Page 1

Page 2

RX-7

CONTENTS

•

TITLE

ENGINE

LUBLICATION

COOLING SYSTEM

FUEL AND EMISSION

CONTROL

-----

---

FUEL AND EMISSION

CONTROL

ENGINE ELECTRICAL SYSTEM

MANUAL

AUTOMATIC TRANSMISSION

(ELECTRONICALLY -CONTROLLED)

FRONT AND REAR AXLES

STEERING SYSTEM

BRAKING SYSTEM

SUSPENSION

BODY 14

BODY ELECTRICAL SYSTEM 15

-

--

--

---

--

--

-

SYSTEM

-

SYSTEMS

--- ---

SYSTEMS (TURBO)

--

TRANSMISSION

--

----

(NON-

----

-

--

-

-----

TURBO)

---

--

SECTION

1

2

3

4

5

7

9

10

11

13

•

Page 3

-

c

ENGINE

e

OUTLINE

OUTLINE OF CONSTRUCTION

STRUCTURAL VIEW

SPECIFICATIONS

INTERCHANGEABILITY

TENSION BOLT

FRONT COVER

ROTOR

..................................................

................................

....................................

............................

........................................

.........................................

....................................................

.................

C-

CC-

C-

C-

C-

CC-

97UOCX

2

2

2

4

5

6

7

8

501

e

Page 4

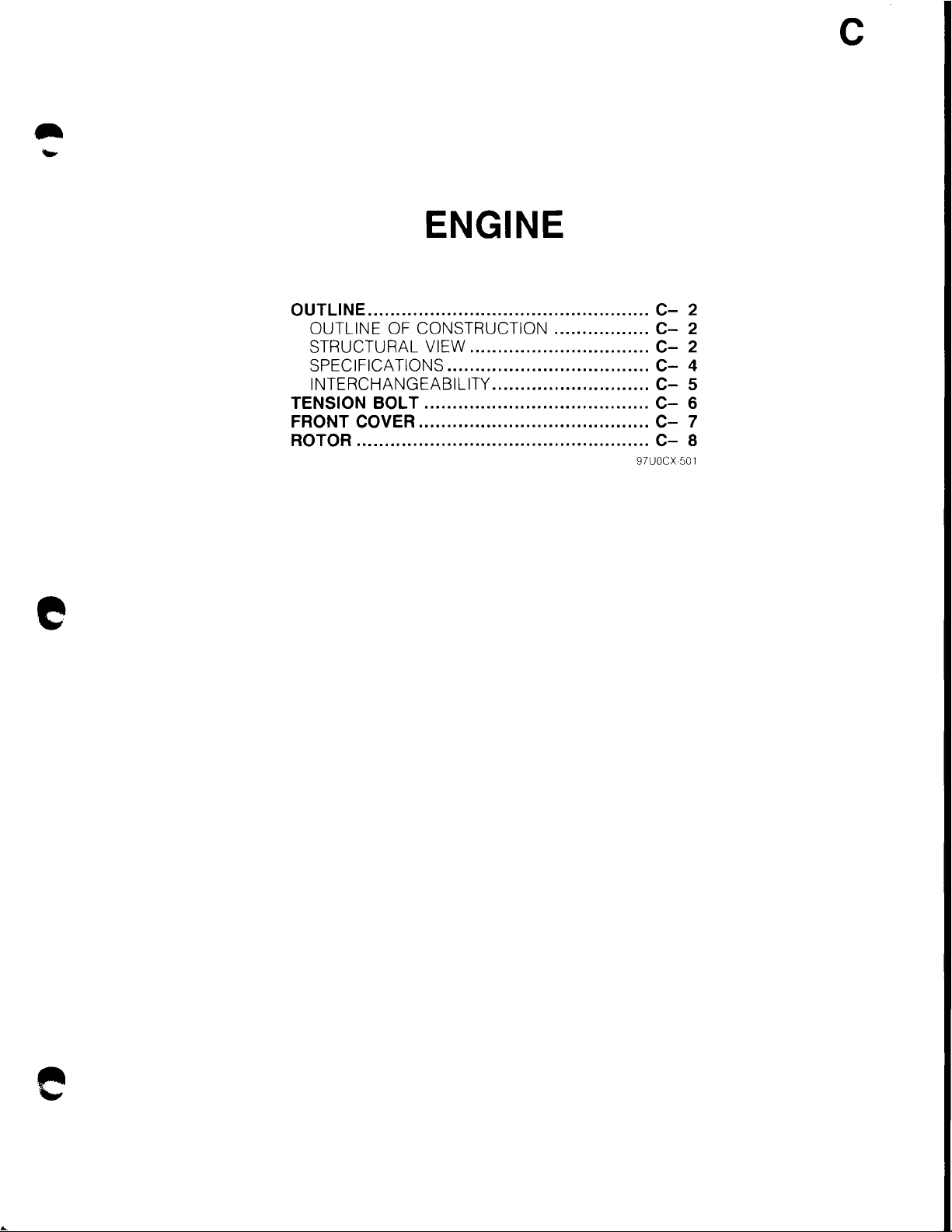

OUTLINE

OUTLINE OF CONSTRUCTION

The 13B

improved engine performance.

Major changes

1.

Rotor : Lighter, rotor recess shape change to increase compression ratio

2.

Tension bolt : Strengthening ribs added

3.

Front cover : Shape changed for new metering

4.

Side housings : Inlet port erea enlarged

STRUCTURAL VIEW

HOUSING-RELATED PARTS

in

the 1989

RX-7

is

basically the same as

FRONT HOUSING

in

the previous model but with some modli

oil

pump

FRONT ROTOR HOUSING

c:=:-

_

FRONT OIL SEAL

._)

REAR HOUSING

REAR ROTOR HOUSING

INTERMEDIATE

HOUSING

C-2

·-

97UOCX·502

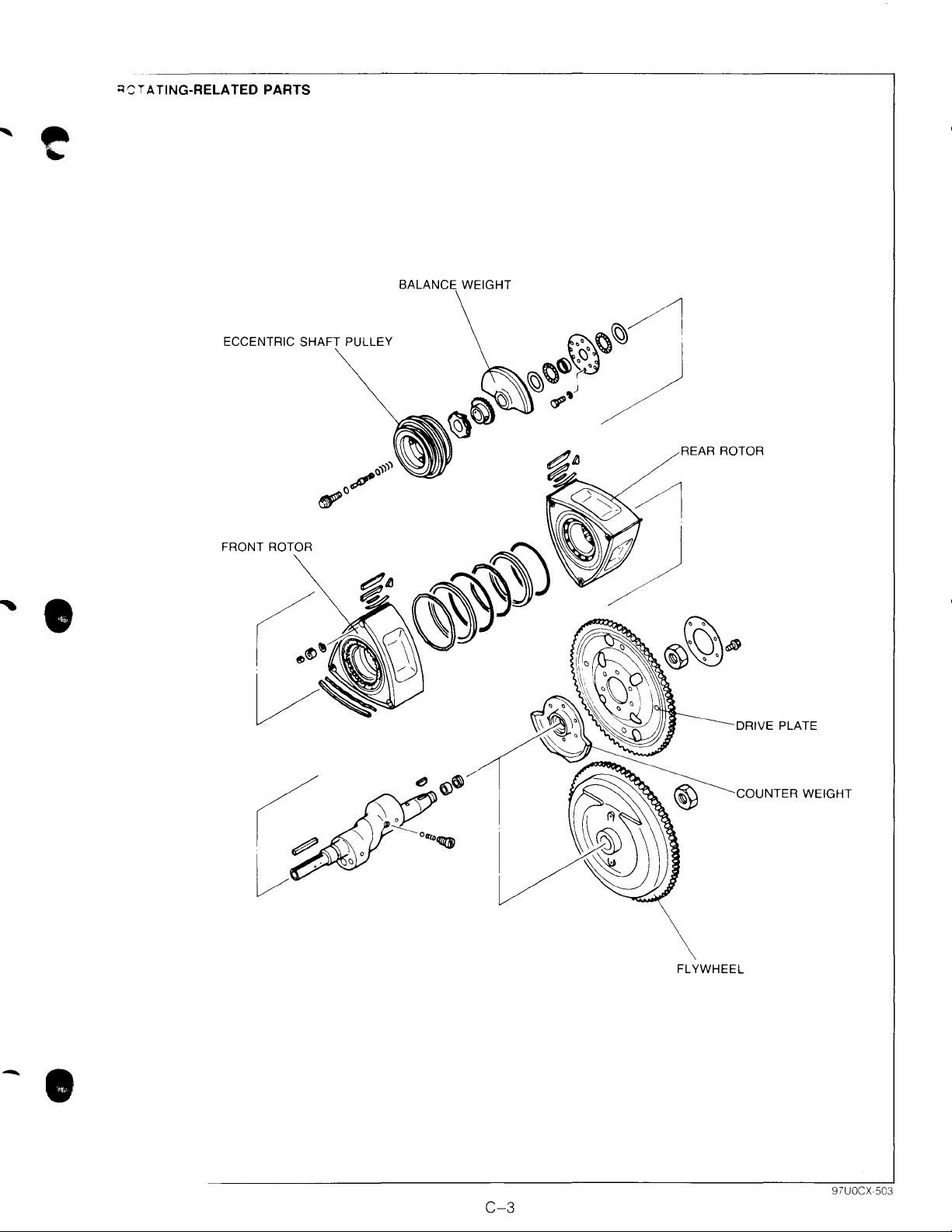

Page 5

;:;'"'TA

~

TING-RELATED

PARTS

BALANCE WEIGHT

ECCENTRIC PULLEY

REAR ROTOR

' •

FRONT ROTOR

DRIVE PLATE

COUNTER WEIGHT

FLYWHEEL

-.

C-3

Page 6

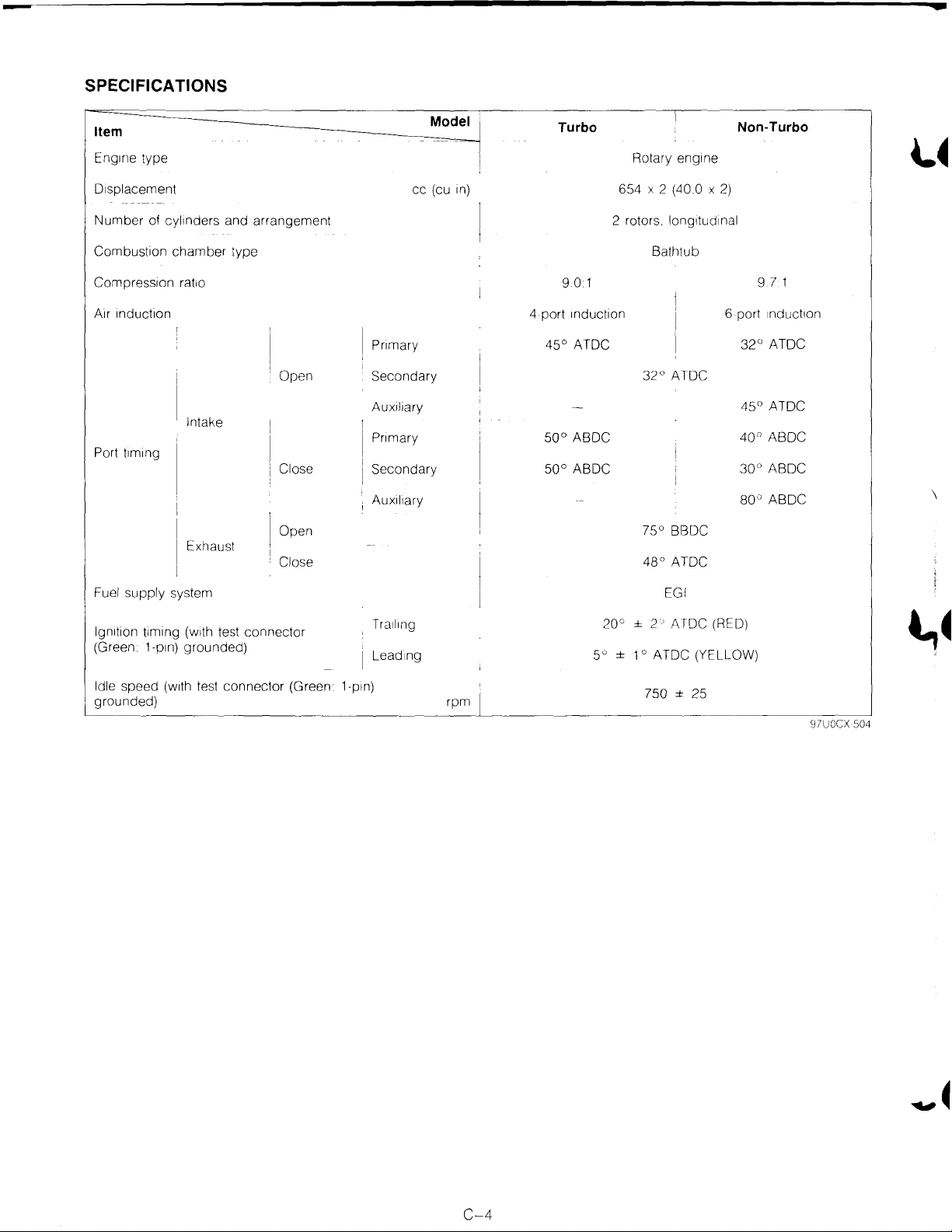

SPECIFICATIONS

cc

Model

(cu

1n)

Item

Eng1ne type Rotary eng1ne

Displacement

Number

Combustion

Compression

A1r

Port

of cyl1nders and

chamber

Induction

t1m1ng

rat10

Intake

Exhaust

arrangement

type

Open

Close

Open

Close

Pnmary 4S0 ATOC

Secondary

Auxiliary

Pnmary

Secondary

Auxil1ary

Turbo Non-Turbo

6S4 X 2 (40.0 X

2 rotors. longitudinal

Bathtub

9.0 1

4 port

1nduct1on

32°

ATOC

S0°

ABOC

soo

ABOC

0

7S

BBDC

48°

ATOC

2)

6 port

32°

4S

40°

30°

80"

9.7 1

1nduct1on

ATOC

0

ATOC

ABOC

ABOC

ABOC

~~

\

Fuel

supply

lgn1t1on

(Green

Idle

grounded)

t1ming

1-p1n)

speed

system EGI

(w1th

grounded)

(w1th

test

test

connector

connector

(Green

Tra1l1ng

Lead1ng

1-pln)

rpm

± 2 ' ATOC (REO)

20°

so

±

1 o ATOC (YELLOW)

750 ± 25

l,~

97UOCX 504

C-4

Page 7

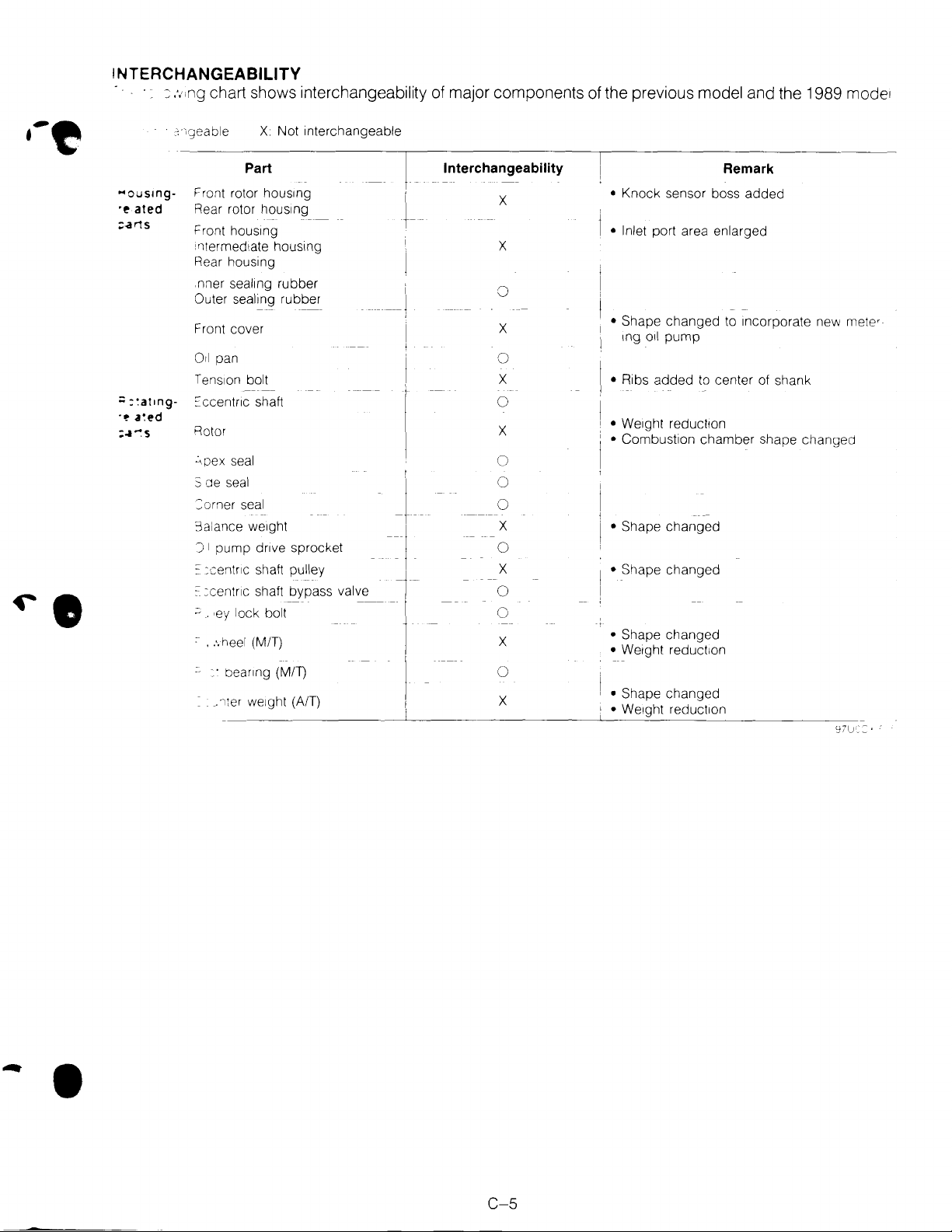

INTERCHANGEABILITY

:::

,.,,ng

chart shows interchangeability of major components of the previous model and the 1989 mode'

X Not interchangeable

...

ousmg-

·~

ated

;:.a

r1S

;;

:~at1ng-

-~

a~ed

=~~s

Part

Front rotor hous1ng

Rear rotor hous1ng

Front

hous1ng

i ntermed1ate housing

Rear housing

seal1ng

nner

Outer sealing rubber

Front cover

Orl

pan

Tens1on

::ccentnc shaft

Rotor

~~pex

S de

seal

:::orner

3a',ance weight I

J I pump dnve sprocket

: :centr1c

'C

=centnc shaft bypass valve - -

~

. ·ey lock bolt

~

.

