Page 1

Mazda6

CONTENTS

Workshop

Manual

Supplement

FOREWORD

This manual contains on-vehicle service

and diagnosis for the Mazda6.

For proper repair and maintenance,

a thorough familiarization with this manual

is important, and it should always be kept

in a handy place for quick and easy

reference.

All the contents of this manual, including

drawings and specifications, are the latest

available at the time of printing.

As modifications affecting repair or

maintenance occur, relevant information

supplementary to this volume will be made

available at Mazda dealers. This manual

should be kept up-to-date.

Mazda Motor Corporation reserves

the right to alter the specifications and

contents of this manual without obligation

or advance notice.

All rights reserved. No part of this book

may be reproduced or used in any form or

by any means, electronic or

mechanical—including photocopying and

recording and the use of any kind of

information storage and retrieval

system—without permission in writing.

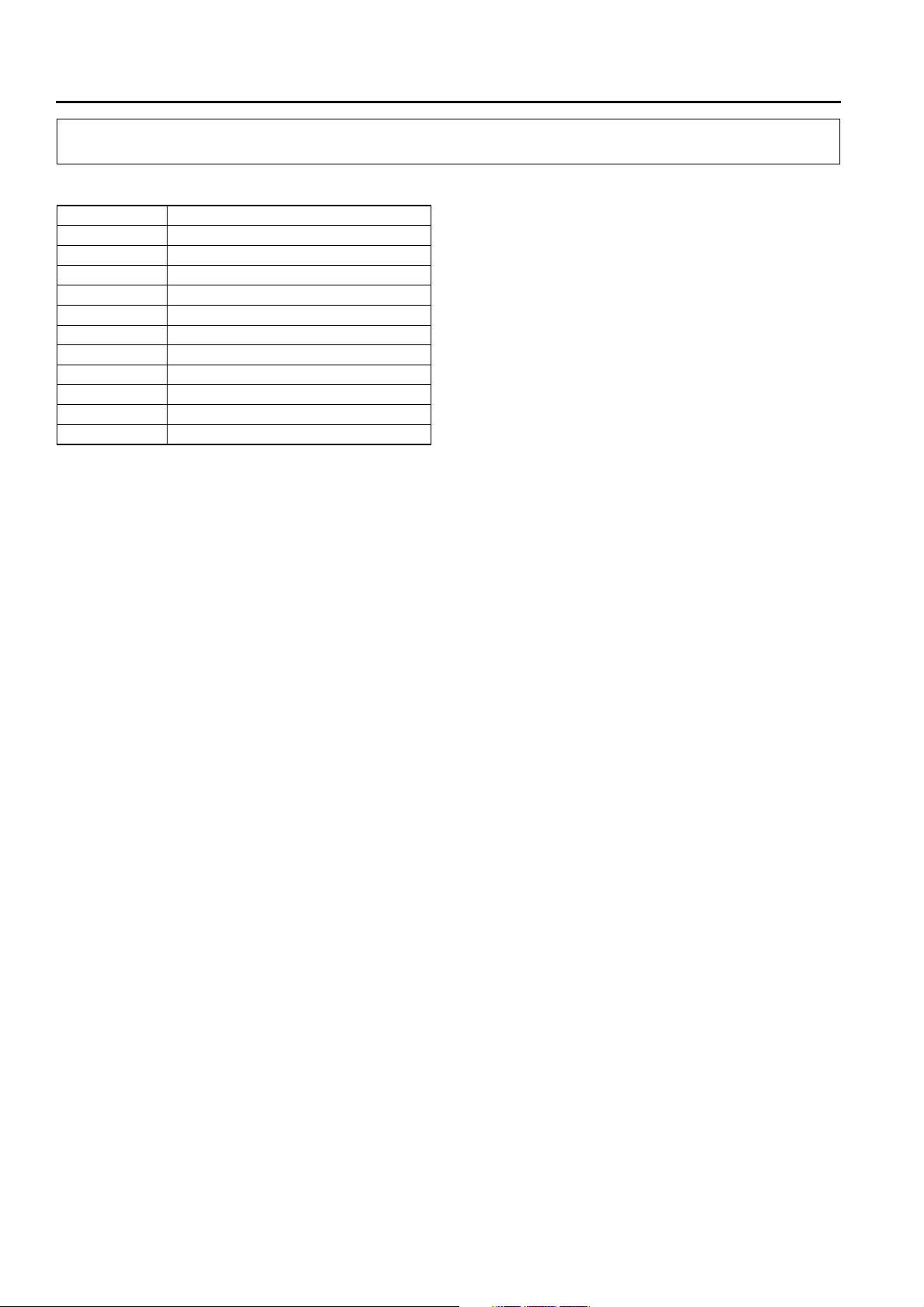

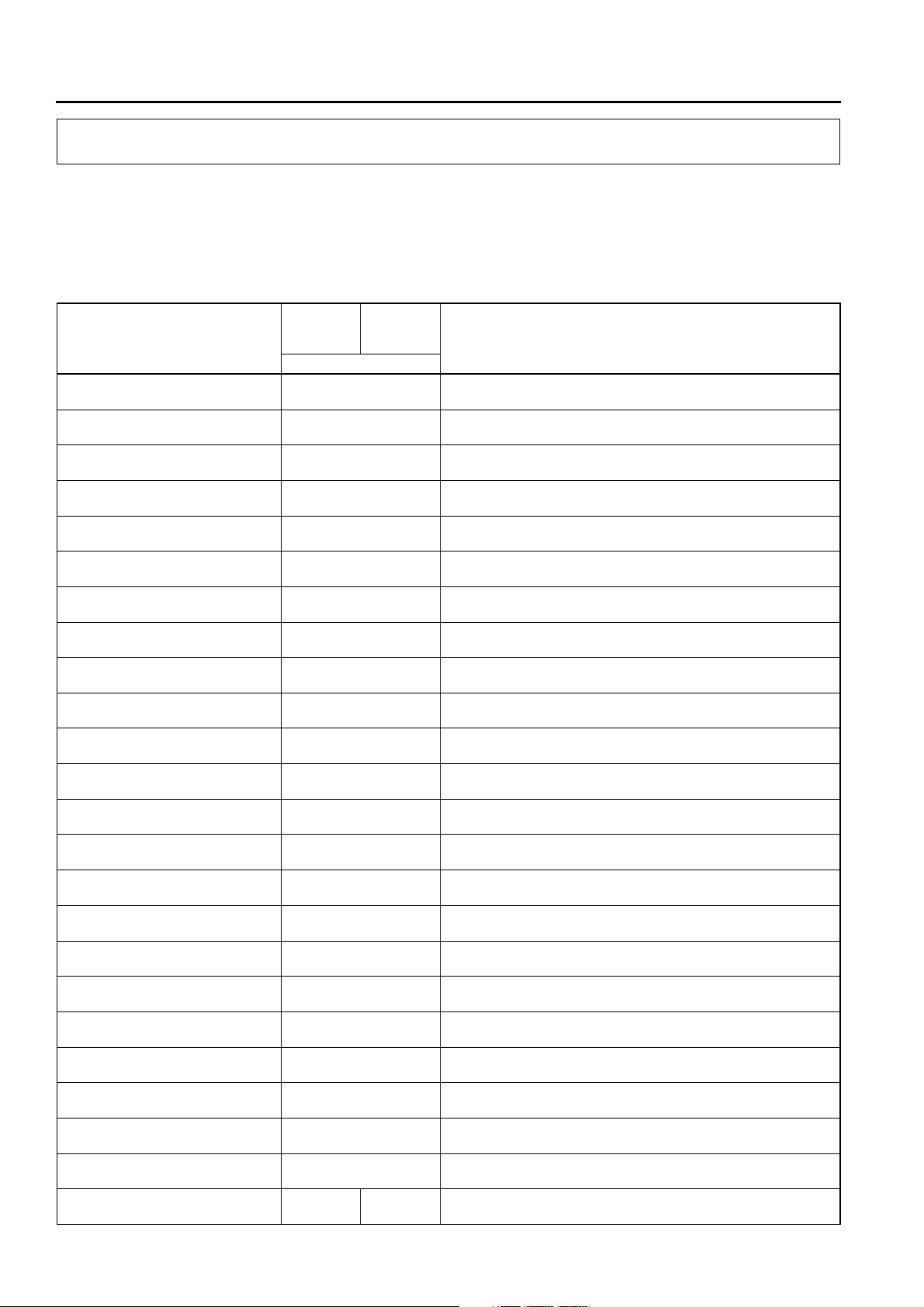

Title Section

General Information

L8, LF, L3

Engine

MZR–CD (RF Turbo)

Lubrication System

Cooling System

Fuel and Emission Control

Systems

Engine Electrical System

Clutch

Manual Transaxle

Automatic Transaxle

Propeller Shaft

Front and Rear Axles

Steering System

Braking System

Suspension

Body

Body Electrical System

Heater and Air Conditioner Systems

L8, LF, L3

MZR–CD (RF Turbo)

G35M

–

A65M

–

FN4A

–

JA5AX

GI

B1

B2

D

E

F1

F2

G

H

R J1

R J2

EL K1

–

EL K2

L

M

N

P

R

S

T

U

Mazda Motor Corporation

HIROSHIMA, JAPAN

APPLICATION:

This manual is applicable to vehicles

beginning with the Vehicle Identification

Numbers (VIN), and related materials shown

on the following page.

Technical Data

Special Tools

There are explanation given only for the sections

marked with shadow ( ).

© 2003 Mazda Motor Corporation

PRINTED IN THE NETHERLANDS, JULY 2003

1789–1E–03G

TD

ST

Page 2

VEHICLE IDENTIFICATION NUMBERS (VIN)

European (L.H.D. U.K.) specs.

JMZ GG12R20# 100001—

JMZ GG12T20# 100001—

JMZ GG14R20# 100001—

JMZ GG14T20# 100001—

JMZ GY19R20# 100001—

JMZ GY19T20# 100001—

RELATED MATERIALS

Mazda6 Training Manual

(European (L.H.D. U.K.), GCC specs.) . . . . . . . . . . . . 3359–1*–02C

Mazda6 Workshop Manual

(European (L.H.D. U.K.), GCC specs.) . . . . . . . . . . . . 1730–1*–02C

Mazda6 Workshop Manual Supplement

(European (L.H.D. U.K.), GCC specs.) . . . . . . . . . . . . 1749–1*–02G

Mazda6 Workshop Manual Supplement

(European (L.H.D. U.K.), GCC specs.) . . . . . . . . . . . . 1776–10–03G

Engine Workshop Manual MZR–CD (RF Turbo) . . . . . 1744–1E–02D

Manual Transaxle Workshop Manual A65M–R . . . . . . 1739–1E–02D

Mazda6 Wiring Diagram

(European (L.H.D.), GCC specs.) . . . . . . . . . . . . . . . . 5558–1*–02G

Mazda6 Wiring Diagram Supplement

(European (L.H.D.), GCC specs.) . . . . . . . . . . . . . . . . 5575–10–03A

Mazda6 Wiring Diagram

(U.K. specs.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5559–1*–02G

Mazda6 Wiring Diagram Supplement

(U.K. specs.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5576–10–03A

Mazda6 Bodyshop Manual

(European (L.H.D. U.K.), GCC specs.) . . . . . . . . . . . . 3360–1*–02C

Mazda6 Bodyshop Manual Supplement Wagon

(European (L.H.D. U.K.), Australian,

General (L.H.D. R.H.D.) specs.). . . . . . . . . . . . . . . . . . 3368–1*–02I

EOBD Training Manual

(General (L.H.D. R.H.D.) specs.) . . . . . . . . . . . . . . . . . 3345–1*–00B

* : Indicates the printing location

E: Europe

0: Japan

Page 3

WARNING

Servicing a vehicle can be dangerous. If you have not received

service-related training, the risks of injury, property damage, and

failure of servicing increase. The recommended servicing procedures

for the vehicle in this workshop manual were developed with

Mazda-trained technicians in mind. This manual may be useful to

non-Mazda trained technicians, but a technician with our

service-related training and experience will be at less risk when

performing service operations. However, all users of this manual are

expected to at least know general safety procedures.

