Page 1

Use & Care Guide

Guide d’utilisation et d’entretien

ELECTRONIC DRYER

SÉCHEUSE ÉLECTRONIQUE

W10885280A

W10885286A - SP

Para obtener acceso

al Manual de uso y

cuidado en español, o para

obtener información adicional

acerca de su producto, visite:

www.maytag.com.

If you have any problems or questions, visit us at www.maytag.com

Pour tout problème ou toute question, consulter www.maytag.ca

Page 2

TABLE OF CONTENTS

DRYER SAFETY .......................................................................................2

CHECK YOUR VENT SYSTEM FOR GOOD AIR FLOW ..............4

CONTROL PANEL AND FEATURES ..................................................5

CYCLE GUIDE ..........................................................................................7

USING YOUR DRYER.............................................................................9

ADDITIONAL FEATURES ................................................................... 11

DRYER CARE.........................................................................................12

TROUBLESHOOTING ......................................................................... 14

WARRANTY ............................................................................................ 17

ASSISTANCE OR SERVICE ............................................. Back Cover

DRYER SAFETY

TABLE DE MATIÈRES

SÉCURITÉ DE LA SÉCHEUSE ......................................................... 18

VÉRIFICATION D’UNE CIRCULATION D’AIR ADÉQUATE

POUR LE SYSTÈME D’ÉVACUATION ............................................. 20

TABLEAU DE COMMANDE ET CARACTÉRISTIQUES .............21

GUIDE DE PROGRAMMES ............................................................... 23

UTILISATION DE LA SÉCHEUSE ..................................................... 25

CARACTÉRISTIQUES SUPPLÉMENTAIRES ................................ 27

ENTRETIEN DE LA SÉCHEUSE ....................................................... 28

DÉPANNAGE ......................................................................................... 30

GARANTIE .............................................................................................. 34

ASSISTANCE OU SERVICE ..................................Couverture arrière

IMPORTANT: When discarding or storing your old clothes dryer, remove the door.

2

Page 3

3

Page 4

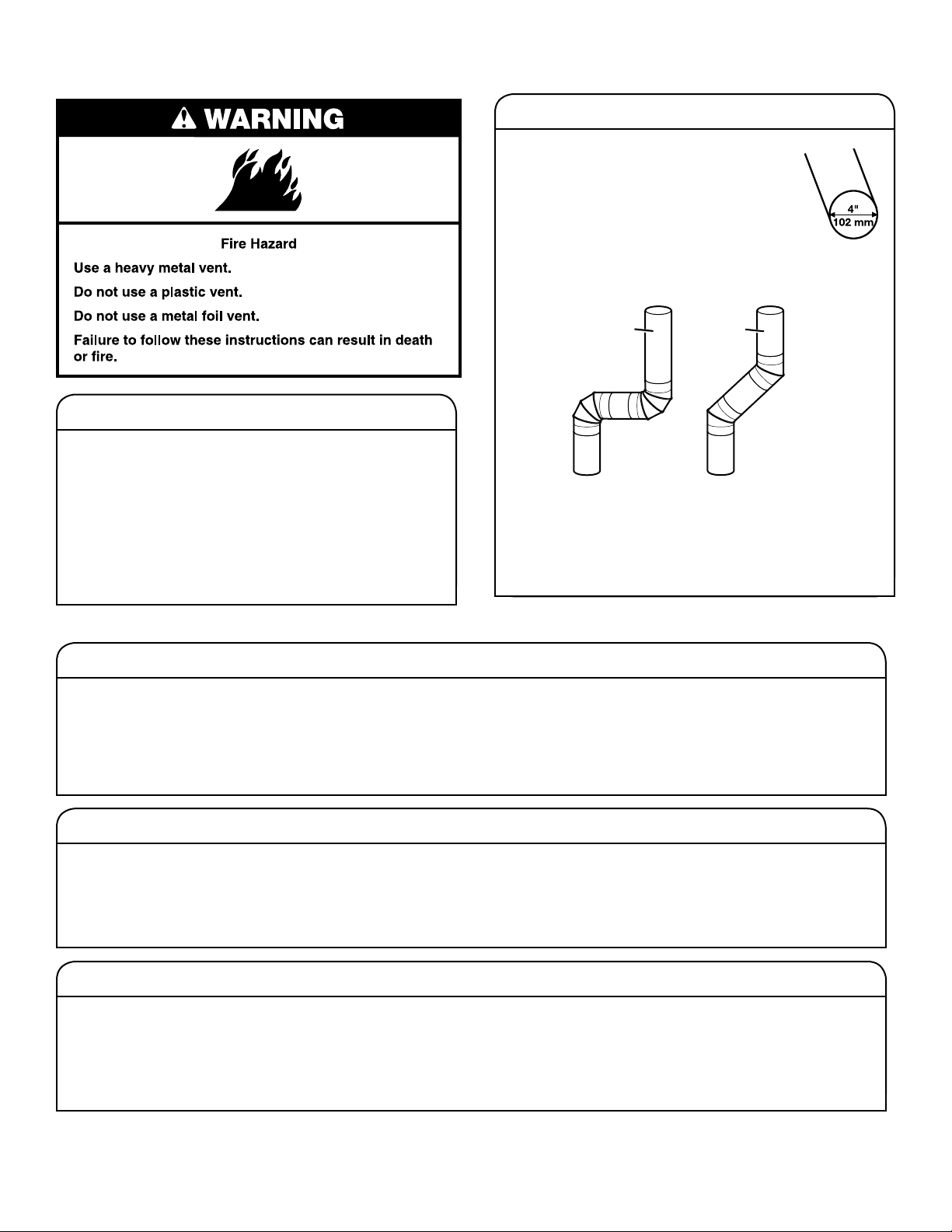

CHECK YOUR VENT SYSTEM FOR GOOD AIR FLOW

Maintain good air flow by:

n

Cleaning your lint screen before each load.

n

Replace plastic or foil vent material

with 4" (102 mm) diameter heavy, rigid

vent material.

n

Use the shortest length of vent possible.

n

Use no more than four 90° elbows in a vent system;

each bend and curve reduces air flow.

Good

Better

Good air flow

Along with heat, dryers require good air flow to efficiently

dry laundry. Proper venting will reduce your drying times and

improve your energy savings. See Installation Instructions.

The venting system attached to the dryer plays a big role

in good air flow. Blocked or crushed vents as well as improper

venting installation will reduce air flow and dryer performance.

Service calls caused by improper venting are not covered by

the warranty and will be paid by the customer, regardless of

who installed the dryer. To clean or repair venting, contact a

venting specialist.

n

Remove lint and debris from the exhaust hood.

n

Remove lint from the entire length of the vent system

at least every 2 years. When cleaning is complete, be

sure to follow the Installation Instructions supplied with

your dryer for final product check.

n

Clear away items from the front of the dryer.

