Mazda 323 GTR 1992, 323 1992 User Manual

Mazda 323

o Workshop

b Manual

Supplement

FOREWORD

This is a supplement to the workshop manua!(s) shown below. This supplement describes

service procedures of. new or modified mechanicat and/or ekctrical systems. For service

procedures and important safety notices not

contained in this supplement, please refer to

the previous workshop manual.

Workshop Manual:

Form No.1 203-l O-89F (vol. 1)

1206-1 O-89F (Vol.2)

1229-l O-89L

1275-l O-91 c

b

All information in this supplement was the

latest available at the time of printing, ail alter-

nations related to modifications will be notified

by Service Sulletin.

Mazda Motor Corporation

HIROSHIMA, JAPAN

P

APPLICATION:

This manual is applicable to vehicles beginning

with the Vehicle Identification Numbers (VIN)

shown on the following page.

CONTENTS

r

eneral Information

IG

Pre-Delivery inspection and

Scheduled Maintenance

I Lubrication System

j Cooling System

Fuel and

Emission

Controt

System

-Electrica I System

Clutch

I--

Manual

Transaxie

Automatic

Transaxle

I

[ Propefier Shaft

1 Front and Rear Axles

ISteerIng System

Braking System

IWheels and Tires

ISusiension

Title Section

Carburetor

m

EGi unieaded Fuel BP (DOHC

and S

Diesel

1 Electronically Co Introlled

Hydraulicaf~y’Co~~~rull=;u

1 Transfer

!I

1 Bodv Electricat System

1 Heater and Air Conditioner System

1 Technical Data

Special Toots

Parts Index

/ Wiring

, Diagram

This manual explains onty the secticlns marked with shadows (-1

0 1992 Mazda Motor Corporation

PR1NTED tN JAPAN, JAN., ‘92 @I

1318010192A

Refer to the form No.

5232-l 0-92A

--

VEHlCLE IDENTlFlCATION NUMBERS (VtN)

3MZ BG83J200 50000t-

Gf

>

3

3

c

m

GENERAL INFORMATION

1MPORTANT INFORMATION

BASIC ASSUMPTIONS ............................ a- 2

SAFETY RISK

POSSIBLE LOSS OF WARRANTY

WARNING ON LUBRICANTS

AND GREASES

HOW TO USE THIS MANUAL..

PREPARATION

REPAtR PROCEDURE .............................

SYMBOLS .............................................

NOTES, CAUTIONS, AND WARNINGS.. .....

FUNDAMENTAL PROCEDURES

PROTECTION OF THE VEHICLE .............. G1- 4

A WORD ABOUT SAFE-T-Y

PREPARATION OF TOOLS

AND MEASURING EQUIPMENT ............. Gi- 5

SPECIAL TOOLS ....................................

REMOVAL OF PARTS .............................

DISASSEMBLY ......................................

REASSEMBLY

ADJUSTMENTS .....................................

RUBBER PARTS AND TUBtNG ................ GI- 7

JACK AND SAFETY STAND POStTlONS .... GI- 8

VEHICLE LIFT (20SUPPORT TYPE)

POSITIONS ............................................

MAINTENANCE NOTE ..............................

SPEEDOMETER TESTER CHECK

BRAKE TESTER CHECK

CHASSIS DYNAMOMETER CHECK.. ......... Gl-I 0

WHEEL BALANCE.R ...............................

TOWtNG ...............................................

IDENTlFiCATlON NUMBER LOCATIONS

.UNlTS .....................................................

ABBREVIATIONS

CAUTION

INSTALLATlON OF MOBILE TWO-WAY

RADIO SYSTEM ...................................

PRECAUTIONS TO TAKE WHEN

SERVICING AN ELECTRICAL SYSTEM ..i GI-f4

HANDLING CONNECTORS ..................... GI-f 5

USING ELECTRICAL

EQUIPMENT ........................................

........................................ Gl- 2

....................................

...................................... GI- 3

....................................... GI- 6

.....................................

................................................

MEASURlNG

..................... GI- 2

............. Gl- 2

GI- 2

.................. GI- 3

GI- 3

GI- 4

Gl- 4

................. GI- 4

....................... Gl- 5

GI- 5

GI- 5

GI- 5

Gl- 7

GI- 6

GI- 9

............. GI- 9

......................... GI- 9

GI-I 0

GI-I 0

GI-I

.....

2

GI-I 2

GI-12

GI-13

Gl-13

GI-16

13EGIX-30

I

1

GI

tMPORTANT INFORMATION

IMPORTANT INFORMATION

BASIC ASSUMPTIONS

This workshop manual assumes that you have certarn special tools that are necessary for the safe and

efficient performance of service operations on Mazda vehicles and that you know how to use them properly.

It also assumes that you are familiar with automobile systems and basic service and repair procedures.

YOU should not attempt to use this manual unless these assumpttons are correct and you understand the

consequences described below.

SAFETY RtSK

This manual contains certain notes, warnings, and other precautionary information that you should care-

fully read and follow to reduce the risk of personal injury to yourself or others and the risk of improper

service that may damage the vehicle or render it unsafe. If there IS no such information in regard to any

specific service method, this does not mean there is no possibility that personal safety or vehicle safety

wili be jeopardized by the use of incorrect methods or tools.

POSStBLE LOSS OF WARRANTY

The manufacturer’s warranty on Mazda vehicles and engines can be voided if improper service or repairs

are performed by persons other than those at an Authorked Mazda Dealer.

WARNtNG ON LUBRtCANTS AND GREASES

Avoid all prolonged and repeated contact with mineral oils, especially used oils. Used oils contaminated

during service (e+g., engine sump oils) are more irritating and more likely to cause serious effects, including skin cancer, in the event of gross and prolonged skin contact.

Wash skin thoroughly after work involving 011.

Protective hand cleaners may be of value provided they can be removed from the skin with water Do

not use gasoline, paraffin, or other solvents to remove oil from the skrn.

Lubricants and greases may be slightly irritating to the eyes.

REP/

I. Mc

pai

2. &

illu:

3. Put

vir:

Exarr

Repeated or protonged skin contact shoutd be avoided by wearing protective clothing if necessary. Par-

ticular care should be taken with used oils and greases containing lead. Do not allow work clothing .to

be contaminated with oil. Dry clean or launder such clothing at regular intervals.

9MtlGIX-002

SHOI

EXPE

PART

SHOW

REUl

PAGE

SEWI

‘1: T

*2: c

Gt-2

HOW TO USE THIS MANUAL

3

PREPARATION

3

,

Examde:

HOW TO USE THIS MANUAL

PREPARATION points out the needed Special Service Tool (SST) for the service operation that it pro- m

ceeds. Gather all necessary SST before beginning work.

MANUAL STEERING

PREPARATlON

SST

49’0118 85oC

Puller, ball tolnt

For

removal of he-rod

end

SST NUMBER

1

49 0118 85oC

USAGE

1

For

removal of Wrod

end

GI

S&T NAME

REPAIR PROCEDURE

>

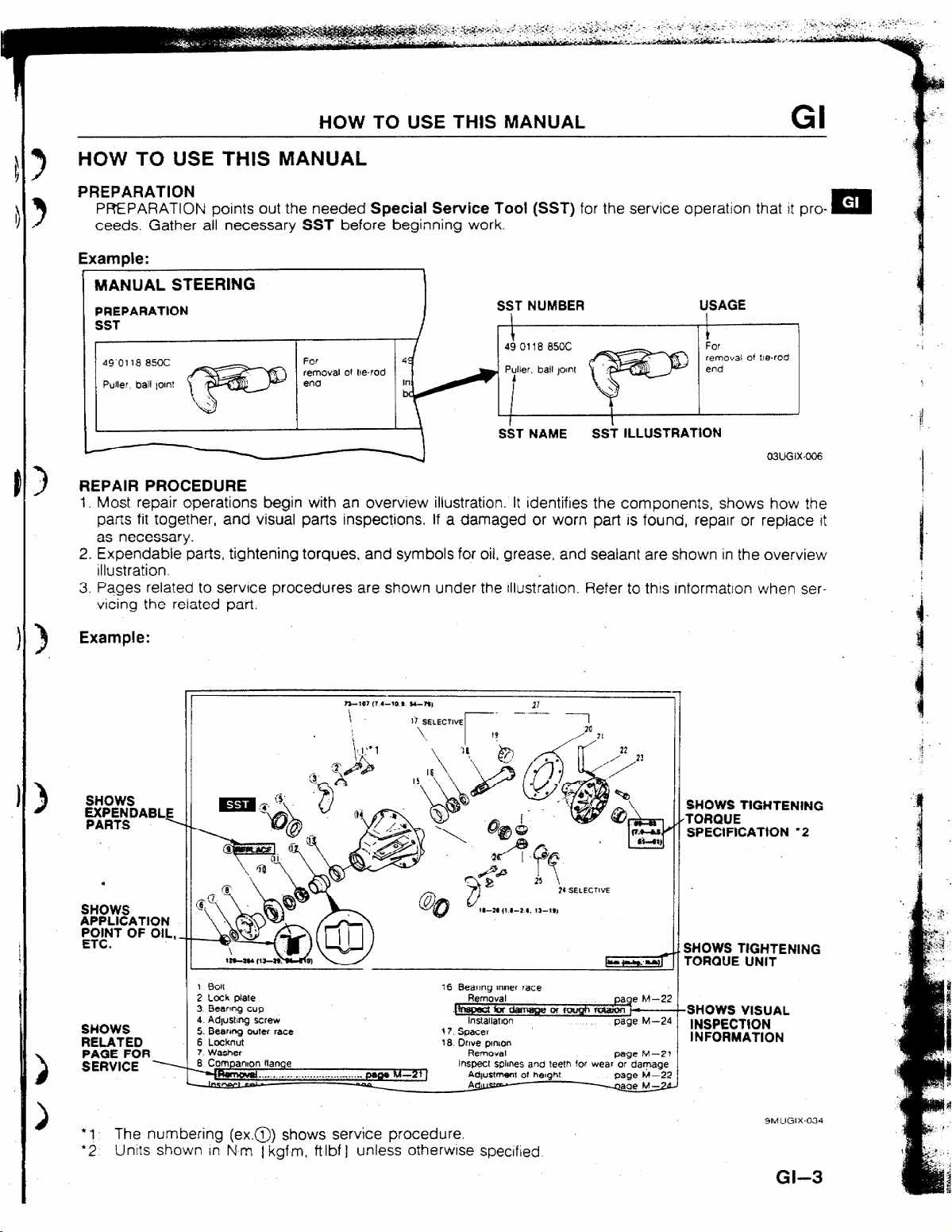

I. Most repair operations begin with an overview illustration. It identifies the components, shows how the

parts fit together, and visual parts inspections. If a damaged or worn part is found, repair or replace it

as necessary.

2. Expendable parts, tightening torques, and symbols for oil, grease, and sealant are shown in the overview

illustration.

3. Pages related to service procedures are shown under the tllustration. Refer to this informatron when ser-

vicing the related part

Example:

1.

3

SHOWS

yA;ytDABLE

.

SS; ILLUSTRATlON

SHOWS TIGHTENING

TORQUE

SPECIFICATION l 2

SHOWS

APPLICATION

;v’dT OF OlL, _

1 Bolt

2 Lock Nate

3 Bearmg cup

SH

3ws

RE

.ATED

3E FOR

?VICE .

2

4 Adtustmg screw

5 Bearing outer race

6 Locknut

7 Washer

>

>

*I The numbering (ex.@> shows service procedure.

l 2 Unrts shown in N m 1 kgf m, ftlbf ] unless otherwlse speclfted

16 Beanno Inner race

Rem&al

17 Spacer

18 lhve olnion

hspect sphes and teeIh for wear ordaqge

page M-24

Daoe M-21

SHOWS TIGHTENING

TORQUE UNIT

SHOWS VISUAL

INSPECTION

INFORMATION

:

9MlJGIX~034

Gl-3

GI

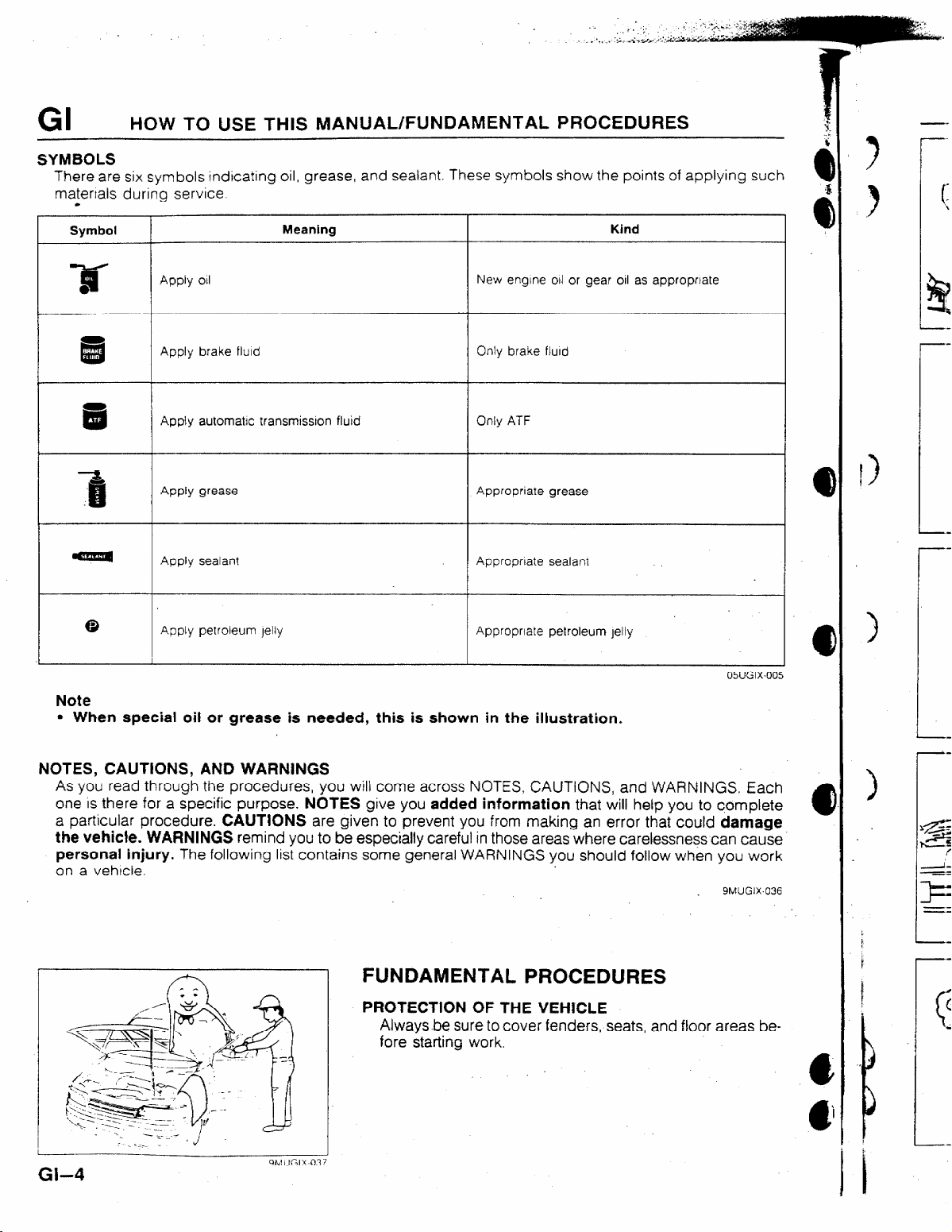

SYM00LS

There are six symbols indicating oil, grease, and sealant. These symbols show the points of applying such

matertals during service

*

Symbol

HOW TO USE THIS MANUAL/FUNDAMENTAL PROCEDURES

Meaning Kind

1

T.

i

8

s

Q

w-

l

0

Note

l

When special

Apply otl

Apply brake fluid Only brake fluId

I

Apply automatic transmtsslon fluid Only ATF

Apply grease Appropriate grease

Apply sealant Approprrate sealant

Apply petroleum Jelly

oil or grease is needed,

this is shown in the illustration.