:.

heel

• · beanng

.1ter

rubber

bolt

seal

seal

shaft pulley t

(MIT)

(MIT)

we1ght

(A/T)

-1

. -

i

---1

I

+

J

-~·

.

l

I,

Interchangeability

X

X

0

X

0

X

0

X

0

0

0

X

0

X

0

0

X

0

X

Remark

• Knock sensor boss added

• Inlet port area enlarged

• Shape changed to Incorporate new

tng

Oil

pump

• Ribs added

•

We1ght

•

Combustion chamber shape changed

• Shape changed

• Shape changed

• Shape changed

•

We1ght

•

Shape changed

•

We1ght

'

to

center of shank

reduct1on

reduct1on

reduct1on

metw

•

C-5

Page 8

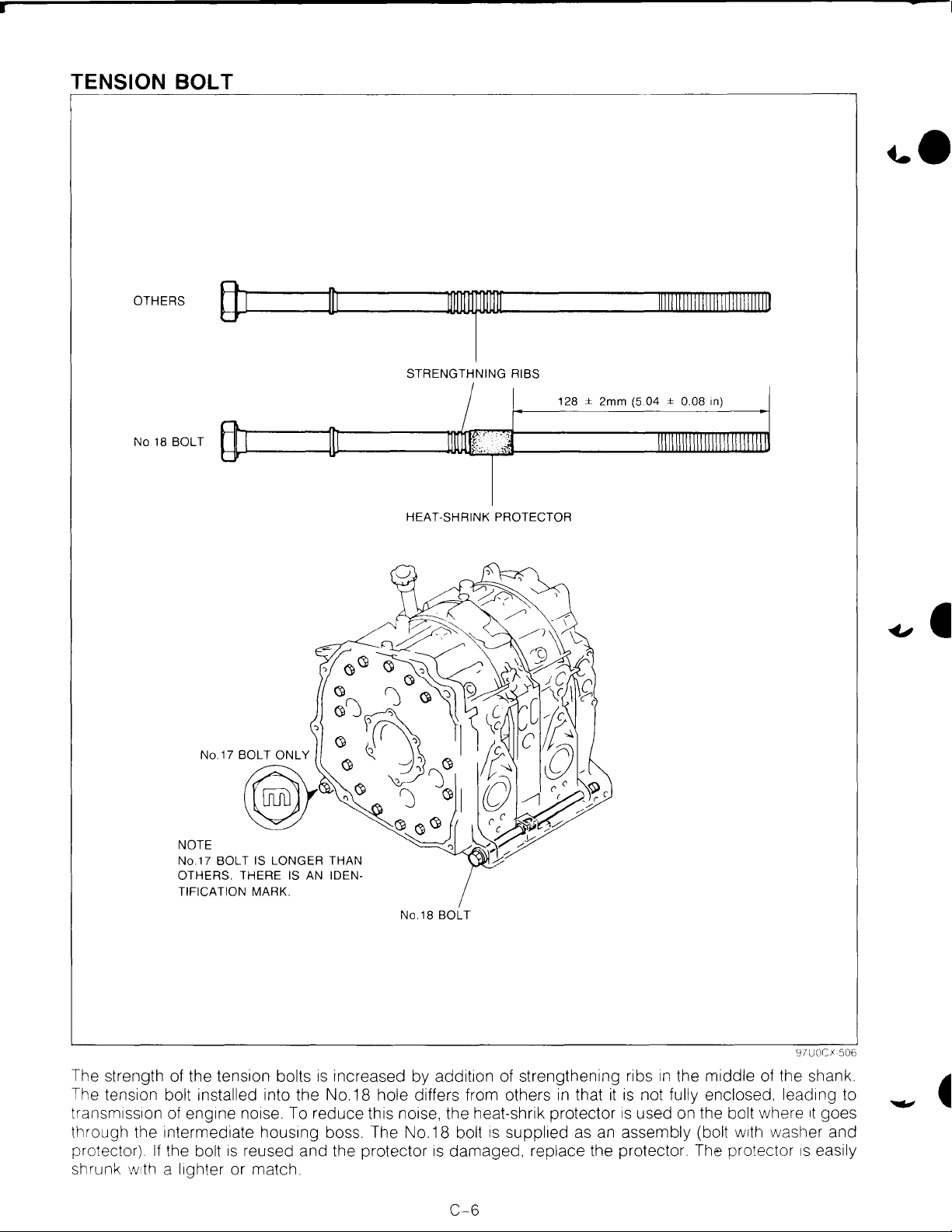

TENSION BOLT

...

OTHERS

No.18 BOLT

(}1

T

STRENGTHNING RIBS

128 ± 2mm

HEAT-SHRINK PROTECTOR

lllllllllllllllllllllllllllllll

(5.04 ± 0.08 in)

NOTE

No.1? SOL

OTHERS. THERE IS AN IDENTIFICATION

The strength of the tension bolts

The tension

transmiss1on of eng1ne noise. To reduce this noise. the heat-shrik protector

through the intermediate housing boss. The No. 18

protector).

shrunk

bolt installed into the No. 18 hole differs from others

If

the bolt

w1th

a l1ghter or match.

T IS LONGER THAN

MARK.

1s

increased by addit1on of strengthening ribs

is

reused and the protector

No.18 BOLT

bolt

is

damaged, replace the protector. The protector

C-6

in

that

is

supplied as an assembly (bolt

in

the middle of the shank.

it

is

not fully enclosed. lead1ng to

is

used on the bolt where

w1th

washer and

97UOCI 506

1t

goes

1s

easily

Page 9

,

.•

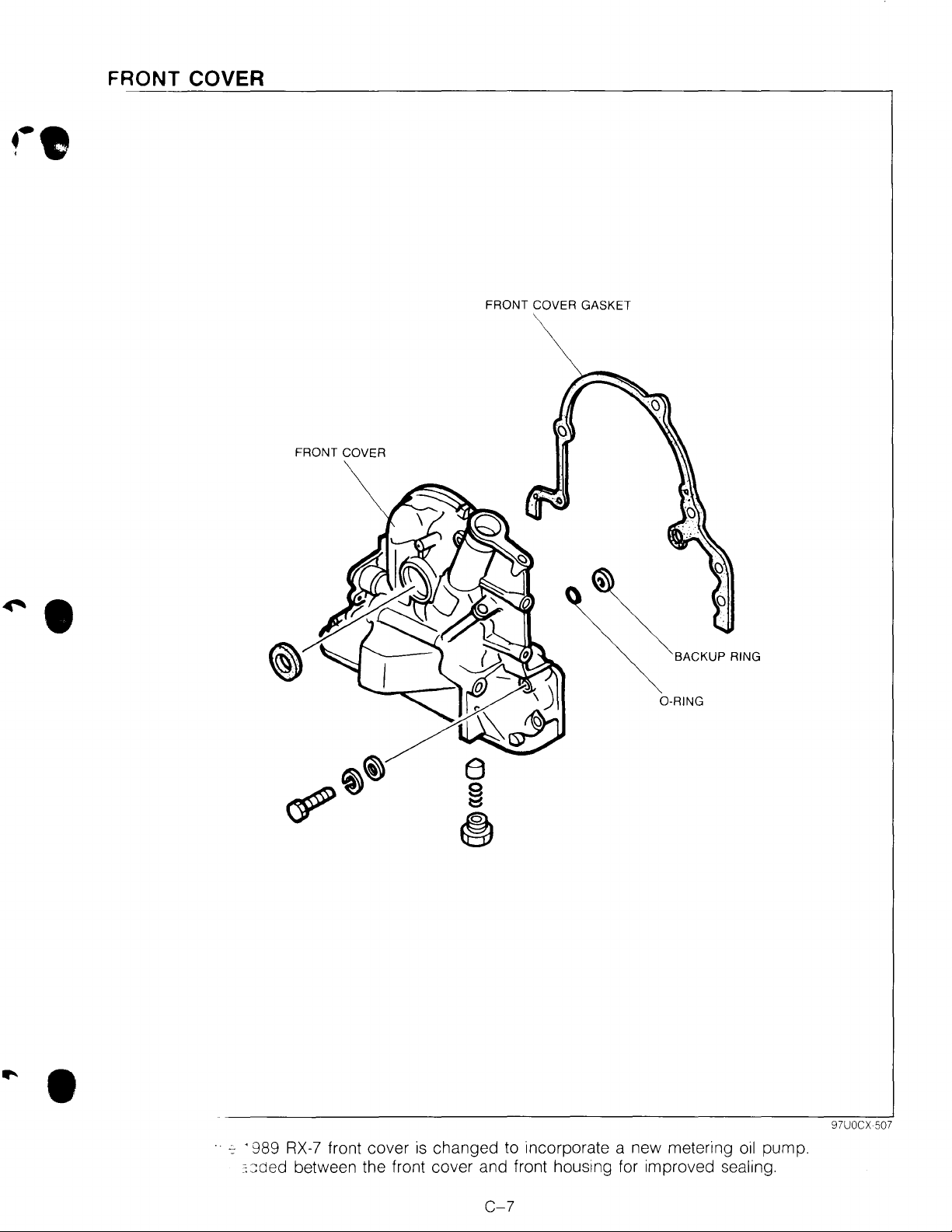

FRONT COVER

FRONT COVER GASKET

FRONT COVER

~.

~BACKUP

0-RING

RING

•

~

· 989

:::::ded

RX-7

front cover

between the front cover and front housing for improved sealing.

is

changed to incorporate a new metering

C-7

oil

97UOCX 507

pump.

Page 10

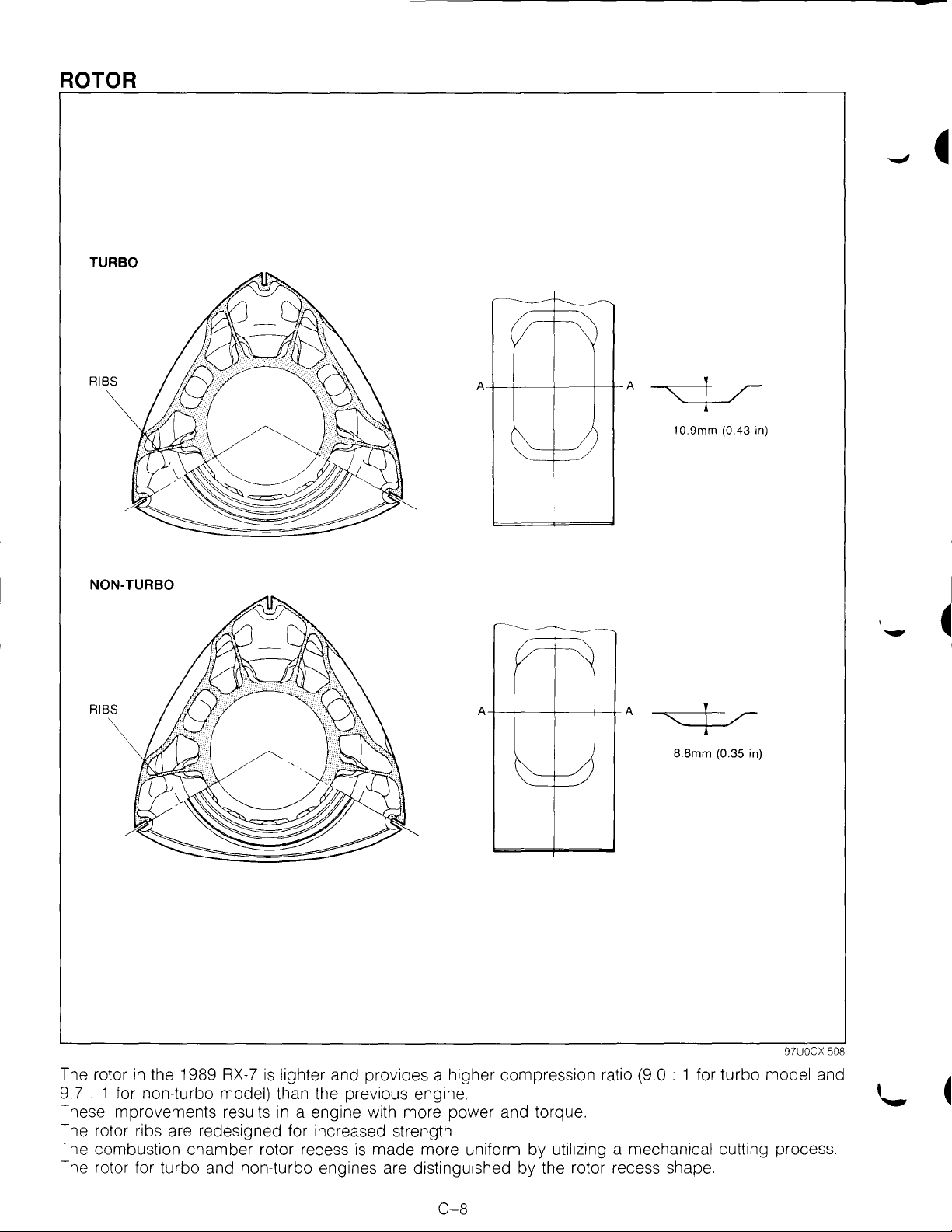

ROTOR

TURBO

RIBS

NON-TURBO

RIBS

~

~

\

A

/J

I

c--~~

v

A A

~

A~

1 0.9mm (0.43 in)

,_

4

8.8mm (0.35 in)

r---/1

~-

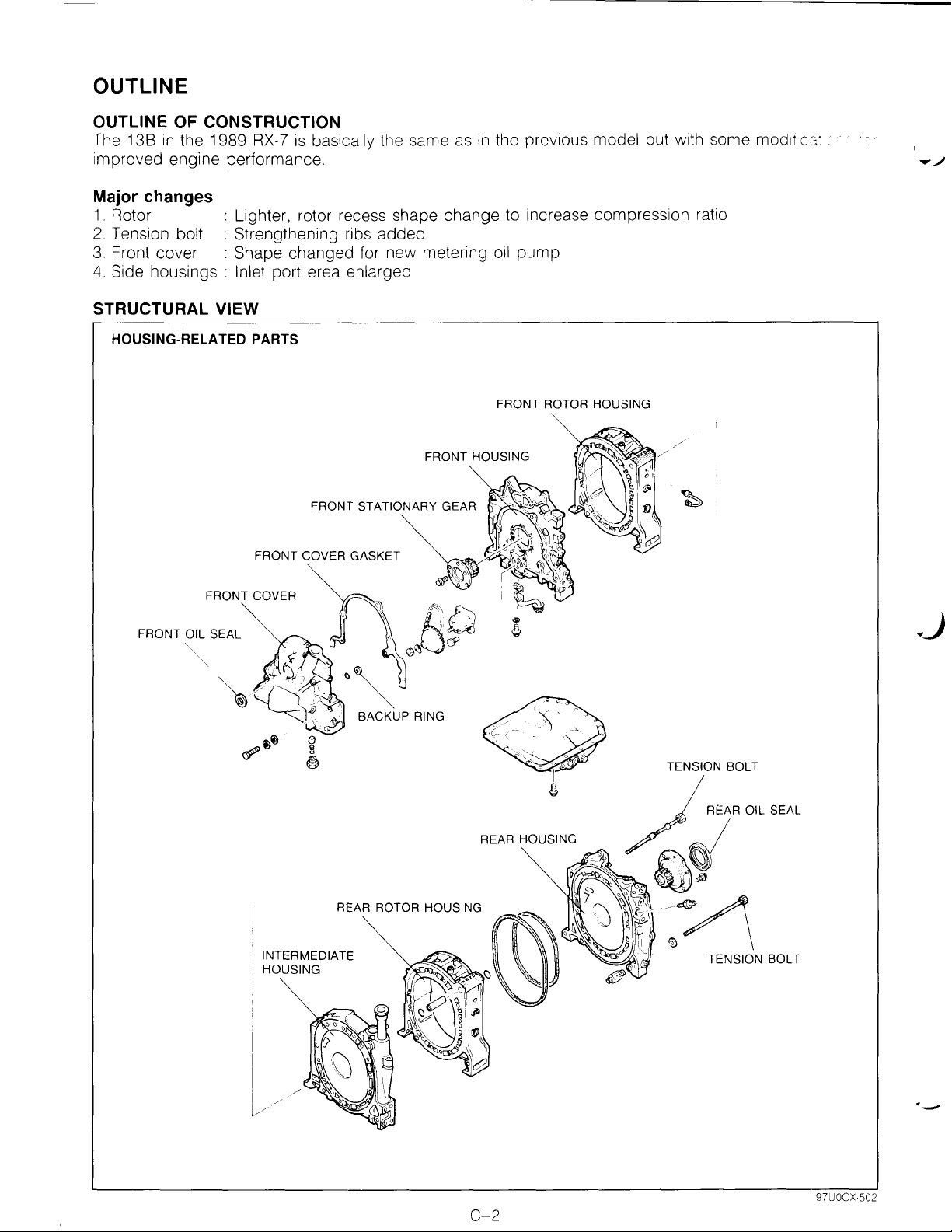

The rotor

9.7 :

These improvements

The rotor ribs are redesigned for increased strength.

The combustion chamber rotor recess

The rotor for turbo and non-turbo engines are distinguished by the rotor recess shape.

in

the 1989

1 for non-turbo model) than the previous engine.

RX-7

results

is

lighter and provides a higher compression ratio (9.0 : 1 for turbo model and

in

a engine with more power and torque.

1s

made more uniform by utilizing a mechanical cutting process.

97UOCX 508

C-8

Page 11

...

