Page 1

COMMERCIAL HE DRYER INSTALLATION INSTRUCTIONS

(original instructions)

Gas

INSTRUCTIONS D’INSTALLATION D’UN SECHE-LINGE HE COMMERCIAL

(traduction des instructions d’origine)

À gaz

INSTRUCCIONES DE INSTALACIÓN – SECADORA HE COMERCIAL

(traducción de las instrucciones originales)

A gas

ISTRUZIONI D’INSTALLAZIONE – ASCIUGATRICE HE COMMERCIALE

(traduzione delle istruzioni originali)

A gas

MDG22PN MDG22PD

W10239207B

www.maytagcommerciallaundry.com

Page 2

TABLE OF CONTENTS

DRYER SAFETY ............................................................................3

DRYER DISPOSAL ........................................................................4

INSTALLATION REQUIREMENTS ..............................................4

Tools and Parts ..........................................................................4

Location Requirements ..............................................................4

Electrical Requirements - Gas Dryer..........................................5

as Supply Requirements ........................................................6

G

Venting Requirements ................................................................7

TABLE DES MATIERES

SECURITE DU SECHE-LINGE ................................................18

ELIMINATION DU SECHE-LINGE ..........................................19

EXIGENCES D’INSTALLATION................................................19

Outillage et pièces ....................................................................19

Exigences d’emplacement ......................................................20

Spécifications électriques - sèche-linge à gaz .......................21

Spécifications de l’alimentation en gaz ..................................22

Exigences concernant l’évacuation..........................................23

INSTALLATION INSTRUCTIONS – GAS DRYER ....................9

Install Leveling Legs....................................................................9

Make Gas Connection................................................................9

Connect Vent ..............................................................................9

Complete Installation ................................................................9

MAINTENANCE INSTRUCTIONS ..........................................10

ECHNICAL SPECIFICATIONS – GAS DRYER......................10

T

REVERSING THE DOOR SWING (OPTIONAL).......................11

ELECTRONIC CONTROL SETUP ..........................................13

WARRANTY..............................................................................17

INSTRUCTIONS D’INSTALLATION –

SECHE-LINGE A GAZ ..............................................................24

Installation des pieds de nivellement........................................24

Raccordement à la canalisation de gaz ..................................25

Raccordement du conduit d’évacuation ................................25

Achever l’installation ................................................................25

INSTRUCTIONS D’ENTRETIEN...............................................25

FICHE TECHNIQUE – SECHE-LINGE A GAZ ........................26

INVERSION DU SENS D’OUVERTURE DE LA PORTE .........27

REGLAGE DE LA CARTE

DE CIRCUITS ELECTRONIQUES ..........................................29

GARANTIE ................................................................................33

ÍNDICE

SEGURIDAD DE LA SECADORA............................................34

ELIMINACIÓN DE LA SECADORA ..........................................35

REQUISITOS DE INSTALACIÓN ............................................35

Piezas y herramientas ..........................................................35

Requisitos de ubicación ........................................................35

Requisitos eléctricos - secadora a gas ................................36

Requisitos del suministro de gas............................................37

Requisitos de ventilación ....................................................38

INDICE

SICUREZZA DELL’ASCIUGATRICE ........................................ 49

L’ELIMINAZIONE DELL’ASCIUGATRICE ..................................50

REQUISITI D’INSTALLAZIONE ................................................ 50

Attrezzi e componenti.............................................................. 50

Requisiti di ubicazione ............................................................ 50

Requisiti elettrici - asciugatrice a gas .................................... 51

Requisiti di alimentazione del gas............................................52

Requisiti di scarico ................................................................53

INSTRUCCIONES DE INSTALACIÓN –

SECADORA A GAS ................................................................40

Instalación de las patas niveladoras ....................................40

Conexión del suministro de gas............................................40

Conexión del ducto de escape ............................................40

Complete la instalación ........................................................40

INSTRUCCIONES DE MANTENIMIENTO ..............................41

ESPECIFICACIONES TÉCNICAS – SECADORA A GAS ......41

CÓMO INVERTIR EL SENTIDO DE APERTURA

DE LA PUERTA .......................................................................42

PROGRAMACIÓN DEL CONTROL ELECTRÓNICO ............44

GARANTÍA................................................................................48

ISTRUZIONI DI INSTALLAZIONE – ASCIUGATRICE

A GAS ...................................................................................... 55

Installazione dei piedini di regolazione ....................................55

Eseguire il colleganento gas ....................................................55

Connessione dello scarico ......................................................55

Completamento dell’installazione ............................................56

ISTRUZIONI DI MANUTENZIONE .........................................57

DATI TECNICI – ASCIUGATRICE A GAS ..............................57

INVERSIONE DELLA ROTAZIONE DI APERTURA ...............58

CONFIGURAZIONE DEI CONTROLLI ELETTRONICI ..........60

GARANZIA ..................................................................................64

2

Page 3

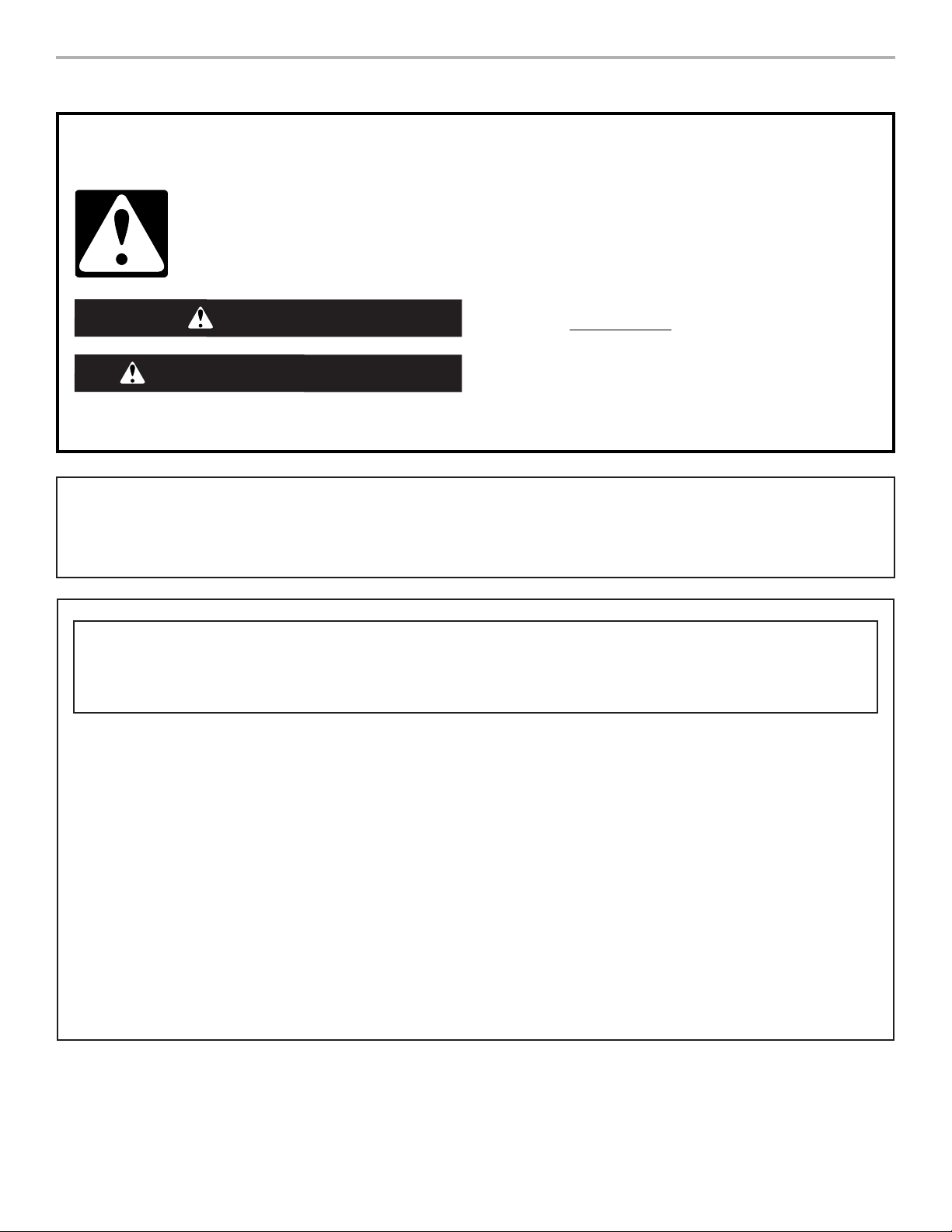

You can be killed or seriously injured if you don't immediately

You

can be killed or seriously injured if you don't

follow

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

follow instructions.

instructions.

DANGER

WARNING

DRYER SAFETY

WARNING: For your safety, the information in this manual must be followed to minimize

the risk of re or explosion, or to prevent property damage, personal injury, or death.

– Do not store or use petrol or other ammable vapors and liquids in the vicinity of this

or any other appliance.

– WHAT TO DO IF YOU SMELL GAS:

•

Do not try to light any appliance.

•

Do not touch any electrical switch; do not use any phone in your building.

•

Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's

instructions.

•

If you cannot reach your gas supplier, call the re department.

– Installation and service must be performed by a qualied installer, service agency, or

the gas supplier.

•

Clear the room, building, or area of all occupants.

FOR YOUR SAFETY

1. Do not use or store petrol or other flammable materials in this appliance or near this appliance.

2. Do not spray aerosols in the vicinity of this appliance while it is in operation.

3. Do not modify this appliance.

3

Page 4

DRYER DISPOSAL

INSTALLATION REQUIREMENTS

Tools and Parts

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools

listed here.

Tools needed:

■ 200 mm (8") or 250 mm

(10") Pipe wrench

■ 200 mm (8") or 250 mm

(10") Adjustable wrench

■ Flat-blade screwdriver

■ Phillips screwdriver

■ Adjustable wrench that

■ 8 mm (

■ Utility knife

■ Vent clamps

■ Pipe-joint compound

■ Sealing gun and sealing

opens to 25 mm (1") or

hex-head socket wrench

■ Level

■ Pliers

■ Stiff-bladed putty knife

Parts supplied:

Remove parts bag from dryer drum. Check that all parts were

included.

■ Foot boot (4)

■ Dryer foot (4)

■ PD models: Cam for

service door lock

NOTE: The circuit diagram for this dryer is located inside the

lower front panel, within the Tech Sheets.

■ PN models: Card reader

5

/16") socket wrench

resistant to LP gas

compound (for installing

new exhaust vent)

bezel, card reader wire

harness, hardware

Location Requirements

If installing a gas dryer:

IMPORTANT: Observe all governing codes and ordinances.

■ Check code requirements: Some codes limit or do not permit

installation of clothes dryers in garages, closets, or sleeping

quarters. Contact your local building inspector.

■ Make sure that lower edges of the cabinet, plus the back and

bottom sides of the dryer, are free of obstructions to permit

adequate clearance of air openings for combustion air. See

“Recessed Area and Closet Installation Instructions” below

for minimum spacing requirements.

■ Do not install on carpet.

NOTE: The dryer must not be installed in an area where it will be

exposed to water and/or weather.