Energy Saver

Touch to activate the Energy Saver option, which allows you to increase your energy savings by using a slightly lower heat level. Energy

Saver will increase drying time by approximately 40 minutes; the LED Display will reflect this time.

Energy Saver will default on for Normal and is only available for that cycle. For optimal energy, turn on the Energy Saver option. For

optimal time, turn off the Energy Saver option.

NOTE: Energy savings may vary across loads.

Use Sensor cycles for better fabric care and energy savings

Use the Sensor Cycles to provide the most energy savings and enhanced fabric care from the dryer. During Sensor Cycles, drying air

temperature and moisture level are sensed in the load. This sensing occurs throughout the drying cycle and the dryer shuts off when the

load reaches the selected dryness. Use the NORMAL dryness level to provide optimal energy savings.

With Timed Dry and Rapid Dry, the dryer runs the amount of time set and sometimes results in shrinkage, wrinkling, and static due to

over-drying. Use Timed Dry for the occasional damp load that needs a little more drying time or when using the drying rack.

Tips for getting the best performance from your steam dryer

n

Results may vary depending on fabric. 100% cotton garments

with wrinkle-free finish may yield better results than those

without. 100% cotton items may require additional touching up

after cycles that use steam.

n

Use of fabric softener sheet is not recommended with cycles

that use steam. It may cause temporary staining on clothes.

4

n

Cycles that use steam are not recommended for items that

have been starched. Wash any starched or new garments prior

to using cycles that use steam.

n

The Steam Refresh cycle is best for reducing light wrinkles

from loads left in the dryer too long.

Page 5

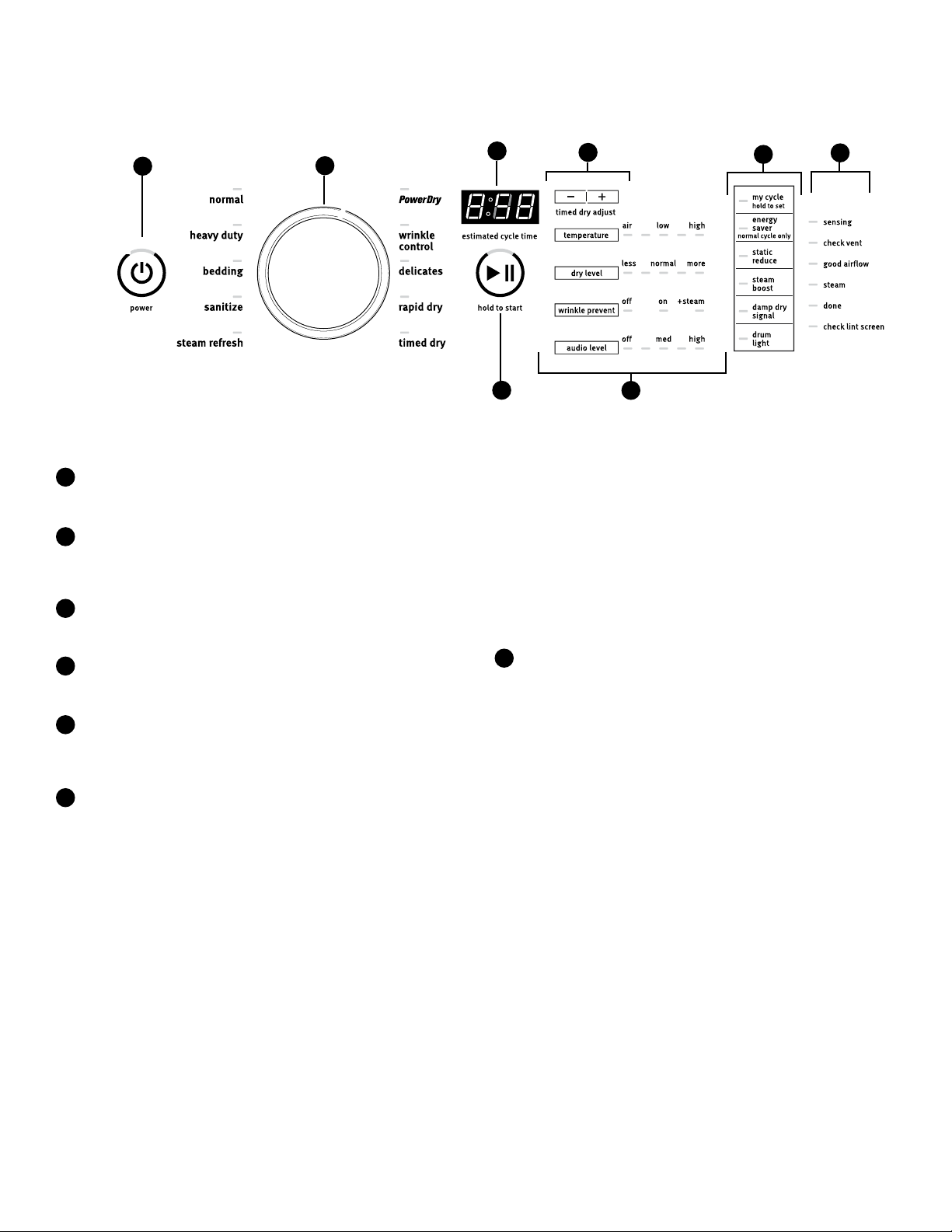

CONTROL PANEL AND FEATURES

Not all features and cycles are available on all models.

1

NOTE: The control panel features a sensitive surface that responds to a light touch of your finger. To ensure your selections are registered,

touch the control panel with your finger tip, not your fingernail. When selecting a setting or option, simply touch its name.

1

POWER

Touch to turn the dryer on and off. Touch to stop/cancel

a cycle at any time.

CYCLE CONTROL KNOB

2

Use your dryer’s cycle control knob to select available cycles

on your dryer. Turn the knob to select a cycle for your laundry

load. See “Cycle Guide” for detailed descriptions of cycles.

3

START/PAUSE

Touch and hold until the LED comes on to start a cycle

or touch once while a cycle is in process to pause it.

4

TIMED DRY ADJUST

Use “+” and “–” with Timed Cycles to increase or

decrease the length of a Timed Dry or Rapid Dry cycle.

5

LED DISPLAY

When you select a cycle, its default settings will light up and

the Estimated Time Remaining (for Sensor Cycles) or actual

time remaining (for Timed Cycles) will be displayed.

6

SETTINGS

Touch the setting names next to the display to adjust settings.

See “Cycle Guide” for available settings on each cycle. Not all

settings are available with all cycles.

Temperature

Timed Cycles: When using Timed Cycles, you may select

a dry temperature based on the type of load you are drying.

Use the warmest setting safe for the garments in the load.

Follow garment label instructions.

Sensor Cycles: Sensor Cycles allow temperature

adjustment. At most, 4 of available temperatures (not

including Air Only) are allowed.