This manual contains "Warnings" and "Cautions" applicable to risks

not normally encountered in a general technician's experience.

They should be followed to reduce the risk of injury and the risk that

improper service or repair may damage the vehicle or render it unsafe.

It is also important to understand that the "Warnings" and "Cautions"

are not exhaustive. It is impossible to warn of all the hazardous

consequences that might result from failure to follow the procedures.

The procedures recommended and described in this manual are

effective methods of performing service and repair. Some require tools

specifically designed for a specific purpose. Persons using procedures

and tools which are not recommended by Mazda Motor Corporation

must satisfy themselves thoroughly that neither personal safety nor

safety of the vehicle will be jeopardized.

The contents of this manual, including drawings and specifications, are

the latest available at the time of printing, and

reserves the right to change the vehicle designs and alter the contents

of this manual without notice and without incurring obligation.

Parts should be replaced with genuine Mazda replacement parts or

with parts which match the quality of genuine Mazda replacement

parts. Persons using replacement parts of lesser quality than that of

genuine Mazda replacement parts must satisfy themselves thoroughly

that neither personal safety nor safety of the vehicle will be

jeopardized.

Mazda Motor Corporation is not responsible for any problems which

may arise from the use of this manual. The cause of such problems

includes but is not limited to insufficient service-related training, use of

improper tools, use of replacement parts of lesser quality than that of

genuine Mazda replacement parts, or not being aware of any revision

of this manual.

Mazda Motor Corporation

Page 4

GI

GENERAL INFORMATION

HOW TO USE THIS MANUAL ............................. GI-2

RANGE OF TOPICS .......................................... GI-2

VIN CODE ............................................................. GI-3

VIN CODE.......................................................... GI-3

NEW STANDARDS .............................................. GI-4

NEW STANDARDS TABLE ............................... GI-4

ABBREVIATIONS ................................................ GI-6

ABBREVIATIONS TABLE .................................. GI-6

SCHEDULED MAINTENANCE ............................ GI-7

SCHEDULED MAINTENANCE TABLE ............. GI-7

GI

GI–1

Page 5

HOW TO USE THIS MANUAL

HOW TO USE THIS MANUAL

RANGE OF TOPICS

• This manual indicates only changes/additions, as it is supplemental to the related materials. Therefore it may

not contain the necessary reference service procedures to perform the service indicated in this manual.

End Of Sie

B6E201000001101

GI–2

Page 6

VIN CODE

VIN CODE

VIN CODE

European (L.H.D. U.K.) specs.

J M Z GG 1 2 3 2 0 # 1 2 3 4 5 6

End Of Sie

Plant

Dammy

Dammy

For Others (Israel etc.) : Model year

Transaxle

Engine

Body style

Remarks

Vehicle type

World manufacturer identification

GI

B6E200800021101

Serial No.

0=Hiroshima

1=Hofu

0

3 to 9 (same as Model year-Israel)

3=2003, 4=2004

2=5MTX

5=4ATX

7=5ATX

3=2.3L (L3)

8=1.8L (L8)

F=2.0L (LF)

R=MZR-CD (RF-Turbo)-Hi

T=MZR-CD (RF-Turbo)-Low

2=4SD

4=5HB

9=WAGON

8=4WD

1=2WD

GG=MAZDA6 (4SD, 5HB)

GY=MAZDA6 (WAGON)

JMZ=Europe (L.H.D. U.K.)

B6E2008W001

GI–3

Page 7

NEW STANDARDS

NEW STANDARDS

NEW STANDARDS TABLE

• The following is a comparison of the previous standard and the new standard.

New Standard Previous Standard

Abbrevi-

ation

AP Accelerator Pedal — Accelerator Pedal

ACL Air Cleaner — Air Cleaner

A/C Air Conditioning — Air Conditioning

BARO Barometric Pressure — Atmospheric Pressure

B+ Battery Positive Voltage

— Brake Switch — Stoplight Switch

— Calibration Resistor — Corrected Resistance #6

CMP sensor Camshaft Position Sensor — Crank Angle Sensor

CAC Charge Air Cooler — Intercooler

CLS Closed Loop System — Feedback System

CTP Closed Throttle Position — Fully Closed

— Closed Throttle Position Switch — Idle Switch

CPP Clutch Pedal Position — Clutch Position

CIS Continuous Fuel Injection System EGI Electronic Gasoline Injection System

CS sensor Control Sleeve Sensor CSP sensor Control Sleeve Position Sensor #6

CKP sensor Crankshaft Position Sensor — Crank Angle Sensor 2

DLC Data Link Connector — Diagnosis Connector

DTM Diagnostic Test Mode — Test Mode #1

DTC Diagnostic Trouble Code — Service Code(s)

DI Distributor Ignition — Spark Ignition

DLI Distributorless Ignition — Direct Ignition

EI Electronic Ignition — Electronic Spark Ignition #2

ECT Engine Coolant Temperature — Water Thermo

EM Engine Modification — Engine Modification

— Engine Speed Input Signal — Engine RPM Signal

EVAP Evaporative Emission — Evaporative Emission

EGR Exhaust Gas Recirculation — Exhaust Gas Recirculation

FC Fan Control — Fan Control

FF Flexible Fuel — Flexible Fuel

4GR Fourth Gear — Overdrive

— Fuel Pump Relay — Circuit Opening Relay #3

FSO

solenoid

GEN Generator — Alternator

GND Ground — Ground/Earth

HO2S Heated Oxygen Sensor — Oxygen Sensor With heater

IAC Idle Air Control — Idle Speed Control

— IDM Relay — Spill Valve Relay #6

— Incorrect Gear Ratio — —

— Injection Pump FIP Fuel Injection Pump #6

— Input/Turbine Speed Sensor — Pulse Generator

IAT Intake Air Temperature — Intake Air Thermo

KS Knock Sensor — Knock Sensor

MIL Malfunction Indicator Lamp — Malfunction Indicator Light

MAP Manifold Absolute Pressure — Intake Air Pressure

MAF sensor Mass Air Flow Sensor — Airflow Sensor

MFI Multiport Fuel Injection — Multiport Fuel Injection

OBD On Board Diagnostic — Diagnosis/Self Diagnosis

Fuel Shut Off Solenoid FCV Fuel Cut Valve #6

Name

Abbrevi-

ation

V

B

Name

Battery Voltage

B6E202800020101

Remark

GI–4

Page 8

NEW STANDARDS

New Standard Previous Standard

Abbrevi-

ation

OL Open Loop — Open Loop

— Output Speed Sensor — Vehicle Speed Sensor 1

OC Oxidation Catalytic Converter — Catalytic Converter

O2S Oxygen Sensor — Oxygen Sensor

PNP Park/Neutral Position — Park/Neutral Range

— PCM Control Relay — Main Relay #6

PSP Power Steering Pressure — Power Steering Pressure

PCM Powertrain Control Module ECU Engine Control Unit #4

— Pressure Control Solenoid — Line Pressure Solenoid Valve

PAIR Pulsed Secondary Air Injection — Secondary Air Injection System

— Pump Speed Sensor — NE Sensor #6

AIR Secondary Air Injection — Secondary Air Injection System

SAPV Secondary Air Pulse Valve — Reed Valve

SFI Sequential Multiport Fuel Injection — Sequential Fuel Injection

— Shift Solenoid A

— Shift Solenoid B

— Shift Solenoid C — 3–4 Shift Solenoid Valve

3GR Third Gear — 3rd Gear

TWC Three Way Catalytic Converter — Catalytic Converter

TB Throttle Body — Throttle Body

TP sensor Throttle Position Sensor — Throttle Sensor

TCV Timer Control Valve TCV Timing Control Valve #6

TCC Torque Converter Clutch — Lockup Position

TCM

—

TR Transmission (Transaxle) Range — Inhibitor Position

TC Turbocharger — Turbocharger

VSS Vehicle Speed Sensor — Vehicle Speed Sensor

VR Voltage Regulator — IC Regulator

VAF sensor Volume Air Flow Sensor — Airflow Meter

WU-TWC

WOT Wide Open Throttle — Fully Open

Transmission (Transaxle) Control

Module

Transmission (Transaxle) Fluid

Temperature Sensor

Warm Up Three Way Catalytic

Converter

Name

Abbrevi-

ation

— 1–2 Shift Solenoid Valve

— Shift A Solenoid Valve

— 2–3 Shift Solenoid Valve

— Shift B Solenoid Valve

— EC-AT Control Unit

— ATF Thermosensor

— Catalytic Converter #5

Name

Remark

GI

Pulsed

injection

Injection

with air

pump

#1 : Diagnostic trouble codes depend on the diagnostic test mode.

#2 : Controlled by the PCM

#3 : In some models, there is a fuel pump relay that controls pump speed. That relay is now called the fuel pump

relay (speed).