D

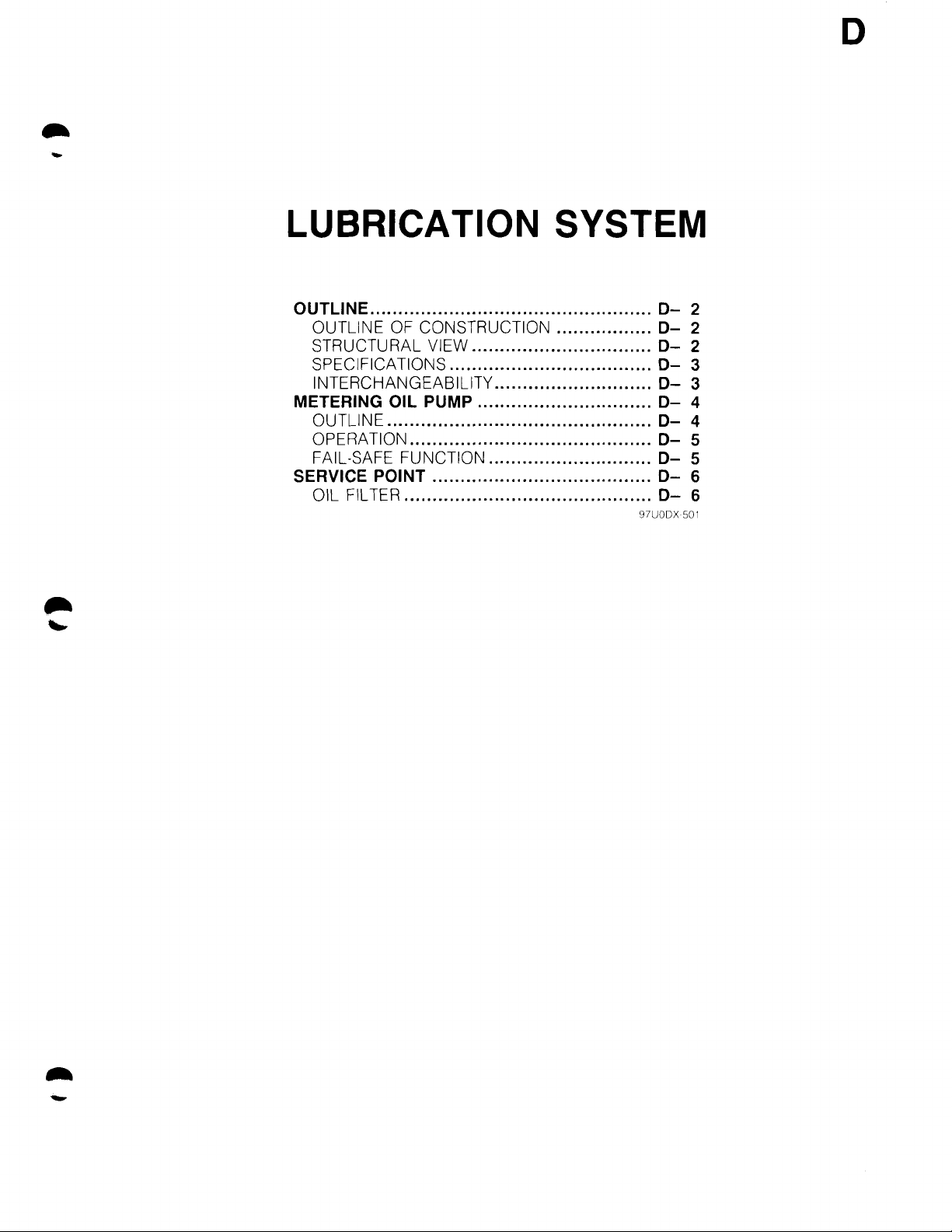

LUBRICATION SYSTEM

OUTLINE

OUTLINE OF CONSTRUCTION

STRUCTURAL VIEW

SPECIFICATIONS

INTERCHANGEABILITY

METERING OIL PUMP

OUTLINE

OPERATION

FAIL-SAFE FUNCTION

SERVICE POINT

OIL FILTER

..................................................

................................

....................................

............................

...............................

...............................................

...........................................

.............................

.......................................

............................................

.................

D-

D-

D-

D-

D-

D-

DDD-

D-

D-

97UODX 501

2

2

2

3

3

4

4

5

5

6

6

-

-

Page 12

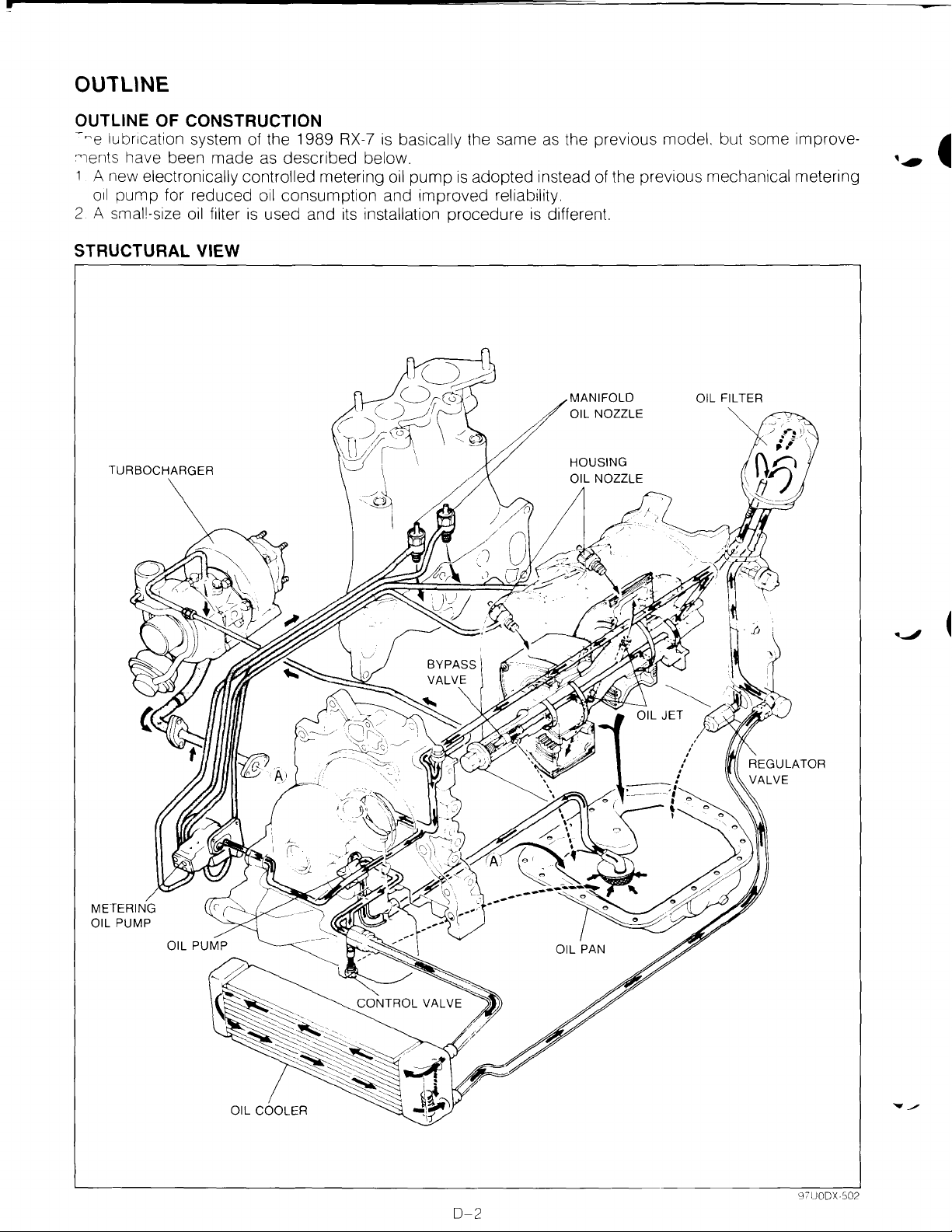

OUTUNE

OUTLINE OF CONSTRUCTION

-~e

lubncation system of the 1989

"lents have been made

1 A new electronically controlled metering

oil

pump for reduced

2 A smal!-size

oil

filter

as

described below.

oil

consumption and improved reliability.

is

used and

STRUCTURAL VIEW

RX-7

its

installation procedure

is

basically the same

oil

pump

is

adopted instead

as

the previous model. but some improve-

of

the previous mechanical metering

is

different.

MANIFOLD

OIL NOZZLE

TURBOCHARGER

HOUSING

0-2

Page 13

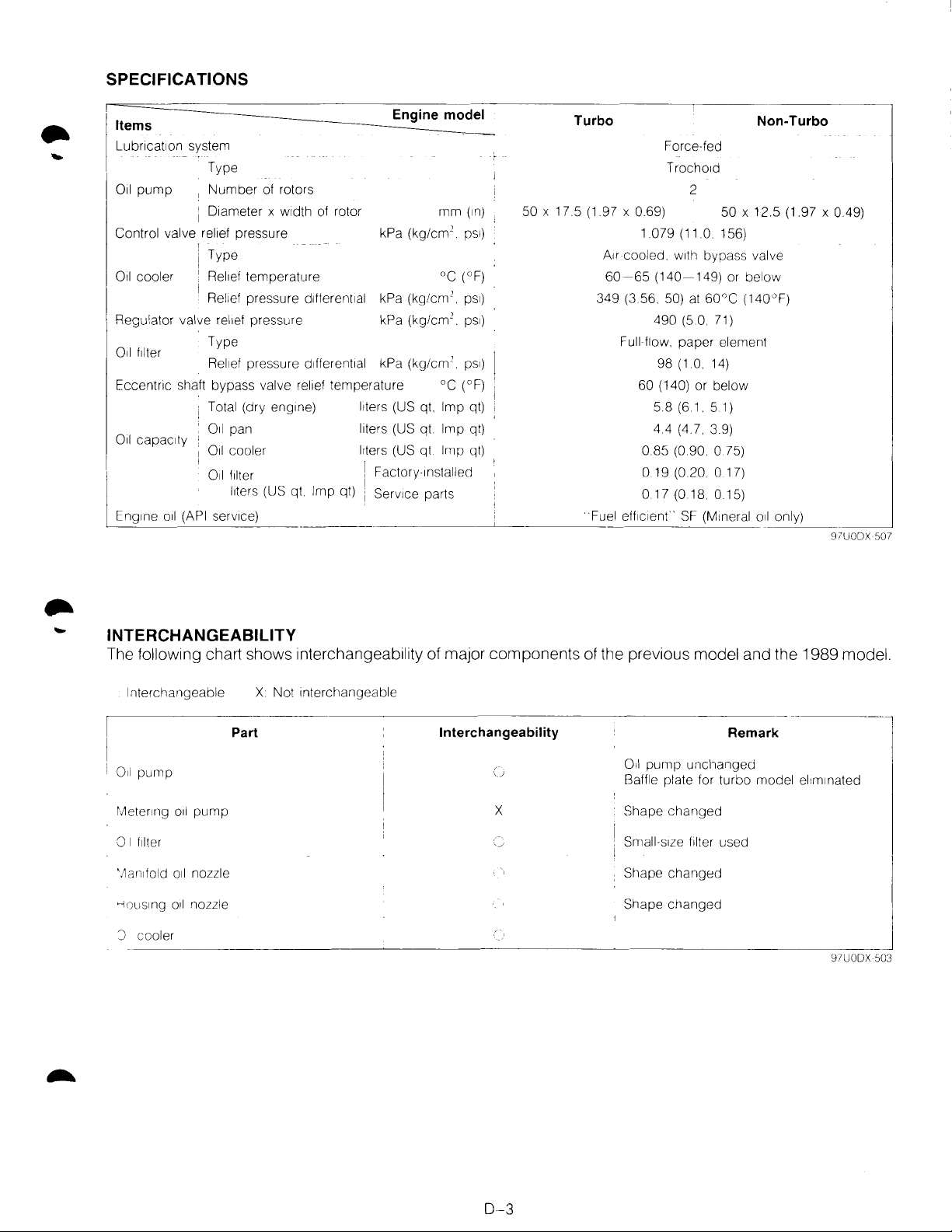

SPECIFICATIONS

Items

Lubncat1on system

Type

011

pump

Control valve relief pressure

Oil cooler

Regulator valve

Oil filter

Eccentnc shaft bypass valve

Oil

capaCity

Eng1ne

oil

(API

Number

1

1 D1ameter x

Type

Rel1ef

Rel1ef

Type

Rel1ef

Total (dry

011

Oil cooler

011

serv1ce)

of rotors

w1dth

temperature

pressure dlfferent1al kPa

rel1ef

pressure kPa

pressure

eng1ne)

pan

filter , actory-1nstalled

l1ters

(US qt Imp qt) i Serv1ce parts

of rotor

d1fferent1al

rel1ef

temperature

Engine model

kPa (kg/cm

(kg/em'.

(kg/em'.

kPa

(kg/em'.

l1ters

(US qt. Imp qt)

liters

(US qt. Imp qt)

l1ters

(US

\ F

I

qt

_____

mm

2

oc

oc

Imp

.

ps1)

(°F)

ps1)

(°F)

(1n)

ps1)

ps1)

qt)

_[_________

50 X 17.5

Turbo

(1

97 X

A1r

349

Fuel

Force-fed

Trocho1d

069)

1.079 (11.0.

cooled.

60-65

(140-149)

(3

56. 50)

490 (5.0. 71)

Full flow.

98

60 (140) or below

5.8 (6 1 5.1)

4.4 (4.7. 3

0.85 (0.90. 0

0.19 (0.20 0 17)

0.17 (0.18. 0 15)

eff1c1enr·

2

50 X 12.5 (1.97 X 0.49)

156)

w1th

bypass valve

or below

at

60°C

paper

element

(1.0. 14)

9)

75)

SF

(M1neral oil only)

Non-Turbo

(140"F)

----

___

97UODX

_j

507

INTERCHANGEABILITY

The following chart shows interchangeability of major components of the previous model and the 1989 model.

Interchangeable X Not Interchangeable

Interchangeability

X

______________________________

Remark

Oil

pump

unchanged

Baffle plate for turbo model

Shape

changed

Small-s1ze filter used

Shape

changed

el1m1nated

97UODX

j

503

011

pump

rl1eterlllg

0 I

f1lter

--1ous1ng

J

_c_o_o_le_r

Part

oil

pump

oil

nozzle Shape cr1anged

______________

~

0-3

Page 14

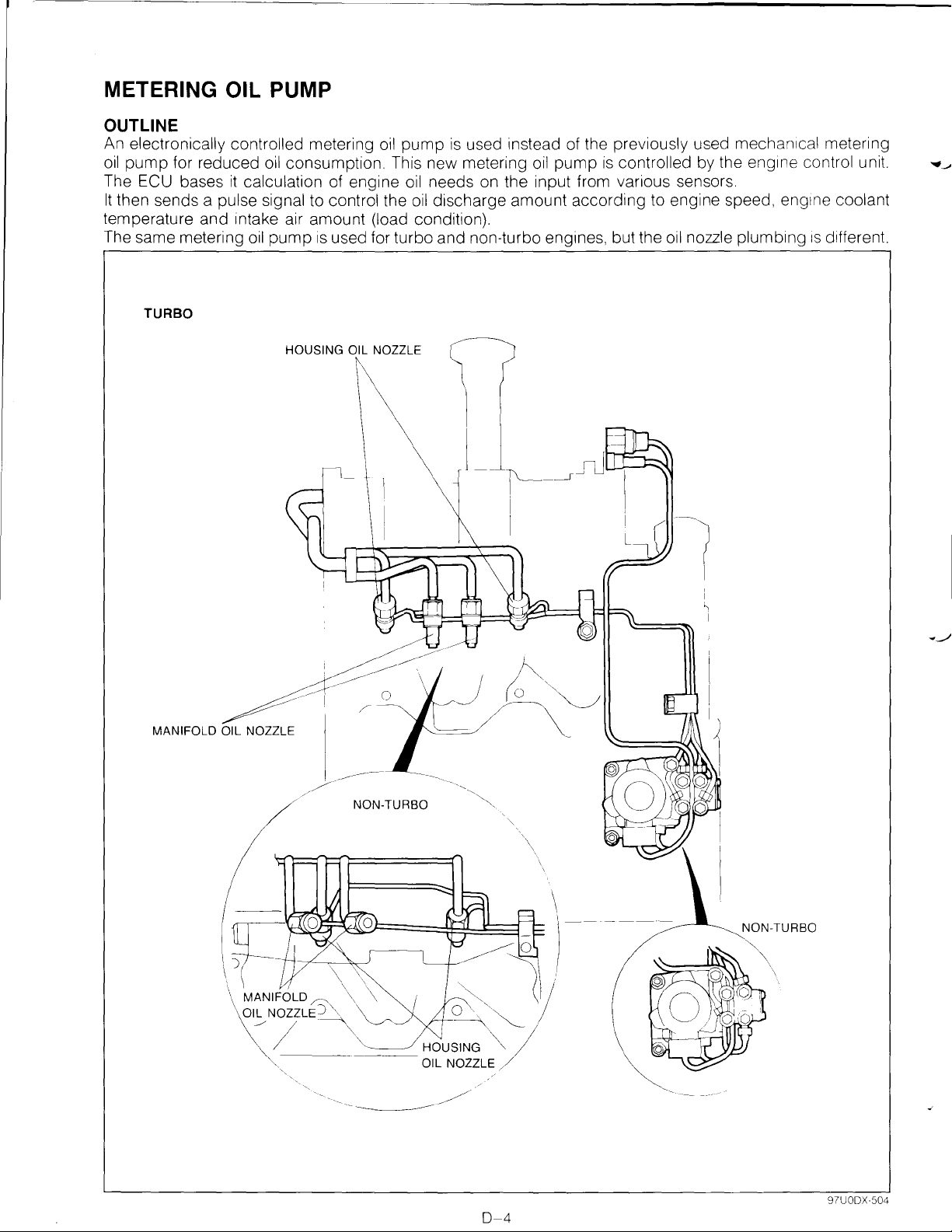

METERING OIL PUMP

OUTLINE

An electronically controlled metering

oil

pump

The ECU bases

It

then sends a pulse signal to control the

for reduced

it

calculation of engine

oil

consumption. This new metering

temperature and intake air amount (load condition).

The same metering

TURBO

oil

pump

is

used for turbo and non-turbo engines, but the

HOUSING OIL NOZZLE

oil

pump

is

used instead of the previously used mechan1cal metering

oil

needs on the input from various sensors.

oil

discharge amount according to engine speed,

oil

pump

is

controlled by the

oil

nozzle plumbing

eng1ne

eng1ne

control unit.

coolant

1s

different

...