Dry Level

You may adjust the Dry Level on Sensor Cycles only

(except for the Sanitize and Steam Refresh cycles), if

desired.

Wrinkle Prevent

If you will be unable to remove a load immediately, touch

Wrinkle Prevent to add up to 150 minutes of periodic

tumbling to help reduce wrinkling. On some cycles, you

may select the “With Steam” setting to add a short steam

cycle after 60 minutes to help smooth out wrinkles.

2

5

3

7

OPTIONS

Use to select available options for your dryer.

4

6

NOTE: If the Wrinkle Prevent option is selected, it is active

even if the done indicator is lit. If you open the dryer door

prior to the end of the Wrinkle Prevent option, the dryer

will go into Pause mode. You will need to touch Power

to turn off or touch Start/Pause to continue the Wrinkle

Prevent option. If the Wrinkle Prevent option is paused, it

will discontinue after 5 minutes of inactivity and turn off.

Audio Level

Touch AUDIO LEVEL to move the volume of the end

signal and button sounds between 5 different settings,

including OFF.

My Cycle

If you have a favorite cycle with custom settings that you

use frequently, you can use the My Cycle feature to keep

your preferred settings ready to use. To save the cycle,

press and hold MY CYCLE (approximately 3 seconds)

until a beep sounds and My Cycle LED is lit. Once a

configuration has been saved, you may power on the

machine and briefly press MY CYCLE to load your saved

cycle and settings.

Energy Saver

Activate the ENERGY SAVER setting to increase your

energy savings. This setting uses a lower heat level and

extends cycle time. Turn on for optimal energy savings.

Turn off for optimal cycle times. ENERGY SAVER is

only available for the Normal cycle and will default on.

NOTE: Energy savings may vary across loads.

Static Reduce

Touch to add the Static Reduce option to selected Sensor

cycles (see “Cycle Guide”). The dryer will automatically

tumble, pause, and introduce a small amount of moisture

into the load to help reduce static. This option will repeat

and adds approximately 8 minutes to the total cycle time.

Steam Boost

Steam Boost adds steam to the end of the cycle to help

smooth wrinkles. See “Cycle Guide.”

7

8

5

Page 6

Damp Dry Signal

Touch to select the Damp Dry Signal to On or Off. When

selected, a series of beeps will sound when the load is

damp, but not completely dry. This will allow you to take

clothes out of the load that do not need to dry completely.

This signal can also be used as a signal to rearrange the

load when drying large bulky items that do not tumble

well, such as comforters. This option is not available on

Sanitize, Steam Refresh, and the Timed Dry cycles.

Drum Light

Select DRUM LIGHT to turn on the light inside the dryer

drum. When touched during a cycle or when the dryer is

not running, the Drum Light turns on and will remain on

until DRUM LIGHT is touched again, the door is opened

and closed, a cycle is started, or the door is left open for

5 minutes.

Touch DRUM LIGHT at any time to turn the drum light on

or off.

8

CYCLE STATUS LIGHTS

The indicator bar on the right side of the control will let you

know what stage of the drying cycle is in process. For more

information on each stage, see “Cycle Status Indicators.”

Sensing

The Sensing indicator will light during Sensor Cycles

to indicate that the moisture sensor on the dryer

is operating. The sensing indicator will light during

timed cycles to show the dryer is functioning. It will

not light during options like wrinkle prevent.

Check Vent

The Check Vent indicator will light if there is a blocked

vent or low airflow.

Good Airflow

This indicator will light if there is no major vent

blockage.

Steam

This indicator will light when a steam function is

active.

NOTE: Steam is not available on all cycles.

Done

This will indicate that the selected cycle has ended

and the load may be removed from the dryer. If

Wrinkle Prevent has been selected, the dryer

may continue to tumble the load, even if the Done

indicator is lit.

Check Lint Screen

The Check Lint Screen indicator light will turn on

when the dryer is powered on as a reminder to clean

the lint screen. It will stay on until the door is opened

or a cycle is started. It will turn off when the dryer is

turned off.

6

Page 7

CYCLE GUIDE — SENSOR CYCLES

Senses moisture in the load and shuts off when the load reaches the selected dryness level. The dry temperature shown is the default

temperature. This setting can be modified on some cycles but is not retained for future drying with this cycle. The dryness level shown is the

default dryness setting. This setting can be changed on some cycles and will be retained for future drying with this cycle. Available options

shown in bold are default settings for that cycle.

To get the most energy savings and enhanced fabric care from your dryer, use the Sensing cycles. These cycles measure the drying air

temperature and moisture levels to turn the dryer off once the load reaches the selected dryness level. For electric models, dryer performance

and results may vary with service voltage less than 240.

Items

to dry:

Large loads

of towels and

heavyweight

Cycle: Temperature: Dry Level: Available

Options:

Power Dry Damp Dry Signal

Wrinkle Prevent

Static Reduce

Cycle Details:

†

This is a high heat cycle. Use

for large loads of heavyweight

fabrics such as cotton towels.

items

Heavyweight

items such as

towels or heavy

work clothes

Heavy Duty Damp Dry Signal

Wrinkle Prevent

Static Reduce

Steam Boost

†

Offers stepped drying starting

with High heat followed by

Medium High heat for enhanced

fabric care and energy savings.

NOTE: Options Static Reduce

and Steam Boost cannot be used

at the same time.

Jackets,

comforters,

pillows

Bedding

Damp Dry

Signal

Wrinkle Prevent

Steam Boost

Use for drying large, bulky

†

items; do not overfill dryer drum.

Partway through the cycle, the

signal will sound to indicate when

it is time to rearrange items for

optimal drying.

Heavyweight

items

Sanitize* Wrinkle Prevent

w/o Steam

†

This is a long cycle with high heat

which has been proven to reduce

household bacteria. This cycle is

not recommended for all fabrics.

Use for loads of heavyweight

fabrics.

Work clothes,

casual wear,

mixed cottons,

sheets,

corduroys

Normal

Energy Saver

Damp Dry Signal

Wrinkle Prevent

Static Reduce

Steam Boost

†

Starts at High Heat, quickly goes

to Medium High, and then ends

on Medium heat to dry large

loads of mixed fabrics and items.

Normal is the preferred energy

cycle. Energy Saver defaults on.

To reduce cycle time, at the cost

of energy savings, turn Energy

Saver off.

NOTE: Options Static Reduce

and Steam Boost cannot be used

at the same time.

Shirts, blouses,

permanent

press, synthetics,

lightweight items

Wrinkle

Control

Damp Dry Signal

Wrinkle

Prevent

†

Steam

w/

Static Reduce

Steam Boost

Uses a stepped drying

temperature from Medium to Low

for improved moisture removal

and enhanced fabric care. Cycle

is designed to help reduce

wrinkles.