4

Page 5

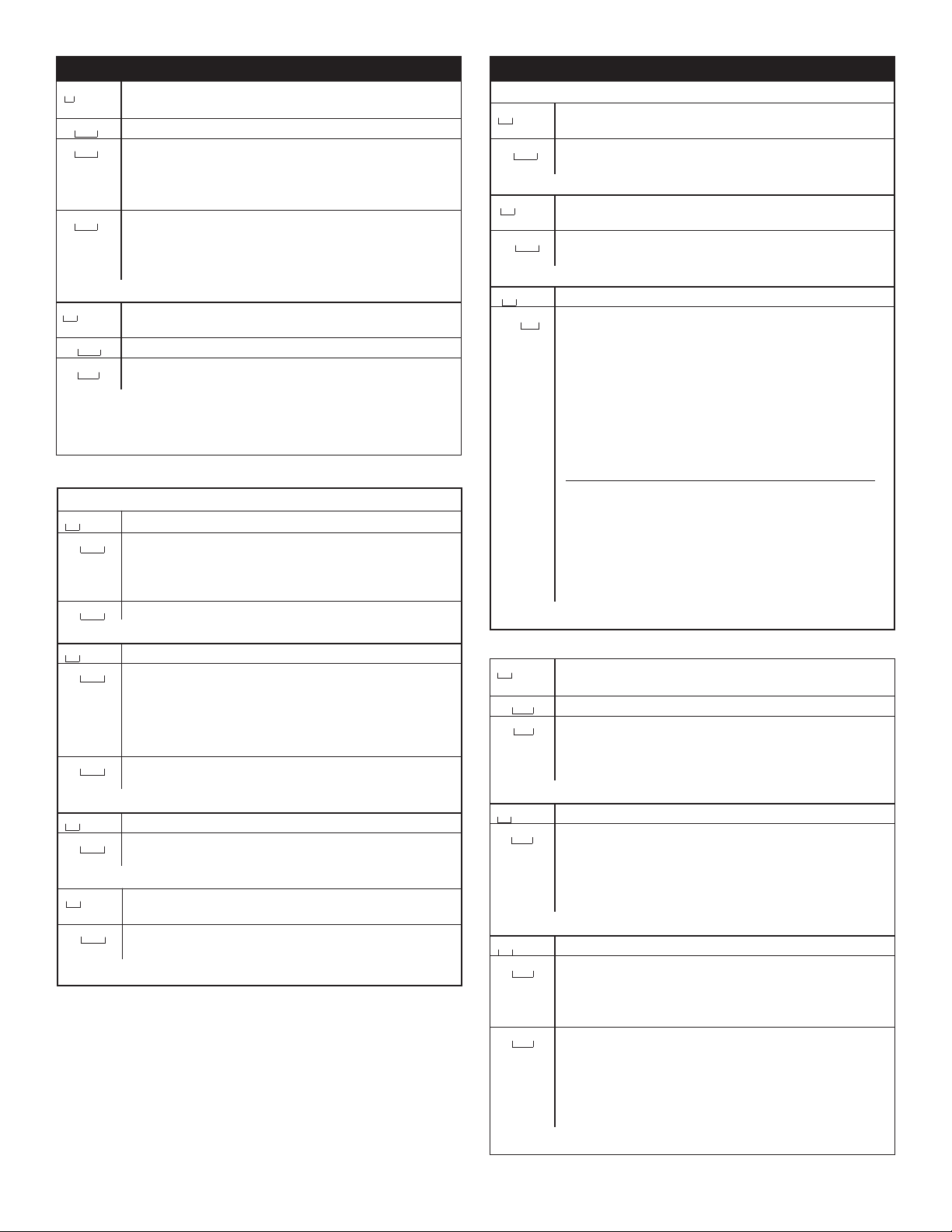

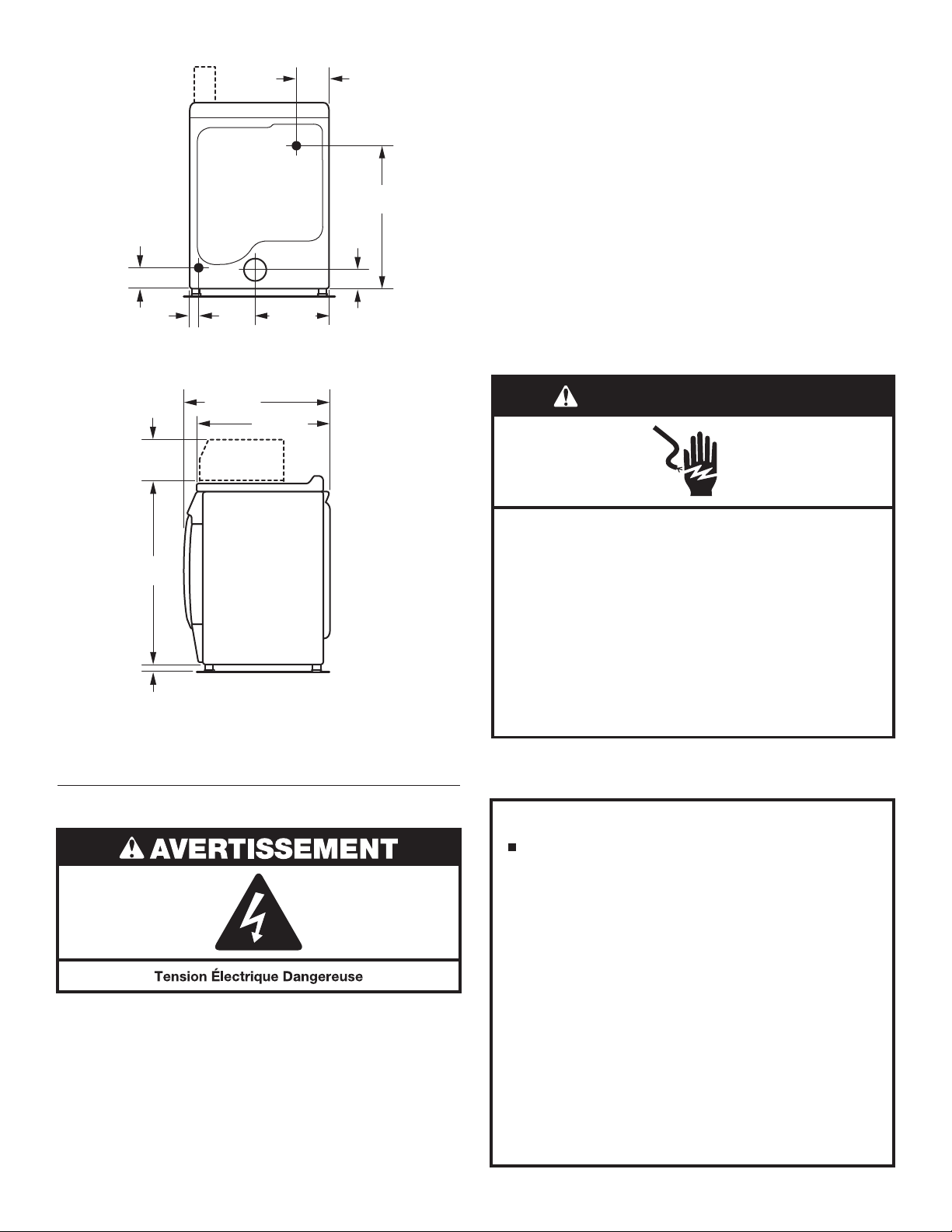

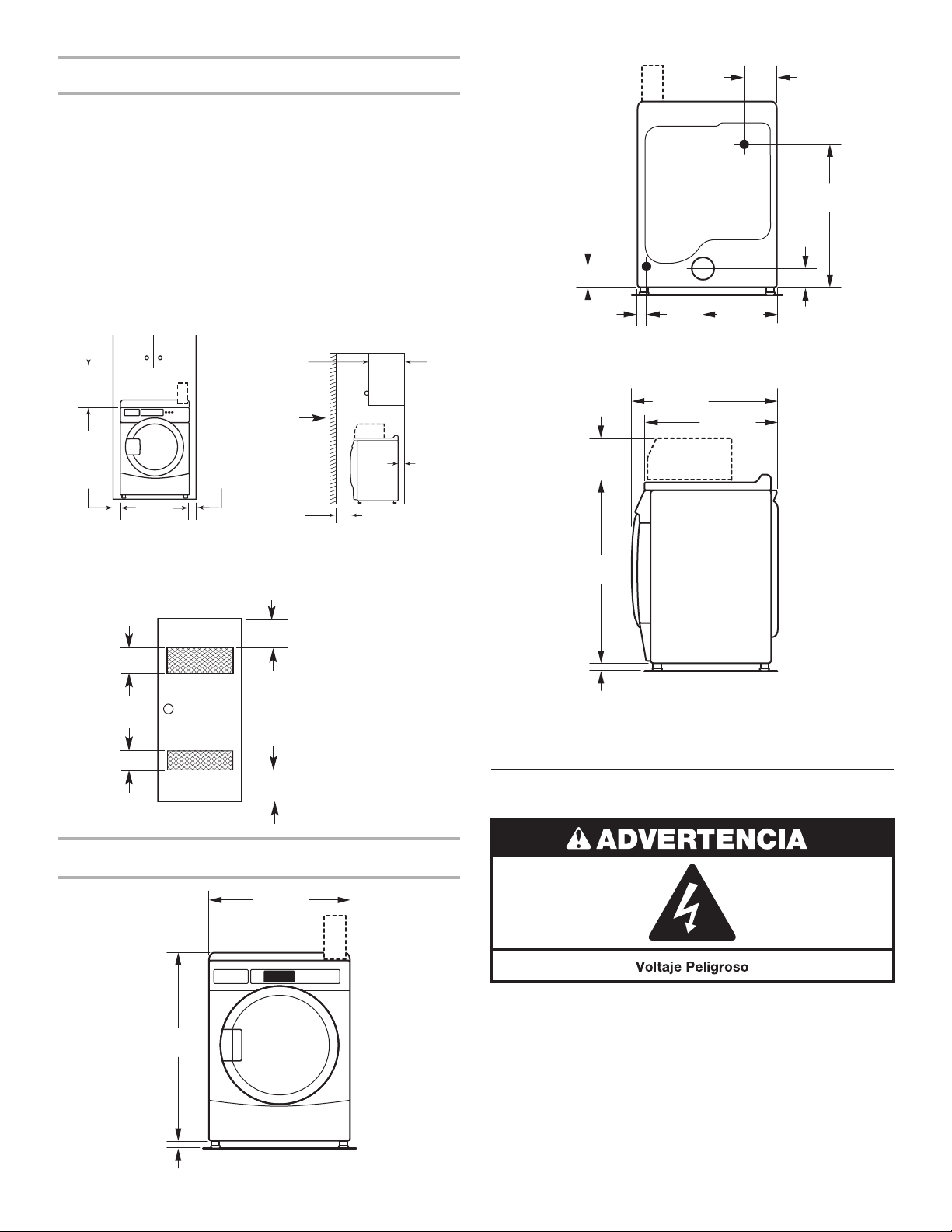

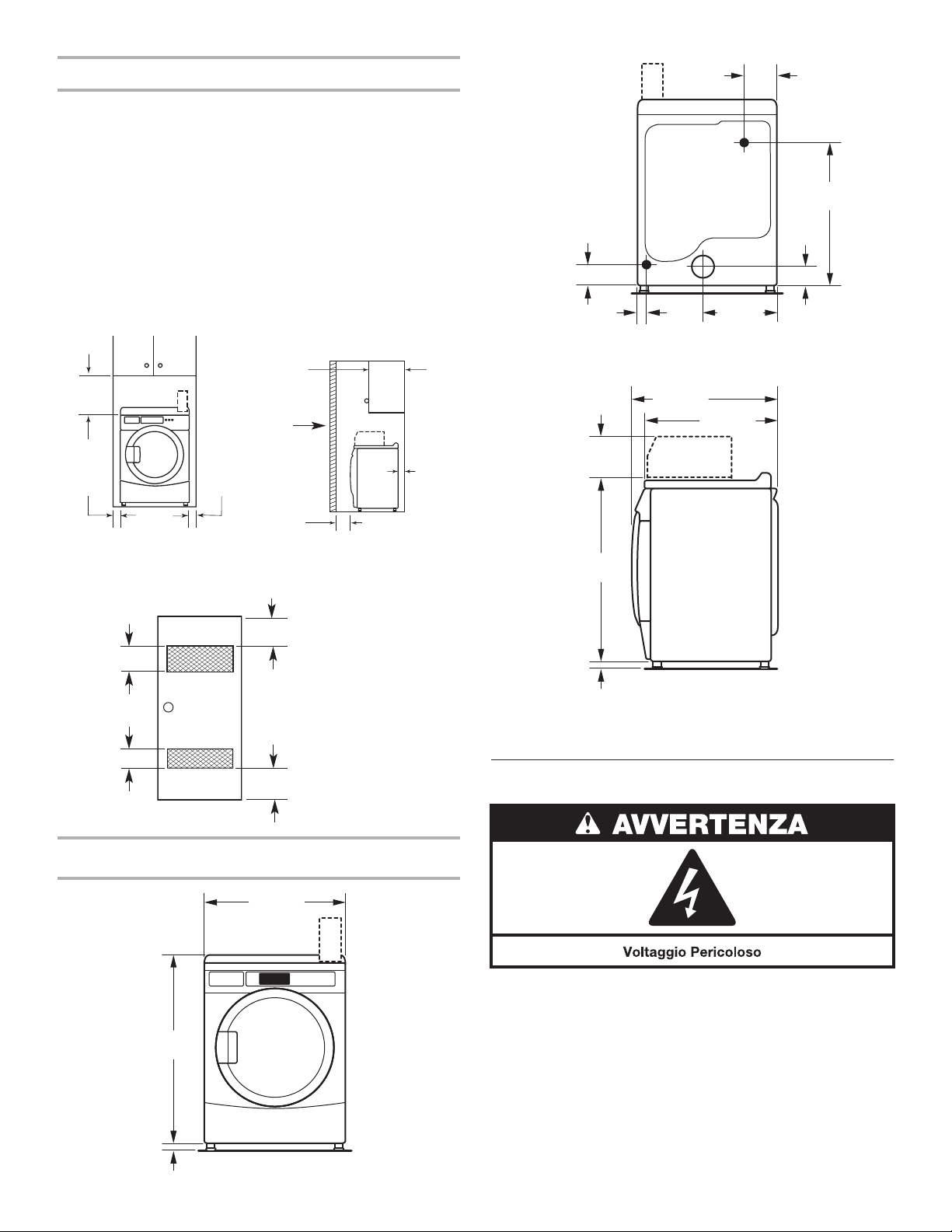

ecessed Area and Closet Installation Instructions

76 mm (3")

155cm

2

*

(24 in.2)

310cm

2

*

(48 in.

2

)

76 mm (3")

381 mm

(15")

0 mm

(0")

0 mm

(0")

356 mm

(14") max

25 mm (1")

0 mm

(0")

686 mm

(27")

965 mm

(38")

25 mm

(1")

159 mm

(6

1

/4")

715 mm

(28

1

/8")

89 mm

(3

1

/2")

358 mm

(14")

32 mm

(11/4")

152 mm

(5

7

/8")

736 mm

(29")

921 mm

(36

1

/4")

203 mm

(8")

25 mm

(1")

695 mm

(271/4")

R

This dryer may be installed in a recessed area or closet. This

dryer must not be installed behind a lockable door, a sliding door,

or a door with a hinge on the opposite side to that of the dryer.

The installation spacing is in millimeters and is the minimum allowable.

Additional spacing should be considered for ease of installation,

servicing, and compliance with local codes and ordinances.

If installed in a closet with a door, the minimum unobstructed air

opening in the top and bottom is required. Louvered doors with

equivalent air openings are acceptable.

The dryer must be exhausted outdoors.

No other fuel-burning appliance may be installed in the same

closet as the dryer.

Minimum Installation Clearances

loset

C

oor

d

LECTRIC

E

AS

G

BACK VIEW

Recessed front view

Additional clearances for wall, door, and floor moldings may be required or if

external exhaust elbow is used.

Front

view

closet

door

Closet side view

*Opening is the minimum

for a closet door. Louvered

doors with equivalent air

openings are acceptable.

Product Dimensions 686 mm (27") dryer

FRONT VIEW

SIDE VIEW

Electrical Requirements – Gas Dryer

Important: Observe all governing codes and ordinances.

You will need an earthed electrical outlet located within 610 mm

(2 feet) of either side of the dryer.

5

Page 6

This dryer is supplied/fitted with an electricity supply cord and plug. It

EARTHING INSTRUCTIONS

SAVE THESE INSTRUCTIONS

should be connected to electricity supply socket at the voltage shown

on the rating plate. The minimum supply fuse capacity should be 5A.

The dryer must be positioned so that the plug is clearly visible and

accessible. This plug also provides the function of an emergency stop

control for theuser. If the fitted plug is notused, the electricalconnection

mustbe carried out by a competent electrician in accordance with local

or national codes.

If the supply cord is damaged, it must be replaced with a specially

terminated cord by an authorized service agentor a similarly competent

person in order to avoid a hazard.

Do not use an adapter.

Do not use an extension cord.

NOTE: In accordance with the European EMC Directive (2004/108/EC),

the maximum electricity supply system impedance to which the gas

dryer should be connected is declared to be 0.054 Ohm + j0.034 Ohm.

NOTE:Electricalsafety standards:Themanufacturerhas chosencompliance

withIEC/EN.60335 standards as the most appropriate for this product.

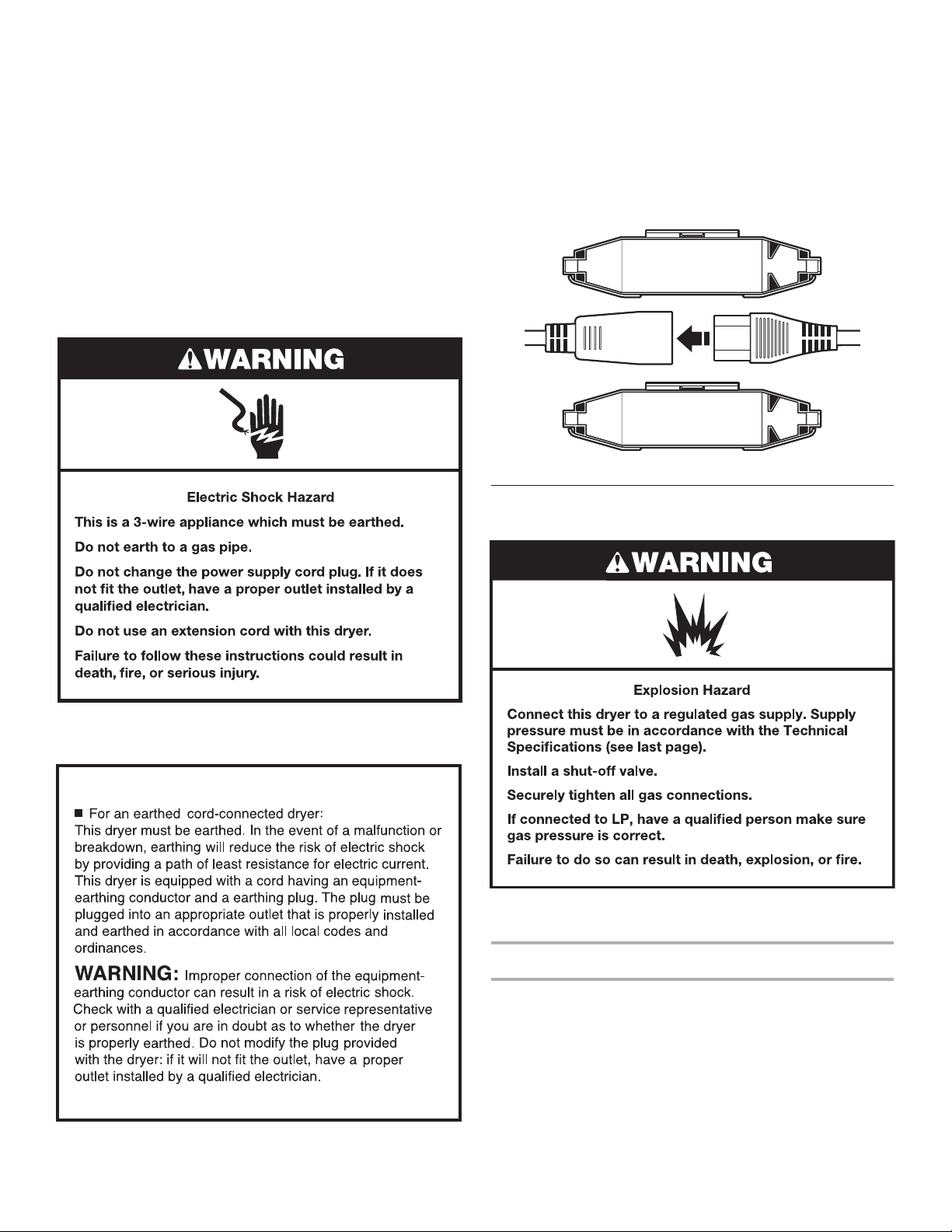

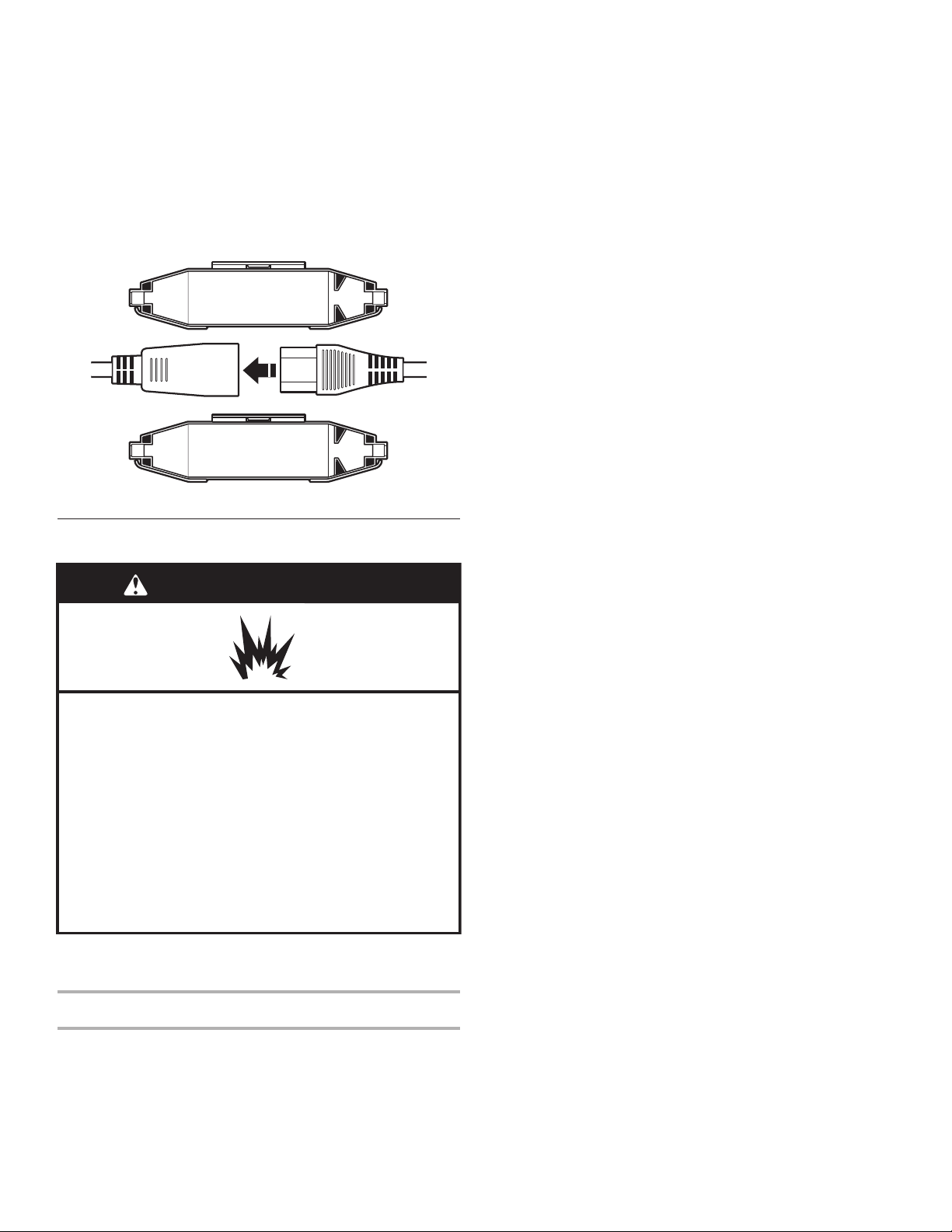

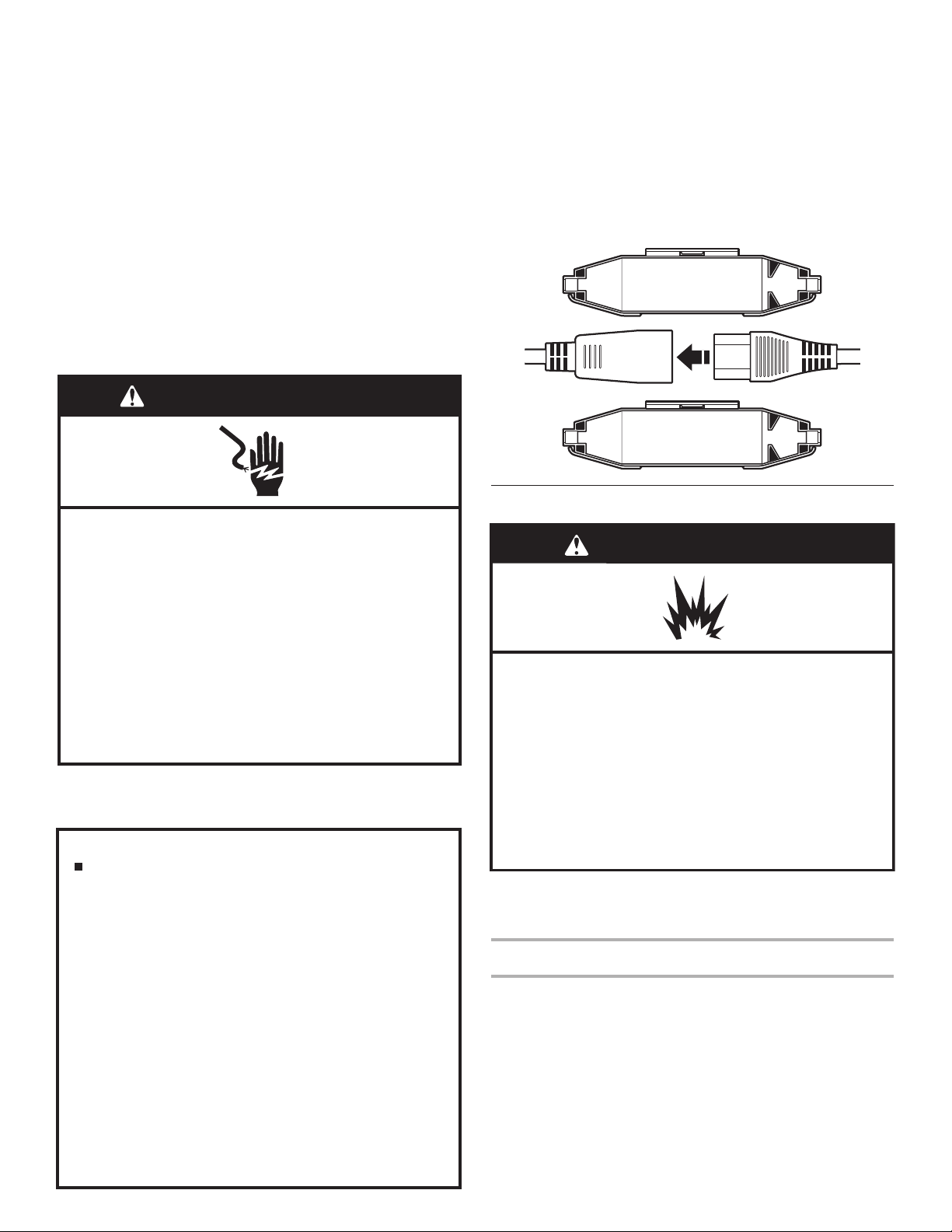

Using the universal cord included with this dryer:

The gas dryer is equipped with a universal cord with

interchangeable plugs.