New engtne 011 or gear 011 as approprkate

Appropriate petroleum jetty

8

e

05UGIX-005

NOTES, CAUTIONS, AND WARNINGS

As you read through the procedures, you will come across NOTES, CAUTIONS, and WARNINGS. Each

one IS there fur a specific purpose.

a particular procedure. CAUTlONS are given to prevent you from making an error that could damage

the vehicle. WARNINGS remind you to be especially careful in those areas where carelessness can cause

personal injury. The following list contains some general WARNINGS you should follow when you work

on a vehrcle

NOTES

give you added information that wilt help you to complete

. 9MUGlX.036

FUNDAMENTAL PROCEDURES

PROTECTION OF THE VEHICLE

Always .be sure to cover fenders, seats, and

fore starting work.

floor areas be-

FUNDAMENTAL PROCEDURES

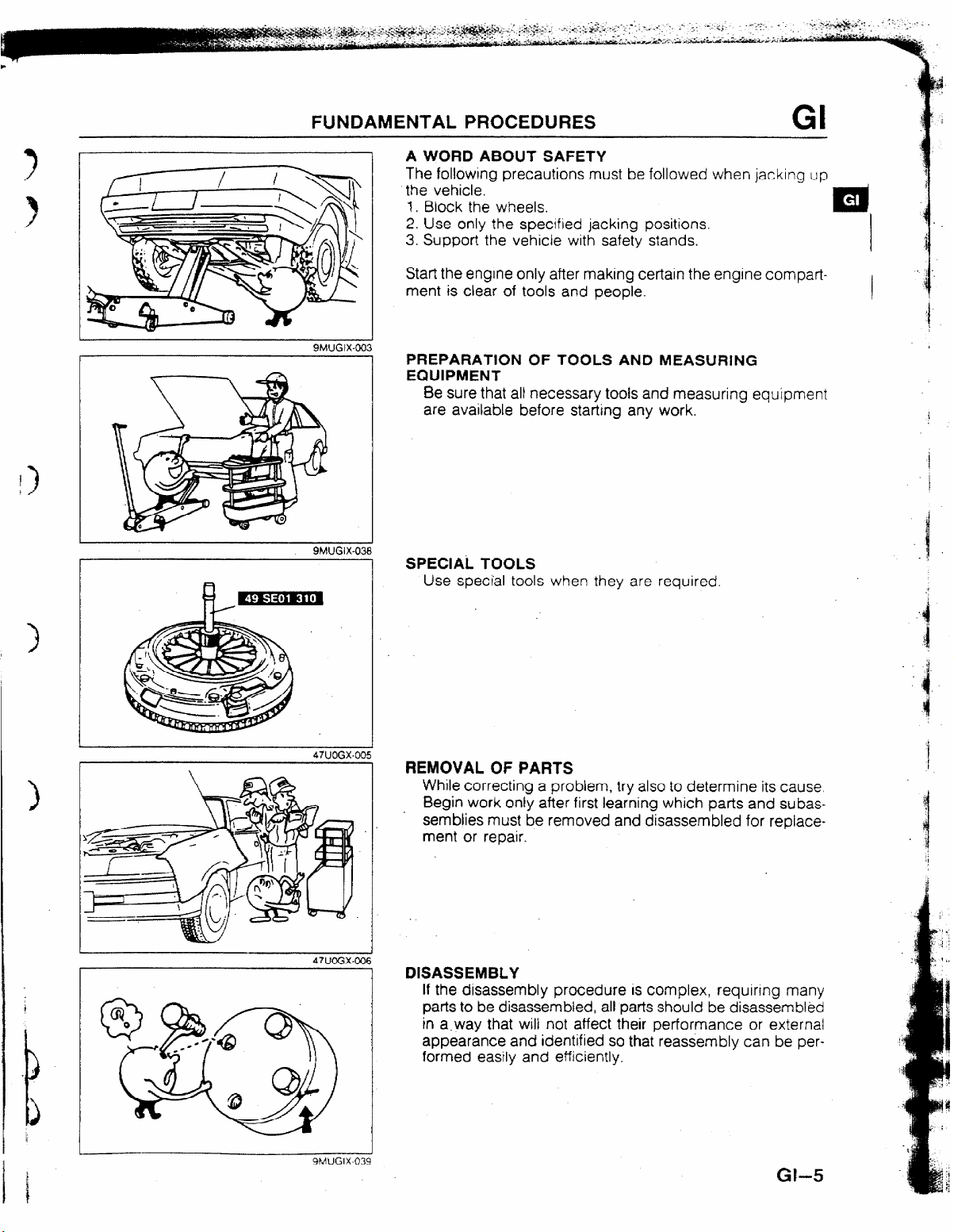

A WORD ABOUT SAFETY

The following precautions must be followed when jacking up

the vehicle.

t . Block the wheels.

2. Use only the specfred jacking positions.

3. Support the vehicle with safety stands.

Start the engine only after making certain the engine compart-

ment is clear of tools and people.

GI

j

>

9MUGtX-003

I 1

47UOGX-Cm

PREPARATION OF TOOLS AND MEASURING

EQUIPMENT

8e sure that al! necessary toois and measuring equipment

are available before starting any work.

SPECIAL TOOLS

Use special tools when they are required.

REMOVAL OF PARTS

While correcting a problem, try also to determine its cause

Begin work only after first learning which parts and subas-

semblies must be removed and disassembled for replacement or repair.

I 1

DISASSEMBLY

If the disassembly procedure is complex, requiring many

parts to be disassembled, all parts should be disassembled

in a.way that wiii not affect their performance or external

appearance and identified so that reassembly can be performed easily and efficiently.

I

9MUGIX 039

J

a-5

GI

FUNDAMENTAL PROCEDURES

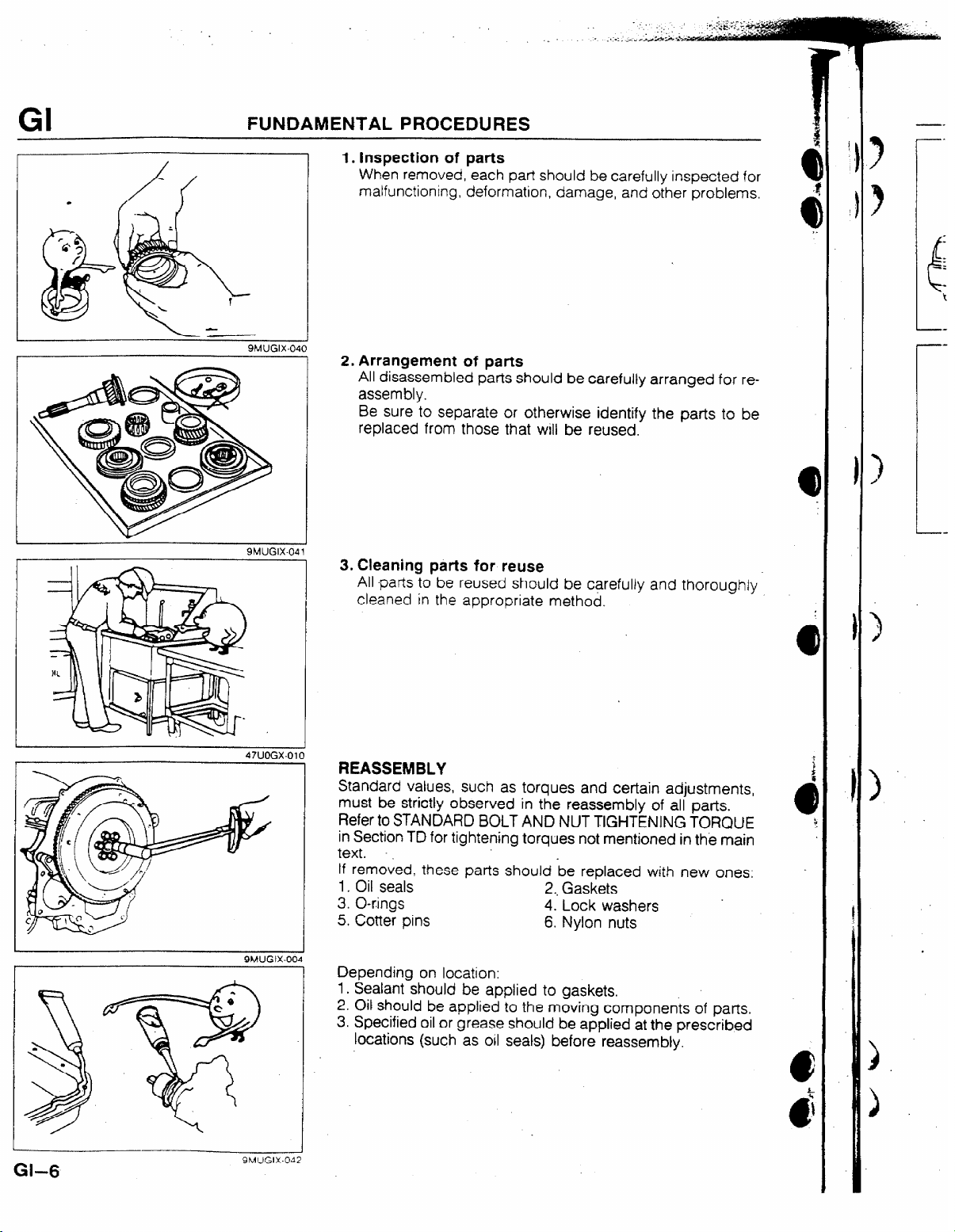

I. Inspection of parts

When removed, each part should be carefully inspected for

malfunctioning, deformation, damage, and other problems.

2. Arrangement of parts

All disassembled parts should be carefully

assembly.

Be sure to separate or otherwise identify the parts to be

replaced from those that will be reused.

3. Cteaning parts for reuse

All parts to be reused should be carefully and thoroughly

cleaned in the appropriate method.

arranged

for re-

Gl-6

9MUGIX-042

REASSEMBtY

Standard values, such as torques and certain adjustments,

must be

Refer to STANDARD BOLT AND NUT TIGHTENING TORQUE

in Section TD for tightening torques not mentioned in the main

text.

tf removed, these parts should be replaced with new ones:

1. Oil seals

3. O-r.ings

5. Cotter pins

Depending on location:

1. Sealant should be applied to gaskets.

2. Oil should be applied

3. Specified oil or grease should be applied at the prescribed

strictly

observed in the reassembly of all parts.

2, Gaskets

4. Lock washers

6. Nylon nuts

to

the moving components of parts.

locations (such as oil seals) before reassembty.

.

FUNDAMENTAL PROCEDURES

ADJUSTMENTS

Use suitable gauges and/or testers when making ad-

justments.

RUBBER PARTS AND TUBING

Prevent gasoline or oil from getting on rubber parts or

tubing.

GI

.

JACK AND SAFETY STAND POSlTiOtWVEHlCLE LIFT (2-SUPPORT TYPE) POSlTlONS

GI

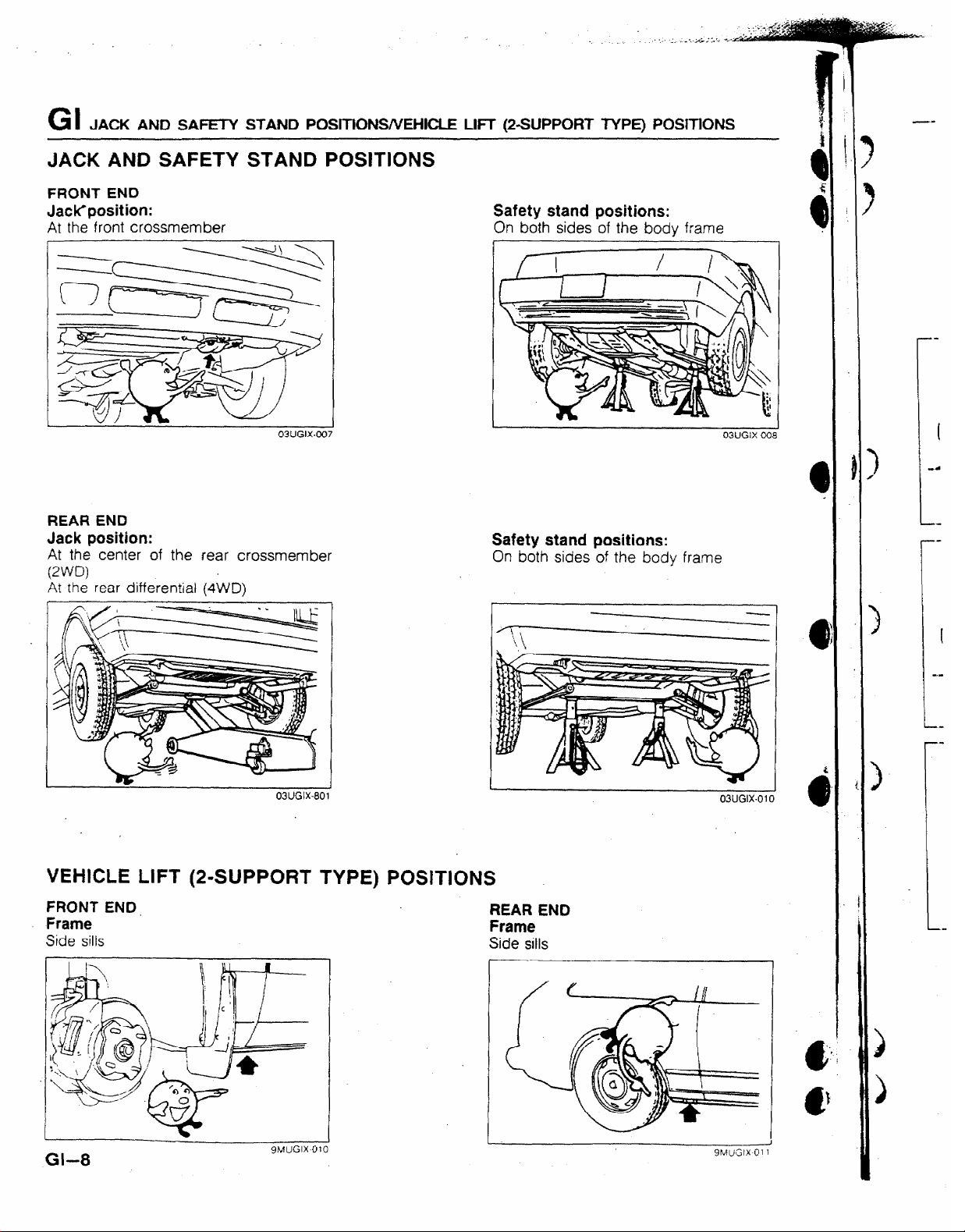

JACK AND SAFETY STAND POSITIONS

_ .