NOTE: Options Static Reduce

and Steam Boost cannot be used

at the same time.

Undergarments,

blouses, lingerie,

performance

Delicates Damp Dry Signal

Wrinkle Prevent

Static Reduce

†

Uses a stepped drying

temperature from Medium to Low

to gently dry delicate items.

wear

* Extended high-heat drying cycle intended to help sanitize items such as sheets and towels. This cycle is not recommended for all fabrics.

For best results, this cycle should be run to completion to ensure sanitization and do not interrupt cycle.

†

You may select the “With Steam” setting to add a short steam cycle after 60 minutes. This is not available on Sanitize, Power Dry, or

Delicates. For these cycles, Wrinkle Prevent without Steam will be run to keep optimal clothes protected/performance.

Load Size Recommendations

For best results, follow the wet load size recommendations noted

Medium load: Fill the dryer drum up to about 1/2 full.

for each cycle.

Small load: Fill the dryer drum with 3–4 items, not more than

1/4 full.

Large load: Fill the dryer drum up to about 3/4 full.

Do not overload. Items need to tumble freely.

7

Page 8

CYCLE GUIDE — TIMED CYCLES

Settings and options shown in bold are default settings for that cycle.

Not all settings and options are available on each cycle.

Adjusting drying time on Timed Cycles

When you select a Timed Cycle,

the default time appears in the

display. Use the “+” and “–”

buttons to increase or decrease

the time in 1-minute increments.

Touch and hold to change the

time in 5-minute increments.

The maximum dry time is 150 minutes.

Items to dry: Cycle: Temperature: Default

Time:

Any load

NOTE: Select Air

Only to dry foam,

rubber, plastic,

or heat-sensitive

fabrics.

Small loads and

sportswear

†

You may select the “Wrinkle Prevent with Steam” setting to add a short steam cycle after 60 minutes. This is available only with High and

Medium Temperature settings.

Depending on settings, steam option may be disabled to protect clothing and optimize performance.

Timed Dry

Rapid Dry

Selecting the Temperature

A High heat setting may be used for drying heavyweight items such

as towels and work clothes.

A Low to Medium heat setting may be used for drying mediumweight items such as sheets, blouses, dresses, underwear, permanent press fabrics, and some knits.

Use a no heat (air dry) setting for foam, rubber, plastic, or heatsensitive fabrics.

Line dry bonded or laminated fabrics.

NOTE: If you have questions about drying temperatures for various

loads, refer to the care label directions.

40

15

Available

Options:

Wrinkle

†

Prevent

Wrinkle

†

Prevent

Use to dry items to a damp level for items

that do not require an entire drying cycle.

Select a drying temperature based on

the type of fabrics in your load. If you are

unsure of the temperature to select for a

load, select the lower setting rather than

the higher setting.

For small loads of 3–4 items.

Cycle Details:

CYCLE GUIDE — STEAM CYCLES

Settings and options shown in bold are default settings for that cycle.

Not all settings and options are available on each cycle.

Steam cycles are designed for use with dry loads to loosen wrinkles, reduce odors, and refresh fabrics.

Items

Items

to refresh:

to refresh:

Mixed Loads Steam Refresh (on

Small Mixed

Loads

†

You may select the “Wrinkle Prevent with Steam” setting to add a short steam cycle after 60 minutes.

Load Size Recommendations

For best results, follow the load size recommendations noted

for each cycle.

Small load: Fill the dryer drum with 3–4 items, not more than

1/4 full.

Steam Refresh Wrinkle

Cycle: Temperature: Available

Cycle: Temperature: Dry Level: Available

some models)

Options:

Wrinkle Prevent

Medium load: Fill the dryer drum up to about 1/2 full.

Large load: Fill the dryer drum up to about 3/4 full.

Do not overload. Items need to tumble freely.

†

Options:

Use to smooth out wrinkles and reduce odors from

loads.

†

Prevent

Cycle Details:

Cycle

Details

Use to smooth out wrinkles

and reduce odors from

loads.

8

Page 9

USING YOUR DRYER

WARNING: To reduce the risk of fire, electric shock, or injury to

persons, read the IMPORTANT SAFETY INSTRUCTIONS before

operating this appliance.

1.

Clean the lint screen

Push down on

tab with thumb

2. Load the dryer

Tab

Clean the lint screen before each load. Pull the lint screen

straight up and out. Press tab down on front to open lint screen.

Roll lint off the screen with your fingers. Do not rinse or wash

screen to remove lint. Wet lint is hard to remove. Close lint

screen and push the lint screen firmly back into place.

For additional cleaning information, see “Dryer Care.”

Open the door by pulling on the handle. Place laundry in the dryer.

Add a dryer sheet to wet load, if desired. Close the door.

IMPORTANT: Do not tightly pack the dryer. Items need to tumble

freely. Tightly packing can lead to poor drying performance and may

increase wrinkling and tangling.

3. Touch POWER

Touch POWER to turn on the dryer.

9

Page 10

4. Select the desired cycle

Select the desired cycle for your load. See the “Cycle Guide”

for more information about each cycle.

Steam Refresh:

Reduces light wrinkles and odors from a few garments at a time.

Do not add dryer sheets.

5. Adjust cycle settings, if desired

6. Select any additional options

Add additional options such as Energy Saver or Static Reduce

by touching that option. If you will be unable to remove the load

promptly, select the Wrinkle Prevent options before touching

START.

NOTE: Not all options and settings are available with all cycles.

7. Touch and hold START to begin cycle

You may adjust different settings, depending on whether you

have selected a Sensor Cycle, TImed Cycle, or Steam Refresh

Cycle. See the “Cycle Guide” for detailed information.

NOTE: Not all options and settings are available with all cycles.

Not all cycles are on all models.

Sensor Cycles:

You can select a different dryness level, depending on your

load, by touching DRY LEVEL to scroll through the 5 different

dryness settings. Changing the dry level automatically adjusts

the dryness level at which the dryer will shut off. Dry Level can be

changed in the first 5-8 minutes of the cycle.

Sensor cycles give the best drying in the shortest time. Drying

time varies based on fabric type, load size, and dryness setting.

Timed Cycles:

When you select a Timed Cycle,

the default time appears in the

display. Touch “+” and “–” to

increase or decrease the time in

1-minute increments. Touch

and hold to change the time in 5-minute increments.

The default temperature may be changed by touching

Temperature until the desired dry temperature is lit.

Touch and hold START to begin the cycle.

8. Remove garments promptly

after cycle is finished

Promptly remove garments after cycle has completed to reduce

wrinkling. If you will be unable to remove the load promptly, select

the Wrinkle Prevent option before the end of a cycle.

10

Page 11

Changing the Sensor Cycle settings

to increase drying time

If all your loads on all Sensor Cycles are consistently less dry

or more dry than you would like, you may change the default

settings to increase or decrease the default dryness level.