~

MANIFOLD OIL NOZZLE

NON-TURBO

~

I

NON-TURBO

0-4

97UODX·504

Page 15

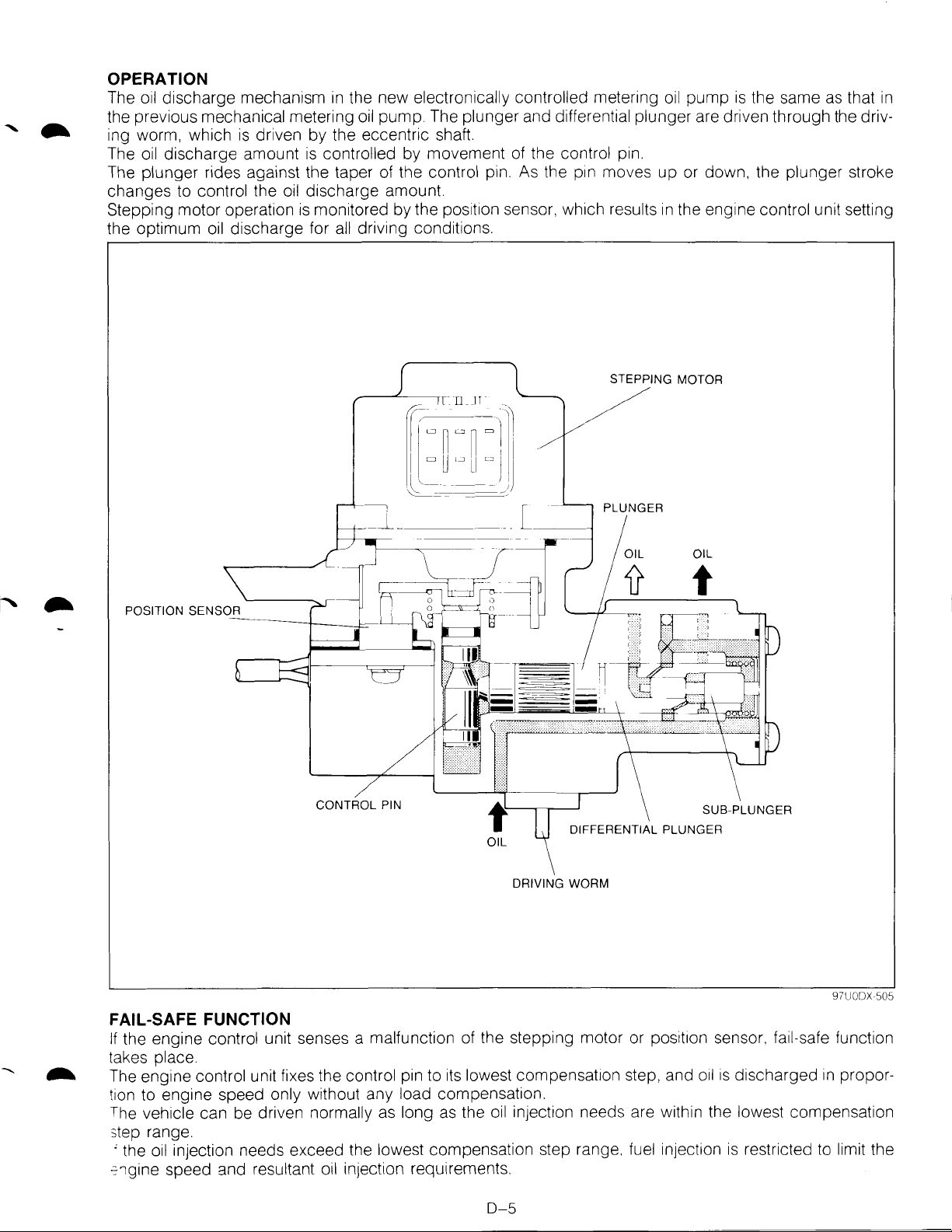

OPERATION

The

oil

discharge mechanism

the previous mechanical metering

is

ing worm, which

The

oil

discharge amount

The plunger rides against the taper

changes to

Stepping motor operation

the optimum

control the

oil

driven by the eccentric shaft.

oil

discharge for

in

the new electronically controlled metering oil pump

oil

is

controlled by movement

discharge amount.

is

monitored by the

all

driving conditions.

is

the same

pump. The plunger and differential plunger are driven through the driv-

of

of

the control pin.

pos1t1on

the control

As

the

sensor, which results

p1n.

p1n

moves up or down, the plunger stroke

in

the engine control unit setting

STEPPING MOTOR

as

that

/

in

CONTROL PIN

f

OIL

DRIVING WORM

DIFFERENTIAL PLUNGER

FAIL-SAFE FUNCTION

If

the engine control unit senses a malfunction of the stepping motor or

place.

takes

The engine control unit fixes the control pin to

tion to engine speed

The

vehicle can be driven normally

step range.

' the

oil

injection needs exceed the lowest compensation step range. fuel injection

~1gine

speed and resultant oil injection requirements.

only without any load compensation.

as

long

its

lowest compensation step, and

as

the

oil

injection needs are within the lowest compensation

D-5

posit1on

SUB-PLUNGER

97UODX 505

sensor. fail-safe function

oil

is

discharged

is

restricted to limit the

in

propor-

Page 16

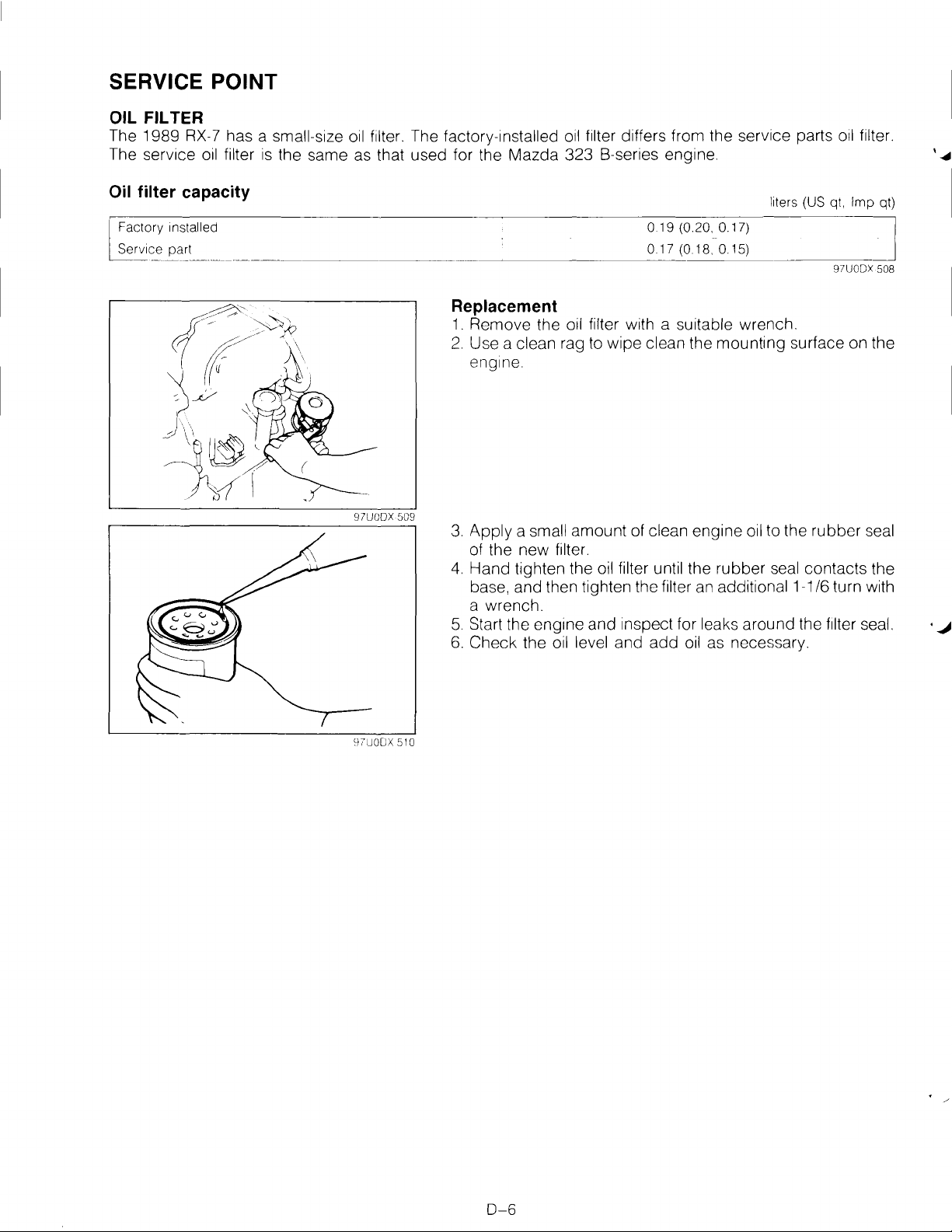

SERVICE POINT

OIL FILTER

The 1989

The service oil filter

RX-7

has a small-size

is

oil

filter. The factory-installed oil filter differs from the service parts oil filter.

the same as that used for the Mazda 323 B-series engine. '

.....

Oil filter capacity

ctory 1nstalled

rvice part

-

--·-----·-----

019

0.17

(0.20, 0.17)

(0

18.

0.15)

liters (US qt,

_,]

Imp

qt)

97UODX 508

Replacement

1.

Remove the oil filter with a suitable wrench.

2.

Use a clean rag to wipe clean the mounting surface on the

engine.

3.

Apply a small amount of clean engine oil to the rubber seal

of the new filter.

4.

Hand tighten the oil filter until the rubber seal contacts the

base, and then tighten the filter an additional 1-1/6 turn with

a wrench.

5.

Start the engtne and inspect for leaks around the filter seal. ·

6.

Check the oil level and

add

oil as necessary.

.J

0-6

Page 17

COOLING SYSTEM

E

OUTLINE

OUTLINE OF CONSTRUCTION

STRUCTURAL VIEW

SPECIFICATIONS

INTERCHANGEABILITY

COOLING FAN

WATER PUMP

THERMOSTAT

RADIATOR

..................................................

................................

....................................

............................

..........................................

..........................................

..........................................

...............................................

..................

E-

EEE-

E-

EEEE-

97UOEX 501

2

2

2

3

3

4

5

6

7

-

Page 18

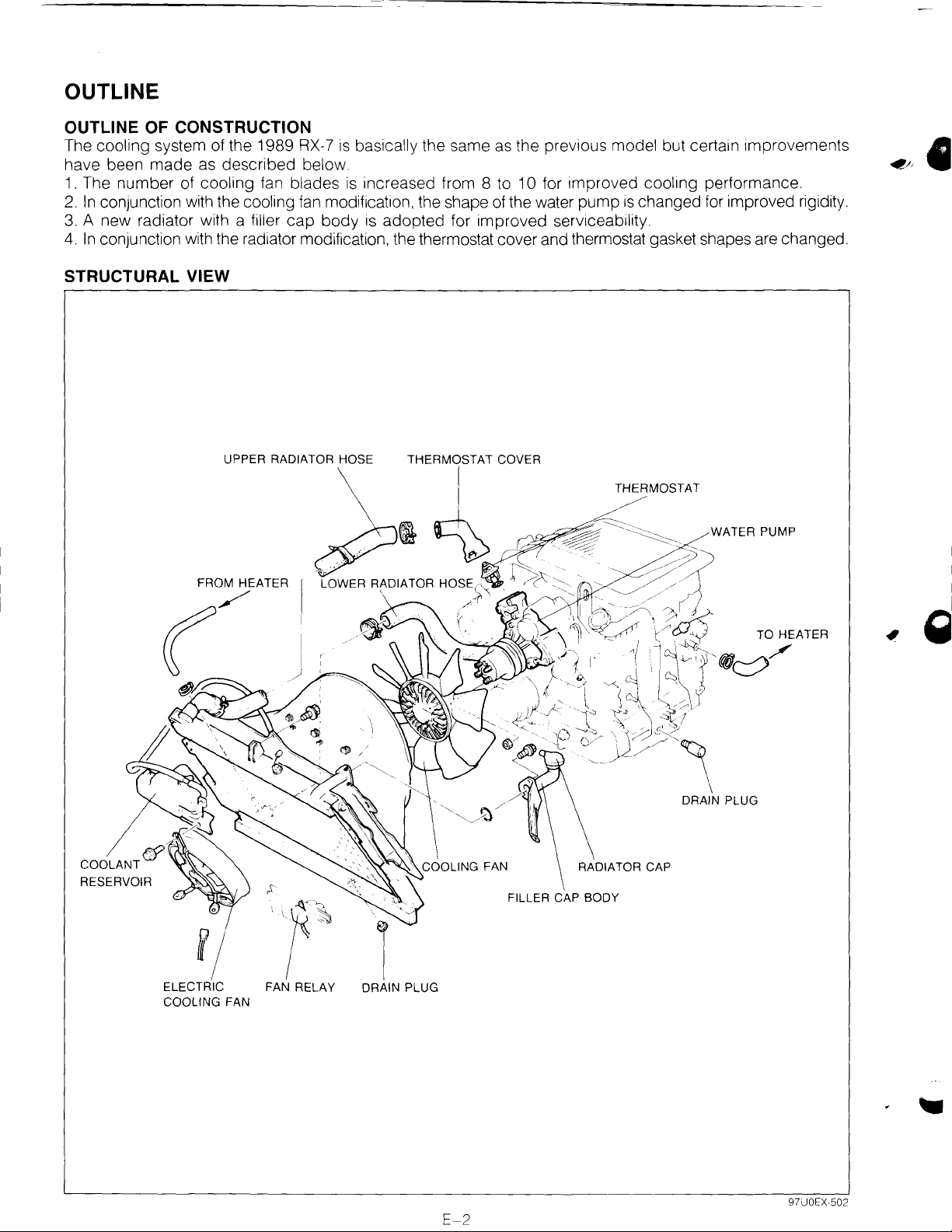

OUTLINE

OUTLINE

The cooling system of the 1989

have been

1.

The number of cooling fan blades

2.

In

3.

A new radiator with a filler

4.

In

STRUCTURAL VIEW

OF

CONSTRUCTION

RX-7

is

basically the same as the previous model but certain improvements

made

conJunction with the cooling

conjunction with the radiator modification, the thermostat cover and thermostat gasket shapes are changed.

as described below.

fan

modification, the shape of the water pump

cap

body

is

increased from 8 to 1 0 for improved cooling performance.

is

changed for improved rigidity.

is adopted for improved serviceability.

THERMOSTAT

~

WATER PUMP

RESERVOIR

FROM HEATER

(/

fj

ELECTRIC

COOLING

FAN

FAN RELAY

RADIATOR CAP

FILLER CAP BODY

DRAIN PLUG

E-2

97UOEX-502

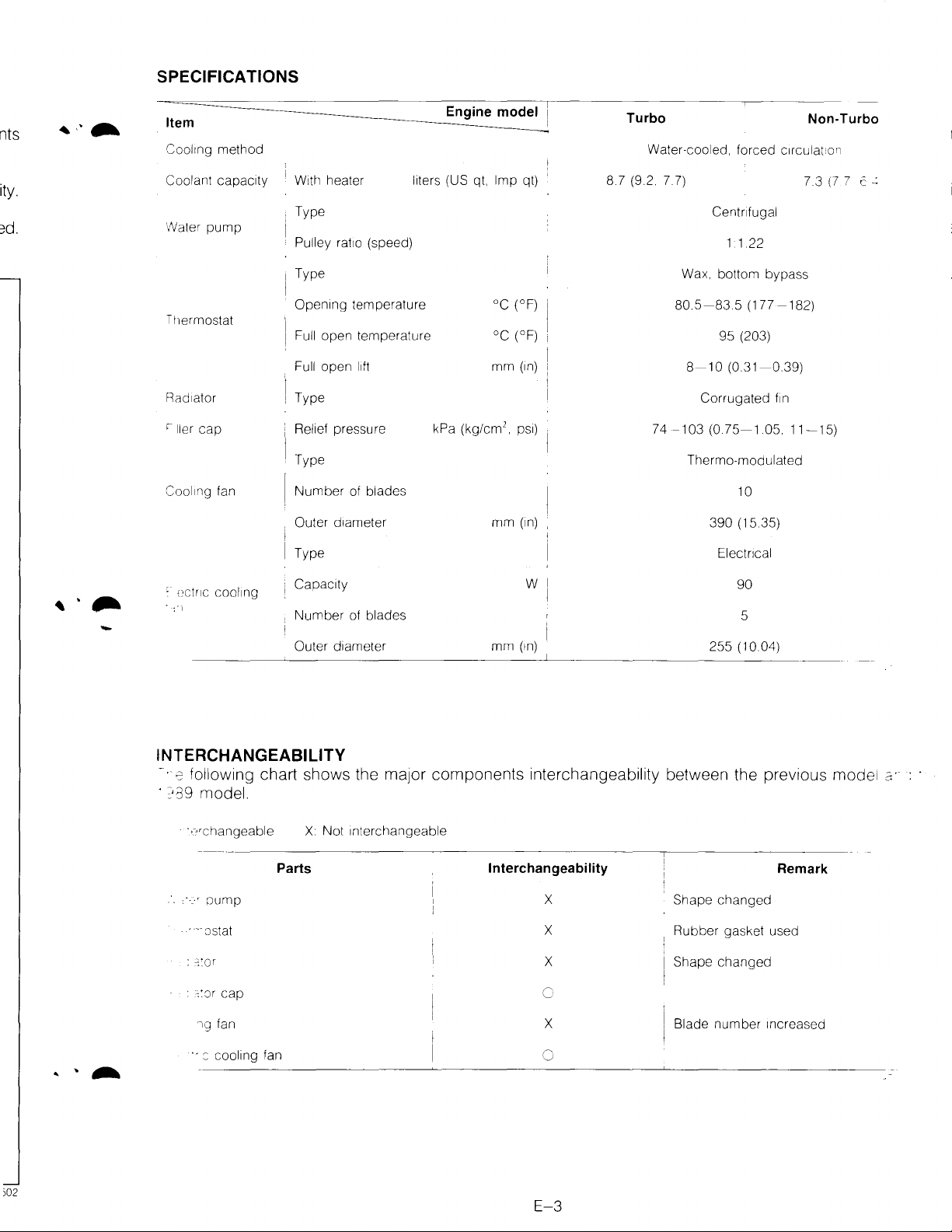

Page 19

SPECIFICATIONS

nts

Item

Cool1ng

Coolant capac1ty

/Vater

Tl1ermostat

Rad1ator

'ller

Cool1ng fan

method

pump

cap

W1th

heater

Type

Pulley

rat1o

Type

Open1ng

Full

Full

[

Type

Relief pressure

Type

Number

Outer

Type

temperature

ope'l

open

of blades

d1ameter

liters (US qt.