FRONT END

JacKposition:

At the front crossmember

REAR END

Jack position:

At the center of the rear crossmember

At the rear differential (4WD)

Safety stand positions:

On both sides of the body frame

Safety stand positions:

On both sides of the body frame

--

03UGW80

VEHICLE LIFT (2-SUPPORT TYPE) POSITIONS

FRONT END,

Frame

Side sills

9MuGIX 010

REAR END

Frame

Side sills

9MVGtX 01

MAlNTENANCE NOTE

MAlNTENANCE NOTE

GI

.

FREE ROLLER

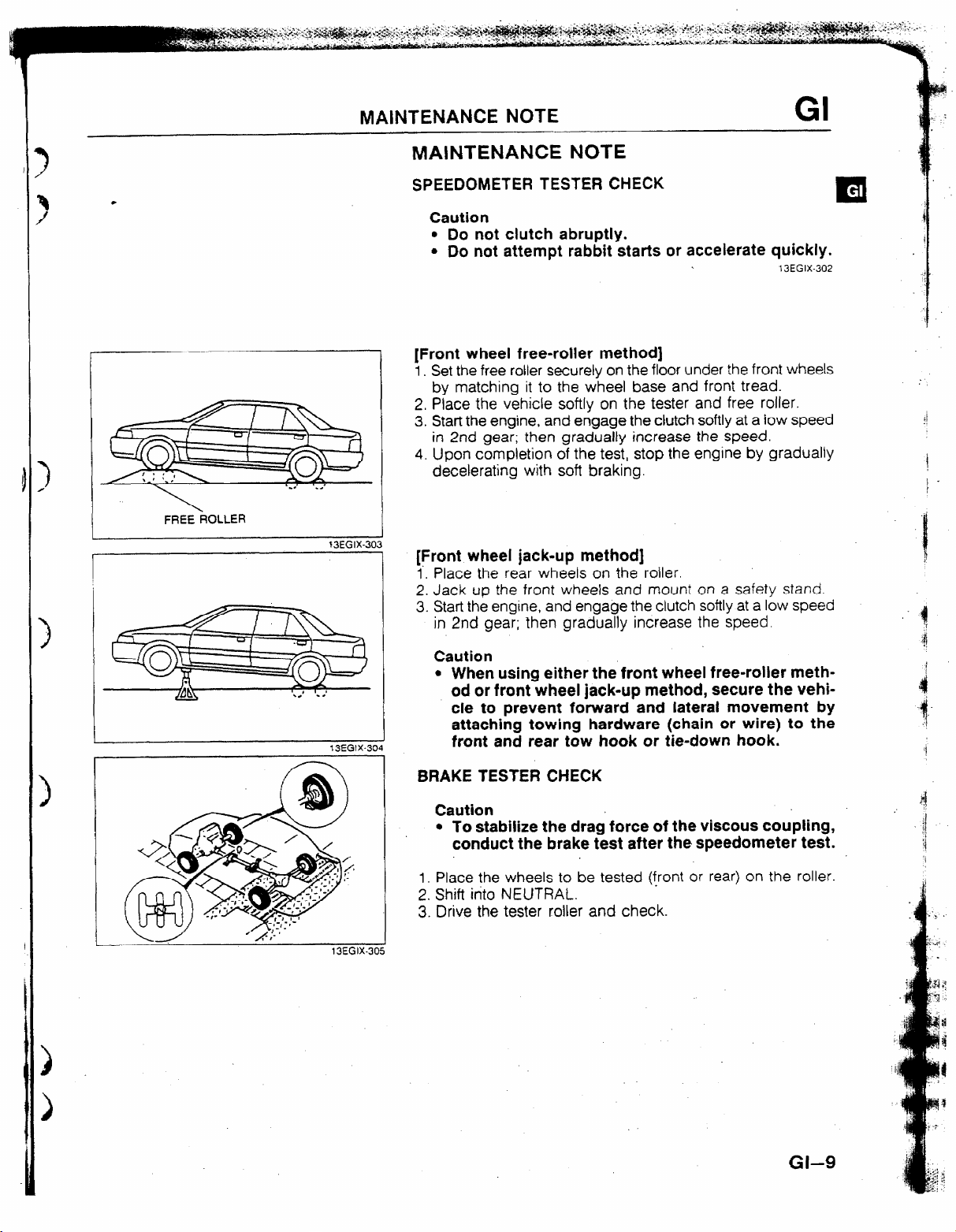

SPEEDOMETER TESTER CHECK

Caution

l

Do not clutch abruptly.

l

Do not attempt rabbit starts or accelerate quickly.

[Front wheel free-roller method]

1. Set the free roller securely on the floor under the front wheels

by matching it to the wheel base and front tread.

2. Place the vehicle softly on the tester and free roller.

3. Start the engine, and engage the clutch softly at a low speed

in 2nd gear; then gradually increase the speed.

4. Upon completion of the test, stop the engine by gradually

decelerating with soft braking.

[Front wheel jack-up method1

1’. Place the rear wheels on the roller.

13EGIX-302

2. Jack up the front wheels and mount on a safety stand.

3. Start the engine, and engage the clutch softly at a low speed

in 2nd gear; then gradually increase the speed.

t 3EGlX-304

Caution

l

When using either the front wheel free-roller method or front wheel jack-up method, secure the vehicle to prevent forward and lateral movement by

I

attaching towing hardware (chain or wire) to the

front and rear tow hook or tie-down hook.

BRAKE TESTER CHECK

Caution

. To stabilize the drag force of the viscous coupling,

conduct the brake test after the speedometer test.

1. Place the wheels to be tested (front or rear) on the roller.

2. Shift itit0 NEUTRAL.

3. Drive the tester roller and check.

a-9

GI

MAINTENANCE NOTE

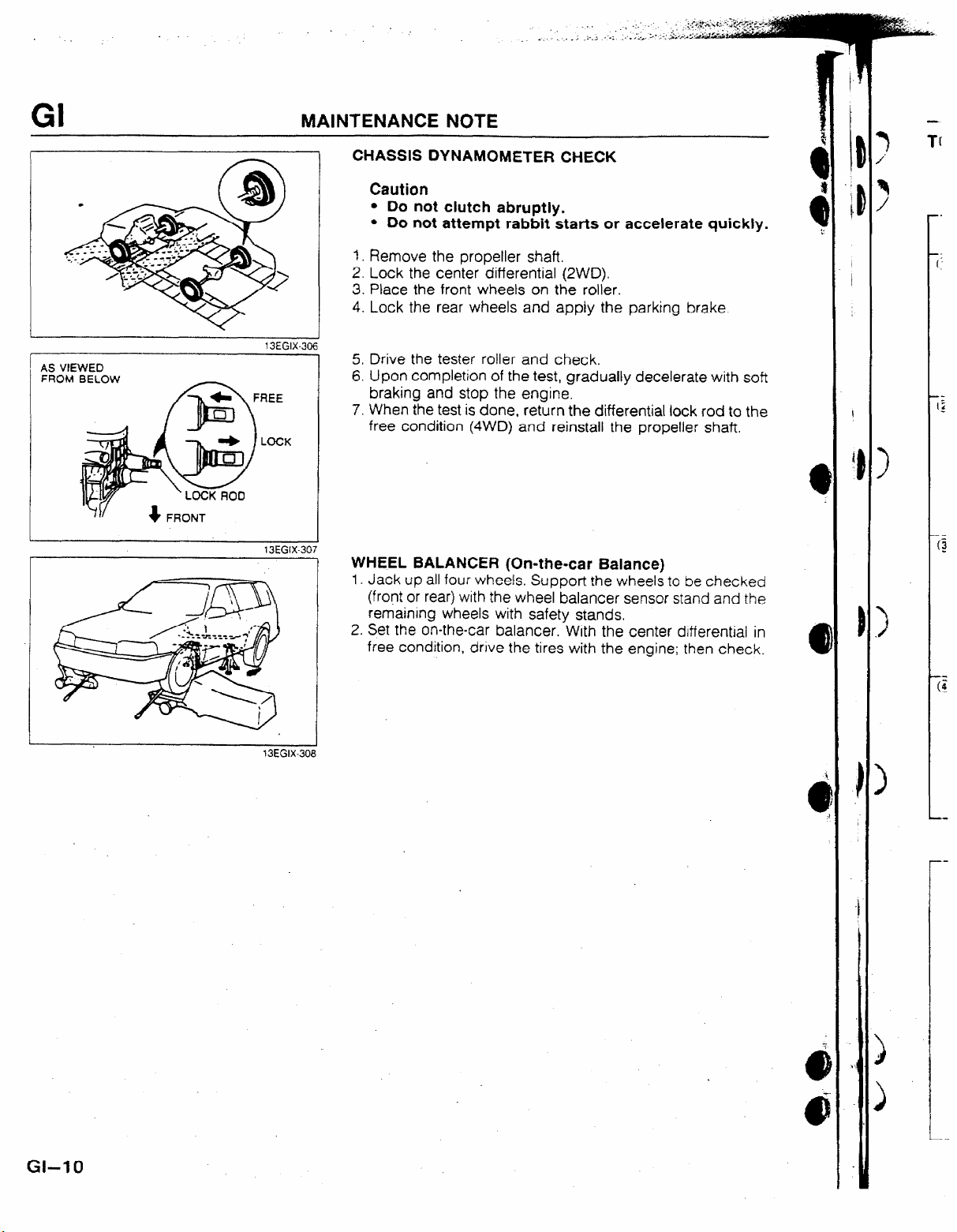

CHASSIS DYNAMOMETER CHECK

Caution

l

Do

not clutch

l

Do not attempt rabbit starts or accelerate quickly.

1. Remove the propeller shaft.

2. Lock the center differential (2WD).

3. Place the front wheets on the roller.

4. Lock the rear wheels and apply the parking brake.

abruptly.

VIEWED

.OM BELOW

‘REE

13EGfX-307

t3EGIX-308

5. Drive the tester roller and check.

6. Upon completion of the test, gradually decelerate with soft

braking

and stop the engine.

7. When the test is done, return the differential lclck rod to the

free condition (4WD) and reinstall the propeller shaft.

WHEEL BALANCER (On-the-car Balance)

I

1.

Jack

up all four wheels. Support the wheels to be checked

(front or rear) with the wheel balancer sensor stand and the

remainrng wheels with safety stands.

2. Set the on-the-car balancer. With the center differential in

free condition, drove the tires with the engine; then check.

I

MAINTENANCE NOTE

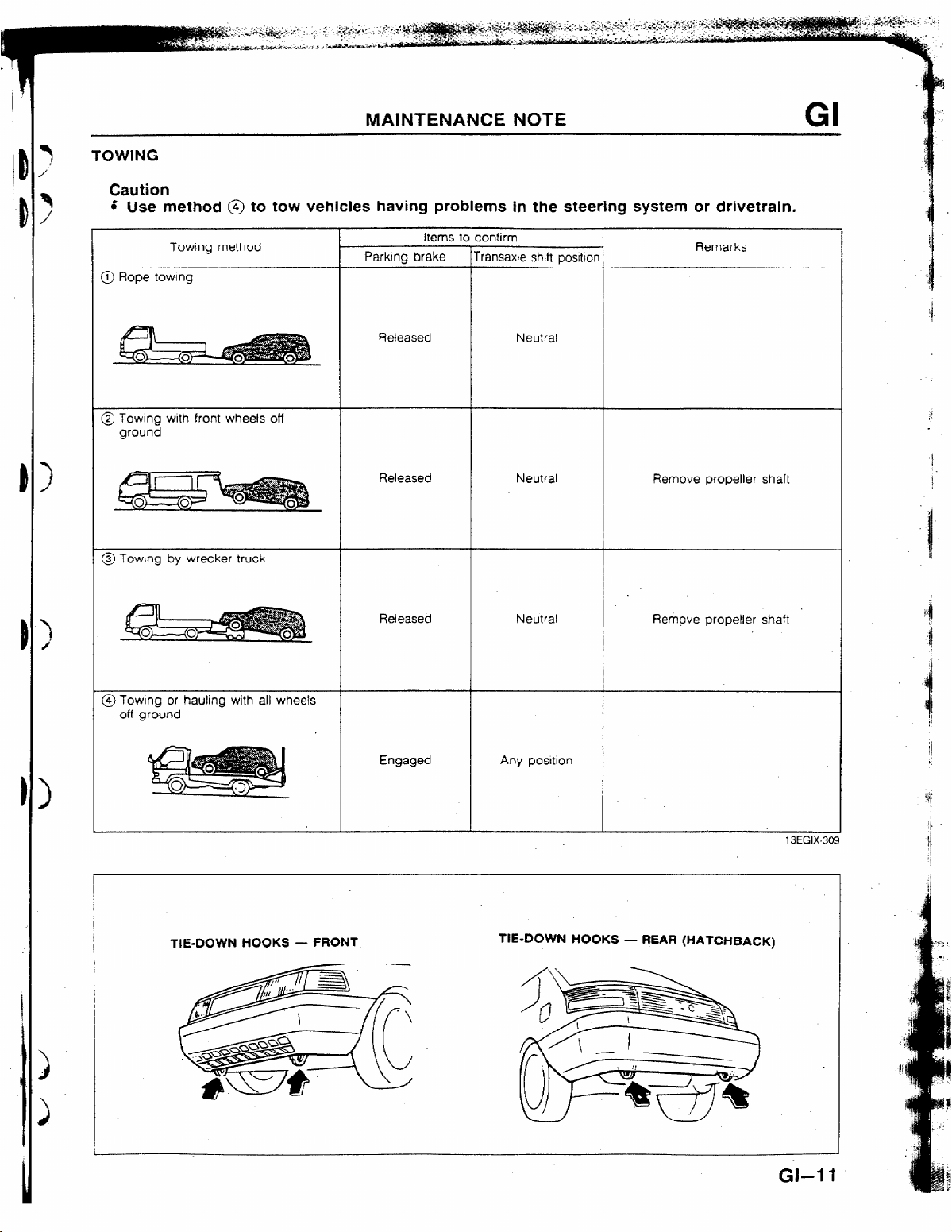

TOWlNG

Caution

g Use method @I to tow vehicles having problems in the steering system or drivetrain.

Towing method

0 Rope towing

@ Towlng with front wheels off

ground

@ Towtng by wrecker truck

@Towing or hauling with all wheels

off ground

items to confirm

Parking brake Transaxle shtft posttton

Released Neutral

Released Neutral Remove propeller shaft

Released Neutral

Remarks

Rempve propetler shaft

!