Your sensor drying settings can be adjusted to adapt to

different installations, environmental conditions, or personal

preference. This change is retained and will affect all of your

Sensor cycles, not just the current cycle/load. There are 5

drying settings, which are displayed using the time display:

0 Much wetter clothes, 30% less drying time.

1 Slightly wetter clothes, 15% less drying time.

2 Factory preset dryness level.

3 Slightly drier clothes, 15% more drying time.

4 Much drier clothes, 30% more drying time.

To change the drying settings:

NOTE: The settings cannot be changed while the dryer is

running or paused. The dryer must be in standby mode (power

is off) to adjust the default settings.

1. Without turning on the dryer, touch and hold DRY LEVEL

for 6 seconds.

2. Touch DRY LEVEL to select the dryness level shown in the

time display: 0, 1, 2, 3, or 4.

3. Touch START to save the new dryness level setting.

NOTE: If any other keypad is touched, or after 20 seconds, the

dryer will return to Standby without saving any changes.

ADDITIONAL FEATURES

USING THE DRYING RACK

USING THE DRYING RACK (cont.)

2. Align the two hooks on the front of the drying rack with the

holes in the dryer door opening and press down fully into

holes. Rest the rear support on the dryer back ledge.

3. Place wet items on top of the drying rack. Allow space

around items for air to circulate. The drying rack does not

move, but the drum will rotate; be sure to leave adequate

clearance between items and the inside of the dryer drum.

Make sure items do not hang over the edges or between

drying rack grille.

4. Close the door.

5. Select a Timed Dry/Air Only, or Low Temperature cycle.

Items containing foam, rubber, or plastic must be dried on a

clothesline or by using the Air Only setting.

6. When the cycle is selected, the Estimated Time Remaining

display shows the default time. You can change the actual

time in the cycle by increasing or decreasing the cycle time.

7. Start the dryer.

NOTE: Check the lint screen and remove any lint accumulated

from items dried on the drying rack after the cycle is finished.

To obtain a drying rack for your dryer, order by calling

1-800-901-2042. You will need your model and serial

number and the purchase date. Remove and discard any

packing material before use.

Use the Drying Rack for items that you do not want to tumble

dry, such as sweaters and tennis shoes. When you use the

drying rack, the drum continues to turn, but the rack remains

stationary.

The drying rack is intended for use with the Timed Dry cycles

only. The drying rack cannot be used with Automatic cycles.

To use the drying rack:

IMPORTANT: Do not remove the lint screen.

1. Open dryer door.

11

Page 12

DRYER CARE

CLEANING THE DRYER LOCATION

Keep dryer area clear and free from items that would block the

air flow for proper dryer operation. This includes clearing piles

of laundry in front of the dryer.

CLEANING THE DRYER INTERIOR

To clean dryer drum

1. Use a mild hand dish detergent mixed at a low

concentration with very warm water, and rub with

a soft cloth.

2. Rinse well with a wet sponge or towel.

3. Tumble a load of clean clothes or towels to dry drum

OR

Use a microfiber cloth and hot water in a spray bottle

to clean the drum and a second microfiber towel to dry.

NOTE: Garments that contain unstable dyes, such as denim

blue jeans or brightly colored cotton items, may discolor the

rear of the dryer interior. These stains are not harmful to your

dryer and will not stain future loads of clothes. Dry unstable

dye items inside out to avoid transfer of dye.

REMOVING ACCUMULATED LINT

From Inside the Dryer Cabinet

Lint should be removed every 2 years, or more often,

depending on dryer usage. Cleaning should be done by a

qualified appliance servicer or ventilation system cleaner.

From the Exhaust Vent

Lint should be removed every 2 years, or more often,

depending on dryer usage.

CLEANING THE LINT SCREEN

Every load cleaning

The lint screen is located in the door opening of the dryer.

The control panel has an indicator light (“Check Lint Screen”)

that comes on before and after each load to remind you to

clean the lint screen.. A screen blocked by lint can increase

drying time.

To clean:

1. Pull the lint screen straight up and out. Press tab down on

front and open lint screen. Roll lint off the screen with your

fingers. Do not rinse or wash screen to remove lint. Wet lint

is hard to remove.

Push down

on tab with

thumb

2. Push the lint screen firmly back into place.

IMPORTANT:

n

Do not run the dryer with the lint screen loose, damaged,

blocked, or missing. Doing so can cause overheating and

damage to both the dryer and fabrics.

n

If lint falls off the screen into the dryer during removal,

check the exhaust hood and remove the lint. See “Venting

Requirements” in the Installation Instructions.

n

Clean space where lint screen

is located, as needed. Using a

vacuum, gently remove any

lint that has accumulated

outside of the lint screen.

As needed cleaning

Laundry detergent and fabric softener residue can build up

on the lint screen. This buildup can cause longer drying times

for your clothes, or cause the dryer to stop before your load is

completely dry. The screen is probably clogged if lint falls off

while the screen is in the dryer.

Clean the lint screen with a nylon brush every 6 months,

or more frequently, if it becomes clogged due to a residue

buildup.

To wash:

1. Roll lint off the screen with your fingers.

2. Wet both sides of lint screen with hot water.

3. Wet a nylon brush with hot water and liquid detergent.

Scrub lint screen with the brush to remove residue buildup.

12

4. Rinse screen with hot water.

5. Thoroughly dry lint screen with a clean towel.

Reinstall screen in dryer.

Page 13

NON-USE, STORAGE, AND MOVING CARE

Steam models only: Install and store your dryer where it will

not freeze. Because some water may stay in the hose, freezing

can damage your dryer. If storing or moving your dryer during

freezing weather, winterize it.

Non-Use or Storage Care

Operate your dryer only when you are at home. If you will be

on vacation or not using your dryer for an extended period of

time, you should:

1. Unplug dryer or disconnect power.

2. Clean lint screen. See “Cleaning the Lint Screen.”

3. Turn off the water supply to the dryer. This helps to avoid

unintended flooding (due to a water pressure surge) while

you are away.

Moving Care

For power supply cord-connected dryers:

1. Unplug the power supply cord.

2. Gas models only: Close shut-off valve in gas supply line.

3. Gas models only: Disconnect gas supply line pipe and

remove fittings attached to dryer pipe.

4. Gas models only: Cap the open fuel supply line.

5. Steam models only: Shut off water faucet.

6. Steam models only: Disconnect the water inlet hose from

faucet, then drain the hose. Transport hose separately.

7. Make sure leveling legs are secure in dryer base.

8. Use tape to secure dryer door.

SPECIAL INSTRUCTIONS

FOR STEAM MODELS

Water Inlet Hose

Replace inlet hose and hose screen after 5 years of use to

reduce the risk of hose failure. Periodically inspect and replace

inlet hose if bulges, kinks, cuts, wear, or leaks are found.