(speed)

temperature

l1ft

Engine

kPa

mode~

Imp

°C

oc

mm

2

(kg/cm

•

mm

qt)

(°F) i

(oF) i

(1n)

ps1)

(1n)

Turbo

Water-cooled,

8.7 (9.2 7.7)

forced

Ce'ltnfugal

Non-Turbo

c1rculat:o'l

7.3

(7

7 c

~

1 1.22

Wax. bottom

I

80.5-83.5

95

I

8-10

Corrugated

74-103

(0.75-1.05.

Thermo-modulated

bypass

(177

-182)

(203)

(0.31-0.39)

f1n

11-15)

10

390

(15 35)

Electncal

-

mm

w

(1n)

255

90

5

(10.04)

:

(;CtriC

COOling

i Capac1ty

Number

Outer d1ameter

of blades

INTERCHANGEABILITY

~.

;co

following chart shows the major components interchangeability between the previous model

· ?39 model.

· ·_?•changeable

· ":Jstat

:

c::or

:

:::Jr

cap

'lQ fan

Parts

X

Not

Interchangeable

Interchangeability

X

X

X

c

X

Shape

Rubber

Shape

Blade

changed

gasket used

changed

number

Increased

Remark

c:·

)02

··::

::ooling fan

0

E-3

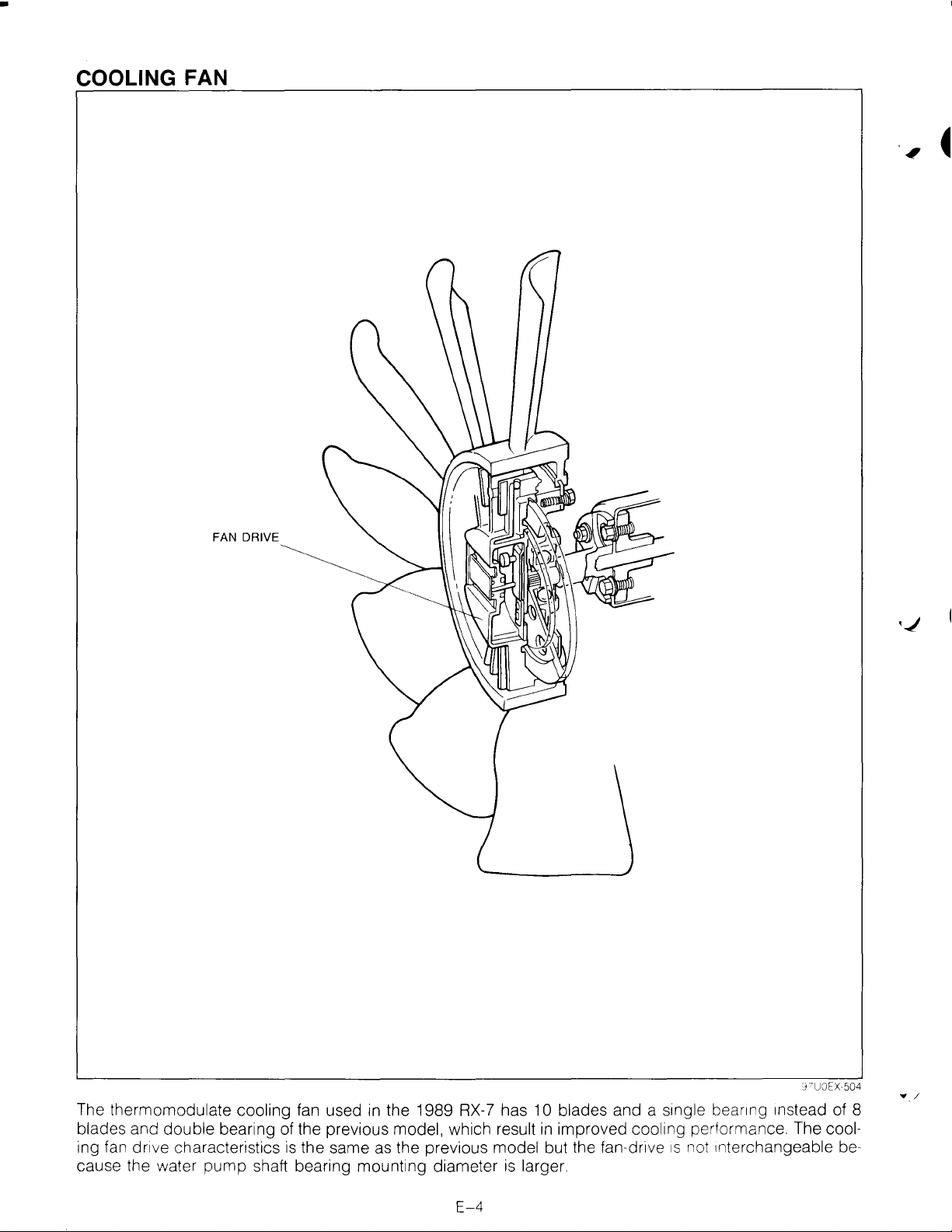

Page 20

COOLING FAN

FAN DRIVE

The thermomodulate cooling fan used

in

the 1989 RX-7 has 10 blades and a

blades and double bearing of the previous model, which result

ing fan drive characteristics

cause the water

pump

is

the same as the previous model but the fan-dr1ve

shaft bearing mounting diameter

is

larger.

E-4

s1ngle

in

improved cooling performance. The cool-

bear1ng 1nstead of 8

1s

not Interchangeable be-

•_/

Page 21

WATER PUMP

SHAFT BEARING

PULLEY BOSS

\

BEARING HOUSING

@~

EXTRA RIBS

I

I

WATER

WATER PUMP BODY

PUMP GASKET

"'

\ -

-

97UOEX

:.

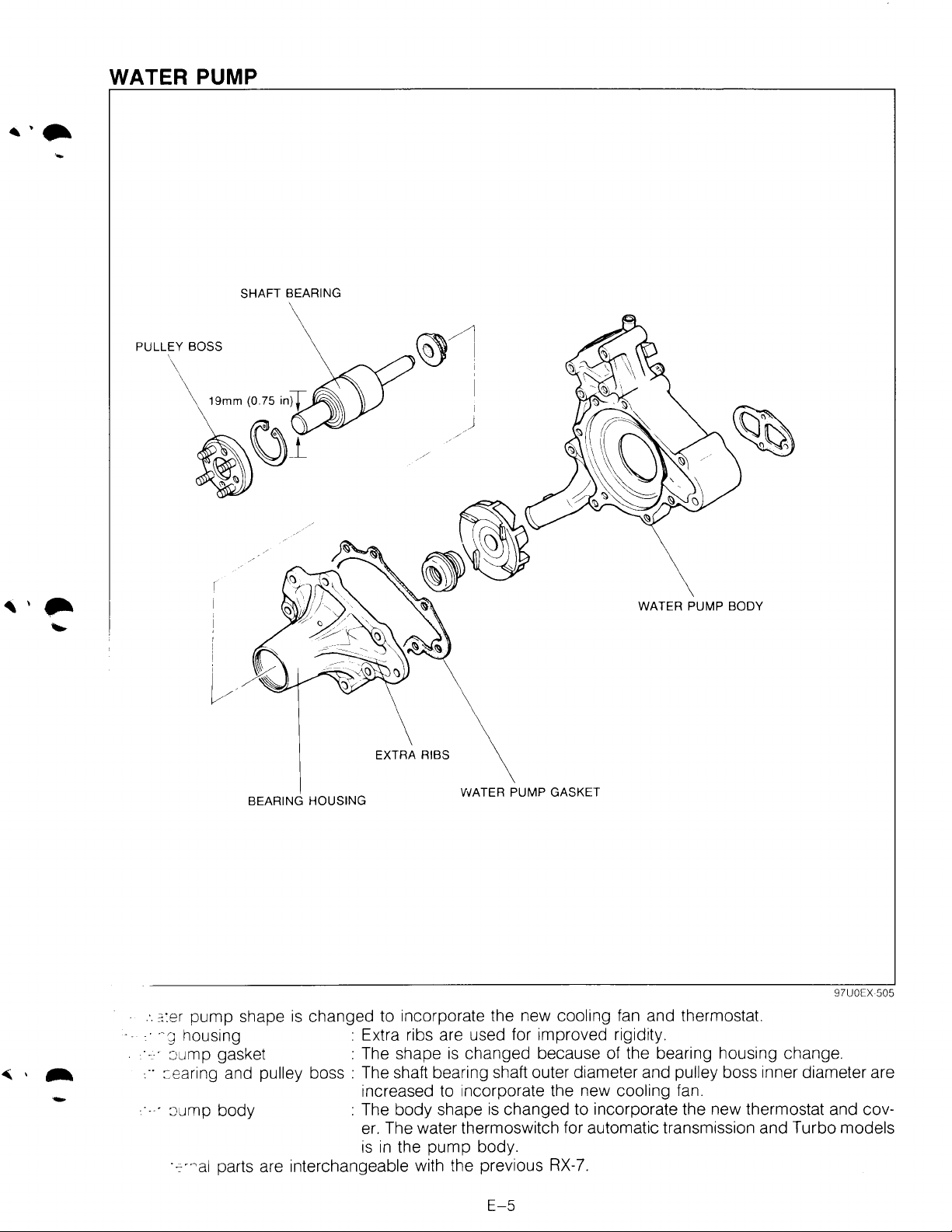

:=::er

pump shape

•.

·-g

housing : Extra ribs are used for improved rigidity.

·-.·

:Jump gasket : The shape

...

:::earing and pulley boss : The shaft bearing shaft outer diameter and pulley boss inner diameter are

·.

· :Jump body : The body shape

·-=-·~al

parts are interchangeable with the previous

is

changed to incorporate the new cooling fan and thermostat.

is

changed because of the bearing housing change .

increased to incorporate the new

is

changed to incorporate the new thermostat and cover. The water thermoswitch for automatic transmission and Turbo

is

in

the

pump

body.

RX-7.

cooling fan.

models

E-5

505

Page 22

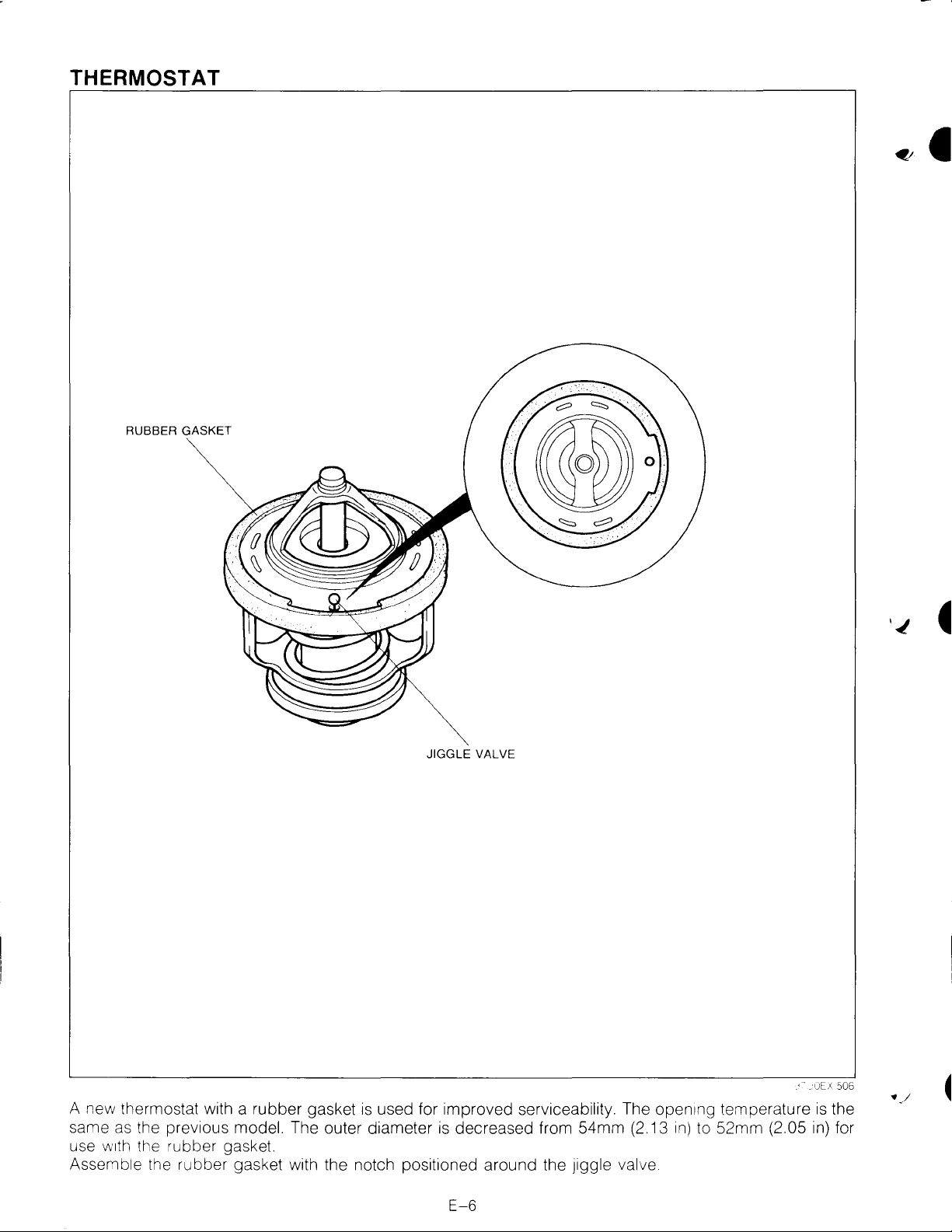

THERMOSTAT

RUBBER GASKET

JIGGLE

A new thermostat with a rubber gasket

same

as

the prev1ous model. The outer diameter

use

w1th

the rubber gasket.

Assemble the rubber gasket with the notch positioned around the Jiggle valve

is

used for improved serviceability. The open1ng temperature

VALVE

is

decreased from 54mm (2.13

1n)

to 52mm (2.05

is

in)

the

for

E-6

Page 23

'

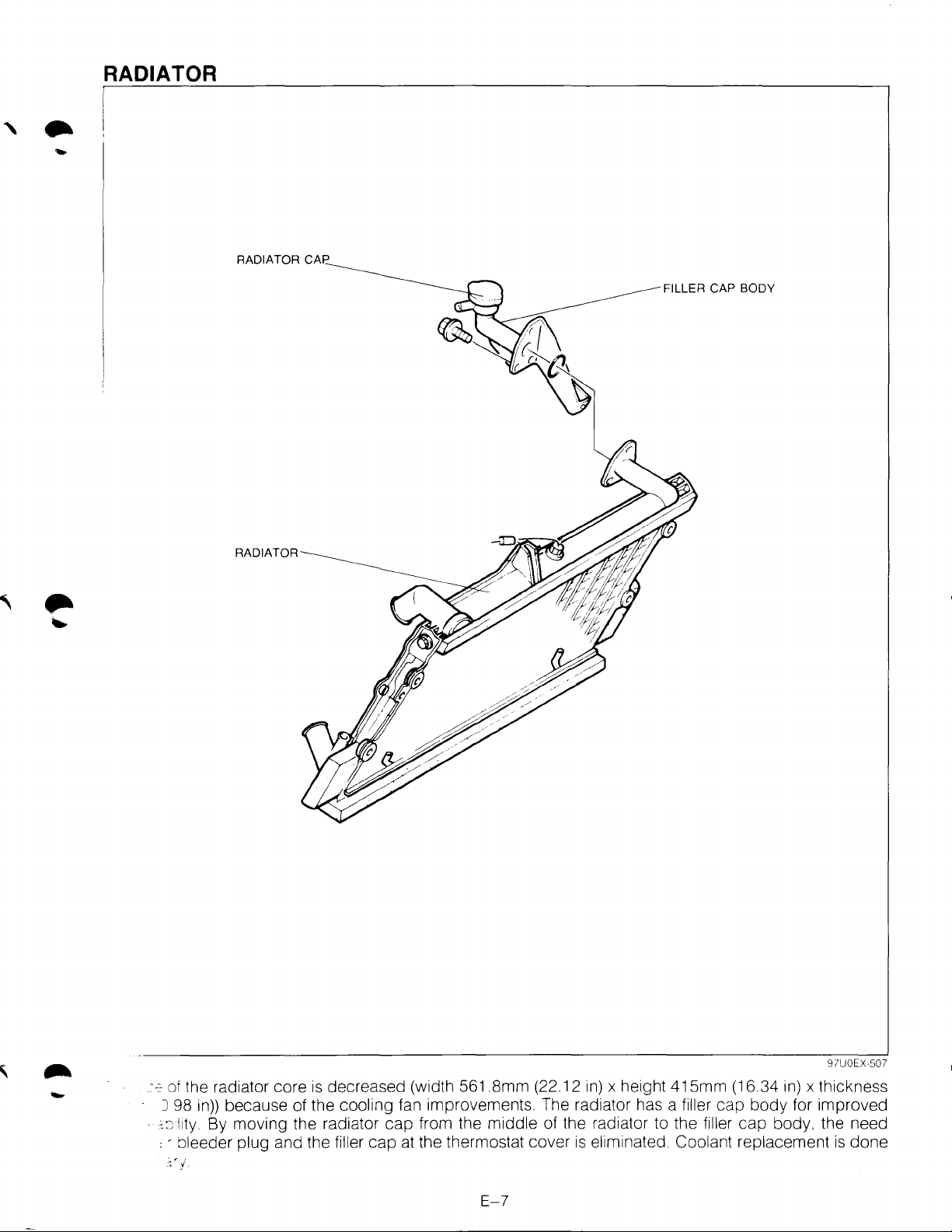

RADIATOR

..