#4 : Device that controls engine and powertrain

#5 : Directly connected to exhaust manifold

#6 : Part name of diesel engine

End Of Sie

GI–5

Page 9

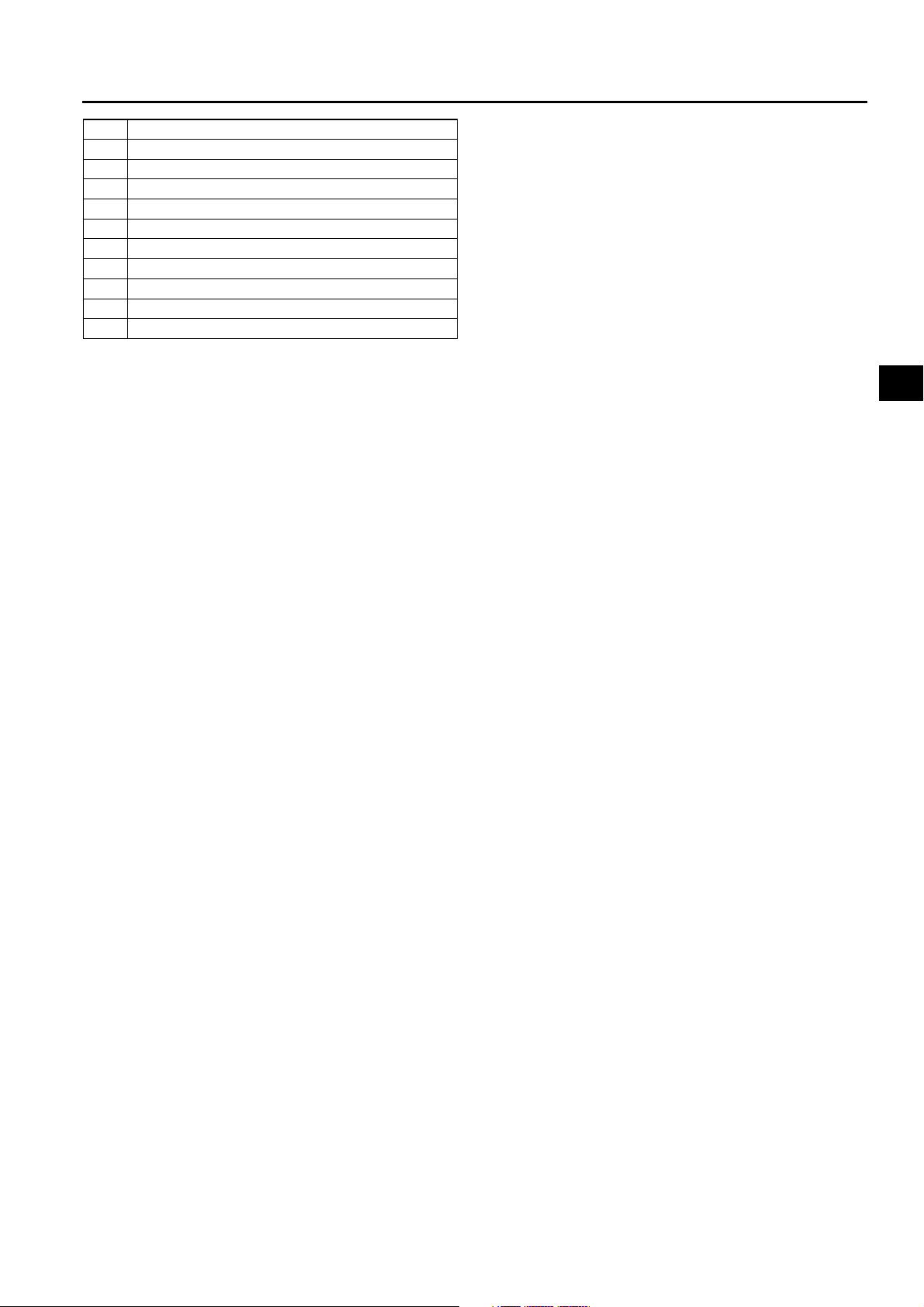

ABBREVIATIONS

ABBREVIATIONS

ABBREVIATIONS TABLE

CAN Controller Area Network

IDM Injector Driver Module

KOEO Key On Engine Off

KOER Key Off Engine Running

OFF Switch Off

ON Switch On

PID Parameter Identification

SW Switch

TCV Timer Control Valve

VBC Variable Boost Control

VSC Variable Swirl Control

WDS Worldwide Diagnostic System

End Of Sie

B6E203000011101

GI–6

Page 10

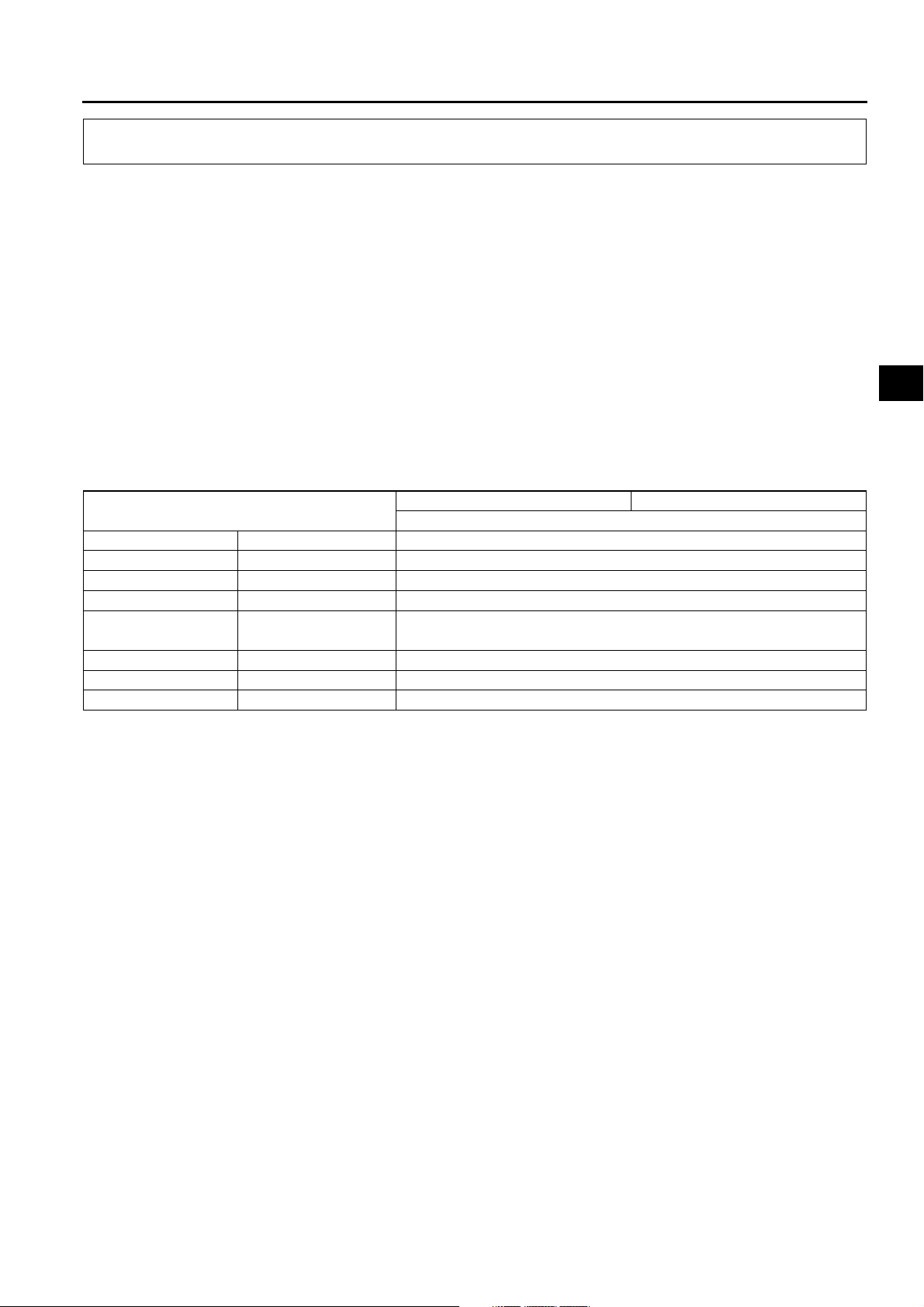

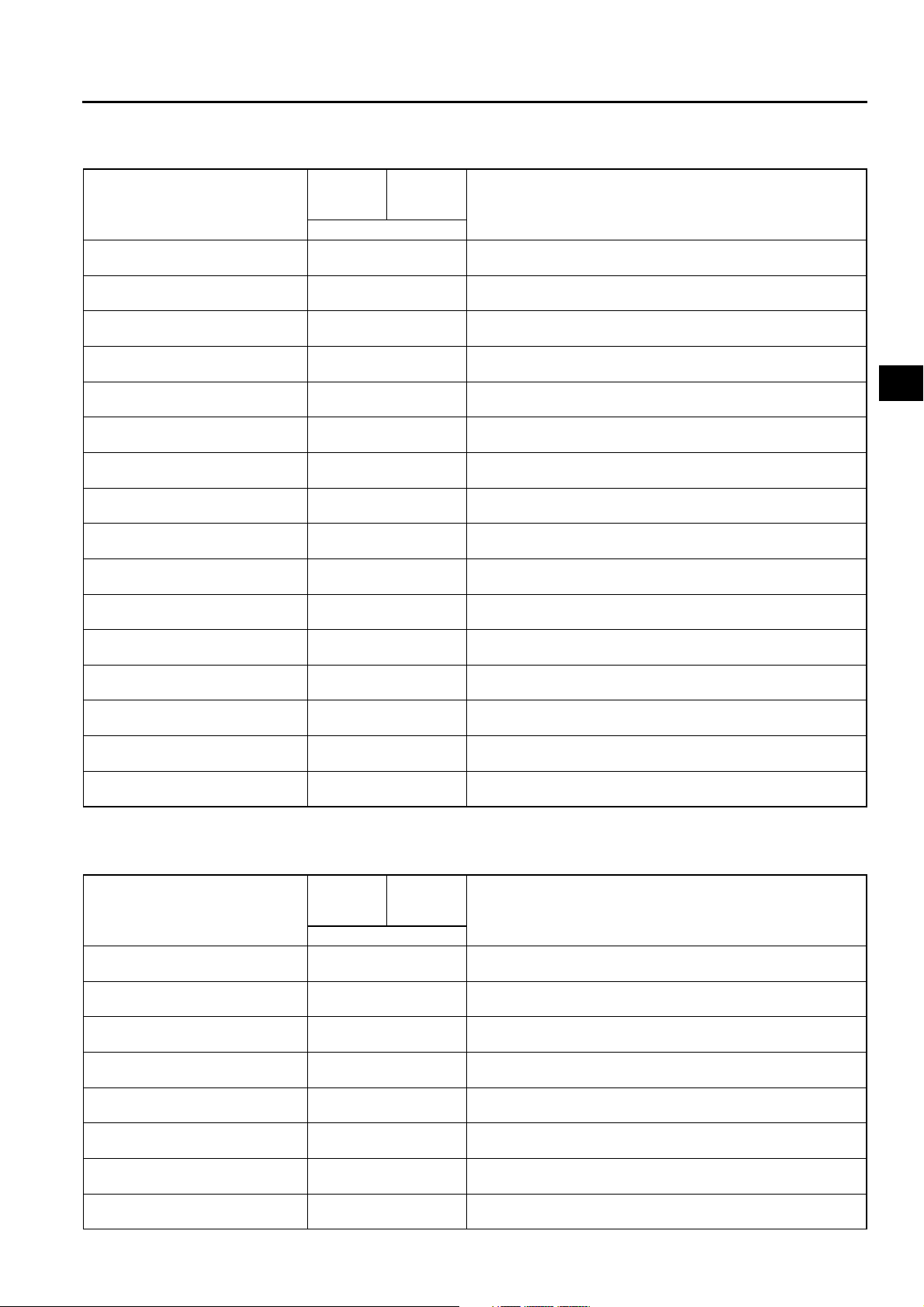

SCHEDULED MAINTENANCE

SCHEDULED MAINTENANCE

SCHEDULED MAINTENANCE TABLE

B6E203400013101

For Europe (L.H.D. U.K.)

Chart symbols:

I : Inspect and clean, repair, adjust, or replace if necessary.

R : Replace

C : Clean

Remarks:

• The ignition and fuel systems are highly important to the emission control system and to efficient engine operation. All

inspections and adjustments must be made by an expert repairer, we recommend an Authorized Mazda Repairer.

• After the described period, continue to follow the described maintenance at the recommended intervals.

• Refer below for a description of items marked* in the maintenance chart.

*1: If the vehicle is operated under any of the following conditions, change the engine oil and oil filter every 10,000 km

(6,250 miles) or shorter.

a. Driving in dusty conditions.

b. Extended periods of idling or low speed operation.

c. Driving for long period in cold temperatures or driving regularly at short distance only.

*2: Also inspect and adjust the power steering and air conditioner drive belts, if installed.

*3: If the brakes are used extensively (for example, continuous hard driving or mountain driving) or if the vehicle is

operated in extremely humid climates, change the brake fluid annually.

*4: If the vehicle is operated in very dusty or sandy areas, clean and if necessary, replace the air cleaner element more

often than the recommended intervals.

*5: Replacement of the timing belt is required at every 100,000 km (62,500 miles).

Failure to replace the timing belt may result in damage to the engine.

*6: Replacement of the timing belt is required at every 120,000 km (75,000 miles).

Failure to replace the timing belt may result in damage to the engine.

*7: If the vehicle is operated under any of the following conditions, change the rear differential oil every 45,000 km (27,000

miles).

a. Towing a trailer or using a car - top carrier

b. Driving in dusty, sandy or wet condition

c. Extended periods of idling or low speed operation

d. Repeated short trips of less than 16 km (10 miles)

*8: If this component has been submerged in water, the oil should be changed.

GI

Maintenance Interval (Number of months or km (miles), whichever comes first)

Maintenance Item

GASOLINE ENGINE

Engine valve clearance Audible inspect every 120,000 km (75,000 miles), if noisy, adjust

Spark plugs Replace every 100,000 km (62,500 miles)

Air cleaner element *4 R R R

Evaporative system (if installed) I I I

DIESEL ENGINE

Engine valve clearance I I

Engine timing belt

Fuel filter R R R

Fuel injection system I I I I

Air cleaner element *4 C C R C C R C C R

E.G.R. system I I I

GASOLINE and DIESEL ENGINE

Engine oil *1 R R R R R R R R R

Engine oil filter *1RRRRRRRRR

Drive belts *2 I I I

Cooling system (including coolant level adjustment) I I I I

Engine coolant

Finland, Sweden, Norway*5 Replace every 100,000 km (62,500 miles)

Months 12 24 36 48 60 72 84 96 108

××××1000 km 20 40 60 80 100 120 140 160 180

××××1000 miles 12.5 25 37.5 50 62.5 75 87.5 100 112.5

Others*6 Replace every 120,000 km (75,000 miles)

Replace at first 4 years or 100,000 km (62,500 miles);

after that, every 2 years

GI–7

Page 11

SCHEDULED MAINTENANCE

Maintenance Interval (Number of months or km (miles), whichever comes first)

Maintenance Item

Fuel lines & hoses I I I I

Battery electrolyte level & specific gravity I I I I I I I I I

Brake fluid *3 R R R R

Brake lines, hoses & connections I I I I I I I I I

Parking brake IIIIIIIII

Power brake unit & hoses I I I I I I I I I

Disc brakes I I I I I I I I I

Power steering fluid, lines, hoses, and connections I I I I I I I I I

Steering operation & linkages I I I I

Manual transaxle oil R

Automatic transaxle fluid level I I I

Rear differential oil (for 4WD)

Transfer oil (for 4WD)

Front & rear suspension & ball joints I I I I

Drive shaft dust boots I I I I

Exhaust system and heat shields I I

Cabin air filter (if installed) (pollen filter) R R R R

Body condition

(for rust, corrosion & perforation)

Tires (including spare tyre)

(with inflation pressure adjustment)

Months 12 24 36 48 60 72 84 96 108

××××1000 km 20 40 60 80 100 120 140 160 180

××××1000 miles 12.5 25 37.5 50 62.5 75 87.5 100 112.5

*7*

8

*

8

Inspect annually

IIIIIIIII

Scheduled Maintenance Service (Specific Work Required)

• The specific work required for each maintenance item is listed in the following table. (Please refer to the section

applicable to the model serviced.)

