear planetary carrier rotates faster than the rear planetary middle sun gear, the rear planetary

middle pinion gear is pushed out by the speed difference, and orbits clockwise while rotating clockwise on its

axis.]

11. Rear planetary ring gear (rotates clockwise)

[because the rear planetary long pinion gear’s rotation is added to the rear planetary carrier revolutions, rear

planetary ring gear revolution is faster than those of the rear planetary carrier]

12. Counter drive gear (rotates clockwise)

[because the rear planetary ring gear is installed on the counter drive gear, the rotational direction and

revolution is the same as the rear planetary ring gear]

13. Counter gear (rotates counterclockwise)

14. Differential ring gear (rotates clockwise)

Engine brake

• When the engine brake is operating, driving force is transmitted from the tires.

6GR

C2 CLUTCH B2 BRAKE

ONE-WAY

CLUTCH

COUNTER DRIVE GEAR

B1 BRAKE

C1 CLUTCH

C3 CLUTCH

RING GEAR

(DIFFERENTIAL)

05-17–12

COUNTER GEAR

acxuun00000626

Page 23

AUTOMATIC TRANSAXLE

Power transmission pathway

[Operating components: B1 brake, C2 clutch]

Planetary gear unit Input, Locked, Output

Front -

Input: Carrier

Rear

1. Input shaft (rotates clockwise) [same revolution as the torque converter’s turbine runner]

2. Intermediate shaft (rotates clockwise) [same revolution as the torque converter’s turbine runner]

3. B1 brake [locks the rear planetary middle sun gear]

4. C2 clutch [connects the intermediate shaft and the rear planetary carrier]

5. Rear planetary carrier (rotates clockwise) [same revolution as the intermediate shaft]

6. Rear planetary long pinion gear (rotates clockwise on its axis, orbits clockwise)

[because the rear planetary middle sun gear is locked, it is always in a speed increasing condition]

7. Rear planetary ring gear (rotates clockwise)

[because the rear planetary long pinion gear’s rotation is added to the rear planetary carrier revolution, the rear

planetary ring gear revolution is faster than those of the rear planetary carrier]

8. Counter drive gear (rotates clockwise)

[because the rear planetary ring gear is installed on the counter drive gear, the rotational direction and

revolution are the same as the rear planetary ring gear]

9. Counter gear (rotates counterclockwise)

10. Differential ring gear (rotates clockwise)

Engine brake

• When the engine brake is operating, driving force is transmitted from the tires.

Locked: Middle Sun gear

Output: Ring gear

05-17

R position

C2 CLUTCH B2 BRAKE

ONE-WAY

CLUTCH

COUNTER DRIVE GEAR

B1 BRAKE

C1 CLUTCH

C3 CLUTCH

RING GEAR

(DIFFERENTIAL)

COUNTER GEAR

acxuun00000627

05-17–13

Page 24

AUTOMATIC TRANSAXLE

Power transmission pathway

[Operating components: C3 clutch, B2 brake]

Planetary gear unit Input, Locked, Output

Front

Rear

1. Input shaft (rotates clockwise) [same revolution as the torque converter’s turbine runner]

2. Front planetary ring gear (rotates clockwise) [same revolution as the input shaft]

3. Front planetary pinion gear (rotates clockwise on its axis, orbits clockwise)

[because the front planetary sun gear is locked by the oil pump, it is pressed against the front planetary ring

gear and orbits the sun gear while rotating on its axis (because the front planetary ring gear has internal gears,

the rotational direction does not change)]

4. Front planetary carrier (rotates clockwise)

[reduction: same revolution as the front planetary pinion gear orbit revolution]

5. C3 clutch (rotates clockwise) [connects the front planetary carrier and the rear planetary middle sun gear]

6. Rear planetary middle sun gear (rotates clockwise)

[same revolutions as the C3 clutch (rotates slower than the input shaft)]

7. B2 brake [locks the rear planetary carrier]

8. Rear planetary long pinion gear (rotates counterclockwise)

9. Rear planetary ring gear (rotates counterclockwise)

[the rear planetary ring gear is rotated by the rear planetary long pinion gear (because the rear planetary ring

gear has internal gears, the rotational direction does not change)]

10. Counter drive gear (rotates counterclockwise)

[because the rear planetary ring gear is installed on the counter drive gear, the rotational direction and

revolution are the same as the rear planetary ring gear]

11. Counter gear (rotates clockwise)

12. Differential ring gear (rotates counterclockwise)

Input: Ring gear

Locked: Sun gear

Output: Carrier

Input: Middle Sun gear

Locked: Carrier

Output: Ring gear

Engine brake

• When the engine brake is operating, driving force is transmitted from the tires.