1. To use the universal cord, select the plug end that fits

our electrical outlet, and plug it into the adapter on the

y

supply cord.

2. Secure the plug end in place on the cord by aligning

the 2 cover halves over the cord adapter and clipping

them together.

Gas Supply Requirements

If codes permit and an additional earth bond wire is used, it is

recommended that a qualified electrician determine that the earth

bond path is adequate.

IMPORTANT: Observe all governing codes and ordinances.

Gas Supply

Before installation, check that the local gas distribution

conditions, nature of gas and pressure, and the adjustment

of the appliance are compatible. Burner information will be

found on the model/serial rating plate in the door recess of

the dryer. If this information does not agree with the type

of gas available, see your dealer.

6

Page 7

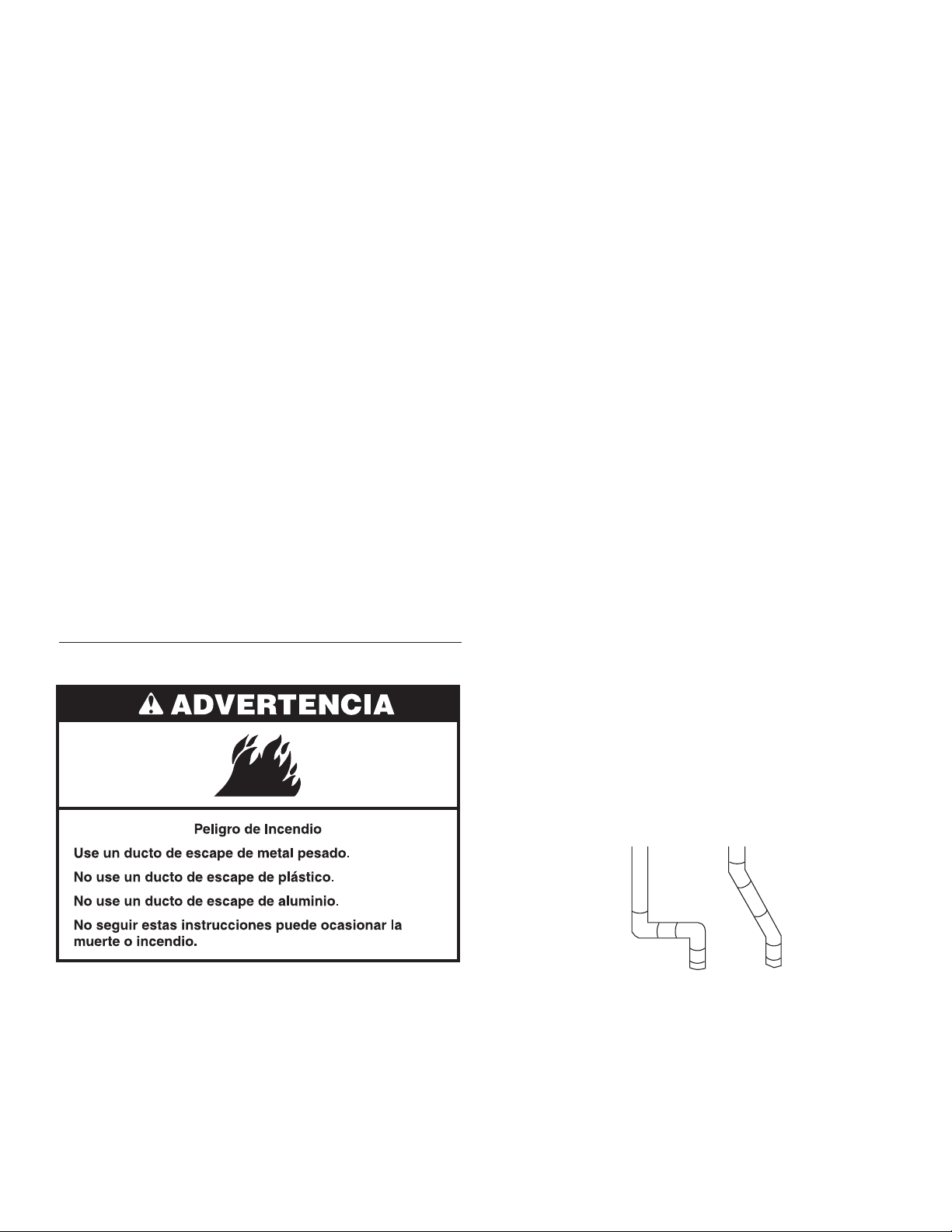

Natural Gas:

WARNING

Fire Hazard

Use a heavy metal vent.

D

o not use a plastic vent.

Do not use a metal foil vent.

Failure to follow these instructions can result in death

or fire.

This dryer is factory adjusted for use with NATURAL GAS (G20),

and no further adjustment should be required at installation.

L.P. Gas:

This dryer is also certified for use with L.P. (propane or butane)

gases with appropriate conversion. No attempt shall be made to

convert the appliance from the gas specified on the model/serial

rating plate for use with a different gas without consulting the

serving gas supplier.

Conversion must be done by a competent service technician.

Gas conversion kit, part number W10233219, is available for

purchase from your dealer. Full instructions are supplied with

the kit.

Natural gas (France/Belgium):

This dryer is also certified for France/Belgium for use with

G20/G25 gases (20 mbar/25 mbar) with appropriate conversion.

No attempt should be made to convert this appliance from the

gas specified on the gas rating label for use with a different gas

without consulting the serving gas supplier. Gas conversion must

be done by a qualified gas service technician. Conversion kit, part

number (W10181947) is available for purchase from your dealer.

Full instructions are supplied with the kit.

Supply line requirements:

Provide a rigid gas supply line to the dryer location. It should be

minimum 12.5 mm (1/2") ID. When acceptable to the gas supplier

and local codes, 10 mm (3/8") ID rigid supply line may be used

for lengths under 6.1 m (20'). Pipe-joint compounds resistant to

the action of L.P. gas must be used.

Gas connection to the dryer itself should be made by means of

a flexible gas hose suitable for the appliance and gas category

in accordance with national installation regulations. If in doubt,

contact the gas supplier. It should be minimum 10 mm (3/8") ID.

A means of restraint should be used between the appliance and

the wall to prevent straining of the rigid gas supply when the

appliance is moved. An appropriate length of chain and a wall

hook is recommended.

The dryer gas inlet connection is a 3/8" NPT thread. An adapter is

supplied for conversion to standard ISO.228-1 thread (3/8" BSP).

Check for leaks by using an approved noncorrosive leakdetection solution. Bubbles will show a leak. Correct any leak

found. A pressure measurement tapping is provided on the

gas valve within the dryer, accessible after removal of the lower

front panel.

The dryer must be disconnected from the gas supply piping

system during any pressure testing of that system.

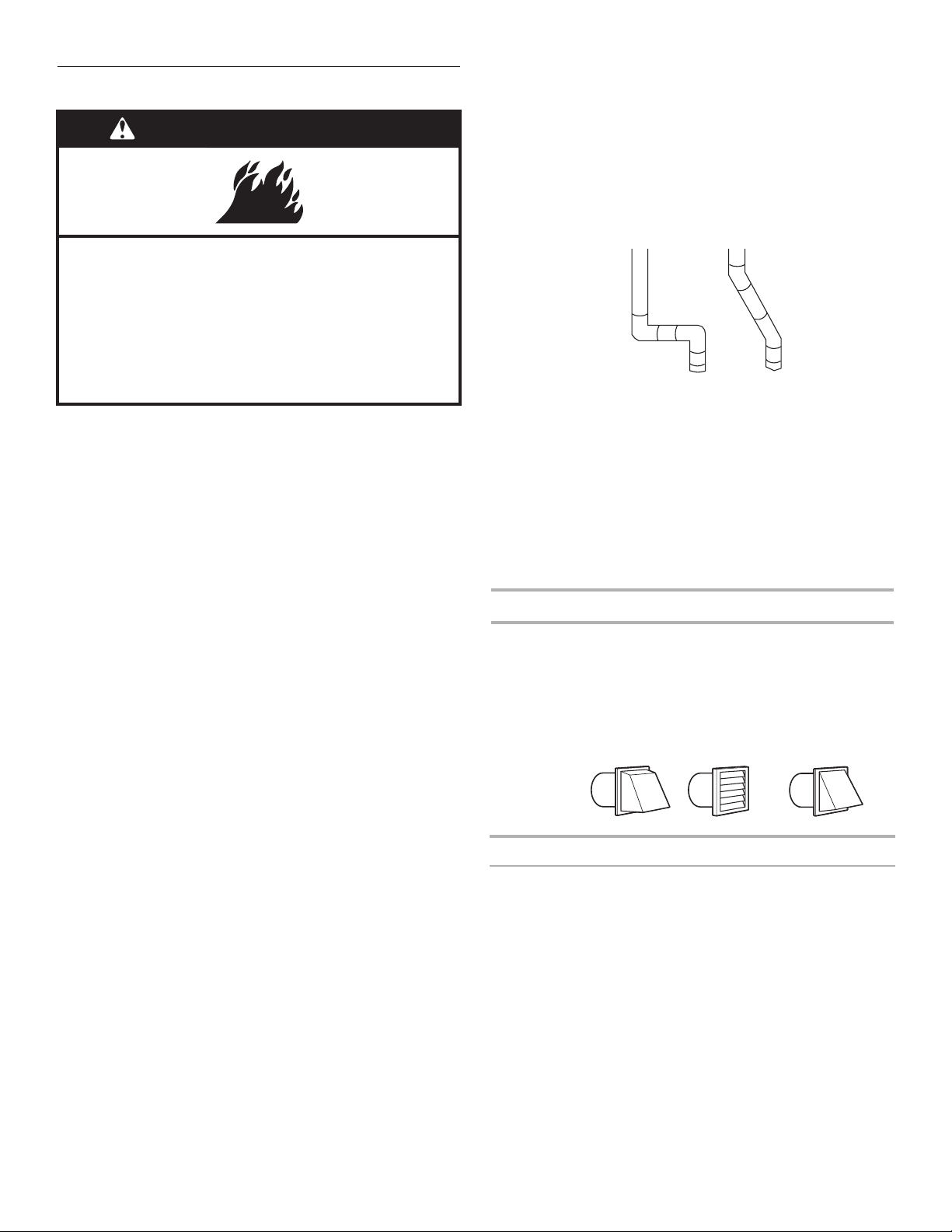

Venting Requirements

WARNING: To reduce the risk of fire, this dryer MUST BE

EXHAUSTED OUTDOORS.

■ Following these venting requirements will minimise ducting

air noise.

■ Gas dryers should only be installed in a room if the room

meets the appropriate ventilation requirements specified

in the national installation regulations. Make sure the room

containing the dryer has an adequate air supply for gas

combustion and drying operation. A window or equivalent

means of ventilation must be opened in the room when the

dryer is in use (an equivalent form of opening includes an

adjustable louver, hinged panel, or other means of ventilation

that opens directly to outside air). Adequate ventilation has to

be provided to avoid the backflow of gases into the room from

other fuel-burning appliances, including open fires (i.e. available

airflow into the room should match airflow out from the room).

■ The design of the flue system should be such that any condensate

formed when operating the dryer from cold shall either be retained

and subsequently re-evaporated or discharged. Following these

instructions should adequately meet this requirement.

■ The dryer vent must not be discharged into a flue which

is used for exhausting fumes from appliances burning gas or

other fuels, chimney, wall, ceiling, or a concealed space of a

building, or any other vent used for venting.

■ Do not use an exhaust hood with a magnetic latch.

■ Do not install flexible metal vent in enclosed walls, ceilings,

or floors.

■ 102 mm (4") heavy metal vent and clamps must be used.

■ Use clamps to seal all joints. Vent must not be connected or

secured with screws or other fastening devices which extend

into the interior of the vent and catch lint. Do not use duct tape.

IMPORTANT: Observe all governing codes and ordinances.

Use a heavy metal vent. Do not use plastic or metal foil vent.

Rigid metal vent is recommended to avoid crushing and kinking.

Flexible metal vent must be fully extended and supported when

the dryer is in its final position. Remove excess flexible metal vent

to avoid sagging and kinking that will result in reduced airflow

and poor performance.

An exhaust hood should cap the vent to keep rodents and

insects from entering the building.

Exhaust hood must be at least 305 mm (12") from the ground

or any object that may be in the path of the exhaust (such as

flowers, rocks, or bushes).

If using an existing vent system, clean lint from the entire length

of the system and make sure exhaust hood is not plugged with

lint. Replace any plastic or metal foil vent with rigid metal or

flexible metal vent.