For Europe (L.H.D. U.K.)

Bold frames: New item

Maintenance Item Specific Work Required

ENGINE

Engine valve clearance Measure clearance

Drive belts

Engine timing belt Replace engine timing belt.

Engine oil Replace engine oil and inspect for leakage.

Oil filter Replace oil filter and inspect for leakage.

COOLING SYSTEM

Cooling system

(including coolant level adjustment)

Engine coolant Replace coolant.

FUEL SYSTEM

Air cleaner element

Fuel filter Replace fuel filter.

Fuel lines & hoses Inspect for cracks, leakage and loose connection.

Fuel injection system (for MZR-CD (RF Turbo)) Update to injection amount correction with WDS. (see W/M)

IGNITION SYSTEM (FOR GASOLINE)

Spark plugs

EMISSION CONTROL SYSTEM

Evaporative system (for gasoline)

E.G.R. system (MZR-CR (RF Turbo))

Inspect for wear, cracks and fraying, and check tension.

Replace drive belt.

Check coolant level and quality, and inspect for leakage.

Inspect for dirt, oil and damage.

Clean air cleaner element (by blowing air).

Replace air cleaner element.

Inspect for wear, damage, carbon, high-tension lead condition and measure

plug gap.

Replace spark plugs.

Check system operation (see W/M), vapor lines, vacuum fitting hoses and

connection.

Check system operation (see W/M), vacuum fitting hoses and connection.

Update to MAF correction for E.G.R control with WDS. (see W/M)

GI–8

Page 12

SCHEDULED MAINTENANCE

Maintenance Item Specific Work Required

ELECTRICAL SYSTEM

Battery electrolyte level & specific gravity Check level and specific gravity.

CHASSIS & BODY

Brake fluid

Brake lines, hoses & connections

Parking brake Check lever stroke.

Power brake unit & hoses

Disc brakes

Power steering fluid & lines

Power steering fluid Check fluid level.

Power steering system & hoses

Steering operation & gear housing

Steering linkages tie rod ends & arms

Front & rear suspension ball joints Inspect for grease leakage, cracks, damage and looseness.

Manual transmission/transaxle oil

Automatic transmission/transaxle fluid level Check fluid level.

Rear differential oil

Transfer oil (for 4×4)

Drive shaft dust boots Inspect for grease leakage, cracks, damage and looseness.

Body condition

(for rust, corrosion & perforation)

Exhaust system and heat shields Inspect for damage, corrosion, looseness of connections and gas leakage.

Tires

(including spare tire)

(with inflation pressure adjustment)

AIR CONDITIONER SYSTEM (IF EQUIPPED)

Cabin air filter Replace cabin air filter.

Check fluid level and inspect for leakage.

Replace brake fluid.

Inspect for cracks, damage, chafing, corrosion, scars, swelling and fluid

leakage.

Check vacuum lines, connections and check valve for improper attachment,

air tightness, cracks chafing and deterioration.

Test for judder and noise. Inspect caliper for correct operation and fluid

leakage, brake pads for wear. Check disc plate condition and thickness.

Check fluid level and lines for improper attachment, leakage, cracks,

damage, loose connections, chafing and deterioration.

Check lines for improper attachment, leakage, cracks, damage, loose

connections, chafing and deterioration.

Check that the steering wheel has the specified play. Be sure to check for

changes, such as excessive play, hard steering or strange noises.

Check gear housing and boots for looseness, damage and grease/gear oil

leakage.

Check ball joint, dust cover and other components for looseness, wear,

damage and grease leakage.

Check oil level and inspect for leakage.

Replace manual transmission/transaxle oil.

Check oil level and inspect for leakage.

Replace rear differential oil.

Check oil level and inspect for leakage.

Replace transfer oil.

Inspect body surface for paint damage, rust, corrosion and perforation.

Check air pressure and inspect tires for tread wear, damage and cracks;

and wheels for damage and corrosion.

GI

End Of Sie

GI–9

Page 13

F2

FUEL AND EMISSION CONTROL SYSTEMS

[MZR-CD (RF Turbo)]

FEATURES

OUTLINE .............................................................. F2-3

OUTLINE OF CONSTRUCTION ....................... F2-3

FEATURES ........................................................ F2-3

SPECIFICATIONS ............................................. F2-3

CONTROL SYSTEM DIAGRAM........................ F2-4

CONTROL SYSTEM WIRING DIAGRAM.......... F2-6

CONTROL SYSTEM........................................... F2-10

CONTROL SYSTEM OUTLINE ....................... F2-10

STRUCTURAL VIEW....................................... F2-13

BLOCK DIAGRAM ........................................... F2-15

CONTROL DEVICE AND CONTROL

RELATIONSHIP CHART .............................. F2-17

ON-BOARD DIAGNOSTIC................................. F2-18

ON-BOARD DIAGNOSTIC OUTLINE.............. F2-18

DIAGNOSTIC TEST MODE............................. F2-18

DTC DETECTION LOGIC AND

CONDITIONS ............................................... F2-21

PID/DATA MONITOR AND RECORD ............. F2-26

SIMULATION TEST ......................................... F2-28

SERVICE

OUTLINE ............................................................ F2-30

SUPPLEMENTAL SERVICE

INFORMATION............................................. F2-30

CONTROL SYSTEM........................................... F2-31

PCM INSPECTION .......................................... F2-31

EGR VALVE POSITION SENSOR

INSPECTION ................................................ F2-37

ON-BOARD DIAGNOSTIC................................. F2-38

FOREWORD.................................................... F2-38

OBD PENDING TROUBLE CODES ................ F2-38

OBD FREEZE FRAME DATA .......................... F2-38

OBD READ/CLEAR DIAGNOSTIC

TEST RESULTS ........................................... F2-38

OBD PARAMETER IDENTIFICATION

(PID) ACCESS.............................................. F2-38

ON-BOARD DIAGNOSTIC TEST .................... F2-38

OBD DRIVE MODE ......................................... F2-39

DTC TABLE ..................................................... F2-40

DTC P0016 ...................................................... F2-42

DTC P0045 ...................................................... F2-43

DTC P0088 ...................................................... F2-46

DTC P0093 ...................................................... F2-47

DTC P0096 ...................................................... F2-48

DTC P0097 ...................................................... F2-49

DTC P0098 ...................................................... F2-51

DTC P0101 ...................................................... F2-54

DTC P0102 ...................................................... F2-55

DTC P0103 ...................................................... F2-58

DTC P0106 ...................................................... F2-60

DTC P0107 ...................................................... F2-61

DTC P0108 ...................................................... F2-64

DTC P0111 ...................................................... F2-66

DTC P0112 ...................................................... F2-67

DTC P0113 ...................................................... F2-69

DTC P0116 ...................................................... F2-72

DTC P0117 ...................................................... F2-74

DTC P0118 ...................................................... F2-75

DTC P0122 ...................................................... F2-78

DTC P0123 ...................................................... F2-80

DTC P0182 ...................................................... F2-82

DTC P0183 ...................................................... F2-84

DTC P0191 ...................................................... F2-86

DTC P0192 ...................................................... F2-87

DTC P0193 ...................................................... F2-90

DTC P0200 ...................................................... F2-92

DTC P0201 ...................................................... F2-95

DTC P0202 ...................................................... F2-98

DTC P0203 .................................................... F2-101

DTC P0204 .................................................... F2-104

DTC P0222 .................................................... F2-107

DTC P0223 .................................................... F2-110

DTC P0225 .................................................... F2-112

DTC P0301, P0302, P0303, P0304 ............... F2-114

DTC P0336 .................................................... F2-116

DTC P0337 .................................................... F2-117

DTC P0341 .................................................... F2-120

DTC P0342 .................................................... F2-121

DTC P0401 .................................................... F2-124

DTC P0402 .................................................... F2-125

DTC P0404 .................................................... F2-126

DTC P0406 .................................................... F2-127

DTC P0489 .................................................... F2-130

DTC P0490 .................................................... F2-132

DTC P0500 .................................................... F2-134

DTC P0504 .................................................... F2-134

DTC P0512 .................................................... F2-137

DTC P0562 .................................................... F2-140

DTC P0563 .................................................... F2-141

DTC P0564 .................................................... F2-144

DTC P0602 .................................................... F2-146

DTC P0606 .................................................... F2-146

DTC P0610 .................................................... F2-147

DTC P0627 .................................................... F2-147

DTC P0628 .................................................... F2-150

DTC P0629 .................................................... F2-152

DTC P0661 .................................................... F2-154

DTC P0662 .................................................... F2-156

DTC P0664 .................................................... F2-158

DTC P0665 .................................................... F2-160

DTC P0704 .................................................... F2-162

DTC P0850 .................................................... F2-164

DTC P1190 .................................................... F2-166

DTC P1211 .................................................... F2-169

DTC P1391 .................................................... F2-170

DTC P1392 .................................................... F2-173

DTC P2009 .................................................... F2-176

DTC P2010 .................................................... F2-178

DTC P2135 .................................................... F2-180

DTC P2136 .................................................... F2-180

DTC P2141 .................................................... F2-182

F2

F2–1

Page 14

DTC P2142 .................................................... F2-185

DTC P2144 .................................................... F2-187

DTC P2145 .................................................... F2-189

DTC P2146 .................................................... F2-191

DTC P2149 .................................................... F2-194

DTC P2227 .................................................... F2-197

DTC P2228 .................................................... F2-197

DTC P2229 .................................................... F2-198

TROUBLESHOOTING...................................... F2-200

SYMPTOM QUICK DIAGNOSIS CHART ...... F2-200

NO.5 ENGINE STALLS-AFTER

START/AT IDLE.......................................... F2-205

NO.6 CRANKS NORMALLY BUT WILL

NOT START................................................ F2-209

NO.8 ENGINE RUNS ROUGH/ROLLING

IDLE ............................................................ F2-212

NO.10 LOW IDLE/STALLS DURING

DECELERATION ........................................ F2-214

NO.11 ENGINE STALLS/QUITS, ENGINE

RUNS ROUGH, MISSES, BUCK/LERK,

HESITATION/STUMBLE............................. F2-217

NO.12 LACK/LOSS OF POWER-

ACCELERATION/CRUISE.......................... F2-220

NO.13 KNOCKING/PINGING ........................ F2-224

NO.15 EMISSION COMPLIANCE ................. F2-227

NO.19 EXCESSIVE BLACK SMOKE............. F2-230

ENGINE CONTROL SYSTEM OPERATION

INSPECTION .............................................. F2-232

F2–2

Page 15

OUTLINE

OUTLINE

OUTLINE OF CONSTRUCTION

B6E400218881101

• The fuel and emission control system is essentially carried over from that of the previous Mazda6 (GG, GY)

MZR-CD (RF Turbo) engine models, except for the following features. (See Mazda6 Workshop Manual

Supplement 1749-1*-02G.)

End Of Sie

FEATURES

Improved Emission Performance

• A EGR valve position sensor has been adopted.

Improved Serviceability

• The number of DTCs has been increased to provide more detail information.

• The DTC troubleshooting procedures have been renewed due to the adoption of the diagnostic test mode and

OBD drive mode.

• The PID item has been added.

• The simulation item has been added.