End Of Sie

05-17–14

Page 25

AUTOMATIC TRANSAXLE

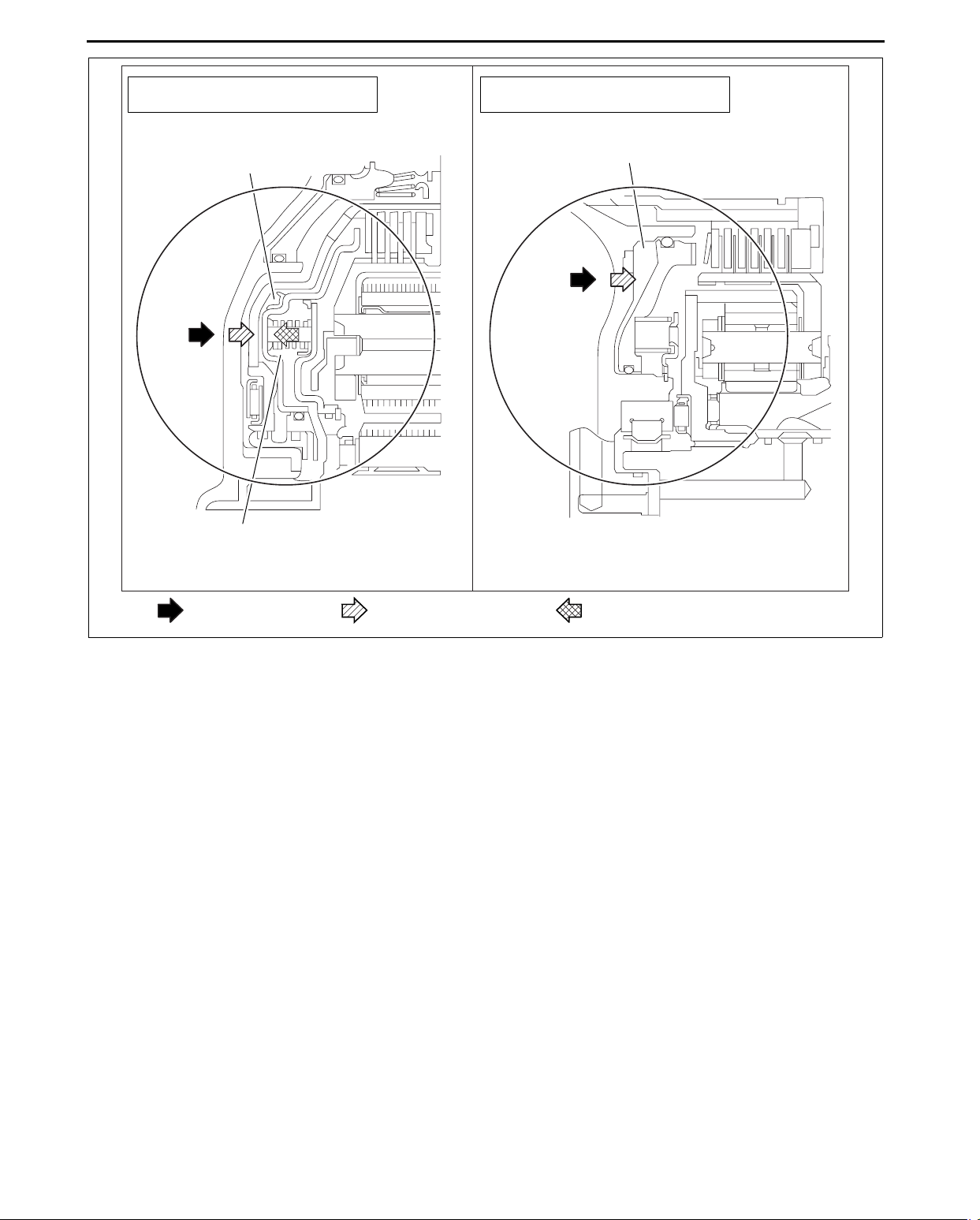

CENTRIFUGAL HYDRAULIC PRESSURE CANCEL CLUTCH OUTLINE

id051700102400

• When the rotation of the clutch rises, centrifugal force operates on the oil inside the clutch, hydraulic pressure

rises, and the clutch is engaged at an earlier timing. Because of this, a difference arises in rotation between the

input shaft and the output shaft, and shift shock may occur. To solve this, an additional chamber has been

provided opposite the piston hydraulic pressure chamber. This causes centrifugal hydraulic pressure to operate

in the opposite direction with the same force as the piston, counteracting that pressure.

C2 CLUTCH

C1 CLUTCH

C3 CLUTCH

05-17

A

B

A : PISTON HYDRAULIC PRESSURE CHAMBER

B : CENTRIFUGAL HYDRAULIC PRESSURE CANCEL CHAMBER

A

B

B

acxuun00000628

05-17–15

Page 26

AUTOMATIC TRANSAXLE

WITH CENTRIFUGAL HYDRAULIC

PRESSURE CANCEL CLUTCH

PISTON HYDRAULIC

PRESSURE CHAMBER

CENTRIFUGAL HYDRAULIC

PRESSURE CANCEL CHAMBER

WITHOUT CENTRIFUGAL HYDRAULIC

PRESSURE CANCEL CLUTCH

PISTON HYDRAULIC

PRESSURE CHAMBER

End Of Sie

NG: TORQUE CONVERTER

PISTON HYDRAULIC

PRESSURE

CENTRIFUGAL HYDRAULIC

PRESSURE

CENTRIFUGAL HYDRAULIC

PRESSURE CANCEL

acxuun00000629

05-17–16

Page 27

AUTOMATIC TRANSAXLE

TORQUE CONVERTER OUTLINE

id051700100700

• The torque converter is composed of the converter cover, pump impeller, turbine runner, stator, one-way clutch,

and TCC. The torque converter transmits and amplifies torque by means of the ATF inside it. In addition, the

use of the TCC is intended to improve fuel economy as a direct coupling between the engine and automatic

transaxle.

CONVERTER

TCC PISTON

COVER

TURBINE

RUNNER

PUMP

IMPELLER

STATER

OIL PUMP

INPUT SHAFT

05-17

End Of Sie

acxuun00000605

05-17–17

Page 28

Page 29

SERVICE

Page 30

Page 31

GENERAL INFORMATION

To c o f S C T

GENERAL INFORMATION . . . .00-00

To c o f S C T

00-00 GENERAL INFORMATION

00

SECTION

00-00

HOW TO USE THIS MANUAL . . . . . . . . . 00-00–2

Range of Topics . . . . . . . . . . . . . . . . . . 00-00–2

Service Procedure . . . . . . . . . . . . . . . . 00-00–2

Symbols . . . . . . . . . . . . . . . . . . . . . . . . 00-00–4

Advisory Messages . . . . . . . . . . . . . . . . 00-00–4

UNITS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 00-00–5

Conversion to SI Units (Système

International d'Unités) . . . . . . . . . . . . 00-00–5

Rounding Off. . . . . . . . . . . . . . . . . . . . . 00-00–5

Upper and Lower Limits . . . . . . . . . . . . 00-00–5

FUNDAMENTAL PROCEDURES. . . . . . . 00-00–6

Preparation of Tools and Measuring

Equipment . . . . . . . . . . . . . . . . . . . . . 00-00–6

Special Service Tools . . . . . . . . . . . . . . 00-00–6

Disassembly . . . . . . . . . . . . . . . . . . . . . 00-00–6

End of Toc

WM: GENERAL INFORMATION

Inspection During Removal,

Disassembly. . . . . . . . . . . . . . . . . . . . 00-00–6

Arrangement of Parts . . . . . . . . . . . . . . 00-00–7

Cleaning of Parts . . . . . . . . . . . . . . . . . 00-00–7

Reassembly . . . . . . . . . . . . . . . . . . . . . 00-00–7

Adjustment . . . . . . . . . . . . . . . . . . . . . . 00-00–8

Rubber Parts and Tubing . . . . . . . . . . . 00-00–8

Hose Clamps . . . . . . . . . . . . . . . . . . . . 00-00–8

Torque Formulas . . . . . . . . . . . . . . . . . 00-00–8

Vise . . . . . . . . . . . . . . . . . . . . . . . . . . . 00-00–9

ELECTRICAL SYSTEM. . . . . . . . . . . . . . 00-00–9

Connectors. . . . . . . . . . . . . . . . . . . . . . 00-00–9

SAE STANDARDS. . . . . . . . . . . . . . . . . . 00-00–10

ABBREVIATIONS . . . . . . . . . . . . . . . . . . 00-00–11

00-00–1

Page 32

GENERAL INFORMATION

HOW TO USE THIS MANUAL

id000000800100

Range of Topics

• This manual contains procedures for performing all required service operations. The procedures are divided

into the following five basic operations:

— Removal/Installation

— Disassembly/Assembly

— Replacement

— Inspection

— Adjustment

• Simple operations which can be performed easily just by looking at the vehicle (i.e., removal/installation of

parts, jacking, vehicle lifting, cleaning of parts, and visual inspection) have been omitted.

Service Procedure

Inspection, adjustment

• Inspection and adjustment procedures are

divided into steps. Important points regarding the

location and contents of the procedures are

SHOWS PROCEDURE ORDER

FOR SERVICE

explained in detail and shown in the illustrations.

Fluid Pressure Inspection

1. Assemble the SSTs as shown in the figure.

Tightening torque

39—49 N·m {4.0—5.0 kgf·m, 29—36 ft·lbf}

49 1232 670A

49 H002 671

49 H032 322

Caution

Connect the gauge set from under

the vehicle to prevent contact with

the drive belt and the cooling fan.