7

Page 8

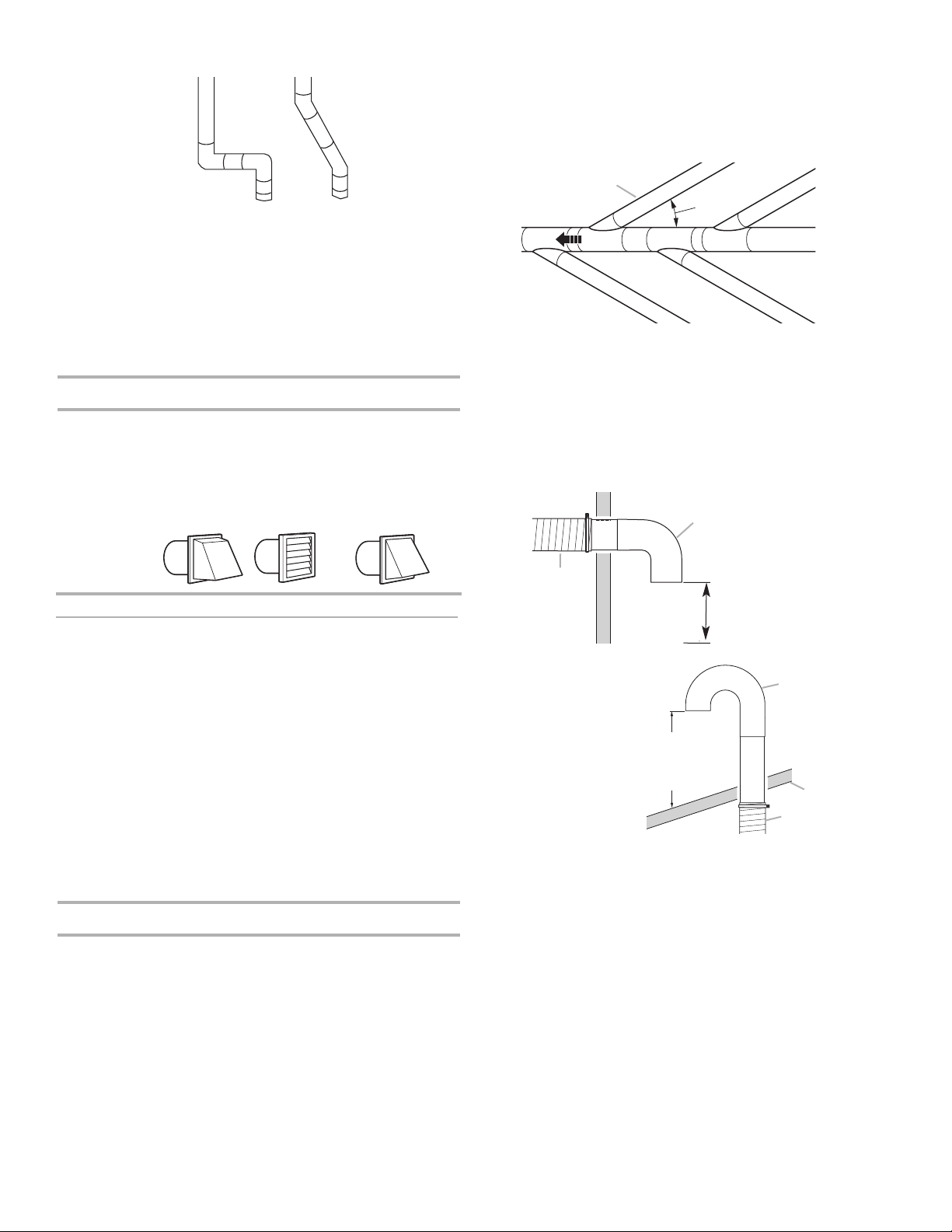

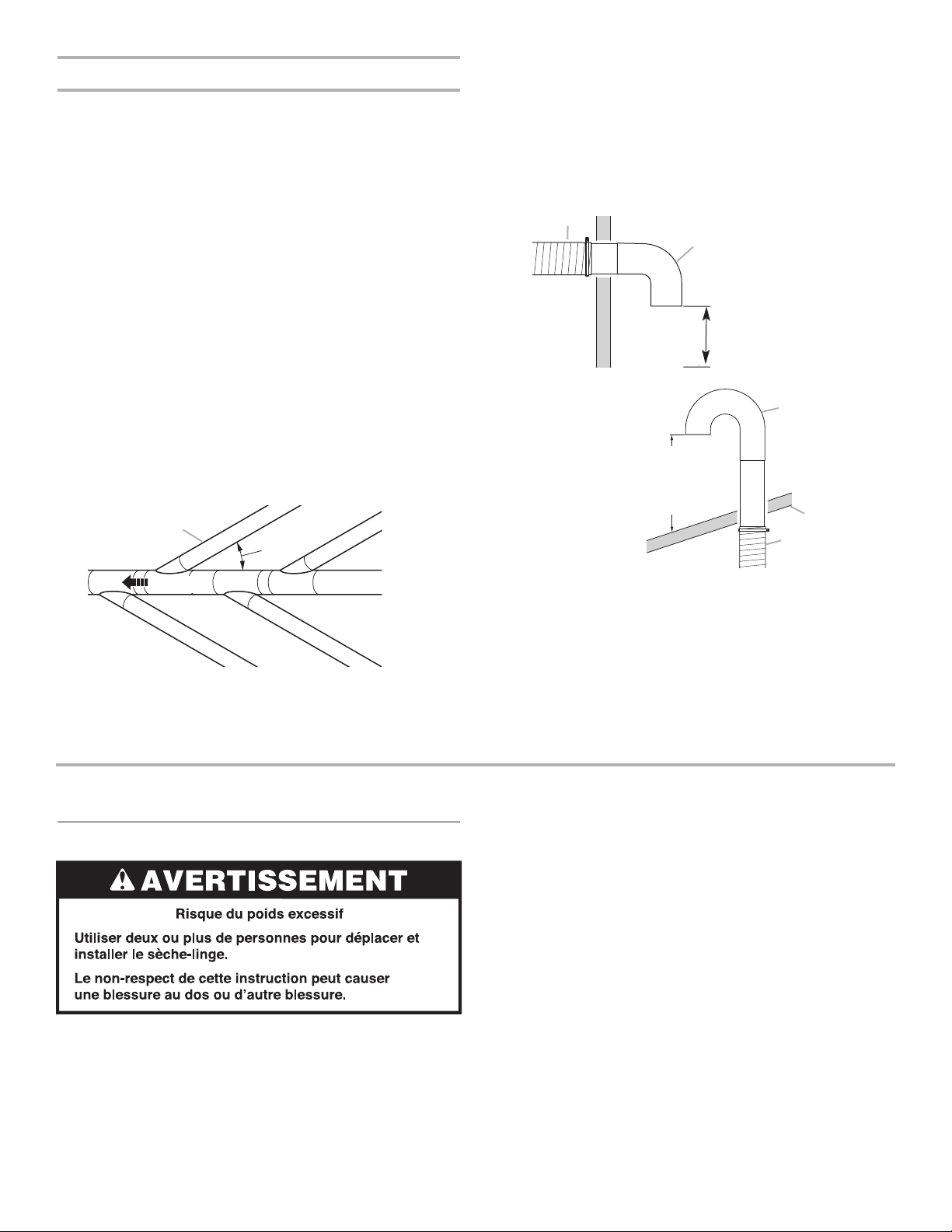

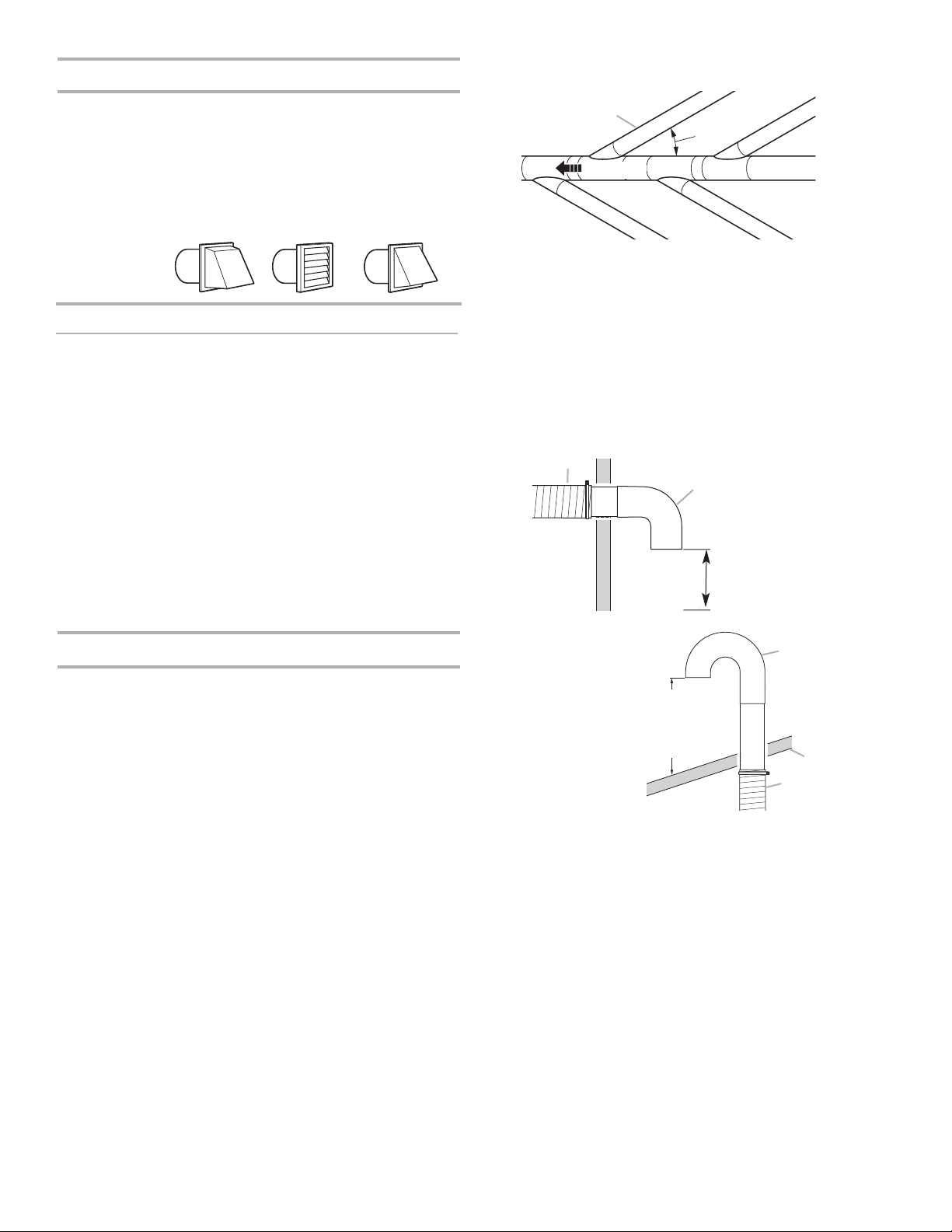

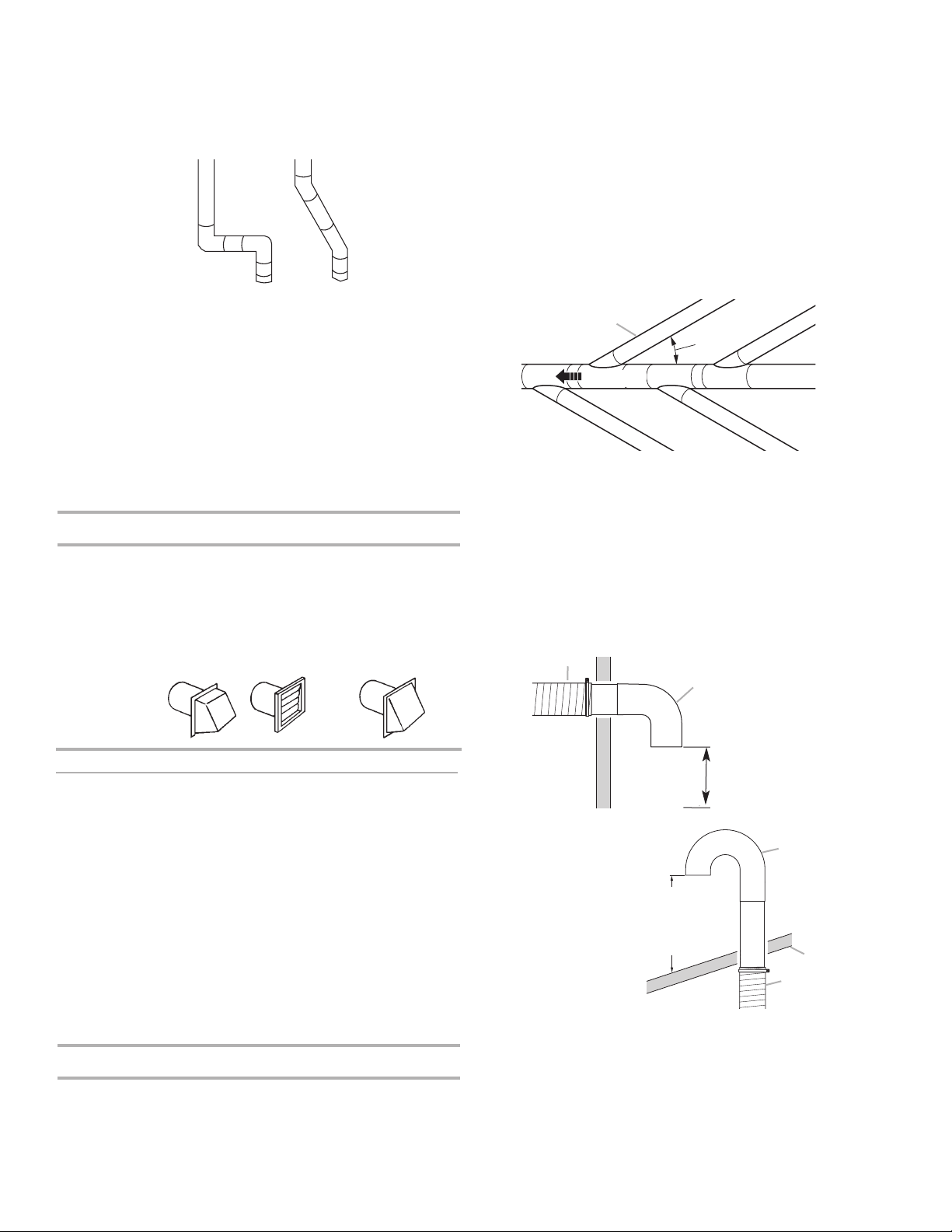

Plan installation to use the fewest number of elbows and turns.

3

0˚ max.

air ow

12" min.

(305 mm)

24" min.

(610 mm)

A

Exhaust Air Flow

A. Good

B. Better

B

Allow as much room as possible when using elbows or making

turns. Bend vent gradually to avoid kinking.

Vent outlet is located at the center of the bottom dryer back.

The vent can be routed up, down, left, right, behind the dryer,

or straight out the back of the dryer.

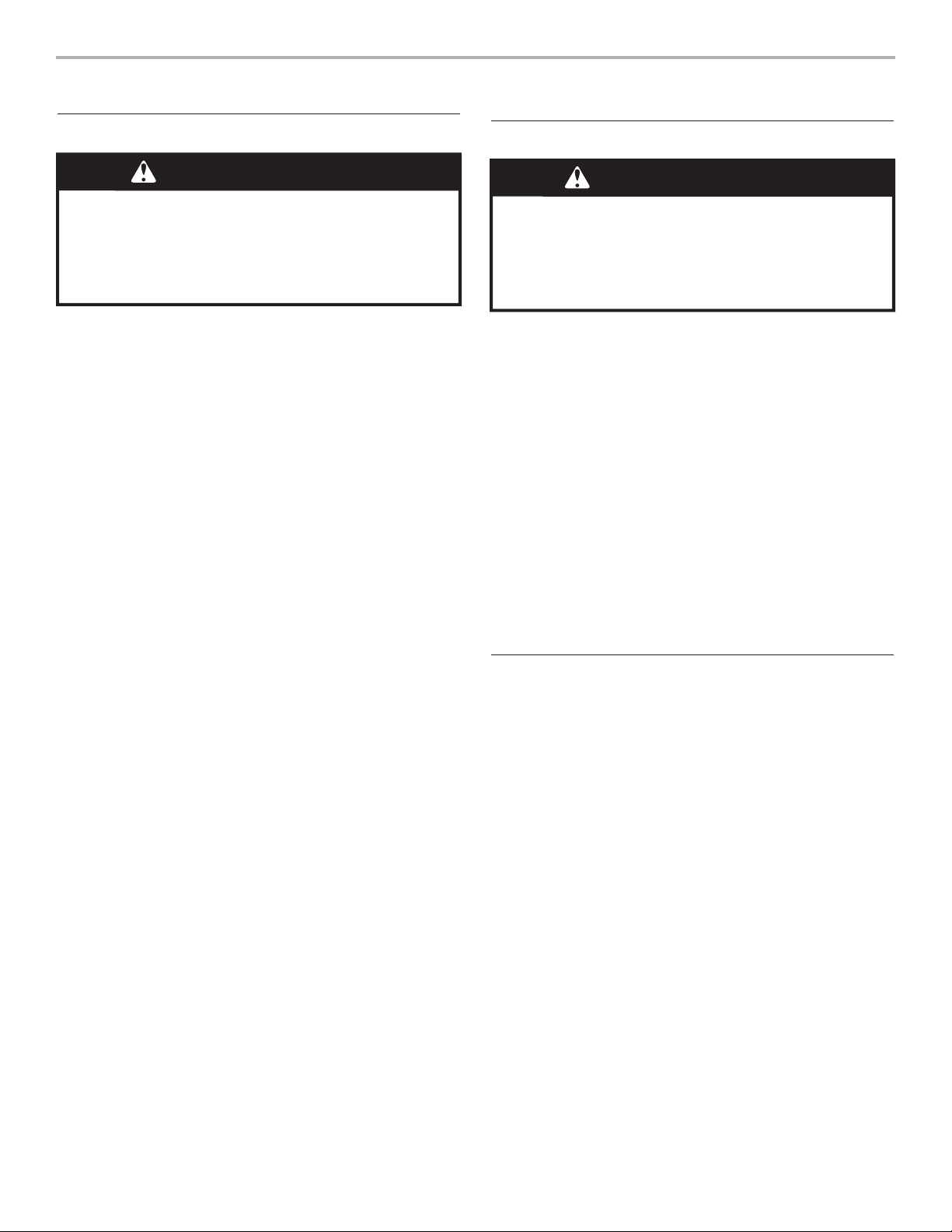

Vent System Length

Maximum length of vent system depends upon the type of vent

used, number of elbows, and type of exhaust hood.

Maximum Vent Length

102 mm (4") Exhaust Hoods

Box Louvered

64 mm (21⁄2") Angled

Each vent should enter the main vent at an angle pointing in the

direction of the airflow. Vents entering from the opposite side

should be staggered to reduce the exhausted air from interfering

with the other vents.

The maximum angle of each vent entering the main vent should

be no more than 30°.

A

B

A. Individual dryer vent

B. Main vent

Keep air openings free of dry cleaning fluid fumes. Fumes create

acids which, when drawn through the dryer heating units, can

damage dryers and items being dried.

A clean-out cover should be located on the main vent for periodic

cleaning of the vent system.

If an exhaust hood cannot be used:

B

A

D

Rigid Metal Vent

No. of 90° turns

0

1

2

3

4

Box Hood and Louvered Style

39.6 m (130 ft.)

38.1 m (125 ft.)

35.1 m (115 ft.)

32.3 m (106 ft.)

98 m (98 ft.)

Angled Hood Style

39.3 m (129 ft.)

36.3 m (119 ft.)

33.2 m (109 ft.)

30.5 m (100 ft.)

28 m (92 ft.)

If dryer is installed in a confined area, such as a bedroom,

bathroom, or closet, provision must be made for enough air

for combustion and ventilation. (Check governing codes and

ordinances.) See “Recessed Area and Closet Installation

Instructions” in the “Location requirements” section.

A 102 mm (4") outlet hood is preferred. However, a 64 mm

1

⁄2"

) outlet exhaust hood may be used. A 64 mm (21⁄2"

(2

outlet creates greater back pressure than other hood types.

For permanent installation, a stationary vent system is required.

Multiple Dryer Venting

■ A main vent can be used for venting a group of dryers. Main

vent should be sized to remove 5663 l/min (200 CFM) of air

per dryer. Large-capacity lint screens of proper design may be

used in the main vent if checked and cleaned frequently. The

room where the dryers are located should have make-up air

equal to or greater than the airflow of all the dryers in the

room.

■ A back-draft damper kit is needed and is available from a

commercial laundry distributor; it should be installed in the

vent of each dryer to keep exhausted air from returning

into the dryers and to keep the exhaust in balance within

the main vent. Unobstructed return air openings are required.

C

Min.

300 mm (12") clearance

above any accumulation

of snow, ice, or debris such

as leaves.

A. Exhaust hood or elbow

B. Wall

C. Main collector vent

D. Horizontal vent

E. 180° sweep elbow

F. Vertical vent

G. Roof

610 mm (24")

min. above

highest point

of building

E

F

G

C

)

The outside end of the main vent should have a sweep elbow

directed downward. If the main vent travels vertically through the

roof, rather than through the wall, install a 180° sweep elbow on

the end of the vent at least 610 mm (2 ft.) above the highest part

of the building. The opening in wall or roof shall have a diameter

13 mm (

1

⁄2

") larger than the vent diameter. The vent should be

centered in the opening.

Do not install screening or cap over the end of the vent.

8

Page 9

INSTALLATION INSTRUCTIONS – GAS DRYER

WARNING

Electric Shock Hazard

This dryer must be earthed.

Securely tighten all electrical connections.

Failure to do so can result in death, fire, or

electric shock.

Install Leveling Legs

NOTE: Slide dryer onto cardboard or hardboard before moving

to avoid damaging floor covering.

1. Using two or more people, move dryer to desired installation

location.