B6E400218881102

End Of Sie

SPECIFICATIONS

Item

Air cleaner element Type Non woven fabric (dry)

Supercharger Type Turbocharger

Glow plug Type Metal

Pump Type Supply pump

Fuel tank

Catalyst Type Warm up oxidation catalyst, Oxidation catalyst

EGR control Type Duty control

PCV system Type Closed

Capacity

(L {US gal, lmp gal})

New Mazda6 (GG, GY) Previous Mazda6 (GG, GY)

MZR-CD (RF Turbo)

64 {17, 14}

B6E400218881103

F2

End Of Sie

F2–3

Page 16

OUTLINE

CONTROL SYSTEM DIAGRAM

.

51

47

48

49

50

52

53

56

45

46

43

44

26

25

24

27

23

22

54

57

15

A

B6E400218881104

5

13

30

16

17

12

14

11

31

10

9

6

55

*

18

19

34

4

8

B

3

2

1

7

29

28

20

35

33

A

21

B

32

39

36

37

42

41

38

40

B6E4002W002

1 Air cleaner

2 Vacuum chamber

3 VBC check valve

4 MAF/IAT sensor

5 VBC solenoid valve

6 Vacuum damper

7 Guide blade actuator

8 Turbocharger

9 Charge air cooler

10 IAT sensor No.2

11 Boost sensor

12 Intake shutter valve actuator

13 Intake shutter solenoid valve (half)

14 Intake shutter solenoid valve (full)

15 EGR solenoid valve (vacuum)

16 EGR solenoid valve (vent)

17 EGR control solenoid valve

18 EGR valve

19 EGR water cooler

20 VSC valve actuator

21 VSC solenoid valve

22 Fuel tank

23 Fuel filter

24 Fuel warmer

25 Supply pump

26 Suction control valve

27 Fuel temperature sensor

28 Common rail

29 Fuel pressure sensor

30 Fuel pressure limiter

F2–4

Page 17

31 Glow plug

32 Fuel injector

33 ECT sensor

34 Calibration resistor

35 CMP sensor

36 Warm up oxidation catalytic converter

37 Oxidation catalytic converter

38 Silencer

39 Vacuum pump

40 CKP sensor

41 Idle switch

42 APP sensor

43 Glow plug relay

44 IDM

45 PCM

46 BARO sensor

47 PCM control relay

48 Engine switch

49 Starter (starter signal)

50 Neutral switch

51 Clutch switch

52 A/C switch

53 CAN bus

54 To PCM

55 EGR valve position sensor

56 DLC-2

57 Fuel flow

OUTLINE

F2

End Of Sie

F2–5

Page 18

OUTLINE

CONTROL SYSTEM WIRING DIAGRAM

4

1A

1B 1C 1D 1E 1F

2

13 39

57

E

C

56

3

5

33 1

80

427 734

2878

1A

1B 1C 1D 1E 1F

1

B6E400218881105

6

1H

65 91

2A

2B 2C2D2E2F2G 2H

30 42

44 45

69E53

79 91460

a

b

c

d

e

f

g

43

h

i

j

k

1G

64

104

103

85

8

LOCK

ACC

ON

ST

9

A

D

15

IG1

ACC

B

IG2

ST

16

14

17

21

20

C

A

D

22

DAE

CB

23

l

m

n

o

18

19

A

10

A

B

D

P

M

11

AA

12

B

13

7

.

1PCM

2DLC-2

3 Water heater unit

4Fuel pump

5 Other unit

6IDM

F2–6

A6E40022002

7Battery

8 Engine switch

9 Starter relay

10 Starter

11 Generator

12 Oil pressure switch

Page 19

13 Sedimentor switch

14 Instrument cluster

15 Neutral switch

16 Clutch switch

17 Coil

18 Brake switch

19 Brake switch 2

20 Cruise control switch

21 With cruise control system

22 PCM control relay

23 MAF/IAT sensor

OUTLINE

F2

F2–7

Page 20

OUTLINE

.

25

24

BD

C

A

27

26

BD

C

A

29

28

BD

C

ACBD

30

31

A

B

100

3938

A

B

67 77

40

A

B

35

a

b

c

d

e

f

g

37

62

89 11

32

A

A

81 55 29 3 99 72

B

B

34

C

A

A

B

3633

A

B

B

101

37

A

B

A

74

1

36

h

i

j

k

10

31

88

61

90

35

87 94 93 8

32

A

B

102

76

84

73 86

68

B

C

60

A

A

B

ABC

A

B

C

41

A

D

BC

43

B

B

C

AB

A

48

4745 4644

65

A

D

61

l

m

n

o

42

24 Calibration resistor No.1

25 Fuel injector No.1

26 Calibration resistor No.2

27 Fuel injector No.2

28 Calibration resistor No.3

29 Fuel injector No.3

64

63

62

59

E

C

49

AB

50

D

A

51

M

52 53

56 54

57

M

58

M

55

B6E4002W001

F2–8

Page 21

30 Calibration resistor No.4

31 Fuel injector No.4

32 CMP sensor

33 CKP sensor

34 EGR solenoid valve (vacuum)

35 EGR solenoid valve (vent)

36 VSC solenoid valve

37 Intake shutter solenoid valve (half)

38 Intake shutter solenoid valve (full)

39 VBC solenoid valve

40 EGR control solenoid valve

41 Boost sensor

42 APP sensor

43 Idle switch

44 Fuel pressure sensor

45 ECT sensor

46 Fuel temperature sensor

47 Suction control valve

48 IAT sensor No.2

49 Cooling fan relay No.2

50 Cooling fan No.1

51 Refrigerant pressure switch (middle)

52 A/C switch

53 A/C amplifier

54 Cooling fan relay No.1

55 Cooling fan No.2

56 A/C relay

57 Refrigerant pressure switch (HI and LO)

58 Magnetic clutch

59 With A/C

60 Glow plug relay

61 Glow plug

62 Vacuum switch

63 Fuel warmer

64 With fuel warmer

65 EGR valve position sensor

OUTLINE

F2

End Of Sie

F2–9

Page 22

CONTROL SYSTEM

CONTROL SYSTEM

CONTROL SYSTEM OUTLINE

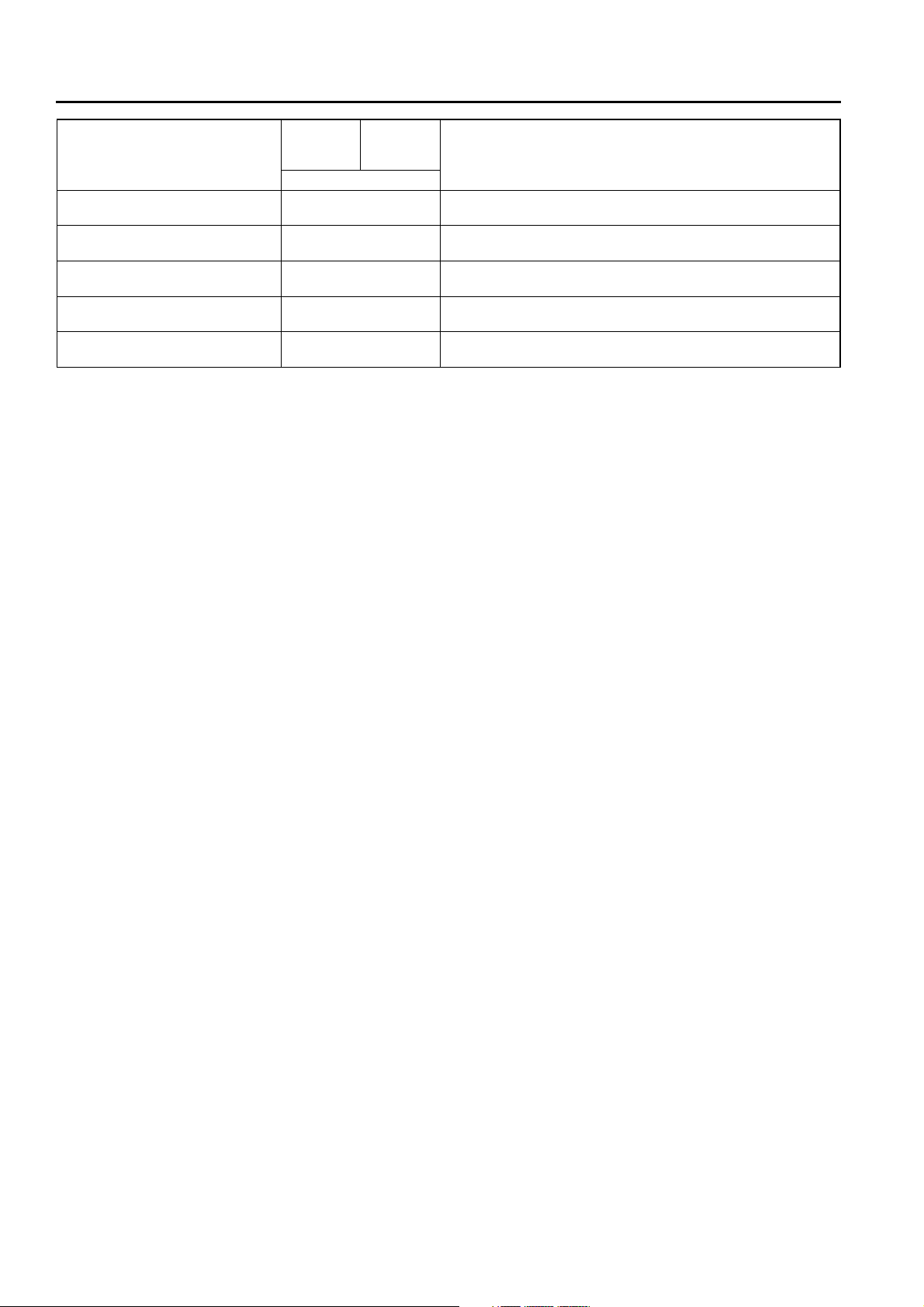

B6E404018881101

• The control system is essentially carried over from that of the previous Mazda6 (GG, GY) MZR-CD (RF Turbo)

engine models. (See Mazda6 Workshop Manual Supplement 1749-1*-02G.)