SHOWS TIGHTENING

TORQUE

SPECIFICATIONS

acxuuw00000434

Repair procedure

1. Most repair operations begin with an overview illustration. It identifies the components, shows how the parts fit

together, and describes visual part inspection. However, only removal/installation procedures that need to be

performed methodically have written instructions.

2. Expendable parts, tightening torques, and symbols for oil, grease, and sealant are shown in the overview

illustration. In addition, symbols indicating parts requiring the use of special service tools or equivalent are also

shown.

3. Procedure steps are numbered and the part that is the main point of that procedure is shown in the illustration

with the corresponding number. Occasionally, there are important points or additional information concerning a

procedure. Refer to this information when servicing the related part.

00-00–2

Page 33

GENERAL INFORMATION

GREASE

GREASE

Procedure

"Removal/Installation"

Portion

"Inspection After

Installation" Portion

INSTALL THE PARTS BY

PERFORMING STEPS

—

1 3 IN REVERSE ORDER

SHOWS REFERRAL

NOTES FOR SERVICE

SHOWS SERVICE

ITEM (S)

LOWER TRAILING LINK, UPPER TRAILING LINK REMOVAL/INSTALLATION

1

1. Jack up the rear of the vehicle and support it with safety stands.

2. Remove the undercover. (See 01-10-4 Undercover Removal)

3. Remove in the order indicated in the table.

4. Install in the reverse order of removal.

5. Inspect the rear wheel alignment and adjust it if necessary.

2

SHOWS PROCEDURE ORDER

FOR SERVICE

44—60 {4.4—6.2, 32—44}

11

10

SST

9

SST

12

43—56 {4.3—5.8, 32—41}

8

R

7

SHOWS TIGHTENING

TORQUE

SPECIFICATIONS

SST

3

5

6

SST

4

94—116 {9.5—11.9, 69—86}

Split pin

1

Nut

2

Lower trailing link ball joint

3

(See 02-14-5 Lower Trailing Link Ball Joint Removal Note)

Bolt

4

Lower trailing link

5

Dust boot (lower trailing link)

6

GREASE

R

Split pin

7

8Nut

9 Upper trailing link ball joint

(See 02-14-5 Upper Trailing Link Ball Joint Removal Note)

10

Nut

Upper trailing link

11

Dust boot (upper trailing link)

12

118—156 {12.0—16.0, 87—115}

2

1

INDICATES RELEVANT

REFERENCES THAT NEED

TO BE FOLLOWED DURING

INSTALLATION

SHOWS SPECIAL

SERVICE TOOL (SST)

FOR SERVICE OPERATION

GREASE

R

SHOWS APPLICATION

POINTS OF GREASE, ETC.

SHOWS EXPENDABLE PARTS

SHOWS DETAILS

R

N·m {kgf·m, ft·lbf}

00-00

SHOWS TIGHTENING

TORQUE UNITS

Lower Trailing Link Ball Joint, Upper Trailing Link

Ball Joint Removal Note

Remove the ball joint using the SSTs.

SHOWS REFERRAL

NOTES FOR

SERVICE

SHOWS SPECIAL

SERVICE TOOL (SST)

NO.

KNUCKLE

49 T028 304

49 T028 305

UPPER TRAILING LINK

LOWER TRAILING LINK

49 T028 303

acxuuw00000435

00-00–3

Page 34

GENERAL INFORMATION

TF

GREASE

Symbols

• There are eight symbols indicating oil, grease, fluids, sealant, and the use of SST or equivalent. These symbols

show application points or use of these materials during service.

Symbol Meaning Kind

OIL

BRAKE

FLUID

AATF

GREASE

SEALANT

P

Apply oil

Apply brake fluid

Apply automatic

transaxle/

transmission fluid

Apply grease

Apply sealant

Apply petroleum

jelly

New appropriate

engine oil or gear

oil

New appropriate

brake fluid

New appropriate

automatic

transaxle/

transmission fluid

Appropriate

grease

Appropriate

sealant

Appropriate

petroleum jelly

R

SST

Replace part

Use SST or

equivalent

O-ring, gasket,

etc.

Appropriate tools

Advisory Messages

• You will find several Warnings, Cautions, Notes, Specifications and Upper and Lower Limits in this

manual.

Warning

• A Warning indicates a situation in which serious injury or death could result if the warning is ignored.

Caution

• A Caution indicates a situation in which damage to the vehicle or parts could result if the caution is ignored.

Note

• A Note provides added information that will help you to complete a particular procedure.

Specification

• The values indicate the allowable range when performing inspections or adjustments.

Upper and lower limits

• The values indicate the upper and lower limits that must not be exceeded when performing inspections or

adjustments.

End Of Sie

NG: GENERAL INFORMATION

00-00–4

Page 35

GENERAL INFORMATION

UNITS

Electrical current A (ampere)

Electric power W (watt)

Electric resistance ohm

Electric voltage V (volt)

Length

Negative pressure

Positive pressure

Number of

revolutions

To r qu e

Volum e

Weight

mm (millimeter)

in (inch)

kPa (kilo pascal)

mmHg (millimeters of mercury)

inHg (inches of mercury)

kPa (kilo pascal)

2

(kilogram force per square

kgf/cm

centimeter)

psi (pounds per square inch)

rpm (revolutions per minute)

N·m (Newton meter)

kgf·m (kilogram force meter)

kgf·cm (kilogram force centimeter)

ft·lbf (foot pound force)

in·lbf (inch pound force)

L (liter)

US qt (U.S. quart)

Imp qt (Imperial quart)

ml (milliliter)

cc (cubic centimeter)

cu in (cubic inch)

fl oz (fluid ounce)

g (gram)

oz (ounce)

id000000100400

00-00

Conversion to SI Units (Système International d'Unités)

• All numerical values in this manual are based on SI units. Numbers shown in conventional units are converted

from these values.

Rounding Off

• Converted values are rounded off to the same number of places as the SI unit value. For example, if the SI unit

value is 17.2 and the value after conversion is 37.84, the converted value will be rounded off to 37.8.

Upper and Lower Limits

• When the data indicates upper and lower limits, the converted values are rounded down if the SI unit value is

an upper limit, and rounded up if the SI unit value is a lower limit. Therefore, converted values for the same SI

unit value may differ after conversion. For example, consider 2.7 kgf/cm

210— 260 kPa {2.1— 2.7 kgf/cm

270— 310 kPa {2.7— 3.2 kgf/cm

• The actual converted values for 2.7 kgf/cm

2

, 30— 38 psi}

2

, 39— 45 psi}

2

are 265 kPa and 38.4 psi. In the first specification, 2.7 is used as

2

in the following specifications:

an upper limit, so the converted values are rounded down to 260 and 38. In the second specification, 2.7 is

used as a lower limit, so the converted values are rounded up to 270 and 39.

End Of Sie

WM: GENERAL INFORMATION

00-00–5

Page 36

GENERAL INFORMATION

FUNDAMENTAL PROCEDURES

Preparation of Tools and Measuring Equipment

• Be sure that all necessary tools and measuring

equipment are available before starting any work.