TIE-DOWN HOOKS - FRONT

Engaged Any posItIon

TIE-DOWN HOOKS

13EGIX.30

- REAR (HATCHBACK)

GI

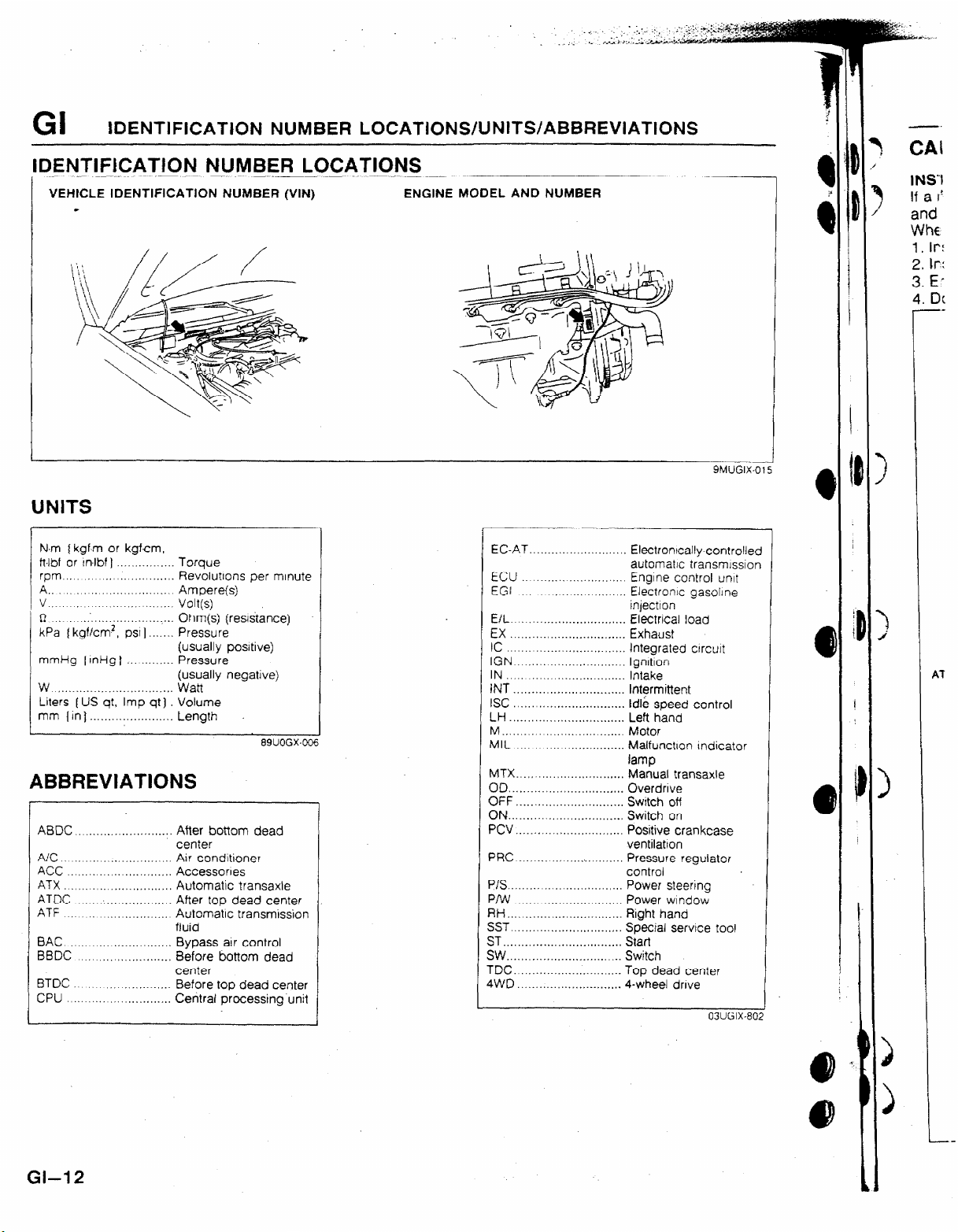

IDENTIFICATION NUMBER tOCATlONS/UNlTS/ABBREVIATlONS

IDENTIFICATION NUMBER LOCATIONS

VEHICLE tDENTtRCATtUN NUM8ER (VIM) ENGINE MODEL AND NUMBER

I

UNITS

N.rn { kgf m or kgfcm,

f-t&f or tn.lbf 1 . . . . . . . . . . . . . . . . Torque

rpm ._ . . . Revolutions per minute

A.. ,_...___.... Ampere(s)

v I... Volt(s)

$2 . .._..__......_.....__... Ohm(s) (resls‘tance)

kPa { kgflcm*, psr] . . . . . . . Pressure

mmHg I inl-lg ] . . . . . . . . . Pressure

W . . . ._ .._.__ .._ . . . . . . ..,......... Watt

titers [US qt, Imp qt 1 . V&me

mm { rn 1 . . . . . . . . . . . . . . . . . . . . . . . Length

{usually positive)

(usually negatrve)

89UOGX-006

ABBREWATIONS

ABDC _. . . . . . . . . . . After bottom dead

A/C . . . . . . . ._.. _. . . . . . . . . Air conditioner

ACC .__ . . . . . . . Accessones

ATX .._ ._ . . . . . . . . . . . . . . Automate transaxle

ATDC _.. __ _. . . . . After top dead center

ATF ,... ._....__._.. Automatic transmission

BAC ._ . . . . . . . . . . . . . . ,. Bypass air control

BBDC _. . . . . . . . . . . . . .._. Before bottom dead

BTDC ., ._._... . . . Before top dead center

CPU . . . . . . . . . Central processrng unit

center

fluid

center

EC-AT

........................... Electronrcally-controlled

ECU ._ ....................... Engine control unit

EG 1 ..................... Electronc gasoll ne

E/L. ............................ Electrrcal load

EX .............................. Exhaust

IC ................................ Integrated clrcult

IGN ........................... lgnrtlon

IN ..... ........................ Intake

INT

............................... Intermittent

ISC ............................ Idle speed control

U-l ................................

M..

........................... Motor

MIL

........ ...................... MatfunctIon Indicator

MTX. ........................... Manual transaxle

00.. .............................. Overdnve

Of F .............................. Swrtch off

ON

...............................

PCV .............................. Positive crankcase

PRC .......................... Pressure regulator

P/S ............................. Power steerrng

P/W ............................

RH

............................... Rlght hand

SST

.............................

ST.. ............................... Starl

SW.. ............................. Switch

TDC. ............................ Top dead center

4WD .............................

automatic transmlsslon

injectron

Left hand

iamp

Switch

on

ventilation

control

Power window

Special service tool

4-wheel drive

03UGIX-802

INS7

If

a

and

Whe

1, II-!

2. II-!

3. E-

4.

Dr

t’

W-1 2

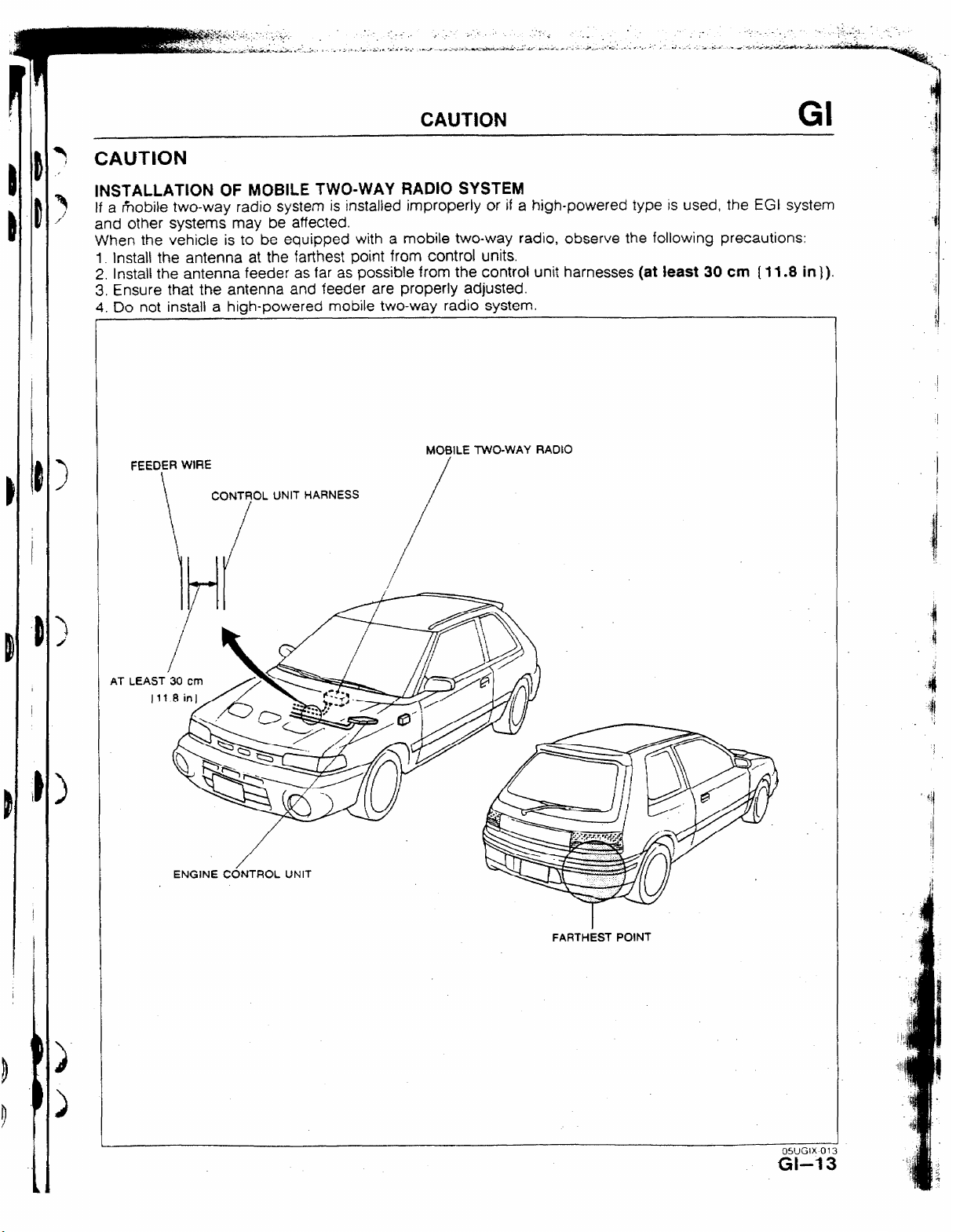

CAUTION

Gl

CAUTlUN

INSTALLATION OF MOBILE TWO-WAY RADIO SYSTEM

If a rkobile two-way radio system is installed improperly or if a high-powered type is used, the EGI system

and other systems may be affected.

When the vehicle is to be equipped with a mobile two-way radio, observe the following precautions:

1. Install the antenna at the farthest point from control units.

2. lnstatt the antenna feeder as far as possible from the control unit harnesses (at least 30 cm [ If .8 in 1).

3. Ensure that the antenna and feeder are properly adjusted.

4. Do not instali a high-powered mobile two-way radio svstem.

MOBlLE TWO-WAY RADIO

AT

FARTHEST POINT

..,. .

._

a

GI

CAUTKN

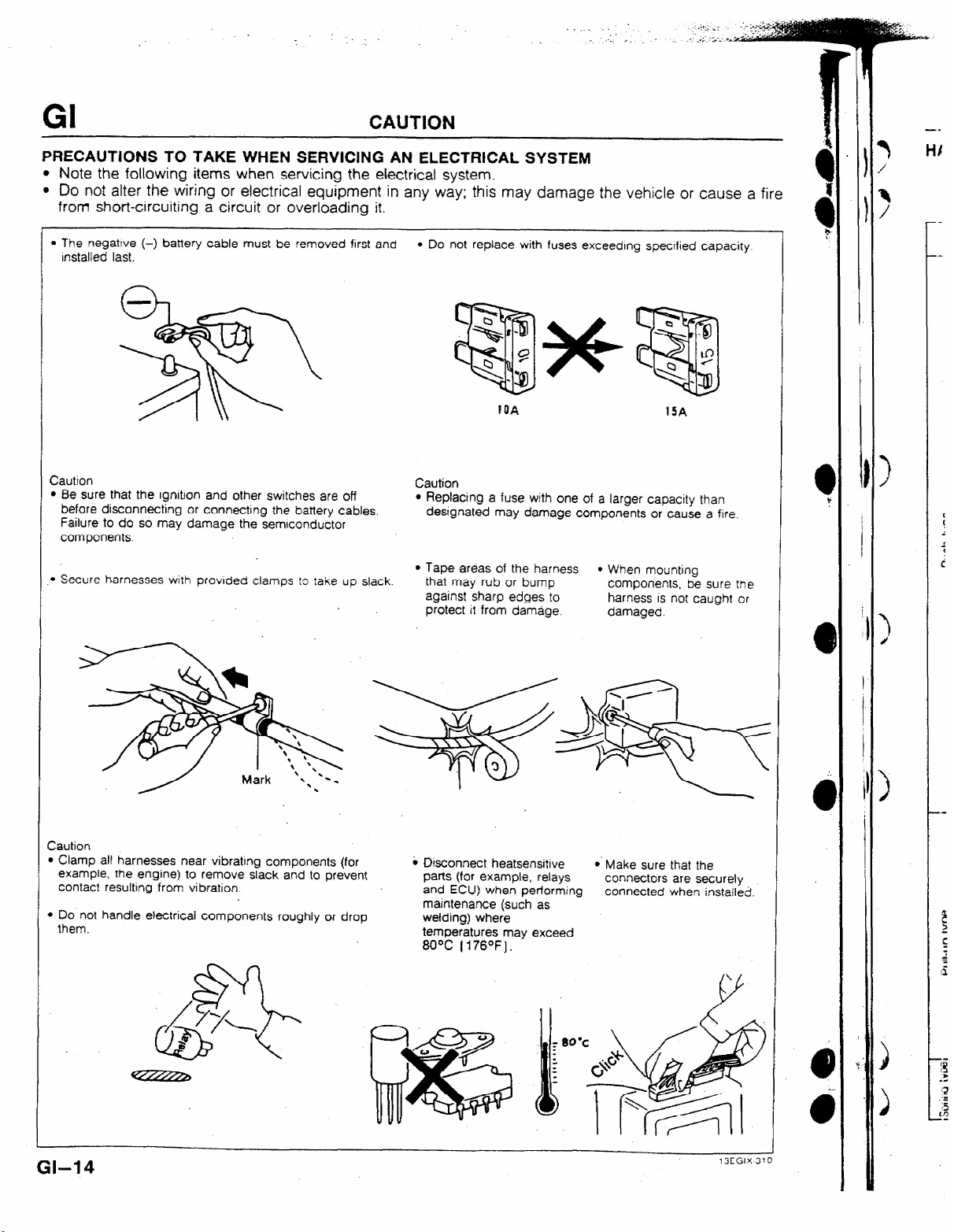

PRECAUTIONS TO TAKE WHEN SERVICING AN ELECTRICAL SYSTEM

l

Note the following items when servicing the electrical system.

l

Do not alter the wiring or electrical equipment in any way; this may damage the vehicle or cause a

from short-circuiting a circuit or overloading it.

l

The negatrve (-) battery cable must be removed first and

rnstalled last.

Cautron

l

8e sure that the ignitton and other switches are off

before disconnectrng or connecting the battery cables.