When replacing your inlet hose, record the date of

replacement.

To Winterize the Dryer:

1. Unplug dryer or disconnect power.

2. Shut off water faucet.

3. Disconnect water inlet hose from faucet and drain.

To Use the Dryer Again:

1. Flush water pipes. Reconnect water inlet hose to faucet.

Turn on water faucet.

2. Plug in dryer or reconnect power as described in the

Installation Instructions.

For direct-wired dryers:

1. Disconnect power.

2. Disconnect wiring from dryer and secure wire ends.

3. Steam models only: Shut off water faucet.

4. Steam models only: Disconnect the water inlet hose from

faucet; then drain the hose. Transport hose separately.

5. Make sure leveling legs are secure in dryer base.

6. Use tape to secure dryer door.

Reinstalling the Dryer

Follow the Installation Instructions to locate, level, and connect

the dryer.

13

Page 14

TROUBLESHOOTING

First try the solutions suggested here or visit our website at www.maytag.com/product_help –

If you experience Possible Causes Solution

Dryer Operation

Dryer will not run Door not closed completely. Make sure the dryer door is closed completely.

Dryer will not heat Incorrect setting. Check that the Temperature setting is not set to “No Heat.”

Unusual Noise

Humming or whining noise

with Steam cycle selected

Thumping noise Dryer hasn’t been used in a while. This is normal. The thumping sound should diminish after a few

Rattling or vibrating noise A small object caught between the

Clicking noise Gas valve operating. On gas dryers, you may hear the gas valve clicking as it opens and

Dryer Results

Clothes are not drying

satisfactorily or drying

times are too long

In Canada www.maytag.ca for assistance and to possibly avoid a service call.

START not touched firmly or held long

enough.

Household fuse is blown, circuit

breaker has tripped, or dryer is not

plugged in.

Incorrect power supply. Electric dryers require 240-volt or 208-volt power supply. Check

Wrong type of fuse. Use a time-delay fuse.

Household fuse is blown or circuit

breaker has tripped.

Incorrect power supply. Electric dryers require 240-volt or 208-volt power supply. Check

The gas supply line valve not open. For gas dryers, make sure that the valve on the gas supply line is

Water inlet valve on dryer is running. The water pump on the dryer is used during the Steam function. If

edges of dryer drum.

Dryer isn’t properly leveled. The dryer may vibrate if not properly installed. See the Installation

Clothing is balled up in dryer. When balled up, the load will bounce, causing the dryer to vibrate.

Lint screen or lint screen housing is

clogged with lint.

The exhaust vent or outside exhaust

hood is clogged with lint, restricting air

movement.

The exhaust vent is not the correct

length.

The exhaust vent diameter is not the

correct size.

The dryer is not level. Clothes not contacting the moisture sensors during Sensor cycles.

The Air Only temperature setting has

been selected.

Touch and hold START 2-5 seconds. The display will count

down 3-2-1.

There may be 2 household fuses or circuit breakers for the dryer.

Check that both fuses are intact and tight, or that both circuit

breakers have not tripped. Replace the fuses or reset the circuit

breaker. If the problem continues, call an electrician.

with a qualified electrician.

The drum may be turning, but you may not have heat. Electric dryers

use 2 household fuses or circuit breakers. Replace the fuses or

reset the circuit breaker. If the problem continues, call an electrician.

with a qualified electrician.

open.

the dryer has just been installed or unused for an extended period,

the pump may be louder and run longer. This is normal.

minutes of use.

Check the front and rear edges of the drum for small objects. Clean

out pockets before laundering.

Instructions. All four dryer feet should be in firm contact with the

floor.

Separate the load items and restart the dryer.

closes. This is normal.

Clean lint screen before each load. Clean space where lint screen is

located, as needed. Using a vacuum, gently remove any lint that has

accumulated outside of the lint screen.

Run the dryer on Air Only for 5–10 minutes. Hold your hand under

the outside exhaust hood to check air movement. If you do not

feel air movement, clean exhaust system of lint or replace exhaust

vent with heavy metal or flexible metal vent. See the Installation

Instructions.

Check that the exhaust vent is not too long or has too many

turns. Long venting will increase drying times. See the Installation

Instructions.

Use 4" (102 mm) diameter vent material.

See “Level Dryer” in the Installation Instructions.

Select the correct temperature for the types of garments being

dried. See “Cycle Guide.”

14

Page 15

TROUBLESHOOTING

First try the solutions suggested here or visit our website at www.maytag.com/product_help –

If you experience Possible Causes Solution

Dryer Results (cont.)

Clothes are not drying

satisfactorily or drying

times are too long

Cycle time is too short The load may not be contacting the

Lint on load Lint screen is clogged with lint. Clean lint screen before each load.

In Canada www.maytag.ca for assistance and to possibly avoid a service call.

The load is too large and heavy to dry

quickly.

Fabric softener sheets are blocking

the grille.

The dryer is located in a room with

temperature below 45ºF (7ºC).

The dryer is located in a closet. Closet doors must have ventilation openings at the top and bottom

sensor strips on Sensor Cycles.

Clothes are coming out of the Steam

Refresh cycle with damp or wet spots.

The Sensor Cycle is ending early. Change the dryness level setting on Sensor Cycles. Increasing

Separate the load to tumble freely.

The air outlet grille is just inside the door, behind the lint screen.

Check that it is not blocked by a fabric softener sheet.

Use only one fabric softener sheet, and use it only once.

Proper operation of dryer cycles requires temperatures above

45ºF (7ºC).

of the door. The front of the dryer requires a minimum of 1" (25 mm)

of airspace, and, for most installations, the rear of the dryer requires

5" (127 mm). See the Installation Instructions.

Level the dryer. See the Installation Instructions. All four dryer feet

should be in firm contact with the floor.

If you are doing a Steam Refresh cycle of 1 or 2 items you can add

a towel to the load to help avoid uneven spraying from the steam

valve. Then select the appropriate time based on the load to be

refreshed.

or decreasing the dryness level will change the amount of drying

time in a cycle. If loads are consistently ending too early, see also

“Changing the Sensor Cycle settings to increase or decrease drying

time.”

Stains on load Improper use of fabric softener. Add dryer fabric softener sheets at the beginning of the cycle.

Stains on drum Loose dyes in clothes. Drum stains are caused by dyes in clothing (usually blue jeans).

Loads are wrinkled The load was not removed from dryer

Odors Recent painting, staining, or varnishing

Steam did not occur

during Wrinkle Prevent

at the end of the cycle.

The dryer was tightly packed. Dry smaller loads that can tumble freely. When using the Steam

For steam cycles, the water is not

properly connected with the dryer.

in the area where your dryer is located.

For steam cycles, the water is not

properly connected with the dryer.

Odors are left in garments after

wearing.

Wrinkle Prevent does not enable Steam

on all cycle/option combinations.