Special Service Tools

• Use special service tools or the equivalent when

they are required.

id000000810000

acxuuw00000006

49 SE01 310

Disassembly

• If the disassembly procedure is complex,

requiring many parts to be disassembled, all parts

should be marked in a place that will not affect

their performance or external appearance, and

identified so that reassembly can be performed

easily and efficiently.

Inspection During Removal, Disassembly

• When removed, each part should be carefully

inspected for malfunction, deformation, damage

and other problems.

acxuuw00000007

acxuuw00000010

00-00–6

acxuuw00000011

Page 37

GENERAL INFORMATION

Arrangement of Parts

• All disassembled parts should be carefully

arranged for reassembly.

• Be sure to separate or otherwise identify the parts

to be replaced from those that will be reused.

Cleaning of Parts

• All parts to be reused should be carefully and

thoroughly cleaned in the appropriate method.

Warning

• Using compressed air can cause dirt and

other particles to fly out causing injury to

the eyes. Wear protective eye wear

whenever using compressed air.

00-00

acxuuw00000012

Reassembly

• Standard values, such as torques and certain

adjustments, must be strictly observed in the

reassembly of all parts.

• If removed, these parts should be replaced with

new ones:

— Oil seals

— Gaskets

— O-rings

— Lock washers

— Cotter pins

— Nylon nuts

• Depending on location:

— Sealant and gaskets, or both, should be

applied to specified locations. When sealant

is applied, parts should be installed before

sealant hardens to prevent leakage.

— Oil should be applied to the moving

components of parts.

— Specified oil or grease should be applied at

the prescribed locations (such as oil seals)

before reassembly.

acxuuw00000013

acxuuw00000014

acxuuw00000326

00-00–7

Page 38

GENERAL INFORMATION

Adjustment

• Use suitable gauges and testers when making

adjustments.

Rubber Parts and Tubing

• Prevent gasoline or oil from getting on rubber

parts or tubing.

acxuuw00000016

Hose Clamps

• When reinstalling, position the hose clamp in the

original location on the hose and squeeze the

clamp lightly with large pliers to ensure a good fit.

Torque Formulas

• When using a torque wrench-SST or equivalent

combination, the specified torque must be

recalculated due to the extra length that the SST

or equivalent adds to the torque wrench.

Recalculate the torque by using the following

formulas. Choose the formula that applies to you.

Torque Unit Formula

N·m N·m × [L/(L+A)]

kgf·m kgf·m × [L/(L+A)]

kgf·cm kgf·cm × [L/(L+A)]

ft·lbf ft·lbf × [L/(L+A)]

in·lbf in·lbf × [L/(L+A)]

acxuuw00000017

acxuuw00000018

SST

A

L

3

2

1

0

1

2

3

acxuuw00000019

A : The length of the SST past the torque wrench drive.

L : The length of the torque wrench.

00-00–8

Page 39

GENERAL INFORMATION

Vise

• When using a vise, put protective plates in the

jaws of the vise to prevent damage to parts.

End Of Sie

ELECTRICAL SYSTEM

Connectors

Disconnecting connectors

• When disconnecting a connector, grasp the

connectors, not the wires.

PROTECTIVE PLATES

GOOD

00-00

acxuuw00000020

id000000800400

NO GOOD

• Connectors can be disconnected by pressing or

pulling the lock lever as shown.

Locking connector

• When locking connectors, listen for a click

indicating they are securely locked.

acxuuw00000454

acxuuw00000455

acxuuw00000456

00-00–9

Page 40

GENERAL INFORMATION

Inspection

Caution

• To prevent damage to the terminal, wrap a thin wire around the tester probe before inserting into

terminal.

• When a tester is used to inspect for continuity or

measuring voltage, insert the tester probe from

the wiring harness side.

• Inspect the terminals of waterproof connectors

from the connector side since they cannot be

accessed from the wiring harness side.

End Of Sie

GOOD

GOOD NO GOOD

NO GOOD

acxuuw00000457

acxuuw00000458

SAE STANDARDS

id000000800900

• In accordance with new regulations, SAE (Society of Automotive Engineers) standard names and abbreviations

are now used in this manual. The table below lists the names and abbreviations that have been used in Mazda

manuals up to now and their SAE equivalents.

SAE Standard

Abbreviation Name Abbreviation Name

AP Accelerator Pedal MAP Manifold Absolute Pressure

APP Accelerator Pedal Position MAF sensor Mass Air Flow Sensor

ACL Air Cleaner MFL Multiport Fuel Injection

A/C Air Conditioning OBD On-board Diagnostic System

BARO Barometric Pressure OL Open Loop

B+ Battery Positive Voltage OC Oxidation Catalytic Converter

CMP sensor Camshaft Position Sensor O2S Oxygen sensor

CAC Charge Air Cooler PNP Park/Neutral Position

CLS Closed Loop System PSP Power Steering Pressure

CTP Closed Throttle Position PCM Powertrain Control Module #3

CPP Clutch Pedal Position

CIS Continuous Fuel Injection System

CKP sensor Crankshaft Position Sensor

DLC Data Link Connector

DTM Diagnostic Test Mode #1

DTC Diagnostic Test Code(s) SAPV Secondary Air Pulse Valve

DI Distributor Ignition

DLI Distributorless Ignition

EI Electronic Ignition #2 3GR Third Gear

ECT Engine Coolant Temperature TWC Three Way Catalytic Converter

EM Engine Modification TB Throttle Body

EVAP Evaporative Emission TP sensor Throttle Position Sensor

Remark

PAIR Pulsed Secondary Air Injection

AIR Secondary Air Injection

SFI

SAE Standard

Sequential Multiport Fuel

Injection

Remark

Pulsed

injection

Injection

with air

pump

00-00–10

Page 41

GENERAL INFORMATION

SAE Standard

Abbreviation Name Abbreviation Name

EGR Exhaust Gas Recirculation TCC Torque Converter Clutch

FC Fan Control

FF Flexible Fuel

4GR Fourth Gear TR Transmission (Transaxle) Range

GEN Generator TC Turbocharger

GND Ground VSS Vehicle Speed Sensor

HO2S Heated Oxygen Sensor

IAC Idle Air Control

IAT Intake Air Temperature

KS Knock Sensor WOP Wide Open Throttle

MIL Malfunction Indicator Lamp

Remark

With

heater

TCM

VR Voltage Regulator

VAF sensor Volume Air Flow Sensor

WU-TWC

SAE Standard

Transmission (Transaxle) Control

Module

Warm Up Three Way Catalytic

Converter

#1: Diagnostic trouble codes depend on the diagnostic test mode.