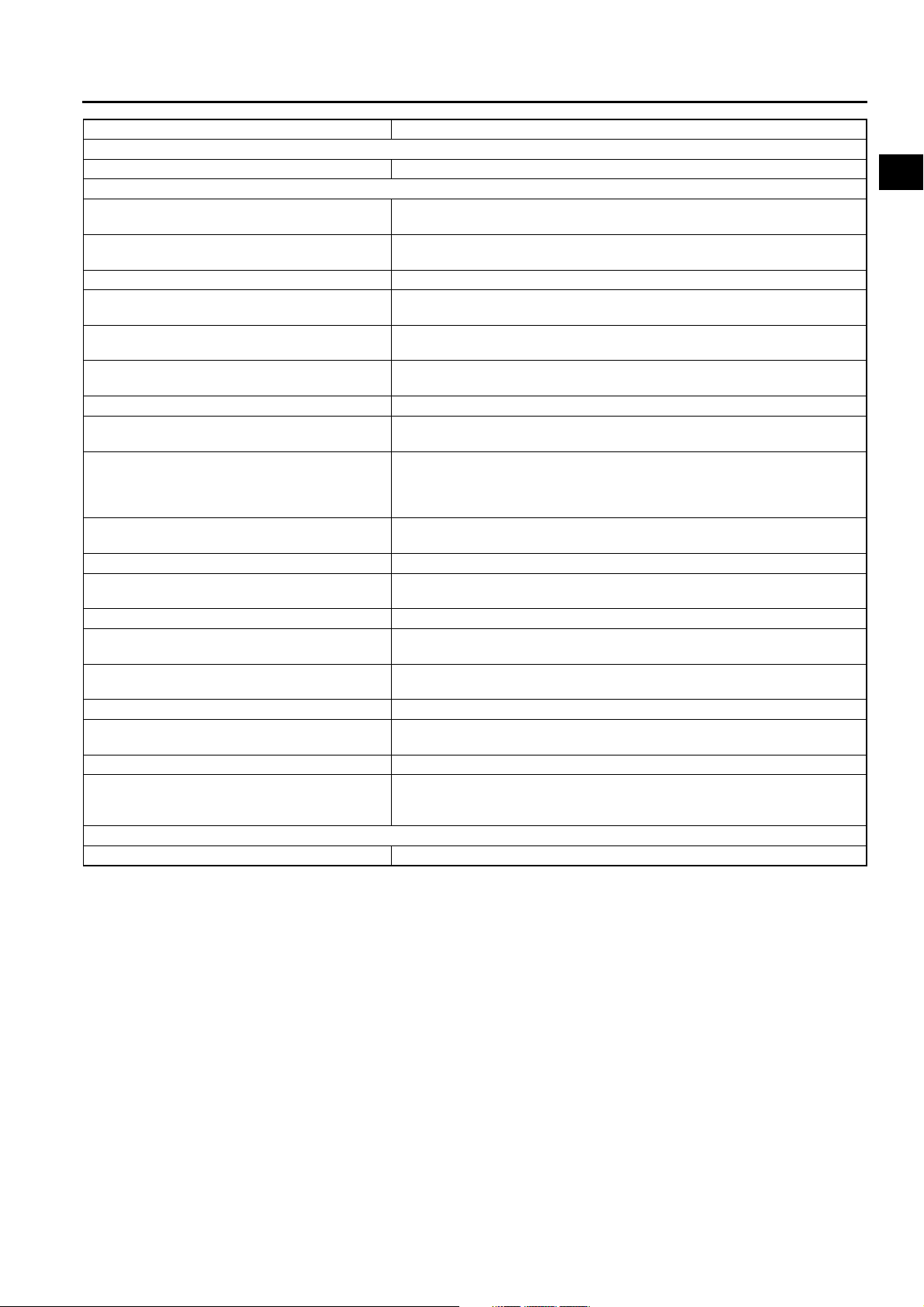

Input Device

×:Applicable –: Not applicable

New

Item

Battery ×

Starter (starter signal) ×

Starter relay ×

Clutch switch ×

Neutral switch ×

Brake switch ×

Idle switch ×

A/C switch ×

Refrigerant pressure switch ×

Cruise control switch ×

Accelerator position sensor ×

MAF/IAT sensor ×

IAT sensor No.2 ×

ECT sensor ×

Fuel temperature sensor ×

BARO sensor (integrated in PCM) ×

Boost sensor ×

Fuel pressure sensor ×

CMP sensor ×

CKP sensor ×

VSS ×

Calibration resistor ×

Immobilizer unit (integrated in

PCM)

EGR valve position sensor × –

Mazda6

(GG, GY)

MZR-CD (RF Turbo)

Previous

Mazda6

(GG, GY)

×

Remark for new model

Same function as previous Mazda6 (GG, GY) MZR-CD (RF

Turbo) engine model

Same function as previous Mazda6 (GG, GY) MZR-CD (RF

Turbo) engine model

Same function as previous Mazda6 (GG, GY) MZR-CD (RF

Turbo) engine model

Same function as previous Mazda6 (GG, GY) MZR-CD (RF

Turbo) engine model

Same function as previous Mazda6 (GG, GY) MZR-CD (RF

Turbo) engine model

Same function as previous Mazda6 (GG, GY) MZR-CD (RF

Turbo) engine model

Same function as previous Mazda6 (GG, GY) MZR-CD (RF

Turbo) engine model

Same function as previous Mazda6 (GG, GY) MZR-CD (RF

Turbo) engine model

Same function as previous Mazda6 (GG, GY) MZR-CD (RF

Turbo) engine model

Same function as previous Mazda6 (GG, GY) MZR-CD (RF

Turbo) engine model

Same function as previous Mazda6 (GG, GY) MZR-CD (RF

Turbo) engine model

Same function as previous Mazda6 (GG, GY) MZR-CD (RF

Turbo) engine model

Same function as previous Mazda6 (GG, GY) MZR-CD (RF

Turbo) engine model

Same function as previous Mazda6 (GG, GY) MZR-CD (RF

Turbo) engine model

Same function as previous Mazda6 (GG, GY) MZR-CD (RF

Turbo) engine model

Same function as previous Mazda6 (GG, GY) MZR-CD (RF

Turbo) engine model

Same function as previous Mazda6 (GG, GY) MZR-CD (RF

Turbo) engine model

Same function as previous Mazda6 (GG, GY) MZR-CD (RF

Turbo) engine model

Same function as previous Mazda6 (GG, GY) MZR-CD (RF

Turbo) engine model

Same function as previous Mazda6 (GG, GY) MZR-CD (RF

Turbo) engine model

Same function as previous Mazda6 (GG, GY) MZR-CD (RF

Turbo) engine model

Same function as previous Mazda6 (GG, GY) MZR-CD (RF

Turbo) engine model

Same function as previous Mazda6 (GG, GY) MZR-CD (RF

Turbo) engine model

Same function as previous Mazda PREMACY (CP) RF Turbo

engine model

F2–10

Page 23

Output Device

New

Item

Suction control valve ×

IDM ×

VSC solenoid valve ×

VBC solenoid valve ×

EGR control solenoid valve ×

EGR solenoid valve (vacuum) ×

EGR solenoid valve (vent) ×

Intake shutter solenoid valve (half) ×

Intake shutter solenoid valve (full) ×

Glow indicator light ×

Cruise main indicator light ×

Cruise set indicator light ×

Glow plug relay ×

Cooling fan relay No.1 ×

Cooling fan relay No.2 ×

A/C relay ×

Mazda6

(GG, GY)

MZR-CD (RF Turbo)

CONTROL SYSTEM

Previous

Mazda6

(GG, GY)

Same function as previous Mazda6 (GG, GY) MZR-CD (RF

Turbo) engine model

Same function as previous Mazda6 (GG, GY) MZR-CD (RF

Turbo) engine model

Same function as previous Mazda6 (GG, GY) MZR-CD (RF

Turbo) engine model

Same function as previous Mazda6 (GG, GY) MZR-CD (RF

Turbo) engine model

Same function as previous Mazda6 (GG, GY) MZR-CD (RF

Turbo) engine model

Same function as previous Mazda6 (GG, GY) MZR-CD (RF

Turbo) engine model

Same function as previous Mazda6 (GG, GY) MZR-CD (RF

Turbo) engine model

Same function as previous Mazda6 (GG, GY) MZR-CD (RF

Turbo) engine model

Same function as previous Mazda6 (GG, GY) MZR-CD (RF

Turbo) engine model

Same function as previous Mazda6 (GG, GY) MZR-CD (RF

Turbo) engine model

Same function as previous Mazda6 (GG, GY) MZR-CD (RF

Turbo) engine model

Same function as previous Mazda6 (GG, GY) MZR-CD (RF

Turbo) engine model

Same function as previous Mazda6 (GG, GY) MZR-CD (RF

Turbo) engine model

Same function as previous Mazda6 (GG, GY) MZR-CD (RF

Turbo) engine model

Same function as previous Mazda6 (GG, GY) MZR-CD (RF

Turbo) engine model

Same function as previous Mazda6 (GG, GY) MZR-CD (RF

Turbo) engine model

×:Applicable –: Not applicable

Remark for new model

F2

Control System

New

Item

Idle speed control ×

Glow control ×

VSC ×

Boost pressure control ×

Fuel injection amount control ×

Fuel injection timing control ×

Multiple fuel injection control ×

Fuel pressure control ×

Mazda6

(GG, GY)

MZR-CD (RF Turbo)

Previous

Mazda6

(GG, GY)

×:Applicable –: Not applicable

Remark for new model

Same function as previous Mazda6 (GG, GY) MZR-CD (RF

Turbo) engine model

Same function as previous Mazda6 (GG, GY) MZR-CD (RF

Turbo) engine model

Same function as previous Mazda6 (GG, GY) MZR-CD (RF

Turbo) engine model

Same function as previous Mazda6 (GG, GY) MZR-CD (RF

Turbo) engine model

Same function as previous Mazda6 (GG, GY) MZR-CD (RF

Turbo) engine model

Same function as previous Mazda6 (GG, GY) MZR-CD (RF

Turbo) engine model

Same function as previous Mazda6 (GG, GY) MZR-CD (RF

Turbo) engine model

Same function as previous Mazda6 (GG, GY) MZR-CD (RF

Turbo) engine model

F2–11

Page 24

CONTROL SYSTEM

New

Item

EGR control ×

Cruise control system ×

Electrical fan control ×

A/C cut-off control ×

Immobilizer system ×

Mazda6

(GG, GY)

MZR-CD (RF Turbo)

End Of Sie

Previous

Mazda6

(GG, GY)

Remark for new model

Same function as previous Mazda6 (GG, GY) MZR-CD (RF

Turbo) engine model

Same function as previous Mazda6 (GG, GY) MZR-CD (RF

Turbo) engine model

Same function as previous Mazda6 (GG, GY) MZR-CD (RF

Turbo) engine model

Same function as previous Mazda6 (GG, GY) MZR-CD (RF

Turbo) engine model

Same function as previous Mazda6 (GG, GY) MZR-CD (RF

Turbo) engine model

F2–12

Page 25

CONTROL SYSTEM

STRUCTURAL VIEW

.

14

40

20

23

17

24

33

36

4

34

B6E404018881102

35

37

F2

2

38

10

21

18

16

13

28

3

22

11

6

29

32

26

25

27

3031

19

39

31

15

12

32

30

19

9

9

5

5

10

1

8

1

7

8

7

PCM (with built-in BARO sensor and immobilizer

1

unit)

2Battery

3Starter

B6E4040W001

F2–13

Page 26

4 Starter relay

5 Clutch switch

6 Neutral switch

7 Brake switch

8 Idle switch

9 Cruise control switch

10 Accelerator position sensor

11 MAF/IAT sensor

12 IAT sensor No.2

13 ECT sensor

14 Fuel temperature sensor

15 Boost sensor

16 Fuel pressure sensor

17 CMP sensor

18 CKP sensor

19 VSS

20 Calibration resistor

21 Suction control valve

22 IDM

23 VSC solenoid valve

24 VBC solenoid valve

25 EGR control solenoid valve

26 EGR solenoid valve (vacuum)

27 EGR solenoid valve (vent)

28 Intake shutter solenoid valve (half)

29 Intake shutter solenoid valve (full)

30 Glow indicator light

31 Cruise main indicator light

32 Cruise set indicator light

33 Glow plug relay

34 Cooling fan relay No.1

35 Cooling fan relay No.2

36 A/C relay

37 PCM control relay

38 L.H.D.

39 R.H.D.

40 EGR valve position sensor

CONTROL SYSTEM

End Of Sie

F2–14

Page 27

CONTROL SYSTEM

BLOCK DIAGRAM

.