RADIATOR CAP

FILLER CAP BODY

RADIATOR

-

.:::::of

the radiator core

J 98

in))

because of the cooling fan improvements. The radiator has a filler cap body for improved

· :::J

l1ty.

By moving the radiator cap from the middle of the radiator to the filler

, - bleeder plug and the filler cap at the thermostat cover

':'j

is

decreased (width

561

.Smm (22.12

E-7

in)

x height 415mm (16.34

is

eliminated. Coolant replacement

in)

cap

body, the need

97UOEX-507

x thickness

is

done

Page 24

F1

•

FUEL

AND

EMISSION

CONTROL SYSTEMS

{NON-

OUTLINE

OUTLINE OF CONSTRUCTION

EMISSION CONTROL SCHEMATIC

DIAGRAM

SYSTEM DIAGRAM

VACUUM

WIRING DIAGRAM

SPECIFICATIONS

VARIABLE DYNAMIC EFFECT INTAKE

(VDI) SYSTEM

FUEL SYSTEM

MIXING PLATE

SERVICE POINT

CONTROL SYSTEM

AIRFLOW METER

THROTTLE-IDLE-POSITION AUTO-

ADJUSTING SYSTEM

LEAN BEST-IDLE CONTROL SYSTEM

SPARK ADVANCE FEEDBACK SYSTEM

SERVICE POINT

SELF-DIAGNOSIS FUNCTION

DESCRIPTION

MALFUNCTION

SWITCH MONITOR FUNCTION

................................................

...........................................

HOSE ROUTING DIAGRAM

.......................................

........................................

......................................

.......................................

TURBO)

................

................................

.......

.................................

...................................

....................................

.................................

..................................

...........................

.......

....................................

...................

CODE

NUMBER

................

.............

....

'J7UOII

F1F1-

F1F1F1F1-10

F1-11

F1-12

F1-13

F1-13

F1-14

F1-15

F1-15

F1-16

F1-17

F1-18

F1-19

F1-20

F1-20

F1-21

F1-25

c,[11

2

2

4

8

9

•

Page 25

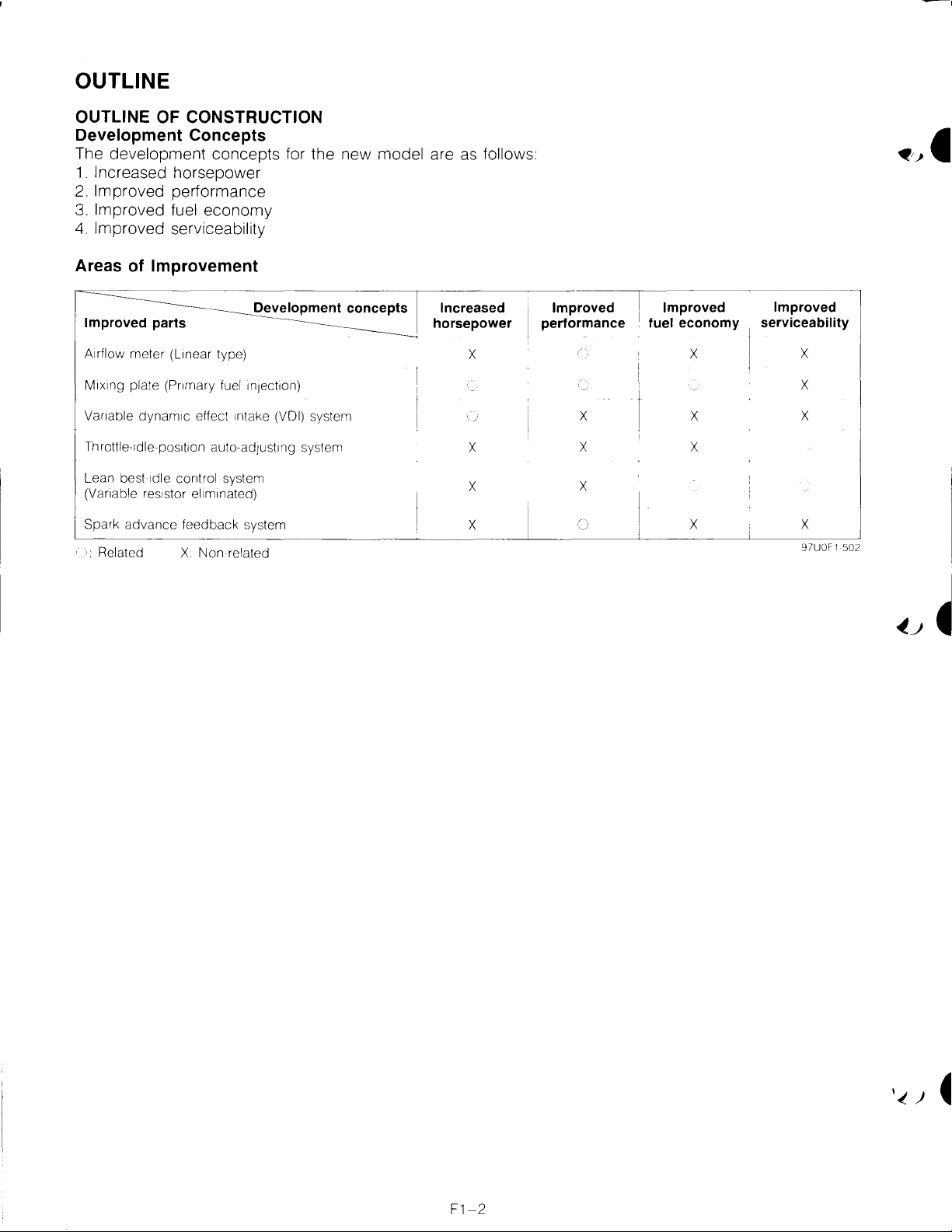

OUTLINE

OUTLINE OF CONSTRUCTION

Development

The

development concepts for the new model are

1.

Increased horsepower

2.

Improved performance

3.

Improved fuel economy

4.

Improved serviceability

Concepts

as

follows

Areas of

Improved parts

Airflow

M1x1ng

Vanable

Throttle-1dle-pos1t1on auto-adJUSting system

Lean best

(Vanable res1stor el1m1nated)

Spark

'.

Related X

Improvement

Development concepts

meter

(L1near type)

plate

(Pnmary

dynam1c effect 1ntake (VOl) system

1dle

advance

fuel

1nJ8ct1on)

control system

feedback

Non

system

related

Increased

horsepower

X

X

X

X

Improved

performance

X

X

X

Improved

fuel

I

I

economy

X

X

X

X

Improved

serviceability

X

X

X

X

97UOF1 502

Page 26

System Construction

ENGINE

CONTROL

UNIT

I

THROTTLE-IDLE-POSITION

AUTO-ADJUSTING SYSTEM

IMPROVED SERVICEABILITY

[AIRFLOW

IMPROVED

PERFORMANCE

METER]

SPARK ADVANCE

FEEDBACK SYSTEM

IMPROVED PERFORMANCE

LEAN BEST-IDLE CONTROL SYSTEM

MPROVED

MPROVED SERVICEABILITY

FUEL ECONOMY

--MIXING

'.CREASED HORSEPOWER

'.'PROVED PERFORMANCE

'.'PROVED

PLATE~~--,

FUEL ECONOMY

'

L____

97UOF1 503

F1-3

Page 27

EMISSION CONTROL SCHEMA TIC DIAGRAM

Input

Devices

OXYGEN SENSOR

ENGINE

CONTROL UNIT

(INCLUDES

ATMOSPHERIC

PRESSURE

SENSOR) i '

WATER

THERMOSENSOR /

PRESSURE

SENSOR

/'J

,../'

/

r,/'•'

THROTTLE SENSOR

(FULL RANGE)

THROTTLE SENSOR

(NARROW

~'

l·

.•

··y"'l

,

(o

;:((/

1

J

..

t',l

-\~v

'\\,

<~))

~

,-,

/'

).\

.-

/,

;J

. I

I

<""'

.,)

RANGE)

HEAT HAZARD

SENSOR

INHIBITOR SWITCH

(A/T)

IGNITION SWITCH

NEUTRAL SWITCH (M/T)

,,~L--,--------BACK-U

LIGHT

(MIT)

5TH

P

AND

SWITCH

AIRFLOW METER

(INCLUDES INTAKE

AIR

THERMOSENSOR) /

CRANK ANGLE SENSOR

F1-4

MILEAGE SENSOR

CIRCUIT OPENING

OIL PRESSURE

SWITCH

MAIN RELAY

RELAY

(A/T)

97UOF1-504

Page 28

Output Devices

SOLENOID VALVE

(BYPASS AIR CONTROL)

FUEL PUMP

RESISTOR

RELAY

INJECTOR

(SECONDARY)

/

DOUBLE

THROTTLE

DIAPHRAGM

DASH POT

.

~~

CHECK CONNECTOR

(GREEN: 3-PIN)

'.

I-::

VALVE

VALVE

AIR CONTROL

INJECTOR (PRIMARY)

SOLENOID

(ACCELERATED

WARM-UP SYSTEM)

PURGE CONTROL

VALVE

··~

/?

(\.

::;c-lEF

c _ENCER

::::

· =

:::n

AIR

CHAMBER

A/C

:..BLE

DYNAMIC EFFECT INTAKE

INDUCTION

RELAY

AIR PUMP

(PRESSURE REGULATOR

SOLENOID

CONTROL)

'A

VALVE

IGNITION COIL WITH IGNITER

(LEADING)

TEST CONNECTOR

(GREEN 1-PIN)

'~~~IGNITION

COIL

L I WITH IGNITER

SOLENOID

(RELIEF)

SOLENOID

(SWITCH)

CHECK CONNECTOR

(SELF-DIAGNOSIS

CHECKER, GREEN: 6-PIN)

VALVE

VALVE

(TRAILING)

F1-5

Page 29

Fuel Devices

TO FUEL FIL TEA

FROM PRESSURE REGULATOR

TO CHARCOAL CANISTER

-

------

FUEL TANK

CHARCOAL----I-CANISTER

CHECK CONNECTOR

(FUEL PUMP,

YELLOW: 2-PIN) ',...

PULSATION DAMPER

(WITH DELIVERY PIPE)

FUEL

PUMP~

RESISTOR

RELAY .

~

~

...

~-

nc-n

•

:-------'-·

-

Q(_

PRESSURE

(WITH DELIVERY PIPE)

"---

REGULATOR

INJECTORS

~

~~F-f-1'"-------1

G

F1-6

'.I

97UOF' 506

Page 30

Exhaust Devices

SPLIT

AIR

MAIN CONVERTER

FRONT CONVERTER

PIPE

INSULATOR COVERS

97UOF1 507

F1-7

Page 31

CJ)

-<

CJ)

-i

m

3:

c

)>

G)

::D

I

II

)>

3:

CJ)

T1

II

I

I

AIRFLOW METER

(INCLUDE INTAKE

THERMOSENSORI

AIR

.

i

if

~==~

~¢-'--~>..I/

PURGE CONTROL

VALVE

INTAKE AIR

THERMOSENSOR

I I

I~

I

!

SOLENiiD

(PRESSURE REGULATOR

I

~C~ON~T~R~O~L~)