#2: Controlled by the PCM

#3: Device that controls engine and powertrain

#4: Directly connected to exhaust manifold

End Of Sie

ABBREVIATIONS

ATF Automatic Transaxle Fluid

LH Left Hand

RH Right Hand

SST Special Service Tool

TFT Transaxle Fluid Temperature

2WD 2 Wheel Drive

Remark

00-00

#4

id000000801000

End Of Sie

00-00–11

Page 42

Page 43

DRIVELINE/AXLE

To c o f S C T

TRANSFER . . . . . . . . . . . . . . . . 03-16

TECHNICAL DATA . . . . . . . . . .03-50

To c o f S C T

03-16 TRANSFER

03

SECTION

03-16

SERVICE TOOLS . . . . . . . . . . . 03-60

TRANSFER CLEANING. . . . . . . . . . . . . . 03-16–1

Cleaning Precautions . . . . . . . . . . . . . . 03-16–1

TRANSFER DISASSEMBLY . . . . . . . . . . 03-16–1

Before Service Precautions. . . . . . . . . . 03-16–1

Transfer Component Disassembly . . . . 03-16–2

Transfer Component Disassembling

Procedure . . . . . . . . . . . . . . . . . . . . . . 03-16–3

Drive Gear Case Component

Disassembly . . . . . . . . . . . . . . . . . . . . 03-16–4

Drive Gear Case Component

Disassembly Procedure . . . . . . . . . . . 03-16–5

Front Carrier Component

Disassembly . . . . . . . . . . . . . . . . . . . . 03-16–9

Front Carrier Component Disassembling

Procedure . . . . . . . . . . . . . . . . . . . . . 03-16–10

TRANSFER ASSEMBLY . . . . . . . . . . . . . 03-16–13

Before Service Precautions . . . . . . . . . 03-16–13

Drive Gear Case Component

Assembly. . . . . . . . . . . . . . . . . . . . . . 03-16–14

Drive Gear Case Component Assembly

Procedure . . . . . . . . . . . . . . . . . . . . . 03-16–15

Front Carrier Component Assembly. . . 03-16–21

Front Carrier Component Assembly

Procedure . . . . . . . . . . . . . . . . . . . . . 03-16–22

Transfer Component Assembly . . . . . . 03-16–28

Transfer Component Assembly

Procedure . . . . . . . . . . . . . . . . . . . . . 03-16–29

End of Toc

AT: TRANSFER

TRANSFER CLEANING

Cleaning Precautions

1. Clean the surface of the transfer using steam and cleaning fluids when disassembly.

Warning

• Always wear safety glasses when using compressed air since the foreign material could be blown

by the compression air and damage your eyes.

2. Clean removed components with cleaning fluids and use compressed air to blow off the oil. Clean the oil holes

and passages with compressed air.

id031600500100

End Of Sie

TRANSFER DISASSEMBLY

Before Service Precautions

• To prevent foreign material from entering the transfer, perform disassembly and servicing in a clean, dust-free

environment.

• Inspect the each part while disassembling.

id031600500200

Warning

• The engine stand is equipped with a self-lock mechanism. However, if the transfer is tilted, the

self-lock mechanism could become inoperative. This could cause the transfer to rotate

accidentally, resulting in injury. Therefore, make sure that the transfer is not tilted when it is on the

engine stand. When turning the transfer, grasp the rotation handle firmly.

03-16–1

Page 44

Transfer Component Disassembly

R

TRANSFER

3

R

5

4

R

2

R

.

1 Drain plug

2 Oil level plug

3 Oil cooler

03-16–2

1

bawuua00000167

4 Drive gear case component

5 Front carrier component

Page 45

Transfer Component Disassembling Procedure

1. Assemble the SSTs.

2. Install the transfer component to the SSTs.

3. Remove the oil cooler.

4. Remove the drive gear case component.

TRANSFER

49 0107 680A

03-16

49 M005 561

bawuua00000168

49 M005 561

49 0107 680A

bawuua00000169

03-16–3

Page 46

Drive Gear Case Component Disassembly

TRANSFER

RH

5

3

4

6

8

SST

9

SST

7

1

R

10

R

SST

11

12

SST

R

15

LH

2

.

1 Oil seal (RH outer)

2 Drive gear shaft

3 Bearing cap

4 Adjustment shim

5 Spacer

6 Drive gear component

7 Bearing outer race (LH)

8 Bearing outer race (RH)

SST

SST

R

14

R

13

R

9 Bearing (RH)

10 Bearing (LH)

11 Drive gear

12 Oil seal (RH inner)

13 Oil seal (LH outer)

14 Oil seal (LH inner)

15 Baffle plate

16 Drive gear case

16

bawuua00000170

03-16–4

Page 47

TRANSFER

Drive Gear Case Component Disassembly Procedure

1. Install the drive gear case component to the SST.

2. Tap the drive gear shaft using a suitable rod and

hammer.

49 M005 561

03-16

bawuua00000171

3. Take out the drive gear shaft from the drive gear

case.

4. Make alignment marks on the bearing cap and

drive gear case.

5. Remove the bearing cap.

bawuua00000172

bawuua00000173

ALIGNMENT MARK

bawuua00000174

03-16–5

Page 48

6. Insert a flathead screwdriver into spacer notch

and remove the adjustment shim.

Caution

• Place a rag on the case to protect it from

damage.

TRANSFER

bawuua00000175

7. Remove the spacer.

8. Remove the drive gear component.

9. Using the SST, remove the oil seal (LH outer).

RAG

bawuua00000176

bawuua00000177

bawuua00000178

03-16–6

49 0839 425C

49 W032 201

bawuua00000179

Page 49

TRANSFER

10. Using the SST, remove the oil seal (LH inner).

11. Using a suitable rod and hammer, remove the oil

seal (RH outer).

12. Using the SST, remove the oil seal (RH inner).

49 0839 425C

03-16

49 W032 201

bawuua00000179

bawuua00000180

13. Using the SST, remove the bearing outer race

(LH).

(1) Install the SSTs (49 W032 202, 49 S019 005).

49 W032 201

49 0839 425C

bawuua00000181

BEARING RACE

bawuua00000182

49 W032 202

49 S019 005

bawuua00000183

03-16–7

Page 50

(2) Connect the SST (49 T032 316, 49 T032 317)

to the SSTs (49 W032 202, 49 S019 005).

14. Remove the baffle plate.

15. Using the SST, remove the bearing (RH).

TRANSFER

49 W032 202

49 T032 316

49 T032 317

49 S019 005

bawuua00000184

bawuua00000185

16. Using a flathead screwdriver, deform the bearing

roller guide (LH) and remove it.

17. Using the SST, remove the bearing inner race

(LH).

49 0839 425C

bawuua00000186

bawuua00000187

49 0636 145

03-16–8

bawuua00000188

Page 51

Front Carrier Component Disassembly

TRANSFER

R

5

17

SST

16

15

R

SST

R

SST

21

22

23

19

10

.

1 Oil pipe

2 Oil strainer

3 Side cover

4 Ring gear lockbolt

5 Oil pump

6 Oil pump shaft

7 Bearing cap

8 Ring gear component

9 Adjustment shim

10 Spacer

11 Bearing outer race (side)

12 Bearing (side)

13 Ring gear

6

03-16

20

25

24

1

SST

LEFT—HAND SCREW

4

A

R

18

R

R

3

2

9

11

12

SST

SST

A

7

14

SST

13

SST

12

11

8

SST

14 Ring gear shaft

15 Locknut

16 Washer

17 Companion flange

18 Oil seal

19 Drive pinion gear

20 Bearing (rear)

21 Distance piece

22 Bearing (front)

23 Spacer

24 Bearing outer race (front)

25 Bearing outer race (rear)

9

bawuua00000189

03-16–9

Page 52

TRANSFER

Front Carrier Component Disassembling Procedure

1. Install the front carrier component to the SST.

2. Remove the oil strainer.

3. Remove the oil pipe.

4. Remove the side cover.

5. Remove the oil pump by turning it using pliers as

shown in the figure.