15

16

17

18

19

20

21

22

23

24

B6E404018881103

1

38

2

39

3

40

4

41

5

6

42

43

F2

44

7

25

26

27

28

29

30

31

32

33

34

35

36

8

9

10

11

12

13

CRUISE

MAIN

CRUISE

45

46

47

48

49

50

51

52

37

54

1PCM

2 Idle speed control

14

53

B6E4040W002

F2–15

Page 28

3 Glow control

4 VSC

5 Boost pressure control

6 Fuel injection amount control

7 Fuel injection timing control

8 Multiple fuel injection control

9 Fuel pressure control

10 EGR control

11 Cruise control system

12 Electrical fan control

13 A/C cut-off control

14 Immobilizer system

15 Battery

16 Starter (starter signal)

17 Starter relay

18 Clutch switch

19 Neutral switch

20 Brake switch

21 Idle switch

22 A/C switch

23 Refrigerant pressure switch

24 Cruise control switch

25 Accelerator position sensor

26 MAF/IAT sensor

27 IAT sensor No.2

28 ECT sensor

29 Fuel temperature sensor

30 BARO sensor (integrated in PCM)

31 Boost sensor

32 Fuel pressure sensor

33 CMP sensor

34 CKP sensor

35 VSS

36 Calibration resistor

37 Immobilizer unit (integrated in PCM)

38 Suction control valve

39 IDM

40 VSC solenoid valve

41 VBC solenoid valve

42 EGR control solenoid valve

43 EGR solenoid valve (vacuum)

44 EGR solenoid valve (vent)

45 Intake shutter solenoid valve (half)

46 Intake shutter solenoid valve (full)

47 Glow indicator light

48 Cruise main indicator light

49 Cruise set indicator light

50 Glow plug relay

51 Cooling fan relay No.1

52 Cooling fan relay No.2

53 A/C relay

54 EGR valve position sensor

CONTROL SYSTEM

End Of Sie

F2–16

Page 29

CONTROL SYSTEM

CONTROL DEVICE AND CONTROL RELATIONSHIP CHART

B6E404018881104

×: Applicable

Item

Idle speed control

Glow control

VSC

Boost pressure control

Fuel injection amount control

Fuel injection timing control

Multiple fuel injection control

Fuel pressure control

EGR control

Cruise control system

Electrical fan control

A/C cut-off control

Immobilizer system

Input device

F2

Battery ××

Starter (starter signal) ЧЧЧЧЧЧЧЧЧ ×

Starter relay ЧЧЧЧЧЧЧЧЧ ×

Clutch switch × × ××× ×× ×

Neutral switch × × ××× ×× ×

Brake switch ×

Idle switch × × ××× × ×

A/C switch ×××××

Refrigerant pressure switch ×××××

Cruise control switch ×

Accelerator position sensor × ××× × × ××

MAF/IAT sensor × ××××

IAT sensor No.2 ××

ECT sensor ××× ЧЧЧЧЧ ××

Fuel temperature sensor ×

BARO sensor (integrated in PCM) ×××

Boost sensor ××× ×

Fuel pressure sensor ×× ××

CMP sensor ЧЧЧЧЧ

CKP sensor × ЧЧЧЧЧЧЧ ×

VSS ××× ××× ××

Calibration resistor ××

Immobilizer unit (integrated in PCM) ×

EGR valve position sensor ×

Output device

Suction control valve ××

IDM × ××× × ×

VSC solenoid valve ×

VBC solenoid valve ×

EGR control solenoid valve ×

EGR solenoid valve (vacuum) ×

EGR solenoid valve (vent) ×

Intake shutter solenoid valve (half) ×

Intake shutter solenoid valve (full) ×

Glow indicator light ×

Cruise main indicator light ×

Cruise set indicator light ×

Glow plug relay ×

Cooling fan relay No.1 ×

Cooling fan relay No.2 ×

A/C relay ×

End Of Sie

F2–17

Page 30

ON-BOARD DIAGNOSTIC

ON-BOARD DIAGNOSTIC

ON-BOARD DIAGNOSTIC OUTLINE

Features

To meet the EOBD regulations • Diagnostic test modes adopted

Improved serviceability • DTC troubleshooting modified

• PID/DATA monitor items added

• Simulation items added

• OBD drive mode adopted

Block Diagram

1

2

5

B6E407000102101

3

4

7

6

8

9

.

1PCM

2 OBD system

3 Malfunction indication function

4MIL

5 Memory function

6 Tester communication function

7DLC-2

8CAN

13

10

11 12

15 1614

BHE0102T001

9 WDS or equivalent

10 Detection function

11 PID data monitor function

12 Simulation test function

13 Fail-safe function

14 Input device

15 Engine control system

16 Output device

End Of Sie

DIAGNOSTIC TEST MODE

• To meet EOBD regulations, the following diagnostic test modes have been adopted.

F2–18

B6E407000102102

Page 31

ON-BOARD DIAGNOSTIC

Diagnostic test mode Item

Mode 01 Sending diagnostic data (PID data monitor/On-board system readiness test)

Mode 02 Sending freeze frame data

Mode 03 Sending emission-related malfunction code (DTC)

Mode 04 Clearing/resetting emission-related malfunction information

Mode 07 Sending continuous monitoring system test results (pending code)

Mode 09 Request vehicle information

Sending Diagnostic Data

PID data monitor

• The PID data monitor items are shown below.

PID data monitor table

—: Not applicable

Full names Unit

Monitor status since DTCs cleared —

Calculated LOAD value %

Engine coolant temperature °C °F

Intake manifold absolute pressure kPa

Engine speed rpm

Vehicle speed km/h mph

Intake air temperature °C °F

Air flow rate from mass air flow sensor g/s

OBD requirement according to vehicle design —

Distance travelled while MIL is activated km miles

Fuel rail pressure kPa

F2

Sending Freeze Frame Data

• The Freeze Frame Data monitor items are shown below.

Freeze Frame Data monitor table

—: Not applicable

Full names Unit

DTC that caused required Freeze Frame Data storage —

Calculated LOAD value %

Engine coolant temperature °C °F

Intake manifold absolute pressure kPa

Engine speed rpm

Vehicle speed km/h mph

Intake air temperature °C °F

Air flow rate from mass air flow sensor g/s

Fuel rail pressure kPa

Sending Emission-related Malfunction Code

• The DTCs are shown below.

F2–19

Page 32

ON-BOARD DIAGNOSTIC

DTC Table

DTC No. Condition MIL DC

P0016 Crankshaft position-camshaft position correlation malfunction OFF 2 ×

P0045 Variable boost control (VBC) solenoid valve control circuit low input ON 2 ×

P0088 Fuel pressure system too high —— ×

P0093 Fuel system leak detection ON 1 ×

P0096 Intake air temperature (IAT) sensor No.2 range/performance problem ON 2 ×

P0097 Intake air temperature (IAT) sensor No.2 circuit low input ON 1 ×

P0098 Intake air temperature (IAT) sensor No.2 circuit high input ON 1 ×

P0101 Mass air flow (MAF) sensor range/performance problem ON 2 ×

P0102 Mass air flow (MAF) sensor circuit low input ON 1 ×

P0103 Mass air flow (MAF) sensor circuit high input ON 1 ×

P0106 Boost sensor range/performance problem ON 2 ×

P0107 Boost sensor circuit low input ON 1 ×

P0108 Boost sensor circuit high input ON 1 ×

P0111 Intake air temperature (IAT) sensor No.1 range/performance problem ON 2 ×

P0112 Intake air temperature (IAT) sensor No.1 circuit low input ON 1 ×

P0113 Intake air temperature (IAT) sensor No.1 circuit high input ON 1 ×

P0116 Engine coolant temperature (ECT) sensor range/performance problem ON 2 ×

P0117 Engine coolant temperature (ECT) sensor circuit low input ON 1 ×

P0118 Engine coolant temperature (ECT) sensor circuit high input ON 1 ×

P0122 Accelerator pedal position (APP) sensor No.1 circuit low input ON 1 ×

P0123 Accelerator pedal position (APP) sensor No.1 circuit high input ON 1 ×

P0182 Fuel temperature sensor circuit low input ON 1 ×

P0183 Fuel temperature sensor circuit high input ON 1 ×

P0191 Fuel pressure sensor range/performance problem OFF 2 ×

P0192 Fuel pressure sensor circuit low input ON 1 ×

P0193 Fuel pressure sensor circuit high input ON 1 ×

P0200 Fuel injector operation identified ON 1 ×

P0201 Fuel injector No.1 operation identified ON 1 ×

P0202 Fuel injector No.2 operation identified ON 1 ×

P0203 Fuel injector No.3 operation identified ON 1 ×

P0204 Fuel injector No.4 operation identified ON 1 ×

P0222 Accelerator pedal position (APP) sensor No.2 circuit low input ON 1 ×

P0223 Accelerator pedal position (APP) sensor No.2 circuit high input ON 1 ×

P0225 Idle switch circuit malfunction ON 2 ×

P0301 Cylinder No.1 misfire detection ON 1 ×

P0302 Cylinder No.2 misfire detection ON 1 ×

P0303 Cylinder No.3 misfire detection ON 1 ×

P0304 Cylinder No.4 misfire detection ON 1 ×

P0336 CKP sensor range/performance problem OFF 2 ×

P0337 CKP sensor circuit low input ON 1 ×

P0341 CMP sensor range/performance problem OFF 2 ×

P0342 CMP sensor circuit low input ON 1 ×

P0401 EGR flow insufficient detected ON 2 ×

P0402 EGR flow excessive detected ON 2 ×

P0404 EGR valve stuck ON 2 ×

P0406 EGR valve position sensor circuit high input ON 1 ×

P0489 EGR solenoid valve (vacuum) control circuit low input ON 2 ×

P0490 EGR solenoid valve (vacuum) control circuit high input ON 2 ×

P0500 Vehicle speed signal problem ON 2 ×

P0504 Brake switch signal correlation malfunction OFF 2 ×

P0512 Engine switch circuit high input ON 1 ×

P0562 Battery voltage low input ON 1 ×

P0563 Battery voltage high input ON 1 ×

Memory

function

F2–20

Page 33

ON-BOARD DIAGNOSTIC

DTC No. Condition MIL DC

P0564 Cruise control signal malfunction OFF 2 ×

P0602 PCM programming error ON 1 ×

P0606 PCM malfunction ON 1 ×

P0610 Control module vehicle options error ON 1 ×

P0627 Suction control valve circuit open ON 1 ×

P0628 Suction control valve circuit low input ON 1 ×

P0629 Suction control valve circuit high input ON 1 ×

P0661 Intake shutter solenoid valve (half) circuit low input ON 2 ×

P0662 Intake shutter solenoid valve (half) circuit high input ON 2 ×

P0664 Intake shutter solenoid valve (full) circuit voltage low input ON 2 ×

P0665 Intake shutter solenoid valve (full) circuit voltage high input ON 2 ×

P0704 Clutch switch circuit malfunction ON 2 ×

P0850 Neutral switch circuit malfunction ON 2 ×

P1190 Calibration resistor circuit malfunction ON 2 ×

P1211 Fuel pressure higher or lower than desired pressure ON 2 ×

P1391 Glow plug circuit low input OFF 2 ×

P1392 Glow plug circuit high input OFF 2 ×

P2009 Variable swirl control (VSC) solenoid valve circuit high input ON 2 ×

P2010 Variable swirl control (VSC) solenoid valve circuit low input ON 2 ×

P2135 Accelerator pedal position (APP) sensor No.1/No.2 voltage correlation ON 1 ×

P2136 Accelerator pedal position (APP) sensor No.1/idle switch correlation ON 1 ×

P2141 EGR solenoid valve (vent) circuit low input ON 2 ×

P2142 EGR solenoid valve (vent) circuit high input ON 2 ×

P2144 EGR solenoid valve circuit low input ON 2 ×

P2145 EGR solenoid valve circuit high input ON 2 ×

P2146 Fuel injector No.1/No.4 circuit malfunction ON 1 ×

P2149 Fuel injector No.2/No.3 circuit malfunction ON 1 ×

P2227 BARO sensor range/performance problem ON 2 ×

P2228 BARO sensor circuit low input ON 1 ×

P2229 BARO sensor circuit high input ON 1 ×

Memory

function

F2

Sending Continuous Monitoring System Test Results

• These appear when a problem is detected in a monitored system.

1-drive cycle type

• If any problems are detected in the first drive cycle, pending codes will be stored in the PCM memory, as well

as DTCs.

• After pending codes are stored, if the PCM determines that the system is normal in any future drive cycle, the

PCM deletes the pending codes.

2-drive cycle type

• The code for a failed system is stored in the PCM memory in the first drive cycle. If the problem is not found in

the second drive cycle, the PCM determines that the system returned to normal or the problem was mistakenly

detected, and deletes the pending code. If the problem is found in the second drive cycle too, the PCM

determines that the system has failed, and stores the pending codes, and the DTCs.

• After pending codes are stored, if the PCM determines that the system is normal in any future drive cycle, the

PCM deletes the pending codes.

End Of Sie

DTC DETECTION LOGIC AND CONDITIONS

P0016 Crankshaft position-camshaft position correlation malfunction

• The PCM monitors the input signals from the CKP sensor and CMP sensor while engine is running. If the input

signals from the CKP sensor and the CMP sensor do not correspond, the PCM determines that there is a

correlation malfunction between crankshaft and camshaft position.

P0045 Variable boost control (VBC) solenoid valve control circuit low input

• The PCM monitors the output signal when the PCM controls the variable boost control solenoid valve between

30 and 70%. If the current of the variable boost control solenoid valve is less than 0.8 A during variable boost

control solenoid valve control, the PCM determines that there is a malfunction in the variable boost control

solenoid valve control circuit.