Fabric softener sheets added to a partially dried load can stain your

garments. Do not use fabric softener sheets with steam cycles.

These will not transfer to other clothing.

Select Steam Refresh Cycle to tumble the load with water

and heat. This cycle is best for smoothing out wrinkles and

reducing odors from dry loads consisting of one to 9 dry items

of wrinkle-free cotton, cotton-polyester blend, common knits,

and synthetic garments.

NOTE: Refer to garment care label instructions. Dry-clean-only

garments are not recommended.

Refresh cycle, adjust the garment number based on the load size.

Results may also vary depending on fabric type. This cycle is best

for reducing wrinkles and odors from loads consisting of wrinkle-free

cotton, cotton-polyester blends, common knits, and synthetics.

Make sure water is connected to the dryer. Check that water inlet

hose is connected to both the faucet and dryer’s water inlet valve.

Check that the water supply is turned on.

Ventilate the area. When the odors or fumes are gone from the area,

rewash and dry the clothing.

Make sure water is connected to the dryer. Check that water inlet

hose is connected to both the faucet and dryer’s water inlet valve.

Check that the water supply is turned on.

To remove odors left in garments after wearing, select Steam

Refresh. This cycle is best for reducing wrinkles and odors from dry

loads consisting of wrinkle-free cotton, cotton-polyester blends,

common knits, and synthetics.

Refer to Cycle Guide to verify which cycles and settings

enable Steam.

15

Page 16

TROUBLESHOOTING

First try the solutions suggested here or visit our website at www.maytag.com/product_help –

If you experience Possible Causes Solution

Dryer Results (cont.)

Load too hot Load removed before cool down

Dryer Displaying Code Message or Indicator Is Lit

“PF” (power failure) The drying cycle has been interrupted

“L2” Diagnostic Code (low

or no line voltage condition)

“Check Vent” indicator

lights up and/or “AF”

appears on the display.

“F# E#” (F1 E1, F3 E1,

etc.) variable service

codes.

In Canada www.maytag.ca for assistance and to possibly avoid a service call.

portion of cycle complete.

Using Timed Dry cycle with a high

temperature setting.

by a power failure.

There may be a problem with your

home power supply, keeping the

dryer’s heater from turning on.

The lint screen or vent is clogged;

the vent is crushed, kinked or has

too many turns.

The dryer is in need of service. If a code beginning with an “F” appears in the display, alternating

Allow the dryer to complete the cool down portion of the cycle

before removing the load.

Select a Sensor Cycle with a lower heat setting to avoid over-drying

the load.

Touch the POWER key to clear the PF error and turn the dryer off.

Check your items in the dryer for dampness and start a new cycle if

desired.

The dryer will continue to run when this diagnostic code is present.

Touch any pad to clear the code from the display and return to the

estimated time remaining.

Try the following:

•

Check to see if a household fuse has blown or circuit breaker

has tripped. Electric dryers use two household fuses or breakers.

Replace the fuse or reset the circuit breaker.

•

Confirm that the power cord is properly installed. Refer to

the Installation Instructions for details.

•

Select a Timed Dry heated cycle, and restart the dryer.

If the message persists, consult a qualified electrician.

The dryer will continue to run when this diagnostic code is present.

Touch any key to clear the code from the display and return to the

estimated time remaining.

Try the following:

•

Clean lint screen.

•

Check to see if the vent run from the dryer to the wall is

crushed or kinked.

•

Confirm that the vent runs from the dryer to the wall is free

of lint and debris.

•

Confirm that the exterior vent exhaust hood is free of lint

and debris.

•

Confirm that your vent system falls within the recommended

run length and number of elbows for the type of vent you are using.

Refer to “Plan Vent System” in the Installation Instructions for details.

Select a Timed Dry heated cycle, and restart the dryer.

If the message persists, have your entire home venting run cleaned.

Contact a venting specialist.

between F# and E#, the dryer control has detected a problem that

requires service. Call for service.

16

Page 17

ATTACH YOUR RECEIPT HERE. PROOF OF PURCHASE IS

REQUIRED TO OBTAIN WARRANTY SERVICE.

MAYTAG® LAUNDRY

LIMITED WARRANTY

Please have the following information available when you call the

Customer eXperience Center:

n

Name, address, and telephone number

n

Model number and serial number

n

A clear, detailed description of the problem

n

Proof of purchase including dealer or retailer name and address

IF YOU NEED SERVICE:

1. Before contacting us to arrange service, please determine whether your product requires repair. Some

questions can be addressed without service. Please take a few minutes to review the Troubleshooting

or Problem Solver section of the Use and Care Guide, scan the QR code on the right to access

additional resources, or visit https://www.maytag.com/product_help.

2. All warranty service is provided exclusively by our authorized Maytag Service Providers.

In the U.S. and Canada, direct all requests for warranty service to:

Maytag Customer eXperience Center

In the U.S.A. call 1-800-688-9900. In Canada call 1-800-807-6777.

If outside the 50 United States and Canada, contact your authorized Maytag dealer to determine if another warranty applies.

TEN YEAR LIMITED WARRANTY

WHAT IS COVERED

FIRST YEAR LIMITED WARRANTY

(PARTS AND LABOR)

For one year from the date of purchase, when this major

appliance is installed, operated, and maintained according to

instructions attached to or furnished with the product, Maytag

brand of Whirlpool Corporation or Whirlpool Canada LP

(hereafter “Maytag”) will pay for factory specified parts and

repair labor to correct defects in materials or workmanship

that existed when this major appliance was purchased, or

at its sole discretion replace the product. In the event of

product replacement, your appliance will be warranted by the

remaining term of the original unit’s warranty period.

SECOND THROUGH TENTH YEAR LIMITED

WARRANTY (DRUM MOTOR AND STAINLESS STEEL

OR POWDER COATED PAINT DRUM ONLY - LABOR

NOT INCLUDED)

In the second through tenth years from the date of original

purchase, when this major appliance is installed, operated, and

maintained according to instructions attached to or furnished

with the product, Maytag will pay for factory specified parts for

the following components to correct non-cosmetic defects in

materials or workmanship in these parts that prevent function

of this major appliance and that existed when this major

appliance was purchased. This is a limited 10 year warranty on

the below named parts only and does not include repair labor.

n Drum (Side Walls Only) n Drive Motor

YOUR SOLE AND EXCLUSIVE REMEDY UNDER THIS

LIMITED WARRANTY SHALL BE PRODUCT REPAIR AS

PROVIDED HEREIN. Service must be provided by a Maytag

designated service company. This limited warranty is valid

only in the United States or Canada and applies only when

the major appliance is used in the country in which it was

purchased. This limited warranty is effective from the date of

original consumer purchase. Proof of original purchase date is

required to obtain service under this limited warranty.