VALVE 1

~~~~~---_j

1

FUEL PUMP

RESISTOR RELAY

EC AT CONTROL p

UNIT

<D

---J

Ell

§ REAR DEFROSTER SWITCH

01

SWITCHES HEADLIGHT SWITCH SWITCH IAiTI

FOG LIGHT SWITCH '¥""

~~-------------B-L_o_w_E_R--SW--IT_c_H

l

_____________________

INHIBITOR •

Q}(

'V I IV

,(\

M_A_,I_N~~C-~0_-N~V-~E--R~T-E-R-----------------------------------------------------------------F~U~E~l~~F~IL~T~E~R----------------------------__j

FRONT CONVERTER .

I CHECK VALVE TANK

I(\

- - -l==r-FUEL PUMP

OXYGEN

SENSOR

-~~~--.

'\I

¥-'

FUEL

l

;-=fT!-;?

r =

CHECK-AND-CUT VALVE

,...

Page 32

VACUUM HOSE ROUTING DIAGRAM

PRESSURE

REGULATOR

---------,

ACTUATOR

(VOl)

(

INTAKE

---"'RESSURE REGULATOR CONTROL

MAN IF OLD--tt--11--+--4+--+-

• ARIABLE

JYNAMIC

;:>QAT

"

EFFECT INTAKE

INDUCTION

\

\

~

SOLENOID VALVE

(VDI: WHITE)

SOLENOID VALVE

ORANGE)

(PAC:

SOLENOID

I (RELIEF BLUE)

SOLENOID VALVE

(SWITCH GRAY)

VALVE

FUEL FILTER

-

--;:

BODY (A/T)

F1-9

97UOF 1

007

Page 33

1N

PST

1(]

Q_T

VALV[

INJECTOR

(FRONT

PRII•t4.RYl

~

INJECTOR

(FRONT

SECONOAIIYl

0

!Gl

-El

INJECT()!;>

II?EAII

Pllltr.IAIIYJ

I

E

A 6

IYI

Q£0<:

(YELLOW:

iNJECTOR

I

REAR

SECONOMlYJ

CCHECT~

2--PINl

.

~

AIR

TI-EFMJ-

SENSrn

Lfi

~

Tf£Ml-

SENSOO

J]

POSITION

""'

SENS<f>

E}J

SENSOR

AIRFLOW

I£TER

c=-

~t---{a]~

~(GY)

SD....e«liD "'ALliE

(SWITOil

~-Ill

SCLENOIO

VALVE

fF£LIEF)

H(G)

~"'

CCHECTOO

GHEEN J P1N1

'-----f-++~---1SQEjjjl_NOIO

'-----+++~-liiil

~(0)

18YPA.SS AIH

POflT

AIR

SCLENOIO

16-PORT

SOlEI'<liO

•PRESSURE

VALVE

CON'HOL

'"'

SOLENOID

68

VALVE

INDUCTION

VALVE

REGULATOH

I

CONTROL!

sa...EN'liO

VALVE

I

>-I-

I

FUEL

PL'o!P

liES I STOll

RELAY

161

jh~

FAN

SWITO+

0

0

:~~:

:~~

:§§:

,,_,_,

•...:...:,

~

~-~

~

(R'

EC-A.T

TH~BmE

SENSOR

1NARROW

1-1ANGE•

~~J

TI-A:ITill

~~ANGE

~------+-~ra~~~

'------------jc---4JE

(ACCELERATED

~~w

SOLENJID

(VAAIABL.E

f--CF=

f--Dn

B

STEP

1MfTEHtNG

EFFECT

;--\

MOTORS

VALVE

DYNAMIC

INTAKE)

OIL

WARM-UP

PUMP

1MOP

SYSlEMt

1

m~--------------------------------------------------------------------------------------------------------------------------------------------------------------~

~

(J

•

Page 34

SPECIFICATIONS

Item

Idle speed (Test connector (green

A1r

cleaner Element type

Type

Throttle body

Dash pot

Fuel

tank

Fuel

f1lter

Pressure regulator

Fuel

pump

11ector

Secondary)

"leal

\,ja1n

(Pnmary and

hazard sensor

silencer

;;n1t1on

t1m1ng

(Test connector (green 1-pln) grounded)

J stnbut1on

advance

Spark

: e up system

= . :lass

a1r

control system

· afterburn valve Operat1on

Throat d1ameter i Pnmary mm

Water

thermovalve

Adjustment speed rpm

Capacity

Low pressure

High pressure _

Type

Regulated pressure

Type

Outlet pressure kPa (kg/cm

Dr1ve

InJeCtion

Operation temperature

Capac1ty cc (cu

Type

Type

A/C

"D"

range

Model

1-p1n)

grounded) rpm

Secondary

Operat1on temp.

l1ters

(US gal. Imp gal)

kPa (kg/cm

volume cc (cu ln)/15 sec. i

t1me

mm

oc

2

2

oc

(In)

(1n)

(oF)

,

ps1)

,

ps1)

(°F) i

in)

rpm

rpm

sec.

138

EGI

750 ± 25 (for AlT

Long

Honzontal - draft

45 (1.772)

(1

45

M/T.

67-77

A/T

60-70

Nylon

235-275

441-588

MIT 10.300 (628.3) x

Lead1ng

Tra1l1ng

(153-171)

(140-158)

2,700-3.100

70 (18.5, 15.4)

6 (164 and 45 mesh)

F1lter

D1aphragm

(2.4-2.8,

Impeller

(4.5-6

Voltage dnve

111-118

105-115

20° ± 2°

Eng1ne

Eng1ne

MIT. 875 A/T 800

750

(at warm

L1near

MIT

AlT. 0

engine

..

N Range)

l1fe

wet

(2

slaj:l~---

772) X 2

paper

34.1-39

(1ntank)

0,

64.0-85

(6.8-7.2)

(221-239)

2,

A/T

5°

± 1 o ATDC

control

control

1.60-2.20

un1t

un1t

eng1ne)

soleno1d

52-0.92

3 barrel)

or more

or more

8)

3)

12.000 (732) x 2

ATDC

97UOF1 511

F1-11

Page 35

VARIABLE DYNAMIC EFFECT INTAKE (VOl) SYSTEM

~.-

s systern cors.sts of the VOl valve, solenoid valve, and actuator. The

.

~

::::

Ooerat

-OeENGINE

~=EED

on

of

th1s

system

OPEN V %

~

,

·.

is

as shown below.

~

0

HIGH ENGINE SPEED J

(VDI VALVE: OPEN CONDITION)

VOl

valve

is

built into the exten mani-

VDI VALVE

= INTAKE AIR

·~

PRESSURE WAVE

•

co...,

I

..

.....

• • • PRESSURE WAVE

ABOVE

5,200

::

:.·,.;

ANGLE SENSOR

:

-::~;Jine

:

·-::::s~re

~~-::speed,

.

::: . ::

·· . ::

:·-::

,·

;:::s

operation, when intake air flows to a port closed by the rotor a pressure wave

wave then goes toward the open intake port, compressing the intake air along the way.

the VOl valve

. e opens and the pressure wave quickly pressurizes the intake air through the shortened path.

'::xced

c-essunzation

1nto

remaining

VDI VALVE

OPENING

AREA

LARGE

rpm

_______

INTAKE AIR

AMOUNT

is

closed, causing the pressure wave path to be long. At high engine speed,

the combustion chamber

is

induced at the time of the opening of the intake port, when the high-pressure

in

the working chamber generates strong pressure waves that rush into the intake

at

all

engine speeds.

(m1/h)

SMALL~--------~------~

0

ENGINE SPEED

JI

5,200 8,000

(rpm)

97UOF1

is

created.

509

At

F1-12

Page 36

FUEL SYSTEM

MIXING PLATE

INJECTOR

SECONDARY

INJECTOR

AIR

SOCKET

BLEED

AIR

BLEED

SOCKET

· 19 plate

·

:J.ke

air port.

97UOF2-508

is

installed at the tip of primary Injector to direct the primary fuel inJection fuel directly into

F1-13

Page 37

SERVICE POINT

PULSATION

®----INSULATOR

NEW 0-RING

~======s~~----AIR

INTERMEDIATE

HOUSING

'---"

~MIXING

BLEED SOCKET

PLATE

~·

MIXING PLATE

The pr1mary inJector

1 Install the parts

2 Use a new

3

A1

gn 1re 1abs

in

Insulator and 0-rings.

of

NOTCH

is

installed noting the following:

the order shown

the mixing plate with the notches

in

the figure.

F1-14

TAB

in

the intermediate housing.

'UDF2 509

~··

Page 38

CONTROL SYSTEM

AIRFLOW METER

SLIDING CORE

INTAKE

THERMOSENSOR

AIR

~

CONNECTOR

I

AIR BYPASS

PASSAGE

INTAKE AIR

THERMOSENSOR

t

AIRFLOW METER

t

~-.

-~

eter

-

:

Jn.

97UOF2-513

is

changed from a vane type to a linear type. The sliding core moves parallel to the airflow

there

is

little air damping and low air resistance

as

a result of the streamlined shape.

F1-15

Page 39

THROTTLE-IDLE-POSITION AUTO-ADJUSTING SYSTEM

· · · SENSOR OPEN

~·

NARROW

FULL

RANGE

NARROW

FULL RANGE

RANGE

RANGE

SENSOR

CLOSED

(0%)

150/o

SENSOR

OPEN (100%)

I

: APPROX.

I

SENSOR CLOSED

AUTO-ADJUSTING

___..~

300/o

SENSOR CLOSED

SENSOR OPEN

AREA

SENSOR

OPEN (100%)

50/o

.:.

··e:.ly

developed

-· ~ system automatically

.:. · =:

e

tre

narrow range throttle sensor

:

=:::on

·

.:: S-::

~:::erat1on

c.·

,

auto-adJUSting system, the eng1ne control unit will compensate for actual output values of

···

e output

respectively for fail-safe operation

:;;

~e

:::

25° o respect1vely for fall-safe operation.

is

for the full range sensor

control

throttle-idle-position auto-adjusting system

less than

un1t

15%

compensates

I~

I~

:

THROTTLE AUTO-ADJUSTING AREA

IDLE

POSITION

compensates

or

more

within the range from

250/o

~'

for certain variations

is

set to

output

than

25%

at idle, the engine control

is

the same. The sensor

is

in

a signal of

is

set to reg1ster a

5%-25%.

850/o

I

FULL

THROTTLE

97UOF2 514

incorporated

the output signal of the throttle sensors .

20%

w1thin

of full-open. With the throttle idle-

the engine control unit.

15%-25%.

un1t

If

over or

fixes the value

15°/o

s1gnal

under

the s1gnal1s fixed at

at

at

1dle,

15%

and the

and

5%

\.!.

F1-16

Page 40

LEAN BEST-IDLE CONTROL SYSTEM

WATER THERMO

INHIBITOR

SWITCH

(A/T )

SENSOR

EC-AT

CONTROL

UNIT

~

rL

NEUTRAL SWITCH (M/T

CLUTCH

PiS PRESSURE SWITC

:::EAR DEFROSTER SWITCH

SWITCH (M/T

A/C SWITCH

BLOWER SWITCH

HEADLIGHT SWITCH

FOG LIGHT SWITCH

(ONLY

CANADA

)

)

H

)

I

~

---c:

=

~~LE

SENSOR (NARROW

RANGE)

ENGINE CONTROL UNIT

DETECTION OF ENGINE

WARM CONDITION

DETECTION OF ENGINE

NO-LOAD CONDITION

(ONLY FOG LIGHT SWITCH:

DETECTION OF

ENGINE LOAD CONDITION)

--

DETECTION OF ENGINE

IDLE CONDITION

t

~

DETERMINA-

TION

LEAN BEST-

~

f-

IDLE

CONDITION

OF

I

FUEL

INJEC-

TOR

BATTER

y

re

--o ••

• ANGLE SENSOR (NE

. _

-::j

fuel consumption and reduced exhaust emissions

·.V1th

this system, the engine control unit sets fuel injection

- .

:;1ng

lean misfire and rough idle.

SIGNAL)

DETERMINATION OF LEAN

BEST-IDLE AMOUNT

at

idle, the lean best-idle control system

F1-17

K

97UOF2-515

at

idle to the leanest amount possible

is

Page 41

SPARK ADVANCE FEEDBACK SYSTEM (ENGINE AT IDLE)

SPARK

ADVANCE

FEEDBACK

AMOUNT

DETECTION OF

ENGINE IDLE

THROTTLE SENSOR

(NARROW RANGE)

CONDITION

1

I

-50-------------~------~----

oo

- - - - - - - - -,..---'--'

I

1

I

CRANK

SENSOR (NE SIGNAL)

ANGLE

DETERMINATION

OF

ADVANCE

SPARK

FEEDBACK

AMOUNT

I

IGNITION COIL

'

RS

rpm

DECREASED

TS:

RS:

TS

TARGET ENGINE SPEED

REAL ENGINE SPEED

RS

INCREASED

rpm

To

prevent rough idle caused by incorrect idle speeds, the spark advance feedback system controls the

spark advance. The engine

tion

timmg to

obta1n

the preprogrammed target speed

control unit judges the engine speed (real speed:

(TS).

RS)

and then adjusts the igni-

F1-18

LJ7UOF2

516

Page 42

SERVICE POINT

THROTTLE SENSOR ADJUSTMENT

IDLE MIXTURE ADJUSTMENT

/

.....

__________________________

::::' adJUStment: Not usually necessary unless throttle sensor unit

auto-adjusting system automatically compensates.

~

JJustment

Not

necessary because of lean best-idle control system. (Varrable

eliminated.)

F1-19

is

replaced.

_

Th

rottle-rdle-pos ~ :::

res

~-

~

=-

Page 43

SELF-DIAGNOSIS FUNCTION

DESCRIPTION

When troubles are suspected

Failures of individual input and output devices are indicated and retrieved from the control unit as malfunc-

tion

code

numbers.

Note

The control unit constantly checks for malfunction of the input devices.

tion of output devices only during a 3-second period after the ignition switch has been turned

ON

while the test connector

in

the

ma1n

is

1nput

devices or output devices, check for the cause with the SST.

grounded.

It checks for malfunc-

IGNITION COIL

WITH

IGNITER---

(TRAILING SIDE)

~JE~~~~::LEJ~~-~

CRANK ANGLE '

SENSOR (G-SIGNAL)

~

_

---.

---,

FAIL-SAFE

FUNCTION

_L

WATER

THERMOSENSOR

AIRFLOW~

METER

INTAKEAIR

THERMOSENSOR

(AFM)

INTAKE AIR

THERMOSENSOR /

(ENGINE)

~~

~

\)

~

~

--

/

DETECTION

OF

MALFUNCTION

WARNING

FUNCTION

&

MALFUNCTION

CODE

FUNCTION

-

-

-=-

~

~

Wu~~~~:GE;-1

~

THROTTLE~

SENSOR Q

(NARROW-RANGE) .

PRESSURE--SENSOR

OXYGEN

METERING

PUMP POSITION c o

SENSOR o

SENSOR-\

OIL--~~1._

-~---·-

-

·-

1

- o

.__/

-~

-----'

ATMOSPHERIC

PRESSURE

SENSOR

TEST CONNECTOR

(GREEN: 1-PIN)

F1-20

97UOF2-024

Page 44

MALFUNCTION CODE NUMBER

SST

Jg H018

3elf-Dragnosis

Checker

9A1

SHF

UIAGIIlSrS

97UOF1-512

CHfClER

Inspection Procedure

1.

Warm

stop

2.

Connect the SST to the check connector (Green: 6-pin) and

the negative battery

Set the select switch to position

3.

Connect a jumper

1-pin)

up

the

engine

it.

and a body

to normal

operating

terminal.

A.

wire between the test

ground.

temperature

connector

(Green:

and

,..

• • I

I~

:: :

J.AGNOSIS

~-,

11\T/"

• G

·1cr1:o:

G/

1_1.11_1!

0

~-,'-[-\-'---\-'-

SElF

--~

DIAGNOSIS

~

CHECKER

MALFUNCTION

V CODE NUMBER

::111-:1/

--

--

CHECKER

97UOF1

97UOF1

514

510

4.

Turn the ignition switch ON.

5.

Check

sounds

6.

If

7.

If

than 20 sec.,

control unit

And

voltage. Replace

88

88

that

88

flashes on the digital display

and

the buzzer

for 3 sec. after turning the ignition switch ON.

does

flashes

check

not flash,

and

check

(1

F)

the

check

the buzzer

the

check

sounds

continuously for

for a short circuit between the

terminal and

engine

the

check

control unit

engine

control unit

connector (Green: 6-pin).

(3X)

connector

and (3Z) terminal

if

necessary

perform Step 4 again.

8.

Check

9.

Start the

for any malfunction

engine

and

check

code

numbers.

for further malfunction

numbers.

10.

If

a malfunction

cause of the

code

problem.

number

is

indicated,

check

Note

Cancel the malfunction code numbers by performing

the after-repair procedure

following repairs.

F1-21

wiring.

more

engine

and

code

for the

Page 45

Principle of code cycle

Malfunction codes are determined

1.

Malfunction code cycle break

The time between malfunction

as

below by use of the MIL and Self-Diagnosis Checker

code

cycles

is

4.0 sec. (the time the MIL and checker buzzer are off).

97UOF1-515

1 CYCLE

ON

OFF

MALFUNCTION CODE

CYCLE

4.0 SEC.

2. Second digit of malfunction code (ones position)

The digit

are on

in

the ones position of the malfunction code represents the number of times the MIL and buzzer

0.4 sec. during one cycle.

4

0.4

~---~

MALFUNCTION

CYCLE BREAK

4.0 SEC.

1 CYCLE CODE

ON

JU\fl"

OFF

-1--!-

0.4

SEC. SEC.

BREAK

ffilll

-----

9MUOF 1

543

CODE No.: 03

89lll!4X

565

3. First digit of malfunction code (tens position)

The digit

are on 1

The MIL and buzzer are off for 1.6 sec. between the long and short pulses.

in

the tens position of the malfunction code represents the number of times the MIL and buzzer

.2

sec. during one cycle.

1 CYCLE

;-----~----.,

FIRST DIGIT SECOND

1.6 4.0 SEC.

SEC.

MALFUNCTION

CODE

CYCLE

BREAK

DIGIT

F1--22

CODE

No.

89U04X

22

566

Page 46

Code number

Caution

a)

If there

is

more than one failure present, the lowest number malfunction code

first, the subsequent malfunction codes appear

b)

After repairing

ble,

at least 5 seconds to erase the malfunction code memory.

In

put devices

all

failures, turn the ignition switch OFF, disconnect the negative battery ca-

in

order.

is

displayed

Code

No.

l'

:2

devices

Input

lgn1110n

with

(Trail1ng

Crank angle sensor Broken

(Ne

coil

1gn1ter

s1de)

s1gnal)

Malfunction

plug. broken

ClfCUit

c1rcuit

Malfunction

of spark

w1re.

w1re.

short

short

Fail-safe function

T

rail1ng-s1de

pulse cut

Fuel

InJeCtion

1 lion cut

1gn1t1on

and

1gn1-

Output signal pattern

(Self-Diagnosis Checker or MIL)

Jl

I

angle sensor Broken

Crank

(G

s1gnal)

ClfCUit

short Fuel InJection and

w1re.

t1on

cut

1gn1

I

Bas1c

A1rflow

meter (AFM) Broken

Water thermosensor

a1r

Intake

'll

t

thermosensor (AFM)

;ntake

a1r

sensor

Throttle

1Full

Pressure sensor Broken

:

·1take

:Yessure)

-'ltmosphenc pres-

~u

Built

J x ygen sensor

:-

eedback system

-

· •ottle sensor

.arrow range)

'.'eter1ng

· -s,t,on sensor

·

.'

.c:enng

'.'8P)

·.·-:c-:er

'.':JP)

thermo- Broken

(Eng1ne)

sensor

range)

man1fold

re

sensor

(A

ECU)

oil

oil

oil

TP)

pump

pump

pump

1n

:1g

ClfCUII

Broken

ClfCUI!

Broken

ClfCUit

ClfCUit

Broken

ClfCUit

ClfCUII

Malfunct1on1ng ECU

Oxygen

below 0 55V

system

operat1on

Oxygen

ma1ns 0 SSV

system

operat1on

Broken

circuit

Broken

CirCUit

Malfunct1onmg

tors.

broken

or

malfunct10n1ng

Malfunct

on1ng

broken

111re.

1

t:on.ng

ECU.

short

w1re.

w1re.

short

short

w1re.

w1re.

short

short

w1re.

short

w1re.

sensor

output

rema1ns

80

sec

aher

beg1n1ng

sensor

output

· 0

sec

after

begm1ng

short Throttle valve open1ng

w1re.

short

w1re.

MOP.

steo

w1re.

short

ECU

MOP.

step

srort c rcu

t.

rralfunc-

alter1ator

or

'

1

FiB

re

FIB

mo

c1rcu1t

,"lotors

battery

fuel InJection

amount and

t1m1ng

Coolant temp. input

f1xed

Intake

f1xed

Intake

f1xed

Throttle valve open1ng

angle input signal

at

20%

Intake

1nput

mmHg (29.9 inHg)

Atmospheric pressure

1nput

760

mmHg

Feedback system canceled (For EGI)

Feedback system canceled (For EGI)

angle

at

full open

MOP

f1xed

Bas1c

and

1Qn1t1on

MOP

Bas1c

and

1Qn1t1on

Basic fuel

amount and ignit1on

t1m1ng

F1-23

f1xed

at

80°C

a1r

temp.

at

20°C

a1r

temp.

at

20°C

open

man1fold

s1gnal

s1gnal

1nput

smallest

fuel

1nJect1on

f1xed

smallest

fuel

1nj8ct1on

InJeCtion

fixed

1gn1!10n

(176°F)

(68°F)

(68°F)

pressure

f1xed

f1xed

(29.9

s1gnal

t1m1ng

tmng

1nput

1nput

at

amount

f1xed

amoun:

f1xed

f1xed

760

at

1nHg)

f1xed

open

open

..

llll

n

fU

Jll

J1l

run

JUI

rull

JUII[

i

m

Jrull

ImJII

97UOFI-516

Page 47

Output devices

Code

No.

25

! Soleno1d valve (Pressure regulator control (PRC))

I

26

Step motor (Metenng oil pump)

1

I

I

I

f Split air solenoid valve

30

I

I

31

Soleno1d valve

j Soleno1d valve

32

Output devices

(Rel1et)

(Sw1tch)

I

Port

a1r

33

34

Soleno1d valve

soleno1d valve

(Bypass

a1r

control)

I

-

~---

1

Soleno1d valve

38

40

Soleno1d valve (6-port

41

Soleno1d valve (Vanable dynam1c ettect 1ntake (VOl))

51

I Fuel

pump

71

Injector

73

InJector (Rear secondary)

(Accelerated warm-up system (AWS))

1nduct1on)

res1stor

(Front secondary)

relay

97UOF1

'-I

517

F1-24

Page 48

SWITCH MONITOR FUNCTION

Preparation

SST

i 49 H018

•

Self-D1agnos1s

· Checker

Individual switches can be monitored by the SST.

19.

9A1

Note

The test connector must

NEUTRAL SWITCH

CLUTCH SWITCH

BACK-UP LIGHT

5TH SWITCH (M/T)

HEADLIGHT

BLOWER

REAR DEFROSTER

SWITCH

FOG LIGHT

INHIBITOR SWITCH

SWITCH---------+---------'

(IF EQUIPPED)

r-.

~

,-,~~-:J

I I I I

1

S!

t:

~IAGJlO~IS

~~~E~K!R

97UOF2 064

BATTERY

(M/T)-------1------------,

(M/T)--------+--------,

AND--------~------~~~~

SWITCH-----------11----------'

________

SWITCH--------:::::;~~=====~----t--.....,.

(A/T)'----------1

be

grounded and the ignition switch

ENGINE CONTROL UNIT

-+------~

ON

(engine stopped).

~~CTOR

IQIIUII:ftll

:1

517

97UOF2066

,..

Inspection Procedure

1.

Warm up the engine to normal operating temperature:::·

stop

it.

2.

Connect the SST

the negative battery terminal.

3.

Connect a jumper wire between the test connector (G';:c-

1-pin) and a ground.

4.

Turn the 1gnition switch ON, then check that the me·

lamp illuminates

cording to the function table.

Caution

a)

When any one of the switches are activated, the

monitor

b)

Do

lamp will be on.

not start the engine.

(GREEN: 1-PIN)

to

the check connector (Green:

when each switch

is

made to funct,c·-

6-pir'

::·

97UOF1 519

F1-25

Page 49

Function Table

Switch

Neutral sw1tch (MIT)

Back-up light

5th

SWitch

Clutch

lnh1b1tor

Headl1ght

Blower sw1tch

and

(MIT)

switch (MIT)

sw1tch (A/T)

sw1tch

Self-Diagnosis Checker (Monitor lamp)

Lamp-ON Lamp-OFF

Sh1ft

1.2.3or4

Sh1ft

5th

1

Pedal

Except

range

Sw1tch

Sw1tch

(At

OK)

gear

any

transmiSSIOn to

transmiSSIOn

depressed

N and P

ON

ON

fan

speed

Neutral

Neutral

Pedal released

N

Sw1tch

Sw1tch

and

pos1t1on

pos1t1on

P range

OFF

OFF

Possible cause

(When incorrect)

• Neutral sw1tch malfunction

•

Open

wcu1t

between neutral

ECU

1R

term1nal. neutral

ground

•

Back-up

Open

•

5th sw1tch

and

• Clutch sw1tch malfunction

•

Open

ECU

ground.