2. Take tape off front corners of dryer. Open dryer and remove

the literature and parts packages. Wipe the interior of the

drum thoroughly with a damp cloth.

3. Take two of the cardboard corners from the carton and place

them on the floor in back of the dryer. Firmly grasp the body

of the dryer and gently lay it on its back on the cardboard

corners.

4. With one of the legs in hand, check the ridges for a diamond

marking. That’s how far the leg is supposed to go into the

hole.

5. Start to screw the leveling legs into the holes by hand. (Use

a small amount of liquid detergent to lubricate the screw

threads so it is easier to turn the legs.) Use a 1" (25 mm)

wrench or socket wrench to finish turning the legs until you

reach the diamond mark. Then fit a protective foot boot over

each foot.

6. Now stand the dryer up.

7. Remove cardboard or hardboard from under dryer. Adjust the

legs of the dryer up or down until the dryer is level.

Connect Vent

1. Using a 102 mm (4") clamp, connect vent to exhaust outlet

in dryer. If connecting to existing vent, make sure the vent is

clean. The dryer vent must fit over the dryer exhaust outlet

and inside the exhaust hood. Make sure the vent is secured

to exhaust hood with a 102 mm (4") clamp.

2. Move dryer into final position. Do not crush or kink vent. Make

sure dryer is level.

3. Check to be sure there are no kinks in the flexible gas line.

Complete Installation

1. With dryer in final position, place level on top of the

dryer, first side to side; then front to back. If the dryer is

not level, adjust the legs of the dryer up or down until the

dryer is level.

Make Gas Connection

1. Remove red cap from gas pipe.

2. Connect gas supply to dryer. If the flexible gas hose has 3/8"

BSP thread, use the supplied conversion thread adapter. Use

pipe-joint compound resistant to the action of L.P. gas for gas

connections.

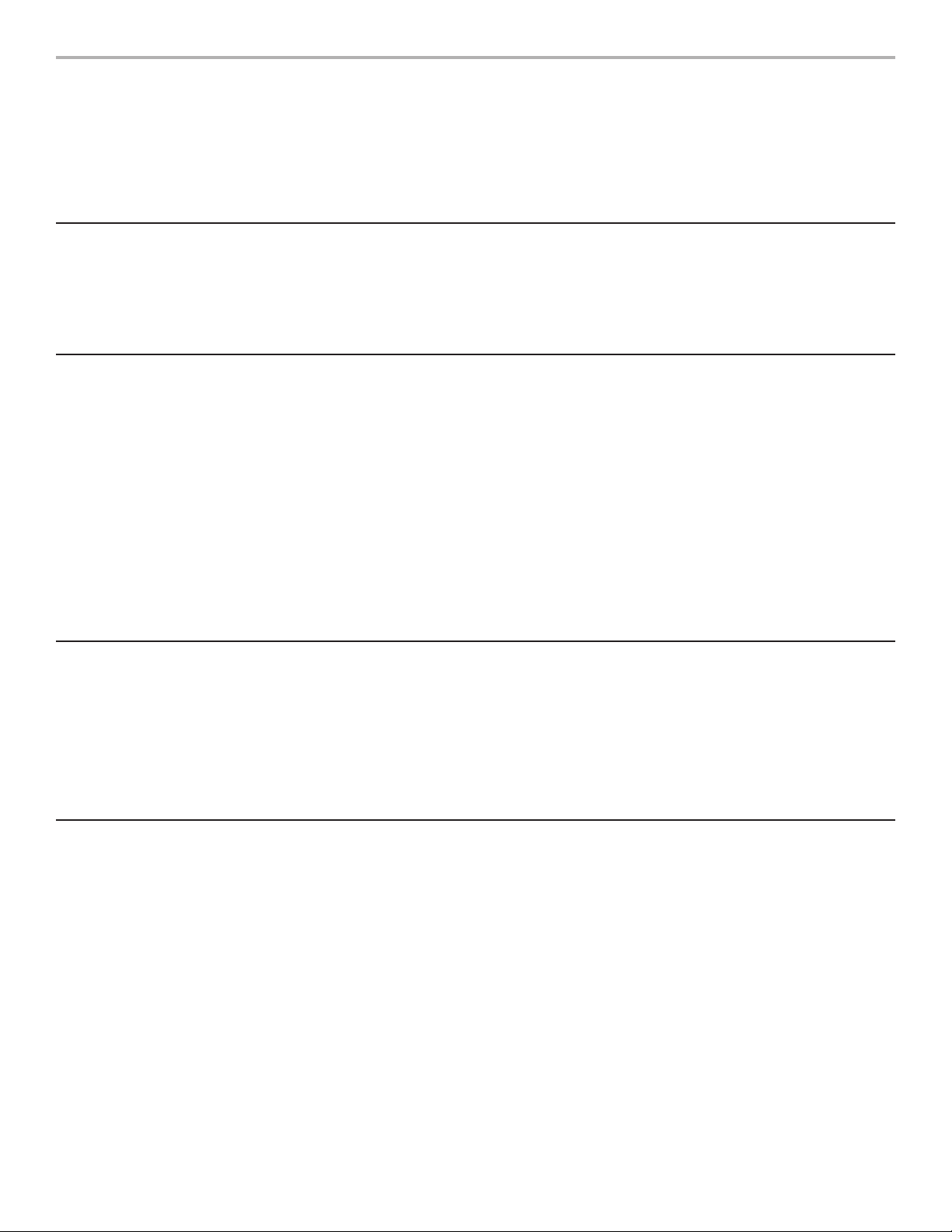

If necessary for service, open the toe panel. Use a putty knife

to press on the 2 toe panel locks located at the top of the toe

panel. Pull downward on the toe panel to open. Toe panel is

hinged at the bottom.

3. Open the shutoff valve in the gas supply line.

4. Test all connections by brushing on an approved noncorrosive

leak-detection solution. Bubbles will show a leak. Correct any

leaks found.

2. Plug into an earthed outlet.

3. Check dryer operation:

Press the selection button for a full cycle and let the dryer run

for at least five minutes. Dryer will stop when time is used up.

NOTE: Dryer door must be closed for dryer to operate.

When door is open, dryer stops, but timer continues to run.

To restart dryer, close door and press a cycle button.

4. If the burner does not ignite and there is no heat inside the

dryer, shut off dryer for five minutes. Check that all gas supply

valves are in the “ON” position and that the electrical cord is

plugged in. Repeat five-minute test.

9

Page 10

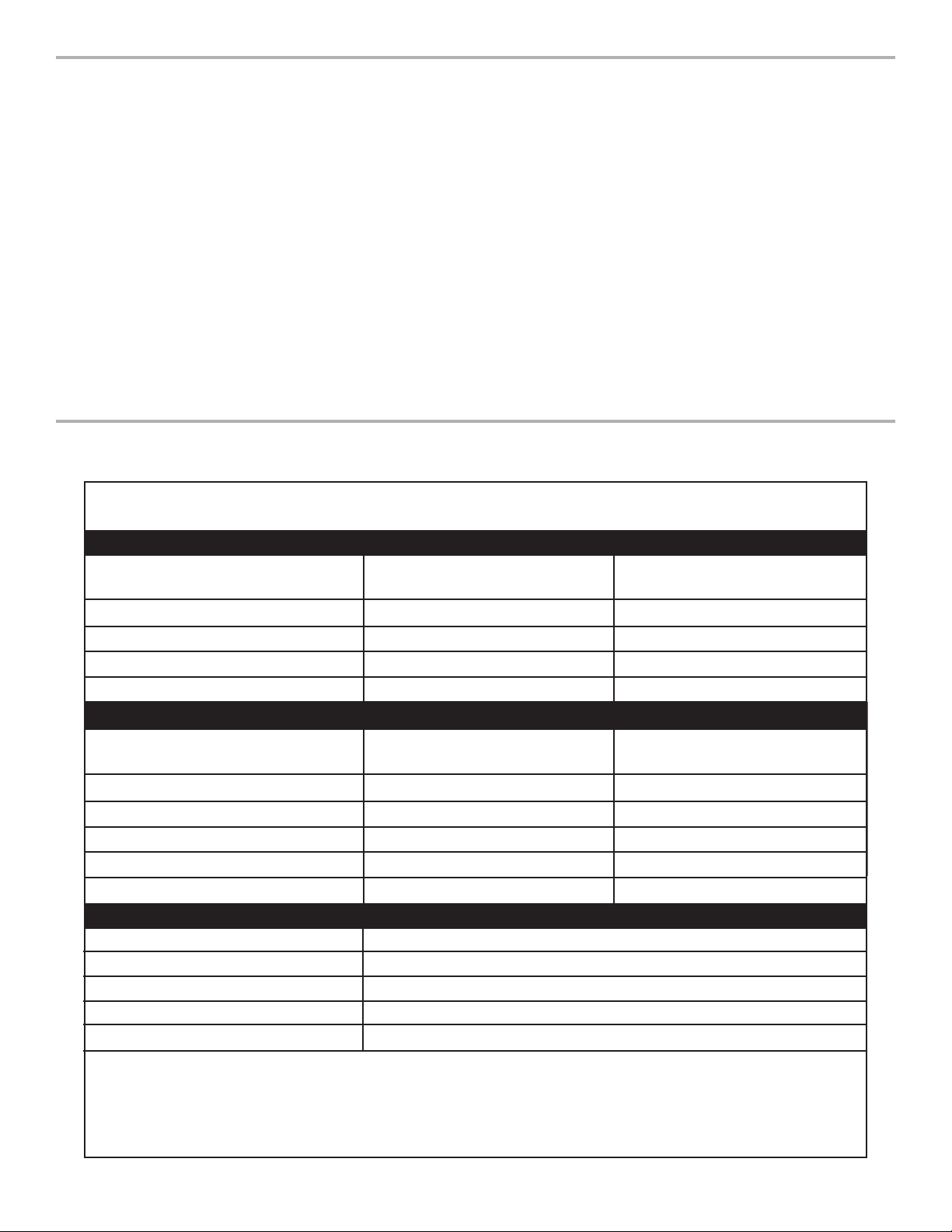

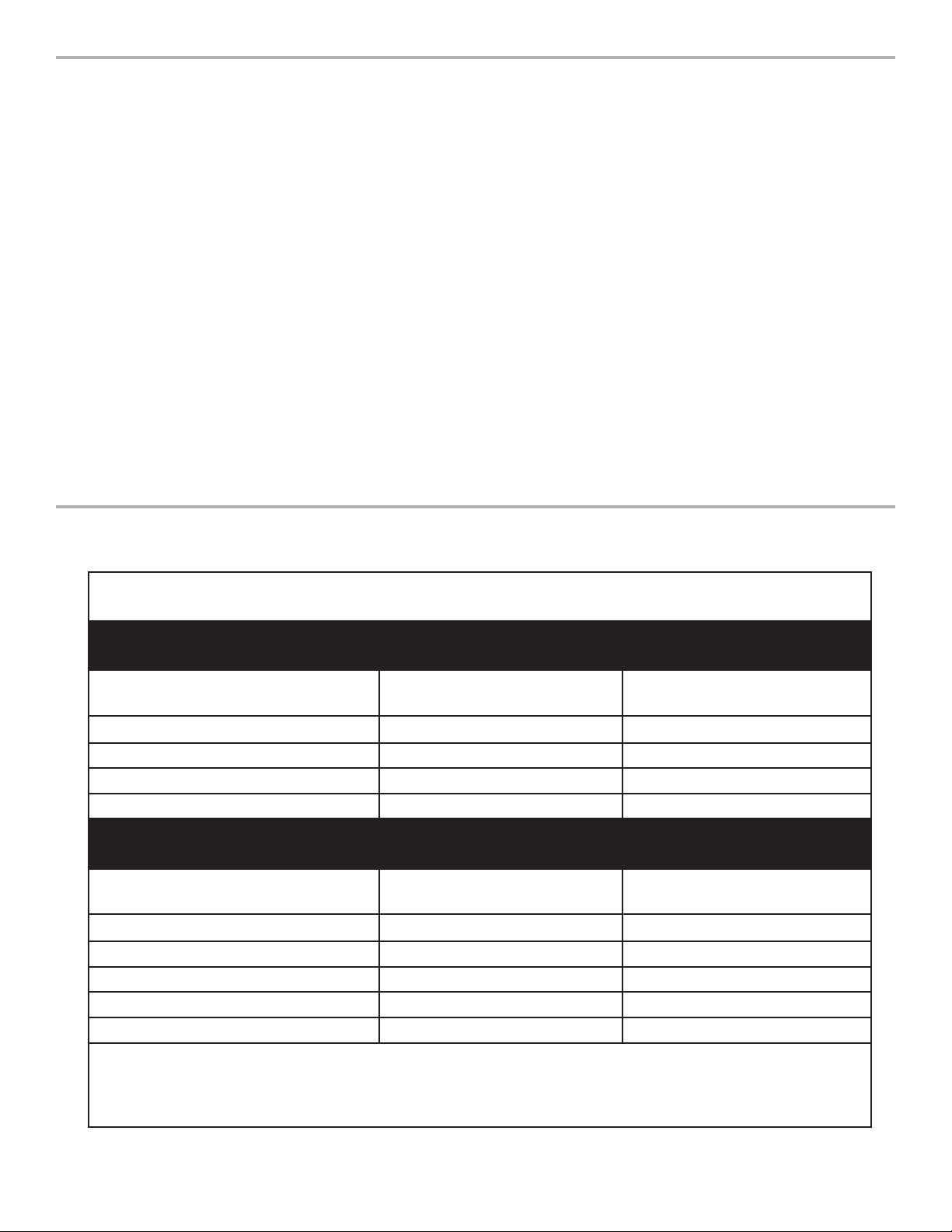

MAINTENANCE INSTRUCTIONS

220-240V~50Hz 1ph 3A max. IP24 Clothes capacity: 9.0 kg max. Sound pressure level, Lpa: 58 dBA

(uncertainty, Kpa: +/–10 dBA) Total mass: 68 kg max.

European Country: CH, CZ, CY, ES, GB, GR, HR,

IE, IT, PT, SI, SK, TR

0.562703 m3/hr

30 mbar

37 mbar 30 mbar

28-30 mbar

N/A N/A

N/A

N/A

N/A

7.4 mbar 7.4 mbar

20 mbar

20 mbar

25 mbar

20 mbar

0.562703 m3/hr

II

2H3+

II

2H3B/P

II

2H3+

I

2E+

II

2H3B/P

CY, CZ, DK, EE, FI, GR, HU, IT,

NO, RO, SE, SK, TR

CY, CZ, DK, EE, FI, GR, HU, IT,

NO, RO, SE, SK, TR

CH, CZ, CY, ES, GB, GR, HR,

IE, IT, PT, SI, SK, TR

European Gas Category:

Gas Flow Rate:

Supply Pressure (G20):

Factory Adjusted Pressure:

European Country:

European Gas Category:

Butane Supply Pressure (G30):

Adjusted Pressure:

Adjusted Pressure:

Propane Supply Pressure (G31):

Factory set for NATURAL GAS: Injector size: 2.2 mm Heat input gross: 5.9 kW

With LP Gas Conversion Kit: Injector size: 1.25 mm Heat input gross: 6.4 kW

With France/Belgium NATURAL GAS conversion kit: Injector size: 1.65 mm Heat input gross: 5.9 kW

FR, BE

European Country:

European Gas Category:

Supply Pressure (G20):

Supply Pressure (G25):

Adjusted Pressure:

NOTE: Conversion kit:From Natural Gas to LP Gas: Whirlpool Part No. W10233219.

Manufacturer: Whirlpool Corporation, 1300 Marion-Agosta Rd., Marion, OH 43302, USA.

Conversion kit:From Natural Gas to Natural Gas - France/Belgium: Whirlpool Part No. W10184947.

EU representatives: Maytag UK Ltd., 2 St. Annes Blvd., Redhill, RH1 1AX, UK

& Bauknecht Hausgeräte GmbH, D-73614 Schorndorf, Germany

Maintenance instructions:

■ Clean lint screen after each cycle.

■ Removing accumulated lint (disconnect dryer from electricity

nd gas supplies before starting this task):

a

• From inside the dryer cabinet:

Lint should be removed every 2 years or more often,

depending on dryer usage. Cleaning should be done

by a qualified person.

rom the exhaust vent:

• F

Lint should be removed every 2 years, or more often,

depending on dryer usage.

f dryer does not operate, check the following:

I

■ Electric supply is connected.

■ Circuit breaker is not tripped or fuse is not blown.

■ Door is closed. Listen closely to hear door switches activate.

■ Selected cycle button has been pressed firmly and display

hows cycle time.

s

■ Check that gas supply shutoff valves are set in open position.

If you need assistance:

Contact your authorized Maytag Commercial Laundry distributor

or visit: www.MaytagCommercialLaundry.com. When you call,

you will need the dryer model number and serial number.

Both numbers can be found on the serial-rating plate located

on your appliance.