• If the oil pump shaft remains in the gear shaft

side, remove the oil pump shaft.

49 M005 561

bawuua00000190

6. Make alignment marks on the bearing caps and

front carrier.

7. Remove the bearing caps.

8. Using a suitable wrench, secure the ring gear

shaft, and remove the ring gear lockbolt.

bawuua00000191

MARK

bawuua00000192

bawuua00000193

03-16–10

Page 53

TRANSFER

9. Using the SST, secure the companion flange, and

remove the locknut and washer.

10. Using the SST, remove the companion flange.

11. Using the SSTs, remove the ring gear

component.

12. Remove the adjustment shims and spacer.

49 S120 710

03-16

bawuua00000546

49 0839 425C

bawuua00000536

13. Install an appropriate nut to the drive pinion to

prevent the thread from being damaged.

14. Lightly tap the drive pinion using a copper

hammer and remove the drive pinion gear.

49 T032 316

49 T032 317

49 L027 004

bawuua00000196

bawuua00000537

03-16–11

Page 54

TRANSFER

15. Using a flathead screwdriver, remove the oil seal.

16. Remove the bearing (rear) and distance piece.

17. Using the SST, remove the bearing (front).

18. Remove the spacer.

19. Attach the brass stick to the notch, tap the race

end lightly and evenly, then remove the bearing

outer races.

bawuua00000198

49 H027 002

bawuua00000199

20. Using the SSTs, remove the bearing (side)

(opposite ring gear side).

bawuua00000200

bawuua00000201

49 0839 425C

(ATTACHMENT

39.5 mm {1.56 in})

49 0710 520

bawuua00000202

03-16–12

Page 55

TRANSFER

21. Using a SST, remove the bearing (side) (ring gear

side) together with ring gear.

Substitution SST

• 49 T032 302

Outer diameter: 25— 30 mm {0.99— 1.18 in}

Plate thickness: 1 mm {0.04 in} or more

End Of Sie

TRANSFER ASSEMBLY

Before Service Precautions

• Assemble with bare hands or using vinyl gloves. To prevent foreign material from entering the transfer, do not

use cotton work gloves or a rag.

• Apply sufficient gear oil to the sliding surfaces and O-rings, and be careful not to damage when assembling.

• Replace the transfer with a new one if the case alignment surface is damaged. Be careful not to damage it

since it may cause oil leakage.

• When installing silicone sealant, clean off the old sealant adhering to the sealing area and clean the sealing

area with cleaning fluids.

• After installing a seal, leave the parts alone for 2 h or more. Do not add oil or operate the vehicle during this

time.

49 T032 302

bawuua00000203

id031600500300

03-16

Warning

• The engine stand is equipped with a self-lock mechanism. However, if the transfer is tilted, the

self-lock mechanism could become inoperative. This could cause the transfer to rotate

accidentally, resulting in injury. Therefore, make sure that the transfer is not tilted when it is on the

engine stand. When turning the transfer, grasp the rotation handle firmly.

03-16–13

Page 56

Drive Gear Case Component Assembly

37—51 N·m

{3.8—5.2 kgf·m, 27.3—37.6 ft·lbf}

TRANSFER

RH

8

10

9

7

4

SST

3

5

6.9—9.8 N·m

1

SST

2

15

{70—99 kgf·cm, 61—86 in·lbf}

6

R

SST

11

R

SST

LH

14

.

1 Drive gear

2 Bearing (LH)

3 Bearing (RH)

4 Bearing outer race (RH)

5 Bearing outer race (LH)

6 Oil seal (RH inner)

7 Drive gear component

8 Spacer

R

SST

RSST

13

R

12

16

bawuua00000204

9 Adjustment shim

10 Bearing cap

11 Oil seal (RH outer)

12 Oil seal (LH inner)

13 Oil seal (LH outer)

14 Drive gear shaft

15 Baffle plate

16 Drive gear case

03-16–14

Page 57

TRANSFER

Drive Gear Case Component Assembly Procedure

1. Install the drive gear case to the SST.

2. Install the baffle plate.

Tightening torque

6.9— 9.8 N·m {70— 99 kgf·cm, 61— 86 in·lbf}

49 M005 561

03-16

bawuua00000205

3. Using a press, assemble the bearing (RH).

Substitution SST

• 49 H028 202

Outer diameter: 58— 61 mm {2.29— 2.40 in}

Inner diameter: 56 mm {2.20 in} or more

Plate thickness: 1 mm {0.04 in} or more

4. Using a press, assemble the bearing (LH).

Substitution SST

• 49 H028 202

Outer diameter: 58— 61 mm {2.29— 2.40 in}

Inner diameter: 56 mm {2.20 in} or more

Plate thickness: 1 mm {0.04 in} or more

5. Temporarily assemble the bearing outer race

(RH) and spacer to the drive gear.

bawuua00000206

49 H028 202

bawuua00000207

49 H028 202

bawuua00000208

03-16–15

Page 58

TRANSFER

6. Place the drive gear component on the surface

plate as shown in the figure, and measure the

height using a vernier caliper or height gauge.

This is dimension A.

7. Measure the width of the drive gear installation

area in the drive gear case. This is dimension B.

8. The maximum and minimum thickness C of the

adjustment shim can be expressed by the

following formula:

C = B - A - (0.01— 0.03 mm {0.00039—

0.00118 in})

9. If the thickness of the installed adjustment shim is

within the C range, use the shim as it is.

10. If the thickness of the installed adjustment shim is

not within the C range, select the appropriate

adjustment shim from the table below and use it.

A

bawuua00000209

B

Adjustment shim

Identification mark Thickness (mm {in}) Identification mark Thickness (mm {in})

350 3.50 {0.1378} 420 4.20 {0.1654}

355 3.55 {0.1398} 425 4.25 {0.1673}

360 3.60 {0.1417} 430 4.30 {0.1693}

365 3.65 {0.1437} 435 4.35 {0.1713}

370 3.70 {0.1457} 440 4.40 {0.1732}

375 3.75 {0.1476} 445 4.45 {0. 1752}

380 3.80 {0.1496} 450 4.50 {0.1772}

385 3.85 {0.1516} 455 4.55 {0.1791}

390 3.90 {0.1535} 460 4.60 {0. 1811}

395 3.95 {0.1555} - 400 4.00 {0.1575} - 405 4.05 {0.1594} - 410 4.10 {0.1614} - 415 4.15 {0.1634} - -

11. Using the plastic hammer, install the bearing

outer race (LH).

bawuua00000210

03-16–16

bawuua00000211

Page 59

TRANSFER

12. Install the drive gear component.

13. Install the spacer with its notch facing the bearing,

and also facing upward, as shown in the figure.

14. Using a plastic hammer, assemble the adjustment

shim.