1 •

lnh1b1tor

! • EC-AT control

Open

•

and

Headlight

•

Open

•

ECU

tery

•

Blower

Heater relay malfunction

•

Heater control

•

Open

•

and

l1ght

and

5th sw1tch malfunction

circuit between

and

ECU 1 T term1nal.

ground

c1rcu1t

between clutch sw1tch

10

term1nal. clutch sw1tch

clutch switch

switch malfunct1on

ur11t

malfunct1on

C1rcu1t

between EC-A T control

ECU.

sw1tch malfunction

c1rcu1t

betweer1 headl1ght

3L

terminal, headl1ght sw1tch

l1ne

sw1tch malfunct1on

un1t

malfunction

c1rcu1t

ECU

between heater control

30

term1nal

sw1tch

Back-up

and

ACC

sw1tch

and

l1ght

overdnve

and

circuit

sw1tch

and

and

and

un1t

and

un1t

and

bat

Rear defroster sw1tch

Fog

l1ght

sw1tch

(If equ1pped)

Sw1tch

1

Sw1tch

(Only

light)

ON

ON

equip

fog

i Sw1tch OFF

Sw1tch

OFF

• Rear

i •

1

1

• Fog

•

defroster

Open

c1rcu1t

and

ECU 3P term1nal. rear defroster sw1tch

and

ground

l1ght

sw1tch malfunction

Open

c1rcuit between fog

ECU 1 S term1nal. fog

battery

sw1tch

malfunction

between rear defroster sw1tch

l1ght

switch

and

l1ght

switch

and

97U0r

I 5?0

F1-26

Page 50

FUEL AND EMISSION

CONTROL SYSTEMS

(TURBO)

F2

20

OUTLINE

OUTLINE OF CONSTRUCTION

EMISSION

DIAGRAM

SYSTEM DIAGRAM

VACUUM

WIRING DIAGRAM

SPECIFICATIONS

FUEL SYSTEM

MIXING PLATE

SERVICE POINT

TURBOCHARGER CONTROL SYSTEM

SYSTEM CONSTRUCTION

COMPLETELY-IN

TWIN SCROLL TURBO

TURBO

SYSTEM

CONTROL SYSTEM

AIRFLOW METER

THROTTLE-IDLE-POSITION AUTO-

ADJUSTING SYSTEM

LEAN BEST-IDLE

SPARK

SERVICE POINT

SELF-DIAGNOSIS FUNCTION

DESCRIPTION

MALFUNCTION

SWITCH MONITOR FUNCTION

................................................

................

CONTROL

...........................................

HOSE ROUTING DIAGRAM

........................................

......................................

BOOST PRESSURE

.............................................

ADVANCE

.......................................

SCHEMATIC

................................

.................................

...................................

....................................

......................

DEPENDENT

.........................

CONTROL

.................................

..................................

...........................

CONTROL

FEEDBACK

....................................

CODE

SYSTEM

SYSTEM

...................

NUMBER

................

.............

.......

.......

.......

....

F2F2-

F2F2F2F2-10

F2-11

F2-12

F2-12

F2-13

F2-14

F2-14

F2-15

F2-16

F2-17

F2-17

F2-18

F2-19

F2-20

F2-21

F2-22

F2-22

F2-23

F2-27

97UOF 2 501

2

2

4

8

9

,.

Page 51

OUTLINE

OUTLINE

Development

OF

CONSTRUCTION

Concepts

The development concepts for the new model are

1.

Increased horsepower

2.

Improved performance

3.

Improved fuel economy

4.

Improved serviceability

Areas of Improvement

Improved parts

Airflow meter (L1near type)

M1x1ng

plate (Pnmary fuel InjeCtion)

Completely-independent

Duty solenoid valve

(Turbo boost pressure control system)

Throttle-idle-position auto-adjuSting system

Lean best-Idle control system

(Vanable resistor elim1nated)

Development concepts

twin scroll turbo

Increased

horsepower

as

X

0

()

C)

X

X

follows:

Improved

.

performance

I

'-

0

X

X

X

X

Improved

fuel

economy serviceability

X

('

J X

X X

X

X

.~\

,j

Improved

X

X

C)

0

Spark

U•

advance

Related

feedback

X Non-related

system

X

0

X X

97UOF2 502

~·

F2-2

Page 52

System construction

LEAN BEST-IDLE CONTROL SYSTEM

IMPROVED

IMPROVED SERVICEABILITY

FUEL ECONOMY

THROTTLE-IDLE-POSITIO;J

AUTO-ADJUSTING SYSTEM

IMPROVED SERVICEABILITY

--SPARK

FEEDBACK

IMPROVED PERFORMANCE

ADVANCE

SYSTEM

DUTY SOLENOID VALVE

.-----MIXING

INCREASED HORSEPOWER

IMPROVED PERFORMANCE

IMPROVED

PLATE---

FUEL ECONOMY

~.

F2-3

[COMPLETELY-INDEPENDENT TWIN SCROLL TURBO

INCREASED HORSEPOWER

97UOF2 503

J

Page 53

EMISSION CONTROL SCHEMATIC DIAGRAM

Input

Devices

INTAKE AIR

THERMOSENSOR

(ENGINE)

NEUTRAL SWITCH

IGNITION SWITCH

ENGINE CONTROL UNIT

(INCLUDES

ATMOSPHERIC

PRESSURE

SENSOR) •

~

~-

PRESSURE /

SENSOR

AIRFLOW METER

(INCLUDES INTAKE

AIR THERMOSENSOR)

~\")

"··!

,VATER

THERMOSENSOR

~

·5-Jt.

'

. " ·

..

:~

··-~c-~.

•

' '

:1•

\ ..

1

CRANK

ANGLE

·'

~·

·'(<)

KNOCK

~

SENSOR

CLUTCH

SWITCH

11.!

''

• P/S PRESSURE SWITCH

/

II''/

iff,~~

i'l/~

I,

-J

:I

BATTERY

SENSOR

TEST CONNECTOR (GREEN

MILEAGE SENSOR

(No.1 AND No.2)

1-PIN)

F2-4

97UOF2 504

Page 54

Output Devices

INTERCOOLER

,.

- = CONTROL VALVE

INJECTOR

SOLENOID

(AIR SUPPLY VALVE

DASH

DOUBLE

DIAPHRAGM

PURGE CONTROL

~CHECK

(GREEN: 3-PIN)

~~

VALVE

POT

THROr

~

CONNECTC=

VAL.

_o:

0:

'504

~.

':"SILENCER

AIR CHAMBER

AIR PUMP

/

IGNITION COIL WITH IGNITER (LEADING)

F2-5

DUTY SOLENOID VALVE

(TURBO BOOST

CONTROL)

"'SOLENOID

REGULATOR CONTROL)

SOLENOID

CHECK CONNECTOR

(SELF-DIAGNOSIS CHECKER,

VALVE

VALVE (SWITCH)

PRESS~=::

(PRESSU~O:

GREEN ~ -

Page 55

Fuel Devices

•

PRESSURE REGULATOR

(WITH DELIVERY PIPE)

CHARCOAL CANISTER

F2-6

/

/

Page 56

•

Exhaust Devices

MAIN SILENCER

:R

=>E)

1

(

SPLIT AIR PIPE

-~"BOCHARGER

MAIN CONVERTER

FRONT CONVERTER

INSULATOR COVERS

J6

l

F2

7

Page 57

MILEAGE SENSOR (No 1

BACK-UP LIGHT

INTAKE AIR

-n

f'\)

I

(X)

PIS

HEAT

MOP

POSITION SENSOR

WATER

THROTTLE

PRESSURE

CRANK

CIRCUIT

REAR DEFROSTER SW

AND

PRESSUA~C

HAZARD

SENSOR

CLUTCH

NEUTRAL

FOG LIGHT SW

AND

5TH SWITCH

AIRFLOW

OXYGEN

SENSSR

THERMOSENS

SENS8R

SENS

THERMOSENS8R

KNOCK

SENS

ANGLE SENSOR

OPENING

HEADLIGHT SW.

BLOWER

CANADA

STAR~TER

D

No

~~

SW

METER

RELAY

SW

SW.

SiGNAL

0

~

2)

SW

R

R

R

~

RELIEF SILENCER

ECU

SELF-DIAGNOSIS

CHECKER

TEST

CONNECTOR

!GREEN

1-PIN)

~

(J)

-<

(J)

-i

m

s::

c

)>

C)

::::0

)>

s::

I

[I

(

FUEL

PUMP

Page 58

-n

1'\.)

I

c.o

'

-

SULlNUID

(ACCELELA TED WARM-UP SYSTEM)

VALVE:

L VALVE

FUEL TANK

<

)>

0

c

c

s::

:I:

0

CJ)

m

JJ

0

c

-i

z

G')

c

)>

G')

:0

)>

s::

CHECK VALVE

(ONE-WAY)

L

FIL TEA (HIGH PRESSURE)

Q) SOLENOID VALVE

CD

§

@SOLENOID

-n

rv

@

:::;

3 SOLENOID VALVE

WAS

ACTUATOR

(SWITCH)-GRAY

VALVE (PRESSURE REGULATOR

(RELIEF)-BLUE

TE

VALVE

CONTROL)-ORANGE

DUTY ENOID VALVE

(TURBO BOOST PRESSURE CONTROL)

'~~--------------------------------------------------------------------~

Page 59

P/5

P~ESSUAE

~

ONLY

CANADA

NEUTRAL

SACK

UP

SWITCH

LIGHT

5TH

TEST CONNECTOR A ( HEUTIIAL ON)

(GREEN:

1-PIN)

SWITCH

AND

SW I TOt

PST

(l_T

~

~

1;3

~~

~ ~

~2

~

~

3

~

~a~~~~~

l*l*l:.l~li!il

u

8

[i]

~~u

3~33

~~~

~

~ ~

~~

1~1~1~1:;:1

~

0~~

·"·

~~~~~

~

~i~~

~l:;:lii!l\il«i

:E

:a

z

G)

c

)>

G)

:a

)>

s::

~

~

~~~~~~

H~H~~~~~~

j;:;j.iil:;;l~~~i!i~lii!~liiil;ll

~

>

.,

~

\

"Tl

N

~

0

II

~

(N_y

CANADA

I

IGl

STARTER A 8 (Y)

AI...

TEJ=HAT(J:l

MALFUNCTION

INDICATOR

LANP

G3

~l

21

... , ·-

u

~

:t

~

~~

~ffi ~ ~

~~ ~~

~U)

::!'

[/)

·~

~

INJECTOR

(FRONT

SECONDARY)

Q£0<

(YELLOW;

I

NJECTOII

<REAR

SECONDARY)

CCN£CTOO

2-piNJ

i~

~h~

g~

~~

-:'

~

........

,...,..,

"""'

''I

!II

!I

~

FUEL

PLNP

RESISTOR

RELAY

(B)

h

FAN

SWITCH

~

~

c

0

~

N

6

0

~

INTAKE

AIR

T>£FM>-

SENSrn

WATER

~(L

II~-

c

"b:

A

...,

POSITION

flJ

AIRFLOW

I£TER

TI-AJTTLE

5ENSCf1

(N.lR"OW

RAta

I

~

THROTTLE

'3ENSOR

1F'JLL

RANGEl

(GY)

SOLENJIO

VALVE

(SWITCH)

SOLENJIO

VALVE

(FB.IEF)

'"'

PORT

AIR

SOLENOID

VALVE

t=u

DUTY

SOLEI'fJIO

VAL

BOOST

181

ID

PFESSIJE

VALVE

RfGULAT()f'l

VALVE

,AL\/f,

liE

I'Tl.RKl

i=::LJ(OI

SOLENOID

,PRESSURE

SOLENJ

,Aifl

')LIPPL•

~

:•H

"Fd-

--

STEP

MOTORS

!METERING

OIL

PU'v1P

r'IAOP))

CCNTROLJ

C()NTHCll

s•s

TE~1

OOL---------------------------------------------------------------------------------------------------------------------------------------------------------------~

(

~o..

~

Page 60

SPECIFICATIONS

Item

Idle

speed

(Test connector (green

A1r

cleaner r Element

Throttle

Dash pot

Turbocharger

Waste gate

Fuel tank

Fuel filter

Pressure regulator

f'uel

irld

--1eat

\1a1n

'J

S:Jark

-~

body

[ Lubncation

valve

f Capactty

pump

''Jector (Pnmary

Secondary)

hazard sensor

silencer

Jn1t1on

t1m1ng

(Test

connector

stnbut1on Type

advance

-:

e

up

system A/C

·1t1-afterburn valve

·:ercooler

Model

1-p1n)

grounded)

type

Type

Throat d1ameter

Water

thermovalve

Adjustment (Throttle sensor (narrow

range)

res1stance A·-r'El)) k\!

Type

Boost pressure kPa (kg/cm

Type

Type

Regulated pressure

Type

Output pressure kPa (kg/cm

Dnve

InJeCtion

Operat1on temperature

Capac1ty

Type

Operat1on

Type

volume

(green 1

t1me

--

·-

Primary

Secondary

Operation temp.

l1ters

(US gal, Imp gal)

1

1

Low

H1gh

kPa

cc

(cu ln)/15 sec

p1n)

grounded)

rpm

mm

(1n)

mm

(1n)

oc

(oF)

2

ps1)

,

pressure

pressure

(kg/cm2 ps1)

2

ps1)

,

oc

(°F)

cc

(cu

1n)

rpm

sec

138

Turbocharged engine

750 ± 25

l1fe

Long

Honzontal draft

45

45

55-65

Incorporated

235--275

490-637

1

(131-149)

Water cooled

57.0 (0.58, 8.25)

Engine

70 (18

Nylon 6 (164 & 45 mesh)

F1lter

D1aphragm

(2.4--2.8,

Impeller (In-tank)

(5

Voltage dnve

133

-142

105-:15

12.000 (732) X 2

Leading 5u ± 1 o ATDC

Tratl1ng

Eng1ne control

Eng1ne control

1.60

A1r

~~~

wet

(2

stage-3 barrel)

(1

772)

(1

772) X 2

1.8-3.8

oil

w1th

turbocharger

5,

15.4)

paper

0-6.5,

(8.1-8.7)

(221

20" ± 2°

800

-2.20

cooled

or

34.

1-39.8)

71

1-924)

-239)

ATDC

un1t

un1t

more

97UOF? 519

,..

F2-11

Page 61

FUEL SYSTEM

MIXING PLATE

•

PRIMARY INJECTOR

A mixing plate

the intake air

PRIMARY INJECTOR

is

installed

port.

at

l b

J~

97UOF2 508

the tip of primary injector to direct the primary fuel inject1on fuel directly into

F2-12

\..··

Page 62

SERVICE POINT

NEW

PULSATION DAMPER

0-RING

2

508

into

l-1-----AIR

~----------MIXING

INTERMEDIATE

HOUSING

BLEED SOCKET

PLATE

MIXING PLATE

NOTCH

·

"lary

injector

·::

the parts

-'

"'

new insulator and 0-rings.

is

installed noting the following

in

the order shown

in

the figure.

:he tabs of the mixing plate with the notches

F2-13

TAB

in

the intermediate housing.

Page 63

TURBOCHARGER CONTROL SYSTEM

SYSTEM CONSTRUCTION

INTERCOOLER

SOLENOID

DUTY

•

FRONT ROTOR

AIR CLEANER

TURBOCHARGER

EXHAUST MANIFOLD

(COMPLETELY-INDEPENDENT

TWIN SCROLL TURBO)

97UOF2-51

Two newly developed systems are employed to increase engine horsepower, a newly des1gned completely-

independent twin scroll turbo and a precise turbo boost pressure control system.

F2-14

0

Page 64

COMPLETEL ¥-INDEPENDENT TWIN SCROLL TURBO

PREVIOUS OPEN-TYPE

SIDE HOUSING

ROTOR HOUSING

INTERMEDIATE

HOUSING

ROTOR HOUSING

SIDE HOUSING

COMPLETELY-INDEPENDENT TYPE

SIDE HOUSING

ROTOR HOUSING

INTERMEDIATE

TURBINE

WHEEL

PRESSURE

WAVE

:.

::ompletely-independent twin scroll turbo improves horsepower by utilizing more fully the inherent

··

:.aves created by the escaping exhaust gases.

· -otors

:

:.

as

it

is

directed straight toward the turb1ne wheel. The pressure waves are thus used rather

ed

to mix with the exhaust gases of the opposite rotor.

HOUSING

ROTOR HOUSING

SIDE HOUSING

97UOF2 5 · ·

It

does this by isolating the gas flow of the front

F2-15

Page 65

TURBO BOOST PRESSURE CONTROL SYSTEM

This system controls the turbocharger maximum boost pressure by the duty signal from the engine control unit.

CRANK ANGLE S

(NE SIGNAL)

THROTTLE SENS

(FULL RANGE)

PRESSURE SENS

ENSOR

OR

OR

,-----------------------------l

ENGINE CONTROL UNIT

I I

I I

I I

I I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

L

______

ATMOSPHERIC

PRESSURE

SENSOR

r-

~

~

BASIC

OUTPUT

DUTY SIGNAL

TARGET

BOOST

PRESSURE

REAL

BOOST

PRESSURE

DETERMINATION

u-~OUTPUT

L__

DUTY SIGNAL

FEEDBACK

DUTY SIGNAL

u

_

_________

OF

__j

I

I

I

I

I

I

I

I

I

'

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

BATTERY

DUTY

SOLEN OlD

VALVE

TURBO BOOST MAXIMUM PRESSURE GRAPH

·1

DUTY SIGNAL

ENGINE

CONTROL UNIT

AIR

CLEANER

BOOST!

PRE-

SSURE

ENGINE SPEED

Operation

1.

The duty signal from engine control unit

is

varied from

5%

to

95%

based on information from the full range

throttle sensor and the crank angle sensor (Ne signal). The output duty signal

gine control unit by the

2 The duty signal

3

As

the duty increases, the duty solenoid valve opening increases, and the pressure

1s

bas1c

output duty signal, and feedback duty signal.

sent to the duty solenoid valve from the engine control unit.

ator decreases.

4 The wastegate valve then closes, and the turbo boost pressure increases.

The

eng1ne

The boost pressure

control

un1t

contains the data to set the turbo boost maximum pressure as shown

is