TECHNICAL SPECIFICATIONS - GAS DRYER

10

Page 11

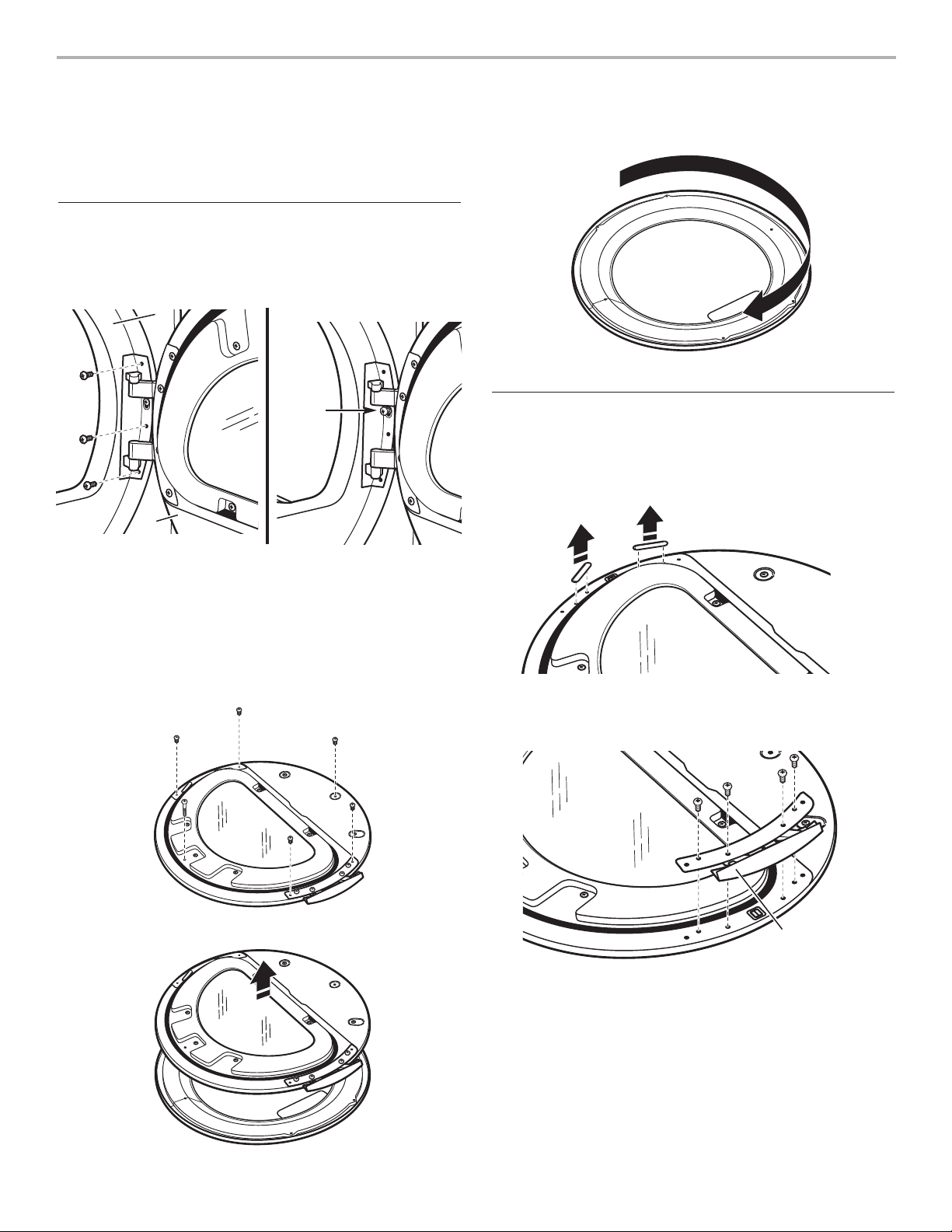

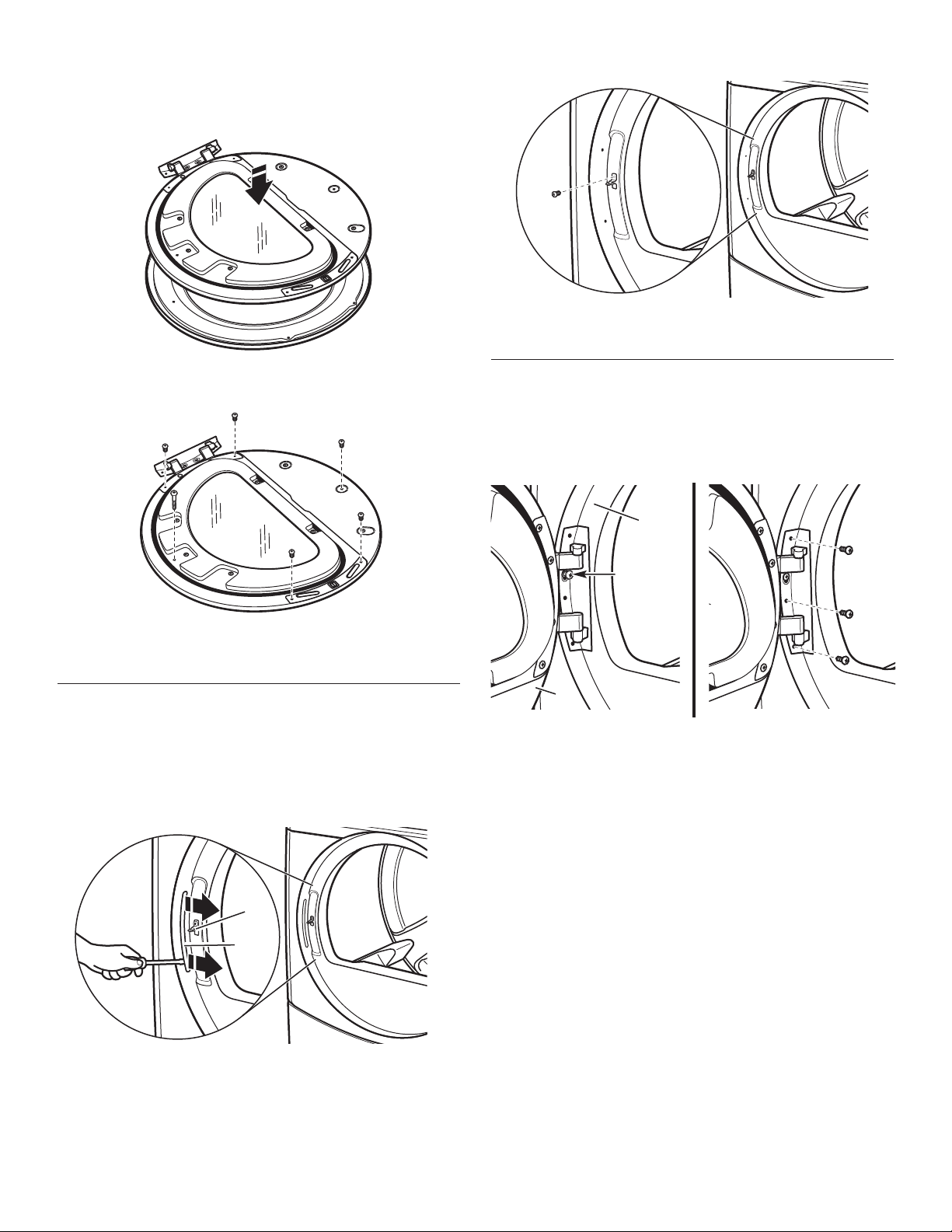

REVERSING THE DOOR SWING

Door swing can be changed from a right-side opening to left-side

opening, if desired.

Place a towel or soft cloth on top of the dryer or work space

to avoid damaging the surface.

Remove the Door Assembly

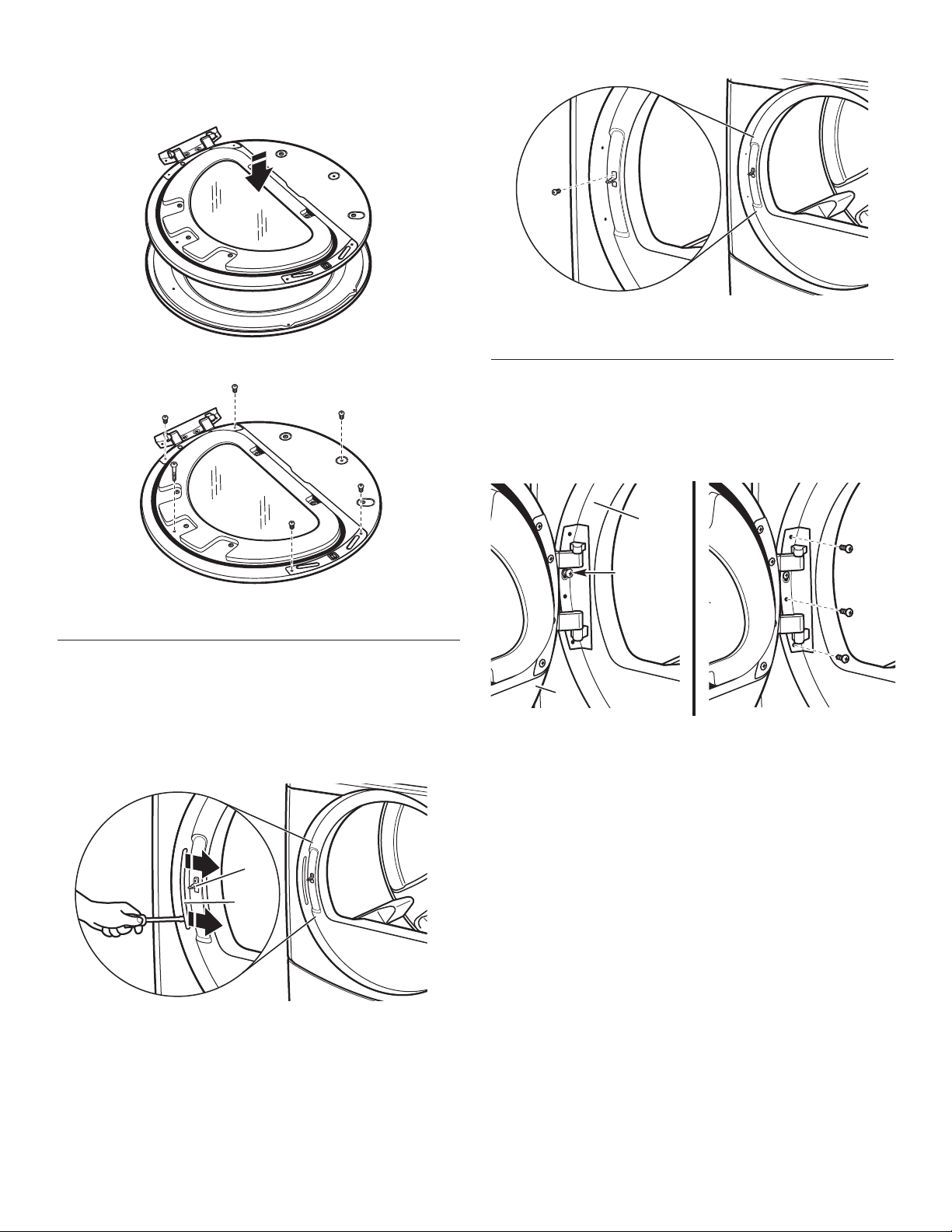

1. Remove 3 of the 4 screws that hold the door hinge on the

front panel of the dryer. Partially loosen the remaining screw

with keyhole opening and lift the door off the screw.

A.

Loosen

screw

with

keyhole

opening

B.

A. Dryer front panel

B. Door assembly

5. Rotate outer door 180°.

Reverse Hinge

1. Use a small flat-blade screwdriver to remove 2 plug strips

from the inner door. Slide the head of the screwdriver under

the plugs, being certain not to scratch the inner door surface.

Lift up.

2. Lay the door assembly on a previously prepared flat surface

with the inside (inner door assembly) facing up.

3. Remove the 6 Phillips head screws to release the outer door

assembly from the inner door assembly, as indicated below.

See illustration. It is important that you remove only the 6

indicated screws.

4. Lift the inner door assembly off the outer door assembly.

2. Remove the 4 screws that attach to the inner door hinge and

move the hinge to the other side. Reinstall the 4 screws.

Door hinge

3. Reinstall plug strips on opposite side of the inner door.

4. Check for fingerprints on the glass. Clean glass if necessary.

11

Page 12

5. Place the inner door assembly inside the outer door assembly.

To fit correctly, the inner door assembly edge fits completely

inside the outer door assembly edge.

6. Reassemble the inner and outer door assemblies with the

6 screws.

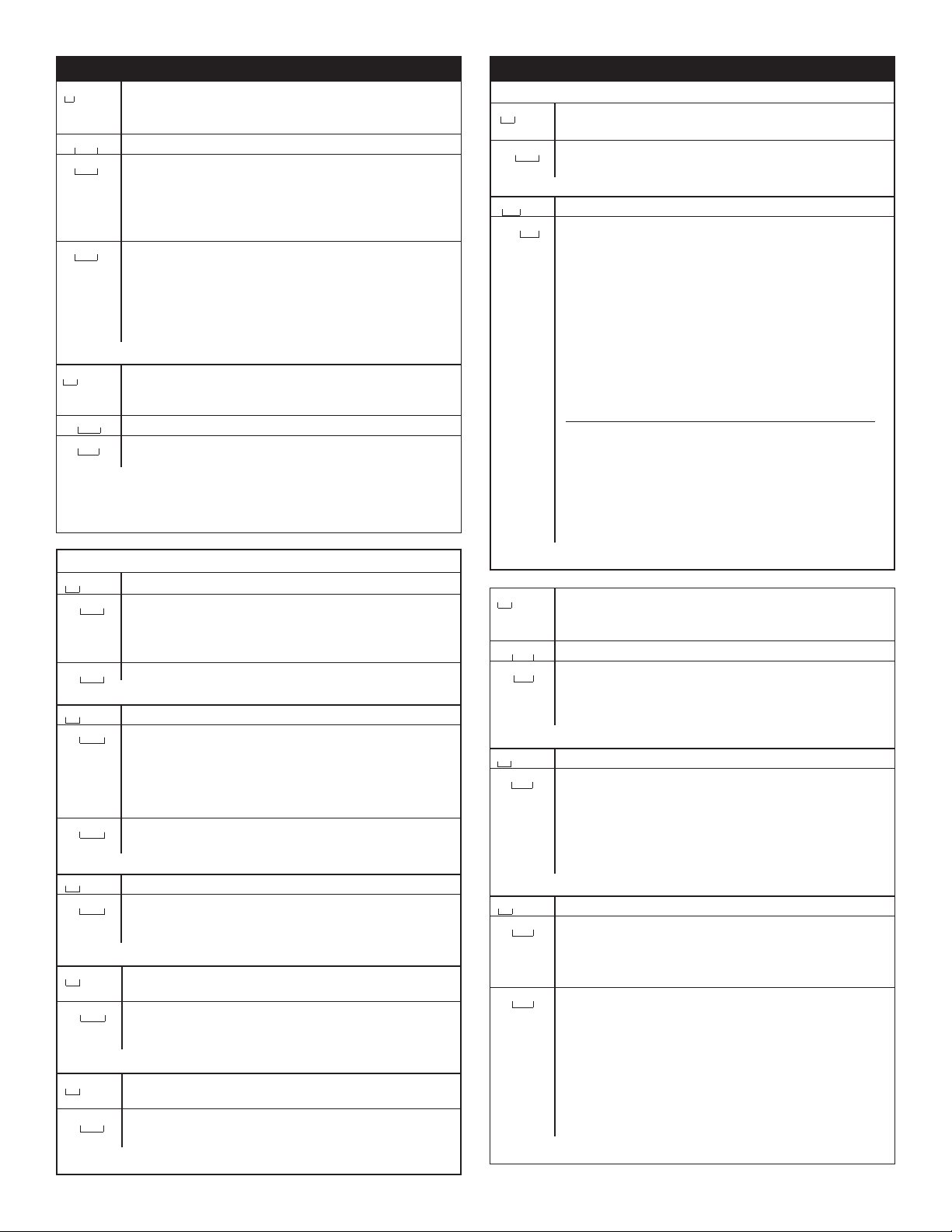

2. Remove the strike using a Phillips screwdriver.

3. Insert strike on the opposite side.

Reinstall the door

1. Reattach door to dryer front panel with the 4 screws.

Partially install the screw with keyhole opening first, and fit

the keyhole opening in the hinge over the screw. Then install

the remaining 3 screws and tighten all 4 screws.

Reverse the strike

1. Use a small flat-blade screwdriver to remove plug strip from

the dryer door opening. Slide the head of the screwdriver

under the plugs, being certain not to scratch the dryer

surface. Lift the plastic strip from the dryer slowly to avoid

distortion of the plug strip.

B.

A.

A.

Install this

screw first

B.

A. Dryer front panel

B. Door assembly

2. Check for fingerprints on the glass. Clean glass if necessary.

3. Close door and check that it latches securely.

12

A. Plug strip

B. Door strike

Page 13

ELECTRONIC CONTROL SETUP

IMPORTANT

Electrostatic Discharge (ESD)

Sensitive Electronics

ESD is present everywhere. ESD may damage or weaken the

electronic control assembly. The new control assembly may

appear to work well after repair is finished, but failure may

occur at a later date due to ESD stress.

■

Use an anti-static wrist strap. Connect wrist strap to green

earth connection point or unpainted metal in the appliance.

Touch your finger repeatedly to a green earth connection point

or unpainted metal in the appliance.

■

Before removing the part from its package, touch the

anti-static bag to a green earth connection point or

unpainted metal in the appliance.

■

Avoid touching electronic parts or terminal contacts; handle

electronic control assembly by edges only.

■

When repackaging failed electronic control assembly in

anti-static bag, observe above instructions.

GENERAL USER INFORMATION

“out of order” showing in display

This condition indicates the dryer is inoperative. Diagnostic or failure

code will follow the scrolling message.

‘0 Minutes’ showing in display

This condition indicates the dryer cannot be operated. Coins

dropped or debit inputs during this condition will be stored in escrow

but cannot be used until normal operation is restored by opening

and closing the door. If a door switch fails, it must be replaced

before normal operation can be restored.

Cold Start (initial first use)

Dryer is programmed at the factory as follows:

■

45 minutes dry time for PN models; 5 minutes per coin

for PD models.

■

1.50 dry price (fixed cycle with top off - PD Models).

■

0.00 dry price (fixed cycle - PN Models).

Warm Start (after power failure)

A few seconds after power is restored, if a cycle was in progress

at the time of the power failure, ‘RESELECT CYCLE’ will flash

in the display. This is to indicate the need for a fabric setting

button to be pressed to restart dryer.

-OR-

Pricing

fter the door is opened and closed following the completion of

A

a cycle, the display indicates the cycle price (unless set for free

operation). As coins or debit inputs arrive, the display will change

to lead the user through the initiation of a cycle.

There are four (4) types of pricing:

Fixed ‘Vend’ Pricing

A dryer set up for ‘Fixed Cycle’ operation can only accept additional

time accumulated by increments equal to the length of a complete

dry cycle. A maximum of 99 minutes may be purchased; no

additional credit is given when 99 minutes is in the display.

Accumulator Pricing

If the price is set to one coin 1, then accumulator mode is in effect.

Cycle time can be purchased one coin at a time (PD models) up to

the maximum time of 99 minutes.

Fixed Cycle With Top Off Pricing

A dryer set to offer ‘Top Off’ capability will allow time to be added to

an existing dry cycle in increments equal to the number of minutes

of dry time per coin (coin 1), up to 99 minutes, regardless of the cost

required to start the dryer. No credit is given for coins or debit inputs

entered when the control is displaying 99 minutes.

PN Models Set Up As PR: In Enhanced Debit Mode, the top off

price can be set independently (see VALUE OF COIN 2), and the top

off time is calculated according to the following equation:

top off price

full cycle price full cycle length

Hundredth increment offset is not applied to top off purchases.

PN Models

The factory has preset the cycle price to zero. When this happens,

‘SELECT CYCLE’ will appear rather than a cycle price. Any cycle

started as a free cycle will automatically terminate when the door

is opened.

Debit Card Ready

This dryer has a control that is debit card ready, but the dryer is not.