DISCLAIMER OF IMPLIED WARRANTIES

IMPLIED WARRANTIES, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR IMPLIED WARRANTY OF FITNESS FOR

A PARTICULAR PURPOSE, ARE LIMITED TO ONE YEAR OR THE SHORTEST PERIOD ALLOWED BY LAW. Some states and provinces

do not allow limitations on the duration of implied warranties of merchantability or fitness, so this limitation may not apply to you. This warranty

gives you specific legal rights, and you also may have other rights that vary from state to state or province to province.

DISCLAIMER OF REPRESENTATIONS OUTSIDE OF WARRANTY

Maytag makes no representations about the quality, durability, or need for service or repair of this major appliance other than the

representations contained in this Warranty. If you want a longer or more comprehensive warranty than the limited warranty that comes

with this major appliance, you should ask Maytag or your retailer about buying an extended warranty.

LIMITATION OF REMEDIES; EXCLUSION OF INCIDENTAL AND CONSEQUENTIAL DAMAGES

YOUR SOLE AND EXCLUSIVE REMEDY UNDER THIS LIMITED WARRANTY SHALL BE PRODUCT REPAIR AS PROVIDED HEREIN.

MAYTAG SHALL NOT BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES. Some states and provinces do not allow the

exclusion or limitation of incidental or consequential damages, so these limitations and exclusions may not apply to you. This warranty gives

you specific legal rights, and you also may have other rights that vary from state to state or province to province.

11/14

1. Commercial, non-residential, multiple-family use, or use inconsistent with

published user, operator, or installation instructions.

2. In-home instruction on how to use your product.

3. Service to correct improper product maintenance or installation,

installation not in accordance with electrical or plumbing codes, or

correction of household electrical or plumbing (i.e. house wiring, fuses,

or water inlet hoses).

4. Consumable parts (i.e. light bulbs, batteries, air or water filters,

preservation solutions, etc.).

5. Defects or damage caused by the use of non-genuine Maytag parts or

accessories.

6. Conversion of your product from natural gas or L.P. gas or reversal of

appliance doors.

7. Damage from accident, misuse, abuse, fire, floods, acts of God, or use

with products not approved by Maytag.

8. Repairs to parts or systems to correct product damage or defects caused

by unauthorized service, alteration, or modification of the appliance.

9. Cosmetic damage including scratches, dents, chips, and other damage

to appliance finishes unless such damage results from defects in

materials and workmanship and is reported to Maytag within 30 days.

10. Discoloration, rust, or oxidation of surfaces resulting from caustic

or corrosive environments, including but not limited to, high salt

concentrations, high moisture or humidity, or exposure to chemicals.

11. Pick-up or delivery. This product is intended for in-home repair.

12. Travel or transportation expenses for service in remote locations where an

authorized Maytag servicer is not available.

13. Removal or reinstallation of inaccessible appliances or built-in fixtures (i.e.

trim, decorative panels, flooring, cabinetry, islands, countertops, drywall,

etc.) that interfere with servicing, removal, or replacement of the product.

14. Service or parts for appliances with original model/serial numbers

removed, altered, or not easily determined.

The cost of repair or replacement under these excluded

circumstances shall be borne by the customer.

WHAT IS NOT COVERED

https://www.maytag.com/product_help

17

Page 18

Assistance or Service

Before calling for assistance or service, please check “Troubleshooting” or visit www.maytag.com/help.

It may save you the cost of a service call. If you still need help, follow the instructions below.

When calling, please know the purchase date and the complete model and serial number of your appliance.

This information will help us to better respond to your request.

If you need replacement parts or to order accessories

We recommend that you use only FSP® Factory Specified Parts.

These parts will fit right and work right because they are made with the same precision

used to build every new MAYTAG

To locate FSP® replacement parts or accessories go to www.maytagpartsonline.com.

Questions? Call us toll free at 1-800-344-1274 or in Canada call 1-800-688-2002.

Our consultants provide assistance with

In the U.S.A.

■ Features and specifications on our full line of appliances.

■ Installation information.

■ Specialized customer assistance (Spanish speaking,

hearing impaired, limited vision, etc.).

You can write with any questions or concerns at:

Maytag Brand Appliances

Customer eXperience Center

553 Benson Road

Benton Harbor, MI 49022-2692

1-800-344-1274

Please include a daytime phone number in your correspondence.

®

appliance.

In the U.S.A. and Canada

■ Use and maintenance procedures.

■ Accessory and repair parts sales.

■ Referrals to local dealers, repair parts distributors,

and service companies. Whirlpool designated service

technicians are trained to fulfill the product warranty and

provide after-warranty service, anywhere in the United

States and Canada.

Maytag Brand Appliances

Customer eXperience Centre

Unit 200-6750 Century Ave

Mississauga, Ontario L5N 0B7

1-800-688-2002

Assistance ou Service

Avant de faire un appel pour obtenir de l’assistance ou un entretient, vérifier la section “Dépannage” ou consulter

www.maytag.com/help. Cette vérification peut vous faire économiser le coût d’une visite de réparation.

Lors d’un appel, garder à portée de main la date d’achat et les numéros de modèle et de série de votre appareil.

Pour commander des pièces de rechange ou des accessoires

Pour commander des pièces de rechange, nous vous recommandons d’utiliser seulement

des pièces spécifiées par l’usine. Ces pièces conviendront et fonctionneront bien parce qu’elles sont fabriquées selon

les mêmes spécifications précises utilisées pour construire chaque nouvel appareil MAYTAG

Pour trouver des pièces de rechange FSP

Nos consultants fournissent

l’assistance pour :

■ Procédés d’utilisation et d’entretien.

■ Vente d’accessoires et de pièces de rechange.

■ Références aux concessionnaires, compagnies de service

de réparation et distributeurs de pièces de rechange

locaux. Les techniciens de service désignés par Whirlpool

sont formés pour remplir la garantie des produits et fournir

un service après la garantie, partout au Canada.

Si vous avez encore besoin d’aide, suivre les instructions ci-dessous.

Ces renseignements nous aideront à mieux répondre à votre demande.

®

ou des accessoires, visiter le www.maytag.ca.

Des questions? Composer le numéro sans frais 1-800-688-2002.

Pour plus d’assistance

Vous pouvez nous soumettre toute question ou toute

problème en écrivant à l’adresse ci-dessous :

Maytag Brand Appliances

Centre pour l’eXpérience de la clientèle

Unit 200-6750 Century Ave

Mississauga, Ontario L5N 0B7

1-800-688-2002

Dans votre correspondance, veuillez indiquer un numéro

de téléphone où nous pouvons vous joindre dans la journée.

®

.

W10885280A

04/16

W10885286A - SP

®/TM

© 2016 Maytag. All rights reserved. Used under license in Canada.

®/TM

© 2016 Maytag. Tous droits réservés. Emploi sous licence au Canada.

Loading...

Loading...