Failure to do so may damage the semrconductor

components.

l

Secure harnesses with provrded clamps to take up slack.

l

Do not reptace with fuses exceedrng specified capacity

Caution

l

Repfacing a fuse with one of a larger capacrty than

desrgnated may damage components or cause a frre.

l

Tape areas of the harness

that may rub or bump

against sharp edges to

protect rt from damage.

l

When mounting

components, be sure the

harness IS not caught or

damaged.

-*

HI

fire

Caution

l

Clamp all harnesses near vibratrng components (for

example, the engine) to remove slack and to prevent

contact resultrng from vibration.

l

Do not handle electrical components roughly or drop

them.

i Drsconnect heatsensitive

parts (for example, relays

and ECU) when performing

maintenance (such as

weldrng) where

temperatures may exceed

80°C [176OFj.

l

Make sure that the

connectors are securely

connected when installed.

CAUTION

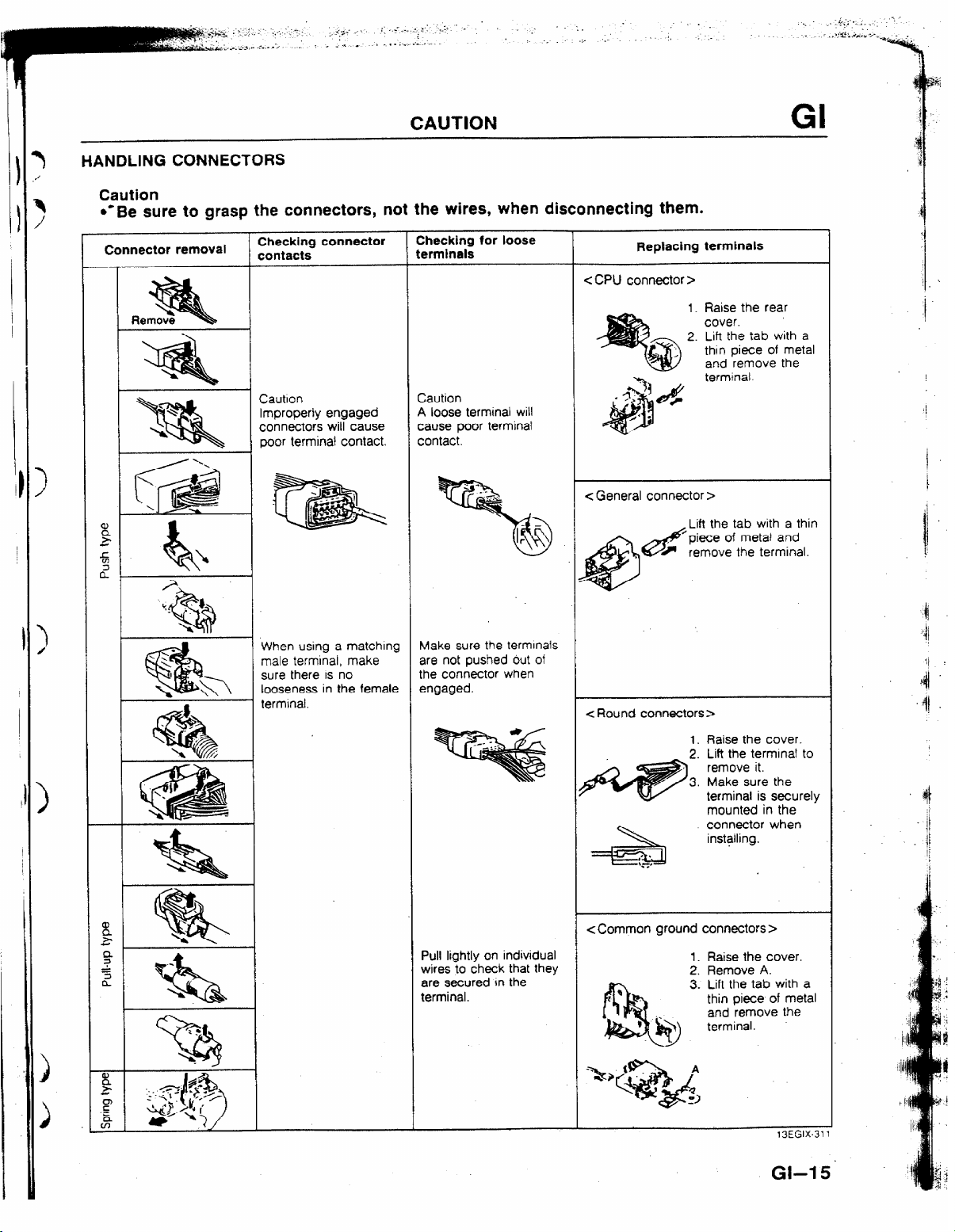

HANDLING CONNECTORS

Caution

*‘Be sure to grasp the connectors, not the wires, when disconnecting them.

poor termrnat contact.

GI

1. Raise the rear

2. Lift the tab with a

thin piece of metal

and remove the

Lift the tab with a thin

When using a matching

male terminal, make

sure there

IS no

Make sure the termmals

are

not pushed out of

Pull lightty on individual

wires to check that they

are secured rn the

c Round connectors >

1. Raise the cover.

2. Lift the termrnal to

3. Make sure the

terminal is securely

mounted in the

1. Raise the cover.

2. Remove A.

3. Lift the tab with a

thin piece of metal

and remove the

:

.

GI

CAUTION

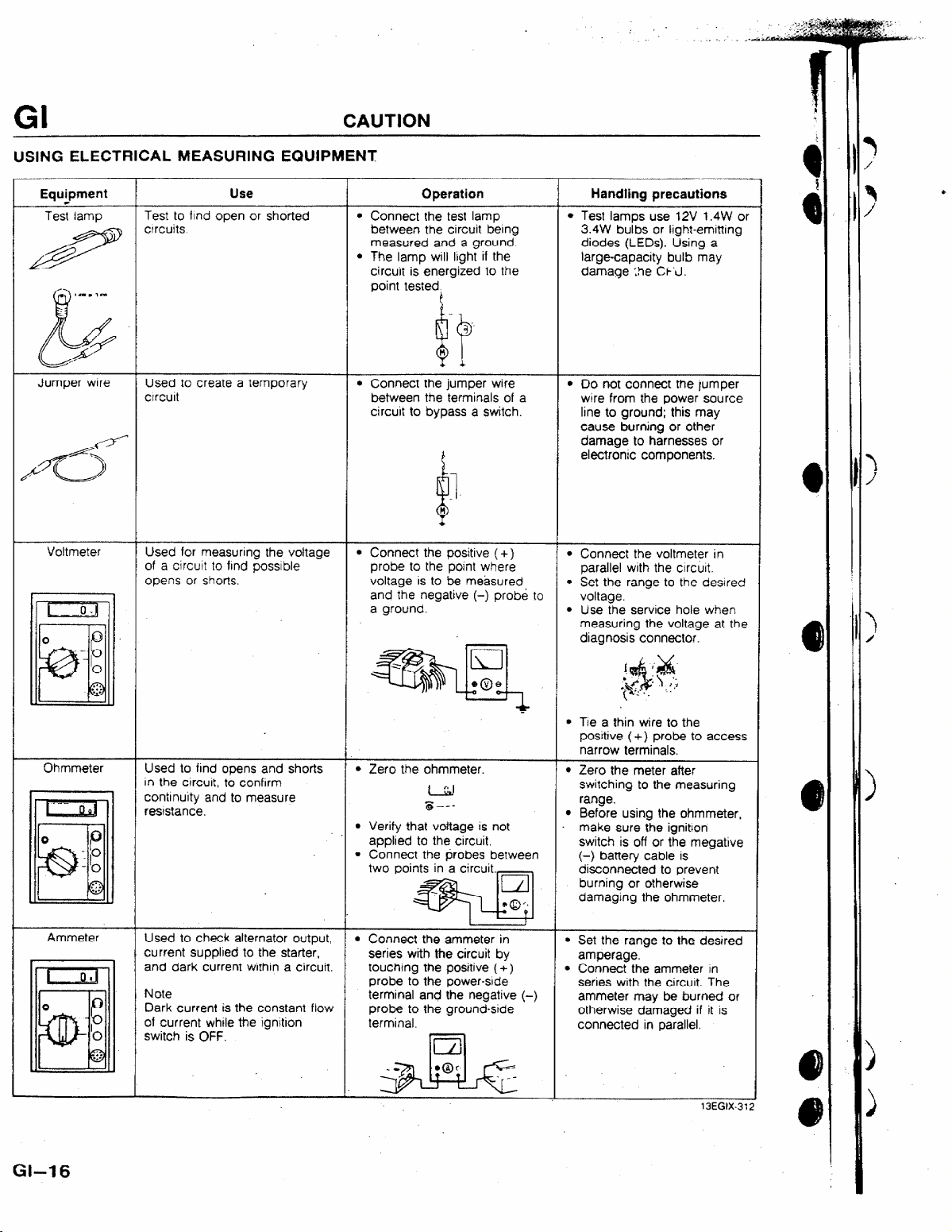

USING ELECTRICAL MEASURING EQUIPMENT

Use Handling precautions Operation Equpment

Test lamp

Test to find open or shorted

l

crrcuits

l

Jumper wrre Used to create a temporary

. Connect the jumper wire

ctrcult

Voltmeter Used for measuring the voltage

of a circutt to find possible

opens or shot-k.

l

Connect the test lamp

between the circuit being

measured and a ground.

The lamp will lrght if the

circurt is energized to the

point testedA

between the terminals of a

cjrcurt to bypass a switch.

Connect the positive (+)

probe to the point where

voltage IS to be. measured

and the negatrve (-) probe to

a ground.

l

Test lamps use 12V t.4W or

3.4W bulbs or light-emitting

diodes (LEOs). Using a

large-capacity bulb may

damage :he Ckil.

l

00 not connect the lumper

wrre from the power source

line to ground; this may

cause burning or other

damage to harnesses or

electrontc components.

l

Connect the voltmeter in

parallel wrth the cjrcurt.

l

Set the range to the dewed

voltage.

l

Use the service hole

when

measuring the voltage at the

diagnosis connector.

Ohmmeter

Ammeter

Gl-t 6

Used to find opens and shorts

In the ctrcurt, to confrrm

contrnurty and to measure

reststance.

Used to check alternator output,

current supplied to the starter.

and dark current wrthrn a circutt.

Note

Dark current IS the constant flow

of current whrle

the

ignitron

switch is OFF.

l

Zero the ohmmeter.

&---

l

Verify that voltage IS not

applied to the circuit

l

Connect

the

probes between

two points in a Circuit.,

I t

+ Connect the ammeter in

series with the circuit by

touchtng the positive ( +)

probe to the power-srde

terminal and the negative (-

probe to the ground-srde

terminal.

l

Tie a thin wire to the

posrtive (+) probe to access

narrow terminals.

l

Zero the meter after

switching to the measuring

range.

l

Before using the ohmmeter,

make sure the ignitron

switch is off or the megatrve

(-) battery cable is

t

disconnected to prevent

burning or otherwise

damaging the ohmmeter.

l

Set the range to the desired

amperage.

l

Connect the ammeter In

series with the circuit. The

ammeter may be burned or

otherwise damaged if it IS

connected in parallel.

13EGIX-31;

c

PRE-DELIVERY

INSPECTION

AND

SCHEDULED MAINTENANCE

SERVICES

ME-DELIVERY INSPECTION TABLE . . . . . . . . . . A-

SCHEDULED MAINTENANCE SERVICES . . . . . A- 3

MAINTENANCE TABLE

REMARKS

. ..*...*...............**~.*...*.....t...*...

..*.*.............,....**a,.

2

A- 3

A- 3

13EOAX.301

A

Char3

PC

F!t

Ti!

The

:

t!

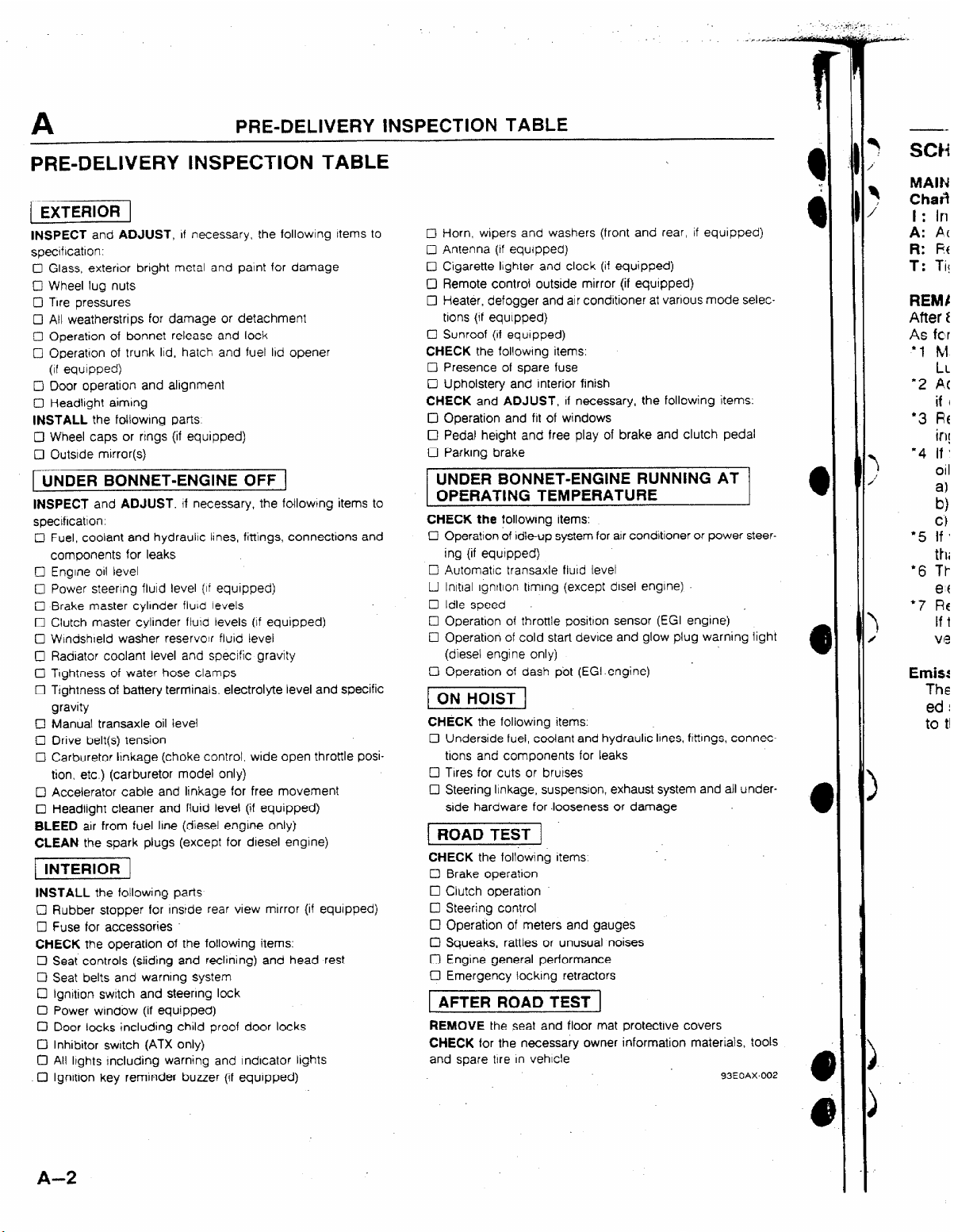

PRE-DELIVERY INSPECTION TABLE

PRE-DELIVERY INSPECTION TABLE

--

MAIN

[EXTERlORI

INSPECT and ADJUST, of necessary. the followlng Items to

specrfrcatron:

0 Glass, exterior bright metal and paint for damage

0 Wheel lug nuts

0 Tire pressures

0 All weatherstrips for damage or detachment

0 Operation of bonnet release and look

0 Operation of trunk Ild, hatch and fuel lbd opener

(of equipped)

0 Door operation and alignment

0 Headtrght aiming

INSTALL the foltowrng parts

0 Wheel caps or rrngs (if equipped)

0 Outsrde mirror(s)

1 UNDER BONNET-ENGINE OFF j

INSPECT and ADJUST. If necessary, the following items to

specrflcatlon.