=

top off time

13

Page 14

CONTROL SET-UP PROCEDURES

PRICE

IMPORTANT: Read all instructions before operating.

The fabric setting buttons along with the digital display are used

to set-up the dryer controls.

he display can contain 4 numbers and/or letters and a decimal

T

point. These are used to indicate the set-up codes and related code

values available for use in programming the dryer.

ow to use the buttons to program the controls

H

1. The WHITES AND COLORS button is used to adjust the

values associated with set-up codes. Pressing the button will

increment the value by one (1). Rapid adjustment is possible

by holding the button down.

2. The PERM. PRESS button advances the display through the set-

up codes. Pressing the button will advance the display to the next

available set-up code. Holding the button down will automatically

dvance through the set-up codes at a rate of one (1) per second.

a

3. The DELICATES button is used to select or deselect options.

Start Operating Set-Up

■

PD Models: Insert service door key, turn, and lift to remove

access door.

■

PN Models: Remove the AA1 jumper from the control board, see

procedure below, or use the Service Access Code below. Once the

debit card reader is installed (according to the reader manufacturer’s

instructions), the set-up mode can be entered by inserting a manual

set-up card (supplied by the reader manufacturer) into the card slot.

If manual set-up card is not available, manual set-up mode cannot

be entered. However, diagnostic mode can be entered by removing

connector AA1 on the circuit board.

IMPORTANT: The console must not be opened unless power is

first removed from the dryer. To access connector AA1:

Unplug dryer or disconnect power.

Open console, disconnect plug on AA1, close console.

Plug in dryer or reconnect power.

■

PN Models Equipped with Programming Switch: Insert access

panel key and turn counter-clockwise.

■

PN Models with Gen. 2 Debit Card Reader: Once a Gen. 2 debit

card reader is installed (according to the reader manufacturer’s

instructions), the set-up mode can only be entered by inserting

a manual set-up card (supplied by the reader manufacturer)

into the card slot.

If manual set-up card is not available, only diagnostic mode

can be entered.

■

Alternate method of entering Set-up Mode by entering Service

Access Code: This code can be entered to access set-up mode

without removing the console on dryers just removed from the

carton, or not yet programmed. The Service Access Code only

functions on dryers set up for 0 vend price without any Special

Pricing set-up, and the Coin/Debit Option must be set to “J._d”.

If the dryer is not in failure mode, the door must be opened to

proceed. Using only the three bottom buttons (numbered 1, 2,

and 3 from left to right):

1. Press 2 for longer than 2 seconds but less than 10 seconds.

2. Press 1 & 3 simultaneously for 2 seconds. Display shows S 3.

3. Press 1 & 2 simultaneously. Display shows S 4.

4. Press 2 & 3 simultaneously. Display shows S 5.

5. Press 2.

6. Wait at least 2 seconds, but not more than 15 seconds,

then press in succession: 3, 2, 1, 3.

The dryer is now in the set-up mode.

Before proceeding, it is worth noting that, despite all the options

available, an owner can simply choose to uncrate a new commercial

dryer, hook it up, plug it in, and have a dryer that operates. NOTE:

PD models require a payment system or OPL kit to be installed prior

to operation.

■

PD dryers are pre-set at the factory for fixed cycle price with top off.

■

PN dryers are pre-set for fixed cycle operation, and they can be

run without payment.

14

DISPLAY

After the dryer has been installed and plugged in, the display will

show ‘0 minutes.’

Once the dryer has been plugged in and the dryer door opened

and closed, the display will show the vend price. PN models are

actory preset for free cycles; the display will flash ‘SELECTCYCLE’.

f

PD Models

PN Models

SET-UP CODES

FOR PN MODELS: The set-up codes are the same as for the PD

models except where noted.

The set-upcode is indicated by theone or two left hand characters. The

set-up code value is indicatedby the two or threeright hand characters.

NOTE: The first line of each code indicates the factory default.

CODE EXPLANATION

606

606

600

Press PERM. PRESS button once to advance to next code.

7 0 5

7 0 5

7 4 5

Press PERM. PRESS button once to advance to next code.

8 0 0

8 0 0

8

Press PERM. PRESS button once to advance to next code.

9 0 0

9 0 0

9 0

Press PERM. PRESS button once to advance to next code.

REGULAR CYCLE PRICE

Represents the number of coins (coin 1); may adjustfrom 0-39

(See b.xx set-up for VALUE OF COIN1). Advance from 0-39 by

pressing WHITES ANDCOLORS. Factory default of 6 x coin 1.

PN MODELS ONLY: Factory default of 6 00, or 0 coins.

REGULAR DRY TIME

Represents the number of minutes per coin (coin 1).

Factory defaultof 5 minutes per coin.

Example: 6 coins x 5 minutes= 30minutes.

By pressing the WHITESAND COLORS button, value adjusts

from 1-99 minutes.

PNMODELS: Represents the cycle length forfree cycles.

As example: ‘7 45’ = 45 minutes.

TYPE OF DRYER PRICING

FixedCycle with Top Off. Fordetailed description, see General

User Information.

FixedCycle. For detaileddescription, seeGeneral User

F C

Information.

UseDELICATES button to make thisselection.

PN MODELS:Factory default of FC.

CYCLE COUNTER OPTION

This option is either SELECTED ‘ON’ or NOT SELECTED ‘OFF’.

Not Selected ‘OFF’.

Selected ‘ON’ and not able to be deselected. Press DELICATES

C

button 3 consecutive times to select ‘ON’. Once selected ‘ON’

it cannot be deselected.

Page 15

CODE EXPLANATION

1.0 0

1.0 0

1.0

1.C0

Press PERM. PRESS button once to advance to next code.

2.0 0

2.0 0

2.

SP

If SPECIAL PRICING OPTION is selected, there is access to codes

‘3.’ through ‘9.’

Press PERM. PRESS button once to advance to next code.

OPTIONS TO USE IF SPECIAL PRICING IS SELECTED:

3. 0 6

3. 0 6

3. 0 0

Press PERM. PRESS button once to advance to next code.

4. 0 5

4. 0 5

4. 4 5

Press PERM. PRESS button once to advance to next code.

5. 0 0

5. 0 0

Press PERM. PRESS button once to advance to next code.

6.0 0

6.0 0

Press PERM. PRESS button once to advance to next code.

MONEY COUNTER OPTION

This option is either SELECTED ‘ON’ or NOT SELECTED ‘OFF’.

Not Selected ‘OFF’.

Selected ‘ON’.

C

Press DELICATES button 3 consecutive times to select ‘ON’

and 3 consecutive times to remove (Not Selected ‘OFF’.)

Counter resets by going from ‘OFF’ to ‘ON’.

Selected ‘ON’ and not able to be deselected.

To select ‘ON’ and not able to be deselected, first select ‘ON’,

then within two seconds press DELICATES twice, WHITESAND

COLORS once, and exit the set-up mode.

SPECIAL PRICING OPTION

This option is either SELECTED ‘ON’ or NOT SELECTED ‘OFF’.

Not Selected ‘OFF’.

Selected ‘ON’. Press DELICATES button once for this

selection.

SPECIAL CYCLE PRICE

Represents the number of coins (coin 1); may adjust from

0-39. (See b.xx set-up for VALUEOF COIN 1). Advance from

0-39 by pressing WHITES AND COLORS. Factory default of

6 x coin 1.

PN MODELS: Factory default of 0 coins.

SPECIAL DRY TIME

Represents the number of minutes per coin (coin 1).

Factory defaultof 5 minutes per coin.

Example: 6 coins x 5 minutes= 30minutes.

By pressing the WHITESAND COLORS button, the value

canbe adjusted from 1-99 minutes.

PNMODELS: Represents the cyclelength for free cycles.

As example: ‘4 45’ = 45 minutes.

TIME-OF-DAY CLOCK, MINUTES

This is the TIME-OF-DAY CLOCK, minute setting; select 0-59

minutes by pressing WHITES ANDCOLORS button.

TIME-OF-DAY CLOCK, HOURS

NOTE: Uses the 24 hr. clock.

This is the TIME-OF-DAY CLOCK, hour setting; select 0-23

hours by pressing WHITES ANDCOLORSbutton.

CODE EXPLANATION

PTIONS TO USE IF SPECIAL PRICINGIS SELECTED(continued):

O

7. 0 0

7. 0 0

Press PERM. PRESS button once to advance to next code.

8. 0 0

8. 0 0

Press PERM. PRESS button once to advance to next code.

9. 1 0

9. 1 0

Press PERM. PRESS button once to advance to next code.

A.

00

A.

00

A.SC

Press PERM. PRESS button once to advance to next code.

6.0 5

6.0 5

Press PERM. PRESS button once to advance to next code.

C

.2 0

C

.2 0

C

.0 5

Press PERM. PRESS button once to advance to next code.

SPECIAL PRICE START HOUR

NOTE: Uses the 24 hr. clock.

This is the start hour, 0-23 hours. Select START HOUR

by pressing WHITESAND COLORS button.

SPECIAL PRICE STOP HOUR

NOTE: Uses the 24 hr. clock.

This is the stop hour; 0-23 hours. Select STOP HOUR

by pressing WHITESAND COLORS button.

SPECIAL PRICE DAY

This represents the day of the week and whether special

pricing is selected for that day. A number followed by ‘0’

indicates no selection that particular day (9.10). A number

followed by an ‘S’ indicates selected for that day (9.1S).

Days of week (1-7) can be chosen by pressing the WHITES

AND COLORS button. Press DELICATES button once to

select special pricing for each day chosen.

When exiting setup code ‘9.’, the display must show current

day of week:

DISPLAY DAY OF WEEK CODE (selected)

10 Day 1 = Sunday 1S

20 Day 2 = Monday 2S

30 Day 3 = Tuesday 3S

40 Day 4 = Wednesday 4S

50 Day 5 = Thursday 5S

60 Day 6 = Friday 6S

70 Day 7 = Saturday 7S

VAULT VIEWING OPTION

This option is either SELECTED ‘ON’ or NOT SELECTED ‘OFF’.

Not Selected ‘OFF’.

Selected ‘ON’. Press DELICATES button once for this

selection. When selected, the money and/or cycle counts

will be viewable (if counting is selected) when the coin box

is removed.

VALUE OF COIN 1

This represents the value of coin 1 in the quantity of 5%

increments of the larger coin value. 5 x 5% = 25%.

By pressing the WHITESAND COLORS button, there is the

option of 1-199 for the quantity of 5% increments.

With coin slide activation, this represents the total vend price.

VALUE OF COIN 2

This represents the value of coin 2 in the quantity of 5%

increments of the larger coin value. 20 x 5% = 100%.

By pressing the WHITESAND COLORS button, there is the

option of 1-199 for the quantity of 5% increments.

PN MODELS: This represents the value of coin 2 in the

quantity of 5% increments of the larger coin value. Factory

default = 5 x 5% of the larger coin value.

PN MODELS USING ENHANCED DEBIT: This represents the

value of top off in quantity of 5% increments of the larger coin

value. Factory default = 5 x 5% of the larger coin value.

15

Page 16

CODE EXPLANATION

EU - DECLARATION OF CONFORMITY

CE - DECLARATION DE CONFORMITE

WE (nous): BAUKNECHT HAUSGERÄTE GmbH, D-73614 Schorndorf

representing (représentant): WHIRLPOOL EUROPE S.r.l I-21025 COMERIO

declare under our sole responsibility that the product

déclarons sous notre propre responsabilité que le produit

dryer Maytag MDG22PD

(sèche-linge) :

Maytag MDG22PN

to which this declaration relates is in conformity with the following standard(s) or other

normative document(s)

auquel se référe cette déclaration est conforme aux normes suivantes ou autres documents normatifs

EN 60335-1:2002+A1+A2+A11+A12+A13

EN 60335-2-11:2003+A1+A2

EN 12752-1:1999

EN 62233:2008

EN ISO 10472-1:2008

EN ISO 10472-4:2008

EN 55014-1:2006

EN 55014-2:1997+A1 :2001

EN 61000-3-11:2000

EN 61000-3-12:2005

following the provisions of Directive(s):

suivant les prévisions des Directives :

2009/142/EC EUROPEAN GAS APPLIANCE DIRECTIVE

2006/95/EC LOW VOLTAGE DIRECTIVE (CEE Directive Basse Tension)

2004/108/EC ELECTROMAGNETIC COMPATIBILITY DIRECTIVE (CEE Directive Compatibilité

Electro-magnétique)

2006/42/EC MACHINERY DIRECTIVE

represented by

Schorndorf, 29.04.2010 Roberto Mottura

Place and date: Director PDC, FC

lieu et date :

Nameand signature of authorised person

Nomet signature de la personne autorisée

8.0 0

COIN SLIDE OPTION

This option is either SELECTED ‘ON’ or NOT SELECTED ‘OFF’.

Replacementof metercasewillbe neededforcoin slide mounting.

8.0 0

8.

CS

Not Selected ‘OFF’.

Selected ‘ON’.

NOTE: This option needs to be set to ‘00’ unless the

metercase has been changed to accept a coin slide device.

Press DELICATES button 3 consecutive times for this

selection. When coin slide mode is selected, set ‘b.’ equal to

value of slide in coins. Set ‘6 xx’ (REGULAR CYCLE PRICE)

and ‘3.xx’ (SPECIAL CYCLE PRICE) to number of slide

operations. 6 01 & 3.01 = 1 slide push.

NOTE: If the installer sets up ‘CS’ on a coin drop model,

it will not register coins.

Press PERM. PRESS button once to advance to next code.

E

. 0 0

ADD COINS OPTION

This option is either SELECTED ‘ON’ or NOT SELECTED ‘OFF’.

This option causes the customer display to show the number

of coins (coin 1) to enter, rather than the amount.

E

. 0 0

E.AC

Not Selected ‘OFF’.

Selected ‘ON’.

PressDELICATES button 3 consecutive times for thisselection.

PN MODELS:This option is not selectable.

Press PERM. PRESS button once to advance to next code.

J.C

J.C

J.C

COIN/DEBIT OPTION

8

Both coin & debit selected. (NOT AVAILABLE)

8

Coins selected, debit disabled.

8

PressDELICATES button 3 consecutive times for thisselection.

J.C

Debit Card selected, coin disabled. Default for PN models,

8

and for PN operation, must be set as J._d.

PressDELICATES button 3 consecutive times for thisselection.

J.E

Enhanced Debit is self-selected when a Generation 2 card

8

reader is installed in the dryer. The ‘Ed’ option cannot be

manually selected or deselected. (NOT AVAILABLE)

Press PERM. PRESS button once to advance to next code.

L

. 0 0

PRICE SUPPRESSION OPTION

This option is either SELECTED ‘ON’ OR NOT SELECTED ‘OFF’.

This option causes the customer display to show ‘AVAILABLE’

or ‘ADD’ rather than the amount of money to add. (Used

L

. 0 0

L.PS

Press PERM. PRESS button once to advance to next code.

8.

CE

8.

CE

8.0 0

Press PERM. PRESS button once to advance to next code.

0.0 0

0.0 0

Press PERM. PRESS button once to advance to next code.

16

mainly in debit installations.)

Not Selected ‘OFF’.

Selected ‘ON’. PressDELICATESbutton once forthisselection.

CLEAR ESCROW OPTION

This option is either SELECTED ‘ON’ OR NOT SELECTED ‘OFF’.

When selected,money held in escrow for 30 minutes without

further escrow or cycle activity will be cleared.

Selected ‘ON’.

Not Selected ‘OFF’.Press DELICATES button once to deselect

this option.

HUNDREDTH INCREMENT OFFSET

This represents the hundredth increment price offset used

in Generation 2 (Enhanced Debit) PN models set up with card

reader.Choose from 0-4 hundredths by pressing the WHITES

AND COLORS button. (NOT AVAILABLE)

If cycle counter (9 0C) is selected, the following is true:

1 00 Represents the number of cycles in HUNDREDS. 1 02

= 200

2 00 Represents the number of cycles in ONES. 2 25 = 225

TOTAL CYCLES = 225

This is ‘VIEW ONLY’ and cannot be cleared.

Press the PERM. PRESS button once to advance

to next code.

If money counter (1.0C or 1.C0) is selected, the following is true:

3 00 Currency amount in HUNDREDS. 3 01

4 00 Currency amount in ONES. 4 68

= 100.00

= 168.00

5 00 Currency amount in HUNDREDTHS. 5 75 = 100.75

TOTAL = 168.75

END OF SET-UP PROCEDURES

EXIT FROM SET-UP MODE

■

PD MODELS: Reinstall access door.

■

PN MODELS where AA1 plug was removed:

1. Unplug dryer or disconnect power.

2. Open console, reinsert jumper into AA1, close console.

3. Plug in dryer or reconnect power.

■

PN WITH PROGRAMMING SWITCH: Turn key clockwise and

remove.

■

If Service Access Code was used to enter set-up mode: From

Set-up Code 8, press button #1 for 4 seconds, wait 2 minutes

without touching any buttons (without diagnostic modes running),

or power down the dryer, then reapply power.

Page 17

MAYTAG COMMERCIAL WASHER, DRYER, STACKED DRYER/

DRYER, COMMERCIAL STACK LAUNDRY, AND MULTI-LOAD

COIN OPERATED COMMERCIAL WASHERS AND DRYERS

WARRANTY

LIMITED WARRANTY ON PARTS

F

or the first five years from the date of purchase, when this commercial appliance is installed, maintained and operated according to the

i

nstructions attached to or furnished with the product, Maytag brand of Whirlpool Corporation (thereafter “Maytag”) will pay for factory

s

pecified parts or original equipment manufacturer parts to correct defects in materials or workmanship. Proof of original purchase date

i

s required to obtain service under this warranty.

ITEMS MAYTAG WILL NOT PAY FOR

1. All other costs including labor, transportation, or custom duties.

2. Service calls to correct the installation of your commercial appliance, to instruct you how to use your commercial appliance, to

replace or repair fuses, or to correct external wiring or plumbing.

3. Repairs when your commercial appliance is used for other than normal, commercial use.

4. Damage resulting from improper handling of product during delivery, theft, accident, alteration, misuse, abuse, fire, flood, acts of

God, improper installation, installation not in accordance with local electrical or plumbing codes, or use of products not approved

by Maytag.

5. Pickup and Delivery. This commercial appliance is designed to be repaired on location.

6. Repairs to parts or systems resulting from unauthorized modifications made to the commercial appliance.

7. The removal and reinstallation of your commercial appliance if it is installed in an inaccessible location or is not installed in

accordance with published installation instructions.