03-16

bawuua00000212

bawuua00000213

15. Align the bearing cap alignment marks, assemble

the bearing cap.

Tightening torque

37— 51 N·m {3.8— 5.2 kgf·m, 27.3— 37.6

ft·lbf}

16. Assemble the SST to the drive gear shaft, and

hand-tighten the nut.

SST tightening torque

2.1 N·m {21 kgf·cm, 19 in·lbf}

bawuua00000214

ALIGNMENT MARK

bawuua00000215

49 L011 201

bawuua00000216

03-16–17

Page 60

TRANSFER

17. Install the drive gear shaft with the SST

assembled and verify that the preload is within the

specification using the torque wrench as shown in

the figure.

Standard drive gear bearing preload

0.6— 2.1 N·m {6.2— 21.4 kgf·cm, 5.4— 18.5

in·lbf}

• If the drive gear rotational torque is not within

the specification, adjust it by selecting the

proper spacer.

18. Remove the drive gear shaft.

19. Using a SSTs, install the oil seals.

Note

• Mark the press-in depth of each oil seal to the SST and press fit oil seals to the specified position.

LH inner

Substitution SST

• 49 S019 006

Outer diameter: 61— 66 mm {2.41— 2.59 in}

Plate thickness: 2 mm {0.08 in} or more

49 G030 797

49 S019 006

bawuua00000217

15.7—17.3

{0.62—0.68}

mm {in}

bawuua00000218

03-16–18

Page 61

LH outer

RH inner

Substitution SST

• 49 B025 001

Outer diameter: 57— 64 mm {2.25— 2.51 in}

Plate thickness: 2 mm {0.08 in} or more

TRANSFER

49 G030 797

49 L019 301

03-16

OIL SEAL

5.0—6.0

{0.20—0.23}

mm {in}

bawuua00000219

49 G030 797

49 B025 001

18.7—20.3

{0.74—0.79}

mm {in}

bawuua00000220

03-16–19

Page 62

TRANSFER

RH outer

Substitution SST

• 49 T034 201A

Outer diameter: 59— 64 mm {2.33— 2.51 in}

Inner diameter: 55 mm {2.17 in} or more

Length: 5 mm {0.20 in} or more

Plate thickness: 2 mm {0.08 in} or more

20. Install the C-ring to the drive gear shaft and insert

the drive gear shaft until it is secured by the Cring.

49 T034 201A

-0.8—0.8

{-0.03—0.03}

mm {in}

bawuua00000221

Caution

• Be careful not to damage the oil seal

when installing the drive gear shaft.

21. Pull the drive gear shaft by hand and verify that

the drive gear shaft is secured by the C-ring at the

specified position.

bawuua00000222

bawuua00000223

03-16–20

Page 63

Front Carrier Component Assembly

GREASE

TRANSFER

R

21

127—284

{13.0—28.9, 93.7—209.4}

SST

11

R

10

GREASE

9

OIL

03-16

R

SST

5

4

3

7

SST

17

63—93 {6.5—9.4, 46.4—68.5}

.

1 Bearing outer race (rear)

2 Bearing outer race (front)

3 Spacer

4 Bearing (front)

5 Distance piece

6 Bearing (rear)

7 Drive pinion gear

8 Oil seal

9 Companion flange

10 Washer

11 Locknut

12 Ring gear shaft

13 Ring gear

16

20

6

SST

1

SST

2

25

SST

R

LEFT—HAND SCREW

22

A

150—200 {15.3—20.3, 110.7—147.4}

SST

R

8

R

23

6.9—9.8 N·m

24

{70—100 kgf·cm, 61—86 in·lbf}

15

R

14

SST

12

A

19

SST

13

SST

R

14

15

18

16

N·m {kgf·m, ft·lbf}

bawuua00000224

14 Bearing (side)

15 Bearing outer race (side)

16 Adjustment shim

17 Spacer

18 Ring gear component

19 Bearing cap

20 Oil pump shaft

21 Oil pump

22 Ring gear lockbolt

23 Side cover

24 Oil strainer

25 Oil pipe

03-16–21

Page 64

TRANSFER

Front Carrier Component Assembly Procedure

1. Using a press, assemble the opposite ring gear

side bearing (side) to the ring gear shaft.

Substitution SST

• 49 G033 105 (A)

Outer diameter: 25 mm {0.99 in} or more

• 49 G033 105 (B)

Outer diameter: 34— 40 mm {1.34— 1.57 in}

Plate thickness: 1 mm {0.04 in} or more

2. Using a press, assemble the ring gear to the ring

gear shaft

Substitution SST

• 49 G033 105

Outer diameter: 15— 30 mm {0.60— 1.18 in}

(A)

49 G033 105

(B)

bawuua00000225

49 G033 105

3. Using a press, assemble the ring gear side

bearing (side).

Substitution SST

• 49 G033 105 (A)

Outer diameter: 15— 30 mm {0.60— 1.18 in}

• 49 G033 105 (B)

Outer diameter: 34— 40 mm {1.34— 1.57 in}

Plate thickness: 1 mm {0.04 in} or more

4. Temporarily assemble the bearing outer races

(side).

5. Place the ring gear component on the surface

plate as shown in the figure, and measure the

height using a vernier caliper or height gauge.

This is dimension A.

49 G033 105

A

bawuua00000226

(A)

(B)

bawuua00000227

bawuua00000228

03-16–22

Page 65

TRANSFER

6. Measure the width of the front carrier ring gear

installation area with the spacer installed. This is

dimension B.

7. The maximum and minimum total thickness C of

the adjustment shims on both sides can be

expressed by the following formula:

B

SPACER

C = B - A - (0.01— 0.03 mm {0.00039— 0.00118

in})

8. If the total thickness of the installed adjustment

shims is within the C range, use the shims as they

are.

9. If the total thickness of the installed adjustment

shims is not within the C range, select the appropriate number of adjustment shims from the table below and

use them.

Adjustment shim

Identification mark Thickness (mm {in}) Identification mark Thickness (mm {in})

350 3.50 {0.1378} 410 4.10 {0.1614}

355 3.55 {0.1398} 415 4.15 {0.1634}

360 3.60 {0.1417} 420 4.20 {0.1654}

365 3.65 {0.1437} 425 4.25 {0.1673}

370 3.70 {0.1457} 430 4.30 {0.1693}

375 3.75 {0.1476} 435 4.35 {0.1713}

380 3.80 {0.1496} 440 4.40 {0.1732}

385 3.85 {0.1516} 445 4.45 {0.1752}

390 3.90 {0.1535} 450 4.50 {0.1772}

395 3.95 {0.1555} 455 4.55 {0.1791}

400 4.00 {0.1574} 460 4.60 {0.1811}

405 4.05 {0.1594} - -

Note

• When reusing adjustment shims, do not mix up the left and right shims.

• Do not mix up the left and right side bearing races and spacers.

03-16

bawuua00000229

10. Install the front carrier to the SST.

11. Install the adjustment shim chosen for the front

carrier ring gear side and spacer on opposite

side.

12. Assemble the ring gear component to the front

carrier.

13. Using the plastic hammer, assemble the selected

adjustment shim in between the spacer and

bearing race as shown in the figure.