0 Fuel, coolant and hydraulic tines, fittings, connectlons and

components for leaks

0 Engine 011 level

0 Power steering fluid level (of equipped)

0 Brake master cylinder fluky levels

0 Clutch master cylinder fturcl levels (If equipped)

0 Wtndshreld washer reservojr flurd level

0 Radiator coolant level and specrfic gravity

0 Tightness of water hose clamps

0 Tightness of battery terminals, electrolyte level and specific

gravity

0 Manual transaxle oil level

0 Drive belt(s) tension

Cl Carburetor lrnkage (choke control, wrde open throttle posi-

tion. etc ) (carburetor model only)

q

Accelerator cable and linkage for free movement

0 Headlight cleaner and flurd level (if equipped)

BLEED air from fuel line (diesel engrne only)

CLEAN the spark plugs (except for diesel engine)

piEi6F]

INSTALL the following parts

0 Rubber stopper for rnsrde rear view mirror (if equjpped)

0 Fuse for accessories

CHECK the operation of the following items.

0 Seat controls (sliding and reclining) and head rest

0 Seat belts and warning system

Cl Ign&on switch and steering lock

0 Power window (if equipped)

D Door tacks including child proof door locks

Cl Inhibitor switch (ATX only)

Cl All Ikghts rncluding warning and Indicator lbghts

0 Ignition key reminder buzzer (If equipped)

0 Horn, wbpers and washers (front and rear, If equipped)

0 Antenna (tf equipped)

0 Cigarette Ibghter and clock (if equipped)

0 Remote control outside mirror (if equrpped)

0 Heater, defogger and air conditioner at various mode selec-

tions (if equlppedj

0 Sunroof (If equipped)

CHECK the following items

0 Presence of spare fuse

0 Upholstery and Interior finish

CHECK and ADJUST, If necessary, the followjng items:

IJ Operation and fit of windows

0 Pedal height and free play of brake and clutch pedal

0 Parking brake

UNDER BONNET-ENGINE RUNNING AT

OPERATING TEMPERATURE

CHECK the following items:

0 Operation of Idle-up system for air condbtroner or power steer-

ing (if equrpped)

0 Automatic transaxle flurd levet

0 tnltial ignrtlon timing (except disel engine)

0 Idle speed

0 Operation of throttle positron. sensor (EGI engrne)

0 Operation of cold start device and glow plug warning light

(diesel engine only)

0 Operation of dash pbt (EGI.engine)

fTiGGJ

CHECK the following items.

0 Underside fuel, coolant and hydraulic Irnes, ftttlngs, connec-

tions and components for leaks

0 Trres for cuts or brurses

0 Steering Itnkage, suspensron, exhaust system and all under-

side hardware for .looseness or damage

1 ROAD TEST j

CHECK the following items

0 8rake operation

0 Clutch operation

0 Steering control

!ZI Operation of meters and gauges

Cl Squeaks, rattles or unusual noises

Cl Engine general performance

0 Emergency locking retractors

1 AFTER ROAD TEST ]

REMOVE the seat and floor mat protective covers

CHECK for the necessary owner information materials, took

and spare tire m vehicle

93EOAX-002

t: In

A:

R:

T:

Emis!

ed

to

A-Z

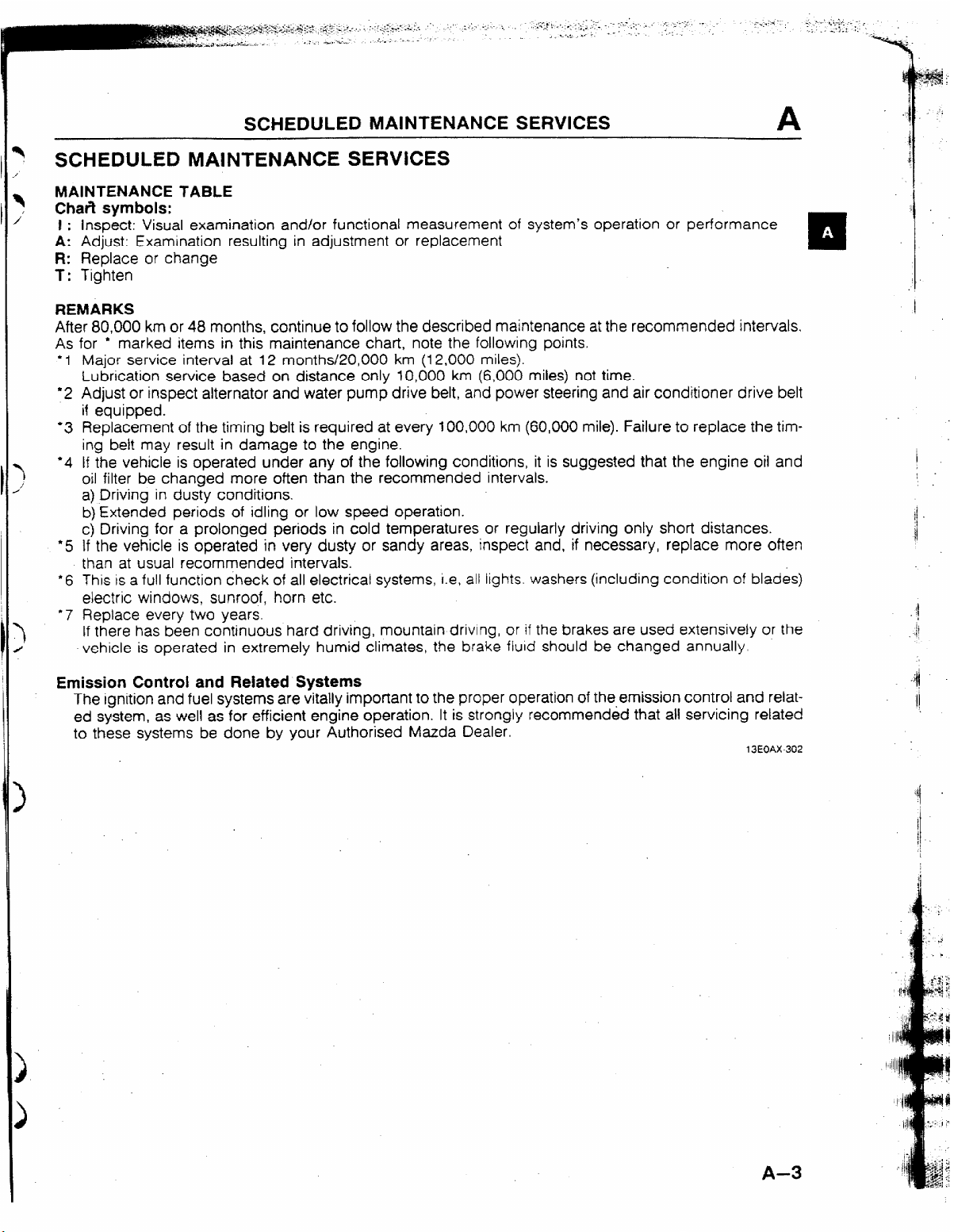

SCHEDULED MAINTENANCE SERVICES

A

SCHEDULED MAINTENANCE SERVICES

MAINTENANCE TABLE

Chafi symbols:

1 : Inspect: Visual examination and/or functional measurement of system’s operation or

A: Adjust: Examination resulting in adjustment or replacement

R: Replace or change

T: Tighten

REMARKS

After 80,000 km or 48 months, continue to follow the described maintenance at the recommended intervals.

As for * marked items in this maintenance chart, note the following points.

+ 1 Major service interval at 12 months/20,000 km (12,000 miles).

Lubrication service based on distance only 10,000 km (6,000 miles) not time.

l 2 Adjust or inspect alternator and water pump drive belt, and power steering and air conditioner drive belt

if equipped.

‘3 Replacement of the timing belt is required at every 100,000 km (60,000 mile). Failure to replace the tim-

ing bett may result in damage to the engine.

‘4 tf the vehicle is operated under any of the following conditions, it is suggested that the engine oil and

oil filter be changed more often than the recommended intervals.

a) Driving in dusty conditions.

b) Extended periods of idling or low speed operation.

c) Driving for a prolonged periods in cold temperatures or regularly driving onty short distances.

*5 If the vehicle is operated in very dusty or sandy areas, inspect and, if necessary, replace more often

than at usual recommended intervals.

l 6 This IS a full function check of all electrical systems, i.e, atl

electric windows, sunroof, horn etc.

‘7 Replace every two years.

If there has been continuous hard driving, mountain

vehicle is operated in extremely humid climates, the brake fluid should be changed annually.

ltghts.

drivtng, or if

washers (including condition

the brakes are used extensively or the

performance ,

of

blades)

n

I

:

i

i!

$1

‘I

Emission Control and Related Systems

The ignition and fuel systems are vitally important to the proper operation of the-emission control and relat-

ed system, as well as for efficient engine operation. It is strongly recommended that all servicing related

to these systems be done by your Authorised Mazda Dealer.

13EOAX-302

-4

I!

A-3

A

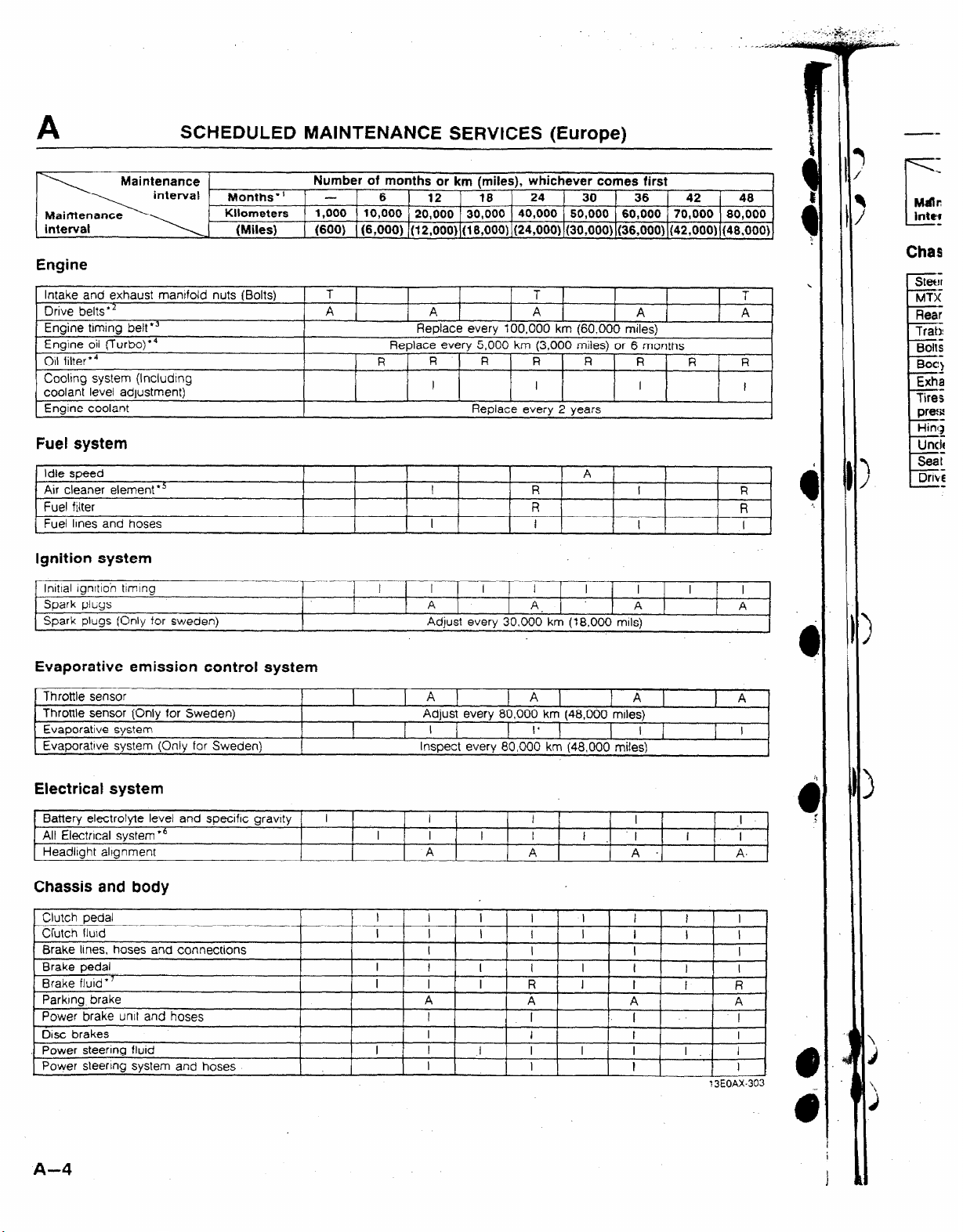

SCHEDULED MAtNTENANCE SERVtCES (Europe)

Maintenance

Months”

Kllometers 1,000 10,000 20,000 30,000 40,000 50,000

{Miles)

Number of months or km (miles), whichever comes first

- 6 12 18 24 30 36

60,000 70,000 80,000

42 48

(600) (6,000) f[t2,000) (18,000) (24,000) (3U,OOO) (36,000) (42,000) {48,000),

Engine

Intake

and exhaust

Drive belts”

i Engine trmlng beltW3

Engine oil (Turbo)‘4

01 filter l *

Cool!ng

coolant level adlustment)

Engrne coolant

system

(Includtng

manrfold nuts (Bolts)

T T T

A A A

Replace every 100,000 km (60,000 miles)

Replace every 5,000 km (3,000 miles) or 6 months

R

R R R R 1 R R R

I I

Replace every 2 years

A A

I I

Fuel system

Idle speed

Air cleaner element * 5

Fuel

falter

Fuel Ilnes and hoses

I R I R

R R

I I f t I ~

A f

Ignition system

lnlttal rgnrtloh trmlng 1 I I I I I I I I

Spark plugs A

Spark plugs (Only for Sweden) Adjust every 30.000 km (t8.000 mrls)

A.