B6E407000102103

F2–21

Page 34

ON-BOARD DIAGNOSTIC

P0088 Fuel pressure system too high

• The PCM monitors the fuel pressure in the common rail from the fuel pressure sensor while the engine running.

If the fuel pressure is more than 188 MPa {1,917 kgf/cm

pressure is too high.

P0093 Fuel system leak detection

• The PCM monitors the fuel pressure in the common rail from the fuel pressure sensor while the engine running.

If the fuel pressure is lower after the fuel injection than the preprogrammed criteria, the PCM determines fuel

system leakage.

P0096 Intake air temperature (IAT) sensor No.2 range/performance problem

• The PCM monitors the input signal from intake air temperature sensor No.2. If the difference between the

maximum and minimum value of the intake air temperature sensor No.2 is less than 1 °°°°C {1.8 °°°°F}, the PCM

determines that there is a malfunction in intake air temperature sensor No.2.

P0097 Intake air temperature (IAT) sensor No.2 circuit low input

• The PCM monitors the input signal from intake air temperature sensor No.2. If the voltage from intake air

temperature sensor No.2 is less than 0.14 V, the PCM determines that there is a malfunction in the intake air

temperature sensor No.2 circuit.

P0098 Intake air temperature (IAT) sensor No.2 circuit high input

• The PCM monitors the input signal from intake air temperature sensor No.2. If the voltage from intake air

temperature sensor No.2 is more than 4.92 V, the PCM determines that there is a malfunction in the intake air

temperature sensor No.2 circuit.

P0101 Mass air flow (MAF) sensor range/performance problem

• The PCM monitors the input signal from the mass air flow sensor when the engine speed is between 600 rpm

and 2,100 rpm. If the voltage characteristic of the air flow sensor signal is out of the threshold, the PCM

determines that there is a malfunction in the mass air flow sensor.

P0102 Mass air flow (MAF) sensor circuit low input

• The PCM monitors the input signal from the air flow sensor. If the voltage from the air flow sensor is less than

0.15 V, the PCM determines that there is a malfunction in the air flow sensor circuit.

P0103 Mass air flow (MAF) sensor circuit high input

• The PCM monitors the input signal from the air flow sensor. If the voltage from the air flow sensor is more than

4.9 V, the PCM determines that there is a malfunction in the intake air temperature sensor No. 2 circuit.

P0106 Boost sensor range/performance problem

• The PCM monitors the vacuum inside the intake manifold. If the difference of the vacuum inside the intake

manifold during middle engine speed and low engine speed is less than the threshold, the PCM determines

that there is a malfunction in the manifold absolute pressure sensor characteristic.

P0107 Boost sensor circuit low input

• The PCM monitors the input signal from the manifold absolute pressure. If the voltage from the manifold

absolute pressure sensor is less than 0.4 V, the PCM determines that there is a malfunction in the manifold

absolute pressure sensor circuit.

P0108 Boost sensor circuit high input

• The PCM monitors the input signal from the manifold absolute pressure sensor. If the voltage from the manifold

absolute pressure sensor is more than 4.8 V, the PCM determines that there is a malfunction in the manifold

absolute pressure sensor circuit.

P0111 Intake air temperature (IAT) sensor No.1 range/performance problem

• The PCM monitors the input signal from intake air temperature sensor No.1. If the difference between the

maximum and minimum value of the intake air temperature sensor No.1 is less than 1 °°°°C {1.8 °°°°F}, the PCM

determines that there is a malfunction in intake air temperature sensor No.1.

P0112 Intake air temperature (IAT) sensor No.1 circuit low input

• The PCM monitors the input signal from intake air temperature sensor No.1. If the voltage from intake air

temperature sensor No.1 is less than 0.14 V, the PCM determines that there is a malfunction in the intake air

temperature sensor No.1 circuit.

P0113 Intake air temperature (IAT) sensor No.1 circuit high input

• The PCM monitors the input signal from intake air temperature sensor No.1. If the voltage from intake air

temperature sensor No.1 is more than 4.92 V, the PCM determines that there is a malfunction in the intake air

temperature sensor No.1 circuit.

P0116 Engine coolant temperature (ECT) sensor range/performance problem

• The PCM monitors the input signal from the engine coolant temperature sensor. If the difference between the

maximum and minimum value of the engine coolant temperature is less than 3 °°°°C {5.4 °°°°F}, the PCM

determines that there is a malfunction in the engine coolant temperature sensor characteristic.

P0117 Engine coolant temperature (ECT) sensor circuit low input

• The PCM monitors the input signal from the engine coolant temperature sensor. If the voltage from the engine

coolant temperature sensor is less than 0.14 V, the PCM determines that there is a malfunction in the engine

coolant temperature sensor circuit.

P0118 Engine coolant temperature (ECT) sensor circuit high input

• The PCM monitors the input signal from the engine coolant temperature sensor. If the voltage from the engine

coolant temperature sensor is more than 4.92 V, the PCM determines that there is a malfunction in the engine

2

, 27,267 psi}, the PCM determines that the fuel

F2–22

Page 35

ON-BOARD DIAGNOSTIC

coolant temperature sensor circuit.

P0122 Accelerator pedal position (APP) sensor No.1 circuit low input

• The PCM monitors the input signal from accelerator pedal position sensor No.1. If the voltage from accelerator

pedal position sensor No.1 is less than 0.3 V, the PCM determines that there is a malfunction in the

accelerator pedal position sensor No.1 circuit.

P0123 Accelerator pedal position (APP) sensor No.1 circuit high input

• The PCM monitors the input signal from accelerator pedal position sensor No.1. If the voltage from accelerator

pedal position sensor No.1 is more than 4.7 V, the PCM determines that there is a malfunction in the

accelerator pedal position sensor No.1 circuit.

P0182 Fuel temperature sensor circuit low input

• The PCM monitors the input signal from the fuel temperature sensor. If the voltage from the fuel temperature

sensor is less than 0.14 V, the PCM determines that there is a malfunction in the fuel temperature sensor

circuit.

P0183 Fuel temperature sensor circuit high input

• The PCM monitors the input signal from the fuel temperature sensor. If the voltage from the fuel temperature

sensor is more than 4.92 V, the PCM determines that there is a malfunction in the fuel temperature sensor

circuit.

P0191 Fuel pressure sensor range/performance problem

• The PCM monitors the fuel pressure in the common rail and input signal from the fuel pressure sensor while

the engine is running. If any one of the following conditions is met, the PCM determines that there is

malfunction in the fuel pressure sensor range/performance problem.

— The PCM calculates the difference between the actual fuel pressure and the target fuel pressure. If the

pressure difference more than 2 MPa {20 kgf/cm

malfunction in fuel pressure sensor range/performance problem.

— The PCM monitors the input signal from fuel pressure sensor. If the difference between the maximum and

minimum value of the fuel pressure sensor is less than 0.015 V, the PCM determines that there is a

malfunction in fuel pressure sensor range/performance problem.

P0192 Fuel pressure sensor circuit low input

• PCM monitors input voltage from fuel pressure sensor while engine is running. If input voltage from fuel

pressure sensor is less than 0.4 V, PCM determines fuel pressure sensor circuit low input.

P0193 Fuel pressure sensor circuit high input

• PCM monitors input voltage from fuel pressure sensor while engine is running. If input voltage from fuel

pressure sensor is more than 4.86 V, PCM determines fuel pressure sensor circuit high input.

P0200 Fuel injector operation identified

• The PCM monitors each cylinder injection confirmation signal from the IDM while the engine is running. If the

PCM does not receive the injection confirmation signal for unspecified cylinder normally, the PCM determines

that the unspecified cylinder fuel injector operation is not verified.

P0201 Fuel injector No.1 operation identified

• The PCM monitors each cylinder injection confirmation signal from the IDM while the engine is running. If the

PCM does not receive the injection confirmation signal for No.1 cylinder normally, PCM determines that the fuel

injector No.1 operation is not verified.

P0202 Fuel injector No.2 operation identified

• The PCM monitors each cylinder injection confirmation signal from the IDM while the engine is running. If the

PCM does not receive the injection confirmation signal for No.2 cylinder normally, the PCM determines that the

fuel injector No.2 operation is not verified.

P0203 Fuel injector No.3 operation identified

• The PCM monitors each cylinder’s injection confirmation signal from the IDM while the engine is running. If the

PCM does not receive the injection confirmation signal for No.3 cylinder normally, the PCM determines that the

fuel injector No.3 operation is not verified.

P0204 Fuel injector No.4 operation identified

• The PCM monitors each cylinder injection confirmation signal from the IDM while the engine is running. If the

PCM does not receive the injection confirmation signal for No.4 cylinder normally, the PCM determines that the

fuel injector No.4 operation is not verified.

P0222 Accelerator pedal position (APP) sensor No.2 circuit low input

• The PCM monitors the input signal from accelerator pedal position sensor No.2. If the voltage from accelerator

pedal position sensor No.2 is less than 0.3 V, the PCM determines that there is a malfunction in the

accelerator pedal position sensor No.2 circuit.

P0223 Accelerator pedal position (APP) sensor No.2 circuit high input

• The PCM monitors the input signal from accelerator pedal position sensor No.2. If the voltage from accelerator

pedal position sensor No.2 is more than 4.7 V, the PCM determines that there is a malfunction in the

accelerator pedal position sensor No.2 circuit.

P0225 Idle switch circuit malfunction

• The PCM monitors the input signals from the accelerator pedal position sensor and the idle switch. If the idle

switch is off even if the voltage from the accelerator pedal position sensor No.2 is less than 0.75 V, the PCM

determines that there is a malfunction in the idle switch circuit.

2

, 290 psi}, the PCM determines that there is a

F2

F2–23

Page 36

ON-BOARD DIAGNOSTIC

P0301, P0302, P0303, P0304 Cylinder No.1/No.2/No.3/No.4 misfire detection

• The PCM monitors the CKP sensor input signal interval time. The PCM calculates the deviation of the interval

time for each cylinder. If the deviation of interval time exceeds the preprogrammed criteria, the PCM detects a

misfire in the corresponding cylinder. While the engine is running, the PCM counts the number of misfires and

calculates misfire ratio for each crankshaft revolution. If the ratio exceeds the preprogrammed criteria, the PCM

determines that a misfire, which can affect emission performance, has occurred.

P0336 CKP sensor range/performance problem

• The PCM monitors input signal from the CKP sensor while the engine is running. If the input signal from the

CKP sensor does not correspond with the proper pulse number, the PCM determines CKP sensor performance

problem.

P0337 CKP sensor circuit low input

• The PCM monitors the input signal from the CKP sensor and the CMP sensor while the engine is running. If the

input signal from the CKP sensor is not input while the PCM detects 28 pulses from the CMP sensor, the PCM

determines that there is a malfunction in the CKP sensor circuit.

P0341 CMP sensor range/performance problem

• The PCM monitors the input signal from the CMP sensor while the engine is running. If the input signal from the

CMP sensor does not correspond with the proper pulse number, the PCM determines CMP sensor

performance problem.

P0342 CMP sensor circuit low input

• The PCM monitors the input signal from the CMP sensor and the CKP sensor while the engine is running. If the

input signal from the CMP sensor is not input while the PCM detects 255 pulses from the CKP sensor, the

PCM determines that there is a malfunction in the CMP sensor circuit.

P0401 EGR flow insufficient detected

• The PCM monitors the difference between the target air amount and intake air amount while the EGR system is

operating. If the difference between the target air amount and the intake air amount is less than the threshold,

the PCM determines that there is a malfunction in the EGR system.

P0402 EGR flow excessive detected

• The PCM monitors the difference between the target air amount and intake air amount while the EGR system is

operating. If the difference between the target air amount and the intake air amount is more than the threshold,

the PCM determines that there is a malfunction in the EGR system.

P0404 EGR valve stuck

• The PCM monitors the input signal from the EGR valve position sensor while the EGR system is operating. If

the output voltage difference is less than threshold when the EGR flow amount changes, the PCM determines

that there is a malfunction in the EGR valve.

P0406 EGR valve position sensor circuit high input

• The PCM monitors the input signal from the EGR valve position sensor. If the voltage from the EGR valve