49 M005 561

bawuua00000230

bawuua00000231

03-16–23

Page 66

TRANSFER

14. Align the alignment marks of the bearing caps,

assemble the bearing caps, and tighten the bolts

temporarily.

Caution

• Locking compound is applied to a new

ring gear lockbolt. Reuse the old ring

gear lock bolt when inspecting the

preload.

15. Install the ring gear lockbolt and inspect the ring

gear bearing preload.

Standard ring gear bearing preload

0.6— 2.1 N·m {6.2— 21.4 kgf·cm, 5.4— 18.5 in·lbf}

• If the rotational torque is not within the specification, select the suitable adjustment shim and reinstall so

that the rotational torque is within the specification.

16. Follow the disassembling procedure in Step 11 to remove the ring gear component.

Note

• Identify the left and right side of the adjustment shim for reinstallation.

17. Using the SSTs, assemble the bearing outer

races.

Substitution SST

49 F027 003

• 49 F027 005

Outer diameter: 61— 61.8 mm {2.41— 2.43

in}

Plate thickness: 1 mm {0.04 in} or more

• 49 F027 007

Outer diameter: 70— 71.8 mm {2.76— 2.82

in}

Plate thickness: 1 mm {0.04 in} or more

49 F027 005

18. Using the SSTs, adjust the drive pinion height as

follows:

(1) Install the SSTs to the removed spacer and

bearing.

(2) Assemble the spacer, bearing and SSTs.

Using an O-ring, secure the SST.

(3) Assemble the bearing, SSTs, washer, and

nut.

(4) Tighten the nut to the SST to where it can still

be rotated by hand.

49 H025 003A

MARK

49 F027 003

49 8531 565

bawuua00000232

49 F027 007

bawuua00000233

(5) Place the SSTs on the plate surface and set

the dial gauge to “0”.

03-16–24

bawuua00000234

49 0727 570

49 8531 555

49 0305 555

bawuua00000235

Page 67

TRANSFER

(6) Position the SST (49 0727 570) on the driver

pinion model.

(7) Attach the dial gauge head to where the

carrier bearing outer race (side) is installed

and measure the lowest position. Also,

measure the value of where the side bearing

outer race (side) is installed on the opposite

side.

(8) Measure the average value between the

values of both sides measured in Step 7. This

value is the spacer thickness which

determines the pinion height.

Pinion height error factor within allowance

limit

± 0.032 mm {± 0.00126 in}

Spacer

Identification mark Thickness (mm {in}) Identification mark Thickness (mm {in})

08 3.08 {0.1213} 29 3.29 {0.1295}

09 3.095 {0.1219} 30 3.305 {0.1301}

11 3.11 {0.1224} 32 3.32 {0.1307}

12 3.125 {0.1230} 33 3.335 {0.1313}

14 3.14 {0.1236} 35 3.35 {0.1319}

15 3.155 {0.1242} 36 3.365 {0.1325}

17 3.17 {0.1248} 38 3.38 {0.1331}

18 3.185 {0.1254} 39 3.395 {0.1335}

20 3.20 {0.1260} 41 3.41 {0.1343}

21 3.215 {0.1266} 42 3.425 {0.1348}

23 3.23 {0.1272} 44 3.44 {0.1354}

24 3.245 {0.1278} 45 3.455 {0.1360}

26 3.26 {0.1283} 47 3.47 {0.1366}

27 3.275 {0.1289} - -

49 0727 570

bawuua00000236

03-16

19. Assemble the spacer selected for pinion height adjustment with the rounded off side facing the gears.

20. Using the SST, assemble the bearing (front) to

the drive pinion gear.

Substitution SST

49 F401 331

SPACER

• 49 F401 331, 49 F401 337A

Outer diameter: 37.2— 43.3 mm {1.47— 1.70

in}

Inner diameter: 35.2 mm {1.39 in} or more

Plate thickness: 1 mm {0.04 in} or more

Inner diameter depth: 140 mm {5.51 in} or

more

49 F401 337A

21. Assemble a new distance piece to the drive pinion

gear.

22. Assemble the drive pinion gear to the front carrier.

23. Install the bearing (rear), companion flange,

washer, and new locknut to the drive pinion and temporarily tighten.

24. Rotate the companion flange by hand and seat the bearing.

bawuua00000237

03-16–25

Page 68

TRANSFER

25. Using the SST, tighten the locknut from the lower

limit of the specified tightening torque and set to

the preload value. Note the tightening torque

when the specified preload value is obtained.

Tightening torque

127— 284 N·m {13.0— 28.9 kgf·m, 93.7—

209.4 ft·lbf}

Drive pinion preload value

0.88— 1.37 N·m {9.0— 14.0 kgf·cm, 7.9— 12.1

in·lbf}

26. Remove the locknut, washer, and companion

flange.

27. Apply oil to the lip area of a new oil seal.

28. Using the SST, assemble the oil seal.

Substitution SST

• 49 U027 003

Outer diameter: 66— 70.8 mm {2.60— 2.78

in}

Inner diameter: 53.7 mm {2.12 in} or more

Plate thickness: 1 mm {0.04 in} or more

Inner diameter depth: 50 mm {1.97 in} or

more

29. Apply the grease to the bearing contact surface of

the companion flange.

30. Assemble the companion flange.

31. Using the SST, tighten the new locknut to the

tightening torque noted when the preload was

adjusted.

32. Reverify the preload.

49 S120 710

bawuua00000546

49 U027 003

bawuua00000538

49 S120 710

Drive pinion preload value

0.88— 1.37 N·m {9.0— 14.0 kgf·cm, 7.9— 12.1

in·lbf}

33. Assemble the ring gear component following the

procedure in Step 11 to 14.

34. Set the dial gauge with the measuring probe

attached perpendicularly to the end of one of the

ring gear teeth.

35. Secure the drive pinion and measure the

backlash from when the ring gear is moved.

Standard drive pinion backlash

0.09— 0.11 mm {0.0035— 0.0043 in}

Caution

• Perform the backlash measurement on

the ring gear circumference at four

points.

36. If the backlash is not within the specified range

above, adjust it by sliding the ring gear in the shaft

direction.

Note

• Slide the ring gear in the shaft direction by replacing the adjustment shim. If the right side adjustment shim

is replaced with one that is 0.05 mm {0.002 in} thicker, the left side shim must be replaced with one that is

0.05 mm {0.002 in} thinner.

bawuua00000546

bawuua00000539

03-16–26

Page 69

37. Tighten the bearing cap bolts.

Tightening torque

63— 93 N·m {6.5— 9.4 kgf·m, 46.4— 68.5 ft·lbf}

38. Perform the drive pinion and ring gear tooth

contact inspection.

(1) Apply tooth marking compound evenly to both

surfaces of the ring gear.

(2) Rotate the ring gear back and forth several

times.

(3) Inspect for gear tooth contact at four points on

the ring gear circumference and verify that the

gear tooth contact indicated by the tooth

marking compound is as indicated in the

figure.

• If the tooth contact points are normal,

wipe off the marking compound.

• If the tooth contact points are not normal,

adjust the pinion height, then adjust the backlash.