A A

Chas

SW31

Rear

I

1

Tires

Hing

Seat

Evaporative emission control system

Throttle sensor

Throttle sensor (Only for Sweden)

Evaporative system

Evaporatrve system (Only for Sweden)

Electrical system

Battery electrolyte level and specific gravity 1

All Electrical system l ’

Headlight alrgnment

Chassis and body

1 A 1

Adjust every 80,000 km (48,000 miles)

1 I 1

Inspect every 80,000 km (48,000 mites)

I f I I I

I 1 I I I

1 A A A . A.

1 A 1 1 A 1 ) A

1 I’ 1 1 I 1 1 I

1 . 1

1 I

I I

t 3EOAX-303

A-4

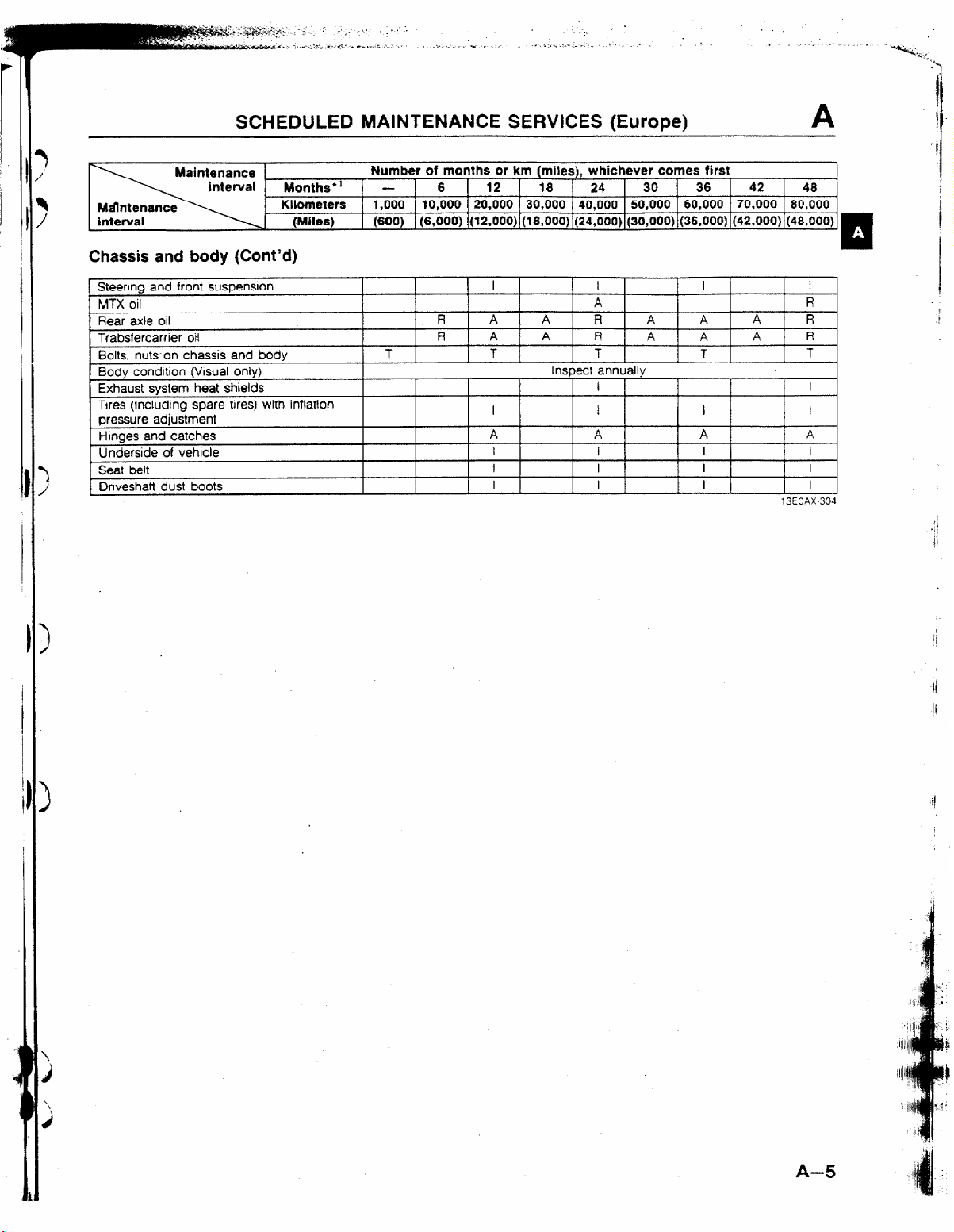

SCHEDULED MAINTENANCE SERVICES (Europe)

A

Maintenance

Months’ ’

Kllometers 1,000

(Miles)

Number of months or km (miles), whichever comes first

- 6 12 18 1 24 30 36 ] 42 48

(600)

10,000 20,000 30,000 1 40,000 50,000 60,000 1 70,000

(6,000) j(12,000)~(18,000)~(24,000) (30,000) (36,000)~(42,000) (48,000)

Chassis and body (Cont’d)

Steering and front suspension

MTX oil A R

Rear axle oil

Trabsfercarrier oil

Bolts, nuts on chassis and body

Body condltlon (Visual only) Inspect annually

Exhaust system heat shields I 1 I

Tires (Including spare tjresj with inflation

pressure adjustment

Hinges and catches

Underside of vehicle

Seat belt

Dnveshafl dust boots I I 1 I I

I

T T 1

I ’

R A A R

R A 1 A

I

A A

I

I

I

A A A R

R A A A R

T , T

I I I

I i 1 I I

I f

I

A 1 A

I ’

1 I

13EOAX.304

80,000

I

T

I

A-5

1 FEATURES j

B2

ENGINE

(DOHC)

OUTLINE ................................................

OUTLINE OF CONSTRUCTION..

SPEClFICATlONS

INTERCHANGEABILITY ..........................

PISTON ...............................................

CONNECTING ROD ...............................

CRANKSHAFT PULLEY ..........................

EXHAUST VALVE ..................................

INSTRUCTION FOR HANDLING METALLIC

SODllJM~FlLLED EXHAUST VALVE .........

SUPPLEMENTAL SERVICE INFORMATION 820 9

..................................

.............. B2- 2

B2- 2

82- 2

B2- 3

82- 4

82- 5

B2- 6

B2- 7

82- 8

13E082-301

4

B2

OUTLINE

OUTLINE

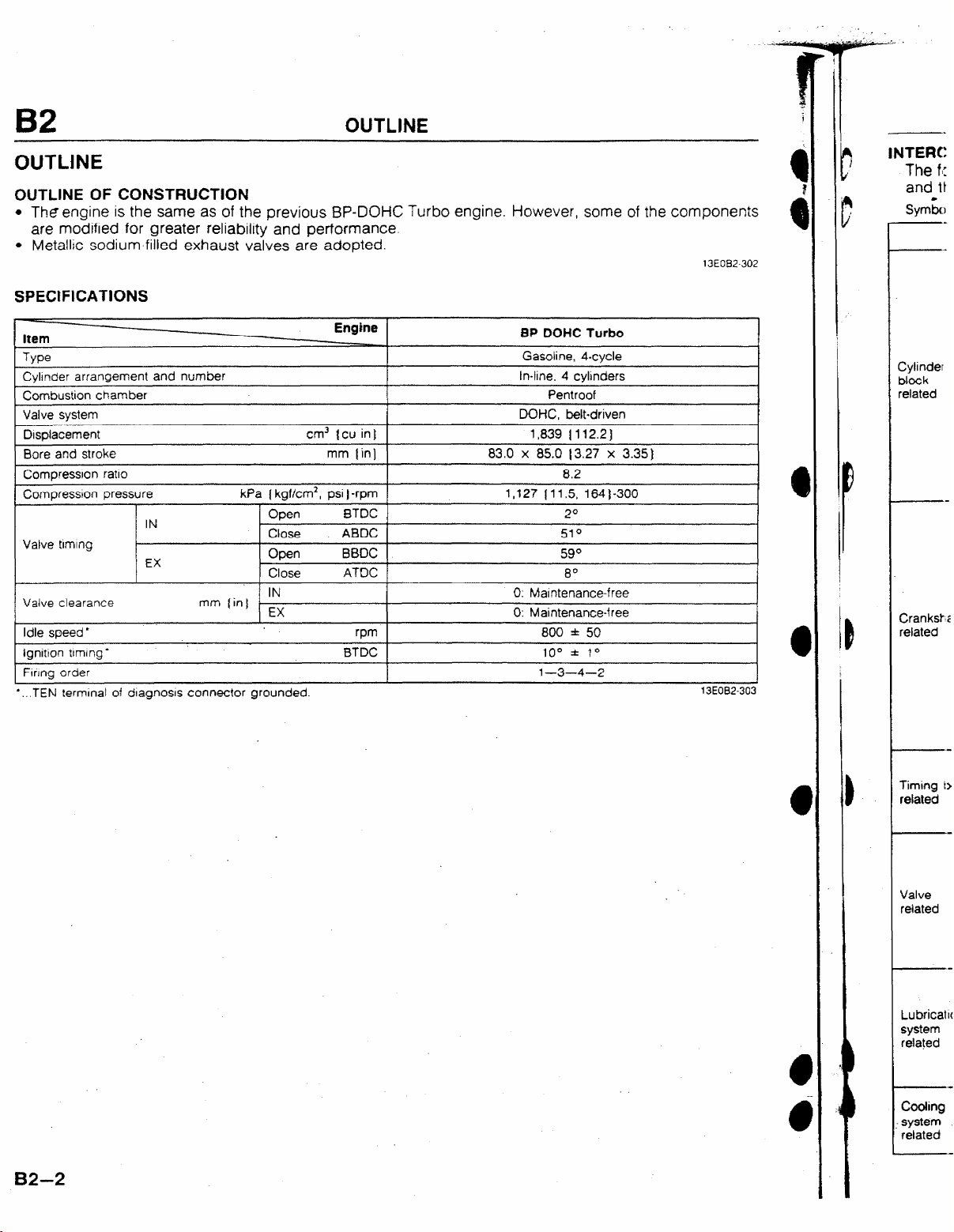

OUTLINE OF CONSTRUCTION

l

Theengine is the same as of the previous BP-DOHC Turbo engine. However, some of the components

are modified for greater reliability and performance.

l

Metallic sodium-filled exhaust valves are adopted.

SPECtFlCATIONS

Item

TYPe

Cyhnder

Combustion chamber

Valve system

Displacement cm3 tcu in]

Bore and stroke

Compressron ratio

Compressron pressure kPa [ kgf/cm2, psi 1

Valve tlmlng

Valve clearance mm (in]

Idle speed *

Ignltlon trmrng’ BTDC

Fwng order

*.. TEN terminal of dragnosrs connector grounded.

arrangement and number

IN

EX

mm {in)

Open

Close ABDC

Open BBDC

Close

IN

EX

BTDC

ATDC

-rpm

rpm

Gasoline, 4-cycle

tn-line, 4 cyljnders

Pentroof

DOHC, belt-driven

1,839 { 112.2)

83.0 x 85.0 13.27 x 3.35)

8.2

1,127 lt1.5, 164)-300

2O

510

590

8O

0. Maintenance-free

0: Maintenance-free

800 f 50

100 f 70

l-3-4-2

13E032-302

13EOB2-303

1NTERC

The f<

and 0

S

ym&l

Cytinder

block

related

Crank&;

related

-

82-2

Timing b

related

Vatve

related

Lubricatrc

system

related

Coohng

. . system

related

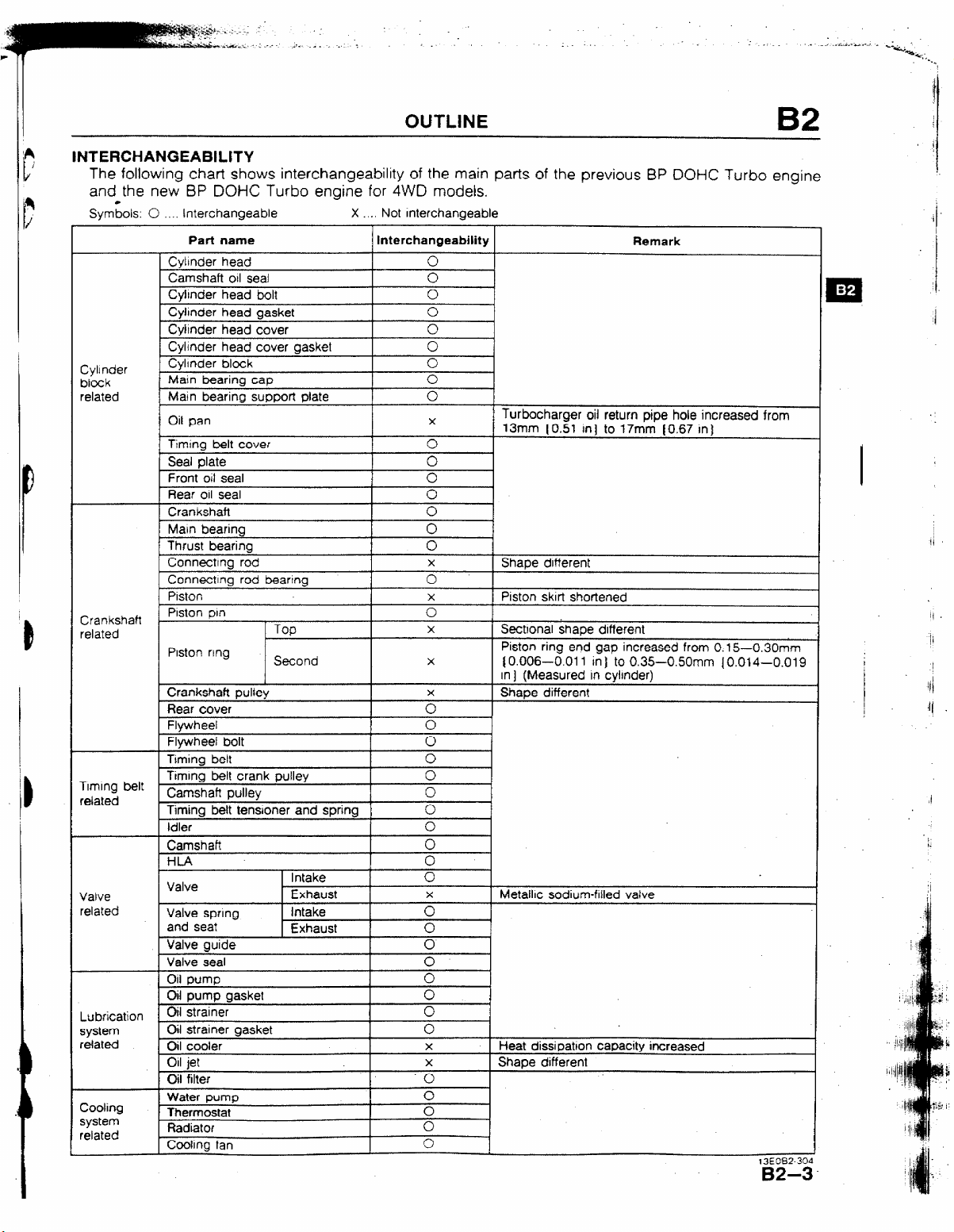

The following chart shows interchangeability of the main parts of the previous BP DOHC Turbo

and the new BP DOHC Turbo engine for 4WD models.