8. Chemical damage is excluded from all warranty coverage.

9. Changes to the building, room, or location needed in order to make the commercial appliance operate correctly.

DISCLAIMER OF IMPLIED WARRANTIES; LIMITATIONS OF REMEDIES

CUSTOMER'S SOLE AND EXCLUSIVE REMEDY UNDER THIS LIMITED WARRANTY SHALL BE PRODUCT REPAIR AS PROVIDED

HEREIN. IMPLIED WARRANTIES, INCLUDING WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE,

ARE LIMITED TO ONE YEAR OR THE SHORTEST PERIOD ALLOWED BY LAW. WHIRLPOOL SHALL NOT BE LIABLE FOR

INCIDENTAL OR CONSEQUENTIAL DAMAGES. SOME STATES AND PROVINCES DO NOT ALLOW THE EXCLUSION OR LIMITATION

OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, OR LIMITATIONS ON THE DURATION OF IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS, SO THESE EXCLUSIONS OR LIMITATIONS MAY NOT APPLY TO YOU. THIS WARRANTY GIVES

YOU SPECIFIC LEGAL RIGHTS AND YOU MAY ALSO HAVE OTHER RIGHTS, WHICH VARY FROM STATE TO STATE OR PROVINCE

TO PROVINCE.

If you need service, please contact your authorized Maytag Commercial Laundry distributor. To locate your authorized Maytag

Commercial Laundry distributor, or for web inquiries, visit www.MaytagCommercialLaundry.com.

9/07

For written correspondence:

Maytag Commercial Laundry Service Department

2000 M-63 North

Benton Harbor, Michigan 49085 USA

17

Page 18

SECURITE DU SECHE-LINGE

Risque possible de décès ou de blessure grave si vous ne

suivez pas immédiatement les instructions.

Risque possible de décès ou de blessure grave si vous

ne suivez pas les instructions.

Tous les messages de sécurité vous diront quel est le danger potentiel et vous disent comment réduire le risque de blessure et

ce qui peut se produire en cas de non-respect des instructions.

Votre sécurité et celle des autres est très importante.

Nous donnons de nombreux messages de sécurité importants dans ce manuel et sur votre appareil ménager. Assurez-vous de

toujours lire tous les messages de sécurité et de vous y conformer.

AVERTISSEMENT

DANGER

V

oici le symbole d’alerte de sécurité.

Ce symbole d’alerte de sécurité vous signale les dangers potentiels de décès et de blessures graves à vous

et à d’autres.

Tous les messages de sécurité suivront le symbole d’alerte de sécurité et le mot “DANGER” ou

“AVERTISSEMENT”. Ces mots signifient :

AVERTISSEMENT : Pour votre sécurité, les renseignements dans ce manuel doivent

être observés pour réduire au minimum les risques d’incendie ou d’explosion ou pour

éviter des dommages au produit, des blessures ou un décès.

– Ne pas entreposer ou utiliser de l’essence ou d’autres vapeurs ou liquides

inflammables à proximité de cet appareil ou de tout autre appareil électroménager.

– QUE FAIRE DANS LE CAS D’UNE ODEUR DE GAZ :

•

Ne pas tenter d’allumer un appareil.

•

Ne pas toucher à un commutateur électrique; ne pas utiliser le téléphone se trouvant

sur les lieux.

•

Évacuer tous les gens de la pièce, de l’édifice ou du quartier.

•

Appeler immédiatement le fournisseur de gaz d’un téléphone voisin. Suivre ses

instructions.

•

À défaut de joindre votre fournisseur de gaz, appeler les pompiers.

– L’installation et l’entretien doivent être effectués par un installateur qualifié, une

agence de service ou le fournisseur de gaz.

POUR VOTRE SECURITE

1. Ne pas utiliser ou remiser d’essence ou autres matériaux inflammables dans cet appareil ménager ou à proximité de celui-ci.

2. Ne pas vaporiser d’aérosols à proximité de cet appareil ménager lorsqu’il est en fonctionnement.

3. Ne pas modifier cet appareil ménager.

18

Page 19

ELIMINATION DU SECHE-LINGE

EXIGENCES D’INSTALLATION

Outillage et pièces

Rassembler les outils et pièces nécessaires avant de commencer

l’installation. Lire et respecter les instructions d’installation

fournies avec chacun des outils de cette liste.

Outillage nécessaire

■ Clé à tube de 200 mm (8")

ou 250 mm (10")

■ Clé à molette de 200 mm

(8") ou 250 mm (10")

■ Tournevis à lame plate

■ Tournevis Phillips

■ Clé à molette avec

ouverture jusqu’à 25 mm

(1") ou clé à douille

hexagonale

■ Niveau

■ Clé à douille de 8 mm

(5/16")

■ Couteau utilitaire

■ Brides de fixation

■ Composé d’étanchéité des

raccords filetés - résistant

au propane

■ Pistolet à calfeutrage et

composé de calfeutrage

(pour l’installation d’un

nouveau circuit

d’évacuation)

■ Pince

■ Couteau à mastic

à lame rigide

Pièces fournies

Retirer le sac de pièces du tambour du sèche-linge. Vérifier la

présence de toutes les pièces.

■ Patin (4)

■ Pied du sèche-linge (4)

■ Modèles PD : Came pour

le verrouillage de la porte

■ Modèles PN : Boîtier du

lecteur de carte, faisceau

de câblage du lecteur de

carte, visserie

de service

REMARQUE : Le schéma de circuits de ce sèche-linge se trouve

à l’intérieur du panneau inférieur avant, dans les fiches techniques.

19

Page 20

Exigences d’emplacement

Risque d'explosion

Garder les matières et les vapeurs inflammables, telle

q

ue l'essence, loin de la sécheuse.

Ne pas installer dans un garage.

Le non-respect de ces instructions peut causer

un décès, une explosion ou un incendie.

AVERTISSEMENT

686 mm

(27")

965 mm

(38")

25 mm

(1")

76 mm (3")

155cm

2

*

(24 in.2)

310cm

2

*

(48 in.

2

)

76 mm (3")

381 mm

(15")

0 mm

(0")

0 mm

(0")

356 mm

(14") max

25 mm (1")

0 mm

(0")

Pour l’installation d’un sèche-linge à gaz :

IMPORTANT : Respecter les dispositions de tous les codes et

règlements en vigueur.

■ Déterminer les exigences des codes : Certains codes limitent

ou prohibent l’installation d’un sèche-linge dans un garage,

un placard, ou une chambre à coucher. Consulter l’inspecteur

local des bâtiments.

■ Veiller à ce que les bords inférieurs de la caisse ainsi que

l’arrière et les côtés inférieurs du sèche-linge soient exempts

d’obstructions, afin de permettre le passage adéquat de l’air

de combustion. Voir la section “Instructions d’installation dans

un placard ou un encastrement” pour l’espace de

dégagement minimal.

■ Ne pas installer sur un tapis.

NOTE : Le sèche-linge ne doit pas être installé en un endroit où il

serait exposé à de l’eau ou aux intempéries.

istances de séparation minimales

D

orte du

P

placard

lacard, vue latérale

Encastrement, vue avant

On doit prévoir un espacement additionnel pour tenir compte éventuellement

des moulures du mur, de la porte et du plancher, ou si le circuit d’évacuation

comporte un coude.

vue

avant

Porte du

placard

P

Taille minimale de

*

l’ouverture pour la porte

du placard. On peut

utiliser une porte à

claire-voie offrant une

surface de passage

d’air équivalente.

Instructions pour l’installation dans un placard ou

un encastrement

Ce sèche-linge peut être installé dans un placard ou un

encastrement. Ce sèche-linge ne doit pas être installé derrrière

une porte verrouillable, coulissante, ou une porte avec charnière

du côté opposé de l’emplacement de celle du sèche-linge.

Les distances de séparation sont exprimées en millimetre;

il s’agit des distances minimales. Il est utile de prévoir des

distances de séparation supérieures pour faciliter l’installation

et les travaux d’entretien, ou si ceci est exigé par les codes et

règlements locaux.

Si la porte du placard est installée, on doit respecter la taille

minimale des ouvertures d’entrée d’air au sommet et en bas. On

peut utiliser une porte à jalousies offrant une surface de passage

d’air équivalente.

Le circuit d’évacuation du sèche-linge doit être relié à l’extérieur.

Aucun autre appareil utilisant un combustible ne doit être installé

dans le même placard.

20

Dimensions du produit – Sèche-linge de 686 mm (27")

VUE AVANT

Page 21

AVERTISSEMENT

Une mise à la terre est nécessaire sur ce sèche-linge.

Ne pas utiliser une tuyauterie de gaz pour le

raccordement à la terre.

Ne pas changer la che du cordon d’alimentation.

Si elle ne correspond pas à la prise de sortie, faire

installer une prise adéquate par un électricien qualié.

Ne pas utiliser de câble de rallonge avec ce sèche-linge.

Le non-respect de ces instructions peut causer

un décès, un incendie ou des blessures graves.

Risque de choc électrique

CONSERVEZ CES INSTRUCTIONS

INSTRUCTIONS DE MISE A LA TERRE

Ce sèche-linge a été conçu pour être raccordé au

secteur et mis à la terre ; la mise à la terre est donc impérative:

En cas disfonctionnement ou de panne, la mise à la terre

réduira le risque de choc électrique en offrant au courant

électrique une voie de moindre résistance. Ce sèche-linge

est alimenté par un cordon électrique comportant un

conducteur de liaison à la terre et une che de mise à la terre.

La che doit être branchée sur une prise de courant

appropriée correctement installée et reliée à la terre

conformément à tous les codes et règlements locaux.

Un raccordement inapproprié

du conducteur de liaison à la terre peut causer un risque

de choc électrique.

En cas de doute concernant la qualité de la liaison à la terre

du sèche-linge, consulter un électricien qualié, un agent

ou personnel d’entretien. Ne pas modier la che fournie

avec ce sèche-linge : Si elle ne correspond pas à la prise

de sortie, faire installer une prise appropriée par un

électricien qualié.

AVERTISSEMENT :

159 mm

(6

1

/4")

715 mm

(28

1

/8")

89 mm

(3

1

/2")

358 mm

(14")

32 mm

(1

1

/4")

152 mm

(5

7

/8")

ÂBLE

736 mm

(29")

921 mm

(36

1

/4")

203 mm

(8")

25 mm

(1")

695 mm

(27

1

/4")

C

LECTRIQUE

É

ANALISATION

C

E GAZ

D

VUE ARRIÈRE

Ce sèche-linge est équipé d’un cordon d’alimentation électrique et

d’une fiche. Il doit être connecté à une prise électrique de tension tel

qu’indiqué sur la plaque signalétique. La capacité minimale du fusible

d’alimentation doit être de 5A. Le sèche-linge doit être installé de

façon à ce que la fiche soit clairement évidente et accessible. Cette

iche remplit également la fonction de commande d’arrêt d’urgence

f

pour l’utilisateur. Si la fiche d’origine n’est pas utilisée, la connexion

électrique doit être effectuée par un électricien compétent

conformément aux codes locaux et nationaux. Si le cordon

d’alimentation est endommagé, il doit être remplacé par un cordon

à embout spécifique par un agent d’entretien autorisé ou une

personne de compétence similaire afin d’éviter tout danger.

Ne pas utiliser d’adaptateur.

Ne pas utiliser de câble de rallonge.

REMARQUE : Conformément à la directive européenne CEM

(2004/108/EC), l’impédance maximale du système d’alimentation

électrique auquel le sèche-linge à gaz doit être connecté est

de 0,054 Ohm + j0,034 Ohm.

NOTE : Normes de sécurité électriques : Pour ce produit, le

fabricant a estimé que la mise en conformité avec les normes

IEC/EN.60335 était la plus appropriée.

VUE LATÉRALE

Spécifications électriques - sèche-linge à gaz

Important : Se conformer à tous les codes et règlements en vigueur.

Une prise électrique avec liaison à la terre située à 610 mm (2 pi)

maximum de l’un des côtés du sèche-linge est nécessaire.

Si les codes le permettent et si un conducteur supplémentaire

de mise à la terre est utilisé, il est recommandé qu’un électricien

qualifié inspecte le parcours du fil de mise à la terre.

21

Page 22

À l’aide du cordon universel fourni avec

AVERTISSEMENT

Connecter ce sèche-linge à une canalisation

d’alimentation en gaz réglementée. La pression

de gaz doit être conforme aux exigences techniques

(voir dernière page).

Installer un robinet d'arrêt.

Bien serrer tous les raccords de la ligne de gaz.

En cas de connexion au gaz propane, demander à

une personne qualiée de s'assurer que la pression

d’alimentation en gaz est correcte.

Le non-respect de ces instructions peut causer

un décès, une explosion ou un incendie.

Risque d'explosion

ce sèche-linge :

Ce sèche-linge à gaz est équipé d’un cordon universel avec des

fiches interchangeables.

. Pour utiliser le cordon universel, sélectionner la fiche amovible

1

qui correspond à votre prise de courant et brancher dans

l’adaptateur placé sur le cordon d’alimentation.

2. Fixer la fiche amovible sur le cordon en alignant les deux

moitiés de couvercle sur l’adaptateur et en les emboîtant.

Gaz naturel :

Ce sèche-linge est configuré en usine pour une utilisation au GAZ

NATUREL (G20) et aucun réglage supplémentaire n’est nécessaire

lors de l’installation.

Gaz propane :

Ce sèche-linge est également homologué pour une utilisation

avec des gaz de pétrole liquéfié (propane ou butane) après

conversion appropriée. Ne pas tenter de convertir l’appareil pour

une utilisation avec un gaz différent de celui indiqué sur la plaque

signalétique sans consulter le fournisseur de gaz au préalable.

La conversion doit être effectuée par un réparateur qualifié.

La trousse de conversion, numéro de référence W10233219,

est disponible à l’achat chez votre revendeur. Des instructions

accompagnent cette trousse.

Gaz naturel (France/Belgique) :

Ce sèche-linge est également homologué par la France/Belgique

pour une utilisation avec un gaz G20/G25 (20 mbar/25 mbar)

avec une conversion appropriée. Il ne faut pas essayer de

convertir ce sèche-linge à partir du gaz indiqué sur l’étiquette

d’indice de gaz vers un gaz différent sans consulter le fournisseur

de gaz. La conversion d’un gaz à un autre doit être faite par

un technicien qualifié de service de gaz. L’ensemble de

conversion (numéro de pièce W10181947) peut être

acheté chez votre marchand. Des instructions complètes

sont fournies avec l’ensemble.

Spécifications de l’alimentation en gaz

IMPORTANT : Se conformer à tous les codes et réglements

en vigueur.

Alimentation en gaz

Avant d’effectuer l’installation, vérifier que les caractéristiques

de distribution, la nature et la pression de gaz locales ainsi que

le réglage de l’appareil sont compatibles. Les informations

concernant le brûleur se trouvent sur la plaque signalétique située

sur la paroi interne de la porte du sèche-linge. Si l’information ne

correspond pas au type de gaz disponible, consulter votre

revendeur.

22

Exigences concernant le conduit d’alimentation :

Installer un conduit rigide d’alimentation en gaz à l’emplacement

du sèche-linge. Le diamètre interne minimal du conduit doit être

de 12,5 mm (1/2"). Lorsque les codes locaux et votre fournisseur

de gaz l’autorisent, un diamètre interne de conduit rigide de

10 mm (3/8") peut être utilisé pour des longueurs inférieures

à 6,1 m (20 pi.). Une pâte d’étanchéité pour joints résistant à

l’action du gaz propane doit être utilisée.

Le raccordement au gaz du sèche-linge lui-même doit être

effectué au moyen d’un conduit de gaz flexible qui convienne à

l’appareil et corresponde à la catégorie de gaz, conformément

aux règlements d’installation nationaux. En cas de doute,

contacter le fournisseur de gaz. Le diamètre interne doit être

d’au moins 10 mm (3/8").

Un dispositif de fixation doit être installé entre l’appareil et le mur

afin d’éviter que la canalisation d’alimentation en gaz rigide ne

subisse de tension lors d’un déplacement de l’appareil. Il est

recommandé d’utiliser une longueur de chaîne appropriée et un

crochet mural.

Le raccord du conduit d’alimentation en gaz du sèche-linge est

un filetage conique NPT de 3/8". Un adaptateur est fourni pour

la conversion à un filetage standard (3/8" BSP) selon la norme

ISO.228-1.

Vérifier l’absence de fuites en utilisant une solution de détection

non-corrosive homologuée. L’apparition de bulles indique la

présence d’une fuite. Réparer toute fuite éventuelle. Un dispositif

de mesure de la pression est fourni avec le robinet de gaz à

l’intérieur du sèche-linge; on peut y accéder après avoir retiré

le panneau avant inférieur.

Le sèche-linge doit être déconnecté du système d’alimentation

en gaz lors de tout test de pression.

Page 23

Exigences concernant l’évacuation

Risque d’incendie

Utiliser un conduit d’évacuation en métal lourd.

Ne pas utiliser un conduit d’évacuation en plastique.

Ne pas utiliser un conduit d’évacuation en feuille

de métal.

Le non-respect de ces instructions peut causer

un décès ou un incendie.

AVERTISSEMENT

Le clapet de décharge doit être situé à au moins 305 mm (12")

au-dessus du sol ou de tout autre objet susceptible de se trouver

sur le trajet de l’air humide rejeté (par exemple, fleurs, roches ou

arbustes).

Lors de l’utilisation d’un circuit d’évacuation existant, nettoyer les

peluches sur toute la longueur du système et veiller à ce que la

bouche de décharge ne soit pas obstruée par une accumulation

de peluches. Remplacer tout conduit de plastique ou de feuille

métallique mince par un conduit métallique flexible ou rigide.

Planifier l’installation pour introduire le nombre minimal de coudes

et de changements de direction.

AVERTISSEMENT : Pour réduire le risque d’incendie,

ce sèche-linge DOIT ÉVACUER L’AIR À L’EXTÉRIEUR.

■ Si l’on suit ces spécifications d’évacuation, le bruit produit

par les conduits sera minimisé.

■ Les sèche-linge à gaz peuvent être installés dans une pièce

uniquement si celle-ci répond aux critères de ventilation

adéquats tels que spécifiés dans les règlements d’installation

nationaux. S’assurer que la pièce renfermant le sèche-linge

possède un approvisionnement en air suffisant pour permettre

la combustion du gaz et le processus de séchage. Une

fenêtre ou un moyen de ventilation équivalent doit être

ouverte dans la pièce lorsque le sèche-linge est utilisé

(comme forme d’ouverture équivalente, on peut citer une

persienne réglable, un panneau ouvrant avec charnière ou