S ymiols: 0 _. lnterc hangeable

Part name

Cytlnder head

Camshaft 011 seal 0

Cvllnder head bolt 0

Cylrnder head gasket 0

Wnder head cover 0

Cylinder head cover gasket

Cyh nder

blcck

related

Cylinder block

MaEn bearina cao

Ma+n bearino suo~oFt elate I

Oil pan

Timrno belt cover

Seal elate

Front orl seal

Rear 011 seal

Crankshaft

Marn bearina 0

Thrust bearing

Connectmg rod

Connecting rod beartng

Piston

Piston

Crankshaft

pm

related

Piston rrng

Crankshaft pulley

Rear cover ;5

Flywheel

Flywheel bolt 0

Tbmlng belt

Timing belt

related

Timing belt crank pulley 0

Camshaft pulley

Timing belt tensioner and spring

Idler

Camshaft

AA

Valve

related

Lubrication

system

related

Coohng

system

related Radiator

Valve

Valve spring

and seat

Vatve wide I

Valve seal

Oil pump

Oil pump gasket 0

oil strainer 0

Oil strainer gasket

Oil cooler

Oil jet

Oil filter

Water pump

1

Thermostat

Cooling fan

” ,I I

Tw

Second

Intake

Exhaust

Intake

Exhaust 0

X . . . Not Interchangeable

tnterchangeability

0

0

0

0

I

0

X

0

I

I

I

0 I

0

0

0

0

;J

X

cl

X

X

I

0

0

0

0

0

0

cl

0

X

I

0

0

0

0

X

0

0

0

0

Remark

I

I

Turbocharger oil return pipe hole increased from

13mm IO.51 in) to 17mm IO.67 in)

1

Shape different

Piston skirt shortened

I

Sectional shape different

Piston ring end gap increased from 0:?5--0.30mm

~0.006-0.011

in

] (Measured

in ) to 0.35-0.50mm IO.01 4-0.019

In cylinder)

Shape different

Metallic sodium-filled valve

Heat dissi patlon capacity increased

Shape different

engine

I 3EO32.304

BZ-3.

CB

:

B2

OUTl1NE

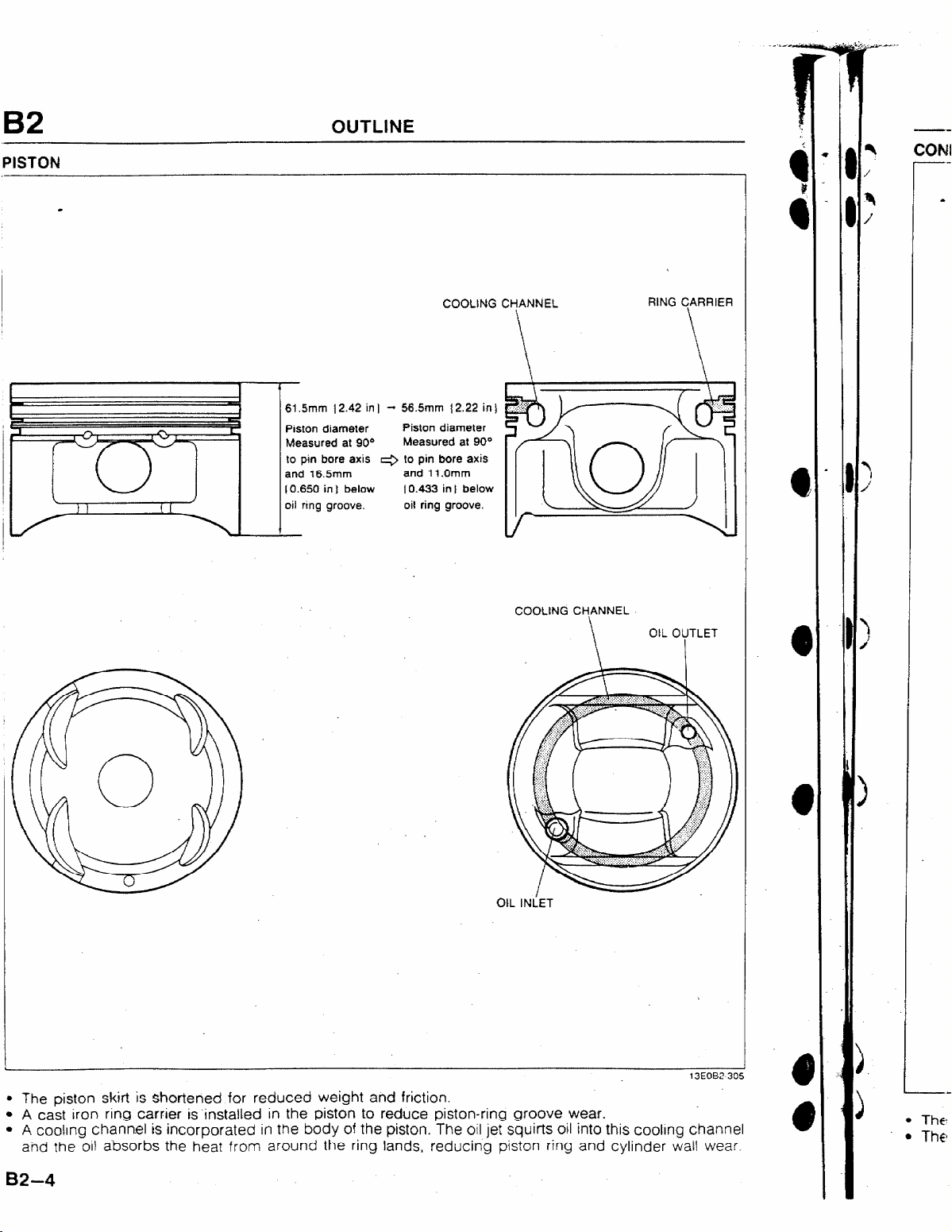

COOUNG CHANNEL

61.5mm i 2.42 in ] Piston diameter

Measured at 90* Measured at 90°

to pin bore axis I+ to pin bore axis

and t6.5mm

IO.650 in 1 below 10.433 in 1 below

oil rmg groove. oil ring groove.

56.5mm (2.22 in

Piston diameter

and 11 .Omm

RtNG CARRtER

COOLING CHANNEL

\ *IL YTLET

l

The piston skirt is shortened for reduced weight and friction.

l

A cast iron

l

A cooling

and the

ring carrier

channel

or! absorbs

is installed in the piston to reduce piston-ring groove wear.

is incorporated in the body of the piston. The 011 jet squirts oil into this cootrng channel

the heat from

around the ring

lands, reducing piston ring and cylinder wat! wear

Bz-4

OIL t NiET

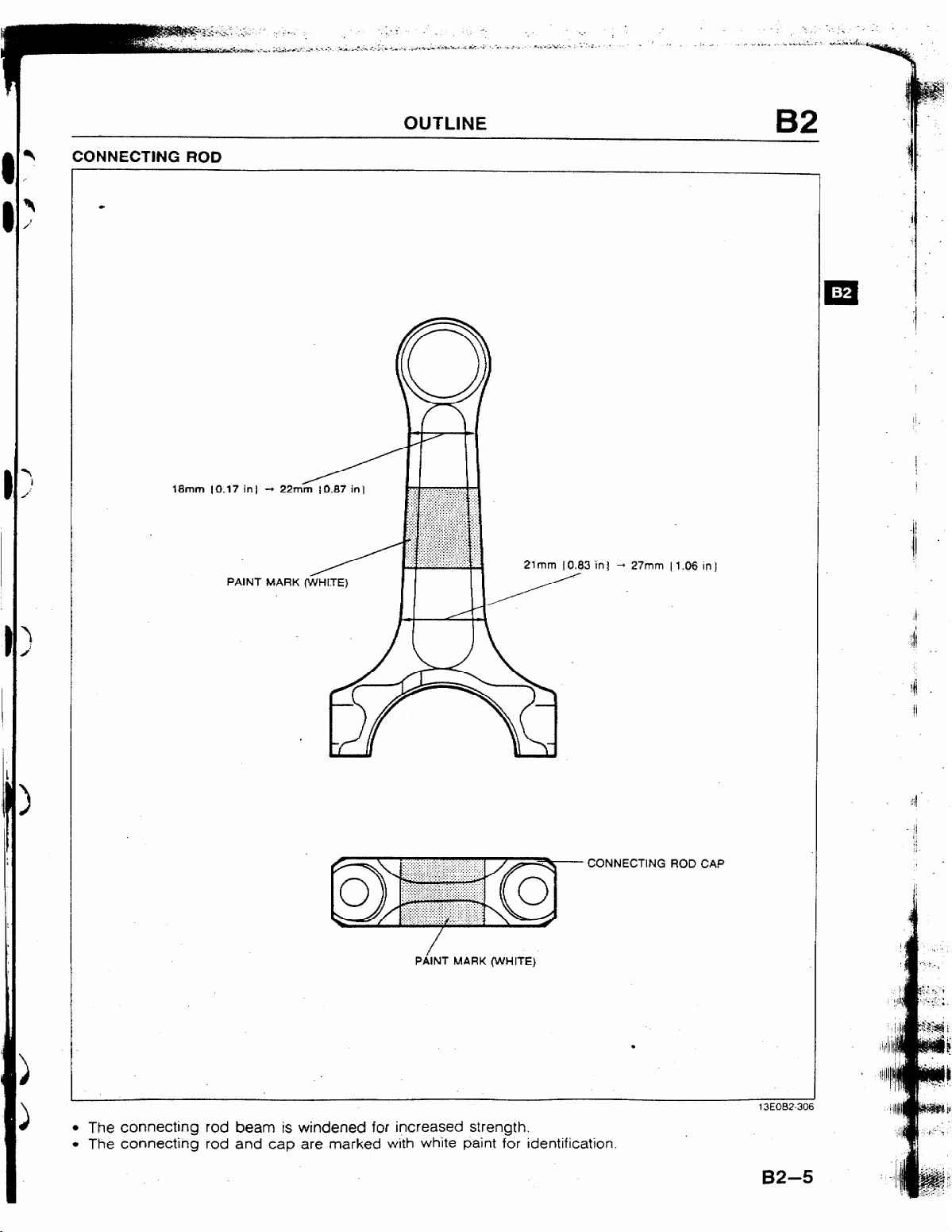

CONNECTING ROD

18mm 10.17 in!

OUTLINE

B2

PAINT

in t - 27mm Il.06 ml

MARK @VHITE)

CONNECTING ROD CAP

PiINT MARK (WHITE)

l

The connecting rod beam is windened for increased strength.

l

The connecting rod and cap are marked with white paint for identification.

B2 CXJTUNE

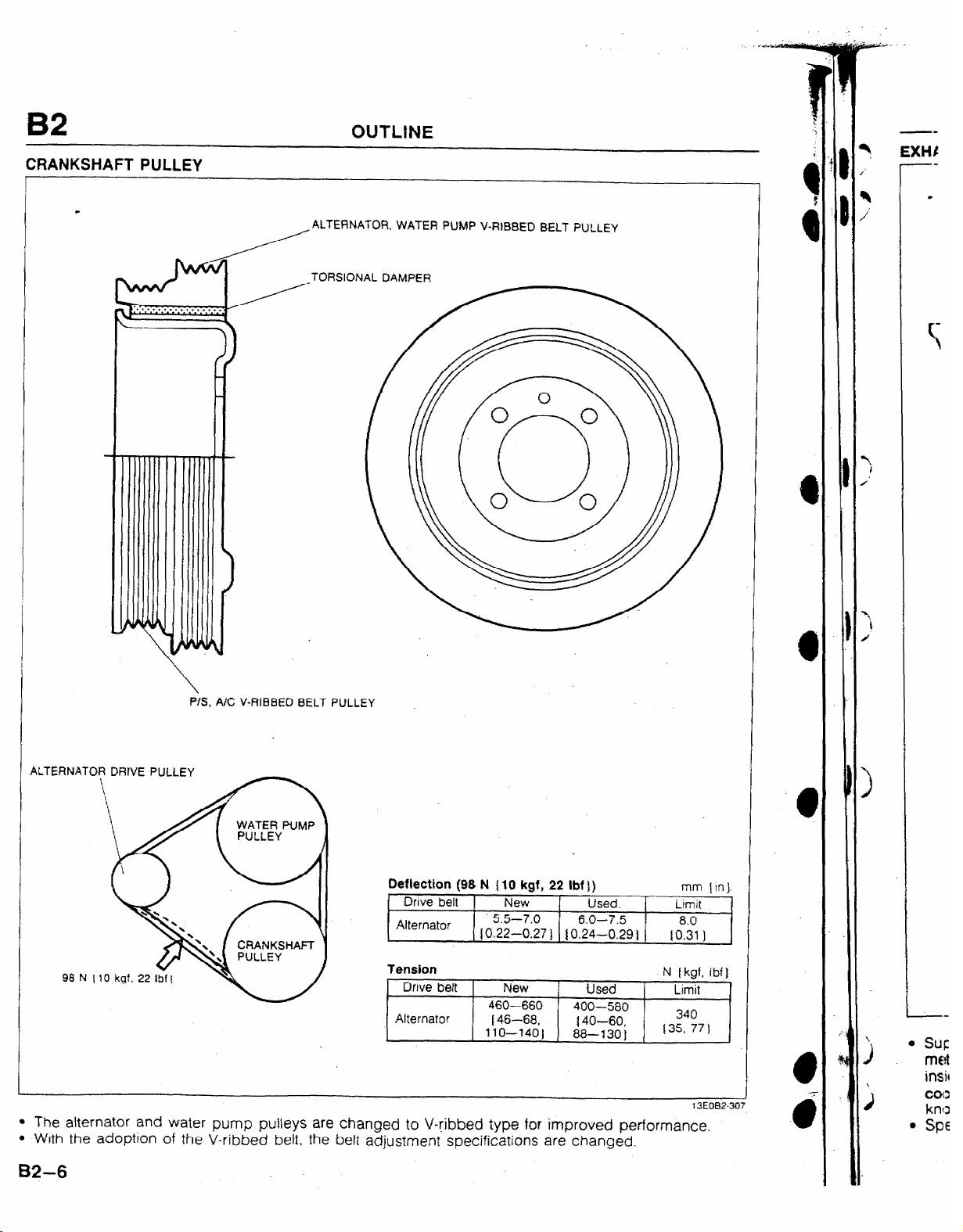

CRANKSHAFT PULLEY

ALTERNATOR, WATER PUMP V-RIBBED BELT PULLEY

/TORSIONAL DAMPER

P/S, A/C V-RI3BED BELT PULLEY

ALTERNATOR DRIVE PULLEY

Deflectton (98 N ( 10 kgf, 22 Ibf f ) mm ftn)

Owe belt New Used. Lrmlt

Alternator

fension

Owe belt

Alternator

l

The alternator and water pump pulleys are changed to V-ribbed type for improved performance

l

With the adoptjon of the V-ribbed betf. the belt adjustment specifications are changed.

5.5-7.0 6.0-7.5 8.0

{0.22-0.27 ) IO.24-0.29) to.31 )

New

460-660

(46-68,

llO--140)

Used

400-580

{‘IO-60,

88-130 1

N I kgf, Ibf]

Ltmit

340

771

135,

B2-6

Loading...

Loading...